ABB ACH550 Product Bulletin

Product Bulletin

ABB drives for HVAC applications

ACH550, 1 to 550 Hp

Contents

ACH550 Product Overview .......................................................2

Standard Features ....................................................................2

Available Options ......................................................................3

Specications ...........................................................................4

Drive Features - Human Interface .............................................6

Drive Features - Terminal Block Interface ..................................10

Drive Features - Communications Suite ....................................11

Drive Features - Power .............................................................12

Drive Features – Protection .......................................................14

Application Control Diagrams ...................................................15

Air Handling Unit Application Functions ....................................16

Chilled Water Pump Application Functions ................................18

Cooling Tower Application Functions ........................................20

Parameter Group Functional Descriptions .................................22

Standard Product Options ........................................................31

E-Clipse Bypass Product Options .............................................33

ACH550 Drive Pack ..................................................................36

Dimensions: ACH550-UH UL Type 1 / NEMA 1 .......................37

Dimensions: ACH550-UH UL Type 12 / NEMA 12 ....................38

Dimensions: ACH550-Vx UL Type 1 / NEMA 1 .........................39

Dimensions: ACH550-BxR UL Type 1 / NEMA 1 .......................40

Dimensions: ACH550-BxR UL Type 12 / NEMA 12 ...................41

Dimensions: ACH550-BxR UL Type 3R/ NEMA 3R ...................42

Dimensions: ACH550-Cx UL Type 1 / NEMA 1 .........................43

Dimensions: ACH550-Cx UL Type 12 / NEMA .......................... 44

Dimensions: ACH550-Cx UL Type 3R / NEMA 3R ....................45

Dimensions: ACH550-PxR UL Type 1 / NEMA 1 .......................46

Dimensions: ACH550-PxR UL Type 12 / NEMA 12 ...................47

Dimensions: ACH550-PxR UL Type 3R / NEMA 3R ..................48

ACH550 Product Bulletin | 1

ACH550 Product Overview

The ACH550 is an variable frequency AC drive designed specifically for the HVAC market that achieves the ultimate in flexible

motor control performance. Offering two modes of motor control: Scalar (V/Hz) and Sensorless Vector, the ACH550 provides

accurate speed control for any standard squirrel cage motor.

With drives ranging from 1 to 550 HP, the ACH550 series features an ‘intuitively obvious’ multi-lingual, graphic display panel that

also provides an assistant to aid users in start-up. The control panel can be mounted on the cover of the drive, or remotely, and

can upload, store, and download parameters.

The ACH550 comes equipped with an extensive library of preprogrammed HVAC application macros that, at the touch of a

button, allow rapid configuration of inputs, outputs, and parameters for specific HVAC applications to maximize convenience and

minimize start-up time.

The ACH550 can be used for the simplest to the most demanding HVAC applications. Two internal option slots can be configured

with additional relay outputs as well as a host of different communication bus adapters.

The ACH550 has a 110% short term overload rating for one (1) minute out of ten (10) and is capable of >130% short-term

overload rating for 2 seconds out of each minute. This provides the torque you need to start high inertia fan(s).

Standard Features

UL, cUL labeled, CE marked, BTL listed (BACnet Testing Lab) &

UL Plenum Rated

EMI/RFI Filter (1st Environment, Restricted Distribution)

Seismic Certification in accordance to

IBC 2000 referencing ASCE 7-98 and ICC AC156

IBC 2003 referencing ASCE 7-02 and ICC AC156

IBC 2006 referencing ASCE 7-05 and ICC AC156

Start-Up Assistants

Maintenance Assistants

Diagnostic Assistants

Real Time Clock

Includes Day, Date and Time

Operator Panel Parameter Backup (read/write)

Full Graphic and Multilingual Display

for Operator Control, Parameter Set-Up and Operating

Data Display:

Output Frequency (Hz)

Speed (RPM)

Motor Current

Calculated % Motor Torque

Calculated Motor Power (kW)

DC Bus Voltage

Output Voltage

Heatsink Temperature

Elapsed Time Meter (resettable)

KWh (reset-able)

Input / Output Terminal Monitor

PID Actual Value (Feedback) & Error

Fault Text

Warning Text

2 | ACH550 Product Bulletin

Three (3) Scalable Process Variable Displays

User Definable Engineering Units

Two (2) Programmable Analog Inputs

Six (6) Programmable Digital Inputs

Two (2) Programmable Analog Outputs

Up to six (6) Programmable Relay Outputs (Three (3) Standard)

Adjustable Filters on Analog Inputs and Outputs

Mathematical Functions on Analog Reference Signals

All Control Inputs Isolated from Ground and Power

Four (4) Resident Serial Communication Protocols

Johnson Controls N2

Siemens Buildings Technologies FLN (P1)

Modbus RTU

BACnet (MS/TP)

Input Speed Signals

Current 0 (4) to 20 mA

Voltage 0 (2) to 10 VDC

Increase/Decrease Reference Contacts (Floating Point)

Serial Communications

Start/Stop

2 Wire (Dry Contact Closure)

3 Wire (Momentary Contact)

Application of Input Power

Application of Reference Signal (PID Sleep/Wake-Up)

Serial Communications

Start Functions

Ramp

Flying Start

Premagnetization (DC brake) on Start

Automatic Torque Boost

Automatic Torque Boost with Flying Start

Standard Features

Auto Restart (Reset) – Customer Selectable and

Adjustable

Stop Functions

Ramp or Coast to Stop

Emergency Stop

DC Braking / Hold at Stop

Flux Braking

Accel/Decel

Two (2) sets of Independently Adjustable Ramps

Linear or Adjustable ‘S’ Curve Accel/Decel Ramps

HVAC Specific Application Macros

Separate Safeties (2) and Run Permissive Inputs

Damper Control

Override Input (Fire Mode)

Timer Functions

Four (4) Daily Start/Stop Time Periods

Four (4) Weekly Start/Stop Time Periods

Four Timers for Collecting Time Periods and Overrides

Seven (7) Preset Speeds

Supervision Functions

Adjustable Current Limit

Electronic Reverse

Automatic Extended Power Loss Ride Through (Selectable)

Programmable Maximum Frequency to 500 Hz

PID Control

Two (2) Integral Independent Programmable PID

Setpoint Controllers (Process and External)

