Page 1

ABB Micro drives

User’s manual

ACS255 drives (0.5…20 hp) (600V Variants)

Page 2

List of related manuals

Option manuals and guides

Code (English)

ACS255 user’s manual for 115-480V variants

3AXD10000528266

Page 3

3

ACS255 drives

0.5…20 hp

User’s manual

3AXD10000528265 Rev A

EN

EFFECTIVE: 2016-09-13

© 2016 ABB Oy. All Rights Reserved.

Page 4

1. Table of Contents

ACS255 – IP20 (600V Variants) EASY START-UP GUIDE ________________________________________ 7

ACS255 – IP66 (600V Variants) EASY START-UP GUIDE ________________________________________ 8

2. Safety ____________________________________________________________________________ 10

What this chapter contains _____________________________________________________________________ 10

Use of warnings ______________________________________________________________________________ 10

Safety in installation and maintenance ____________________________________________________________ 10

Safety in start-up and operation _________________________________________________________________ 11

3. General Information and Ratings ______________________________________________________ 13

3.1. Type designation key ___________________________________________________________________ 13

3.2. Drive model numbers – IP20 _____________________________________________________________ 14

3.3. Drive model numbers – IP66 _____________________________________________________________ 14

4. Mechanical Installation______________________________________________________________ 15

5

4.1. General ______________________________________________________________________________ 15

4.2. Before Installation _____________________________________________________________________ 15

4.3. UL Compliant Installation ________________________________________________________________ 15

4.4. Mechanical dimensions and weights _______________________________________________________ 15

4.5. Guidelines for Enclosure mounting (IP20 Units) ______________________________________________ 17

4.6. Mounting the Drive – IP20 Units __________________________________________________________ 17

4.7. Guidelines for mounting (IP66 Units) _______________________________________________________ 18

4.8. Removing the Terminal Cover ____________________________________________________________ 18

4.9. Routine Maintenance ___________________________________________________________________ 18

5. Electrical Installation ________________________________________________________________ 19

5.1. Grounding the Drive ____________________________________________________________________ 19

5.2. Wiring Precautions _____________________________________________________________________ 20

5.3. Incoming Power Connection ______________________________________________________________ 20

5.4. Compatibility with IT (ungrounded) and corner-grounded TN systems ____________________________ 21

5.5. Drive and Motor Connection _____________________________________________________________ 22

5.6. Motor Terminal Box Connections __________________________________________________________ 22

___________________________________________________________________________________________ 22

5.7. Motor Thermal overload Protection. _______________________________________________________ 22

5.8. Control Terminal Wiring _________________________________________________________________ 22

5.9. Connection Diagram ____________________________________________________________________ 23

5.10. Safe Torque Off ________________________________________________________________________ 24

6. Managing the Keypad _______________________________________________________________ 28

6.1. Keypad Layout and Function _____________________________________________________________ 28

6.2. Changing Parameters ___________________________________________________________________ 28

Page 5

6

6.3. Resetting Parameters to Factory Default Settings _____________________________________________ 29

6.4. Advanced Keypad Operation ShortCuts _____________________________________________________ 30

6.5. Drive Operating Displays ________________________________________________________________ 30

7. Quick Start-up and Control ___________________________________________________________ 31

7.1. Quick Start-up Terminal Control __________________________________________________________ 31

7.2. Quick Start-up Keypad Control ____________________________________________________________ 31

7.3. Sensorless Vector Speed Control Mode _____________________________________________________ 32

8. Application Macros _________________________________________________________________ 33

8.1. Overview of macros ____________________________________________________________________ 33

8.2. Macro wiring configurations. _____________________________________________________________ 34

9. Parameters _______________________________________________________________________ 38

9.1. Parameter Structure ____________________________________________________________________ 38

9.2. Parameters in the Short parameter mode ___________________________________________________ 39

9.3. Read Only Status parameters _____________________________________________________________ 41

9.4. Parameters in the Long parameter mode ___________________________________________________ 43

9.5. Preventing un-authorized parameter editing. ________________________________________________ 54

10. Serial communications ______________________________________________________________ 55

10.1. RJ45 Connector Pin Assignment ___________________________________________________________ 55

10.2. Modbus RTU Communications ____________________________________________________________ 55

11. Technical Data _____________________________________________________________________ 59

11.1. Environmental _________________________________________________________________________ 59

11.2. Input/Output Current ratings and fuses ____________________________________________________ 59

11.3. Overload _____________________________________________________________________________ 59

11.4. Additional Information for UL Approved Installations _________________________________________ 60

11.5. Derating Information ___________________________________________________________________ 60

12. Appendix: Permanent magnet synchronous motors (PMSMs) _______________________________ 61

13. Troubleshooting ___________________________________________________________________ 62

13.1. Fault messages ________________________________________________________________________ 62

Page 6

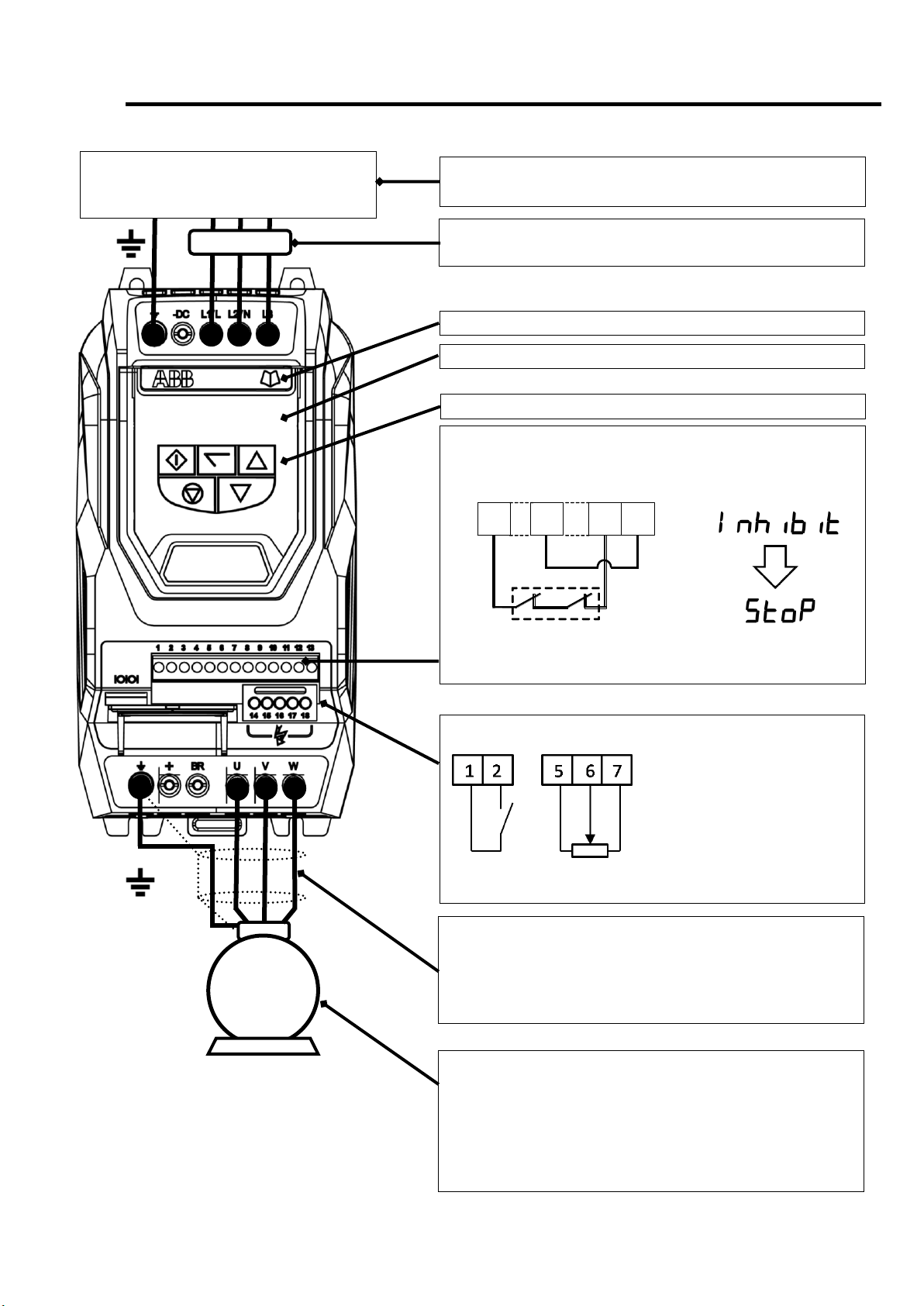

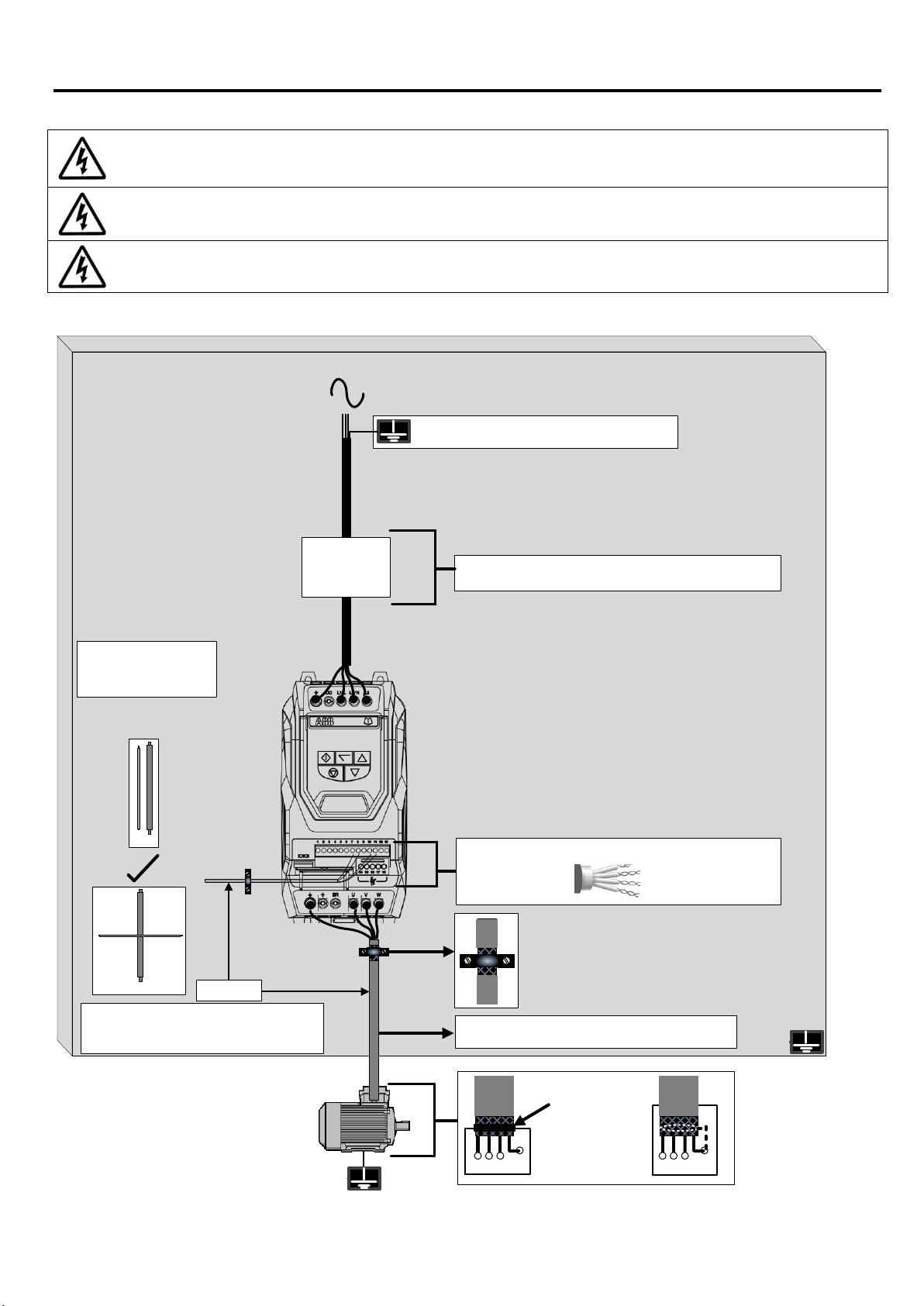

ACS255 – IP20 (600V Variants) EASY START-UP GUIDE

Fuses or MCB

M

1 9 12 13

P20 Easy Start

AC Supply Connection Supply Voltage

3 Phase : Connect L1 L2 L3, PE 500-600 Volts + / - 10%

Fuses

Fuse rating recommendation values given on page 59

Help Card

Display

Keypad Operation can be found in section 6 and 7.2

IMPORTANT!

