ABB ACH550 User Manual

ACH550

User’s Manual

ACH550-01 Drives

Kit, IP21 /

UL type 1

Frame

size

Code (English)

FMK-A-R1 R1 100000982

FMK-A-R2 R2 100000984

FMK-A-R3 R3 100000986

FMK-A-R4 R4 100000988

Kit, IP54 /

UL type 12

Frame

size

Code (English)

FMK-B-R1 R1 100000990

FMK-B-R2 R2 100000992

FMK-B-R3 R3 100000994

FMK-B-R4 R4 100000996

ACH550-01 Drive manuals

GENERAL MANUALS

ACH550-01 User's Manual

3AFE68258537 (English)

HVAC Info Guide CD

3AFE68338743 (English)

• Detailed product description

– Technical product description incl.

dimensional drawings

– Cabinet mounting information

including power losses

– Software and control

– User interfaces and control

connections

– Complete options descriptions

– Spare parts etc.

• Practical engineering guides

– PID & PFA engineering guide

– Dimensioning and sizing

– Diagnostics and maintenance

–Etc.

Flange Mounting Instructions

RBIP-01 BACnet/IP Router

Module Installation Manual

3AUA0000040168 (English)

RBIP-01 BACnet/IP Router

Module User’s Manual

3AUA0000040159 (English)

RCAN-01 CANopen Adapter

User's Manual

3AFE64504231 (English)

RCCL-01 CC-Link Adapter

Module User's Manual

3AUA0000061340 (English)

RCNA-01 ControlNet Adapter

User's Manual

3AFE64506005 (English)

RDNA-01 DeviceNet Adapter

User's Manual

3AFE64504223 (English)

OPTION MANUALS

(delivered with optional equipment)

ACH550-01+B055+F278 Drives

Installation Supplement

3AUA0000040634 (Multilingual)

BACnet® Protocol

3AUA0000004591 (English)

Embedded Fieldbus (EFB)

Control

3AFE68320658 (English)

REPL-01 Ethernet POWERLINK

Adapter Module User's Manual

3AUA0000052289 (English)

RETA-01 Ethernet Adapter

Module User's Manual

3AFE64539736 (English)

RETA-02 Ethernet Adapter

Module User's Manual

3AFE68895383 (English)

RLON-01 L

ONWORKS® Adapter

Module User’s Manual

3AFE64798693 (English)

RPBA-01 PROFIBUS DP Adapter

User's Manual

3AFE64504215 (English)

SREA-01 Ethernet Adapter User's

Manual

3AUA0000042896 (English)

MAINTENANCE MANUALS

MFDT-01 FlashDrop User’s

Manual

3AFE68591074 (English)

OREL-01 Relay Output Extension

Module User's Manual

3AUA0000001935 (English)

Guide for Capacitor Reforming in

ACS50, ACS55, ACS150, ACS310,

ACS320, ACS350, ACS550 and

ACH550

3AFE68735190 (English)

