ABB ACH550 Instruction Manual

ACH550

Installation, Operation and Maintenance Manual (I, O & M)

ACH550-UH HVAC Drives (1

ACH550-BCR/BDR/VCR/VDR E-Clipse Bypass Drives (1

…550 HP)

…400 HP)

ACH550-PCR/PDR Packaged Drives with Disconnect (1

…550 HP)

2 ACH550 Installation, Operation and Maintenance Manual

Safety

Use of warnings and notes

There are two types of safety instructions throughout this manual:

• Notes draw attention to a particular condition or fact, or give information on a

subject.

• Warnings caution you about con ditions whic h can result in serious injury or death

and/or damage to the equipment. They also tell you how to avoid the danger . The

warning symbols are used as follows:

Electricity warning warns of hazards

from electricity which can cause

physical injury and/or damage to the

equipment.

• WARNING! The ACH550 adjustable speed

AC drive should ONLY be installed by a

qualified electrician.

• WARNING! Even when the motor is

stopped, dangerous voltage is present at the

power circuit terminals U1, V1, W1 (L1, L2,

L3) and U2, V2, W2 (T1, T2 T3) and,

depending on the frame size, UDC+ and

UDC-, or BRK+ and BRK-.

• WARNING! Dangerous voltage is present

when input power is connected. After

disconnecting the supply, wait at least 5

minutes (to let the intermediate circuit

capacitors discharge) before removing the

cover.

• WARNING! Even when power is switched

off from the input terminals of the ACH550,

there may be dangerous voltage (from

external sources) on the terminals of the

relay outputs.

• WARNING! When the control terminals of

two or more drives are connected in parallel,

the auxiliary voltage for these control

connections must be taken from a single

source which can either be one of the drives

or an external supply.

• WARNING! Disconnect the internal EMC

filter when installing the drive on an IT

system (an ungrounded power system or a

high-resistance-grounded [over 30 ohm]

power system).

• WARNING! Do not attempt to install or

remove EM1, EM3, F1 or F2 screws while

power is applied to the drive’s input

terminals.

General warning warns about

conditions, other than those caused

by electricity, which can result in

physical injury and/or damage to the

equipment.

• WARNING! Do not control the motor with

the disconnecting device (disconnecting

means); instead, use the control panel keys

or commands via the I/O board of the drive.

The maximum allowed number of charging

cycles of the DC capacitors (i.e. power-ups

by applying power) is five in ten minutes.

• WARNING! Never attempt to repair a

malfunctioning ACH550; contact the factory

or your local Authorized Service Center for

repair or replacement.

• WARNING! The ACH550 will start up

automatically after an input voltage

interruption if the external run command is

on.

• WARNING! The heat sink may reach a high

temperature.

Note: For more technical information, contact

the factory or your local ABB representative.

Safety

ACH550 Installation, Operation and Maintenance Manual 3

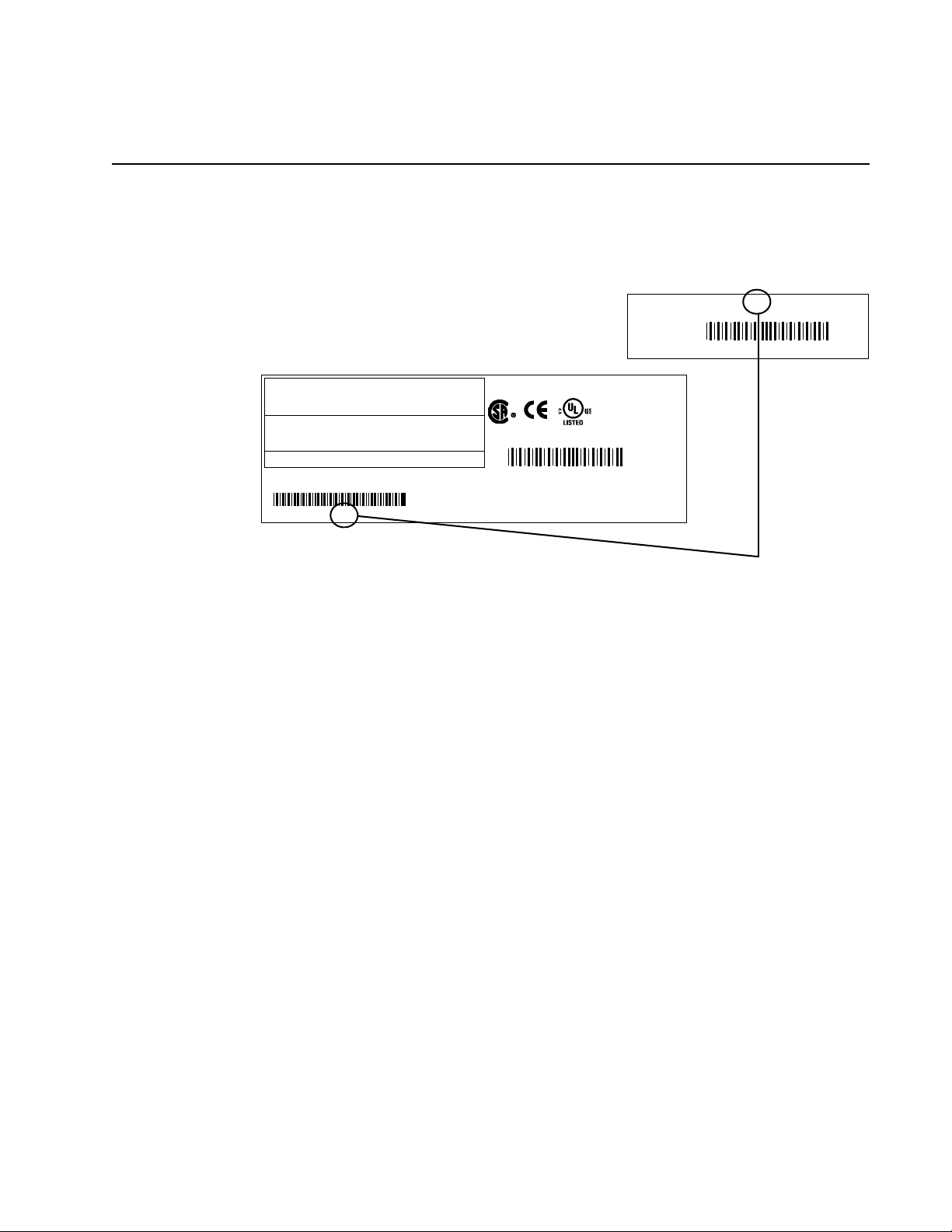

S/N

ACH550-UH-059A-2

2030700001

SW:

V.2.06B

2030700001

Input

Voltage (U1)

Current (I1n)

3 PH 48…63 Hz

200…240 Vac

59.4 A

1 PH 4…63 Hz

200…240 Vac

59.4 A

Output

Voltage (U2)

Current (I2n)

3 PH 0…500 Hz

0…U1 Vac

59.4 A

3 PH 0…500 Hz

0…U1 Vac

28 A

ACH550-UH-059A-2

Power (Pn)

Mfg. Date: 01-December-2005

Org. Firmware: V.2.06B

ABB Inc.

