Page 1

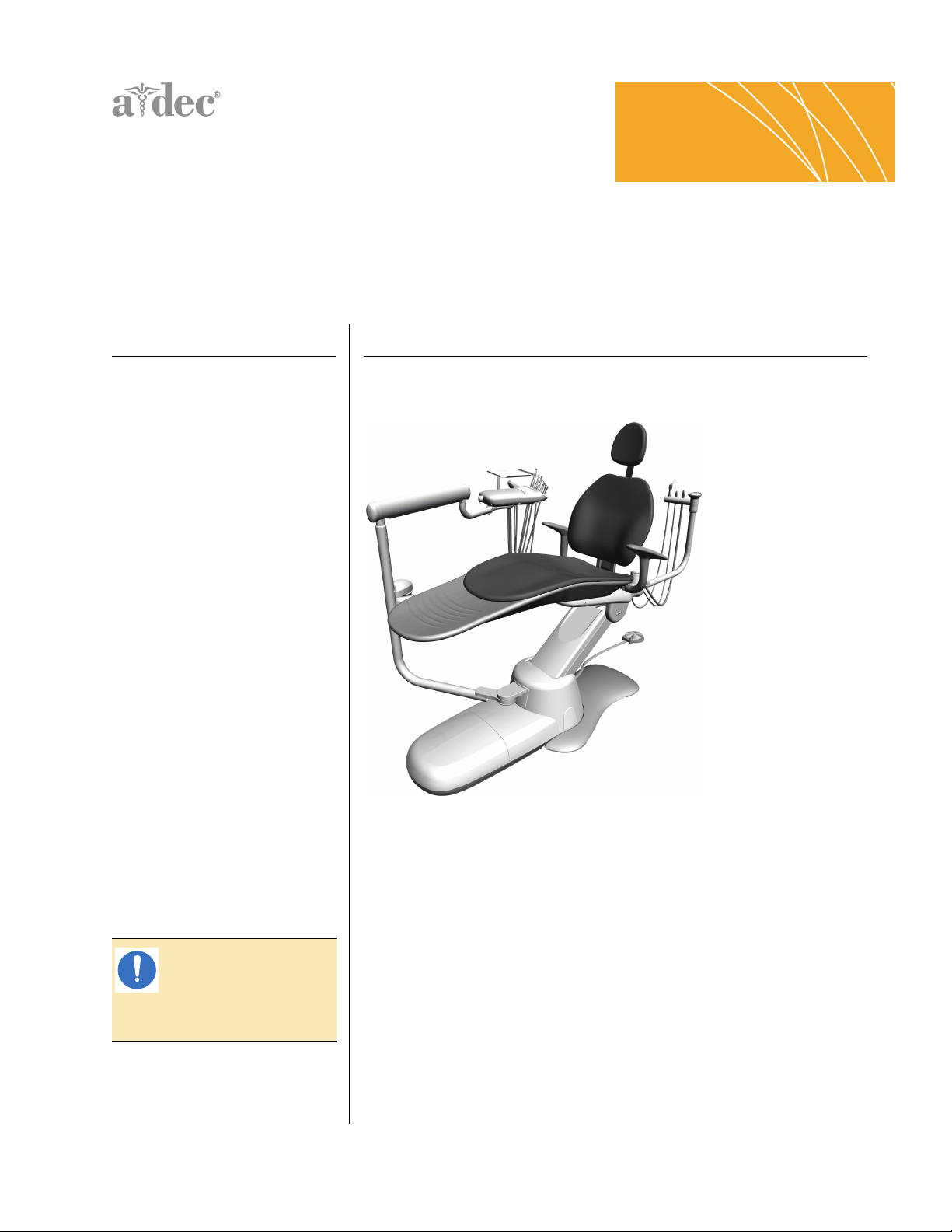

A-dec 300® System

I NSTALLATION GUIDE

C ONTENTS

Introduction ................... 1

Install the Chair ............... 3

Install the Support Center .. 9

Install the Assistant's

Instrumentation ............. 15

Install the Delivery System 22

Install the Dental Light .... 34

Install the Monitor Mount . 36

Install the Contoured Floor

Box ............................ 37

Install the Remote Floor

Box ............................. 39

Connect the Utilities ....... 40

Install the Cuspidor ........ 60

Install Upholstery ........... 61

Prepare and Adjust the

System ........................ 64

Level the System ........... 77

Touchpad Settings .......... 80

Test the System ............. 93

Verify Proper Clearance

Between the Cuspidor Bowl

and the Armrest ............ 94

Install the Covers ........... 96

Appendix: Install the Air

Vacuum System (AVS) .....105

Regulatory Information ...108

NOTE Information that

is critical to a successful

and safe installation is

shaded like this note

throughout the guide.

I NTRODUCTION

This document contains installation instructions for the A-dec 300 system.

Before you begin:

• Clear the room of all debris and thoroughly clean the floors.

• Check that manual air and water shut-offs are installed.

• Purge any debris from air and water lines.

• Check with local building and code authorities about installation

requirements. They differ from state to state and internationally.

Your installation may not require all components described in this document.

Before you begin:

86.0087.00 Rev E

1. Assess what modules you will install.

2. Use “Installation Sequence” on page 2 to note the order of the modules

that are to be installed.

Page 2

A-dec 300 System Installation Guide

Dental Chair

Support Center

Assistant’s Instrumentation Monitor Mount

Dental Light

Delivery System

2

3

4

5

6

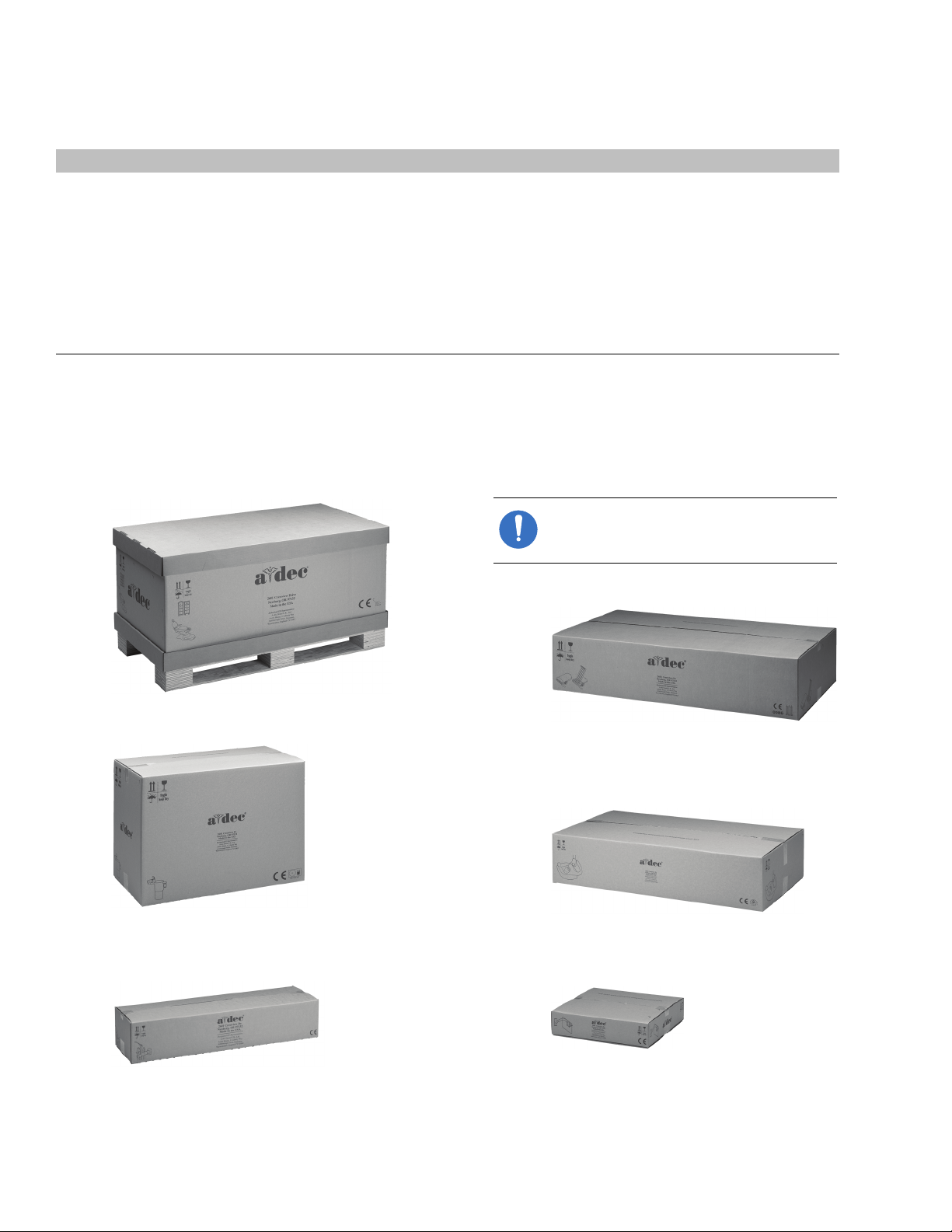

NOTE The box for each module contains

all of the parts needed to install that

module.

1

Recommended Tools

Tools Needed For This Installation

Hex key set Drill

5/16" hex key driver Diagonal cutters A-dec silicone lubricant

Ball driver set Needle nose and standard pliers Umbilical snake

Adjustable wrench Phillips head screwdriver Rubber mallet

3/4" and 9/16" socket and ratchets Roto hammer drill Sleeve pusher

1/4", 1/2", and 3/4" combination

wrenches

Tape measure Pliers

Magnetic level Voltmeter

Drill bits: 3/8" wood, 1/4"

and 1/2" masonry

Installation Sequence

Modules for the A-dec 300 system installation are shown in Figure 1. Install the modules for your configuration in

the order they are listed.

Figure 1. A-dec 300 System Shipping Boxes

2 86.0087.00 Rev E

Page 3

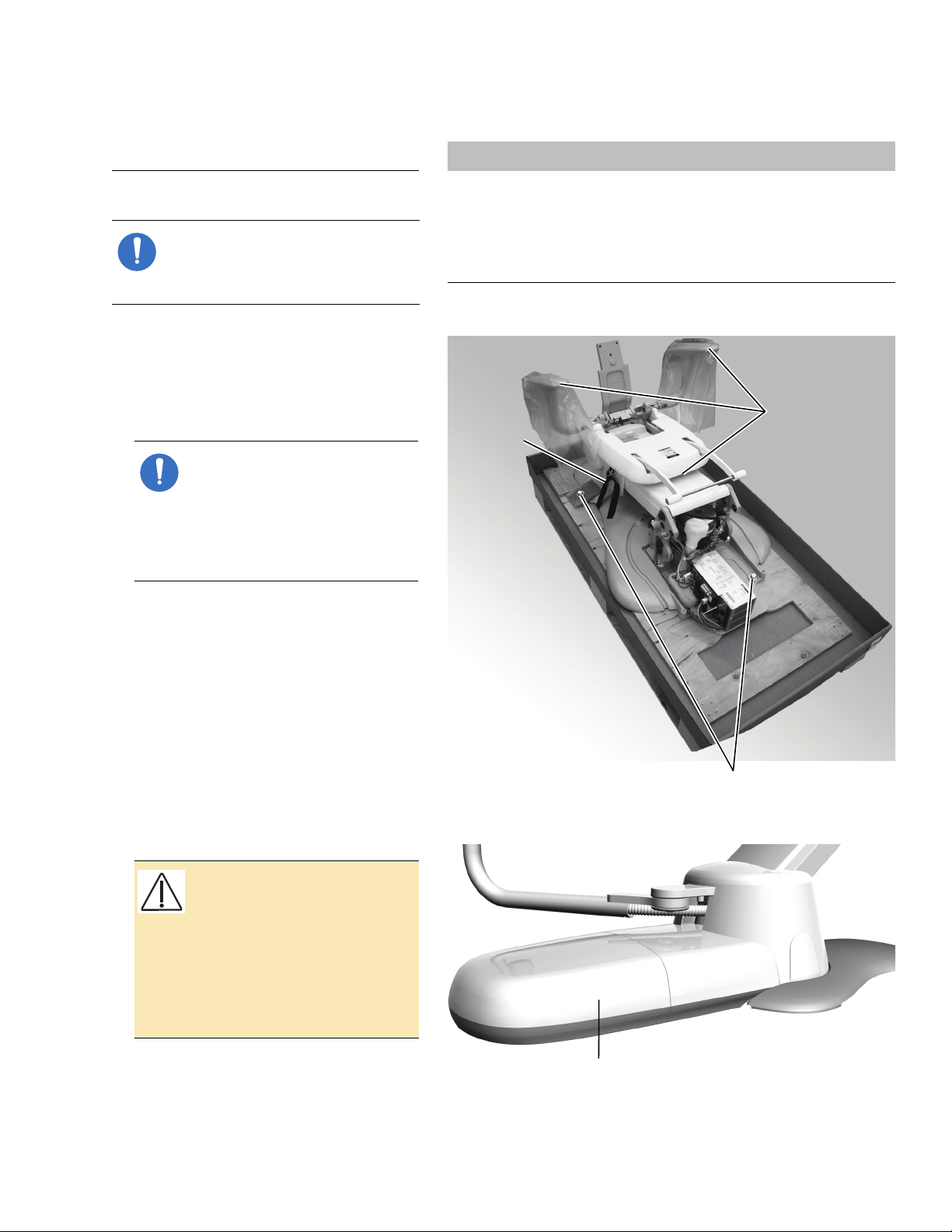

I NSTALL THE

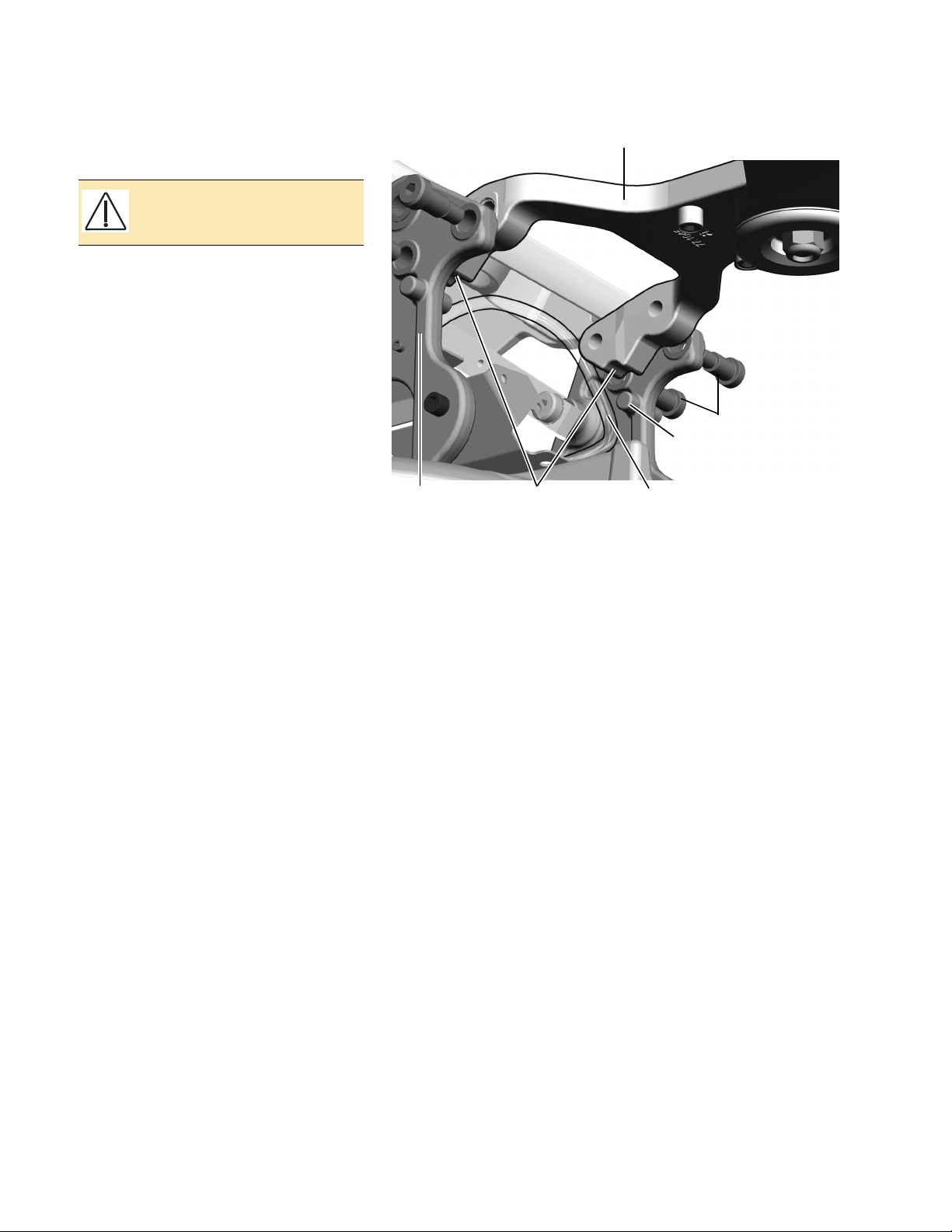

Grab Points

Shipping

Strap

Shipping Bolts

Contoured Floor Box

Install the Chair

C HAIR

NOTE If you have a post mount

system, skip this section and go to

“Install the Support Center” on

page 9.

Position the Chair

1. Remove all items and cardboard from

around the chair.

NOTE When removing modules

from their packaging, watch for

kits and manuals included for

the doctor (such as the A-dec 311

Dental Chair Instructions For Use).

Set these aside during

installation.

Tools Needed For This Section

and 9/16" socket and

3/4"

ratchets

Drill 3/16" hex key

Roto hammer drill 3/4" combination wrench

Phillips head screwdriver

Figure 2. Place the Chair

3/8" wood drill bit or

1/4" and 1/2"

masonry drill bits

2. Remove the covers.

3. Use a 3/4" socket and ratchet to remove

the bolts securing the chair to the pallet.

4. Grasp an armrest and the front of the

chair frame. Lift and place the chair in

position in the treatment room.

CAUTION If the system includes

a contoured floor box, failure to

provide enough space between

the utilities and the contoured

floor box cover will prevent the

installation of the power supply

cover. For more information, see

“Install the Contoured Floor Box

Frame” on page 37.

Figure 3. Contoured Floor Box

5. Remove the shipping strap and the

packaging from the armrests.

