Page 1

DIY

KITS

Y6

FRAME KIT

Thank you for purchasing a

3DR Y6 DIY Kit!

These instructions will guide

you through assembling and

wiring your new autonomous

multicopter.

Page 2

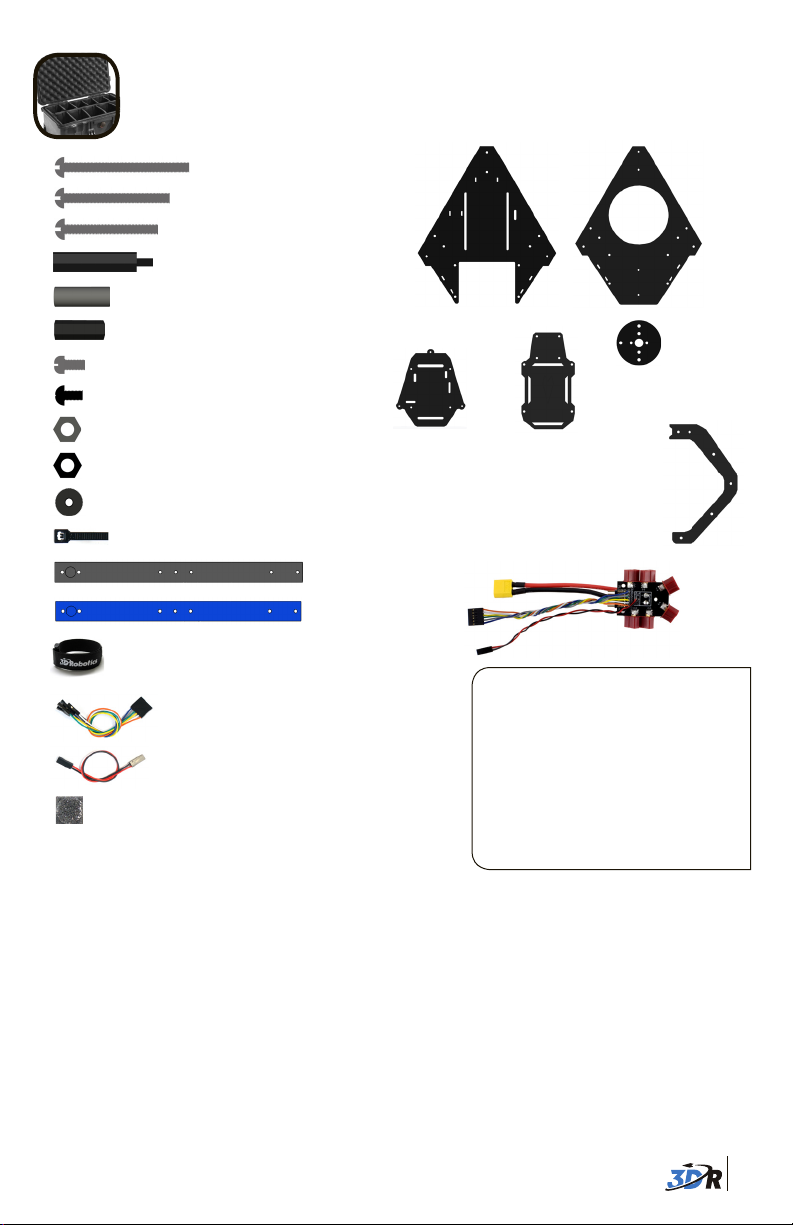

CONTENTS

35 mm steel bolts (3)

30 mm steel bolts (2)

25 mm steel bolts (20)

30 mm threaded spacers (8)

19 mm hollow spacers (13)

18 mm threaded spacers (12)

Your 3DR Y6 Kit contains:

Top plate

Bottom plate

6 mm steel bolts (12)

5 mm nylon bolts (40)

Metal nuts (23)

Nylon nuts (8)

Thumb nuts (5)

11” zip ties (6)

Battery straps (2)

Six-wire RC receiver cable

Two-wire RC receiver cable

Double-adhesive foam mounting squares (4)

Threadlocking compound

You will also need:

Frame:

Electronics:

» Phillips screwdriver (small)

» 5.5 mm (7/32) wrench

» 2 mm (5/64) hex wrench

» Blue threadlocking compound

» Double-sided foam mounting tape

» Soldering equipment

APM plate

Black arm (1)

Blue arm (2)

Co-axial motor

mounting plates (6)

Accessory

plate

C-type landing gear

plates (6)

Power distribution board

These instructions require some minor

soldering. If you’re unfamiliar with

soldering, our friends at Sparkfun have

some great tutorials that can get you

started, including this comic:

learn.sparkfun.com/curriculum/42.

For an example of exactly what you’ll

be doing for this assembly (soldering

Deans connectors to ESCs), check out

this video: youtu.be/3LJIQeKuLLU.

These instructions show the complete assembly and wiring process for a 3DR Y6 using

3DR electronics. For assembling your Y6 Frame Kit using other electronic components,

please adjust these instructions accordingly.