External Selection between Two (2) Sets of Process

PID Controller Parameters

PID Sleep/Wake-Up

Motor Control Features

Scalar (V/Hz) and Vector Modes of Motor Control

V/Hz Shapes

Linear

Squared

Energy Optimization

IR Compensation

Slip Compensation

Three (3) Critical Frequency Lockout Bands

Preprogrammed Protection Circuits

Overcurrent

Short Circuit

Ground Fault

Overvoltage

Undervoltage

Input Phase Loss

Output Device (IGBT) Overtemperature

Adjustable Current Limit Regulator

UL508C approved Electronic Motor Overload (I2T)

Programmable Fault Functions for Protection Include

Loss of Analog Input

Panel Loss

External Fault

Motor Thermal Protection

Stall

Underload

Motor Phase Loss

Ground Fault

5% Equivalent Impedance

5% Equivalent Impedance with Internal Reactor(s)

Patented Swinging Choke Design for Superior Harmonic

Mitigation in frame sizes (R1 to R6)

3% Equivalent Impedance for frame R8

Available Options

3 Relay Extension Module (OREL-01)

115/230 V Digital input Interface Card (OHDI-01)

Fieldbus Adapter Modules

LonWorks

Profibus

DeviceNet

Ethernet

ControlNet

BACnet IP to MS/TP router

DriveWindow Light Start-up, Operation, Programming and

Diagnostic Tool

ACH550 Product Bulletin | 3

Specifications

Input Connection

Input Voltage (U1) ..................................................................... 208/220/230/240 VAC 3-phase +/-10%

208/220/230/240 VAC 1-phase +/-10%

380/400/415/440/460/480 VAC 3-phase +/-10%

500/575/600 VAC 3-phase +/- 10%

Frequency: ................................................................................ 48 - 63 Hz

Line Limitations: ........................................................................ Max +/-3% of nominal phase to phase input voltage

Fundamental Power Factor (cosj): .............................................. 0.98 at nominal load

Connection: ............................................................................... U1, V1, W1 (U1, V1, 1-phase)

Output (Motor) Connection

Output Voltage: ......................................................................... 0 to U1, 3-phase symmetrical, U2 at the field weakening point

Output Frequency: ..................................................................... -500 to 500 Hz

Frequency Resolution: ............................................................... 0.01 Hz

Continuous Output Current:

Variable Torque: ................................................................. 1.0 * I2N (Nominal rated output current, Variable Torque)

Short Term Overload Capacity:

Variable Torque: ................................................................. 1.1 * I2N, (1 min/10 min)

Peak Overload Capacity:

Variable Torque: ................................................................. 1.35 * I2N, (2 sec/1 min)

Base Motor Frequency Range: .................................................. 10 to 500 Hz

Switching Frequency: ................................................................ 1, 4, 8 or 12 kHz

Acceleration Time: ..................................................................... 0.1 to 1800 s

Deceleration Time: ..................................................................... 0.1 to 1800 s

Efficiency: .................................................................................. 0.98 at nominal power level

Short Circuit Withstand Rating: .................................................. 100,000 AIC (UL)

Connection: ............................................................................... U2, V2, W2

Enclosure Style: ......................................................................... UL (NEMA) Type 1, Type 12, or Type 3R

Agency Approval Listing and Compliance: ................................. UL, cUL, CE, BTL (BACnet Testing Laboratory), IBC2000, 2003, 2006

Ambient Conditions, Operation

Air Temperature: ........................................................................ -15° to 40°C (5° to 104°F), above 40°C the maximum output current is de-rated 1% for

every additional 1°C (up to 50°C (122°F) maximum limit.

Relative Humidity: ...................................................................... 5 to 95%, no condensation allowed, maximum relative humidity is 60% in the presence of

corrosive gasses

Contamination Levels:

IEC: ................................................................................... 60721-3-1, 60721-3-2 and 60721-3-3

Chemical Gasses: .............................................................. 3C1 and 3C2

Solid Particles: ................................................................... 3S2

Installation Site Altitude: ............................................................. 0 to 1000 m (3300 ft) above sea level. At sites over 1000 m (3300 ft) above sea level, the

maximum power is de-rated 1% for every additional 100 m (330 ft). If the installation site is

higher than 2000 m (6600 ft) above sea level, please contact your local ABB distributor or

representative for further information

Vibration: ................................................................................... Max 3.0 mm (0.12 in) 2 to 9 Hz, Max 10 m/s2 (33 ft/s2) 9 to 200 Hz sinusoidal

Seismic Certified referencing IBC 2000, 2003 and 2006

Ambient Conditions, Storage (in Protective Shipping Package)

Air Temperature: ........................................................................ -40° to 70°C (-40° to 158°F)

Relative Humidity: ...................................................................... Less than 95%, no condensation allowed

Vibration: ................................................................................... In accordance with ISTA 1A and 1B specifications

Shock (IEC 60086-2-29): ........................................................... Max 100 m/s2 (330 ft/s2) 11 ms

Ambient Conditions, Transportation (in Protective Shipping Package)

Air Temperature: ........................................................................ -40° to 70°C (-40° to 158°F)

Relative Humidity: ...................................................................... Less than 95%, no condensation allowed

Atmospheric Pressure: .............................................................. 60 to 106 kPa (8.7 to 15.4 PSI)

Vibration: ................................................................................... Max 3.5 mm (0.14 in) 2 to 9 Hz, Max 15 m/s2 (49 ft/s2) 9 to 200 Hz sinusoidal

Shock (IEC 60086-2-29): ........................................................... Max 100 m/s2 (330 ft/s2) 11 ms

Free Fall: .................................................................................... R1: 76 cm (30 in)

R2: 61 cm (24 in)

R3: 46 cm (18 in)

R4 31 cm (12 in)

R5 & 6: 25 cm (10 in)

Cooling Information

Cooling Method: ........................................................................ Integral fan(s)

Power Loss: .............................................................................. Approximately 3% of rated power

4 | ACH550 Product Bulletin

Specifications

Analog Inputs

Quantity ..................................................................................... Two (2) programmable

Voltage Reference: .................................................................... 0 (2) to 10 V, 250kOhm, single ended

Current Reference: .................................................................... 0 (4) to 20 mA, 100Ohm, single ended

Potentiometer: ........................................................................... 10 VDC, 10 mA (1K to 10KOhms)

Input Updating Time .................................................................. 8 ms

Terminal Block Size .................................................................... 2.3mm2 / 14AWG

Reference Power Supply

Reference Voltage ..................................................................... +10 VDC, 1% at 25°C (77°F)

Maximum Load ......................................................................... 10 mA

Applicable Potentiometer ........................................................... 1 kOhm to 10 kOhm

Terminal Block Size .................................................................... 2.3mm2 / 14AWG

Analog Outputs

Quantity ..................................................................................... Two (2) programmable current outputs

