Page 1

®

10BASE-FB Transceiver

Installation Guide

Document Number 17-00325-3

Model Numbers: 5101T-FB-SMA

5101T-FB-ST

5101T-FB-FC

3Com Corporation

118 Turnpike Road

Southborough, MA 01772-1886

U.S.A.

Page 2

Federal Communications

Commission Notice

This equipment has been tested and found to comply with the

limits for a Class A digital device, pursuant to Part 15 of the FCC

Rules. These limits are designed to provide re asona ble protection

against harmful interference when the equipment is operated in

a commercial environment. This equipment generates, uses, and

can radiate radio frequency energy and, if not installed and used

in accordance with the instruction manual, may cause harmful

interference to radio communications. Operation of this equipment in a residential area is likely to cause harmful interference in

which case the user will be required to correct the interference at

his own expense.

Canadian Emissions Requirements

Cet appareil numérique respecte les limites de bruits radioélectriques applicables aux appareils numériques de Class A prescrites

dans le norme sur le materièl brouilleur : “Appareils Numériques”,

NMB-003 édictée par le ministrè des Communications.

This digital apparatus does not exceed the Class A limits for radio

noise emissions from digital apparatus as set out in the interference-causing equipment standard entitled “Digital Apparatus”,

ICES-003 of the Department of Communications.

Page ii

Page 3

VDE CLASS B COMPLIANCE

Hiermit wird bescheinigt, dass der (5101T-FB) in Uebereinstimmung mit den Bestimmungen der Vfg 243/1991 funk-entstort ist.

Der Deutschen Bundespost wurde das Inverkehrbringen dieses

Gerates engezeigt und die Berechtigung zur Ueberprufung der

Serie auf Einhaltung der Bestimmungen eingeraumt.

This is to certify that the (5101T-FB) is shielded against radio interference in accordance with the provisions of Vfg 243/1991.

The German Postal Services have been advised that this device is

being put on the market and that they have been given the right

to inspect the series for compliance with the regulations.

CAUTION

Do not install in air ducts or plenums. For installation in other

environmental air handling spaces, use only with cable classified

by Underwriters Laboratories as to fire and smoke characteristics

in accordance with Section 770-2(b) and Section 725- 2(b) of the

National Electrical Code.

DISCLAIMER

The information in this document is subject to change without

notice and should not be construed as a commitment by 3Com

Corporation. 3Com Corporation assumes no responsibility for any

errors that may appear in this document.

Page iii

Page 4

COPYRIGHT STATEMENT

ø19 96 by 3Com Corporation. All rights reserved. The information

contained herein is the exclusive and confidential property of

3Com Corporation. No part of this manual may be disclosed or

reproduced in whole or in part without permission from 3Com

Corporation.

Printed in the U.S.A.

TRADEMARKS

Because of the nature of this material, numerous hardware and

software products are mentioned by name. In most, if not all

cases, these product names are claimed as trademarks by the

companies that manufacture the products. It is not our intent to

claim these names or trademarks as our own.

The ONline logo, TriChannel, and Midnight are trademarks, and

Ethermodem, ORnet, ONcore, and Chipcom are registered

trademarks of 3Com Corporation.

Ethernet is a registered tr ademark of Xerox Corporation.

DEC, the digital logo, DELNI, DECnet, and VAX are trademarks of

Digital Equipment Corporation.

IBM is a registered trademark of International Business Machines.