86.0087.00 Rev E

3

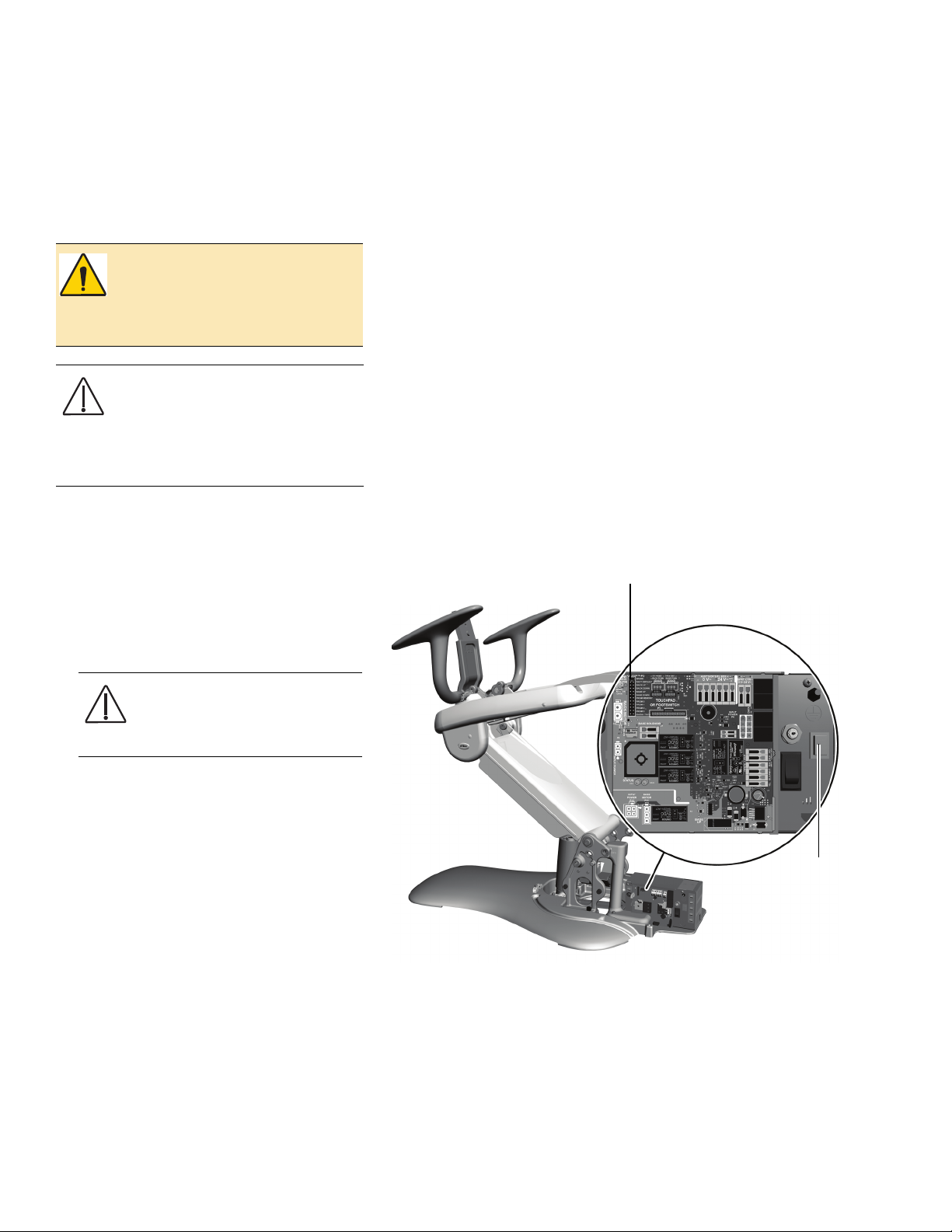

Page 4

A-dec 300 System Installation Guide

Mains

On/Off

Button

P3

Anchor the Chair

Use the lag screw or masonry anchor with

the cleat to anchor the chair to the floor.

Select the procedure for your type of

flooring structure.

WARNIN G Anchoring the chair to

the floor is required for mechanical

stability. Failure to anchor properly

could result in damage, serious

injury, or death.

CAUTION Check the flooring

and/or framing material where you

will anchor the chair. If it is not at

least 3-1/4" (82 mm) thick, contact a

licensed contractor about

reinforcing the floor.

Anchor to a Concrete Floor

Prepare the Installation Area

1. Plug in the chair and press the Mains

On/Off button on the lower right of the

power supply to turn it on.

CAUTION Electric components

on the circuit board are static

sensitive and require handling

precautions.

2. Move the jumper in P3 of the chair circuit

board to the Base Up position. Once the

chair is raised, return the jumper to the

Spare position.

3. Turn off the power.

4. Unplug the chair.

Figure 4. Prepare the Chair

4 86.0087.00 Rev E

Page 5

5. Place the cleat in the large circle in the

Cleat

Masonry

Anchor

chair base (see Figure 5).

6. Mark where to drill the hole for the

masonry anchor and move the chair.

7. Use a 1/2" bit and roto hammer to drill a

4" (101 mm) deep hole; then remove any

debris.

Install the Chair

Secure the Chair

1. Drive the 3-1/2" masonry anchor into the

hole until the washer is flush with the

floor.

2. Use a 9/16" socket and ratchet to tighten

the anchor until it is securely fixed in the

hole then remove the screw and washer.

3. Return the chair to position.

4. From the left front of the chair, place the

screw through the washer and cleat and

into the hole.

5. Use a 9/16" socket and ratchet to tighten

the bolt against the cleat until it firmly

holds the chair to the floor.

Figure 5. Anchor the Chair to a Concrete Floor

86.0087.00 Rev E

5

Page 6

A-dec 300 System Installation Guide

Cleat

Lag Screw

3/4"

Socket

and

Ratchet

Lag

Screw

3/4" Combination Wrench

Cleat

Anchor to a Wood Floor

Prepare the Installation Area

1. Plug in the chair and press the Mains

On/Off button on the lower right of the

power supply to turn it on (see Figure 4

on page 4).

CAUTION Electric components

on the circuit board are static

sensitive and require handling

precautions.

2. Move the jumper in P3 of the chair circuit

board to the Base Up position. Once the

chair is raised, return the jumper to the

Spare position.

3. Turn off the power and unplug the chair.

4. Place the cleat in the large circle in the

chair base.

5. Mark where to drill the hole for the lag

screw and move the chair.

6. Use a 3/8" bit to drill a 2" (50 mm)

deep hole; then remove any debris.

7. To thread the hole, use a 3/4" socket and

ratchet to drive the 2-1/2" lag screw

about 1/2" (12.8 mm) into the hole; then

remove the lag screw.

Figure 6. Start the Lag Screw

Figure 7. Tighten the Lag Screw

Secure the Chair

1. Put the chair back into position so that

the hole is positioned on the right rear

edge of the circle in the chair base (see

Figure 6).

2. From the right rear of the chair, place the

lag screw through the cleat and into the

hole.

3. With your fingers, start the lag screw as

far as you can; then use a 3/4" socket and

ratchet with a short extension to tighten

the lag screw until it is almost flush

against the cleat.

4. Move the chair into position and use a

3/4” combination wrench to tighten the

lag screw against the cleat until it firmly

holds the chair to the floor.

6 86.0087.00 Rev E

Page 7

Install the Chair

Integrated Floor Box

Cover Frame

Power Supply Cover Frame

Power Supply

Cover Frame

Attach Frame

to Floor

Mains On/Off Button

Attach Frame to

Chair Base

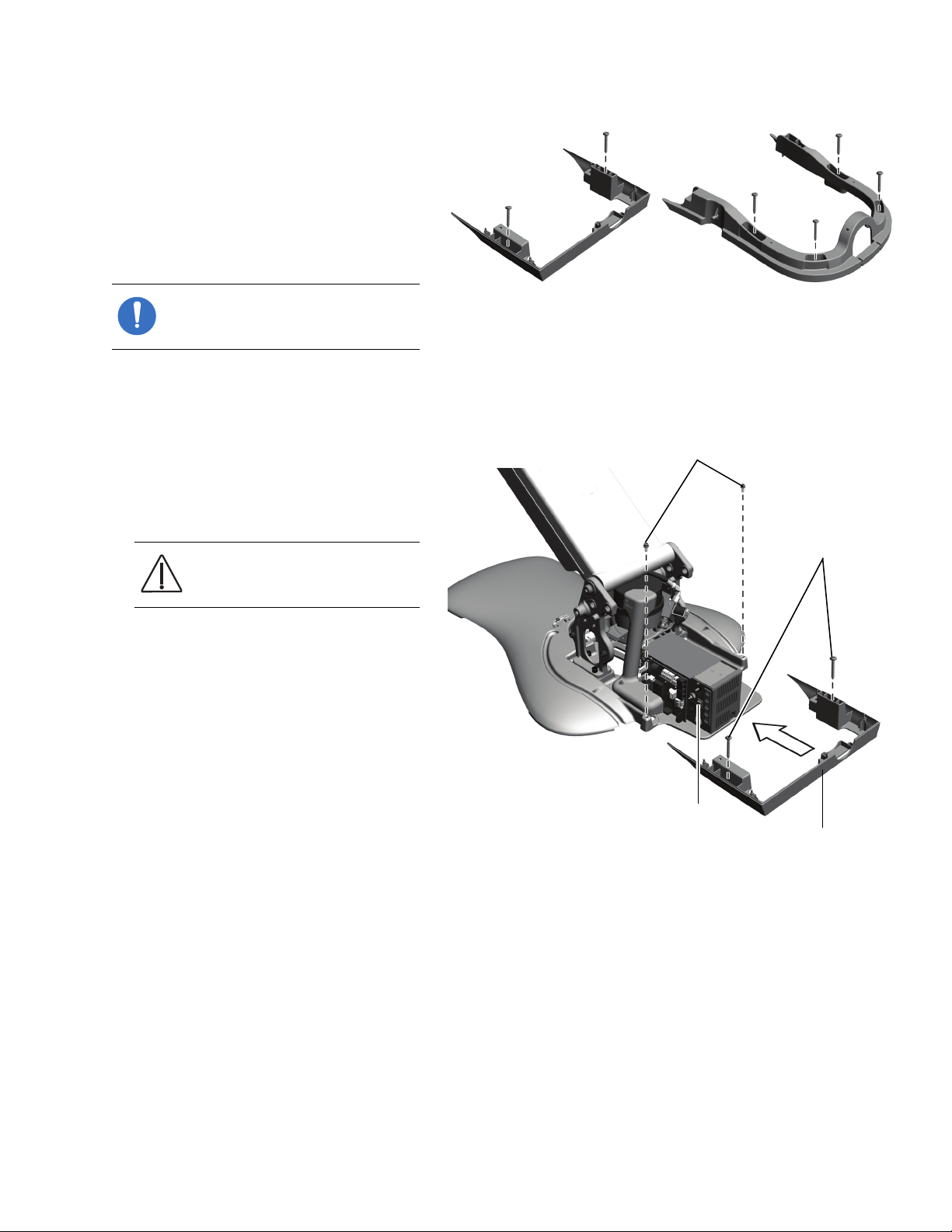

Install the Power Supply or Integrated Floor Box Cover Frames

A-dec 300 systems come with either a power

supply cover or an integrated floor box

cover.

NOTE The power supply cover

frame ships attached to the power

supply cover.

The steps for installing their frames are the

same.

1. With the chair fully raised, use a 3/16"

hex key to remove the two mounting

screws from the chair base.

2. Attach the cover frame to the chair base

with the two mounting screws.

CAUTION Never use a cover

frame as a handle when moving

the chair.

Figure 8. Cover Frames

Figure 9. Install the Cover Frame

3. Attach the cover frame to the floor.

○ If the floor is made of wood, use a

Phillips head screwdriver and 1-1/4"

size #10 screws.

○ If it is a concrete floor, use a 1/4"

masonry drill bit to make holes where

the screws fit through the frame.

Insert the plastic anchors in the holes

then use a Phillips head screwdriver

and 1-1/4" size #10 screws.

86.0087.00 Rev E

7

Page 8

A-dec 300 System Installation Guide

Back Support

Mounting Screws

Chair Back

Strain

Relief

Circuit Board

Touchpad Or Footswitch Connection

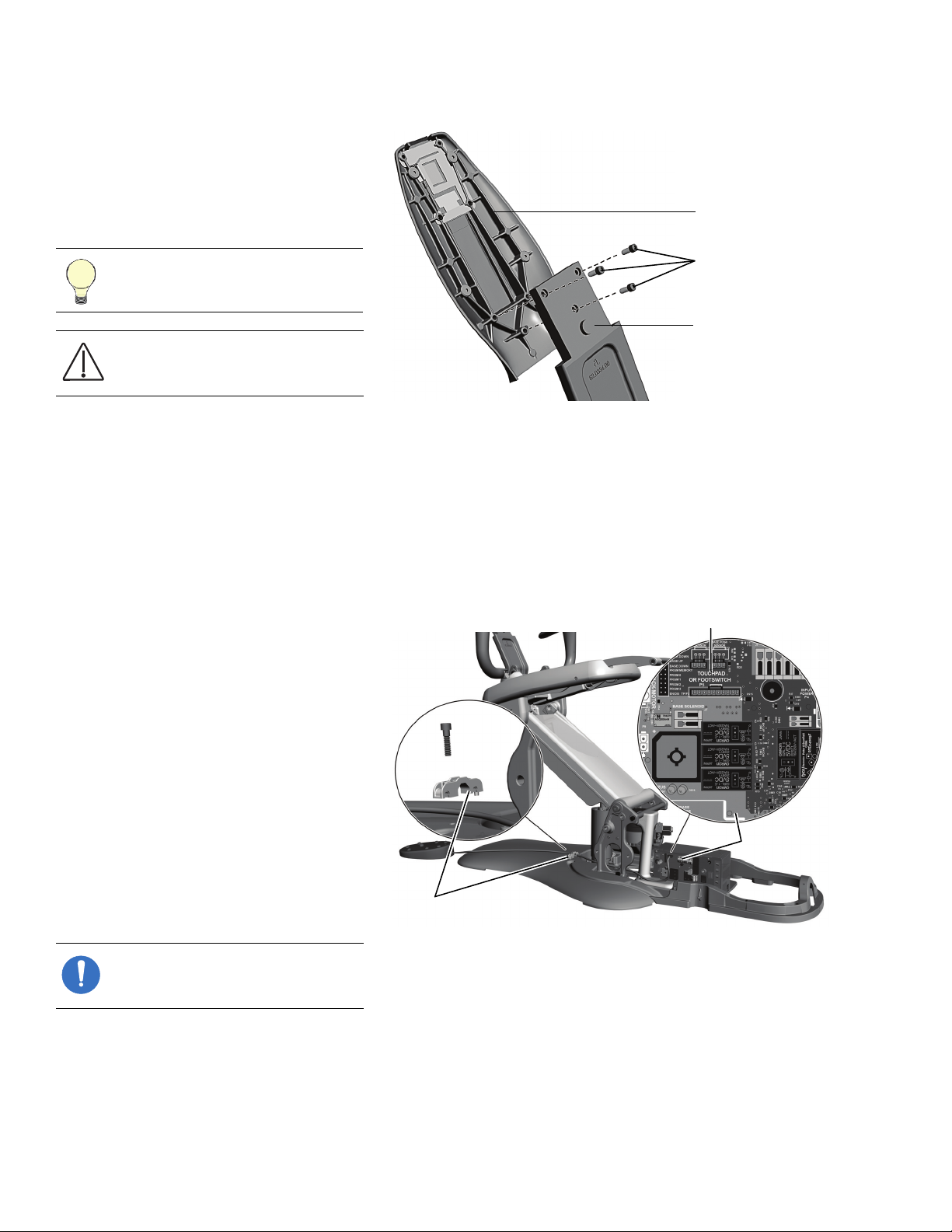

Install the Back Support

1. Use a 3/16" hex key to remove the 3

mounting screws from the back support.

2. Attach the back support to the chair

back with the mounting screws.

TIP Start all three screws before

tightening them.

CAUTION Be sure to tighten the

screws firmly to avoid the back

becoming loose during use.

Figure 10. Install the Back Support

Install the Footswitch (Optional)

If the system contains a footswitch, complete

the following steps to install it.

1. From the rear of the chair, route the cord

to the chair’s circuit board and connect it

to the Touchpad Or Footswitch P5

connector on the chair circuit board.

2. Use a 3/16" hex key to secure the

footswitch cord in one of the side holes of

the strain relief.

NOTE If you are not installing any

modules on to the chair, go to

“Install Upholstery” on page 61.

Figure 11. Install the Footswitch

8 86.0087.00 Rev E

Page 9

I NSTALL THE

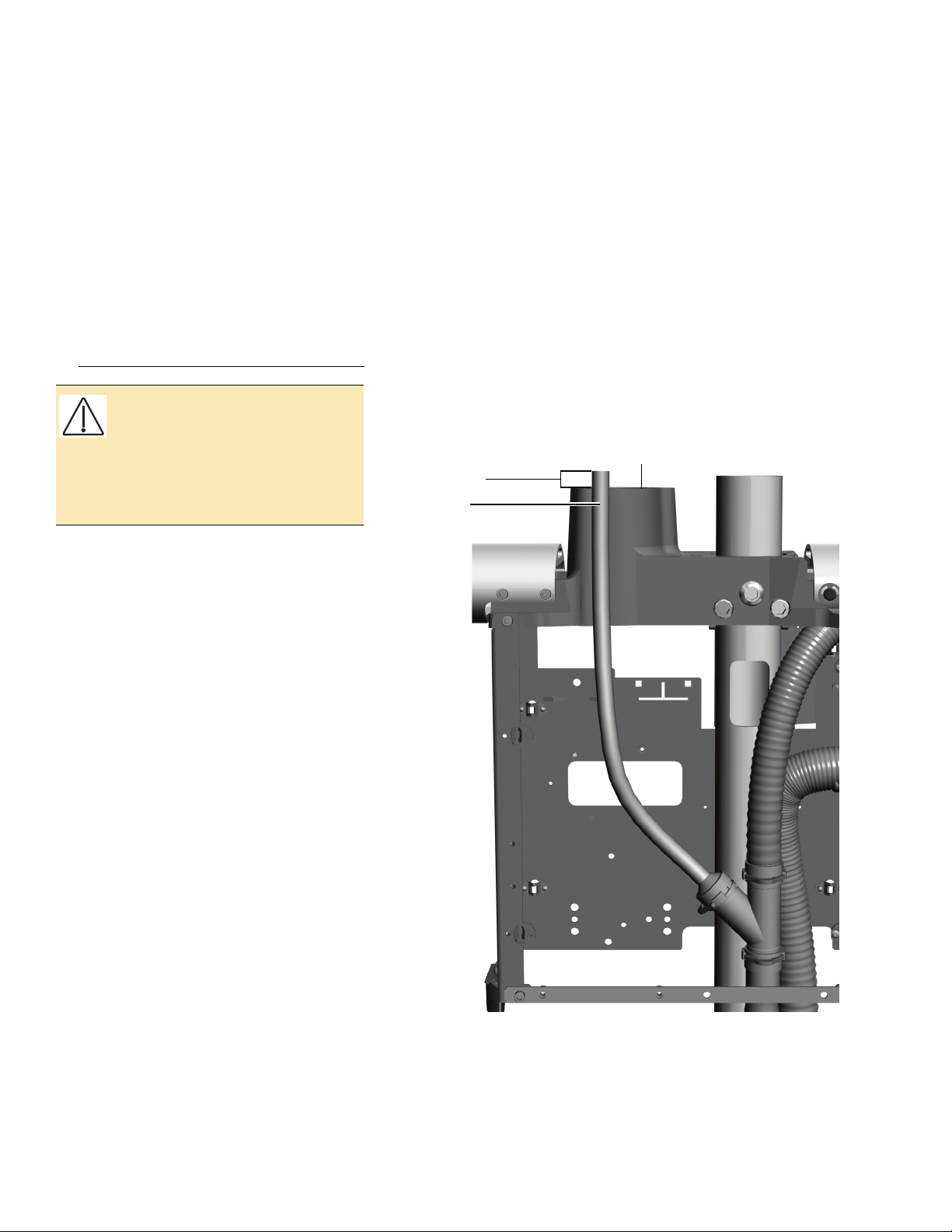

Chair-Base Mount

Use a 5/16" hex key driver to apply

30 ft-lb (4.15 m-kgs) of torque pressure.

