ABB ACQ580-31-039A-4, ACQ580-31-09A5-4, ACQ580-31-033A-4, ACQ580-31-026A-4, ACQ580-31-046A-4 Quick Installation Manual

...

—

EN

US

ABB DRIVES FOR HVAC

ACH580-31 drives

Quick installation guide

List of related manuals in English

ACH580-31 manuals

Drive manuals and guides Code (English)

ACH580 HVAC control program firmware manual 3AXD50000027537

Quick start-up guide fo r ACH580 HVAC control program 3AXD50000047658

ACH580-31 hardware m anual

ACH580-31 quick installation guide

ACX-AP-x assistant control panels user’s manual

Option manuals and guides

ACS580, ACH580 and ACQ580 drive module frames R3, R5 to

R9 for cabinet installation (options +P940 and +P944)

supplement

ACS880-11, ACS880-31, ACH580-31 and ACQ580-31 UK

gland plate (+H358) installation guide

CDPI-01 communication adapter module user's manual

FBIP-21 BACnet/IP adapter module

FCAN-01 CANopen adapter module user's manual

FCNA-01 ControlNet a dapter module user's manual

FDNA-01 DeviceNet™ adapter module user's manual

FECA-01 EtherCAT adapter module user's manual

FENA-01/-11/-21 Ethernet adapter module user's manual 3AUA0000093568

FEPL-02 Ethernet P OWERLINK adapter module user's manual 3AUA0000123527

FLON-01 L

FPBA-01 PROFIBUS DP adapter module user's manua l

FSCA-01 RS-485 adapter module user's manual 3AUA0000109533

Tool and maintenance manuals and guides

Drive composer PC to ol user's manual 3AUA0000094606

Converter module capacitor reforming instructions

NETA-21 remote monitoring tool user's manual

NETA-21 remote monitoring tool installation and start-up guide 3AUA0000096881

ONWORKS® adapter module user’s manual 3AUA0000041017

You can find manuals and other product documents in PDF format on the Internet.

See section

Document library on the Internet

on the inside of the back cover. For manuals not

available in the Document library, contact your local ABB representative.

3AXD50000037066

3AXD50000048001

3AUA0000085685

3AXD50000210305

3AXD50000110711

3AXD50000009929

3AXD50000028468

3AFE68615500

3AUA0000141650

3AFE68573360

3AUA0000068940

3AFE68573271

3BFE64059629

3AUA0000096939

The code below opens an online listing of the manuals applicable to this product.

EN – Quick installation guide 3

EN – Quick installation guide

This guide briefly describes how to install the drive. For complete information on

installation, see ACH580-31 drives hardware manual (3AXD50000037066 [English]).

For cabinet installation, see also ACS580, ACH580 and ACQ580 drive module

frames R3, R5 to R9 for cabinet installation (options +P940 and +P944) supplement

(3AXD50000210305 [English]). For start-up instructions, see ACH580 drives with

HVAC control program quick start-up guide (3AXD50000047658 [English]).

To read a manual, go to www.abb.com/drives/documents

number.

and search for the document

EN

DA

Obey the safety instructions

WARNING! Obey these instructions. If you ignore them, injury or death, or

damage to the equipment can occur:

• Only qualified electrical professionals are allowed to install and maintain the

drive.

• Never work on the drive, motor cable or motor when main power is applied. If

the drive is already connected to the input power, wait for 5 minutes after

disconnecting the input power.

• Never work on the control cables when power is applied to the drive or to the

external control circuits.

• Do not connect the drive to a voltage higher than what is marked on the type

designation label.

• Always ground the drive, the motor and adjoining equipment to the protective

earth (PE) bus of the power supply.

•Frame

• Make sure that debris from drilling, cutting and grinding does not enter the drive.

• Make sure that the floor below the drive and the wall where the drive is installed

s R6 and R8: The drive module is heavy and its center of gravity is high.

Use a lifting device for lifting. Do not tilt the drive. Manual lifting, or overturning due

to the tilting, can cause physical injury. Make sure that the wall and the fixing

devices can carry the weight.

are non-flammable.

