Page 1

Belt

Switch

Washer,’

Roller

witch,

Circuit

Electronic

valve,

Valve,

Valve,

Levelery

Pump

Switch

Switch,

Fin,

Fin

Belt,

Fuse,

Fuse,

teeper,

Bear,

bear,

king,

fastener,

fear,

fear

ear,

ear,

leeper,

3 ,

jear,

iparing

i

use,

pring,

11

unit,

straight,

roller

bearing

na

,DCCL

flat

assembly

reed

card

component

globe

globe

whiteC-ohe

foot,

reciproca

assembiy

box

round

cartridge

cart.

cart.

slide

worm

worm

retaining

snap

spur

roller,

spur

worm

slide

Spur

worm

dryer

element

assembl

(red)

(blue)

proce

head

(1.6

(400ma

(6.25a

proc

annular

A

310-01-

6525-01-361-8541

5930-01-361-7823

ee

8.9432.

8.9432

\

ŘS

.9452.1090.0

1070.

-1110.4

a

ee

8.9452.1080.2

8.8370.2615.0

8.8966.0067.1

9.8148.6611.0

6.0200.4390.0

6

0200.4490

7.0389.6536.0

7.0451.9608.0

7.0451.9630.0

7.0451.9705.0

7.8185.6023.1

7.8187.6655.1

7.8187.6865.0

7.9402.1129.0

7.94=2.

2022

50

o

대

시

에

에

에

DO)

II

CTA

10

0

N

NU

ten

eta

5999-01-561-7856

5999-01-361-7855

4820-01-361-7817

4820-01-361-7818

6525-01-

4320-01-361-7827

5930-01-361-7866

5930-01-361-7822

53157

5920-01-361-7810

5920-01-561-7811

5920-01-361-7808

5340-01-361-7837

3020-01

3020-01

5365-01

S325-01-361-7824

3020-01

6525-01

“361-7814

AD

-O

73617

01-361-7830

01-

01-361-7836

ο.

-8542

340 - <

!

Page 2

sive,

alve,

eveler,

‘ump

jin,

fin

jear,

unit,

witch

witch,

straight,

eli,

use,

use,

use,

esper,

gar,

ing,

astener,

ear,

pring,

ear

roller

reed

cara

nic

component

giobe

globe

white

foot,

reciproca

assembly

box

rouno

cartriage

cart.

cart.

slide

worm

worm

retaining

snan

spur

rolier,

ето?

ired)

(blue)

proce

head

(1.6

1400ma

(6.258

=

prac

0329

3.8185.6580.1

B.P462.2510.1

8.9462,4546

8.9452.1070.4

8.9432.1110.4

8.9432.1090.0

8.9432.1080.%

8.8370.2615.0

8.8966.0067.1

9.8148.6611

6.0200,4390.

7

7.0451.9608.0

7.0451.9630.0

7.0451.9705.0

7.B185.6023,1

7.8187,6655.1

7.8187.6863.0

7.9402.1129

7.9432.2022.0

.4640

2.2710.0

9200.4490.0

89.6556.0

432.2025.0

ne

RİN

o

mn

pon

a

PS

5999-01-561-7855

4820-01-361-7817

4820-01-361-7818

6525-01-561-8542

4320-01-361-7827

5950-01-561-7866

5950-01-561-7822

5515-01-3561-7850

3030-01-361-78736

5920-01-361-7810

5920-01-361-7811

5920-01-361-7808

5340-01-361-7837

3020-01-361-7844

3020-01-361-7845

5365-01-361-7868

5525-01-561-7824

3020-01-361=

6S25-01-262-8621

WOT

arıng

dryer

element

aonular

Page 3

TABLETOP

CURIX

PROCESSOR

60

OPERATOR'S

INSTALLATION

INSTRUCTION

CURIX

AND

MANUAL

60

ee

АСРА

<>

Page 4

Scope of

this

&

Purpose

manual

Scope

This

Manual

and

operations

maintenance

Purpose

This

Manual

operation

minimum

by a dealer,

SECTION

and

of

2. -

provides

instructions,

is

intended

maintenance

technical

the

Getting

step-by-step

of

the

CURIX®

assistance.

customer

Started.

and

to

provide

may

of

60

an

the

skip

instructions

Processor.

illustrated

an

overview

CURIX

However,

60

SECTION

for

unpacking,

Routine

parts

list

of

the

Processor

if

the

processor

1.

and

set-up,

cleaning

are

installation,

with

proceed

also

a

is

and

included.

installed

to

a

Getting

If

you

encounter

or

if

the

dealer

for

The

SECTION

SECTION

SECTION

SECTION

SECTION

Appendix

Appendix

Appendix

Appendix

Reader’s

Warranty

or

instructions

Manual

Assistance

difficulty

processor

AGFA

1.-

2.-

3.-

4.-

5. - Maintenance

A. - Exploded

B. - Parts

C.-

D.-

Comment

Card

fails to

CORPORATION,

on

“How

consists

of

Unpacking

Getting

Cleaning

Troubleshooting

List

How

To

Equipment

Form

with

the

operate

Agfa

to

get

help

the

following

and

Installation

Started

the

CURIX

Procedures

Views

of

Get

Help

Specifications

installation

as

specified,

Matrix

when

you

Sections:

Procedures

60

Processor

Processor

When

You

or

operating

contact

Division.

need

it.”

Need

It

instructions,

your

Agfa

See

Appendix

C,

©

The information

changes

This

or

please

the

AGFA

100

ATT:

Agfa

information

without

®

Copyright

|

Scope & Purpose

will

publication could

typographical

use

Appendixes,

CORPORATION,

Challenger

Product

Corporation

incurring

1991,

provided

be

incorporated

errors.

the

Postage-Free

or

address

Road,

Manager,

may

you

supply

any

Agfa

Corporation.

of

this

in

this

in

new

inadvertently

If

you

wish

Reader

your

Agfa

Matrix

Ridgefield

Special

use

and

distribute

in a way

obligation

manual

All

rights

whatever.

Manual

comments

Products

it

reserved.

is

editions

contain

to

comment

Comment

Division

Park,

believes

subject

NJ

Group

any

appropriate

to

of

this

technical

on

Form

to:

07660

of

the

change.

publication.

inaccuracies

this

located

Such

publication,

after

a

ui

Page 5

Table

of

Contents

Introduction

SECTION

1.1

1.2

1.3

1.4

SECTION

2.1

2.2

2.3

2.4

2.5

2.6

2.7

2.8

2.9

SECTION

Each

Each

Each

©

3.1

1.

Unpacking

Working

Basic

Unpacking

Optional

Components

Operating

Processor

Clean

Checking

Standard

“Quick”

Mixing

Start-up

Day.

Wee!

Month.

Removing

Area

Installation

Fixed

2.

Getting

Controls

the

Tanks

the

Replenishment

Replenishment

the

Procedures

3.

Cleaning

and

Requirements..

Requirements

the

CURIX

Water

of

the

Functions

Before

Current

Developer

Cleaning

and

Installation

60

Processor

Connection

Started

CURIX

...

Adding

Replenishment

Rate

Rate

and

Fixer

.....

the

CURIX

of

Accessory

60

Processor

Chemicals

Adjustment.

Adjustment

Chemicals

60

Processor

the

Tanks

Procedures

...

Rate

.

Procedure

.

.

SECTION

4.1

4.2

4.3

4.4

4.5

SECTION

5.1

5.2

-5.3

5.4

5.5

APPENDIX

APPENDIX

APPENDIX

APPENDIX

Reader's

4.

Troubleshooting

Processor

Film

Film

Appearance

Excessive

Replacement

Replacement

Maintenance

Replacement

Replacement

Fails

Transport

Drying

Problems

Replenishment......

5.

Maintenance

A.

Exploded

B.

Parts

C.

How

D.

Eguipment

Comment

to

Operate - Power

Failure - Power

of

Processed

of

Fuses.

of

Defective

of

the

Main

of

Springs...

of

Dryer

Guide

Views

Lis:

to

Get

Specifications

Form

Checklist

Switch

Film

Procedures

Gears

.

Drive

Assembh

Plate

of

Processor

Help

When

Switch

Keepers....

You

is

On

Need

is

On.

....

....

It

Table

of

Contents

Page 6

Introduction

The

cal

to

It

O

Q

Q

|

Q

Q

Q

Q

Q

CAUTION:

read

CURIX

features

the

features:

Easy

Low

Rapid

Precise

High-efficiency

mum

Simplified,

resistant

Handles

Processing

60

Tabletop

of

high-capacity

highest

SECTION

standards

installation — just

operating

start-up

control

of

excess

rackless

rollers

film

time,

Processor

Agfa

Film

of

quality

plug

it

in

cost - economical

time - only 7 minutes

of

temperature

modular

heat - no

from

4" x 4"

dry-to-dry

Before

1

carefully.

film

transport

you

and

infrared

venting

up

to

14"

in

only 3 minutes

unpack

incorporates

Processors.

and

reliability.

stand-by

chemistry

dryer

is

needed

system

wide

for

rapid drying

with

and

the

processor

mode

many

of

the

It

is

manufactured

replenishment

with a mini-

chemical

36"

long

please

technologi-

|

CURIX

60

Introduction

1

6

Page 7

v

SECTION

Unpacking

and

Procedure

1.1

Requirements

NOTE:

processor,

darkroom

working

installation

Installation

Working

Before

make

which

area

and

requirements.

1

Area

unpacking

sure

you

has

an

adequate

meets

the

the

have

basic

a

The

CURIX

The

counter

must

have a minimum

leveling

is

Top

FZ3H2003)

feet

recommended

Extension

60

or

are

are

Processor

support

approximately

for

(Cat.

available

upon

working

safety

No.

F8AM4440)

as

LIGHT

is

x

;

(am

i

designed

which

purposes.

accessories

COVER

to

the

surface

23"

COUNTER

of

apart.) A larger

or

Processor

224 一 一

MINIMUM

26" x 26"

be

installed

processor

26" x 26"

If

needed, a suitable

from

Agfa

SIZE

in a darkroom.

is

to

(the

working

Stand

Corporation.

本

一

be

一

set

up

centers

surface

Counter

(Cat.

No.

|

of

the

Figure

The

certain

Q

Q

Q

1.

Dimension

processor

minimum

Full

access

Minimum

Minimum

should

from

clearance

clearance

===

=-

Drawing

be

accessible

clearance

front

rear,

above

for

must

of

processor

left

counter

37

Processor

from

be

provided

and

right

all

top:

y

Π

Installation

sides

if

for

use.

side:

1"

28"

IS

possible,

As

follows:

but

Section

1:

Unpacking

and

Installation

Procedures

7

Page 8

1.2

Basic

Requirements

Installation

Complete

APPENDIX

Power

outlet

Water

water

should

nient sink

bottle,

Disposal

specifications

Requirement:

is

required.

Requirement:

connection.

be

and

mixing

of

WARNING:

to

local

codes

Care

should

Please

chemistry

from

Ventilation

does

sive

normal

Agfa

not

external

operator

observe

require a separate

D.

The

following

Water

at

normal

Waste

labels.

Corporation.

