Agilent 4294A Service Manual

Agilent 4294A Precision Impedance Analyzer

Service Manual

Third Edition

Manufacturing No. 04294-90110

January 2007

Notices

The information contained in this document is subject to change without notice.

This document contains proprietary information that is protected by copyright. All rights are reserved. No part of this document may be photocopied, reproduced, or translated to another language without the prior written consent of Agilent Technologies.

Microsoft®,MS-DOS®,Windows®,Visual C++®,Visual Basic®,VBA® and Excel® are registered

UNIX is a registered trademark in U.S. and other countries, licensed exclusively through X/Open Company Limited.

Portions ©Copyright 1996, Microsoft Corporation. All rights reserved.

© Copyright 1999, 2000, 2007 Agilent Technologies

Manual Printing History

The manual’s printing date and part number indicate its current edition. The printing date changes when a new edition is printed. (Minor corrections and updates that are incorporated at reprint do not cause the date to change.) The manual part number changes when extensive technical changes are incorporated.

October 1999 |

First Edition |

June 2000 |

Second Edition |

January 2007 |

Third Edition |

2

NOTE

NOTE

WARNING

Safety Summary

The following general safety precautions must be observed during all phases of operation, service, and repair of this instrument. Failure to comply with these precautions or with specific WARNINGS elsewhere in this manual may impair the protection provided by the equipment. In addition it violates safety standards of design, manufacture, and intended use of the instrument.

The Agilent Technologies Company assumes no liability for the customer’s failure to comply with these requirements.

4294A comply with INSTALLATION CATEGORY II and POLLUTION DEGREE 2 in IEC61010-1. 4294A are INDOOR USE product.

LEDs in 4294A are Class 1 in accordance with IEC60825-1.

CLASS 1 LED PRODUCT

•Ground The Instrument

To avoid electric shock hazard, the instrument chassis and cabinet must be connected to a safety earth ground by the supplied power cable with earth blade.

•DO NOT Operate In An Explosive Atmosphere

Do not operate the instrument in the presence of flammable gasses or fumes. Operation of any electrical instrument in such an environment constitutes a definite safety hazard.

•Keep Away From Live Circuits

Operating personnel must not remove instrument covers. Component replacement and internal adjustments must be made by qualified maintenance personnel. Do not replace components with the power cable connected. Under certain conditions, dangerous voltages may exist even with the power cable removed. To avoid injuries, always disconnect power and discharge circuits before touching them.

•DO NOT Service Or Adjust Alone

Do not attempt internal service or adjustment unless another person, capable of rendering first aid and resuscitation, is present.

•DO NOT Substitute Parts Or Modify Instrument

Because of the danger of introducing additional hazards, do not install substitute parts or perform unauthorized modifications to the instrument. Return the instrument to a Agilent Technologies Sales and Service Office for service and repair to ensure that safety features are maintained.

•Dangerous Procedure Warnings

Warnings, such as the example below, precede potentially dangerous procedures throughout this manual. Instructions contained in the warnings must be followed.

Dangerous voltages, capable of causing death, are presenting this instrument. Use extreme caution when handling, testing, and adjusting this instrument.

3

WARNING

CAUTION

NOTE

Safety Symbol

General definitions of safety symbols used on the instrument or in manuals are listed below.

Instruction Manual symbol: the product is marked with this symbol when it is necessary for the user to refer to the instrument manual.

Alternating current.

Direct current.

On (Supply).

Off (Supply).

In position of push-button switch.

Out position of push-button switch.

Frame (or chassis) terminal. A connection to the frame (chassis) of the equipment which normally include all exposed metal structure.

This warning sign denotes a hazard. It calls attention to a procedure, practice, condition or the like, which, if not correctly performed or adhered to, could result in injury or death to personnel.

This Caution sign denotes a hazard. It calls attention to a procedure, practice, condition or the like, which, if not correctly performed or adhered to, could result in damage to or destruction of part or all of the product.

Note denotes important information. It calls attention to a procedure, practice, condition or the like, which is essential to highlight.

Certification

Agilent Technologies Company certifies that this product met its published specifications at the time of shipment from the factory. Agilent Technologies further certifies that its calibration measurements are traceable to the United States National Institute of Standards and Technology, to the extent allowed by the Institution’s calibration facility, or to the calibration facilities of other International Standards Organization members.

4

Warranty

This Agilent Technologies instrument product is warranted against defects in material and workmanship for a period corresponding to the individual warranty periods of its component products. Instruments are warranted for a period of one year. Fixtures and adapters are warranted for a period of 90 days. During the warranty period, Agilent Technologies Company will, at its option, either repair or replace products that prove to be defective.

For warranty service or repair, this product must be returned to a service facility designated by Agilent Technologies. Buyer shall prepay shipping charges to Agilent Technologies and Agilent Technologies shall pay shipping charges to return the product to Buyer. However, Buyer shall pay all shipping charges, duties, and taxes for products returned to Agilent Technologies from another country.

Agilent Technologies warrants that its software and firmware designated by Agilent Technologies for use with an instrument will execute its programming instruction when property installed on that instrument. Agilent Technologies does not warrant that the operation of the instrument, or software, or firmware will be uninterrupted or error free.

|

Limitation of Warranty |

|

The foregoing warranty shall not apply to defects resulting from improper or inadequate |

|

maintenance by Buyer, Buyer-supplied software or interfacing, unauthorized modification |

|

or misuse, operation outside the environmental specifications for the product, or improper |

|

site preparation or maintenance. |

|

|

IMPORTANT |

No other warranty is expressed or implied. Agilent Technologies specifically disclaims the |

|

implied warranties of merchantability and fitness for a particular purpose. |

Exclusive Remedies

The remedies provided herein are buyer’s sole and exclusive remedies. Agilent Technologies shall not be liable for any direct, indirect, special, incidental, or consequential damages, whether based on contract, tort, or any other legal theory.

