AAON HB-005 User Manual

B

H

Package Units

& Air Handlers

• R-410A DX or Chilled Water Cooling

• Gas, Electric or Hot Water Heat

• Bottom or Side Discharge

FOR YOUR SAFETY

WHAT TO DO IF YOU SMELL GAS

• EXTINGUISH ANY OPEN FLAME

• DO NOT TOUCH ANY ELECTRICAL SWITCH

• DO NOT TRY TO LIGHT ANY APPLIANCE

• DO NOT USE ANY PHONE IN YOUR BUILDING

• IMMEDIATELY CALL YOUR GAS SUPPLIER

FROM A NEIGHBOR’S PHONE. FOLLOW THE

GAS SUPPLIER’S INSTRUCTIONS.

• IF YOU CANNOT REACH YOUR GAS

SUPPLIER, CALL THE FIRE DEPARTMENT.

Series

Installation and User Manual

R-410A Package

Air Handler

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER

FLAMMABLE VAPORS AND LIQUIDS IN THE

VICINITY OF THIS OR ANY OTHER APPLIANCE.

WARNING

If the information in this manual is not followed

exactly, a fire or explosion may result causing

property damage, personal injury, or loss of life.

Owner should pay particular attention to the words: NOTE, CAUTION, and WARNING. NOTES are

intended to clarify or make the installation easier. CAUTIONS are given to prevent equipment damage.

Contents

WARNINGS are given to alert owner that personal injury and/or equipment damage may result if installation

is not handled properly.

1. Description ………………………………... 3

Important Safety Information

Package Unit Orientation

Air Handling Unit Orientation

2. Model Number Description ....………….. 6

Unit Model Number

3. User’s Information ……….....…………… 7

DX Cooling Units (and Remote Cond. Units)

Hydronic Cooling & Heating

Gas or Electric Heating

Filter Sizes

Multiple Unit Operation

Wiring Diagrams

Condensate Piping

Normal Thermostat Operation

Night and Vacancy Operation

Gas Heating System

Hot Gas Reheat & Hot Gas Bypass System

Filter Sizes

Cabinet Construction

4. Delivery ……………………………………. 10

Receipt & Inspection

Storage

5. Installation ………………………………… 10

General

Codes & Ordinances

Handling

Heating and Cooling Systems

Service & Installation Clearances

Setting the Unit

Electrical

Standard Control Board

Optional Control Board

Optional Control Board

Table Index: Figure Index

4.1

5.1

9.1

16.1

16.2

16.3

21.1

21.2

27.1

Package Unit Dimensions

AHU Dimensions

Filter Sizes

Blink Codes: Standard Board

Blink Codes: Optional Board

Low Voltage Wiring Sizes

Minimum Gas Piping Sizes

Gas Piping Support Intervals

Filter Sizes

4a

5a

7a

8a

9a

9b

12a

12b

12c

Thermostat

6. Start-Up …………………………….. 23

7. Operation & Maintenance ……….. 26

8. Hot Gas Bypass (External) …..….. 28

9. Hot Gas Reheat (Modulating) …... 28

10. Pressure-Temperature Chart …… 31

Economizer Option

Return Air Bypass Option

Modulating Hot Gas Reheat

Gas Piping

Condensate Piping

General

Procedures

Air Balancing

Water Balancing

Controls

General

Maintenance Schedule

Cooling

Condenser Fan

Blower Assembly

Heating Sequence

Chilled Water

Filters

Cleaning

Service

Pkg. Unit Orientation

AHU Orientation

Piping Chase Location

Heat Exchangers

MHGRH+HGBP System

Foam Panel (HPCP)

Service Clearances

Airflow Clearances

Other Clearances

2

13a

14a

15a

18a

20a

22a

26a

27a

28a

Removing Shipping Brackets

Lifting Lugs and Outside Air Hood

Power and Control Wiring

External Control Inputs to Control Board

Reheated Supply Air Temperature

Gas Piping

Blower Section

Filter Section

Hot Gas Reheat System

1. Description

Important Safety Information

ONLY QUALIFIED PERSONNEL SHOULD

PERFORM INSTALLATION, OPERATION, AND

MAINTENANCE OF EQUIPMENT DESCRIBED IN

THIS MANUAL.

HB series package units are designed for safe

operation when installed, operated, and maintained

within design specifications, and the instructions set

forth in this manual. It is necessary to follow these

instructions to avoid personal injury or damage to

equipment or property during equipment installation,

operation, and maintenance.

This equipment is protected by a standard limited

warranty under the condition that initial installation,

service, and maintenance is performed according

to the instructions set forth in this manual. This

manual should be read in its entirety prior to

installation, and before performing any service or

maintenance work.

Units described in this manual are available with

many optional accessories. If you have questions

after reading this manual in its entirety, consult

other factory documentation, or contact your sales

representative to obtain further information before

manipulating this equipment, or its optional

accessories.