Requirement:

heat.

water

the

chemicals

It

is

regarding

be

taken

Therefore,

comfort

room

Chemistry

the

for

the

are the

120

VAC,

The

CURIX

is

supplied

temperature

hose

is

recommended

and

the

purchaser’s

when

hazard

Material

The

exhaust

for

short

CURIX

basic

60

Hz,

60

Processor

by a water

cleaning

and

Waste

the

disposal

handling

instructions

Safety

Infrared

system

the

only

periods.

60

Processor

requirements

1100 W max.

does

replenisher

(59º

to

77º

F)

for

filling

the

processor.

Water:

responsibility

of

waste

chemistry

provided

Data

Sheets

Dryer

in

the

and

does

darkroom

ventilation

are

provided

for

installation:

Grounded,

not

need a separate

However, a conve-

the

water

to

chemistry.

at

are

CURIX

not

60

produce

required

in

15

bottle.

replenisher

conform

all

times.

on

the

available

Processor

Amp

Water

exces-

is

for

The

processor

and

86º

F,

and a relative

Darkroom

package

After

is

closed,

Lighting

for

exposed

the

will

operate

Reguirement:

recommended

film

is

inserted

darkroom

properly

humidity

darkroom

into

door

may

at a room

between

Consult

lighting

the

processor

be

opened.

temperature

25%

and

the

medical

conditions.

and

between

80%.

imaging

the

Light-tight

film

Cover

59°

F

Section

1:

Unpacking

and

Installation

Procedures

Page 9

1.3

CURIX

Unpacking

Processor

60

the

|

|

following

By

plastic

the

opened

You

have

items:

the

wrapper,

small

the

also

preliminary

lifted

carton

inner

verified

that

unpacking

large

the

obtain

to

you

have

instructions

carton

cover

manual.

this

received

from

the

following

you

the

removed

have

pallet,

standard

and

|

|

Remove

The

number

Remove

as

Lift

|

The

|

surface

|

CAUTION:

|

processor

remove

Tray/Cover

|

The

CURIX

Six

Three

Three

Adapter

Light-tight

And,

Waste

Agfa

Specific

shown

60

Processor

replenisher

bottle

valves

caps

for

hose

accessory

Cover

if

ordered,

bottles

Developer

type,

size,

Polyfoam

processor

Processor

processor

as

pallet & packaging

of

polyfoam

the

polyfoam

in

Figure

shown

since

the

is

onto

may now

It

tape

at

bottles

replenisher

(drain)

Accessory

the

following

and

Fixer

concentrate

and

quantity

Protective

protected

sheets.

2.

in

Figure

is

it

holding

this

by

sheets

Work

Surface

be

lifted

3.

recommended

weighs

time.

components

bottles

optional

of

Agfa

Packing

large

rigid

and

slide out

and

placed

approximately

the

processor

may now

accessories:

solutions

Film

polyfoam

the

rigid

in

position

that

two

Receiving

be

discarded.

supports,

polyfoam

on

people

120

Ib.

and

supports

the

work

lift

the

Do

a

not

NOTE:

Drain

Hoses

Developer

Water

(white).

color

coded,

each

Drain

Then,

lower

operating

The

order

from

(red),

Fixer

If

they

place a mark

Hose

for

the

processor

position.

of

the

three

left

to

right are:

(blue),

and

are

not

on

identification.

to

|

Disengage

Lift

three Drain

Hoses

ber

|

Unpack

If

cartons

|

Arrange

Arrange

Water

be

|

Waste

|

Section

the

processor

are

bands

the

you

have

and

the

Hoses

inserted

Bottles

1:

Unpacking

the

Hoses.

held

and

(optional)

ordered

place

the

Hoses

Drain

are

into

Drain

and

Do

in

place

withdraw

the

near

Hoses

inserted

the

second

may

be

and

Hoses

set

it

down

not

use

by

two

rubber bands.

the

Drain

Waste

optional

the

used.

Installation

Bottles

processor.

as

shown

into

one

Waste

on

its

the

legs

Hoses

Waste

in

Waste

Bottle.

Procedures

rear

as a pivot

as

shown

Bottles,

Figure

5.

Bottle.

Optionally,

end

to

gain

Carefully

in

remove

Developer

The

access

point.

remove

Figure

them

Fixer

three

to

The

Drain

the

4.

from

and

Waste-

Hose

should

separate

the

rub-

their

Page 10

Figure

2.

Remove

Polyfoam

Protective

Packing

Figure

4.

Disengage

Drain

Hoses

©

e

Hoses

Figure

3. Lift

Processor

onto

Work

Surface

Figure

Arrangement

5.

of

Section

1:

Unpacking

and

Installation

Procedures

Page 11

NOTE:

delivered

attached

permit

them

the

processor

any

of

the

If

necessary,

Clamps

Unions.

retighten

See

to

Afterwards,

Figure

The

processor

with

Elbow

to

the

Drain

to

pass

for

four

sides.

open

reposition

the

Hose

6.

Unions

Hoses

underneath

draining

the

Hose

the

carefully

Clamps.

is

to

from

Elbow

—

CAUTION:

cals,

shown

Hose

of

solution.

If

|

stored

|

Hoses

If

opening

2

To

replaced

for

change.

To

1.

2.

3.

4.

the

in

length

space

the

processor

beneath,

passed

the

processor

is

already

straighten

with

this

purpose.

Change

Loosen

Remove

Cut

Attach

Drain

Adapter

in

in

Drain

Figure

should

between

is

holes

through

is

the

straight

to

Straight

Hose

Elbow

Hose

place

order

Hoses

to

to

provided

Drain

See

Union

of

to

prevent

must

6.

Hose

be

cut

its

end and

be

installed

should

to

the

mounted

for

Hoses

sections. A length

Figure 7 for

Hose

clamps

“C”

and

“E”

into

Elbow

Unions

be

installed

ends

should

to

provide

the

on a counter

be

cut

into

Waste

Bottles.

on the

the

Drain

the

rubber

instruction

Sections

“A"

and

Reducer

three

equal

and

back-up

highest

the

CURIX

Hoses.

Elbow

of

Adapter

“B".

“D”.

lengths.

reclamp.

of

used

without

not

be

submerged.

approximately

level

with

the

Waste

counter

Processor

on

top

Unions

Hose

making

Stand,

must

chemi-

dips

of

and

is

this

as

1

inch

waste

Bottles

the

Drain

an

be

provided

simple

Removal

Remove

Lift

off

the

as

shown

Lift

the

remove

small

rectangular

of

Covers

tape

that

Receiving

in

Figure

covers

the

polyfoam

is

from

polyfoam

and

Removal

securing

Tray/Cover

8.

The

Dryer

the

Developer,

sheet

as

cushion

the

Receiving

first,

Section

Fixer,

shown

of

Polyfoam

and

and

in

Figure

next

to

Sheets

Tray/Cover.

then,

the

Cover

lifts

Wash-Water

9.

the

Wash-Water

See

Dryer

straight

Also,

remove

Figure

Section

up.

Tanks

the

Tank.

3.

Cover

and

Section

1:

Unpacking

and

Installation

Procedures

Page 12

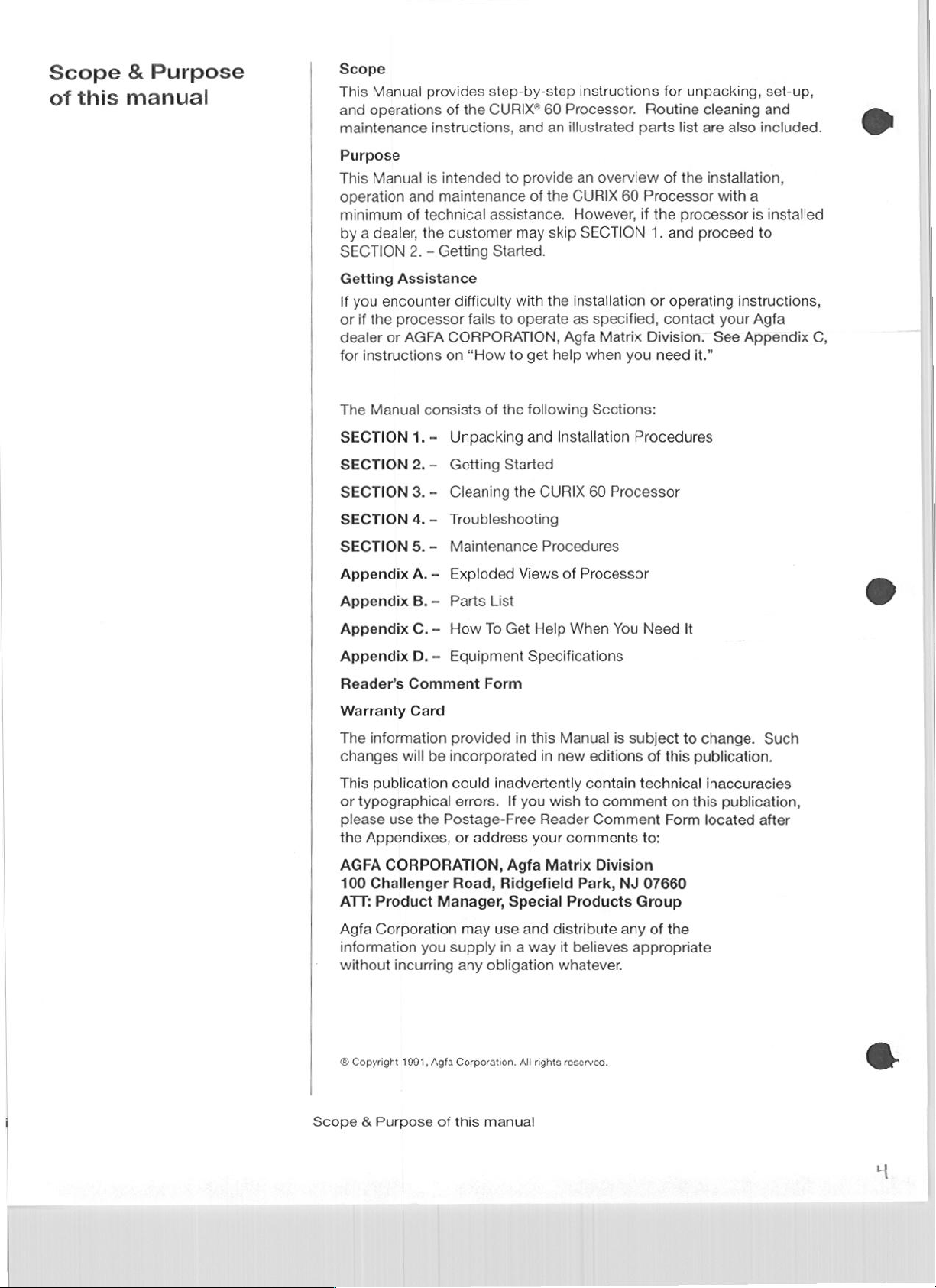

INCORRECT

CORRECT

Figure

。

A

G

6.