Assistance

Product maintenance agreements and other customer assistance agreements are available for Agilent Technologies products.

5

For any assistance, contact your nearest Agilent Technologies Sales and Service Office. Addresses are provided at the back of this manual.

Typeface Conventions

Bold |

Boldface type is used when a term is defined. For |

|

example: icons are symbols. |

Italic |

Italic type is used for emphasis and for titles of |

|

manuals and other publications. |

[Hardkey] |

Indicates a hardkey labeled “Hardkey.” |

Softkey |

Indicates a softkey labeled “Softkey.” |

[Hardkey] - Softkey1 - Softkey2 |

Indicates keystrokes [Hardkey] - Softkey1 - |

|

Softkey2. |

4294A Documentation Map

The following manuals are available for the 4294A.

•Operation Manual (Agilent P/N: 04294-900x0)

Most of basic information necessary for using 4294A is described in this manual. It includes the way of installation, preparation, measurement operation including calibration, performances (specifications), key definitions, and error messages. For GPIB programming, see the Programming Manual together with “HP Instrument BASIC User's Handbook”.

•Programming Manual (Agilent P/N: 04294-900x1)

The Programming Manual shows how to write and use BASIC program to control the 4294A and describes how HP Instrument BASIC works with the analyzer.

•HP Instrument BASIC User's Handbook (Agilent P/N: E2083-90005)

The HP Instrument BASIC User’s Handbook introduces you to the HP Instrument BASIC programming language, provide some helpful hints on getting the most use from it, and provide a general programming reference. It is divided into three books,

HP Instrument BASIC Programming Techniques, HP Instrument BASIC Interface Techniques, and HP Instrument BASIC Language Reference.

•Service Manual (Agilent P/N: 04294-901x0, Option 0BW only)

This manual describes how to adjust and repair the 4294A, and how to carry out performance tests. This manual will be attached if you take the Option 0BW.

NOTE |

The number position shown by “x” in the part numbers above indicates the edition number. |

6

Contents

1. |

General Information |

|

|

Organization of Service Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

14 |

|

Instruments Covered by This Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

15 |

|

Require Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

16 |

2. |

Performance Test |

|

|

Performance Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

20 |

|

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

20 |

|

Test Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

20 |

|

Frequency Accuracy Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

21 |

|

OSC Level Accuracy Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

23 |

|

DC Bias Monitor Accuracy Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

31 |

|

DC Bias Level Accuracy Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

35 |

|

Measurement Accuracy Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

38 |

|

Calculation Sheet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

52 |

|

OSC Level Accuracy Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

52 |

|

DC Bias Monitor Accuracy Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

54 |

|

DC Bias Level Accuracy Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

55 |

|

Measurement Accuracy Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

56 |

|

Performance Test Record . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

68 |

|

Frequency Accuracy Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

68 |

|

OSC Level Accuracy Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

69 |

|

DC Bias Monitor Accuracy Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

70 |

|

DC Bias Level Accuracy Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

71 |

|

Measurement Accuracy Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

72 |

3. |

Adjustment |

|

|

Safety Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

82 |

|

Required Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

82 |

|

Required Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

82 |

|

Warm-up for Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

82 |

|

Order of Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

83 |

|

Preparation for using the Adjustment Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

84 |

|

Installing an GPIB Card (82340, 82341 or 82350) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

84 |

|

Installing HP VEE for Personal Computer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

84 |

|

Installing Adjustment Program into Your PC (preliminary) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

84 |

|

Equipment Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

84 |

|

Running the Adjustment Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

86 |

|

Frequency Accuracy Correction Constants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

87 |

|

Required Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

87 |

|

Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

87 |

|

Image Rejection Correction Constants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

88 |

|

Required Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

88 |

|

Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

88 |

|

LPOT-Mixer Offset Correction Constants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

89 |

|

Required Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

89 |

|

Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

89 |

|

Null Detector Offset Correction Constants. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

90 |

7

Contents

Required Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90 Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90 Null Loop Phase Correction Constants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91 Required Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91 Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91 HPOT-Amplifier Offset Correction Constants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92 Required Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92 Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92 Relative Impedance Correction Constants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93 Required Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93 Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93 DC Bias Monitor Correction Constants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94 Required Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94 Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94 DC Bias Level Correction Constants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96 Required Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96 Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96 OSC Level Monitor Correction Constants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97 Required Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97 Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97 OSC Level Correction Constants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99 Required Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99 Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99 Impedance Measurement Correction Constants. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100 Required Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100 Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100 Frequency Reference Adjustment (Opt.1D5 only). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103 Required Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103 Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

4. Troubleshooting

TROUBLESHOOTING SUMMARY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106 START HERE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108 INSPECT THE POWER ON SEQUENCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109 Check the Fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109 Check the Front Panel LEDs and Displays. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109 Check Error Message . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109 INSPECT THE REAR PANEL FEATURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110 Check the GPIB Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110 Check the Parallel Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110 Check the mini DIN Keyboard Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110 Internal Tests Failure Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111 Check the Power-On Selftest . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111 Execute All Internal Tests. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111 Execute the Individual Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111 External Tests Failure Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113 Performance Tests Failure Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115 Perform Adjustments and Correction Constants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

8

Contents

5. Power Supply Troubleshooting |

|

|

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

118 |

|

START HERE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

120 |

|

1. |

Check the Fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

120 |

2.Check the A50 SHUTDOWN LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

120 |

|

A50 Shutdown LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

121 |

|

3.Check the A50 Five LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

121 |

|

4. Check the A1 +5 VD LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

121 |

|

5. Check the A9 Two LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

122 |

|

FIND OUT WHY THE FAN IS NOT ROTATING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

125 |

|

1. |

Check the Line Voltage, Selector Switch Setting, and Fuse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

125 |

2. |

Check the A40 Pre-Regulator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

125 |

3. Check the A50 SHUTDOWN LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

126 |

|

FIND OUT WHY THE A50 SHUTDOWN LED IS OFF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