1

Page 3

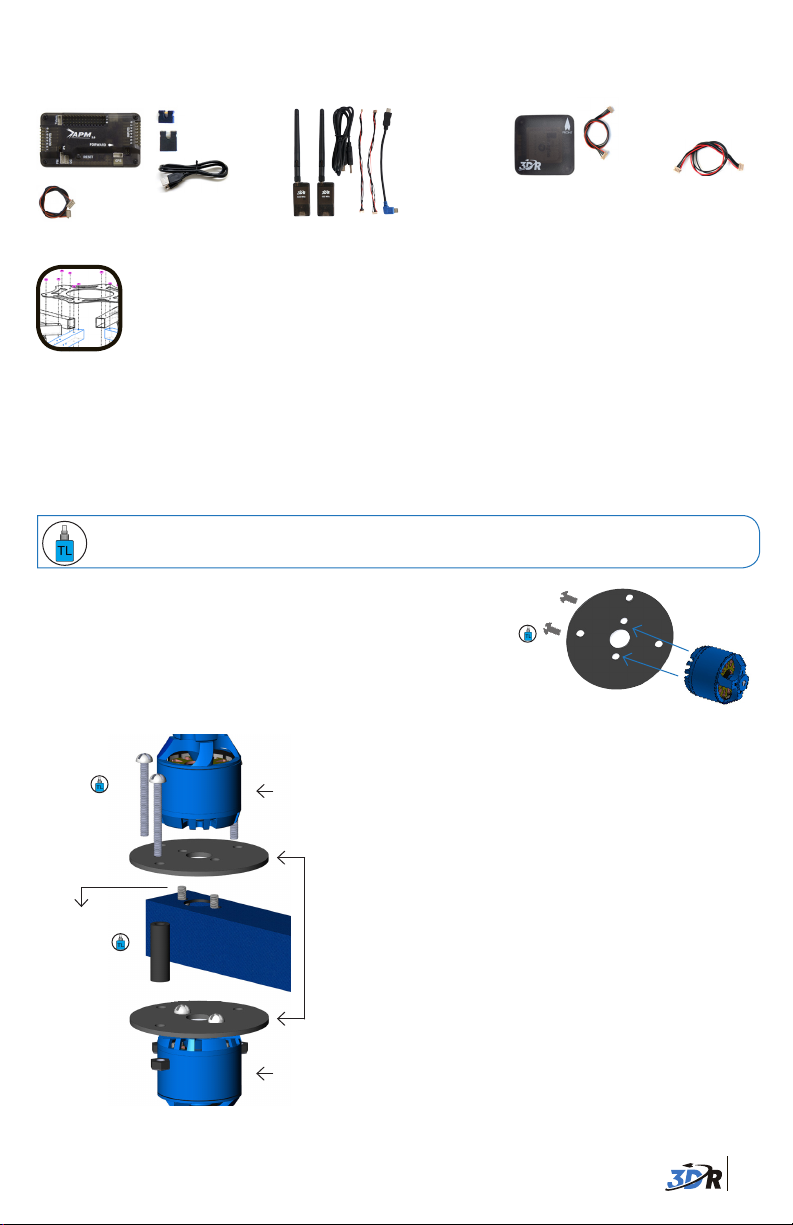

You may have opted to also receive:

3DR APM 2.6:

3DR APM 2.6

Telemetry adapter

cable

4 mm JP1

jumper connector

6 mm PPM

jumper connector

Micro USB cable

3DR Radio:

Radios (2)

Antennas (2)

Micro-USB cable

Android OTG cable

Autopilot connectors

3DR uBlox GPS+Compass:

6-position to

5-position GPS

cable

3DR uBlox GPS

board with compass

4-position compass

cable

FRAME ASSEMBLY

1 Attach motors to arms

Each arm of your Y6 will have a top motor and a bottom motor attached to the arm using

co-axial motor mounting plates. To ensure motors are securely bolted to arms, apply a small

amount of threadlock to each bolt before fastening.

Threadlocking compound is an important component to ensure your motors remain

firmly attached! For application tips, check out this video: goo.gl/bM3MA.