Correct

REDUCER

Hose

RUBBER

ELBOW

ATTACHED

PROCESSOR

в:

TO

А*

Peg

Length

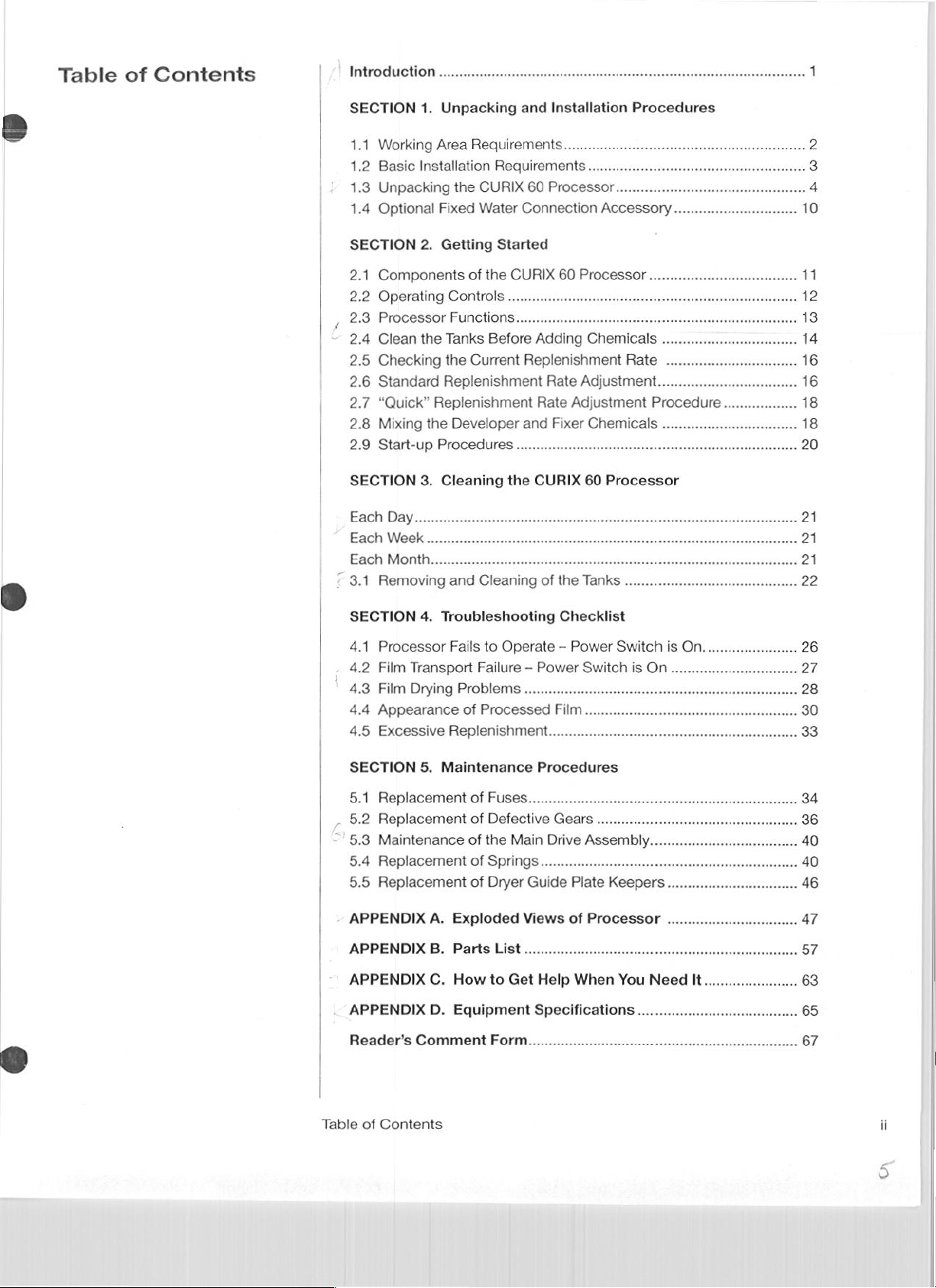

Figure

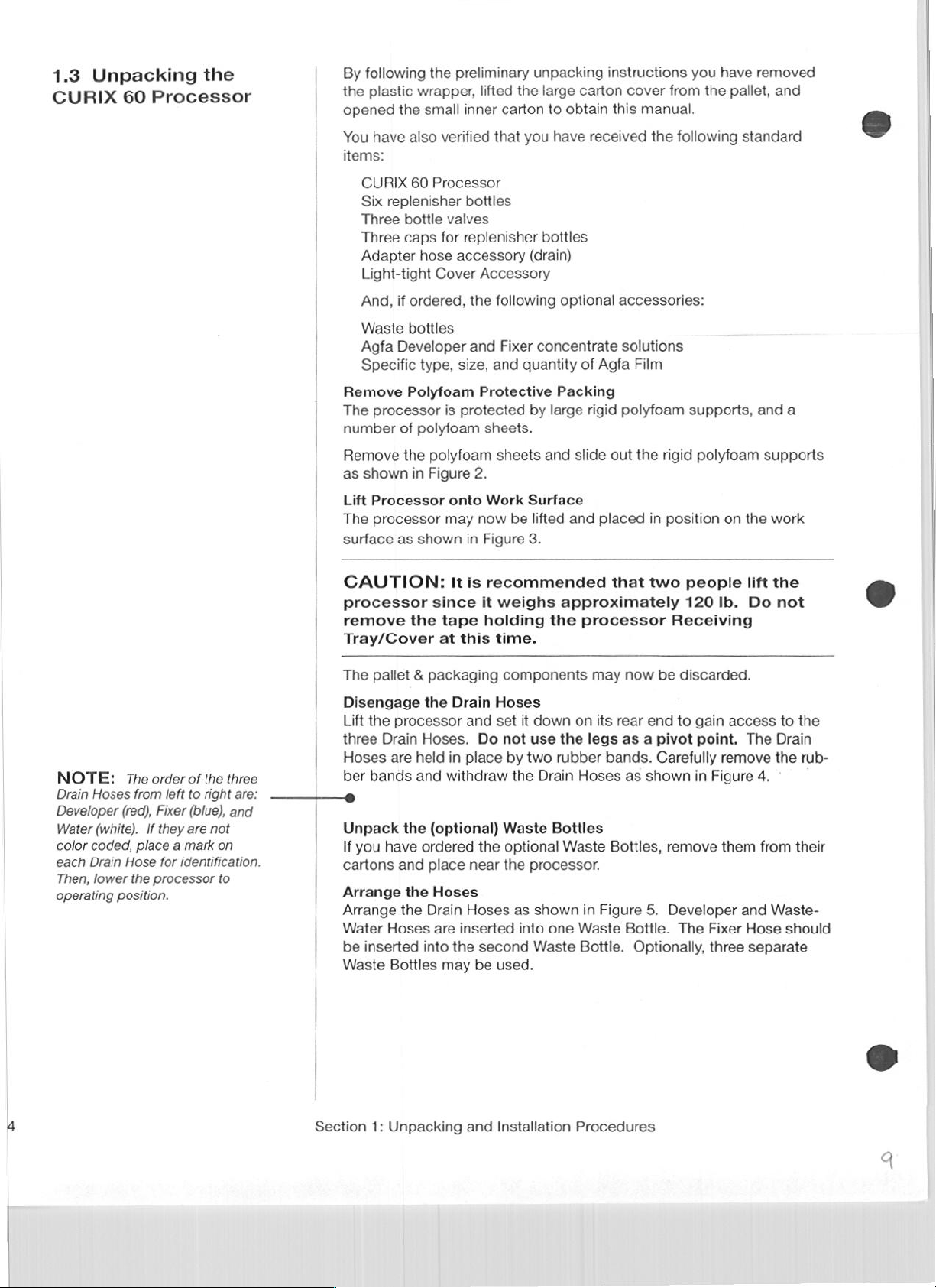

Figure

8.

9.

Removal

Removal

of

Covers

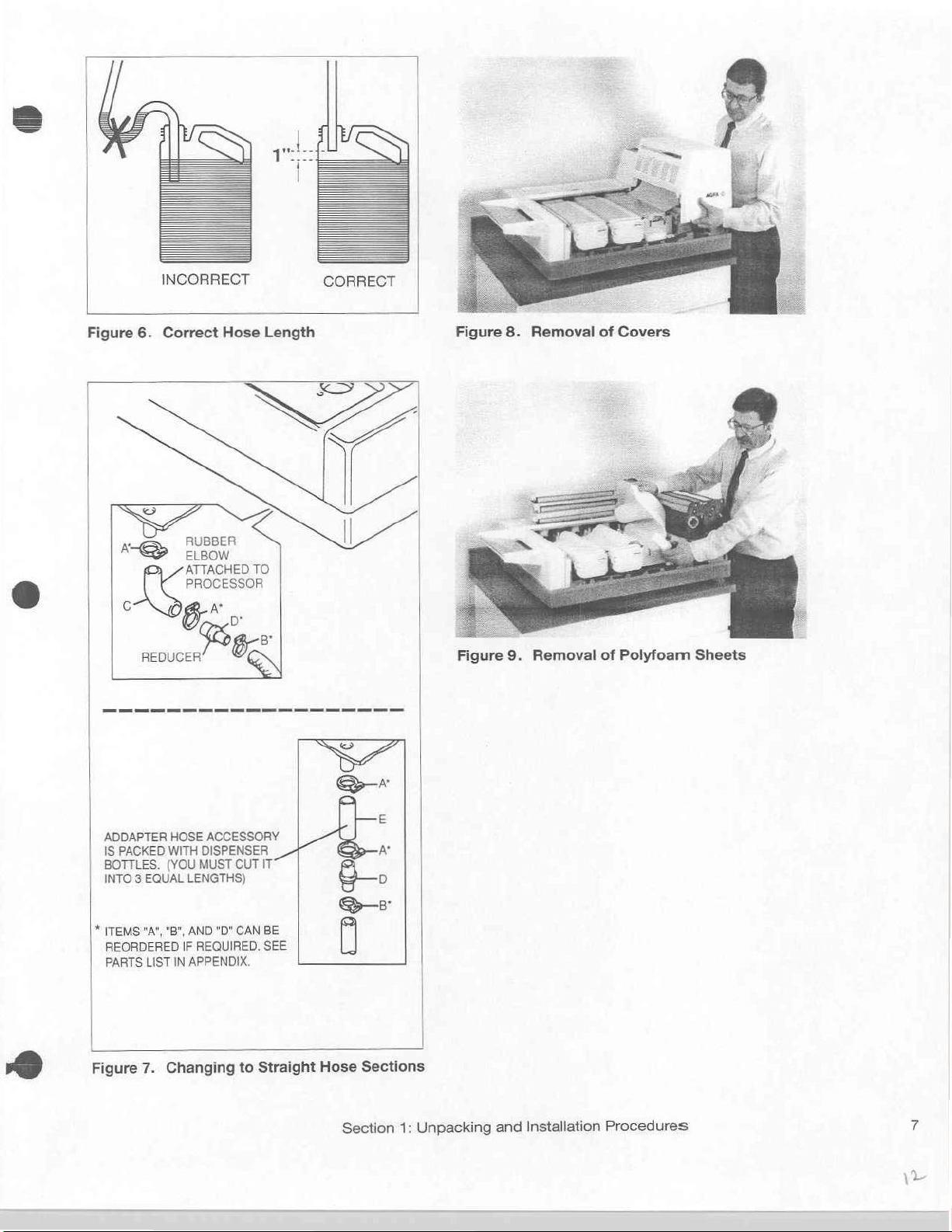

of

Polyfoam

Sheets

ADDAPTER

|

IS

PACKED

BOTTLES.

