Page 1

requerimiento para el buen funcionamiento y

facilidad de manejo del motor.

2. Ajustes de la inyección de combustible - Algunos sistemas de inyección de combustible

tienen un ajuste de autoridad mínimo y máximo

que se debe comprobar durante la puesta a

punto periódica o cuandoquiera que se encuentre algún problema con la velocidad en vacío.

3. Pruebas misceláneas del motor - Muchos de

los procedimientos de prueba indicados en el

manual de servicio del motor requieren que el

motor funcione a una velocidad especí ca durante la prueba. Este instrumento proporciona

excelentes capacidades de monitoreo para este

propósito.

CP7605

OPERATING INSTRUCTIONS

FULL ONE (1) YEAR WARRANTY

Actron Manufacturing Company, 9999 Walford Avenue, Cleveland, Ohio 44102, warrants to the user

that this unit will be free from defects in materials

and workmanship for a period of one (1) year from

the date of original purchase. Any unit that fails within

this period will be repaired without charge when

returned to the Factory. Actron requests that a copy

of the original, dated sales receipt be returned with

the unit to determine if the warranty period is still

in e ect. This warranty does not apply to damages

caused by accident, alterations, or improper or unreasonable use. Expendable items, such as batteries,

fuses, lamp bulbs, ash tubes also are excluded from

the scope of this warranty. ACTRON MANUFACTURING

COMPANY DISCLAIMS ANY LIABILITY FOR INCIDENTAL

OR CONSEQUENTIAL DAMAGES FOR BREACH OF ANY

WRITTEN WARRANTY ON THE UNIT. Some states do

not allow the disclaimer of liability for incidental or

consequential damages, so the above disclaimer

may not apply to you. This warranty gives speci c

legal rights, and you may also have rights which vary

from state to state.

©1996, Actron Manufacturing Company

Sunpro is a registered trademark of Sun Electric Corporation and is

used under exclusive license.

2-219301

GARANTIA COMPLETA DE UN AÑO

Actron Manufacturing Company, 9999 Walford Avenue,

Cleveland, Ohio 44102, EE.UU., garantiza al usuario que esta

unidad estará libre de defectos de materiales y mano de

obra por un (1) año a partir de la fecha de compra del comprador original. Cualquier unidad que falle dentro de este

período será reparada opción de Actron sin cargo cuando

se regrese a la fábrica. Actron requiere que un comprobante

de compra (recibo de venta) fechado acompañe la unidad

para determinar si está en garantía. Esta garantía no es

aplicable a daños causados por accidente, alteraciones,

usos impropios o no razonables. Artículos consumibles,

tales como baterías, fusibles, lámparas y tubos de destello

quedan excluidos de esta garantía. Actron Manufacturing

Company rechaza cualquier responsabilidad de daños

incidentales o indirectos por incumplimiento de cualquier

garantía escrita de la unidad. Algunos estados de los

EE.UU. y ciertos países no permiten el rechazo de cualquier

responsabilidad de daños incidentales o indirectos, por

lo que el rechazo anterior puede no ser aplicable en su

caso. Esta garantía concede derechos legales especí cos

y es posible que Ud. tenga otros derechos que varían de

estado a estado de los EE.UU. y de país a país.

Actron Manufacturing Co.

9999 Walford Avenue

Cleveland, Ohio 44102-4696

20

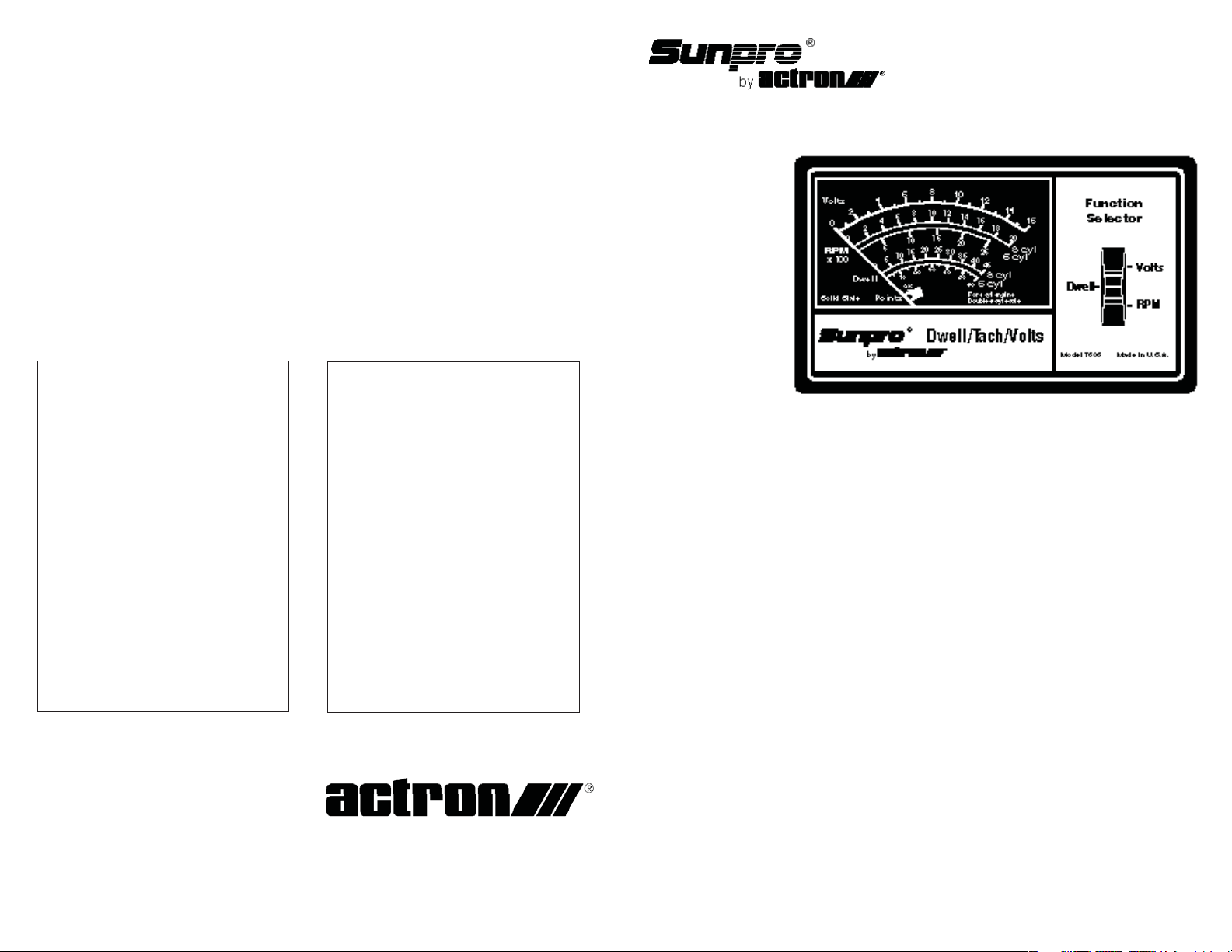

Dwell/Tach/Voltmeter

FOR 12 VOLT ELECTRONIC OR

CONVENTIONAL IGNITION SYSTEMS

• OPERATING INSTRUCTIONS

• SAFETY RULES

• TUNE-UP PROCEDURES

• REPAIR PARTS

Angulo de cierre/Tacómetro/Voltímetro

PARA SISTEMAS DE ENCENDIDO ELECTRONICO O CONVENCIONAL DE 12 VOLTIOS

• INSTRUCCIONES DE OPERACION

• REGLAS DE SEGURIDAD

• PROCEDIMIENTOS PARA LA PUESTA A PUNTO

• PIEZAS DE REPUESTO

Instrucciones en español — página 11

Page 2

SAFETY GUIDELINES

TO PREVENT ACCIDENTS THAT COULD RESULT IN SERIOUS INJURY AND/OR DAM

AGE TO YOUR VEHICLE OR TEST EQUIPMENT, CAREFULLY FOLLOW THESE SAFETY

RULES AND TEST PROCEDURES

SAFETY EQUIPMENT

Fire Extinguisher

Never work on your car without having a suitable

re extinguisher handy. A 5-lb or larger CO2 or

dry chemical unit speci ed for gasoline/chemical/electrical res is recommended.