1. Contents of this manual

2. Preparing for installation

3. Installing the drive

4. Start-up and control panel

5. Application macros and wiring

6. Real-time clock and timed functions

7. Serial communications

8. Parameter listing and descriptions

3AFE68258537 REV F

EN

EFFECTIVE: 2009-07-07

9. Diagnostics and maintenance

10. Technical data

Index

ACH550-01 User's Manual

Table of contents

1. Contents of this manual ............................................. 5

What this chapter contains .......................................... 5

Compatibility ................................................................5

Intended use................................................................5

Intended audience ....................................................... 5

Use of warnings and notes.......................................... 6

Safety instructions ....................................................... 6

Drive package..............................................................9

Lifting the drive .......................................................... 10

Product and service inquiries..................................... 11

Product training..........................................................11

Providing feedback on ABB Drives manuals .............11

Document library on the Internet ............................... 11

2. Preparing for installation.......................................... 13

What this chapter contains ........................................ 13

Drive identification ..................................................... 14

Frame size.................................................................17

Motor identification..................................................... 19

Motor compatibility.....................................................21

Suitable environment and enclosure ......................... 22

Suitable mounting location......................................... 23

Wiring and EMC considerations ................................ 26

Cabling instructions ................................................... 28

Input power (mains) cables........................................ 28

Motor cables .............................................................. 28

Control cables............................................................32

Tools required............................................................35

Checklist for installation preparations........................36

3. Installing the drive..................................................... 37

What this chapter contains ........................................ 37

Preparing the mounting location................................38

Table of contents 1

ACH550-01 User's Manual

Removing front cover (IP54)......................................39

Removing front cover (IP21)......................................40

Mounting the drive (IP54)........................................... 41

Mounting the drive (IP21)........................................... 42

Overview of wiring installation (R1…R4) ...................43

Overview of wiring installation (R5…R6) ...................44

Checking the insulation of the assembly....................46

Power wiring (IP54)....................................................47

Control wiring (IP54)..................................................50

Power wiring (IP21)....................................................51

Control wiring (IP21)..................................................54

Check installation.......................................................56

Re-install cover (IP54) ...............................................58

Re-install cover (IP21) ...............................................59

Apply power...............................................................60

4. Start-up and control panel........................................ 63

What this chapter contains.........................................63

Control panel compatibility.........................................63

HVAC control panel (ACH-CP-B) features................. 63

Start-up......................................................................64

Modes........................................................................67

Output (Standard display) mode................................ 68

Parameters mode ......................................................70

Assistants mode.........................................................72

Changed parameters mode.......................................76

Drive parameter backup mode................................... 77

Time and date mode..................................................84

I/O settings mode.......................................................87

Fault logger mode......................................................88

5. Application macros and wiring................................ 89

What this chapter contains.........................................89

Applications................................................................89

Selecting an application macro..................................90

Restoring defaults......................................................91

1. HVAC default.........................................................92

2. Supply fan..............................................................94

2 Table of contents

ACH550-01 User's Manual

3. Return fan..............................................................96

4. Cooling tower fan................................................... 98

5. Condenser ........................................................... 100

6. Booster pump ...................................................... 102

7. Pump alternation.................................................. 104

8. Internal timer........................................................106

9. Internal timer with constant speeds / Powered

roof ventilator .......................................................108

10. Floating point ..................................................... 110

11. Dual setpoint PID............................................... 112

12. Dual setpoint PID with constant speeds ............ 114

13. E-bypass (USA only) ......................................... 116

14. Hand control ...................................................... 118

Connection examples of two-wire and three-wire

sensors................................................................. 120

6. Real-time clock and timed functions..................... 121

What this chapter contains ...................................... 121

Real-time clock and timed functions........................121

Using the timer.........................................................122

Example of timer use...............................................129

7. Serial communications........................................... 133

What this chapter contains ...................................... 133

System overview...................................................... 134

Embedded fieldbus (EFB)........................................ 136

Fieldbus adapter (EXT FBA).................................... 141

Drive control parameters ......................................... 147

Fault handling .......................................................... 156

8. Parameter listing and descriptions ....................... 159

What this chapter contains ...................................... 159

Parameter groups....................................................159

Complete parameter list........................................... 322

9. Diagnostics and maintenance................................ 363

What this chapter contains ...................................... 363

Table of contents 3

ACH550-01 User's Manual

Diagnostics displays ................................................364

Correcting faults.......................................................365

Fault resetting..........................................................374

History......................................................................375

Correcting alarms.....................................................375

Maintenance intervals..............................................380

Heatsink...................................................................381

Main fan replacement ..............................................381

Internal enclosure fan replacement.......................... 385

Capacitors................................................................386

Control panel............................................................387

10. Technical data........................................................ 389

What this chapter contains.......................................389

Ratings.....................................................................389

Input power (mains) cable, fuses and circuit

breakers ...............................................................395

Input power and motor connection terminals........... 402

Input power (mains) connection...............................403

Motor connection .....................................................404

Control connections.................................................408

Efficiency..................................................................412

Cooling.....................................................................412

Dimensions and weights..........................................414

Ambient conditions...................................................434

Materials ..................................................................435

Applicable standards................................................436

CE marking..............................................................436

C-Tick marking.........................................................437

UL marking...............................................................437

IEC/EN 61800-3 (2004) Definitions..........................438

Compliance with the IEC/EN 61800-3 (2004)..........438

Product protection in the USA..................................440

Contact information..................................................441

Index........................................................................445

4 Table of contents

ACH550-01 User's Manual

Contents of this manual

What this chapter contains

This chapter contains the safety instructions which you must

follow when installing, operating and servicing the drive. If

ignored, physical injury or death may follow, or damage may

occur to the drive, the motor or driven equipment. Read the

safety instructions before you work on the unit.

This chapter also contains an introduction to the contents of this

manual.

At the end of the chapter you find instructions on how to make

inquiries about products and service, find information on product

training and give feedback on the drive manuals.

Compatibility

This manual covers ACH550-01 drives. For ACH550-UH drive

data and instructions, please refer to ACH550-UH HVAC Drives

User’s Manual (3AUA0000004092 [English]).

The manual is compatible with the ACH550-01 drive firmware

version 3.13d or later. See parameter 3301 FIRMWARE on page

250.

Intended use

The ACH550 and the instructions in this manual are intended for

use in HV AC applications. The macros should only be applied to

the applications defined in the respective section.

Intended audience

This manual is intended for personnel who install, commission,

operate and service the drive. Read the manual before working

on the drive. The reader is expected to know the fundamentals

of electricity, wiring, electrical components and electrical

schematic symbols.

Contents of this manual 5

Use of warnings and notes

There are two types of safety instructions throughout this

manual:

• Warnings caution you about conditions which can result in

serious injury or death and/or damage to the equipment.

They also tell you how to avoid the danger.

• Notes draw attention to a particular condition or fact, or give

information on a subject.

The warning symbols are used as follows:

Electricity warning warns of hazards from electricity

which can cause physical injury and/or damage to the

equipment.

General warning warns about conditions, other than

those caused by electricity, which can result in physical

injury and/or damage to the equipment.

ACH550-01 User's Manual

Safety instructions

WARNING! The ACH550 should ONLY be installed by a

qualified technician.

WARNING! Even when the motor is stopped, dangerous voltage

is present at the power circuit terminals U1, V1, W1 and U2, V2,

W2, and, depending on the frame size, UDC+/BRK+ and

UDC-/BRK-.

WARNING! Dangerous voltage is present when input power is

connected. After disconnecting the supply, wait at least 5

minutes before removing the cover. To check, measure for zero

voltage at the DC terminals, which are, depending on the frame

size, UDC+/BRK+ and UDC-/BRK-.

6 Contents of this manual

ACH550-01 User's Manual

WARNING! Even when the power is switched off from the input

terminals of the ACH550, there may be dangerous voltage (from

external sources) on the terminals of the relay outputs

RO1…RO3 and, if the relay extension board is included in the

installation, RO4…RO6.

WARNING! When the control terminals of two or more drive

units are connected in parallel, the auxiliary voltage for these

control connections must be taken from a single source which

can either be one of the units or an external supply.

WARNING! Disconnect the EMC filter when installing the drive

on an IT system (an unearthed power system, a high-resistanceearthed [over 30 ohms] power system or a power system

equipped with residual current circuit breakers), otherwise the

system will be connected to earth potential through the EMC

filter capacitors. This may cause danger or damage the drive.

Disconnect the EMC filter when installing the drive on a cornerearthed TN system, otherwise the drive will be damaged.

Note: When the EMC filter is disconnected, the drive is not EMC

compatible.

For disconnecting the EMC filter, see Disconnecting the internal

EMC filter on page 45.

WARNING! The ACH550 is not a field repairable unit. Never

attempt to repair a malfunctioning unit; contact the factory or

your local Authorized Service Centre for replacement.

WARNING! The ACH550 will start up automatically after an

input voltage interruption if the external run command is on.

WARNING! The heat sink may reach a high temperature. See

chapter Technical data.

Contents of this manual 7

ACH550-01 User's Manual

WARNING! Do not control the motor with an AC contactor or

disconnecting device (disconnecting means); use instead the

control panel (operator keypad) start (HAND ), AUTO )

and stop (OFF ) keys or external commands (I/O or

fieldbus). The maximum allowed number of charging cycles of

the DC capacitors (i.e. power-ups by applying power) is five in

ten minutes.

Note: For more technical information, contact your local ABB

representative (see page 441).

