Page 1

®

ONline Ethernet Management

Module Installation and

Operation Guide

Document Number 17-00087-7

Printed March 1995

Model Number: 5101M-MGT

Software Version: 4.0

3Com Co rporation

118 Turnpike Road

Southbo rough, MA 0177 2-1886

U.S.A.

(508) 46 0- 8900

FAX (508) 460-8950

Page 2

Federal Communications Comm ission

Notice

This equipment has been tested and found to comply with the

limits for a Class A digital device, pursuant to Part 15 of the FCC

Rules. These limits are designed to provide reasonable protection

against harmful interference when the equipment i s operated in a

commercial environment. This equipment generates, uses, and can

radiate radio frequency energy and, if not installed and used in

accordance with the instruction manual, may cause harmful

interference to rad io communications. Operation of this equipment

in a residential area is likely to cause harmful interfer ence, in which

case you must correct the interference at your own expense.

Canadian Emissions Requirements

Cet appareil numérique respecte les limites de bruits

radioélectriques applicables aux appareils numériques de Classe A

prescrites dans la norme sur la matériel brou illeur: "Appareils

Numériques", NMB-003 édictée par le Ministère des

Communications.

This digital apparatus does not exceed the Class A limits for radio

noise emissions from digital apparatus as set out in the

interference-causing equipment standard entitled "Digital

Apparatus", ICES-003 of the Department of Communications.

VDE Class B Compl ianc e

Hiermit wird bescheinigt, dass der 5101M-MGT in

Üebereinstimmung mit den Bestimmungen der Vfg 243/1991

funkentstöert ist.

Der Deutschen Bundespost wurde das Inverkehrbringen dieses

Geraetes angezeigt und die Berechtigung zur Üeberprüefung der

Serie auf Einhaltung der Bestimmungen eingeräeumt.

Einhaltung mit betreffenden Bestimmugen kommt darauf an, dass

geschirmte Ausfuehrungen gebraucht werden. Fuer die

Beschaffung richtiger Ausfuehrungen ist der Betreiber

verantwortlich.

This is to certify that the 5101M-MGT is shielded against radio

interference in accordance with the provisions of Vfg 243/1991.

The German Postal Services have been advised that this equipment

is being placed on the market and that they have been given the

right to inspect the series for compliance with regulations.

Compliance with applicable regulations depends on the use of

shielded cables. The user is responsible for procuring the

appropriate cables.

EN55022/CISPR22 Com p lian ce

This equipment conforms to the Class A emissions limits for a

digital device as defin ed by EN55022 (CISPR22).

VCCI Class 1 Com pl ian c e

This equipment is in the 1st Class category (information equipment

to be used in commercial or industrial areas) and conforms to the

standards set by the V oluntary Control Council for Inter fere nce by

Information Technology Equipment aimed at preventing radio

interference in commercial or industrial areas.

Consequently, when the equipment is used in a residential area or

in an adjacent area, r adio interferenc e may be caused to radio and

TV receivers, and so on.

Read the instructions for correct handling.

UK General Approval Statem en t

The ONcore Switching Hub, ONline System Concentrator, and

ONsemble StackSyste m Hub are manufactur ed to the International

Safety Standard EN 60950 and are approve d in the UK under the

Genera l Approval Number NS/G/12345/J/100003 for indirect

connection to the public telecommunication network.

Disclaimer

The information in this document is subject to change without

notice and should not be construed as a commitment by 3Com

Corporation. 3Com Corporation assumes no responsibility for any

errors that may appear in this document.

Copyright Statement

©

1995, by Chipcom Corporation, a subsidiary of 3Com

Corporation. Printed in U.S.A. All rights reserved. 3Com is a

registere d trade mark of 3Com Corporat ion. ONcore is a registered

trademark of Chipcom Corporation. The information contained

herein is the exclusive and confidential property of 3Com

Corporation. No part of this manual may be disclosed or

reproduced in whole or in part without permission from 3Com

Corporation.

Trademarks

Because of the nature of this material, numerous hardware and

software products are mentioned by name. In most, if not all

cases, these product names are claimed as trademarks by the

companies that man ufacture the products. It is not our intent to

claim these names or trademarks as our own.

Artel, Chipcom, Ethermo dem, Galactica, ONcore, ORnet,

StarBridge, and Tr iChannel are reg ister e d tra demark s of C hipcom

Corporation.