HARDWARE ENABLE FUNCTION

7

Run – Stop 10K Speed Pot

Link the terminals as shown, optionally through switch contacts, to

enable the drive.

Control Terminals

Based on the factory default parameter settings

Close the switch to run (enable), open to stop

Motor Cable

o Cable size recommendation values given on page 59.

o Observe the maximum permissible motor cable length

o For Motor cable lengths > 50 metres, an output filter is

recommended

o Use a screened (shielded cable)

Motor Connection

Check for Star or Delta Connection according to the motor voltage rating

(See page 22)

Enter the Motor Nameplate Data into the drive Parameters as follows

o Motor Rated Voltage : 9905

o Motor Rated Current : 9906

o Motor Rated Frequency : 9907

o Motor Rated Speed (Optional) : 9908

Page 7

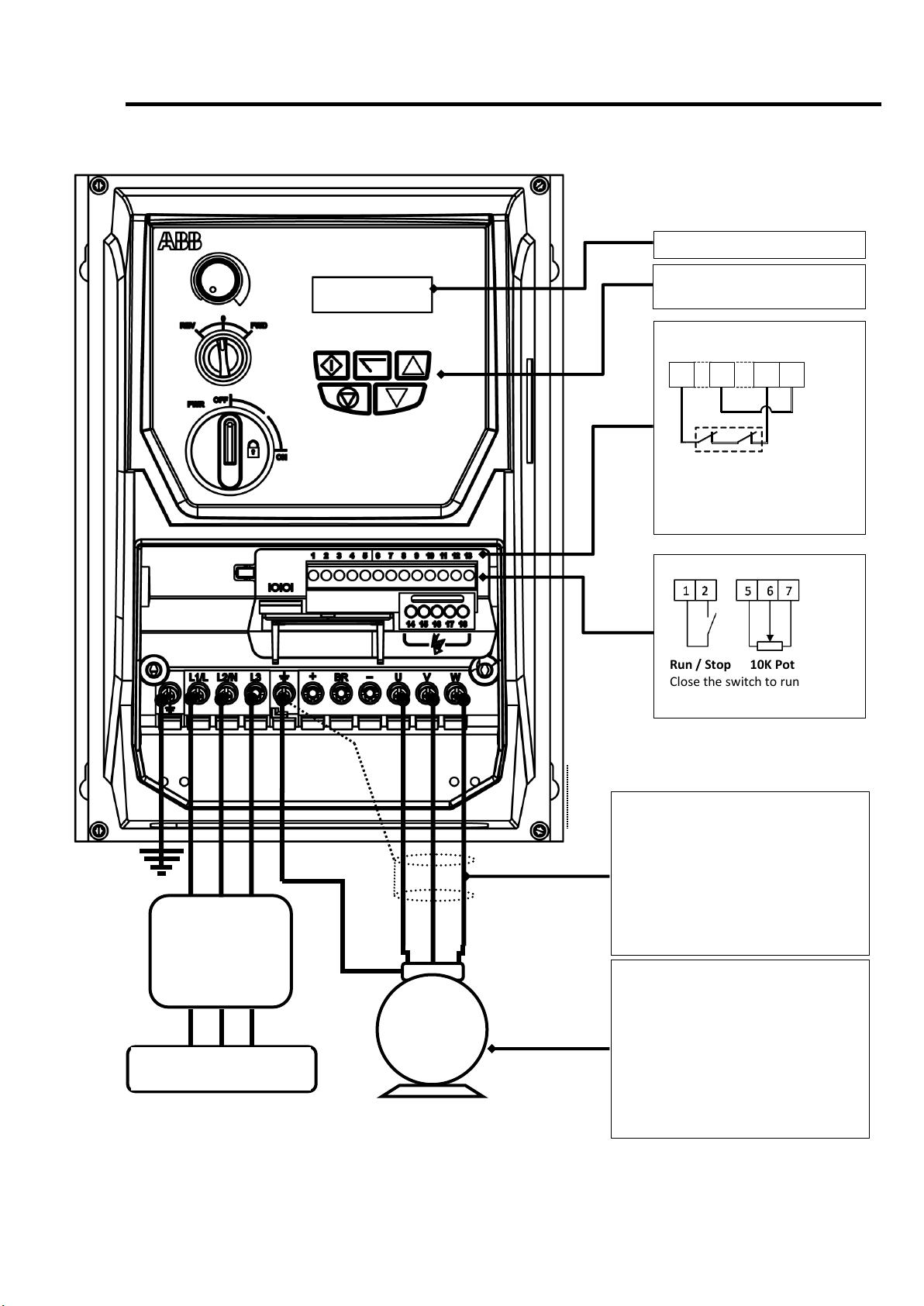

8

M

1 9 12 13

Fuse rating

recommendation

values given on

page 59

AC Supply Connection

500 – 600 Volts + / - 10%

ACS255 – IP66 (600V Variants) EASY START-UP GUIDE

Display

Keypad Operation can be found

In Section 6 and 7.2.

IMPORTANT

HARDWARE ENABLE

Link the terminals as shown

Above, optionally through switch

contacts to enable the drive

Control Terminals

Run / Stop 10K Pot

Close the switch to run (enable)

Open the switch to stop

Motor Cable

Cable size recommendation values given

on page 59.

Observe the maximum permissible motor

cable length

For Motor cable lengths > 50 metres, an

output filter is recommended

Use a screened (shielded) cable. The shield

should be bonded to earth at both ends

Motor Connection

Check for Star or Delta Connection according

to the motor voltage rating (See page 22).

Enter the Motor Nameplate Data into the

drive Parameters as follows

Motor Rated Voltage : 9905

Motor Rated Current : 9906

Motor Rated Frequency : 9907

Motor Rated Speed (Optional) : 9908

Page 8

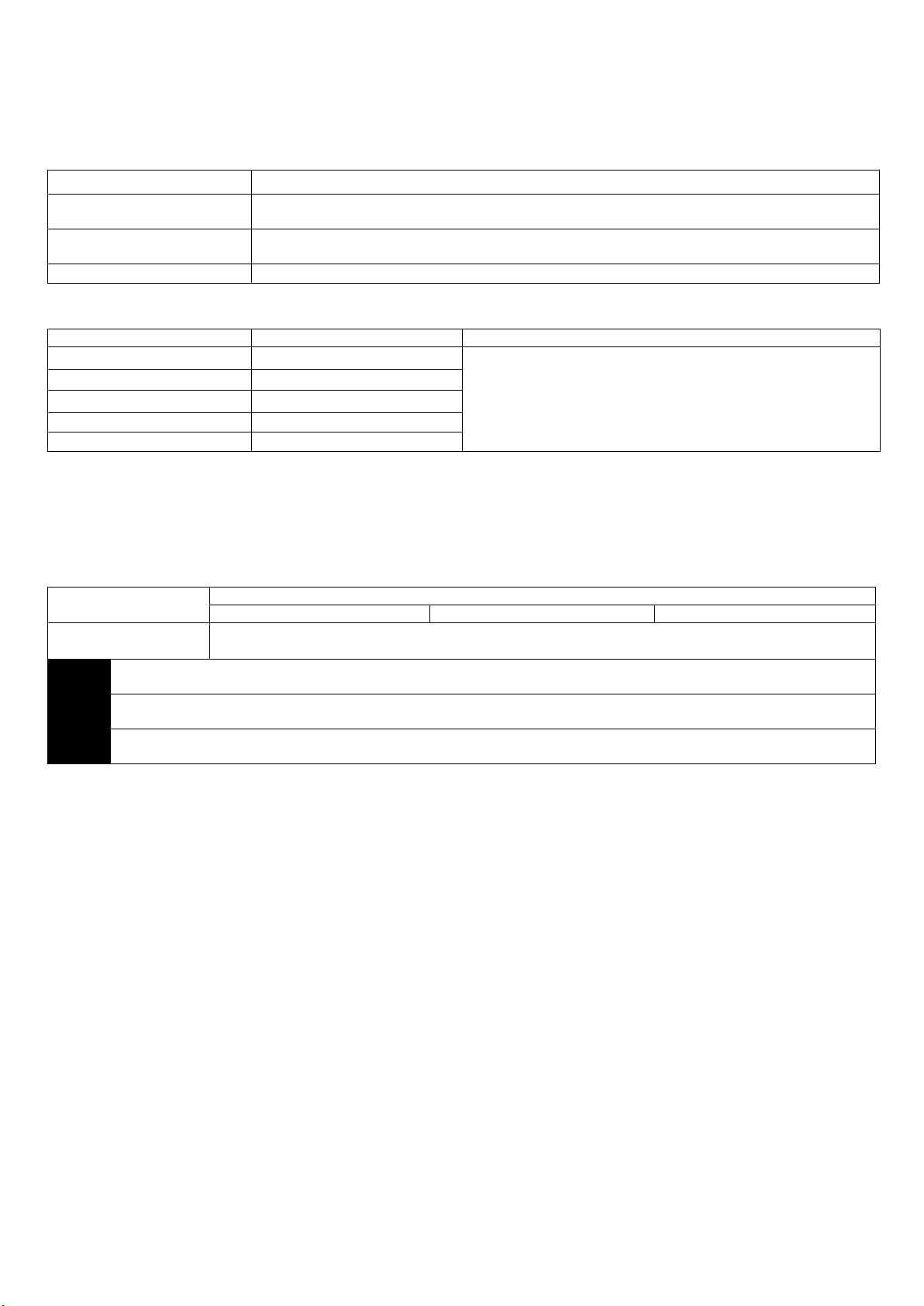

Declaration of Conformity:

EN 61800-5-1: 2007

Adjustable speed electrical power drive systems. Safety requirements. Electrical, thermal and energy.

EN 61800-3 2nd Ed: 2004

/ A1:2012

Adjustable speed electrical power drive systems. EMC requirements and specific test methods

EN 55011: 2007

Limits and Methods of measurement of radio disturbance characteristics of industrial, scientific and

medical (ISM) radio-frequency equipment (EMC)

EN60529 : 1992

Specifications for degrees of protection provided by enclosures

Standard

Classification

Independent Approval

EN 61800-5-2:2007

Type 2

*TUV

EN ISO 13849-1:2006

PL “d”

EN 61508 (Part 1 to 7)

SIL 2

EN60204-1

Uncontrolled Stop “Category 0”

EN 62061

SIL CL 2

Drive Type / Rating

EMC Category – Conducted Emissions

First Environment Category C1

First Environment Category C2

Second Environment Category C3

ACS255..

Use additional External EMC Filter

Note

Compliance with EMC standards is dependent on a number of factors including the environment in which the drive is installed,

motor switching frequency, motor, cable lengths and installation methods adopted.

For motor cable lengths greater than 100m, an output dv / dt filter must be used, please refer to the (please refer to the

http://www.abb.com/ProductGuide/ for further details).

Vector Speed and Torque control modes may not operate correctly with long motor cables and output filters. It is recommended to

operate in V/F mode only for cable lengths exceeding 50m.

ABB Drives Ltd hereby states that the ACS255 product range conforms to the relevant safety provisions of the following council directives:

2014/30/EU (EMC) and 2014/35/EU (LVD)

2011/65/EU (RoHS)

STO Function

ACS255 incorporates a hardware STO (Safe Torque Off) Function, designed in accordance with the standards listed below.

*Note : TUV Approval of the “STO” function is relevant for drives which have a TUV logo applied on the drive rating label.

Electromagnetic Compatibility

It is the responsibility of the installer to ensure that the equipment or system into which the product is incorporated complies with the EMC

legislation of the country of use. Within the European Union, equipment into which this product is incorporated must comply with the EMC

Directive 2004/108/EC. When using an ACS255 with an internal or optional external filter, compliance with the following EMC Categories, as

defined by EN61800-3:2004 can be achieved:

9

All rights reserved. No part of this User Guide may be reproduced or transmitted in any form or by any means, electrical or mechanical including

photocopying, recording or by any information storage or retrieval system without permission in writing from the publisher.

Copyright ABB Drives Ltd © 2016

The manufacturer accepts no liability for any damage caused during or resulting from transport, receipt of delivery, installation or

commissioning. The manufacturer also accepts no liability for damage or consequences resulting from inappropriate, negligent or incorrect

installation, incorrect adjustment of the operating parameters of the drive, incorrect matching of the drive to the motor, incorrect installation,

unacceptable dust, moisture, corrosive substances, excessive vibration or ambient temperatures outside of the design specification.

Contents of this User Guide are believed to be correct at the time of printing. In the interest of a commitment to a policy of continuous

improvement, the manufacturer reserves the right to change the specification of the product or its performance or the contents of the User

Guide without notice.

