Page 1

User Interface Guide

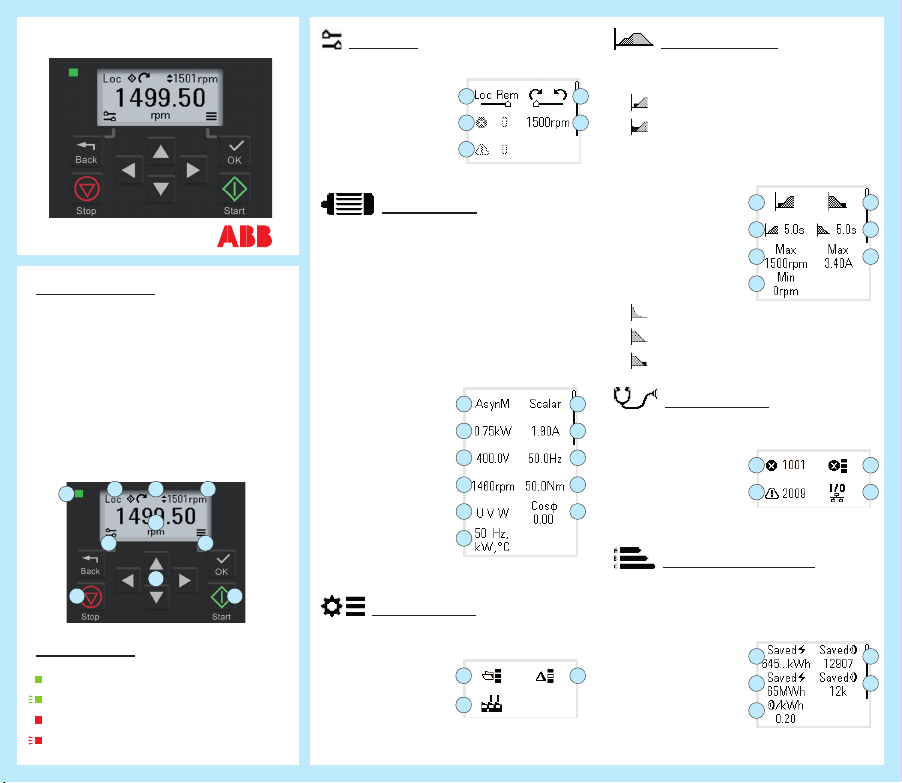

ACS380

Control panel

1. Status light

2. Local /

remote

3. Status icons

4. Reference

value

5. Actual value

6. Back /

Options

1

6

7

Status light

green, steady: OK

green, blinking: Warning

red, steady: Fault

red, blinking: Fault, turn power off

to reset

7. Stop

8. Edit value /

Move in

menus

9. OK / Select /

Save / Menu

10. Start

2 43

5

9

8

10

Options

1. Control location

2. Active fault

3. Active warnings

4. Forward /

Reverse

1 4

2 5

3

5. Reference

Motor data

1. Motor type

• AsynM

• PMSM

• SynRM

2. Nominal

power

3. Nominal

voltage

4. Nominal

speed

5. Phase order

Change

direction without

reconnecting

motor cables

6. Unit

selection

7. Control

mode

Scalar or vector

8. Nominal

current

9. Nominal

frequency

10. Nominal

torque

11. Nominal

cos phi

1 7

2

3

4

5

6

Parameters

Direct access to all functions (advanced)