Chipcom OpenHub, G-Man, LANsentry, MultiProbe, ONdemand,

ONline, ONsemble, PowerRing, SL2000, SL3000, SL4000,

ii ONline Ethernet Management Module Installation and Operation Guide

Page 3

StackJack, StackSystem, and SwitchC entral are trademarks of

Chipcom Corporation.

The Chipcom Multichannel Architecture Communications System is

registered under U.S. Patent Number 5,301,303.

DEC, DECnet, the Digital logo, DELNI, POLYCENTER, VAX, VT100,

and VT220 are trademarks of Digital Equipment Corporation.

IBM is a registered trademark of International Business Machines.

NetView is a trademark of International Business Machines.

ST is a registerd trademark of AT&T.

UNIX is a registered trademark in the U.S.A. and other countries

licensed exclusively through X/Open Company, Ltd.

XNS is a trade mark a nd Ethernet is a r egistered trademark of Xerox

Corporation.

3ComFacts, Ask 3Com, CardFacts, NetFacts, and CardBoard are

service marks of 3Com Corporation.

3Com, LANplex, BoundaryRouting, LanScanner, LinkBuilder,

NETBuilder, NETBuilderII, ParallelTasking, ViewBuilder, EtherDisk,

Etherl\Link, Ether Link Plus, EtherLink II, TokenLink, T okenLink Plus,

and TokenDisk are registered trademarks of 3Com Corporation.

3ComLaser Library, 3TECH, CacheCard, FDDILink, FMS, NetProbe,

SmartAgent, Star-Tek, and Transcend are trademarks of 3Com

Corporation.

CompuServe is a registered trademark of CompuServe, Inc.

3Com registered trademarks are registered in the United States,

and may or may not be register ed i n other countrie s. Other brand

and product names may be reg istered tradema rks or trademark s of

their respective holders.

Restricte d Righ ts

Use, duplication, or disclosure by the Government is s ubject to

restrictions as set forth in subparagraph (c)(1) (ii) of the Rights in

Technical Data and Computer Software clause at

DFARS 252.227-7013.

Printed on recycled paper.

ONline Ethernet Management Modul e Installation and Operation Guide iii

Page 4

iv ONline Ethern et Management Mo dule Installation and Operation Guide

Page 5

How to Use This Guide

Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xiv

Structure of This Guid e . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xiv

Document Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

Related Documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvii

3Com Documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xviii

Reference Documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xviii

Chapter 1 — Introduction

The ONline Ethernet Managem ent Module . . . . . . . . . . . . . . . . . . . . . . . 1-1

Theory of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Complete ON lin e C on trol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

ONline Ethernet Management Mo du le Versions . . . . . . . . . . . . . . . . 1-5

The EMM Starter Version . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

The EMM Basic Version . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

The EMM Advanced Version . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Network Management Access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Network Management Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

ONline Backplane Archi tectu r e . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Where To Go From Here . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

Contents

Chapter 2 — Unpacking and Installin g the Mod ul e

Precautionary Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Unpacking Procedu re . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Installation Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Verifying Operatio n . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

The EMM Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Status LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Master Mgt Module LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Download in Progress LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

ONline Ethernet Management Module Installation and Operation Guide v

Page 6

Reset Button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

RS-232 Serial Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Where to go From Here . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Chapter 3 — Startup and Management Functions

Quick Reference for Getti ng Starte d . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Saving and Reverting Configuratio n Values . . . . . . . . . . . . . . . . . . . . 3-3

Configuring the Terminal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Optional Termi nal Setting s . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Setting Terminal Hang up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Setting Terminal Promp t . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Setting Terminal Tim eo ut . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Configuring the EMM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Setting Device Password . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Establishing the Administrator Password . . . . . . . . . . . . . . . . . . 3-10

Establishing the User Password . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Assigning an EMM Name . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

Setting Device Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

Assigning a Contact N am e and Locatio n . . . . . . . . . . . . . . . . . . . . . 3-12

Configuring SNMP Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

Assigning IP Addresses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

Creating a Community Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

Configuring the Alert Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

Setting a Subnetwork Mask . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

Defining the Default Gateway . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

Enabling Trap Receive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

Configuring Modules and Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

Assigning Modu le Networks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 -17

