Page 1

85.0812.00, 2003 CH-1

Chairs Overview

A-dec model 1040, 1021 and 8000 chairs are electronically controlled, hydraulically powered

dental chairs. Buttons on both the touchpad and 8-button footswitch and actuators on the

8-function footswitch are used to position and program auto-positioning functions into the chair.

The hydraulic system is controlled by the electronic control module using relays and solenoidactuated valves.

This section provides information related to locating serial/model numbers, servicing,

maintenance, and adjustment of chairs. Detail on how to service chairs and troubleshoot specific

problems related to them is presented.

Page 2

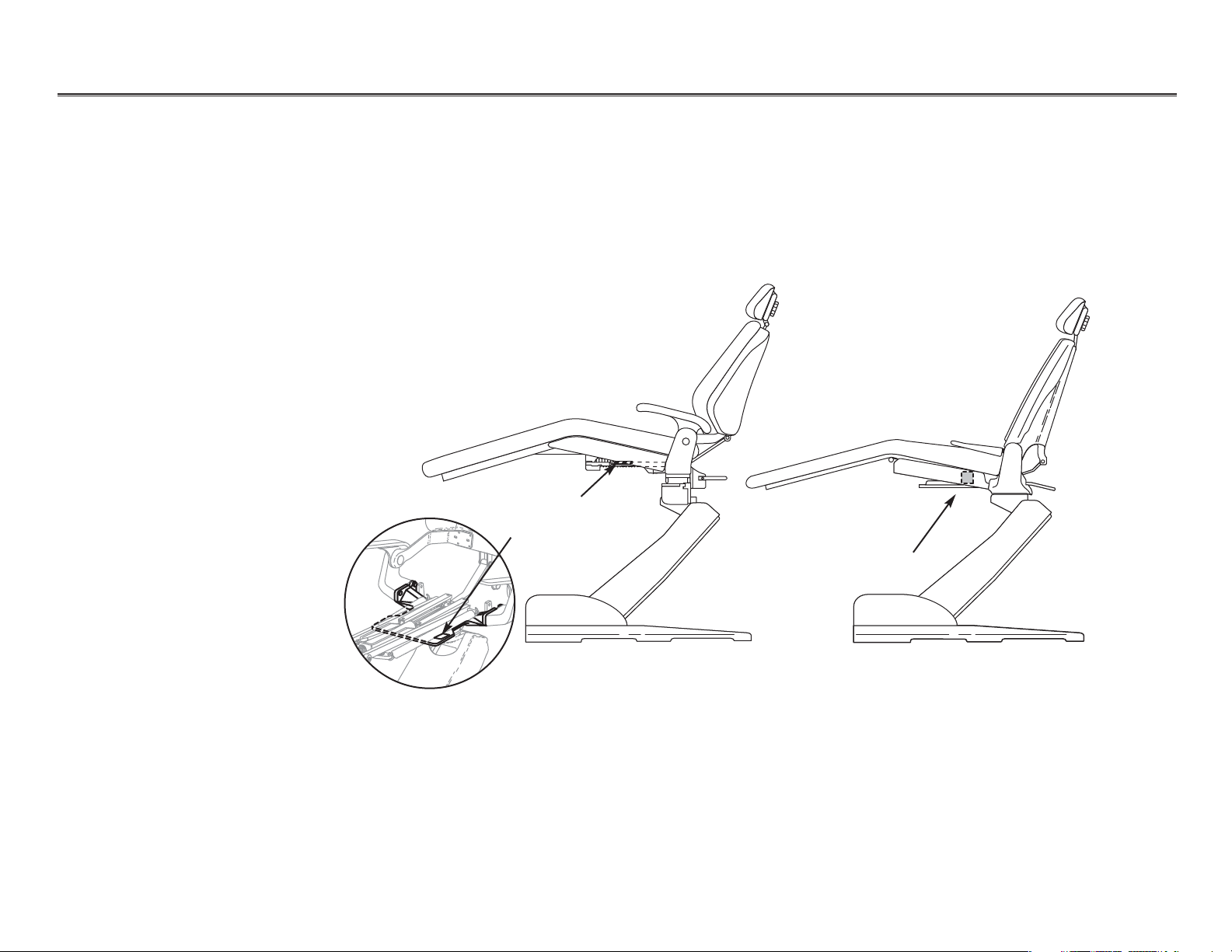

Locating

Serial/Model

Number

85.0812.00, 2003 CH-2

Chairs Serial/Model Number Locations

Cascade 1040 ChairDecade 1021/1011 Chair

Serial number

label location

Serial number

label location

The serial/model number tags identify the chair model and manufacture date. The label can be

found either on the top surface of a chair’s upper structure (raise the toeboard) or on the righthand side of the upper structure. If you have difficulty locating the serial/model number label,

the following example may be helpful.

Page 3

85.0812.00, 2003 CH-3

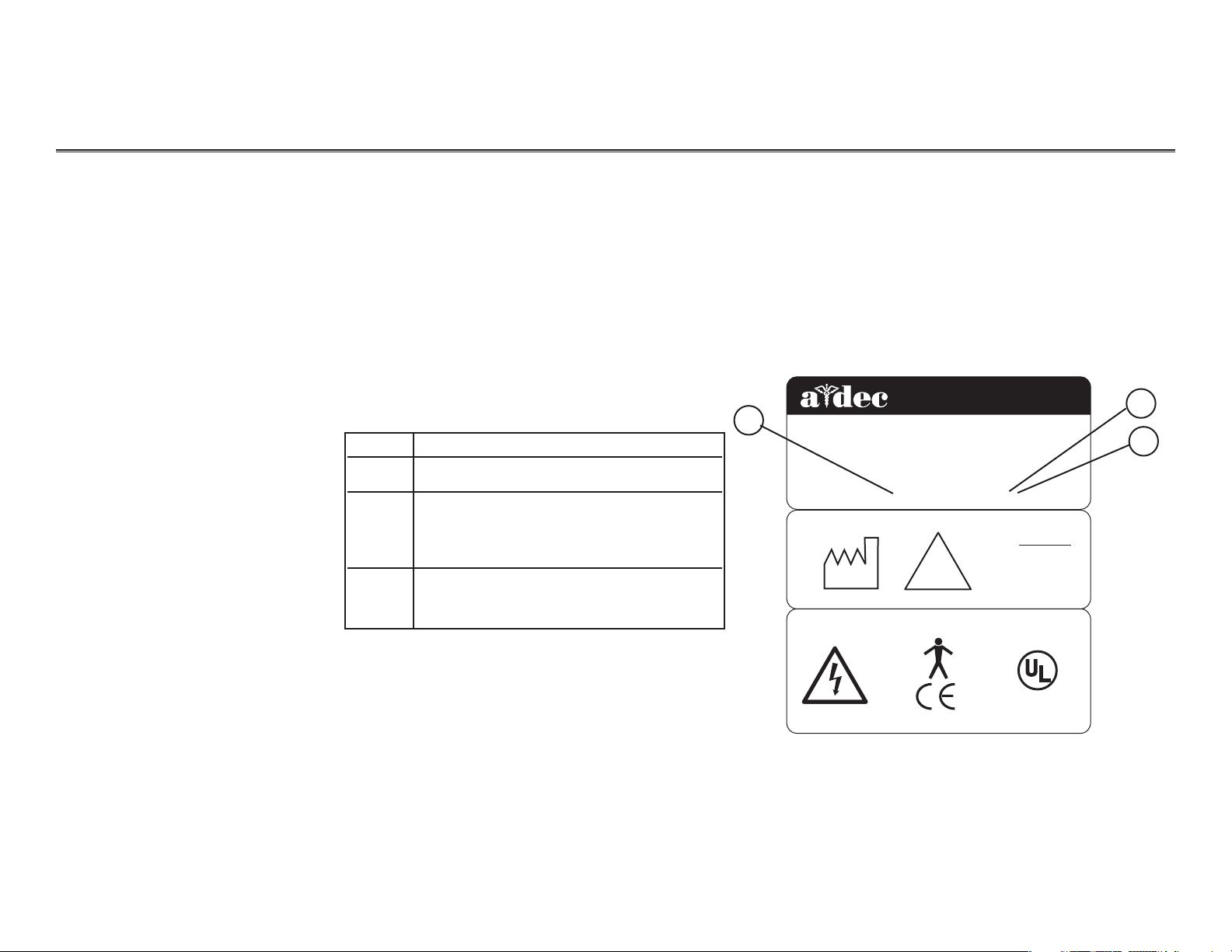

Chairs Manufacture Date

Serial/Model Number Label

Reading the

Manufacture Date

1

Item # Description

1Model number

2 The first letter of the serial number

indicates the month the product was

manufactured; e.g., A is January.

3First digit indicates the year

of manufacture.

2

1

Different models of the chair can be identified by referring to the “REF” number. Each chair is further

identified by its month and year of manufacture.

This example shows how to identify the model and month and year of manufacture of the chair.

2601 CRESTVIEW DRIVE

®

NEWBERG, OREGON 97132 USA

Designated EU Representative: A-dec Dental U.K., Ltd.

Austin House, 11 Liberty Way, Attleborough Fields,

Nuneaton, Warwickshire, England CV 116RZ

DENTAL

CHAIR

Tele: (44) 1203-350901

REF: 1040

S/N: J167856

2001

MADE IN

USA

!

DENTAL CHAIR

INPUTS

-

120 V

10 AMPS MAX

50-60 Hz

CAUTION!

