Page 1

HEALTHCARE

Imaging Services

ReadMeFirst

How to print and add Comments

1 Printing single Pages, Chapters or the complete Manual

IMPORTANT:

This PDF manual is screen optimized – nevertheless it is possible to print single pages,

single chapters or the complete manual on paper size DIN A4 or Letter.

Some pages – especially circuit diagrams for equipment – have been created on paper

size larger than DIN A4/Letter. Printing these pages on DIN A4/Letter may result in

reduced legibility.

Preferably print circuit diagrams on a DIN A3/ANSI B (Ledger) printer, if available.

1.1 Printing single Pages or Chapters

To print single chapters or pages of a chapter proceed as follows:

(1) Click the bookmark of the desired chapter

(2) Write down or remember the shown page number

(3) Go the end of the section or desired range of pages

(4) Select "Print"

(5) Select the page range

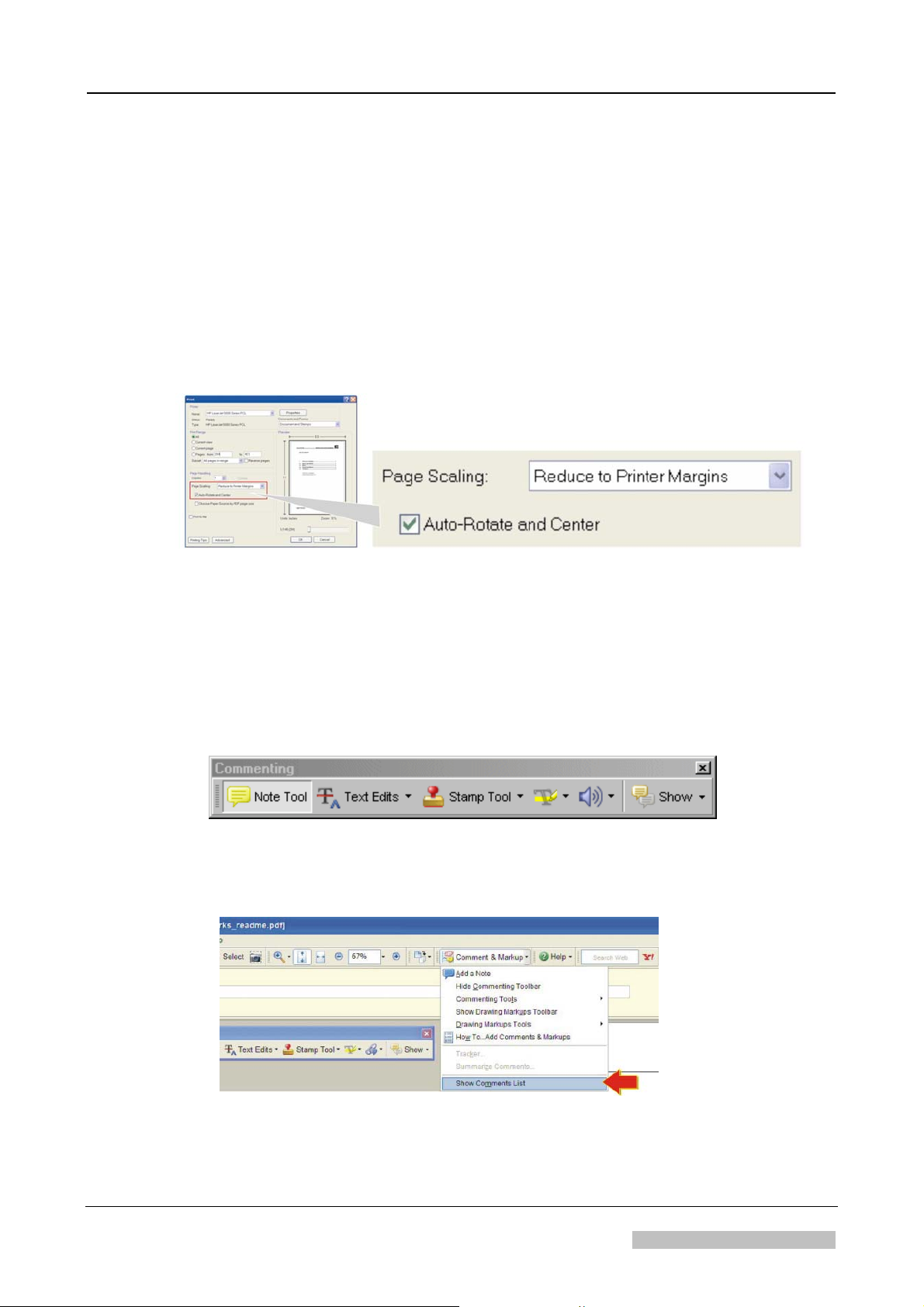

(6) Select "Reduce to printer margins" and "Auto-rotate and Center".

(7) Select “OK”

NOTE:

“Reduce to printer margins” may be named on other Adobe Reader versions

“shrink to printable area” or “shrink oversized pages to paper size”

2007-05-31 printed in Germany

Agfa Company Confidential

Document Node ID: 16099429

Copyright © 2006 Agfa-Gevaert HealthCare

Page 2

1.2 Printing the complete Service Manual

To print the complete service manual proceed as follows:

(1) Select "Print"

(2) Select “All”

(3) Select "Reduce to printer margins" and "Auto-rotate and Center".

(see NOTE previous page)

(4) Select “OK”

ReadMeFirst

2 Adding Comments

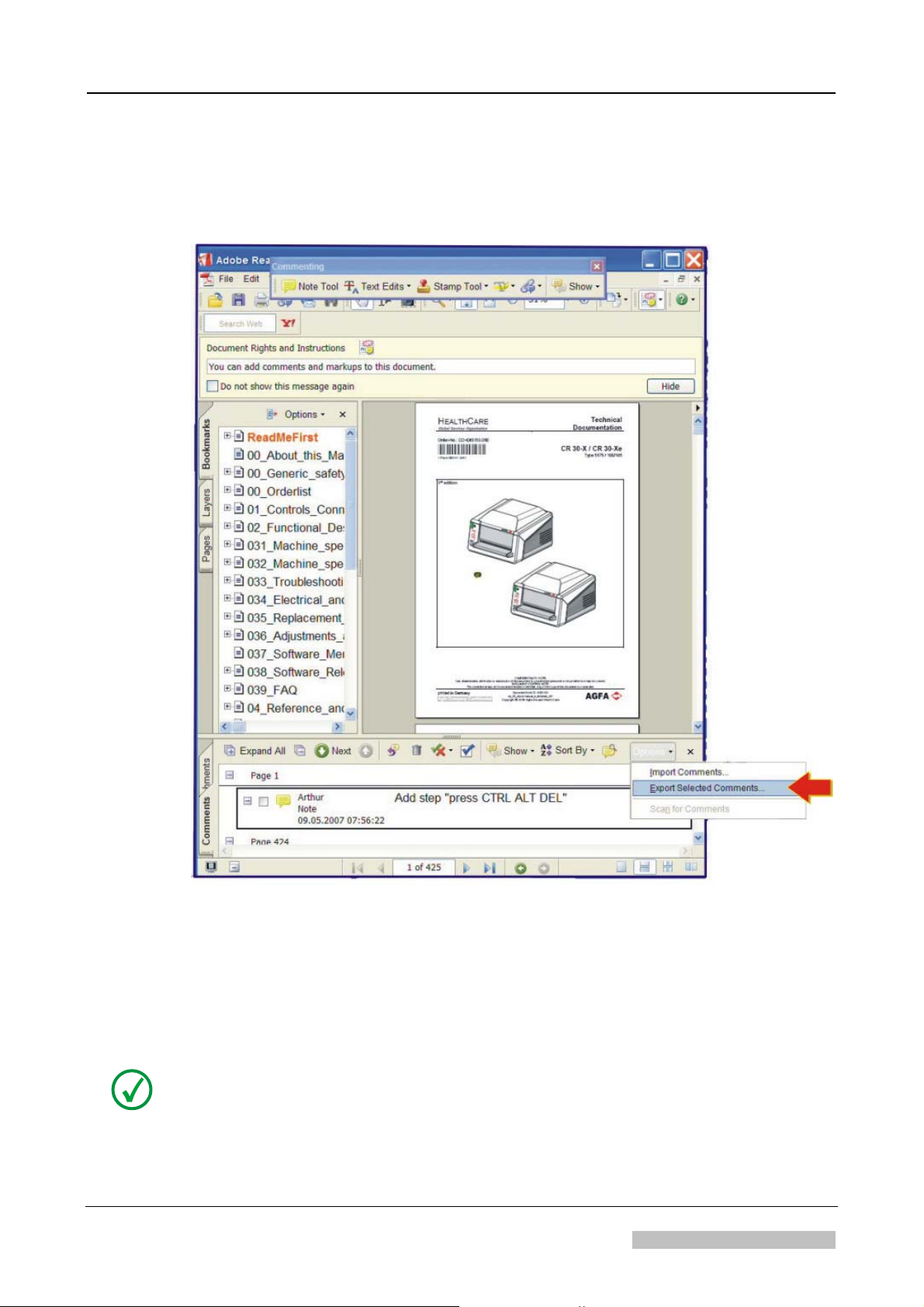

• If you open this file in an Adobe Reader version ≥ 7, the comment toolbar will

show-up.

• This allows adding comments, to highlight or underline text and many more text

manipulations.

2.1 How to export your Comments

(1) In the drop down menu “Comment & Markup” select "Show comments List"

(2) Select the desired comments: Press the CTRL-key for multiple selections.

The controlled version of this document resides on MedNet. Any printed copy of this document is uncontrolled.

DOCUMENT CONTROL NOTE:

Revision 1 How to print and add Comments Page 2 of 3

2007-05-31 Agfa Company Confidential

Page 3

ReadMeFirst

(3) Select “Options - Export Selected Comments”

(4) Save the file with any name

2.2 How to import Comments

(1) In the drop down menu “Comment & Markup” select "Show comments List"

(2) Select “Options - Import Comments”

(3) Browse for the comments file and press “select”

NOTE:

The imported comments possibly appear on different pages, if the file where the

comments have been imported has a different number of pages.

DOCUMENT CONTROL NOTE:

The controlled version of this document resides on MedNet. Any printed copy of this document is uncontrolled.

Revision 1 How to print and add Comments Page 3 of 3

2007-05-31 Agfa Company Confidential

Page 4

Page 5

HEALTHCARE

Global Services Organisation

Order No.: DD+DIS301.03E

*1WACEX1*

1 piece WACEX MA1

Edition 6

Technical

Documentation

Classic E.O.S.

Type 5270 / 100

as of SN 4500

Classic E.O.S. CL

Type 5270 / 105

as of SN 1138

printed in Germany 02 / 2005

Agfa Company Confidential

R

D

C

.

2

0

_

0

0

0

0

1

_

0

7

2

5

Page 6

Page 7

HEALTHCARE

Global Services Organisation

Order No.: DD+DIS301.03E

*1WACEX1*

1 piece WACEX MA1

Technical

Documentation

Classic E.O.S.

Type 5270 / 100

as of SN 4500

Classic E.O.S. CL

Type 5270 / 105

as of SN 1138

6. Edition

Ordering of spare parts Phone: xx49 - (0)89 - 6207 -3760

and spare part kits: Fax: xx49 - (0)89 - 6207 -7388

Ordering of documentation: Phone: xx49 - (0)89 - 6207 -3553

Caution:

This system uses mains voltage. Please observe the pertinent safety instructions.

These instructions describe adjustments and routines which must only be

performed by qualified technical personnel.

Note:

Electrical repairs and connections must only be made by certified electricians.

Mechanical repairs and connections must only be made by certified technicians.

CE Declaration:

According to the medical directives the CE Declaration

(CE Conformity) becomes void if the product is modified without permission of the

manufacturer!

R

D

C

.

2

0

_

0

0

0

0

1

_

0

7

2

5

This applies to all parts, not only the safety devices!

printed in Germany 05 / 2005

Agfa Company Confidential

AGFA-GEVAERT AG HE/S&S - GSO

Tegernseer Landstr. 161 D-81539 Munich

Page 8

Contents

Pictographs and conventions for this documentation

This documentation uses certain conventions (pictographs, styles) to help you find information

faster and easier.

0. Order list

1. Installation preparations

2. Controls and connectors

3. Installation / start-up

4. Operating instructions

5. Theory of function

6. Repair and Service

7. Reference and circuit diagrams

8. Spare parts list

9. Accessories

10. Modifications

11. Technical standard modifications

Meaning of the pictographs

High voltage!

Attention!