Signal Level ............................................................................... 0 (4) to 20 mA

Accuracy ................................................................................... +/- 1% full scale range at 25°C (77°F)

Maximum Load Impedance ....................................................... 500 Ohms

Output Updating Time ............................................................... 2 ms

Terminal Block Size .................................................................... 2.3mm2 / 14AWG

Digital Inputs

Quantity ..................................................................................... Six (6) programmable digital inputs

Isolation ..................................................................................... Isolated as one group

Signal Level ............................................................................... 24 VDC, (10V Logic 0)

Input Current ............................................................................. 15 mA at 24 VDC

Input Updating Time: ................................................................. 4 ms

Terminal Block Size .................................................................... 2.3mm2 / 14AWG

Internal Power Supply

Primary Use ............................................................................... Internal supply for digital inputs

Voltage: ..................................................................................... +24 VDC, max 250 mA

Maximum Current: ..................................................................... 250 mA

Protection: ................................................................................. Short circuit protected

Relay Outputs

Quantity ..................................................................................... Three (3) programmable relay (Form C) outputs

Switching Capacity: ................................................................... 8 A at 24 VDC or 250 VAC, 0.4 A at 120 VDC

Max Continuous Current: ........................................................... 2A RMS

Contact Material: ....................................................................... Silver Cadmium Oxide (AgCdO)

Isolation Test Voltage ................................................................. 4 kVAC, 1 minute

Output Updating Time ............................................................... 12 ms

Terminal Block Size .................................................................... 2.3mm2 / 14AWG

Protections

Single Phase ............................................................................. Protected (input & output)

Overcurrent Trip Limit: ................................................................ 3.5 x I2N instantaneous

Adjustable Current Regulation Limit: .......................................... 1.3 x I2N (RMS) max.

Overvoltage Trip Limit: ............................................................... 1.30 x UN

Undervoltage Trip Limit: ............................................................. 0.65 x UN

Overtemperature (Heatsink): ...................................................... +115°C (+239°F)

Auxiliary Voltage: ........................................................................ Short Circuit Protected

Ground Fault: ............................................................................ Protected

Short Circuit: ............................................................................. Protected

Microprocessor fault: ................................................................. Protected

Motor Stall Protection: ............................................................... Protected

Motor Overtemperature Protection (I2t): ..................................... Protected

Input Power Loss of Phase: ....................................................... Protected

Loss of Reference: ..................................................................... Protected

Short Circuit Current Rating: ...................................................... 100,000 RMS symmetrical Amperes

Input Line Impedance: ............................................................... 5% Equivalent Input Impedance with internal reactor(s)

Patented swinging choke design for superior harmonic mitigation in frame sizes

R1-R6

Printed Circuit Boards ................................................................ Conformal coated

Notes

U1 = Input Voltage PN = Power – Normal Duty (HP)

U2 = Output Voltage 2N = Nominal Motor Current Normal Duty

UN = Nominal Motor Voltage

fN = Nominal Motor Frequency

ACH550 Product Bulletin | 5

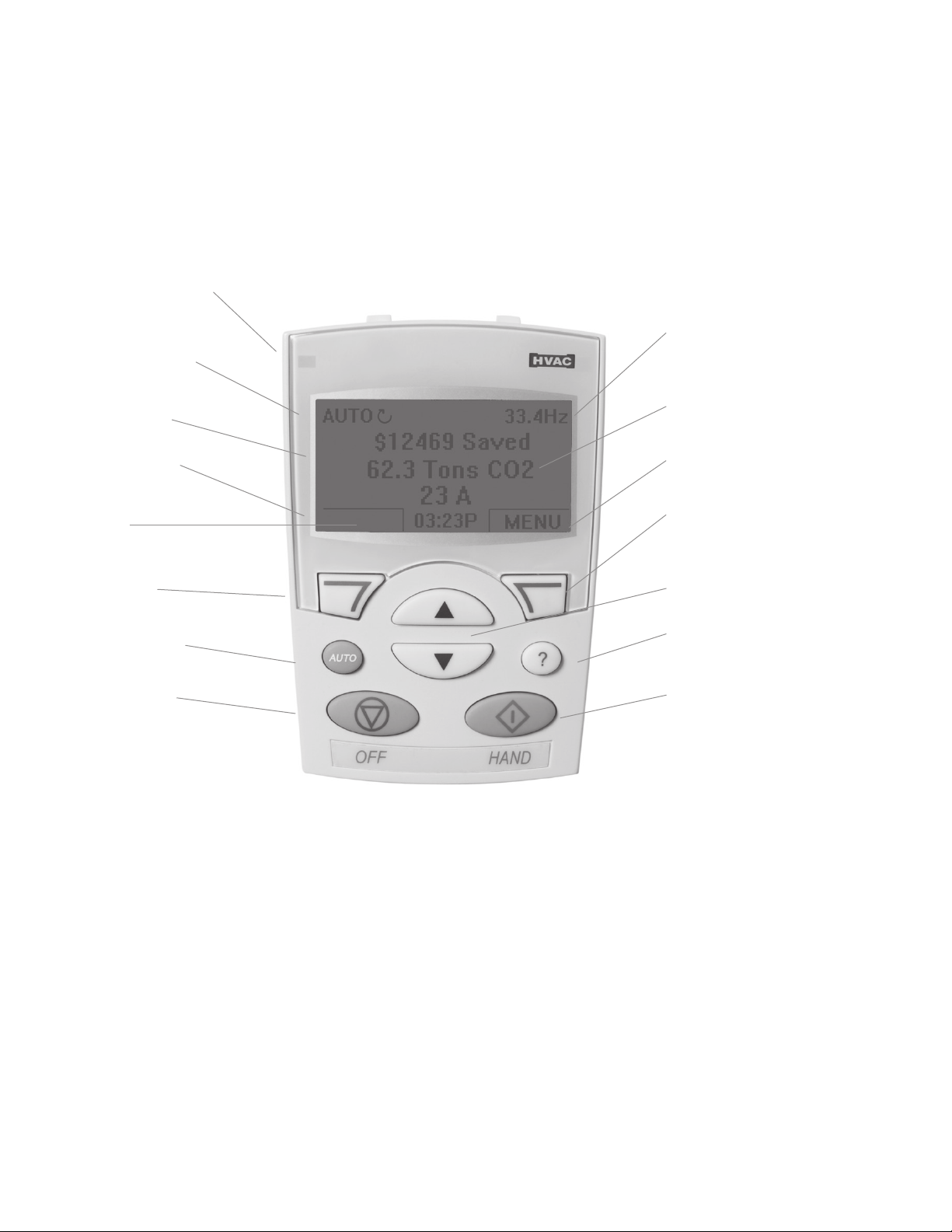

Drive Features - Human Interface

User Friendly Operator Control Panel

The ACH550 includes an operator control panel that is as easy to understand and use as a cell phone. The standard display

mode can be user-configured to show the operating status information that you want to see. The panel is mounted on the

front face of the drive and can be hand held or mounted remotely.