U

®

LISTE

15VJ

S

D

C

LABEL P/N: 051.515.02 REV L

Page 4

85.0812.00, 2003 CH-4

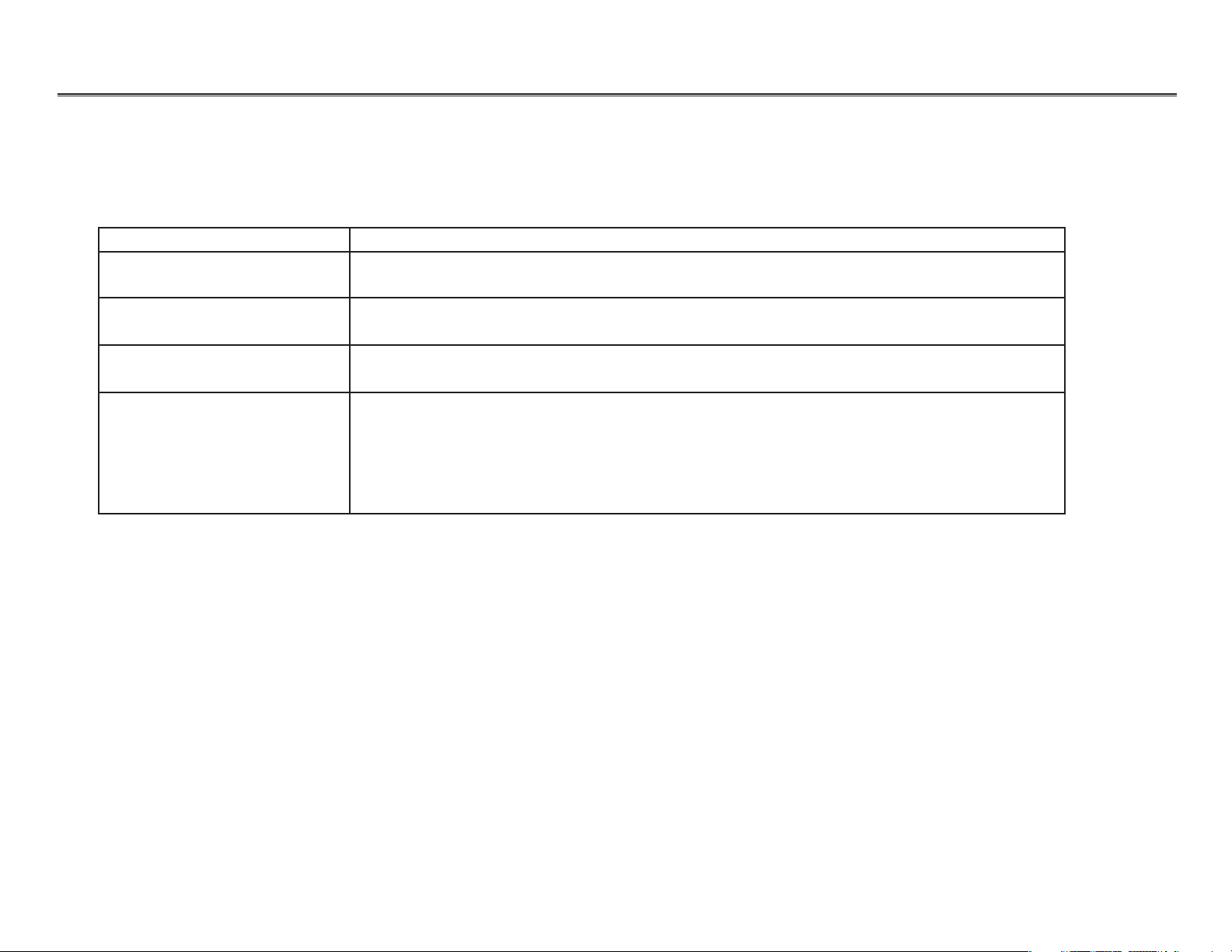

Chairs Hydraulics

Working with

Hydraulics

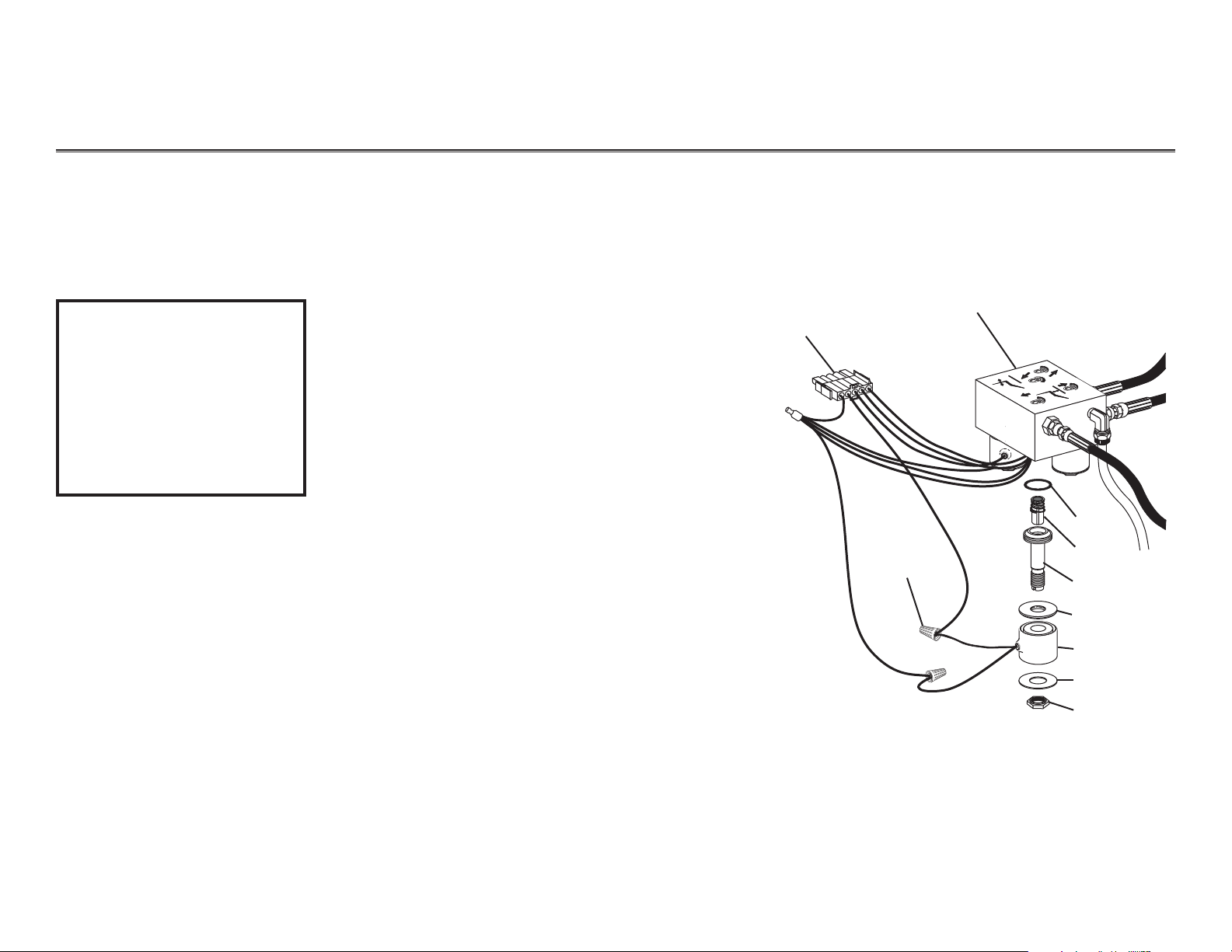

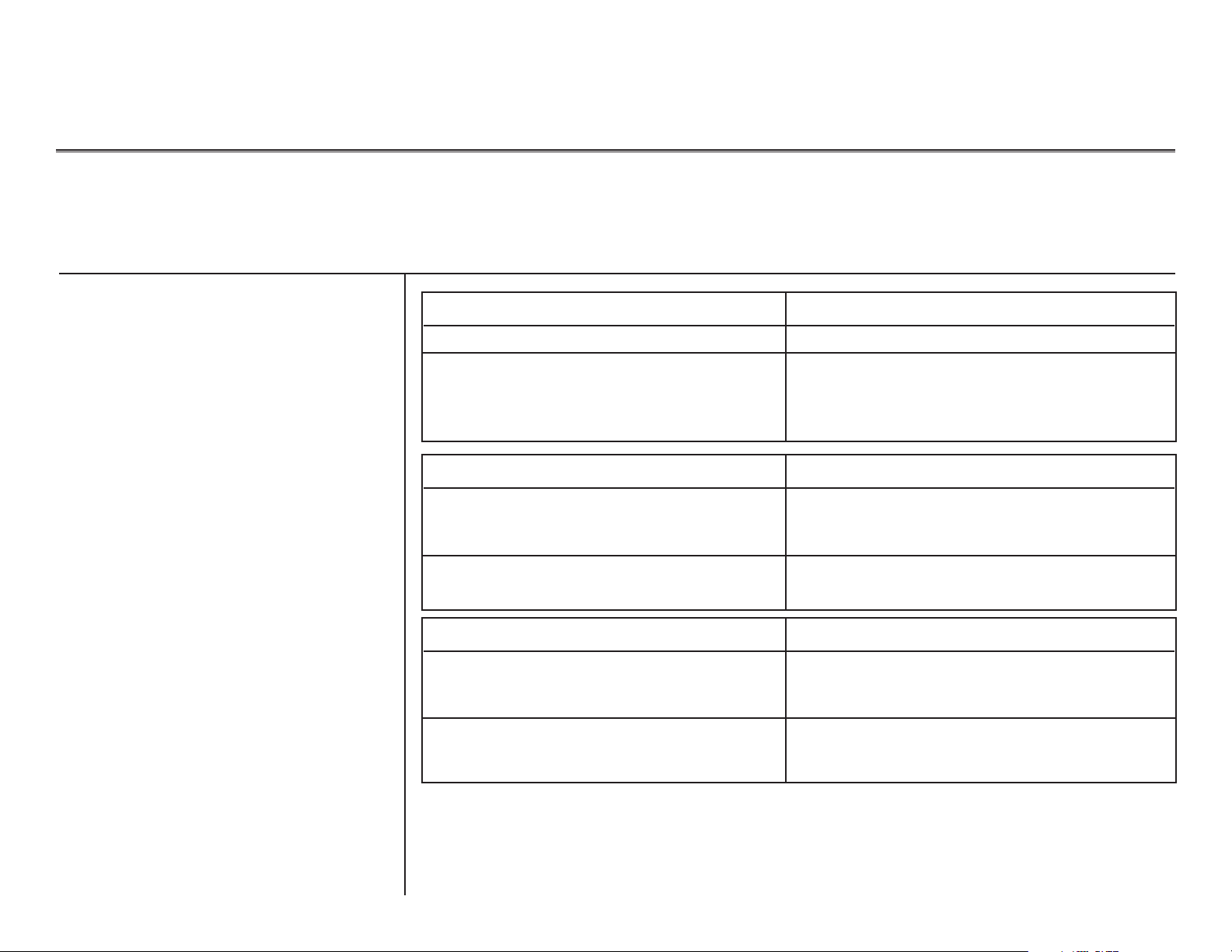

Part Description

Hydraulic fluid reservoir The fluid level in the reservoir can be seen through the sides of the reservoir and is serviced via a

top fill cap.

Hydraulic cylinders The hydraulic cylinders control the base lift and back functions. Springs and gravity retract the

rod during base and back down functions.

Motor-driven hydraulic pump The hydraulic pump and the starter capacitor supply hydraulic fluid from the reservoir, under

pressure, to the chair lift and tilt hydraulic cylinders for back up and base up functions.

Solenoid/manifold assembly This assembly gates hydraulic fluid to and from the two cylinders. Depending on the chair

function called for, the controller selects which solenoid-actuated manifold valves are opened or

closed. The solenoid/manifold assembly also includes four adjustable needle valves used to

restrict or divert the flow of hydraulic fluid to and from the lift and tilt cylinders. These valves

provide the rate of travel adjustment for chair base and back movement.

The hydraulic system consists of the following:

Page 5

85.0812.00, 2003 CH-5

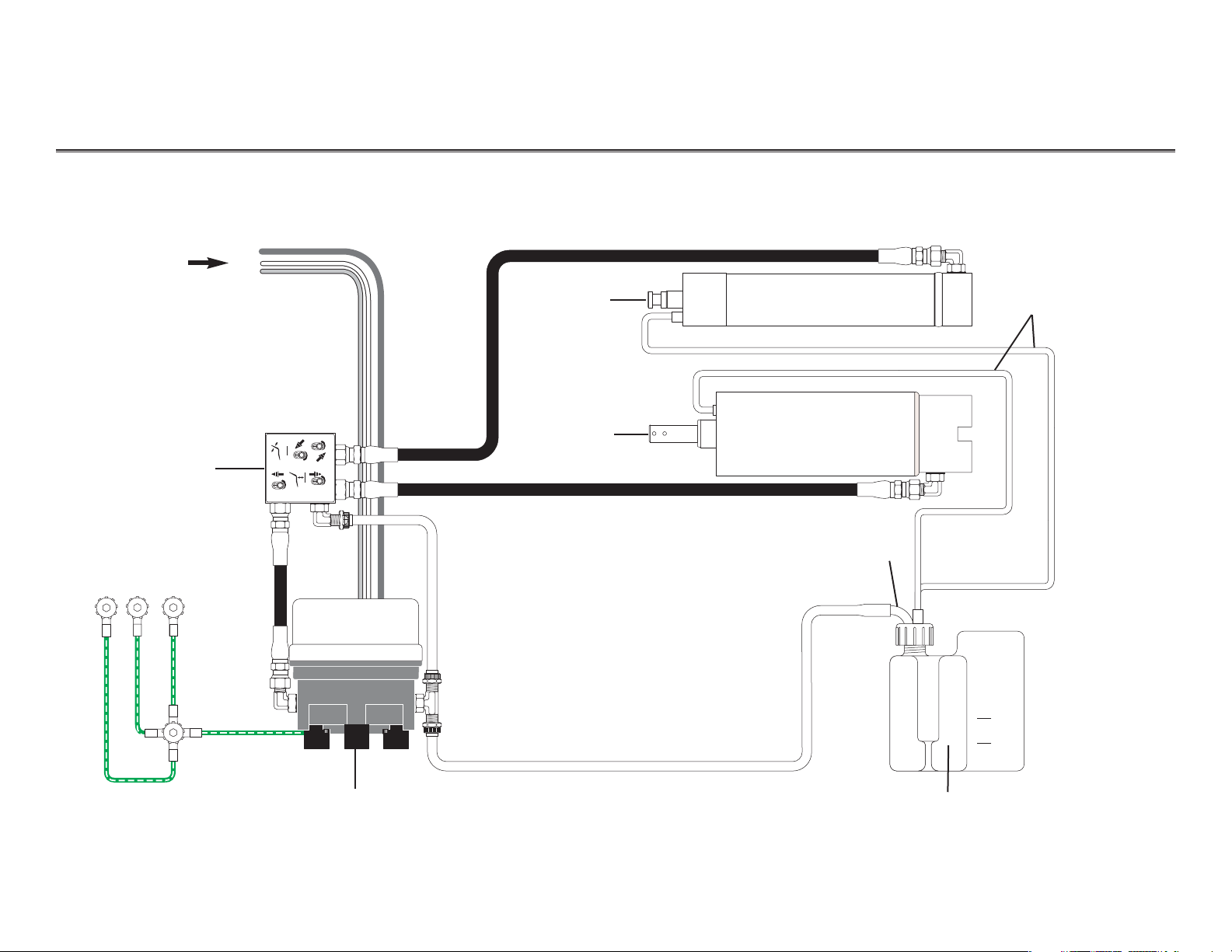

Chairs Hydraulic System Flow Diagram

From

motor/pump

start capacitor

{

Solenoid

manifold

assembly

Tilt cylinder

Lift cylinder

Vent tubes

Pickup tube

Hydraulic fluid reservoir (check fluid level with base and

back full up)

NOTE: Use only A-dec fluid P/N 61.0197.00.

Hydraulic

pump

motor

MAX

MIN

Page 6

85.0812.00, 2003 CH-6

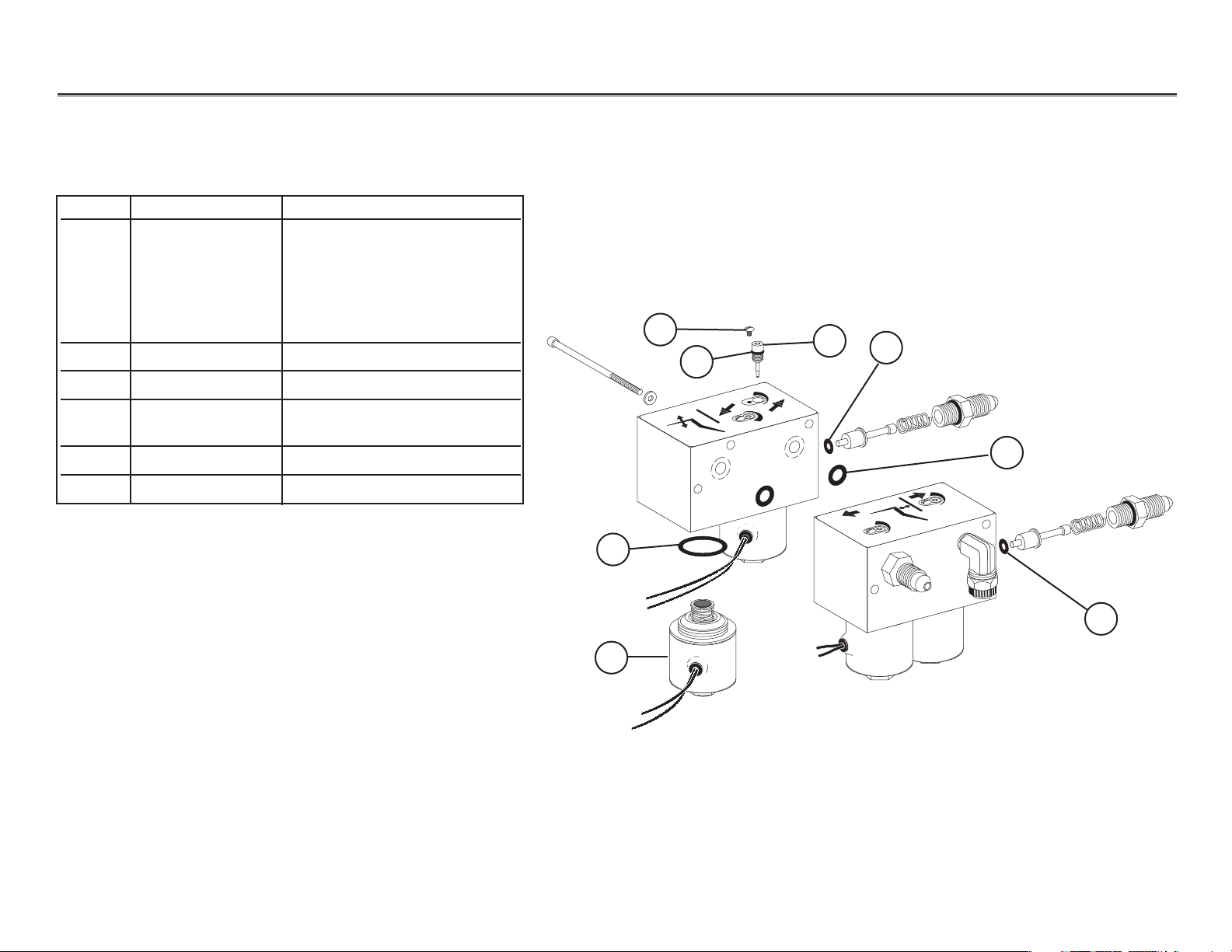

Chairs Hydraulic Manifold

Hydraulic Manifold

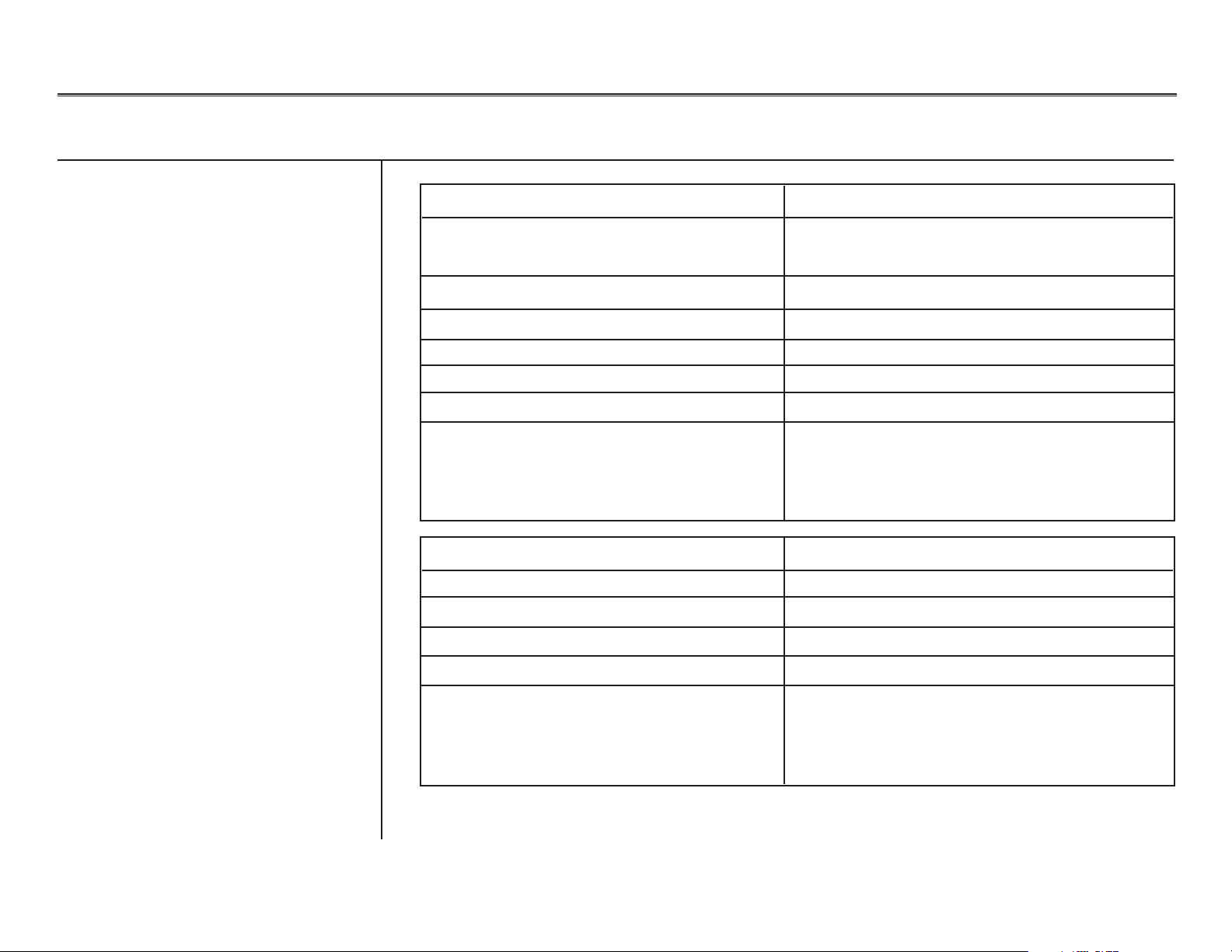

Item # Part Number Description

1 61.1335.00 Solenoid, (8-watt, 100V,

Yellow wires)