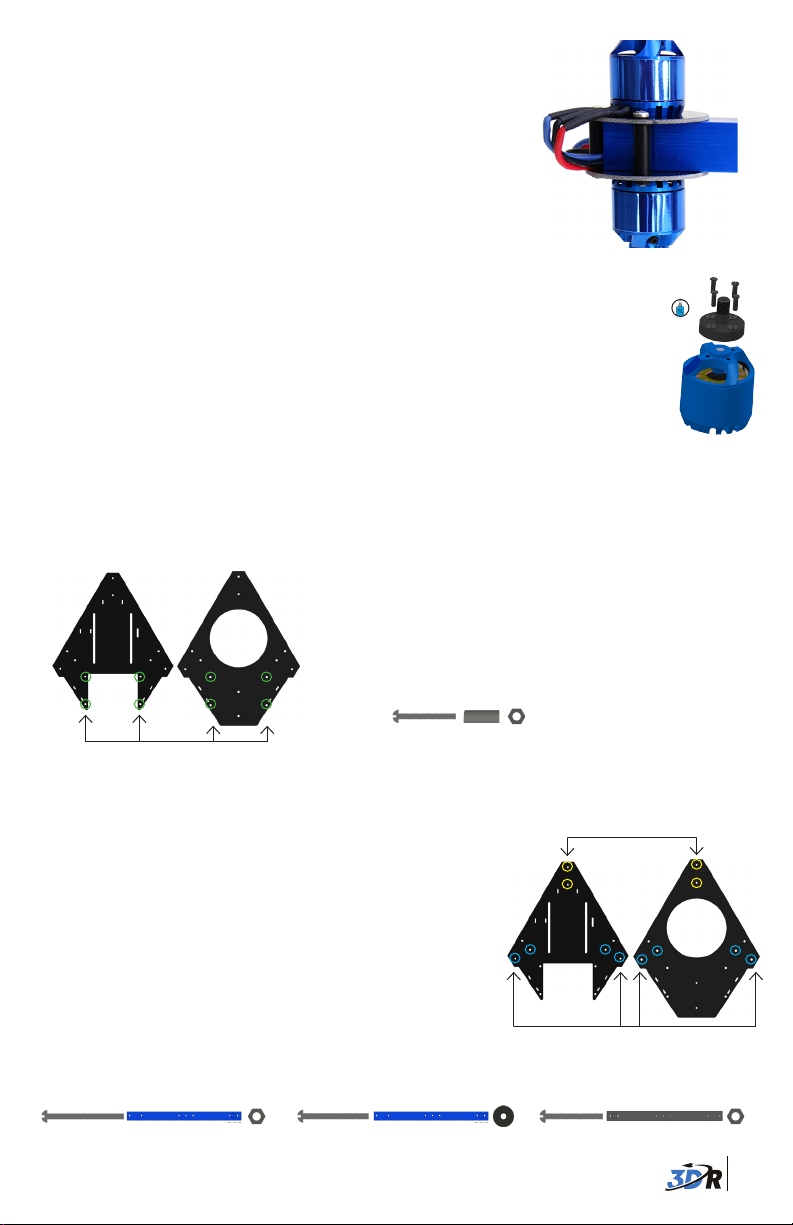

Attach mounting plates to bottom motors:

Using two 6 mm steel bolts and one co-axial motor

mounting plate, fasten motor onto plate as shown.

Repeat for three of six motors.

Secure with

6 mm bolts

Attach

motor

here

25 mm

bolts

6 mm bolts

19 mm hollow

spacers

Top and bottom motors attached to

arm with mounting plates

Top motor

Mounting

plates

Bottom

motor

Bottom motor assembly

Attach top motors to arms:

Insert mounting plate between top motor and

arm. Make sure motor cables protrude in the

direction of the end of the arm.

Fasten motor and plate to arm using two 6 mm

steel bolts by accessing through the two large

holes in the bottom of the arm. Repeat for all

three arms.

Secure mounting plates together:

Place mounting plates with bottom motors

attached on underside of arm so that the three

outer holes in the plates align. Insert a 19 mm

hollow spacer between top and bottom holes;

thread a 25 mm bolt through spacer and plates.

Secure with a metal nut. Repeat for all three

holes on mounting plates. Repeat for all three

arms.

2

Page 4

Thread motor cables through arms:

Thread the cables from the top motors through

the ends of the arms. You’ll want to distinguish

between top and bottom motor cables, so use a

pen or piece of tape to mark the protruding ends of

the top motor cables before threading the bottom

motor cables through the arms.

Completed motor assembly

Install motor collets2

Attach a threaded collet to the top of each motor using the

four small screws included with collets. Apply threadlock to

each screw before fastening. Repeat for all six motors.

Motor collet assembly

3 Attach top and bottom plates to arms

The top and bottom plates will form the main frame of your copter. We’ll attach these plates

both to each other and to your copter’s arms.

Top plateBottom plate

Attach top and bottom plates together through the

four aligning holes near the front ends of the plates as

shown using a 25 mm bolt, 19 mm hollow spacer, and

metal nut.

25 mm bolt + 19 mm spacer + metal nut

Attach at four points

Next attach the arms to the plates. The black arm will

attach to the narrowest angle of the triangular plates.

The two blue arms indicate your copter’s front-facing

Attach black arm here

direction and will attach to either side of the front of the

plates.

Place the arm between the two plates so the two holes

in the arm align with the holes in the plates. Insert a bolt

into each hole from under the bottom plate and secure

with nuts above the top plate. For inner holes use 35 mm

bolts and metal nuts; for outer holes on blue arms use 30

mm bolts and thumb nuts; for the outer hole on the black

arm use a 25 mm bolt and metal nut. Insert bolts from

below the bottom plate so that nuts are attached above

Attach blue arms here

the top plate.