8 Contents of this manual

ACH550-01 User's Manual

1

2

3

4

5

6

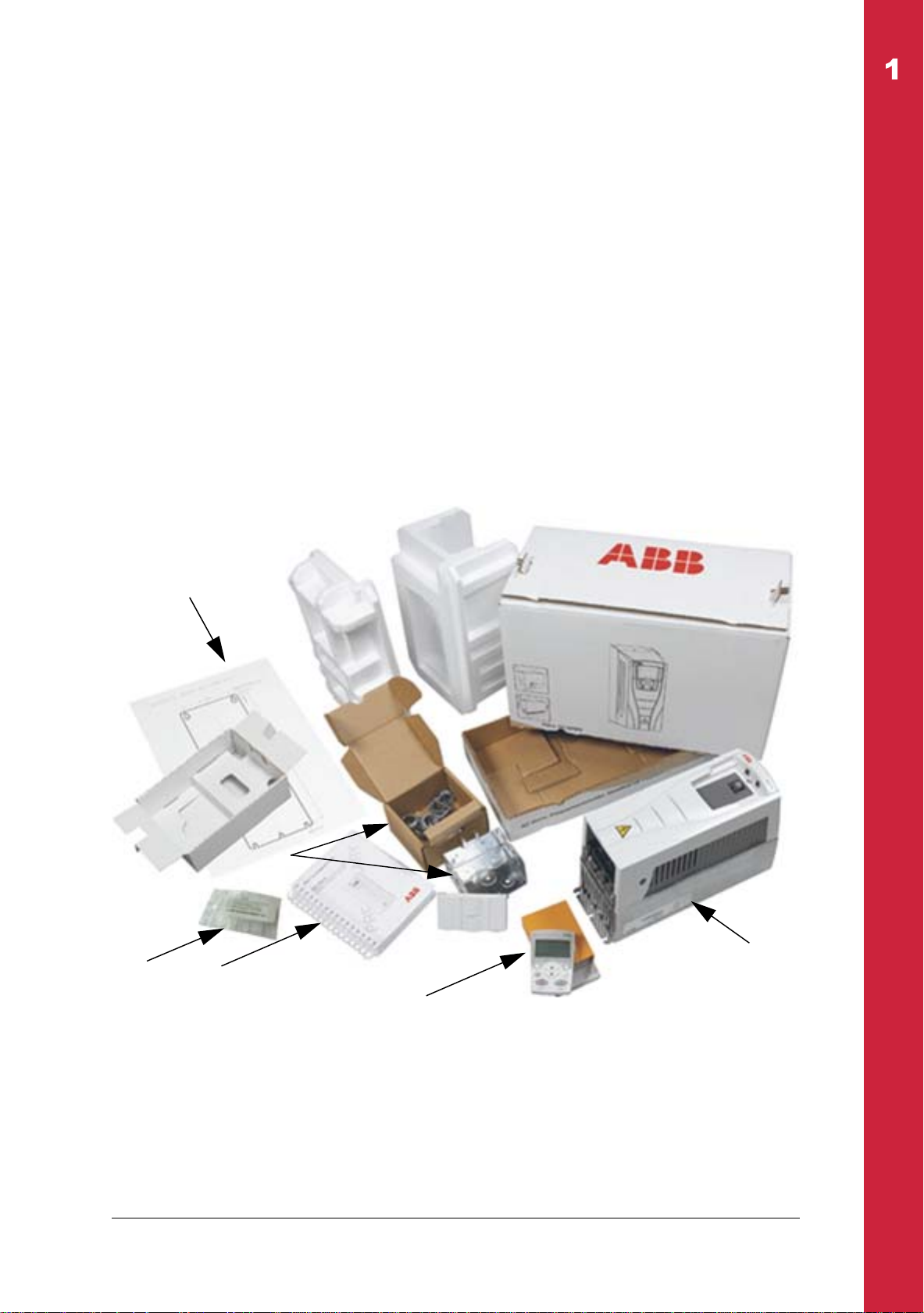

Drive package

After opening the package, check that the following items are

included:

• ACH550 drive (1)

• type IP21: box containing clamps and connection box (2),

type IP54: top cover

• box containing control panel (operator keypad) ACH-CP-B

and panel connector (3)

• cardboard mounting template (4)

• user’s manual (5)

• warning stickers

• polyamide screws (in the R1, R2 and R3 packages) (6).

The figure below shows the contents of the drive package.

Contents of this manual 9

Lifting the drive

The figure below shows how to lift the drive.

Note: Lift the drive only from the metal chassis.

ACH550-01 User's Manual

10 Contents of this manual

ACH550-01 User's Manual

Product and service inquiries

Address any inquiries about the product to your local ABB

representative, quoting the type designation and serial number

of the unit in question. A listing of ABB sales, support and

service contacts can be found by navigating to

www.abb.com/drives and selecting Sales, Support and Service

Network.

Product training

For information on ABB product training, navigate to

www.abb.com/drives

and select Training courses.

Providing feedback on ABB Drives manuals

Your comments on our manuals are welcome. Go to

www.abb.com/drives and select Document Library – Manuals

feedback form (LV AC drives).

Document library on the Internet

You can find manuals and other product documents in PDF

format on the Internet. Go to www.abb.com/drives and select

Document Library. You can browse the library or enter selection

criteria, for example a document code, in the search field.

Contents of this manual 11

ACH550-01 User's Manual

12 Contents of this manual

ACH550-01 User's Manual

Preparing for installation

What this chapter contains

This chapter contains instructions for preparing for the

installation of the drive. It contains the drive identification, wiring

and EMC guidelines and a list of tools necessary for the

installation.

Note: The installation must always be designed and made

according to applicable local laws and regulations. ABB does

not assume any liability whatsoever for any installation which

breaches the local laws and/or other regulations. Furthermore, if

the recommendations given by ABB are not followed, the drive

may experience problems that the warranty does not cover.