61.1336.00 Solenoid, (8-watt, 120 V,

Black wires)

61.1337.00 Solenoid, (8-watt, 240 V,

Red wires)

2 035.041.02 O-ring, special pkg 10

3 030.004.02 O-ring, AS568-004 pkg 10

4 030.010.00 O-ring, AS568-010

(only on dual-block manifolds)

5 61.0460.00 Flow adjust screw with o-ring

6 001.002.00 Screw, truss-head slot

1

2

3

4

5

6

3

3

Before January 1999

Page 7

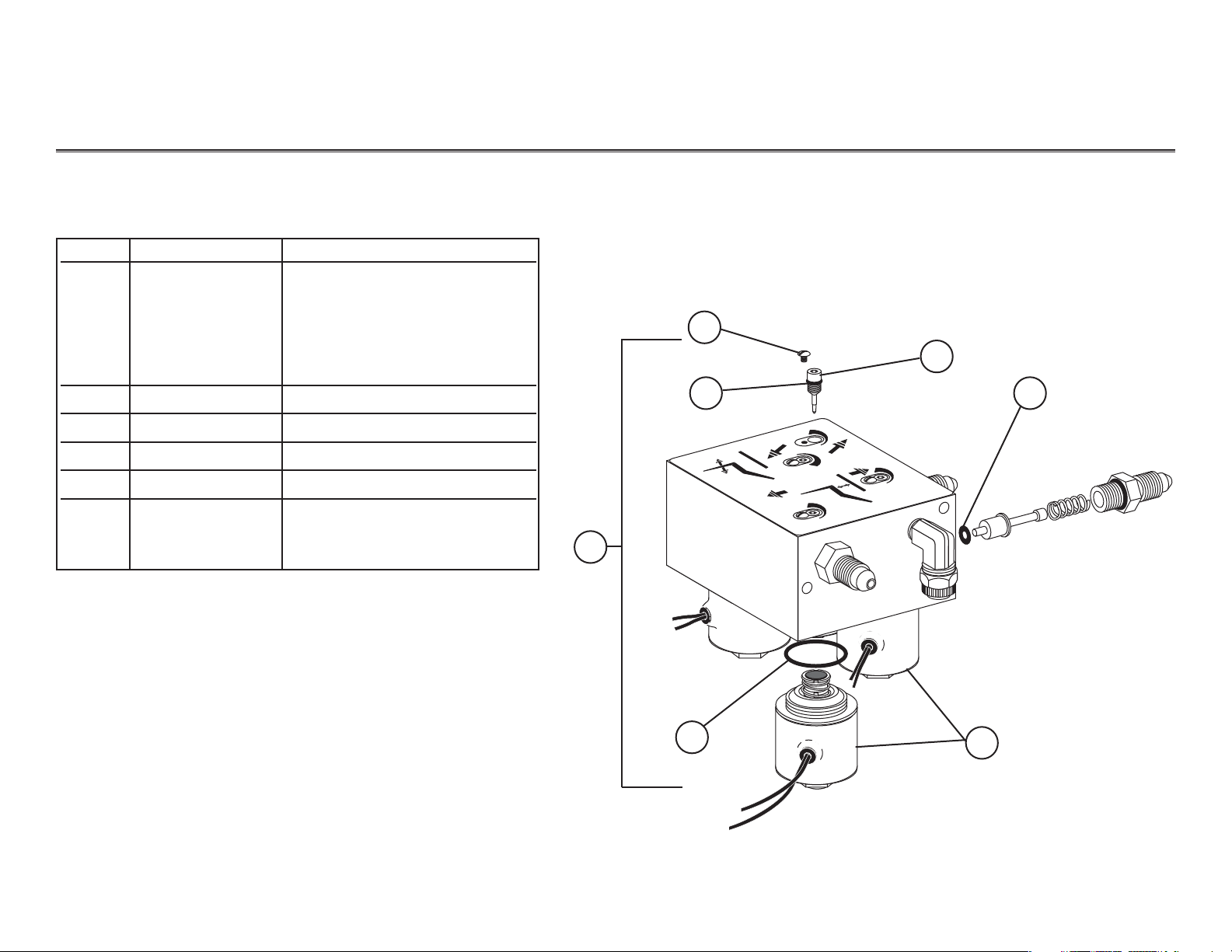

85.0812.00, 2003 CH-7

Chairs Hydraulic Manifold

Hydraulic Manifold

Item # Part Number Description

1 61.1335.01 Solenoid, (8-watt, 100V,

Yellow wires)

61.1336.01 Solenoid, (8-watt, 120V,

Black wires)

61.1337.01 Solenoid, (8-watt, 240V,

Red wires)

2 030.015.02 O-ring, pkg 10

3 030.004.02 O-ring, AS568-004 pkg 10

4 61.0460.00 Flow adjust screw with o-ring

5 002.118.01 Screw, button-head, socket

6 61.1332.00 Manifold assy, hyd, 100V

61.1333.00 Manifold assy, hyd, 120V

61.1334.00 Manifold assy, hyd, 240V

3

4

5

2

6

1

3

After January 1999

Page 8

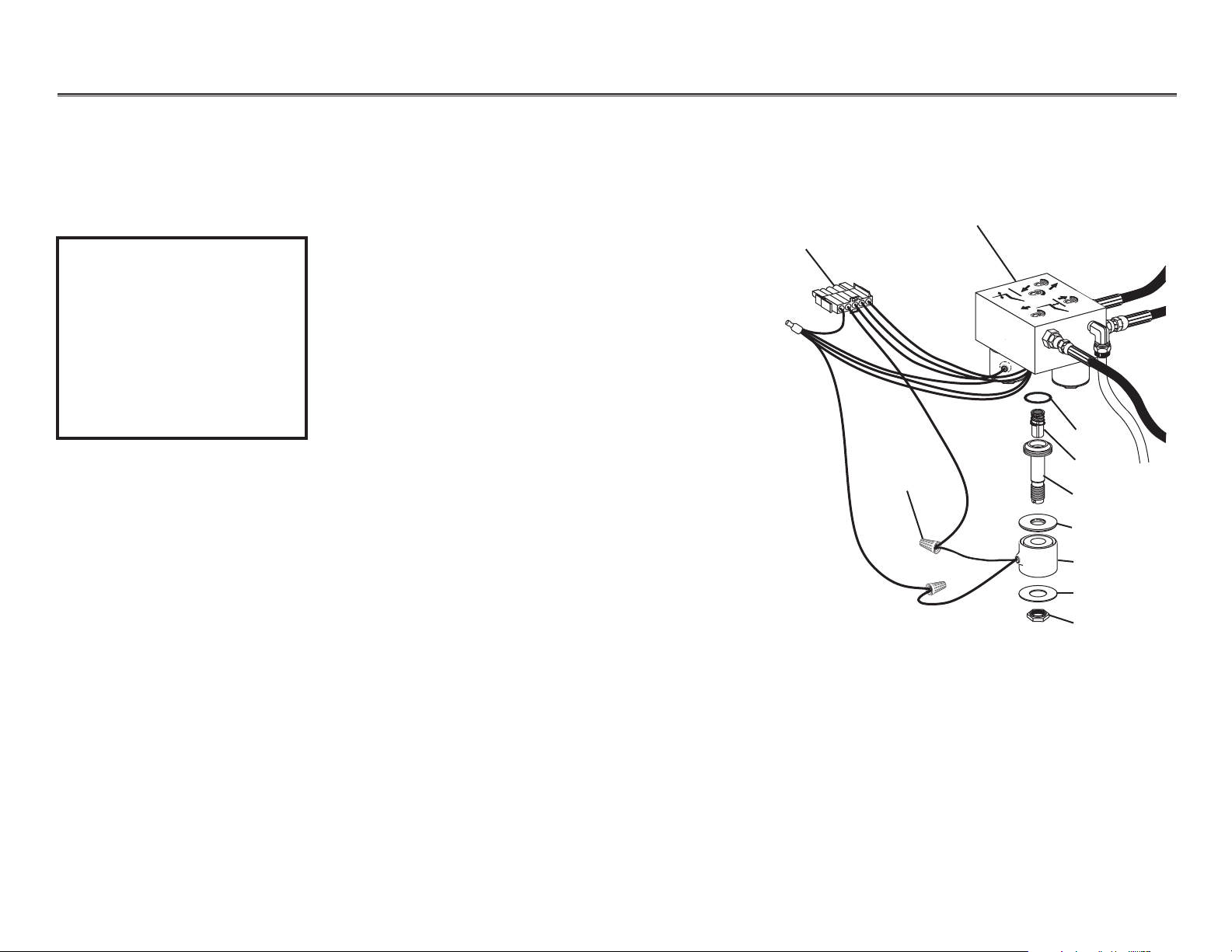

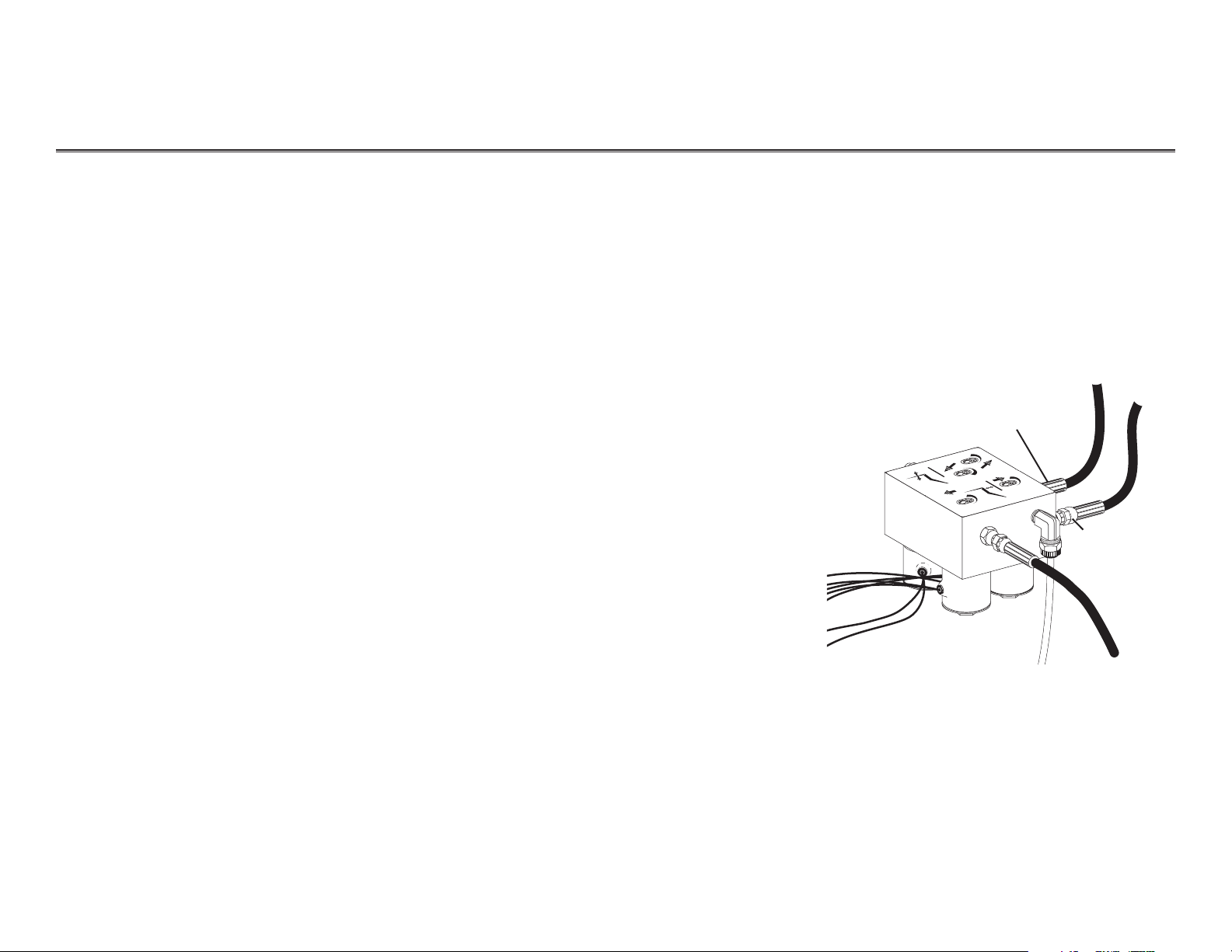

85.0812.00, 2003 CH-8

Chair Hydraulic Manifold

The following steps will guide you through the

removal of a solenoid.

Task Description

1 Lower the chair base and back to the

full down position to depressurize the

hydraulic system. Remove the motor

pump cover, then unplug the chair.

2 If necessary, remove the two mounting

screws that secure the manifold to the

hydraulic tray. Rotate the manifold so

the solenoids are accessible.

3Using a flat blade screwdriver and a 9/16"

wrench, remove the defective solenoid.

4 Cut the defective solenoid wires 3" (74mm)

from the coil and discard.

5Remove the old o-ring from the solenoid

cavity and completely dry the cavity.

Replace the o-ring (refer to Solenoid

installation instructions for correct o-ring).

Hydraulic manifold

O-ring

Poppet sleeve

Washer

ID washer

Retaining nut

Poppet

Coil

Wire nut

J10

Removing a

Solenoid

WARNING

The solenoid coils are

powered by line voltage

(100, 120, or 240V AC).

Failure to unplug the

chair may result in

serious injury from

electrical shock.

Removing a Solenoid

Page 9

85.0812.00, 2003 CH-9

Chair Hydraulic Manifold

The following steps will guide you through

replacing a solenoid.

Task Description

1 Install the new solenoid stem and poppet into

the manifold and tighten to 35-40 in lb

(.11085-.2284 Nm). Position the remaining

solenoid parts on the stem and secure by

tightening the retaining nut to 25-30 in lb

(.14275-.1713 Nm).

2 Cut the solenoid wires 3" (75 mm) from the coil.

Install the stripped wires from the solenoid and

the connector housing into a wire nut. Repeat

for the remaining wire.

3Using the mounting screws, secure the

manifold to the hydraulic tray.

4. Plug in the chair. Test the chair functions to

ensure proper operations and that no fluid

leakage occurs. Reinstall the motor pump cover.

Hydraulic manifold

O-ring

Poppet sleeve

Washer

ID washer

Retaining nut

Poppet

Coil

Wire nut

J10

Replacing a

Solenoid

WARNING

The solenoid coils are

powered by line voltage

(100, 120, or 240V AC).

Failure to unplug the

chair may result in

serious injury from

electrical shock.

