Page 1

DIY QUAD

Build Manual

V.A

2014

1

Page 2

Contents

Thanks for purchasing a DIY Quad!

These instructions will show you how to assemble a Quad using the Pixhawk

autopilot system and ArduCopter/APM:Copter firmware. If you plan to use

other components in your build, please adjust these instructions accordingly.

For online instructions, visit 3dr.com/diy-quad-kit.

Frame parts 3

Electronics 4

Tools 4

1 Motor assembly 5

2 Power system wiring 8

3 Body plate assembly 10

4 Pixhawk assembly 15

5 Leg assembly 21

6 Calibration 22

7 Propeller assembly 22

2

Page 3

Frame parts

blue arms (2)

black arms (2)

velcro strips (one pair)

velcro straps (3)

base plate

top plate

Pixhawk plate

accessory plate

leg plates (8)

leg support plates (4)

motor plates (8)

30 mm bolts (6)

25 mm bolts (30)

5 mm bolts (32)

nylon bolts (4)

30 mm male-female standos (4)

dual lock

zip ties

power distribution board

15 cm four-wire cable

15 cm six-wire cable

15 cm female-female servo cable

30 cm male-female servo cable

threadlocker

19 mm hollow spacers (20)

18 mm female-female standos (12)

metal nuts (42)

nylon nuts (4)

thumb nuts (2)