1. Complete list

2. Reset to

factory

defaults

3. Modied only

1

2

1. Start mode

2. Acceleration

3. Max.

4. Min. allowed

5. Stop mode

8

1. Active fault

2. Active

9

10

3. Fault history

4. Connection

11

1. Saved

2. Saved

3

3. Cost per

4. Saved

Motor control

Const time

Automatic

time

allowed

speed

speed

Coast

Ramp

DC Hold

Diagnostics

warnings

status

Energy efciency

energy in

kWh

energy in

MWh

kWh

money

6. Deceleration

time

7. Max.

allowed

current

1 5

2 6

3 7

4

1 3

2 4

5. Saved

money

x1000

1 4

2 5

3

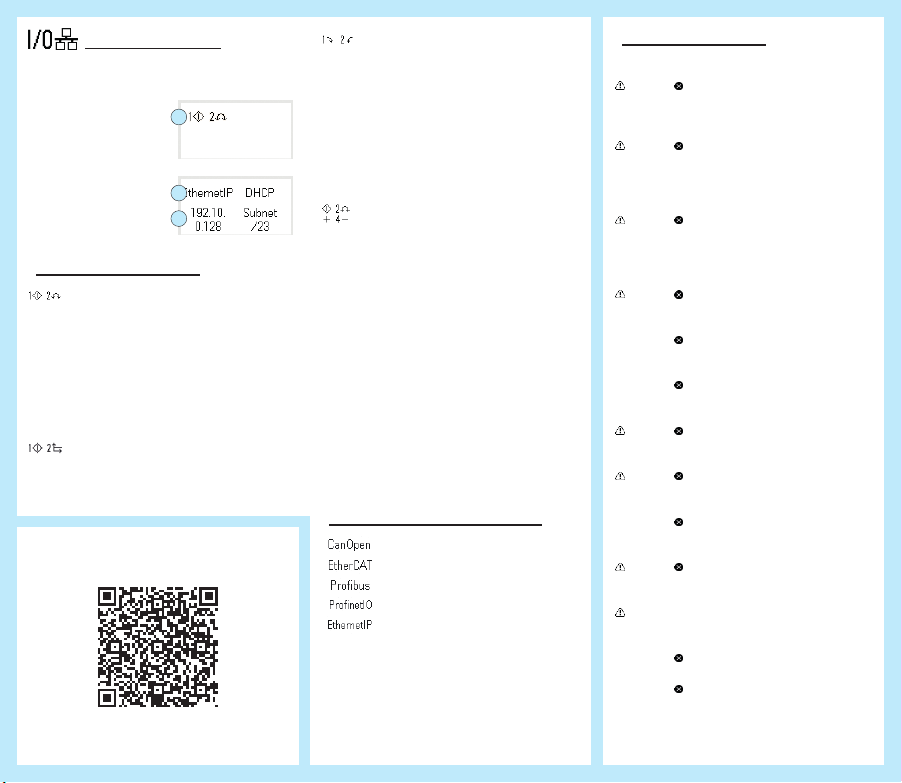

Page 2

Control macros

The menu content depends on the installed

extension module.

I/O control:

1

1. I/O control

macro

Fieldbus control:

1. Protocol

2. Address

1

2

settings

I/O control macros

Standard (2-wire)

AI1: Reference

DI1: Start / Stop

DI2: Forward / Reverse

DI3: Constant speed sel1

DI4: Constant speed sel2

DIO1: Ramp pair selection

DIO2: Ready run

ABB limited 2-wire

Integrated panel: Reference

DI1: Start / Stop

DI2: Constant speed sel1

For the full manual, go to:

3AXD50000022224 Rev. B EN

Alternate

AI1: Reference

DI1: Start forward

DI2: Start reverse

(if DI1 = DI2, stop)

DI3: Constant speed sel1

DI4: Constant speed sel2

DIO1: Ramp pair selection

DIO2: Ready run

Motor potentiometer

DI1: Start / Stop

DI2: Forward / Reverse

DI3: Reference up

DI4: Reference down

DIO1: Constant sel1

DIO2: Ready run

PID

PID

AI1: Setpoint

AI2: Feedback

DI1: Start / Stop

DI2: Constant setpoint 1

DI3: Constant setpoint 2

DI4: Constant speed 1

DIO1: Ramp pair selection

DIO2: Ready run

Fieldbus control macros

CANopen

EtherCAT

PROFIBUS

Pronet

Ethernet/IP

Modbus

Modbus TCP

TCP

Modbus

Modbus RTU

RTU

Start/stop/reference from the eldbus

DI1: Fault reset

DI2: Not congured

Warnings/Faults

Warning Fault Description

A2A1 2281 Warning: Current calibration

A2B1 2310 Overcurrent. The output

A2B3 2330 Earth leakage. A load

A2B4 2340 Short circuit. There is a

A3A1 3210 DC link overvoltage. There

A3A2 3220 DC link undervoltage. There

A5A0 5091 Safe torque off. The Safe

AFF6 Identication run. The motor

is done at the next start.

Fault: Output phase current

measurement fault

current is more than the

internal limit. This can be

caused by an earth fault or

phase loss.

unbalance that is typically

caused by an earth fault

in the motor or the motor

cable.

short circuit in the motor or

the motor cable.

3130 Input phase loss. The

intermediate DC circuit

voltage oscillates.

3181 Cross connection. The

input and motor cable

connections are incorrect.

is an overvoltage in the

intermediate DC circuit.

is an undervoltage in the

intermediate DC circuit.

3381 Output phase loss. All three

phases are not connected

to the motor.

torque off (STO) function

is on.

ID run occurs at the next

start.

FA81 Safe torque off 1. The Safe

torque off circuit 1 is broken.

FA82 Safe torque off 2. The Safe

torque off circuit 2 is broken.

Loading...

Loading...