Replacing a Solenoid

Page 10

85.0812.00, 2003 CH-10

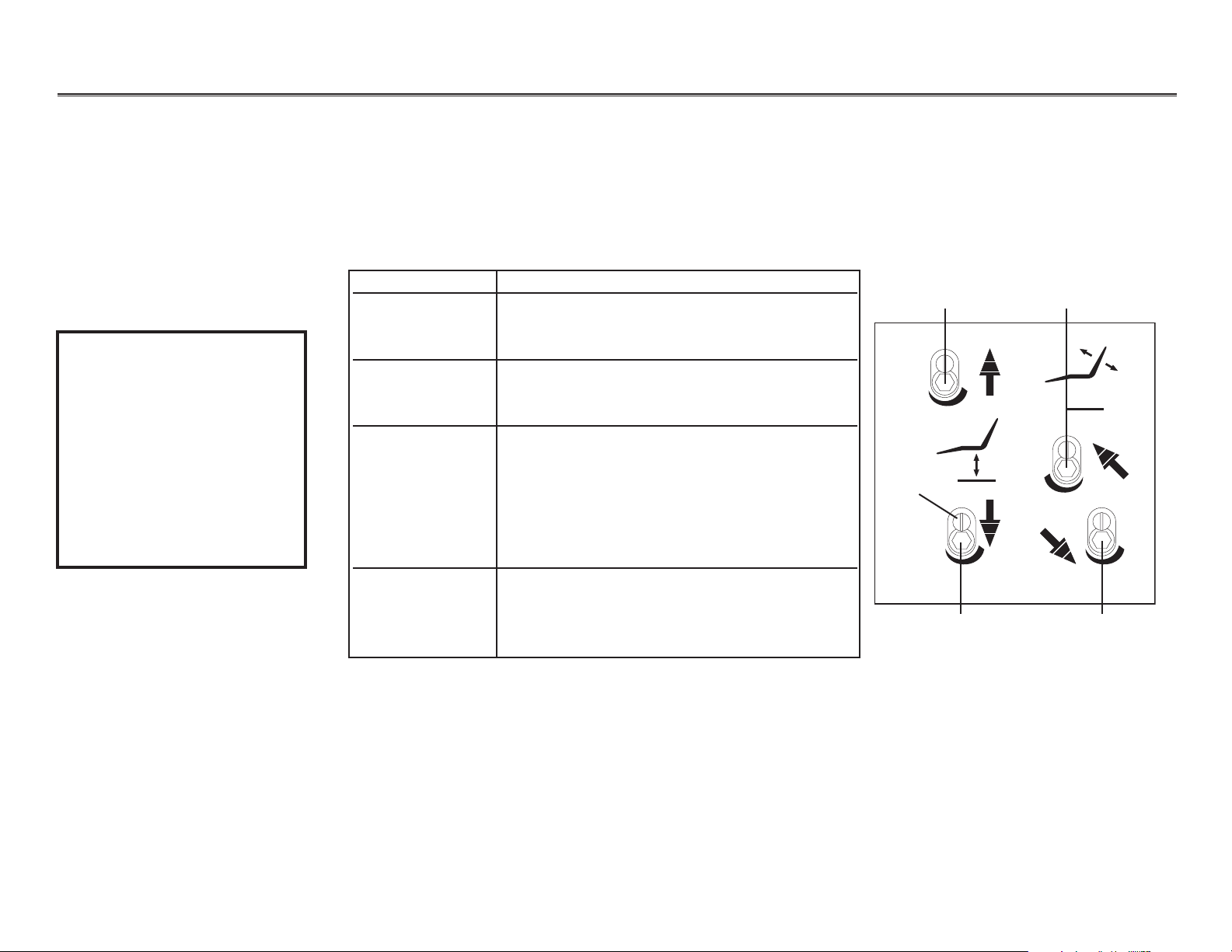

Chairs Hydraulic Manifold

Base down

control valve

Base up

control valve

Back down

control valve

Back up

control valve

CAUTION

Do not completely close

a speed control valve.

The motor/pump could

overheat and become

damaged from pumping

against a closed valve.

Do not remove retaining

screw from the control

valves.

Retaining

screw

The hydraulic manifold incorporates four speed control valves, which restrict or divert the flow of

hydraulic fluid to and from the lift and tilt cylinders.

NOTE: The speed control valves are hex drive.

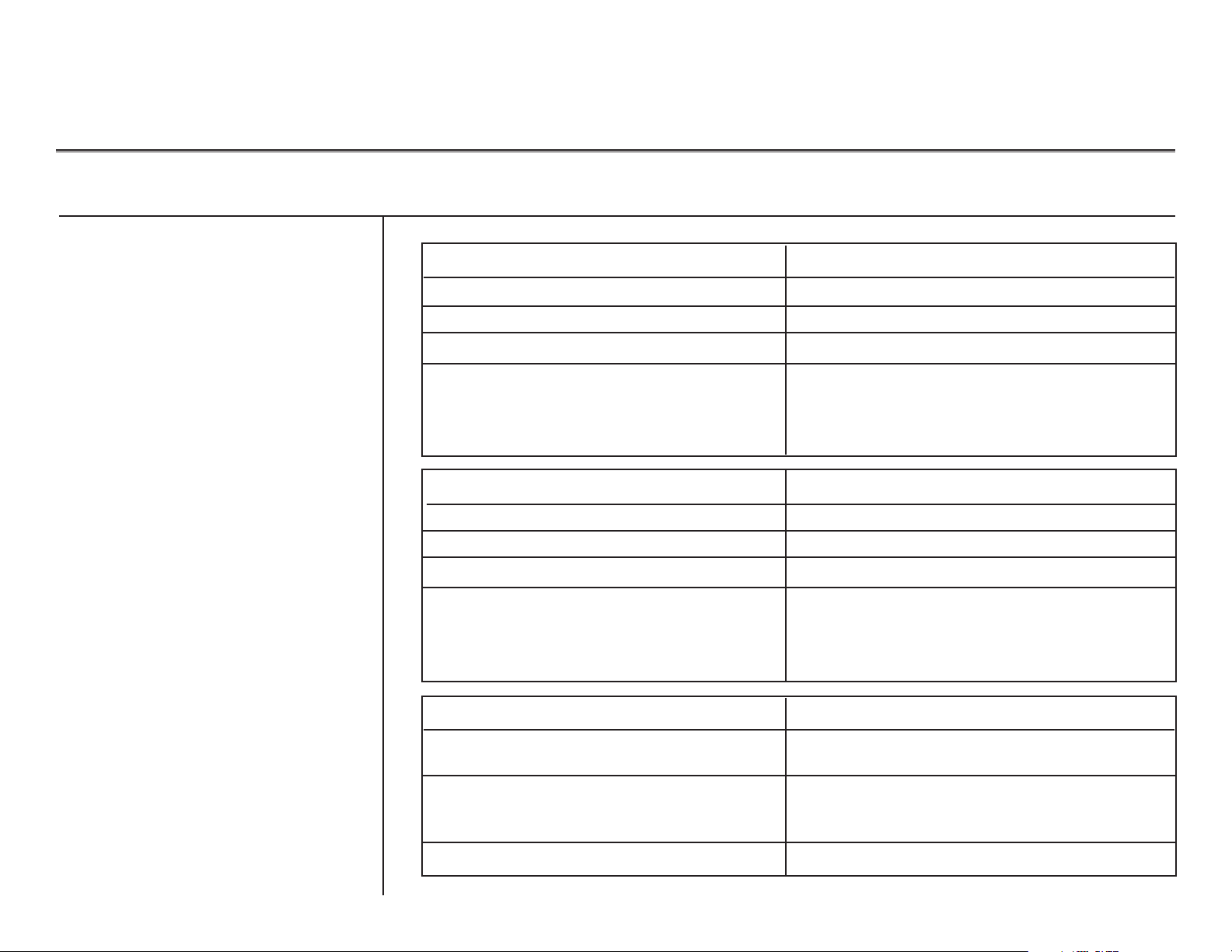

To adjust... Do this...

Base up speed Turn base up control valve:

clockwise to decrease speed, or

counterclockwise to increase speed.

Base down speed Turn base down control valve:

clockwise to decrease speed, or

counterclockwise to increase speed

Back up speed Turn back up control valve

counterclockwise to decrease speed, or

clockwise to increase speed.

NOTE: This is opposite of the other

three control valves. Turning the back

up valve counterclockwise too far may

prevent the back from moving up.

Back down speed Turn the back down control valve:

clockwise to decrease speed, or

counterclockwise to increase speed.

Adjusting the Hydraulic Manifold

Adjusting the

Hydraulic Manifold

Page 11

85.0812.00, 2003 CH-11

Chairs Hydraulic Manifold

Task Description

1 Remove the motor/pump cover from the chair.

2 Fit a 5/8" wrench to the high pressure outlet port

(either lift or tilt, whichever is in hydrostatic lock) of

the hydraulic manifold. Hold the port still and use a

9/16" wrench to loosen the hose fitting.

3 Place a shop rag around the fitting to absorb

the fluid.

4 Carefully loosen the fitting counterclockwise until oil

begins to leak from the fitting. Retighten the fitting.

Operate the down function. A second release of

hydraulic fluid may be required.

5 Adjust the limit switch that caused the hydrostatic

lock (refer to Adjusting the Base Up Limit Switch). In

some cases, it may be necessary to remove and

replace the limit switch. Adjust the new limit switch

as needed. Also ensure that the large gear/actuator

is securely installed and not slipping.

6Cycle the chair a couple of times to verify it is no

longer in hydrostatic lock.

Tilt cylinder

high pressure

fitting

Lift cylinder

high pressure

fitting

Correcting

Hydrostatic

Lock

Hydraulic lock occurs based on the following conditions:

•chair base or back is stuck in full up position

• limit switch not activated, or

• down solenoid poppet is unable to open based on excess hydraulic pressure.

Correcting Hydrostatic Lock

Page 12

85.0812.00, 2003 CH-12

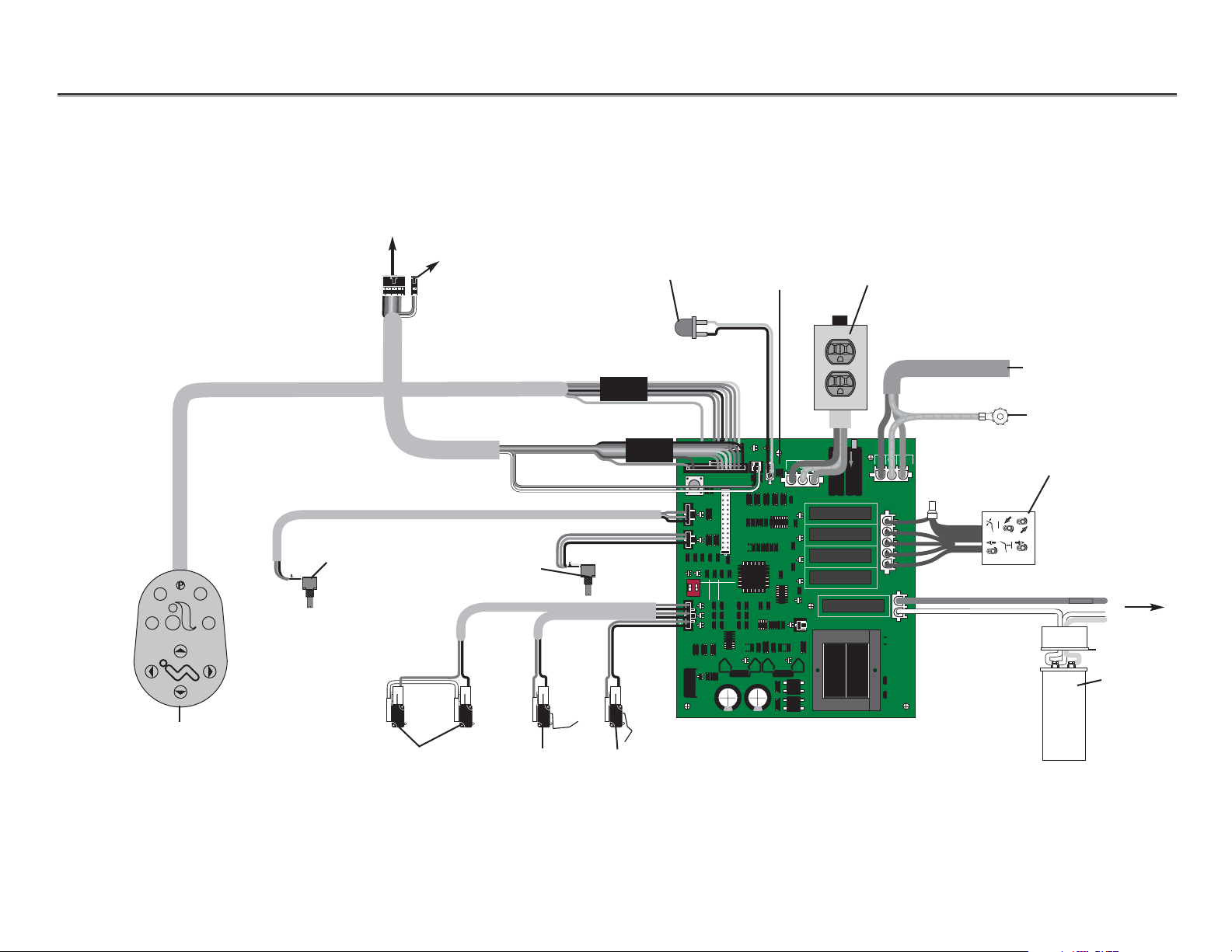

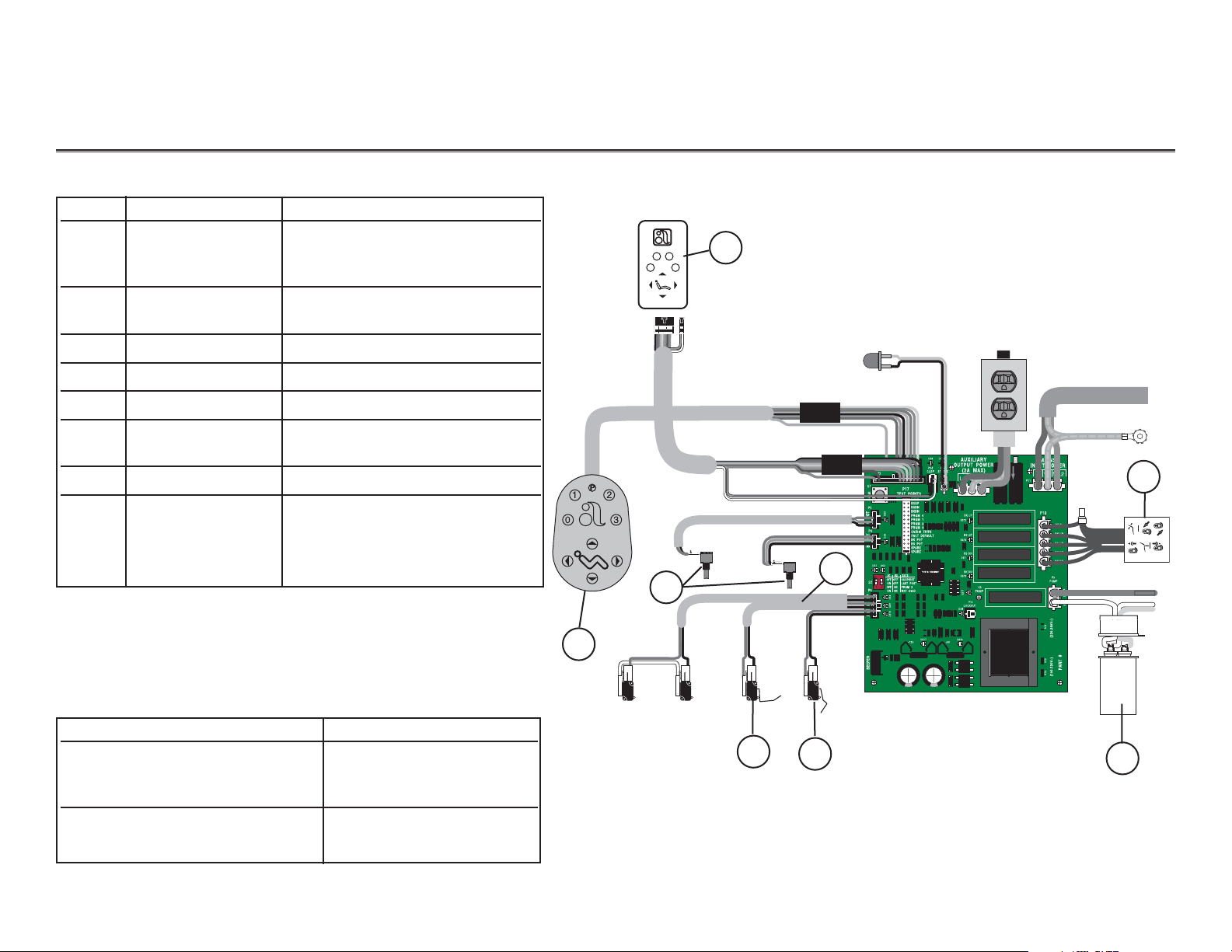

Chairs Electrical System Wiring Diagram

Optional duplex

100V and 120V only

Ground

Footswitch

LED light

Back positioning

potentiometer

Base positioning

potentiometer

Main power from

electrical outlet

Hydraulic manifold

To post box, or

Radius lift arm connector

Stop plate

limit switches

Base up limit

switch

Back up limit

switch

Capacitor

To hydraulic

motor/pump

}

To cuspidor

stop switch

NOTE: If there is no cuspidor, remove

jumper from cable and place

on board

Place jumper

here if there is

no cuspidor

DS8

P

17

BKUP

BSU

P

BSDN

BK

DN

PRGM

0

PRGM

1

PRGM

2

PRGM

3

EN/DIS TP/F

FACT DEFAU

BK POT

BS PO

T

SPAR

E

SPAR

E

"STATIC SENSITIVE

CUSP/RET

AST POS

T

L

PRGM

3

NOT USE

D

+12V +5V

P14

CUSP STATUS

S

LT

DS15

P16

"