127 |

|

1. |

Disconnect the Cable from the A50P3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

127 |

2. Remove A50 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

127 |

|

3. |

Remove Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

127 |

FIND OUT WHY THE A1 +5 VD LED IS NOT ON STEADILY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

128 |

|

1. |

Check the A50 DC-DC Converter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

128 |

2. |

Measure the A1 +5VD Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

128 |

3. |

Disconnect Cables on the A1 CPU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

128 |

3. |

Remove Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

129 |

TROUBLSHOOT THE FAN AND THE A50 DC-DC CONVERTER . . . . . . . . . . . . . . . . . . . . . . . . . . . |

131 |

|

1. |

Troubleshoot the Fan. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

131 |

2. |

Troubleshoot the A50 DC-DC Converter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

132 |

6. Digital Control Troubleshooting |

|

|

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

134 |

|

A1 CPU Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

136 |

|

FIRMWARE INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

137 |

|

Ordering the Firmware Diskette . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

137 |

|

Installing the Firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

137 |

|

START HERE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

139 |

|

1. |

Check the Power-On Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

139 |

2. Check the A1 CPU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

141 |

|

3. Check the A1 DRAM and Flash Memory. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

141 |

|

4. |

Check the A1 Volatile Memory. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

142 |

5. |

Check the A30 Front Keyboard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

142 |

6. Check the A53 FDD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

143 |

|

7. |

Check the A32 I-BASIC Interface and the mini DIN Keyboard . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

143 |

8. |

Check the 24 BIT I/O PORT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

143 |

9. |

Check the LAN Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

144 |

TROUBLESHOOT THE A51 GSP and A52 LCD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

146 |

|

1. |

Run the Internal Test 4: A51 GSP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

146 |

2. |

Check the A52 LCD (Liquid Crystal Display) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

146 |

7. Service Related Menus |

|

DIAGNOSTIC TEST Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

148 |

9

Contents

Test Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

Test Descriptions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

8. |

Theory of Operation |

|

|

OVERALL OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

156 |

|

OVERALL MEASUREMENT THEORY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

156 |

|

OVERALL OPERATION AND FUNCTIONAL GROUPS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

156 |

|

POWER SUPPLY OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

158 |

|

Line Power Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

159 |

|

A40 Preregulator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

160 |

|

A50 DC-DC Converter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

160 |

|

Regulated + 5V Digital Supply( + 5VD) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

160 |

|

A50 Shutdown LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

160 |

|

A9 Floating Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

160 |

|

DIGITAL CONTROL OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

161 |

|

A1 CPU. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

163 |

|

A30 Front Keyboard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

163 |

|

A32 I-BASIC Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

163 |

|

A34 I/O Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

163 |

|

A51 GSP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

164 |

|

A54 Inverter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

164 |

|

A52 LCD (Liquid Crystal Display) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

164 |

|

A53 FDD. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

164 |

|

SOURCE THEORY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

165 |

|

A7 Synthesizer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

165 |

|

A2 Hc Amp. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

166 |

|

TRANSDUCER THEORY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

167 |

|

A3 Hp Amp. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

168 |

|

A4 Lc Amp. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

168 |

|

A5 IV Converter & Lp Amp. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

168 |

|

A6 Vector Generator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

168 |

|

VECTOR RATIO DETECTOR THEORY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

169 |

|

A8 Vector Ratio Detector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

169 |

9. |

Parts Replacement |

|

|

Replaceable Part List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

172 |

|

Ordering Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

172 |

|

Exchange Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

172 |

|

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

173 |

|

Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

203 |

|

Top Cover Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

203 |

|

Bottom Cover Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

203 |

|

Side Cover Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

203 |

|

Front Panel Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

204 |

|

Rear Panel Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

204 |

|

A1 CPU Board Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

205 |

|

A2/A8/A50/A51 Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

205 |

|

A3 Hp Amplifier Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

205 |

10

Contents

A4 Lc Amplifier Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206

A5 IV Convertor & Lp Amplifier Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206

A6 Vector Generator Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206

A7 Synthesizer Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 207

A9 Floating Power Supply Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 207

A53 FDD Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 208

A52 LCD Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

A40 Preregulator Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

Power Switch Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 210

10. |

Post Repair Procedures |

|

|

POST REPAIR PROCEDURES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

214 |

A. |

Manual Changes |

|

|

Manual Changes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

218 |

B. |

Power Requirement |

|

|

Replacing Fuse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

220 |

|

Fuse Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

220 |

|

Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

221 |

|

Power Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

221 |

C. |

Error messages |

|

|

Order of Alphabet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

224 |

11

Contents

12

Information General .1

1 |

General Information |

This Service Manual is a guide to servicing the 4294A Precision Impedance Analyzer. The Service Manual provides information about performance testing, adjusting, troubleshooting, and repairing the 4294A.

13

General Information

Organization of Service Manual

Organization of Service Manual

This manual consists of the major chapters listed below. This section describes the names of the chapters and the content of each chapter.

•Performance Test provides procedures for performance testing the 4294A.

•Adjustment provides procedures for adjusting the 4294A after repair or replacement of an assembly. Most of the adjustments update the correction constants stored into the EEPROM on the A1 CPU. The correction constants are updated by using the adjustment program.

•Troubleshooting provides troubleshooting procedures to isolate any faulty functional group or faulty assembly. Faulty assembly isolation procedures for the faulty functional group follow this chapter.

•Power Supply Troubleshooting provides troubleshooting procedures to isolate any faulty assembly within the power supply functional group.

•Digital Control Troubleshooting provides troubleshooting procedures to isolate any faulty assembly within the digital control functional group.

•Service Related Menus documents the functions of the menus accessed from [System], DIAGNOSTIC TEST. These menus are used to test, verify, and troubleshoot the 4294A.

•Theory of Operation explains the overall operation of the 4294A, the division into functional groups, and the operation of each functional group.

