Adams Rite EX88-R313, EX88-M628, EX88-M335M, EX88-M335, EX88-M313M Installation Instructions

...

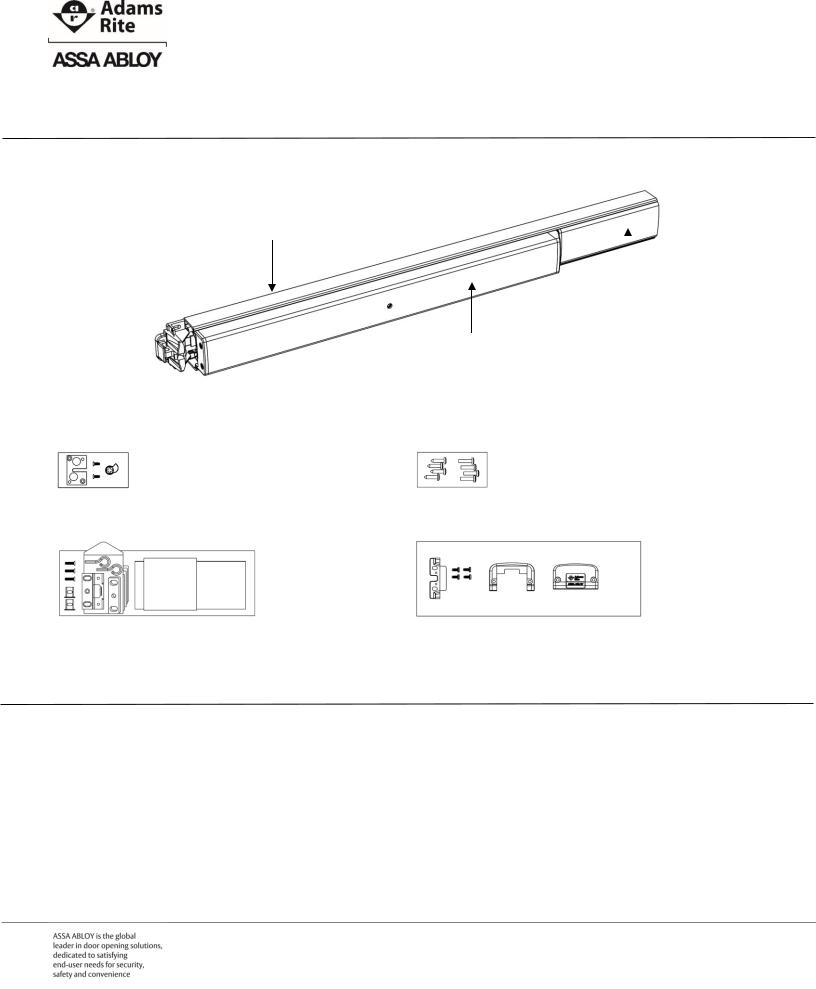

EX88 Interlocking Rim Exit Device

Preparation Guide and Installation Instructions

Box Contents

EX88 Interlocking Rim Exit Device

|

Back Bar |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Filler Plate |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Active Push Bar |

|

|

|

|

|

|

|

|

Cylinder and Trim Interface Kit |

Mounting Hardware Kit |

||||

Frame Kit with Templates |

Mounting End Cap Kit |

||||

Recommended Installation Tools

Safety glasses |

Measuring tape |

Level |

Pencil |

Power drill |

Drill bits: 5/32”, 3/4” |

Center punch |

Phillips screw driver |

IMPORTANT NOTE 1: All work must be performed to applicable building, regulatory and lifesafety codes. Please consult local Authority Having Jurisdiction (AHJ) for more information.

IMPORTANT NOTE 2: The Americans with Disabilities Act (ADA) guidelines specify door hardware be mounted 34”-48” above the finished floor.

P 800.872.3267 F 800.232.7329 E techsupport.adamsrite@assaabloy.com www.adamsrite.com