Inner holes use: Outer hole (black arm) use:

35 mm bolt + arm + metal nut

Outer holes (blue arms) use:

30 mm bolt + arm + thumb nut

25 mm bolt + arm + metal nut

3

Page 5

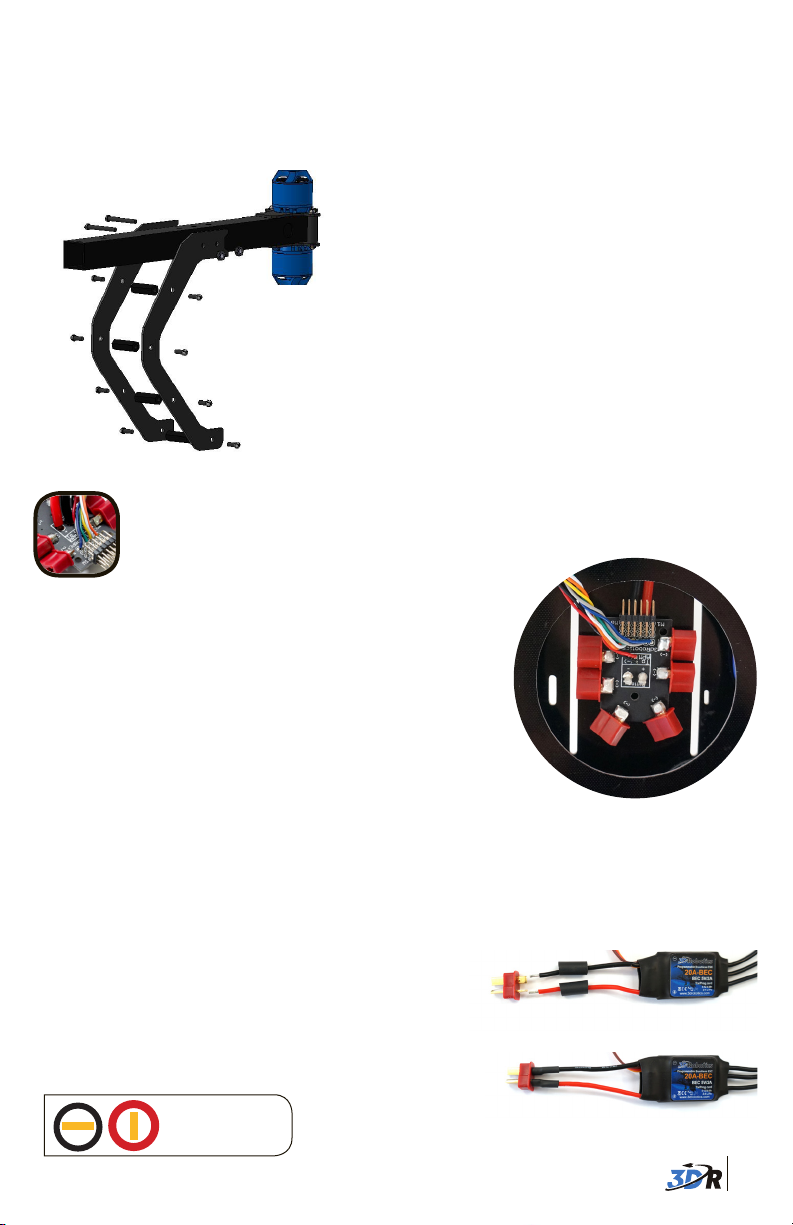

4 Assemble legs

Your Y6 has three legs, each comprised of two C-type landing gear pieces. To assemble each

leg, align the two pieces and attach through four bottom holes using four 18 mm threaded

spacers and eight 5 mm nylon bolts.

25 mm bolts

Leg assembly

Metal nuts

18 mm

spacers

5 mm

nylon

bolts

For each hole, position spacer between holes;

secure from each side with nylon bolts.

Repeat for all three legs.

Attach legs to arms with C-shape facing

toward motors (to provide clearance for

propellers on bottom motors). Align the two

top holes in the leg with the two holes in the

center of the arm. Insert two 25 mm bolts and

secure with metal nuts.

POWER WIRING

Place power distribution board

1

The power distribution board (PDB) allocates power to

your copter’s motors. Place the PDB in the center of

your copter through the hole in the top plate, resting on

top of the bottom plate. You may want to experiment

with the orientation of the board to accommodate all

necessary wiring.

PDB between top and bottom plates

2 Solder Deans connectors to ESCs

Electronic speed controllers (ESCs) regulate how much power is applied to each motor. To

connect the six ESCs to the PDB, you will need to solder the provided Deans connectors to the

ESCs’ black and red wires.

Add a half-inch length of heat shrink tubing onto

each ESC red wire and black wire. Solder the

positive Deans connector plug to the red wire

and the negative Deans connector plug to the

black wire. Shrink tubing over connections.

Deans to ESC:

Negative = Black

+

-

Positive = Red

Add heat shrink and align wires to correct plugs.