•Parts Replacement provides part numbers and illustrations of the replaceable assemblies and miscellaneous chassis parts. This chapter also provides procedures to disassemble portions of the analyzer when certain assemblies have to be replaced.

•Post Repair Procedures contains the table of related service procedures. It is a table of adjustments and verification procedures to be performed after repair or replacement of each assembly.

•Appendices contains manual change information (required to make this manual compatible with earlier shipment configurations of the analyzer), power requirements and error messages of the analyzer.

14 |

1 |

General Information

Instruments Covered by This Manual

|

Instruments Covered by This Manual |

|

Agilent Technologies uses a two-part, ten-character serial number label (See Figure 1-1) |

|

attached to the instrument’s rear panel. The first five characters are the serial prefix and the |

|

last five digits are the suffix. |

Figure 1-1 |

Serial Number Label |

An instrument manufactured after the printing date of this manual may have serial number prefix that is not listed on the title page. This unlisted serial number prefix indicates the instrument is different from those described in this manual. The manual for this new instrument may be accompanied by a yellow Manual Changes supplement or have a different manual part number. This sheet contains “change information” that explains how to adapt the manual to the newer instrument.

In addition to change information, the supplement may contain information for correcting errors (Errata) in the manual. To keep this manual as current and accurate as possible, Agilent Technologies recommends that you periodically request the latest Manual Changes supplement. The supplement for this manual is identified by this manual’s printing data and is available from Agilent Technologies. If the serial prefix or number of an instrument is lower than that on the title page of this manual, see Appendix A, Manual Changes. For information concerning, a serial number prefix that is not listed on the title page or in the Manual Changes supplement, contact the nearest Agilent Technologies office.

Information General .1

1 |

15 |

General Information

Require Equipment

Require Equipment

|

Table 1-1 lists the recommended equipment for performing maintenance on the 4294A. |

||||

Table 1-1 |

Recommended Test Equipment |

|

|

|

|

|

|

|

|

|

|

Equipment |

|

Critical Specifications |

Recommended Model |

Qty. |

Use*1 |

Frequency Counter |

|

Frequency Range: 10 MHz, Time |

5334B, |

1 |

P,A |

|

|

Base Error: ≤ ±1.9×10–7 /year |

or 53181A |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Frequency Standard |

|

Frequency: 10 MHz, Time Base Error: |

5061B, |

1 |

P,A |

|

|

≤ ±1×10–10/year |

or 5071A |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Multimeter |

|

No Substitute |

3458A |

1 |

P,A |

|

|

|

|

|

|

Power Meter |

|

No Substitute |

437B, |

1 |

P,A |

|

|

|

438A, |

|

|

|

|

|

E4418A/B, |

|

|

|

|

|

or E4419A/B |

|

|

|

|

|

|

|

|

Power Sensor |

|

Frequency Range: 1 MHz to 110 MHz |

8482A |

1 |

P,A |

|

|

Power: –30 dBm to 20 dBm |

|

|

|

|

|

|

|

|

|

Standard Capacitor |

|

No substitute |

16380A |

1 |

P,A |

|

|

|

|

|

|

Standard Capacitor |

|

No substitute |

16380C |

1 |

P |

|

|

|

|

|

|

Standard Resistor |

|

No substitute |

42030A |

1 |

P |

|

|

|

|

|

|

4TP OPEN termination |

No substitute |

42090A |

1 |

P,A |

|

|

|

|

|

|

|

4TP SHORT termination |

No substitute |

42091A |

1 |

P,A |

|

|

|

|

|

|

|

Performance Test Kit |

|

No substitute |

16190A |

1 |

P |

|

|

|

|

|

|

7mm Terminal Adapter |

No substitute |

42942A |

1 |

P |

|

|

|

|

|

|

|

Test Leads 1m |

|

No substitute |

16048G*2 |

1 |

P |

Test Leads 2m |

|

No substitute |

16048H*2 |

1 |

P |

100 Ω Resistor |

|

No substitute |

p/n 04294-61001*3 |

1 |

P,A |

4TP to BNC Interface |

|

No substitute |

p/n 04294-61002 |

1 |

P,A |

Box |

|

|

|

|

|

|

|

|

|

|

|

Two-Way Power Splitter |

Frequency Range 1 MHz to 110 MHz, |

11667A |

1 |

P,A |

|

|

|

Output Tracking ≤ 0.15 dB |

|

|

|

|

|

|

|

|

|

Cables |

|

BNC(m)-BNC(m) Cable, 61 cm |

p/n 8120-1839 |

1 |

P,A |

|

|

Banana(m)-Banana(m) Cable |

11058A |

2 |

A |

|

|

|

|

|

|

16 |

1 |

General Information

Require Equipment

Table 1-1 |

Recommended Test Equipment |

|

|

|

|

|

|

|

|

|

|

Equipment |

|

Critical Specifications |

Recommended Model |

Qty. |

Use*1 |

Adapter |

|

7 mm-N(m) Adapter |

11525A |

1 |

P |

|

|

Dual Banana-BNC(f) Adapter |

p/n 1251-2277 |

1 |

P,A |

|

|

N(m)-BNC(m) Adapter |

p/n 1250-0077 |

1 |

P,A |

|

|

BNC(f)-BNC(f) Adapter |

p/n 1250-1830 |

4 |

A |

|

|

BNC(m)-Banana(m) Adapter |

p/n 1250-1263 |

4 |

A |

|

|

|

|

|

|

Termination |

|

50 Ω termination |

909C Opt.012 |

1 |

P,A |

|

|

|

|

|

|

*1.P:Performance Test A:Adjustment

*2.16048A/D cannot be used for a substitute.

*3.furnished with the 4294A

Information General .1

1 |

17 |

General Information

Require Equipment

18 |

1 |

Test Performance .2

2 |

Performance Test |

This chapter contains the performance test for the 4294A Precision Impedance Analyzer. These performance tests are used to verify that the analyzer’s performance meets its specifications.