INTO 3 EQUAL

*

ТЕМ$

REORDERED

PARTS

"А",

LIST

HOSE

WITH

(YOU

LENGTHS)

"В",

АМО

IF

IN

APPENDIX.

ACCESSORY

DISPENSER

MUST

"О"

REQUIRED.

Figure

7.

Changing

CUT

IT

CAN

BE

SEE

to

Straight

Hose

Section

Sections

1:

Unpacking

and

Installation

Procedures

Page 13

NOTE:

be

level

replenishment

Leveling

make

wise

counter-clockwise

processor,

made

the

appropriate

for

screws

this

adjustment.

to

raise

easier

The

processor

proper

operation

of

chemistry.

are

provided

the

processor.

to

Turning

by

lifting

the

corner.

lower

slightly

must

and

Turn

clock-

Turn

the

screws

to

on

is

|

Replace

Developer

Section

e

Level

Place

clockwise

Level

Place

sor

the

Cover,

the

the

the

the

left-to-right.

Tank

Covers.

(red),

Fixer

(blue),

and

the

Processor

builder's

or

counter-clockwise

Processor

level

as

Front-to-Back

level

Left-to-Right

shown

They

are

Water

Receiving

as

shown

to

in

Figure

color

coded

(white.)

Tray/Cover.

in

level

11 to

Next,

Figure

the

adjust

10.

processor

for

replace

Turn

the

easy

identification;

the

Dryer

the

leveling

front-to-back.

level

of

the

s

screw

proces-

Unpack

Open

out

Install

Slide

firmly

|

Insert

Two

also

valves

bottle

Water

Select

receptacles

empty

Fully

The

Figure

the

Light-tight

the

carton

vertically

the

into

sets

contained

to

as

the

Light-tight

Light-tight

position

the

Dispenser

of

Dispenser

the

attached.

avoid

contamination

(white.)

the

at

Never

Dispenser

in

the

this

time.

shown

Assembled

fully

assembled CURIX

15.

Cover

containing

in

Figure

Cover

Cover

as

shown

Bottles

Bottles

Operator’s

The

color-codes

interchange

Bottles

Bottle

Holder

CURIX

60

the

Light-tight

12.

Accessory

Accessory

in

are

Manual.

of

with

onto

Figure

13.

packaged

match

chemistry.

the

valves.

valves

as

shown

Processor

60

Processor

Cover

the

One

them

and

in

should

Accessory

Feed

in

the

small

of

the

sets

to

their

Developer

place

them

Figure

14.

appear

and

Tray

and

press

carton

has

corresponding

(red),

into

The

as

which

color-coded

Fixer

their

bottles

shown

lift

it

(blue),

are

in

@

Section

1:

Unpacking

and

Installation

Procedures

Page 14

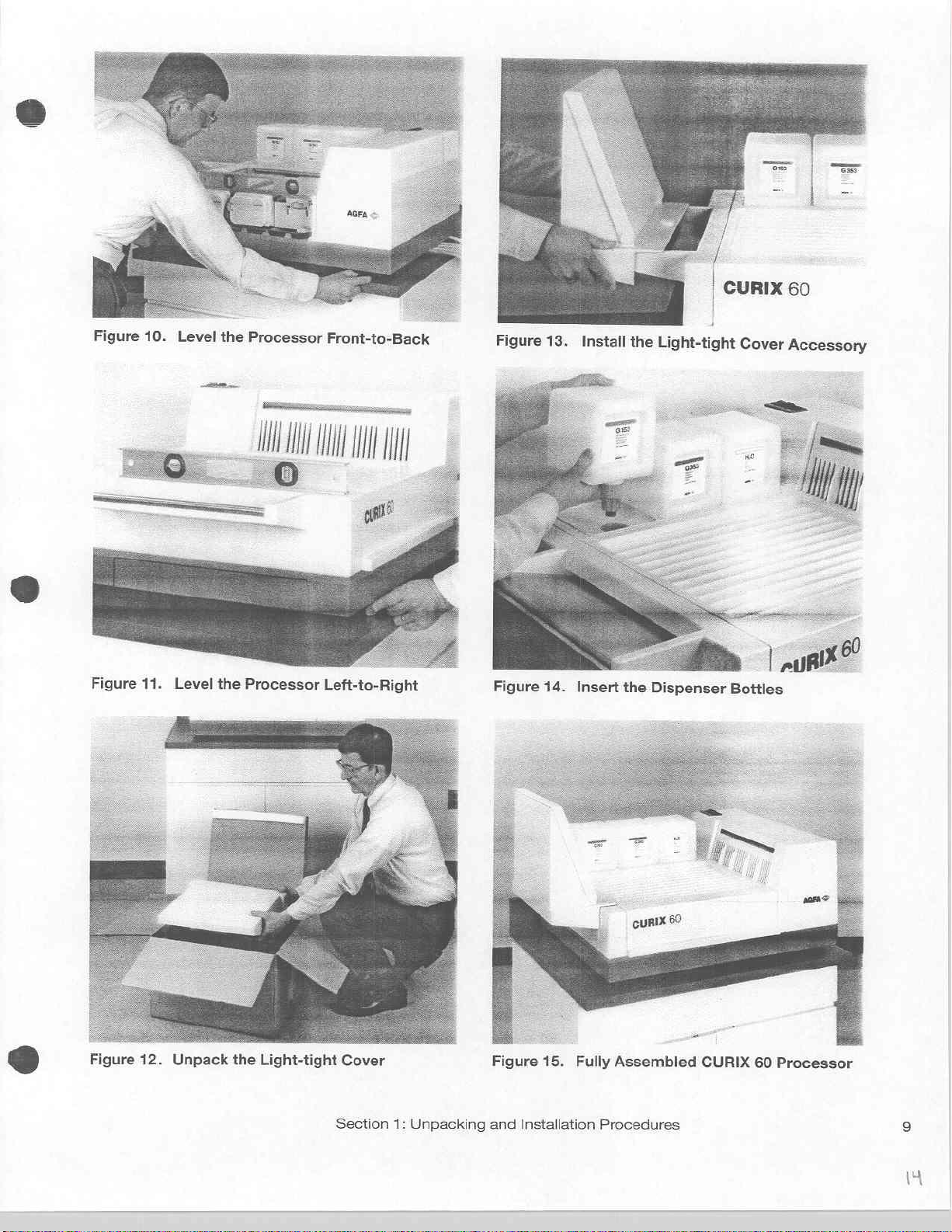

Figure

11.

Level

the

Processor

Left-to-Right

Figure

14.

Insert

the

Dispenser

Bottles

Figure

12.

Unpack

the

Light-tight

Cover

Section

1:

Unpacking

Figure

and

Installation

15.

Fully

Procedures

Assembled

CURIX

60

Processor

Page 15

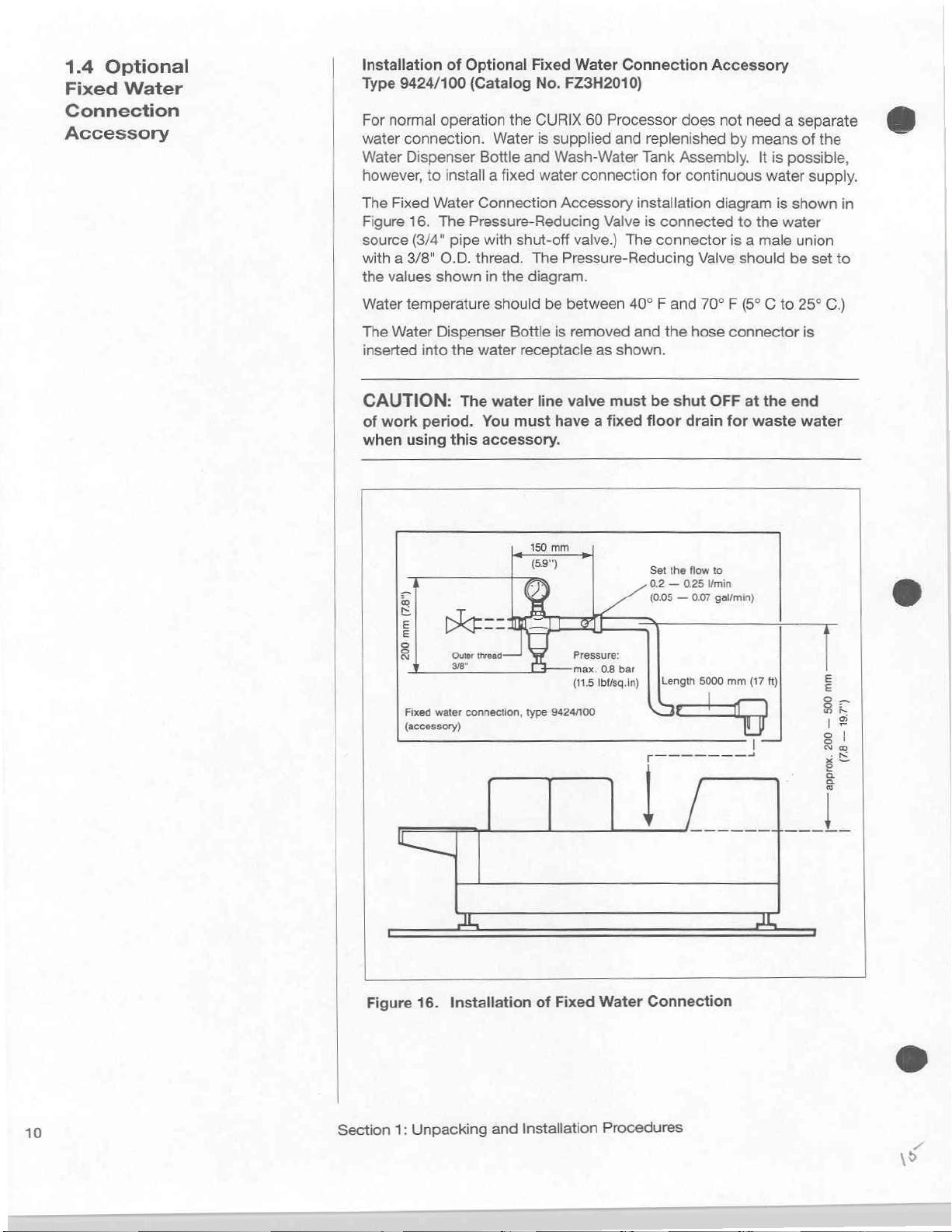

1.4

Optional

Fixed

Connection

Accessory

Water

|

Installation

Type

For

water

Water

however,

The

Figure

source

with a 3/8"

the

Water

The

inserted

of

Optional

9424/100

normal

connection. Water

Dispenser

Fixed

16.

