Page 1

85.0812.00, 2003 HC-1

Handpiece Controls Overview

Controls

Holders

This section provides information related to the servicing, maintenance, and adjustment of

handpiece controls. Detail on how to service control heads, control blocks, and troubleshoot

specific problems related to them is presented.

Additional information covered in this section includes assembly, service, and maintenance

information for A-dec handpiece holders. Flow diagrams, replacement part information, and

troubleshooting tips are presented.

Page 2

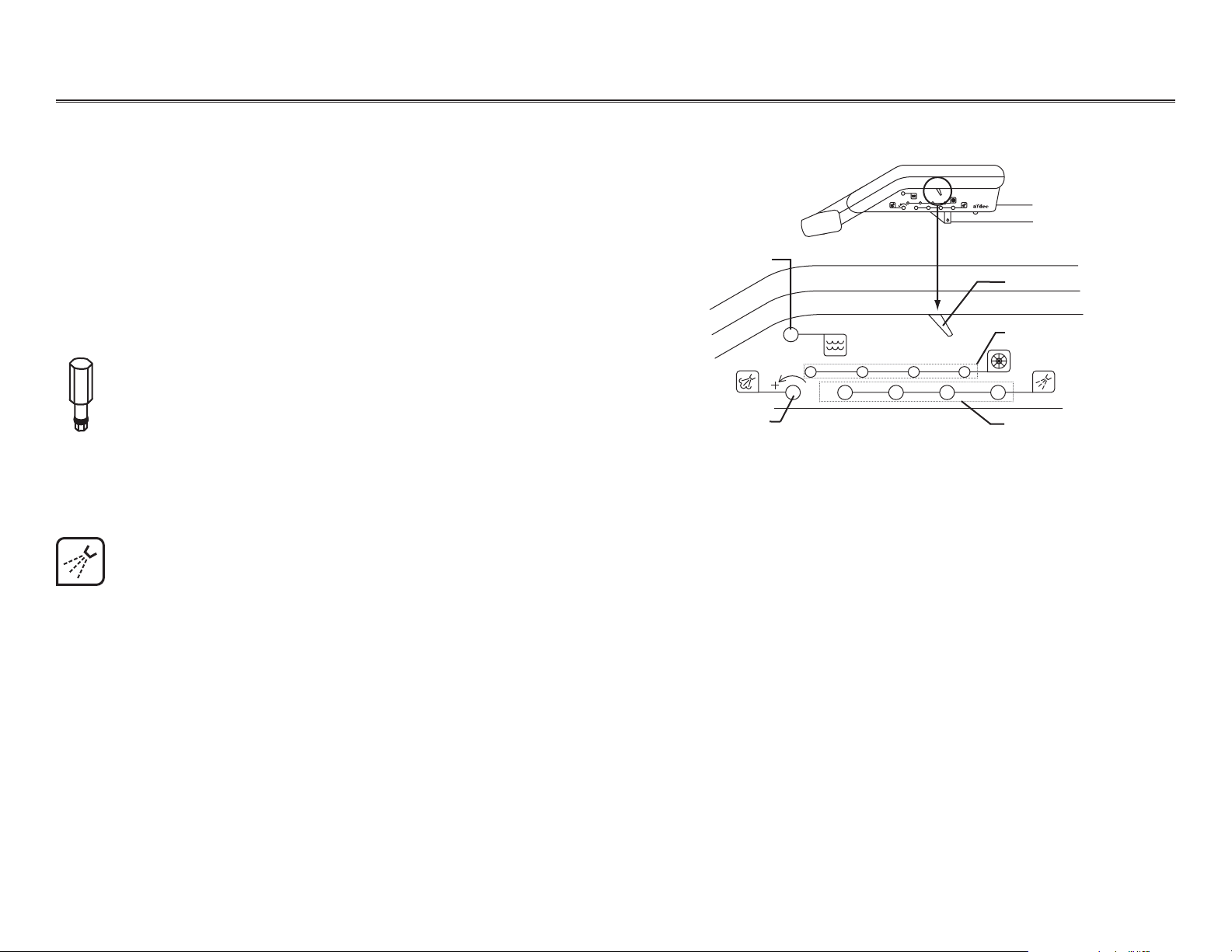

Making Handpiece Control Adjustments

Location of Control Adjustments

The control adjustments for the handpiece flush control,

drive air pressure, coolant air flow, and coolant water

flow are located on the side of the control head.

Operators Adjustments

Use the adjustment key to make adjustments, with the

exception of the drive air pressure. The adjustment key

will not fit the drive air control ports. This was done to

prevent unintentional changes to drive air settings. To

adjust the drive air, use a 3/32" hex key.

85.0812.00, 2003

Handpiece Controls Handpiece Control Adjustments

Location of Control Adjustments on the Control Head

Master On/Off toggle

Handpiece flush control

Coolant water

flow controls

Coolant air flow control

Drive air pressure controls

Adjusting

Coolant Water

Using the adjustment key or a 1/8" hex key, follow these steps to adjust the coolant water flow for

each handpiece. Turn the key clockwise to decrease the coolant water flow and counterclockwise

to increase the coolant water flow.

Task Description

1Insert the key into the adjustment port for the handpiece

being adjusted.

2Turn clockwise until it seats softly.

3Move the foot control’s wet/dry toggle to the ON position (toward blue dot).

4 Run the handpiece at medium speed.

5Adjust the coolant water until 2-3 drops per second are visible.

HC-2

PUSH

I MASTER O

1234

®

PUSH

1234

I MASTER O

Page 3

85.0812.00, 2003 HC-3

Handpiece Controls Handpiece Control Adjustments

Adjusting Coolant

Air

Adjusting

Drive Air

Using the adjustment key (or a 1/8" hex key), follow these steps to adjust the coolant air flow for

each handpiece. Turn the key clockwise to decrease the coolant air flow and counterclockwise to

increase the coolant air flow.

Task Description

1Insert the key into the adjustment port (one location for all handpieces).

2Run the handpiece at medium speed.

3 Adjust the coolant air by turning the key counterclockwise (until a fine mist is

visible around the bur).

Follow these steps to adjust the drive air using a 3/32" hex key.

Task Description

1 Install the handpiece on a drive air pressure gauge.

2 Locate drive air control for the handpiece being adjusted and insert the hex key.

3Install the handpiece gauge on the coupler.

4Move the foot control’s wet/dry toggle to OFF (away from blue dot) and fully depress the foot

control cover.