Designed specifically for HVAC applications, the operator panel includes HAND, OFF, AUTO and speed INCREASE and

DECREASE keys are provided for manual operation. Two multi-function Soft Keys are provided for navigating through the

menus and setting parameters. A HELP key pulls up a brief description of the displayed or highlighted item.

Red/Green Status LED

Operating Status and

Direction

Values of Three Userselected Parameters

Soft Key Function

Time of Day

Soft Key

AUTO Key

OFF Key

Set Speed

User-configured

Units of Measurement

Soft Key Function

Soft Key

IINCREASE/DECREASE or

SCROLL UP/DOWN Keys

HELP Key

HAND Key

Backlit, Multilingual, Text/Graphics Display

The liquid crystal display (LCD) is backlit and provided with

a contrast adjustment for optimum legibility under a range of

viewing conditions.

Graphical Display

Parameter values can be displayed in bar graph

meter format.

Plain English

The ACH550 presents information in “plain” English

(no codes).

User-selected Languages

In addition to US English, ten other languages are

available including French, Spanish, German, Italian,

Swedish, Finnish, Danish, Portuguese, Dutch and

international English.

6 | ACH550 Product Bulletin

Standard Display Mode

When the operator panel is in the standard display mode as

shown above, the top line of the display always shows the

drive operating status, HAND, OFF or AUTO, the direction of

motor rotation and the speed command setting.

The center three lines show the values of three user-selected

parameters in large numbers with user-selected units of

measurement.

The bottom line shows the functions assigned to the Soft

Keys for that particular display. In the menus, the function

of the Soft Key on the left is generally EXIT or CANCEL.

Repeatedly pressing the EXIT or CANCEL key brings the

display back to the standard display mode.

The local time is displayed in the center of the bottom line of

the standard display (12 or 24 hour format).

Drive Features - Human Interface

Control Panel Mounting Options

An optional panel mounting kit (OPMP-01) allows the control

panel to be mounted remotely or hand held. See “Control Panel

Mounting Kit” on page 33.

The control panel can be connected to and disconnected

from the drive at any time. If the drive is running under HAND

keypad control, disconnecting the keypad will cause the drive

to stop and display a fault message. Alternatively, the drive

can be programmed to continue operation after the keypad

is disconnected and run at a preset speed or at the average

speed over the previous 10 seconds.

Control Panel Keypad Operating Modes

Start/Stop and Speed Reference commands can be given

from the control panel keypad, from external command signals

connected to the customer terminal strip or transmitted

through a serial communication interface.

• Hand – Off – Auto Control

When the HAND key is pressed, the drive starts and

the reference frequency can be modified by pressing

the UP/DOWN keys. The HAND (keypad) control mode

is indicated on the LCD display.

When the OFF key is pressed, the drive stops and the

OFF control mode is indicated on the LCD display.

When the AUTO key is pressed, the AUTO mode

is indicated on the LCD display. The drive can be

started and stopped using whichever remote start/

stop command has been configured, a contact

closure applied to the Start/Stop input or a serial

communication command. The drive speed is

controlled by the external speed reference input or by

the PID controller.

Help Key

The HELP key pulls up a brief description of various displayed

or highlighted items including the Main Menu items, parameter

groups and individual parameters. In addition, help messages

and warnings are displayed automatically when parameter

changes or set-up procedures are initiated. The HELP Key also

displays possible causes and corrective actions for drive faults

• Bumpless Transfer

If the HAND key is pressed while the drive is running

in the AUTO control mode, the drive continues to

run without changing speed, but ceases to respond

to external input or PID speed reference changes

(Bumpless transfer). The reference frequency can be

modified by pressing the UP/DOWN keys.

If the AUTO key is pressed while the drive is running

in the HAND control mode, the drive continues to run

and follows the acceleration or deceleration control

ramp to the speed set by the external input or PID

speed reference (Bumpless transfer).

• Keypad Control Lock

Keypad HAND – OFF – AUTO control can be locked

out or enabled only when permitted by a terminal block

or serial communications input.

Date and Time Clock

The operator panel contains a clock with a battery backup (10

year life). The clock provides the date and time for use in the

FAULT LOGGER and timer functions.

ACH550 Product Bulletin | 7

Drive Features - Human Interface

• User Friendly Menu Structure

The MAIN MENU contains just seven items:

• PARAMETERS

The parameter menu displays the parameter values

and allows them to be edited. The parameters are

organized by function into numbered groups. See

“Parameter Group Functional Descriptions” on page

22. The first two digits of the parameter number are

the group number. Parameters include items with

adjustable values, configuration alternative selections

and read-only displays of actual values of operating

data items.

• ASSISTANTS

The programming assistants provide help in

configuring the drive. See below.

• CHANGED PAR

The changed parameters menu displays only the

parameters that have been changed from the default

values as loaded at the factory or loaded by executing

an application macro.

• FAULT LOGGER

The FAULT LOGGER displays the most recent faults.

See “Fault Logger” on page 9.

• CLOCK SET

The clock setting menu provides a means for selecting

the display format and setting the date and time.

• PAR BACKUP

The parameter backup menu has commands for

uploading the parameter settings to the operator panel

and downloading all or subsets of stored parameters

to any ACH550 drive.

• I/O SETTINGS

The I/O settings menu displays the I/O configuration

settings and allows them to be edited.

Programming Assistants

The programming assistants, used in conjunction with the

HELP key, provide a guided, step-by-step method for setting

parameters.

• Spin the Motor

For use prior to commissioning or during

troubleshooting. Allows manual operation with minimal

control functionality using the control panel keypad.

• Commission Drive

Provides a step-by-step procedure for the drive

commissioning configuration.

• Application

Provides direct access for loading an Application

Macro. Loading an application macro configures

the I/O parameters for the typical control circuit

connections required for common applications. The

ACH550 User’s Manual contains the appropriate

control circuit connection diagram for each macro.

In addition to the I/O configurations, some macros

also set other parameters such as initial PID tuning

adjustments. Loading the HVAC DEFAULT macro

resets the drive to the factory default I.O configuration.