This User Guide is for use with version 2.0 Firmware.

User Guide Revision A

This user guide is the “original instructions” document. All non-English versions are translations of the “original instructions”.

The manufacturer adopts a policy of continuous improvement and while every effort has been made to provide accurate and up to date

information, the information contained in this User Guide should be used for guidance purposes only and does not form the part of any contract.

Page 9

10

Electricity warning warns of hazards from electricity which can cause physical injury and/or damage to

the equipment.

General warning warns about conditions, other than those caused by electricity, which can result in

physical injury and/or damage to the equipment.

WARNING! Ignoring the instructions can cause physical injury or death, or damage to the equipment.

Only qualified electricians are allowed to install and maintain the drive!

2. Safety

What this chapter contains

This chapter contains the safety instructions which you must follow when installing, operating and servicing the drive. If ignored,

physical injury or death may follow, or damage may occur to the drive, motor or driven equipment. Read the safety instructions before

you work on the unit.

Use of warnings

Warnings caution you about conditions which can result in serious injury or death and/or damage to the equipment and advice on how

to avoid the danger. The following warning symbols are used in this manual:

Safety in installation and maintenance

These warnings are intended for all who work on the drive, motor cable or motor.

Electricity safety

Never work on the drive, motor cable or motor when input power is applied. After disconnecting the input power, always

wait for 10 minutes to let the intermediate circuit capacitors discharge before you start working on the drive, motor or motor

cable.

Always ensure by measuring with a multimeter (impedance at least 1 Mohm) that:

1. There is no voltage between the drive input phases L1, L2 and L3 and the ground.

2. There is no voltage between terminals + and BR and the ground.

Do not work on the control cables when power is applied to the drive or to the external control circuits. Externally supplied

control circuits may carry dangerous voltage even when the input power of the drive is switched off.

Do not make any insulation or voltage withstand tests on the drive.

Be sure the system is properly grounded before applying power. Do not apply AC power before you ensure that all grounding

instructions have been followed. Electrical shock can cause serious or fatal injury

Note:

Even when the motor is stopped, dangerous voltage is present at the power circuit terminals L1, L2, L3 and U, V, W and + and BR.

Page 10

General safety

WARNING! Ignoring the following instructions can cause physical injury or death, or damage to the equipment.

The drive is not field repairable. Never attempt to repair a malfunctioning drive; contact your local ABB representative or

Authorized Service Centre for replacement.

Make sure that dust from drilling does not enter the drive during the installation. Electrically conductive dust inside the drive may

cause damage or lead to malfunction.

Ensure sufficient cooling.

Safety in start-up and operation

These warnings are intended for all who plan the operation, start up or operate the drive.

11

WARNING! Ignoring the following instructions can cause physical injury or death, or damage to the equipment.

Before adjusting the drive and putting it into service, make sure that the motor and all driven equipment are suitable for

operation throughout the speed range provided by the drive. The drive can be adjusted to operate the motor at speeds

above and below the speed provided by connecting the motor directly to the power line.

Do not activate automatic fault reset functions if dangerous situations can occur. When activated, these functions reset the

drive and resume operation after a fault.

Do not control the motor with an AC contactor or disconnecting device (disconnecting means); use instead the control panel

start and stop keys and or external commands (I/O). The maximum allowed number of charging cycles of the DC capacitors

(that is, power-ups by applying power) is two per minute.

Note:

When parameter 1103 PRIMARY COMMAND SOURCE MODE is not set to 1 or 2, the stop key on the control panel will not

stop the drive. To stop the drive open terminal 2 of the drive control terminals.

Page 11

12

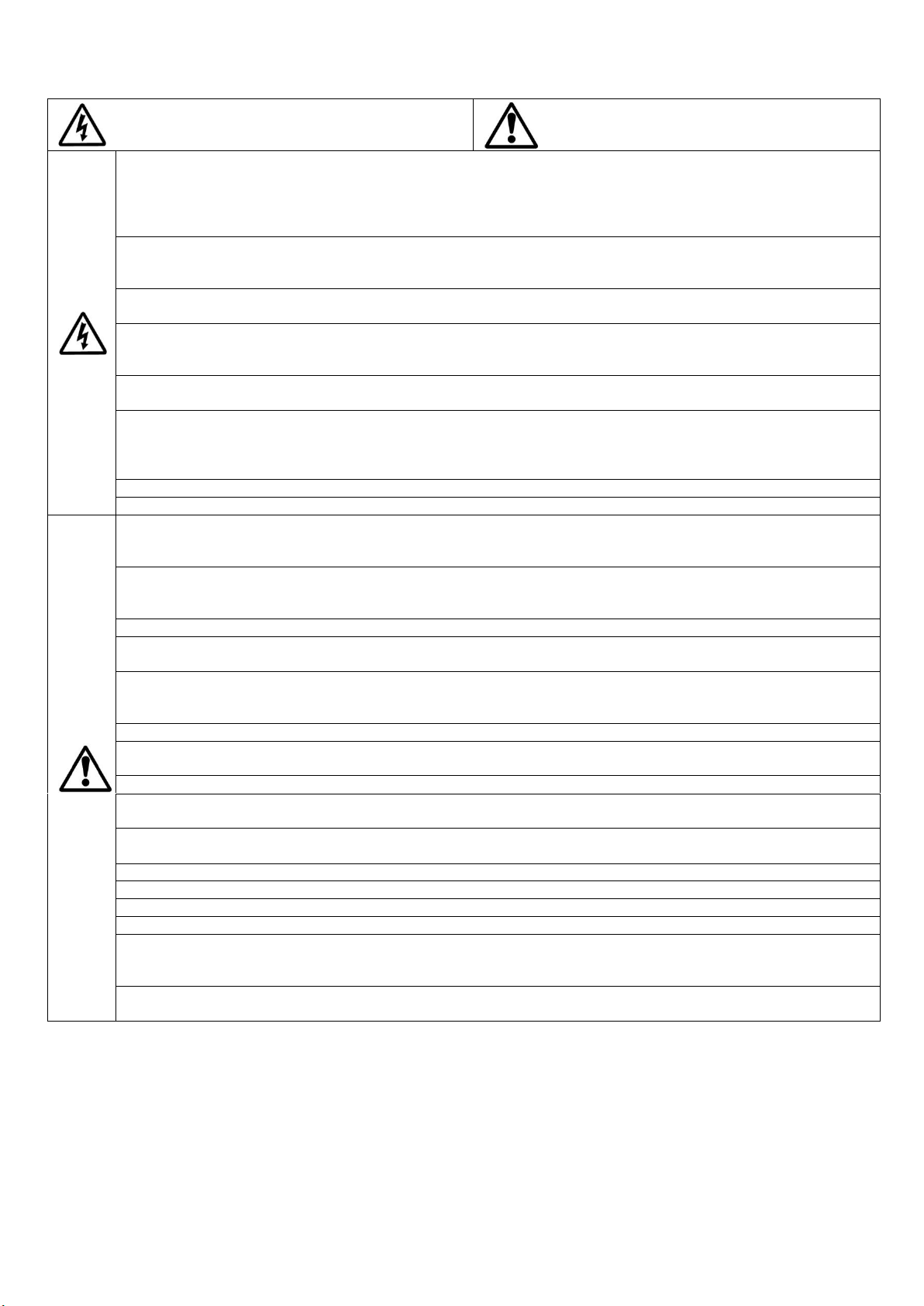

Danger : Indicates a risk of electric shock, which, if not

avoided, could result in damage to the equipment and

possible injury or death.

Danger : Indicates a potentially hazardous situation

other than electrical, which if not avoided, could result

in damage to property.

This ACS255 variable speed drive is intended for professional installation and commissioning into complete equipment or systems

as part of a fixed installation. If installed incorrectly it may present a safety hazard. The ACS255 uses high voltages and currents,

carries a high level of stored electrical energy, and is used to control mechanical plant that may cause injury. Close attention is

required to system design and electrical installation to avoid hazards in either normal operation or in the event of equipment

malfunction. Only qualified electricians are allowed to install and maintain this product.

System design, installation, commissioning and maintenance must be carried out only by personnel who have the necessary

training and experience. They must carefully read this safety information and the instructions in this Guide and follow all

information regarding transport, storage, installation and use of the ACS255, including the specified environmental limitations.

Do not perform any flash test or voltage withstand test on the ACS255. Any electrical measurements required should be carried out

with the ACS255 disconnected.

Electric shock hazard! Disconnect and ISOLATE the ACS255 before attempting any work on it. High voltages are present at the

terminals and within the drive for up to 10 minutes after disconnection of the electrical supply. Always ensure by using a suitable

multimeter that no voltage is present on any drive power terminals prior to commencing any work.

Where supply to the drive is through a plug and socket connector, do not disconnect until 10 minutes have elapsed after turning off

the supply.

Ensure correct grounding connections and cable selection as per defined by local legislation or codes. The drive may have a leakage

current of greater than 3.5mA; furthermore the earth cable must be sufficient to carry the maximum supply fault current which

normally will be limited by the fuses. Suitably rated fuses should be fitted in the mains supply to the drive, according to any local

legislation or codes.

Do not carry out any work on the drive control cables when power is applied to the drive or to the external control circuits.

The “Safe Torque Off” Function does not prevent high voltages from being present at the drives power terminals.

Within the European Union, all machinery in which this product is used must comply with the Machinery Directive 2006/42/EC,

Safety of Machinery. In particular, the machine manufacturer is responsible for providing a main switch and ensuring the electrical

equipment complies with EN60204-1.

The level of integrity offered by the ACS255 control input functions – for example stop/start, forward/reverse and maximum speed,

is not sufficient for use in safety-critical applications without independent channels of protection. All applications where

malfunction could cause injury or loss of life must be subject to a risk assessment and further protection provided where needed.

The driven motor can start at power up if the enable input signal is present.

The STOP function does not remove potentially lethal high voltages. ISOLATE the drive and wait 10 minutes before starting any

work on it. Never carry out any work on the Drive, Motor or Motor cable when the input power is still applied.

The ACS255 can be programmed to operate the driven motor at speeds above or below the speed achieved when connecting the

motor directly to the mains supply. Obtain confirmation from the manufacturers of the motor and the driven machine about

suitability for operation over the intended speed range prior to machine start up.

Do not activate the automatic fault reset function on any systems whereby this may cause a potentially dangerous situation.

IP66 drives provide their own pollution degree 2 environments. IP20 drives must be installed in a pollution degree 2 environment,

mounted in a cabinet with IP54 or better.

ACS255s are intended for indoor use only.

When mounting the drive, ensure that sufficient cooling is provided. Do not carry out drilling operations with the drive in place,

dust and metal shavings from drilling may lead to damage.

The entry of conductive or flammable foreign bodies should be prevented. Flammable material should not be placed close to the

drive

Relative humidity must be less than 95% (non-condensing).

Ensure that the supply voltage, frequency and number of phases correspond to the rating of the ACS255 as delivered.

Never connect the mains power supply to the Output terminals U, V, W.

Do not install any type of automatic switchgear between the drive and the motor

Wherever control cabling is close to power cabling, maintain a minimum separation of 4in. (100 mm) and arrange crossings at 90

degrees

Ensure that all terminals are tightened to the appropriate torque setting

Do not attempt to carry out any repair of the ACS255. In the case of suspected fault or malfunction, contact your local ABB Drives

representative for further assistance.

Please read the IMPORTANT SAFETY INFORMATION below, and all Warning and Caution information elsewhere.

Page 12

13

3. General Information and Ratings

This chapter contains information about the ACS255 including how to identify the drive.