5Turn the drive air control counterclockwise until the handpiece is running slightly above

the manufacturer’s specified drive air pressure, then turn clockwise until it is at the

specified pressure.

6 Repeat adjustments 1-5 for each handpiece position.

Page 4

85.0812.00, 2003 HC-4

Handpiece Controls Delivery Systems

1

2

3

4

5

6

7

8

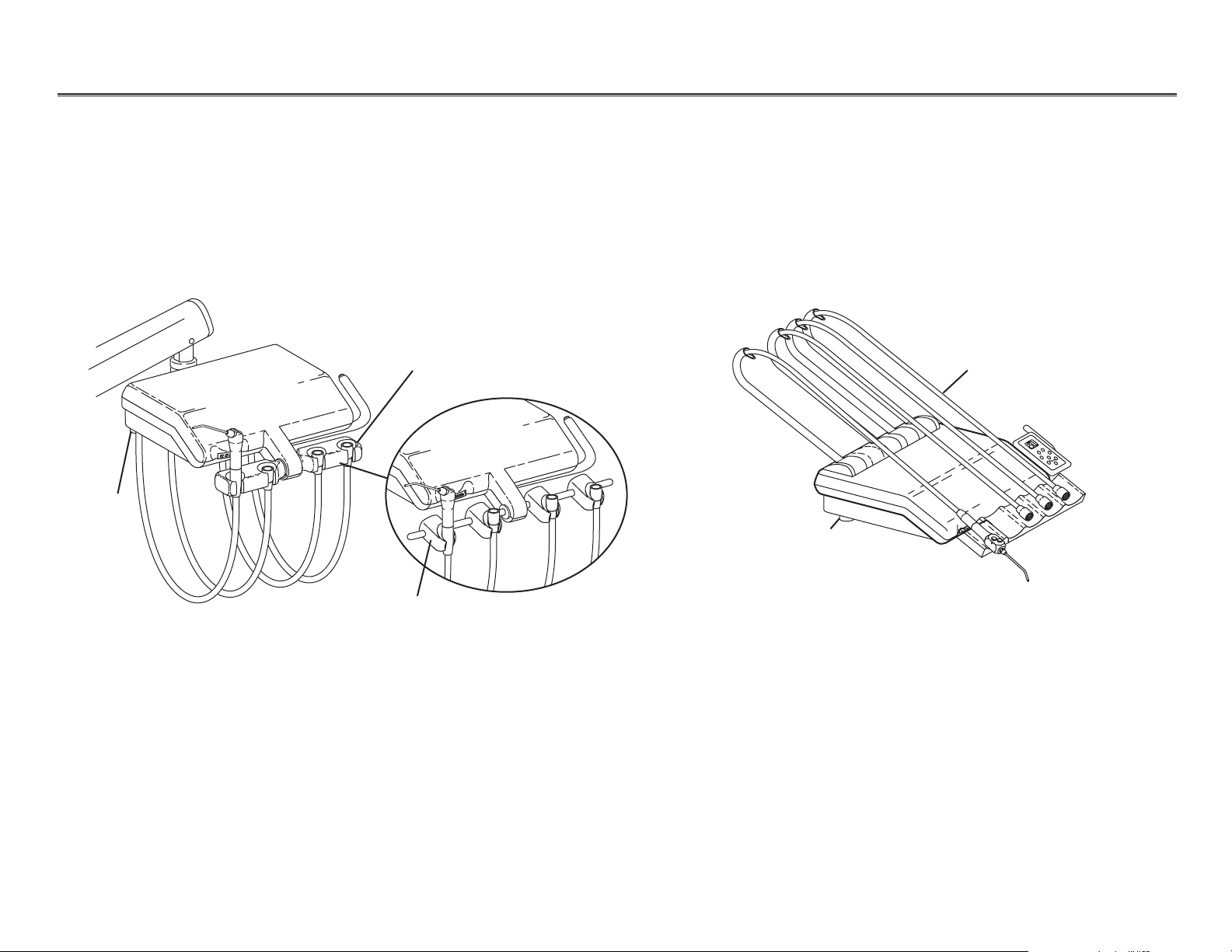

Cascade Traditional Delivery System

Unitized holder

Individual holder

Cascade Continental Delivery System

Continental whip

assemblies

Oil collector

Oil collector

Working with

Delivery Systems

The following pages provide instructions and service information on parts associated with

A-dec’s delivery systems.