Fireproof Container

Rags and ammable liquids should be stored only

in reproof, closed metal containers. A gasolinesoaked rag should be allowed to dry thoroughly

outdoors before being discarded.

Safety Goggles

We recommend wearing safety goggles when

working on your car, to protect your eyes from

battery acid, gasoline, and dust and dirt ying o

moving engine parts.

NOTE: Never look directly into the carburetor throat

while the engine is cranking or running, as sudden

back re can cause burns.

LOOSE CLOTHING AND LONG HAIR

(MOVING PARTS)

Be very careful not to get your hands, hair or clothes

near any moving parts such as fan blades, belts

and pulleys or throttle and transmission linkages.

Never wear neckties or loose clothing when working on your car.

JEWELRY

Never wear wrist watches, rings or other jewelry

when working on your car. You’ll avoid the possibility of catching on moving parts or causing

an electrical short circuit which could shock or

burn you.

VENTILATION

The carbon monoxide in exhaust gas is highly toxic.

To avoid asphyxiation, always operate vehicle in a

well-ventilated area. If vehicle is in an enclosed area,

exhaust should be routed directly to the outside

via leakproof exhaust hose.

SETTING THE BRAKE

Make sure that your car is in Park or Neutral, and

that the parking brake is rmly set.

NOTE: Some vehicles have an automatic release

on the parking brake when the gear shift lever

is removed from the PARK position. This feature

must be disabled when it is necessary (for testing)

to have the parking brake engaged when in the

DRIVE position. Refer to your vehicle service manual

for more information.

HOT SURFACES

Avoid contact with hot surfaces such as exhaust

manifolds and pipes, mu ers (catalytic converters),

radiator and hoses. Never remove the radiator cap

while the engine is hot, as escaping coolant under

pressure may seriously burn you.

SMOKING AND OPEN FLAMES

Never smoke while working on your car. Gasoline

vapor is highly ammable, and the gas formed in

a charging battery is explosive.

BATTERY

Do not lay tools or equipment on the battery. Ac-

cidentally grounding the “HOT ” batter y terminal can

shock or burn you and damage wiring, the battery

or your tools and testers. Be careful of contact with

battery acid. It can burn holes in your clothing and

burn your skin or eyes.

When operating any test instrument from an

auxiliary battery, connect a jumper wire between

the negative terminal of the auxiliary battery and

ground on the vehicle under test. When working

in a garage or other enclosed area, auxiliary battery should be located at least 18 inches above

the oor to minimize the possibility of igniting

gasoline vapors

HIGH VOLTAGE

High voltage — 30,000 to 50,000 volts — is present

in the ignition coil, distributor cap, ignition wires

and spark plugs. When handling ignition wires

while the engine is running, use insulated pliers to

avoid a shock. While not lethal, a shock may cause

you to jerk involuntarily and hurt yourself.

JACK

The jack supplied with the vehicle should be used

only for changing wheels. Never crawl under car

or run engine while vehicle is on a jack.

VEHICLE MANUAL, SOURCES FOR SERVICE INFORMATION

The following is a list of publishers who have service manuals for your speci c vehicle at

nominal cost.

Write to them for availability and prices, specifying the make, style, and model year of your

vehicle.

American Motors Corporation

Myriad

8835 General Drive

Plymouth Township, MI 48170

Chrysler Corporation

Dyment Distribution Service

Service Publication

20770 Westwood Drive

Strongsville, OH 44136

Ford Publications Department

Helm Incorporated

Post O ce Box 07150

Detroit, MI 48207

Buick

Tuar Company

Post O ce Box 354

Flint, MI 48501

Oldsmobile

Lansing Lithographers

Post O ce Box 23188

Lansing, MI 48909

Cadillac, Chevrolet, Pontiac

Helm Incorporated

Post O ce Box 07130

Detroit, MI 48207

OTHER SOURCES- Nonfactory

Domestic and Import Cars

Chilton Book Company

Chilton Way

Radnor, PA 19089

Cordura Publications

Mitchell Manuals, Inc.

Post O ce Box 26260

San Diego, CA. 92126

Motor’s Auto Repair Manual

Hearst Company

250 W. 55th Street

New York, NY 10019

IMPORTANT

THIS MANUAL PRESENTS COMPLETE HOOKUP INSTRUCTIONS FOR THE

DWELL/TACH/VOLTMETER, IT ALSO DESCRIBES MANY OF THE TESTS THAT THIS

INSTRUMENT IS CAPABLE OF PERFORMING AS WELL AS WHEN THEY SHOULD

BE USED BASED ON VEHICLE PERFORMANCE, TUNE-UP OR TROUBLE ENCOUNTERED. CONSULT YOUR VEHICLE SERVICE MANUAL FOR SPECIFIC TUNE-UP INFORMATION AND TEST PROCEDURES. ALWAYS FOLLOW THE MANUFACTURER’S

SPECIFICATIONS AND TEST PROCEDURES FOR ADJUSTING DWELL ANGLE AND

IDLE SPEED, ESPECIALLY ON VEHICLES WITH MODERN ELECTRONIC IGNITION

AND EMISSION CONTROLS. DO NOT ATTEMPT TO SERVICE A VEHICLE WITHOUT

THE MANUFACTURER’S INSTRUCTIONS AND SPECIFICATIONS.