Made in USA of foreign parts

10 HP20 HP

kAIC

S/N

2030700001

Construction

code

Contents

This manual is the Operation and Maintenance Manual for the ACH550 Drives.

Complete technical details and programming information are available in the

ACH550 User’s Manual, publication number 3AUA0000081823.

1. To determine the type of your drive, refer to its construction code on either:

• Serial number label attached on upper part of

the chokeplate between the mounting holes.

• Type code label attached on the heat sink – on

the side of the enclosure.

ACH550 Installation, Operation and Maintenance Manual 39

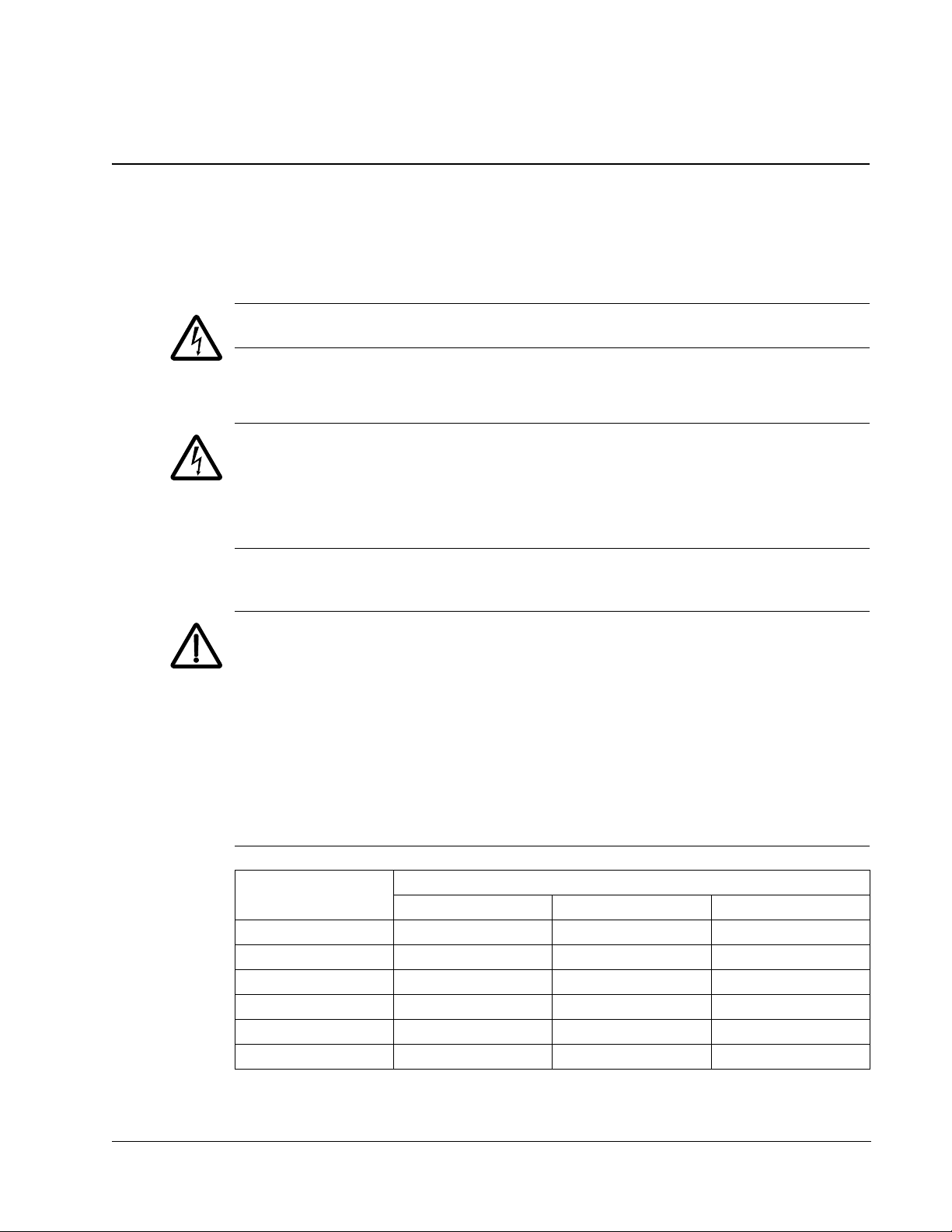

ACH550 E-Clipse Bypass

Installation – drive

Follow the Installation instructions for the drive on page 3. Failure to observe the

warnings and instructions may cause a malfunction or personal hazard.

WARNING! Before you begin read Safety on page 2.

Installation – bypass

WARNING! When the ACH550 with E-Clip se Byp ass is connected to the line power,

the Motor Terminals T1, T2, and T3 are live even if the motor is not running. Do not

make any connections when the ACH550 with E-Clipse Bypass is connected to the

line. Disconnect and lock out power to the drive before servicing the drive. Failure to

disconnect power may cause serious injury or death.

1. Install wiring – bypass

WARNING!

• Do not connect or disconnect input or output power wiring, or control wires, when

power is applied.

• Never connect line voltage to drive output Terminals T1, T2, and T3.

• Do not make any voltage tolerance tests (Hi Pot or Megger) on any part of the

unit. Disconnect motor wires before taking any measurements in the motor or

motor wires.

• Make sure that power factor correction capacitors are not connected between the

drive and the motor.