3

Page 4

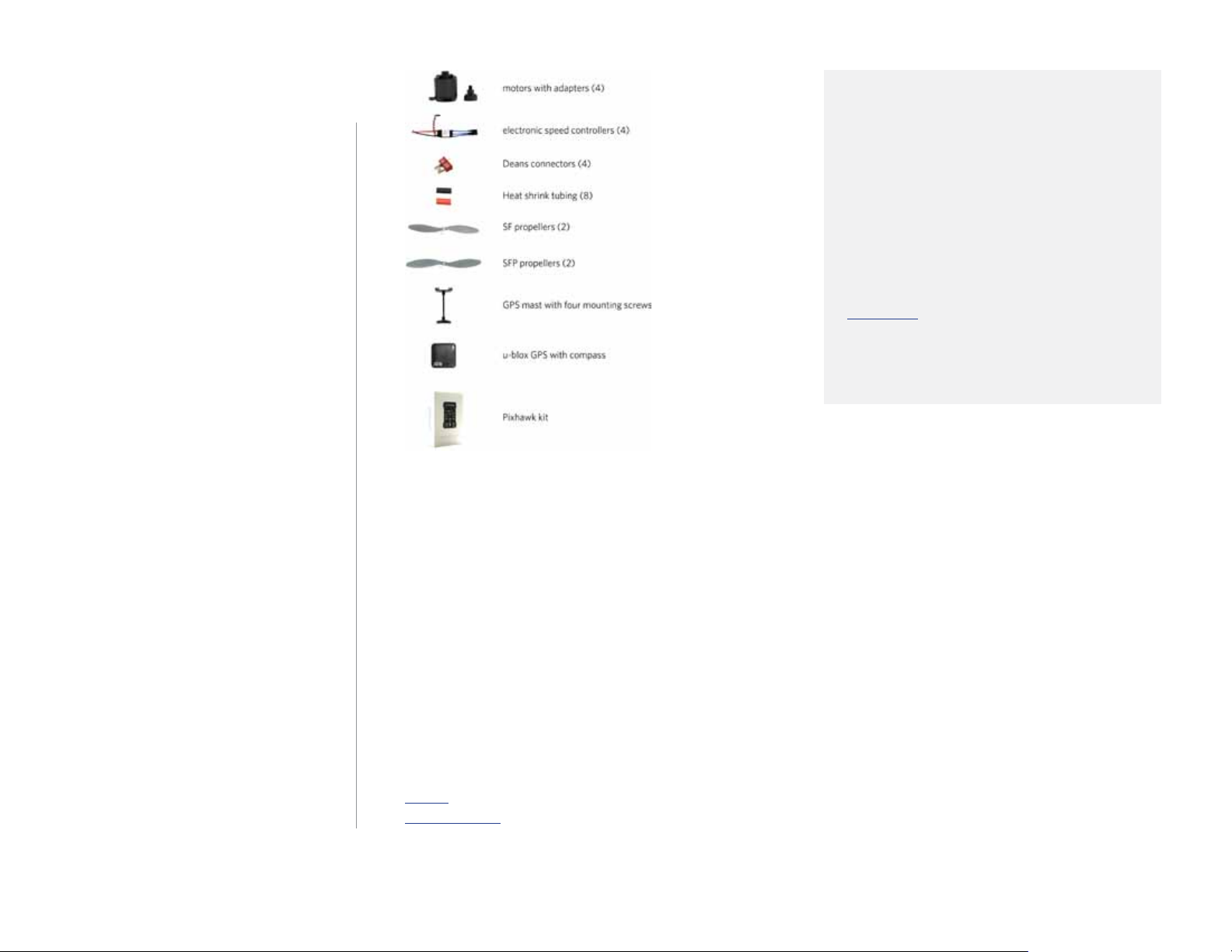

Electronics

This build uses the Pixhawk autopilot

system, including these components:

• Pixhawk autopilot

• u-blox GPS with Compass

• Telemetry radios

• Radio control system

• ArduCopter/APM:Copter firmware

Click here for more information

about these components and to view

compatible radio control systems.

Tools

To complete this build, you will need the following tools not included with your kit:

• Phillips screwdriver

• Double-side foam tape or other mounting adhesive

• Soldering equipment

Note: The electronics for this build require soldering. If you’re unfamiliar with soldering,

our friends at Sparkfun have some great tutorials that can get you started, including this

comic. For an example of exactly what soldering you’ll be doing in this build, view this

video tutorial.

4

Page 5

1 Motor

assembly

Follow these instructions to assemble

one motor.