2

3

Page 3

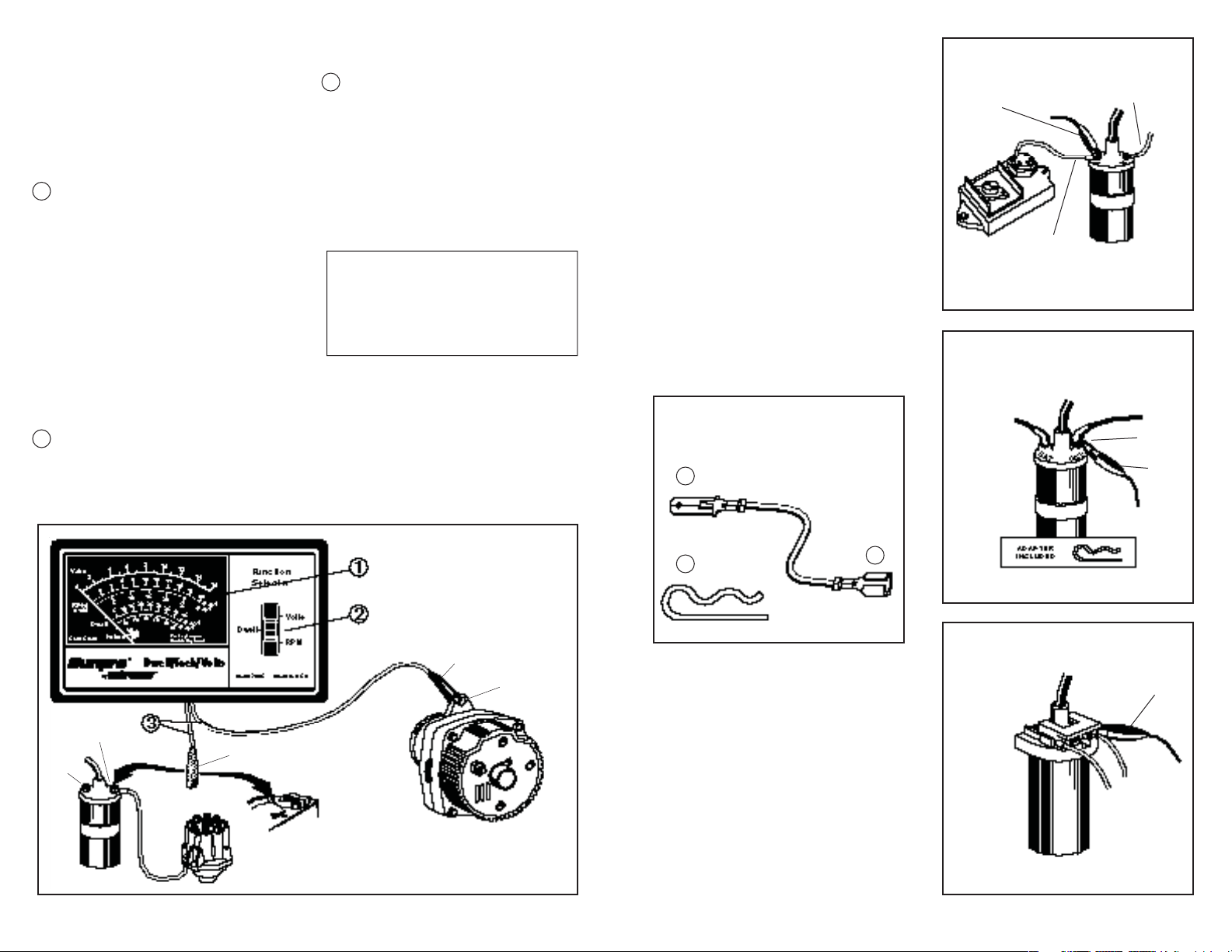

FUNCTIONS, CONNECTIONS AND ACCESSORIES

DESCRIPTION

The Model CP7605 Dwell/Tach/Voltmeter has a

clearly labeled function switch and meter as shown

in the Master Hookup diagram, Figure 1 below.

1. METER

This meter displays the following scales:

• Volts 0-16

• RPM 0-2000 (8 cylinder)

0-4000 (4 cylinder

– multiply

8 cylinder scale

by 2)

• RPM 0-2500 (6 cylinder)

• Dwell 0-45 degrees (8 cylinder)

0-90 degrees (4

cylinder–

multiply 8 cylinder by 2)

• Dwell 0-60 degrees (6 cylinder)

• Points OK/Defective

2. FUNCTION SELECTOR

This selects the RPM, Dwell, or Volts functions

of the instrument.

3. TEST LEAD

Hook this lead to the proper test point in the

vehicle to perform tests as required and as

described below:

VOLTAGE MEASUREMENTS

GREEN CLIP – Connect to the Positive (+) volt-

age source to be measured. (+ Battery terminal,

alternator output terminal, lamp socket, etc.).

BLACK CLIP – Vehicle ground.

CAUTION!

Avoid connecting the BLACK CLIP to the

negative(-) battery terminal or any fuel system components in the event that glasses are

present which could explode from sparking

connections.

DWELL/TACH/BREAKER POINT RESISTANCE

MEASUREMENT

GREEN CLIP – Connect to the Tach or negative

(-) ignition coil terminal. See Figures 3 through

10 for speci c applications

BLACK CLIP – Vehicle Ground. See CAUTION

under voltage measurements.

ACCESSORIES

See Figure 2.

1. GM DIAGNOSTIC ADAPTOR

The GM Diagnostic Adaptor is used to make

connection to vehicle equipped with the GM Diagnostic Connector, (1976 –1982). It is also used

to make connection to Toyota vehicles which

use the IIA (Integrated Ignition Assembly). See

Figures 9 and 10 for adaptor application.

2. GM HEI ADAPTOR

The GM HEI Adaptor is used to provide connec-

tion to the “TACH” terminal on GM HEI systems.

See Figure 7 for typical installation.

3. FORD COIL CLIP

The Ford Coil Clip is used for ignition systems

which have booted ignition coil connections.

See Figure 4 for clip application.

ELECTRICAL SYSTEM TESTS –

"VOLTS" POSITION

Fig. 2

Accessories

1

Fig. 3 Primary Tach Connection —

GREEN Clip

TO BAL

GREEN

CLIP

CONTROL

UNIT

TO CONTROL

UNIT

All Chrysler Corporation Electronic Ignitions, 6 & 8 cylinder shown

1972 - 1986

Fig. 4

GREEN Clip

Primary Tach/Dwell Connection –

TO IGNITION

SWITCH

LAST

COIL

BAT.

TO DIST.

FORD

ADAPTER

GREEN

CLIP

BAT.

DIST. OR

TAC H

COIL

GREEN

DISTRIBUTOR

Fig. 1

Master Hookup Diagram

3

2

1974 Ford Electronic and All Breaker

Points Ignition Systems

Fig. 5 Primary Tach Connection —

BLACK

ENGINE

GROUND

4

GREEN Clip

Ford Solid State & Dura Spark systems

1975 - 1986

5

GREEN

CLIP

Page 4

Fig. 6 Primary Tach Connection —

GREEN Clip

GREEN

CLIP

Ford TFI Systems 1981 - 1986

Fig. 7 Primary Tach Connection —

GREEN Clip

GREEN

CLIP

ADAPTER

Delco HEI 1974 - 1986 Integral Coil

Fig. 8 Primary Tach Connection —

GREEN Clip

Delco HEI 1974 - 1986 External Coil

TO

IGNITION

SWITCH

GREEN

CLIP

Fig. 9 Primary Tach Connection —

GREEN Clip

SPADE

GREEN

CLIP

TERMINAL

ADAPTER

GM Diagnostic Connector and

Delco HEI Systems 1976 - 1982

Fig. 10 Primary Tach Connection —

GREEN Clip

INSERT

DIAGNOSTIC

ADAPTER

REMOVE CAP

FROM TACH

TEST CONNEC

GREEN

CLIP

TOR

Toyota IIA (Integrated Ignition Assembly) 1983 - 1986

Fig. 11 Performance Check ONLY

Note: This is NOT a Tach Connection point.

DWELL CONNEC

TOR GREEN

GREEN CLIP or

Ground Jumper

– See Vehicle

Service Manual

GM C3 (Computer Command Control)

BASIC SYSTEM CHECK – Charging Voltage

1. GREEN CLIP – Connect to the Positive (+) Battery

terminal.