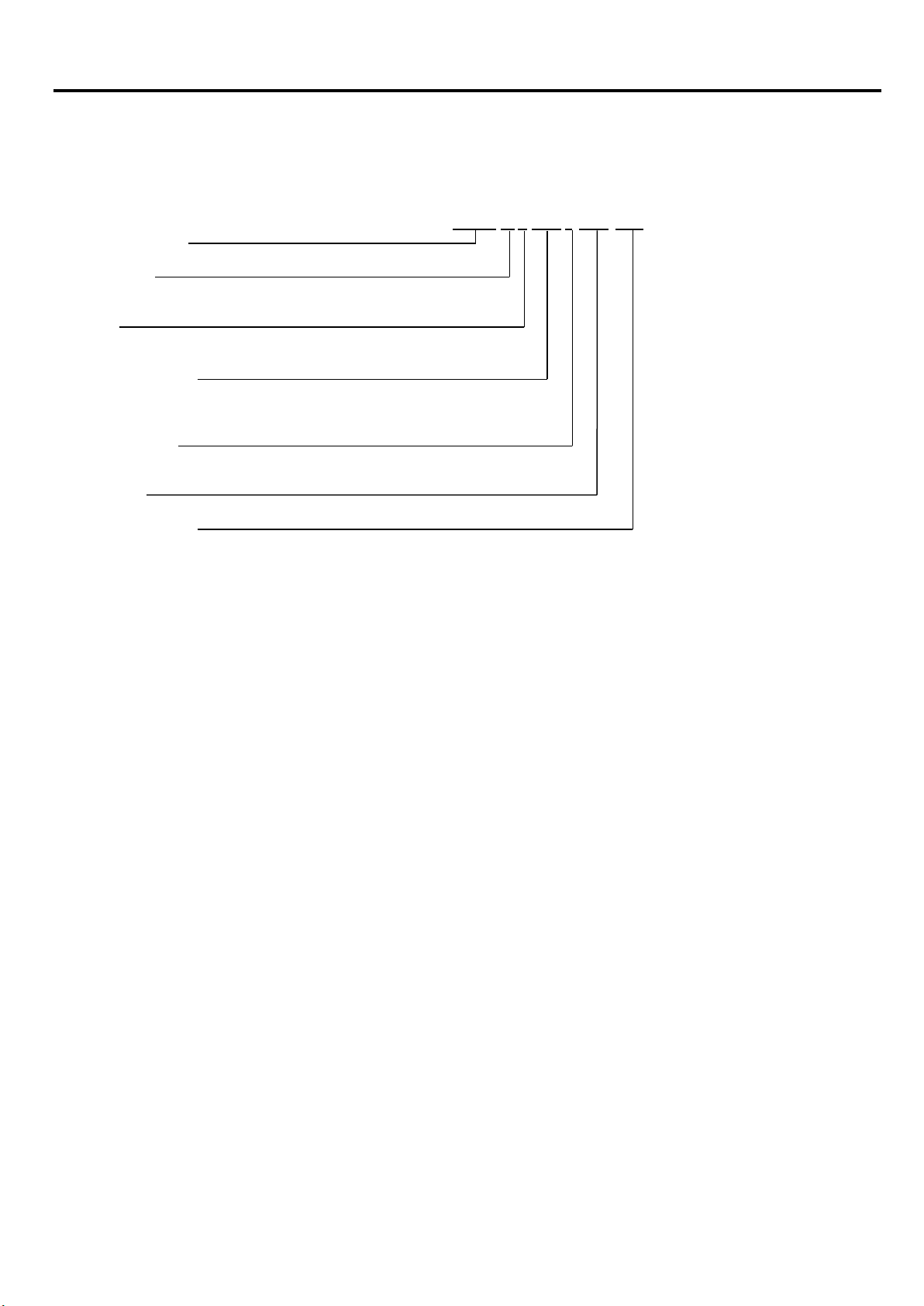

3.1. Type designation key

The type designation contains information on the specification and configuration of the drive. You find the type designation label attached to the

drive. The first digits from the left express the basic configuration, for example ACS255-03U-02A1-6. The explanations of the type designation

label selections are described below.

ACS255-03 U-02A1-6+B063+F278

ACS255 product series

1-phase/3 phase

03 = 3-phase input

EMC Filter

E = Filtered

U = Non-Filtered

Output Current Rating

In format xxAy, where xx indicates the integer part and y the fractional part,

For example, 02A1 means 2.1 A.

Input Voltage Range

6 = 500…600VAC

IP66 Enclosure

Input switch assembly

(Speed potentiometer, run/stop and mains disconnect switch)

Page 13

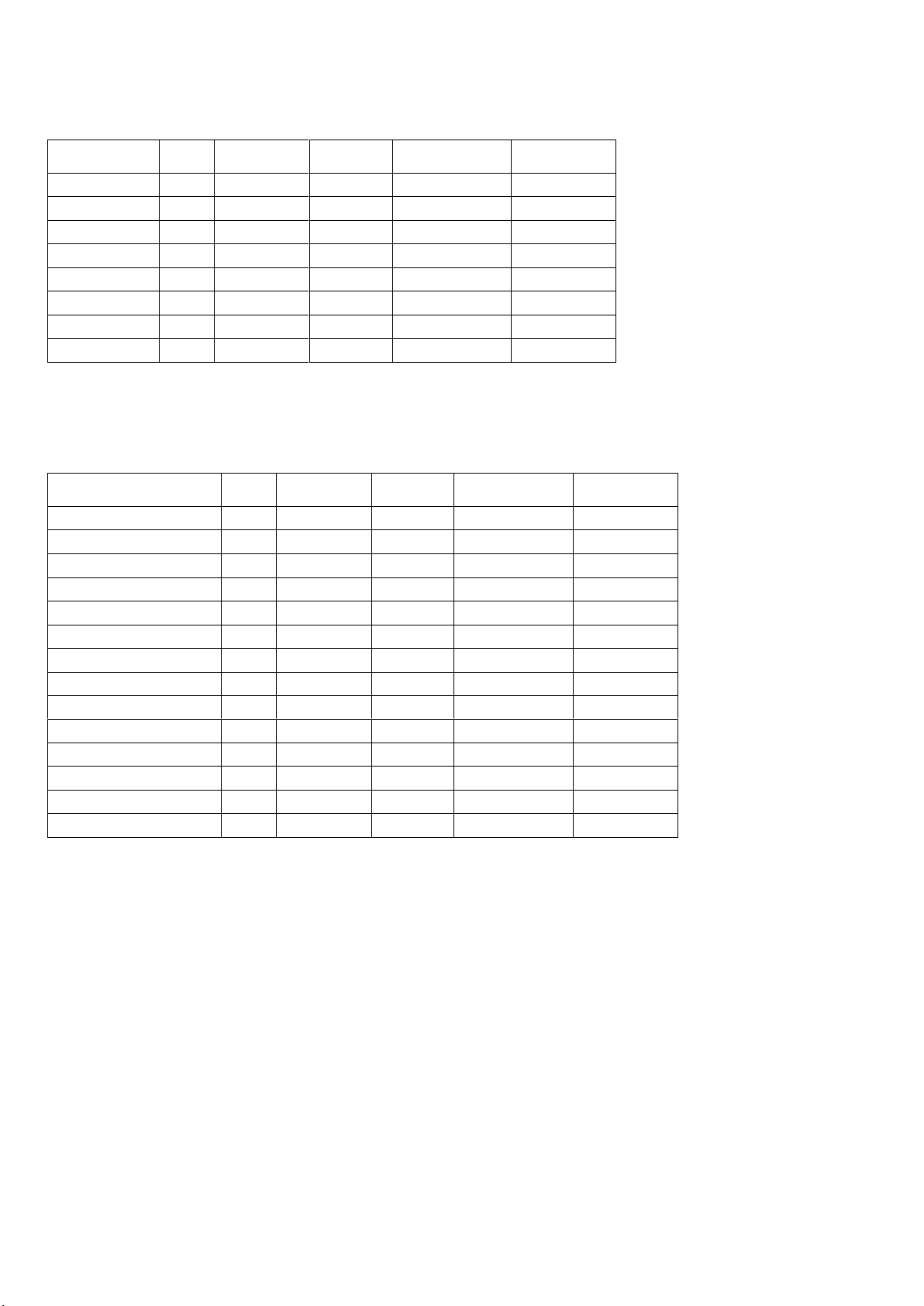

14

Model Number

Power

(HP)

Output Current

(A)

Input switch

assembly

Internal DB transistor

Frame Size

ACS255-03U-02A1-6

1

2.1

No

Yes

P2

ACS255-03U-03A1-6

2

3.1

No

Yes

P2

ACS255-03U-04A1-6

3

4.1

No

Yes

P2

ACS255-03U-06A5-6

5

6.5

No

Yes

P2

ACS255-03U-09A0-6

7.5 9 No

Yes

P2

ACS255-03U-12A0-6

10

12

No

Yes

P3

ACS255-03U-17A0-6

15

17

No

Yes

P3

ACS255-03U-22A0-6

20

22

No

Yes

P3

Model Number

Power

(HP)

Output Current

(A)

Input switch

assembly

Internal DB transistor

Frame Size

ACS255-03U-02A1-6 +B063

1

2.1

No

Yes

P2

ACS255-03U-03A1-6 +B063

2

3.1

No

Yes

P2

ACS255-03U-04A1-6 +B063

3

4.1

No

Yes

P2

ACS255-03U-06A5-6 +B063

5

6.5

No

Yes

P2

ACS255-03U-09A0-6 +B063

7.5 9 No

Yes

P2

ACS255-03U-12A0-6 +B063

10

12

No

Yes

P3

ACS255-03U-17A0-6 +B063

15

17

No

Yes

P3

ACS255-03U-02A1-6 +B063 +F278

1

2.1

Yes

Yes

P2

ACS255-03U-03A1-6 +B063 +F278

2

3.1

Yes

Yes

P2

ACS255-03U-04A1-6 +B063 +F278

3

4.1

Yes

Yes

P2

ACS255-03U-06A5-6 +B063 +F278

5

6.5

Yes

Yes

P2

ACS255-03U-09A0-6 +B063 +F278

7.5

9

Yes

Yes

P2

ACS255-03U-12A0-6 +B063 +F278

10

12

Yes

Yes

P3

ACS255-03U-17A0-6 +B063 +F278

15

17

Yes

Yes

P3

3.2. Drive model numbers – IP20

Mechanical Dimensions and Mounting information is shown from page 15.

Electrical Specifications are shown on page 59.

3.3. Drive model numbers – IP66

Mechanical Dimensions and Mounting information is shown from page 15.

Electrical Specifications are shown on page 59.

Page 14

4. Mechanical Installation

Drive

Size

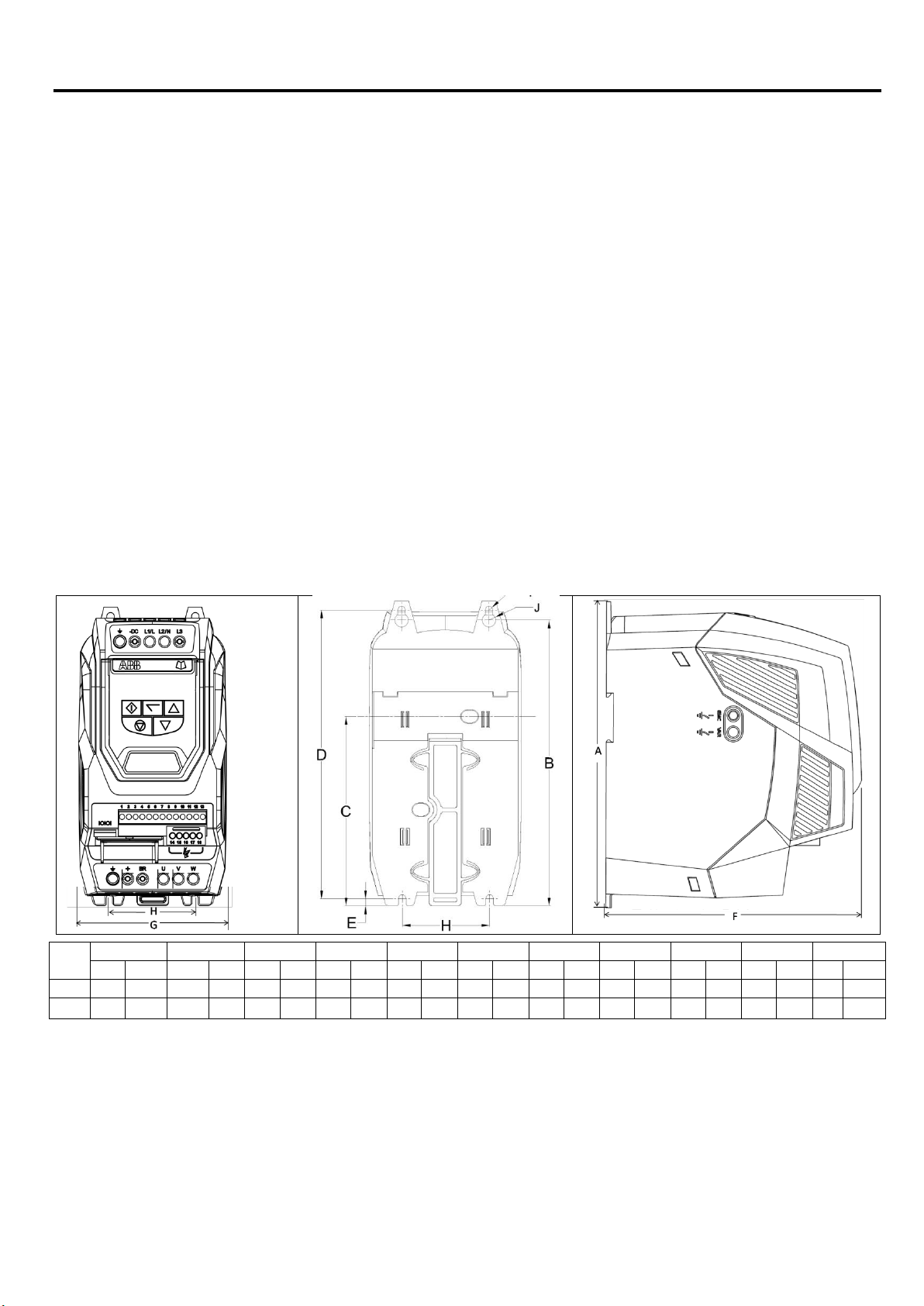

A B C D E F G H I J Weight

mm

in

mm

in

mm

in

mm

in

mm

in

mm

in

mm

in

mm

in

mm

in

mm

in

Kg

Ib

2

221

8.70

207

8.15

137

5.39

209

8.23

5.3

0.21

185

7.28

112

4.41

63

2.48

5.5

0.22

10

0.39

1.8

4

3

261

10.28

246

9.69 - -

247

9.72 6 0.24

205

8.07

131

5.16

80

3.15

5.5

0.22

10

0.39

3.5

7.7

4.1. General

The ACS255 should be mounted in a vertical position only, on a flat, flame resistant, vibration free mounting using the integral

mounting holes or DIN Rail clip (Size P2 only).