Page iv

Page 5

Table of Contents

Table of Contents ................................................. v

Preface.................................................................. 1

Intended Audience............ ......... ... ......... ...... 1

Transceiver Overview .......................................... 3

Transceiver Top Panel.................................. 3

Transceiver Front Panel..................... ......... ......... . 6

Transceiver Rear Panel............................... ..........7

Alternate Collision Mode ........ ..................... 9

SQE Test .......................................... .......... 10

High Power (PWR) .................................... 10

Half Step Mode ........... ...... ...... ...... ...... ...... . 11

Installation................................... ......... ......... ... .. 11

Site Preparation and Placement.................. 12

Unpacking Procedures ....................... ................. 13

Verifying Transceiver Switch Settings...............14

Connecting to Ethernet V2.0 and IEEE 802.3

Controllers..........................................................17

Connecting to Ethernet V2.0 and IEEE 802.3

Repeaters............................................................ 18

Connecting Fiber Cables....................................19

Page v

Page 6

Connecting the AUI Cable......................... 20

Verifying Physical Link Operation ............ 21

Troubleshooting.................................................. 22

Status LED ................................................. 22

Troubleshooting Link Problems................. 27

Troubleshooting System P r oblems.....................28

Excessive Collisions............................... .... 28

Late Collisions and Failure to Defer.......... 29

Miscellaneous Errors.................................. 30

Transceiver Cables .............................................31

Signal Differences....... ............................... 31

EEE 802.3 ....................... ......... ...........32

Version 2.0 .......................................... 32

Version 1.0 .......................................... 32

Wire Sizes ............................ ...................... 33

Cable Pinouts ............................................. 35

Troubleshooting Transceiver Cables..................37

Symptoms of Faulty Transceiver Cables.. . 37

Causes of Fault Transceiver Cables........... 38

Cable Recommendations............................ 39

Specifications .....................................................39

General Specifications ............................... 40

Page vi

Page 7

Optical Interface Specifications. ................ 41

Transmit Power Specifications .................. 42

Fiber Optic Cables Compatibility .............. 42

Attachment Unit Interface Specificati ons .. 43

Page vii

Page 8

Page 9

Preface

This guide describes the features, DIP switch,

installation steps, operation verification, and

problem diagnosis for the 3Com 10BASE-FB

Transceiver.

Intended Audience

This guide is intended for use by installers, users,

and network managers. It does not include

detailed service information. This product must

be serviced by personnel at, or approved by,

3Com Corporation or the warranty is voided.

Before you use the 10BASE-FB Transceiver, read

this guide to familiarize yourself with the

product. Also read the reference manual for the

product to which you are connecting the

10BASE-FB Transceiver.

Page 1

Page 10

This guide is divided into five sections:

■ Transceiver Overview - Describes the

transceiver controls and indicators.

■ Installation - Describes how to unpack,

power up, and verify transceiver operation.

■ Troubleshooting - Provides help in isolating

problems that can occ ur during installation

and provides procedures for correcting them

through use of the extensive diagnostic

features built into the product set.

■ AUI Cables and Pinouts - Describes common

problems with IEEE 802.3 and Ethernet

Transceiver (AUI) cables. Cable pinouts as

well as rules for proper cabling are

described.

■ Specifications - Describes the transceiver

optical specifications and AUI specifications.

Page 2

Page 11

Transceiver Overview

This section provides descriptions of the AUI

connector, fiber optic ports, indicators, and DIP

switch on the transceiver front, rear, and top

panel (respectively). 3Com recommends that you

become familiar with these features prior to

installation.

Note: Do not under any circumstances

attempt to open the transceiver

enclosure.

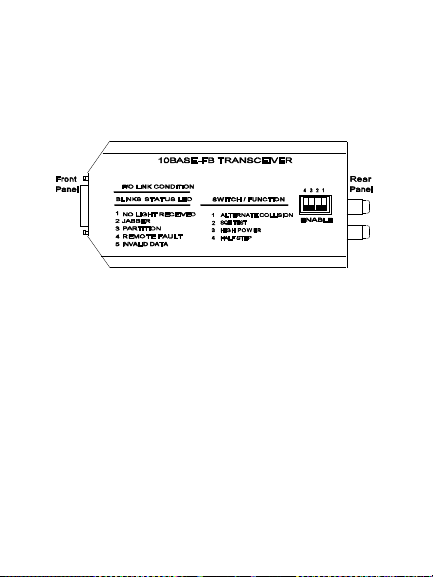

Transceiver To p Panel

The top panel of the Transceiver contains a label

briefly describing:

■ LED blink sequences

■ Functions of the DIP switch

The DIP switch has four switches for configuring

transceiver operation.

Page 3

Page 12

Figure 1 illustrates the top panel of the 3Com

10BASE-FB Transceiver. Table 1 provides a

description of the DIP switches.