The following programming assistants can be used to step

through and manually set the more common configuration

parameters without entering the PARAMETERS menu.

• References 1 & 2

Defines the speed reference source or the means of

selecting the speed reference. Sets the reference and

output frequency limits.

• Start/Stop Control

Defines the source and configuration of the Start/Stop

and Direction commands. Selects start/stop functions

such as ramp or coast stop and flying start. Sets

acceleration and deceleration times.

• Protections

Configures protective functions such as current limit,

external interlocks, fault trip functions and automatic

reset functions.

• Constant Speeds

Configures preset speed selection functions.

• PID Control

Enables and configures the process PID controller.

• Low Noise Set-up

Configures the drive to minimize acoustical noise

produced by the motor. Sets the switching frequency,

enables flux optimization and configures the critical

speed avoidance feature.

• Panel Display

Selects the process variables displayed on the

operator’s panel and configures the display.

• Timed Functions

Configures the daily and weekly event program timers.

• Outputs

Configures the relay outputs and sets their delay times.

Configures and adjusts the analog outputs.

Application Macros

The ACH550 offers a choice of fourteen (14) HVAC application

macros and has been designed to offer users the ability to

program common applications in a simple and flexible manner.

By using the application macros supplied as standard with all

ACH550 drives, building-wide standardization will be greatly

simplified.

8 | ACH550 Product Bulletin

Drive Features - Human Interface

• Configure I/O Terminals Automatically

Application macros allow for complete configuring

of the analog and digital I/O’s, and certain drive

parameters for specific applications.

• Edit Automatically Configured Settings

The function of automatically configured analog or

digital I/O or drive parameters may be customized,

providing added flexibility.

• User 1 / User 2 Macros for Customized Settings

Customized user settings can be saved as USER S1

and USER S2 macros, and reloaded or loaded into

other drives for quicker set-up in installations with

multiple drives or switch between two different settings

and drive operation profile on one drive

Maintenance Assistant

The maintenance assistant is a series of usage level

measurement functions and trigger points that can be used to

prompt users to perform periodic preventative maintenance

tasks. When usage reaches the set trigger point, a notice is

displayed on the operator’s panel.

• Maintenance Trigger Parameters

The maintenance trigger parameters include the

following operating data items and associated trigger

setpoints. See “Maintenance Triggers – Group 29” on

page 27.

- Cooling fan accumulated operating time

- Accumulated motor revolutions

- Accumulated hours of drive run time

- Accumulated megawatt hours of drive power

usage

• Supervision Functions

Supervision functions monitor up to three user-selected

operating data parameters and energize relay outputs

if the parameter values deviate beyond user-set limits.

These functions can be used to set up maintenance

prompts based on deviations from normal operating

conditions. See “Supervision – Group 32” on page 28.

- Air Filter Alarm

With a fan drive, high load current can indicate

restricted air flow due to a dirty air filter.

- Broken Belt Alarm or Proof of Flow

An unusually low load current can indicate a

broken fan drive belt or a dry pump.

• Diagnostic Assistance Message

If a fault message is displayed, pressing the HELP

key displays a diagnostic assistance message. The

message displays, in plain language, possible causes

of the problem and potential solutions. For example:

- Fault 2

DC OVERVOLT

Check: Overvoltage in the input power supply,

insuff decel time, undersized brake chopper.

• Fault Logger

The three most recent fault messages are displayed by

entering the FAULT LOGGER, a MAIN MENU item.

Detail Key

For the most recent fault message, pressing the

DETAIL Soft Key displays additional operating data

including:

- Operating speed and frequency

- Motor voltage, current and torque

- Status of the digital inputs

Diagnostic Message Key

From the Detail display, pressing the DIAG Soft Key

displays the diagnostic assistance message.

The FAULT LOGGER data is also available in

parameter group 04. See “Fault History – Group 04”

on page 22.

• Test Meter and Monitoring Functions

The capability to display an extensive range of

operating data means that the ACH550 control

panel is a powerful tool for use in commissioning

and troubleshooting. It can be used to monitor

performance and diagnose problems in the ACH550,

the motor or the driven equipment and process. See

“Operating Data – Group 01 and Information – Group

33” on page 22.

• Load Analyzer

Used for analyzing the customer’s process and sizing

the drive and motor the peak value is logged at a 2

ms level, and the distribution loggers are updated on

a 0.2 (200 ms) time level. Three different valves can be

logged.

Diagnostic Assistant

The ACH550 includes several valuable diagnostic tools to

assist in getting the drive back into operation quickly if a

protective shutdown occurs.

• Fault Messages

When the drive detects a severe error or hazardous

operating condition, the motor is stopped, the

red operator’s panel LED is illuminated and a fault

message is displayed on the operator’s panel.

ACH550 Product Bulletin | 9

Drive Features - Terminal Block Interface

Introduction

The ACH550 is equipped with a very flexible complement of

programmable inputs and outputs for connecting a wide variety

of field devices to the drive.

Programmable Analog and Digital Inputs and Outputs

The ACH550 includes 13 I/O terminals as standard and 3

additional relay outputs can be added (page 24). I/O functions

are assigned by the user by loading an application macro or by

setting individual parameters (Group 10 to 81 pages 22 to 31.).

• 2 Analog Inputs

Group 11 & 12 Speed Reference inputs.

Group 35 Motor Temp PT100 or PTC input.

Group 40, 41 & 42 Process or External PID set point

and feedback inputs.

• 2 Analog Outputs

Group 15 Analog Outputs

Group 35 Motor Temp PT100 or PTC regulated

current.

• 6 Digital Inputs

Group 10 & 21 Start/Stop/Direction control functions

Group 11 & 12 Speed Reference and Preset Speed

selection functions

Group 16, 17 & 30 System Control, Override, and

• External Fault functions

Group 20 Torque Limit functions

Group 22 Accel/Decel time select and reset functions

Group 35 Motor Temp thermistor input

Group 36 Timer functions

Group 40 & 42 PID functions

Group 81 Pump or Fan Alternation (PFA) functions

Group 99 USER1 and USER2 save and load

• 3 Standard and 3 Optional Relay Outputs

Group 14 Relay Outputs

The Drive Provides Unitary Control Functions

The drive’s control capabilities and I/O complement allow the

ACH550 to handle auxiliary device functions in addition to

controlling the motor.