DE

ES

FI

FR

IT

NL

PL

PT

RU

SV

TR

ZH

4 EN – Quick installation guide

Check if capacitors need to be reformed

Reform the capacitors if the drive has not been powered up (either in storage or

unused) for a year or more.

You can determine the manufacturing date from the serial number, which you find on

the type designation label attached to the drive. The serial number is of format

XYYWWRXXXX. YY and WW tell the manufacturing year and week as follows:

YY: 17, 18, 19, … for 2017, 2018, 2019,

…

WW: 01, 02, 03, … for week 1, week 2, week 3, …

For information on reforming the capacitors, see Converter modules with

EN

electrolytic DC capacitors in the DC link capacitor reforming instructions

(3BFE64059629 [English]), available on the Internet at

DA

www.abb.com/drives/documents

.

DE

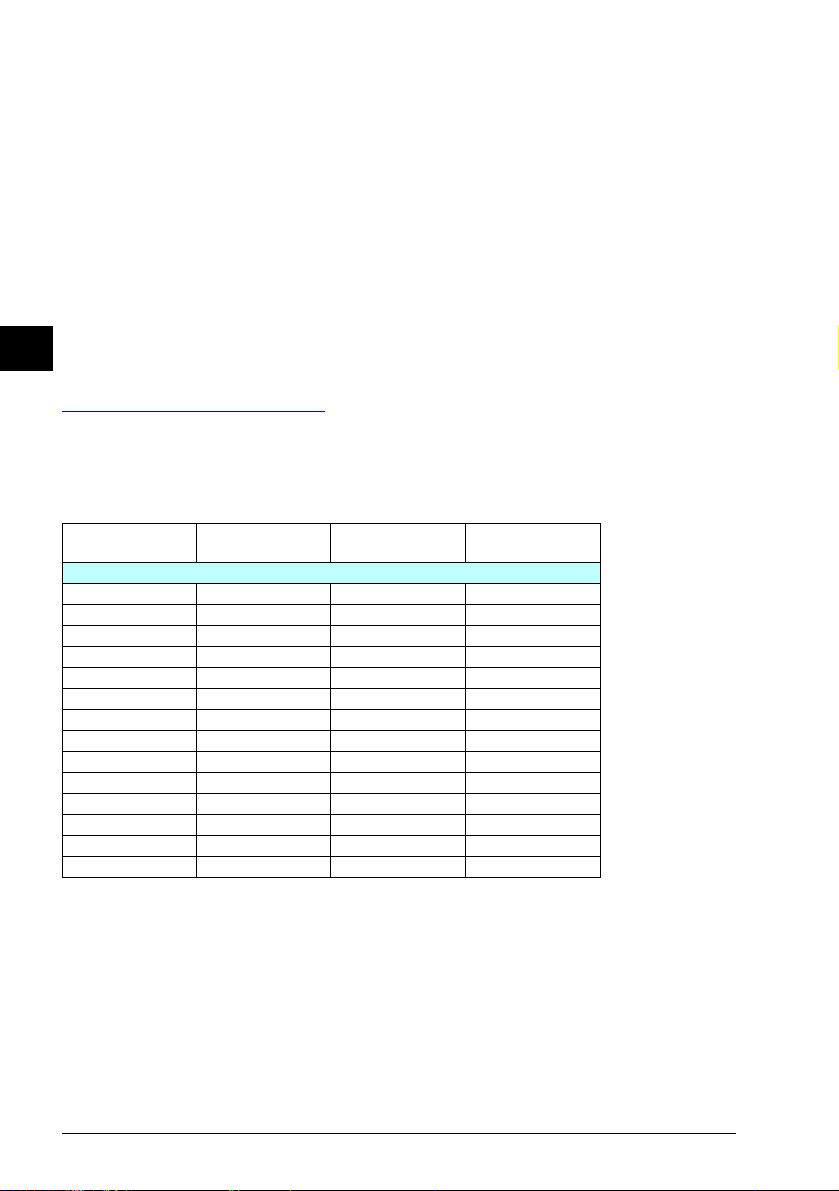

Data

ES

IEC ratings

FI

ACH580-31-

FR

3-phase UN = 400 V

09A5-4 3×2.5+2.5 170M1561 226

FR

NL

PL

PT

RU

SV

12A7-4 3×2.5+2.5 170M1561 329

018A-4 3×2.5+2.5 170M1563 395

026A-4 3×6+6 170M1563 579

033A-4 3×10+10 170M1565 625

039A-4 3×10+10 170M1565 751

046A-4 3×16+16 170M1566 912

062A-4 3×25+16 170M1567 1088

073A-4 3×35+16 170M1568 1502

088A-4 3×50+25 170M1568 1904

106A-4 3×70+35 170M1569 1877

145A-4 3×95+50 170M1570 2963

169A-4 3×120+70 170M5809 3168

206A-4 3×150+70 170M5810 3990

TR

Cable

Cu (mm2) aR fuse Losses

(W)

3AXD00000586715

ZH

Select the power cables

See Data on page 4.

Ensure cooling

See Data on page 4. No condensation or frost is allowed. The allowed operating

temperature range of the drive without derating is -15 to +40 °C.

EN – Quick installation guide 5

Protect the drive and input power cable with correct fusing

See Data on page 4.

A – Install the drive on the wall

See figure A on page 19.

B – Remove the cover

Remove the cover/s. See figures B (R3)... and ...B (R6, R8)... on page 19.

C – Check the compatibility with IT (ungrounded), cornergrounded delta, midpoint-grounded delta and TT systems

The standard drive with ground-to-phase varistors connected can be installed to a

symmetrically grounded TN-S system. For other systems, see the drive hardware

manual and figure C on page 19.

WARNING! Do not install the drive with the EMC filter connected to a system

that the filter is not suitable for. This can cause danger, or damage the drive.

See the drive hardware manual.

WARNING! Do not install the drive with the ground-to-phase varistor

connected to a system that the varistor is not suitable for. If you do, the varistor

circuit can be damaged. See the drive hardware manual.