Info

Hint

Required

spare part

Required

time

Waiting time

Required

tools

Removal

Installation

Mechanical adjustment

Electrical adjustment

Calibration

Conventions

Activity Type face Example

Instruction,

Explanation

Mouse activities,

or Return key

Text input via keyboard

required

Switch on machine

<omni-cd.exe>

vips

Switch on machine

Doubleclick the icon

<omni-cd.exe>

Enter vips and click

<Continue>

12. Maintenance

13. Field Service Bulletins

14. Installation planning

15. Glossary / key word index

Agfa Company Confidential

Page 9

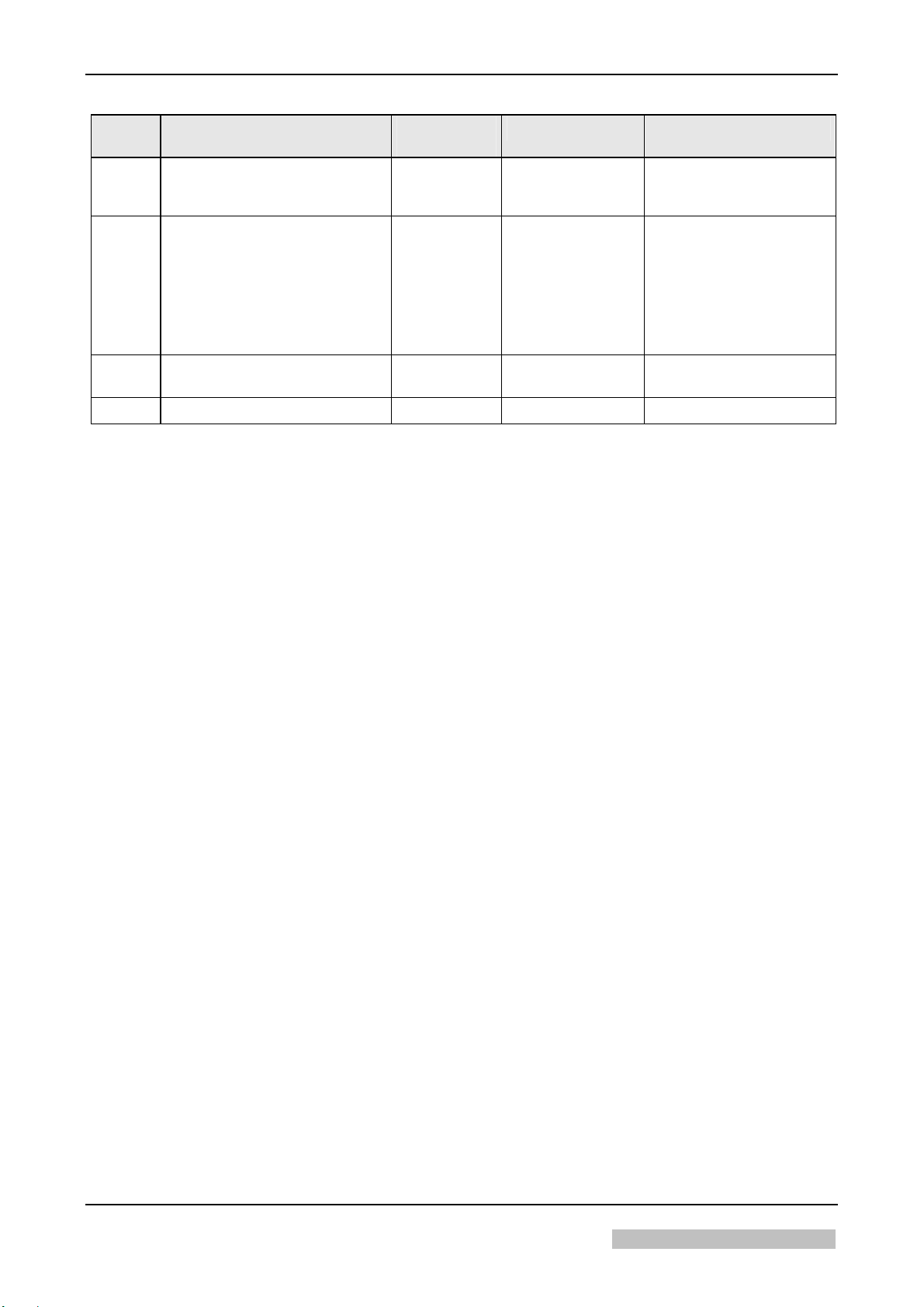

DD+DIS441.04E General Information

_

_

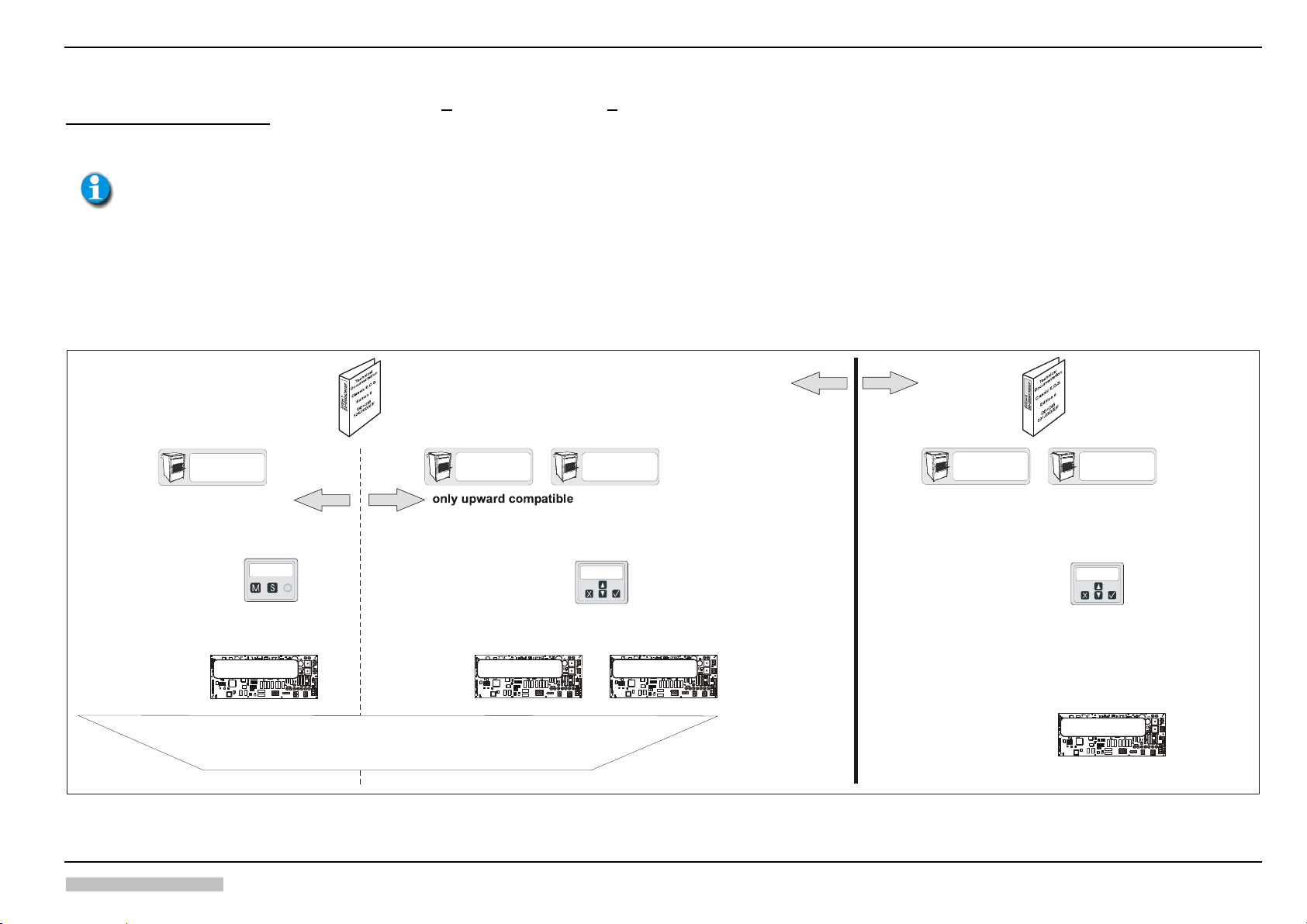

Classic E.O.S. / Classic E.O.S. CL (Type 5270/100/105) Edition 6

th

The 6

edition is the Service Documentation applying to the machines > SN4500 (Type 5270/100) or > SN1138 (Type 5270/105)

It is not a replacement for Edition 5.

The 5th edition remains the Service Documentation applying to the machines < SN4500 (Type 5270/100) or < SN1138 (Type 5270/105)

and it includes the information about technical modifications in the machines up to these serial numbers.

All previous information regarding the serial number of Type 5270/105 (SN 1500) to differentiate compatibility

is void. The new valid threshold for compatibility differentiation of Type 5270/105 is the serial number SN 1138.

This serial number refers to the complete documentation.

Edition 6 provides information about technical modifications in the production standard as of serial numbers 4500 or 1138 respectively.

The technical modifications are:

x A new Control Board (with label F8.5270.7890) has been introduced, and this board only works with Software Version CLLC1107 and up. It is not compatible with the previous control boards and their software.

x The water circulation pump became an option.

x A level sensor in the fixer tank 2 has been added.

x The 24V crossflow fan has been replaced by crossflow fan with 230V.

TYPE 5270/100

only downward compatible

Software versions:

Techn. characteristics:

Control board:

SN 1001

CEOS1117 - CEOS1801

- 3-key control panel

As of CEOS1714:

- Must calibration

- Selection of application

C210

MC31

R

e

v

IC57

D

e

p

l

ST55

MC29

u

l

C

t

c

h

MC28

MC27

y

l

p

S

p

u

ST63

ST57

D

r

a

i

n

ST89

F

a

n

2

ST90

SI2

ST85

ST66

MC13

ST62

MC2

ST54

S1

MC20

MC34

IC52

F8.5270.7750._

ST64

ST65

ST67

ST68ST69

ST70

ST53

IC51

IC50

ST88

IC63

ST73ST72

ST71

ST81

IC78

ST76

ST79

ST74

ST82

R464

R465

ST15

ST77

ST78ST75

IC79

ST87

IC88

Contrast

Brightness

Film Out

SI9

D48

MC32

MC22

ST4

RS4 RS1RS3

SI8

R477

L11

MC16

MC4

MC17

ST5

TY2

R410

C80

D50

BU9

12V2

+24V2

C64

ST45

C63

Circ.Fan1

RS2

RS9

MC24

MC23

D49

TY1

MC3

+24V

C79

BU1

D2

BU4

IC65

+12MOT

IR

Blowe

HeatF

HeatD

R476

R380

RS19

RS21

RS23

SI12

MC35

MC36

R377

RS20

RS24

R485

RS22

R475

R381

R378

R379

RS6 RS7RS5

RS8

SI1

SI3SI5

SI10

SI11 SI6 SI7

BU10

ST86

XK1

BU7

BU6

fuj07903E.cdr

Software version:

Techn. characteristics:

Edition 5

DD+DIS324.00D/E/F

TYPE 5270/100

SN 2200

Software versions:

Techn. characteristics:

IC57

ST55

MC29

MC28

MC27

Steuerkarten:

ST63

ST89

ST90

ST85

ST66

S1

IC52

F8.5270.7750._

ST53

IC50

ST81

ST82

R464

R465

ST15

IC88

ST87

Contrast

Brightness

Film Out

EOSUNIV1007

- Must calibration

- Selection of application

only downward

compatible

TYPE 5270/105

SN 1001

MEOS1201 - MEOS1401

- 4-key control panel

Software versions:

Techn. characteristics

- Current sensor

- Integrated repair routine

C210

ST57

SI2

ST54

ST64

ST65

IC51

IC63

IC78

IC79

- Cross-flow fan 24V

R477

D48

L11

MC32

MC31

MC16

e

R

v

l

D

e

p

MC4

MC17

C

l

u

t

c

h

TY2

R410

C80

l

y

p

p

u

BU9

S

+24V2

12V2

C64

D

in

r

a

ST45

C63

F

a

n

2

Circ.Fan1

MC22

MC13

ST62

MC2

TY1

MC3

MC20

+24V

MC34

C79

BU1

D2

IC65

ST4

ST67

ST68ST69

ST70

+12MOT

ST88

HeatD

ST73ST72

ST71

R476

R380

SI12

MC35

MC36

ST79

ST76

ST74

RS24

R485

RS22

R475

R378

RS4 RS1RS3 RS6 RS7RS5

RS8

ST77

ST78ST75

SI11 SI6 SI7 SI1

SI10

RS2

BU10

RS9

ST86

BU7

C210

SI9 SI8

ST55

ST5

D50

ST66

MC24

MC23

D49

S1

BU4

ST53

IR

HeatF

Blowe

RS19

RS21

RS23

R377

RS20

R379

R381

ST15

ST87

SI3SI5

Film Out

XK1

BU6

fuj07903E.cdr

MC32

MC31

D

e

p

l

R477

e

v

R

IC57

MC29

C

l

u

t

c

h

MC28

MC27

ST89

ST82

R410

p

p

l

y

u

S

BU9

ST63

ST57

12V2

D

r

a

i

n

ST45

a

n

F

ST90

2

SI2

ST85

Fan1

Circ.

MC22

ST62

MC13

MC2

ST54

MC20

MC34

IC52

F8.5270.7950.

ST64

ST65

ST67

ST68ST69

ST4

ST70

IC51

IC50

ST88

IC63

ST73ST72

ST71

ST81

IC78

ST76

ST79

ST74

R464

R465

ST77

ST78ST75

RS4 RS1RS3 RS6 RS7RS5

IC79

IC88

RS2

Contrast

Brightness

RS9

SI9 SI8

D48

L11

MC16

MC4

MC17

ST5

TY2

C80

D50

+24V2

C64

C63

MC24

MC23

D49

MC3

TY1

+24V

C79

BU1

D2

IC65

BU4

+12MOT

IR

HeatF

HeatD

Blowe

R476

R380

RS19

RS21

RS23

SI12

MC35

MC36

R377

RS20

RS24

R485

RS22

R475

R379

R381

R378

RS8

SI11 SI6 SI7 SI1

SI3SI5

SI10

BU10

ST86

XK1

BU7

BU6

fuj07903E.cdr

only upward

compatible

TYPE 5270/100

Control board:

SN 4500

Edition 6

DD+DIS301.03D/E/F

TYPE 5270/105

SN 1138

CLLC1107

- 4-key control panel

- Current sensor

- Integrated repair routines

- Selection of applications

- Water circulation pump

becomes optional

- Level sensor for fixer tank 2

- Cross-flow fan 230V

C210

MC32

BU9

MC22

ST4

RS4 RS1RS3 RS6 RS7RS5

SI9 SI8

R477

D48

L11

MC16

MC4

MC17

ST5

TY2

R410

C80

D50

12V2

+24V2

C64

ST45

C63

MC24

Circ.