19

NOTE

Performance Test

Performance Test

Performance Test

Introduction

This section provides the test procedures used to verify that the 4294A’s specifications are met. The performance tests can also be used for incoming inspection, and for verification after troubleshooting or adjustment. If the performance tests indicate that the 4294A is NOT operating within the specified limits, check your test setup, then proceed with troubleshooting if necessary.

Warm Up Time

Allow the 4294A to warm up for at least 30 minutes before you execute any of the performance tests

Ambient Conditions

Perform all performance tests in ambient conditions of 23 °C ± 5 °C, ≤ 70% RH.

Performance Test Interval

The performance test should be performed periodically. The recommended test interval is 12 months.

The test interval depends on maintenance of use and the environmental conditions under which the instrument is used. You may find that the test interval could be shortened or lengthened; however, such a decision should be based on substantial quantitative data.

Performance Test Record and Calculation Sheet

Performance test record lists all test points, acceptable test limits, test result entry columns, and measurement uncertainties. The listed measurement uncertainties are valid only when the recommended test equipment is used.

The calculation sheet is used as an aid for recording raw measurement data, and for calculating the performance test results.

The procedure for using the calculation sheet and performance test record is;

1.Photo copy the calculation sheet.

2.Follow the performance test procedure and record the measurement values, the 4294A’s reading, etc., into the specified column on the calculation sheet.

3.Calculate the test result using the appropriate equation given on the calculation sheet, and record the test result into the Test Result column of the performance test record.

Test Equipment

Table 1-1 lists the recommended equipment for performing maintenance on the 4294A.

20 |

2 |

Performance Test

Performance Test

Frequency Accuracy Test

This test checks the frequency accuracy of the internal frequency reference with a frequency counter and a frequency standard.

Specification

Frequency Accuracy: |

± 20 ppm at (23±5) ºC (without Option 1D5) |

|

||

|

± 0.13 ppm at 0 ºC to 55 ºC (with Option 1D5) |

|

||

Test Equipment |

|

|

|

.2 |

|

|

|

Performance |

|

|

|

|

|

|

|

Description |

Recommended Model |

|

|

|

|

|

|

|

|

Frequency Counter |

5334B or 53181A |

|

|

|

|

|

|

Test |

|

Frequency Standard |

5071A |

|

|

|

|

|

|

|

|

4TP to BNC Interface Box |

p/n 04294-61002 |

|

|

|

|

|

|

|

|

BNC(m) -BNC(m) Cable, 61 cm |

p/n 8120-1839 |

|

|

|

|

|

|

|

|

BNC(m)-BNC(m) Cable, 122 cm |

p/n 8120-1840 |

|

|

|

|

|

|

|

|

Procedure |

|

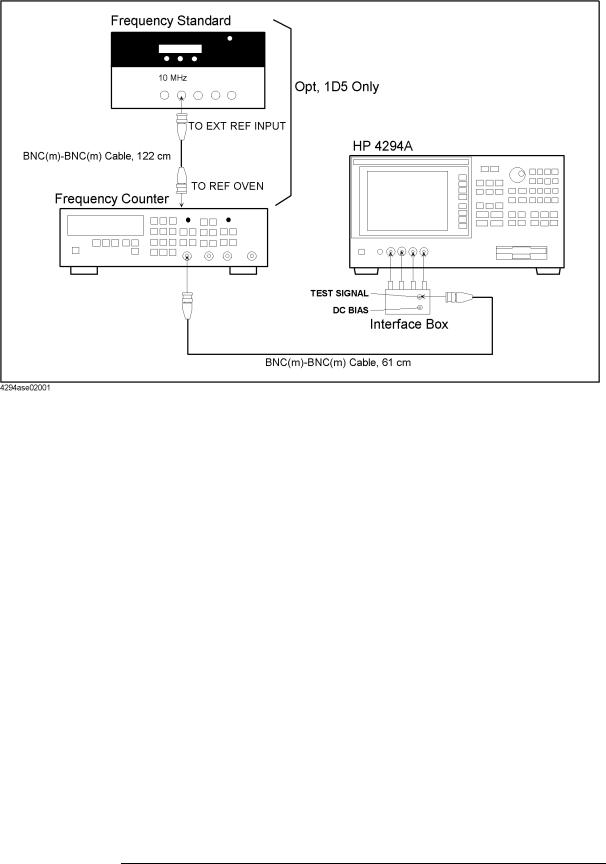

1. Connect the test equipment as shown in Figure 2-1. For testing the 4294A with Option |

|

1D5, connect a BNC(m)-BNC(m) cable between the EXT REF Input connector and the |

|

REF OVEN connector on the analyzer rear panel. |

|

|

NOTE |

If testing the 4294A without Option 1D5, the frequency standard is not required. |

2 |

21 |

Performance Test

Performance Test

Figure 2-1 |

Frequency Accuracy Test Setup |

2. Initialize the frequency counter. Then set the controls as follows.

Gate Time: |

1 sec. |

INT/EXT Switch (rear panel, 5334B only) |

EXT*1 |

*1.If the frequency standard is not connected, set the switch to INT.

3. Press [Preset] to initialize the 4294A. Then set the controls as follows.

Setting |

Operation |

Frequency Span: 0 Hz |

[Span] - [0] - [×1] |

Center Frequency: 10 MHz |

[Center] - [1] - [0] - [M/m] |

OSC Level: 0.25 V |

[Source] - LEVEL - [.] - [2] - [5] - [×1] |

Number of Points: 2 |

[Sweep] - NUMBER OF POINTS - [2] - [×1] |

Trigger Mode: Single |

[Trigger] - Single |

4.Subtract 10 MHz (analyzer setting) from the frequency counter reading, and record the result on the performance test record.