AUXILIARY

OUTPUT POWE

(2A MAX

L1 N/L2

BK UP

DS12

BS UP

DS14

BS DN

DS7

BK DN

DS13

K5

PUMP

DS11

P13

LOCKOUT

DS4

DS16DS17

CB2

CB1

R

)

P12

MAINS

INPUT POWER

L1

P11

P10

R74 R72 R73

N/L2

N/L2

BK UP

BS UP

BS DN

BK DN

P9

PUMP

PUMP

N/L2

)

~

V

240

220

(

#

)

~

T

V

R

A

120

-

P

100

(

P1

P2

S1

TEST POINTS

PRGM

P5

T

DS3DS5

O

P

BK

P4

T

O

SP

2

1

0

3

B

DS1

DS2

#1 #2SETS

ON

O

FF

O

FF

S2

O

N

O

FF

12

O

FF

O

N

P6

O

N

O

N

SP

DS6DS9DS10

BK

S

B

R

E

P

EE

B

Page 13

85.0812.00, 2003 CH-13

Chairs Electrical Systems Service Parts

Item # Part Number Description

1 61.1332.00 100V, Yellow wires

61.1333.00 120V, Black wires

61.1334.00 240V, Red wires

2 90.1031.00 Capacitor with boot (100-120V)

90.1034.00 Capacitor with boot (240V)

3 041.372.00 Positioning potentiometer

4 61.2065.00 Back up limit switch

5 044.184.01 Base up limit switch

6 61.2099.00 Cable assy, tilt switch

(1040) only

7 61.3043.00 8-button footswitch

8 39.1045.00 Chair touchpad

39.1385.00 Performer touchpad

39.1090.00 Cascade Master with cuspidor

39.1090.00 Cascade Master w/o cuspidor

To Replace Circuit Board P/N Order this kit

61.2510.00 90.1029.00 (100-120V)

61.1214.01

61.1373.01

61.2512.00 90.1029.01(220-240V)

61.1217.01

1

2

3

4

5

6

7

8

21

0

3

Page 14

CH-14

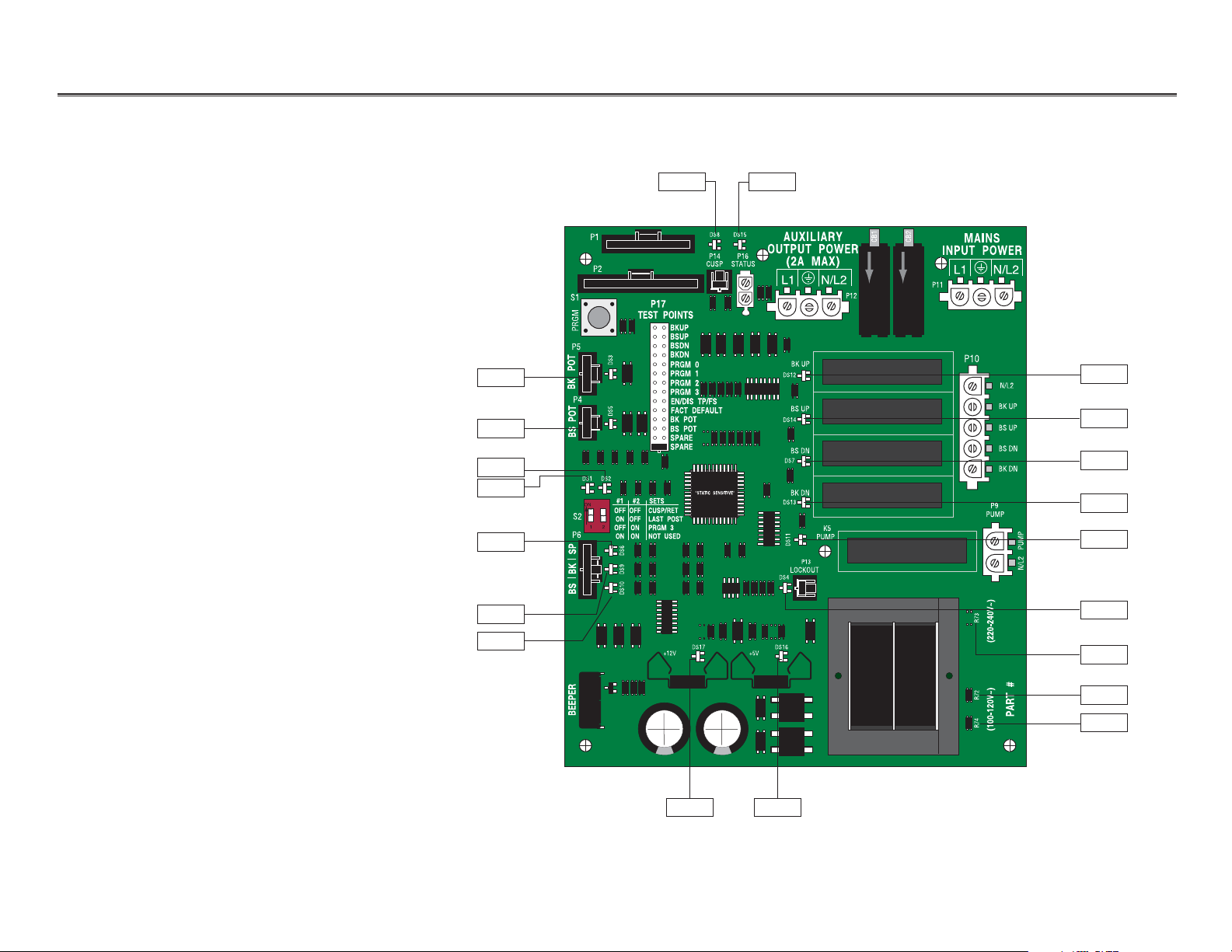

Chairs Diagnostic LEDs for the Circuit Board

LEDs

NOTE: Refer to Testing Factory Defaults

for more details.

DS1

DS2

DS3

DS7

DS8

DS9

DS10

DS11

DS12

DS13

DS4

DS5

DS6

DS14

DS15

DS16

DS17

R73

R72

R74

85.0812.00, 2003

Page 15

85.0812.00, 2003 CH-15

Chairs Diagnostic LEDs for the Circuit Board

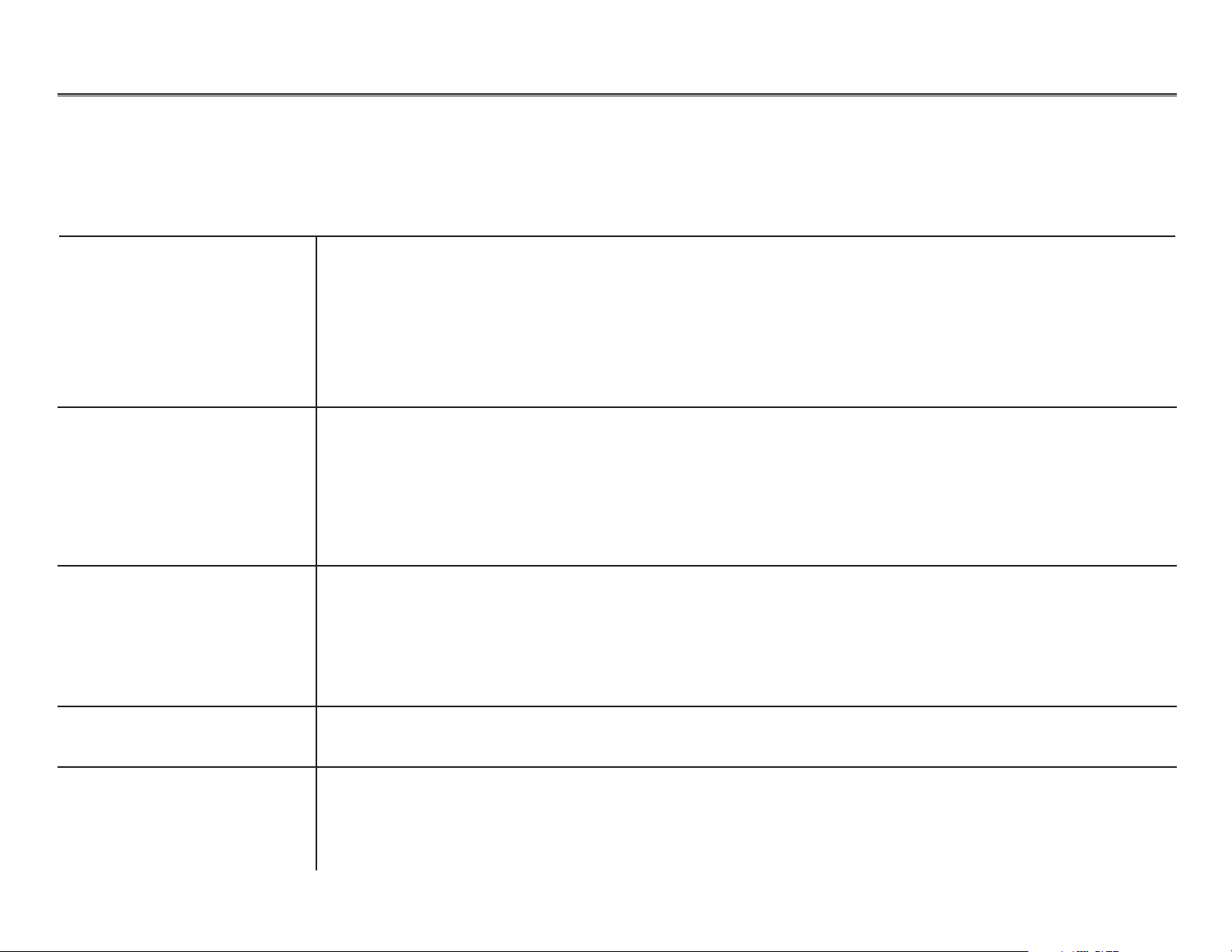

LED Description Information Communicated

DS1 S2 (red DIP switch) is ON Switch is ON

DS2

DS3 Back Potentiometer LED ON Back potentiometer is functioning normally when the chair back is moving

DS4 Handpiece Lockout LED ON Lockout enabled

DS5 Base Potentiometer LED ON Base potentiometer is functioning normally when the chair base is moving

DS6 Chair Stop Plate Limit Switch LED ON Chair stop plate limit switch activated

DS7 Base Down LED Relay is ON when LED is ON and the function is moving

DS11 Pump LED

DS12 Back Up LED

DS13 Back Down LED

DS14 Base Up LED

DS8 Cuspidor Limit Switch LED ON Cuspidor limit switch activated, or jumper is missing

DS9 Back Up Limit Switch LED ON Back Up limit switch activated

DS10 Base Up Limit Switch LED ON Base Up limit switch activated

DS15 Status LED ON ON: Normal operation

OFF: Microcontroller is not functioning. Verify voltage regulator LEDs

(DS16 and DS17) are ON. Is the chair plugged in? Circuit breaker tripped?

Slow Blink: Check cuspidor (DS8) and stop plate (DS6) limit switch LEDs

Fast Blink: Check handpiece lockout (DS4) LED

Double Blink: A SPARE jumper is in the FACT DEFAULT position

DS16 5V Regulator LED OFF 1. Power to circuit board is OFF, or

2. There is a short in the cable to the base or back potentiometer. Disconnect all cables

except the power cable. Plug the cables in one at a time (the LED will turn ON when the

problem is fixed).

DS17 12V Regulator LED OFF 1. Power to circuit board is OFF, or

2. There is a short in the cable to the status light or limit switch (the LED will turn ON when

the problem is fixed).

Page 16

85.0812.00, 2003 CH-16

Chairs Chair Printed Circuit Board (PCB)

Testing and

Programming

the Circuit Board

WARNING

The chair will begin to

move automatically

during this test; to avoid

injury or equipment

damage, remove all

possible obstructions and

maintain a safe distance

from the chair. To

interrupt the chair cycle,

press any button on the

touchpad or footswitch,

or activate the chair

stop plate.

Follow these steps to test and program the chair circuit board.

Task Description

1 Insert the SPARE jumper into the FACT DEFAULT location (on P17).

Result: The chair will cycle the base and back movements and automatically

reprogram the memory positions to the factory settings

(position 0 to entry/exit; 1 and 2 to the same pre-programmed positions;

and 3 to cuspidor/return).

If the circuit board beeps three times, continue with step two.

If the circuit board beeps just once, the chair cycle has been interrupted. Diagnose

and correct any errors, then press either circuit breaker for five seconds to restart

the cycle (refer to Testing Factory Defaults).

2Move the jumper from the FACT DEFAULT location (on P17) back to the

SPARE location.

NOTE: The jumper must be in the SPARE position for normal chair functions and

safe operation.

3Press “1” on the touchpad or footswitch, or the green position on the

8-function footswitch.

Result: The chair will move to the operating position.

4Press “0” on the touchpad or footswitch, or the red button on the 8-function

footswitch.

Result: The chair will move to the entry/exit position.

NOTE: The chair programmable position buttons can be reprogrammed to the

desired positions as specified by the dental team.

Page 17

85.0812.00, 2003 CH-17

Chairs Tests

Problem Action

Factory Default test will not start

(LEDs DS15, DS16 and DS17

are Off)

Factory Default test will not start

(LED DS15 is Off; DS16 and DS17

are ON)

Factory Default test will not start

(LED DS15 is blinking; DS16 and

DS17 are ON)

If . . .

Then . . .

Transformer thermal limiter is open

Circuit breaker is tripped

Wait for transformer to cool off.

Reset circuit breaker (short circuit fault currents

may damage the circuit breaker and prevent it

from resetting).

If . . .

Then . . .

Input voltage is too low or is outside the

required range

Microcontroller is not functioning

Ve rify input voltage and voltage selection

resistors (100-120VAC=R72 and R74)

(220-240VAC=R73).

Replace the circuit board.

If . . .

Then . . .

Input voltage is too low or is outside the

required range

Microcontroller is not functioning

Ve rify input voltage and voltage selection

resistors (100-120VAC=R72 and R74)

(220-240VAC=R73).

Replace the circuit board.

Testing Factory Defaults

The table lists conditions and corrective actions for testing the factory defaults for LEDs.

Page 18

85.0812.00, 2003 CH-18

Chairs Tests

Problem Action

Factory Default test halts during

the BASE UP test and the PCB

board beeps one time

Factory Default test halts during

the BACK DOWN test and PCB

board beeps one time

If . . .

Then . . .

Input voltage is too low or is outside the

required range

Base Up limit switch is activated

Motor thermal limiter is open, motor is hot

Motor capacitor is defective

Base Up solenoid is defective

Base is in hydrostatic lock

Potentiometer is not changing voltage

Ve rify input voltage and voltage selection

resistors (100-120VAC=R72 and

R74 (220-240VAC=R73).

Verify switch operation.

Wait for motor to cool off.

Test capacitor and replace, if needed.

Test solenoid and replace, if needed.

Refer to Correcting Hydrostatic Lock.

Ve rify potentiometer LED comes ON when base

is moving.

Check potentiometer mechanical drive and

electrical connections.

If . . .

Then . . .

Stop plate limit switch is activated

Stop plate is jammed

Back Down solenoid is defective

Back is in hydrostatic lock

Potentiometer is not changing voltage

Verify switch operation.

Remove and reinstall the stop plate.

Test solenoid and replace if needed.

Refer to Correcting Hydrostatic Lock.

Ve rify potentiometer LED is ON when back

is moving.

Check potentiometer mechanical drive and

electrical connections.

Page 19

85.0812.00, 2003

CH-19

Chairs Tests

Problem Action

Factory Default test halts during

the BACK UP test

Factory Default test halts during

the BASE DOWN test

Chair moves by itself when power

is turned ON

If . . .

Then . . .

Back up limit switch is activated

Back Up solenoid is defective

Back is in hydrostatic lock

Potentiometer is not changing voltage

Verify switch operation.

Test solenoid and replace, if needed.

Refer to the Correcting Hydrostatic Lock.

Ve rify potentiometer LED is ON when back

is moving.

Check potentiometer mechanical drive and

electrical connections.

If . . .

Then . . .