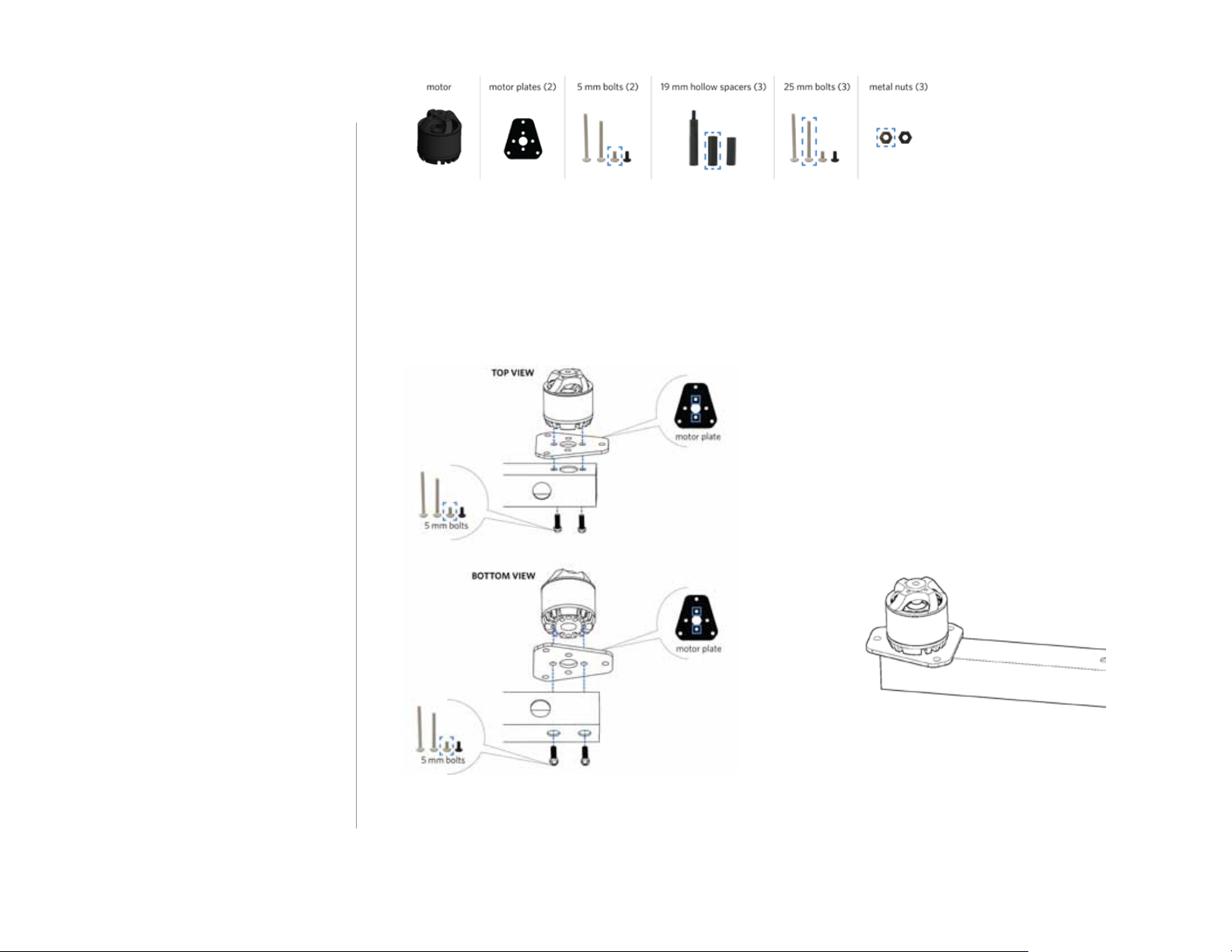

1 Attach motor to arm

Place a motor plate on top of the arm

with the short end of the plate facing

towards the end of the arm. Place the

motor on top of the plate, and align

the two small holes in the motor,

plate, and arm. Orient the motor with

the cables as close as possible to the

hole in the side of the arm.

Apply threadlocker to two 5 mm

bolts, and secure the motor and plate

to the arm from below by accessing

through the two large holes in the

bottom of the arm. When applying

threadlocker, use less than one drop,

and cover only four or five threads

where the bolt connects with the

motor. Make sure to insert the bolts

into the holes in the bottom of the

motor and not into the slots where

they could interfere with the motor.

5

Page 6

2 Thread motor cables through arm

Thread the motor cables through the

hole in the side of the arm.