Enclosure

Designation

V1/V2 1 to 7.5 HP 1 to 15 HP 2 to 15 HP

V3/V4 10 to 25 HP 20 to 60 HP 20 to 60 HP

B1 1 to 7.5 HP 1 to 15 HP 2 to 15 HP

B2 10 to 25 HP 20 to 60 HP 20 to 60 HP

B3 30 to 100 HP 75 to 200 HP 75 to 150 HP

B4 N/A 250 to 550 HP N/A

208/240V 480V 600V

Horsepower Range by Voltage Rating

ACH550 E-Clipse Bypass

40 ACH550 Installation, Operation and Maintenance Manual

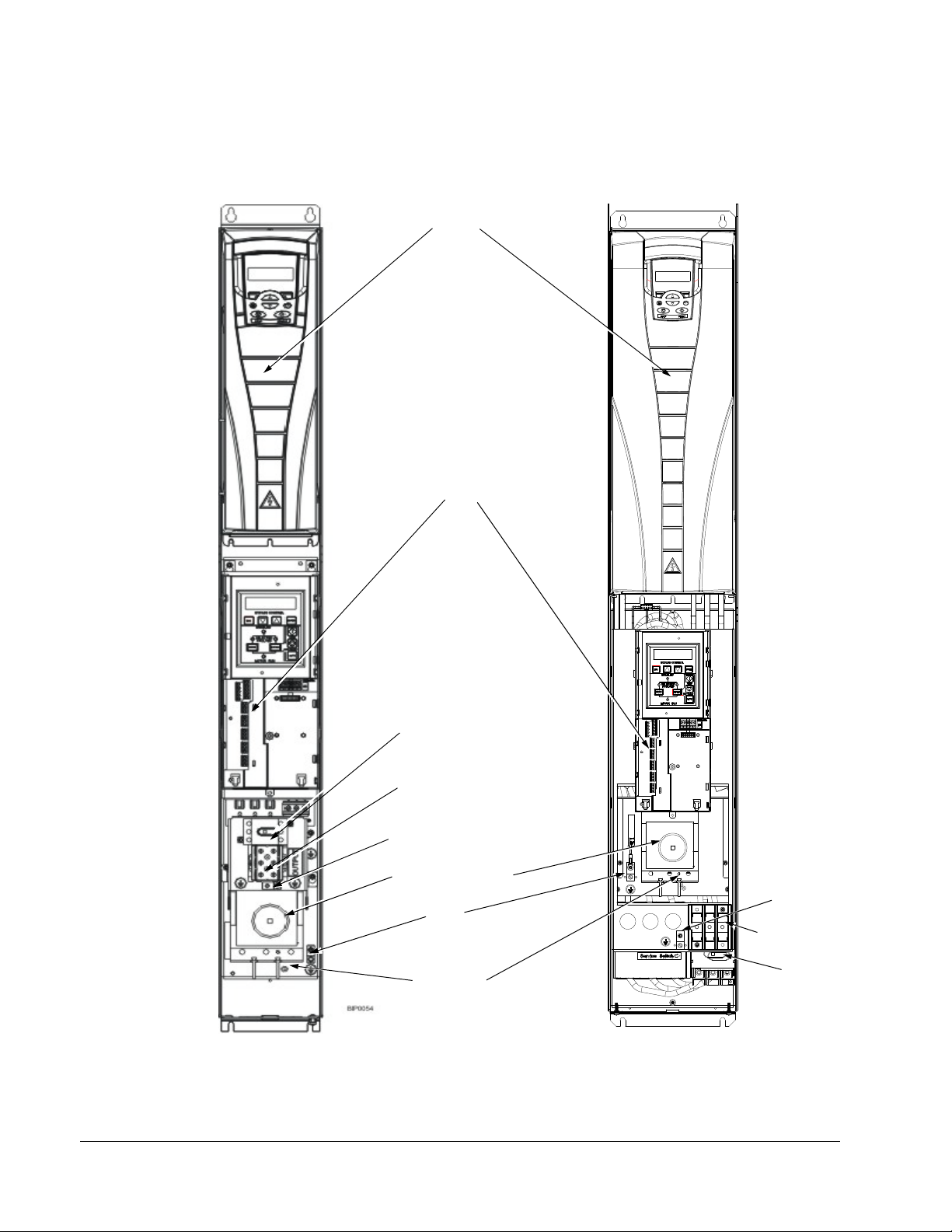

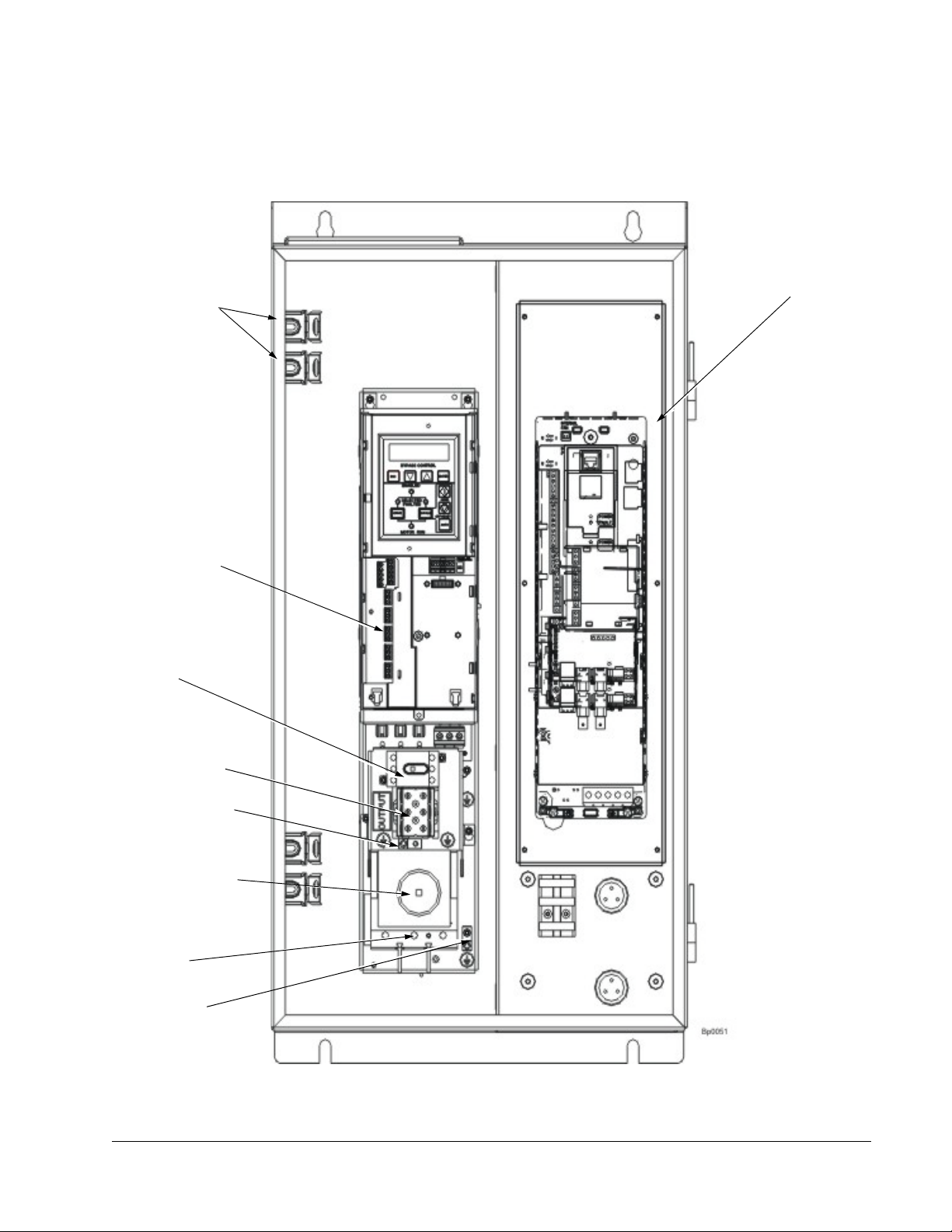

BP0054

ACH550

E-Clipse Bypass

Control Board

Terminals (X2)

Disconnect Switch

or Circuit Breaker

Output

Input Power

Output Ground

Lug(s)

Cable

Terminals

Output

Ground Lug(s)

Output

Terminals

V1/V2

V3/V4

Service Switch

(Optional)

Input

Ground Lug

Terminals

Service Switch

(Optional)