Stop plate limit switch is activated

Base Down solenoid is defective

Base is in hydrostatic lock

Potentiometer is not changing voltage

Verify switch operation.

Test solenoid and replace if needed.

Refer to Correcting Hydrostatic Lock.

Ve rify potentiometer LED is ON when base

is moving.

Check potentiometer mechanical drive and

electrical connections.

If . . .

Then . . .

The jumper is in FACT DEFAULT position

Short circuit in touchpad or footswitch

Short circuit on circuit board

Verify that the jumper is in the

SPARE position.

Unplug the touchpad and footswitch; reset the

circuit breaker. If the problem isn’t repeated, the

touchpad or footswitch may have shorted.

Replace the circuit board.

Page 20

Chairs Chair Printed Circuit Board (PCB)

Raise the chair with the

stop plate limit switch

Enable and disable touchpad

and footswitch buttons

Handpiece lockout

Diagnostic LEDs

Test Points Header

Plug the chair into an electrical outlet.

Tap the chair stop plate three times within five seconds and hold on the third tap.

Result: The chair base will continue to rise as long as the stop plate is held in. This function is

automatically disabled after five minutes but is re-enabled upon each power up. To reset the

five-minute timer, depress either circuit breaker until the LEDs turn OFF, then release the

circuit breaker.

Place the SPARE jumper in the EN/DIS TP/FS position of the Test Points header P17.

Push the buttons to be Enabled or Disabled (PRGM, PRGM 0, PRGM 1, PRGM 2, PRGM 3).

Result: One beep indicates the button is disabled. Three beeps indicate the button in enabled.

Place the SPARE jumper back into the SPARE position of the Test Points header P17.

Plumb a normally open air-electric switch ( kit P/N 61.1384.00) to the air-coolant tubing (green with

long white dashes).

Insert the two position connector from the air-electric switch into P13 Lockout (next to the transformer)

See Diagnostic LEDs for the Circuit Board.

Use a SPARE jumper to test the chair manual functions (BKUP, BSUP, BSDN, BKDN).

BK POT and BS POT points allow test meter check of potentiometer voltages and

measurement of the analog DC voltage from pin 2 of the potentiometer.

Feature Programming

The chart provides information on new features and associated programming on the PCB.

CH-2085.0812.00, 2003

Identifying

New Features

Page 21

85.0812.00, 2003 CH-21

Chairs Electrical System Wiring Diagram (for PCB with no LEDs)

Item # Part Number Description

1 61.3043.00 8-button footswitch

2 041.372.00 Back positioning potentiometer

3 041.372.00 Base positioning potentiometer

4 61.2065.00 Back up limit switch

5 044.184.01 Base up limit switch

1

2

4

5

3

Back

Base

LED light

Printed

circuit

board

See next page

To post box, or Radius lift

arm connector

To cuspidor

stop switch

1

0

2

3

S1

P5

P4

S2

P14 CUSP

12

P6

TEST

POINTS

ENTR

EXIT

BSDN

BSUP

Bk DN

Bk UP

#1 #2 SETS

- - - - - - - - - - - - - - - - - - -

ON

OFF OFF sCUSP/RET

ON OFF LAST POS

OFF ON PRGM 3

P11

P1

30A, 240VAC

10A, 240VAC

30A, 240VAC

Potter & Brumfield

T90S1D12-24

Coil: 24VDC

Potter & Brumfield

T90S1D12-24

Coil: 24VDC

T90S1D12-24

Coil: 24VDC

10A, 240VAC

30A, 240VAC

30A, 240VAC

10A, 240VAC

T90S1D12-24

Coil: 24VDC

T90S1D12-24

Coil: 24VDC

9412

9412

P7

MADE IN U.S.A.

MADE IN U.S.A.

15A, 125VAC

MADE IN U.S.A.

15A, 125VAC

MADE IN U.S.A.

15A, 125VAC

5687

5687

P10

9412

Potter & Brumfield

9412

Potter & Brumfield

P12

MADE IN U.S.A.

15A, 125VAC

MADE IN U.S.A.

15A, 125VAC

P9

10A, 240VAC

10A, 240VAC

30A, 240VAC

30A, 240VAC

1243

1243

T90S1D12-24

Coil: 24VDC

T90S1D12-24

Coil: 24VDC

9412

Potter & Brumfield

9412

Potter & Brumfield

30A, 240VAC

MADE IN U.S.A.

10A, 240VAC

15A, 125VAC

30A, 240VAC

MADE IN U.S.A.

10A, 240VAC

T90S1D12-24

Coil: 24VDC

T90S1D12-24

Coil: 24VDC

15A, 125VAC

9412

Potter & Brumfield

9412

Potter & Brumfield

9412

Potter & Brumfield

T90S1D12-24

Coil: 24VDC

9412

Potter & Brumfield

T90S1D12-24

Coil: 24VDC

30A, 240VAC

30A, 240VAC

10A, 240VAC

15A, 125VAC

10A, 240VAC

15A, 125VAC

MADE IN U.S.A.

MADE IN U.S.A.

Page 22

85.0812.00, 2003 CH-22

Chairs Electrical System Wiring Diagram (for PCB with no LEDs)

From electrical outlet

Ground

Optional duplex

100V and 120V only

Item # Part Number Description

1 Hydraulic manifold with

61.1332.00 100V, Yellow wires

61.1333.00 120 V, Black wires

61.1334.00 240 V, Red wires

2 90.1031.00 Capacitor with boot (100-120V)

90.1034.00 Capacitor with boot (240V)

1

2

To hydraulic

motor/pump

See previous page

Printed circuit board

NOTE: P11 must be used

for the power cord

White

Yel low

S1

S1

P5

P5

P4

P4

S2

S2

P14 CUSP

P14 CUSP

TEST

TEST

POINTS

POINTS

ENTR

ENTR

EXIT

EXIT

BSDN

BSDN

BSUP

BSUP

Bk DN

Bk DN

Bk UP

Bk UP

#1 #2 SETS

#1 #2 SETS

- - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - -

ON

ON

12

12

OFF OFF sCUSP/RET

OFF OFF CUSP/RET

ON OFF LAST POS

ON OFF LAST POS

OFF ON PRGM 3

OFF ON PRGM 3

ON ON DUPLEX

ON ON DUPLEX

P6

P6

100 - 120 V

P2

P1

P1

P7

P7

115V

9412

Potter & Brumfield

T90S1D12-24

Coil: 24VDC

9412

Potter & Brumfield

MADE IN U.S.A.

10A, 240VAC

15A, 125VAC

MADE IN U.S.A.

15A, 125VAC

30A, 240VAC

9412

Potter & Brumfield

T90S1D12-24

Coil: 24VDC

9412

Potter & Brumfield

A-DEC 61-1215-00 REV L ASSY 61-1214-01 REV E

30A, 240VAC

10A, 240VAC

15A, 125VAC

5687

Potter & Brumfield

T90S1D12-24

Coil: 24VDC

30A, 240VAC

10A, 240VAC

15A, 125VAC

MADE IN U.S.A.

9412

MADE IN U.S.A.

P11P2

P12

P9

1243

P10

MADE IN U.S.A.

10A, 240VAC

15A, 125VAC

9412

Potter & Brumfield

T90S1D12-24

30A, 240VAC

Coil: 24VDC

9412

Potter & Brumfield

T90S1D12-24

Coil: 24VDC

30A, 240VAC

10A, 240VAC

15A, 125VAC

MADE IN U.S.A.

Page 23

85.0812.00, 2003 CH-23

Chairs Fuse Table for Old-style Circuit Boards (no LEDs)

Amps Description Where used Part Number

.125 3AG, Slo-Blo, 250V Chairs, 100/120V 041.360.00

.150 3AG, Slo-Blo, 250V Chairs, 240V 046.126.00

.300 3AG, Slo-Blo, 250V 1040, 1030 Chairs 100/120V 046.069.00

1010/1015/1020/1021 Chair, 120V

1010/1020 Chair, 100V

1005 Priority Chair 240V

.375 3AG, Slo-Blo, 250V Transformer 120V/24V Accessory 046.021.00

.600 3AG, Slo-Blo, 250V 1005 Priority Chair 100/120V 046.070.00

5.0 3AG, Slo-Blo, 250V Chairs 240V UK 046.100.00

Slo-Blo Fuses 3AG, 1 1/4" X 1/4" (31.75mm X 6.35mm)

Time Lag Fuses, 5mm X 20mm (1/5" X 3/4")

Actual Size

Actual Size

NOTE: There are no replaceable fuses on the following circuit boards:

90.1029.00 (100-120V) and 90.1029.01 (220-240V).

*Decade chairs after E863254; Cascade chairs after E863116

Amps Description Where used Part Number

.040 Time Lag, 250V Chairs 230V* 044.194.00

.063 Time Lag, 250V Chairs 115V* 044.193.00

6.30 Time Lag, 250V Chairs 230V* 044.147.00

10.0 Time Lag, 250V Chairs 115V* 044.192.00

Page 24

85.0812.00, 2003 CH-24

Chairs Cascade 1040 Back Positioning Potentiometer and Limit Switch

Removing the

Helical Drive Shaft

(Cascade 1040 Chair )

Task Description

1 Position the chair back full down and

remove the seat upholstery.

2Disconnect the limit switch wiring

harness from the limit switch.

3Remove the limit switch mounting

screws and limit switch from the bracket.

Lower the toeboard, if necessary, to

access the rear mounting screw. Do not

bend the switch arm.

4Remove the bracket mounting screws.

5Remove the helical drive shaft from the

potentiometer shaft. While holding the

helical shaft, reach underneath the chair

to th base of the backrest. Grasp the

bracket and pull it away from the

helical shaft.

6Remove the helical drive shaft from the

chair by moving it toward the chair

backrest and then slightly to the side to

dislodge it from the holder and guide.

Limit switch

mounting screws

Switch arm

Potentiometer

shaft

Urethane

tubing 3/8" OD

Bracket mounting

screws

Helical

drive shaft

Holder

Cascade 1040 Back Positioning Potentiometer

and Limit Switch

Tip

Follow these steps to remove the limit switch and

the helical drive shaft from the potentiometer shaft.

Page 25

85.0812.00, 2003 CH-25

Chairs Cascade 1040 Back Positioning Potentiometer and Limit Switch

Reinstalling the

Helical Drive Shaft

(Cascade 1040 Chair)

Task Description

1 Reinstall the helical drive shaft by fully inserting the tip through the guide and into the holder.

2Install the helical shaft onto the potentiometer shaft.

3 Reinstall the mounting screws, being careful not to pinch any wires.

4 Reinstall the limit switch on the bracket and reconnect it with the wiring harness.

5 Ensure the positioning potentiometer electrical connections are complete.

6 Reprogram the auto-positioning functions (refer to Programming the Chair).

7 Reinstall the upholstery.

Adjusting the

Potentiometer

(Cascade 1040 Chair)

Turn the potentiometer shaft counterclockwise

until it will no longer turn. Then turn the shaft

clockwise 1/8 of a turn.

Potentiometer Shaft

Clockwise

Setting the Back Potentiometer on the

Cascade 1040 Chair

Counterclockwise

Follow these steps to reinstall the back positioning potentiometer helical shaft and adjust the limit switch.

Page 26

85.0812.00, 2003 CH-26

Chairs Decade 1011/1021 Back Positioning Potentiometer and Limit Switch

Removing the

Helical Drive Shaft

(Decade 1011/1021 Chairs)

Task Description

1 Position the chair back full up and

remove the seat upholstery.

2Disconnect the limit switch wiring

harness from the limit switch.

3Remove the limit switch mounting

screws and limit switch from the

bracket. Do not bend the switch arm.

4Remove the bracket mounting screws.

5Remove the helical drive shaft from the

potentiometer shaft. While holding

the helical shaft, reach underneath the

chair to the base of the backrest. Grasp

the bracket and pull away from the

helical shaft.

6Remove the helical drive shaft from the

chair by moving it toward the chair

backrest and then slightly to the side to

dislodge it from the holder and guide.

Limit switch

mounting screws

Switch arm

Potentiometer

shaft

Urethane

tubing 3/8" OD

Bracket mounting

screws

Helical

drive shaft

Decade 1011/1021 Back Positioning

Potentiometer and Limit Switch

Tip

Follow these steps to remove the limit

switch and helical drive shaft from the chair.

Page 27

85.0812.00, 2003 CH-27

Chairs Decade 1011/1021 Back Positioning Potentiometer and Limit Switch

Reinstalling the

Helical Shaft

(Decade 1011/1021

Chairs)

Task Description

1 Reinstall the helical drive shaft by fully inserting the tip through the guide and into the holder.

2Install the helical shaft onto the potentiometer shaft.

3 Reinstall the mounting screws, being careful not to pinch any wires.

4Reinstall the limit switch on the bracket and reconnect it with the wiring harness.

5 Ensure the positioning potentiometer electrical connections are complete.

6 Reprogram the auto-positioning functions (refer to Programming the Chair).

7 Reinstall the upholstery.

Turn the potentiometer shaft clockwise until

it will no longer turn. Then turn the shaft

counterclockwise 1/8 of a turn.

Potentiometer shaft

Counterclockwise

Setting the Back Potentiometer on the

Decade 1011/1021 Chair

Clockwise

Follow these steps to reinstall the back positioning potentiometer helical shaft and to reposition the

limit switch.

Adjusting the

Potentiometer

(Decade 1011/1021 Chairs)

Page 28

85.0812.00, 2003 CH-28

Chairs Cascade and Decade Base Positioning Potentiometer

Working with the

Back and Base

Positioning

Potentiometers

The back and base positioning potentiometers (pots) perform two tasks for the controller:

•Provide the controller with a voltage level representing the current position of the chair base and back.

The voltage level is stored by the controller for later reference during auto-positioning.

•Tell the controller where the chair base and back are currently positioned. The controller compares the

current voltage level to the voltage level stored during auto-positioning programming.

The base positioning pot is gear-driven by movement of the chair lift arm. The back positioning pot is

driven by movement of the chair back.

Page 29

85.0812.00, 2003 CH-29

Chairs Cascade and Decade Base Positioning Potentiometer

Adjusting the

Base Positioning

Potentiometer

Task Description

1 Remove the motor/pump cover and

position the chair base down.

2Remove the mounting screw.

3Turn the potentiometer gear clockwise

until it stops.

4Align the potentiometer assembly, then

turn the potentiometer gear

counterclockwise two teeth (relative to

one tooth on the large drive gear).

5 Ensure all electrical connections to the

limit switch and positioning

potentiometer are properly connected

6Raise the chair base while observing the

two gears for binding.

7Reinstall the motor/pump cover

and reprogram the pre-positioning

functions.

Limit switch

Large drive

gear

Potentiometer gear

Positioning

potentiometer

Mounting

screw

Clockwise

Counterclockwise

Adjusting the Base Positioning Potentiometer

Base down

Follow these steps to adjust the base positioning potentiometer.

NOTE: Do not raise the base to full up

until you have adjusted the base

up limit switch (see Adjusting

the Base Up Limit Switch).

Page 30

85.0812.00, 2003 CH-30

Chairs Cascade and Decade Base Positioning Potentiometer

2

1

3

Item # Part Number Description

1 041.372.00 Potentiometer w/nut

5K ohm, +20%, 1W

2 044.184.01 Limit switch, modified

3 61.1295.00 Gear, 24 pitch 30 tooth

4 61.1222.00 Potentiometer gear

Replacing Base Positioning Potentiometer,

Limit Switch and Gears

4

Base Positoning Potentiometer

Page 31

85.0812.00, 2003 CH-31

Chairs Cascade and Decade Base Up Limit Switches

Working with the

Back Up and Base

Up Limit Switches

The chair base and back up limit switches detect when the maximum allowed up travel is reached.

The two limit switches are normally closed enabling the base and back up relay circuits. If an up limit

switch is opened, two things occur:

•The base or back up function relay is disabled causing the up function solenoid to shut off the

flow of hydraulic fluid to the cylinder.

• The controller, sensing that a back up or base up relay has been disabled, turns off the

hydraulic pump.

The base up limit switch is actuated by a pin located on the positioning potentiometer drive gear.

The back up limit switch is actuated by a glide block, which is part of the back tilt mechanism.

Page 32

85.0812.00, 2003 CH-32

Chairs Cascade and Decade Base Up Limit Switches

Adjusting the Base

Up Limit Switch

NOTE: For correct limit switch actuation,

the actuator tab on the large gear

should be at approximately the 5:30

clock position when the chair is full

base down.