8

7

6

5

4

3

2

1

Page 5

85.0812.00, 2003 HC-5

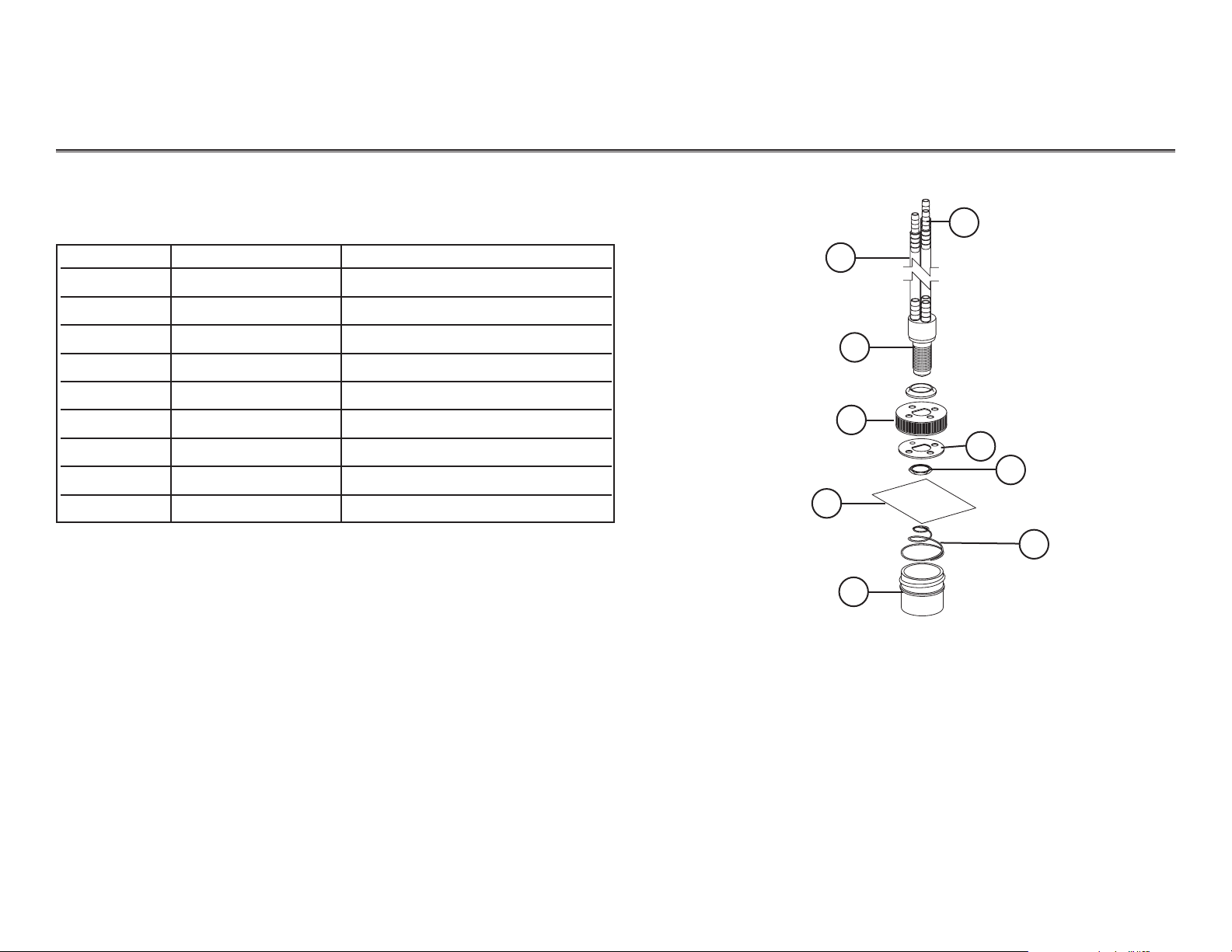

Handpiece Controls Oil Collector

Oil Collector

1

6

2

3

4

5

7

8

9

Item # Part Number Description

1— Clear tubing, 1/4"

2— Oil collector manifold

3 24.0416.00 Cap

4— Gauze pad

5 052.023.00 Jar

6 023.045.02 Inline barbs

7— Deflector spacer

8 006.009.00 Nut

9 013.090.00 Spring

Oil Collector

Page 6

85.0812.00, 2003 HC-6

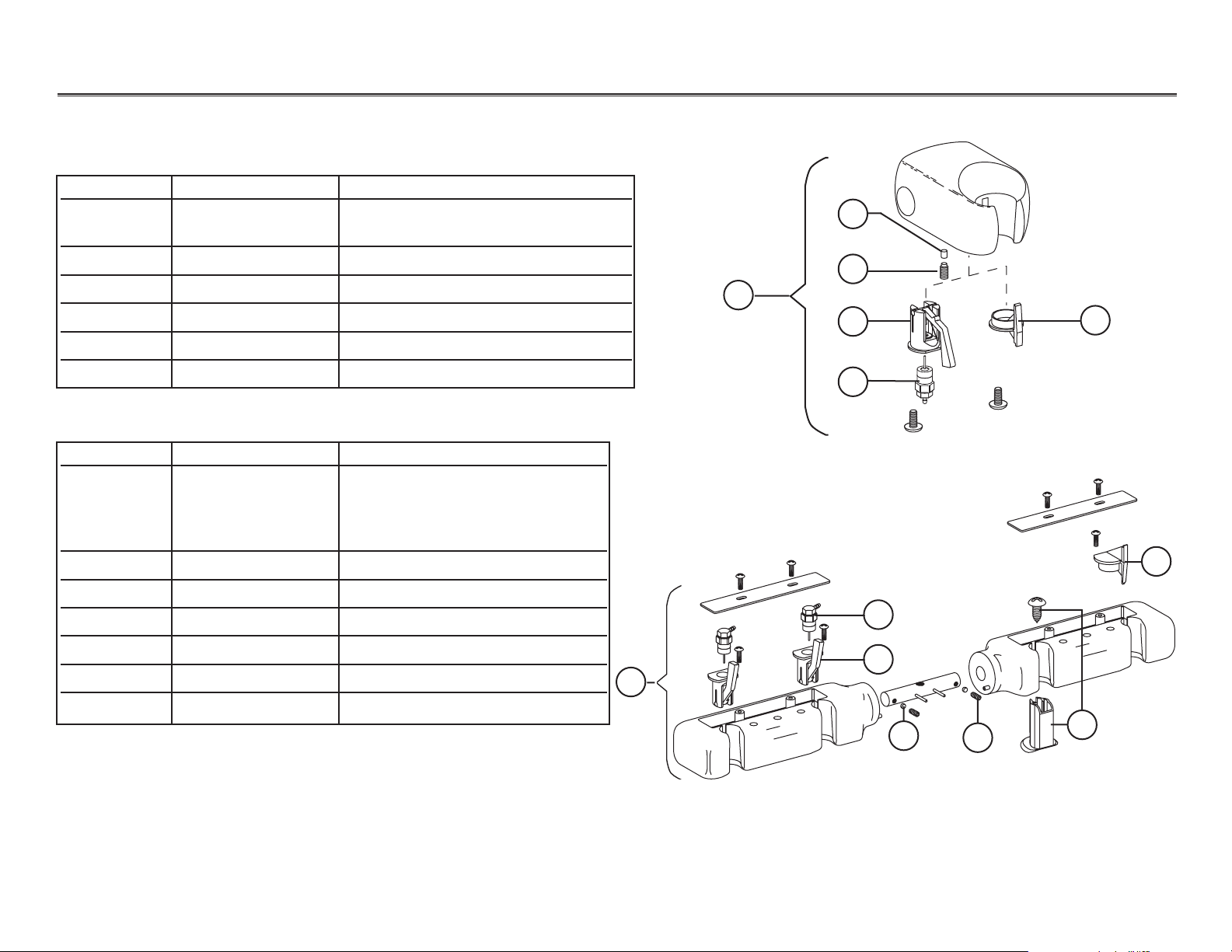

Handpiece Controls Traditional Holders

Individual Holder

Unitized Holder (Two and Three-Position)

2

3

4

5

6

7

6

5

Item # Part Number Description

1 99.0583.00 Auto holder assy

99.0584.00 Assistant’s holder assy

2 45.0403.00 Friction pad

3 007.056.00 Setscrew, socket cup point

4 99.0590.00 Actuator, auto holder

5 33.0025.01 Air bleed valve (individual)

6 99.0587.00 Slot plug

Individual Holder

1

2

Item # Part Number Description

1 99.0603.00 Traditional, 3-position

99.0604.00 Traditional, 4-position

99.0605.00 Traditional, 5-position

99.0606.00 Traditional, 6-position

2 33.0132.00 Air bleed valve (unitized)

3 99.0590.00 Actuator, auto holder

4 45.0403.00 Friction pad

5 007.056.00 Setscrew, socket cup point

6 99.0607.00 Plug and screw

7 99.0587.00 Slot plug

Unitized Holder

1

4

3

NOTE: Complete holder replacement is recommended if a holder is

broken. For more information on service parts, see the

Genuine A-dec Service Parts Catalog

(P/N 85.5000.00) or

contact customer service.