Soldered connectors

4

Page 6

3 Connect motors to ESCs

Conect each motor to an ESC using bullet connectors. The order of the bullet connectors

doesn’t matter at this point but will become important later when we set motor directions,

so make sure you can still access these bullet connectors after assembly is complete. Each

ESC should connect to only one motor. Label your ESCs by motor number according to the

diagram below.

Y6 motor order

Starting with the ESC labeled 1 , connect the ESC three-wire cable to the corresponding

position on the PDB pins (M1 - M6 for motors 1 - 6) with orange wire positioned at the top.

Connect ESC Deans connector to any PDB Deans connector. Note that the order of the ESC

Deans connectors does not matter, while the ESC three-wires cables must match the

motor numbers on the PDB pins. Repeat for all motors and ESCs.

Deans

Pins

Motor #

labels

#1

Motor connected to ESC

Don’t secure the ESCs to the frame until you have confirmed that each motor spins

in the direction specified in the diagram above (see motor setup instructions at

copter.ardupilot.com).

ESC connected to PDB

Label ESCs by motor

number; match ESC

motor number to

PDB pin number.

4 Connect power module to PDB

Connect power module 6-position cable to the power module 6-position port. Place power

module in the center of your copter near the PDB. Connect PDB red and black cable (with

XT60 connector) to power module XT60 connectors.

Power module with 6-wire cable

PDB

5

Page 7

INSTALL APM

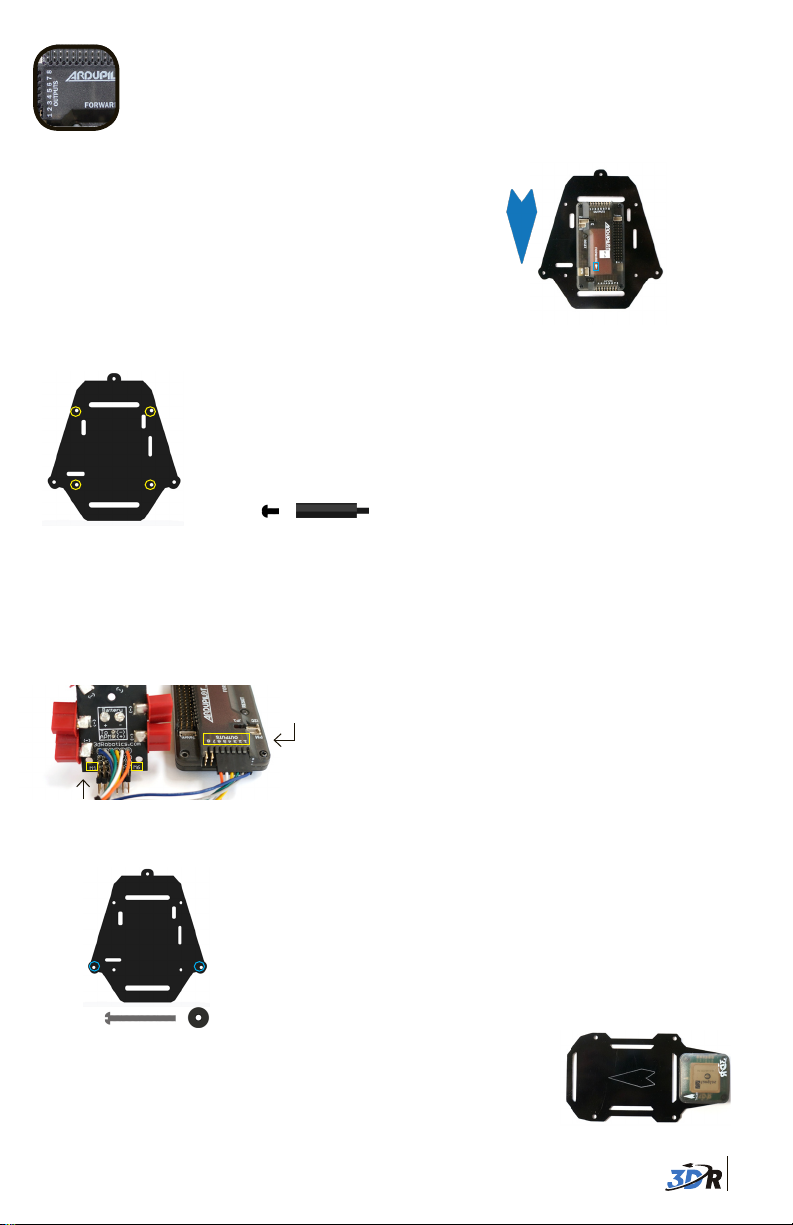

1 Mount APM

Place APM 2.6 in the center of the APM plate

with the arrow on the case facing forward

(toward wide end). Use four adhesive

foam squares to secure the bottom of the

case to the plate (one on each corner).

Ensure APM and foam squares are firmly

attached so the position of APM does not shift during flight.

For APM 2.5: Mount APM to the top of the accessory plate.

Using the four holes shown across, insert a 30 mm

threaded spacer over each hole and secure from

below with a 5 mm nylon bolt.