Figure 1. Transceiver Top Panel

Page 13

Table 1. Transceiver DIP Switch Settings

Switch Setting Description

1 Alternate

2 SQE Test Enables or disable s SQE

3 High

4 Half Step Enables Half Step Signaling

Collision

Power

Enables or disable s

Alternate collision

Presence Signaling mode.

Test.

Enables High Power.

Disable set tin g invokes

Normal Power.

on AUI Receive (DI) Pa ir.

Disable set tin g invokes Full

Step Signaling.

Page 5

Page 14

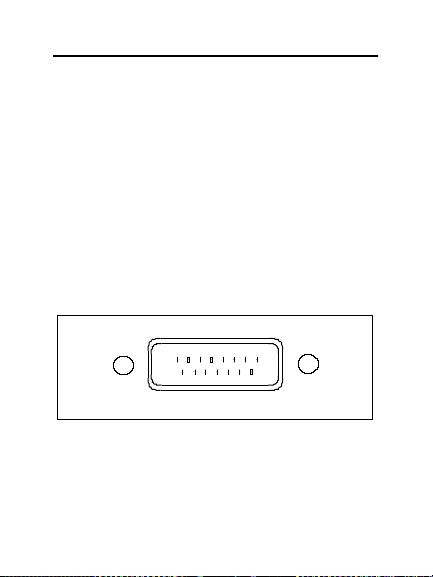

Transce i ver Front Panel

The Transceiver front panel contains the 15-pin

AUI (Attachment Unit Interface) connector. The

AUI 15-pin D subminiature male connector

conforms to IEEE 802.3 and Ethernet Version 2.0

requirements. The shell of the connector is not

insulated from the transceiver case, thereby

providing optimal shielding and minimizing

radiation.

Figure 2 shows the AUI connector on the

Transceiver front panel.

Figure 2. Trans ceiver Front Panel

Page 6

Page 15

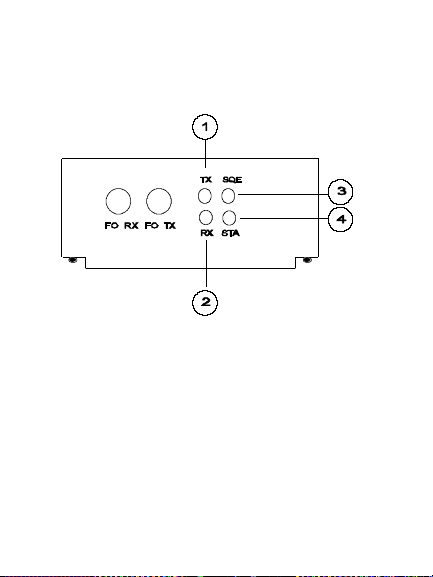

Transceiver Rear Panel

The Transceiver rear panel contains the Fiber

Optic (SMA, ST, or FC) connectors and four indicators (LEDs). The LEDs provide status for:

■ Fiber link (transmit and receive)

■ SQE Test

■ Ports

The LEDs can be On, Off, or Blinking. The number of consecutive blinks before a longer pause

on the STA (status) LED indicates the type of failure detected on the link. For ease of interpretation, a table is printed on the top panel of the

transceiver to briefly describe the type of failure.

This table is also repeated in greater detail in the

Troubleshooting section later i n this manual.

Refer to the Troubleshooting section later in this

manual for a description of the LED blink

sequences.

Page 7

Page 16

Figure 3 shows the rear panel on the 10BASE-FB

Transceiver. Table 2 provides a description of the

LEDs.

Figure 3. Trans ceiver Rear Panel

Page 8

Page 17

Table 2. Transceiver LED Descriptions

Switch Setting Description

1 TX Transmit Port

2 RX Receive Port

3 SQE Squelch Test

4 STA Status Indicator

Alternate Collision Mode

When enabled, the timing and duration of the

collision presence signal (CI) at the AUI is altered

to facilitate operation with certain controller

chips. The default setting is enabled. When

disabled, collisions are signaled to the AUI for as

long as they last on the medium.