Preparing for installation 13

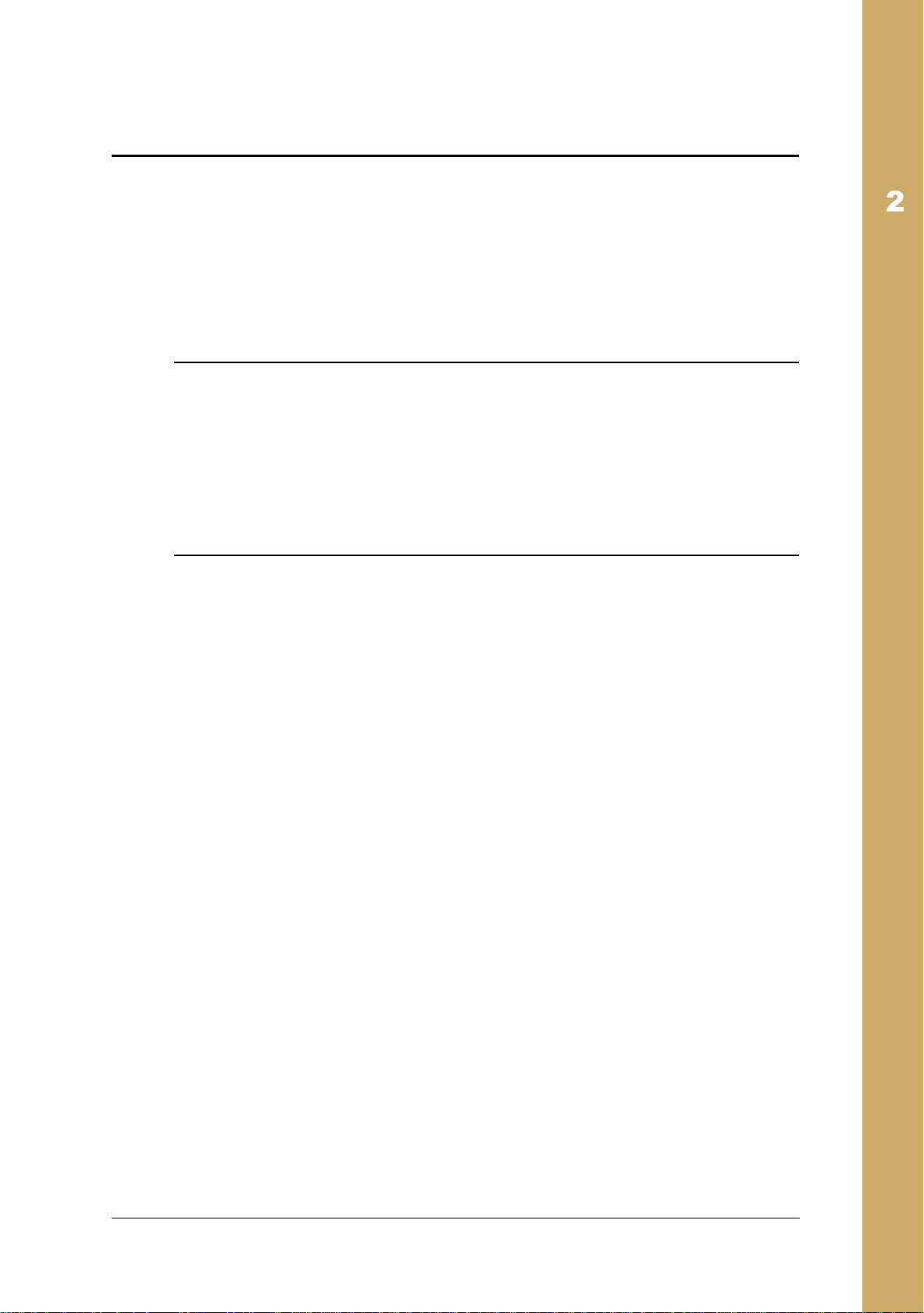

Drive identification

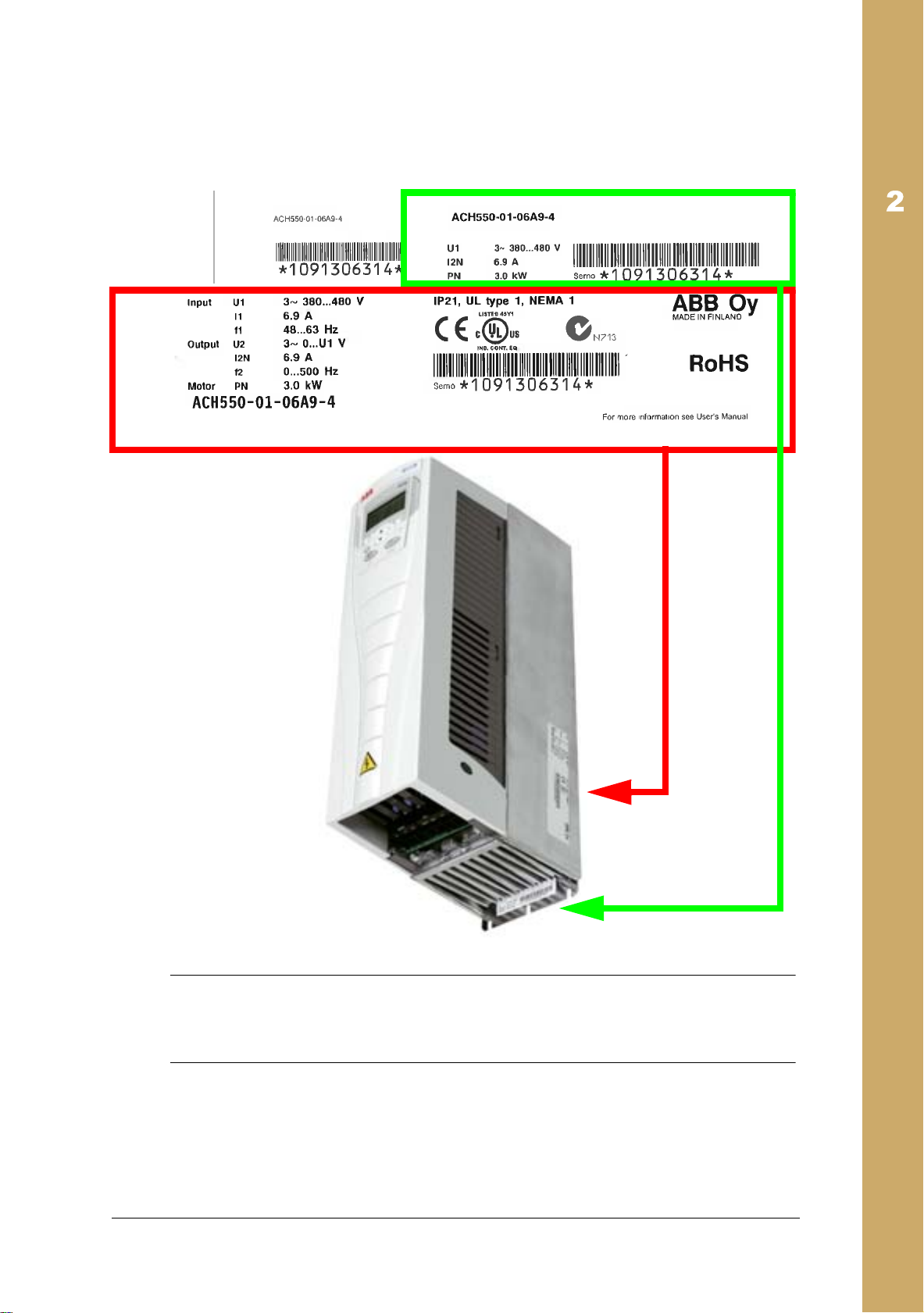

IP54 drive labels

The location and the contents of the labels for the IP54 degree

of protection are shown in the figure below.

ACH550-01 User's Manual

Note: The location of the labels may vary between different

frame sizes.

14 Preparing for installation

ACH550-01 User's Manual

IP21 drive labels

The location and the contents of the labels for the IP21 degree

of protection are shown in the figure below.

Note: The location of the labels may vary between different

frame sizes.