RS2

RS9

MC23

D49

TY1

MC3

+24V

C79

BU1

D2

IC65

BU4

+12MOT

IR

HeatF

HeatD

Blowe

R476

R380

RS19

RS21

RS23

MC35

MC36

SI12

R377

RS20

RS24

R485

RS22

R475

R379

R381

R378

RS8

SI11 SI6 SI7 SI1

SI3SI5

SI10

BU10

ST86

XK1

BU7

BU6

fuj07903E.cdr

p

l

D

e

v

e

R

MC31

IC57

ST55

MC29

c

h

C

l

u

t

MC28

MC27

S

u

p

p

ly

ST63

ST57

r

a

D

i

n

ST89

F

ST90

a

SI2

n

2

ST85

ST66

Fan1

ST62

MC13

MC2

ST54

S1

MC20

MC34

IC52

F8.5270.7890.

ST64

ST65

ST67

ST68ST69

ST53

IC51

IC50

ST88

IC63

ST73ST72

ST71

ST81

IC78

ST74

ST76

ST79

ST82

R464

R465

ST15

ST77

ST78ST75

IC79

ST87

IC88

Contrast

Brightness

Film Out

ST70

5270_10000_003-e.cdr

Edition 6, Revision 1 Classic E.O.S. / Classic E.O.S. CL Chapter 0 / I

Agfa Company Confidential (Type 5270 / 100 / 105)

Page 10

Page 11

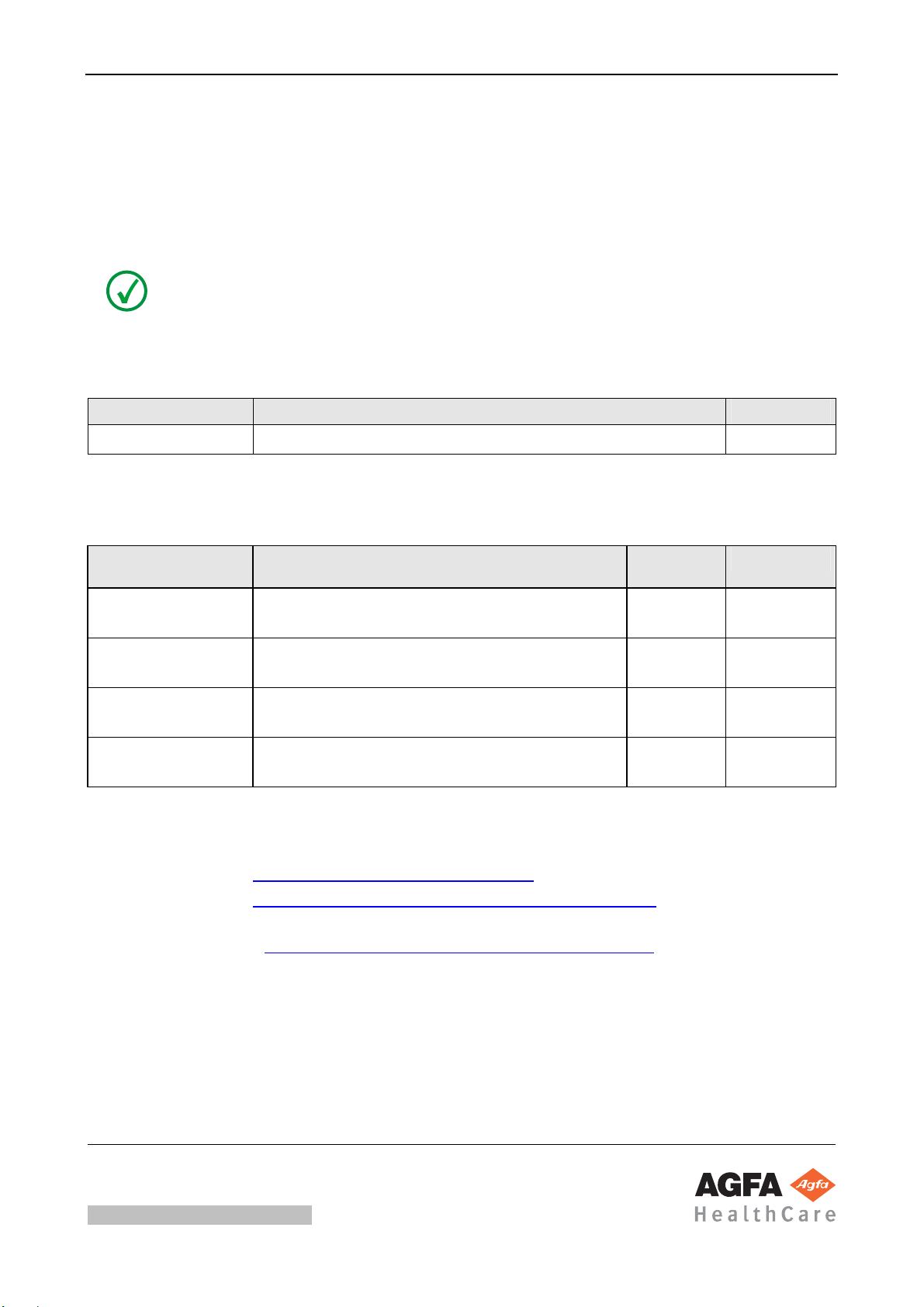

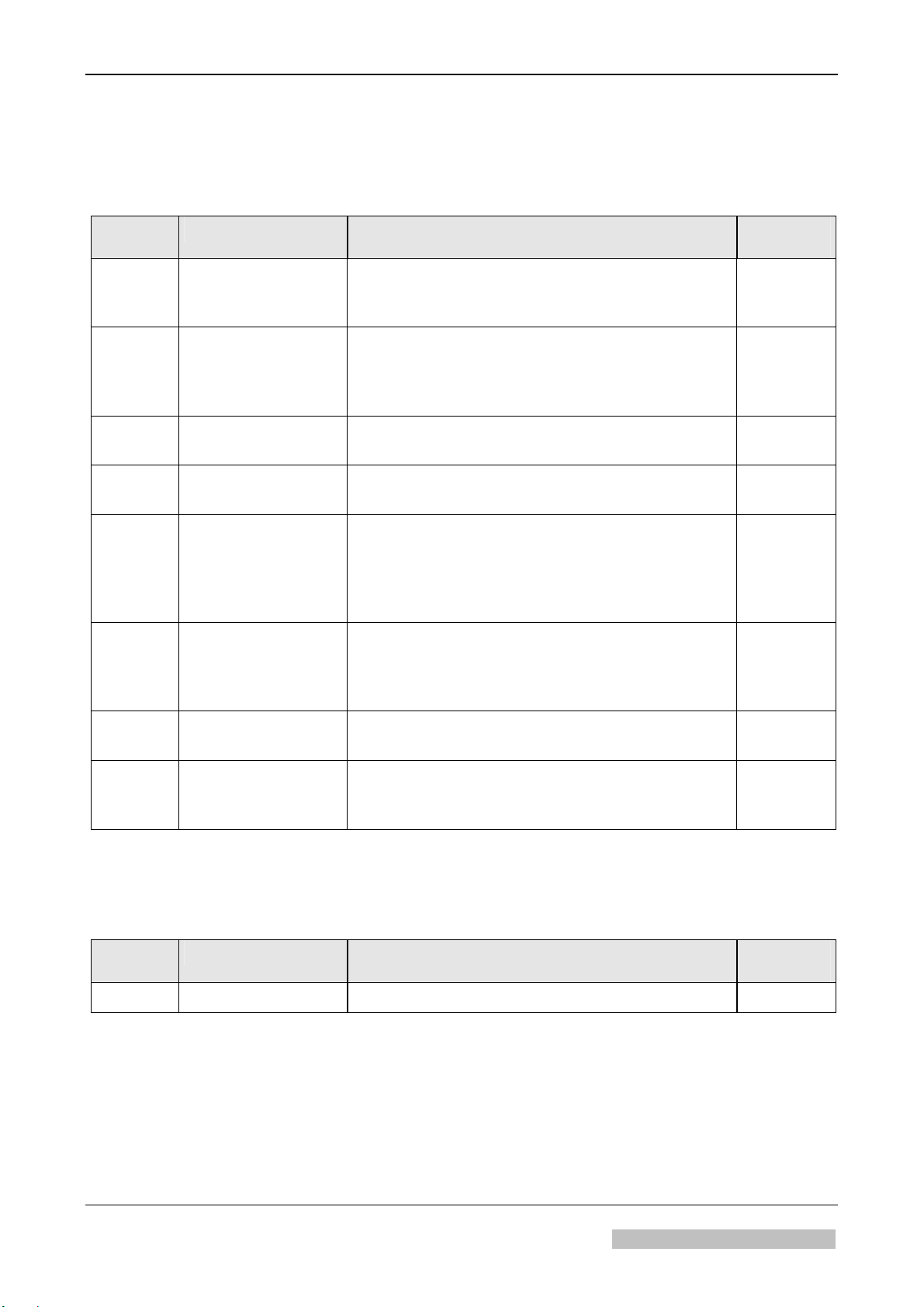

Order List for Documentation

Order List for Documentation Classic E.O.S.

Type 5270/100, from SN4500

Classic E.O.S. CL

Type 5270/105, from SN1138

NOTE:

Daily updated order lists are available in MedNet.

Order number for a complete Service Manual:

Order number Edition

DD+DIS301.03E Complete Service Manual 6

Order numbers for separately available chapters of the Service Manual:

Order number Contents Revision

of document

Approval Date

DD+DIS302.03E Chapter 12:

Maintenance Instructions, Edition 6

DD+DIS303.03E Chapter 14:

Installation Planning, Edition 6

DD+DIS022.05M Chapter 08:

Spare Parts List

DD+DIS060.03E Chapter 08:

Spare Parts List, Thoramat Docking Unit

Access to MedNet GSO Library:

• *IntraNet: http://docs.agfanet/mednetcso-library

• *ExtraNet: http://extranet.agfa.com/bu/mi/mednet/mednetcso.nsf

* to request an account to the MedNet GSO Library go to:

http://intra.agfanet/bu/mi/mednethelp.nsf/EN/gettingaccess.htm

Inquiries:

• Phone + 49 89 6207 3949 Fax +49 89 6207 7274

0 2004-03-12

0 2004-02-05

4 2007-11-28

3 2006-12-08

The controlled version of this document resides on MedNet. Any printed copy of this document is uncontrolled.

2007-11-28 printed in Germany

Agfa Company Confidential

DOCUMENT CONTROL NOTE:

Document Node ID: 14037585

eq_00_orderlist_e_template_v04

Copyright © 2007 Agfa HealthCare N.V.

Page 12

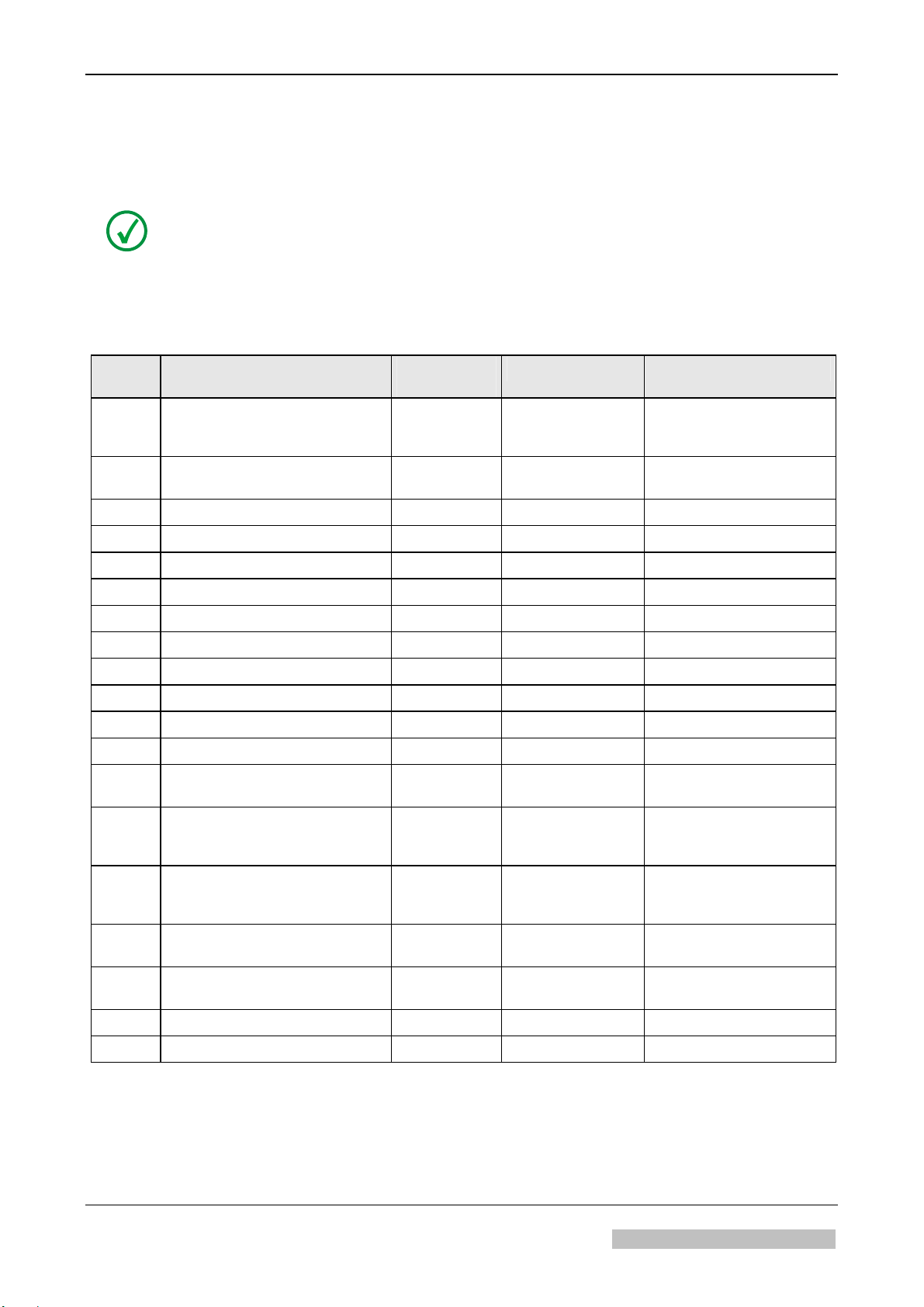

Checklist for Completeness

Checklist for Completeness Classic E.O.S. / Classic E.O.S. CL

Type 5270/100/105

NOTE:

Verify latest level and completeness of your Service Manual by means of this checklist

for completeness.