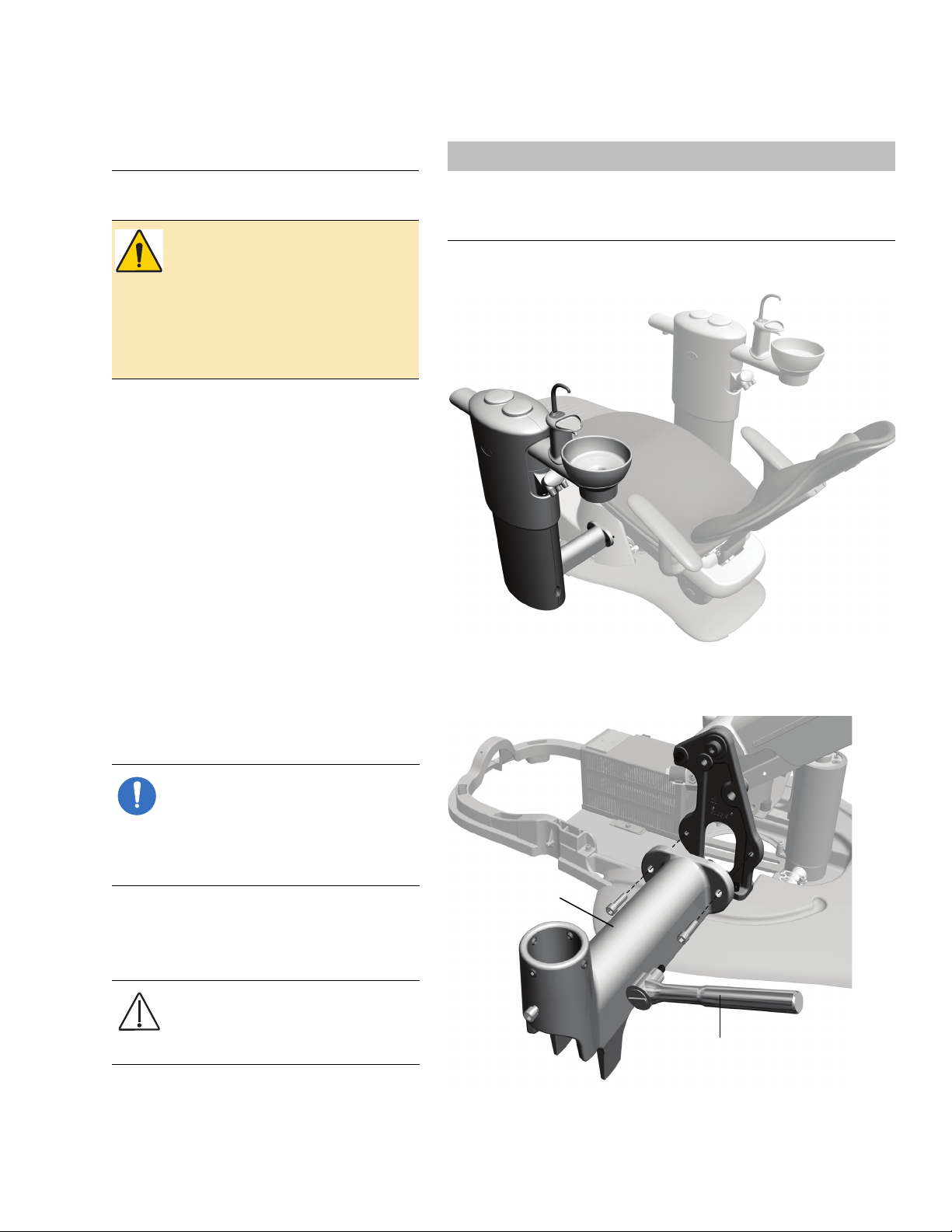

Install the Support Center

S UPPORT CENTER

WARNIN G If the system includes a

cuspidor, do not remove the

positioning guide that is cable tied

to the cuspidor bowl support until

the support center is properly

aligned. Complete the following

section to ensure proper alignment

of the support center.

You can mount the support center on either

side of the chair. This section describes how

to install the support center and connect the

utilities.

Tools Needed For This Section

5/16" hex key driver 3/16" hex key

Level Diagonal cutters

Adjustable wrench Sleeve pusher

Figure 12. A-dec 361 Support Center and Cuspidor

Install the Chair-Base Mount

NOTE If you have a post mount

system, skip this procedure and

follow the directions provided with

the chair adaptor kit. Then go to

“Install the Support Center Post” on

the next page.

Use a 5/16" hex key driver and two 1-1/2"

socket head screws to attach the chair-base

mount to the side of the chair frame.

CAUTION Be sure to tighten the

screws securely (approximately 30

ft-lb [4.15 m-kgs] of torque) so the

mount does not loosen during use.

Figure 13. Install the Chair-Base Mount

86.0087.00 Rev E

9

Page 10

A-dec 300 System Installation Guide

Square

Hole

One Set Of

Leveling

Screws

Notch

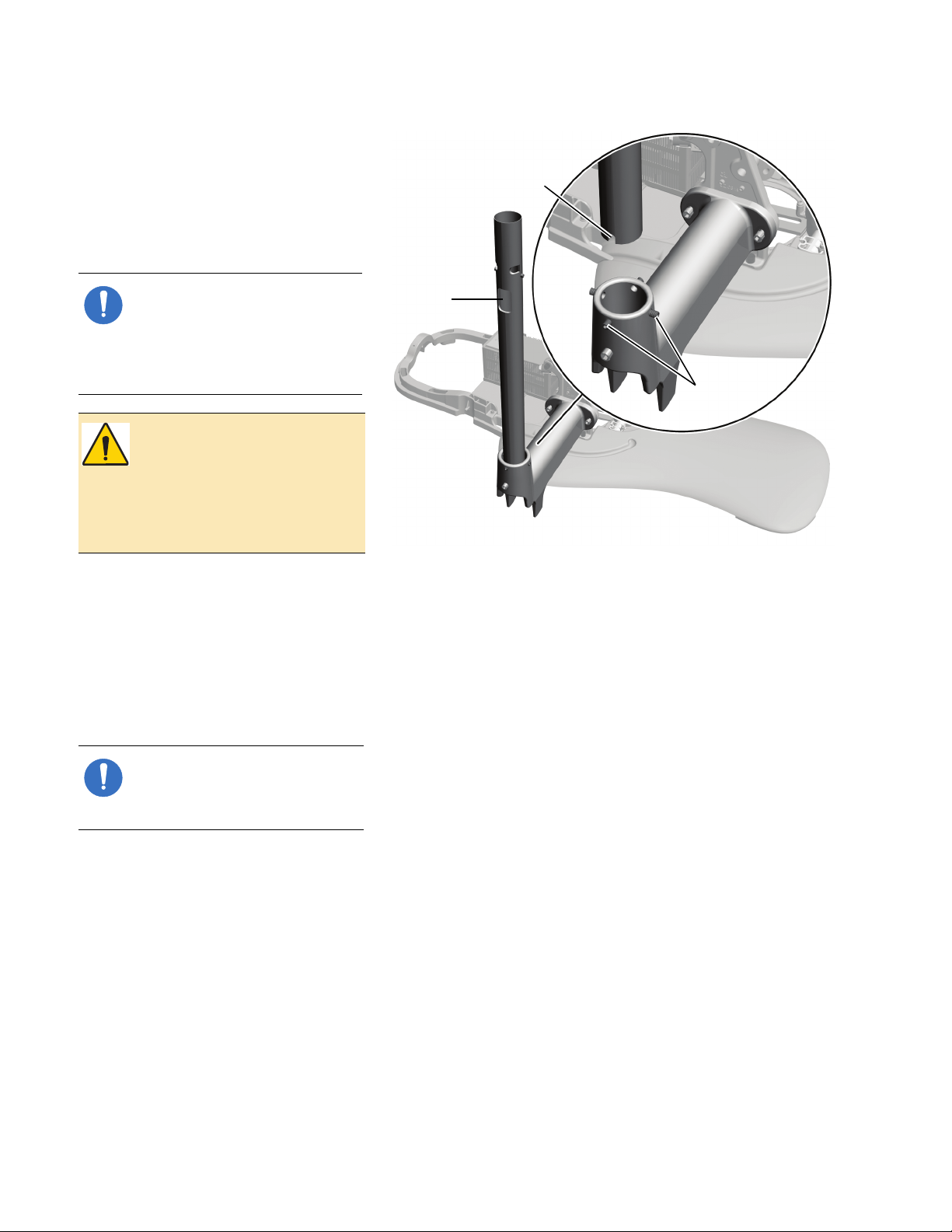

Install the Support Center Post

1. Place the support center post in the chair-

base mount with the notched bottom

over the screw near the base of the

mount.

NOTE If you have a post mount

system, the support center post

installs into a chair adaptor

instead of the chair-base mount

and the post does not have

notches in the bottom.

WARNIN G If you’re installing a

post mount system, anchoring

the chair to the floor is required

for mechanical stability. Failure

to anchor properly could result

in damage, serious injury, or

death.

Figure 14. Install the Support Center Post

If the support center is installed to the

left of the patient, face the square hole

away from the chair. If the support center

is installed to the right of the patient, face

the square hole toward the chair.

2. Place a level vertically against the post

and align it with the four leveling screws

near the top of the chair-base mount.

NOTE If you have a post mount

system on an A-dec 511 chair, the

chair adaptor has eight leveling

screws.

10 86.0087.00 Rev E

Page 11

3. Use a 3/16" hex key to adjust the screws,

Support

Screw

switching from one set of leveling screws

to the other until the post is level. Always

align the level with the screws you are

adjusting.

4. Once the post is level, evenly tighten the

leveling screws to secure it.

NOTE This is the initial leveling of

the post. The system requires a final

level after everything is installed.

For final leveling instructions, see

“Level the System” on page 77.

Install the Support Center

Install the Support Center

1. Wrap the support center tubing bundle

around your arm and lift the support

center out of the box.

2. Remove the covers from the support

center.

3. Place the support center over the support

center post with the water bottle

connection toward the toe of the chair.

CAUTION Be careful to clear all

wires and tubing so they stay on

the open side of the support

center frame and do not get

pinched or kinked.

4. Slide the support center down the post

until its frame rests on the support

screws on the support center post.

Figure 15. Position the Support Center

86.0087.00 Rev E

11

Page 12

A-dec 300 System Installation Guide

Position ing

guide must

clear armrest.

Position ing

Guide

5. Align the support center depending on

the configuration of the system:

○ If you have an A-dec 300 system that

includes a cuspidor, align the support

center so the positioning guide clears

the armrest. Use the jumper and test

points to move the chair up and down

when testing clearance.

WARNIN G The positioning

guide must clear the armrest to

provide the proper clearance of

1-1/8" (29 mm) between the

cuspidor bowl and armrest.

○ If you have a base mount system

without a cuspidor, or a post mount

system, align the support center so it

is parallel to the dental chair.

Figure 16. Ensure the Positioning Guide Clears the Armrest

12 86.0087.00 Rev E

Page 13

Install the Support Center

Install two

1-1/2" Socket

Head Screws.

Button Head Screw

Use a 5/16" hex key driver to

apply 13 ft-lb (1.8 m-kgs) of

torque pressure to the screws.

Chair-Base Mount

Utilities Area

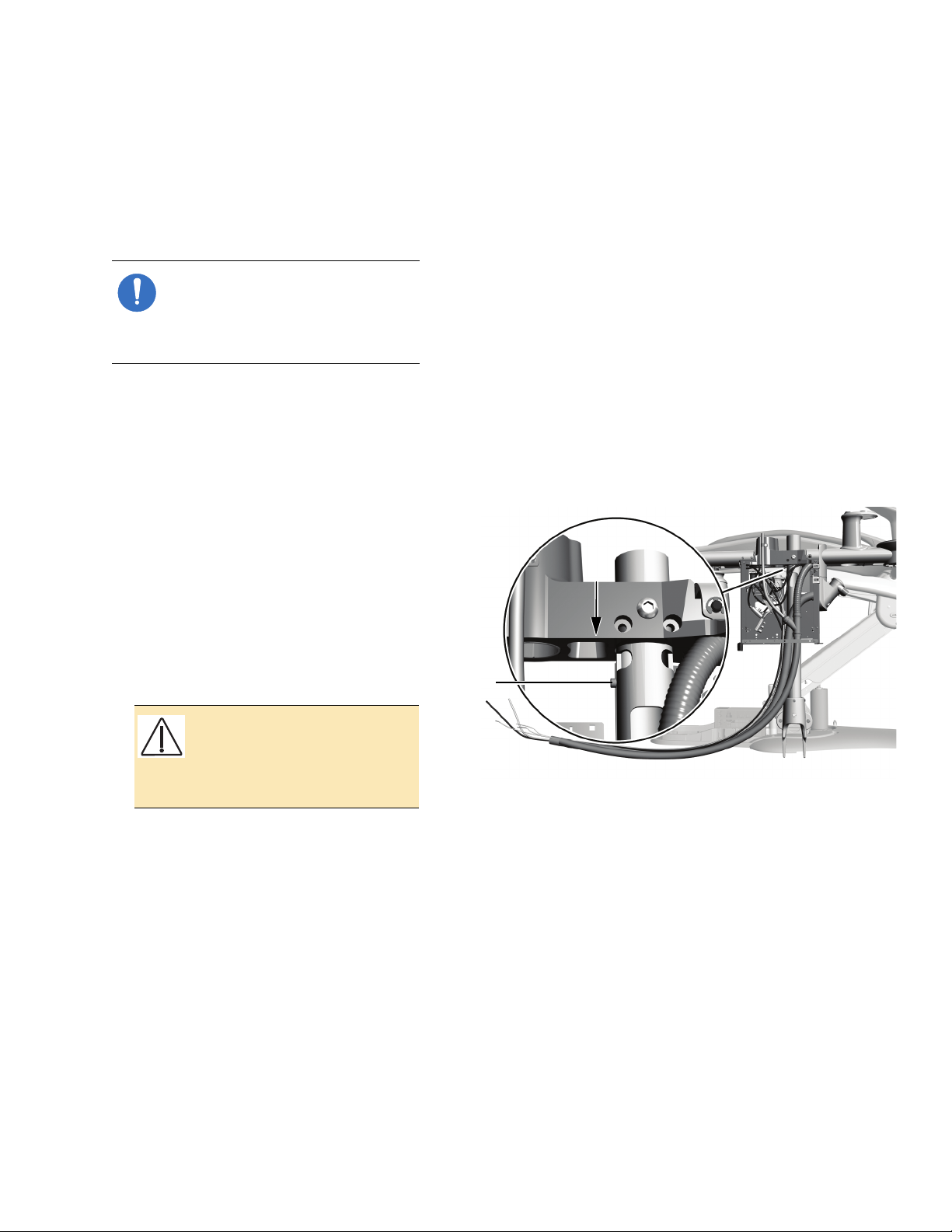

6. Use a 5/16" hex key driver to tighten the

button-head screw. While tightening the

screw, ensure the positioning guide

retains its clearance of the armrest.

CAUTION To ensure that the

button-head screw is properly

tightened, use approximately

13 ft-lb. (1.8 m-kgs) of torque.

NOTE If you have a post mount

system, you are finished

installing the support center.

Skip to the note after step 9 for

instructions on routing tubing

and wiring.

7. Use a 5/16" hex key driver to install each

of the two 1-1/2" socket head screws

until they are touching the back of the

holes in the support center post.

8. Alternately tighten both socket head

screws until they are firmly secure (use

approximately 13 ft-lb.

[1.8 m-kgs] of torque). While tightening

the screws, ensure the positioning guide

retains its clearance of the armrest.

9. Route the support center tubing and

wiring through the chair-base mount into

the utilities area at the base of the chair.

Figure 17. Secure the Support Center

Figure 18. Route the Support Center Tubing Bundle

86.0087.00 Rev E

NOTE If you are installing a

post mount system, remove the

Y-connector from the data line

before routing the tubing. (The

Y-connector is provided to

connect to multiple data

communication system devices.)

Route the tubing and wiring

from the bottom of the support

center through the convolute

into the remote floor box.

If you are installing a post mount

system on an A-dec 511 chair,

13

Page 14

A-dec 300 System Installation Guide

1/2" (13mm)

Support

Center

Frame

Cuspidor

Ventilation

Tu be

separate the power cables and

data line from the tubing group

and route them from the support

center, underneath the mount,

and down the lift arm to the

power supply. Route the rest of

the tubing bundle through the

convolute into the remote floor

box.

For information about installing

the remote floor box, see “Install

the Remote Floor Box” on

page 39.

CAUTION Once you’ve completed

installing the support center, verify

that the end of the cuspidor

ventilation tube is 1/2" (13 mm)

above the support center frame.

This ensures that the cuspidor

drains properly.

Install the Moisture Separator (Optional)

To install the moisture separator, use the

directions included in the moisture

separator kit (p/n 41.1477.00); then see

“Connect the Utilities” on page 40.

Figure 19. Verify the Cuspidor Ventilation Tubing Position

14 86.0087.00 Rev E

Page 15

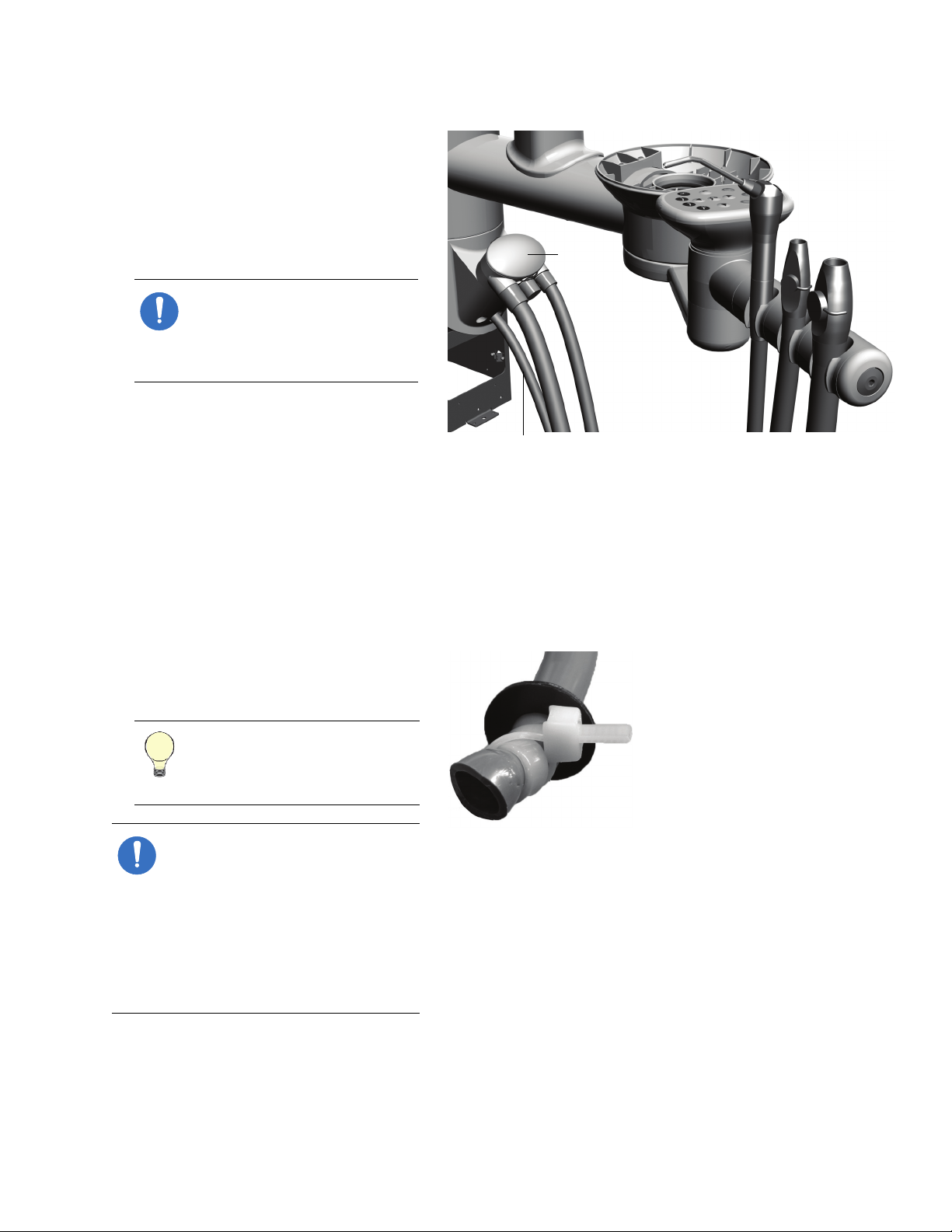

I NSTALL THE

A-dec 352 Telescoping

Assistant’s Instrumentation

with Optional Touchpad

A-dec 351 Radius-Style

Assistant’s Instrumentation

with Touchpad

A-dec 353

Cuspidor-Mounted

Assistant’s Instrumentation

with Optional Touchpad

SSISTANT' S

A

Install the Assistant's Instrumentation

I NSTRUMENTATION

Assistant’s instrumentation can be mounted

three ways.