Built-in Control Capabilities

• Two Independent PID Controllers

Setpoints sent via serial communications or set locally

Feedback hard-wired to drive I/O terminals

- Flow or Pressure Control Based on Motor

Speed

Air duct static pressure control

- Independent PID Control for an External

Device

Chilled water valve control

Cooling tower bypass valve control

• Direct-to-Drive Contact-Closure Inputs

Firestat/Freezestat safety contacts

Fireman’s override (smoke purge) command

Damper end-switch proof contact

• Direct-from-Drive Contact-Closure Outputs

Maintained contact to open isolation damper

Maintained contact to override VAV box

• Built-In Timers

Built-in timers - utilizing the real-time clock - allow

starting and stopping the drive or changing the speed

according to the time of day or night. Relay outputs

can be operated with timers to control any auxiliary

equipment on site.

• Monitor Hard-Wired Devices Over Serial Link

All hard-wired analog and digital I/O points can be

monitored over the serial link.

• Pass-Thru I/O

Serial communications can be used to send and

receive analog signals and digital commands

through the ACH550 I/O points that are used not for

control functions provided by the drive. The Building

Management System can use the drive’s I/O to control

auxiliary devices.

• Advantages of Offloading Unitary Control

Functions to the Drive

- Eliminating external control components

simplifies the system and provides a more

economical installation.

- Integrating the auxiliary control into the drive

provides closer functional coordination and

better compatibility.

Customer Terminal Block

The analog I/O and digital input circuit common potential of

the customer terminal block is optically isolated from power

circuits and resistively isolated from the chassis by a 1 MegaOhm resistor. Shielded cable screen connection terminals are

connected to the drive chassis.

• 24VDC Control Power Supply

An internal power supply is available for contact

closure digital inputs.

• External 24VDC Control Voltage Inputs

Digital inputs can be supplied by an external voltage

source of either polarity.

• Optional 115/230VAC Control Voltage Inputs

See “115/230v digital input Interface Module” on page

32.

• 10VDC Reference Power Supply

An internal power supply is provided for potentiometer

voltage inputs.

• Several Separate Circuit Common and Grounding

Terminals

Separate terminals are provided for shielded cable

screen connections, analog input signal common,

analog output signal common, and digital input signal

common.

10 | ACH550 Product Bulletin

Drive Features - Communications Suite

Introduction

Serial communications is a powerful mode of operator and

supervisory control interface that provides a number of benefits

compared to other types of interface. The ACH550 is equipped

with an (RS) EIA-485 serial communications port that supports

a full range of drive monitoring and control functions through

serial communications.

Fieldbus

A fieldbus is serial communications network that connects a

master control unit such as a Building Management System

with several or many slave devices such as AFDs.

• ABB Leadership in Fieldbus Technology

ABB is a leading drives supplier to the U.S. HVAC

market, and has connected hundreds of thousands

of drives to building automation systems. Using its

standard (RS) EIA-485 port and embedded protocols

or internally mounted fieldbus adapter modules the

ACH550 can be connected directly to any of the

fieldbus network configurations commonly used in the

US HVAC industry. ABB is the first drive manufacturer

to offer BACnet as an embedded protocol.

• Embedded Fieldbus Protocols

Using the drive’s standard (RS) EIA-485 port, the

ACH550 can communicate using any of the following

protocols:

- Modbus®

- Metasys® N2

- APOGEE® FLN

- BACnet® (BTL Listed)

• Fieldbus Adapter Modules

Internally mounted adapter modules are available for

communication using the following protocols:

- DeviceNet®

- LonWorks®

- Profibus-DP®

- ControlNet

- EtherNet

- BACnet IP to MS/TP

Benefits of Serial Communications

• Reduced I/O Connections

One serial I/O connection can provide the functions of

multiple conventional I/O connections. This provides

wiring cost savings and savings in the number of I/O

points required in the Building Management System.

• Enhanced Energy Management Strategies

Low cost data collection through serial

communications makes it feasible to use enhanced

energy management strategies that result in lower

operating costs.

DriveWindow® Light PC Software

ABB’s DriveWindow Light provides a user-friendly way to set

up and control a drive system easily and comfortably from a

PC. It is ideal for drive commissioning as well as maintenance

and service purposes, troubleshooting and training. Learning

and using DriveWindow is easy – the look and feel of the user

interface is just like that of any Windows® application. All

features are easily accessed by clicking an icon or through a

clearly structured menu tree. This makes drive programming

and system configuration management simpler than ever.

The following are the DriveWindow Light features that are

available for use with ACH550 drives.

• System Configuration

The starting point of DriveWindow, providing an

overview of the system. All drives connected to the

system are clearly indicated here, along with the type

and status of each drive.

• Drives Panel

Enables full control of a drive with the following

commands: Local/Remote, Start, Stop, Change

Direction, Reference Setting, Step Function and Fault

Reset.

• Signals and Parameters Tool

Displays a list of all or selected signals and parameters,

along with their values, units, types and setting ranges.

Features include parameter upload and download,

changing parameter values, saving values to a file,

reading values from a file, comparing two parameter

sets, and finding a parameter.

• Monitor

A trending tool providing a graphic interface to actual

drive values. Up to six items from different drives can

be selected for monitoring simultaneously. Actions

such as setting triggering conditions, scaling the axis,

zooming and printing the graphs can be performed.

• Data Logger Tool

Used for controlling the drive data loggers, selecting

their variables and setting triggering conditions. It

allows high-precision analyses of rapid phenomena.

Data logger contents can be presented in a numeric or

graphic form.

• Event logger

Shows the application specific drive events, each with

a description and a time stamp.

• Fault Logger

Shows the last 10 faults and warnings, each with a

time stamp. The FAULT LOGGER also allows resetting

of an active fault.

ACH550 Product Bulletin | 11

Drive Features - Power

Introduction

The ABB ACH550 AC drive combines a sophisticated

microprocessor with an advanced IGBT power switching

technology to deliver a full featured drive in an extremely

compact design. The ACH550 is a highly efficient and

dependable (PWM) drive designed specifically for the HVAC

industry.

• Input Power – Tolerated Voltage Window

The ACH550 is available in three line voltage ratings

each with a 35% undervoltage to 30% overvoltage

window of tolerated voltage deviation.

Line Voltage

Range

208 - 240V 135V 312V

380 - 480V 247V 624V

500 - 600V 325V 780V

• Low Line Harmonics – Swinging Choke

Drives and other non-linear load equipment contribute

to harmonic currents in a power distribution system.

IEEE Standard 519-1992 explains the reasons for

limiting harmonics and recommends limits to be

applied in various situations.

• Swinging Choke

ACH 550 drives have a unique, built-in harmonic

limiting device, a swinging choke. The swinging choke

is an inductor that has an inductance value that is

inversely proportional to its operating current.