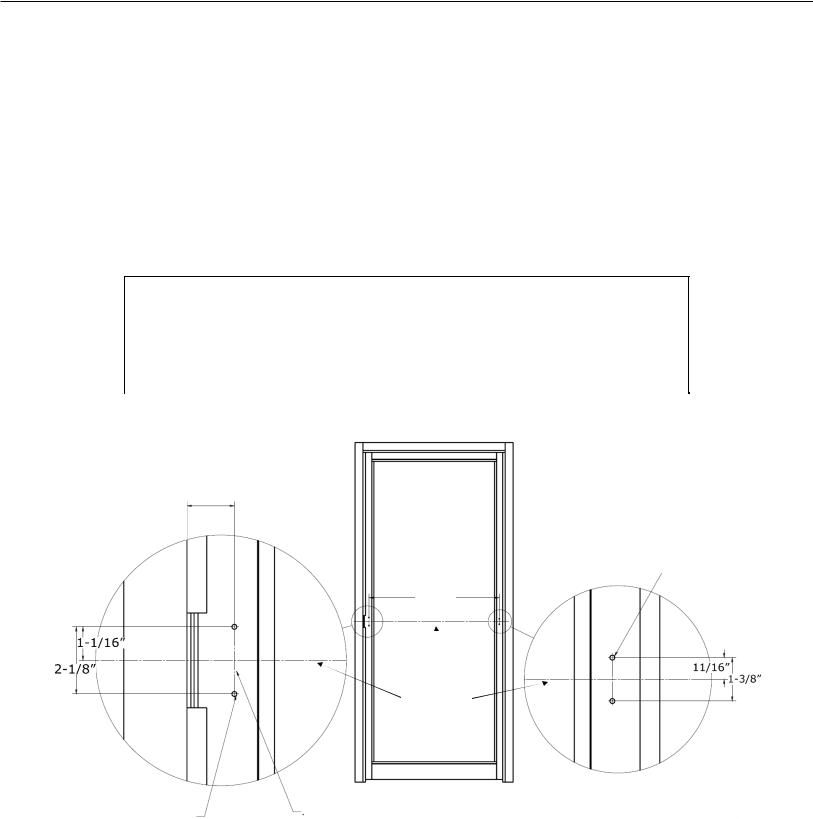

Preparing the Inside of the Door (LHR Shown)

1.DETERMINE and MARK the applicable bar height centerline (horizontal line) of the exit device on the interior of the door.

2.DETERMINE the location of the latch end door template by using the bar height centerline of the exit device and aligning the template with the mounting centerline (vertical line) of the door.

3.AFFIX the latch end door template to the door.

4.DETERMINE and MARK the hinge side preparation using dimension “A” as shown in the chart below.

5.IF standard door widths, as shown in the chart below, are not being used, THEN CUT to proper length using Sizing the Exit Device chart on page 4.

6.MARK, CENTER PUNCH, DRILL all holes.

7.PREPARE door for cylinder and/or trim using Preparing the Door for Cylinder or Trim on page 5, if required.

8.REMOVE the templates.

Standard Door Widths and Mounting Hole Spacing

Exit Device Length |

Regular (R) |

Midlength (M) |

Long (L) |

|

|

|

|

|

|

Standard Door |

36” |

42” |

48” |

|

Opening Width |

||||

|

|

|

||

Dimension “A” |

33” |

39” |

45” |

|

|

|

|

|

1-1/2” from surface of strike to mounting

centerline

Drill 5/32”dia pilot holes for self-tapping screws, 2 places

“A”