Radius

Cuspidor-Mounted (353) . . . . . . . . . . 18

Telescoping (352) . . . . . . . . . . . . . . 20

®

-Style (351) . . . . . . . . . . . . . 16

Figure 20. Assistant’s Instrumentation

86.0087.00 Rev E

15

Page 16

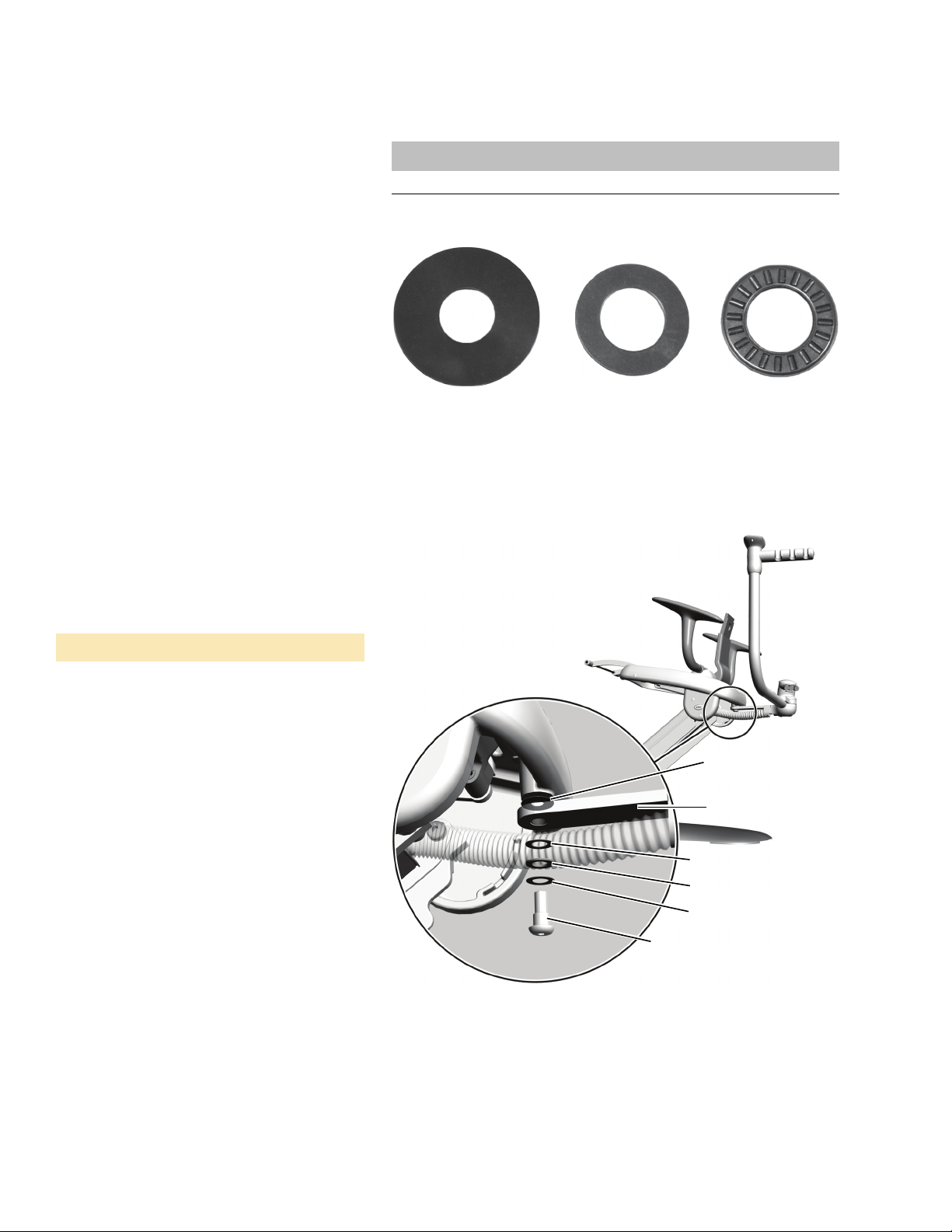

A-dec 300 System Installation Guide

Flat Washer Bearing

Nylatron Washer

Flat Washer

Bearing

Flat Washer

Assistant’s

Instrumentation Arm

Nylatron Washer

Screw

Install a Radius-Style Assistant’s Instrumentation (351)

Install the Assistant’s Instrumentation Arm

1. Slide the bearing and two washers from

the kit onto the screw.

2. Insert the screw through the hole in the

assistant’s instrumentation arm.

3. Slide the Nylatron

screw.

®

washer onto the

Tools Needed For This Section

Hex key set

Figure 21. Types of Washers Used

Figure 22. Install the Assistant’s Instrumentation Arm

4. Put Loctite® on the end of the screw.

5. Use a 1/4" hex key to securely tighten the

arm to the chair. The arm should rotate

smoothly and not drift.

6. Place the syringe in its holder on the

assistant’s instrumentation.

7. Place the high volume evacuation (HVE)

and saliva ejector in their holders; then

attach their tubing to the vacuum

canister.

16 86.0087.00 Rev E

Page 17

Install the Assistant's Instrumentation

Overflow

Bottle

Plate

Loosen

Middle

Screw

Notch

To p

Mount

Screw

Tu bi ng

and

Cables

Vacuum

Line

Clear

Hydraulic

Line

Cable Tie

to These

Blocks

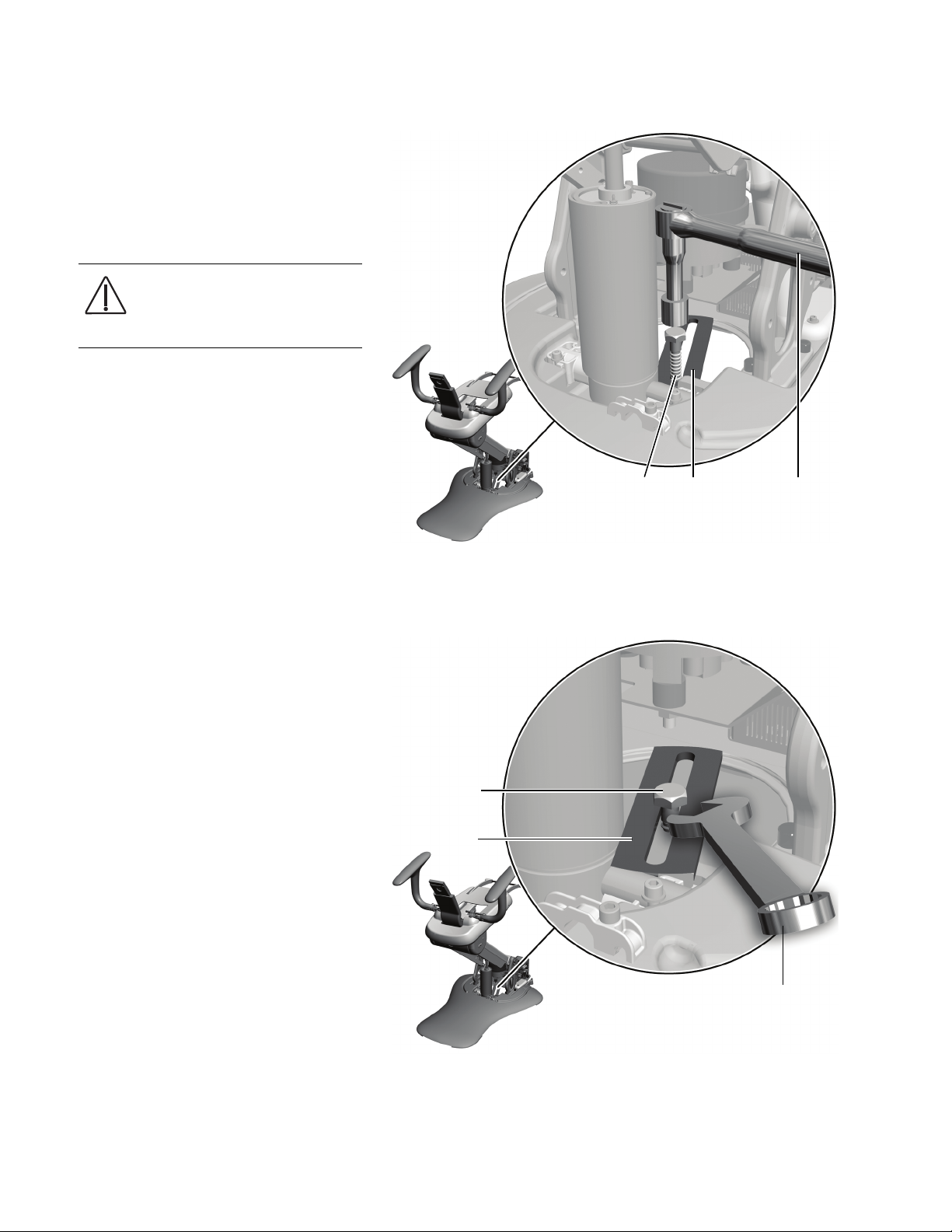

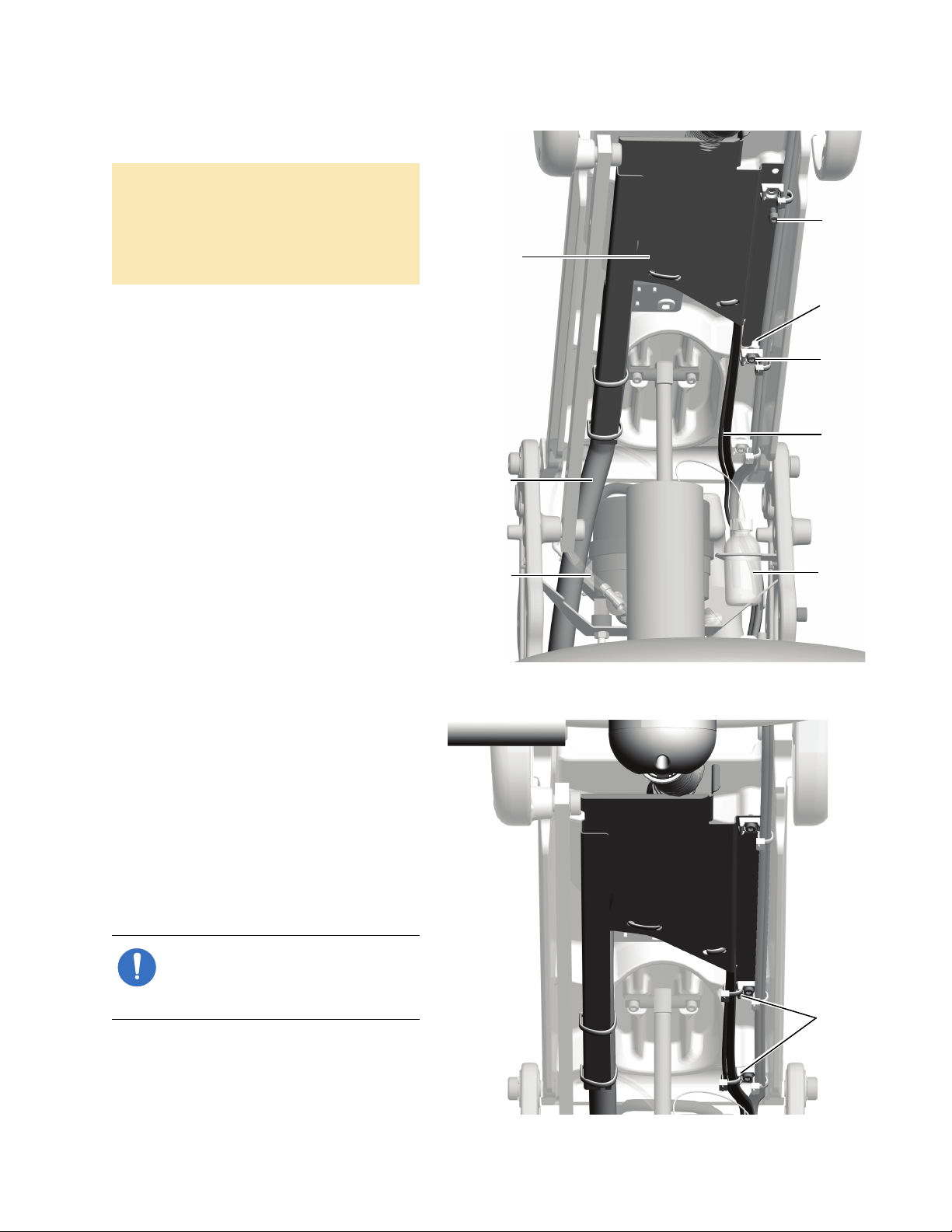

Route the Tubing, Cables, and Lines

1. From the back of the chair, route the

vacuum line to the left of the lift cylinder

and above the clear hydraulic tubing.

2. Route the tubing, power cables, and data

line to the right of the lift cylinder and

above the overflow bottle.

3. Use a 3/16" hex key to loosen the socket

head screw securing the middle white

mounting block.

4. Remove the top screw and mounting

block.

5. Slide the notch in the plate between the

middle mounting block and the lift arm.

6. Replace the top screw and mounting

block. Make sure the screw is securely

tightened.

7. Tighten the middle socket head screw.

Figure 23. Install the Assistant’s Instrumentation Plate

8. Cable tie the tubing, power cables, and

data line to the bottom two mounting

blocks.

Figure 24. Cable Tie the Tubing and Wires

9. Route the syringe tubing between the

motor pump and the wire cover, then

behind the power supply.

10.Route the power cables and data line to

the chair circuit board.

NOTE If the system does not

include other modules, go to “Install

the Contoured Floor Box” on

page 37.

86.0087.00 Rev E

17

Page 18

A-dec 300 System Installation Guide

WAGO

Connectors

Data

Ports

Data Line and Power Cable

Fit in Cuspidor Grooves

1/4-20 x 1" - Goes in

the Middle Hole

10-32 x 5/8" - Goes in

the Recessed Hole

Install a Cuspidor-Mounted Assistant’s Instrumentation (353)

1. Use diagonal cutters to cut the cable tie

and remove the positioning guide.

NOTE Save the positioning

guide and the foam plug holding

it in the cuspidor bowl support.

You will need it later to verify

proper clearance between the

cuspidor bowl and armrest. For

more information, see “Verify

Proper Clearance Between the

Cuspidor Bowl and the Armrest”

on page 94.

2. If the system includes an AVS, use a 1/8"

hex key to remove the two screws

connecting the toggle assembly to the

bottom of the cuspidor bowl support.

3. If the assistant's instrumentation includes

a touchpad, route the power cable and

data line up through the cuspidor holder.

For the wires to fit properly, place the

power cable into the grooves first then

the data line.

4. Place the assistant's instrumentation

under the cuspidor holder and angle it

away from the chair so that the post fits

into the hole in the bottom of the

cuspidor bowl support.

5. To attach the assistant’s instrumentation

to the bottom of the cuspidor holder, use

a 3/16" hex key to install the 1/4-20 x 1"

screw in the middle and a 5/32" hex key

to install the 10-32 x 5/8" screw in the

large recessed hole that is off center.

6. If you disconnected the AVS toggle

assembly in step 2, reconnect it now.

Tools Needed For This Section

Diagonal cutters Sleeve pusher

Hex key set

Figure 25. Routing with a Touchpad Viewed From Below

Figure 26. Routing with a Touchpad Viewed From Above

Figure 27. Socket Head Screws (Actual Size Shown)

18 86.0087.00 Rev E

Page 19

Install the Assistant's Instrumentation

Vacuum

Canister

Syringe

Tu bi ng

7. If the system includes a touchpad, route

the data line and power cable through

the support center (see Figure 25 on

page 18).

8. Place the high volume evacuation (HVE)

and saliva ejector in their holders; then

attach their tubing to the vacuum

canister.

NOTE If the system includes an

AVS, the HVE and saliva ejector

are installed before the product

is shipped and cannot be

removed.

9. Place the syringe in the holder and route

its tubing under the vacuum canister

through the center hole.

Figure 28. Route the HVE, Saliva Ejector, and Syringe Tubing

10.Use a cable tie and a washer to create a

strain relief for the syringe tubing. Make

a double loop with the cable tie to firmly

hold the tubing.

TIP When setting the strain

relief, leave enough tubing to

match the drape of the

instrument tubing.

NOTE If the system does not

include other modules, go to the

section for the system’s

configuration:

• Base Mount System - “Install the

Contoured Floor Box” on

page 37

• Post Mount System - “Install the

Remote Floor Box” on page 39

Figure 29. Install the Strain Relief for the Assistant’s Syringe

86.0087.00 Rev E

19

Page 20

A-dec 300 System Installation Guide

Stop

Toe of the Chair

Wave Washer

Assistant’s

Holder

Assembly

Sheath

Install an Assistant’s Instrumentation Mounted on a Telescoping Arm (352)

1. Use a 3/16" hex key and three 1" socket

head screws to mount the hub for the

telescoping arm on the support center.

The stop on the hub goes toward the toe

of the chair.

2. Push the sheath onto the barb on the

bottom of the assistant’s holder

assembly.

3. Set the assistant’s arm on the hub.

4. Push down one end of the wave washer

and catch it on the hub ridge. Continue

to work systematically around the hub to

push the washer down until it is

completely installed.

5. Place the HVE and saliva ejector in their

holders; then attach their tubing to the

vacuum canister.

6. If the system includes a touchpad:

(1) Route the touchpad tubing under the

vacuum canister through the hole on

the right (it is the largest hole).

Tools Needed For This Section

3/16" hex key Sleeve pusher

Diagonal cutters

Figure 30. Install the Telescoping Arm Hub

Figure 31. Install the Telescoping Arm

Figure 32. Install the Strain Relief for the Touchpad Tubing

(2) Install the strain relief by placing the

washer on the tubing then inserting

the bushing into the tube.

TIP When setting the strain

relief, leave enough tubing to

match the drape of the

instrument tubing.

20 86.0087.00 Rev E

Page 21

Install the Assistant's Instrumentation

WAGO

Connectors

Syringe

Tu bi ng

(3) Route the data line and power cables

through the support center.

7. Place the syringe in the holder and route

its tubing under the vacuum canister

through the center hole (see Figure 31 on

page 20).

Figure 33. Route the Data Line and Power Cables

Figure 34. Route the Syringe Tubing

8. Use a cable tie and a washer to create a

strain relief for the syringe tubing. Make

a double loop with the cable tie to firmly

hold the tubing.

TIP When setting the strain

relief, leave enough tubing to

match the drape of the

instrument tubing.

NOTE If the system does not

include other modules, go to the

section for the system’s

configuration:

• Base Mount System - “Install the

Contoured Floor Box” on

page 37

• Post Mount System - “Install the

Remote Floor Box” on page 39

Figure 35. Install the Strain Relief for the Assistant’s Syringe

86.0087.00 Rev E

21

Page 22

A-dec 300 System Installation Guide

A-dec 335 Continental Delivery System

mounted on a Support Center

A-dec 332 Radius-Style Traditional Delivery System

I NSTALL THE D ELIVERY SYSTEM

The A-dec 300 system can be configured

with a Traditional or Continental delivery

system. The installation steps are the same

for both of them.

Delivery systems can be Radius-style or

mounted on a support center.

Radius-Style (332 & 333) . . . . . . . . . . 23

Support Center Mounted (354 & 335) . 29

Figure 36. Delivery Systems

22 86.0087.00 Rev E

Page 23

Install a Radius-Style

Cable

Tie

Post

Clear Tubing

Install the Delivery System

Delivery System

(332 & 333)

Install the Rigid Arm

1. Raise the chair all the way up.

2. Turn off the power.

3. Cut the cable tie holding the clear

hydraulic tubing that goes from the lift

cylinder to the motor pump.