IMPORTANT!

WARNING

RISK OF DAMAGE, INJURY, AND LOSS OF LIFE

- Improper installation, adjustment, alteration,

service or maintenance can cause property

damage, personal injury, or loss of life. A qualified

installer or service agency must perform

installation and service.

NOTE

RISK OF ELECTRICAL SHOCK Before attempting to perform any service or

maintenance, turn the electrical power to the unit

OFF at disconnect switch(es). Unit may have

multiple power supplies.

WARNING

RISK OF INJURY FROM MOVING PARTS Disconnect all power before servicing to prevent

serious injury resulting from automatic starts. Unit

may have multiple power supplies.

WARNING

WARNING

ON 3 PHASE UNITS ONLY - Scroll compressors

will be damaged by operation with the wrong

rotation. THE LOW PRESSURE SWITCH HAS

BEEN DISCONNECTED AFTER TESTING AT

THE FACTORY. The wiring must be reconnected

and proper rotation determined at the time of startup by a qualified service technician using suction

and discharge pressure gauges. Any alteration

should only be made at the unit power connection.

This equipment uses R-410A only, and operates at

higher pressures than standard R-22 systems. Do

not use R-22 service equipment or tools on R410A systems. Improper use or service may result

in injuries from parts under high pressure.

WARNING

The Clean Air Act of 1990 bans the intentional

venting of refrigerant (CFC’s and HCFC’s) as of

July 1, 1992. Approved methods of recovery,

recycling or reclaiming must be followed. Fines

and/or incarceration may be levied for noncompliance.

WARNING

3

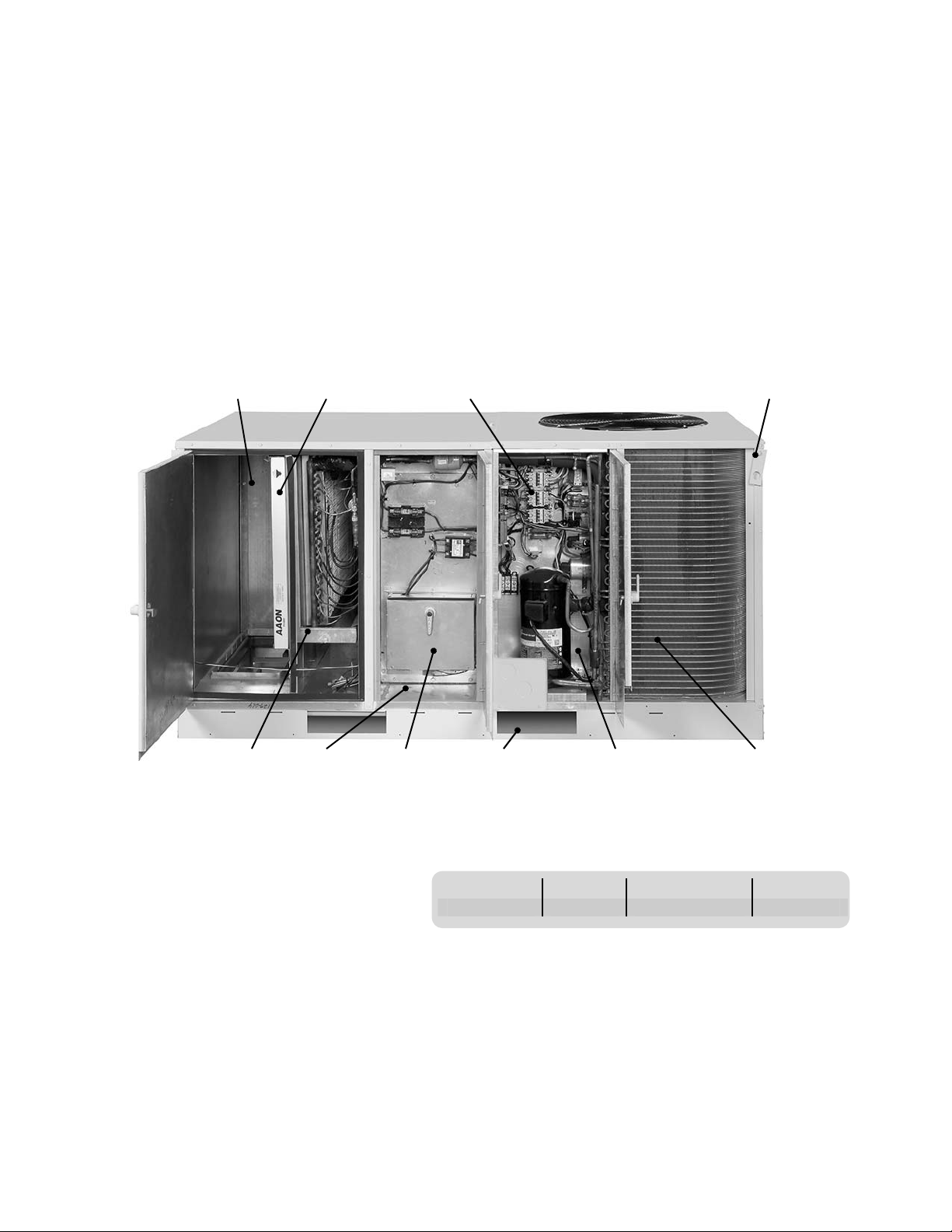

Package Unit Orientation (Compressorized)

Service access is from the front of the unit.