Page 9

Page 18

SQE Te st

When enabled, the collision detection capability

of the transceiver is tested after each transmission. If the test is successful, the SQE test (Signal

Quality Error test, or heartbeat) signal is sent on

the AUI to the attached controller. The default

setting is enabled.

When disabled, this test is not performed and no

SQE test signal is sent to the AUI. Always disable

this function when connecting to an IEEE 802.3

repeater.

High Power (PW R)

When enabled, the optical power output on the

main link is in the High range. The default setting

is disabled, which invokes the optical power

output on the main link in the Normal range.

Page 10

Page 19

Half Step Mode

When enabled, half step is signaled at the

beginning of packets, as re q uired in IEEE 802.3

and Ethernet Version 2.0. The default setting is

enabled.

When disabled, the signaling on the AUI receive

pair (DI) is the same as defined in Ethernet

Version 1.0. This is a full step waveform at the

beginning of a packet.

Installation

This section describes the following considerations for the 10BASE-F B Transceiver:

■ Site Preparation and Placement

■ Unpacking Procedures

Page 11

Page 20

Site Preparation and Placement

The 10BASE-FB Transceiver can be placed in the

following locations:

■ On top of the device to which it is attached

■ On top of a desk

■ Attached directly to the AUI connection on

the DTE

To avoid damage to the Fiber Optic cable and

prevent accidental disconnection from the AUI

cable, secure the transceiver and cables connections.

3Com offers a velcro mount kit

(part # 9 3 0 0-TM3) to secure y our tr ansceiv ers. To

order this kit, contact your supplier or call 3Com

Technical Support.

Page 12

Page 21

Unpacking Procedures

To unpack the transceiver:

1. Remove the unit from the shipping carton.

2. Inspect the unit closely for da mage.

If the unit appears to be damaged, return it

to the shipping carton and conta ct you r local

supplier.

3. Verify that the transceiver is the correct

model by matching the model number listed

on the side of the shipping carton to the

model number you ordered (5101T-FB-SMA,

5101T-FB-ST, or5101T-FB-FC).

Note that the product model number

printed on the shipping box differs from the

model number on the product. The model

number on the shipping box contains the

prefix ’3C9’.

Page 13

Page 22

Verifying Transceiver Switch Settings

Factory-set default settings for the transceiver

are defined in Table 3.

Table 3. Transceiver DIP Switch Default

Settings

Switch Function Default Setting

1 Alter nate

2 SQE Test Enabled

3 High Power Disabled

4 Hal f Step Enabled

Page 14

Collision

Enabled

Page 23

These switch settings typically work with any

Ethernet Version 2.0 or IEEE 802.3 controller

device. You may change the Half Step switch

and Collision Mode switch to optimize operational parameters for a particular controller type.

To make these optimizations, you must know

the following two facts about your Ethernet controller:

1. Is the controller Ether net V2.0 or IEEE

802.3?

Most new products today are based on the

IEEE 802.3 AUI interface standard. Some

controllers are still based on Ethernet V2.0.

Differences exist between the two standards

in AUI pinouts and signaling characteristics.

If you are in doubt, keep the Half Step

switch enabled.

Page 15

Page 24

2. Does the controller use the AMD L ANCE or

Intel 82586 controller chip?

The Transceiver can accommodate certain

operational characteristics of these two

widely used controller chips. The optimizations made by the Transceiver to more suitably support these chips during collision

recovery are not detrimental to operation

with other Ethernet controllers. If there is

any doubt about the type of controller chip

used by your equipment, leave the Alternate

Collision Mode switch enabled.

Page 16

Page 25

Connecting to Ethernet V2.0

and IEEE 802.3 Controllers

Refer to Table 4 for the settings to use for connecting the transceiver to Ethernet Version 2.0

and IEEE 802.3 controller devices.

Table 4. DIP Switch Settings for Ethernet

V2.0 and IEEE 802.3 Controllers

Ethernet

V2.0

Controllers

SQE Test Enabled Enabled

Alternate

Collision Mode

Half Step Mode Enabled May be

* May be Disabled for IEEE compliance.

