Page 1

Deconstruct frame

1

First deconstruct your Hexa’s frame to allow us to alter the conguration

of the motors and arms.

Remove legs

Remove the two bolts securing leg to the arm. Repeat for all three legs.

3DR Hexa-to-Y6 Conversion Kit

ASSEMBLY INSTRUCTIONS

Introducing the 3DR Y6 – an exciting new option in the 3D

Robotics product lineup. With its lightweight and compact

design, the Y6 provides enhanced agility and stability in all

conditions, an open-view camera platform, and operational

redundancy to withstand in-ight motor failure. This manual

will guide you through the process of transforming your 3DR

Hexa into a Y6.

Remove propellers

Unscrew nut; remove spacer and propeller. Repeat for all six propellers.

Separate stack-ups, APM, and mounting plate

Unscrew the top four bolts of the stack.

Remove top plate. Disconnect any cables

connected to your APM.

Unscrew spacers; remove bottom stack-up

plate (with APM).

Remove remaining spacers and thumbnuts

to detach mounting plate.

Stack-ups

Disconnect ESCs

Disconnect electronic speed controller (ESC) three-wire cables from power

distribution board (PDB) signal pins. Disconnect ESC Deans connectors from

Deans connectors on PDB.

Disconnect ESC bullet connectors from motor cables; cut zip ties attaching ESC

to arm. Repeat for all six ESCs.

Note: If you soldered ESCs directly to motor cables, you’ll need to cut the cables

between ESCs and motors attached to arms we will remove in the next step.

Wait to resolder until you’ve veried motor spin direction.

Disconnect motors

Remove two bolts attaching motor to arm. Repeat for all six motors.

CONTENTS

Thank you for purchasing a 3DR Y6 conversion package!

This kit contains:

25 mm stainless steel bolt

x6

Co-axial motor mounting plate

18 mm threaded hex spacer

19 mm hollow spacer

x6

C-type landing gear

11 x 4.7 normal propeller

11 x 4.7 pusher propeller

You will also need:

» A fully assembled 3DR Hexa-C or Hexa-B

» Phillips screwdriver (small)

» 5.5 mm (7/32) wrench

» Threadlock compound

x2

x1 (+1 spare)

Safety Check! Disconnect battery before modifying your copter.