As you face the front of the unit, the condensing section will be on

the right end of the unit, and the air handling section on the left.

The drain connection is located on the back.

Figure 4a, Package Unit Orientation

Return /

Outside Air /

Economizer

Section

Filter

Section

Controls

Section

Evaporator

Section

Supply Air

Section

Heating

Section

Forklift

Openings

Table 4.1, Package Unit Dimensions

Model Width Length Height

002 - 005 42.25” 74.25” (93.25”)* 38”

*If present, the outside air hood will increase the overall

installed unit length by 19” for a total length of 93.25”.

Compressor

Compartment

Top Lifting Lugs

on Each Corner

Condenser

Section

4

Air Handling Unit Orientation (Non-Compressorized)

Service access is from the front of the unit.

As you face the front of the unit, the controls section will be on the

right end of the unit, and the air handling section on the left.

The drain connection is located on the back.

Figure 5a, Air Handler (Non-Compressorized) Unit Orientation

Return /

Outside Air /

Economizer

Section

Filter

Section

Coil Section

Heating

Section

Table 5.1, AHU Dimensions

Model Width Length Height

002 - 005 42.25” 44.75” (63.75”)* 38”

*If present, the outside air hood will increase the overall

installed unit length by 19” for a total length of 63.75”.

Top Lifting Lugs

on Each Corner

Controls

Section

Power Disconnect

Switch

Forklift

Openings

5

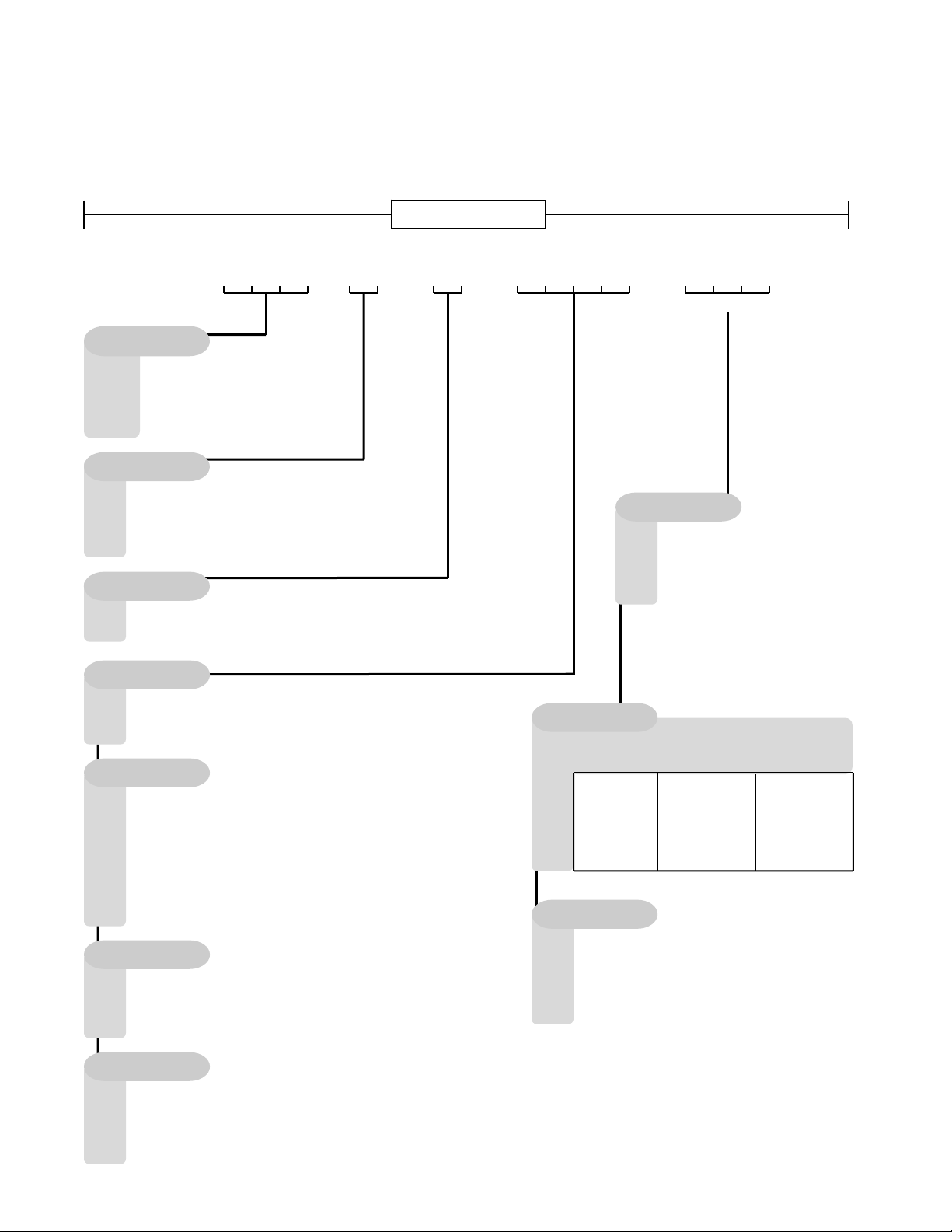

2. Model Number Description

Unit Model Number

002 =

003 =

004 =

005 =

3 =

A =

B =

V =

H =

A1

0 =

A =

B =

A2

0 =

2 =

3 =

A =

Q =

U =

W =

Y =

Z =

A3

0 =

1 =

8 =

9 =

A4

Nom. Tons Model

HB

Nominal Tons

2 Tons

3 Tons

4 Tons

5 Tons

Voltage

460V/3∅/60HZ

208-230V/1∅/60HZ

208-230V/3∅/60HZ

- -

Discharge

Vertical

Horizontal

Style

No Refrigerant

R-410A

R-410A w/ 2 Step Compressor

Configuration

No Cooling

Non-comp. w/ Std. DX Coil

Non-comp. w/ Std. DX Coil w/ RA Bypass

Air Cooled Cond. w/ Std. DX Coil

Air Cooled Cond. w/ Std. DX Coil w/ RA Bypass

Chilled Water 4 Row Coil

Chilled Water 4 Row Coil w/ RA Bypass

Chilled Water 3 Row Coil w/ 1 Row Preheat

Chilled Water 3 Row Coil w/ RA Bypass & 1 Row Preheat

Coating

No Coating

Phenolic Coated Coils - Evap. & Cond.

Phenolic Coated Condenser Coil Only

Phenolic Coated Evaporator Coil Only

Staging

No Cooling

0 =

Single Stage

1 =

Dual Stage (w/ 2 step compressor)

2 =