D – Check the insulation of the power cables and the motor

Connect the motor cable at the motor end. For minimum radio frequency interference,

ground the motor cable shield 360 degrees at the cable entry of the motor terminal

box. See figure D on page 19.

Check the insulation of motor and motor cable. See figure D on page 19. Note:

Moisture inside the motor casing will reduce the insulation resistance. If moisture is

suspected, dry the motor and repeat the measurement.

Check the insulation of the input cable before you connect it to the drive. Obey the local

regulations.

EN

DA

DE

ES

FI

FR

IT

NL

PL

PT

RU

SV

TR

ZH

E – Attach the warning stickers in local languages

See figure E on page 20.

6 EN – Quick installation guide

F – Connect the power cables

Use symmetrical shielded cable for motor cabling. If the cable shield is the sole PE

conductor, make sure that is has sufficient conductivity for the PE.

Note for frame R3:

power cabling. See the hardware manual for more information.

Procedure:

1. Frames R6 and R8:

F (R6, R8)… on page 20. Frame R8

EN

DA

DE

ES

FR

FR

NL

PL

PT

RU

SV

TR

ZH

plates.

2. Remove the rubber grommets from the bottom plate for the cables to be

connected. See figure …F… on page 20.

3. Cut an adequate hole into the rubber grommets. Slide the grommets onto the

cables. Attach the unused grommets to holes cone pointing downwards.

4. Prepare the ends of the cables. See figure …F… on page 20.

The bare shield will be grounded 360 degrees. Mark the pigtail made from the

FI

shield as a PE conductor with yellow-and-green color.

Two alternative symmetrical three-conductor cable types are shown, and one

four-conductor cable type. The four-conductor cable is only allowed for the input

power cabling.

If you use aluminum cables, put grease to the peeled aluminum cable before

connecting it to the drive.

5. Put the cables through the holes of the cable entry plate and attach the grommets

to the holes.

6. Connect the cables (use the torques defined in the figure). See figures …F… on

page 20 and 21:

• Ground the shield 360 degrees by tightening the clamp of the power cable

grounding shelf onto the stripped part of the cable.

• Connect the twisted shield of the cable to the grounding terminal.

• Use a separate grounding PE cable (6a) or a cable with a separate PE

conductor (6b) if the conductivity of the shield does not meet the requirements

for the PE conductor. If the protective PE conductor is smaller than 10 mm

you must use a second earthing conductor. See the hardware manual for

more information.