The ACS255 must be installed in a pollution degree 1 or 2 environment only.

Do not mount flammable material close to the ACS255

Ensure that the minimum cooling air gaps, as detailed in section 4.5 and 4.7 are left clear.

Ensure that the ambient temperature range does not exceed the permissible limits for the ACS255 are given on page 60.

Provide suitable clean, moisture and contaminant free cooling air sufficient to fulfil the cooling requirements of the ACS255.

4.2. Before Installation

Carefully Unpack the ACS255 and check for any signs of damage. Notify the shipper immediately if any exist.

Check the drive rating label to ensure it is of the correct type and power requirements for the application.

To prevent accidental damage always store the ACS255 in its original box until required. Storage should be clean and dry and within

the temperature range –40°C to +60°C.

4.3. UL Compliant Installation

Note the following for UL-compliant installation:

For an up to date list of UL compliant products, please refer to UL listing NMMS.E211945.

The drive can be operated within an ambient temperature range as stated in section 11.1.

For IP20 units, installation is required in a pollution degree 1 environment.

For IP66 units, installation in a pollution degree 2 environment is permissible.

UL Listed ring terminals / lugs must be used for all bus bar and grounding connections.

4.4. Mechanical dimensions and weights

4.4.1. IP20 Units

15

Mounting Bolts

All Frame Sizes : 4 x M4

Tightening Torques

Recommended Control Terminal Torque Settings : All Sizes : 0.8 Nm (7 lb-in)

Recommended Power Terminal Torque Settings : All Sizes : 1 Nm (8.85 lb-in)

Page 15

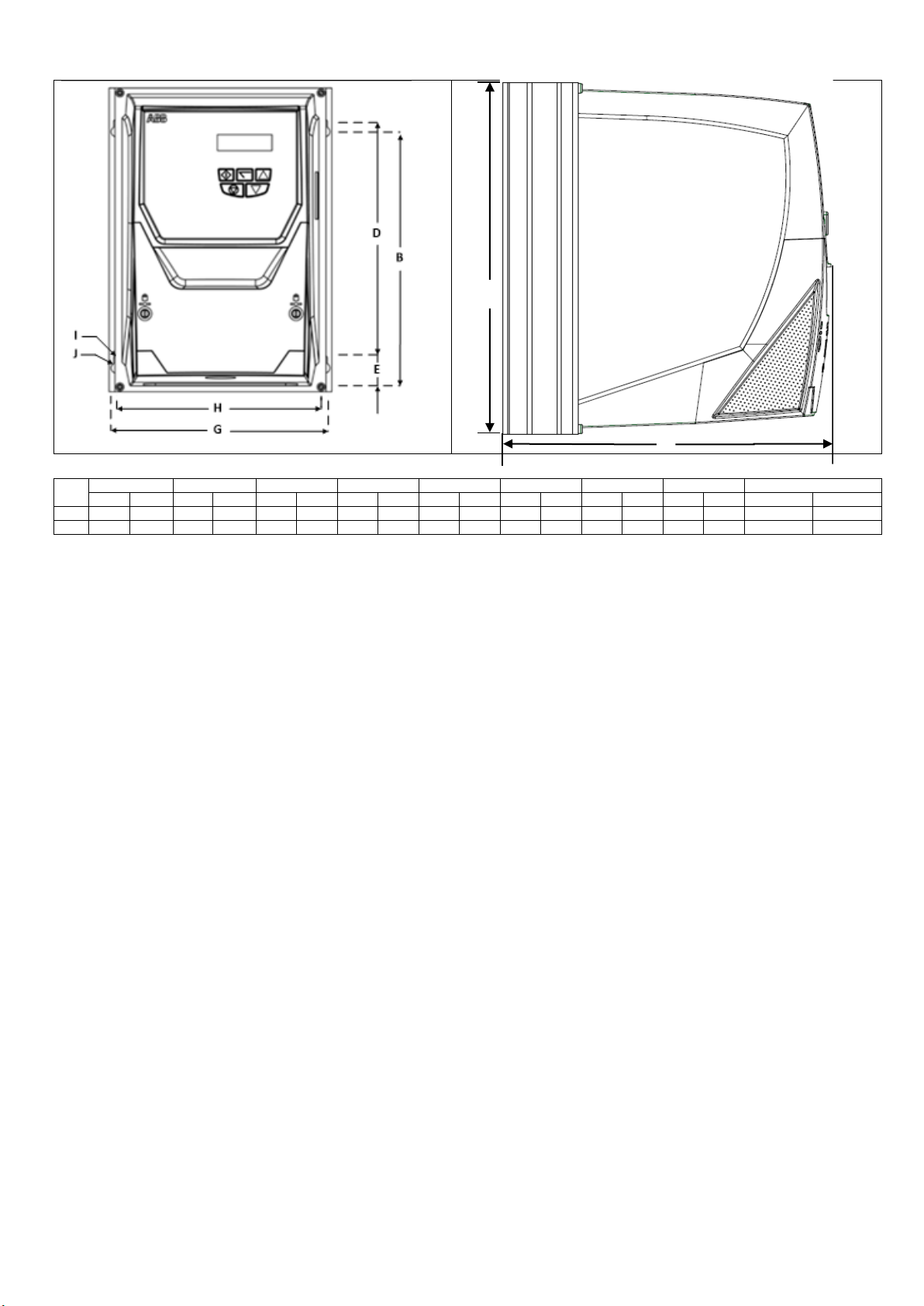

16

F

Drive

Size

A B D F G H I J Weight

mm

in

mm

in

mm

in

mm

in

mm

in

mm

in

mm

in

mm

in

Kg

Ib

2

257

10.12

220

8.66

200

7.87

239

9.41

188

7.40

176

6.93

4.2

0.17

8.5

0.33

4.8

10.6

3

310

12.20

277

10.89

252

9.90

251

9.88

211

8.29

198

7.78

4.2

0.17

8.5

0.33

7.3

16.1

A

4.4.2. IP66 Units

Mounting Bolt Sizes

All Frame Sizes 4 x M4

Tightening Torques

Recommended Control Terminal Torque Settings :All Sizes : 0.8 Nm (7 lb-in)

Recommended Power Terminal Torque Settings : Frame Size 2 : 1.2 – 1.5 Nm (10 – 15 lb-in)

Page 16

4.5. Guidelines for Enclosure mounting (IP20 Units)

Drive

Frame

Size

X

Above &

Below

Y

Either

Side

Z

Between

mm

in

mm

in

mm

in

2

75

2.95

50

1.97

46

1.81

3

100

3.94

50

1.97

52

2.05

Note :

Dimension Z assumes that the drives are mounted sideby-side with no clearance.

Typical drive heat losses are 3% of operating load

conditions.

Above are guidelines only and the operating ambient

temperature of the drive MUST be maintained at all

times.

IP20 drives must be installed in a pollution degree 2 environment, mounted in a cabinet with IP54 or better.

Installation should be in a suitable enclosure, according to EN60529 or other relevant local codes or standards.

Enclosures should be made from a thermally conductive material.

Where vented enclosures are used, there should be free space clearance above and below the drive to ensure good air circulation –

see the diagram below for minimum free space clearance. Air should be drawn in below the drive and expelled above the drive.

In any environments where the conditions require it, the enclosure must be designed to protect the ACS255 against ingress of airborne

dust, corrosive gases or liquids, conductive contaminants (such as condensation, carbon dust, and metallic particles) and sprays or

splashing water from all directions.

High moisture, salt or chemical content environments should use a suitably sealed (non-vented) enclosure.

The enclosure design and layout should ensure that the adequate ventilation paths and clearances are left to allow air to circulate through the

drive heatsink. Recommend below is the minimum mounting clearance requirements for drives mounted in non-ventilated metallic enclosures.

17

4.6. Mounting the Drive – IP20 Units

IP20 Units are intended for installation within a control cabinet.

When mounting with screws

o Using the drive as a template, or the dimensions shown above, mark the locations for drilling

o Ensure that when mounting locations are drilled, the dust from drilling does not enter the drive

o Mount the drive to the cabinet backplate using suitable M4 mounting screws

o Position the drive, and tighten the mounting screws securely

When Din Rail Mounting (Frame Size 2 Only)

o Locate the DIN rail mounting slot on the rear of the drive onto the top of the DIN rail first

o Press the bottom of the drive onto the DIN rail until the lower clip attaches to the DIN rail

o If necessary, use a suitable flat blade screw driver to pull the DIN rail clip down to allow the drive to mount securely on the

rail

o To remove the drive from the DIN rail, use a suitable flat blade screwdriver to pull the release tab downwards, and lift the

bottom of the drive away from the rail first

Page 17

18

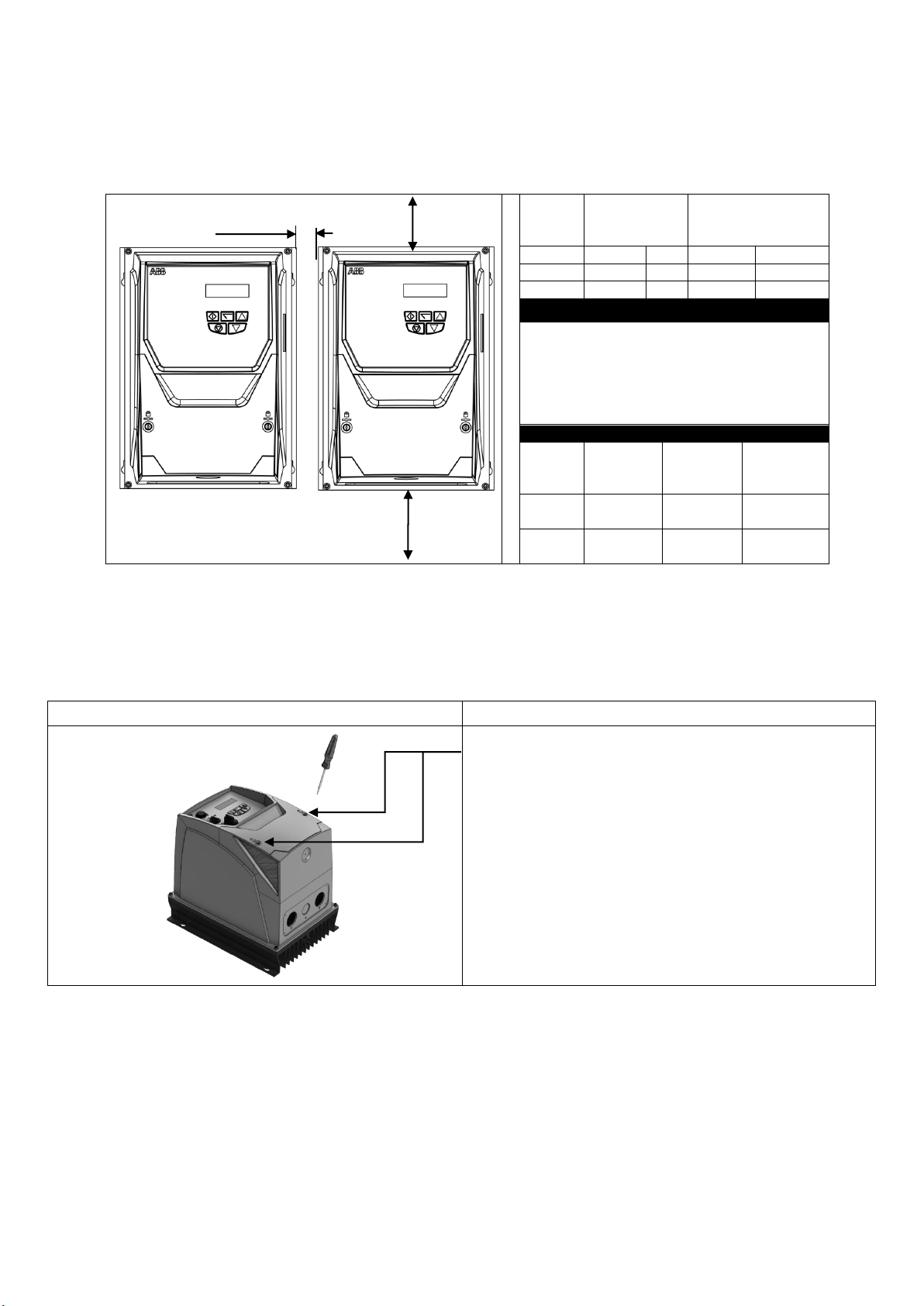

Y

X

X

Drive

Frame

Size

X

Above &

Below

Y

Either

Side

mm

in

mm

in

2

200

7.87

10

0.39

3

200

7.87

10

0.39

Note :

Typical drive heat losses are approximately 3% of

operating load conditions.