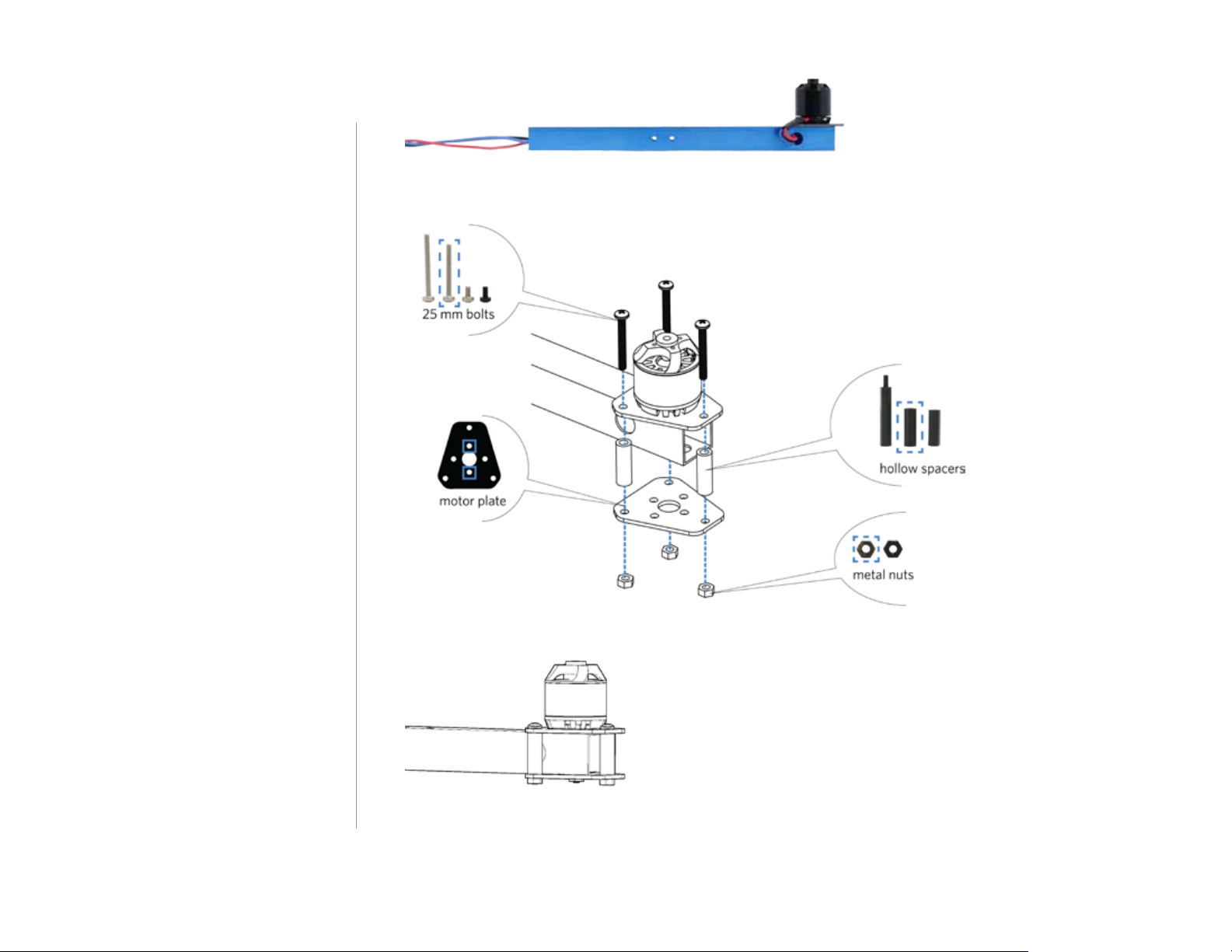

3 Attach bottom plate to arm

Place a motor plate against the

bottom of the arm with the short end

of the plate facing towards the end

of the arm. Apply threadlocker to the

ends of three 25 mm bolts (less than

one drop covering four or five threads

at the end of the bolt). Place a 19 mm

hollow spacer between each of the

pairs of holes in the two motor plates.

Place the bolt through the motor

plates and spacer, and secure from

below with a metal nut.

Repeat these instructions for all

motors.

6

Page 7

2 Power system

wiring

Follow these instructions to connect

the power system.