•Frame R3:

• Connect the phase conductors of the motor cable to the T1/U, T2/V and T3/W

terminals and the phase conductors of the input cable to the L1, L2 and L3

terminals.

Make sure that you have an additional PE conductor in the input

Remove the shroud on the power cable terminals. See figure

: For easier installation, remove the side

Connect the additional PE conductor of the input power cabling.

2

,

EN – Quick installation guide 7

•For frame R8: Install the common mode filter. For instructions, see Common

mode filter kit for frames R7 and R8 (option +E208) installation guide

(3AXD50000015179 [English]).

7. Frame R6 types

cables. Frame R8:

shroud for the input cables. See figure …F (R6, R8) on page 21.

8. Frames R6 and R8:

…F (R6, R8) on page 21.

9. Secure the cables outside the drive mechanically.

-046A-4 and greater: Cut tabs in the shroud for the installed

Install the side plates if removed. Knock out holes in the

Install the shroud on the power cable terminals. See figure

G – Connect the control cables

Procedure:

1. Remove the front cover(s) if not already removed.

2. Frame R3

3. Cut an adequate hole into the rubber grommet and slide the grommet onto the

cable. Slide the cable through a hole in the bottom plate and attach the grommet

to the hole. Attach the unused grommets to holes cone pointing downwards.

4. Route the cables. Frame R3:

Frame R6:

on page 22.

5. Ground the outer shield of the cable 360 degrees under the grounding clamp.

Keep the cable unstripped as close to the terminals of the control board as

possible.

6. Secure the cables inside the drive mechanically.

7.

Ground the pair-cable shields and grounding wire at the grounding terminal (SCR)

of the control unit.

8. Connect the conductors to the appropriate terminals of the control unit. See

Default IO connection diagram on page 9.

9. Wire the optional modules if included in the delivery. See the option module user's

manual or installation guide.

10. Secure the cables outside the drive mechanically.

: Lift the control panel holder up. See figure G (R3)… on page 21.

See figure …G (R3)… on page 21.

See figure …G (R6)… on page 22. Frame R8: See figure …G (R8)…

EN

DA

DE

ES

FI

FR

IT

NL

PL

PT

RU

SV

TR

ZH

Note:

• Leave the other ends of the control cable shields unconnected.

• Keep any signal wire pairs twisted as close to the terminals as possible.

8 EN – Quick installation guide

H – Reinstall cover(s)

See figures H (R3, R6, R8) on page 23.

EN

DA

DE

ES

FI

FR

FR

NL

PL

PT

RU

SV

TR

ZH

Run status

Fault status

Damper actuator

max.