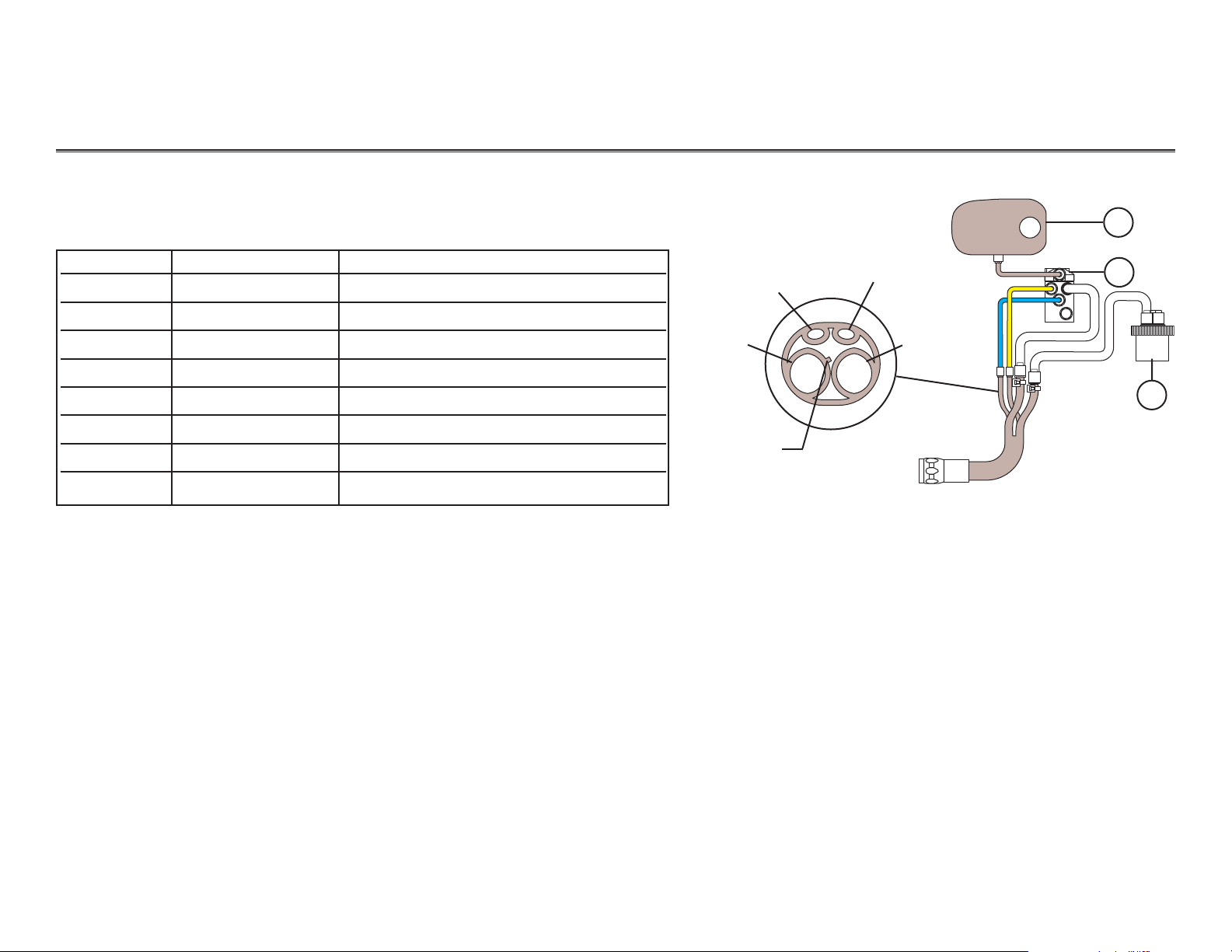

Page 7

85.0812.00, 2003 HC-7

Handpiece Controls Traditional Holder Flow Diagrams

Holder and Handpiece Tubing to Control Block

Item # Part Number Description

1 99.0584.00 Single molded holder, assistant, Surf 4

99.0583.00 Single molded holder, auto, Surf 4

99.0629.00 2-position unitized holder, LH

99.0619.00 3-position unitized holder, LH

99.0628.00 2-position unitized holder, RH

99.0618.00 3-position unitized holder, RH

2 38.0509.00 Century Plus control block

3 24.0410.00 Oil collector

1

2

3

Coolant water

Coolant air

Drive air

Exhaust

Rib identifies

drive air

Traditional Holder

D

A

1

W

D

2

Page 8

85.0812.00, 2003 HC-8

Handpiece Controls Continental Holders

Continental Whip Assembly

1

5

2

3

Item # Part Number Description

1 002.034.01 Screw, button head socket

2 39.1054.00 Continental whip assembly

3 33.0025.01 Air bleed valve, long stem

4 013.015.00 Spring, Red (standard 3 lb pull)