2. BLACK CLIP – Connect to Vehicle Ground.

3. FUNCTION SELECTOR – Volts

4. Start engine and allow it to warm up completely.

Operate it at curb idle.

5. With all accessories o observe the 16 volt scale

on the analyzer.

6. Normal Result – 13.2 to 15.2 volts or as speci ed

in the vehicle service manual.

7. FUNCTION SELECTOR – RPM

8. Select a step on the fast idle cam which will

maintain engine speed between l800 and 2000

RPM (or have an assistant hold engine speed

in this range) through Step 12.

9. FUNCTION SELECTOR – Volts

10. Observe the 16 volt scale on the analyzer. The

voltage should not have changed from Step 6

more than about .5 volts.

11. Load the electrical system by turning on the

lights, Hi fan, and wipers.

12. Observe the 16 volt scale on the analyzer. The

voltage should not drop below about 13.0

volts.

13. Shut o all accessories, return the engine to

curb idle, and shut it o . If the results obtained

in Step 6, 10 or 12 are signi cantly di erent

from those shown or from the vehicle service

manual values, further diagnosis is required:

see your vehicle service manual.

CRANKING VOLTAGE AND BATTERY CONDITION

If the engine cranks slowly or not at all, the battery,

cranking motor, and associated wiring may be

at fault. Check the cranking voltage as indicated

below.

1. Connect the analyzer to the vehicle battery as

shown in Figure 1.

2. Disable the engine from starting as shown in

Figure 12 or as explained in your vehicle service

manual

3. FUNCTION SELECTOR – Volts

4. Crank the engine while observing the 16 volt

scale on the analyzer.

5. Normal Result – 9.6 volts or more at 70°F. Voltage

will drop slightly as temperature decreases.

6. I f the results are signi cantly out of speci cation

consult your vehicle service manual for further

diagnosis.

7. If battery voltage remains abnormally high

(above approximately 10.5 volts) on a slow

or no cranking engine, the problem may be

loose or corroded connection(s) in the cranking

circuit.

MISCELLANEOUS VOLTAGE TESTS

This instrument can perform many of the voltage

tests called out in the vehicle service manual, such

as voltages at lamp sockets, motors, solenoids

and relays.

NOTE: The voltmeter function of this instrument can

be used anywhere the vehicle service manual calls

for voltage measurement except in those applications which call for 10 Megohm input impedance

or a digital voltmeter.

IGNITION SYSTEM TEST –

"VOLTS" POSITION

BREAKER POINT RESISTANCE TEST (Breaker Point

Systems Only)

1. Visually check the breaker points and associated wiring and connections. Check to see that

the lead from the distributor to the Negative

(-) terminal of the ignition coil is not damaged

(nicked insulation, etc.)

2. Remove the distributor cap and inspect the

breaker points. Properly adjusted breaker

points become light gray in color in normal

use. If they are blued, blackened or pitted, they

have exceeded their normal life.

3. To prevent the engine from starting, disable

the ignition system by grounding the coil tower

wire as shown in Figure 12.

4. Connect the GREEN and BLACK clips as de-

Fig. 12 Disabling Procedure

Breaker Point Ignition System

ENGINE GROUND

6

7

Page 5

scribed under DWELL/TACH/BREAKER POINT

RESISTANCE MEASUREMENTS

NOTE: When testing a vehicle with dual points,

alternately block one set of points open with a

piece of insulating material while the other set is

being tested.

5. Turn the ignition key ON. If the meter reads

voltage, (12.5 - 13.0) the points are OPEN. Crank

the engine a fraction of a revolution at a time

until the meter reads in the left hand area of

the scale.

The points are now closed.

Test Results:

Normal – Meter reads in the OK zone of the Points

scale. The Analyzer may indicate high point resistance on a new set of points until they have been

run in the vehicle for a few miles and have been

properly seated. This condition may be ignored as

long as any defects discovered during the previous

visual check have been corrected.

Abnormal – If the meter indicates in the Bad zone

when the points are closed, the points may be

defective or the following faults may exist:

Poor distributor ground

Poor connection on the primary lead from

the distributor to the ignition coil

Defective distributor pigtail lead

Misaligned points

Poor points/plate ground inside distributor

Correct the defect and repeat the test.

IGNITION SYSTEM TEST –

"DWELL" POSITION

DWELL TEST AND ADJUSTMENT Breaker Point

Systems Only or Transistorized Systems which Use

Breaker Points.

1. Preparation:

Before performing the DWELL TEST AND

ADJUSTMENT PROCEDURE, read the vehicle

emission control label or the vehicle service

manual to determine what should be done with

the vacuum hoses connected to the distributor

and the various advance/retard solenoids. Most

often, the vacuum hose must be disconnected

from the distributor and the end plugged with

a plastic golf “tee” or other plug.

Connect the GREEN and BLACK clips as de-

scribed under TACH/DWELL/BREAKER POINT

RESISTANCE MEASUREMENTS.

2. Test Procedure:

Star t the engine and allow it to warm up (upper

radiator hose hot.)

Fig. 13 Typical General Motors

Breaker Points Distributor

Operate the engine at curb idle OR the RPM

speci ed by the vehicle emission control label

or the vehicle service manual for measuring

dwell.

1/8" ALLEN

WRENCH

WINDOW

Check the RPM by switching the FUNCTION

SELECTOR TO RPM and reading the appropriate

meter scale. Return the FUNCTION SELECTOR to

DWELL and observe the correct dwell scale

NOTE: There is a direct relationship between dwell

and timing. However, it is only a one way relationship.

If you change the dwell angle of the breaker points,

you will automatically change the ignition timing.

Changing the timing, though, has no e ect on the

ADJUSTMENT

SCREW

dwell angle. FOR THIS REASON, IT IS IMPORTANT

TO RE-CHECK THE TIMING WHEN EVER THE DWELL

ANGLE HAS BEEN ADJUSTED.

checking DWELL angle. Usually, the vacuum hose

DWELL ADJUSTMENT – Conventional Breaker Point

Systems

On GM distributors with a small metal slide cover,

lift the cover and insert a l/8" Allen wrench in the

adjusting screw socket and adjust the dwell by

turning the wrench, as shown in Figure 13.

On Ford, Chrysler, American Motors, and other

distributors not equipped with a small metal access slide cover, perform the following steps while

referring to Figure 14.

must be disconnected from the distributor and

plugged

Increase the engine speed from idle to about

1500 RPM and note the dwell angle (Figure 15).

Return the engine speed to idle and again note

the dwell angle. If the di erence between the two

dwell angle readings is more than 3 degrees, check

for excessive wear in the breaker point plate and

couplings or excessive wear in the distributor shaft

gear and bushings.

1. Remove coil wire from center tower of distributor

cap and ground the wire by connecting the loose

end to the engine or frame, See Figure 12.

2. Remove the distributor cap and rotor.

Fig. 14 Dwell Adjustment

(All, except Delco-Remy Sliding Window Distributors)

3. Connect a remote starter switch to the vehicle

or have an assistant crank the engine for you.

4. With ignition switch ON and engine cranking

observe reading on the Dwell scale.

5. To adjust Dwell, loosen the locking screw

slightly and adjust the point gap with a feeler

gauge according to the procedure outlined in

the vehicle service manual. After adjustment,

tighten locking screw, and recheck dwell while

ADJUSTMENT

SLOTTED HOLE

BREAKER

POINTS

cranking engine. Repeat procedure if necessary.