4. Push the tubing back so that it is behind

the post on the chair tower.

Tools Needed For This Section

Hex key set Diagonal cutters

Sleeve pusher Adjustable wrench

Tape measure

Figure 37. Prepare the Chair Tower

86.0087.00 Rev E

23

Page 24

A-dec 300 System Installation Guide

Chair

To we r

Front Mount Casting

Post

Clear Hydraulic Tubing

Positioned Between the Post

and Axle for the Link Arm

Mount Bolts

Notches

5. Place the notches in the front mount

casting over the posts on the chair

towers.

CAUTION Make sure all tubing

and wiring are away from the

posts so they do not get pinched.

6. While holding the rigid arm in place,

install the front bolt then the back bolt on

one side and finger tighten.

7. Install the bolts on the other side; then

use a 5/16" hex key to securely tighten all

bolts.

Figure 38. Install the Rigid Arm

24 86.0087.00 Rev E

Page 25

Install the Delivery System

Mount Screw

Water Bottle

Housing

Rigid Arm

Hole

Flexarm

Rigid Arm

Tubing Bundle

Tr i m R i n g

Install the Water Bottle

1. Use a 1/8" hex key to loosen the screw

below the hole in the rigid arm.

2. Route the water bottle tubing into the

hole, through the arm and out the

bottom.

3. Slide the water bottle housing down over

the mount screw and secure it to the arm.

Figure 39. Install the Water Bottle

Install the Flexarm and Control Head

1. Cut the cable tie holding the trim ring to

the delivery system tubing bundle.

2. Remove the delivery system from the

box and balance it over your shoulder,

with the control head in back of you, so

one hand is free to route the tubing

bundle.

3. Route the delivery system tubing bundle

down through the rigid arm.

TIP To keep Traditional delivery

system handpiece tubing out of

the way, wrap them around the

control head before installing the

flexarm.

4. Insert the flex arm into the rigid arm

until it is fully seated.

Figure 40. Install the Flexarm

86.0087.00 Rev E

25

Page 26

A-dec 300 System Installation Guide

Install and Tighten

1/4-20 x 1/2"

Leveling Screw

Loosen

Button Head

Screw

Hole for Missing

Leveling Screw

Install 3/8"

Setscrew

1/4-20 x 1/2"

Leveling Screw

5/16-18 x 3/8"

Setscrew

Adjustment Key

Whip Hook

5. Use a 5/32" hex key to loosen the

button-head screw that holds the control

head’s position.

6. Rotate the control head so it is positioned

over the hole for the missing leveling

screw.

7. To hold the control head in place, use a

5/32" hex key to install and tighten the

1/4-20 x 1/2" leveling screw.

8. Use a 5/32" hex key to install the 3/8"

setscrew.

Figure 41. Install the Control Head

Figure 42. Leveling and Setscrews (Actual Size Shown)

9. Place the handpiece tubing in their

holders and insert the adjustment keys

into their holes on the side of the control

head.

26 86.0087.00 Rev E

NOTE If you are installing a

Continental delivery system,

insert the whip hooks into the

whips. The top ends of the

whip hooks face the front of the

control head.

Figure 43. Insert Whip Hooks and Adjustment Keys

Page 27

Install the Delivery System

Tubing Ridges

Face Up

Convolute

Secure with Cable Tie

Rigid Arm

Front Mount Casting

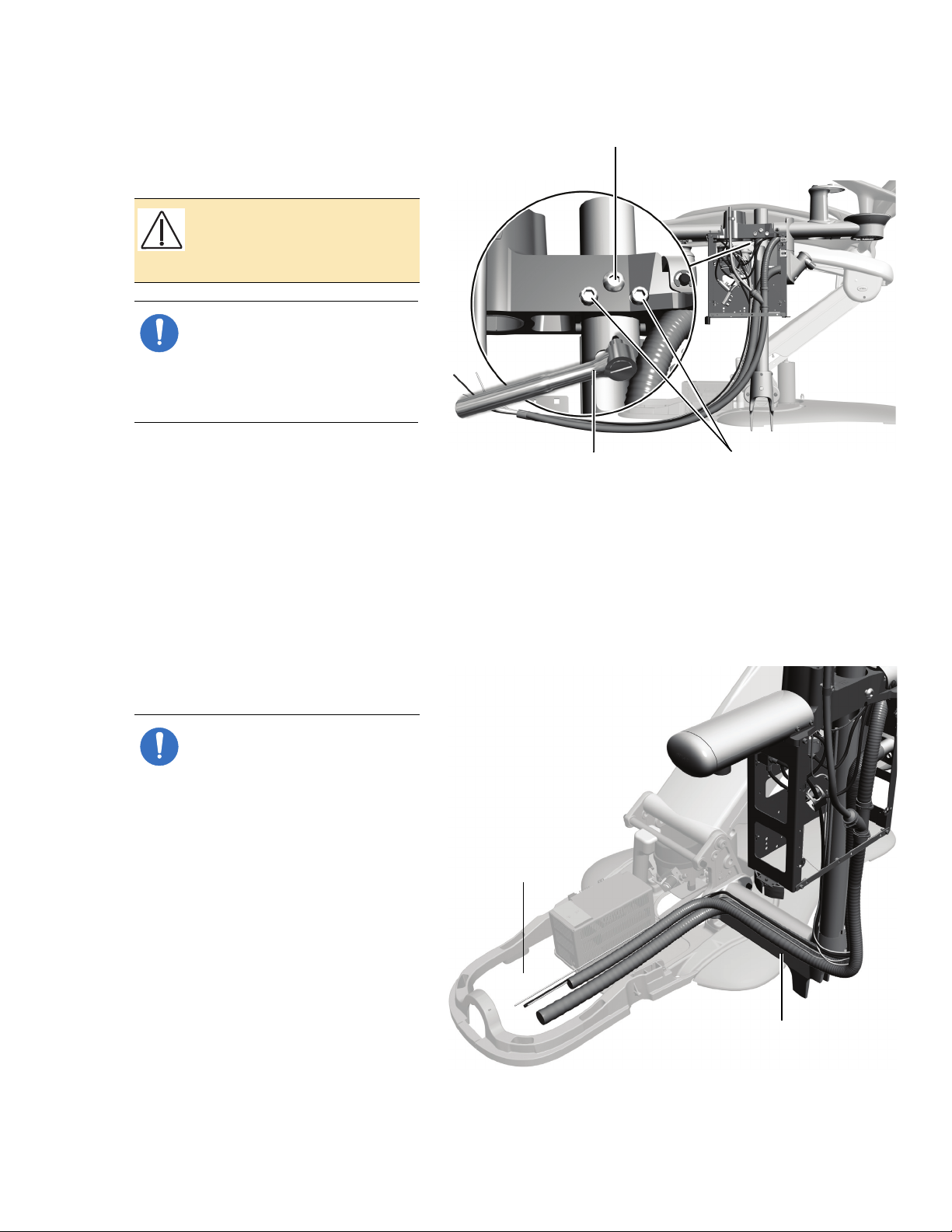

Route the Tubing and Wiring

1. From the back of the chair, route the

foot control tubing over the strain relief

and behind the power supply.

2. Measure three feet of the water bottle

tubing from where it comes out of the

rigid arm. Cut off the excess.

3. Strip the sheath around the water bottle

tubing back to the rigid arm.

TIP Mark the ends of the water

bottle tubing to distinguish them

from the delivery system tubing

when connecting the utilities.

4. Route both the water bottle and delivery

system tubing bundles through the

convolute (see Figure 45).

Figure 44. Route the Foot Control Tubing

5. Form a loop with a cable tie through the

two holes in the rigid arm.

6. Push the convolute about an inch (a few

centimeters) through the loop into the

rigid arm.

7. Tighten the cable tie to secure the

convolute.

Figure 45. Route the Tubing Bundles Through the Convolute

86.0087.00 Rev E

27

Page 28

A-dec 300 System Installation Guide

Water

Bottle and

Delivery

System

Tubi n g

Power Cabl es

and Data Line

Assistant’s Syringe

Tu b in g

Rigid Arm

Straight Out

Cable Tie

Front Mount

Hydraulic

Tubi n g

Foot Control

Tu bi ng

8. Remove the tape from the ends of the

water bottle and delivery system tubing.

9. Route the water bottle and delivery

system tubing up through the front

mount (be sure to go behind the black

hydraulic tubing) then down to behind

the power supply.

NOTE Improper routing of the

tubing can hinder the movement

of the delivery system rigid arm.

10.Route the delivery system power cables,

ground wire, and data line up through

the front mount and down to the chair

circuit board on the power supply.

11.If the system includes an assistant’s

instrumentation, route its syringe tubing

around the lift cylinder to behind the

power supply.

Arrange the Tubing

Figure 46. Route the Tubing and Wires

1. Position the rigid arm so that it is

2. Neatly gather the tubing. Cable tie it to

straight out from the middle of the chair,

in line with the front mount.

the chair tower.

NOTE If the system includes a tray

holder, see “Install the Tray Holder

(Optional)” on page 32. If not, go to

“Install the Contoured Floor Box”

on page 37.

28 86.0087.00 Rev E

Page 29

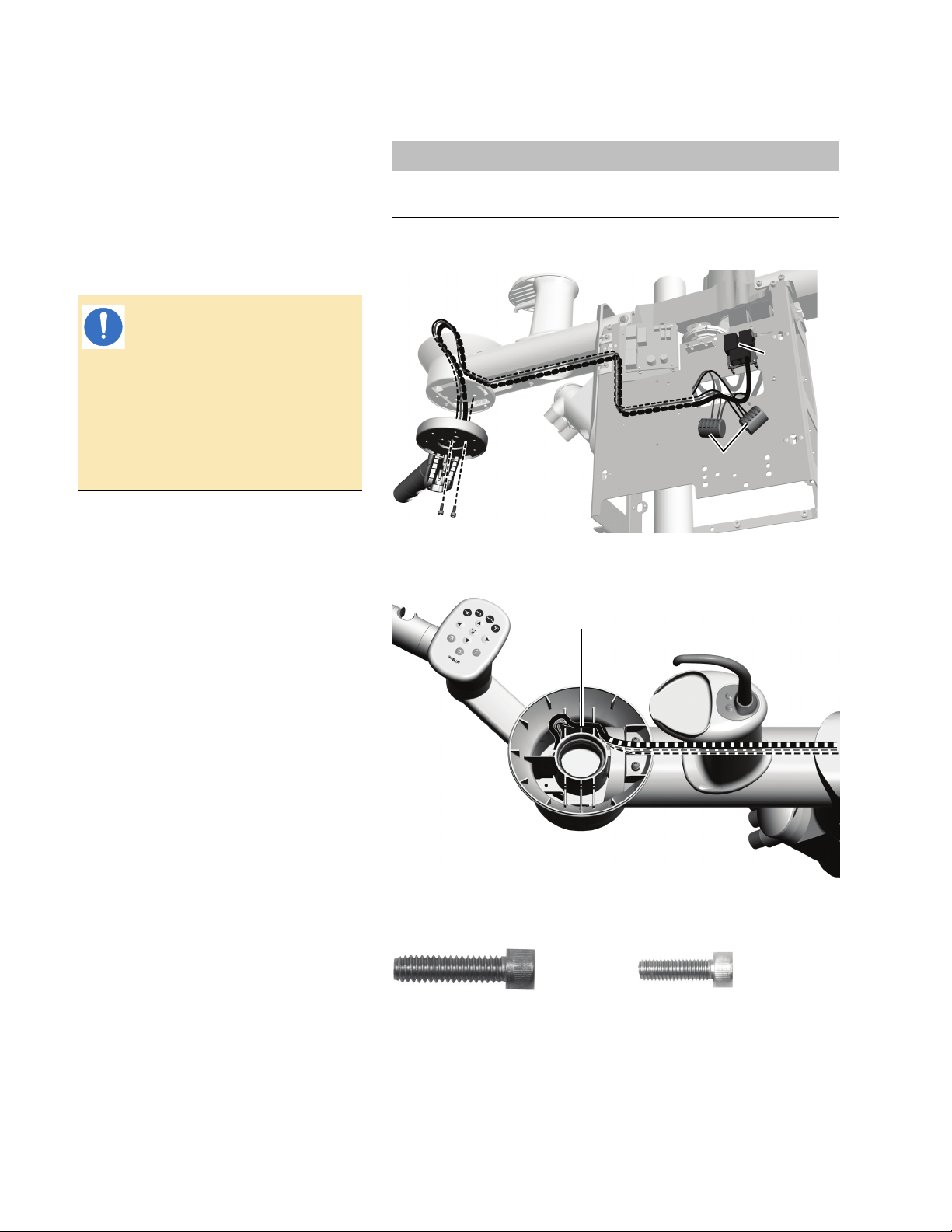

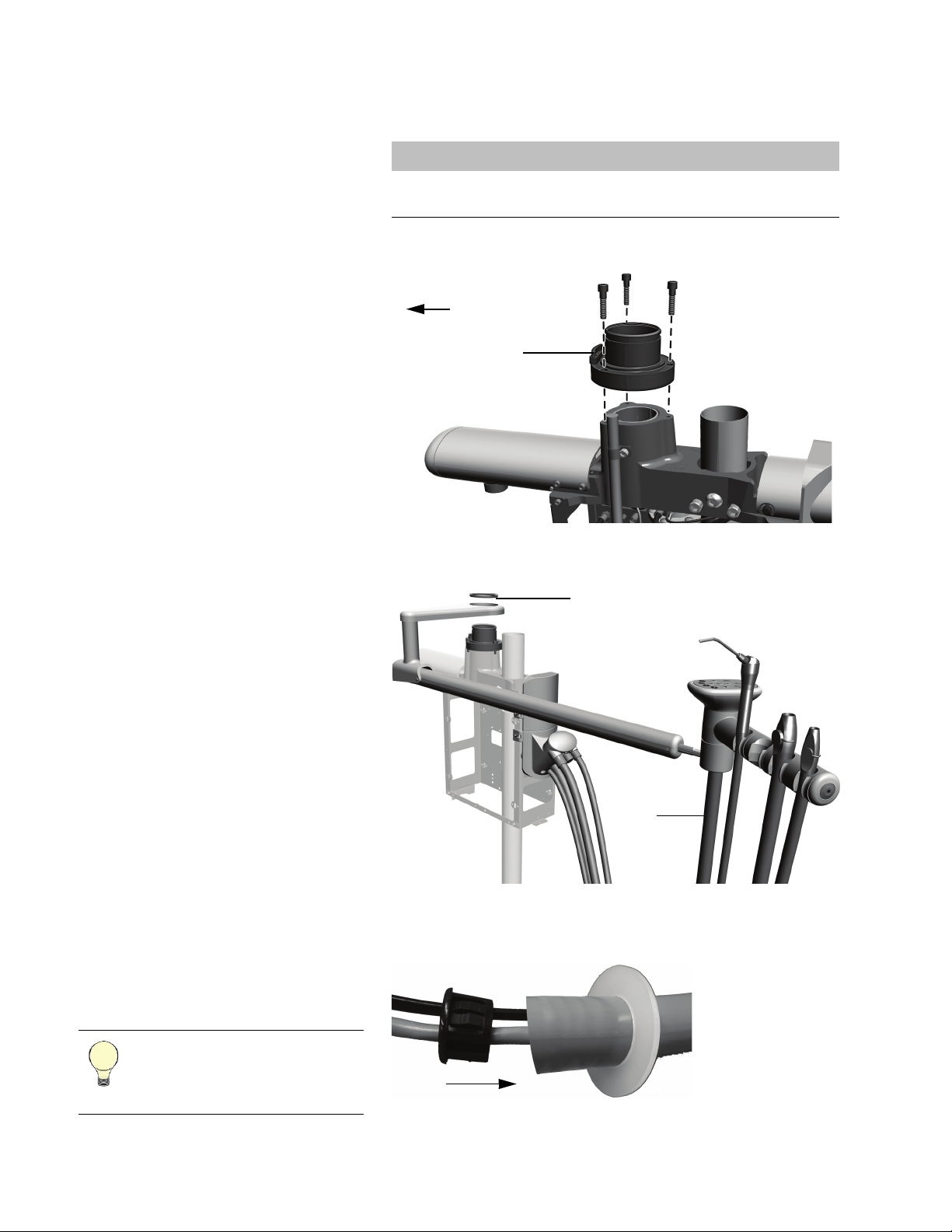

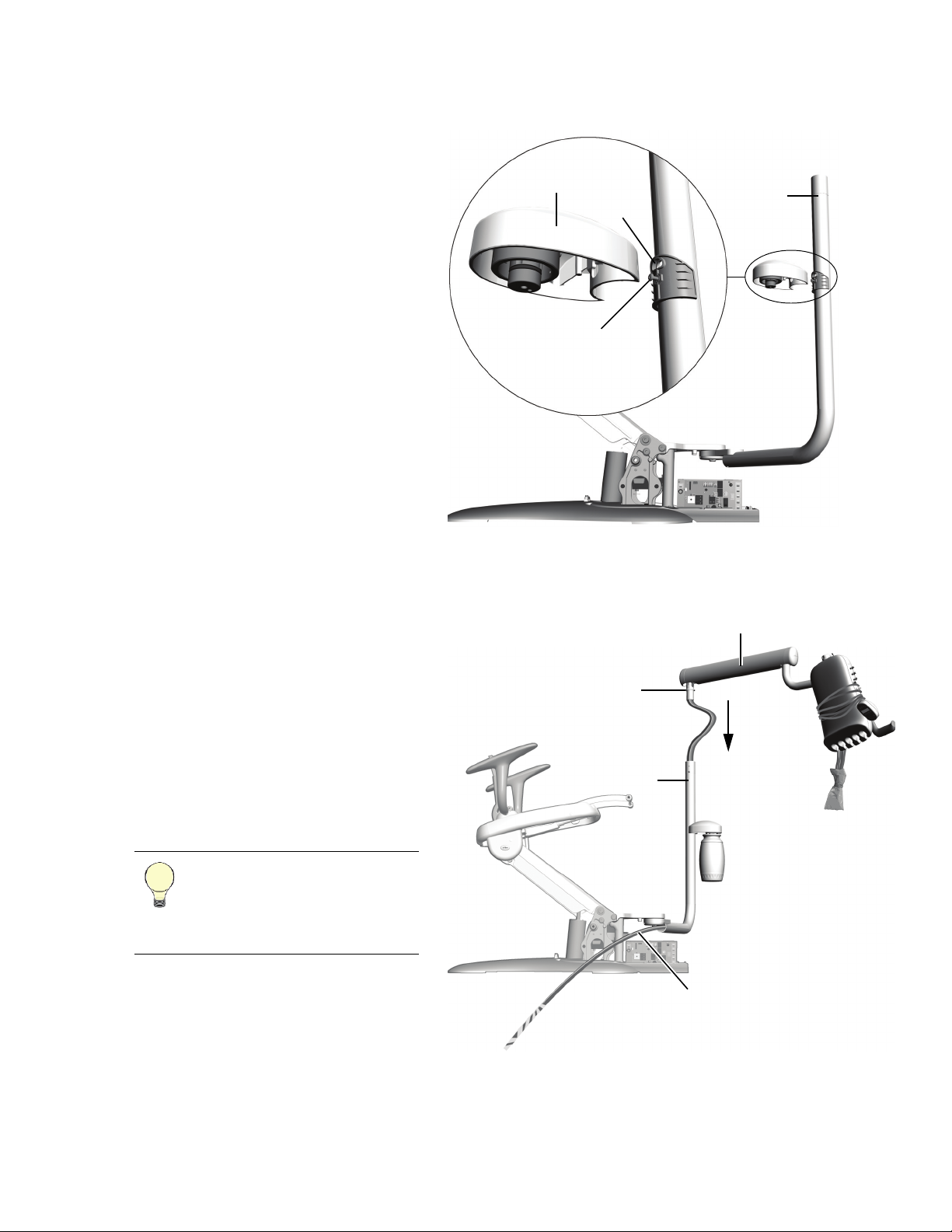

Install a Delivery System

This trim ring

ships on the

delivery system

post.