Single Serpentine Chilled Water

M =

Half Serpentine Chilled Water

N =

Voltage

Main Features

Discharge

Location

- - -

A1 A2 A3 A4

Cooling

Heating

B1 B2 B3

B1

Type*

0 =

No Heat

1 =

Electric Heat

2 =

Natural Gas Aluminized

E =

Hot Water

F =

Hot Water w/ Phenolic Coating

Note: LP gas and high altitude

conversion kits are available

for field installation.

B2

Designation

Gas Capacity Electric Capacity

Mbtu kW 208V kW 240-480V

0 =

1 =

2 =

3 =

4 =

5 =

No Heat

45

60

75

100

125

-

7.5

15

22.5

-

-

B3

Staging

No Heat

0 =

1 Stage (Gas or Electric)

1 =

2 Stage (Gas or Electric)

2 =

3 Stage (Electric Only)

3 =

Single Serpentine (Hot Water)

M =

Half Serpentine (Hot Water)

N =

6

10

20

30

-

-

3. User’s Information

Failure to observe the following instructions may

result in premature failure of your system, and

possible voiding of the warranty.

WARNING

DX (Direct Expansion) Package Units and DX

Units with Remote Condenser

Never cut off the main power supply to the unit, except

for complete shutdown.

Always control the system from the thermostat, or

control panel, and never at the main power supply

(except in an emergency, or complete shutdown of the

system).

During the cooling season, if the airflow is reduced due

to dirty air filters, or other reasons, the cooling coils will

get too cold and result in excessive liquid return to the

compressor. As the liquid concentration accumulates,

oil is washed out of the compressor leaving it starved

for lubrication.

The compressors must be on a minimum of four

minutes, and off for a minimum of five minutes. The

cycle rate must not exceed eight starts per hour.

THE COMPRESSOR LIFE WILL BE SERIOUSLY

SHORTENED BY RESULTING REDUCED

LUBRICATION, AND THE PUMPING OF EXCESS

AMOUNTS OF LIQUID OIL AND REFRIGERANT.

Hydronic Cooling and Heating

Non-compressorized units may contain chilled water

and/or hot water coils. Units are provided with internal

header connections for field piping. Vent and drain

connections can be accessed within the unit.

Piping is to be run via the 4” x 7” piping chase located

in the cabinet floor inside the coil compartment,

accessible through the coil compartment access door

on the front of the unit. Piping to coil header

connections must be supported independently of the

coil to prevent undue stress from weakening

connections over time. Allow adequate flexibility for

thermal expansion of the piping.