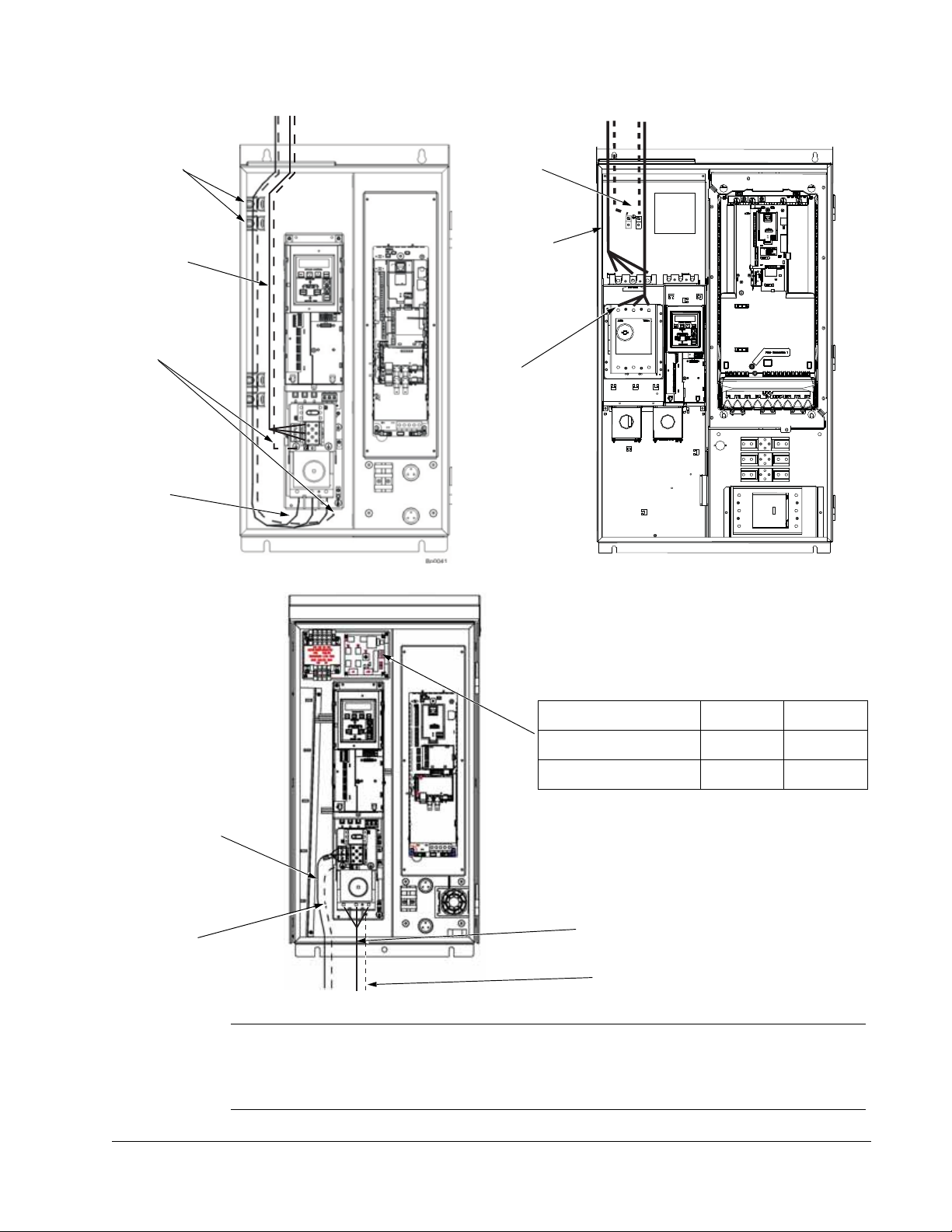

Connection diagrams – Vertical E-Clipse Bypass

ACH550 Vertical E-Clipse Bypass units are configured for wiring access from the

bottom only. The following figure shows the Vertical E-Clipse Bypass wiring

connection points.

ACH550 E-Clipse Bypass

ACH550 Installation, Operation and Maintenance Manual 41

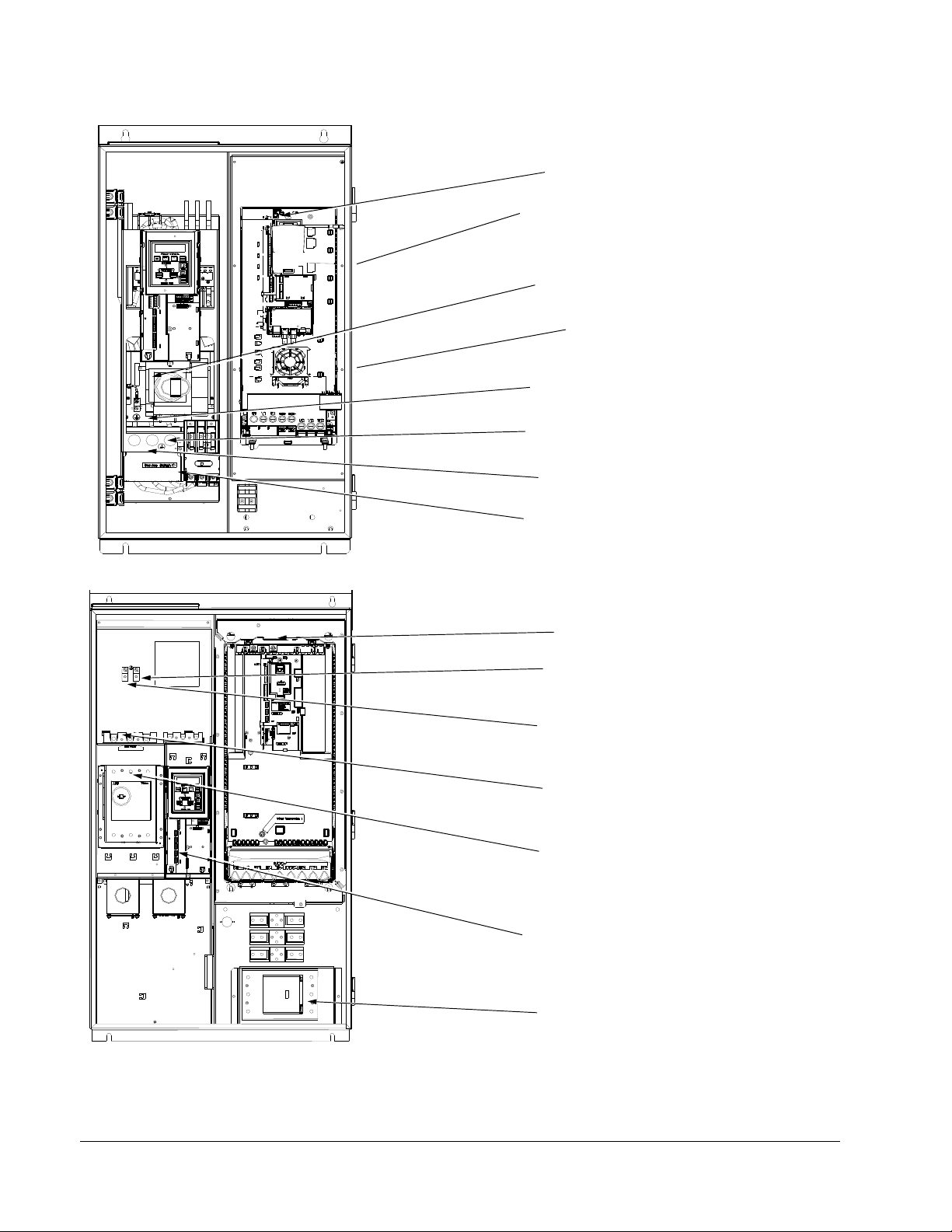

ACH550

Motor

Input Power

Output Ground

Terminals

Terminals

Disconnect Switch

or Circuit Breaker

B1

Service Switch

(Optional)

E-Clipse Bypass

Control Board

Terminals X2

User Power

Cable Guides

Input Ground

Lug(s)

Lug

Connection diagrams – Standard E-Clipse Bypass (wall mounted)

ACH550 Standard E-Clipse Bypass units are configured for wiring access from the

top. The following figure shows the St anda rd E-Clip se Bypass (wall mounted) wiring

connection points.