5 mm black nylon bolt

Metal hex nut

x12

x12

x12

x24

x12

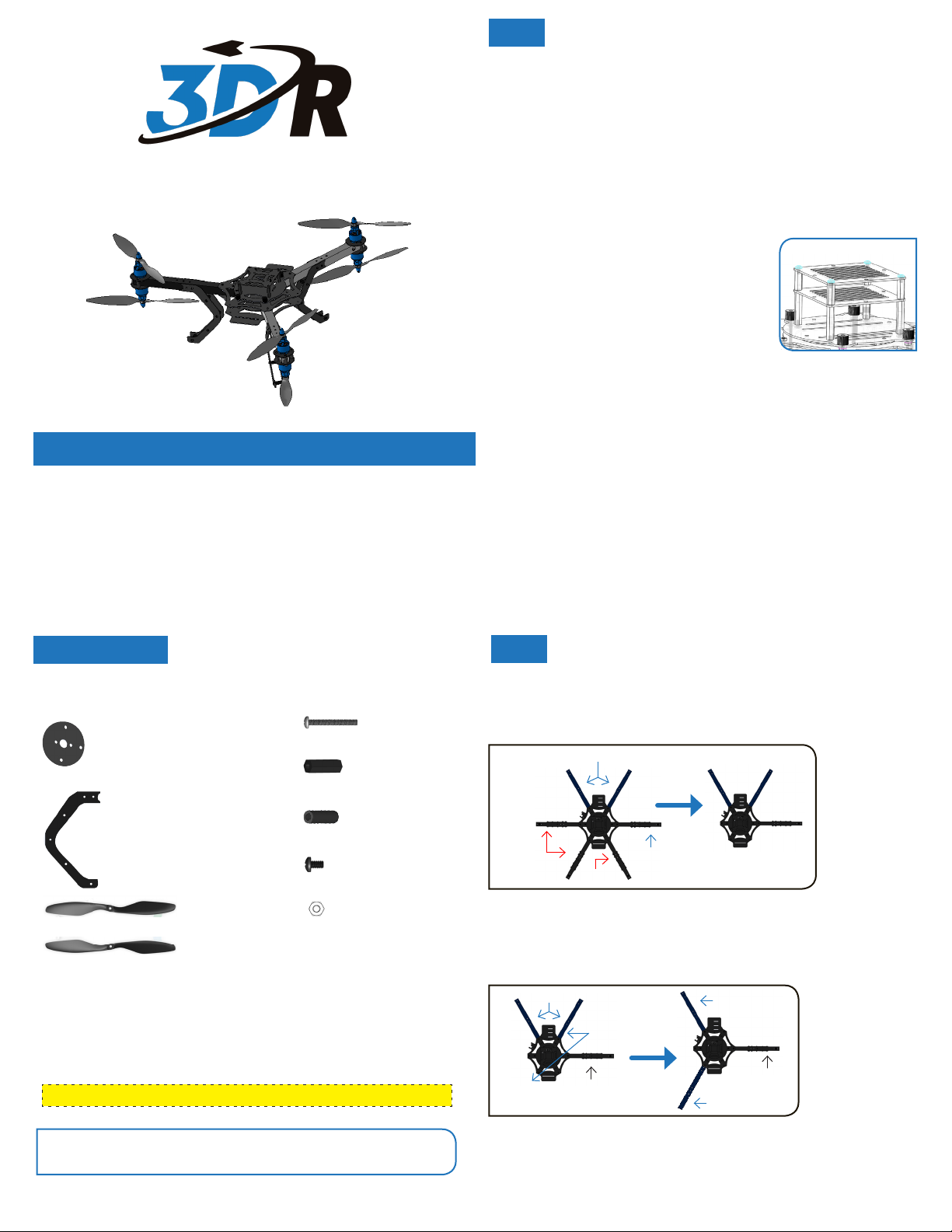

Create the Y

2

Detach extra arms

Remove three black arms, leaving one black arm directly to the right of the

blue arms.

Blue arms: keep!

Remove

extra black

arms

For each extra arm, remove the two bolts securing arm to frame. Remove

motors completely from detached arms.

Remove

Keep!

Move blue arm

Blue arms

Move to position

directly across

Black arm

Blue arm

Black arm

Blue arm

Make sure to save your parts during the following steps. We’ll

reuse them later in the conversion process.

©2013 3D Robotics

Detach the blue arm adjacent to remaining black arm. Move to position

directly across frame. Reattach to frame in new position using the same two

bolts. Your copter’s arms should now form an evenly spaced Y.

Page 2

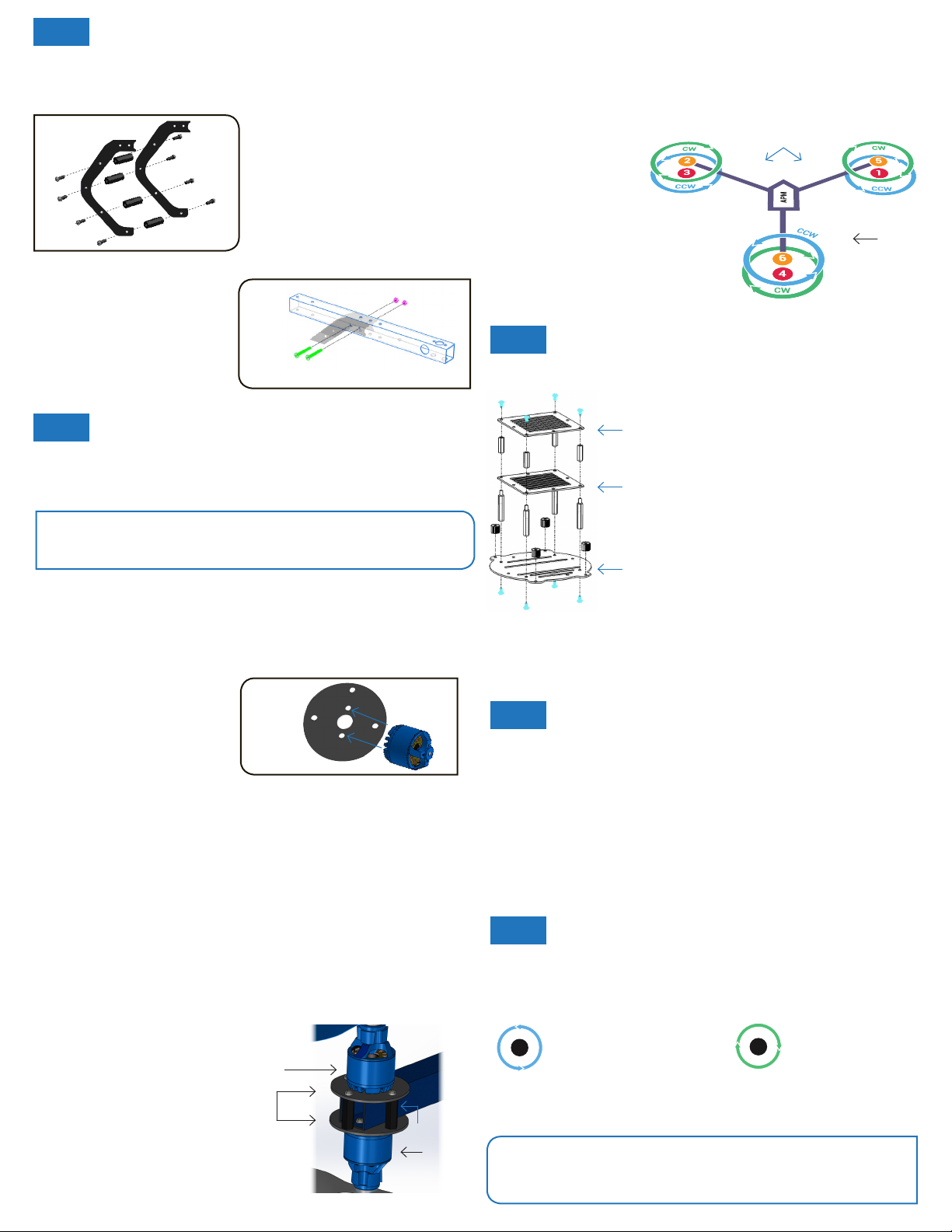

Attach legs

!