Use proper glycol solutions or brines to help prevent

coil freezing. Consult the designer or project engineer

if you have concerns about lower than normal entering

air temperatures (typically air temperatures below

40°F) that could cause coils to freeze.

Figure 7a, Piping Chase Location

Utility Entry

4” x 2 1/2”

Shipping

Bracket

Piping Chase

4” x 7”

Front

Return Supply

Back

Gas or Electric Heating

The system is designed to heat a given amount of air

each minute of operation. If the amount of air heated

is greatly reduced (approximately 1/3 capacity), the

heat exchanger (or heater coil if electric) temperature

will increase above acceptable levels, and will result in

shut down by a high temperature safety switch

incorporated into either the heat exchanger, or the

heater area.

GAS HEAT UNITS – If heat shuts off due to safety

switch, or gas supply shut off failure, then always

close manual gas valve to unit prior to any

electrical service. Prolonged overheating of the

heat exchanger will shorten its life.

Improper installation, adjustment, alteration,

service, or maintenance can cause property

damage, personal injury, or loss of life. Installation

and service must be performed by a qualified

installer, service agency, or if gas fired units, the

gas supplier. Refer to installation instructions

provided with the unit, and this manual.

WARNING

WARNING

7

Multiple Unit Operation

When several units are used in conditioning the space,

and any are combination heating-cooling units, all

system thermostat switches must be set at either

heating, cooling, or set at ‘OFF’. Do not run part of a

system switched to an opposite mode. Cooling only

units should be switched to ‘OFF’ at the thermostat

during the heating season.

Wiring Diagrams

A complete set of unit specific wiring diagrams in both

ladder and point-to-point form are laminated in plastic

and affixed to the inside of the service access door.

Condensate Piping

A drain trap must be connected to the drain connection

located on the back of the unit. If codes require a

condensate drain line, it should be the same pipe size

as the drain nipple and should pitch downward for its

entire length toward the drain.

A “P” Trap is factory supplied and shipped in the

control access compartment for field installation. An

air break should be used with long runs of cond ensate

lines.

Normal Thermostat Operation

For Heating

- Set system switch to ‘HEAT’

- Set fan switch to ‘AUTO’ or ‘ON’

- Set the desired temperature

For Cooling

- Set system switch to ‘COOL’

- Set fan switch to ‘AUTO’ or ‘ON’

Air Circulation

Set the system switch to ‘OFF’

-

Set the fan switch to ‘ON’

System Off

-

Set the system switch to ‘OFF’

Set the fan switch to ‘AUTO’

-

-

Do not change temperature setting

With these settings the system is shut down,

-

except for the 24-volt control system power, and

the compressor crankcase heater (approx. 60W).

Night and Vacancy Operation

To reduce the operation time during low load periods,

it is recommended that the temperature setting be

increased by 5°F during non-occupied periods of the

cooling season in commercial buildings, such as nights

and weekends. Decrease the temperature by 10°F at

these times during the heating season.

Gas Heating System

The heating section is for use with natural gas supply

pressure of 6” to 10.5” w.g. The unit may also utilize

propane gas (after installation of a field conversion kit)

with a supply pressure to the valve of 11” to 12” w.g.

The rating plate on the furnace must be inspected to

make sure the unit is stamped for proper gas. A 1/8”

pressure tap should be field supplied by the installer in

the piping just ahead of the gas valve. The pressure

tap on the outlet end of the gas valve can be checked

to verify manifold pressure of 3.2” to 3.5” w.g. for

natural gas or 11” to 12” w.g. for propane.

A centrifugal blower that draws in outside air through a

protected opening supplies combustion air.

This induced draft blower introduces the air to the

blower tubes, which assures even primary and

secondary airflow.