Assigning Module Mastersh ip Prio rity . . . . . . . . . . . . . . . . . . . . . . . 3-18

Setting Port Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 -19

Setting Port Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-19

Setting Redundant Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-19

Configuring Address-to-Port Sec urit y . . . . . . . . . . . . . . . . . . . . . . . . . . 3-20

Managing Security with EMM Master and Slaves . . . . . . . . . . . . . . 3-21

Establishing Rem ot e Logins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-22

Logging Out From a Remote Session . . . . . . . . . . . . . . . . . . . . . . . 3-24

Monitoring With SHOW Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-24

Showing Device Informa t ion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 -24

vi ONline Ethernet Management Module Installation and Operation Guide

Page 7

Showing Mod ule Informa t ion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 -25

Showing Port Inform atio n . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-26

Showing Conc entr at or Information . . . . . . . . . . . . . . . . . . . . . . . . 3 -26

Showing Coun ter Statistic s . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-27

Using the MONI TO R Co mm and . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 -28

Where To Go From Here . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-28

Chapter 4 — Troubleshooting

Applying Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

EMM and Terminal Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

EMM Trap Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Technical Assistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

EMM Network Impact . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

3Com Protocols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Chapter 5 — Software Download Instructions

Download Requ irements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

How the FDK and UDK Process Works . . . . . . . . . . . . . . . . . . . . . . . 5-3

Out-of-Band Do wn load Instru ctions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Installing the ProComm Software . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Connect the RS-23 2 Cabl e . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

Preparing to Download the New Software . . . . . . . . . . . . . . . . . . . . 5-8

Downloading the New Software . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

Inband Downl oad In structions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-15

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-19

ProComm Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-20

Ethernet Managemen t Modu le Problems . . . . . . . . . . . . . . . . . 5-21

Appendix A — Specifications

General Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Electrical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Environmental Spec ific ation s . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Mechanical Specificatio ns . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-3

Hardware Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-3

Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-3

Special Circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-3

ONline Ethernet Management Module Installation and Operation Guide vii

Page 8

Appendix B — RS-232 Cable Specs and Modem Use

RS-232 Cable Specification s . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Modem Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

Appendix C — MIB Group s

MIB-II Grou p s . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1

3Com MIB G roups . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-2

Appendix D — Technical Support

On-line Technical Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D-1

Email Technical Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-2

World Wide Web Site . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-2

Support from Your Netw ork Sup plier . . . . . . . . . . . . . . . . . . . . . . . . . . . D-2

Support from 3Com . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D-3

Returning Produ cts for Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-4

Accessing the 3Com MIB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D-4

3Com Technical Publications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-5

Index

viii ONline Ethernet Management Module Installatio n and Operation Guide

Page 9

Figures

Figure 1-1. EMMs in Network Config uration . . . . . . . . . . . . . . . . . . 1-3

Figure 1-2. Ethernet Management Module Communication in the

Figure 1-3. TriChannel Backplane Archit ectu re Assignments . . . . . . . 1-9

Figure 2-1. Installing the Ethernet Management Module . . . . . . . . . . 2-4

Figure 2-2. Installed EMM Connected to a Terminal . . . . . . . . . . . . . 2-5

Figure 2-3. Ethernet Management Module Faceplate . . . . . . . . . . . . 2-6

Figure 3-1. The 17-Slot ONline System Con cent rator . . . . . . . . . . . . 3-8

Figure 3-2. The 6-Slot ONline System Concentrat or . . . . . . . . . . . . . 3-9

Figure 3-3. The 6-Slot ONline System Concentrator with Integrated

Figure 3-4. Sample Remote Conn ec tio n . . . . . . . . . . . . . . . . . . . . . 3-23

Figure 5-1. Initial Installation Screen . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Figure 5-2. ProComm Installatio n Scr een . . . . . . . . . . . . . . . . . . . . . 5-7

Figure 5-3. Post-ProComm Installation Screen . . . . . . . . . . . . . . . . . . 5-7

Figure 5-4. Initial UDK Installation Screen . . . . . . . . . . . . . . . . . . . . . 5-9

Figure 5-5. ProComm Status Line Screen . . . . . . . . . . . . . . . . . . . . 5-10

Figure 5-6. ProComm Menu Screen . . . . . . . . . . . . . . . . . . . . . . . . 5 -13

Figure 5-7. ProComm Downl oad Screen . . . . . . . . . . . . . . . . . . . . . 5-14