013.027.00 Spring, Green (optional 4 lb pull)

5 39.1053.00 Spring rod

4

Cascade Continental Whip Assembly

Page 9

85.0812.00, 2003 HC-9

Handpiece Controls Continental Holders

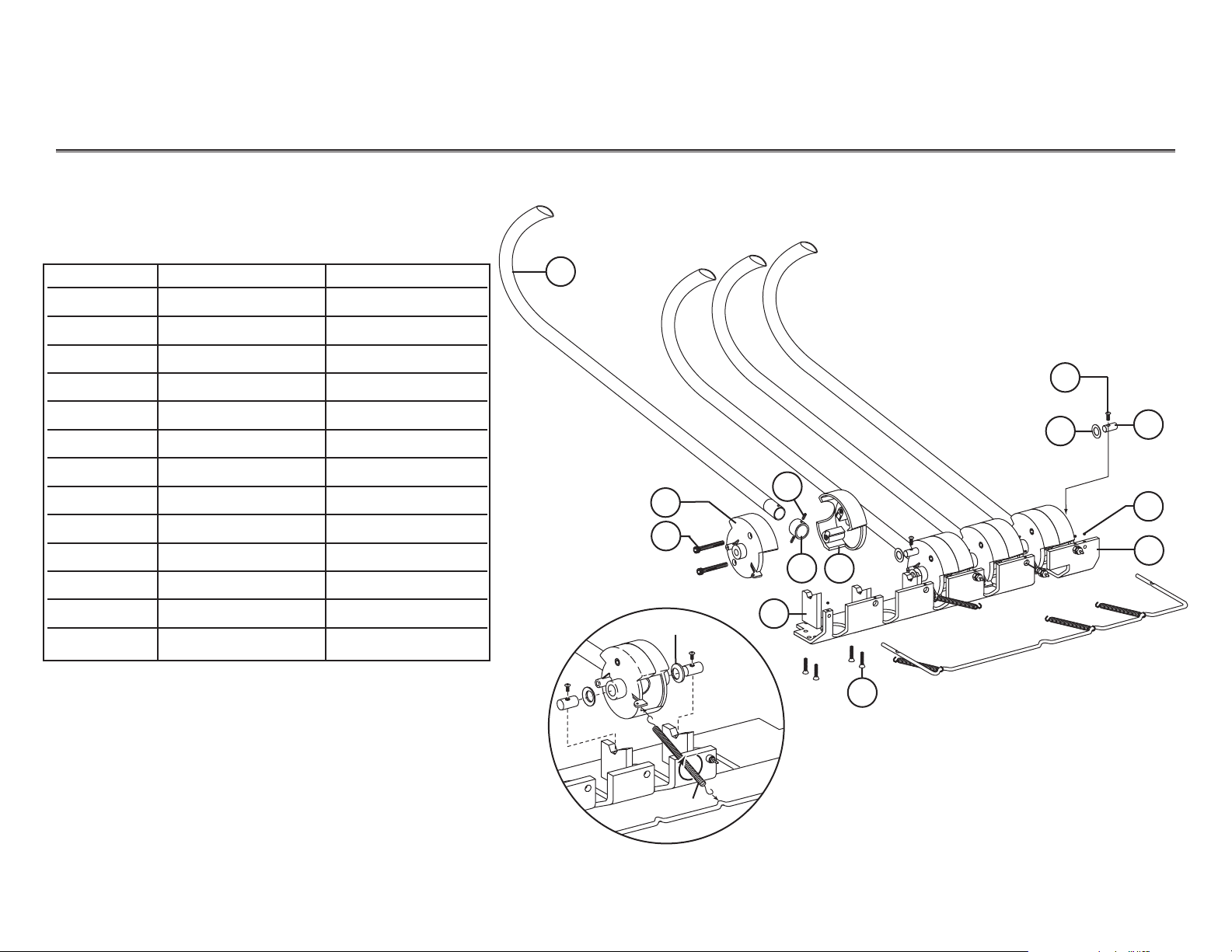

34.1054.00 Continental Whip Assembly

Item # Part Number Description

1 39.1060.00 Whip

2 001.026.00 Screw, socket head

3 75.0066.00 Pivot wheel

4 39.1055.00 Post

5 001.121.01 Screw, socket head

6011.091.00 Spring pin

7 39.1059.00 Whip ring

8 75.0067.00 Pivot wheel

9 004.162.00 Spring washer

10 002.034.01 Screw, button head

11 39.1050.00 Short pin

12 007.010.00 Setscrew

13 39.1052.00 Mounting bracket

1

3

2

8

7

6

4

5

13

12

11

10

9

Spring washer

NOTE: Spring washer curve

is towards the whip

assembly(ies).

Spring

NOTE:Pre-load the spring by rotating it clockwise

until both hooks point up.

Continental Whip

Page 10

85.0812.00, 2003 HC-10

Handpiece Controls Cascade Continental Flow Diagram

Holder and Handpiece Tubing to Control Block

1

2

3

Coolant water

Coolant air

Drive air

Exhaust air

Rib identifies

drive air

Item # Part Number Description

1 99.0613.00 Continental whip assembly, 3-position

99.0614.00 Continental whip assembly, 4-position

99.0615.00 Continental whip assembly, 5-position

2 38.0509.00 Century Plus control block

3 24.0410.00 Oil collector

Continental Holder

D

A

1

W

D

2

Page 11

85.0812.00, 2003 HC-11

Handpiece Controls Syringes

Autoclavable Syringe

Item # Part Number Description

23.1011.00 Autoclavable syringe head assembly

23.1150.00 Autoclavable syringe assembly and 7' tubing

23.1099.00 Autoclavable syringe service kit, 2 button

23.1012.00 Autoclavable syringe service kit, soft button

1 23.1232.01 Valve assembly with o-rings, autoclavable

2 23.1193.01 Screw pkg 5

3 013.064.01 Spring pkg 10

4 23.1112.00 Syringe tip retainer, non-locking

5 035.048.01 O-ring pkg 10

6 034.003.01 O-ring pkg 10

7 23.1028.00 Soft button, autoclavable

8 001.002.01 Screw pkg 5

9 23.1021.01 Valve assembly with o-rings pkg 2

10 013.064.01 Spring pkg 10

11 23.1194.00 Two-button valve conversion kit

1

2

3

4

5

6

7

8

9

10

11

Beginning

October 1995

Before

October 1995

Page 12

85.0812.00, 2003 HC-12

Handpiece Controls Syringe

Syringe Terminal, 2 Barb, Non-Quick Disconnect

Item # Part Number Description

1 030.002.02 O-ring pkg 10

2 23.1015.00 Handle

3 024.155.02 Syringe tubing assembly, straight 7'

1

2

3

23.1208.00

Page 13

85.0812.00, 2003 HC-13

Handpiece Controls Handpiece Tubing Terminals

Item # Part Number Description

1 98.0879.00 Four-hole tubing (straight) with

Midwest terminal, 84" (2134mm), Surf 4

2 98.0882.00 Three-hole tubing (straight) with Borden

terminal, 84" (2134mm), Surf 4

3 98.0262.02 Fiber-optic tubing (straight, with bulb)