Bar Height

Centerline

|

|

Mounting |

Drill 5/32”dia pilot |

|

|

|

Centerline |

|

holes for self-tapping |

|

|

|

|

|

screws, 2 places |

|

|

|

|

|

|

|

|

Page | 2 |

P 800.872.3267 F 800.232.7329 |

E |

techsupport.adamsrite@assaabloy.com |

|

www.adamsrite.com |

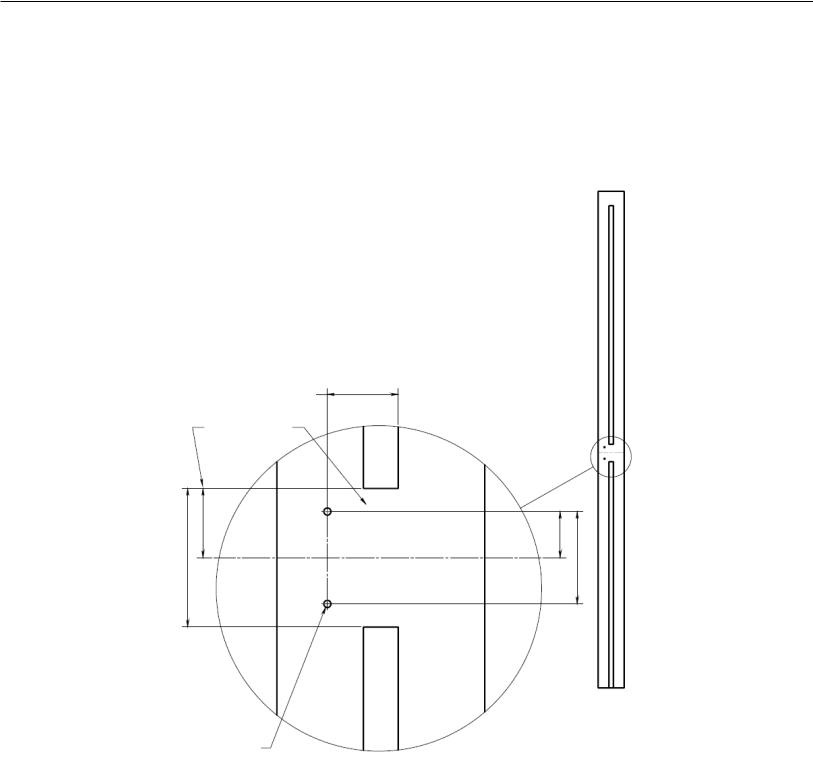

Prepping the Frame (LHR Shown)

1.DETERMINE and MARK the applicable bar height centerline (horizontal line) of the exit device on the frame for the strike plate.

2.DETERMINE the location of the strike plate template by using the bar height centerline of the exit device and aligning the template with the surface of the closed door.

3.MARK, CENTER PUNCH, DRILL all holes.

4.REMOVE the template.

1-17/32” from inside surface of closed door

Cut away stop

|

1-1/2” |

|

|

|

|

|

|

Bar Height Centerline |

1” |

|

|||

|

|

|

|

|||

|

|

|

||||

3” |

|

|

|

|

|

|

|

|

|

2” |

|||

|

|

|

||||

|

|

|

|

|||

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Drill 5/32”dia pilot holes for self-tapping screws, 2 places

Page | 3 |

P 800.872.3267 F 800.232.7329 |

E |

techsupport.adamsrite@assaabloy.com |

|

www.adamsrite.com |

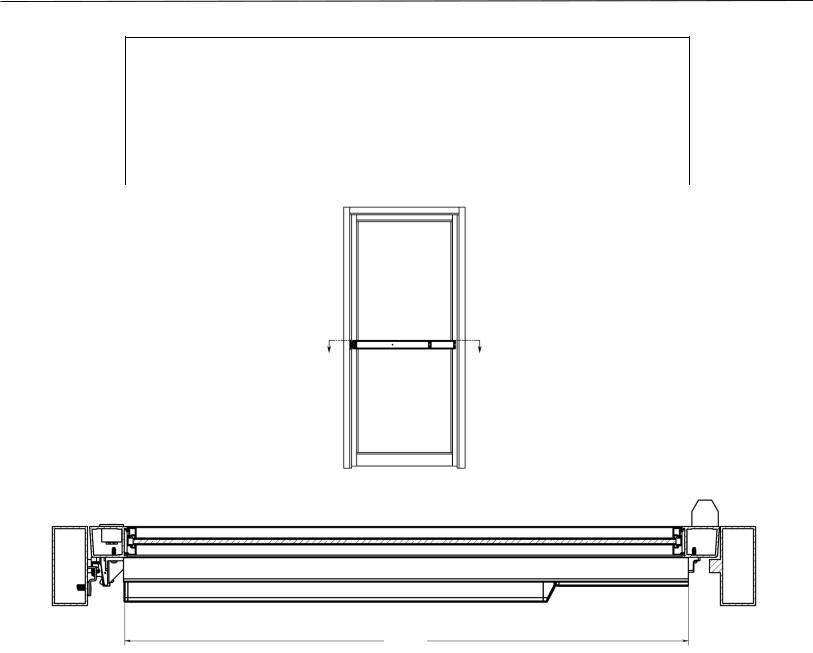

Sizing the Exit Device

Standard Door Widths and Mounting Hole Spacing

Exit Device Length |

Regular (R) |

Midlength (M) |

Long (L) |

|

|

|

|

Standard Door |

|

|

|

Width |

36” |

42” |

48” |

No Cut Required |

|

|

|

Minimum Door |

|

|

|

Width Exit Device |

30” |

30” |

42” |

Can Support |

|

|

|

“B”

NOTE: All EX Series Exit Devices are sized at the factory for 5/8” frame stop in narrow stile aluminum applications.

1.DETERMINE cut off dimension “B” Back Bar extrusion length by subtracting 3-7/8” from door opening width.

2.MARK cut off line “B” on Filler Plate and Back Bar.

3.REMOVE Filler Plate from Back Bar and CUT along lines on both pieces. REPLACE Filler Plate into Back Bar.

IMPORTANT NOTE: Do not cut Active Push Bar

Page | 4 |

P 800.872.3267 F 800.232.7329 |

E |

techsupport.adamsrite@assaabloy.com |

|

www.adamsrite.com |

Loading...

Loading...