Task Description

1 Remove the motor/pump cover.

2 Loosen the two screws clamping the

limit switch to the mounting bracket.

3 Position the chair base up until

the distance from the floor to the

base of the upper chair casting is

23" (584mm).

4 Push the limit switch against the

actuator on the drive gear until the

switch opens (clicks).

5Tighten the clamping screws, making

sure they do not hit the gear.

6Lower the chair base down until the

limit switch has closed, then raise the

chair full base up. Check the distance

between from the floor to the base of

the upper chair casting to ensure it is

23" (584mm).

Raising the Chair to the Correct Base Up Height

Adjusting the Base Up Limit Switch

23"

584mm

Limit switch

Switch arm

Mounting

bracket

Actuator

Clamping

screws

NOTE: Positioning

potentiometer

omitted for clarity.

Follow these steps for adjusting the base up limit switch.

Page 33

85.0812.00, 2003 CH-33

Chairs Auto-Positioning

Programming

the Chair

Task Description

1Use the footswitch or touchpad to set the chair at the

desired position for base and back.

2Press and release the program button.

Result: You will hear a single beep.

3Within four seconds, press an automatic position button

(0, 1, 2, or 3) on the footswitch or touchpad to store the

chair position. On an 8-function footswitch, move the

actuator to the desired position.

Result: You will hear three beeps confirming that

the function has been programmed.

NOTE: PCBs manufactured before 1994, do not beep.

Test the programming by trying it.

Performer III Touchpad

8-Button Footswitch8-Function Footswitch

Left

actuator

Right

actuator

Pre-position (1)

Pre-position (2)

Entry/Exit (0)

Cuspidor/return,

last position, or

pre-position (3)

Program

button

Program

button

Program

button

Base up

Back down

Back up

Base down

Programmable

position (1)

Programmable

entry/exit (0)

Programmable

position (2)

Cuspidor

return (3)

Base up

Back up

Base down

Back down

Replacement membrane P/N 61.2189.00

Replacement membrane P/N 61.3048.00

Follow these steps to set the auto-positioning for the chair.

Chair Touchpad

Program

button

Programmable

position (1)

Programmable

entry/exit (0)

Cuspidor

return (3)

Back down

Base up

Back up

Base down

Programmable

position (2)

21

0

3

1

0

2

3

1

0

2

3

Page 34

85.0812.00, 2003 CH-34

Chairs Function 3 Programming

Programming

Function 3

Function

Programming

Cuspidor/Return

NOTE: Chairs with S/N J467728

and later are factory set with

function 3 as cuspidor/return

Last Position

Programmable Position

NOTE: Chairs up to S/N J467727

are factory set with function 3

as a programmable position

Description

Switches 1 and 2 are OFF.

Switch 1 is ON and switch 2 is OFF.

Go back and forth between two

positions by momentarily moving

the righthand actuator on the

8-function footswitch to position 3 or

pressing number 3 on the touchpad or

8-button footswitch.

Switch 1 is OFF and switch 2 is ON.

Move the chair to the desired position.

Press and release the program button.

After the beep, push button 3 on the

touchpad or 8-button footswitch or

move the actuator to position 3 on the

8-function footswitch. The single beep

confirms the position is programmed.

Used to raise the chair back to a

programmable upright position

providing the patient access to the

cuspidor. Momentarily pushing button 3

on the touchpad or 8-button footswitch,

or moving the actuator to position three

on the 8-function footswitch, returns the

back to the previous position.

Anon-programmable position that

simply moves the chair base and back to

their previous positions.

This option is used to set the base and

back to a predesignated

position. It allows this function to be

programmed like 0, 1, and 2.

Switch 2

Function 3 DIP Switch

before 2000

Switch 1

Before 2000

1 2

ON

Page 35

85.0812.00, 2003 CH-35

Chairs Function 3 Programming

Switch 1

Switch 2

Function 3 DIP Switch

after 2000

Programming

Function 3

Function

Programming

Cuspidor/Return

Last Position

Programmable Position

Description

Both switches 1 and 2 are OFF.

Switch 1 is ON and switch 2 is OFF.

Go back and forth between two

positions by momentarily pushing the

right hand rocker button to position 3

or pressing number 3 on the touchpad.

Switch 1 is OFF and switch 2 is ON.

Move the chair to the desired position.

Press and release the program button.

After the tone, push button 3 on the

touchpad or footswitch or move the

actuator to position 3 on the 8-function

footswitch. The audible tone confirms

the position is programmed.

Used to raise the chair back to a

programmable upright position

providing the patient access to the

cuspidor. Momentarily pushing button 3

on the touchpad or 8-button footswitch,

or the actuator to position 3 on the

8-function footswitch will return the

back to the previous position.

Anon-programmable position that

simply moves the chair base and back

to their previous positions.

Used to set the base and back to a

predesignated position.

After 2000

Page 36

85.0812.00, 2003 CH-36

Chairs Cascade 1040 Vac Back Floor Box with Utilities

Air

Water

Water shutoff valve

Circulating

syringe drip

tube

NOTE: Ribbed tubing is

connected to pilot air

To/from vac back

assistant’s

instrumentation

}

Item # Part Number Description

1. 33.0048.04 Valve, toggle, 3-way, ON/OFF

2. 24.0100.03 Pressure indicator

2

1

Page 37

85.0812.00, 2003 CH-37

Chairs Cascade 1040 Vac Back Assistant’s Instrumentation

HVE valve

Vacuum canister

Saliva ejector

NOTE: Ribbed tubing connects

to syringe air

To/from floor box

2

1

{

Item # Part Number Description

1 23.0172.00 Pinched valve assy, single

2 23.1011.00 Syringe head assy

Page 38

85.0812.00, 2003 CH-38

Chairs Water Shutoff Valve and 3-way Toggle Valve

Item # Part Number Description

1 24.0137.01 9-hole gasket, pkg 10

2 013.032.00 Spring, conc, comp, .260/.350 OD

3 24.0132.00 Piston with O-ring, Delrin

4 24.0440.02 Diaphragm, pkg 10

Item # Part Number Description

1 33.0031.01 Toggle with pin, Gray

2 29.0840.00 Stem with O-rings, 3-way

3 22.0040.00 Spring, comp., .300 OD x .40

1

2

3

4

1

2

3

Water Shutoff Valve

34.0031.00

3-Way Toggle Valve

33.0048.04

Page 39

85.0812.00, 2003 CH-39

Chairs Glide Bar Tension Block and Swivel Brake

Item # Part Number Description

1 61.1569.00 Wearpad, sliding wedge

Cascade 1040 Glide Bar Tension Block

Decade 1011/1021 Glide Bar Tension Block

Cascade 1040 Swivel Brake

61.2055.00

Item # Part Number Description

1 61.1569.00 Wearpad, sliding wedge

Item # Part Number Description

1 61.1228.00 Thrust washer-brake pad assy

2 61.2227.00 Nut-brake pad assy

Decade 1011/1021 Swivel Brake

61.1538.01

Item # Part Number Description

1 61.1537.01 Replacement brake pads

2

1

1

1

1

Page 40

85.0812.00, 2003 CH-40

Chairs Double-Articulating Headrest

Adjusting the

DoubleArticulating

Headrest

Adjust Cascade 1040 Headrest

Glide Bar Tension

Double-Articulating Headrest

61.2265.00

Item # Part Number Description

1 61.2116.XX Double articulating

headrest upholstery

— 61.3046.00 Conversion kit, 1040

screw-on headrest

cushion. Applies to

chairs with the wire

formed headrest cushion

(S/N E442969 and before).

1

Upholstery

Replacement

Follow these steps to adjust the headrest.

Task Description

1 Adjust the glide bar until the headrest moves freely yet

maintains its position.

2Turn the screw clockwise to increase friction and hold

the headrest more securely.

3Turn the screw counterclockwise to decrease

friction and allow the headrest to move up and down

more freely. The Decade chair adjustment screw is

located in back of the glide bar.

NOTE: Use a phillips head screwdriver to adjust the glide

bar tension. You may need to remove the back

upholstery to access the adjustment screw.

Page 41

85.0812.00, 2003 CH-41

Chairs

Problem Action

Chair is inoperative

1 Do any relays on the printed circuit board click? Refer to Testing Relay Click.

YES: Go to step 2.

NO: Go to step 3.

2 Is the base/back all the way down?

YES: Go to Base or Back Up Function is Inoperative.

NO: Go to step 3.

3Has the solenoid fuse blown (120V only)?

YES: Replace the fuse. Check for shorted solenoids or shorted wiring to the solenoids (refer to

Testing Solenoid Continuity and Testing Wiring Harness Continuity). Retest chair functions.

NO: Go to step 4.

4 Complete the steps outlined in Testing Magnetic Pull. Is there magnetic pull at each solenoid?

YES: Go to step 5.

NO: Remove and replace the faulty solenoid (refer to Removing a Solenoid and

Replacing a Solenoid). Retest chair functions.

5 Is the chair in hydrostatic lock?

YES: Remedy hydrostatic lock (refer to Correcting Hydrostatic Lock). Retest chair functions.

NO: Check for and replace a faulty manifold or valve.

Troubleshooting

PCBs with no LEDs

Diagnostic information is presented in the following charts.

Page 42

85.0812.00, 2003 CH-42

Chairs Troubleshooting (for PCB with no LEDs)

Problem Action

6Is the printed circuit board fuse(s) blown?

YES: Remove and replace the fuse, then check the potentiometer wiring for damage, shorts, or

improper wiring. If the fuse blows again, disconnect the potentiometer wiring at P4 and

P5 on the printed circuit board. If the fuse still blows, remove and replace the printed

circuit board. Otherwise remove and replace the potentiometer wiring.

NO: Check the condition of the stop plate limit switches and wiring. Check the printed

circuit board connector P6 (limit switches). Unplug the chair from its power outlet and

plug it in again. If the chair is still inoperative, make sure there is power at the outlet. If

the preceding steps do not solve the problem, go to step 7.

7Disconnect the footswitch and, if installed, the touchpad. Use the printed circuit board test points to

activate chair up functions (refer to Using Chair Test Points). Does the chair work now?

YES: If there is a footswitch only, remove and replace the footswitch. If there is a touchpad

only, remove and replace the touchpad. If there is both a footswitch and touchpad,

go to step 8.

NO: The printed circuit board is faulty, remove and replace the printed circuit board.

8Reconnect the footswitch to the printed circuit board. Using the footswitch, operate the chair. Does

the chair work properly?

YES: Remove and replace the touchpad.

NO: Go to step 9.

9Reconnect the touchpad to the printed circuit board. Using the touchpad, operate the chair. Does the

chair work properly?

YES: Remove and replace the footswitch.

NO: The printed circuit board is faulty, remove and replace the printed circuit board.

Chair is inoperative

Page 43

Problem Action

85.0812.00, 2003 CH-43

Chairs Troubleshooting (for PCB with no LEDs)

1 Is the chair base or back up?

YES: Go to step 2.

NO: Go to step 3.

2Has the up limit switch activated (opened)? Refer to Testing Limit Switch Continuity and

Testing Limit and Stop Switches Voltage.

YES: Normal chair operation, check base up limit switch adjustment

(refer to Adjusting the Base Up Limit Switch). The back up limit switch is not adjustable.

NO: The chair may be in hydraulic lock. Remedy the hydrostatic lock

(refer to Correcting Hydrostatic Lock).

3Has the solenoid fuse blown (120V only)?

YES: Replace the fuse. Complete Testing Solenoid Continuity.

Replace shorted solenoids or shorted wiring to the solenoids, as necessary.

NO: Go to step 4.

4 Is the motor/pump hot?

YES: Wait 20 minutes for the thermal limiter to reset. If the Up function works, check for other

problems. If the Up function is still inoperative, go to step 5.

NO: Go to step 5.

5 Does a relay on the printed circuit board click (refer to Testing Relay Click)?

YES: Go to step 6.

NO: Go to step 7.

6 Complete the steps outlined in Testing Magnetic Pull. Is there magnetic pull at the solenoid?

YES: Go to step 12.

NO: The solenoid is faulty. Remove and replace the solenoid

(refer to Removing a Solenoid and Replacing a Solenoid).

Base or back up function

is inoperative

Page 44

Problem Action

Base or back up function

is inoperative

85.0812.00, 2003 CH-44

Chairs Troubleshooting (for PCB with no LEDs)

7Disconnect the footswitch and, if installed, the touchpad. Use the printed circuit board test points to

activate chair up function (refer to Using Chair Test Points). Does a relay on the printed circuit board

click (refer to Testing Relay Click)?

YES: Go to step 8.

NO: Go to step 10.

8 Does the UP function work?

YES: If there is a footswitch only, remove and replace the footswitch. If there is a touchpad

only, remove and replace the touchpad. If there is both a footswitch and touchpad,

go to step 9.

NO: Go to step 11.

9Reconnect the footswitch to the printed circuit board. Using the footswitch, operate the chair. Does

the UP function work?

YES: Remove and replace the touchpad.

NO: Go to step 10.

10 Reconnect the touchpad to the printed circuit board. Using the touchpad, operate the chair. Does the

UP function work?

YES: Remove and replace the footswitch.

NO: Go to step 11.

11 Complete the steps for Testing Magnetic Pull. Is there magnetic pull at the solenoid?

YES: Go to step 14.

NO: Remove and replace the faulty solenoid(s) (refer to Removing a Solenoid and

Replacing a Solenoid).

Page 45

Problem Action

85.0812.00, 2003 CH-45

Chairs Troubleshooting (for PCB with no LEDs)

Base or back up function

is inoperative

12 Is the limit switch faulty or open (refer to Testing Limit Switch Continuity and

Testing Limit and Stop Switches Voltage)?

YES: Adjust or remove and replace the limit switch. Adjust the base up limit switch

(refer to Adjusting the Base Up Limit Switch).

NO: Go to step 13.

13 Is the limit switch wiring faulty (refer to Testing Wiring Harness Continuity)?

YES: Repair or replace the limit switch wiring.

NO: Unplug the chair and plug it back in. If the problem remains, the printed circuit board is

faulty, replace the printed circuit board.

14 Is there an open in the limit switch wiring (refer to Testing Wiring Harness Continuity)?

YES: Repair or replace the wiring.

NO: Go to step 15.

15 Is the base up limit switch out of adjustment?

YES: Adjust the limit switch (refer to Adjusting the Base Up Limit Switch). The back up limit

switch is not adjustable.

NO: Go to step 16.

16 Is there noise from the motor/pump?

YES: Go to step 17.

NO: Go to step 18.

Page 46

85.0812.00, 2003 CH-46

Chairs Troubleshooting (for PCB with no LEDs)

Problem Action

Base or back up function

is inoperative

Base or back down

function is inoperative

17 Is the motor current more than 5 Amps (refer to Testing the Motor/Pump)?

YES: The motor/pump is faulty. Remove and replace the motor/pump.

NO: Remove and replace the motor/pump capacitor. Test the Up function. If it still does not

work,the manifold is faulty. Remove and replace it.

18 Is there an open or short in the motor/capacitor wiring (refer to Testing Wiring Harness Continuity)?

YES: Contact an A-dec customer service representative for proper repair procedures of the

motor/pump capacitor wiring.

NO: The printed circuit board is faulty, remove and replace the printed circuit board.

1Try an Up function first, then a Down function. Is the base or back still up?

YES: Go to step 2.

NO: Go to step 3.

2Has the limit switch activated (opened) (refer to Testing Limit Switch Continuity and Testing Limit and

Stop Switches Voltage)?

YES: Go to step 3.

NO: The chair may be in hydrostatic lock. Remedy hydrostatic lock

(refer to Correcting Hydrostatic Lock). Retest chair functions.

3 Does a relay on the printed circuit board click (refer to Testing Relay Click)?

YES: Go to step 7.

NO: Go to step 4.

Page 47

85.0812.00, 2003 CH-47

Chair Troubleshooting (for PCB with no LEDs)

Problem Action

Base or back down

function is inoperative

4Disconnect the footswitch and, if installed, the touchpad. Use the printed circuit board test points to

activate chair down functions (refer to Using Chair Test Points). Does the down function work?

YES: If there is a footswitch only, remove and replace the footswitch. If there is a touchpad

only, remove and replace the touchpad. If there is both a footswitch and touchpad,

go to step 5.