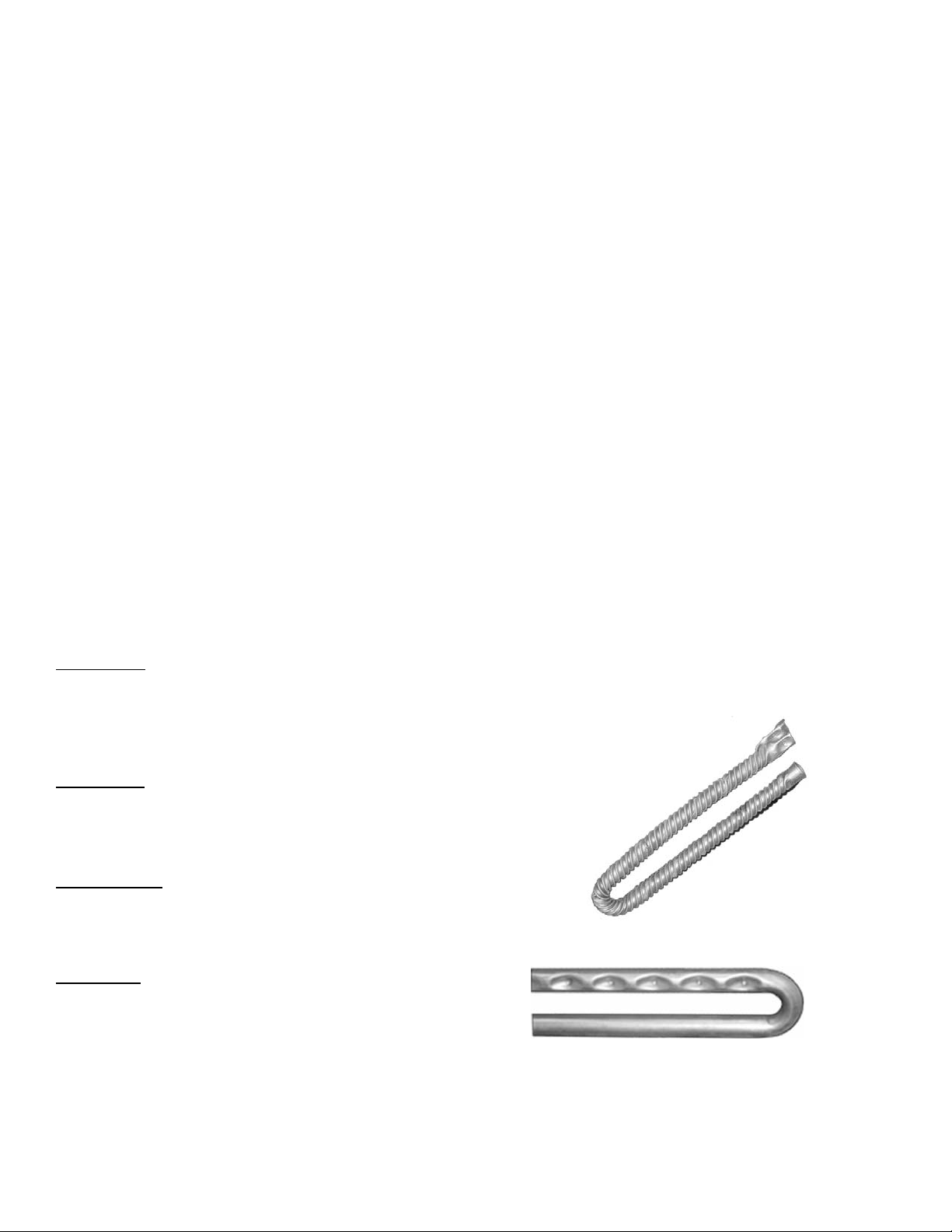

Gas heating units use AAON’s patented high efficiency

twisted tube, or dimpled heat exchanger. All heating

system and related safety controls are 100% tested on

each unit prior to shipment.

Figure 8a, HB Gas Heat Exchangers

Dimpled Tube

Twisted Tube

8

Modulating Hot Gas Reheat and Hot Gas

Bypass Systems on DX Units

Some DX cooling units may contain Modulating Hot

Gas Reheat (MHGRH) and/or Hot Gas Bypass

(HGBP) systems as factory installed options. Piping

and valves for these systems will be located on the

inside wall of the condenser section. The condenser

top must be removed for access to these components.