22 |

2 |

Performance Test

Performance Test

OSC Level Accuracy Test

This test checks the actual power level of the test signal at 10 MHz.

Specification

OSC Level Accuracy: ±[(10 + 0.05 × f [MHz]) % + 1mV]

Test Equipment |

|

|

.2 |

|

|

|

|

|

|

|

Description |

Recommended Model |

|

Performance |

|

|

|

||

|

|

|

|

|

|

Multimeter |

3458A |

|

|

|

|

|

|

|

|

Power Meter |

437B, 438A, |

|

|

|

|

E4418A/B, |

|

Test |

|

|

or E4419A/B |

|

|

|

|

|

|

|

|

Power Sensor |

8482A |

|

|

|

|

|

|

|

|

Two-way Power Splitter |

11667A |

|

|

|

|

|

|

|

|

61 cm BNC(m) to BNC(m) |

p/n 8120-1839 |

|

|

|

Cable |

|

|

|

|

|

|

|

|

|

7 mm-N(m) Adapter |

11525A |

|

|

|

|

|

|

|

|

Dual Banana-BNC(f) Adapter |

p/n 1251-2277 |

|

|

|

|

|

|

|

|

N(m)-BNC(m) Adapter |

p/n 1250-0077 |

|

|

|

|

|

|

|

|

4TP-BNC Interface Box |

p/n 04294-61002 |

|

|

|

|

|

|

|

|

OPEN Termination |

42090A |

|

|

|

|

|

|

|

|

N(m)-Termination, 50 Ω |

909C Opt.012 |

|

|

|

|

|

|

|

Procedure

Accessory: Nothing, 40 Hz to 100 kHz

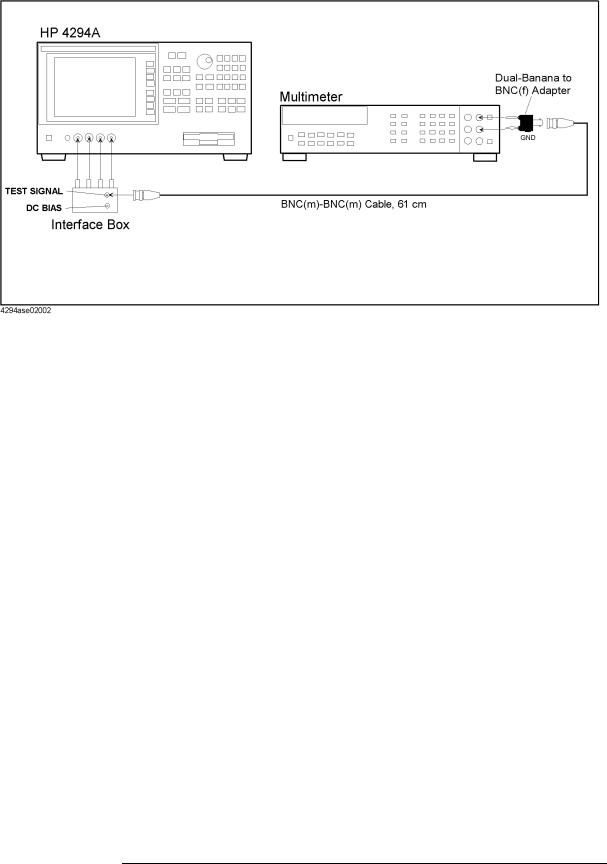

1. Connect the equipment as shown in Figure 2-2.

2 |

23 |

Performance Test

Performance Test

Figure 2-2 |

OSC Level Accuracy Test Setup 1 |

|

2. |

Press Reset key (blue, ) to initialize the multimeter, then Set it as follows. |

|

|

|

a. Press [ACV] to set the measurement mode to AC voltage. |

|

|

|

b. Press S(blue - N Rdgs/Trig), , , to display SETACV. |

|

|

|

c. Press , , , to display SYNC, then press [Enter] |

|

|

|

d. Press [NPLC] - [1] - [0] - [0] - [Enter] |

|

|

3. |

Press [Preset] to initialize the 4294A. Then set the controls as follows. |

|

|

|

Setting |

Operation |

|

|

Frequency Span: 0 Hz |

[Span] - [0] - [×1] |

|

|

Center Frequency: 1 kHz |

[Center] - [1] - [k/m] |

|

|

OSC Level: 1 V |

[Source] - LEVEL - [1] - [×1] |

|

|

OSC Level Monitor: ON |

[Display] - OSC MON |

|

|

Number of Points |

[Sweep] - NUMBER OF POINTS - [2] - [×1] |

|

4. |

Press [Trigger] - Single for a single sweep measurement: |

|

|

5. |

Record the multimeter reading and the OSC Level Monitor Reading to the calculation |

|

|

|

sheet. |

|

|

6. |

Calculate the monitor accuracy according to the calculation sheet, and record the |