Above are guidelines only and the operating

ambient temperature of the drive MUST be

maintained at all times.

Cable Gland Sizes

Drive

Frame

Size

Power

Cable

Motor

Cable

Control

Cables

2

M25

(PG21)

M25

(PG21)

M20

(PG13.5)

3

M25

(PG21)

M25

(PG21)

M20

(PG13.5)

Frame Sizes 2 & 3

Using a suitable flat blade screwdriver, rotate the two retaining

screws indicated until the screw slot is vertical.

X

4.7. Guidelines for mounting (IP66 Units)

Before mounting the drive, ensure that the chosen location meets the environmental condition requirements for the drive shown in

section 11.1.

The drive must be mounted vertically, on a suitable flat surface

The minimum mounting clearances as shown in the table below must be observed

The mounting site and chosen mountings should be sufficient to support the weight of the drives

Using the drive as a template, or the dimensions shown above, mark the locations required for drilling

Suitable cable glands to maintain the ingress protection of the drive are required.

Gland holes for power and motor cables are pre-moulded into the drive enclosure, recommended gland sizes are shown above, gland

holes for control cables may be cut as required.

4.8. Removing the Terminal Cover

4.9. Routine Maintenance

The drive should be included within the scheduled maintenance program so that the installation maintains a suitable operating environment,

this should include:

Ambient temperature is at or below that set out in the “Environment” section on page 59.

Heat sink fans freely rotating and dust free.

The Enclosure in which the drive is installed should be free from dust and condensation; furthermore ventilation fans and air filters

should be checked for correct air flow.

Checks should also be made on all electrical connections, ensuring screw terminals are correctly torqued; and that power cables have no signs of

heat damage.

Page 18

5. Electrical Installation

This manual is intended as a guide for proper installation. ABB Drives Ltd cannot assume responsibility for the compliance or the

non-compliance to any code, national, local or otherwise, for the proper installation of this drive or associated equipment. A

hazard of personal injury and/or equipment damage exists if codes are ignored during installation.

This ACS255 contains high voltage capacitors that take time to discharge after removal of the main supply. Before working on the

drive, ensure isolation of the main supply from line inputs. Wait ten (10) minutes for the capacitors to discharge to safe voltage

levels. Failure to observe this precaution could result in severe bodily injury or loss of life.

Only qualified electrical personnel familiar with the construction and operation of this equipment and the hazards involved should

install, adjust, operate, or service this equipment. Read and understand this manual and other applicable manuals in their entirety

before proceeding. Failure to observe this precaution could result in severe bodily injury or loss of life.

Whenever possible use Shielded motor cablesmaintaining shield as far as possible along the cable.

=/>100mm

Twisted-Pair shielded cables for analog control and motor

feedback signals.

Ensure Filter chassis is making metal-metal contact with

Mounting panel.

RFI Filter

Option

Site Ground Bus-Bar bonded to Metal Back-Panel

panel which is bonded to main power ground.

Metal Back-Panel

U V W

PE

U V W

PE

360° bonding

EMC cable gland

(Best-Practice)

(Shield to Motor

Chassis)

X

Avoid long parallel

runs of motor cables

with other cables

Where control cables must cross power

cables make sure they are as near to 90

degrees as possible.

5.1. Grounding the Drive

5.1.1. Recommended installation for EMC compliance.

19

Page 19

20

5.1.2. Grounding Guidelines

The ground terminal of each ACS255 should be individually connected DIRECTLY to the site ground bus bar (through the filter if installed).

The ACS255 ground connections should not loop from one drive to another, or to, or from any other equipment. Ground loop impedance must

confirm to local industrial safety regulations. To meet UL regulations, UL approved ring crimp terminals should be used for all ground wiring

connections.

The drive Safety Ground must be connected to system ground. Ground impedance must conform to the requirements of national and local

industrial safety regulations and/or electrical codes. The integrity of all ground connections should be checked periodically.

5.1.3. Protective Earth Conductor

The Cross sectional area of the PE Conductor must be at least equal to that of the incoming supply conductor.

5.1.4. Safety Ground

This is the safety ground for the drive that is required by code. One of these points must be connected to adjacent building steel (girder, joist), a

floor ground rod, or bus bar. Grounding points must comply with national and local industrial safety regulations and/or electrical codes.

5.1.5. Motor Ground

The motor ground must be connected to one of the ground terminals on the drive.

5.1.6. Ground Fault Monitoring

As with all inverters, a leakage current to earth can exist. The ACS255 is designed to produce the minimum possible leakage current while

complying with worldwide standards. The level of current is affected by motor cable length and type, the effective switching frequency, the

earth connections used and the type of RFI filter installed. If a GFCI (Ground Fault Current Interrupter) is to be used, the following conditions

apply:

The device must be suitable for protecting equipment with a DC component in the leakage current

Individual GFCI’s should be used for each ACS255

5.1.7. Shield Termination (Cable Screen)

The safety ground terminal provides a grounding point for the motor cable shield. The motor cable shield connected to this terminal (drive end)

should also be connected to the motor frame (motor end). Use a shield terminating or EMI clamp to connect the shield to the safety ground

terminal.

5.2. Wiring Precautions

Connect the ACS255 according to section 5.9, ensuring that motor terminal box connections are correct. There are two connections in general:

Star and Delta. It is essential to ensure that the motor is connected in accordance with the voltage at which it will be operated. For more

information, refer to section 5.6 Motor Terminal Box Connections.

Type MC continuous corrugated aluminium armour cable with symmetrical grounds or shielded power cable is recommended for the motor

cables if metallic conduit is not used.

The power cables must be rated for 75 °C (167 °F).

5.3. Incoming Power Connection

Power should be connected to L1, L2, and L3. Phase sequence is not important.

For compliance with CE and C Tick EMC requirements, a symmetrical shielded cable is recommended.

For compliance with CSA requirements, transient surge suppression shall be installed on the line side of this equipment and shall be

rated 600V (phase to ground), 600V (phase to phase), suitable for overvoltage category III, and shall provide protection for a rated

impulse withstand voltage peak of 4 kV or equivalent.

A fixed installation is required according to IEC61800-5-1 with a suitable disconnecting device installed between the ACS255 and the AC

Power Source. The disconnecting device must conform to the local safety code / regulations (e.g. within Europe, EN60204-1, Safety of

machinery).

The cables should be dimensioned according to any local codes or regulations. Guideline dimensions are given in section 11.2.

Suitable fuses to provide wiring protection of the input power cable should be installed in the incoming supply line, according to the

data in section 11.2. The fuses must comply with any local codes or regulations in place. In general, type gG (IEC 60269) or UL type T

fuses are suitable; however in some cases type aR fuses may be required. The operating time of the fuses must be below 0.5 seconds.

When the power supply is removed from the drive, a minimum of 30 seconds should be allowed before re-applying the power. A

minimum of 5 minutes should be allowed before removing the terminal covers or connection.

The maximum permissible short circuit current at the ACS255 Power terminals as defined in IEC60439-1 is 100kA.

An optional Input Choke is recommended to be installed in the supply line for drives where any of the following conditions occur:-

o The incoming supply impedance is low or the fault level / short circuit current is high.

o If the transformer kVA rating is more than 10x the kVA rating of the drive or ensure that the per drive source

impedance is less than 0.5%

o The supply is prone to dips or brown outs

o An imbalance exists on the supply (3 phase drives)

o The power supply to the drive is via a busbar and brush gear system (typically overhead Cranes).

In all other installations, an input choke is recommended to ensure protection of the drive against power supply faults.

Page 20

5.4. Compatibility with IT (ungrounded) and corner-grounded TN systems

WARNING! EMC filters should not be used when installing the drive on an IT system (an ungrounded

power system or high-resistance-grounded power system, otherwise the system will be connected to

ground potential through the EMC capacitors. This may cause danger or damage to the EMC filter.

If you have an IT (ungrounded) system or corner-grounded TN system, disconnect the internal Varistor

screw as shown below.

21

Page 21

22

Additional Information

Compatible Thermistor : PTC Type, 2.5kΩ trip level Use a setting of

parameter 9902 DIGITAL INPUTS FUNCTION SELECT that has Input 5

(terminal 10) function as External Trip, e.g. 9902 = 6.

Refer to section 8.1 for further details.

5.5. Drive and Motor Connection

The drive inherently produces fast switching of the output voltage (PWM) to the motor compared to the mains supply, for motors

which have been wound for operation with a variable speed drive then there is no preventative measures required, however if the

quality of insulation is unknown then the motor manufacturer should be consulted and preventative measures may be required.

The motor should be connected to the ACS255 U, V, and W terminals using a suitable 3 or 4 core cable. Where a 3 core cable is utilised,

with the shield operating as an earth conductor, the shield must have a cross sectional area at least equal to the phase conductors

when they are made from the same material. Where a 4 core cable is utilised, the earth conductor must be of at least equal cross

sectional area and manufactured from the same material as the phase conductors.

The motor earth must be connected to one of the ACS255 earth terminals.

For compliance with the European EMC directive, a suitable screened (shielded) cable should be used. Braided or twisted type

screened cable where the screen covers at least 85% of the cable surface area, designed with low impedance to HF signals are

recommended as a minimum. Installation within a suitable steel or copper tube is generally also acceptable.

The cable screen should be terminated at the motor end using an EMC type gland allowing connection to the motor body through the

largest possible surface area

Where drives are mounted in a steel control panel enclosure, the cable screen may be terminated directly to the control panel using a

suitable EMC clamp or gland, as close to the drive as possible.

For IP66 drives, connect the motor cable screen to the internal ground clamp

5.6. Motor Terminal Box Connections

Most general purpose motors are wound for operation on dual voltage supplies. This is indicated on the nameplate of the motor

This operational voltage is normally selected when installing the motor by selecting either STAR or DELTA connection. STAR always gives the

higher of the two voltage ratings. . Example Motor nameplate shown below (380V Delta illustrated):

5.7. Motor Thermal overload Protection.

5.7.1. Internal Thermal overload protection.

The drive has an in-built motor thermal overload function; this is in the form of an “F0009” trip after delivering >100% of the value set in

parameter 9906 MOTOR RATED CURRENT for a sustained period of time (e.g. 150% for 60 seconds).

5.7.2. Motor Thermistor Connection

Where a motor thermistor is to be used, it should be connected as follows :-

5.8. Control Terminal Wiring

All analog signal cables should be suitably shielded. Twisted pair cables are recommended.

Power and Control Signal cables should be routed separately where possible, and must not be routed parallel to each other.

Signal levels of different voltages e.g. 24 Volt DC and 600 Volt AC, should not be routed in the same cable.

Maximum control terminal tightening torque is 0.5Nm.

Control Cable entry conductor size: 0.05 – 2.5mm2 / 30 – 12 AWG.

Page 22

5.9. Connection Diagram

5.9.1. Power Terminal Designations

Incoming Power Source

Connect to L1, L2 & L3

terminals.

Phase sequence is not

important.

Motor Connections

Connect the motor to the U, V & W

terminals.

The motor earth must be connected

to the drive

Optional Brake Resistor & DC Bus

Connections

Where a Brake resistor is used, it

must be connected to the “BR” and

“+” terminals.

Protective Earth / Ground

connection.