ACH550 E-Clipse Bypass

42 ACH550 Installation, Operation and Maintenance Manual

B3

ACH550 Drive

E-Clipse Bypass

Control Board

Terminals (X2)

Input Ground Lug

Input Power

Terminals

Motor Terminals

Output Ground Lug

Service Switch

(optional)

B2

ACH550 Drive

Cable Guides

E-Clipse Bypass

Control Board

Terminals (X2)

Disconnect Switch

or Circuit Breaker

Input Ground Lug

Input Power

Terminals

Motor Terminals

Output Ground Lug

Service Switch

(optional)

User Power

ACH550 E-Clipse Bypass

ACH550 Installation, Operation and Maintenance Manual 43

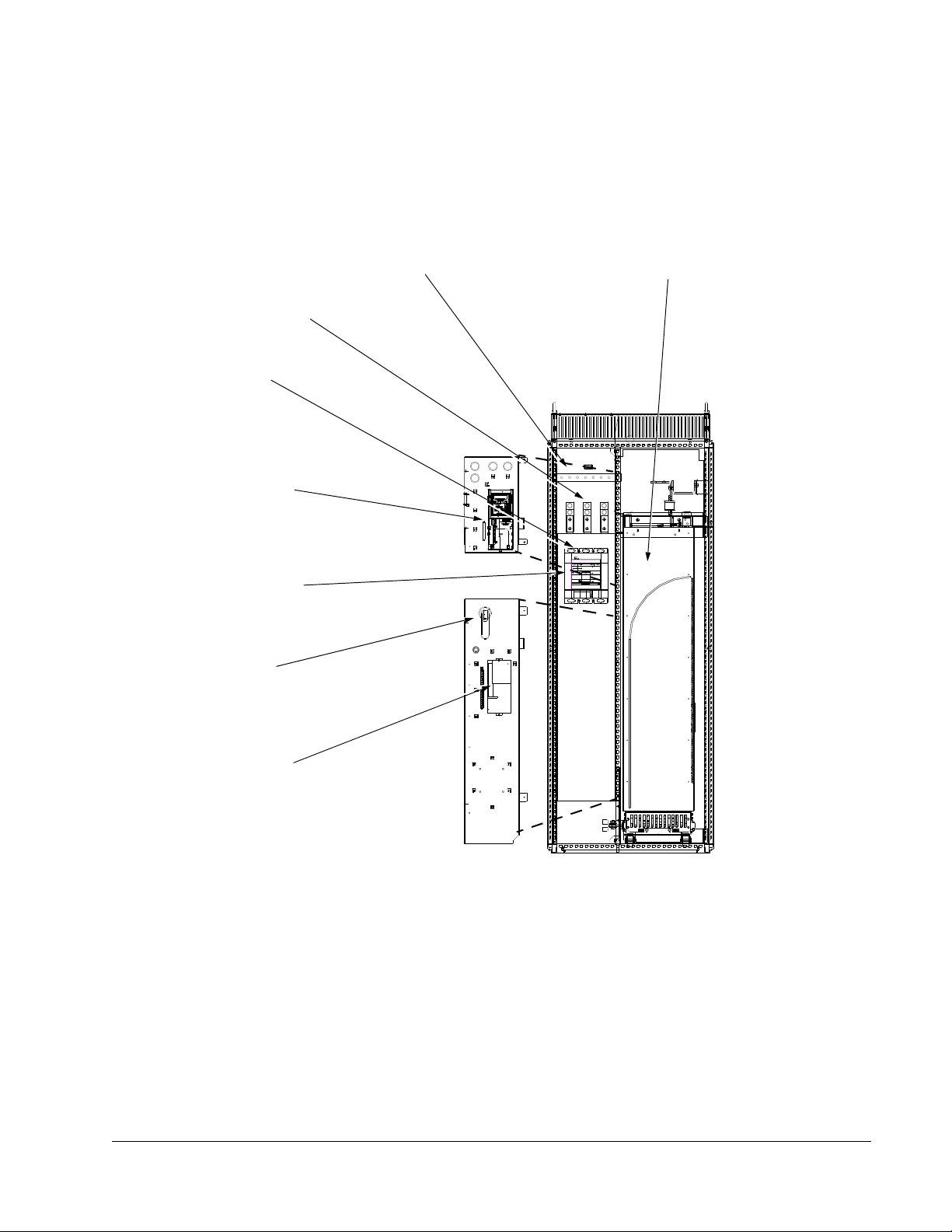

B4

ACH550 Drive

E-Clipse Bypass

Control Board

Terminals ( x2)

Disconnect Switch

or Circuit Breaker

Ground Lug Bar

Input Power

Terminals

Motor Terminals

Service Switch

(optional)

ACH550

Control Board

Terminals ( x1)

Connection diagrams – Standard E-Clipse Bypass (R8, floor mounted)

ACH550 Standard E-Clipse Bypass units are configured for wiring access from the

top. The following figure shows the S ta ndard E-Clipse Byp ass (floor mounted) wiring

connection points.