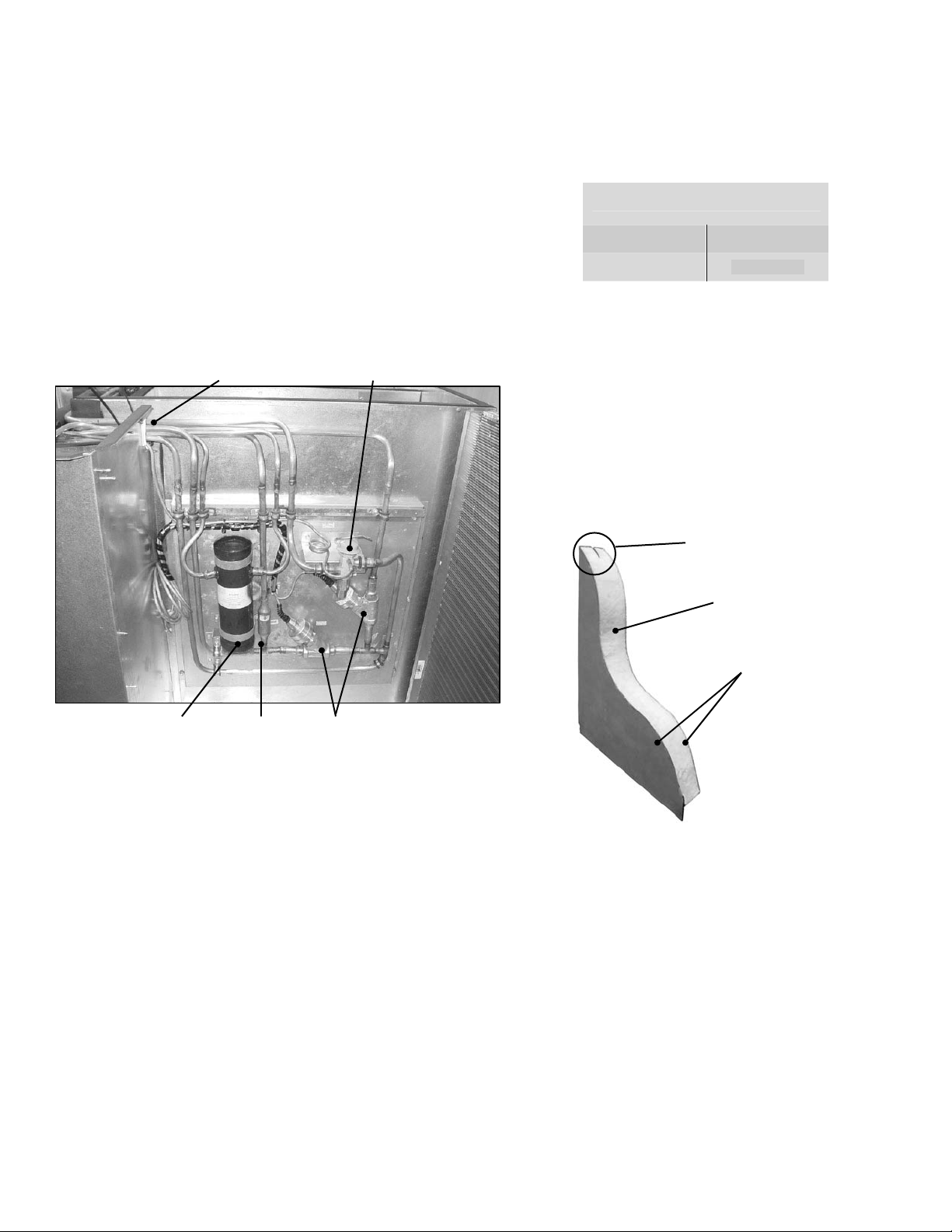

Figure 9a, MHGRH and HGBP System

Piping to

Compressor and

Coil Compartments

HGBP

Valve

Receiver

Tank

Check

Valve

MHGRH

Valves

Filter Sizes

Table 9.1, Pleated Filter Sizes

All 2-5 Ton HB Packaged Units

Qty. Size

2 20” x 25” x 2”