(Figure 14.)

6. Reassemble distributor and recheck dwell reading with engine operating at idle speed. Repeat

LOCKING SCREW

BREAKER

POINTS

ADJUSTMENT

SCREW

steps 5 and 6 if necessary.

DWELL VARIATION TEST

Read the owner’s manual or engine compartment

decal and follow the instructions regarding vacuum

line or advance-retard solenoid connections when

8 9

Fig. 15 Dwell Variation

MORE THAN 3 DEGREES

FIRST

READING

SECOND

READING

FUEL SYSTEM TESTS –

"DWELL" POSITION

1. General Motors C-3 (Computer Command Control) Mixture Control Solenoid Dwell (Carburetor equipped vehicles only). The GMC-3 system

controls Air/Fuel ratio with a mixture control

solenoid mounted in the carburetor. The basic

system performance check of this system calls

for the checking of the duty cycle or dwell of

the M/C solenoid. Note that regardless of the

number of cylinders in the vehicle, the reading

is always taken from the 6 cylinder scale.

2. This analyzer may be used to check C-3 Dwell

(duty cycle). Refer to your vehicle service

manual for hookup instructions and performance results. See Figure 11.

ENGINE TESTS –

"RPM" POSITION

1. Carburetor Adjustments – There are several

adjustments which should be checked as part

of a performance tune-up. Those which require

engine RPM monitoring are:

a. Curb idle

b. Base idle

c. Solenoid Controlled idle

d. Fast idle

Your vehicle will likely have some combination

of these adjustments. Proper adjustment of

these settings is a requirement for good engine

performance and driveability.

2. Fuel Injection Adjustments – Some fuel injection systems have a minimum and maximum

authority adjustment which should be checked

during routine performance tune-up or whenever idle problems are encountered.

3. Miscellaneous Engine Test – Many of the test

Page 6

procedures in your vehicle service manual

require the engine to run at a speci c RPM during the test. Your instrument provides excellent

monitoring capabilities for this purpose.

REGLAS DE SEGURIDAD

PARA IMPEDIR ACCIDENTES QUE PUEDAN CAUSAR GRAVES LESIONES Y/O

DAÑAR EL VEHICULO O EL EQUIPO DE PRUEBA, SEGUIR ATENTAMENTE ESTAS REGLAS DE

SEGURIDAD Y LOS PROCEDIMIENTOS DE PRUEBA.

Model CP7605

Replacement Parts

Key Part

No. No. Description

1 400-857 Case, bottom

2 270-117 Screw, Case self-tap. #6-20 x 1"

3 38-726 Cable Assembly, Green and Black Clip

4 450-133 Cap, Glamour

5 180-300 Ford Adapter

6 38-1342 GM Adapter

7 1-1086 Switch Decal

8 1-1085 Meter Decal

9 400-855 Window

— 2-219301 Instruction Manual (Not shown)

NOTE: The circuit board and meter are not replacement parts

since the replacement of either requires recalibration of the instrument.

EQUIPO DE SEGURIDAD

Extinguidor de incendios

Nunca trabajar en un automóvil sin tener a mano un

extinguidor de incendios. Se recomienda un aparato

de CO2 ó agente químico seco de 5 lbs o más grande

especi cado para incendios de gasolina/químicos/

eléctricos.

Envase ignífugo

Los trapos y líquidos in amables deben guardarse

solamente en envases metálicos cerrados e ignífugos.

Los trapos empapados en gasolina deben dejarse

secar al aire libre antes de botarlos.

Gafas protectoras

Recomendamos usar gafas cuando se trabaje en el

automóvil para protegerse los ojos contra el ácido de

la batería, la gasolina y el polvo y suciedad desprendidos de las piezas en movimiento del motor.

NOTA: Nunca mirar directamente al interior del

cuello del carburador mientras el motor está girando

o funcionando, pues el petardeo puede causar

quemaduras.

ROPA SUELTA Y CABELLO LARGO (PIEZAS MOVILES)

Tener cuidado de no tener las manos, cabello o

ropa cerca de las piezas móviles como las aspas del

ventilador, correas y poleas o varillaje del acelerador y

transmisión. Nunca usar corbata o ropa suelta cuando

se trabaje en el automóvil.

JOYAS

Nunca usar reloj pulsera, anillos u otras joyas cuando

se trabaje en el automóvil. Se evitará la posibilidad

de engancharse en las piezas móviles o causar un

cortocircuito que podría electrocutar o quemar.

VENTILACION

El monóxido de carbono en los gases de escape es

sumamente tóxico. Para evitar as xia, siempre hacer

funcionar el vehículo en un lugar bien ventilado. Si

el vehículo está en un lugar encerrado, instalar una

manguera a prueba de fugas en el tubo de escape

para expulsar los gases al exterior.

FRENO

Asegurar que el vehículo esté en PARK o punto muerto y que el freno de estacionamiento esté aplicado.

NOTA: Algunos vehículos tienen desconexión

automática en el freno de estacionamiento cuando

se saca la palanca de cambio de la posición PARK.

Se deberá inhabilitar esta características cuando sea

necesario (para pruebas) con el n de tener el freno

de estacionamiento aplicado cuando la palanca esté

en DRIVE. Para más información al respecto, consultar

el manual de servicio del vehículo.

SUPERFICIES CALIENTES

Evitar el contacto con las super cies calientes como

múltiples y tubo de escape, silenciadores (catalíticos), radiador y mangueras. Nunca quitar la tapa

del radiador mientras el motor esté caliente, pues el

escape de refrigerante a presión puede causar graves

quemaduras.

CIGARRILLOS Y LLAMAS EXPUESTAS

Nunca fumar mientras se trabaje en el automóvil. El

vapor de gasolina es muy in amable, y el gas emitido

por una batería en carga es explosivo.

BATERIA

No apoyar las herramientas o el equipo encima de

la batería. La conexión a tierra imprevista del borne

“HOT” (VIVO) de la batería puede electrocutar o quemar y dañar los cables, la batería o las herramientas y

probadores. Tener cuidado de no tocar el ácido de la

batería. Puede quemar y agujerear la ropa y quemar

la piel o los ojos.

Cuando se haga funcionar un instrumento de prueba

desde una batería auxiliar, conectar un cable puente

entre el borne negativo de la batería auxiliar y tierra

en el vehículo que se esté probando. Cuando se esté

trabajando en un garage u otro ugar bajo techo,

situar la batería auxiliar a por lo menos 18 pulgadas

del suelo para reducir al mínimo la posibilidad de

in amar los vapores de gasolina.

ALTO VOLTAJE

Hay alto voltaje—30.000 a 50.000 voltios— en la

bobina de encendido, tapa del distribuidor, cables del

encendido y bujías. Para mover los cables del encendido mientras el motor está funcionando, hacerlo con

alicates aislados para evitar electrochoque. Aunque

no es mortal, un electrochoque puede causar una

sacudida involuntaria y lastimadura.

GATO

El gato que se suministra con el vehículo debe usarse

solamente para cambiar las ruedas. Nunca meterse

debajo de un automóvil o motor funcionando mientras el vehículo esté apoyado en el gato.

10 11

Page 7

MANUAL DEL VEHICULO, FUENTES DE INFORMACION ACERCA DE SERVICIO.

La siguiente es una lista de editores que publican manuales de servicio para vehículos especí cos a por

un precio nominal.