• Swinging Choke Advantages

- Limits harmonics as effectively as a 5% linear

choke but requires less space in the drive

- A built-in component, no extra equipment to

purchase, mount and wire

- High efficiency, minimal power loss

- Configured as a 3-phase input reactor or dual DC

bus choke for added impedance

- No need to oversize branch circuit wiring

The swinging choke assures that the drive’s

input current will never exceed the output current

supplied to the motor. The rated input current

marked on the drive’s nameplate is the same as

the rated output current. This means that there

is no need to oversize the branch circuit wiring,

disconnecting means and protection to comply

with the National Electrical Code.

- Contributes to electromagnetic compatibility and

transient voltage protection

Undervoltage

-35% Trip Point

Overvoltage

+30% Trip Point

• Electromagnetic Compatibility (EMC)

Electromagnetic compatibility (EMC) is the ability

of electrical/electronic equipment to operate in its

installation environment while neither causing nor

experiencing electromagnetic interference (EMI). EMI

is any interference with normal equipment operation

caused by abnormal energy entering the equipment

either by conduction though wiring connections or by

radiated wave reception. Radiated EMI is also called

radio frequency interference (RFI). Conducted EMI is

also called high frequency line noise.

The ACH550 is equipped with built-in EMI / RFI filters

to assure that the drive will not interfere with any

sensitive equipment.

EMC Standards

• IEC EN61800-3

The ACH550 includes standard filters that meet the

IEC 61800-3 EMI/RFI standards and emission limits

for Restricted Distribution and installation in the First

Environment.

• Federal Communications Commission Regulations,

Part 15, Requirements for Class A Digital Devices

As an item of industrial equipment or a component of

a commercial HVAC system, an adjustable frequency

drive is exempt from any FCC labeling or authorization

requirements.

• CE Marking

The ACH550 conforms to the European Union

Electromagnetic Compatibility directive and meets

the other requirements that allow it to carry the CE

marking.

Easily Serviceable Cooling Fans

The cooling fans in the ACH550 can easily be removed to clean

the heatsink and fans or to replace the fans. The fans can be

removed without removing the drive from the wall or removing

circuit boards. To maximize their operating life, the fans are

cycled on and off as required to maintain the drive at a safe

operating temperature.

Vector Drive – Vector or Scalar Control Mode

The ACH550 is a sensorless vector controlled drive with userselectable vector and scalar control modes.

• Scalar Control – Optimum for HVAC Drives

The scalar control mode is normally used in HVAC

applications. It provides all the performance you want

with no motor profiling.

• Vector Control Advantages in the Scalar Control

Mode

The ACH550 vector control design enhances scalar

mode performance of the following features:

- High Performance Current Limit

The ACH550 current limit is fast, accurate and

reliable.

- Flying Start to Catch a Forward or Reverse

12 | ACH550 Product Bulletin

Drive Features - Power

Spinning Motor

The ACH550 starts smoothly and reliably with a

spinning motor connected. If the motor is spinning

in the forward direction, the drive simply picks

up the motor at its current speed and smoothly

accelerates or decelerates to the desired operating

speed. If the motor is spinning in the reverse

direction the drive decelerates the motor and reaccelerates in the forward direction.

- Flux Optimization

Flux Optimization provides the right motor

excitation for every set of operating conditions.

This results in reduced energy consumption plus

cooler and quieter motor operation.

- The Vector Mode is Available if Needed

For unusually demanding applications, the

sensorless vector mode of operation can be

engaged by making the appropriate parameter

selections.

Energy Savings

The ACH550 provides some unique energy savings features to

complement the inherent energy savings gained by using an

adjustable frequency drive to modulate flow.

• Swinging Choke DC Bus Filter Design

The swinging choke helps provide the ACH550 with

a DC bus filter that saves energy both inside the drive

and in the power distribution system. See “Low Line

Harmonics – Swinging Choke” on page 12.

• Fan Modulation

The cooling fans in the ACH550 operate upon

application of power to provide indication of their

proper operation. The fans turn on given a run

command and remains on after a stop command is

give until drive temperature is to an acceptable level.

• Flux Optimization

The flux optimization feature monitors the load and

automatically adjusts the motor excitation to suit

the operating conditions. Whenever load conditions

permit, the magnetic flux in the motor is reduced

to save energy, and provide cooler and quieter

motor operation. The energy used by the motor is

automatically optimized in balance with the load

requirements.

ACH550 Product Bulletin | 13

Drive Features – Protection

Introduction

Drive protection features assure reliable operation and longlasting equipment. The ACH550 has a very flexible and

extensive line-up of protection features.

Power Line Protection

Surge Withstand Capability

ACH550 drives include a coordinated AC transient voltage

protection system consisting of four Metal Oxide Varistors

(MOVs) rated 120 joules each (phase to phase & phase to

ground), a capacitor clamp, and 5% impedance swinging

chokes.

Short Circuit Current Rating

The UL 508A or 508C labeled short circuit current rating

of the ACH550 is 100,000 A when installed with any NEC

compliant branch circuit protection. Class T (Bussmann Type

JJS) fuses are recommended but not required. The ACH550

has electronic protection circuits and other design features that

eliminate the need for fast acting semiconductor input fuses.

The drive is fully protected from an output short circuit whether

it is present when the drive is started or occurs after the drive is

running.

Mis-wiring Protection

ACH550 units rated 75 Hp and smaller are protected from

input and output power mis-wiring. If one or more input power

conductors are connected to motor terminals, the drive will

sense the problem and display an OUTPUT WIRING fault

message.

Switching Frequency Foldback

Since reducing the drive’s switching frequency reduces the

heat generated by the IGBTs, the ACH550 has a switching

frequency control feature that can be set to reduce the drive’s

switching frequency if the heatsink temperature rises above

80-90°C. This would only engage when both the ambient and

load are at the maximum load. When the load and temperature

drops, the carrier frequency will revert back to the initial setting.