The drive must be Earthed /

Grounded

5.9.2. Control Terminal Connections & Factory Settings

Open

Closed

+24V Supply (100mA) / External Input

+24V 1

Digital Input 1

Stop

Run (Enable)

DI1 2

Digital Input 2

Forward Rotation

Reverse Rotation

DI2 3

Digital Input 3

Analog Speed Ref

Preset Speed

DI3 4

Digital Inputs : 8 – 30 Volt DC

+ 10 Volt, 10mA Output

+10V 5

Analog Input 1

DI/AI4 6

0V 7 0V

Output Speed

Analog Output : 0 – 10 Volt / 4-20mA, 20mA Max

8 AO1

0 Volt Supply / External Input

0V 9 0V

Output Current

Analog Input 2

DI/AI5

10

Analog Output : 0 – 10 Volt / 4-20mA, 20mA Max

11

AO2

SAFE TORQUE OFF Input

Also refer to page 24 for further information on the STO

Function.

Logic High = 18-30 Volt DC (“SAFE TORQUE OFF” Standby

mode)

STO+

12

STO-

13

Relay Contacts (Terminals 14-18)

250VAC / 30VDC

5A Maximum

14

R01COM

Default Function :

Drive Ready

/ Fault

15

R01NO

16

R01NC

17

R02NO

Default Function :

Running

18

R02COM

L1

L3

The brake resistor

should be protected from

overheating by means of a

thermal switch which interrupts

the mains supply in a brake

23

Page 23

24

SIL

(Safety Integrity Level)

PFH

D

(Probability of dangerous Failures per Hour)

SFF

(Safe failure fraction %)

Lifetime assumed

EN 61800-5-2

2

1.23E-09 1/h (0.12 % of SIL 2)

50

20 Yrs

PL

(Performance level)

CCF (%)

(Common Cause Failure)

EN ISO 13849-1

PL d

1

SILCL

EN 62061

SILCL 2

5.10. Safe Torque Off

Safe Torque OFF will be referred to as “STO” through the remainder of this section.

5.10.1. Responsibilities

The overall system designer is responsible for defining the requirements of the overall “Safety Control System” within which the drive will be

incorporated; furthermore the system designer is responsible for ensuring that the complete system is risk assessed and that the “Safety control

System” requirements have been entirely met and that the function is fully verified, this must include confirmation testing of the “STO” function

before drive commissioning.

The system designer shall determine the possible risks and hazards within the system by carrying out a thorough risk and hazard analysis, the

outcome of the analysis should provide an estimate of the possible hazards, furthermore determine the risk levels and identify any needs for risk

reduction. The “STO” function should be evaluated to ensure it can sufficiently meet the risk level required.

5.10.2. What STO Provides

The purpose of the “STO“ function is to provide a method of preventing the drive from creating torque in the motor in the absence of the “STO“

input signals (Terminal 12 with respect to Terminal 13), this allows the drive to be incorporated into a complete safety control system where

“STO“ requirements need to be fulfilled.1

The “STO“ function can typically eliminate the need for electro-mechanical contactors with cross-checking auxiliary contacts as per normally

required to provide safety functions.2

The drive has the “STO“ Function built-in as standard and complies with the definition of “Safe torque off“ as defined by IEC 61800-5-2:2007.

The “STO“ Function also corresponds to an uncontrolled stop in accordance with category 0 (Emergency Off), of IEC 60204-1. This means that

the motor will coast to a stop when the “STO” function is activated, this method of stopping should be confirmed as being acceptable to the

system the motor is driving.

The “STO“ function is recognised as a fail safe method even in the case where the “STO“ signal is absent and a single fault within the drive has

occured, the drive has been proven in respect of this by meeting the following safety standards :

Note : The values acheived above maybe jepardised if the drive is installed outside of the Environmental limits detailed in section 11.1 on page

59.

5.10.3. What STO does not provide

Disconnect and ISOLATE the drive before attempting any work on it. The “STO“ function does not prevent high voltages from being

present at the drive power terminals.

1

Note : The “STO“ function does not prevent the drive from an unexpected re-start. As soon as the “STO“inputs receive the relevant

signal it is possible (subject to parameter settings) to restart automatically, Based on this, the function should not be used for

carrying out short-term non-electrical machinery operations (such as cleaning or maintenance work).

2

Note : In some applications additional measures may be required to fulfil the systems safety function needs : the “STO“ function

does not provide motor braking. In the case where motor braking is required a time delay safety relay and/or a mechanical brake

arrangement or similar method should be adopted, consideration should be made over the required safety function when braking as

the drive braking circuit alone cannot be relied upon as a fail safe method.

Page 24

5.10.4. “STO“ Operation

Fault

Code

Code

Number

Description

Corrective Action

“Sto-F”

29

A fault has been detected within either of the

internal channels of the “STO” circuit.

Refer to local ABB representative

When the “STO” inputs are energised, the “STO” function is in a standby state, if the drive is then given a “Start signal/command” (as per the

start source method selected in parameter 9902 DIGITAL INPUTS FUNCTION SELECT) then the drive will start and operate normally.

When the “STO” inputs are de-energised then the STO Function is activated and stops the drive (Motor will coast), the drive is now in “Safe

Torque Off” mode.

To get the drive out of “Safe Torque Off” mode then any “Fault messages” need to be reset and the drive “STO” input needs to be re-energised.

5.10.5. “STO” Status and Monitoring

There are a number of methods for monitoring the status of the “STO” input, these are detailed below:

Drive Display

In Normal drive operation (Mains AC power applied), when the drives “STO” input is de-energised (“STO” Function activated) the drive will

highlight this by displaying “InHibit”, (Note: If the drive is in a tripped condition then the relevant trip will be displayed and not “InHibit”).

Drive Output Relay

Drive relay 1: Setting parameter 1401 USER RELAY 1 OUTPUT (TERMINALS 14, 15 & 16) FUNCTION SELECT to a value of “13” will result

in relay opening when the “STO” function is activated.

Drive relay 2: Setting parameter 1402 USER RELAY 2 OUTPUT (TERMINALS 17 & 18) FUNCTION SELECT to a value of “13” will result in

relay opening when the “STO” function is activated.

“STO” Fault Codes

25

5.10.6. “STO” Function response time

The total response time is the time from a safety related event occurring to the components (sum of) within the system responding and

becoming safe. (Stop Category 0 in accordance with IEC 60204-1)

The response time from the “STO” inputs being de-energised to the output of the drive being in a state that will not produce torque in

the motor (“STO” active) is less than 1ms.

The response time from the “STO” inputs being de-energised to the “STO” monitoring status changing state is less than 20ms

The response time from the drive sensing a fault in the STO circuit to the drive displaying the fault on the display/Digital output

showing drive not healthy is less than 20ms.

Page 25

26

- Twisted-Pair

- Shielded cables

1213

0V

+24Vdc

Safety relay

Protective Capped Trunking

or equivalent to prevent

STO Cable short circuit to an

external Voltage source.

External

Power

Supply

Protected

shielded cables

1213

Protective Capped Trunking

or equivalent to prevent

STO Cable short circuit to an

external Voltage source.

1 7

Safety

relay

Voltage Rating (Nominal)

24Vdc

STO Logic High

18-30Vdc (Safe torque off in standby)

Current Consumption (Maximum)

100mA

Standard Requirements

SIL2 or PLd SC3 or better (With Forcibly guided Contacts)

Number of Output Contacts

2 independent

Switching Voltage Rating

30Vdc

Switching Current

100mA

Wires should be

protected

against short

circuits as

shown above

1 2 3 4 5 6 7 8 9 10 11 12 13

0V

+24Vdc

External

Power

Supply

Safety relay

1 2 3 4 5 6 7 8 9 10 11 12 13

Safety relay

5.10.7. “STO” Electrical Installation

The “STO” wiring shall be protected from inadvertent short circuits or tampering which could lead to failure of the “STO” input signal,

further guidance is given in the diagrams below.

In addition to the wiring guidelines for the “STO” circuit below, section 5.1.1 “Recommended installation for EMC compliance should also be

followed.

The drive should be wired as illustrated below; the 24Vdc signal source applied to the “STO” input can be either from the 24Vdc on the drive or

from an External 24Vdc power supply.

5.10.7.1. Recommended “STO” wiring

Using an External 24Vdc Power Supply. Using the drives on-board 24Vdc supply

Note : The Maximum cable length from Voltage source to the drive terminals should not exceed 25 metres.

5.10.7.2. External Power supply Specification.

5.10.7.3. Safety Relay Specification.

The safety relay should be chosen so that at minimum it meets the safety standards in which the drive meets.

Page 26

5.10.8. Enabling the “STO” Function

The “STO” function is always enabled in the drive regardless of operating mode or parameter changes made by the user.

5.10.9. Testing the “STO” Function

Before commissioning the system the “STO” function should always be tested for correct operation, this should include the following tests:

With the motor at standstill, and a stop command given to the drive (as per the start source method selected in parameter 9902

DIGITAL INPUTS FUNCTION SELECT):

o De-energise the “STO” inputs (Drive will display ““InHibit”).

o Give a start command (as per the start source method selected in parameter 9902 DIGITAL INPUTS FUNCTION SELECT) and

check that the drive still displays “Inhibit” and that the operation is in line with the section 5.10.4 “STO“ Operation and

section 5.10.5 “STO” Status and Monitoring

With the motor running normally (from the drive):

o De-energise the “STO” inputs

o Check that the drive displays “InHibit” and that the motor stops and that the operation is in line with the section 5.10.4

“STO“ Operation and section 5.10.5 “STO” Status and Monitoring

5.10.10. “STO” Function Maintenance.

The “STO” function should be included within the control systems scheduled maintenance program so that the function is regularly tested for

integrity (Minimum once per Year), furthermore the function should be integrity tested following any safety system modifications or

maintenance work.

If drive fault messages are observed refer to section 13.1 for further guidance.

27

Page 27

28

NAVIGATE

Used to display real-time information, to access and exit

parameter edit mode and to store parameter changes (press

for >1 second to toggle between status and parameter mode)

UP

Used to increase speed in real-time mode or to increase

parameter values in parameter edit mode

DOWN

Used to decrease speed in real-time mode or to decrease

parameter values in parameter edit mode

RESET /

STOP

Used to reset a tripped drive.

When in Keypad mode is used to Stop a running drive.

START

When in keypad mode, used to Start a stopped drive or to

reverse the direction of rotation if bi-directional keypad mode

is enabled.

6. Managing the Keypad

The drive is configured and its operation monitored via the keypad and display.

6.1. Keypad Layout and Function

6.2. Changing Parameters

Page 28

6.3. Resetting Parameters to Factory Default Settings

29

Page 29

30

Function

When Display shows...

Press...

Result

Example

Select lowest Parameter

within Group

i.e.

+

The first parameter of the

group is selected

Display shows

Press

Display shows

Set Parameter to

minimum value

Any numerical value

(Whilst editing a

parameter value)

+

The parameter is set to

the minimum value

When editing

Display shows

Press

Display shows

Adjusting individual digits

within a parameter value

Any numerical value

(Whilst editing a

parameter value)

+

Individual parameter

digits can be adjusted

When editing

Display shows

Press

Display shows.

Press

Display shows.

Press

Display shows.

Press

Display shows.

Display

Status

Drive mains power applied, but no Enable or Run signal applied

Motor Autotune in progress.

x.x

Drive running, display shows output frequency (Hz)

Whilst the drive is running, the following displays

can be selected by briefly pressing the

button on the drive. Each press of the button will

cycle the display through to the next selection.

x.x

Drive running, display shows motor current (Amps)

x.x

Drive Running, display shows motor power (kW)

x.x

Drive Running, display shows customer selected units, see parameters

3400 DISPLAY SCALING FACTOR and 3405 DISPLAY SCALING SOURCE

Drive mains power not present, external 24 Volt control power supply present only

Output power hardware inhibited, hardware enable circuit open. External links are required to the STO inputs (terminals 12

and 13) as shown on page 23.

Parameters reset to factory default settings

For drive fault code displays, refer to section 13.1 on page 62

6.4. Advanced Keypad Operation ShortCuts

6.5. Drive Operating Displays

Page 30

7. Quick Start-up and Control

7.1. Quick Start-up Terminal Control

When delivered, the ACS255 is in the factory default state, meaning that it is set to operate in terminal control mode and all parameters have

the default values as indicated in section 9.

Perform mechanical and electrical installations per section 4 and 5.

Connect the motor to the drive, ensuring the correct star/delta connection for the voltage rating - see section 5.6 on page 22.

Apply the mains power to the drive, then enter the motor data from motor nameplate; 9905 = motor rated voltage, 9906 = motor

rated current, 9907 = motor rated frequency, & 9908 = motor rated speed.

Connect the Drive Hardware Enable (STO) circuit as follows (see section 5.10.7 “STO” Electrical Installation for further details)

o Link Terminal 1 to Terminals 12 (STO +)

o Link Terminal 9 to Terminal 13 (STO -)

Note : If the “STO“ function is being utilised as part of an overall safety system then the circuit should be

installed and integrity tested as per the guidance given in section 5.10 “Safe Torque Off”.