Ensure arrow

on APM points

forward!

3DR APM 2.6

APM plate

APM plate

5 mm nylon bolt + 30 mm spacer

2 Connect APM to power module and PDB

Locate the PDB six-wire cable (multicolored) and the power module six-position cable (red

and black); thread these cables up through the slots in the APM plate where they can connect

to APM.

Connect the power module six-position cable

(red and black) to APM’s PM port. Connect the

PDB six-wire cable (multicolored) to the APM

output signal pins (top row). Ensure that the

individual PDB wires are connected to the

corresponding APM output signal pins. For

example, the wire originating in the position

marked M1 (motor 1) on the PDB must connect

to APM output signal pin 1.

Accessory plate

PDB wire

positions

APM plate

35 mm bolt + thumb nut

3

Mount GPS

APM output

pin positions

PDB to APM wiring

The APM plate connects to the ends of the three 35 mm bolts

securing the inside holes of the arms. Place the three outer holes in

the APM plate over the exposed 35 mm bolts on the top plate and

secure with thumb nuts.

Place the GPS module onto the square end of the accessory

plate with the arrow pointing towards the center of the plate. Use

double-sided foam tape to secure case to plate.

Ensure arrow on

GPS points forward!

6

Page 8

For GPS without compass: Attach GPS board to four holes

as shown using four 5 mm nylon bolts, four 30 mm

spacers, and four nylon nuts.

GPS without compass: 5 mm nylon bolt + 30 mm spacer + GPS + nylon nut

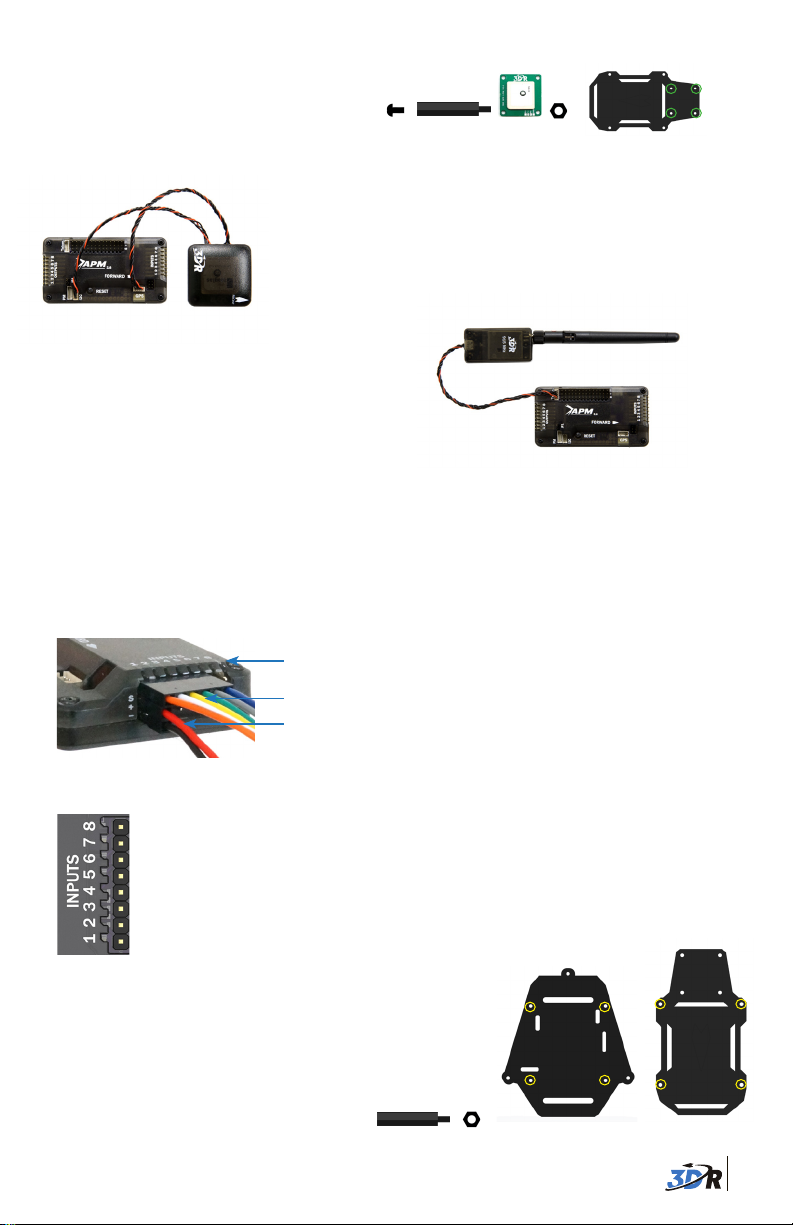

4 Wire additional components to APM

3DR uBlox GPS with Compass:

Connect the 6-position to 5-position cable to the GPS

6-position port and to the 5-position APM GPS port (use

top-entry port not side-entry port). Connect the 4-position

cable to the GPS 4-position MAG port and to the APM I2C port.