Only the document numbers listed here are valid. Discard documents with different

numbers if necessary.

Chapter Order number / Designation Revision

of document

Approval date Pages

0 Order list

Checklist for completeness

List of Service Bulletins

0 DD+DIS301.03E 0 2004-03-12 Cover sheet and list of

1 DD+DIS301.03E 0 2004-03-12 1/I, 1/1 – 1/13

2 DD+DIS301.03E 0 2004-03-12 2/I, 2/1 – 2/6

3 DD+DIS301.03E 0 2004-03-12 3/I-II, 3/1 – 3/57

4 Intentionally left blank - - -

5 DD+DIS301.03E 0 2004-03-12 5/I-II, 5/1 – 5/42

6.1 DD+DIS301.03E 0 2004-03-12 6.1/I, 6.1/1 – 6.1/8

6.2 DD+DIS301.03E 0 2004-03-12 6.2/I, 6.2/1 – 6.2/10

6.3 DD+DIS301.03E 0 2004-03-12 6.3/I, 6.3/1 – 6.3/24

6.4 DD+DIS301.03E 0 2004-03-12 6.4/I, 6.4/1

6.5 DD+DIS301.03E 0 2004-03-12 6.5/I-II, 6.5/1 – 6.5/28

6.6 DD+DIS301.03E 0 2004-03-12 6.6/I, 6.6/1 – 6.6/6 (A3)

6.7 DD+DIS131.05E 2 2005-05-03 6.7/I,

- 2007-11-28 0/1-4

contents

6.6/7 – 6.6/15

6.7/1 – 6.7/2,

6.7/3

7 DD+DIS301.03E

F1.5272.7005.0

Overview Control Board PCB1

8 DD+DIS022.05M

DD+DIS060.03M

9 DD+DIS301.03E

DD+DIS309.00E

10 Intentionally left blank - - -

11 DD+DIS441.04E 1 2004-12-22 11/I, 11/1

DOCUMENT CONTROL NOTE:

The controlled version of this document resides on MedNet. Any printed copy of this document is uncontrolled.

0 2004-03-12 7/I, 7/1-13

Sh. 1-1 (A1)

(A3)

4

3

0 2004-03-12 9/I

2007-11-28

2006-12-08

8/1 - 8/76

8/1 – 8/22

Cover sheet, 9/I, 9/1 – 9/8

2007-11-28 Classic E.O.S. / Classic E.O.S. CL Chapter 0 / 2

Type 5270/100/105 Agfa Company Confidential

Page 13

Checklist for Completeness

Chapter Order number / Designation Revision

of document

12 DD+DIS302.03E 0 2004-03-12 Cover sheet

Approval date Pages

12/I, 12/1 - 12/25

Checklist 1-3

13 SB 01 DD+DIS157.04E

SB 02 DD+DIS249.04E

SB 03 DD+DIS277.04E

SB 04 DD+DIS288.04E

SB 05 DD+DIS214.04E

SB 06 DD+DIS184.05E

SB 07 DD+DIS009.07E

SB 08 DD+DIS223.07E

14 DD+DIS303.03E 0 2004-02-05 Cover sheet

15 DD+DIS301.03E 0 2004-03-12 15/I, 15/1 – 15/3

n.a. 2004-05-07

2004-08-04

2004-08-31

2004-08-31

2004-07-06

2005-07-06

2007-01-29

2007-10-23

13/1-5

13/1-4

13/1-/3

13/1-/2

13/1-/2

13/1-/3

13/1-/3

13/1-/15

14/I-II, 14/1 – 14/41

The controlled version of this document resides on MedNet. Any printed copy of this document is uncontrolled.

DOCUMENT CONTROL NOTE:

2007-11-28 Classic E.O.S. / Classic E.O.S. CL Chapter 0 / 3

Type 5270/100/105 Agfa Company Confidential

Page 14

List of Service Bulletins

List of Service Bulletins Classic E.O.S. / Classic E.O.S. CL

Type 5270/100/105

• The following SB’s are valid:

SB Document number Contents Revision

of document

SB 01 DD+DIS157.04E Control Board PCB1 (CM+9 5270 9450 0) and

Processor SOFTWARE CLLC1107

(CM+9 5270 9410 0) available as Spare Part

SB 02 DD+DIS249.04E Introduction of Processor Software CLLC_1203

Order Number: CM+9 5270 9410 1

Control Board PCB1 incl. CLLC_1203

Order Number: CM+9 5270 9450 1

SB 03 DD+DIS277.04E Magnet Not Sufficiently Fixed in the Machine

Cover

SB 04 DD+DIS288.04E Introduction of Anti-Algae-Unit

Type: 5279/100

SB 05 DD+DIS214.04E Installation of the Tank Reinforcement

CM+9 5270 9071 0

This document describes the installation of a tank

reinforcement that prevents bending of the

intermediate tank walls.

SB 06 DD+DIS184.05E Service 574:

“IR heater in dryer defective” due to measuring

error caused by wrong cable positioning at the

Current Sensor Board PCB2.

0

0

0

0

0

0

SB 07 DD+DIS009.07E Manufacturer’s Warning about Ground Fault

0

Interrupters with Possibly Higher Trigger Current.

SB 08 DD+DIS223.07E Empty Battery of the Clock Chip Causes Incorrect

0

Date and Incorrect Time Display Followed by a

Calibration Request

• The following SB's are no longer valid

(integrated in the chapters of the Service Manual, or technically obsolete):

SB Document number Contents Revision

of document

-- -- -- --

The controlled version of this document resides on MedNet. Any printed copy of this document is uncontrolled.

DOCUMENT CONTROL NOTE:

2007-11-28 Classic E.O.S. / Classic E.O.S. CL Chapter 0 / 4

Type 5270/100/105 Agfa Company Confidential

Page 15

Preinstallation

1

Section 1

contains all important preinstallation data for the machine:

• Inspection of the packing material for transport damage and complete

shipment

• Unpacking and packing notes

• Machine positioning at the installation site

• Requirements on the installation site

• Connection data (electrical, if necessary, connections to chemical supply and

disposal, fiber optic connections)

Make sure to study this section and before starting the installation check if all

preparations have been made as specified.

Section 1

Page 16

Page 17

DD+DIS301.03E Installation Preparations

Chapter 1

Contents

1 Safety ......................................................................... 1

2 Installation Preparations ..........................................3

2.1 Machine transport ...................................................................3

2.2 Checking the shipment ........................................................... 3

2.3 Transport check....................................................................... 3

2.4 Checking safety indicators on the machine box ..................3

2.5 Transport path .........................................................................4

2.6 Required space at the installation site ..................................5

2.6.1 Classic E.O.S. Type 5270/100...........................................................5

2.6.2 Classic E.O.S. CL Type 5270/105 .................................................... 6

2.7 Unpacking ................................................................................7

2.8 Checking the type label ..........................................................8

2.9 Checking the accessory box ..................................................8

3 Technical Data........................................................... 9

3.1 Electrical data ..........................................................................9

3.2 Ambient and climatic conditions ...........................................9

4 Dimensions and Weights........................................ 11

4.1 Classic E.O.S. Type 5270/100 .............................................. 11

4.2 Classic E.O.S. CL Type 5270/105 ........................................11

5 Machine Standards and Directives........................ 12

5.1 Safety...................................................................................... 12

5.2 Radio interference suppression...........................................12

5.3 Electromagnetic compatibility.............................................. 12

5.4 Certificates and guidelines...................................................13

Edition 6, Revision 0 Classic E.O.S. / Classic E.O.S. CL Chapter 1 / I

Agfa Group Confidential (Type 5270 / 100 / 105)

Page 18

Page 19

DD+DIS301.03E Installation Preparations

1 Safety

General safety instructions

• The machine must only be used as described in the operating instructions.

Any other use may result in damage to the machine or may affect the

machine function with the consequence that the machine can no longer be

used as intended, and therefore presents a risk for patients, user, and

environment.

• The machine must only be operated by qualified personnel trained on the

machine.

• Ensure that only trained personnel have access to the machine.

• Ensure that the machine can always be supervised and that any tampering

is prevented.

• Repairs or modifications on the machine must only be performed by trained

service personnel authorized by Agfa.

• In case of visible damage on the machine housing the machine must not be

operated or used, and must immediately be disconnected from the mains.

• Built-in or external safety devices must not be circumvented or disabled.

• Disconnect the machine from the mains before starting any maintenance.

• If a mains connection is absolutely required these maintenance routines

must only be made by specially trained personnel.

• Like all technical devices, this machine must be operated, cared for and

serviced correctly as described in the documentation provided with the

machine.

• If the machine is not operated correctly, or if it is not serviced correctly,

Agfa will not be liable for any resulting disturbances, damage or injuries.

• When installing the machine make sure that either the mains plug or an all-

cable disconnecting device is provided in the internal installation close to

the machine and is easily accessible.

• If the machine is connected with other components or assemblies, Agfa will

guarantee safety only for combinations which are approved by Agfa.

• In case of conspicuous smoke or noises, immediately disconnect the

machine from the mains.

Special instructions for the handling of chemicals

• When handling chemicals, always observe the applying safety and

environmental regulations, as well as the operating and warning

instructions pertaining to these chemicals.

• Wear stipulated protective clothing and safety goggles.

• When disposing of chemicals and waste water, you must comply with the

local regulations concerning waste water and environmental protection.

• If photo-chemicals get in your eyes, proceed exactly according to the

warning instructions and/or the instructions published by the manufacturers

of the chemicals. If required, immediately rinse your eyes with cold water.

Afterwards see the doctor immediately.

• Avoid inhaling of chemical fumes. Make sure that there is sufficient

ventilation at the installation site of the machine, i.e. an air exchange that is

Edition 6, Revision 0 Classic E.O.S. / Classic E.O.S. CL Chapter 1 / 1

Agfa Group Confidential (Type 5270 / 100 / 105)

Page 20

Installation Preparations DD+DIS301.03E

at least ten times the room volume per hour.

• Always comply with the installation instructions.

• Verify tightness of all connections for chemicals and water, as well as

waste water, on the machine in regular intervals. At least check whenever

suggested in the operating instructions and/or service instructions.

• If solution gets into the inside of the machine (e.g. by spilling during tank

filling), the machine must immediately be disconnected from the mains and

cleaned thoroughly by the service personnel.

• Do not use additional chlorine or chlorine containing substances inside the

processor. The use of additional chlorine or chlorine containing substances

can lead to irreversible damage of the equipment. Using these substances

may void the manufacturers warranty.

The film processor must not be operated in the direct vicinity of the

patients as defined in EN60601-1 and IEC 601-1.

Adherence to safety regulations

• This film processor meets the safety requirements as defined in EN 60950:

1997 (IEC 950) and EN 60601-1-2: 1993, UL 1950 and CSA C22.2 No. 950

and has interference suppression as defined in EN 50081-1, EN 55011,

and FCC 47 Part 15, Subchapter B, Class A.

• The water connection complies with DIN 1988 / EN 1717:2001.

Chapter 1 / 2 Classic E.O.S. / Classic E.O.S. CL Edition 6, Revision 0

(Type 5270 / 100 / 105) Agfa Group Confidential

Page 21

DD+DIS301.03E Installation Preparations

2 Installation Preparations

2.1 Machine transport

The freight forwarder transports the machine up to the final installation site.

The responsible technician should be present during delivery.

2.2 Checking the shipment

Compare the labels on the boxes with the customer’s order list and the bill of

lading.