|

|

|

monitor accuracy into the calculation sheet. |

|

|

|

||

NOTE |

OPEN Reading is recorded in the Step22. |

||

24 |

2 |

|

|

|

Performance Test |

|

|

|

|

|

Performance Test |

|

|

|

7. Confirm that the monitor accuracy is within the monitor accuracy limit. |

|

|||

|

|

|

|

|

|

NOTE |

If the monitor accuracy is beyond the limit, OSC Level Test fails. |

|

|||

|

8. Repeat from Step 4 to 7 for all OSC level and frequency setting in Table 2-1 |

|

|||

|

Table 2-1 |

OSC Level Accuracy Test (Interface box) Settings 1 |

|

||

|

|

|

|

|

|

|

|

OSC Level |

Frequency |

|

|

|

|

|

|

|

.2 |

|

|

1.0 V |

1 kHz |

|

|

|

|

|

Performance |

||

|

|

|

100 kHz |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0.5 V |

40 Hz |

|

|

|

|

|

1 kHz |

|

Test |

|

|

|

10 kHz |

|

|

|

|

|

|

|

|

|

|

|

100 kHz |

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

0.25 V |

1 kHz |

|

|

|

|

|

100 kHz |

|

|

|

|

|

|

|

|

|

|

0.125 V |

1 kHz |

|

|

|

|

|

100 kHz |

|

|

|

|

|

|

|

|

|

|

0.064 V |

1 kHz |

|

|

|

|

|

100 kHz |

|

|

|

|

|

|

|

|

|

|

0.016 V |

1 kHz |

|

|

|

|

|

100 kHz |

|

|

|

|

|

|

|

|

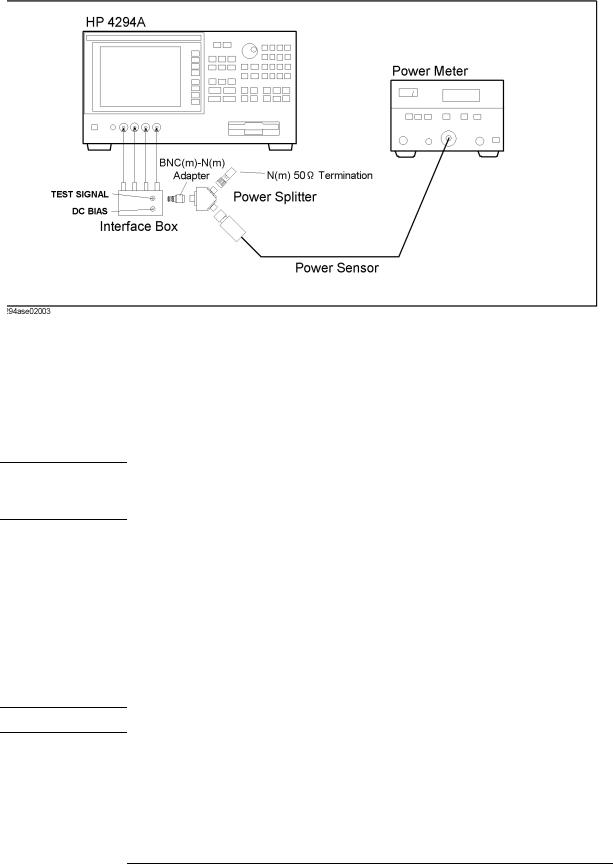

Accessory: Nothing, 1 MHz to 110 MHz

9.Connect the power sensor to the power meter. Calibrate the power meter for the power sensor.

10.Set the power meter measurement mode to “Watt”

11.Disconnect the BNC(m)-BNC(m) Cable from the interface box, and connect the equipment as shown in Figure 2-3.

2 |

25 |

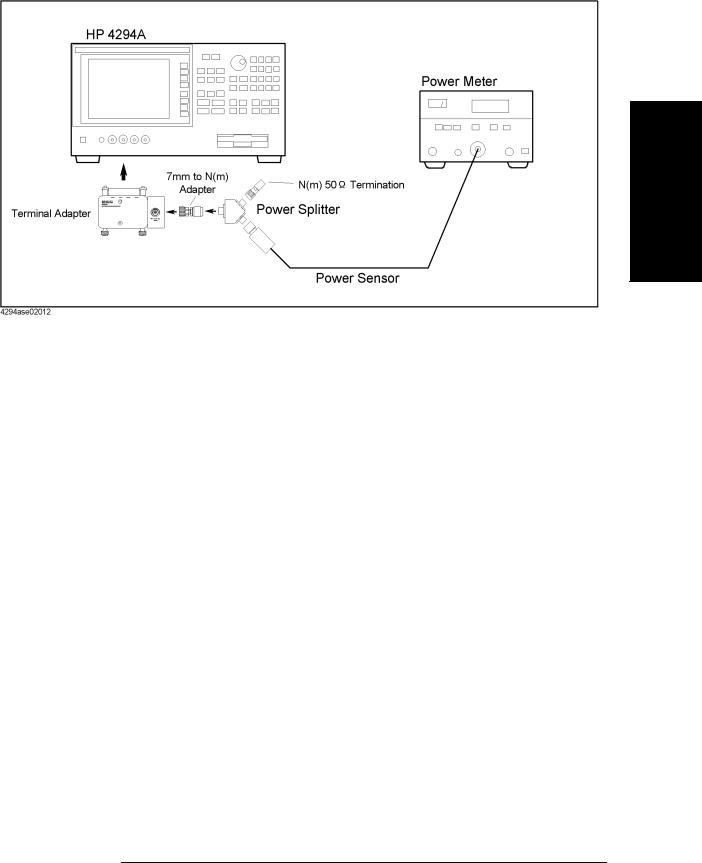

Figure 2-3

NOTE

NOTE

Performance Test

Performance Test

OSC Level Accuracy Test Setup 2

12. Set the 4294A as follows. |

|

Setting |

Operation |

Center Frequency: 1 MHz |

[Center] - [1] - [M/μ] |

OSC Level: 0.75 V |

[Source] - LEVEL - [.] - [7] - [5] - [×1] |

The OSC level must be set to 0.75V because impedance mismatching occurs between the 4294A and the power sensor. The calculation sheet and the test record say the OSC level is 0.5 V.

13.Press [Trigger] - Single for a single sweep measurement:

14.Record the following values according to the calculation sheet.

a.OSC level monitor reading

b.Power meter reading

c.OSC level calculated from the power meter reading.

d.OSC level monitor accuracy.

15.Confirm that the OSC level monitor accuracy is within the monitor accuracy limit.

If the monitor accuracy is beyond the limit, OSC Level Test fails.