NO: Check condition of stop and/or cuspidor limit switches and wiring (refer to Testing Limit

and Stop Switches Voltage, Testing Limit Switch Continuity, and Testing Wiring Harness

Continuity). Check the printed circuit board connector P6 (limit switches). Unplug the

chair and plug it back in. If the problem remains, the printed circuit board is faulty.

Replace the printed circuit board.

5Reconnect the footswitch to the printed circuit board. Using the footswitch, operate the chair. Does

the chair down function work?

YES: Remove and replace the touchpad.

NO: Go to step 6.

6Reconnect the touchpad to the printed circuit board. Using the touchpad, operate the chair. Does the

chair down function work?

YES: Remove and replace the footswitch.

NO: Check condition of stop switch and/or cuspidor limit switch and wiring (refer to Testing

Limit and Stop Switches Voltage, Testing Limit Switch Continuity, and Testing Wiring Harness

Continuity). Check the printed circuit board connector P6 (limit switches). Unplug the

chair and plug it back in. If the problem remains, the printed circuit board is faulty.

Replace the printed circuit board.

7 Complete the steps for Testing Magnetic Pull. Is there magnetic pull at each solenoid?

YES: Replace faulty manifold/valve.

NO: Go to step 8.

8Has the solenoid fuse blown (120V only)?

YES: Replace the fuse. Complete the steps for Testing Solenoid Continuity. Replace shorted

solenoids or shorted wiring to the solenoids as necessary.

NO: Replace the faulty solenoid.

Page 48

85.0812.00, 2003 CH-48

Chairs Troubleshooting (for PCB with no LEDs)

Problem Action

Back moves for base only

function or base moves for

back only function

Only chair function is

base up

1Disconnect the footswitch and, if installed, the touchpad. Use the printed circuit board test points to

activate chair functions (refer to Using the Chair Test Points). Does the chair work properly now?

YES: If there is a footswitch only, remove and replace the footswitch. If there is a touchpad

only, remove and replace the touchpad. If there is both a footswitch and touchpad, go to

step 2.

NO: The printed circuit board is faulty. Replace the printed circuit board.

2Reconnect the footswitch to the printed circuit board. Using the footswitch, operate the chair. Does

the chair work properly?

YES: Remove and replace the touchpad.

NO: Go to step 3.

3Reconnect the touchpad to the printed circuit board. Using the touchpad, operate the chair. Does the

chair work properly?

YES: Remove and replace the footswitch.

NO: The printed circuit board is faulty. Remove and replace the printed circuit board.

1Are the stop plate limit switches activated?

YES: Go to step 2.

NO: Go to step 3.

2 Is the stop plate stuck?

YES: Remove obstruction from the stop plate.

NO: Go to step 3.

3 Check the connections and the limit switches (refer to Testing Limit and Stop Switches Voltage, Testing

Limit Switch Continuity, and Testing Wiring Harness Continuity). Are wire connections or limits

switches faulty?

YES: Repair or replace components, as necessary.

NO: Go to step 4.

Page 49

85.0812.00, 2003 CH-49

Chairs Troubleshooting (for PCB with no LEDs)

Problem Action

Only chair function is

base up

Unable to program

auto-positioning

4 If there is a cuspidor, check for proper activation of the limit switch when gently lifting up on the

cuspidor bowl. Is there a clicking sound?

YES: Go to step 5.

NO: Replace the switch (refer to Post Boxes and Cuspidors (PB) for the part number).

5Disconnect the 2-pin connector at P14 on the printed circuit board. Gently short across P14 with a

small flat-blade screwdriver. Does the chair operate correctly?

YES: Replace the cuspidor cable (P/N 41.1148.00).

NO: Replace the printed circuit board.

1 Review auto-positioning procedures (refer to Programming the Chair). Does the chair move when you

try to program it?

YES: Check for shorted wires at footswitch connector P2, and at touchpad connector P1, if

installed, on the printed circuit board (refer to Testing Wiring Harness Continuity).

NO: Go to step 2.

2 Does the chair move to the wrong position?

YES: Go to Incomplete auto-positioning cycle.

NO: Go to step 3.

3Disconnect the footswitch and, if installed, the touchpad. Use the printed circuit board test points to

program the chair (refer to Using Chair Test Points). Did the chair program satisfactorily?

YES: If there is a footswitch only, remove and replace the footswitch. If there is a touchpad

only, remove and replace the touchpad. If there are both a footswitch and touchpad,

go to step 7.

NO: Go to step 6.

4Reconnect the footswitch to the printed circuit board. Using the footswitch, program the chair. Did

the chair program satisfactorily?

YES: Remove and replace the touchpad.

NO: Go to step 5.

Page 50

85.0812.00, 2003 CH-50

Chairs Troubleshooting (for PCB with no LEDs)

Problem Action

Unable to program

auto-positioning

Unable to program

auto-positioning for the

touchpad and footswitch

5Reconnect the touchpad to the printed circuit board. Using the touchpad, program the chair. Did the

chair program satisfactorily?

YES: Remove and replace the footswitch.

NO: Go to step 6.

6Is there an open or short in the positioning potentiometer wiring (refer to Testing Wiring

Harness Continuity)?

YES: Repair positioning potentiometer wiring.

NO: Go to step 7.

7Are there any poor or reversed potentiometer connections (refer to Testing Positioning

Potentiometer Voltage)?

YES: Repair positioning potentiometer connections.

NO: The printed circuit board is faulty. Replace the printed circuit board.

1Disconnect the footswitch and try to operate the automatic functions from the touchpad. Does the

touchpad work properly?

YES: Replace the footswitch.

NO: Go to step 2.

2 Plug the footswitch back in and disconnect the touchpad. Try to operate the automatic functions

from the foot control. Does the footswitch work properly?

YES: Replace the touchpad.

NO: Call your A-dec customer service representative for assistance.

Page 51

85.0812.00, 2003 CH-51

Chairs Troubleshooting (for PCB with no LEDs)

Problem Action

Incomplete

auto-positioning cycle

1Has a new printed circuit board been installed?

YES: Reprogram the chair printed circuit board.

NO: Go to step 2.

2 Has a new potentiometer been installed?

YES: Verify that the positioning potentiometer has been installed correctly and that positions

have been properly programmed.

NO: Go to step 3.

3 Does base or back travel time exceed 40–45 seconds?

YES: Adjust the manifold speed control valves (refer to Adjusting the Hydraulic Manifold).

NO: Go to step 4.

4 Is the back stopping short of full upright?

YES: Positioning potentiometer is defective or in deadband. Adjust the potentiometer

(refer to Adjusting the Base Positioning Potentiometer).

NO: Go to step 5.

5Does the base or back only go in one direction?

YES: Check for faulty positioning potentiometers, wiring, and connections.

NO: Go to step 6.

6Does the base or back go in the wrong direction?

YES: Go to step 7.

NO: Go to step 8.

7 Is the potentiometer mechanical drive slipping?

YES: Tighten the gear setscrew, or replace the connecting tubing, and then adjust the

potentiometer (refer to Adjusting the Base Positioning Potentiometer).

NO: Go to step 8.

Page 52

85.0812.00, 2003 CH-52

Chairs Troubleshooting (for PCB with no LEDs)

Problem Action

Incomplete

auto-positioning cycle

8 Does the base or back shut off at the same time?

YES: The printed circuit board is faulty. Replace the printed circuit board.

NO: Go to step 9.

9 Is the potentiometer resistance 0–5K ± 20% ohm (Ω)? Refer to Testing Positioning Potentiometer

Continuity, Testing Wiring Harness Continuity, and Testing Base and Back Positioning

Potentiometer Voltage.

YES: Go to step 10.

NO: Positioning potentiometer is faulty. Replace the potentiometer.

10 Are the potentiometer wiring and connections equal to 0Ω (refer to Testing Positioning Potentiometer

Continuity, Testing Wiring Harness Continuity and Testing Base and Back Positioning

Potentiometer Voltage)?

YES: Go to step 11.

NO: Repair or replace the wiring and connections.

11 Is the potentiometer mechanical drive slipping?

YES: Tighten the gear setscrew, or replace the connecting tubing, and then adjust

the potentiometer.

NO: Go to step 12.

12 Are the potentiometers turning?

YES: The printed circuit board is faulty. Replace the printed circuit board.

NO: Check for a loose or damaged potentiometer mount or improper adjustment

(refer to Adjusting the Base Positioning Potentiometer and Adjusting the Base Up Limit Switch).

Page 53

85.0812.00, 2003 CH-53

Chairs Troubleshooting (for PCB with no LEDs)

Problem Action

Auto-positioning function

is inoperative

1 Reprogram the chair auto-positioning settings (refer to Programming the Chair). Does the chair go to

the wrong position?

YES: Go to Incomplete auto-positioning cycle.

NO: Go to step 2.

2Disconnect the footswitch and, if installed, the touchpad. Use the printed circuit board test points to

activate chair auto functions (refer to Using Chair Test Points). Does the chair function properly?

YES: If there is a footswitch only, remove and replace the footswitch. If there is a touchpad

only, remove and replace the touchpad. If there is both a footswitch and touchpad,

go to step 3.

NO: Unplug the chair and plug it back in. If the problem remains, the printed circuit board

is faulty. Replace the printed circuit board

3Reconnect the footswitch to the printed circuit board. Using the footswitch, operate the chair. Does

the chair work properly now?

YES: Remove and replace the touchpad.

NO: Go to step 4.

4Reconnect the touchpad to the printed circuit board. Using the touchpad, operate the chair. Does the

chair work properly now?

YES: Remove and replace the footswitch.

NO: Unplug the chair and plug it back in. If the problem remains, the printed circuit board is

faulty, remove and replace the printed circuit board.

Page 54

85.0812.00, 2003 CH-54

Chairs Troubleshooting (for PCB with no LEDs)

Problem Action

Auto-positioning for one

or more functions is

inoperative on a unit with

both a footswitch and

a touchpad

1 Unplug the footswitch and try to operate the automatic functions from the touchpad. Does the

touchpad work properly?

YES: Replace the footswitch.

NO: Go to step 2.

2 Plug the footswitch back in and disconnect the touchpad. Try to operate the automatic functions

from the foot control. Does the footswitch work properly?

YES: Replace the touchpad.

NO: The printed circuit board is faulty. Replace the printed circuit board.

Page 55

85.0812.00, 2003 CH-55

Chairs Test Procedures

Using Chair

Test Points

• The chair test points are used to test chair function without a footswitch connected to the printed

circuit board.

•To access the test points, you must remove the motor/pump housing and the circuit board cover.

• Short the test points next to the function you wish to test.

NOTE: New style test positions

ENTR = Position 0 (Red)

EXIT = Position 2 (Green)

NOTE: Old style test positions

ENT = Position 0

EX = Position 2

WARNING

Hazardous AC voltages

are present on the

printed circuit board. Do

not touch any part on

the printed circuit board

except the test points.

NOTE: Connector P1 omitted for clarity.

Before June 2000

P2

SW1

TEST

POINTS

ENTR

EXIT

BS DN

BS UP

BK DN

BK UP

P1

Page 56

85.0812.00, 2003 CH-56

Chairs Test Procedures

Testing Relay Click

•When you activate any function, you

should hear a clicking noise coming from

the printed circuit board.

• The motor relay is activated only for base

up and back up functions.

Motor relay

Back down

Relay

Back up

Relay

Base up

relay

Base Down

Relay

Printed Circuit Board Relays

Page 57

85.0812.00, 2003

Chairs Test Procedures

Testing the

Motor/Pump

Testing Magnetic Pull

White wire

Red wire

Motor/pump

Motor/pump

capacitor

Motor/Pump Test

Back up

solenoid

Hydraulic

manifold

Base down

solenoid

Base up

solenoid

Magnetic Pull Test

Back down

solenoid (hidden)

CH-57

NOTE: This test requires the use of a current

pickup probe.

• Clip the probe onto the red wire going to

the motor/pump.

•Activate a base up or back up function.

Result: You should read 5 Amps

(maximum) of current for

120V motor/pump.

You should read 2.5 Amps

(maximum) of current

for 240V motor/pump.

• While holding the tip of screwdriver

near a solenoid, activate the appropriate

chair function.

Result: You should feel the tug of

the magnetic field

generated around

the solenoid.

Page 58

85.0812.00, 2003 CH-58

Chairs Test Procedures

Testing Power

Cord Continuity

WARNING

Hazardous AC voltages

are present on the

printed circuit board.

Make sure power has

been removed from the

chair before proceeding.

Failure to remove power

from the chair may result

in serious injury from

electrical shock.

Follow these steps to test power cord continuity.

Task Description

1Disconnect the power cord (J1) from the

chair printed circuit board.

2Touch a volt-ohmmeter (VOM) probe to

pin 1 of J1 and the other probe to first one

and then the other blade of the power plug.

Result: One blade should read 1/2 ohm

or less, the other blade should

read infinite (∞) resistance.

If both blades read infinite (∞)

resistance, the power cord is

defective and must be replaced.

3Touch a VOM probe to pin 3 of J1 and

repeat the second step.

4Touch a VOM probe to pin 2 or J1 and the

other probe to ground on the plug.

Result: The resistance should be

1/2 ohm or less.

Pin 3

Pin 2

Pin 1

Pin 1

marker

J1

Ground

J1

Power Cord Continuity Test

Page 59

85.0812.00, 2003 CH-59

Chairs Test Procedures

Testing Limit

Switch Continuity

WARNING

Hazardous AC voltages

are present on the

printed circuit board.

Make sure power has

been removed from the

chair before proceeding.

Failure to remove power

from the chair may result

in serious injury from

electrical shock.

Follow these steps to test limit switch continuity.

Task Description

1Disconnect the wiring harness from the limit

switch. It is not necessary to remove the

limit switch.

2Touch a volt-ohmmeter (VOM) probe to the

common terminal and the other probe to the

normally open terminal and then to the

normally closed terminal.

Result: The normally closed terminal

should give a reading of 1/2 ohm

(Ω) or less.

The normally open terminal

should read infinite (∞)resistance.

If both terminals indicate infinite

(∞) resistance or indicate 1/2 ohm

(Ω) or less, the switch is defective

and must be replaced.

NOTE: If you are replacing a base up limit switch,

adjust the switch after replacement (refer to

Adjusting the Base Up Limit Switch).

Normally open

Limit Switch Continuity Test

Normally closed

Switch arm

Common terminal

Page 60

85.0812.00, 2003 CH-60

Chairs Test Procedures

Testing Positioning

Potentiometer

Continuity

NOTE: If you are replacing a

positioning potentiometer,

refer to Adjusting the

Base Positioning

Potentiometer and

Adjusting the Base Up

Limit Switch.

WARNING

Hazardous AC voltages

are present on the

printed circuit board.

Make sure power has

been removed from the

chair before proceeding.

Failure to remove power

from the chair may result

in serious injury from

electrical shock.

Task Description

1. Disconnect the wiring harness from the

positioning potentiometer and remove the

potentiometer assembly from the chair.

2. Touch a volt-ohmmeter (VOM) probe to an outside

pin of the potentiometer and the other probe to the

other outside pin.

Result: The resistance of the potentiometer

should be approximately

4-6 KΩ (5KΩ+20%).

If the potentiometer resistance is

outside the limits, the potentiometer

is defective and must be replaced.

3. Move one probe to the center pin of

the potentiometer.

4. While observing the VOM, turn the potentiometer

fully one direction and then the other.

Result: Your VOM should indicate a

smooth increase or decrease in

resistance as you turn the shaft.

If the resistance fluctuates in a

jerky manner while the shaft is

being turned, the potentiometer

is defective and must be replaced.

Positioning

potentiometer

Positioning

potentiometer

shaft and gear

Positioning Potentiometer

Continuity Test

Base

Black 1

Green 2

Red 3

Back

Red 1

White 2

Black 3

Cascade and Decade

Positioning Potentiometer Wiring

Follow these steps to test positioning potentiometer continuity.

3

2

1

3

2

1

Page 61

85.0812.00, 2003 CH-61

Chairs Test Procedures

Testing Wiring

Harness Continuity

WARNING

Hazardous AC voltages

are present on the

printed circuit board.

Make sure power has

been removed from the

chair before proceeding.

Failure to remove power

from the chair may

result in serious injury

from electrical shock.

Follow these steps to test wiring harness continuity.

Task Descriptions

1Disconnect the wiring harness from the

limit switch or positioning potentiometer