2.3 Transport check

Check the packing material for visible transport damage:

• dented edges

• damaged box

• torn fixing elements (metal straps, screws)

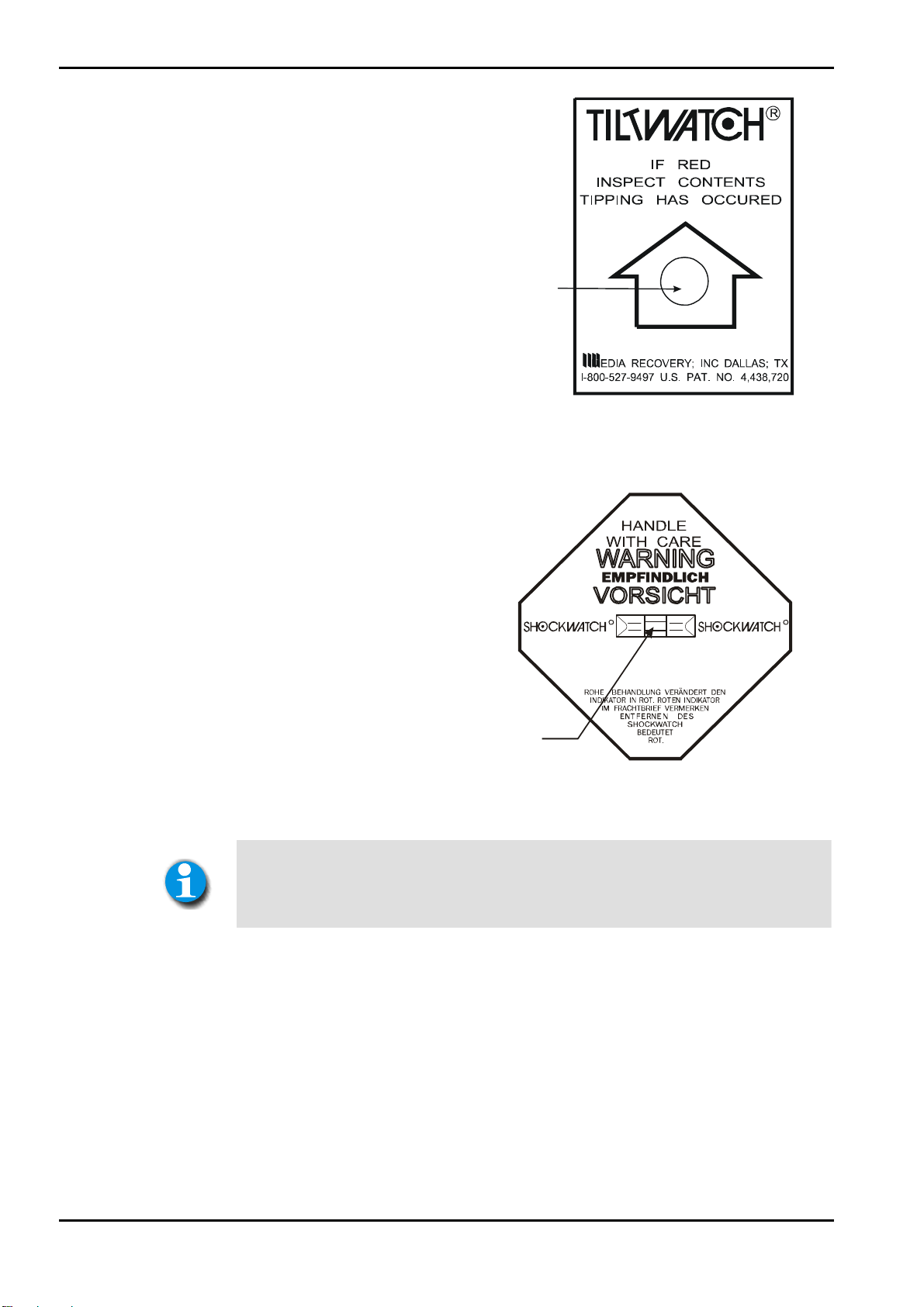

2.4 Checking safety indicators on the machine box

The machine is shipped on a pallet.

The box has a TILTWATCH indicator (A), a SHOCKWATCH indicator (B), and

a packing seal (C) attached.

They are attached to the outside of the box and indicate if the machine has

been tilted, was exposed to shocks, or has been opened during transport.

Figure 1

Edition 6, Revision 0 Classic E.O.S. / Classic E.O.S. CL Chapter 1 / 3

Agfa Group Confidential (Type 5270 / 100 / 105)

Page 22

Installation Preparations DD+DIS301.03E

If the machine was tilted, the

arrow head in the circle of the

TILTWATCH indicator (A)

changed from white to red.

A

5270_10001_002.cdr

Figure 2

D

A

L

LA

S, T

X

.

U

.S.

P

AT.

N

, FRA

H

GMB

X

E

KON

5270_10001_003.cdr

If the machine was subjected to

shocks, the square field in the

middle of the SHOCKWATCH

indicator (B) changed from white

to red.

NC.

I

OVERY,

OF MEDIA REC

PRODUCT

INDICATOR INDIKATOR

ROUGH HANDLING WILL CHANGE INDICATOR TO

IMPORT ED

BRIGHT RED. IF SHOCKWATCH IS RED NOTE

ON BILL OF LADING. INSPECTION MAY

B

Y / IMPOR

B

Model/Modell L-65

R R

BE WARRENTE D.

TIER T D

U

RCH

Figure 3

Note all detected damage in the installation report!

In case of a damaged machine make sure to keep the packing material for

proof (transport insurance)!

Send the damage report to the insurance company.

#

KFURT

40

68613

/

IN

A

M

2.5 Transport path

The film processor must fit through all doors and hallways on its transport path

to the installation site.

Classic E.O.S. / Classic E.O.S. CL

(Type 5270/100/105)

without pallet

with pallet

Chapter 1 / 4 Classic E.O.S. / Classic E.O.S. CL Edition 6, Revision 0

(Type 5270 / 100 / 105) Agfa Group Confidential

smallest door width

at least 73 cm (29 inch)

at least 82 cm (32 inch)

Page 23

DD+DIS301.03E Installation Preparations

2.6 Required space at the installation site

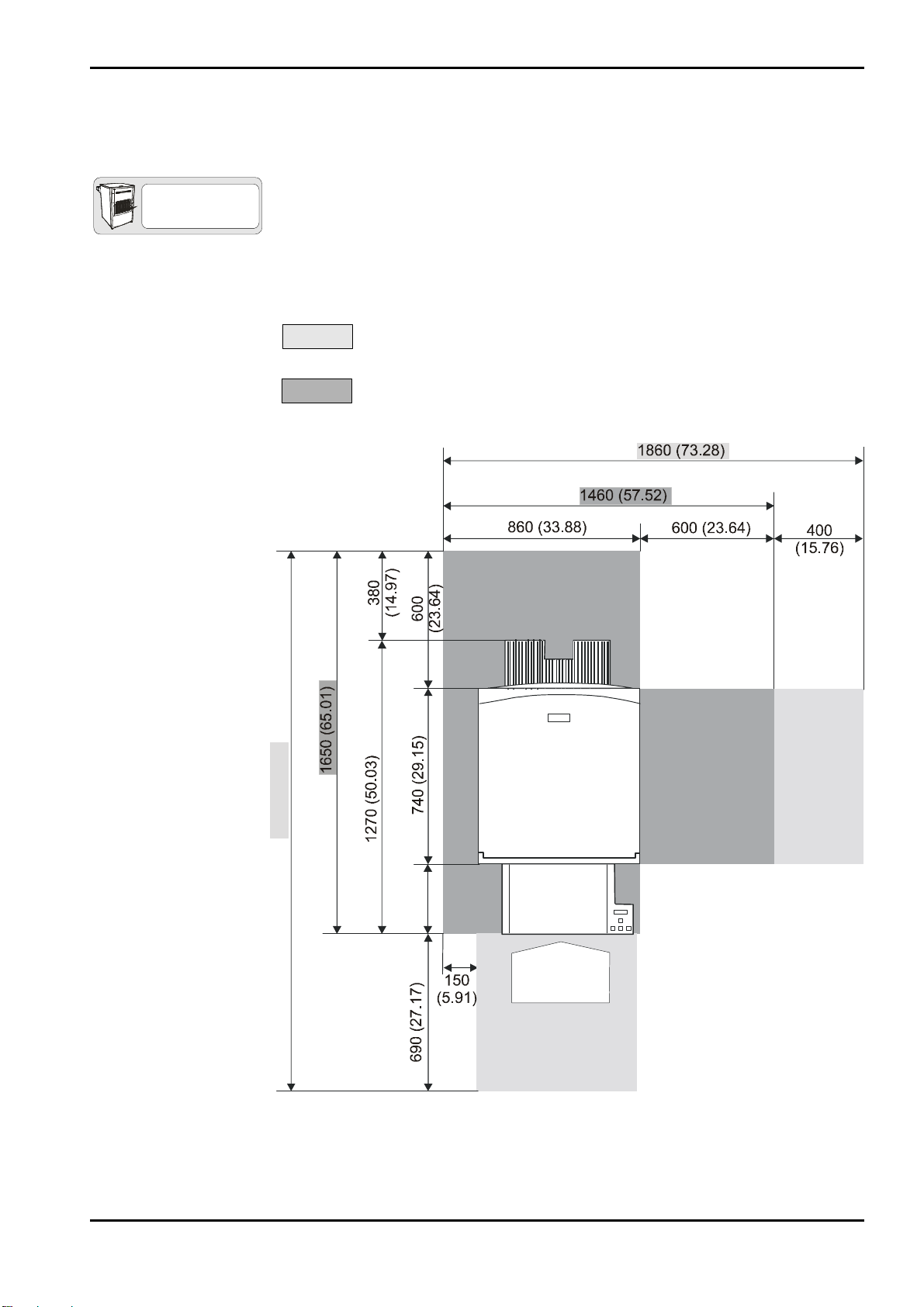

2.6.1 Classic E.O.S. Type 5270/100

The required floor space for the film processor (with feed table, chute and the

TYPE 5270/100

required clearance on the left) is 1260 x 860 mm (50.03 x 33.88 inch).

The free space indicated in the illustration must be guaranteed for repair and

maintenance, otherwise the time required for service will increase.

Optimum dimensions:

We recommend to plan on this free space.

Minimum dimensions:

Do not go below this minimum space.

2340 (92.19)

5270_10001_004.cdr

310

(12.21)

A

Figure 4

(A) Operation side

Dimensions in mm (inch)

Edition 6, Revision 0 Classic E.O.S. / Classic E.O.S. CL Chapter 1 / 5

Agfa Group Confidential (Type 5270 / 100 / 105)

Page 24

Installation Preparations DD+DIS301.03E

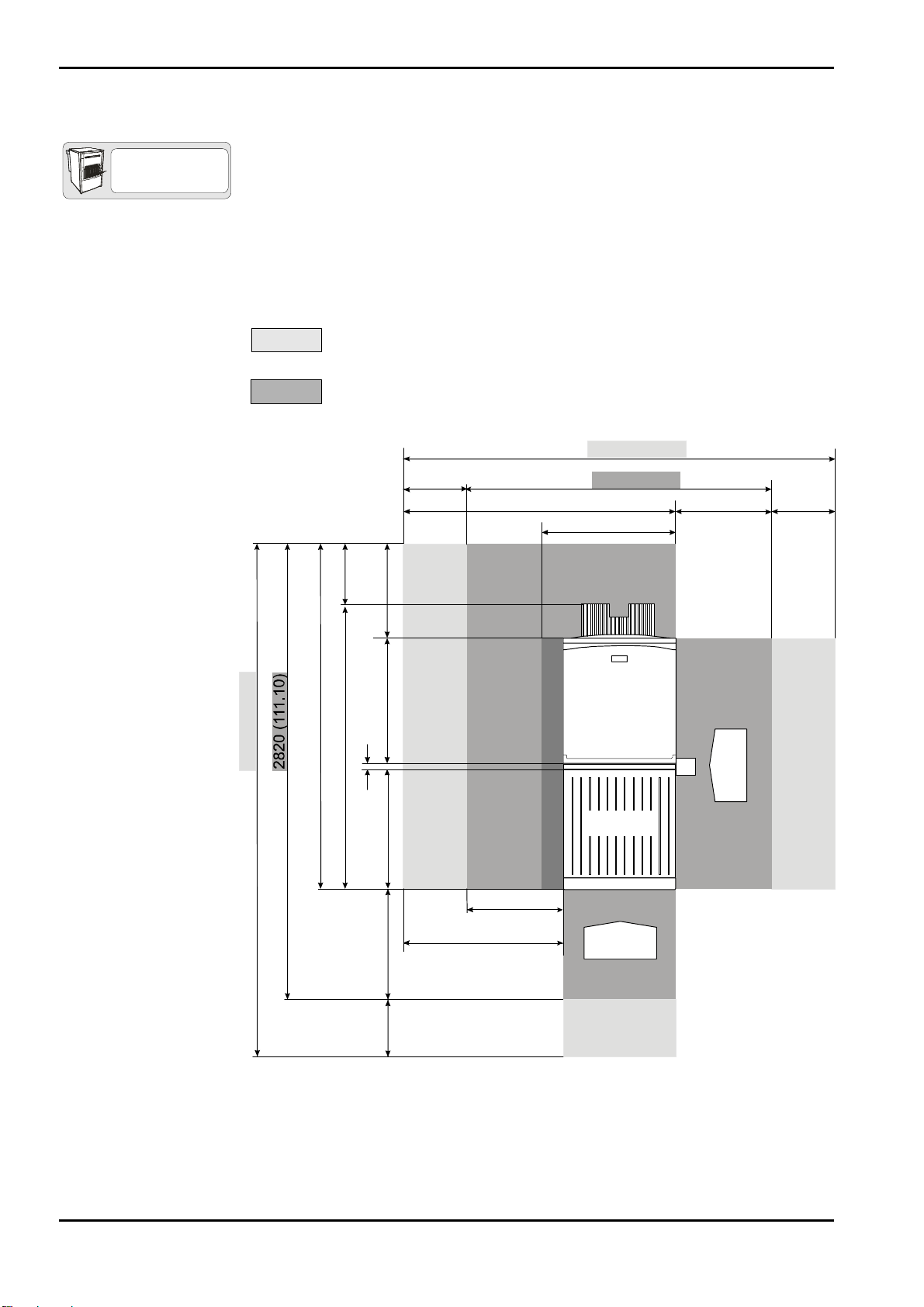

2.6.2 Classic E.O.S. CL Type 5270/105

The required floor space for the film processor in combination with the Laser

TYPE 5270/105

Imager LR3300 (with feed table, chute and the required clearance on the left)

is 1700 x 860 mm (66.98 x 33.88 inch). In case of an installation of the Laser

Imager LR3300 or another daylight system observe the installation

documentation enclosed with the machine.

The free space indicated in the illustration must be guaranteed for repair and

maintenance, otherwise the time required for service will increase.

Optimum dimensions:

We recommend to plan on this free space.

Minimum dimensions:

Do not go below this minimum space.

2710 (106.77)

3120 (122.92)

2120 (83.52)

380

1700 (66.98)

(14.97)

40 (1.57)

600

740 (29.15)

740 (29.15)

400

(15.76)

(23.64)

1710 (67.37)

600 (23.64)

1910 (75.25)

860 (33.88)

LR3300

600

(23.64)

(15.76)

A

5270_10001_005.cdr

400

700 (27.58)

300

1000 (39.4)

(11.82)

A

Figure 5

(A) Operation side

Dimensions in mm (inch)

Chapter 1 / 6 Classic E.O.S. / Classic E.O.S. CL Edition 6, Revision 0

(Type 5270 / 100 / 105) Agfa Group Confidential

Page 25

DD+DIS301.03E Installation Preparations

2.7 Unpacking

For unpacking follow the illustrated instructions attached to the outside of the

packing box and enclosed inside the box.