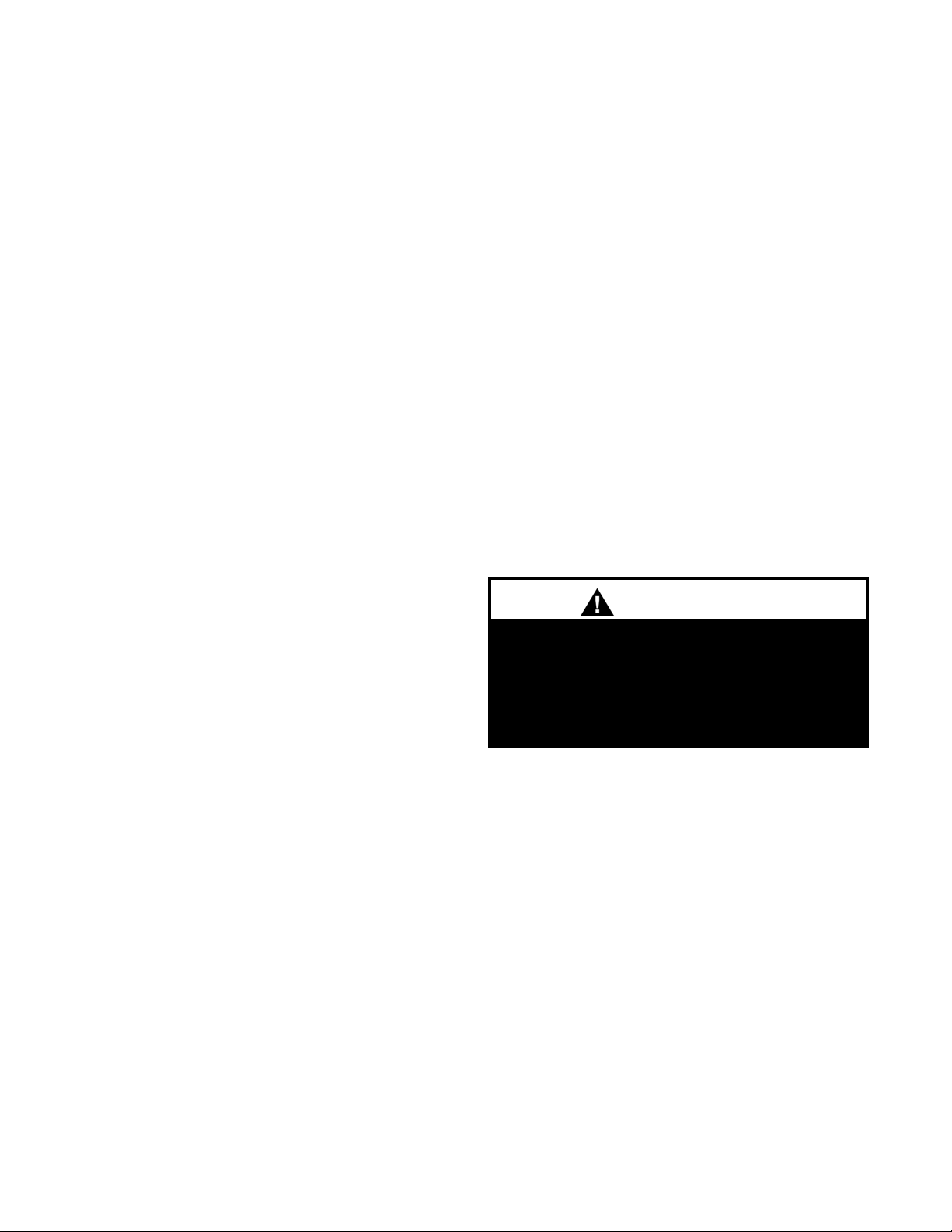

Cabinet Construction

All HB units are insulated with closed-cell polyurethane

foam, which has twice the R-value of fiberglass

insulation. All cabinet walls and roof use double-wall

G90 galvanized steel. The solid core foam interior

provides a rigid, impact resistant surface. All panels

have a thermal break with no metal-to-metal contact

from outside to inside.

Figure 9b, High Performance Composite Panel

Thermal Break

Foam Core

Double-Wall

9

4. Delivery

ALL SHIPMENTS ARE F.O.B. THE FACTORY. IT IS

THE RESPONSIBILITY OF THE RECEIVING PARTY

TO INSPECT THE EQUIPMENT UPON ARRIVAL.

Receipt & Inspection

The unit should be inspected for damage that may

have occurred in transit. Do the following upon

receipt:

1. Inspect all items for internal, external, and

concealed damage before accepting

2. Assure carrier is in compliance with Bill of

Lading instructions

If damage is found:

1. Note all damage on Bill of Lading immediately

− Photograph damage if possible

− Do not move or discard damaged

packaging materials

2. Call carrier immediately to file a freight claim,

and to schedule a freight inspection

3. When damage is repairable, contact the

factory for replacement parts: 918-583-2266

4. With permission of carrier, make the repairs

5. Stay in contact with carrier to ensure payment

of your claim

If repairs must be made to damaged goods, the factory

must be notified before any repair action is taken.

Equipment alteration, repair, or unauthorized

manipulation of damaged equipment without the

manufacturer’s consent will void all product warranties.

Contact the AAON Warranty Department for

assistance with handling damaged goods, repairs, and

freight claims: 918-583-2266.

Verify the equipment against the order documents

upon delivery. If what you received does not match

your order exactly, then notify your Sales

Representative at once.

Storage

This equipment is designed for outdoor use. However,

if installation will not occur immediately following

delivery, then store equipment in a protected area, and

in the proper orientation as marked on the packaging

with all internal packaging in place. Secure all looseshipped items.

5. Installation

General

DX models of this unit use R-410A refrigerant only,

and should not be used with any other refrigerant. HB

package units are for outdoor installation only.

Codes & Ordinances

System should be sized in accordance with National

Warm Air Heating and Air Conditioning Association

Literature, or the Guide of American Society of

Heating, Refrigeration and Air Conditioning Engineers.

The installation must conform with local building

codes, or in the absence of local codes, with (United

States) National Fuel Gas Code “ANSI-Z223.1”,

(Canada) current CAN/CGA-B149.1 or B149.2.

Installation codes for Gas Burning Appliances and

Equipment, current C.S.A. Standard C22.1, Canadian

Electrical Code Part 1, and C.S.A. Standard B52

Mechanical Refrigeration Code, and Local Plumbing or

Waste Water Codes.

It is the responsibility of the installing contractor to

comply with codes, ordinances, local and

municipal building laws, and manufacturer’s

instructions. Personal injury and/or equipment

damage may result if proper procedures are not

followed.

Handling

Be aware of what is contained in the equipment!

Dependent upon the optional accessories that were

ordered, this equipment may contain fragile

components and delicate electronics. Although the

unit is constructed of sturdy materials, avoid impacts

and handling methods that may damage internal

apparatus and structure, or the exterior painted

surfaces of the unit. Take care not to apply destructive

force to coils, or other parts protruding beyond the

extents of the unit casing. Always handle the unit by

its exterior casing.

Keep equipment free from debris, and construction

waste during installation. Foreign materials may

adversely affect unit operation resulting in premature

failures that will not be covered by the manufacturer’s

WARNING

10

Loading...

Loading...