Escribirles para averiguar la disponibilidad y precios, especi cando la marca, estilo y año del modelo del

vehículo.

American Motors Corporation

Myriad

8835 General Drive

Plymouth Township, MI 48170

Chrysler Corporation

Dyment Distribution Service

Service Publication

20770 Westwood Drive

Strongsville, OH 44136

Ford Publications Department

Helm Incorporated

Post O ce Box 07150

Detroit, MI 48207

Buick

Tuar Company

Post O ce Box 354

Flint, MI 48501

Oldsmobile

Lansing Lithographers

Post O ce Box 23188

Lansing, MI 48909

Cadillac, Chevrolet, Pontiac

Helm Incorporated

Post O ce Box 07130

Detroit, MI 48207

OTRAS FUENTES-Privadas

Automóviles norteamericanos y

extranjeros

Chilton Book Company

Chilton Way

Radnor, PA 19089

Cordura Publications

Mitchell Manuals, Inc.

Post O ce Box 26260

San Diego, CA. 92126

Motor’s Auto Repair Manual

Hearst Company

250 W. 55th Street

New York, NY 10019

IMPORTANTE

ESTE MANUAL PRESENTA LAS INSTRUCCIONES COMPLETAS PARA LA CONEXION DEL ANALIZADOR DE VIBRACIONES DEL MOTOR. ADEMAS DESCRIBE

MUCHAS DE LAS PRUEBAS QUE ESTE INSTRUMENTO ES CAPAZ DE REALIZAR COMO ASIMISMO CUANDO SE DEBEN USAR EN BASE AL RENDIMIENTO

DEL VEHICULO, PUESTA A PUNTO DEL MOTOR O PROBLEMA ENCONTRADO.

CONSULTAR EL MANUAL DE SERVICIO DEL VEHICULO PARA LA INFORMACION

ESPECIFICA DE LA PUESTA A PUNTO Y LOS PROCEDIMIENTOS DE PRUEBA.

SEGUIR LAS ESPECIFICACIONES DEL FABRICANTE Y LOS PROCEDIMIENTOS

DE PRUEBA PARA AJUSTAR EL ANGULO DE CIERRE Y LA VELOCIDAD EN VACIO

(RALENTI), ESPECIALMENTE EN VEHICULOS CON ENCENDIDO ELECTRONICO Y

CONTROLES DE EMISION MODERNOS. NO TRATAR DE REPARAR UN VEHICULO

SIN TENER LAS INSTRUCCIONES Y ESPECIFICACIONES DEL FABRICANTE.

CONTROLES, CONEXIONES Y ACCESORIOS DEL ANGULO DE CIERRE/

TACOMETRO/VOLTIMETRO

DESCRIPCION

El ángulo de cierre/tacómetro/voltímetro modelo

CP7605 tiene un interruptor y medidor claramente

rotulados como se muestra en el diagrama de conexiones principal, gura 1 a continuación.

1 MEDIDOR

Este medidor indica las escalas siguientes:

• Voltios 0-16

• RPM 0-2000 (8 cilindros)

0-4000 (4 cilindros - multiplicar la

escala de 8 cilindros por 2)

• RPM 0-2500 (6 cilindros)

• Angulo de cierre 0-45 grados (8 cilindros)

0-90 grados (4 cilindros -

multiplicar la escala de 8

cilindros por 2)

• Angulo de cierre 0-60 grados (6 cilindros)

• Platinos Correctos/Defectuosos

2 SELECTOR DE FUNCION

Este selecciona las funciones de RPM, ángulo de

cierre o voltios del instrumento.

3 CONDUCTOR DE PRUEBA

Conectar este conductor al punto de prueba

correcto en el vehículo para efectuar las pruebas según se requiera y describen más abajo.

MEDICIONES DE VOLTAJE

PINZA VERDE - Conectar la fuente de voltaje

positivo (+) que se va a medir. (Borne + de la

batería, terminal de salida del alternador, receptáculo de bombilla, etc.).

PINZA NEGRA - Puesta a tierra del vehículo.

¡PRECAUCION!

Evitar conectar la

(-) de la batería o a cualquier componente del

sistema de combustible, ya que si llegaran a

haber gases presenten podrían explotar debido a

las chispas producidas al hacer las conexiones.

PINZA NEGRA al borne negativo

Fig. 1

Diagrama de conexiones principales

NEGRO

TIERRA DEL

MOTOR

DISTRIBUIDOR O

TACOMETRO

BAT.

BOBINA

VERDE

DISTRIBUIDOR

12 13

Page 8

MEDICION DE LA RESISTENCIA DEL ANGULO DE

CIERRE/TACOMETRO/PLATINOS

PINZA VERDE - Conectar al tacómetro o terminal

negativo (-) de la bobina de encendido. Ver las guras 3 a la 10 para las aplicaciones especí cas.

PINZA NEGRA - Puesta a tierra del vehículo. Ver

PRECAUCION en las mediciones de voltaje.

ACCESORIOS

Ver la gura 2.

1. ADAPTADOR DE DIAGNOSTICO GM

El adaptador de diagnóstico se usa para conec-

tarse a los vehículos dotados del conector de

diagnóstico GM (1976-1982). Además se usa

para conectarse a los vehículos Toyota que usan

el conjunto de encendido integrado (IIA). Ver las

guras 9 y 10 para la instalación.

2. ADAPTADOR HEI GM

El adaptador HEI GM se usa para proveer conex-

ión al terminal “TACH” en los sistemas HEI GM.

Ver la gura 7 para la instalación típica.

3. CHAVETA DE LA BOBINA FORD

La chaveta de la bobina Ford se usa para los

sistemas de encendido que tienen conexiones

de la bobina de encendido con manguito aislador. Ver la gura 4 para la instalación.

Fig. 2

Accesorios

1

Fig. 3 CONEXION PRINCIPAL DEL

TACOMETRO - Pinza VERDE

AL EQUILIBRA

PINZA

VERDE

UNIDAD DE

CONTROL

A LA UNIDAD

DE CONTROL

DOR

BAT.

BOBINA

Todos los encendidos electrónicos de Chrysler Corporation, se muestran 6 y 8 cilindros

1972 - 1985

Fig. 4 CONEXION PRINCIPAL DEL

TACOMETRO/ANGULO DE

CIERRE - Pinza VERDE

AL INTERRUPTOR DE

ENCENDIDO

ADAPTADOR

INCLUIDO

Sistema de encendido electrónico Ford y

todos los sistemas con platinos

AL DISTRIBUIDOR

ADAPTADOR

FORD

PINZA

VERDE

Fig. 6 CONEXION PRINCIPAL DEL

TACOMETRO - Pinza VERDE

PINZA

VERDE

Sistemas TFI Ford 1981 - 1985

Fig. 7 CONEXION PRINCIPAL DEL

TACOMETRO - Pinza VERDE

ADAPTADOR

INCLUIDO

PINZA

VERDE

AL INTERRUPTOR DE

ENCENDIDO

ADAPTADOR

HEI Delco 1974 - 1985

Fig. 9 CONEXION PRINCIPAL DEL

TACOMETRO - Pinza VERDE

ADAPTADOR DE TER

PINZA

VERDE

MINAL DE HORQUILLA

ADAP

TAD OR

Conector de diagnóstico GM y

sistemas HEI Delco 1976 - 1982

Fig. 10 CONEXION PRINCIPAL DEL

TACOMETRO - Pinza VERDE

INSERTAR EL

ADAPTADOR DE

DIAGNOSTICO

QUITAR LA TAPA

PINZA

VERDE

Conjunto de encendido integrado (IIA)

Toyota 1983-1985

DEL CONECTOR

DE PRUEBA DEL

TACOMETRO

Fig. 5 CONEXION PRINCIPAL DEL

TACOMETRO - Pinza VERDE

PINZA

3

2

VERDE

Fig. 8 CONEXION PRINCIPAL DEL

TACOMETRO - Pinza VERDE

PINZA

VERDE

Sistemas de estado sólido y Dura Spark

Ford 1975 - 1985

HEI Delco 1974 - 1985 Bobina externa

14

Fig. 11 Veri cación de rendimiento

SOLAMENTE

Nota: Este NO es un punto de conexión del tacométro.