This trim ring

ships in the

assistant’s

instrumentation

box.

Trim Ring Used With Delivery System

Trim Ring Used With Delivery System and

Assistant’s Instrumentation Mounted on a

Telescoping Arm

Install the Delivery System

Mounted on a Support

Center (334 & 335)

Install the Components

1. Lower the chair. Turn off the power.

2. Ensure the correct trim ring is on the

delivery system post.

○ If the system includes a delivery

system but no assistant’s

instrumentation mounted on a

telescoping arm, use the top trim ring

in Figure 47.

○ If the system includes a delivery

system and assistant’s

instrumentation mounted on a

telescoping arm, use the bottom trim

ring in Figure 47.

Tools Needed For This Section

Hex key set Diagonal cutters

Adjustable wrench Sleeve pusher

Figure 47. Delivery System Post Trim Rings

86.0087.00 Rev E

29

Page 30

A-dec 300 System Installation Guide

Install and Tighten

1/4-20 x 1/2"

Leveling Screw

Loosen

Button Head

Screw

Hole For Missing

Leveling Screw

Install 3/8"

Setscrew

1/4-20 x 1/2"

Leveling Screw

3/8"

Setscrew

3. Remove the delivery system from the

box and balance it over your shoulder so

one hand is free to route the tubing

bundle.

The delivery system post inserts into the

support center in the post hole toward

the toe of the chair.

4. Route the tubing bundle into the support

center then insert the delivery system

post into the support center until it is

fully seated.

5. Use a 5/32" hex key to loosen the

button-head screw that holds the control

head’s position.

6. Rotate the control head so it is positioned

over the hole for the missing leveling

screw.

Figure 48. Carry the Delivery System

Figure 49. Install the Control Head

7. To hold the control head in place, use a

5/32" hex key to install and tighten the

1/4-20 x 1/2" leveling screw.

8. Use a 5/32" hex key to install the 3/8"

setscrew.

30 86.0087.00 Rev E

Figure 50. Leveling and Setscrews (Actual Size Shown)

Page 31

Install the Delivery System

Adjustment Key

Whip Hook

Tubing Ridges Face Up

9. Place the handpiece tubings in their

holders and insert the adjustment keys

into their holes on the side of the control

head.

NOTE If you are installing a

Continental delivery system, insert

the whip hooks into the whips. The

top ends of the whip hooks face the

front of the control head.

Route the Foot Control Tubing

1. Raise the chair all the way up.

2. From the back of the chair, route the

foot control tubing through the chairbase mount and up into the support

center.

Figure 51. Insert Whip Hooks and Adjustment Keys

Figure 52. Route the Foot Control Tubing

NOTE If you have a post mount

system, the foot control tubing

routes through a hole in the

bracket in the bottom of the

support center that holds the

convolute.

If the system includes a tray holder,

see “Install the Tray Holder

(Optional)” on the next page. If not,

go to the section for the system

configuration:

• Base Mount System - “Install the

Contoured Floor Box” on page 37

• Post Mount System - “Install the

Remote Floor Box” on page 39

86.0087.00 Rev E

31

Page 32

A-dec 300 System Installation Guide

Tra y Mo u n t

Location

Install the Tray Holder (Optional)

To install the tray holder, select the type of

delivery system and complete the steps.

Continental Delivery System

Use a 5/32" hex key and three 10-32 x 3/4"

screws to attach the mount arm to the

middle of the bottom of the control head.

Figure 53. Tray Mount Position on a Continental Control Head

32 86.0087.00 Rev E

Page 33

Install the Delivery System

Tr a y H o l d e rMount Arm

When installing a large tray holder, face the four screw holes in

the mount away from the side of the control head.

Mount

Four

Screw

Holes

Tr a y M o u n t

Locations

When installing a small tray holder, face the four screw holes in

the mount toward the front of the control head.

Tra y

Holder

Mount

Arm

Mount

Four

Screw

Holes

Tra y Mo u n t

Locations

Traditional Delivery System

NOTE Large tray holders attach to

mount arms in a different

orientation than small tray holders.

For proper orientation, see Figure 54

and Figure 55.

1. Use a 1/8" hex key and the 10-32 x

1/2" screws to attach the bottom of the

tray holder to the mount arm.

CAUTION Do not over tighten

the screws or you may damage

the surface of the tray or break

the mount.

2. Use a 1/8" hex key and two 10-32 x

1" button head screws to attach the

mount arm to the side of the bottom of

the control head.

TIP While the tray holder can be

installed on either side of the

control head, it is helpful to

mount it on the side opposite of

the adjustment keys to provide

better access to the keys.

Figure 54. Install a Large Tray Holder

Figure 55. Install a Small Tray Holder

NOTE If the system does not

include other modules, go to the

section for the system’s

configuration:

• Base Mount System - “Install the

Contoured Floor Box” on

page 37

• Post Mount System - “Install the

86.0087.00 Rev E

Remote Floor Box” on page 39

33

Page 34

A-dec 300 System Installation Guide

Connect

Wires

Tr i m C o v e r

Plastic

Bearing

Intermediate

Post

Light Post

Chair-Base

Mount

Tri m Ri n g

Plug

Chair

Circuit

Board

I NSTALL THE D ENTAL LIGHT

The procedure for installing A-dec 371 or

A-dec 571 for 300 dental light components is

the same regardless of the type of chair they

are installed on. Routing and connecting the

light cable varies depending on the system

you are installing.

Install the Dental Light Components

1. Slide the trim ring onto the top of the

support center post then insert the

intermediate post into the support center

post.

Orient the plugged hole in the

intermediate post toward the toeboard.

NOTE When the post is fully

seated, there is still a gap

between the white painted

sections. The gap will be behind

the support center covers.

Tools Needed For This Section

Rubber mallet Phillips head screwdriver

Figure 56. A-dec 371 Dental Light

Figure 57. Install the Dental Light

2. Lightly tap the top of the intermediate

post with a rubber mallet. Do not hit it

too hard or it will be difficult to remove.

3. Insert the plastic bearing into the

intermediate post.

4. Place the trim cover on the light post.

5. Route the light cable into the

intermediate post.

6. Insert the light post into the intermediate

post until fully seated and slip the trim

cover down over the bearing and

intermediate post.

34 86.0087.00 Rev E

Page 35

Install the Dental Light

A-dec 371 Light Cable

A-dec 571 for 300 Light Cable

Chair Circuit Board

Route and Connect the Dental Light Cables

CAUTION Electric components on the circuit board are static sensitive and require handling precautions.

1. With the dental light components installed, finish routing the light cable through the bottom of the support

center and the chair-base mount to the chair circuit board in the utilities area below the chair (see Figure 57 on

the previous page).

2. Turn off the power.

3. Attach the dental light wires for the system’s type of light to their corresponding connections on the chair

circuit board.

○ A-dec 371 has black and violet wires which connect to terminal strip J5 plus black/white and white wires

that connect to terminal strip J6.

○ A-dec 571 for 300 has black and violet wires which connect to terminal strip J5 plus black/white, white,

blue, and yellow wires that connect to terminal strip J6.

Figure 58. Dental Light Wire Connections

NOTE If you have a post mount system, see the following documents that come with the kit for installing

the A-dec 371 or A-dec 571 for 300 light on those chairs:

• A-dec 511 Dental Chair - p/n 86.0119.00

• A-dec Cascade, Decade, Performer, or Priority Dental Chairs - p/n 86.0018.00

86.0087.00 Rev E

35

Page 36

A-dec 300 System Installation Guide

Mount Arm

Clamp

Slotted Plug

Toe of the Chair

Power and

Video

Cables

Thrust Washer

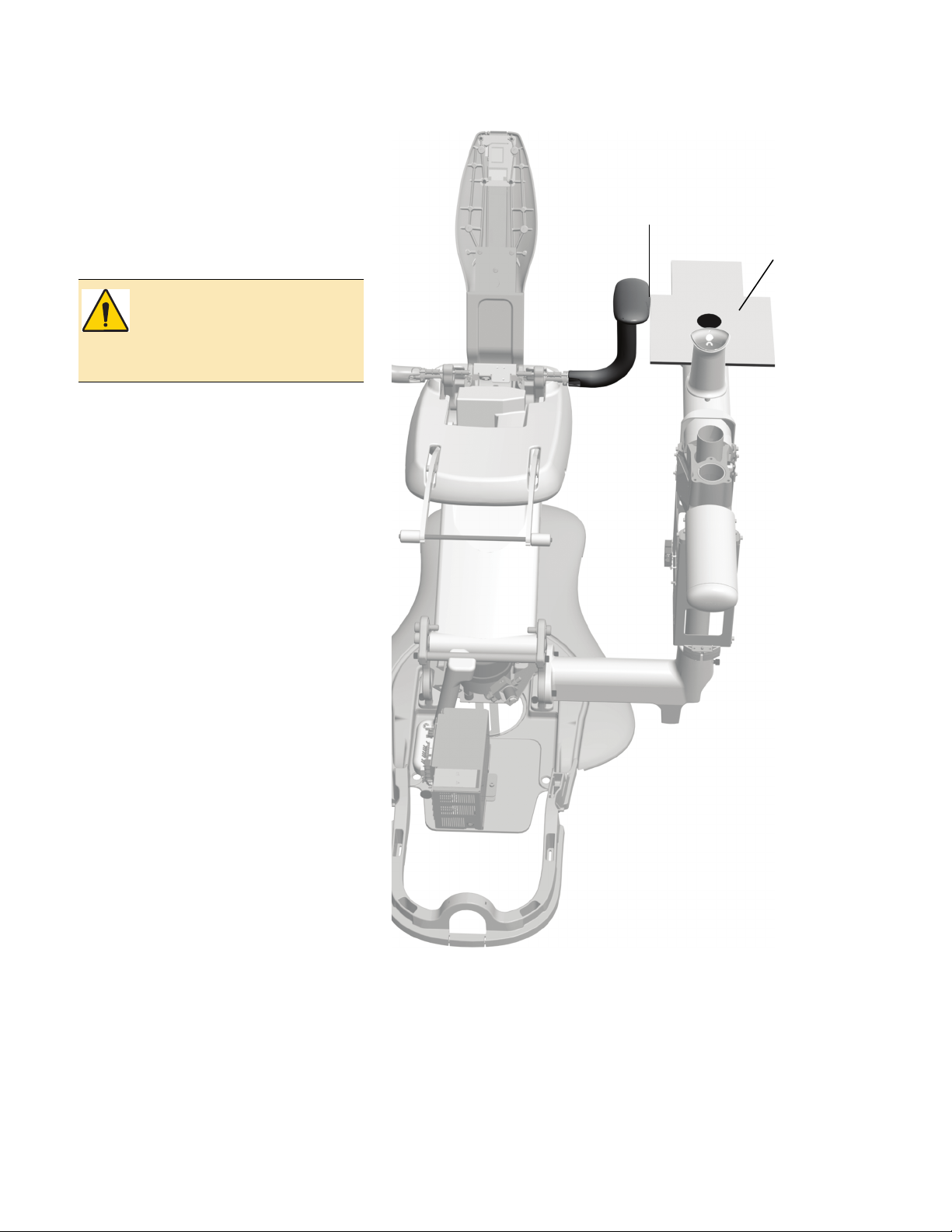

I NSTALL THE M ONITOR MOUNT

The monitor mount installs on the

intermediate post.

NOTE Monitor cables are not

supplied by A-dec.

1. Use a 5/32" hex key and four 3/4" socket

head screws to attach the clamp for the

monitor toward the top of the

intermediate post. Position the mounting

hole for the monitor arm toward the toe

of the chair.

2. Use a 1/8" hex key to remove the ends

from the monitor arm.

3. Route the power and video cables

through the arm and replace the end

caps.

4. Install the thrust washer on the post on

the end of the mount arm then insert the

post into the clamp.

Tools Needed For This Section

5/32" and 1/8" hex keys

Figure 59. Monitor Mount

Figure 60. Install the Monitor Mount

5. Route the cables down through the

6. Insert the slotted plug into the square

36 86.0087.00 Rev E

TIP To make it easier for the

monitor arm to fit in the clamp

and to avoid pinching the cables,

pull the cables back into the slot

of the monitor arm.

square hole in the intermediate post and

into the support center.

hole around the wires.

Page 37

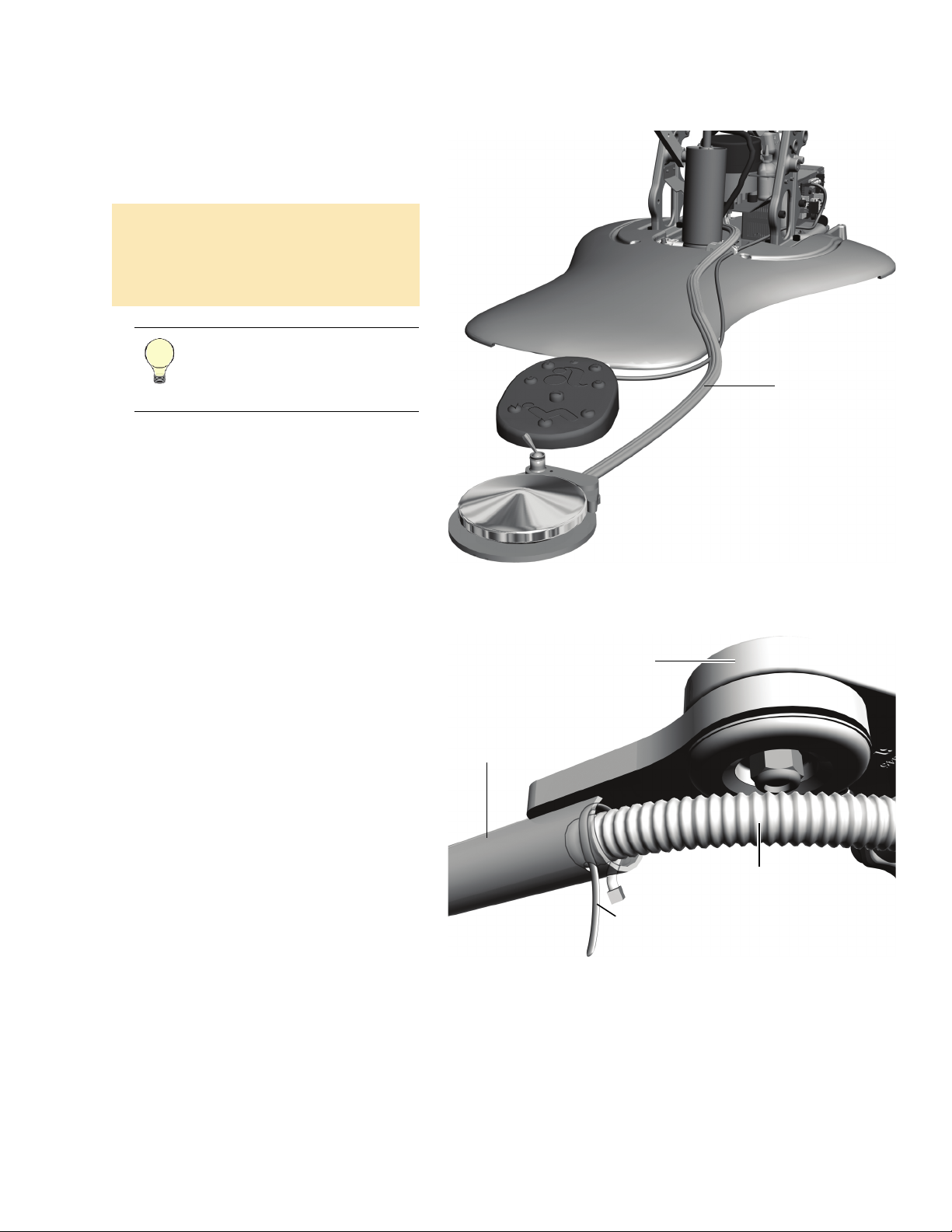

I NSTALL THE

Nothing can

extend into

this zone.

Contoured

Floor Box

Cover

Contoured Floor Box Frame

3"

76 mm

4.5"

114 mm

ONTOURED

C

F LOOR BOX

Install the Contoured Floor Box

Tools Needed For This Section

Tape measure 1/4" masonry drill bit

Phillips head screwdriver Sleeve pusher

Diagonal cutters Pliers

Install the Contoured Floor Box Frame

1. Place the contoured floor box frame

around the utilities, leaving at least

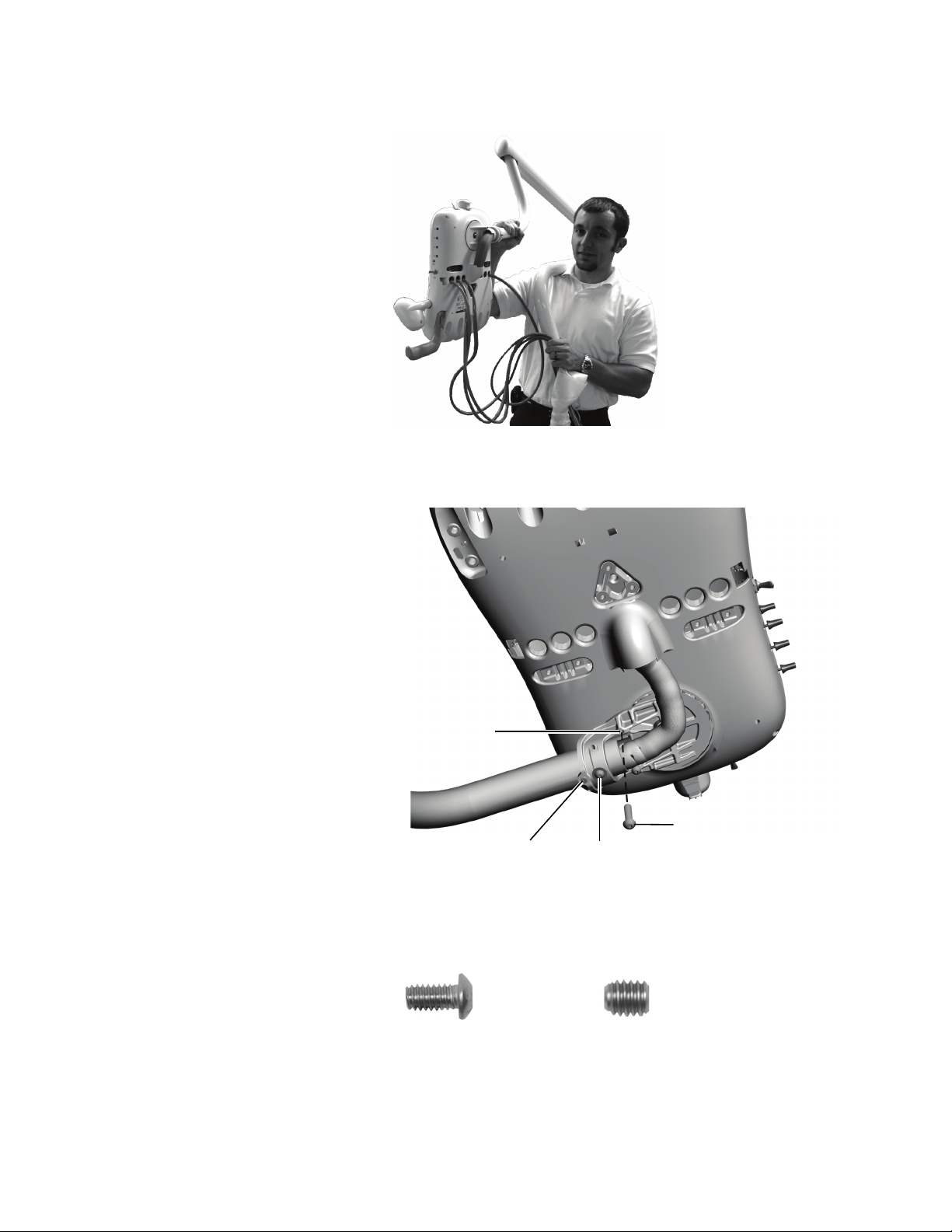

3" (76 mm) between any object that is

taller than 4.5" (114 mm) and the back of

the frame. Make sure that nothing

extends into the gray striped area in

Figure 61.