84" (2134mm), Surf 4

4 98.0885.00 Fiber-optic tubing (straight), six pin,

84" (2134mm), Surf 4

5 041.317.00 Fiber-optic lamp, Xenon 3.5V, .75 amp

Tubing Terminals

1

2

3

4

5

TubingTerminal

Tubing to Terminal

4-hole

3-hole

5-hole

6-hole

Page 14

85.0812.00, 2003 HC-14

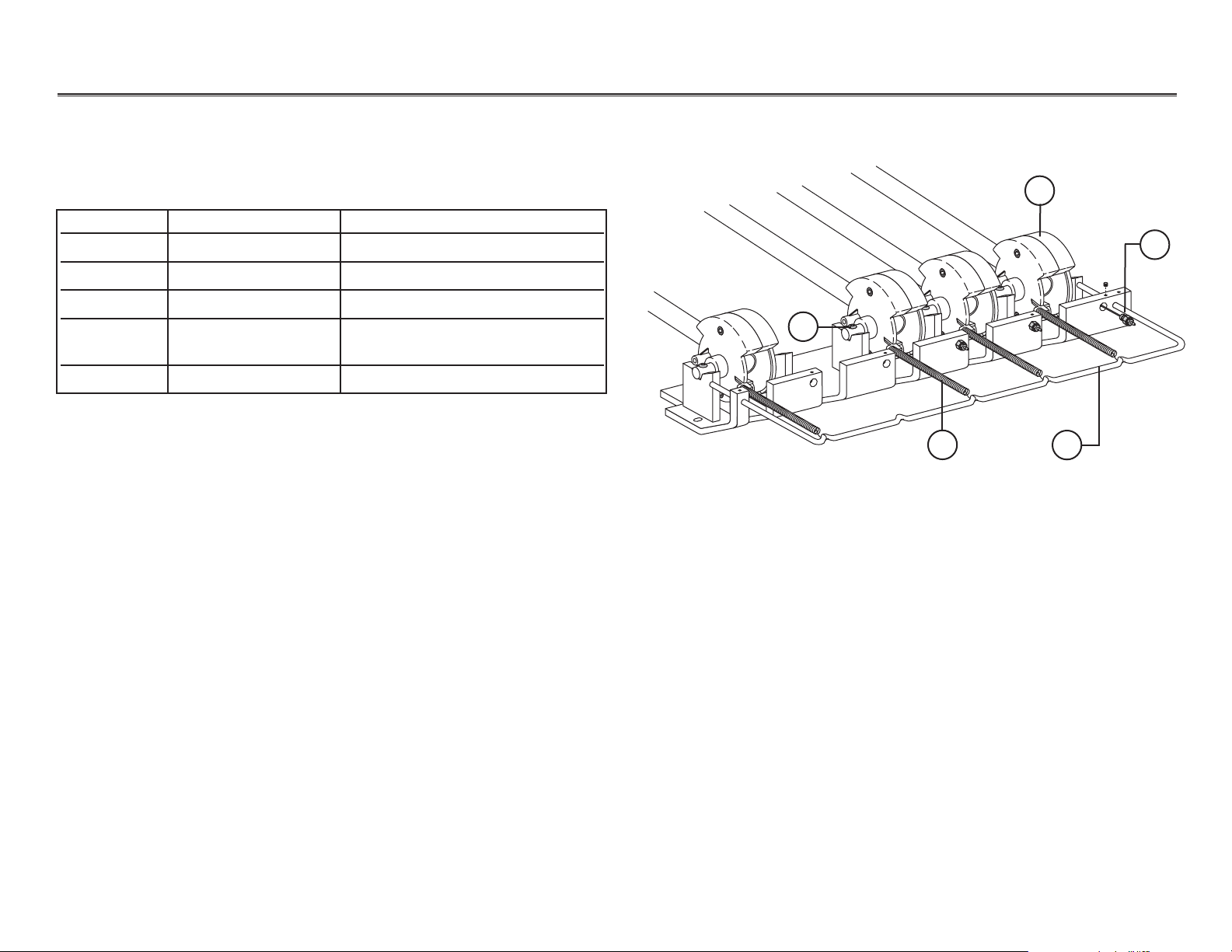

Handpiece Controls Century Plus Control Block

Century Plus Control Block Assembly

Item # Part Number Description

1 38.0524.00 Manifold assembly

38.0528.00 Manifold assembly, Century Plus, IC

2 38.0509.00 Century Plus control block

3 38.0507.01 Gasket

4 38.0505.00 End cap

5 38.0504.06 Tie bolt kit, 2 block

38.0504.07 Tie bolt kit, 3 block

38.0504.08 Tie bolt kit, 4 block

38.0504.09 Tie bolt kit, 5 block

6 004.036.00 Nylon float washer

7 38.0508.00 Nut, special

4

3

2

7

6

5

1

Working with

the Century Plus

Control Assembly

The A-dec Century Plus handpiece control system incorporates a master block, handpiece flush,

and air bleed functions into the control block system, reducing external tubing and connections.

The following pages provide illustrations, flow diagrams, and service information on parts that

are used to maintain and adjust the control block assembly.

2

1

3

0

8

7

6

5

4

3

2

1

Page 15

85.0812.00, 2003 HC-15

Handpiece Controls Century Plus Control Block

Century Plus Control Block Serviceable Parts

Item Part Number Description

1 001.021.01 Screw, socket head

2 001.024.01 Screw, socket head

3 38.0546.00 Cap assembly

4 38.0519.01 Diaphragm

5 38.0514.00 Water valve actuator

6 013.021.00 Spring, compression

7 38.0507.01 Molded side gasket

8 38.0510.00 Drive air flow adjustment stem

035.034.01 Drive air flow adjustment stem w/o-ring

9 38.0516.00 Water flow adjustment stem

035.034.01 Water flow adjustment stem w/o-ring

10 002.118.00 Screw, button head

11 38.0520.00 Water valve cartridge assembly

12 38.0518.00 Check valve (with duckbill) cartridge

13 38.0517.00 Air bleed cartridge (with o-rings)

For information about Century Plus handpiece control kits or A-dec replacement parts,

refer to the Genuine A-dec Service Parts Catalog, P/N 85.5000.00.