PINZA VERDE

o cable puente

a tierra - Ver el

manual de servicio

del vehículo

CONECTOR DEL ANGULO DE

CIERRE VERDE

GM C3 (Control de comando por computadora)

15

Page 9

PRUEBAS DEL SISTEMA ELECTRICO - POSICION PARA "VOLTS"

(VOLTIOS)

COMPROBACION BASICA DEL SISTEMA - Voltaje de carga

1. PINZA VERDE - Conectarla al borne positivo (+)

de la batería.

2. PINZA NEGRA - Conectar a tierra en el vehículo.

3. SELECTOR DE FUNCION - Voltios

4. Arrancar el motor y dejar que se caliente totalmente. Hacerlo funcionar a velocidad en vacío

lenta.

5. Con todos los accesorios desactivados observar

la escala de 16 voltios en el analizador.

6. Resultado normal - 13.2 a 15.2 voltios o según lo

especi cado en el manual de servicio del vehículo.

7. Selector de función - RPM

8. Escoger un paso en la leva de velocidad en vacío

rápida que mantenga la velocidad del motor

entre 1800 y 2800 rpm, o pedir que un ayudante

mantenga la velocidad del motor en esta gama.

Mantener esta velocidad hasta el paso 12.

9. Selector de función - Voltios

10. Observar la escala de 16 voltios en el analizador.

El voltaje no debiera haber cambiado desde el

paso 5 más de unos 0.5 voltios.

11. Cargar el sistema eléctrico encendiendo las

luces, el ventilador a alta velocidad y los limpiaparabrisas.

12. Observar la escala de 16 voltios en el analizador. El

voltaje no debe bajar a menos de unos 13.0 voltios.

13. Apagar todos los accesorios, volver a dejar el

motor a velocidad en vacío y después apagarlo.

Si los resultados obtenidos en los pasos 6, 10 ó

12 son muy diferentes de aquéllos mostrados

o de los valores indicados en el manual de

servicio del vehículo, pueden ser necesarios más

diagnósticos; consultar el manual de servicio del

vehículo.

VOLTAJE DE ARRANQUE Y CONDICION DE LA BATERIA

Si el motor gira lentamente o simplemente no

gira, la falla puede estar en la batería, el motor de

arranque y la cablería respectiva. Probar el voltaje de

arranque como se indica a continuación.

1. Conectar el analizador al vehículo como se

muestra en la gura 1.

2. Inhabilitar el motor para que no arranque, como

se explica en el manual de servicio del vehículo

o como se muestra en la gura 12.

3. Selector de función - Voltios

4. Girar el motor mientras se observa la escala de 16

voltios en el analizador.

5. Resultado normal - 9.6 voltios o más a 70°F. El

voltaje bajará un poco cuando la temperatura

disminuye.

6. Si los resultados están muy desviados de la

especi cación, consultar el manual de servicio del

vehículo para continuar el diagnóstico.

7. Si el voltaje de la batería permanece anormalmente

alto (sobre aproximadamente 10.5 voltios) en un

motor que arranca lento o no arranca, el problema

puede ser una conexión o conexiones sueltas o corroídas en el circuito de arranque.

PRUEBAS MISCELÁNEAS DE VOLTAJE

Este instrumento puede realizar muchas de las pruebas

de voltaje indicadas en el manual de servicio del

vehículo, tales como el voltaje en los receptáculos de

bombillas, motores, solenoides y relés.

NOTA: Las funciones del voltímetro de este instrumento se pueden usar en cualquier parte que el

manual de servicio del vehículo lo indique para

medir el voltaje excepto en aquellas aplicaciones que

exigen el uso de una impedancia de entrada de 10

megaohmios o un voltímetro digital.

PRUEBA DEL SISTEMA DE ENCENDIDO - POSICION PARA "VOLTS"

(VOLTIOS)

RESISTENCIA DE LOS PLATINOS (sistemas con platinos solamente).

1. Revisar visualmente el platino y la cablería y

conexiones asociadas. Ver que el conductor del

distribuidor al terminal negativo (-) de la bobina

de encendido no esté dañado (aislante mellado,

etc.).

Fig. 12 Procedimiento de inhabilitación

Sistema de encendido con platinos

TIERRA DEL MOTOR

16

2. Quitar la tapa del distribuidor e inspeccionar los

platinos. Los platinos bien ajustados adquieren

un color gris claro con el uso normal. Si están

azulados, ennegrecidos o picados, ya han excedido su vida útil normal.

3. Para impedir que el motor arranque, inhabilitar

el sistema de encendido conectando a tierra

el alambre de la torre de la bobina, como se

muestra en la gura 12.

4. Conectar las pinzas VERDE y NEGRA tal como se

describe en la sección MEDICION DE LA RESISTENCIA DEL ANGULO DE CIERRE/TACOMETRO/

VOLTIMETRO.

NOTA: Cuando se pruebe un vehículo con platinos

dobles, bloquear alternadamente un juego de

platinos abierto con un pedazo de material aislante

mientras se prueba el otro juego.

5. CONECTAR la llave de contacto. Si el medidor

indica voltaje de la batería (12.5 - 13.0) los platinos están ABIERTOS. Girar el motor una fracción

de una revolución a la vez hasta que el medidor

indique en el lado izquierdo de la escala.

Los platinos ahora están cerrados.

Resultados de la prueba:

Normal – El medidor indica en la zona OK (CORRECTO) de la escala para platinos. El analizador

puede indicar una resistencia alta de los platinos

cuando el juego de platinos es nuevo hasta que han

funcionado en el vehículo por unos pocos kilómetros y están bien asentados. Esta condición puede

pasarse por alto siempre que se haya corregido

cualquier defecto descubierto durante la revisión

visual previa.

Anormal – Si el medidor indica en la zona BAD (DEFICIENTE) de la escala para platinos puede indicar

platinos defectuosos o que existe cualquiera de las

averías siguientes:

Mala conexión a tierra del distribuidor

Mala conexión en el conductor primario del

distribuidor a la bobina de encendido

Cable de llegada al distribuidor defectuoso

Platinos desalineados

Mala conexión a tierra de los platinos/placa

dentro del distribuidor

Corregir el defecto y repetir la prueba.

PRUEBA DEL SISTEMA DE ENCENDIDO - POSICION PARA "DWELL"

(ANGULO DE CIERRE)

PRUEBA Y AJUSTE DEL ÁNGULO DE CIERRE Sistemas con platinos solamente o sistemas transistorizados que utilizan platinos).