CAUTION Failure to provide

adequate space as described

above will prevent installation

of the power supply cover.

2. Attach the frame to the floor.

○ On a wood floor, use a Phillips head

screwdriver and 1-1/4" size #10

screws.

○ On a concrete floor, use a 1/4"

masonry drill bit to make holes where

the screws fit through the frame.

Insert the plastic anchors into the

holes; then use a Phillips head

screwdriver and 1-1/4" size #10

screws.

Figure 61. Contoured Floor Box Cover and Frame

86.0087.00 Rev E

37

Page 38

A-dec 300 System Installation Guide

ConvoluteCable Ties

Contoured Floor Box Frame

Power Supply Frame

Install the Convolute

1. Unplug the chair.

2. Measure the distance between the power

supply cover frame and the contoured

floor box cover frame and cut the

convolute to size.

TIP The convolute should

extend a few inches past each

frame so you can secure it to the

frames.

3. Route the convolute through the cable tie

in the power supply frame until it is

2" (5 cm) past the cable tie.

4. Use pliers to tighten the cable tie so it

securely holds the convolute. Trim the

excess tie.

5. Route the convolute through the cable tie

in the contoured floor box frame until it

is 2" (5 cm) past the cable tie.

6. Use pliers to tighten the cable tie so it

securely holds the convolute. Trim the

excess tie.

7. Route the tubing, power cord, and

vacuum line through the convolute.

Figure 62. Install the Convolute and Route the Utilities

You are ready to connect the system. See

“Connect the Utilities” on page 40 for

further instructions.

38 86.0087.00 Rev E

Page 39

I NSTALL THE

EMOTE FLOOR

R

B OX

Install the Remote Floor Box

Tools Needed For This Section

Diagonal cutters Phillips head screwdriver

5/64" hex key Sleeve pusher

1. Remove the protective layer from the

remote floor box; then position the floor

box over the utilities.

2. Measure the distance from the floor box

to the bottom of the support center and

cut the convolute to match that distance.

3. Use a Phillips head screwdriver and 6

size #10 screws to secure the floor box to

the floor.

You are ready to connect the system. See

“Connect the Utilities” on the next page for

further instructions.

Figure 63. Remote Floor Box

86.0087.00 Rev E

39

Page 40

A-dec 300 System Installation Guide

C ONNECT THE U TILITIES

See the section for the system’s

configuration.

Radius-Style Floor Box Utilities . . . . . 40

Radius-Style Modules . . . . . . . . . . . . 42

Radius-Style Assistant’s Instrumentation

(only) . . . . . . . . . . . . . . . . . . . . . . . 46

Support Center Power and Data . . . . . 47

Support Center Floor Box Utilities . . . 53

Support Center Modules . . . . . . . . . . 56

Radius-Style Floor Box Utilities

Radius-style modules connect to the utilities

in the contoured floor box. Use the umbilical

from the kit to complete the air and water

connections pictured in Figure 65.

CAUTION There is a blue tubing in

the umbilical from the kit.

Do not connect the blue tubing.

Figure 64. Radius-Style Modules with Contoured Floor Box Set

40 86.0087.00 Rev E

Page 41

Figure 65. Floor Box Tubing Connections for Radius-Style Modules

To t h e C h a i r B a s e

CAUTION Do not connect this blue tubing.

Umbilical from

the Kit

Connect the Utilities

86.0087.00 Rev E

41

Page 42

A-dec 300 System Installation Guide

Connect

Black

Wires

Connect

Gray

Wires

Plug In

Data

Lines

Connect

Ground

Wire

Mains

On/Off

Button

Blue Power Light Indicator

Cable

Ties

Radius-Style Modules

Connect the Power and Data

CAUTION Electric components on

the circuit board are static sensitive

and require handling precautions.

NOTE This procedure is for both

the assistant’s instrumentation and

the delivery system.

1. Turn off the power.

2. Use an adjustable wrench to attach the

delivery system’s ground wire to the

post on the power supply.

3. Connect the power cables to the chair

circuit board. The black wire connects to

0 VAC and the gray wire to 24 VAC.

4. Plug the data lines into any data port.

NOTE The top of the 311

power supply has a diagram of

the electrical connections for the

chair circuit board.

Figure 66. Electrical and Data Line Connections

5. Gather and cable tie the wiring.

NOTE Make sure the power

cables and data lines do not come

between the power indicator

light and the lens in the power

supply cover.

Figure 67. Properly Tied Wiring

42 86.0087.00 Rev E

Page 43

Connect the Tubing

Use the umbilical from the kit to complete

the air and water connections pictured in

Figure 68.

CAUTION There is a blue tubing in

the umbilical from the kit. Do not

connect the blue tubing.

NOTE When installing the water

manifold, be sure to connect to the

barb on the end to prevent standing

water in the manifold (see Figure 69

on page 45).

Connect the Utilities

86.0087.00 Rev E

43

Page 44

A-dec 300 System Installation Guide

To F l o o r B o x

To Assistant’s

Syringe

To F o o t C o n t r o l

Power Supply

To D e l i v e r y S y s t e m

With a Moisture Separator (Optional)

If the system includes a moisture separator, make the

connections in this gray area.

To install the moisture separator, use the directions

included in the moisture separator kit

(p/n 41.1477.00).

Umbilical from

the Kit

Pinch

Valve

CAUTION Do not

connect this blue tubing.

Figure 68. Radius-Style Modules Utility Connections

44 86.0087.00 Rev E

Page 45

Connect the Utilities

Make sure

to connect

to this barb.

Pinch Valve

Tubing Ridges Face Up

Remove This Sticker

6. If the system has an assistant’s

instrumentation, install the pinch valve

on the syringe yellow and red tubing.

7. Use a 3/16" hex key to secure the foot

control tubing to the chair base in the

strain relief.

NOTE For proper positioning, the

ridges on the foot control tubing

face up to match the grooves in the

strain relief.

Figure 69. Install the Pinch Valve

Figure 70. Secure the Foot Control Tubing

8. Carefully remove the sticker from the top

of the front mount.

Figure 71. Remove the Routing Sticker

86.0087.00 Rev E

45

Page 46

A-dec 300 System Installation Guide

Connect

Black

Wires

Connect

Gray

Wires

Plug In

Data

Lines

Syringe

Water

Syringe

Air

Pinch

Valve

Radius-Style Assistant’s Instrumentation (only)

Connect the Power and Data

CAUTION Electric components on

the circuit board are static sensitive

and require handling precautions.

1. Turn off the power.

2. Connect the power cables to the chair

circuit board. The black wire connects to

0 VAC and the gray wire to 24 VAC.

3. Plug the data lines into any data port.

Figure 72. Electrical and Data Line Connections

Connect the Tubing

1. Connect the utilities as shown in

Figure 73:

○ Use the umbilical from the kit to

complete the air connection.

○ Connect the water manifold to a

2. Install the pinch valve on the syringe

tubing.

3. For the rest of the utility connections, see

“Install the Contoured Floor Box” on

page 37 and the instructions that come

with the remote water bottle.

remote water bottle.

NOTE When installing the

water manifold, be sure to

connect to the barb on the end to

prevent standing water in the

manifold.

Figure 73. Route and Connect the Syringe Tubing

46 86.0087.00 Rev E

Page 47

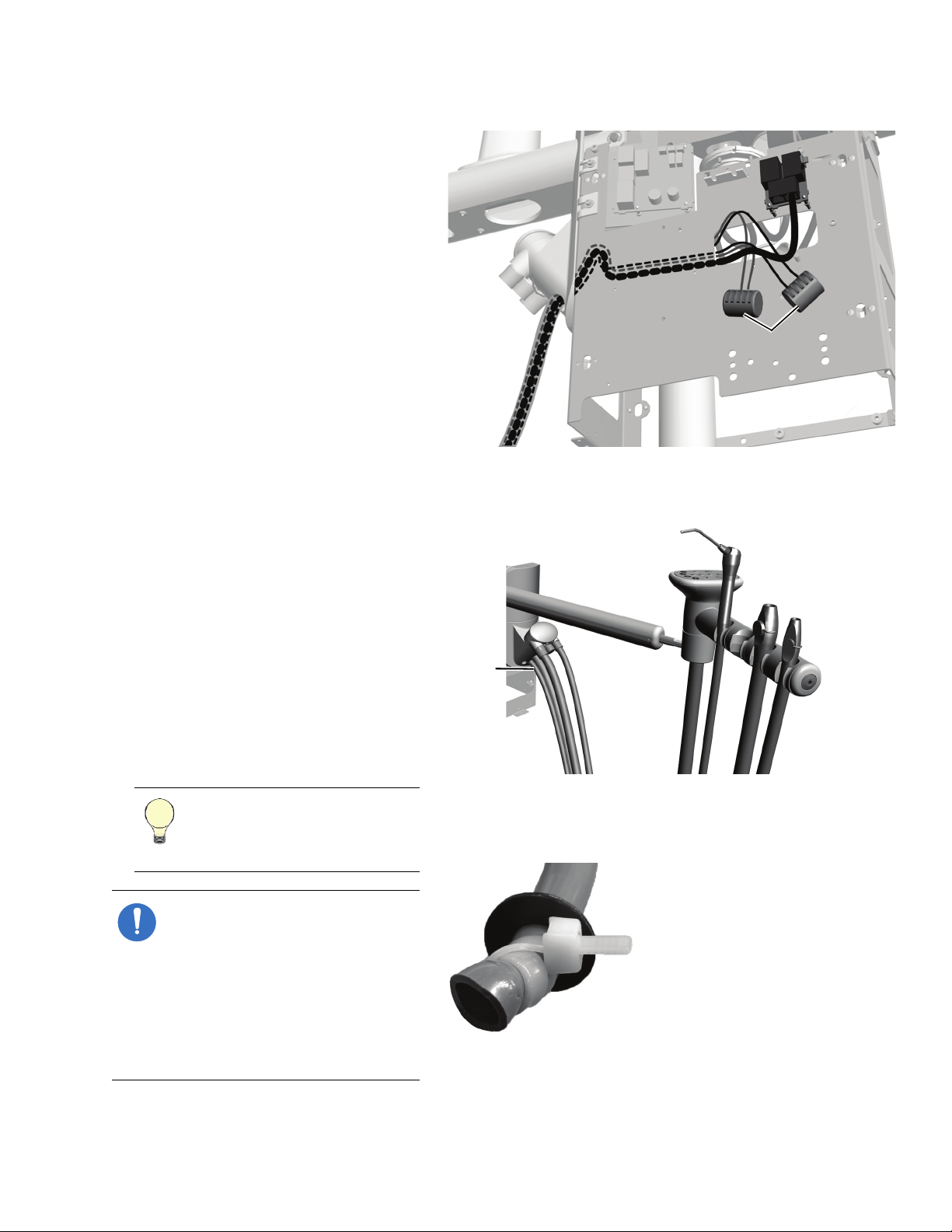

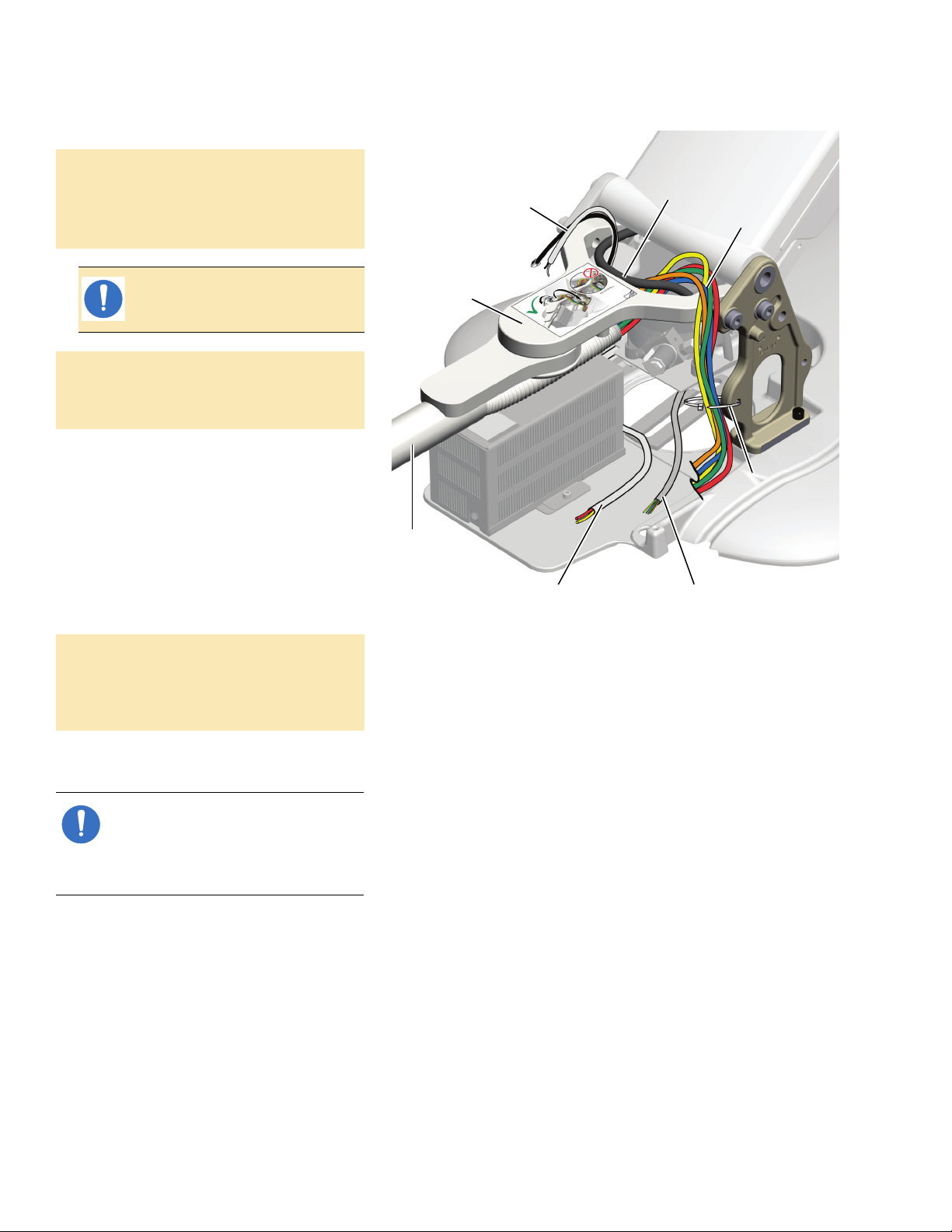

Support Center Power and

Connect

Black

Wire

Connect

Gray

Wire

Plug In

Data

Line

Connect

Ground

Wire

Mains

On/Off

Button

Data

CAUTION Electric components on

the circuit board are static sensitive

and require handling precautions.

Base Mount Systems

1. Turn off the power.

2. Use an adjustable wrench to connect the

ground wire.

3. Connect the power cables to the chair

circuit board terminal strip J3. The black

wire connects to 0 VAC and the gray

wire to 24 VAC.

4. Plug the data line into any data port.

NOTE The top of the 311 power

supply has a diagram of the

electrical connections for the chair

circuit board.

Connect the Utilities

Figure 74. Electrical and Data Line Connections

86.0087.00 Rev E

47

Page 48

A-dec 300 System Installation Guide

Power

Cables

Data

Line

Ground Wire

Power Sup ply

Retaining

Clip

Inside of Floor Box

Post Mount System on an A-dec 511 Dental Chair

1. Route the power cables and data line

through the bottom of the support center,

underneath the mount, and down the lift

arm to where the power supply is

located.

2. Turn off the power.

3. Use a Phillips head screwdriver to

connect the ground wire to the screw on

top of the power supply.

4. Connect the power cables to the chair

circuit board terminal strip J2. The black

wire connects to 0 VAC and the gray

wire to 24 VAC.

5. Plug the data line into a data port on the

chair circuit board.

6. Route the support center tubing group

through the convolute.

7. Push the convolute up several inches

through the bracket in the bottom of the

support center frame until it is securely

attached.

8. Connect master toggle to power supply

air electric switch.

Figure 75. A-dec 511 Power and Data Connections

9. Route the umbilical into the floor box.

10.Use a 5/64" hex key to attach the

retaining clip to the floor box and secure

the convolute.

11.Insert the plugs into the unused holes in

the floor box.

Figure 76. Attach the Retaining Clip Inside the Remote Floor Box

48 86.0087.00 Rev E

Page 49

Connect the Utilities

Retaining Clip

Inside of Floor Box

Ground Wire

0 VAC

24 VAC

Post Mount System on an A-dec Cascade, Decade, or Performer Dental Chair

Complete the procedure for the system’s

type of chair circuit board.

Chair Circuit Board Without Data Ports

NOTE A-dec 300 touchpads cannot

operate the auto dental light and

chair movements when using this

chair circuit board.

1. Route the tubing group and wires from

the bottom of the support center through

the convolute.

2. Push the convolute up several inches

through the bracket in the bottom of the

support center frame until it is securely

attached.

Figure 77. Chair Circuit Board Without Data Ports

Figure 78. Attach the Retaining Clip Inside the Remote Floor Box

3. Route the umbilical into the floor box.

4. Use a 5/64" hex key to attach the

retaining clip to the floor box and secure

the convolute.

5. Turn off the power.

6. In the floor box, use a Phillips head

screwdriver to connect the ground wire

to the top of the power supply.

7. Connect the power cables to the power

supply. The black wire connects to

0 VAC and the gray wire to 24 VAC.

8. Insert the plugs into the unused holes in

the floor box.

Figure 79. Power Supply Connections

86.0087.00 Rev E

49

Page 50

A-dec 300 System Installation Guide

Data Ports

Chair Circuit Board With Data Ports

NOTE A-dec 300 touchpads can

operate the auto dental light and

chair positions when using this

chair circuit board.

1. Take the extra data line from the floor

box kit and plug it into a data port on the

support center port board.

2. Route the data line under the support

center mount and through the chair to

the chair circuit board.

NOTE Cable ties and

adhesive-backed mounts are

provided with the Performer

post mount chair adaptor

(p/n 77.0922.00). Use them to

secure the data line under the

chair adaptor.

3. Plug the data line into a data port on the

chair circuit board.

4. Route the tubing group and wires from

the bottom of the support center through

the convolute.

5. Push the convolute up several inches

through the bracket in the bottom of the

support center frame until it is securely

attached.

Figure 80. Chair Circuit Board With Data Ports

50 86.0087.00 Rev E

Page 51

Connect the Utilities

Retaining

Clip

Inside of Floor Box

Ground

Wire

0 VAC 24 VAC

6. Route the umbilical into the floor box.

7. Use a 5/64" hex key to attach the

retaining clip to the floor box and secure

the convolute.

Figure 81. Attach the Retaining Clip Inside the Remote Floor Box

8. Turn off the power.

9. In the floor box, use a Phillips head

screwdriver to connect the ground wire

to the top of the power supply.

10.Connect the power cables to the

power supply. The black wire connects

to 0 VAC and the gray wire to 24 VAC.

11.Insert the plugs into the unused holes in

the floor box.

Figure 82. Power Supply Connections

86.0087.00 Rev E

51

Page 52

A-dec 300 System Installation Guide

Retaining

Clip

Inside of Floor Box

Ground

Wire

0 VAC 24 VAC

Post Mount System on an A-dec Priority Dental Chair

1. Route the tubing group, power cables,

and data line from the support center

through the convolute.