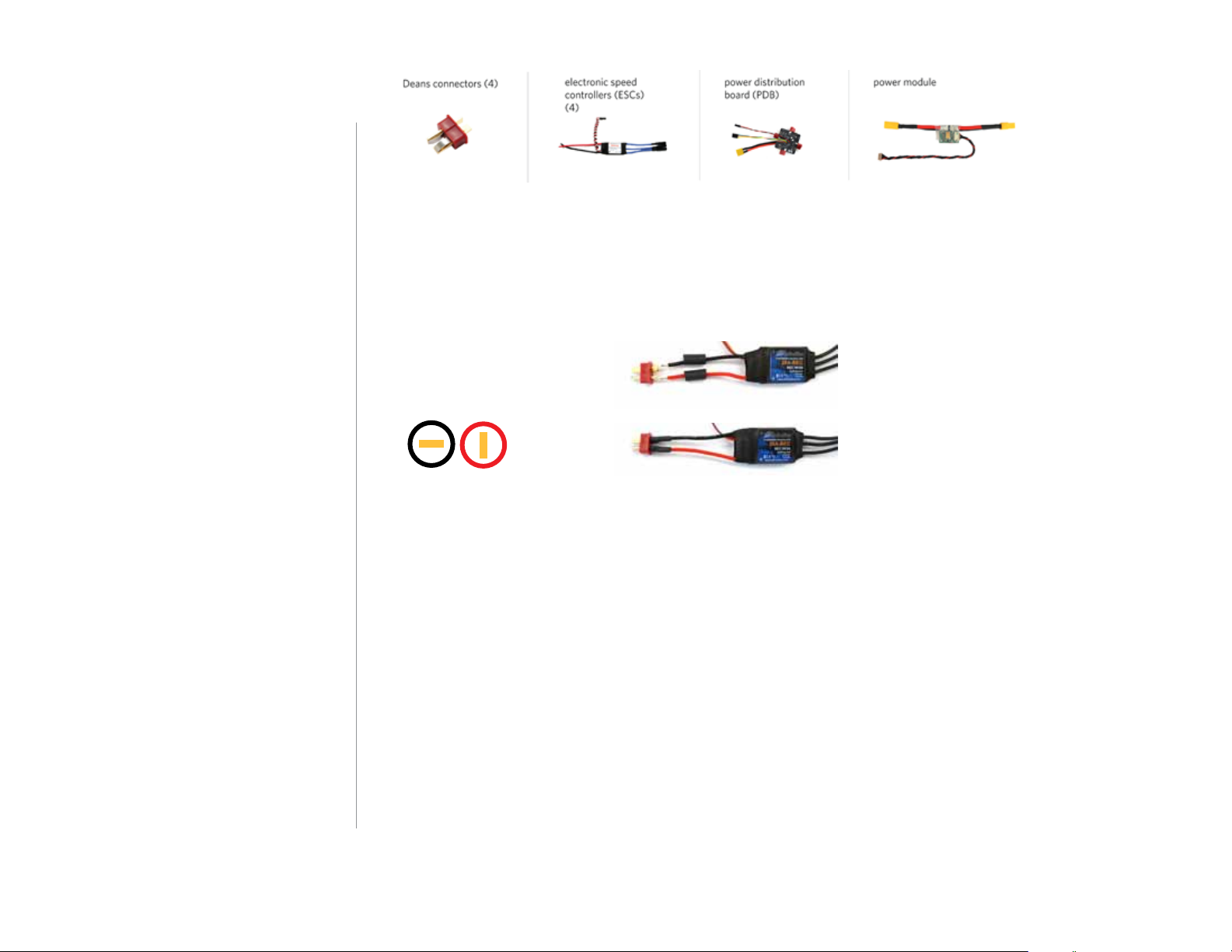

1 Solder Deans to ESCs

Solder a Deans connector to the red

and black wires on each electronic

speed controller (ESC). Check the

Deans connectors for the + and –

markings, and solder the + side to

the red wire and the – side to the

black wire. Don’t forget to add heat

shrink tubing to the wires before

soldering, and shrink the tubing over

the finished connections.

2 Number ESCs

Use tape (or other method) to label

each ESC with a number one through

four.

Deans to ESC:

negative = black

positive = red

-

+

7

Page 8

3 Connect ESCs to PDB

Connect the Deans connectors

(red) on the ESCs to the Deans

connectors on the power distribution

board (PDB) in any order.