ACH550 E-Clipse Bypass

44 ACH550 Installation, Operation and Maintenance Manual

Ground

Ground

Input Power

Cables

Motor

Cables

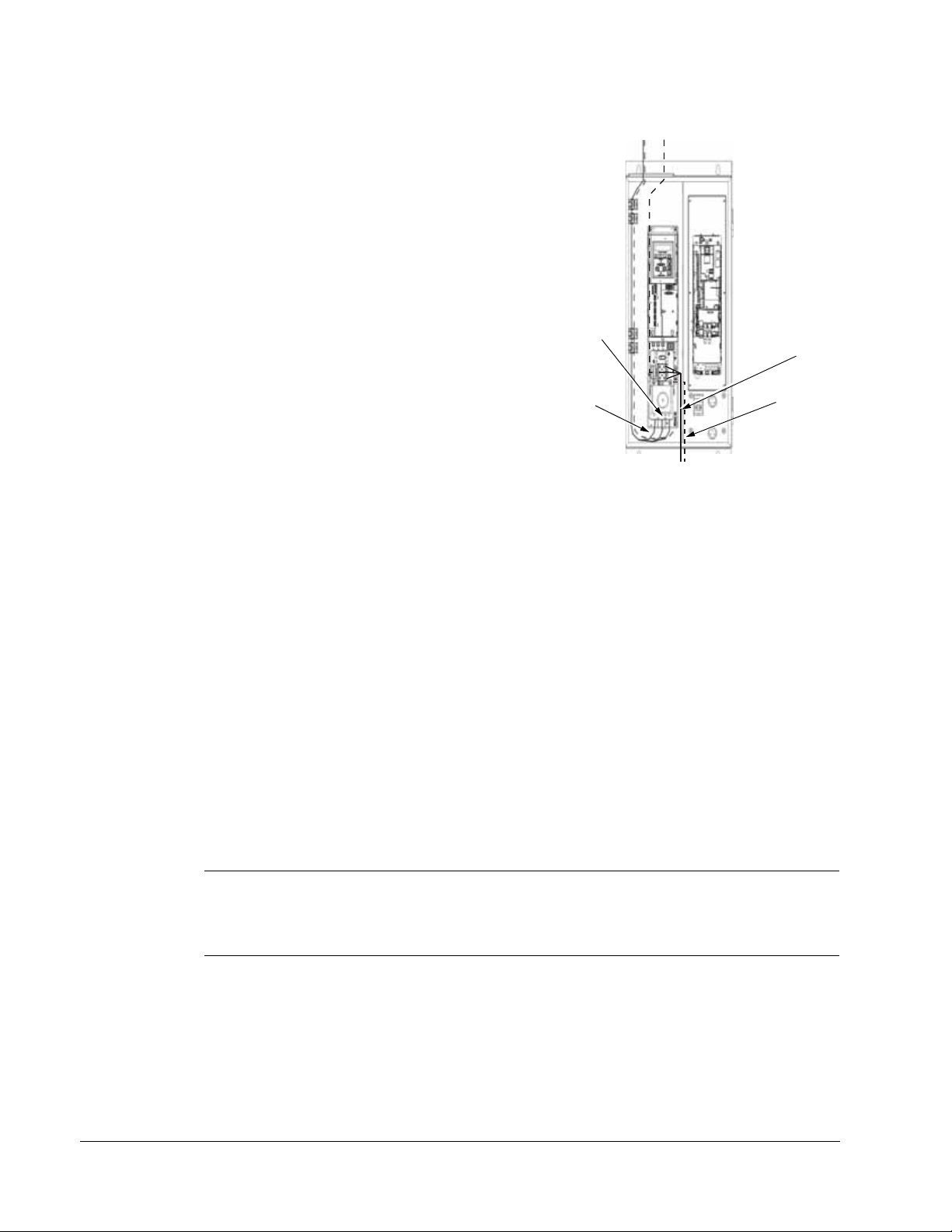

Power connections – Vertical E-Clipse Bypass configurations

Line input connections

Connect the input power to the terminals

at the bottom of the disconnect switch or

circuit breaker as shown below. Also see

Connection diagrams – Vertical E-Clipse

Bypass on page 40. Connect the

equipment grounding conductor to the

ground lug near the input power

connection point.

Motor connections

Connect the motor cables to the terminals

at the bottom of the bypass section as

shown in the figure. Also see Connection

diagrams – Vertical E-Clipse Bypass on

page 43. Connect the motor grounding

conductor to the ground lug near the

motor cable terminal block connection

point.

Power connections – Standard E-Clipse Bypass configurations (wall mounted)

Line input connections

Connect input power to the terminals of the disconnect switch or circuit breaker.

Connect the equipment grounding conductor to the ground lug at the top of the

enclosure. The figure below shows the connection points for Standard E-Clipse

Bypass configurations. Also see Connection diagrams – Standard E-Clipse Bypass

(wall mounted) on page 41 and Connection diagrams – Standard E-Clipse Bypass

(R8, floor mounted) on page 43.

Motor connections

Connect the motor cables to the output terminal block as shown in the figure below.

Also see Connection diagrams – St andard E-Clipse Bypass (wall mounted) on page

41 and Connection diagrams – Standard E-Clipse Bypass (R8, floor mounted) on

page 43. The motor grounding conductor can be connected to the ground lug near

the terminal block.

Note: Route cables through the cable guides on the left side of the enclosure. Use

separate conduits for input power and motor cables. Follow the guides to separate

the cables from each other.

ACH550 E-Clipse Bypass

ACH550 Installation, Operation and Maintenance Manual 45

Standard Configuration (B3)

Input

Ground

Standard Configuration (B1/B2)

Power

Cables

User Power

Cable Guides

Motor

Cables

Ground

Motor

Cables

Input Power

Cables

Ground

UL Type 3R Configuration (B1/B2)

Motor Cables

Ground

Input Power

Cables

RHTR Temperature

HI / LO Jumper (X1)

Heater ON

Temperature

Heater OFF

Temperature

Default Setting

(X1 jumper in LO position)

14.4 °C

58 °F

21.4 °C

70.5 °F

Alternate Setting

(X1 jumper in HI position)

17.8 °C

64 °F

24.7 °C

76.5 °C

The alternate (HI) setting further reduces the likelihood

of condensate in high humidity environments.

Note: UL Type 3R, B1/B2 enclosures are designed to be mounted on a wall.

Mounting these 3R enclosures on an open rack system requires the use of the

supplied 3R enclosure back plates to maintain 3R integrity.

ACH550 E-Clipse Bypass

46 ACH550 Installation, Operation and Maintenance Manual

WARNING! Check the motor and motor wiring insulation before connecting the

ACH550 to line power . Follow the procedure on page 12. Before proce eding with the

insulation resistance measurements, check that the ACH550 is disconnected from

incoming line power. Failure to disconnect li ne power could result in death or serious

injury.

Install the control wiring

Connect control wiring to terminal block X1 on the ACH550 control board and to

terminal block X2 on the E-Clipse Bypass control board. For more information on

these connections, refer to the following:

• X1 terminal block location and terminal data are defined in the ACH550-UH

User’s Manual.

• X2 terminal block location is illustrated in the figures starting with Connection

diagrams – Vertical E-Clipse Bypass on page 40.

• X2 terminal data are provided in Basic control connections for E-Clipse HVAC

Default on page 53.

• Basic connections are described in the following paragraphs. Alternate

configurations using the E-Clipse Bypass macro are described in the ACH550

User’s Manual.

• On Terminal Block X1 inside the ACH550, analog inputs and outputs and

additional digital input and relay output connections (AI1, AI2, AO1, AO2,

DI1…DI6 and RO1…RO6) are available for use.

Note: The E-Clipse Bypass control circuitry uses serial communications connections

(X1:28…X1:32) inside the ACH550. These connections are not available for any

other purpose and must not be reconfigured.