Required tools:

• Knife, scissors, or side cutting pliers to cut the straps

• Phillips screwdriver size 2

• Wrench size 10 mm

• Wrench size 13 mm

• Wrench size 17 mm

• Screwdriver 10 mm

• The forwarder will take back

the packing material and

dispose of it in compliance with

the local regulations.

527001vh.cdr

Figure 6

• Check the SHOCKWATCH

indicator (A) inside the

machine.

If the machine was subjected to

shocks, the square field in the

middle of the SHOCKWATCH

indicator (A) changed from white

to red.

A

PRODU

I

M

P

O

.

D

NC

ALL

I

,

AS,

TX.

OVERY

EC

R

F MEDIA

O

T

C

INDICATOR INDI KATOR

ROUGH HANDLING WILL CHANGE INDICATOR TO

BRIGHT RED. IF SHOCKWATCH IS RED NOTE

R

ON BILL OF LADING. INSPECTION MAY

T

E

D

B

Y

/

IM

P

O

R

T

I

E

R

U

.

S.

Model/Modell L- 65

R R

BE WARRENTED.

T

D

EX GMBH, FRANKFURT /

U

N

R

C

KO

H

P

A

T.

#

40

6

86

1

3

MAIN

5270_10001_006.cdr

Figure 7

Note all detected damage in the installation report!

In case of a damaged machine make sure to keep the packing material for

proof (transport insurance)! Send the damage report to the insurance

company.

Edition 6, Revision 0 Classic E.O.S. / Classic E.O.S. CL Chapter 1 / 7

Agfa Group Confidential (Type 5270 / 100 / 105)

Page 26

Installation Preparations DD+DIS301.03E

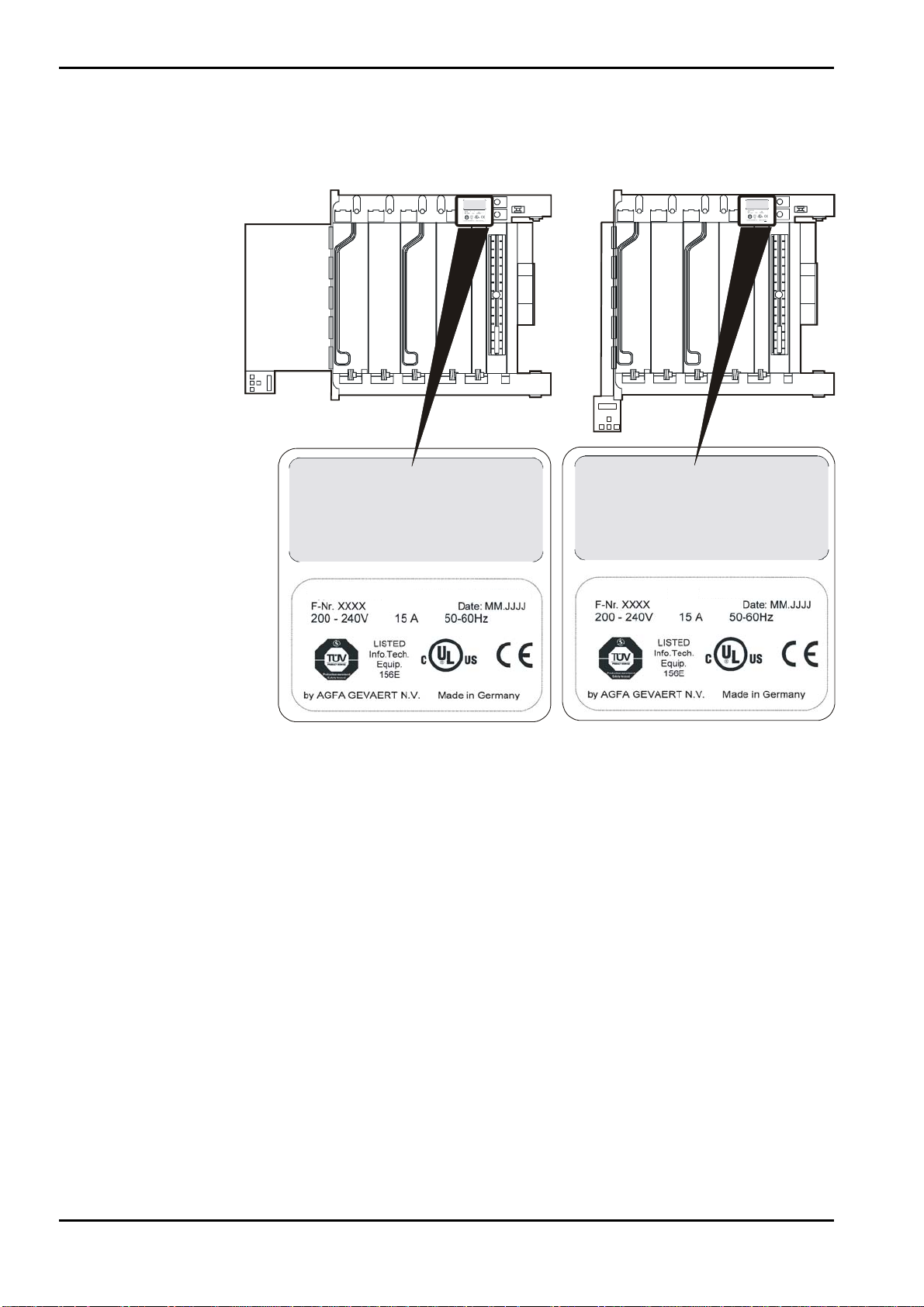

2.8 Checking the type label

Classic E.O.S. Type 5270/100 Classic E.O.S. CL Type 5270/105

This device complies with Part 15 of the FCC Rules.

Operation is subject to the following two conditions:

(1) this device may not cause harmful interference,

and (2) this device must accept any interference

received, inc lu ding int erfer ence that may cause

undesired operation.

527301zy.cdr

FUJIFILM FPM 3800AD

11.1999

1009

This device complies with Part 15 of the FCC Rules.

Operation is subject to the following two conditions:

(1) this device may not cause harmful interference,

and (2) this device must accept any interference

received, including interference that may cause

undesired operation.

Type 5270/100

This device complies with Part 15 of the FCC Rules.

Operation is subject to the following two conditions:

(1) this device may not cause harmful interference,

and (2) this device must accept any interference

received, inclu din g int er ference tha t may cause

undesired operation.

527301zy.cdr

FUJIFILM FPM 3800AD

1009

11.1999

This device complies with Part 15 of the FCC Rules.

Operation is subject to the following two conditions:

(1) this device may not cause harmful interference,

and (2) this device must accept any interference

received, including interference that may cause

undesired operation.

Typ e 5 273 /10 5

Type 5270/105

Explanation of the type label:

F-Nr. xxxx:

Date: MM.JJJJ:

V 200-240 15 A 50-60 HZ:

This is the consecutive serial number.

This is the production date (month/year).

Mains power supply

• Compare the information at "TYPE" and "F-Nr." on the type label with the

bill of lading.

• Compare the rated voltage with the power supply at the installation site.

2.9 Checking the accessory box

• Compare the contents of the accessory box with the list of contents

(included in the enclosed documentation pack).

5270_10001_001.cdr

Figure 8

Chapter 1 / 8 Classic E.O.S. / Classic E.O.S. CL Edition 6, Revision 0

(Type 5270 / 100 / 105) Agfa Group Confidential

Page 27

DD+DIS301.03E Installation Preparations

3 Technical Data

3.1 Electrical data

This is a summary of the technical data which serve to inspect the installation

site. For further technical, electrical, and climatic data and information

regarding the ambient conditions refer to Chapter 14.

Mains voltage connection

1N~ 230 - 240 V; 50/60 Hz (200 - 240 V)

Power consumption:

Standby

(room temperature ~ 20 °C)

During film processing

Fuse protection

Leakage current towards

ground

Main switch

Safety rules

0.45 kW/h (1620 kJ/h)

2.9 kW/h (10440 kJ/h)

max. 3.45 kW/h (12420 kJ/h)

15 A / 16 A

< 3.5 mA

Upon machine installation it must be

ensured that either the power plug or an

all-pole circuit breaker for the installation

on site is located close to the machine and

easily accessible.

Electrical installations in the installation

room must be in compliance with IEC 364

(VDE 0100 / 0107).

A GFI switch (I

with VDE 664) is integrated in the machine.

= 30 mA in compliance

N

3.2 Ambient and climatic conditions

Ventilation

Light-tightness

Acoustic test

ISO 7779 (airborne noise)

Edition 6, Revision 0 Classic E.O.S. / Classic E.O.S. CL Chapter 1 / 9

Agfa Group Confidential (Type 5270 / 100 / 105)

Avoid inhaling of chemical fumes. Make

sure that there is sufficient ventilation at the

installation site of the machine, i.e. an air

exchange that is at least ten times the

room volume per hour.

maximum 2500 Lux

during standby max. 35 dB (A)

during film cycle max. 48 dB (A)

Page 28

Installation Preparations DD+DIS301.03E

Heat emission

(all values are

approximate)

Standby (max.) into the room 250 W / 900 kJ/h

Room temperature

Relative humidity

Floor conditions

Floor load

Film cycle

(max.)

into the room 900 W / 3240 kJ/h

total 2100 W / 7560 kJ/h

Exhaust

connection

min. 10 °C (50 °F), max. 30 °C (86 °F)

Room temperature min. 5 °C (41 °F) below the set

developer temperature

min. 10 %, max. 80 %, no condensation

Waterproof, chemical-resistant floor covering

(pH value 4 - 11)

A floor drain close to the film processor is

recommended.

50 N / cm² (7.75 N / in²)

into the

connected

exhaust

The exhaust is a standard feature of

the dryer.

During film cycle the exhaust runs at

full power. During standby mode the

exhaust can be set to half-power via

the service program.

1200 W / 4320 kJ/h

Cleaning sink

A cleaning sink with water tap and hose shower should

be provided for maintenance work.

Minimum inside dimensions of the sink:

Width

Depth

Height

70 cm (27.56 inch)

40 cm (15.75 inch)

20 cm (7.87 inch)

Chapter 1 / 10 Classic E.O.S. / Classic E.O.S. CL Edition 6, Revision 0

(Type 5270 / 100 / 105) Agfa Group Confidential

Page 29

DD+DIS301.03E Installation Preparations

4 Dimensions and Weights

4.1 Classic E.O.S. Type 5270/100

TYPE 5270/100

Dimensions

incl. packing box 1200 (47.28) 800 (31.52) 1460 (57.52)

Length mm

(inch)

Width mm (inch) Height mm

(inch)

without packing

material

(with feed table

and chute)

Weight

with packing material 200 (441)

without packing material 135 (297)

with full tanks 165 (364)

1270 (50.03) 710 (27.97) 1130 (44.52)

4.2 Classic E.O.S. CL Type 5270/105

TYPE 5270/105

Dimensions

incl. packing box 1200 (47.28) 800 (31.52) 1460 (57.52)

Length mm

(inch)

Weight approx. kg (lbs)

Width mm (inch) Height mm

(inch)

without packing

material

(with docking unit

and chute)

Weight

with packing material 200 (441)

without packing material 135 (297)

with full tanks 165 (364)

Edition 6, Revision 0 Classic E.O.S. / Classic E.O.S. CL Chapter 1 / 11

Agfa Group Confidential (Type 5270 / 100 / 105)

1070 (42.15) 710 (27.97) 1130 (44.52)

Weight approx. kg (lbs)

Page 30

Installation Preparations DD+DIS301.03E

5 Machine Standards and Directives

5.1 Safety

Europe

EN 60950 / A11 1997 "Safety of Information Technology Equipment"

(identical with IEC 950: 1992 and VDE 0805/ 11. 97)

USA

UL 1950 3. July 1995 "Safety of Information Technology Equipment,

Including Electrical Business Equipment"

Canada

CSA 22.2 No. 950 - 95 "Safety of Information Technology Equipment,

Including Electrical Business Equipment”

5.2 Radio interference suppression

Europe

In compliance with EN 50081-1: 1992 "Generic Standard for Emission

Requirements", (identical with VDE 0839, Part 81-1/ 03. 93)

EN 55011 1998, Class B "Radio Disturbance Characteristics of Medical

Equipment" (corresponds to VDE 0878, Part 22 / 04.98)

For equipment in residential areas, business and commercial areas, and in

doctors’ offices.