Take a look at the PDB and find the

pins labelled M1 through M4

(motors 1 through 4), and make a

note of which color wire connects to

each. Now connect the three-wire

cables from each ESC to these pins

on the PDB according to the ESC

numbers. This is where the order is

critical. Connect the ESC that you

labelled as “1” to the pins on the PDB

labelled “M1”, ESC 2 to PDB pins M2,

ESC 3 to PDB pins M3, and ESC 4 to

PDB pins M4. Connect the white wire

to the signal pin (labelled “M1”), the

red wire to the power pin (labelled

“+”), and the black wire to the ground

pin (labelled “-”).

4 Connect PDB to power module

Attach the XT60 connector (yellow)

on the PDB to the XT60 connector on

the power module.

8

Page 9

3 Body plate

assembly

Follow these instructions to assemble

the body plates.

1 Add velcro straps to base plate

Thread the two velcro straps through

the slots in the base plate. These

straps will hold the battery to the

bottom of your copter. The perfectly

flat side of the plate (without the

protruding nuts) should face down.

Your kit includes two velcro strips to

attach to the battery and the bottom

of the copter. To install, attach the

strip with loops (fuzzy) to the bottom

of the plate between the straps, and

attach the strip with hooks (smooth)

to your battery.

Visit the APM:Copter Wiki and learn

more about which batteries to use

with your copter.

2 Attach arms to base plate

Now we’ll attach the four arms with

assembled motors to the base plate.

Using the innermost hole in the arm

and the hole in the base plate marked

below, insert a 30 mm screw from

the bottom, up through the plate and

the arm. Attach the two black arms

and two blue arms as shown in

relation to the shape of the plate.

(Attach the black arms to the more

elongated end of the plate.)

9

Page 10

It may be helpful to secure each arm

in place temporarily with a metal nut.

3 Label motors

Use tape (or other method) to label

the motors by the numbers shown

here.

4 Connect ESC and motor cables

Connect the motor cables to the

corresponding ESC cables according

to the labelled numbers (connect

motor 1 to ESC 1, motor 2 to ESC 2,

etc). The order of the three cables

determines which direction the

motors will spin and is critical for the

copter to fly correctly. The diagram

above shows which motors need to

spin clockwise (CW) and counterclockwise (CCW).

top = blue

center = black

bottom = red

COUNTERCLOCKWISE (CCW) ROTATION WIRING

top = blue

center = red

bottom = black

CLOCKWISE (CW) ROTATION WIRING

The images below show the correct wiring to produce each direction of rotation. The motor

cables are dierentiated by color. To dierentiate the ESC cables, orient the ESC with the

label facing up, and use the relation of the cables to the label.

10

Page 11

5 Assemble electronics onto base

plate

The base plate holds the power

system: power distribution board

(PDB), power module, and four

electronic speed controllers (ESCs).

Place the assembled power system

onto the base plate. Attach the four

ESCs to the base plate using zip ties.

Orient the ESCs with the labels

down into the holes in the plate.

Alternatively, you can mount the

ESCs to the front of the copter,

perpendicular to the plates, by

securing the zip ties to the small slots

along the front edge of the plates. In

this case, orient the ESCs with the

labels facing out. Ensure that the

power module XT60 connector

protrudes from the back end of the

copter (behind one of the black

arms) where it can easily connect to

the battery.

6 Assemble top plate

Remove any nuts that you may

have used to secure the arms

temporarily to the base plate, and

add the top plate directly on top of

the arms. Secure the four existing

screws with metal nuts, and add a

nylon nut on top of each metal nut.

TOP VIEW

3

3

2

3

1

3

2

1

2

1

3

3

1

3

2

3

11

Page 12

Secure the arms to the plates through

the holes in the end of the arms and

the holes in the plates shown below.

Use 30 mm bolts and thumb nuts to

attach the black arms, and use 25

mm bolts and metal nuts to attach

the blue arms. Finally, attach the base

and top plates together with 25 mm

bolts, 19 mm hollow spacers, and

metal nuts where marked below.