500 ohm

1…10 kohm

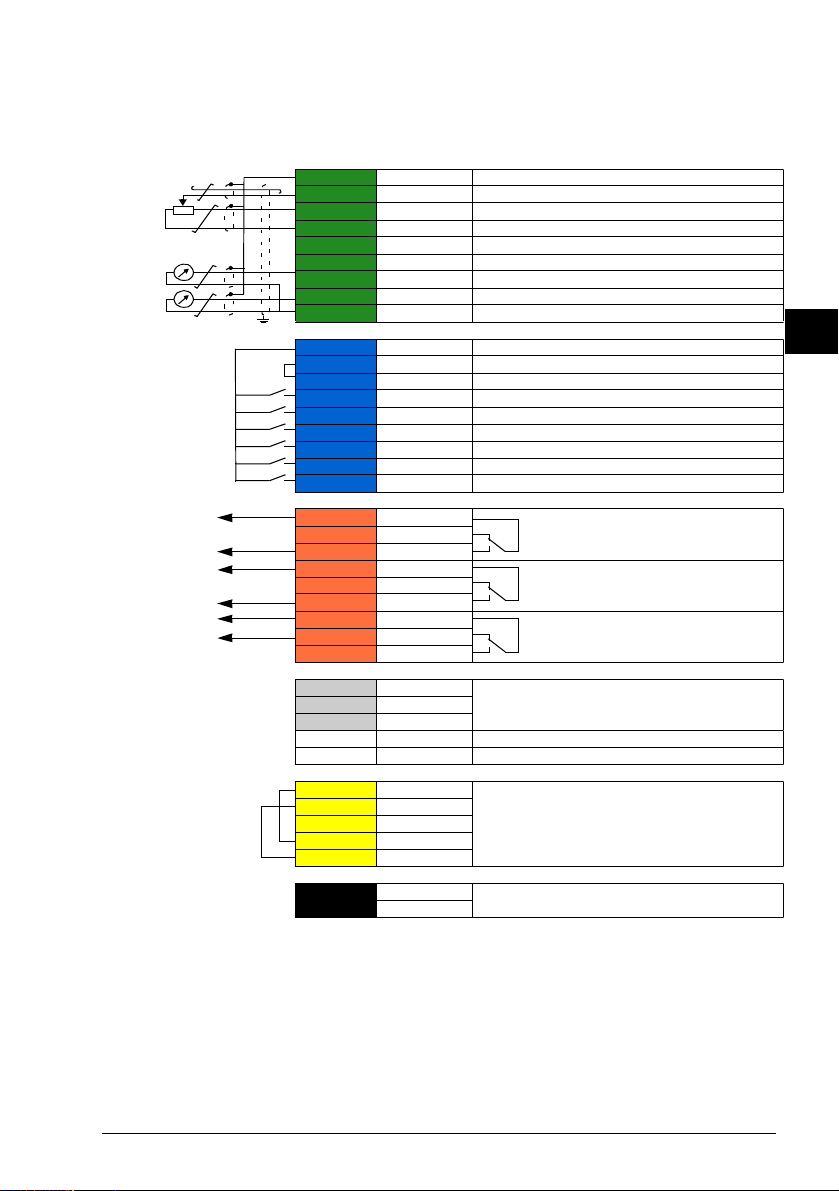

X1 Reference voltage and analog inputs and outputs

1 SCR Signal cable shield (screen)

2 AI1 Output frequency/speed reference: 0…10 V

3 AGND Analog input circuit common

4 +10V Reference voltage 10 V DC

5 AI2 Actual feedback: 0…20 mA

6 AGND Analog input circuit common

7 AO1 Output frequency: 0…10 V

8 AO2 Motor current: 0…20 mA

9 AGND Analog output circuit common

X2 & X3 Aux. voltage output and programmable digital inputs

10 +24V Aux. voltage output +24 V DC, max. 250 mA

11 DGND Aux. voltage ou tput common

12 DCOM Digital input common for all

13 DI1 Stop (0) / Start (1)

14 DI2 Not configured

15 DI3 Constant frequency/speed selection

16 DI4 Start interlock 1 (1 = allow start)

17 DI5 Not configured

18 DI6 Not configured

X6, X7, X8 Relay outputs

19 RO1C

Damper control

250 V AC / 30 V DC

2 A

20 RO1A

21 RO1B

22 RO2C

Running

250 V AC / 30 V DC

2 A

23 RO2A

24 RO2B

25 RO3C

Fault (-1)

250 V AC / 30 V DC

2 A

26 RO3A

27 RO3B

X5 Embedded fieldbus

29 B+

Embedded fieldbus, EFB (EIA-485)

30 A-

31 DGND

S4 TERM Termination switch

S5 BI AS Bias resistors switch

X4 Safe torque off

34 OUT1

Safe torque off. Factory connection. Both circuits

must be closed for the drive to start.

35 OUT2

36 SGND

37 IN1

38 IN2

X10 24VAC/DC

40

24 V AC/DC+ in

Ext. 24V AC/DC input to power up the control unit

when the main supply is

disconnected.

41

24 V AC/DC- in

Total load capacity of the Auxiliary voltage output +24V (X2:10) is 6.0 W (250 mA / 24 V DC).

Wire sizes: 0.14…2.5 mm

2

(26…14 AWG): All terminals

Tightening torques: 0.5…0.6 N·m (0.4 lbf·ft)

Default IO connection diagram

EN – Quick installation guide 9

EN

DA

DE

ES

FI

FR

IT

NL

PL

PT

RU

SV

TR

ZH

10 EN – Quick installation guide

EN

DA

DE

ES

FI

FR

FR

NL

PL

PT

RU

SV

TR

ZH

Loading...

Loading...