Connect a control switch between the control terminals 1 and 2 ensuring that the contact is open (drive disabled).

Connect a potentiometer (1kΩ min to 10kΩ max) between terminals 5 and 7, and the wiper to terminal 6.

With the potentiometer set to zero, switch on the supply to the drive. The display will show .

Close the control switch, terminals 1-2. The drive is now ‘enabled’ and the output frequency/speed are controlled by the

potentiometer. The display shows zero speed in Hz (.) with the potentiometer turned to minimum.

Turn the potentiometer to maximum. The motor will accelerate to 60Hz, the default value of parameter 2008, under the control of the

acceleration ramp time parameter 2202.

If the potentiometer is turned to minimum, the motor will decelerate to 0Hz, the default minimum speed set in parameter 2007, under

the control of the deceleration ramp parameter 2203. The output speed can be adjusted anywhere between minimum and maximum

speed using the potentiometer.

31

To display motor current (Amps), briefly press the (Navigate) key.

Press again to display the motor power.

Press again to display the estimated motor speed (RPM). (Motor nameplate RPM must be entered in 9908 = motor rated speed)

Press again to return to speed (Hz) display.

To stop the motor, disable the drive by opening the control switch (terminals 1-2).

If the enable/disable switch is opened the drive will decelerate to stop at which time the display will show . If the potentiometer

is turned to zero with the enable/disable closed the display will show .(0.0Hz), if left like this for 20 seconds the drive will go

into standby mode, display shows , waiting for a speed reference signal.

7.2. Quick Start-up Keypad Control

To allow the ACS255 to be controlled from the keypad in a forward direction only, set parameter 1103 PRIMARY COMMAND SOURCE MODE to 1:

Connect the drive to the supply, ensuring the correct voltage and fusing protection – see section 11.2 on page 59.

Connect the motor to the drive, ensuring the correct star/delta connection for the voltage rating - see section 5.6 on page 22.

Apply the mains power to the drive, then enter the motor data from motor nameplate; 9905 = motor rated voltage, 9906 = motor

rated current, 9907 = motor rated frequency.

Connect the Drive Hardware Enable (STO) circuit as follows (see section 5.10.7 “STO“Electrical Installation for further details)

o Link Terminal 1 to Terminals 12 (STO +)

o Link Terminal 9 to Terminal 13 (STO -)

Note : If the “STO“ function is being utilised as part of an overall safety system then the circuit should be

installed and integrity tested as per the guidance given in section 5.10 “Safe Torque Off”.

Connect a control switch between the control terminals 1 and 2 ensuring that the contact is open (drive disabled).

Enable the drive by closing the switch between control terminals 1 & 2. The display will show .

Press the key. The display shows ..

Press to increase speed.

The drive will run forward, increasing speed until is released.

Press to decrease speed. The drive will decrease speed until is released. The rate of deceleration is limited by the

setting in parameter 2203.

Press the key. The drive will decelerate to rest at the rate set in parameter 2203.

The display will finally show at which point the drive is disabled

Page 31

32

The Autotune will begin immediately when parameter 9910 MOTOR PARAMETER AUTO-TUNE ENABLE = 1 is set regardless of

the status of the drive enable signal. Whilst the autotune procedure does not drive or spin the motor, the motor shaft may still

turn slightly. It is not normally necessary to uncouple the load from the motor; however the user should ensure that no risk

arises from the possible movement of the motor shaft.

It is essential that the correct motor data is entered into the relevant drive parameters. Incorrect parameter settings can result

in poor or even dangerous performance.

To preset a target speed prior to enable, press the key whilst the drive is stopped. The display will show the target speed,

use the & keys to adjust as required then press the key to return the display to .

Pressing the key will start the drive accelerating to the target speed.

To allow the ACS255 to be controlled from the keypad in a forward and reverse direction, set parameter 1103 =2:

Operation is the same as when parameter 1103=1 for start, stop and changing speed.

Press the key. The display changes to ..

Press to increase speed

The drive will run forward, increasing speed until is released. Acceleration is limited by the setting in parameter 2202. The

maximum speed is the speed set in parameter 2008.

To reverse the direction of rotation of the motor, press the key again.

7.3. Sensorless Vector Speed Control Mode

ACS255 can be programmed by the user to operate in Sensorless Vector mode, which provides enhanced low speed torque, optimum motor

speed regulation regardless of load and accurate control of the motor torque. In most applications, the default Voltage Vector control mode will

provide adequate performance, however if Sensorless Vector operation is required, use the following procedure.

Enter the motor nameplate details into the relevant parameters as follows

o 9905 MOTOR RATED VOLTAGE

o 9906 MOTOR RATED CURRENT

o 9907 MOTOR RATED FREQUENCY

o (Optional) 9908 MOTOR RATED SPEED (Rpm)

o 9915 Motor Power Factor Cos Ø

Select Sensorless Vector control mode by setting parameter 9903 MOTOR CONTROL MODE = 0

Ensure that the motor is correctly connected to the drive

Carry out a motor data Autotune by setting parameter 9910 MOTOR PARAMETER AUTO-TUNE ENABLE = 1

Page 32

8. Application Macros

1103 (control Mode)

Selected Speed Reference

0 : Terminal Mode

Analog input 1

1 : Keypad Mode (uni-directional)

Digital Potentiometer

2 : Keypad Mode (bi-directional)

Digital Potentiometer

3 : User PI mode

PI controller output

4 : Fieldbus Control

Speed reference via Fieldbus

5 : CANopen

Speed reference via CANopen

11

O: Stop

C: Run Fwd

O: Stop

C: Run Rev

O: Selected Speed Ref

C: Preset speed 1, 2

Analog 1 Speed reference

O: Preset speed 1

C: Preset speed 2

12

O: Stop

C: Run Fwd

O: Stop

C: Run Rev

Digital input 3

Analog input 1

Analog input 2

Preset Speed

Off

Off

Off

Preset Speed 1

On

Off

Off

Preset Speed 2

Off

On

Off

Preset Speed 3

On

On

Off

Preset Speed 4

13

O: Stop

C: Run Fwd

O: Stop

C: Run Rev

O: Selected Speed Ref

C: Preset speed 1

Analog 1 Speed reference

Analog torque reference

14

O: Stop

C: Run Fwd

O: Stop

C: Run Rev

O: Selected Speed Ref

C: Preset speed 1

Analog 1 Speed reference

O: Decel ramp 1 (Par 2203)

C: Decel ramp 2 (Par 2206)1)

15

O: Stop

C: Run Fwd

O: Stop

C: Run Rev

O: Selected Speed Ref

C: Analog input 2

Analog 1 Speed reference

Analog 2 Speed reference

16

O: Stop

C: Run Fwd

O: Stop

C: Run Rev

O: Selected Speed Ref

C: Preset speed 1

Analog 1 Speed reference

External trip 2)

O: trip C: Run

17

O: Stop

C: Run Fwd

O: Stop

C: Run Rev

Digital input 3

Analog input 1

Preset Speed

External trip 2)

O: trip C: Run

Off

Off

Preset Speed 1

On

Off

Preset Speed 2

Off

On

Preset Speed 3

On

On

Preset Speed 4

18

O: Stop

C: Run Fwd

O: Stop

C: Run Rev

Digital input 3

Analog input 1

Preset Speed

O: Decel ramp 1 (Par 2203)

C: Decel ramp 2 (Par 2206)1)

Off

Off

Preset Speed 1

On

Off

Preset Speed 2

Off

On

Preset Speed 3

On

On

Preset Speed 4

9902

Digital Input 1

(Terminal 2)

Digital Input 2

(Terminal 3)

Digital Input 3

(Terminal 4)

Analog Input 1

(Terminal 6)

Analog Input 2

(Terminal 10)

1

O: Stop

C: Run

O: Forward

C: Reverse

O: Selected Speed Ref

C: Preset speed 1, 2

Analog 1 Speed reference

O: Preset speed 1

C: Preset speed 2

2

O: Stop

C: Run

O: Forward

C: Reverse

Digital input 3

Analog input 1

Analog input 2

Preset Speed

Off

Off

Off

Preset Speed 1

On

Off

Off

Preset Speed 2

Off

On

Off

Preset Speed 3

On

On

Off

Preset Speed 4

3

O: Stop

C: Run

O: Forward

C: Reverse

O: Selected Speed Ref

C: Preset speed 1

Analog 1 Speed reference

Analog torque reference

4

O: Stop

C: Run

O: Forward

C: Reverse

O: Selected Speed Ref

C: Preset speed 1

Analog 1 Speed reference

O: Decel ramp 1 (Par 2203)

C: Decel ramp 2 (Par 2206)1)

5

O: Stop

C: Run

O: Forward

C: Reverse

O: Selected Speed Ref

C: Analog input 2

Analog 1 Speed reference

Analog 2 Speed reference

6

O: Stop

C: Run

O: Forward

C: Reverse

O: Selected Speed Ref

C: Preset speed 1

Analog 1 Speed reference

External trip 2)

O: trip C: Run

7

O: Stop

C: Run

O: Forward

C: Reverse

Digital input 3

Analog input 1

Preset Speed

External trip 2)

O: trip C: Run

Off

Off

Preset Speed 1

On

Off

Preset Speed 2

Off

On

Preset Speed 3

On

On

Preset Speed 4

8

O: Stop

C: Run

O: Forward

C: Reverse

Digital input 3

Analog input 1

Preset Speed

O: Decel ramp 1 (Par 2203)

C: Decel ramp 2 (Par 2206)1)

Off

Off

Preset Speed 1

On

Off

Preset Speed 2

Off

On

Preset Speed 3

On

On

Preset Speed 4

9

O: Stop

C: Run

O: Forward

C: Reverse

Digital input 3

Analog input 1

Preset Speed

O: Selected Speed Ref

C: Preset speed 1 .. 4

Off

Off

Preset Speed 1

On

Off

Preset Speed 2

Off

On

Preset Speed 3

On

On

Preset Speed 4

10

O: Stop

C: Run

O: Forward

C: Reverse

Normally Open (N.O.)

Close to increase speed

Normally Open (N.O.)

Close to reduce speed

O: Selected Speed Ref

C: Preset speed 1

8.1. Overview of macros

Application macros are pre-programmed parameter sets. While starting up the drive, the user selects the macro best suited for the

purpose with parameter 9902 DIGITAL INPUTS FUNCTION SELECT and 1103 PRIMARY COMMAND SOURCE MODE.

The term “Selected Speed Reference” in the table below is determined by the value set in 1103 PRIMARY COMMAND SOURCE MODE.

33

Page 33

34

19

O: Stop

C: Run Fwd

O: Stop

C: Run Rev

Digital input 3

Analog input 1

Preset Speed

O: Selected Speed Ref

C: Preset speed 1 .. 4

Off

Off

Preset Speed 1

On

Off

Preset Speed 2

Off

On

Preset Speed 3

On

On

Preset Speed 4

20

O: Stop

C: Run Fwd

O: Stop

C: Run Rev

Normally Open (N.O.)

Close to increase speed

Normally Open (N.O.)

Close to reduce speed

O: Selected Speed Ref

C: Preset speed 1

21

Normally Open (N.O.)

Close to run Fwd

Normally Closed

(N.C.)

Open to Stop

Normally Open (N.O.)

Close to run Rev

Analog 1 Speed reference

O: Selected Speed Ref

C: Preset speed 1

9902 = 1

(Default Macro)

Open

Closed

9902 = 2

Open

Closed

1

+24 Volt Common

1 +24 Volt Common

2

Stop

Run 2

Stop

Run

3

Forward Rotation

Reverse Rotation

3 Forward Rotation

Reverse Rotation

4

Selected Speed ref

Preset Speed ref

4

T4 T6

T10

Preset

5

+10 Volt

5 6

Analog Input 1

6

Open

Open

Open

1202

7

0 Volts

7

Closed

Open

Open

1203

8

8

Open

Closed

Open

1204

9

0 Volts

9

Closed

Closed

Open

1205

10

Preset Speed 1(1202)

Preset Speed 2(1203)

10

11

11

12

Safe Inhibit

Normal Operation

12

Safe Inhibit

Normal Operation

13

Safe Inhibit

Normal Operation

13

Safe Inhibit

Normal Operation

9902 = 3

Open

Closed

9902 = 4

Open

Closed

1

+24 Volt Common

1 +24 Volt Common

2

Stop

Run 2

Stop

Run

3

Forward Rotation

Reverse Rotation

3 Forward Rotation

Reverse Rotation

4

Selected Speed ref

Preset Speed 1 (1202)