CW

3

Your Y6 has three legs, each comprised of two C-type landing gear pieces. To

assemble each leg, align the two pieces and attach through four bottom holes

using four 18 mm threaded hex spacers and eight 5 mm nylon bolts.

Reconnect motors to ESCs and PDB

Thread top and bottom motor cables through opening in end of arm.

Connect motor cable bullet connectors to ESC bullet connectors.

Connect ESC Deans connectors to PDB Deans connectors. (Order doesn’t

matter; this is just to provide power to the motors.) Repeat for all three arms.

For each hole, position spacer between

holes; secure from each side with bolts.

Repeat for all four holes. Repeat for all

three legs.

Leg assembly I

Attach legs to arms

Attach legs to arms with C-shape

facing outwards using two 25 mm

steel bolts and two metal nuts.

(You should have bolts and nuts

from when we detached the legs

from the Hexa.)

Attach motors

4

Each arm of your Y6 will have a top motor and a bottom motor attached to the

arm using a motor mounting plate. To ensure motors are securely bolted to

arms, apply a small amount of threadlock to each bolt before fastening.

Threadlocking compound is an important component to ensure your motors

remain rmly attached! For more information, check out this helpful video:

http://goo.gl/bM3MA

Leg assembly II

Attach mounting plates to bottom motors

First we’ll attach the mounting plates to the bottom motors using two 5 mm

bolts (you should have these from when we disconnected the motors from the

arms) and one motor mounting plate (from conversion kit).

Bottom motor

assembly

Position motor onto plate as shown.

Fasten plate to motor using two

bolts. Repeat for three motors.

Attach

motor

here

Insert mounting plate between top motor and arm

Now we’ll attach the top motors to the arms. Insert mounting plate between

top motor and arm. Make sure motor cables protrude in the direction of the

end of the arm.

Fasten motor and plate to arm using two 5 mm bolts by accessing through

the two large holes in the bottom of the arm.

Repeat for all three arms.

Attach top and bottom mounting plates

Place mounting plate (with bottom motor attached) on underside of arm so

that three outer holes align. Insert 19 mm hollow spacer between top and

bottom hole; thread 25 mm steel bolt through spacer and plates. Secure

with nut. Repeat for all three holes on mounting plates.

Repeat for all three arms.

Note: Bottom motor

does not connect

directly to arm.

©2013 3D Robotics

Top and bottom motors attached

to arm with mounting plates

Top motor

Mounting

plates

Spacer

Bottom

motor

Connect ESC three-wire

cables to signal pins on

PDB according to motor

number. Motor numbers

are congured as shown.

PDB signal pins are labelled M1 through

M6. Connect motors to their respective

signal pins with white wire positioned

upward.

Reassemble stack-ups and APM

5

Now that your copter is congured into a Y6, we’ll reattach the stack-ups and

reconnect the hardware.

Top stack-up

Attach mounting plate to frame with

thumbnuts. Attach stack-ups to mounting

Bottom

stack-up

Mounting

plate

Reconnect GPS cable, power module cable, cables from PDB into output pins,

cables from receiver into input pins, 3DR Radio into telemetry port, and any

other cables that were disconnected from your APM during step 1.

Test motor spin directions

6

Connect battery to your Y6. Test motors to ensure that propellers will spin in

the correct directions as specied in the diagram above. CW (green) signies

clockwise rotation; CCW (blue) signies counterclockwise rotation.

If motor spins in the incorrect direction, switch two of the three cables

joining the motor and ESC. Once correct spin directions are conrmed,

secure ESCs to arms using zip ties.

Note: If your motor and ESC cables were originally soldered, resolder cables

here once motors are conrmed to spin in correct directions.

Attach propellers

7

Attach 10-inch propellers to top motors and 11-inch propellers to bottom

motors according to the conguration shown above. Pusher propellers are

marked “4.7P”; normal propellers are marked “4.7”. If using metal spacers,

place metal spacer on top of propeller before adding prop nut.

CCW

COUNTERCLOCKWISE ROTATION:

!

USE NORMAL PROPELLER

Regardless of motor orientation, all propellers must face up (markings on

top). This means that you’ll need to attach propellers to bottom motors

upside down.

plate using original spacers and bolts as

shown.

Make sure your APM is facing forward,

between the two blue arms as shown in

the diagram above.

If necessary rotate the APM and/or stack-

up plate to achieve this.

Blue arms

CW

CLOCKWISE ROTATION:

!

USE PUSHER PROPELLER

Black

arm

Your Y6 conversion is complete! For pre-ight conguration, Y6

rmware download, and additional setup instructions, please visit:

www.copter.ardupilot.com/apmcopter. Happy ying!

Loading...

Loading...