Enabled * Enabled *

IEEE 802.3

Control lers

Disabled

Page 17

Page 26

Connecting to Ethernet V2.0

and IEEE 802.3 Repeaters

Refer to Table 5 for the settings to use for

connecting the transceiver to Ethernet Version

2.0 and IEEE 802.3 repeaters. The tr ansceiv er DIP

switches must be changed for conn ection to IEEE

802.3 Repeaters.

Table 5. DIP Switch Settings for Ethernet

V2.0 and IEEE 802.3 Repeaters

Ethernet V2.0

Repeaters

SQE Test Disabled * Disabled

Alternate

Collision Mode

Half Step Mode Disabled * Disabled

Disabled * Disabled

IEEE 802.3

Repeaters

Page 18

Page 27

* Functional differences exist whereby

Ethernet V2.0 repeaters are not

suppo rted by the 10BASE-FB

Transceiver. If you are in doubt about

the type of your repeater, contact your

3Com supplier for more information.

Connecting Fiber Cables

To connect fiber cables to the transceiver:

1. Remove the plastic protection caps from the

fiber optic port only when ready to install

cables. Transceiver ports that are not in use

should remain capped.

2. Ensure tha t transmit and receive cables are

clearly marked or color coded and are

connected to the appropriate ports on the

Transceiver.

3. Ensure the cables have been properly

cleaned with an appropriate fiber optic

cleaning solution before installation.

Page 19

Page 28

4. Connect the remote end of the fiber optic

cables to the 10BASE-FB Star Coupler , ONline

Ethernet 10BASE-FB Module, or ONcore

Ethernet 10BASE-FB Module ports. Ensure

the transmit fiber at one end connects to a

receive port at the other end.

Connectin g the AUI Cable

Apply power to the transceiver by connecting it

to:

■ AUI transceiver cables

■ Directly to AUI connectors coming from

active IEEE 802.3/Ethernet nodes

Upon powerup, the transceiver status indicator

and the port status indicator on the other unit

(Star or Ethernet 10BASE-FB Module port) stops

blinking and turns on solid.

Connect the 10BASE-FB Transceiver to an

Ethernet device using proper AUI (transce iver)

cables.

Page 20

Page 29

There are differences between IEEE 802.3 and

Ethernet Version 2.0 AUI cables. While the

10BASE-FB Transceiver is compatible with both,

ensure that the AUI cable being used is appropriate for the device being connected. Refer to the

section, AUI Cables and Pinouts, later in this

manual for cable specifications.

Note: The AUI cable can not exceed 50 meters

in length.

Verif ying Ph ysical Link Ope ration

To verify physical link ope ration:

1. Verify that every transceiver on the network

has its status indicator ON and not blinking.

2. Verify that each 3Com 10BASE-FB Sta

Coupler or Ethernet 10 BA SE-FB Module port

status indicator is ON and not blinking.

If after completing Steps 1 and 2 you find no

blinking Status indicators, you can now use your

network nodes and verify data connectivity.

Page 21

Page 30

If after completing Steps 1 and 2 you find blinking Status indicators on connected and enabled

modules or devices, refer to the Troubleshooting

section in this manual.

Troubleshooting

This section explains how to use the diagnostic

features of the 10BASE-FB Transceiver for fault

isolation. This section describes:

■ Status LED

■ Troubleshooting Fiber Links

■ System Problems

Status LED

The 10BASE-FB Transceiver provides a

diagnostic status LED that indicates link status.

The normal state for this indicator is the steady

ON state. If the LED is OFF, this usually indicates

lack of power.

Page 22

Page 31

A blinking status indicator is always a sign of a

detected problem.

The status of the 10BASE-FB Transceiver can be

easily and quickly determined by scanning for a

blinking LED. Interpretation of the blinking

sequences is provided in Table 6 and is also

printed on the Transceiver top panel.

Ta ble 6 lists the most common cause s of link

failures and the steps that should be taken to

correct them. If the indicat or r emains off or none

of the possible problems listed in Table 6 apply,

try another port on the connecting device or

replace the Transceiver.