(3/4"

values

temperature

Water

into

(Catalog

operation

Bottle

to

install a fixed

Water

Connection

The

Pressure-Reducing

pipe

with

O.D.

thread.

shown

Dispenser

the

in

should

water

Fixed

No.

the

CURIX

is

and

water

shut-off

The

the

diagram.

be

Bottle

receptacle

Water

FZ3H2010)

supplied

Wash-Water

Accessory

valve.)

Pressure-Reducing

between

is

removed

Connection

60

Processor

and

replenished

Tank

connection

installation

Valve

is

The

40° F and

and

as

shown.

for

connected

connector

the

Accessory

does

not

by

Assembly.

continuous

diagram

to

is a male

Valve

should

70° F (5° C to

hose

connector

need a separate

means

the

It

is

possible,

water

is

water

of

the

supply.

shown

union

be

set

25°

is

in

to

C.)

68

CAUTION:

of

work

period.

when

using

(789

mm

200

」

|

Fixed

(accessory)

Cai

The

You

this

accessory.

water

connection,

water

must

type

line

valve

must

have a fixed floor

150

mm

593

Pressure:

max.

0.8

bar

(115

Ibí/sg.in) | [Length

9424/100

be

shut

OFF

drain

Set

the flow

02 — 025

(005 一 0.07

to

ilmin

gal/min)

5000

for

mm

at

the

waste

(17

ft)

end

water

Е

8 =

¡$

e

8

Na

хе

è

|

10

Figure

16.

Installation

of

Fixed

Section

1:

Unpacking

and

Installation

Water

Connection

Procedures

Page 16

SECTION

Getting

2.1

Components

CURIX

Before

the

a

few

yourself

See

60

attempting

CURIX

moments

with

Figure

2

Started

Processor

to

60

Processor,

to

familiarize

its

components.

17.

of

operate

take

the

TRANSPORT

ROLLERS

(2

REPLENISHMENT

PUMPS

©

BOTTLE

HOLDER

DISPENSER

BOTTLES

©

REAR

TRANSPORT

DRYER

GUIDE

PLATES

TANK

HEATERS

e

Shown

with

Figure

Figure

Exposed

processor

The

ment

and

After

Receiving

17.

Components

18

shows a functional

film

is

or

through

film

first

passes

and

dryer

Wash-Water

drying,

the

Tray/Cover.

TANK GUIDE

PLATES

© ©

Receiving

inserted

the

the

systems

Tanks,

film

and

exits the

TANK

‘COVERS

Tray/Cover

of

directly

Light-tight

Film

and

and Dryer

the

CURIX

diagram

into

Scanner

then

passes

into

the

Dryer

INTERLOCK = SQUEEGEE

SWITCH

of

the

Cover

which

Infrared

Section

Film

Assembly

60

Processor

the

processor.

Feed

Slot

and

regulates

through

Dryer

and

exit

and

ROLLERS

©

Cover

at

then

into

the

Section.

is

deposited

deposit

the

DAYER

FANS

©

removed.

left

side

the

Feed

the

replenish-

Developer,

on

of

the

Slot.

Fixer

the

©

PVC

Rubber

©

|

Figure

Section

Rollers

Rollers

18.

CURIX

2:

Getting

60

Processor

Started

Infrared

Dryer

exchange

Air

Functional

with 6 heat

80

about

Diagram

steps

m3/h

ft3/n)

(2825

11

\6

Page 17

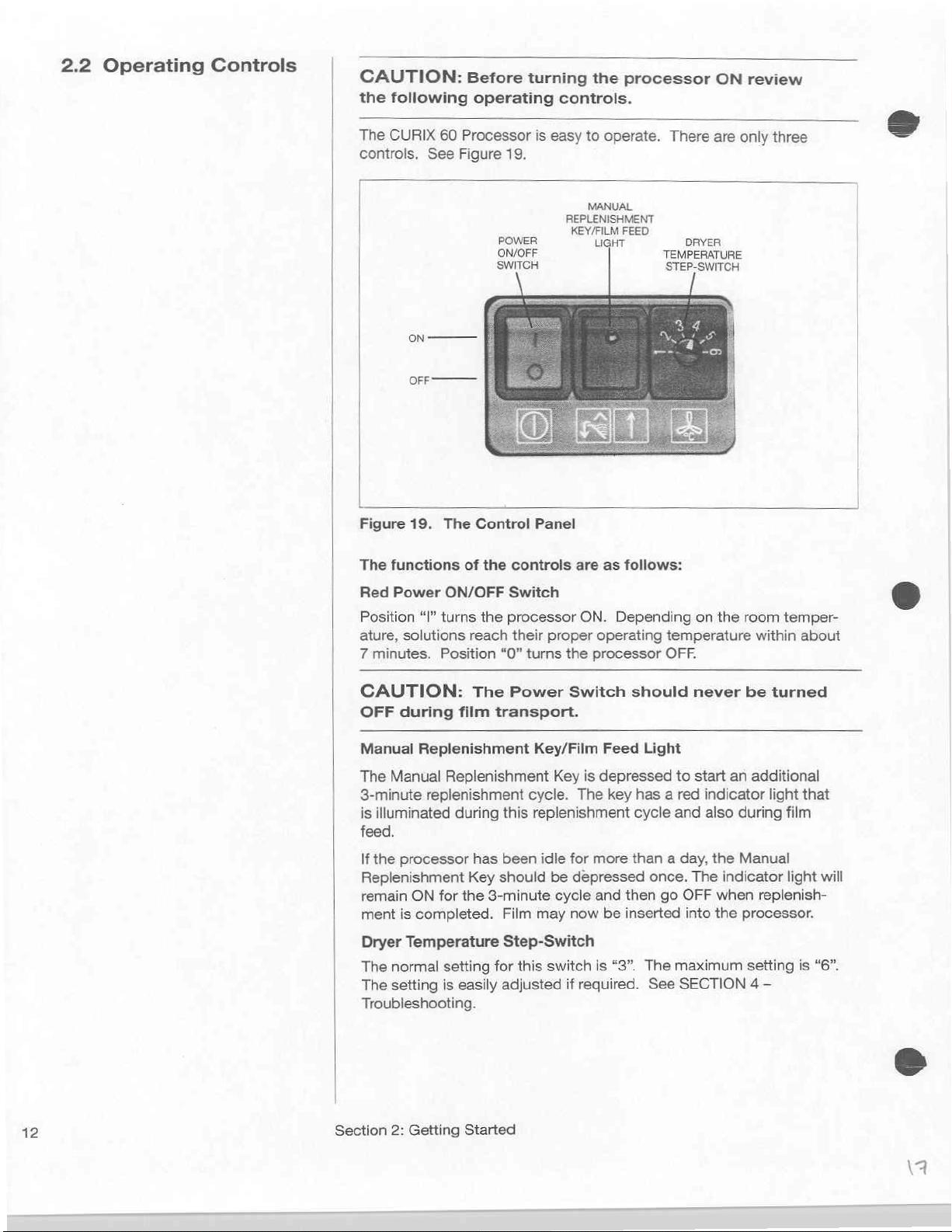

2.2

Operating

Controls

CAUTION:

the

following

The

CURIX

controls,

|

|

|

60

See

Figure

Before

operating

Processor

19.

POWER

ON/OFF

SWITCH

turning

controls.

is

easy

MANUAL

REPLENISHMENT

KEY/FILM

the

processor

to

operate.

FEED

LIGHT

ON

review

There

are

only

DRYER

TEMPERATURE

STEP-SWITCH

three

|

Figure

The

Red

Position

ature,

7

minutes.

>

OFF

19.

functions

Power

“I”

solutions

CAUTION:

OFF

during

Manual

The

3-minute

is

feed.

Replenishment

Manual

replenishment

illuminated

The

Control

of

the

controls

ON/OFF

turns

Position

film

Replenishment

during

Switch

the

processor

reach

“0”

The

Power

transport.

this

their

turns

cycle.

Panel

are

as

ON.

Depending

proper

the

processor

operating

Switch should

Key/Film

Key

replenishment

Feed

is

depressed

The

key has a red

follows:

temperature

OFF.

Light

to

cycle

and

on

the

room

never

start

be

an

indicator

also

during

temper-

within

about

turned

additional

light

that

film

If

the

processor

Replenishment

remain

ment

Dryer

The

The

Troubleshooting.

ON

is

completed.

Temperature

normal

setting

has

Key

for

the

setting

is

easily

been

idle

should

3-minute

Film

Step-Switch

for

adjusted

may

this

be

cycle

switch

for

depressed

now

if

Section

2:

Getting

Started

more

than a day,

and

then

be

inserted

is

“3”.

The

required.

once.

go

maximum

See

the

The

indicator

OFF

when

into

the

SECTION

Manual

light

replenish-

processor.

setting

4 —

is

will

“6”.

ma

Page 18

2.3

Processor

Functions

An

understanding

normal

When

are

must

are

When

Motor,

A

ratures

activated

operates

It

and

When a film

a

Replenishment

Dryer Fan

the

When

no

and

abnormal

the

Dispenser

automatically

be

level

covered

starting

takes

Fixer

pair

length

longer

The

another

on

the

Power

Tank

Heaters

cycle

and

levels.

for

for

265

about 7 minutes

solutions.

is

of

magnetic

are

of

the

end

turning,

indicator

film

to

225

the

of

the

processor

operation.

Bottles

filled to

prevent

Page 8 in

ON/OFF

is

carried

seconds

seconds

fed

into

Key

immediately

film

of

the

the

light

can

the

premature

SECTION

Switch

and

Dryer

out

During

for

The

Tank

the

rollers.

is

illuminated

to

determine

film

is

following

stays

be

fed

functions

are

inserted

bottom edge

drainage.

1.)

is

turned

Fans

start

that

is

independent

this

cycle

the

(about 3 3/4

(about 4 1/2

the

Tank

Heaters

Heaters

processor

The

activated.

detected

on

into

it

indicator

and

The

replenishment

and

occurs:

for

15

seconds.

the

processor.

will

into

the

of

the

(Instructions

ON,

to

operate.

Infrared

minutes)

minutes.)

to

are

factory

is

detected

light

on

the

Infrared

Film

the

Film

help

you

processor,

bottle

the

Drive

of

solution

Dryer

and

the

warm

the

set

at

by

the

the

Manual

Dryer

Scanner

rate.

Scanner

When

it

to

recognize

the

valves.

for

Motor,

tempe-

Heaters

Dryer

Developer

93°

F.

Film

Heaters

also

measures

rollers

goes

tanks

Tanks

leveling

Pump

are

Fan

Scanner,

and

are

off,

Provided

after

the

and

after

As

long

as

double

tents

pump

solution

their

of

the

tubes

that

last

film

an

additional

film-feed

normal speed.

Developer,

and

flow

and

wash

no

additional

exits

is

detected,

Fixer,

into

water

films

the

Dryer

40

seconds

the

This

increased

and

Wash-Water

the

drains.

is

replenished

have

been

inserted,

the

Infrared

the

Replenishment

An

automatically

Dryer

Fans

turn

circulation

Tanks

equivalent

40

Heaters

off.