2. Push the convolute up several inches

through the bracket in the bottom of the

support center frame until it is securely

attached.

3. Route the umbilical into the floor box.

4. Use a 5/64" hex key to attach the

retaining clip to the floor box and secure

the convolute.

Figure 83. Attach the Retaining Clip Inside the Remote Floor Box

5. In the floor box, plug in the data line.

6. Turn off the power.

7. Use a Phillips head screwdriver to

connect the ground wire to the top of the

power supply.

8. Connect the power cables to the power

supply. The black wire connects to 0

VAC and the gray wire to 24 VAC.

9. Insert the plugs into the unused holes in

the floor box.

Figure 84. Power Supply Connections

52 86.0087.00 Rev E

Page 53

Connect the Utilities

To the Support

Center

NOTE For moisture separator tubing connections, see Figure 86.

Support Center Floor Box Utilities

The following instructions are for both base mount and post mount systems.

Support Center tubing can connect in several locations. See the section that applies to where your system’s

utilities are located.

• Contoured Floor Box – See Figure 85 below.

• Integrated Floor Box and Remote Floor Box – See Figure 87 on page 55.

NOTE There is an overall flow diagram on the inside of the support center cover.

Contoured Floor Box

Figure 85. Support Center Utility Connections in a Contoured Floor Box

86.0087.00 Rev E

53

Page 54

A-dec 300 System Installation Guide

From the Floor Box

Power Supply

Figure 86. Moisture Separator Tubing Connections for Support Center Modules with a Contoured Floor Box Cover Set

54 86.0087.00 Rev E

Page 55

Integrated and Remote Floor Boxes

With a Moisture Separator (Optional)

If the system includes a moisture separator, make the

connections in this gray area.

To install the moisture separator, use the directions

included in the moisture separator kit

(p/n 41.1477.00).

Power Supply

To Support Center

Support center utilities in integrated and remote floor boxes connect in the same way.

Figure 87. Support Center Utility Connections in Integrated and Remote Floor Boxes

Connect the Utilities

86.0087.00 Rev E

55

Page 56

A-dec 300 System Installation Guide

Data Ports

Ground Wire

WAGO Connector

Support Center Modules

Connect the Power and Data

CAUTION Electric components on

the circuit board are static sensitive

and require handling precautions.

NOTE This procedure is for both

the assistant’s instrumentation and

the delivery system.

1. Turn off the power.

2. Use an adjustable wrench to attach the

delivery system’s ground wire to the

post below the window in the support

center frame.

3. Attach the power cables to the WAGO

connectors, keeping the gray wires with

gray wires (24 VAC) and black wires

(0 VAC) with black.

4. Plug the data line into any data port.

Figure 88. Delivery System Electrical and Data Line Connections

Connect the Tubing

1. For utility connections, see the diagram

for your system’s configuration:

○ System without a cuspidor - Figure 89

on page 57

○ System with a cuspidor - Figure 90 on

page 58

56 86.0087.00 Rev E

NOTE When making the

connections, be sure the tubing is

routed through the bottom of the

support center frame and you

make all connections inside of

the support center frame.

Page 57

Figure 89. Support Center Modules Utility Connections - No Cuspidor

To D e l i v e r y S y s t e m

To

Assistant’s

Syringe

To F o o t C o n t r o lTo F l o o r B o x

Connect the Utilities

86.0087.00 Rev E

57

Page 58

A-dec 300 System Installation Guide

To D e l i v e r y S y s t e m

To

Assistant’s

Syringe

To F o o t C o n t r o lTo F l o o r B o x

To C u s p i d o r

Figure 90. Support Center Modules Utility Connections - With Cuspidor

58 86.0087.00 Rev E

Page 59

Connect the Utilities

Pinch Valve

Tubing Ridges Face Up

2. If the system has an assistant’s

instrumentation, install the pinch valve

on the syringe yellow and red tubing.

3. Use a 3/16" hex key to secure the foot

control tubing to the chair base in the

strain relief.

NOTE For proper positioning, the

ridges on the foot control tubing

face up to match the grooves in the

strain relief.

Figure 91. Install the Pinch Valve

Figure 92. Secure the Foot Control Tubing

86.0087.00 Rev E

59

Page 60

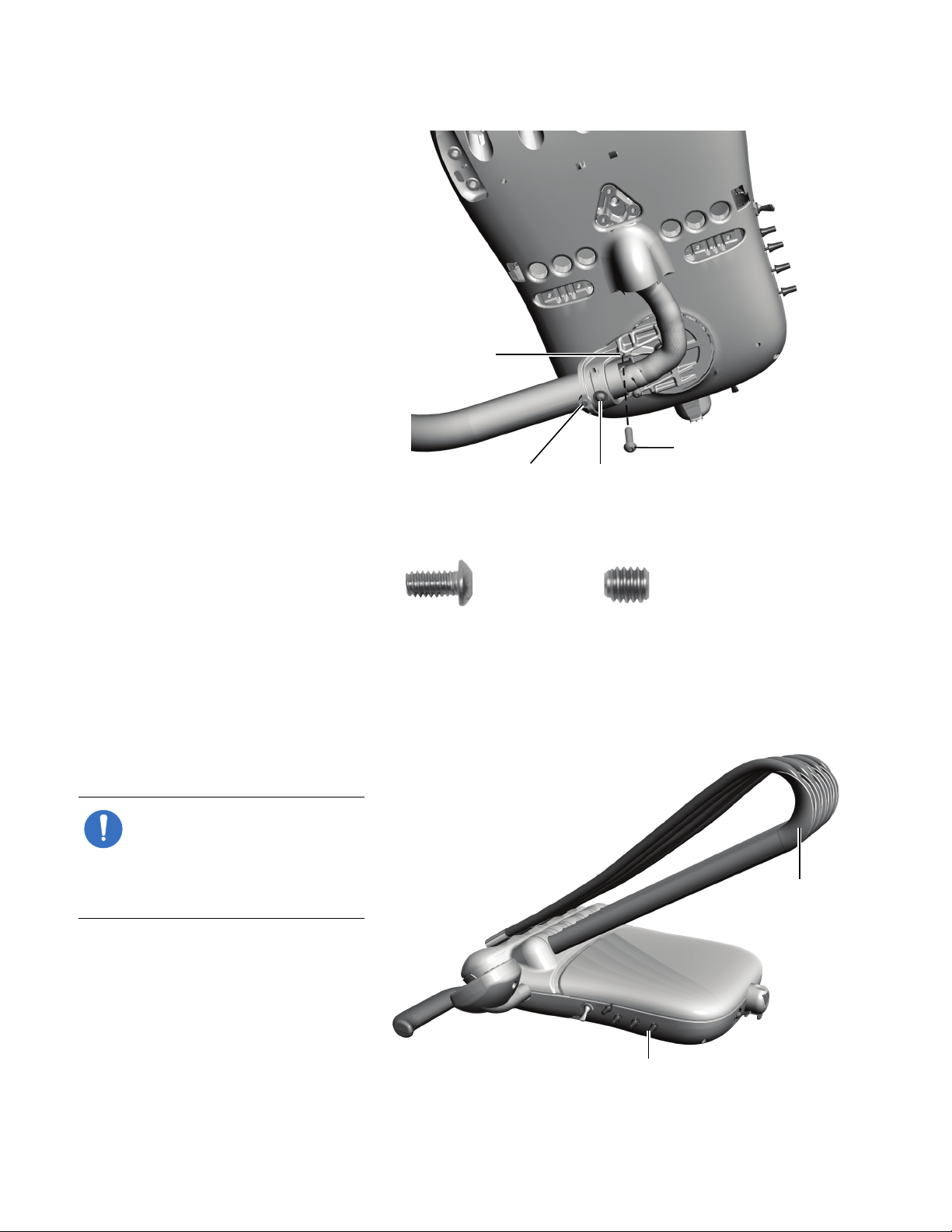

A-dec 300 System Installation Guide

Cupfill Spout

Bowl Screen

Bowl Rinse Spout

Cuspidor Bowl

I NSTALL THE C USPIDOR

If the system has a cuspidor, install its

components.

Install the Cupfill Spout

To install the cupfill spout, push it straight

down.

CAUTION When installing the

cupfill spout, do not rotate it or it

may break.

Install the Bowl Rinse Spout

To install the bowl rinse spout, push it

straight in.

Tools Needed For This Section

Diagonal cutters

Figure 93. A-dec 361 Support Center with Cuspidor

Figure 94. Cuspidor Components

Install the Cuspidor Bowl and Bowl Strainer

1. Use diagonal cutters to cut the cable tie

and remove the positioning guide.

2. Place the cuspidor bowl in its holder

with the high side away from the patient.

3. Place the bowl screen in the bottom of

the bowl.

NOTE Save the positioning

guide and the foam plug holding

it in the cuspidor bowl support.

You will need them later to

verify proper clearance between

the cuspidor bowl and armrest.

For more information, see

“Verify Proper Clearance

Between the Cuspidor Bowl and

the Armrest” on page 94.

60 86.0087.00 Rev E

Page 61

I NSTALL

Upholstery

Pin

Install Upholstery

U PHOLSTERY

The upholstery for the A-dec 311 Dental

Chair includes the seat, back, and either a

patient-adjustable neck support or

double-articulating headrest.

Tools Needed For This Section

7/64" hex key

Figure 95. A-dec 311 Thin-Line Back with Adjustable Neck Support

Install the Seat Upholstery

1. Raise the chair and lower the chair back

until the holes in the chair frame are

accessible.

2. Move the armrests back.

3. Pull the pins out of the upholstery far

enough so the seat upholstery can sit

properly on the chair frame.

4. Place the seat upholstery in position and

line up its holes for the pins with the

holes in the chair frame.

5. Push the pins back through the seat

upholstery and chair frame until the

rings touch the seat.

86.0087.00 Rev E

Figure 96. Install the Seat Upholstery

61

Page 62

A-dec 300 System Installation Guide

Key Hole

Fastener Post

Install the Back Upholstery

NOTE Back upholstery installation

is the same for both back styles.

1. Put the chair back up and lower the

chair.

2. Place the key holes in the back

upholstery over the fastener posts on the

chair back.

3. Slide the back upholstery into place and

push down until the back upholstery

aligns with the chair back.

Figure 97. Install the Back Upholstery

Install the Neck Support or Headrest

Install a Patient-Adjustable Neck Support

Snap the neck support armature into the

neck support track.

Figure 98. Install the Patient-Adjustable Neck Support

62 86.0087.00 Rev E

Page 63

Install Upholstery

Mounting

Screws

Headrest Back

Plate

Glide Bar

Install the Double-Articulating Headrest

1. Use a 1/8" hex key to remove the

mounting screws from the headrest

upholstery.

2. Line up the holes in the headrest

upholstery with those in the headrest

back plate.

3. Insert and tighten the mounting screws.

Figure 99. Install the Double-Articulating Headrest Upholstery

4. Place the glide bar into the slot at the top

of the back upholstery and push it down

into place.

Figure 100. Install the Double-Articulating Headrest

86.0087.00 Rev E

63

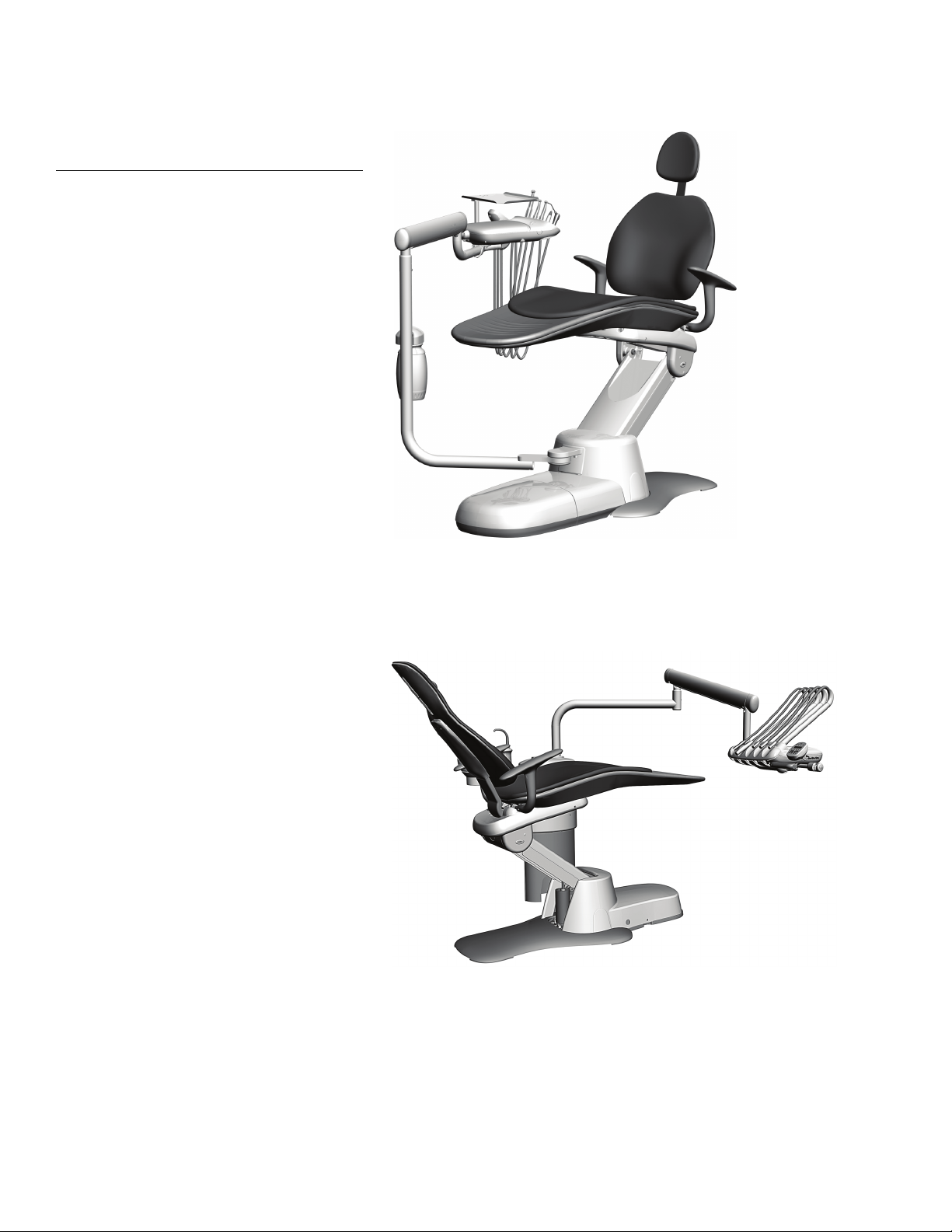

Page 64

A-dec 300 System Installation Guide

Cable Tie

Around

Support

Center

Post

Cable Tie Around Tubing

Bundle Inside Mount

Cable Tie

Around Corner

of the Mount

Lubricate

O-Ring

P REPARE AND

DJUST THE

A

S YSTEM

Secure the Base Mount System Tubing Bundle

1. Loosely loop a cable tie around the

tubing bundle and slide the tie under the

chair-base mount.

2. From the utilities area, pull the tubing

bundle to take up any slack.

3. Tighten the cable tie under the mount

and push the tubing bundle up into the

mount so it is not visible.

4. Use a cable tie around the corner of the

mount to secure the wires and tubing so

nothing is hanging down under the

mount.

5. Use a cable tie to secure the tubing group

to the support center post so it does not

push against the lower covers.

Tools Needed For This Section

1/2" combination wrench Voltmeter

Hex key set Phillips head screwdriver

Figure 101. Secure the Tubing Bundle

Figure 102. Install the Water Bottle

Install the Water Bottle

The instructions for installing a water bottle

are the same regardless of where it is

located.

1. Following ICX instructions, place an ICX

tablet (p/n 90.1065.00) in the water

bottle.

2. Fill the bottle with water.

3. Put A-dec silicone lubricant on the

receptacle O-ring.

CAUTION Use only A-dec

silicone lubricant or the O-ring

may be damaged.

4. Push the water bottle up onto the water

bottle receptacle and turn it to the right.

64 86.0087.00 Rev E

Page 65

Prepare and Adjust the System

Stop Screw

(From Front)

Stop Screw

(From Back)

Te ns io n

Adjustment

Screw

Tension

Adjustment

Screw

Adjustments

Lock the Armrests (Optional)

When the dental chair is shipped, the

armrests rotate back and forth. The armrests

can be locked into the upright position if

preferred. To lock an armrest:

1. Use a 3/16" hex key to remove the stop

screw from the front of the armrest.

2. Install the stop screw in the back of the

armrest.

3. Use a 1/8" hex key to tighten the tension

adjustment screw on the front of the

armrest.

Figure 103. Adjust the Armrest Position

Adjust the Double-Articulating Headrest Glide Bar Tension

A double-articulating headrest may be

difficult to move or may drift downward

because of the amount of tension on the

glide bar.

To adjust the tension, use a 1/8'' hex key and

turn the tension adjustment screw clockwise

to increase friction or counterclockwise to

decrease friction.

Figure 104. Adjust the Double-Articulating Headrest Glide Bar

Ten si on

86.0087.00 Rev E

65

Page 66

A-dec 300 System Installation Guide

Base Down

Control Valve

Adjustment

Screw

Adjust the Speed for Lowering the Chair

To adjust the speed at which the chair

lowers, raise the chair and use a 3/32" hex

key to adjust the base down control valve.

Turn the screw clockwise to decrease speed

or counterclockwise to increase speed.

TIP For an accurate estimate of

down travel speed, have someone

sit in the chair when making the

adjustments.

Figure 105. Adjust the Base Down Control Valve

66 86.0087.00 Rev E

Page 67

Prepare and Adjust the System

End Cap

Button

Head

Screw

Flexarm Spring Adjustment Screw

Adjust the Delivery System Spring-Assisted Flexarm

If the control head drifts up or down,

complete the following steps to adjust the

spring-assisted flexarm.

NOTE After adjusting the flexarm,

test for balance at its normal

working position.

1. Turn off the power.

2. Load the control head for normal use,

attaching handpieces and placing a tray

with instruments on the tray holder.

3. Use a 1/8" hex key to loosen the screw

that secures the end cap.

TIP Lower the control head

for easier access to the

button head screw.

4. Remove the flexarm end cap.

5. Use a 3/16" hex key to adjust the flexarm

spring adjustment screw until the control

head maintains position at the normal

working position.

TIP To make it easier to adjust

the spring, raise the control head

to the highest point.

○ If the control head drifts up, turn the

screw counterclockwise.

○ If the control head drifts down, turn

the screw clockwise.

Figure 106. Adjust the Spring-Assisted Flexarm

86.0087.00 Rev E

67

Page 68

A-dec 300 System Installation Guide

Install the

10-32 x 1/2"

button head

stop screw

(actual size)

in the

bottom hole.

Adjust the Delivery System Flexarm Rotation Tension

Do not adjust the flexarm rotation tension

until the system has been leveled. For

information on adjusting the flexarm

rotation, see “Adjust the Delivery System

Flexarm Rotation Tension” on page 79.

Install the Delivery System Flexarm Rotation Stop Screw

Use a 1/8" hex key to install the 10-32 x 1/2"

button head screw in the bottom hole on the

knuckle of the delivery system. Tighten it all

the way down.

Adjust the Control Head Rotation Tension

Figure 107. Install the Flexarm Rotation Stop Screw

Figure 108. Adjust the Control Head Rotation Tension

If the control head rotation is too tight or too

loose, adjust the rotation tension by

tightening or loosening the screw under the

control head.

Use a 5/32" hex key to turn the screw

clockwise to increase tension and

counterclockwise to decrease tension.

68 86.0087.00 Rev E

Page 69

Prepare and Adjust the System

Hex Key

Control

Head

Tr ay

Holder

Tr ay

Arm

Mounting