Preparing for installation 15

ACH550-01 User's Manual

ACH550-01-08A8-4+…

AC, HVAC Drive – 550 product series

Construction (region specific)

Output current rating

Voltage rating

Degree of protection

No specification = IP21

B055 = IP54

08A8 = 8.8 A, see the table in section

Frame size

on page 17 for details

2 = 208…240 VAC

4 = 380…480 VAC

01 = Setup and parts specific to IEC installation and compliance

UH = Setup and parts specific to US installation and NEMA compliance

Type designation

The contents of the drive type designation shown on the labels

are described below.

Serial number

The format of the drive serial number shown on the labels is

described below.

Serial number is of format CYYWWXXXXX, where

C: Country of manufacture

YY: Year of manufacture

WW: Week of manufacture; 01, 02, 03, … for week 1, week 2, week 3, …

XXXXX: Integer starting every week from 00001.

16 Preparing for installation

ACH550-01 User's Manual

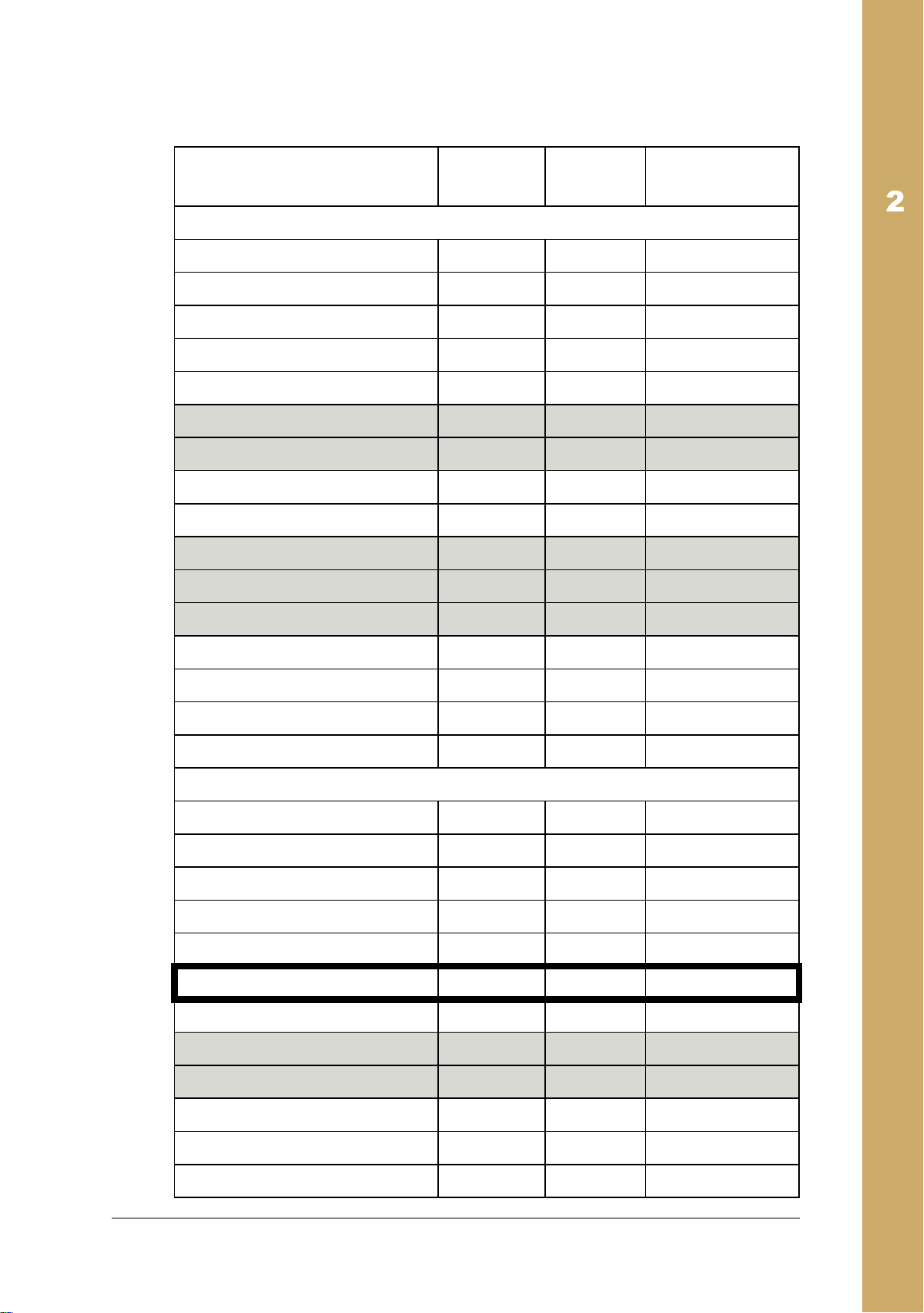

Frame size

Type

ACH550-01-

I

2N

A

P

N

kW

Frame size

Three-phase supply voltage, 220…240 V

04A6-2 4.6 0.75 R1

06A6-2 6.6 1.1 R1

07A5-2 7.5 1.5 R1

012A-2 11.8 2.2 R1

017A-2 16.7 4.0 R1

024A-2 24.2 5.5 R2

031A-2 30.8 7.5 R2

046A-2 46 11 R3

059A-2 59 15 R3

075A-2 75 18.5 R4

088A-2 88 22 R4

114A-2 114 30 R4

143A-2 143 37 R6

178A-2 178 45 R6

221A-2 221 55 R6

248A-2 248 75 R6

Three-phase supply voltage, 380…480 V

02A4-4 2.4 0.75 R1

03A3-4 3.3 1.1 R1

04A1-4 4.1 1.5 R1

05A4-4 5.4 2.2 R1

06A9-4 6.9 3.0 R1

08A8-4 8.8 4.0 R1

012A-4 11.9 5.5 R1

015A-4 15.4 7.5 R2

023A-4 23 11 R2

031A-4 31 15 R3

038A-4 38 18.5 R3

045A-4 45 22 R3

Preparing for installation 17

ACH550-01 User's Manual

Type

ACH550-01-

I

2N

A

P

N

kW

Frame size

059A-4 59 30 R4

072A-4 72 37 R4

087A-4 87 45 R4

125A-4 125 55 R5

157A-4 157 75 R6

180A-4 180 90 R6

195A-4 205 110 R6

246A-4 246 132 R6

290A-4 290 160 R6

00467918.xls C

Mark the frame size of your drive in the box on

the right.

Note: For detailed technical information, see chapter Technical

data.

18 Preparing for installation

ACH550-01 User's Manual

6313/C3

F

M3JP 250SMA 4 EExd IIB T4 B3

3492820

IEC 60034-1

LV Motors, Vaasa, Finland

ABB Oy, Electrical Machines

5814795550Y690

Prod.code 3GJP252210-ADG138148

6315/C3

LCIE 00 ATEX 6030

415

380

660

400

D

D

50

50

D

Y

50

50

ABB

1480

1475

1475

1479

99

104

101

60

IEC 250S/M 65

S1

3 Motor

VHz r/minkW

No.