ACH550 E-Clipse Bypass

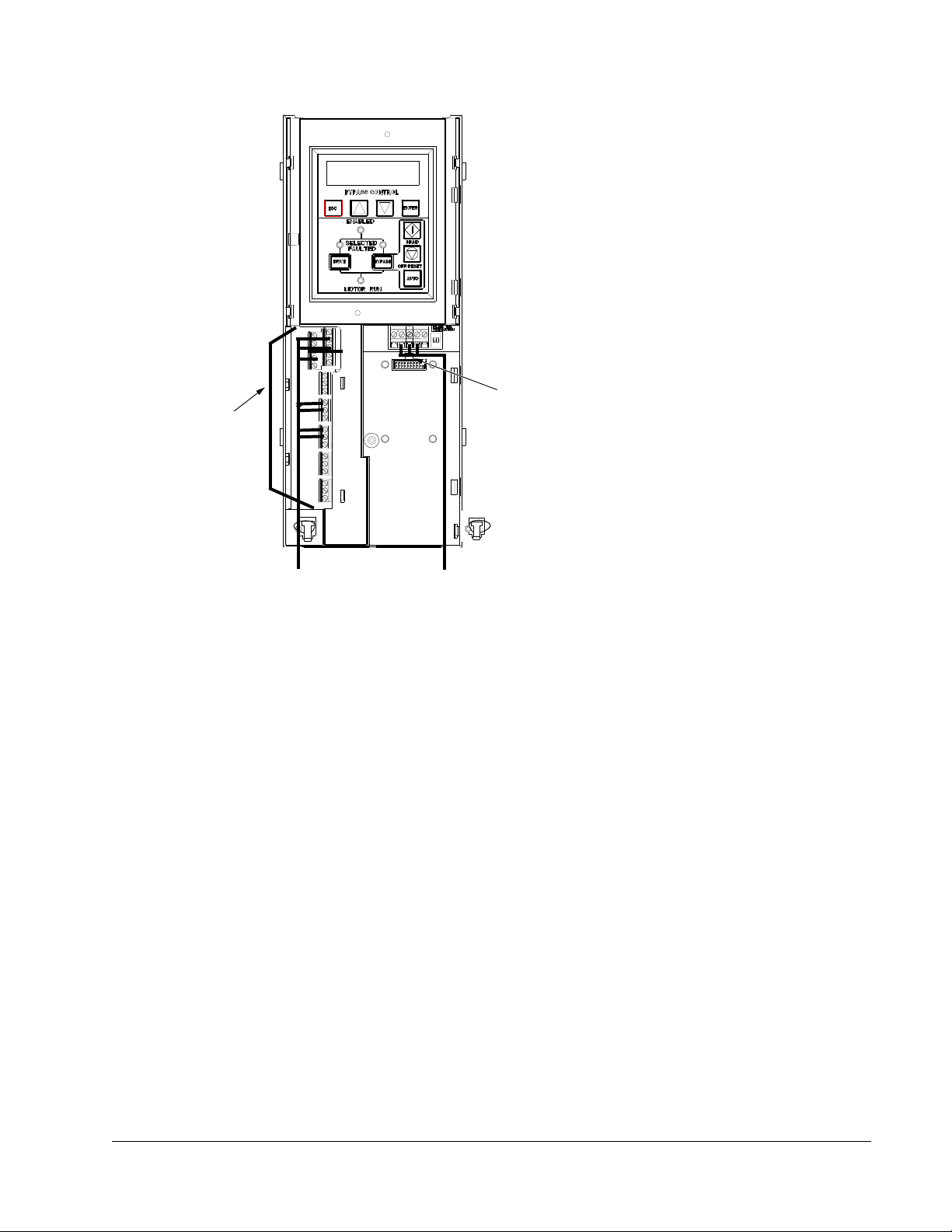

ACH550 Installation, Operation and Maintenance Manual 47

EIA-485

port

control

terminals

Digital I/O

control

terminals

Basic connections

The figure on page 53 shows the basic

control connections for use with the EClipse Bypass HVAC Default macro.

These connections are described in the

following paragraphs.

In typical installations, only analog input

wires connect to the ACH550 terminal

block, with other control connections

made on the E-Clipse Bypass control

board.

Use wire ties to permanently affix control/

communications wiring to the hooked wire

race tie points provided, maintaining a

minimum 6 mm (1/4") spacing from power

wiring.

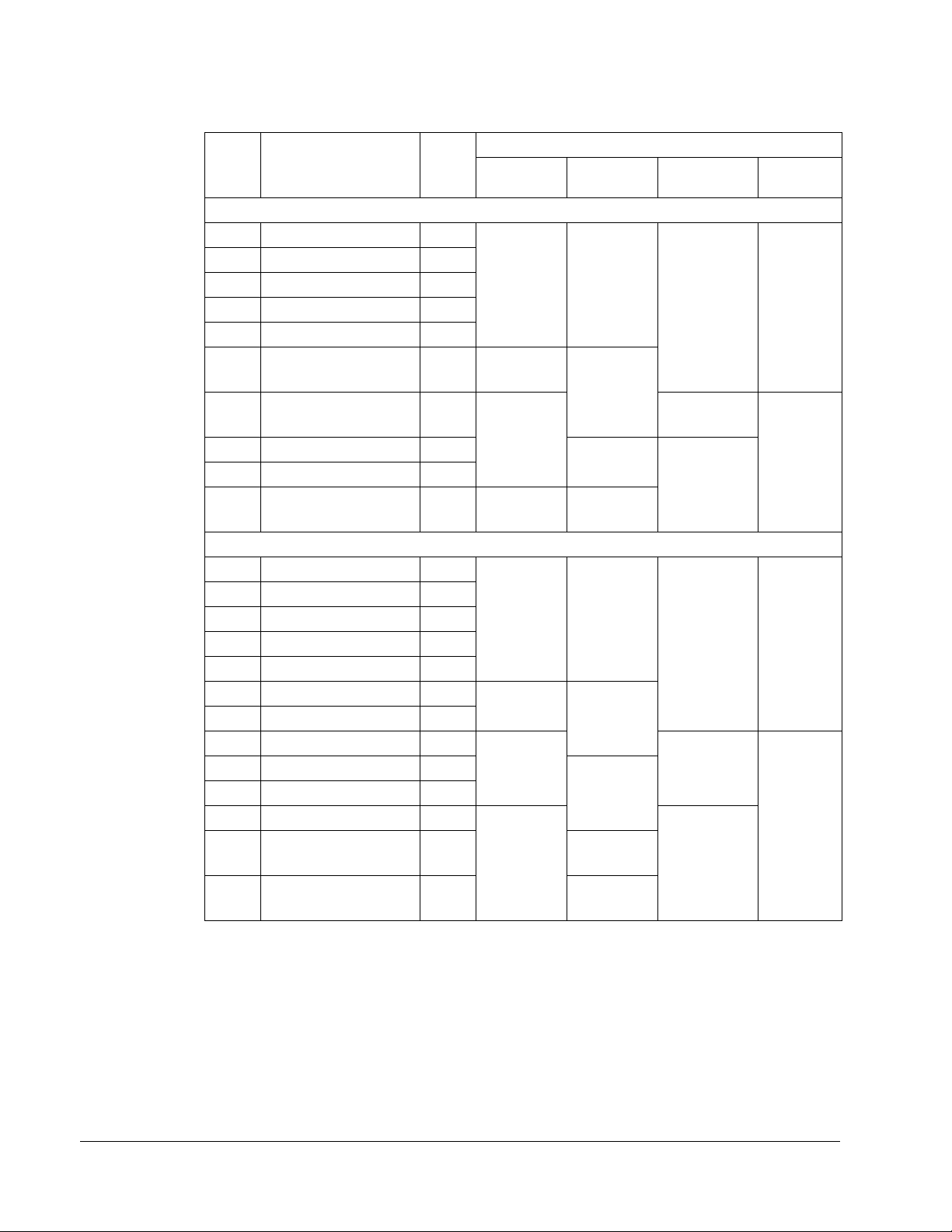

Drive’s power connection terminals

The following tables list power and motor cable terminal sizes for connections to an

input circuit breaker or disconnect switch, a motor terminal block and ground lugs.

The tables also list torque that should be applied when tightening the terminals.