Pumps

causes

to

rise

amount

from

seconds

turn

operate

the

in

their

of

fresh

the

supply.

off,

at

con-

Section

2:

Getting Started

13

\8

Page 19

2.4

Clean

Tanks

Before

Chemicals

NOTE:

Tanks

recommended

removed

and

This

the

procedure

will

After

reassembling

components,

replenishment

checked.

Prior

for

the

from

rinsed

with

will

require

standard

except

be

no

chemicals

rinsing

and

IMPORTANT:

The

Replenishment

been

factory-set

replenishment

processing

The

controlled

film

(EX:

the

width

replenishment

If

you

mainly

will

be

pumps.

Page

To

save

the

replenishment

water

Bottles.

is

satisfactory,

the

other

with

24 x 30

replenishment

by

length = 30

of

will

be

larger

necessary

See

16.

chemicals,

in

the

three

If

the

set

chemicals.

the

Adding

to

filling

the

first

time

it

is

that

they

be

the

processor

tap

water.

performing

cleaning

that

there

to

drain.

the

the

processor

rate

should

Pumps

for

average

rates

based

cm

films.

cycle

the

length

cm).

However,

the

film

will

affect

rate.

processing

or

smaller

Table 1 on

replenishment

you

of

Dispenser

to

adjust

first

rate

spare

can

either

sizes

check

using

Dispenser

then

be

have

upon

is

of

the

it

the

rate

fill

Bottles

Fr

1.

2.

3.

4.

6.

7.

8.

9.

10.

CAUTION:

Wash-Water

gears;

position;

and

replacing

is

inserted

numbered

respective

and

prd

FILL

WITH

Insert

receptacles.

proper

Lift

off

the

Receiving

Disengage

in

Figure

20.

Lift

the

Wash-Water

as

the

its

and

it

Fixer

drive

the

remove

remove

Lift

from

Remove

Lift

aside.

Remove

retaining

in

Figures

Follow

Take

and

from

replacement.

After

reversing

the

the

THE

the

the

space

24A

the

all

rinse

the

rinsing

the

the

Heater

Dryer

CHEMISTRY

WATER

Dispenser

level.

the

slots

same

the

them

Tanks

the

drain

the

into

rollers.

color-codes

TO

The

See

the

Tank

The

Wash-Water

shown

Tank

Assembly

gears.

Fixer

Tank

the

Tank

Heater,

in

the

previously

&

24B.

procedure

Tanks,

Rollers,

with

for

cleaning,

the

Tanks

disassembly

Make

Tanks

valves

Heaters

Cables

Guide

the

Check

Assembly

THE

Bottles

Tanks

Figure

Tray/Cover.

Heater

Cables

Tank

Tank

Assembly

21.

Figure

in

and

Cover

as

Guide

Plate

by

lifting

tank.

Set

the

occupied

for

Tank

luke-warm

and

and

tank

procedure.

sure

that:

are

properly

are

fastened

are

engaged

are

back

Plates,

groove

AND

2.50

are

25.

make

in

that

and

that the

Cover

WASH-WATER

LITER

into

their

automatically

from

has

slightly,

aside.

it

Set

withdraw

shown

as

shown

vertically

Heater

by

the

removal

Covers

water.

they

are

components,

the

Developer,

engaged

in

in

their

sure

the

tank

all

parts

are

MARK

color-coded

filled to

their

retaining

no

Heater

pull

it

it

enough

in

Figure

22,

in

Figure

to

disengage

(with

cable

Waste-Water

of

the

Developer

and

Guide

Rollers

may

numbered

replace

with

in

the

their

upright/closed

retaining

clips.

that

adjacent

match

Receiving/

properly

DISPENSER

the

clips as

or

Heater

forward

to

disengage

and

23,

and

attached)

Tank.

Tank.

Plates

be

removed

for

easy

them

Fixer

their

When

the

bent

to

their

Tray

closed.

BOTTLES

shown

Cable.

and

set

it

aside.

set

it

it

from

the

aside

See

to a sink

by

and

drive

slots

edge

the

even

Cover

it

Section

2:

Getting

Started

Page 20

Figure

24A.

Dise

ngage

and

Remove

Tank

Heater

Figure

23.

Remove

Guide

Plate

Section

2:

Getting

Started

Page 21

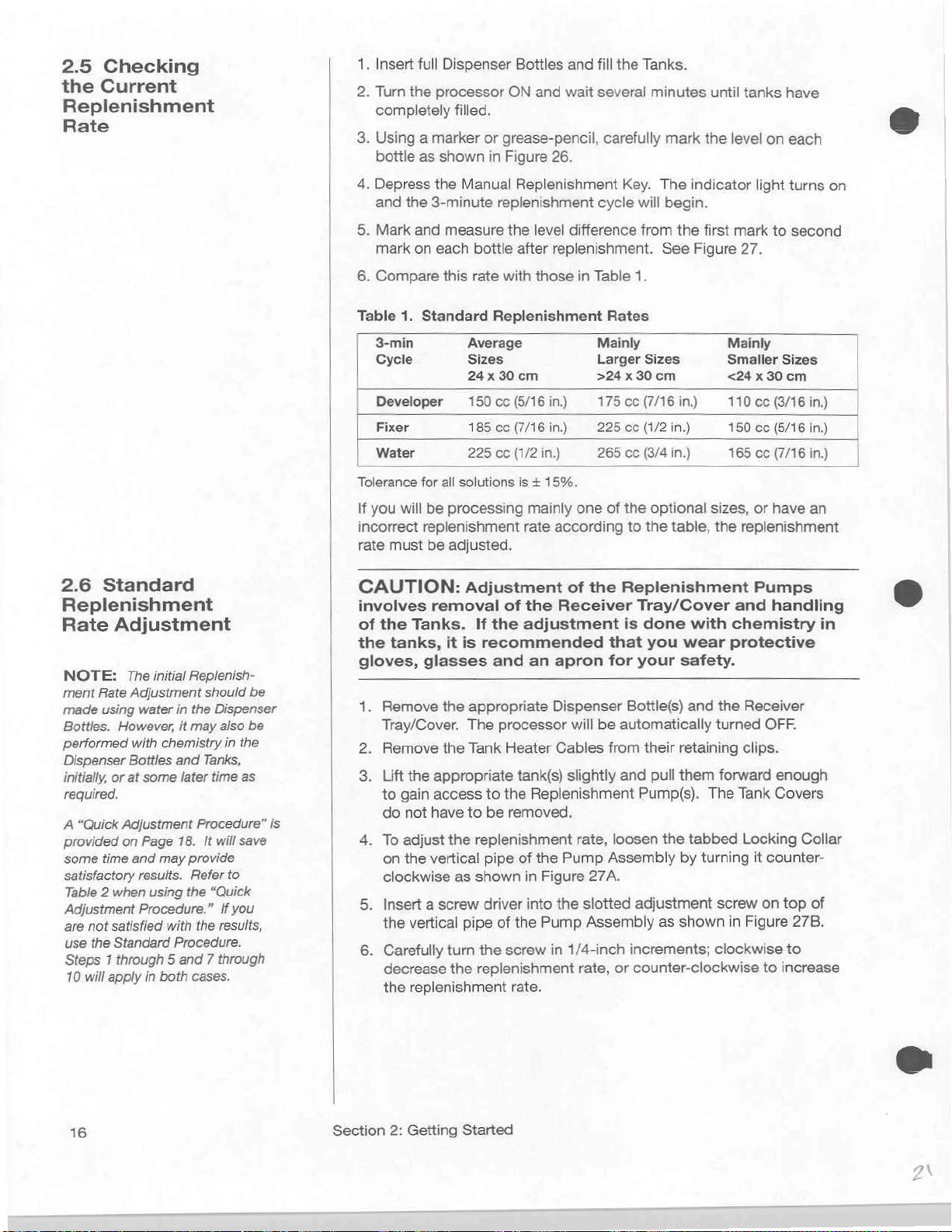

2.5

Checking

the

Current

Replenishment

Rate

2.6

Standard

Replenishment

Rate

NOTE:

ment

made

Bottles.

performed

Dispenser

initially,

required.

A

provided

some

satisfactory

Table 2 when

Adjustment

are

use

Steps 1 through 5 and 7 through

“Quick

not

the

10

will

Rate

using

time

Adjustment

The

initial

Adjustment

water

in

However,

with

Bottles

or

at

Adjustment

on

and

satisfied

Standard

apply

it

chemistry

and

some

later

Page

18.

may

results.

using

Procedure.”

with

Procedure.

in

both

Replenish-

should

be

the

Dispenser

may

also

be

in

the

Tanks,

time

as

Procedure”

It

will

save

provide

Refer

to

the

“Quick

If

you

the

results,

cases.

is

1.

Insert

full

2.

Turn

the

processor

completely

3.

Using a marker

bottle

as

4,

Depress

and

5.

Mark

mark

6.

Compare

Table

3-min

Cycle

Developer

Fixer

Water

Tolerance

If

you

incorrect

rate

the

the

3-minute

and

on

each

1.

Standard

for

will

be

replenishment

must

be

CAUTION:

involves

of

the

the

gloves,

1.

Remove

Tray/Cover.

2.

Remove

3.

Lift

to

do

4.

To

on

clockwise

5.

Insert a screw

the

6.

Carefully

decrease

the

removal

Tanks.

tanks,

glasses

the

appropriate

gain

access

not

have

adjust

the

vertical

vertical

replenishment

Dispenser

filled,

or

shown

all

in

Manual

replenishment

measure

bottle

this

rate

Replenishment

Average

Sizes

24 x 30

150

cc

185

cc

225

cc

solutions

processing

adjusted,

Adjustment

If

the

it

is

recommended

and

the

appropriate

The

processor

the

Tank

to

to

be

the

replenishment

pipe

as

shown

driver

pipe

of

turn

the

the

replenishment

Bottles

ON

grease-pencil,

Figure

Replenishment

the

after

with

cm

(5/16

(7/16

(1/2

is + 15%.

of

Heater

tank(s)

the

removed.

of

the

screw

rate.

and

fill

and

wait

several

26.

cycle

level

difference

replenishment.

those

in

Table

Mainly

Larger

>24 x 30

in.)

in.)

in.)

mainly

rate

the

adjustment

an

Replenishment

the

in

Figure

into

Pump

in

175

225

265

one

according

of

the

Receiver

apron

Dispenser

will

be

Cables

slightly

rate,

Pump

27A.

the

slotted

Assembly

1/4-inch

rate,

carefully

the

Tanks.

minutes

mark

Key.

The

indicator

will

begin.

from

the

See

Figure

1.

Rates

Sizes

cm

ce

(7/16

in.)

cc

(1/2

in.)

cc

(3/4

in.)

of

the

optional

to

the

table,

Replenishment

Tray/Cover

is

done

with

that

you

wear

for

your

safety.

Bottle(s)

automatically

from

and

Pump(s).

loosen

Assembly

adjustment

increments;

or

counter-clockwise

their

pull

the

as

and

retaining

them

tabbed

by

shown

until

tanks

the

level

first

mark

27.