North-America (USA, Canada)

US-Standard FCC 47 Part 15, Subchapter B, Class A / Edition 8/ 1976

Equipment considered “Non-Household Appliances”

5.3 Electromagnetic compatibility

EMVG and EG Regulation 89 / 336 / EEC

EN 50082-1: 1997

EN 61000-3-2 “Limit Values for Harmonic Emissions”

EN 61000-3-3 “Limit Values for Flicker”

Chapter 1 / 12 Classic E.O.S. / Classic E.O.S. CL Edition 6, Revision 0

(Type 5270 / 100 / 105) Agfa Group Confidential

Page 31

DD+DIS301.03E Installation Preparations

5.4 Certificates and guidelines

CE Medical Device Directive 93/42 EEC

TÜV Product Service Mark “Design tested and monitored”

UL Approbation E 477 50 (M)

C-UL Approbation E 477 50 (M)

"Technical directives for

drinking water installations,

protection against reflux”

General conditions and

administrative regulations for

minimum requirements on the

disposal of waste water into

public waters, dated

31.01.1994 (Germany)

Ministre de l’environment

(France)

DIN 1988, Part 4/ 1988 / EN 1717:2001

Appendix 53 – Photographic Processes

(silver halide photography)

Rubrique No. 2950

Maximum water consumption for

- single-layer emulsions must not exceed a

maximum of 15l/m

- double-sided emulsions must not exceed

a maximum of 30l/m

2

*

2

*

* activated in the program <Service Settings

/ Replenishment / Wat. Repl. Value>

Edition 6, Revision 0 Classic E.O.S. / Classic E.O.S. CL Chapter 1 / 13

Agfa Group Confidential (Type 5270 / 100 / 105)

Page 32

Page 33

Controls and Connections

2

Section 2

describes the controls and the connectors of the machine:

• Position and function of the controls

• Layout of the connectors and their modalities

Section 2

Page 34

Page 35

DD+DIS301.03E Controls and Connections

Chapter 2

Contents

1 Control panel ............................................................. 1

2 Switches.....................................................................2

2.1 Machine switches .................................................................... 2

2.2 Safety switches........................................................................3

3 Installation Connections........................................... 4

3.1 Installation through the front panel

(only for Classic E.O.S. Type 5270/100)................................. 4

3.2 Installation through the bottom..............................................5

3.2.1 Classic E.O.S. (5270/100)...................................................................5

3.2.2 Classic E.O.S. CL (5270/105).............................................................6

Edition 6, Revision 0 Classic E.O.S. / Classic E.O.S. CL Chapter 2 / I

Agfa Group Confidential (Type 5270 / 100 / 105)

Page 36

DD+DIS301.03E Controls and Connections

1 Control panel

Classic E.O.S. Type 5270/100 Classic E.O.S. CL Type 5270/105

(A) LCD

Display window consisting of 2 lines with 16 characters each.

Back key

Press this key to exit a dialog or a menu. If you press this key in an

input window any modifications made in this window will be canceled

and reset to the initial values.

Selection / Scroll keys

Use these keys to scroll through the options in the menus or to

change values in input windows.

Enter / Confirmation key

Use this key to show the options in a menu or to confirm a dialog. A

confirmed dialog opens the corresponding input window. Entered

data is confirmed and accepted.

A

5270_10002_003.cdr

Figure 1

Edition 6, Revision 0 Classic E.O.S. / Classic E.O.S. CL Chapter 2 / 1

Agfa Group Confidential (Type 5270 / 100 / 105)

Page 37

Controls and Connections DD+DIS301.03E

_

A

2 Switches

2.1 Machine switches

ST66

ST89

B

S1

ST53

IC52

C

Figure 2

(A) Main switch film processor

(B) Ground fault interrupter (GFI switch)

(C) Mains cable (VDE)

(D) Reset key PCB1

CM+952709450_ (F8.5270.7890._)

5270_10002

001.cdr

Chapter 2 / 2 Classic E.O.S. / Classic E.O.S. CL Edition 6, Revision 0

(Type 5270 / 100 / 105) Agfa Group Confidential

Page 38

DD+DIS301.03E Controls and Connections

2.2 Safety switches

A

B

5273_10002_006.CDR

Figure 3

(A) 0SW2 Safety switch for machine cover

(B) 0SW3 Safety switch for dryer

The machine has two safety switches, which interrupt the circuit when the

dryer is opened or the machine cover is removed.

Even with interrupted safety switches 0SW2 (A) and/or 0SW3 (B), and

the main switch 0SW1 in off position, there is still voltage applied on

the following components as long as the power cord is plugged in:

Ground fault interrupter 0FI

Mains switch 0SW1

Edition 6, Revision 0 Classic E.O.S. / Classic E.O.S. CL Chapter 2 / 3

Agfa Group Confidential (Type 5270 / 100 / 105)

Page 39

Controls and Connections DD+DIS301.03E

3 Installation Connections

3.1 Installation through the front panel (only for Classic E.O.S. Type 5270/100)

TYPE 5270/100

E

D

C

B

A

(A) Exhaust connection

5273_10002_004.cdr

Figure 4

F

G

H

(B) Developer overflow / drain (DEV)

(C) Fixer overflow / drain (FIX)

(D) Water overflow / drain (WAT)

(E) Tank safety overflow (OVERFLOW)

(F) Developer supply (DEV)

(G) Fixer 2 supply (FIX)

(H) Water supply (WAT)

Chapter 2 / 4 Classic E.O.S. / Classic E.O.S. CL Edition 6, Revision 0

(Type 5270 / 100 / 105) Agfa Group Confidential

Page 40

DD+DIS301.03E Controls and Connections

3.2 Installation through the bottom

3.2.1 Classic E.O.S. (5270/100)

TYPE 5270/100

FIX2 FIX1WAT DEV

EHF

D

(A) Exhaust connection

I

C

BA

G

5270_10002_002.cdr

Figure 5

(B) Developer overflow / drain (DEV)

(C) Fixer overflow / drain (FIX)

(D) Water overflow / drain (WAT)

(E) Tank safety overflow (OVERFLOW)

(F) Developer supply (DEV)

(G) Fixer 2 supply (FIX)

(H) Solenoid valve (and filter) water supply

(I) Solenoid valve water drain (anti-algae)

Edition 6, Revision 0 Classic E.O.S. / Classic E.O.S. CL Chapter 2 / 5

Agfa Group Confidential (Type 5270 / 100 / 105)

Page 41

Controls and Connections DD+DIS301.03E

3.2.2 Classic E.O.S. CL (5270/105)

TYPE 5270/105

FIX2 FIX1WAT DEV

DEHF

(A) Exhaust connection

I

BA

C

G

5270_10002_004.CDR

Figure 6

(B) Developer overflow / drain (DEV)

(C) Fixer overflow / drain (FIX)

(D) Water overflow / drain (WAT)

(E) Tank safety overflow (OVERFLOW)

(F) Developer supply (DEV)

(G) Fixer 2 supply (FIX)

(H) Solenoid valve (and filter) water supply

(I) Solenoid valve water drain (anti-algae)

Chapter 2 / 6 Classic E.O.S. / Classic E.O.S. CL Edition 6, Revision 0

(Type 5270 / 100 / 105) Agfa Group Confidential

Page 42

Page 43

Installation / Machine Start-up

3

Section 3

describes the exact routines necessary to start the machine operation.

Before putting the machine in operation you should be familiar with

the information of section 2 (controls and connectors).

Section 3

Page 44

Page 45

DD+DIS301.03E Installation and Startup

Chapter 3

Contents

1 Notes on the Installation and Startup

Procedures ................................................................ 1

2 Removal of Transport Protections .......................... 2

3 Installation ................................................................. 3

3.1 Height coarse adjustment.......................................................3

3.2 Height fine adjustment............................................................4

4 Power Cable Adaptation........................................... 5

5 Daylight / Darkroom Installation

(only Classic E.O.S. Type 5270/100) ........................ 6

5.1 Machine in the daylight, film feed in the darkroom,

light seal at the darkroom feed table .....................................6

5.1.1 Installation at the wall opening............................................................ 6

5.1.2 Installation with light tight wall.............................................................7

5.2 Machine in the darkroom, film exit in the daylight,

light seal at the dryer with light tight wall .............................8

5.2.1 Installation at the wall opening with light tight wall..............................8

5.2.2 Light tight wall ..................................................................................... 9

6 Supply and Disposal Connections ........................ 10

6.1 Installation diagram............................................................... 10

6.2 Overview of supply and disposal.........................................11

6.2.1 Classic E.O.S. (5270/100).................................................................11

6.2.2 Classic E.O.S. CL (5270/105)...........................................................12

6.3 Supply and disposal hoses .................................................. 13

6.3.1 Hoses inside the machine................................................................. 13

6.3.2 Hoses outside the machine............................................................... 13

6.4 Supply and disposal through the lower front panel

(only Classic E.O.S. Type 5270/100) ....................................14

6.4.1 Instructions for breaking out the openings ........................................ 14

6.4.2 Required openings for standard installations.................................... 14

6.4.3 Installing the exhaust connection...................................................... 15

6.4.4 Installing the developer / fixer supply hoses .....................................16

6.4.5 Installing the disposal hoses............................................................. 18

6.5 Supply and disposal through the floor................................19

6.5.1 Installing the exhaust connection...................................................... 19

6.5.2 Installing supply hoses...................................................................... 21

6.5.3 Installing the disposal hoses............................................................. 24

Edition 6, Revision 0 Classic E.O.S. / Classic E.O.S. CL Chapter 3 / I

Agfa Group Confidential (Type 5270 / 100 / 105)

Page 46

Installation and Startup DD+DIS301.03E

7 Connecting the Level Sensors...............................25

7.1 Replenisher tanks.................................................................. 25

7.1.1 Connect the level sensors of the replenisher tanks...........................25

7.1.2 Set the code for the replenisher tank level connection......................25

7.2 Mixer ....................................................................................... 26

7.2.1 Connecting the Mixer communication cable......................................26

7.2.2 Set the code of the mixer communication .........................................26

7.3 Disposal tanks ....................................................................... 27

7.3.1 Connect the level sensors of the disposal tanks ...............................27

7.3.2 Set the code for the disposal tank level sensors ...............................27

8 Adjusting Volume, Brightness, and Contrast

on the Control Board PCB1.................................... 28

9 Starting Operation...................................................29

9.1 Preparing the startup procedure.......................................... 29

9.2 Adapting the mains supply................................................... 29

9.3 Checking the function of the GFI switch 0FI.......................30

9.4 Filling the developer and fixer tanks ...................................31

9.4.1 Manual filling (in Type 5270/100 and Type 5270/105) ......................31

9.4.2 Automatic filling with the AUTOFILL function

(only in Type 5270/105).....................................................................32

9.5 Switching on the machine .................................................... 32

9.6 Calibrating the replenishment rate of

developer and fixer upon first startup ................................. 33

9.7 Reset after switching on the machine ................................. 37

9.8 BASEINIT................................................................................ 38

9.8.1 Only execute a BASEINIT in case of:................................................38

9.8.2 Initiate a BASEINIT:...........................................................................38

9.9 System settings..................................................................... 39

9.9.1 Setting the software switches in the SERVICE program...................39

9.9.2 Setting the process parameters on the control panel ........................39

9.9.3 Access to the SERVICE program......................................................41

9.9.4 Setting date and time.........................................................................41

9.9.5 Setting the service intervals in the SERVICE program......................42

9.9.6 Executing a <Teach In> in the SERVICE program ........................43

9.9.7 Calibrating the Developer Temperature (CAL)..................................45

9.9.8 Resetting the temporary infocounters

in the SERVICE program...................................................................46

9.9.9 Display all <Service Settings>

in the SERVICE program with <Quick Display>.........................47

9.9.10 Setting the customer specific settings

in the SERVICE program <Service Settings>..........................48

9.9.11 DEFAULT settings ex factory / after BASEINIT.................................56

9.9.12 Processes..........................................................................................56

9.9.13 Process data......................................................................................57

9.9.14 Application dependent process parameter........................................57

Chapter 3 / II Classic E.O.S. / Classic E.O.S. CL Edition 6, Revision 0

(Type 5270 / 100 / 105) Agfa Group Confidential

Page 47

DD+DIS301.03E Installation and Startup

1 Notes on the Installation and Startup Procedures

The manufacturer tested this machine with chemicals and film material.

Therefore any possible traces of chemicals do not indicate a used machine

but they are the proof of a function-tested and perfect machine.

The sequence of listed installation steps depends on the following parameters:

• Size of the installation room

• Type of installation:

Daylight / darkroom installation

Light seal feed table / dryer directly against installation wall or light-tight

wall

• Supply / disposal connections through the lower front panel or below the

machine

• Machine standing free in the room or with the left hand machine side at a

distance from the wall of at least 15 cm (5.91 inch)

Please go through these procedures and arrange a sequence required for

your installation.

The sequence described below corresponds to a standard installation with the

following parameters:

• Film feed in the darkroom, machine in the daylight

Light seal at the film feed table without / with light tight wall

• Film feed / machine in the darkroom, film exit in the daylight

Light seal with light-tight wall behind the dryer / film exit

• Installation connections through the lower front panel (below the film feed

table)

• Installation connections through the floor

• Machine with the left hand machine side at a distance from the wall of at

least 15 cm (5.91 inch)

Edition 6, Revision 0 Classic E.O.S. / Classic E.O.S. CL Chapter 3 / 1

Agfa Group Confidential (Type 5270 / 100 / 105)

Page 48

Installation and Startup DD+DIS301.03E

2 Removal of Transport Protections

(1) Undo 2 screws on the dryer

panels and remove the dryer

panels, open the dryer flap.

(2) Remove the transport protection

from the dryer.

(3) Remove the transport protection

from the film transport flap (only in

Type 5270/105).

1

2

3

(4) Close the dryer flap and dryer

panels, tighten the screws of the

dryer panels.

B

4

5270_10003_016.cdr

15 cm (5.91 inch)

Figure 1

A

5270_10003_001 .cdr

Figure 2

(A) Lock nuts

(B) Film transport direction

• If a machine is installed with the left hand side only 15 cm (5.91 inch) from

the wall, the lock nuts (A) must be removed during installation to make the

maintenance easier.

Chapter 3 / 2 Classic E.O.S. / Classic E.O.S. CL Edition 6, Revision 0

(Type 5270 / 100 / 105) Agfa Group Confidential

Page 49

DD+DIS301.03E Installation and Startup

A

3 Installation

Wrench (Ø 17 mm)

3.1 Height coarse adjustment

TYPE 5270/100

• Slacken the lock nuts (A).

• Adjust the hex nuts (B) to a

height of 30 mm (1.18 inch).

Clockwise = higher

Counterclockwise = lower

• Adjust the height of the

adjustable machine feet to level

the machine.

30 mm

1.18 inch

Figure 3

Edition 6, Revision 0 Classic E.O.S. / Classic E.O.S. CL Chapter 3 / 3

Agfa Group Confidential (Type 5270 / 100 / 105)

Page 50

Installation and Startup DD+DIS301.03E

3.2 Height fine adjustment

The fine adjustment should only be made when the machine is at its final

installation site.

A poorly adjusted machine installation may result in film processing errors!