Page 23

Page 32

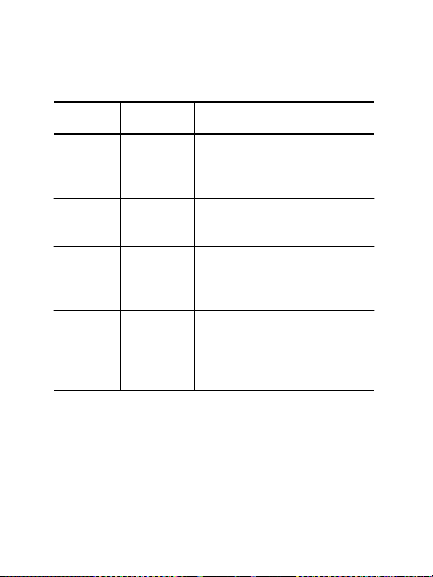

Table 6. Troubleshooting Using the

Status LEDs

LED

Indicates

Status

Off No power Computer

Possible

Problem

not powered

Disconnected

AUI cable

Broken AUI

cable

Bad

controller

Page 24

Possible

Solution

Turn on the

computer

Check AUI

conne c ti on

Replace AUI

cable

Follow

vendor’s

instructions

Page 33

Table 6. Troubleshooting Using the

Status LEDs

LED

Indicates

Status

1 Blink No light

received

2

Jabber Jabbering

Blinks

3

Partition Bad port on

Blinks

Possible

Problem

Bad fiber

connections

Broken fiber Check and fix

Bad port on

other end

controller

Noisy AUI

cable

other end

Possible

Solution

Clean RX

fiber on

both ends

RX fiber link

Try another

port or

replace unit

Follow

vendor’s

instructions

Replace AUI

cable

Try another

port or

replace unit

Page 25

Page 34

Table 6. Troubleshooting Using the

Status LEDs

LED

Status

4

Blinks

5

Blinks

Page 26

Indicates

Remote

fault

Invalid

data

Possible

Problem

Bad fiber

connections

Bad port on

other end

Broken fiber Check and fix

Bad fiber

connections

Possible

Solution

Clean TX

fiber on

both ends

Try another

port or

replace unit

TX fiber link

Clean RX

fiber on

both ends

Page 35

Table 6. Troubleshooting Using the

Status LEDs

LED

Status

5

Blinks

(con’t)

Indicates

Invalid

data

Possible

Problem

Broken or

degraded

fiber

Bad or

degraded

port on other

end

Possible

Solution

Check and fix

RX fiber link

Try another

port or

replace unit

Troubleshooting Link Problems

Each full duplex fiber link is monitored at both

ends. The 1 0B ASE-FB Star Coupler and the 3Com

Ethernet 10 BASE-FB Modules contain status

indicators (one for each port). The Transceiver

contains a single status indicator. In addition to

signifying link problems, the T r an sceiver indica tor

also indicates a local or remote jabber condition.

Page 27

Page 36

All link problems cause the link to be inoperable.

If a link problem is indicated, check the indica tors

at both sides of the link, and then consult

Table 6.

Troubleshooting System Problems

This section addresses some of the system

problems that can be corrected using the options

on the 10BASE-FB Transceiver. If problems occur,

always check the diagnostics indicators on the

Transceiver.

Excessive Collisions

Collisions can be caused by loops in the

10BASE-FB network. Such loops cause every

packet to collide with itself. If you cannot locate

the loop, try segmenting your network (by disconnecting Star Couplers, or ONline and ONcore

Hubs one at a time) until the loop is located.

Page 28

Page 37

If you have IEEE 80 2.3 repea ters in you r netw ork,

ensure that the SQE Mode and Alternate Collision Mode switches are disabled for 10BASE-FB

Transceivers connected to these repeaters.

Late Collisions and Failure to Defer

Late collisions ca n be caused by exceeding the

distance rules of Ethernet, or by controllers that

do not fully comply 100% with the IEEE standard.

To verify that your network satisfies the distance

rules, refer to the configuration rules in:

■ 10BASE-FB Star Coupler Installation and

Operation Guide, Chapter 6

■ ONline or ONcore Ethernet 10BASE-FB

Module Installation Guide, Chapter 2

Activating the Alternate Collision Mode on the

Transceiver may solve this problem in many

cases.