Ins.cl.

A

0.83

450 kg

0.82

0.85

0.83

0.85

55

Duty

cos

IP

LJ-20964-1 / 2001

440 D 60 1775 103 0.85

55

55

55

63

55

Motor identification

An example motor rating plate for an IEC motor is shown below.

Collect the following information:

•voltage

• nominal motor current

• nominal frequency

• nominal speed

• nominal power.

Preparing for installation 19

ACH550-01 User's Manual

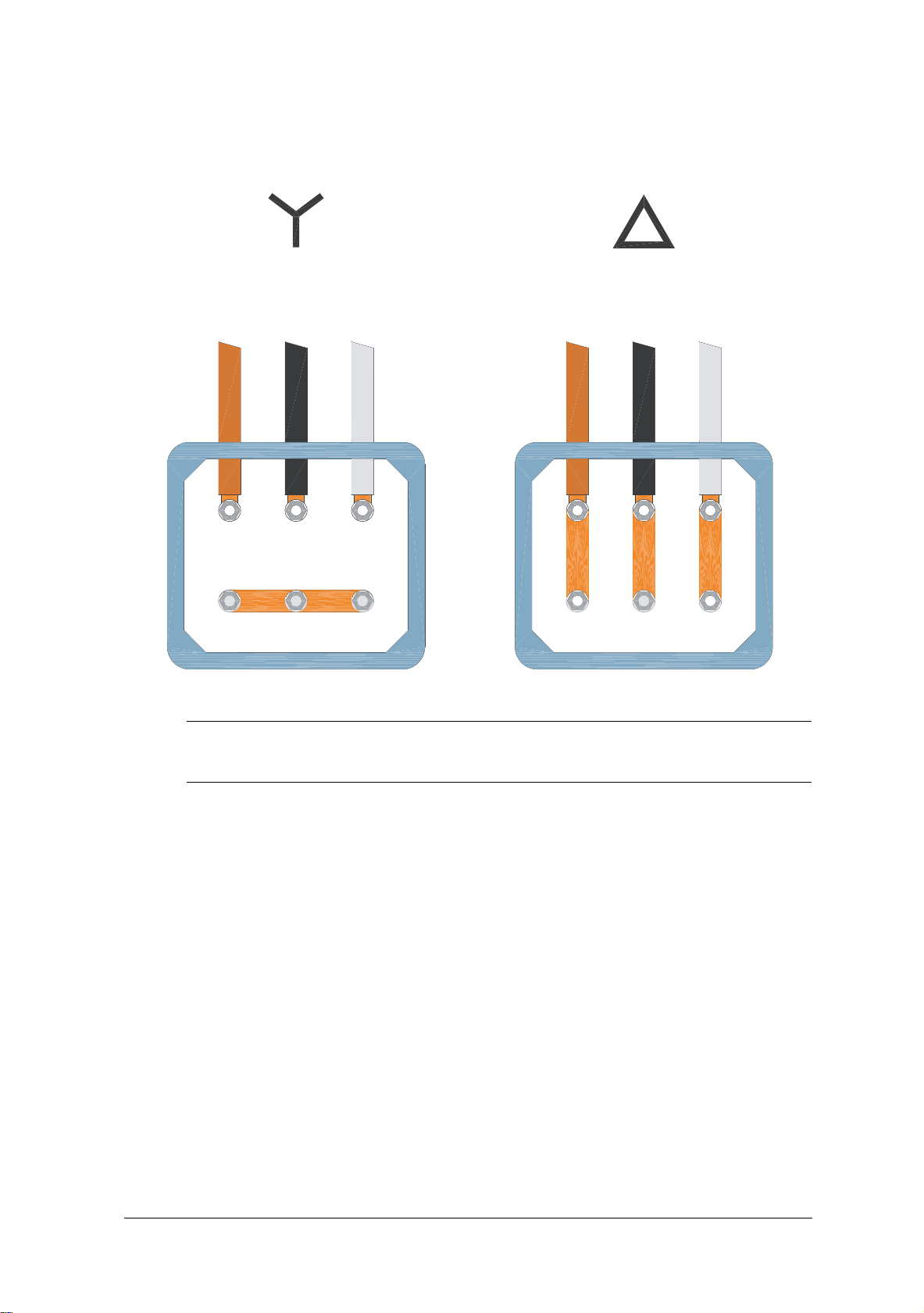

L1 L2 L3 L1 L2 L3

W2 U2 V2 W2 U2 V2

U1 V1 W1 U1 V1 W1

The figure below shows a motor with star and delta connections.

For the highlighted row of the example motor rating plate on

page 19, the connection is delta.

Note: Check which connection is correct for your motor type.