Mainly

Smaller

<24 x 30

110

150

165

sizes,

the

replenishment

and

chemistry

protective

the

Receiver

turned

clips.

forward

The

Tank

Locking

turning

screw

in

Figure

clockwise

have

on

each

light

turns

to

second

Sizes

cm

cc

(8/16

cc

(5/16

cc

(7/16

or

have

Pumps

handling

OFF.

enough

Covers

it

counter-

on

top

27B.

to

to

increase

on

in.)

in.)

in.)

an

in

Collar

of

16

|

Section

2:

Getting

Started

Page 22

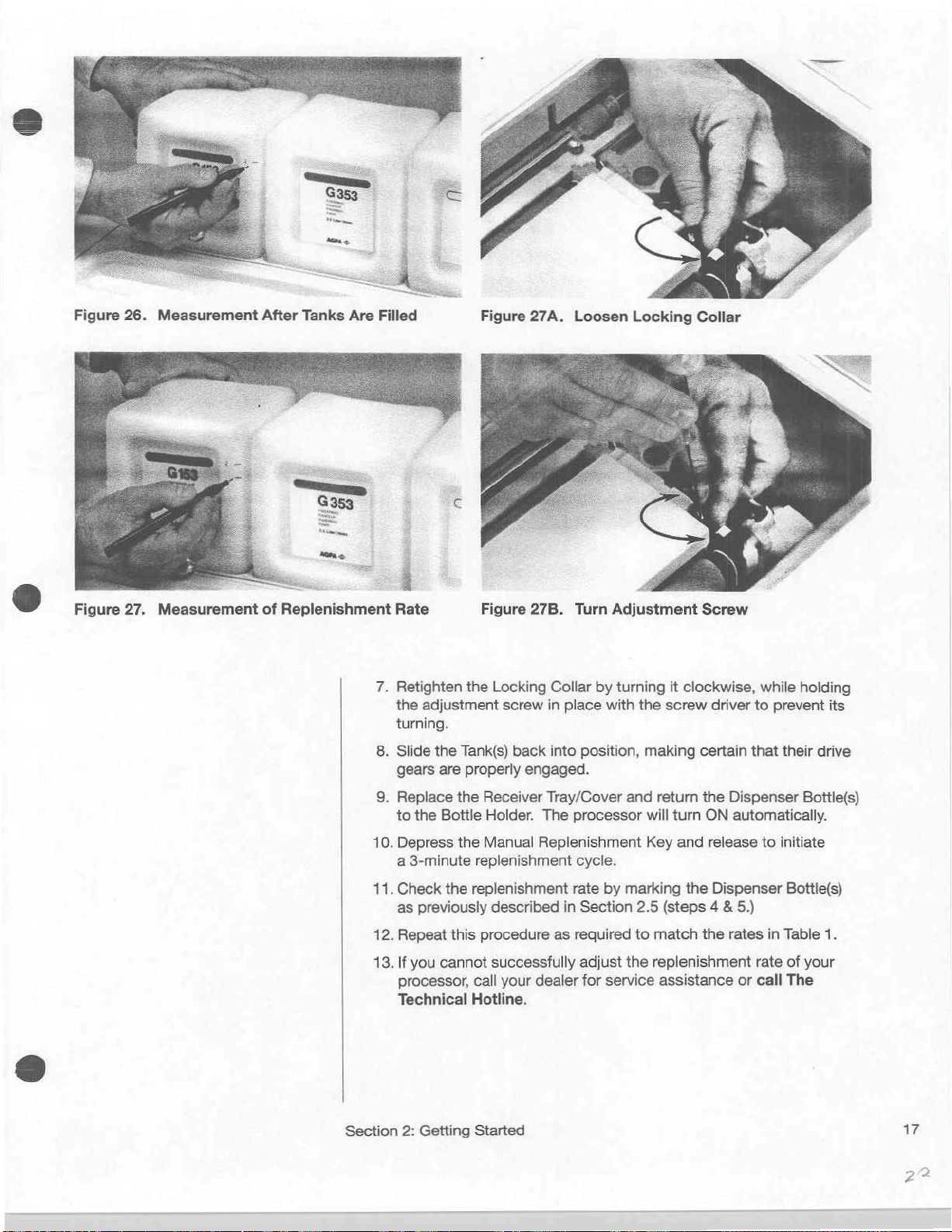

Figure

26.

Measurement

After

Tanks

Are

Filled

ῶ

Figure

27.

Measurement

of

Replenishment

Rate

7.

Retighten

the

turning.

8.

Slide

gears

9.

Replace

to

the

10.

Depress

a

3-minute

11.

Check

as

previously

12.

Repeat

13.

If

you

processor,

Technical

Figure

the

adjustment

the

Tank(s)

are

properly

the

Receiver

Bottle

Holder.

the

Manual

replenishment

the

replenishment

this

procedure

cannot

call

Hotline.

27B. Turn

Locking

screw

described

successfully

your

Collar

in

place

back

into

engaged.

Tray/Cover

The

processor

Replenishment

cycle.

rate

in

as

required

dealer

Adjustment

by

turning

with

position,

and

by

marking

Section

adjust

for

2.5

to

the

service

Screw

it

clockwise,

the

screw

driver

making

will

Key and

match

replenishment

certain

return

the

turn

ON

release

the

Dispenser

(steps 4 &

the rates

assistance

while

holding

to

prevent

that

their

drive

Dispenser

automatically.

5.)

rate

or

to

initiate

Bottie(s)

in

Table

of

call

The

Bottle(s)

your

its

1.

Section

2:

Getting Started

17

Page 23

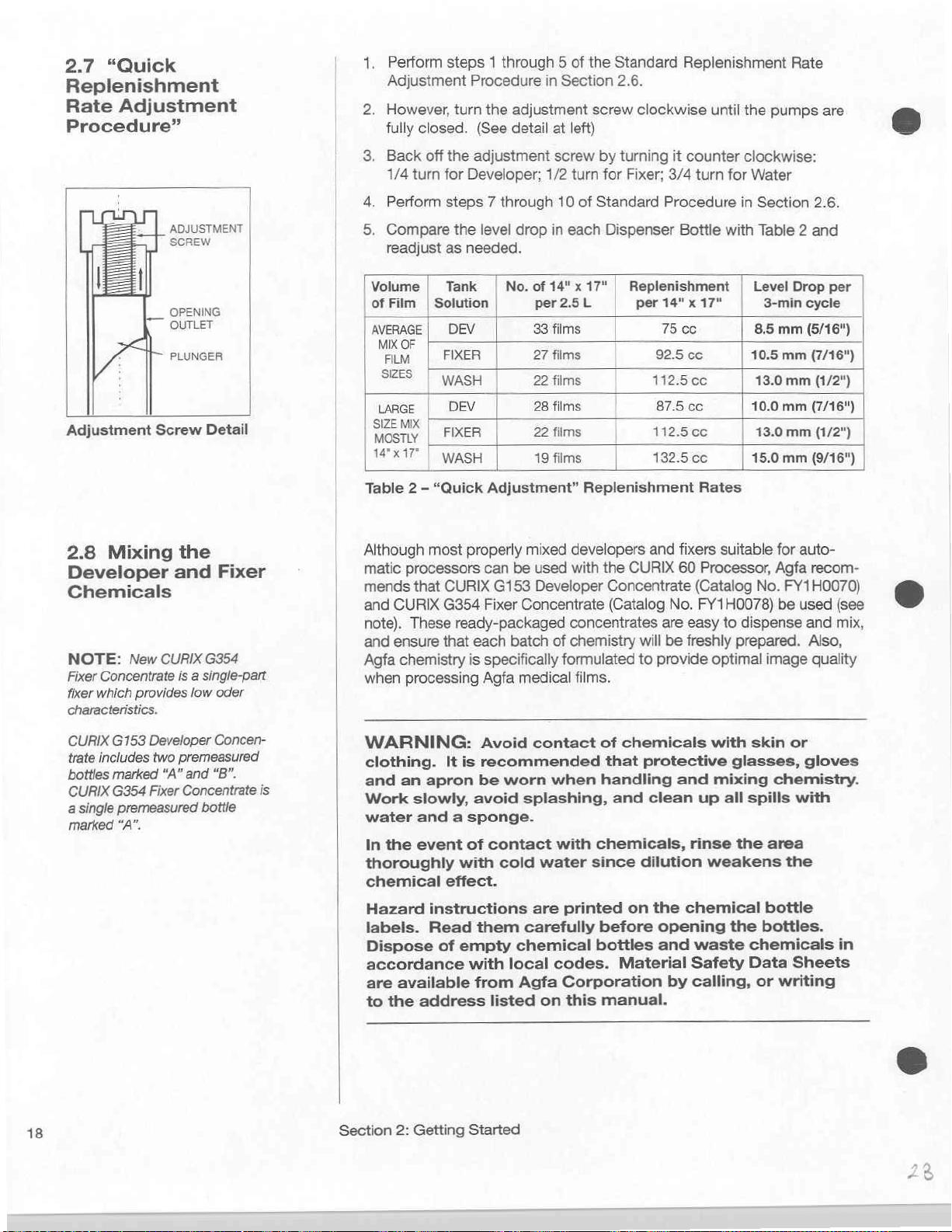

2.7

“Quick

Replenishment

Rate

Procedure”

Adjustment

Adjustment

|

|.

Va

[>

ADJUSTMENT

SCREW

OPENING

OUTLET

PLUNGER

Screw

Detail

1.

Perform

Adjustment

2.

However,

fully

3.

Back

1/4

4.

Perform

|

5.

Compare

readjust

[Volume | Tank | No.

|

of

Film | Solution

AVERAGE | DEV

MIX

OF

FILM | FIXER

|

SZES | WASH

|

LARGE | DEV

|

SIZE

MIX

Masný. | FIXER

|

Xİ”

Table 2 -

steps 1 through 5 of

Procedure

turn

the

closed.

off

turn

|

|

(See

the

adjustment

for

Developer;

steps 7 through

the

level

as

needed.

WASH

“Quick

Adjustment”

in

Section

adjustment

detail

at

left)

screw

1/2

turn

10

of

drop

in

each

of

14"x

per

2.5L

33

films

27

films

22 films

28 films

22 films

19

films

Replenishment

the

Standard

2.6.

screw

by

turning

for

Fixer;

Standard

Dispenser

17" | Replenishment | Level

per

Replenishment

clockwise

it

counter

3/4

turn

Procedure

Bottle

14" x 17"

75 00

92.5

сс

112.5

cc

87.5

сс

1

12.5

cc

132.5

co

Rates

until

the

clockwise:

for

in

with

Rate

pumps

Water

Section

Table 2 and

Drop

3-min

8.5

mm

10.5

mm

13.0

mm

10.0

mm

13.0

mm

15.0

mm

are

2.6.

per

cycle

(5/16")

(7/16")

(1/2")

(7/16")

n

(1/2")

(9/16")

|

2.8

Mixing

Developer

Chemicals

NOTE:

Fixer

fixer

characteristics.

CURIX

trate

bottles

CURIX

a

single

marked

New

CURIX

Concentrate

which

provides

G153

Developer

includes

two

marked

G354

“A”

Fixer

premeasured

“A”.

the

and

Fixer

G354

is a single-part

low

oder

Concen-

premeasured

and

“B".