Century Plus Control Block

1

3

4

7

5

8

9

10

6

11

12

13

2

D

1

A

W

D

2

Page 16

85.0812.00, 2003

HC-16

Handpiece Controls Control Block Manifolds

38.0524.00 Century Plus Control Block

Manifold for Cascade

Item # Part Number Description

1 38.0526.00 Air coolant stem with o-rings

2 030.003.02 O-ring

3 002.118.00 Screw, button head

4 004.005.02 Washer

5 023.001.03 Barb, 1/4"

6 023.004.03 Barb, 1/8"

7 38.0555.00 Syringe water flow control barb assembly

38.0555.00 Syringe air flow control barb assembly

8 38.0525.00 Flush valve stem with o-rings

9 034.001.01 O-ring, E, .029 10 x .040 W

8

4

5

2

3

6

7

38.0528.00 Century Plus Control Block

Manifold for Decade Carts

6

2

3

4

5

1

1

9

Century Plus Control Block

Page 17

85.0812.00, 2003 HC-17

Handpiece Controls Control Block Flow Diagram

Item# Part Number Description

1 39.0822.00 Horizontal gauge

2 38.0524.00 Century Plus manifold assy

3 33.0048.04 Manual brake toggle

4 29.0146.00 Reverse micro valve, 3-way

5 33.0131.01 Master On/Off toggle

6 40.1075.00 Low voltage water heater

1

3

4

2

6

Master air

Chip blower air

Signal water (coolant water )

Signal air (coolant air)

Drive air

Pilot air

Regulated air

Oral cavity water

Return water

Special use

From air regulator or

post box

5

From air regulator or

foot control

To post box or utilities

From post box or utilities

To post box or utilities

Special use

Electrical accessories power

From post box

Autoclavable syringe

(optional heated syringe tubing shown)

Syringe

water flow

control

Syringe

water flow

control

Flexarm brake

Ground

Number Color Voltage

1Black 0

2Brown0

3Red 6

4Orange 24

5Yellow 24

6Green/Yellow Ground

7Blue 24

8Violet 17

Terminal Strip Wiring Voltage

(before May 1998)

Before May 1999

2345678

1

Page 18

85.0812.00, 2003 HC-18

Handpiece Controls Control Block Flow Diagram

Item Part Number Description

1 39.0822.00 Horizontal gauge

2 38.0524.00 Century Plus manifold assy

3 33.0048.04 Manual brake toggle

4 29.0146.00 Reverse micro valve, 3-way

5 33.0131.01 Master On/Off toggle

6 40.1075.00 Low voltage water heater

1

3

4

2

6

Master air

Chip blower air

Signal water (coolant water )

Signal air (coolant air)

Drive air

Pilot air

Regulated air

Oral cavity water

Return water

Special use

From air regulator or

post box

5

From air regulator or

post box

To post box or utilities

From post box or utilities

To post box or utilities

Special use

Electrical accessories power

From post box

Autoclavable syringe

(optional heated syringe tubing shown)

Syringe

water flow

control

Syringe

water flow

control

Flexarm brake

Number Color Voltage

1Black 0

2Brown0

3Red 6

4Orange 24

5Yellow 24

6Green/Yellow Ground

7 Blue 24

8Violet 17

Terminal Strip Wiring Voltage

(before May 1998)

After April 1998

2345678

1

Page 19

85.0812.00, 2003 HC-19

Handpiece Controls Radius Delivery System Flow Diagram

After November 1999

Control head

Floor box

Radius cuspidor

Foot control

Brake assembly

Flexarm brake

Master On/Off

Century Plus

control block

Air bleed valve

Syringe

Horizontal gauge

Air filter/regulator assembly

Water filter/regulator assembly

(80 psi)

(40 psi — non-adjustable)

(40 psi)

Syringe

Saliva ejector

HVE

Wet/dry

toggle

Chip

blower

Water manifold

Bowl

rinse

Cup

fill

Cup fill

air relay

Water relay

Cup fill

bleed

valve

(Fiber-optic

switch)

Self-contained water

Foot control III valve

34

50

40

60

5

2

30

70

20

80

1

6

90

10

100

0

psi

2

7

0

kg/cm

34

50

40

60

5

2

30

70

20

80

1

6

90

10

100

0

psi

2

7

0

kg/cm

Page 20

85.0812.00, 2003 HC-20

After November 1999

Control head

Floor box

Radius cuspidor

Foot control

Brake assembly

Flexarm brake

Master On/Off

Century

Plus control

block

Air bleed valve

Syringe

Horizontal

gauge

Air filter/regulator assembly

Water filter/regulator assembly

(80 psi)

(40 psi — non-adjustable)

(40 psi)

Syringe

Saliva ejector

HVE

Wet/dry

toggle

Chip

blower

Water manifold

Bowl

rinse

Cup

fill

Cup fill air

relay

Water relay

Cup fill

bleed

valve

(Fiber-optic

switch)

Self-contained water

Foot control III valve

Post box

Handpiece Controls Cascade Delivery System Flow Diagram

a

a

34

50

40

60

5

2

30

70

20

80

1

6

90

10

100

0

psi

2

7

0

kg/cm

34

50

40

60

5

2

30

70

20

80

1

6

90

10

100

0

psi

2

7

0

kg/cm

Page 21

Handpiece Controls Cascade Delivery System Flow Diagram

85.0812.00, 2003 HC-21

Control head

Floor box

Radius cuspidor

Foot control

Brake assembly

Flexarm brake

Master On/Off

Century Plus

control block

Air bleed valve

Syringe

Horizontal

gauge

Air filter/regulator assembly

Water filter/regulator assembly

80 psi pre-regulator

40 psi pre-regulator

Syringe

Saliva ejector

HVE

Wet/dry toggle

Chip blower

or scaler

Water manifold

Bowl

rinse

Cup

fill

Cup fill air

relay

Water relay

Cup fill

bleed

valve

(Fiber-optic

switch)

Self-contained water

Water quick disconnect

Foot control II valve

Before December 1999

Post box

34

50

40

60

5

2

30

70

20

80

1

6

90

10

100

0

psi

2

7

0

kg/cm

a

a

2

1

34

40

30

20

10

0

0

50

60

5

70

80

6

90

100

psi

2

7

kg/cm

Page 22

Handpiece Controls Cascade Control Head Flexarm Adjustment

85.0812.00, 2003 HC-22

Adjusting

Horizontal Drift

(Cascade)

Cascade Control Head Flexarm

Item # Part Number Description

1 35.1514.00 Flexarm assembly

2 007.024.00 Tension setscrew

3 007.058.00 Retaining/alignment setscrew

4 35.1386.00 Rigid arm post assembly

1

4

3

2

To eliminate horizontal drift of the control head, adjust the tension

setscrew. This causes the cup point to seat itself against the wall of

the internal bushing. Use a 3/32" hex key for adjusting both the

tension and the retaining/alignment setscrews.

Page 23

Handpiece Controls Cascade Control Head Flexarm Adjustment

85.0812.00, 2003 HC-23

Adjusting the

Tension

Setscrew

(Cascade)

Adjusting the

Retaining/

Alignment

Setscrew

(Cascade)

Follow these steps to adjust the tension setscrew.

Task Description

1Remove the tension setscrew and the

retaining /alignment setscrew. Reinstall both,

making sure they are in the correct locations.

Do not tighten.