BOTTOM VIEW

12

Page 13

7 Thread cables through top plate

Locate the following three cables, and

thread them up through the central

space in the top plate: PDB two-wire

cable (red and black), PDB four-wire

cable (multicolor), and power module

six-wire cable (red and black). These

cables will connect to Pixhawk.

13

Page 14

4 Pixhawk

assembly

Follow these instructions to assemble

the Pixhawk and accessory plates.

1 Mount Pixhawk

Separate the four foam pieces

provided with the Pixhawk kit, and

attach them to the bottom four

corners of the board. Mount Pixhawk

to the Pixhawk plate with the arrow

facing as shown below (towards the

less elongated end of the plate).

2 Mount buzzer and switch

The switch (button) snaps into the

round hole in the accessory plate.

Thread the switch cable through the

hole in the accessory plate from the

top, and gently pull the switch into

place. Using double-sided foam tape,

mount the buzzer to the underside of

the accessory plate.

BOTTOM VIEW

14

Page 15

3 Mount GPS

Place the base of the GPS mast over

the four holes in the accessory plate

with the shorter side of the top of the

mast facing the left side of the plate

(the arrow-shaped holes in the plate

face forward). Add a mounting screw

to each hole, and secure with nuts.

Remove the adhesive backing from

the mast and place the GPS module

onto the mast with the connectors

facing the shorter side and the

arrow on the GPS pointing in the

same direction as the arrow-shaped

holes in the plate.

4 Insert SD card

Insert the micro-SD card into the

slot at the end of Pixhawk. The

APM:Copter sticker can be attached

to the front of Pixhawk.

15

Page 16

5 Connect modules to Pixhawk

Connect the buzzer, switch, splitter,

GPS, power, and telemetry modules

to Pixhawk.

To ensure the most secure cable

assembly, thread the cables through

the holes in the plates where

possible. Where the cables dangle

away from the frame, such as along

the mast, use zip ties to secure the

cables to the frame.

Note: Pixhawk’s DF13 connectors

can be fragile when disconnected

and reconnected multiple times. Do

not pull on the cables to disconnect,

use a fingernail or small, flat tool to

loosen the edges of the connector

until it pops out.

1

5

4

Buzzer and switch: Connect the buzzer to Pixhawk’s BUZZER port, and connect the switch (safety

1

button) to the SWITCH port. These components are mandatory for Pixhawk.

3

2

I2C splitter: Connect the four-wire cable to one of the ports on the splitter and to Pixhawk’s I2C port.

2

GPS with compass: Use the long cables provided with the GPS mast to connect the GPS with

3

compass module to Pixhawk. Connect the four-wire cable to the GPS’ MAG port and to one of the

ports on the I2C splitter. Connect the six-wire cable to the GPS port on the GPS module and to

Pixhawk’s GPS port.

Power module: Connect the six-wire cable (red and black cable protruding from the central space in

4

the top plate of the copter) to Pixhawk’s POWER port.

Telemetry radio: Connect the six-wire cable to a telemetry radio module and Pixhawk’s TELEM 1 port.

5

16

Page 17

6 Connect RC receiver

7 Connect motor outputs

Pixhawk is compatible with PPM RC receivers or PWM receivers with an additional PPM encoder

module. Connect the three-wire cable (red, black, and white) from your PPM receiver or PPM

encoder to Pixhawk’s RC pins with the white wire connected to the signal (s) pin, the black wire

connected to the ground (-) pin, and the red wire connected to the power (+) pin. Click here for

more information on using a PPM encoder or Spektrum Satellite receiver.

Locate the four-wire cable (multicolor) protruding from the

central space in the top plate. Connect it to the main output

signal (s) pins on Pixhawk according to motor number. Recall

your notes from the power system wiring and see which color

wire corresponds to motor 1. Ensure that that color wire is

connected to the main output 1 signal (s) pin. Do not rely on

the colors of the wires shown here, the accuracy of this

component is critical.