1. Preparación:

Antes de efectuar el PROCEDIMIENTO DE PRUEBA

Y AJUSTE DEL ANGULO DE CIERRE, leer la etiqueta de control de emisiones del vehículo o el

manual de servicio del vehículo para determinar

lo que se debe hacer con las mangueras de vacío

conectadas al distribuidor y los distintos solenoides de avance/retardo. En la mayoría de los

casos, la manguera de vacío debe desconectarse

del distribuidor y el extremo taparse con un “tee”

de plástico de golf u otro tapón.

Conectar las pinzas VERDE y NEGRA según lo

descrito en la sección MEDICION DE LA RESISTENCIA DEL TACOMETRO/ANGULO DE CIERRE/VOLTIMETRO.

2. Procedimiento de prueba:

Arrancar el motor y dejar que se caliente

(manguera superior del radiador caliente).

Hacer funcionar el motor a velocidad en vacío

lenta O a las revoluciones por minuto especi cadas en la etiqueta de control de emisiones del

vehículo o en el manual de servicio del vehículo

para medir el ángulo de cierre. Comprobar las

RPM cambiando el SELECTOR DE FUNCION a la

posición RPM correcta y leer en la escala apropiada del medidor. Volver a poner el SELECTOR

DE FUNCION en Angulo de cierre y observar la

escala correcta para ángulo de cierre.

NOTA: Existe una relación directa entre el ángulo de

cierre y el reglaje del encendido. Sin embargo, es una

relación en un solo sentido. Si se cambia el ángulo de

cierre de los platinos, se cambiará automáticamente

el reglaje del encendido. No obstante, cambiar el reglaje del encendido no tiene ningún efecto sobre el

ángulo de cierre. POR ESTA RAZON, ES IMPORTANTE

VOLVER A COMPROBAR EL REGLAJE DEL ENCENDIDO

CADA VEZ QUE SE AJUSTA EL ANGULO DE CIERRE.

AJUSTE DEL ANGULO DE CIERRE - Sistemas con

platinos convencionales

En los distribuidores de GM con una tapa deslizante

metálica pequeña, levantar la tapa e insertar una

llave allen de 1/8” en el hueco del tornillo de ajuste y

ajustar el ángulo de cierre girando la llave, como se

muestra en la gura 13.

En los distribuidores de la Ford, Chrysler, American

Motors y otros sin la tapita metálica deslizante,

17

Page 10

Fig. 13 DISTRIBUIDOR CON PLATINOS

TIPICO GENERAL MOTORS

VENTANILLA

LLAVE

ALLEN DE

1/8”

TORNILLO DE

AJUSTE

proceder de la manera siguiente, teniendo como

guía la gura 14.

1. Desconectar el cable de la bobina de la torre

central en la tapa del distribuidor y ponerlo a

tierra conectando el extremo suelto al motor o

chasis. Ver la gura 12.

2. Quitar la tapa del distribuidor y el rotor.

3. Conectar un interruptor de arranque remoto al

vehículo o pedir a un ayudante que haga girar el

motor.

Fig. 14 Ajuste del ángulo de cierre

(Todos los distribuidores excepto los con tapita deslizante

Delco-Remy)

AGUJERO RANU

RADO PARA

AJUSTE

TORNILLO DE

FIJACIÓN

PLATINOS

PLATINOS

TORNILLO DE

AJUSTE

Fig. 15 Variacion del ángulo de cierre

MAS DE 3 GRADOS

PRIMERA

LECTURA

4. Con la llave de contacto CONECTADA y el motor

girando observar la indicación en la escala para

ángulo de cierre.

5. Para ajustar el ángulo de cierre, soltar un poco el

tornillo de jación y ajustar la separación de los

platinos con un calibrador de separaciones de

acuerdo al procedimiento descrito en el manual

de servicio del vehículo. Después del ajuste, apretar el tornillo de jación y volver a comprobar el

ángulo de cierre mientras el motor está girando.

Si es necesario, repetir el procedimiento. (Figura

14).

6. Volver a armar el distribuidor y comprobar la

indicación del ángulo de cierre con el motor

funcionando a velocidad en vacío. Si es necesario,

repetir los pasos 5 y 6.

PRUEBA DE VARIACION DEL ANGULO DE CIERRE

Cuando se compruebe el ángulo de cierre, leer

el manual del propietario o la calcomanía en el

compartimento del motor y seguir las instrucciones

respecto a lo que se debe hacer con las conexiones de las mangueras de vacío y de los solenoides

de avance/retardo. En la mayoría de los casos, la

manguera de vacío debe desconectarse del distribuidor y el extremo taparse con un tapón.

Aumentar la velocidad del motor desde vacío lento

hasta aproximadamente 1500 rpm y anotar el ángulo de cierre. Volver el motor a velocidad en vacío y

nuevamente anotar el ángulo de cierre. Si la diferencia entre las dos indicaciones es más de 3 grados, ver

si la placa y acoplamientos de los platinos están muy

desgastados o si los bujes y el engranaje del eje del

distribuidor están demasiado desgastados.

SEGUNDA

LECTURA

"DWELL" (ANGULO DE CIERRE)

1. Angulo de cierre del solenoide de control de la

mezcla C-3 (control de comando por computadora) de General Motors - (Vehículos dotados

de carburador solamente). El sistema C-3 de

GM controla la relación aire/combustible con

un solenoide de control de la mezcla ubicado

en el carburador. La comprobación básica

del funcionamiento de este sistema requiere

comprobar el ciclo de servicio o “ángulo de

cierre” del solenoide M/C. Notar que indiferente

al número de cilindros en el motor, la lectura del

“ángulo de cierre” siempre se hace en la escala

para ángulo de cierre de 6 cilindros.

2. Este analizador se puede usar para comprobar

el ángulo de cierre C-3 (ciclo de servicio). Consultar el manual de servicio del vehículo para

las instrucciones para hacer las conexiones y los

resultados del funcionamiento. Ver la gura 11.

PRUEBAS DEL MOTOR - POSICION PARA "RPM"

1. Ajustes del carburador - Hay varios ajustes que

se deben veri car como parte de la puesta a

punto. Aquellos que requieren vigilar las revoluciones por minuto del motor son:

a. Velocidad en vacío lenta

b. Velocidad en vacío básica

c. Velocidad en vacío controlada por solenoide

d. Velocidad en vacío rápida

El vehículo que se está probando probable-

mente tendrá alguna combinación de estos

ajustes. El ajuste correcto de estos valores es un

Modelo CP7605

Piezas de Repuesto

NO. NO. DE

REF. PIEZA DESCRIPCION

1 400-857 Caja inferior

2 270-117 Tornillo autorroscante #6-20 x 1” de la caja

3 38-726 Conjunto de cables de las pinzas verde y negra

4 450-133 Pestillo de tapa

5 180-300 Ford Adaptador

6 38-1342 GM Adaptador

7 1-1086 Calcomanía del interruptor

8 1-1085 Calcomanía del medidor

9 400-855 Ventanilla

— 2-168203 Manual de instrucciones (no se ilustra)

NOTA: La tarjeta de circuitos y

el medidor no son piezas de

repuesto, ya que el reemplazo

de cualquiera de ellos requiere

la recalibración del instru-

PRUEBAS DEL SISTEMA DE

COMBUSTIBLE - POSICION PARA

18

19

Loading...

Loading...