Figure 5-8. Exit ProComm Screen . . . . . . . . . . . . . . . . . . . . . . . . . . 5-14

Figure 5-9. UDK Completion Screen . . . . . . . . . . . . . . . . . . . . . . . . 5-15

Figure B-1. Management Interface RS-232 Connector and Cable

ONline System Concentrator . . . . . . . . . . . . . . . . . . . . . . 1-3

Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Pinouts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

ONline Ethernet Management M odule Installation and Operation Guide ix

Page 10

x ONline Ethernet Management Module Installation and Operation Guide

Page 11

Tables

Table 1-1. Ethernet Backp lane Combination Reference Chart. . . . . 1-10

Table 1-2. Token Ring Backplane Com bination Reference

Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Table 1-3. FDDI Backplane Combination Reference Chart. . . . . . . . 1-11

Table 2-1. Interpretation of the Ethernet Management Module

LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Table 3-1. Quick Reference for Getting Started. . . . . . . . . . . . . . . . . 3-2

Table 3-2. EMM Terminal Parameter Options and

Factory Defaults. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Table 4-1. Applying Power Suggestions . . . . . . . . . . . . . . . . . . . . . . 4-2

Table 4-2. EMM Terminal Interface Suggestions . . . . . . . . . . . . . . . . 4-3

Table 4-3. EMM Trap Message Fields . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Table 5-1. UDK Er ror Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-20

Table 5-2. EMM Down load Error Message s . . . . . . . . . . . . . . . . . . 5-22

Table B-1. RS-232 Cable Gu idelin es . . . . . . . . . . . . . . . . . . . . . . . . . B-1

ONline Ethernet Management M odule Installation and Operation Guide xi

Page 12

Page 13

How to Use This Guide

This guide presents the principal features of the 3Com ONline™ Ethernet

Network Management Module (EMM) for version 4.0 software. It includes

instructions for installing the EMM into the ONline System Concentrator

and it also gives a physical description of the EMM, including the LEDs,

Reset Button, and RS-232 serial port con nector on the mo dule faceplate.

Instructions are also provided for using the EMM to manage the

concentrator through a terminal connected to the RS-232 serial port

connector. The commands used to configure the EMM to manage the

concentrator and modules are described in Chapter 3.

Troubleshootin g procedures that may help diagnose problem s during

installation and d uring operation are provided in Chapter 4.

A complete set of alphabetized ONline management commands is provided

in the ONline Management Commands Guide (17-00403). Each command

is described in detail with examp les of its syntax, options, and use.

ONline Ethernet Management Module Installation and Operation G uide xiii

Page 14

Audience

This guide is intended for the following people at your site:

❑ Network manager or administrator

❑ Hardware installer

Structure of This Guide

This guide contains five ch apters, three append ices, and an index:

Chapter 1 - Introduction – Presents the key features and management

functions of the EMM.

Chapter 2, Unpacking a nd Installing the Module – Pr ovides illustrated

procedures for installing the EMM into the ONline System Concentrator.

This chapter also describes the front panel in dic ators (LEDs), the Reset

Button, and RS-232 serial port connector. It also explains how to connect a

terminal to the EMM.

Chapter 3, Startup and Management Functions – Explains how to

configure the EMM to manage an Ethernet network. These configurations

include terminal settings, default system values, and configuring the EMM

for communication with SNMP-based management systems. This chapter

also describes how to monitor your Ethernet network using the SH O W

commands.

Chapter 4, Troubleshooting – Provides help in isolating and correcting

problems that may arise during installation and during normal operation.

Chapter 5, Software Download Instructions – Explains how to

download new software code to the Flash EPROM in th e EMM.

Appendix A, Specifications – Provides tech nical specification s for the

EMM, such as the electrical and environmental specifications.

xiv ONline Ethernet Management Module Installation and Operation Guide

Page 15

Appendix B, RS-232 Cable Specification and Modem Use –Describes

the various RS-232 cable configurations that can be used to connect a

device to the EMM serial port. This appendix also explains how a modem

should be configured for connection to the EMM.

Appendix C, - MIB Groups – Lists the 3Com MIB groups and the MIB II

groups that the EMM supports.

Appendix D, - Technical Support – Lists the various method s fo r

contacting the 3Com technical support organization and for accessing

other product support services.