Connect backup power (optional)

Connect the two-wire cable (red and black) protruding from the top plate to provide a backup

power source for Pixhawk. Connect the black wire to any of Pixhawk’s main output ground

(-) pins and the red wire to any of the main output power pins (+). This configuration is best

supplemented with a zener diode (visit the APM:Copter Wiki to learn more), but the backup

power method can be used without implementing the additional diode. If you do not wish to

connect backup power, leave the cable disconnected.

17

Page 18

8 Assemble plates

Add a 5 mm nylon bolt to the four

holes in the accessory plate marked

below, and attach a 30 mm stando

to each one below the plate. Add

the Pixhawk plate to the ends of the

standos and secure with metal nuts.

Pixhawk plate

nylon bolts

accessory plate

30 mm spacers

metal nuts

18

Page 19

Place the assembled plates over the

exposed bolts in the top plate, with

the arrows facing towards the blue

arms, and secure with metal nuts.

metal nuts

Pixhawk plate

9 Mount remaining components

Select a location on the copter to

mount the I2C splitter, telemetry

radio, and RC receiver. Use dual lock

or double-sided foam tape to mount

the components. Check that all

components are connected securely

to Pixhawk.

Where you place the components on

the copter is ultimately limited by

the length of the cables between

modules. Experiment with the

dierent length cables provided with

your kit, and find the best place for

each module on your copter.

top plate

(mast not pictured)

19

Page 20

5 Leg assembly

Follow these instructions to assemble

one leg.

5 mm bolts (6)leg plates (2) leg support plate

18 mm female-to-female

threaded standos (3)

25 mm bolts (2)

metal nuts (2)

1 Assemble leg

Align the leg plates, and place a

stando between each of the bottom

three pairs of holes in the plates.

Secure each stando to the plates

with a 5 mm bolt on each end. Insert

the support plate into the horizontal

slots at the top of the leg.

2 Attach leg to arm

Align the two holes in the top of the

leg with the two holes in the center of

the arm. Orient the leg with the point

facing towards the center of the

copter. Insert two 25 mm bolts

through the arm and the leg, and

secure with metal nuts.

leg support plate

18 mm spacers

5 mm bolts

5 mm bolts

metal nuts

25 mm bolts

Repeat these steps for each leg of

your copter.

20

Page 21

6 Calibration

Your Y6 assembly is almost

complete. Now it’s time to go

online, download software, and begin

calibrating Pixhawk to work with your

new frame. Do not proceed to

propeller assembly with performing

calibration.

7 Propeller

assembly

View the calibration instructions online at

3dr.com/diy-y6-kit.

Follow these instructions to assemble

propellers.

1 Assemble propellers

Remove the rings from the

propeller package. Select the ring

with the smaller internal diameter,

and insert it into the back of the

propeller hub.

21

Page 22

2 Assemble propeller adapters

Select the propeller adapters and

the longer screws provided with the

adapters. Do not use the x-shaped

plate. Apply threadlocker to the three

small screws included with the

propeller adapters (less than one

drop covering four to five threads).

Attach an adapter to the top of each

motor.

3 Add propellers

Your Quad uses SF and SFP

propellers. These propellers are

labelled on the package and on the

propeller itself. Add SF and SFP

propellers to the arms shown in the

diagram below with the writing on

the propeller facing towards the sky.

The right propeller order and

orientation is critical for your

copter to fly correctly. Add the

washer above the propeller, and

secure the nut tightly on top.

Ensure that the writing on the propellers faces the

sky.

22

Page 23

Your Quad build is now complete! Before your first flight,

please read all safety information

and first flight instructions at

copter.ardupilot.com/wiki/tableof-contents/.

COMPLETE QUAD

For customer support, contact us

at help@3dr.com or call our

support line at +1 (858) 225-1414

Monday through Friday, from 8

am to 5 pm, PST.

23

Loading...

Loading...