Page 29

Page 38

Also, ensure that you have accounted for the

distance reduction caused by external baseband

repeaters that were added and by baseband

segments connected to those repeaters.

Miscellaneous Errors

Many types of physical layer errors can occur if

the controller AUI interfac e is Ethernet Version

1.0 or not fully compliant with Version 2.0 and

IEEE 802.3.

If errors occur:

1. Try switching between the Full Step and Half

Step options on the 10BASE-FB Transce iver.

2. Verify that an IEEE 802.3 AUI cable is being

used with 802.3 controllers

3. Verify that Ethernet V2.0 cables are being

used with Ethernet V2.0 controllers.

Refer to the next section for more information

on AUI cables.

Page 30

Page 39

Transceiver Cables

This section explains the signal differences

among the various types of AUI transceiver

cables. It also explains wire sizes and the proper

pinouts for Ethernet Version 2.0 and IEEE 802.3

AUI cables.

Signal Differ en ces

Signal differences occur between different types

of transceiver cables because there are three

Ethernet standards:

■ V1.0

■ V2.0

■ IEEE 802.3

These three standards also affect the shielding

and grounding of the cables and the size of the

wires used in the cables.

The most significant difference among AUI

Page 31

Page 40

cables occurs in the shielding and grounding of

the individual signal and power pairs. IEEE 802.3

and Ethernet V2.0 specify a requirement for

signal isolation due to AC-coupling of the AUI

connection. The V1.0 standard does not contain

this requirement.

The three standards specify different techniques

for shielding and grounding.

EEE 802.3

All shields of the individual signal and power

pairs are connected to pin 4. The overall AUI

cable shield is connected to the AUI connector

shell to provide a cable ground. Pin 1 is not used.

Version 2.0

All shields are connected to pin 1 and the AUI

connector shell. Pin 4 is not used. Most Ethernet

cables are built this way.

Version 1.0

Page 32

Page 41

Shielding of individual signal or power pairs is

not required because most V1.0 controllers and

transceivers are DC-coupled. The overall AUI

cable shield provides for shielding and grounding

and is connected to pin 1 and the AUI connector

shell.

In practice, most Ethernet V1.0 equipment uses

version 2.0 cables due to cross-talk problems

caused by the lack of individual shielding of the

pairs in Version 1.0 cables.

Wire Sizes

The three versions of AUI cables also use different wire sizes for the signal and power pairs.

Table 7 describes the wiring that each type of

transceiver cable uses.

Page 33

Page 42

Table 7. Transceiver Cable Wire Sizes

Cable Type Signal Pair Power Pair

V1.0 AWG # 22 AW G # 20

V2.0 and IEEE 802.3 AWG # 2 0 AWG # 2 0

Non-stan dard

“office” ca ble *

* More flexible, but is limited to 5.0

meters in length.

AWG # 24 * AWG #24 *

Signal deterioration along the signal pairs is most

likely to happen as the AUI cable reaches the

maximum length of 50 meters. Signal deterioration is due to the filtering action of the cable.

IEEE 802.3 AUI cables a re designed to reduce

this effect.

Page 34

Page 43

Because 802.3 AUI cables provide a ground

shield isolated from the signal and power pair

shields, the cables provide additional noise

immunity in noisy operating environments.

Cable Pinouts

Table 8 shows the proper pinouts for Ethernet

Version 2.0 and IEEE 802.3 AUI cables.

Table 8. AUI Cable Pinout Chart

Pin 802.3 V2.0, V1.0

1CI-SShield

2 CI-A Collision Presence +

3 DO-A Transmit +

4 DI-S Reserved

5 DI-A Receive +

6 V Power Return

Page 35

Page 44

Table 8. AUI Cable Pinout Chart

Pin 802.3 V2.0, V1.0

7CO-AReserved

8CO-SReserved

9 CI-B Collision Presence 10 DO-B Tran smit -

802.3 - All signal and power pair shields can be

connected to pin 4. The braided AUI cable shield

connects to the AUI shell and not to pin 1.

V2.0 - All shields (external and internal) connect

to pin 1 and to the connector shell.