26 |

2 |

|

|

|

Performance Test |

|

|

|

|

Performance Test |

|

16. |

Repeat from Step 13 to 15 for all frequency settings in Table 2-2 |

|

||

Table 2-2 |

OSC Level Accuracy Test (Interface box) Settings 2 |

|

||

|

|

|

|

|

|

|

Frequency |

|

|

|

|

|

|

|

|

|

1 MHz |

|

|

|

|

10 MHz |

|

|

|

|

15 MHz |

|

.2 |

|

|

16 MHz |

|

|

|

|

|

TestPerformance |

|

17. |

Disconnect the all test equipment from |

the 4294A, then connect the OPEN termination |

||

|

|

50 MHz |

|

|

|

|

110 MHz |

|

|

|

directly to the 4294A UNKNOWN terminals. |

|

||

18. |

Press [Source] - LEVEL - [.] - [5] - [×1] to set the 4294A OSC level to 0.5 V. |

|

||

|

||||

19. |

Press [Trigger] - Single for a single sweep measurement: |

|

||

20. |

Read the level monitor reading for all OSC level and frequency setting in Table 2-2, |

|

||

|

then record them to the OPEN Reading column in the calculation sheet. |

|

||

21. |

Press [Trigger] - Single for a single sweep measurement: |

|

||

22. |

Read the level monitor reading for all OSC level and frequency setting in Table 2-1, |

|

||

|

then record them to the OPEN Reading column in the calculation sheet. |

|

||

23. |

Calculate the test results according to the calculation sheet, then record them to the test |

|

||

|

record. |

|

|

|

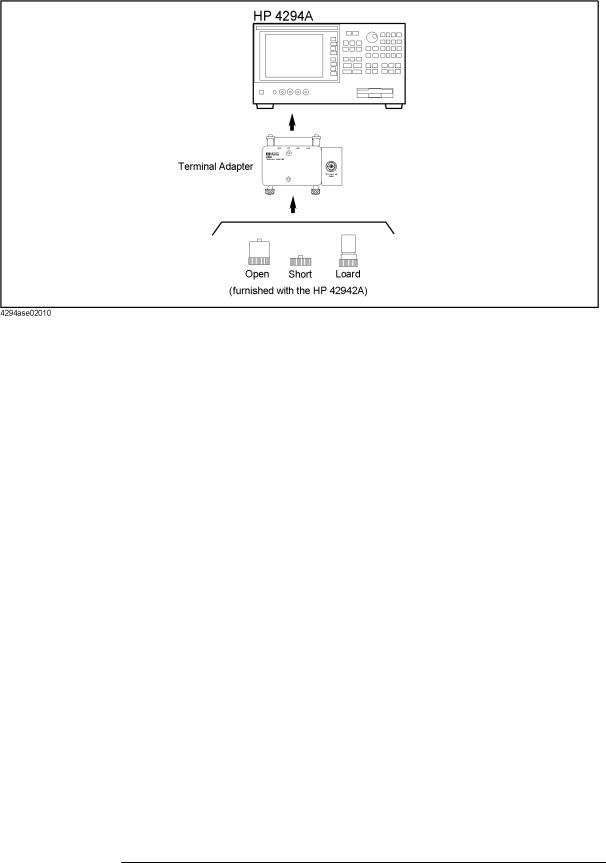

With 42942A Terminal Adapter

24.Disconnect the all test equipment from the 4294A, then connect the equipment as shown in Figure 2-4

2 |

27 |

Performance Test

Performance Test

Figure 2-4 |

42942A Setup |

25.Setup the 42942A as follows.

a.Press [Cal],Adapter,7mm 42942A,SETUP.

b.Connect the OPEN termination furnished with the 42942A to the 7mm connector.

c.Press PHASE COMP to measure the phase compensation data.

d.Press OPEN to measure the open compensation data.

e.Connect the SHORT termination furnished with the 42942A instead of the OPEN termination.

f.Press SHORT to measure the short compensation data.

g.Connect the 50 Ω termination furnished with the 42942A instead of the SHORT termination.

h.Press LOAD to measure the load compensation data.

i.Press done to activate the measured compensation data.

26.Connect the instruments as shown in Figure 2-5.

28 |

2 |

Performance Test

Performance Test

Figure 2-5 |

OSC Level Accuracy Test Setup 3 |

Test Performance .2

|

27. |

Set the 4294A as follows. |

|

|

Setting |

Operation |

|

|

Center Frequency: 1 MHz |

[Center] - [1] - [M/m] |

|

|

OSC Level: 0.75 V |

[Source] - LEVEL - [.] - [7] - [5] - [×1] |

|

|

|

||

NOTE |

The OSC level must be set to 0.75V because a impedance mismatch occurs between the |

||

|

4294A and the power sensor. |

|

|

|

28. |

Press [Trigger] - Single for a single sweep measurement: |

|

|

29. |

Record the following values according to the calculation sheet. |

|

|

|

a. OSC level monitor reading |

|

|

|

b. Power meter reading |

|

|

|

c. OSC level calculated from the power meter reading. |

|

|

|

d. OSC level monitor accuracy. |

|

|

30. |

Confirm that the monitor accuracy is within the monitor accuracy limit. |

|

|

|

||

NOTE |

If the monitor accuracy is beyond the limit, OSC Level Test fails. |

||

2 |

29 |

Performance Test

Performance Test

31. Repeat from Step 28 to 30 for all frequency settings in Table 2-3

Table 2-3 |

OSC Level Accuracy Test (Interface box) Settings 3 |

Frequency

1 MHz

10 MHz

15MHz

16MHz

50MHz

110MHz

32.Disconnect the test equipment from the 7mm connect, then connect the OPEN termination to the 7mm connector.

33.Press [Source] - LEVEL - [.] - [5] - [×1] to set the 4294A OSC level to 0.5 V.

34.Press [Trigger] - Single for a single sweep measurement:

35.Read the level monitor reading for all OSC level and frequency setting in Table 2-3, then record them to the calculation sheet.

36.Calculate the test results according to the calculation sheet, then record them to the test record.

30 |

2 |

Loading...

Loading...