20 Preparing for installation

ACH550-01 User's Manual

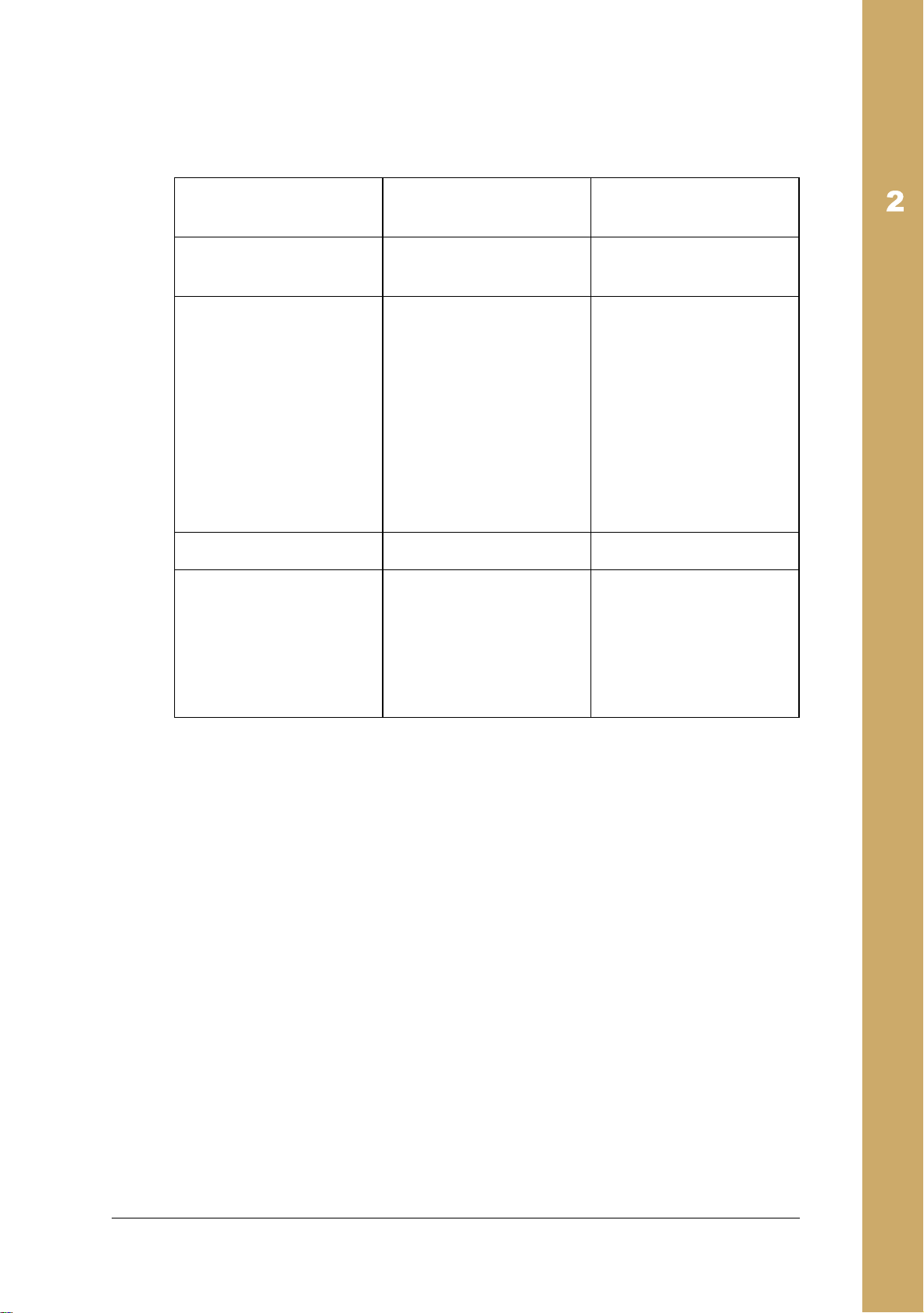

Motor compatibility

The motor, drive and supply power must be compatible:

Motor

specification

Motor type 3-phase induction

motor

Nominal current type dependent • type designation

Nominal frequency 10…500 Hz Voltage range Motor requirement

and supply voltage

are both 3-phase

voltage and are

within the ACH550

voltage range.

Verify Reference

-

label on drive,

entry for “Output

I2N” (current), or

• type designation

on drive and

rating table in

Ratings in

chapter

Technical data.

208…240 V

380…480 V

Preparing for installation 21

ACH550-01 User's Manual

Suitable environment and enclosure

Confirm that the site meets the environmental requirements. To

prevent damage prior to installation, store and transport the

drive according to the environmental requirements specified for

storage and transportation. See section Ambient conditions on

page 434.

Confirm that the enclosure (degree of protection) is appropriate,

based on the site containment level:

• IP21 type enclosure. The site must be free from airborne

dust, corrosive gases or liquids, and conductive

contaminants such as dripping water, condensation, carbon

dust, and metallic particles.

• IP54 type enclosure. This enclosure provides protection from

airborne dust and light sprays or splashing water from all

directions.

Compared to the IP21 enclosure, the IP54 enclosure has:

• the same internal plastic shell as the IP21 enclosure

• a different outer plastic cover

• an additional internal fan to improve cooling

• larger dimensions

• the same rating (does not require a derating).

If, for some reason, an IP21 drive needs to be installed without

the conduit box or cover, or an IP54 drive without the conduit

plate or top cover, see the note on page 437.

22 Preparing for installation

ACH550-01 User's Manual

R1…R6

IP21 & IP54: 200 mm [8 in]

IP21 & IP54: 200 mm [8 in]

IP21 & IP54: 0 mm [0 in]IP21 & IP54: 0 mm [0 in]