V1.0 - Braided AUI cable shield connects to

connector shield and pin 1.

Page 36

Page 45

Troubleshooting Transceiver Cables

This section describes some of the common

problems you may have with transceiver cables

and provides possible solutions to the problems.

Sympto ms of Faulty Transceiver Cables

The follow ing list describes symptoms of faulty

transceiver cables:

■ False or excessive collisions.

■ Jabber condition on transceiver.

■ Receive Errors (CRC and Alignment).

■ Severe degradation of system performance

Page 37

Page 46

Causes of Fault Transceiver Cables

The follow i ng list describes causes of faulty transceiver cables:

■ Improper Grounding (pin 1 vs. pin 4).

■ Bad ground:

■ Shell connector not crimped onto AUI

cable braid.

■ Ribbon cables in computers not shielded

or improperly mounted.

■ Broken pair wires or unseated AUI connec-

tor pin.

■ Improper pairing - Verify that signal and

power wires are paired (for example,

Transmit + paired with Transmit -)

■ Individual pairs not individually shielded (for

example, Ethernet V1.0 type cable).

Page 38

Page 47

Cable Recommendations

The 10BASE-FB Transceiver is fully compatible

with IEEE 802.3 and Ethernet V2.0. The use of

Ethernet V1.0 AUI cables and cont rollers is not

recommended.

The 10BASE-FB Transceiver accepts either 802.3

or V2.0 AUI cables. Use the proper AUI cable for

the appropriate controller being used. For example, if you use an 802.3 controller, then use an

802.3 AUI cable.

Specifications

This section lists the following specifications for

the 10BASE-FB Transceiver:

■ General

■ Optical Interface

■ Transmit Power

■ Fiber Optic Cable Compatibility

Page 39

Page 48

■ Attachment Unit Interface

General Specifications

Table 9. General Specifications

Specification Value

Dimensions 4.8" x 2.4" x 0.9"

Weight 4 oz. (115 g)

Operating Temperature 32° to 104° F

Operating Humi di t y Less tha n 95%

Power 5 Watts

Page 40

(122mm x 61mm x

23mm)

(0° to 40° C)

non-condensing

Page 49

Optical Interface Specifications

Table 10. Optical Interface Specifications

Specification Value

Data Rate 10 Mi llion bits per second

Encoding Compliant with 10BASE-FB

Connector s SMA, ST, and FC

Connectors spacing 0.8 inch

Tran smit Source Type GaAlAs LED

Transmit Wavele n g th 820

Receiver Detector Type Silicon PIN photodiode

Receive Power for

better than 10

err or rate (minimal

guarantee d dynam ic

range)

-9

synchronous signaling

standard

-29.5 dBm peak to

bit

-9 dBm peak

± 20nm

Page 41

Page 50

Transmit Power Specifications

Tab le 11. Transmit Power

Cable Size

(micron)

50/125 NA 0.20 -21.3 ± 2.5 -13.8 ± 1. 5

62.5/125 NA 0.275 -17.5 ± 2.5 -10.5 ± 1.5

100/140 NA 0.30 -12.0 ± 2.5 -5.0 ± 1.5

Normal

Power

(dBm Peak)

High Power

(dBm Peak)

Fiber Optic Cables Compatibility

Tab le 12. Fiber Optic Cable Specifications

Specification Value

Cable size 50/125, 62.5/ 125, 100/140

Cable bandwidth 40 MHzKm minimum

Jabber protection 30 ± 3 msec (Non-Latching)

Page 42

micron diameter

Page 51

Attachme nt Unit Interfa ce Specifications

Table 13. AUI Specifications

Specification Value

Connector Standard male 15-pin

Standards

conformance

DC Power

requirements

DC line

current

consumption

D-subminiature

IEEE 802.3, Ethernet V2.0

12-15 Volts ± 10% applied at AUI

(pins 13, 6)

200 mA min @ 16.5 V, 77° F (25° C)

300 mA typ @ 12.0 V, 77° F (25° C)

500 mA max @ 10.8 V, 77° F (25° C)

Page 43

Page 52

Loading...

Loading...