3DR Radio air module:

Attach antenna to 3DR Radio air module.

Connect telemetry cable to the air module pins

(ensuring that the red wire aligns with the pin

marked 5V) and to the APM Telem port.

Radio control (RC) receiver:

To connect an RC receiver to APM, use the six-wire and two-wire cables provided with

your copter.

Note: APM also supports one-wire PPM connection with supported receivers.

See copter.ardupilot.com for instructions.

Use the six-wire cable to connect the receiver’s signal pins to APM’s input signal pins.

Use the two-wire cable to connect power and ground pins between APM and the receiver.

APM input pin numbers

Connect six-wire cable to signal pins (top row, “S”).

Connect red wire to power pin (center row, “+”) and

APM inputs wiring

APM Input Signal Pins

6 AUX 2 (OPTIONAL)

5 AUX 1 (MODE SWITCH)

4 YAW / RUDDER

3 THROTTLE

2 PITCH / ELEVATOR

1 ROLL / AILERON

black wire to ground pin (bottom row, “-”).

Match the correct control channel

with its corresponding APM input

signal pin.

5 Attach accessory plate to APM plate

Place accessory plate onto the four 30 mm spacers

protruding from the APM plate, and secure with four

nylon nuts.

30 mm spacer + nylon nut

APM plate

Accessory plate

7

Page 9

Now that your Y6 assembly is complete, the following

steps will get you started configuring your copter.

INSTALL SOFTWARE

Mission Planner is free, open-source software providing multiplatform configuration and fullfeatured waypoint mission scripting for autonomous vehicles.

To install Mission Planner on your ground station computer (Windows only), visit ardupilot.

com/downloads, select Mission Planner, and select sort by date (short link: goo.gl/Si5grC).

Select the MissionPlanner - MSI (Microsoft installer package). For the same features as

Mission Planner for Mac, download APM Planner from ardupilot.com.

Mission Planner Downloads Screen

Mission Planner « Downloads

Sort by: Title | Hits | Date

■ MissionPlanner - MSI - 1.2.62

After selecting the most recent MSI, read the

safety information and select Download:

Open the downloaded file to run the Mission Planner Setup Wizard. Select the option to

proceed if prompted with a security warning.

Device Driver Installation Wizard Mission Planner Setup Wizard

Mission Planner Setup Wizard will

automatically install the correct device

drivers.

Mission Planner will notify you when an update is available;

please always run the most current version of Mission Planner.

Launch Mission Planner to explore

the capabilities of your autonomous

vehicle!

Select MSI to download

most recent version.

Download

Mission Planner: Update Message

8

Page 10

Mission Planner: Flight Data Screen

Before flying, complete Mission

Planner’s configuration utilities,

including RC (shown below),

compass, accelerometer, frame

type, and flight mode calibrations.

Visit planner.ardupilot.com for

complete Mission Planner

instructions.

CALIBRATION

Mission Planner’s mandatory hardware calibration steps allow you to

program and configure the APM autopilot for your copter.

Connect APM to your computer using the provided micro-USB cable.

Windows will automatically install the correct drivers for APM.

Select Initial Setup, Install Firmware, and Quad to install flight code firmware onto APM.

APM USB port

Now you can connect APM to Mission Planner.

1

2

3

On the left side of the Initial Setup screen, select Mandatory Hardware. You will need to

perform each of the calibration procedures listed under this menu.

Frame Type: Select your configuration: Plus or X (cross).

Compass: Select the options to enable the compass, to allow automatic declination, and

to select your autopilot type. Select Live Calibration to launch the wizard, and follow the

prompts.

Accel Calibration: Check the box for AC 3.0+, select Calibrate, and follow the prompts to

calibrate the autopilot’s accelerometer. Make sure to wait a couple of seconds before and

after changing the positions of the copter.

Connect APM to Mission Planner:

1 Select Arduino Mega.

2 Select 115200.

3 Select Connect.

9

Page 11

!

CW

CCW

CW

Radio Calibration: Turn on your RC transmitter, select Calibrate Radio, and move all sticks and

switches to their extreme positions. Select Click when Done once the red bars are set for all

available channels.

Show me! Watch videos demonstrating live calibration techniques at 3DRobotics.com/learn.

Complete all configuration procedures as described at copter.ardupilot.com

before attempting your first flight.