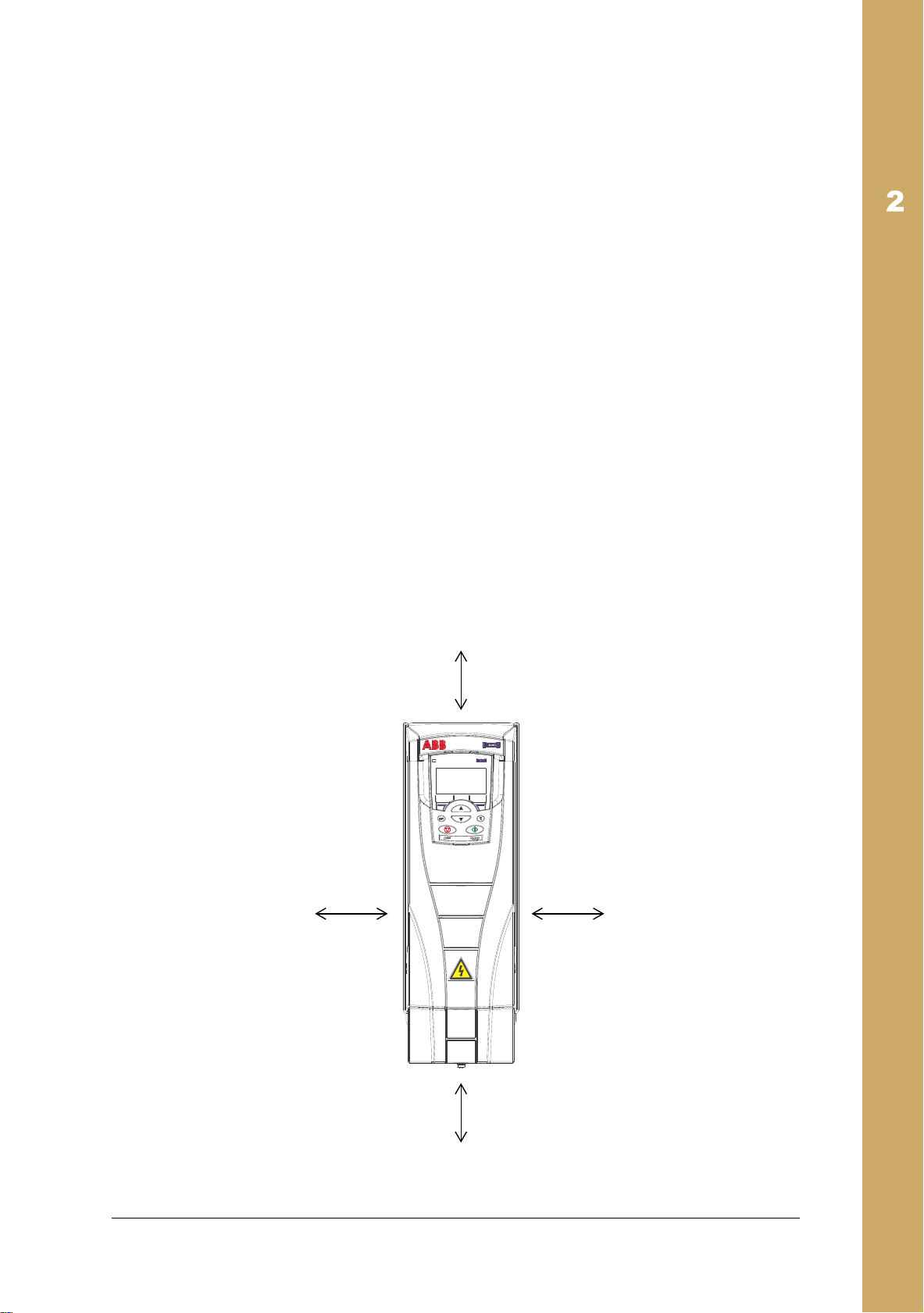

Suitable mounting location

Confirm that the mounting location meets the following

constraints:

• The drive must be mounted vertically on a smooth,

non-flammable, solid surface or frame, and in a suitable

environment as defined in section Suitable environment and

enclosure on page 22.

• For horizontal installation, contact ABB for more information

(see page 441).

Mounting on a machine frame is also possible. No additional

plates are needed for cooling as the drive has an integral

heatsink backplate.

See section Mounting dimensions on page 415 for mounting

dimensions for all frame sizes and protection types.

The figure below shows the necessary free space for the

installation of the unit.

Preparing for installation 23

ACH550-01 User's Manual

200 mm

200 mm

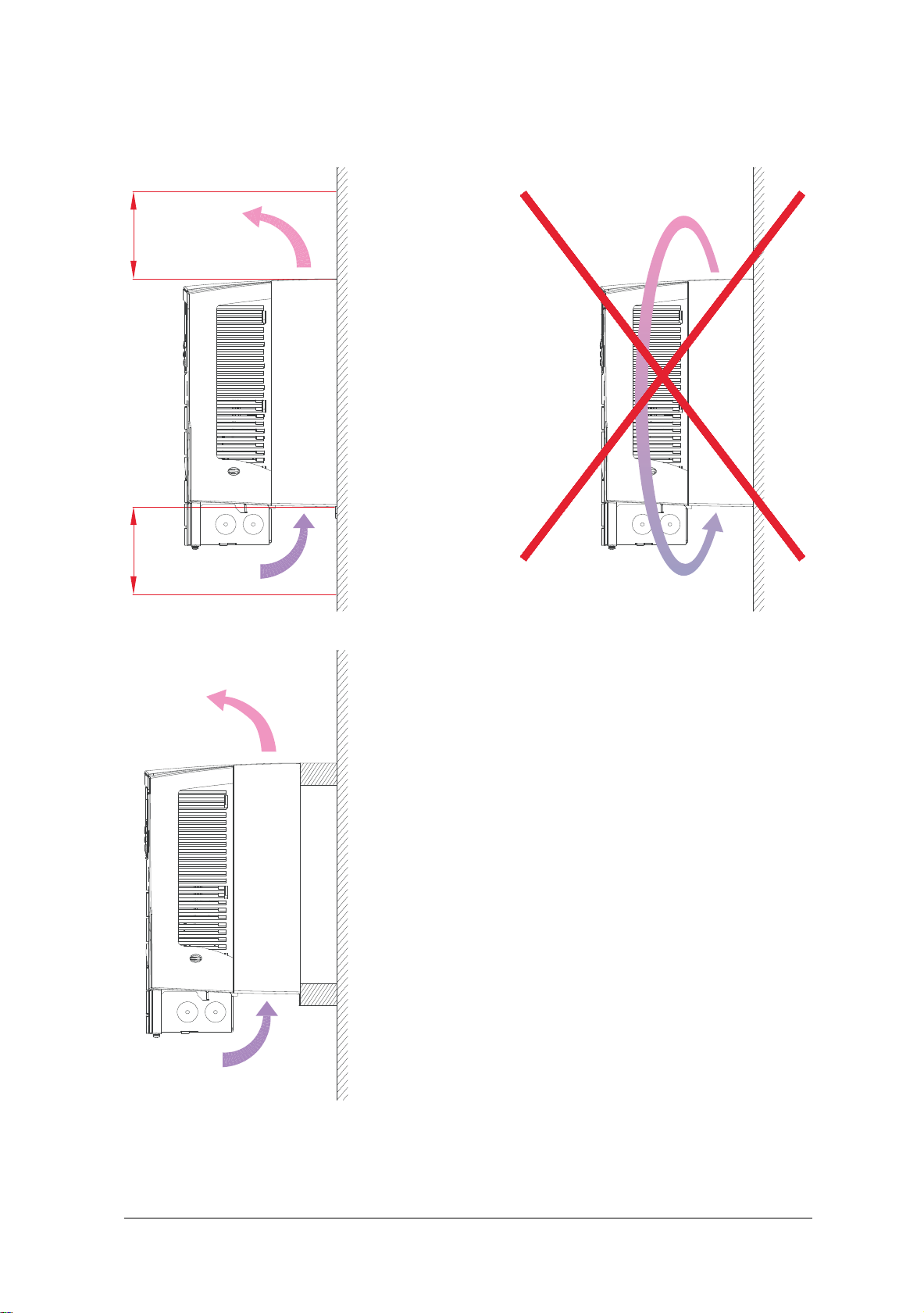

Make sure that the hot air does not re-circulate into the drive.

The figure below show the minimum space for cooling air.

24 Preparing for installation

ACH550-01 User's Manual

200 mm

200 mm

200 mm

200 mm

Stop the hot air from a drive from entering the cooling air intake

of another drive with an adequate mechanical obstacle between

the drives. The figure below shows the minimum space for

cooling air.

Preparing for installation 25

Wiring and EMC considerations

Determine electro-magnetic compliance (EMC) requirements

per local codes. In general:

• Follow local codes for cable size.

• Keep these three classes of wiring separated: input power

wiring, motor wiring and control/communications wiring.

• Check the operational limits for the allowed maximum motor

cable length in section Motor connection on page 404.

• If the installation must meet the European EMC Directive

requirements (see section Compliance with the IEC/

EN 61800-3 (2004) on page 438), check also the EMC limits

for the allowed maximum motor cable length in section Motor

connection on page 404.

Note: Non-proper wiring is the source of the majority of EMC

problems. Please follow the instructions to avoid these

problems.

ACH550-01 User's Manual

26 Preparing for installation

Loading...

Loading...