Concentrate

bottle

is

Although

matic

mends

and

note).

and

Agfa

when

most

processors

that

CURIX

ensure

G354

These

that

chemistry

processing

WARNING:

clothing.

and

an

apron

Work

water

In

thoroughly

chemical

Hazard

labels.

Dispose

accordance

are

to

slowly,

and a sponge.

the

event

instructions

Read

of

available

the

address

properly

can

be

CURIX

G153

Fixer

Concentrate

ready-packaged

each

batch

is

specifically

Agfa

medical

Avoid

It

is

recommended

be

worn

avoid

of

with

effect.

them

empty

with

from

splashing,

contact

cold

carefully

chemical

local

Agfa

listed

mixed

developers

used

with

Developer

concentrates

of

chemistry

formulated

films.

contact

when

with

water

are

printed

codes.

Corporation

on

this

and

the

CURIX

Concentrate

(Catalog

will

to

provide

of

chemicals

that

protective

handling

and

clean

chemicals,

since

dilution

on

before

bottles

Material

manual.

the

opening

and

fixers

suitable

60

Processor,

(Catalog

No.

FY1H0078)

are

easy

to

be

freshly

optimal

with

and

mixing

up

all

rinse

weakens

chemical

the

waste

Safety

by calling,

for

Agfa

No.

FY1H0070)

be

dispense

prepared.

image

skin

or

glasses,

chemistry.

spills

the

area

the

bottle

bottles.

chemicals

Data

or

writing

auto-

recom-

used

and

Also,

quality

gloves

with

Sheets

(see

mix,

in

18

Section

2:

Getting

Started

Page 24

Figure

29.

Fill

G153

Dispenser

Bottle

with

Water

Figure

1.

Remove

processor.

bottles

from

the

bottle,

the

2.

Rinse

water

pour

Dispenser

slowly

3.

Pierce

and

Fill

replace

mix

4.

Follow

off

5.

Fill

mark

31.

of

the

cap

of

turn

bottle

the

to

G153

to

the seal

pour

the

bottle

the

the

solution.

the

with

water,

the

Water

and

the

G153

the

Pour

in

G153

three

empty

Take

the

concentrate

Developer

the

G153

the

cap

over

as

shown

G153

Dispenser

1.25 L mark

Developer

Bottle

as

shown

mix

the

solution.

of

G153

it

into

the

Dispenser

with

water

valve.

same

replace

Shake

procedure

if

necessary

Dispenser

the

Concentrate

Dispenser

Dispenser

to a sink.

Dispenser

Developer

and

cut

in

Figure

Bottle

as

shown

Concentrate

in

Developer

to

FULL

the

for

to

Bottle

valve.

“B”

Bottles

Bottles

Remove

Bottle.

Concentrate

through

28.

and

then

in

Figure

“A”

Figure

30.

Concentrate

Bottle.

bottle

reach

to

(2.5

to

mixing

the

the

See

L)

thoroughly

FULL

from

and

the

three

the

valve

Unscrew

“A”

the

seal

fill

it

with

29.

into

the

Agitate

Figure

mark

and

Fixer,

topping

2.5 L mark.

(2.5

the

of

Then,

“B”

31.

L)

Figure

30.

Pour

In

G153

Concentrate

“A”

Section

Getting

2:

6.

Clean

Started

up

the

work

area

with a wet

sponge.

19

Page 25

2.9

Start-up

NOTE:

will

automatically

OFF

if

the

Cover

or

Receiving

are

not

properly

NOTE:

operating

SECTION

or

call

the

But,

first

try

processor

This

can

often

problem.

The

processor

be

Dryer

Assembly

Tray/Cover

closed.

/f

you

detect

problem,

4 -

Technical

OFF

refer

Troubleshooting,

Hotline.

switching

and

ON

correct

Procedure

switched

an

to

the

again.

the

1.

Plug

the

Turn

off

2 8 Turn

the

>

Wait 7 minutes

5.

Run a test

exposed

Replenishment

the

next

6.

Check

seems

to

power

all

Processor

film

satisfactory

cord

lights

to

film

first.

film into

Switch

can

see

if

processing

but

achieve

the

be

into

the

the

darkroom

ON.

operating

Open

Feed

Slot

lights

inserted.

and

you can

start

wall

outlet.

the

Light-tight

until

(red).

drying

regular

safelight.

temperature.

Cover

the

indicator

When

the

indicator

is

satisfactory.

processing.

and

lamp

Insert

the

on

the

light

turns

If

everything

off,

20

Section

2:

Getting

Started

Page 26

SECTION

Cleaning

CURIX

3

the

60

Processor

The

following

EACH

At

the

end

prevent

should

DAY:

of

each

day’s

condensation

be

performed

work,

of

chemicals.

raise

on a regular

the

Receiving

basis:

Tray/Cover

slightly

to

NOTE:

processor

optimal

the

designed

tenance.

have

parts

easy

image

CURIX

been used

that

to

remove

Proper

cleaning

is

essential

60

Processor

for

easy

Non-corrosive

require

to

quality.

However,

cleaning

throughout,

regular

without

of

your

maintain

has

been

and

main-

materials

and

cleaning

tools.

all

are

EACH WEEK:

w

Drain

and

If

you

are

processing

following

v

ど

Tanks

If

you

perform

EACH

Vv

every

Drain

Developer

Replace

Clean

Tank

and

Film

Scanner,

are

processing

the

MONTH:

Clean

the

exhausted

CAUTION:

chemicals

apron

for

disposal

When

ing

to

your

safety

cleaning

general

protect

of

clean

Wash-Water

less

week:

and

Fixer

chemicals.

Covers

Replenishing

above

Distribution

You

with

waste

directions:

and

Feed

every

are

care,

your

and

chemistry.

the

and

more

Roller

reminded

conform

processor

Tank

than

80

Tanks

Rollers,

Pumps,

Tray.

than

80

two

weeks:

Assembly

to

wear

clothing,

films

per

and

Dispenser

Transport

Dispenser

films

per

(Squeegee

again

protective

to

wear

to

local

always

week

Bottles.

Rollers,

Bottles

week

to

handle

gloves,

protective

codes

adhere

perform

Guide

Plates,

and

Bottle

Rollers.)

all

and

glasses

regarding

to

the

the

Valves,

an

the

follow-

.

DISCONNECT

2.

Never

3.

Electric

use

hot

cables

POWER

water.

to

heaters

CORD

The

highest

are

disconnected.

4.

Never

clean

Wipe

5.

Roller

Developer

Fixer

Wash-Water

6.

The

tanks

for

ease

proper

chassis

with a damp

sets

are

Roller

Roller

sets

Roller

Tank

Covers,

are

color

of

assembly

location

or

cloth

numbered

sets

are

are

numbered

sets

Bottle

coded

after

after

cleaning.

plastic

or

sponge.

for

numbered

are

numbered

Valves,

to

prevent

cleaning.

FROM

temperature

permanent

parts

of

proper

replacement

“1” & “2”

“3” & “4”

Bottle

contamination

They

OUTLET.

and

heaters

“5” & “6”

Holder

must

allowed

must

not

in

running

after

and

chemical

of

the

be

returned

is

104°F

be

water.

cleaning.

and

chemicals

to

their

(40°C).

water

and

Section

Cleaning

3:

the

CURIX

Processor

60

21

19

S

Page 27

3.1

Removing

Cleaning

of

the

and

Tanks

-

Turn

the

=

|

.

Remove

ND

.

Remove

BO

.

Disengage

See

5.

Lift

|

|

|

gears,

6.

Remove

7.

Remove

Power

the

the

Figure

up

and

and

power

Dispenser

the

32.

forward

to

gain

the

Tank

the

Guide

Switch

cord from

Tank

to

access

Cover.

Plate.

OFF.

Bottles

Heater

Cables

disengage

to

See

See

the

and

the

the

Tank

Figure

Figure

wall

receptacle.

Receiving

from

their

Wash-Water

Drain

34.

35.

Tray/Cover.

retaining

Tank

Valves.

See

clips.

from

its

Figures

O

drive

33.

22

Section

Cleaning

3:

Figure

CURIX

the

35.

Remove

Processor

60

Guide

Plate

Page 28

.

Drain

Figure

Drain

Tube

.

Take

.

Repeat

Fixer

Чи

Remove

slots.

12.

Place

See

13.

Take

to a sink

14.

Disengage

for

the

Tank

36.

It

Tube

to

should

the

Wash-Water

steps

Tanks.

the

See

Figure

the

Heaters

Figure

38.

the

Developer

for

the

cleaning.

by

releasing

may

be

necessary

facilitate

not

be

kinked.

Tank

shown

Tank

in

Heaters

37.

in

the

and

cleaning.

Film

Scanner.

the

proper

to a sink

Figures

by

disengaging

space

Fixer

Tanks,

See

Drain

Valve

to

gently

draining.

for

33

through

vacated

Tank

Figure

Clamp

pull

on

the

For

easy

flow

cleaning.

36

for

them

from

by

the

Wash-Water

Covers

39.

Take

as

shown

end

of

the

Drain

Developer

their

retaining

and

Guide

it

to a sink

in

the

and

Tank.

Plates

Figure

Figure

36.

Drain

37.

Disengage

the

Tank

Heater

Section

3:

Cleaning

Figure

Figure

the

CURIX

38.

39.

Set

Heater

Disengage

60

Processor

in

Vacated

Film

Tank

Scanner

Space

23

N

=

Page 29

|

Perform

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

Chemistry

the

the

Remove

sponge

Unfasten

Remove

Replenishment

Observe

(black),

With

the

water,

close

the

Wash

the

If

Squeegee

washed,

Wash

and

Squeegee

Remove

Using a sponge

Clean

Clean

Clean

surface

Replace

Replace

install

codes

Replace

Cover

Tanks

following

the

Transport

and

running

the

Replenishment

and

wash

Pumps

the

Pump

to

avoid

Tank

Drain

allowing

the

the

any

of

the

carefully.

and

and

will

water

Tank

Drain

Guide

Rollers

lift

them

replace

Rollers.

the

Light-tight

Feed

Drainage

chemical

the

processor

the

Light-tight

the

Rollers,

Tank

Assemblies

the

Film

Receiver

Water

be

automatically

steps

at

the

Rollers

water.

the

color-codes,

contamination.

Valve

Plates,

(Distribution

from

them

and

Slot

and

Troughs.

residue

Scanner

Tray/Cover.

Dispenser

See

Pumps

Pumps.

and

refasten

open,

to

drain

Valve.

Tank

Covers

their

support

as

one

Cover

luke-warm

Tray.

on

chassis.

Cover

Guide

Plates,

into

and

sink:

from

the

Tanks

Figure

40.

by

See Figures

them

Developer

wash

each

through

Accessory.

See

See

Accessory.

securely

refilled.

and

Roller

blocks

unit.

Do

water:

Figure

Figure

the

Bottle

Heaters,

the

processor,

Bottles

the

Assembly)

and

rotating

41 & 42.

with

the

(red),

Tank

valve.

Rollers.

as

shown

not

disassemble

44.

45.

Holder

and

close

the

may

now

wash

the

retaining

retaining

Fixer

under

After

have

in

and any

Tank

Follow

Dryer

be

inserted

them

with

levers.

Replace

levers.

(white),

running

draining,

to

be