ACH550 E-Clipse Bypass

48 ACH550 Installation, Operation and Maintenance Manual

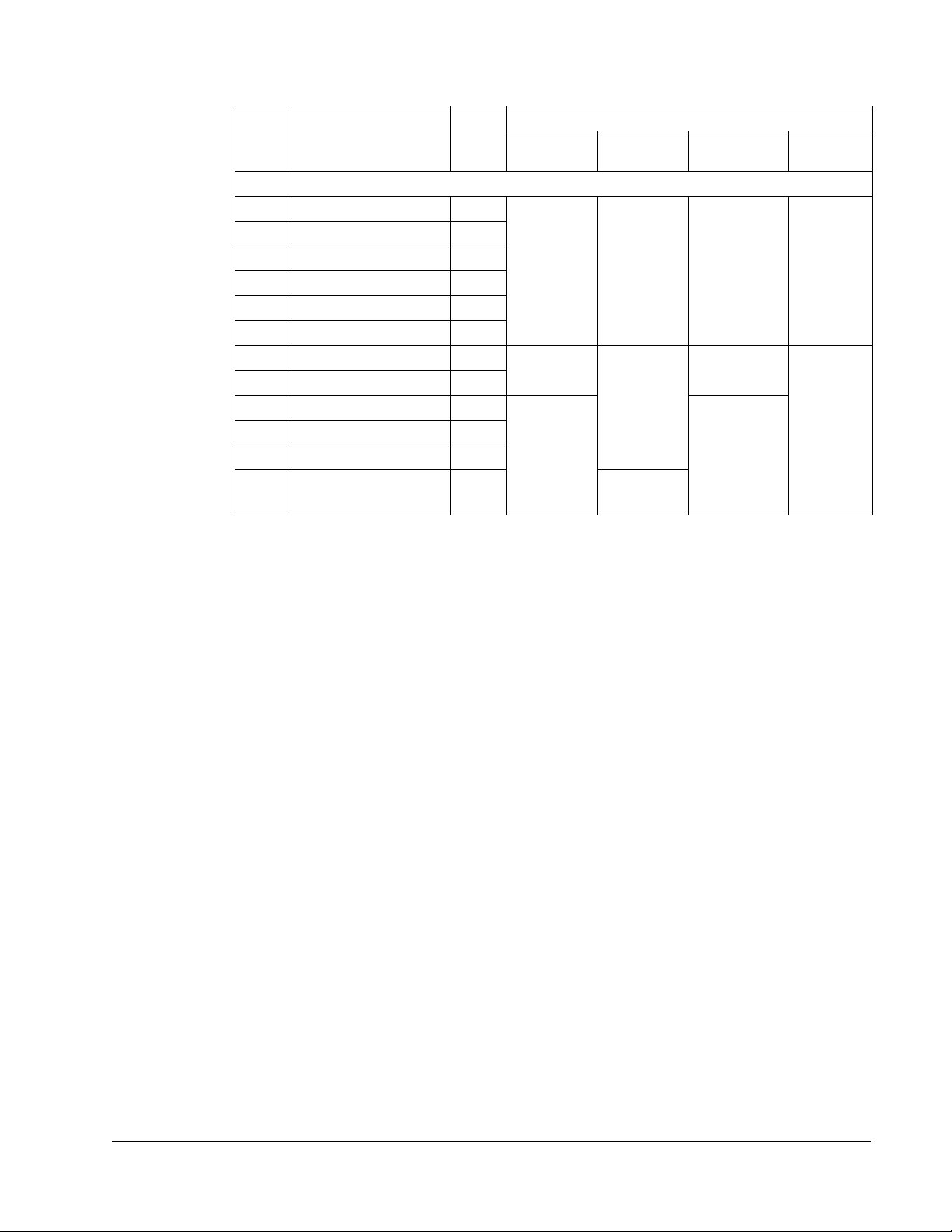

Vertical enclosure terminals

HP Identification

1 ACH550-VxR-04A6-2 R1

1.5 ACH550-VxR-06A6-2 R1

2 ACH550-VxR-07A5-2 R1

3 ACH550-VxR-012A-2 R1

5 ACH550-VxR-017A-2 R1

7.5 ACH550-VxR-024A-2 R2

10 ACH550-VxR-031A-2 R2

15 ACH550-VxR-046A-2 R3

20 ACH550-VxR-059A-2 R3

25 ACH550-VxR-075A-2 R4

1/1.5 ACH550-VxR-03A3-4 R1

2 ACH550-VxR-04A1-4 R1

3 ACH550-VxR-06A9-4 R1

5 ACH550-VxR-08A8-4 R1

7.5 ACH550-VxR-012A-4 R1

10 ACH550-VxR-015A-4 R2

15 ACH550-VxR-023A-4 R2

20 ACH550-VxR-031A-4 R3

25 ACH550-VxR-038A-4 R3

30 ACH550-VxR-045A-4 R3

40 ACH550-VxR-059A-4 R4

50 ACH550-VxR-072A-4 R4

60 ACH550-VxR-078A-4 R4

Frame

Size

Maximum Wire Size Capacities of Power Terminals

Circuit

Breaker

208…240 Volt

#10

35 in-lbs

#8

40 in-lbs

#2

50 in-lbs

#1

50 in-lbs

380…480 Volt

#10

35 in-lbs

#8

40 in-lbs

#3

50 in-lbs

#1

50 in-lbs

Disconnect

Switch

#10

7 in-lbs

#8

7 in-lbs

#4

18 in-lbs

#1

55 in-lbs

#10

7 in-lbs

#8

7 in-lbs

#4

18 in-lbs

#1

55 in-lbs

#1

70 in-lbs

Motor

Termination

#6

30 in-lbs

#2

50 in-lbs

#2/0

120 in-lbs

#6

30 in-lbs

#2

50 in-lbs

#2/0

120 in-lbs

Ground

Lugs

35 in-lbs

50 in-lbs

35 in-lbs

50 in-lbs

#4

#2

#4

#2

ACH550 E-Clipse Bypass

ACH550 Installation, Operation and Maintenance Manual 49

HP Identification

2 ACH550-VxR-02A7-6 R2

3 ACH550-VxR-03A9-6 R2

5 ACH550-VxR-06A1-6 R2

7.5 ACH550-VxR-09A0-6 R2

10 ACH550-VxR-011A-6 R2

15 ACH550-VxR-017A-6 R2

20 ACH550-VxR-022A-6 R3

25 ACH550-VxR-027A-6 R3

30 ACH550-VxR-032A-6 R4

40 ACH550-VxR-041A-6 R4

50 ACH550-VxR-052A-6 R4

60 ACH550-VxR-062A-6 R4

Frame

Size

Maximum Wire Size Capacities of Power Terminals

Circuit

Breaker

500…600 Volt

#8

62 in-lbs

#4

62 in-lbs

#1

62 in-lbs

Disconnect

Switch

#4

18 in-lbs

#1

55 in-lbs

#1

70 in-lbs

Motor

Termination

#6

30 in-lbs

#2

50 in-lbs

#2/0

120 in-lbs

Ground

Lugs

35 in-lbs

50 in-lbs

#4

#2

ACH550 E-Clipse Bypass

Loading...

Loading...