Measure in film transport

direction:

• Remove the machine cover.

• Remove the crossovers above

the racks.

• Place a spirit level (A) on the

upper tie rod of the fixer rack (3)

and the water rack (4). Adjust

the height of the rear and front

feet until the machine is level in

transport direction.

Measure across film transport

direction:

• Place a second spirit level (B)

on the upper tie rods of the

developer rack (1) and then on

the tie rods of the water rack (4).

• Adjust the foot height left and

right.

• Readjust the height of the rear

and front feet.

• Check the adjustment in and

across the film transport

direction, and readjust if

necessary.

(A/B)

(C)

(1)

(2)

(3)

(4)

2

3

4

Spirit level

Film transport direction

Developer rack

Fixer rack1

Fixer rack2

Water rack

2

3

4

Figure 4

A

1

1

5273_10003_007.cdr

B

C

Chapter 3 / 4 Classic E.O.S. / Classic E.O.S. CL Edition 6, Revision 0

(Type 5270 / 100 / 105) Agfa Group Confidential

Page 51

DD+DIS301.03E Installation and Startup

A

4 Power Cable Adaptation

Ex-factory the machine configuration includes a VDE cable.

If there are only UL/CSA connections available the VDE power cable must be

replaced by the UL/CSA cable enclosed in the accessory box.

The power cable must only be exchanged when the film processor has

no power supply. The installed power cable must not be plugged into an

outlet!

B

C

Figure 5

• Replace the VDE power cable by the UL/CSA cable.

Make sure• to tighten clamping screw (A) if plug (B) is connected in

outlet (C).

Edition 6, Revision 0 Classic E.O.S. / Classic E.O.S. CL Chapter 3 / 5

Agfa Group Confidential (Type 5270 / 100 / 105)

Page 52

Installation and Startup DD+DIS301.03E

5 Daylight / Darkroom Installation

(only Classic E.O.S. Type 5270/100)

For installation of the Classic E.O.S CL Type 5270/105 please refer to the

installation instructions in Chapter 9: Accessories and Options.

5.1 Machine in the daylight, film feed in the darkroom, light seal at the darkroom feed table

5.1.1 Installation at the wall opening

Darkroom Daylight

4

6

3

1

2

TYPE 5270/100

Film feed

Film output (wire chute)

A 60° chamfer must be provided

on the wall opening

Wall

Wall base

Light seal

(foam rubber – by the meter)

Order no. CM+0000014259

Wall opening:

Wall

Wall base

Wall opening

5

min. 1120 (44.1)

50 (1.97)

Figure 6

Dimensions in mm (inch)

min. 580 (22.8)

max. 680 (26.8)

3

max. 1120 (44.1)

2

50 (1.97)

Figure 7

527214nm.cdr

1

527014jm.cdr

Dimensions in mm (inch)

Chapter 3 / 6 Classic E.O.S. / Classic E.O.S. CL Edition 6, Revision 0

(Type 5270 / 100 / 105) Agfa Group Confidential

Page 53

DD+DIS301.03E Installation and Startup

5.1.2 Installation with light tight wall

Darkroom Daylight

3

2

4

TYPE 5270/100

Film feed

A 60° chamfer must be provided

on the wall opening.

Wall

Light tight wall

Film output (wire chute)

1

Wall base

Light seal

(foam rubber – by the meter)

Order no. CM+0000014259

min. 1120 (44.1)

max. 1500 (59.1)

7

6

5

Wall opening

Wall

Wall overlap

Wooden board, 20 mm

(0.79 inch), with opening

Figure 8

Dimensions in mm (inch)

3

1550 (61.0)

min. 1110 (43.7)

max. 1120 (44.1)

50 (1.97)

min. 670 (26.4)

max. 680 (26.8)

527014pm.cdr

2

2

1

1

527014lm.cdr

Figure 9

Dimensions in mm (inch)

See Chapter 3, Section 5.2.2 Light tight wall

Edition 6, Revision 0 Classic E.O.S. / Classic E.O.S. CL Chapter 3 / 7

Agfa Group Confidential (Type 5270 / 100 / 105)

Page 54

Installation and Startup DD+DIS301.03E

5.2 Machine in the darkroom, film exit in the daylight, light seal at the dryer with light tight wall

5.2.1 Installation at the wall opening with light tight wall

Darkroom Daylight

2

3

1

6

7

527014rm.cdr

min. 1120 (44.1)

max. 1500 (59.1)

TYPE 5270/100

Film feed

Wall

A 60° chamfer must be provided

on the wall opening.

Light tight wall

Film output (wire chute)

Light seal

(foam rubber – by the meter)

Order no. CM+0000014259

Wall base

Wall opening

Wall

Wall overlap / light tight wall

overlapping by at least 50 mm

(1.97 inch) on all sides

Wooden board, 20 mm

(0.79 inch), with opening

Figure 10

Dimensions in mm (inch)

3

1550 (61.0)

min. 1110 (43.7)

max. 1120 (44.1)

50 (1.97)

min. 670 (26.4)

max. 680 (26.8)

Figure 11

2

2

1

1

527014lm.cdr

Dimensions in mm (inch)

See Chapter 3, Section 5.2.2 Light tight wall

Chapter 3 / 8 Classic E.O.S. / Classic E.O.S. CL Edition 6, Revision 0

(Type 5270 / 100 / 105) Agfa Group Confidential

Page 55

DD+DIS301.03E Installation and Startup

5.2.2 Light tight wall

TYPE 5270/100

5273_10003_004.cdr

min. 1110 (43.7)

max. 1120 (44.1)

min. 670 (26.4)

max. 680 (26.8)

1020 (40.2)

Figure 12

Coverage of a wall opening of up to 1500 mm x 920 mm

(57.09 inch x 36.22 inch) is possible.

An overlap of 50 mm (1.97 inch) must be guaranteed on all sides.

The manufacturer does not supply the light tight wall (wooden board) required

for the installation of a film processor!

Dimensions in mm (inch)

Edition 6, Revision 0 Classic E.O.S. / Classic E.O.S. CL Chapter 3 / 9

Agfa Group Confidential (Type 5270 / 100 / 105)

Page 56

Installation and Startup DD+DIS301.03E

6 Supply and Disposal Connections

6.1 Installation diagram

8

E

D

WAT

FIX 1FIX 2

DEV

7

5

DEV

FIX

B

C

4

6

G

2

F

3

H

1

FIX

Figure 13

(D) Water overflow / drain (WAT) (1) Mixer

(E) Tank safety overflow (OVERFLOW) (2) Fixer replenishment pump

(C) Fixer overflow / drain (FIX) (4) Solenoid valve water drain

(B) Developer overflow / drain (DEV) (5) Individual disposal tanks or

(G) Fixer 2 supply (FIX) (6) Solenoid water supply (anti-

(F) Developer supply (DEV) (7) Overflow tray

(H) Water supply (WAT) (8) Film transport direction

The connections of supply and disposal hoses may be at the bottom (through

the floor) or in the front (through the front panel – only for Type 5270/100).

DEV

(3) Developer replenishment

pump

centralized disposal

algae)

5273_100003_018.cdr

Chapter 3 / 10 Classic E.O.S. / Classic E.O.S. CL Edition 6, Revision 0

(Type 5270 / 100 / 105) Agfa Group Confidential

Page 57

DD+DIS301.03E Installation and Startup

6.2 Overview of supply and disposal

6.2.1 Classic E.O.S. (5270/100)

TYPE 5270/100

FIX2 FIX1WAT DEV

I

EHF

C

D

BA

Figure 14

(A) Exhaust connection

(B) Developer overflow / drain (DEV)

G

5273_10002_005.CDR

(C) Fixer overflow / drain (FIX)

(D) Water overflow / drain (WAT)

(E) Tank safety overflow (OVERFLOW)

(F) Developer supply (DEV)

(G) Fixer 2 supply (FIX)

(H) Solenoid valve (and filter) water drain (WAT)

(I) Solenoid water supply (anti-algae)

Edition 6, Revision 0 Classic E.O.S. / Classic E.O.S. CL Chapter 3 / 11

Agfa Group Confidential (Type 5270 / 100 / 105)

Page 58

Installation and Startup DD+DIS301.03E

6.2.2 Classic E.O.S. CL (5270/105)

TYPE 5270/105

FIX2 FIX1WAT DEV

I

DEHF

BA

C

Figure 15

G

5270_10002_004.CDR

(A) Exhaust connection

(B) Developer overflow / drain (DEV)

(C) Fixer overflow / drain (FIX)

(D) Water overflow / drain (WAT)

(E) Tank safety overflow (OVERFLOW)

(F) Developer supply (DEV)

(G) Fixer 2 supply (FIX)

(H) Solenoid valve (and filter) water drain (WAT)

(I) Solenoid water supply (anti-algae)

Chapter 3 / 12 Classic E.O.S. / Classic E.O.S. CL Edition 6, Revision 0

(Type 5270 / 100 / 105) Agfa Group Confidential

Page 59

DD+DIS301.03E Installation and Startup

6.3 Supply and disposal hoses

6.3.1 Hoses inside the machine

Internal hoses are pre-installed.

The supply and disposal hoses for developer, fixer, water, and safety overflow

in the machine are marked by tapes:

DEV WAT

FIX

Tapes to be wrapped around external hoses are included in the accessory

box.

6.3.2 Hoses outside the machine

External hoses can be ordered by the meter.

For the installation of external hoses only use fiber-reinforced hoses!

The following hoses are to be used for the supply connections:

Supply

connection

Developer red (DEV) 10x3 / 0.39x0.12

Fixer blue (FIX) 10x3 / 0.39x0.12

The following hoses are to be used for the disposal connections:

Disposal

connection

Developer red (DEV) 19x4 / 0.75x0.16

Fixer blue (FIX) 19x4 / 0.75x0.16

Water transparent

safety overflow fiber-reinforced

The accessory box includes an approx. 50 cm (19.69 inch) long PAP hose for

the exhaust connection.

The PAP hose (Ø 100 mm / Ø 3.94 inch) can be ordered by the meter:

Order number CM+0000064117

= developer = water

= fixer

Color Dimensions Order number

Color Dimensions Order number

(WAT)

OVERFLOW

(mm / inch)

fiber-reinforced

fiber-reinforced

(mm / inch)

fiber-reinforced

fiber-reinforced

19x4 / 0.75x0.16

= safety overflow

CM+0000064082

CM+0000064083

CM+0000064133

CM+0000064134

CM+0000007620

Edition 6, Revision 0 Classic E.O.S. / Classic E.O.S. CL Chapter 3 / 13

Agfa Group Confidential (Type 5270 / 100 / 105)

Page 60

Installation and Startup DD+DIS301.03E

6.4 Supply and disposal through the lower front panel (only Classic E.O.S. Type 5270/100)

6.4.1 Instructions for breaking out the openings

It is not necessary to remove the

TYPE 5270/100

6.4.2 Required openings for standard installations

TYPE 5270/100

front panel in order to break out

the openings.

• Mark the recesses to be

broken out with a felt-tip

marker.

• The recessed material can be

broken out with a screwdriver

applied in the groove at the

outside and a blow with the

hammer.

(A) Exhaust connection

(B) Developer overflow / drain

(C) Fixer overflow / drain

Figure 16

(D) Water overflow / drain

(E) Safety overflow, tanks

(F) Developer supply

(G) Fixer 2 supply

(H) Water supply

E

D

B

C

A

Figure 17

G

H

5273_10002_004.cdr

F

Chapter 3 / 14 Classic E.O.S. / Classic E.O.S. CL Edition 6, Revision 0

(Type 5270 / 100 / 105) Agfa Group Confidential

Page 61

DD+DIS301.03E Installation and Startup

6.4.3 Installing the exhaust connection

TYPE 5270/100

The machine internal exhaust must always be guided out of the machine.

- The film processor has an integrated exhaust duct (A).

Crossover (B) and the flexible exhaust hose (C) (∅ 100 mm / 3.94 inch)

are pre-mounted and included in the accessory box.

- Exhaust connection: ∅ 100 mm (3.94 inch)

- Max. length of the exhaust hose: 5 m (196.85 inch) (if this length is

exceeded install an additional fan!)

- Exhaust min. 50 m³/h

volume: max. 100 m³/h

A

G

E

B

C

(A)

Exhaust duct

(B)

Crossover

(C)

Flexible exhaust hose inside

(D)

Exhaust connection stub

(E)

Frame

• Break out the recess for the exhaust connection (Figure 17).

• Screw the exhaust connection stub (D) to the front panel using the

3 Phillips screws included in the accessory box.

• Loosen the mounting screw (G) located between the exhaust duct (A) and

frame (E).

• Push the crossover section (B) onto the exhaust duct.

• Mount both ducts on the frame with mounting screw (G).

• Push the exhaust hose (C) onto the exhaust connection stub (D)

integrated inside the front panel.

D

Figure 18

(F)

(G)

5273_10003_022.CDR

Exhaust duct to the room

exhaust (PAP hose)

Mounting screw for crossover

(B)

F

• Push exhaust hose (F) on the exhaust connection stub (D) and connect it

to the room exhaust.

Edition 6, Revision 0 Classic E.O.S. / Classic E.O.S. CL Chapter 3 / 15

Agfa Group Confidential (Type 5270 / 100 / 105)

Page 62

Installation and Startup DD+DIS301.03E

6.4.4 Installing the developer / fixer supply hoses

TYPE 5270/100

Only use fiber-reinforced PVC hoses Ø 10x3 mm (0.39x0.12 inch) for the

external hose connections (outside the machine)!

Position the hoses without kinks!

Installing the developer / fixer supply:

2

1

3

4

5

7

6

7

G

8

10

9

F

A

527003OM.CDR

Figure 19

(F) Developer (DEV) (A) Supply direction

(G) Fixer (FIX)

POS Designation Configuration

1 PVC hose

Ø 9x1.5 mm (0.35x0.06 inch)

2 Hose positioning /