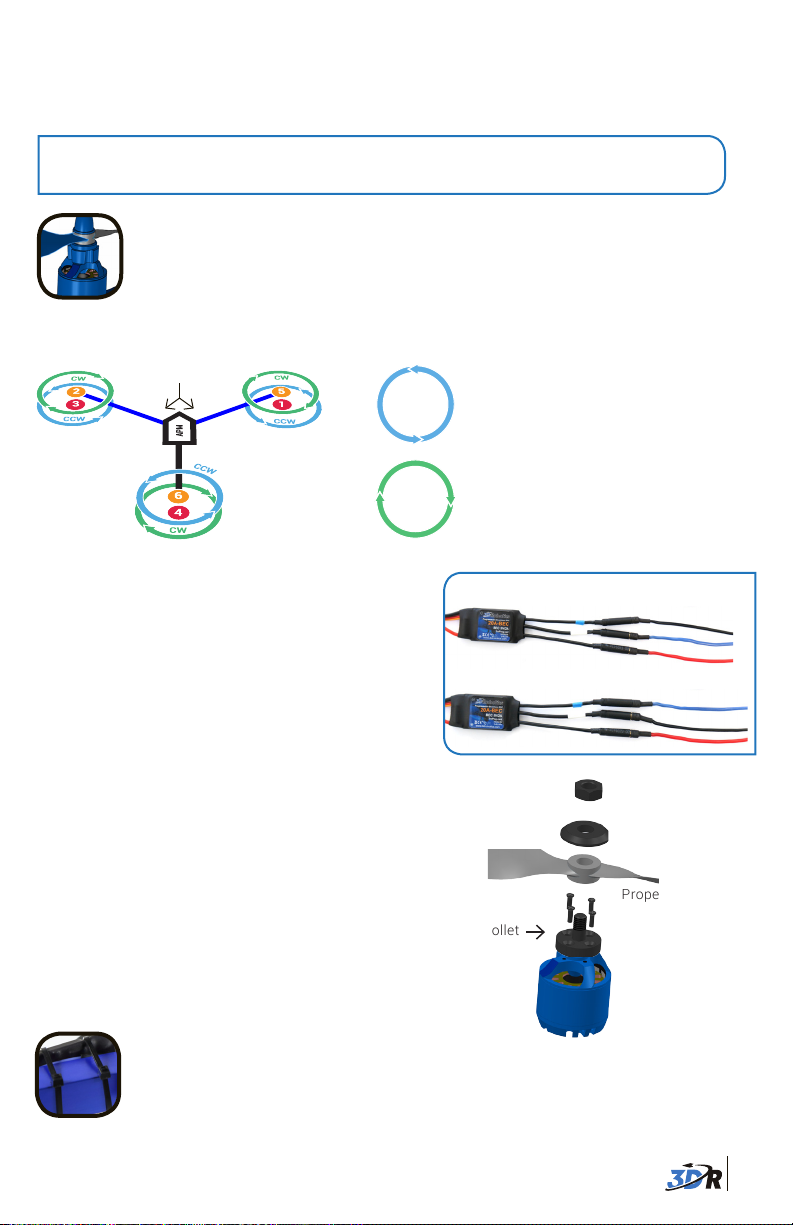

MOTORS & PROPELLERS

The diagram below shows the correct rotation direction for each motor. Before attaching propellers, test the motors to ensure the motor rotation is correct.

Blue arms

Y6 motor order

The rotation direction for each motor is determined

by the connections between the motor and the ESC.

To reverse the rotation direction for a motor, switch

two of the three wires connecting the motor and

the ESC.

Your copter includes normal propellers (unmarked

or marked “SF”) and pusher propellers (marked

“SFP” or “P“). Add pusher propellers to motors

marked clockwise, add normal propellers to motors

marked counterclockwise. Use 10-inch props for

top motors and 11-inch props for bottom motors.

CCW

COUNTERCLOCKWISE ROTATION:

!

USE NORMAL PROPELLER

CW

CLOCKWISE ROTATION:

!

USE PUSHER PROPELLER

1. Connection between motor and ESC

2. Switch two wires to reverse motor rotation.

Prop nut

Remove plastic rings from propeller package, select

the one with the larger internal diameter, and insert it

into the back of the propeller hub.

Add propeller to motor collet with writing

facing up in relation to the sky. This means

you’ll need to attach props to bottom motors

upside down! Add the washer and prop nut above

the propeller; tightly fasten prop nut to threaded collet.

Safety Check! Ensure writing on props faces up.

SECURE WIRING

Before flying, use zip ties to secure ESCs to the frame.

Washer

Propeller

Collet

Motor

10

Page 12

Ensure that all wires are secured so they

will not become entangled in spinning

propellers, are not too tight around corners

(no hard 90-180 degree bends), and do not

pull on the APM or other components.

ESCs and wiring secured with zip ties

FOLDING

Your Y6 can fold for ease of transport. To collapse the blue arms, remove thumb nuts and bolts

from outer holes, and slide blue arms toward black arm.

Remove thumb nuts and

bolts from outer holes.

Travel positionFlight position

To collapse the legs, remove the bolts and nuts from the inner holes where the legs attach to

the arms.

Remove nut and bolt

from inner hole.

Travel positionFlight position

Fold.

Fold.

Visit copter.ardupilot.com to learn about multicopter safety, hardware

and software configuration, using autonomous flight modes, tuning,

designing missions with waypoints and events, troubleshooting, and

more. For customer support, contact us at help@3DRobotics.com or

call our support line at +1 (858) 225-1414 M-F 8-5 PST Happy flying!

11

Loading...

Loading...