2Tighten the tension setscrew until it comes

to a stop. Then tighten it an additional

quarter turn (20 - 24 inch pounds).

NOTE: It is important to repeat step two. Loosen

the setscrew and repeat the step twice.

This will ensure the setscrew is seated.

3Check flexarm tension and adjust the setscrew

to achieve the desired result.

Follow these points to adjust the retaining/

alignment setscrew.

•Tighten the retaining alignment setscrew

until it passes through the opening of the

bushing and presses against the knuckle.

• Loosen the setscrew a quarter turn.

NOTE: The brass colored tip on the end of the

retaining alignment setscrew shouldn’t

touch the knuckle when loosened a

quarter turn.

Adjustment Setscrews

1

2

Item # Part Number Description

1 007.058.00 Retaining/

alignment setscrew

2 007.024.00 Tension setscrew

Long, black

setscrew with

brass colored tip

Short, silver

colored setscrew

Page 24

Handpiece Controls Radius Control Head Flexarm Adjustment

85.0812.00, 2003 HC-24

Adjusting

Horizontal Drift

(Radius)

Cascade Control Head Flexarm

Item # Part Number Description

1 35.1514.00 Flexarm assembly

2 35.1611.01 Unit mount post assembly

3 007.024.00 Tension setscrew

4 007.058.00 Retaining/alignment setscrew, Black

1

2

4

3

To eliminate horizontal drift of the control head, adjust the

tension setscrew. This causes the cup point to seat itself against

the wall of the internal bushing. Use a 3/32" hex key for adjusting both the tension and the retaining/alignment setscrews.

Page 25

Handpiece Controls Radius Control Head Flexarm Adjustment

85.0812.00, 2003 HC-25

Follow these steps to adjust the tension setscrew.

Task Description

1 Remove the tension setscrew and the

retaining /alignment setscrew. Reinstall

both, making sure they are in the correct

locations. Do not tighten.

2 Tighten the tension setscrew until it comes

to a stop. Then tighten it an additional

quarter turn (20 - 24 inch pounds).

NOTE: It is important to repeat step two.

Loosen the setscrew and repeat the

step twice. This will ensure the

setscrew is seated.

3Check flexarm tension and adjust the

setscrew to achieve the desired result.

Follow these points to adjust the retaining/

alignment setscrew.

•Tighten the retaining alignment setscrew

until it passes through the opening of the

bushing and presses against the knuckle.

• Loosen the setscrew a quarter turn.

NOTE: The brass colored tip on the end of the

retaining alignment setscrew shouldn’t

touch the knuckle when loosened a

quarter turn.

Adjustment Setscrews

1

2

Item # Part Number Description

1 007.024.00 Tension setscrew

2 007.058.00 Retaining/

alignment setscrew

Long, black

setscrew with

brass colored tip

Short, silver

colored setscrew

Adjusting the

Tension Setscrew

(Radius)

Adjusting the

Retaining/Alignment

Setscrew

(Radius)

Page 26

Handpiece Controls Troubleshooting

85.0812.00, 2003 HC-26

Problem

Action

Holder(s) is difficult or too easy

to rotate

Whip assembly(ies) doesn’t

actuate the bleed valve(s)

Adjust the tension by loosening or tightening the friction pad setscrew (see Individual and

Unitized Holder).

Task Descriptions

1Verify spring washers are installed between the whip assembly(ies) and mounting

posts. If missing, install them between the whip assemblies and the whip mounting posts

(see Continental Whip).

2Add washers to both sides of the wheel assembly(ies).

•Remove the button-head screw from the appropriate pin and post.

•Slide the pin away from the whip assembly.

•Install the spring washer between the wheel and post with curved side

toward the whip assembly (see Continental Whip).

•Slide the pin into the pin opening in the whip assembly. Secure the pin

with the screw removed above.

• Repeat for each whip assembly with whisker valve actuation.

If this does not resolve the problem, go to step 3.

3 Inspect the air bleed valves and replace those that are defective.

4Test the whip assemblies with the control head cover in place. Make sure

the handpieces activate and deactivate as the whip assembly is pulled and released.

Tips and troubleshooting information are listed in the following charts to assist in diagnosing

handpiece control problems. These charts are not intended to cover every situation, but do include

the most common problems you may encounter.

Troubleshooting

Handpiece Controls

Page 27

Handpiece Controls Troubleshooting

85.0812.00, 2003 HC-27

Problem Action

Whip assemblies don’t move

freely or interfere with cover

Water leaks from the water vent

hole on control blocks

Check for an improperly aligned mounting bracket. Slightly loosen the two screws securing the

assembly in place (underside of control head). Do not remove the cover. Move the whip assembly

until it moves freely.

Follow these steps to check for water leaks.

Task Descriptions

1Check for a failed water valve cartridge

• determine which block is leaking

• exchange the water valve cartridge with a known good one, and

• test the unit.

2 If the water leakage has stopped, replace the failed water valve cartridge. Retest the unit and

make sure there are no more leaks. If water is still leaking, continue with step 3.

3 Remove the water flow adjustment stem from the control block and inspect the o-ring and stem.

Replace defective parts and test the unit. If water is still leaking, continue with step 4.

4Check for a leaking valve stem

•Tighten the valve stem to make sure it’s not leaking and test the unit.

• If the valve stem is still leaking, exchange it with a known good one and test the unit.

• If the water leakage has stopped, replace the failed valve stem cartridge.

•Test the unit.

5Check for loose tie bolts.

Page 28

Handpiece Controls Troubleshooting

85.0812.00, 2003 HC-28

Problem Action

Coolant water is leaking from

one handpiece control block

Follow these steps to check if coolant water is leaking.

Task Descriptions

1 Remove the valve stem from the control block and inspect the o-ring and stem.

2Replace defective parts and test the unit. If water is still leaking, continue with step 3.

3Check for a leaking valve stem

•Tighten the valve stem to make sure its not leaking. Test the unit.

• If the valve stem still leaks, exchange the cartridge with a known good one.

Retest the unit.

Air or water leakage from one of

the valve assemblies

Air or water leakage from the

syringe nut assembly

No air and/or water from

the syringe

Replace the valve assemblies.

Check the following steps to stop leakage from the syringe nut assembly.

•Make sure the syringe nut assembly is properly installed and tightened. Use a 5/32" hex key

to tighten.

•Replace o-rings, and syringe nut assembly.

Check the following steps to fix the syringe.

• Check to make sure the master On/Off toggle and the air and water supplies are turned ON.

• Check tubing for kinks or breaks.

Loading...

Loading...