Integral Protection Circuits

The ACH550 was designed to protect the drive and motor from

the hazards of continuous service in the most demanding of

applications. Built-in protection circuits include the following:

• Overcurrent trip limit - 350% instantaneous

• Adjustable current regulator limit - 130%

• Overvoltage trip limit - 130%

• Undervoltage trip limit - 65%

• Over temperature protection (heatsink)

• Switching frequency foldback temperature

limiter

• Auxiliary voltage short circuit protection

• Output ground fault and mis-wiring protection

• Output short circuit protection

• Microprocessor fault protection

• Adjustable motor stall protection

• Adjustable motor overload protection (I2t) - UL

listed

• Motor PTC thermistor and Pt100 RTD inputs

• Loss of reference protection (programmable)

• Single phasing protection on input and output

• Underload protection (programmable)

• Keypad control panel loss protection

(programmable)

• Serial communication loss protection

• Two (2) programmable external fault interlock

inputs

• Adjustable output frequency and motor speed

limits

• Pass code parameter-change protection

• Keypad operator control lockout

• Extended power loss ride-thru by inertial energy

recovery

Automatic Reset

In order to minimize the nuisance shutdowns, the ACH550

can be set to automatically reset certain faults and attempt to

restart. See “Automatic Reset (Auto Restart) – Group 31” on

page 28.

Enclosure Offerings

Since the NEMA enclosure designations can be used without

third party certification, ABB has chosen to obtain UL listings

that include the enclosures to assure customers that the

ACH550 enclosures meet nationally recognized standards.

• UL Type 1 (NEMA 1)

Suitable for most mounting locations

• UL Type 12 (NEMA 12)

Increased protection from dirt and dust but still rated to

deliver continuous full output current at 40°C.

• UL Type 3R (NEMA 3R)

Increased protection against falling rain and is

undamaged with the formation of ice on the enclosure

• Enclosures are Plenum Rated by UL

Offers more flexibility in selecting a mounting location.

Note that plenum ratings are available only for UL listed

enclosures.

14 | ACH550 Product Bulletin

Versatile Protection

Many of the protection features are adjustable or programmable

to suit the requirements of individual applications. Refer to

the following parameter group descriptions for additional

information:

• “System Controls – Group 16” on page 24

• “Limits – Group 20” on page 25

• “Motor Control – Group 26” on page 26

• “Fault Functions – Group 30” on page 27

• “Automatic Reset (Auto Restart) – Group 31” on

page 28

• “Supervision – Group 32” on page 28

• “Motor Temperature Measurement – Group 35” on

page 28

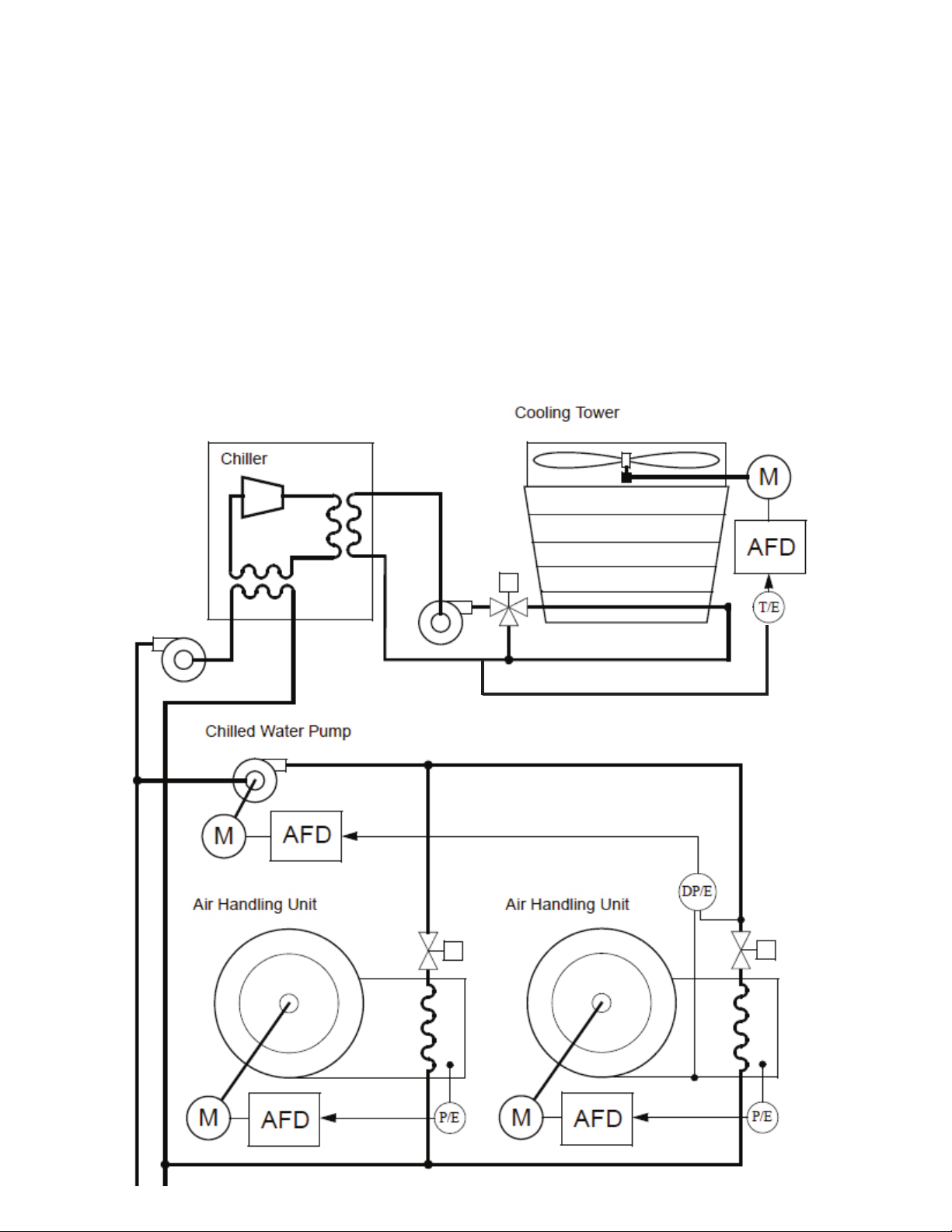

Application Control Diagrams

HVAC System Overview

The HVAC System Diagram on the following page shows

the principal elements of an HVAC system including typical

adjustable frequency drive applications.

• Chiller

Speed control of the chiller compressor is a special

application undertaken only with close coordination

between the drive and chiller manufacturer.

• Cooling Tower

The cooling tower fan speed control is typically based

on the water temperature at the discharge point.

See “Air Handling Unit Application Functions” on page

16

HVAC System Overview Diagram

• Chilled Water Pump

The chilled water pump speed control is typically

based on the differential pressure across the cooling

coil that is located farthest from the chiller or the most

distant significant load.

See “Chilled Water Pump Application Functions” on

page 18.

• Air Handling Units (AHU)

The AHU fan speed control is typically based on the

pressure in the air duct.

See “Cooling Tower Application Functions” on page

20.

ACH550 Product Bulletin | 15

Loading...

Loading...