Index

ONline Ethernet Management Module Installation and Operation Guide xv

Page 16

Document Conventions

The following document conventions are used in this manual:

Convention Indicates Example

Courier text User input In the Agent Information Form,

System output After pressing the Apply

enter MIS in the New Contact

field.

button, the system displays

the message

Transmi tt in g da ta .

Bold command

string

Italic text in braces User-substituted

Capitalized text in

plain brackets

Italics Text em phasis,

Path names Before you begin, read the

identifiers

Keyboard entry

by the user

document titles

readme.txt file located in

/usr/snm/agents.

Use the following command to

show port details:

SHOW PORT {

Type your password and press

[ENTER].

Ensure that you press the Apply

button after you add the new

search parameters.

slot

.all} VERBOSE

xvi ONline Ethernet Management Module Installation and Operation Guide

Page 17

Convention Indicates Example

Note: A Note. The

Caution: A Caution. A

Warning: A Warning. A

Related Documents

This section provides infor mation on supporting documentation, including:

❑ 3Com Documents

information is

important

condition may

damage

software or

hardware

condition may

threaten

personal safety

Note: Use STP lobe

cables for your system.

Caution: Do not put

your installation

diskettes on a

magnetic surfac e.

This may damage the

diskettes.

Warning: Wear eye

protection when

performin g these

maintenance

procedures.

❑ Reference Documents

ONline Ethernet Management Module Installation and Operation Guide xvii

Page 18

3Com Documents

The following documents provide additional info rmation on 3Com

products:

17-Slot ONlin e System Concen trator Ins tallatio n and O pera tion

Guide – Explains how to install, operate, and manage the 3Com ONline

17-Slot System Concentrator (Models 5017C-LS and 5017C with load

sharing).

6-Slot ONline System Concentrator Installation and Operation

Guide – Explains ho w to install, operate, and manage the 3Com ONline

6-Slot System Concentrator.

ONline Token Ring Management Module Installation and Operation

Guide – Explains how to install, operate, and use the 3Com ONline T oken

Ring Manageme nt Module.

ONline Management Commands Guide – Provides an alphabetized

reference resource describing all ONline management commands.

For a complete list of 3Com documents, contact your 3Com representative.

Reference Documents

The following documents supply related background information:

Case, J., Fedor, M., Scoffstall, M., and J. Davin, The Simple Network

Management Protocol, RFC 1 157, University of Tenne ssee at Knox ville,

Performance Systems International and the MIT Laboratory for Computer

Science, May 1990.

Rose, M., and K. McCloghrie, Structure and Identification of

Management Information for TCP/IP-based Internets, RFC 1155,

Performance Systems International and Hughes LAN Systems, May 199 0 .

xviii ONline Ethernet Management Module Installation and Operation Guide

Page 19

Introduction

1

This chapter presents an overview of the ONline™ Ethernet Management

Module (EMM) for software version 4.0 software. A brief description of the

new features in version 4.0 is presented first. Also included is a sample

application of using the EMM in a network configuration.

The remainder of this chapter describes:

❑ EMM Overview

❑ Network Management Acce ss

❑ The ONline Backplane Architecture

The ONline Ethernet Management Module

The EMM is a single-slot module designed to work with the 3Com ONline

System Concentrators. The EMM provides connection to an IEEE 802.3

Ethernet Local Area Networ k (LAN ), enab ling you to fully manage and

control your Ethernet network down to the port level. In addition, the EMM

contains advanced monitoring and control capabilities which allow you to

configure and check status on all Ethernet m odules.

Introduction 1 - 1

Page 20

The major features of the EMM include:

❑ Telnet support for remotely managing the EMM via inband

connection

❑ Inband network management via SNMP for local and remote

configuration cap abilities for all concentrators in th e network.

❑ Out-of-band network management via an RS-232 terminal connection

for local and remot e configuration capabilities for all concentrators

on the netwo rk

❑ Dynamic network control and management to the module and port

level

❑ Flash PROM designed for quick upgrade to the newest version of

software using inband or out-of-band downloads

❑ Automatic detection of faults and failures

❑ Security features to prevent unauthorized use

❑ Continuous monitoring and reporting of key network statistics

❑ Support of the 3Com Tr iChannel Architecture, ONdemand

Port-Switching, and fault tolerance capabilities

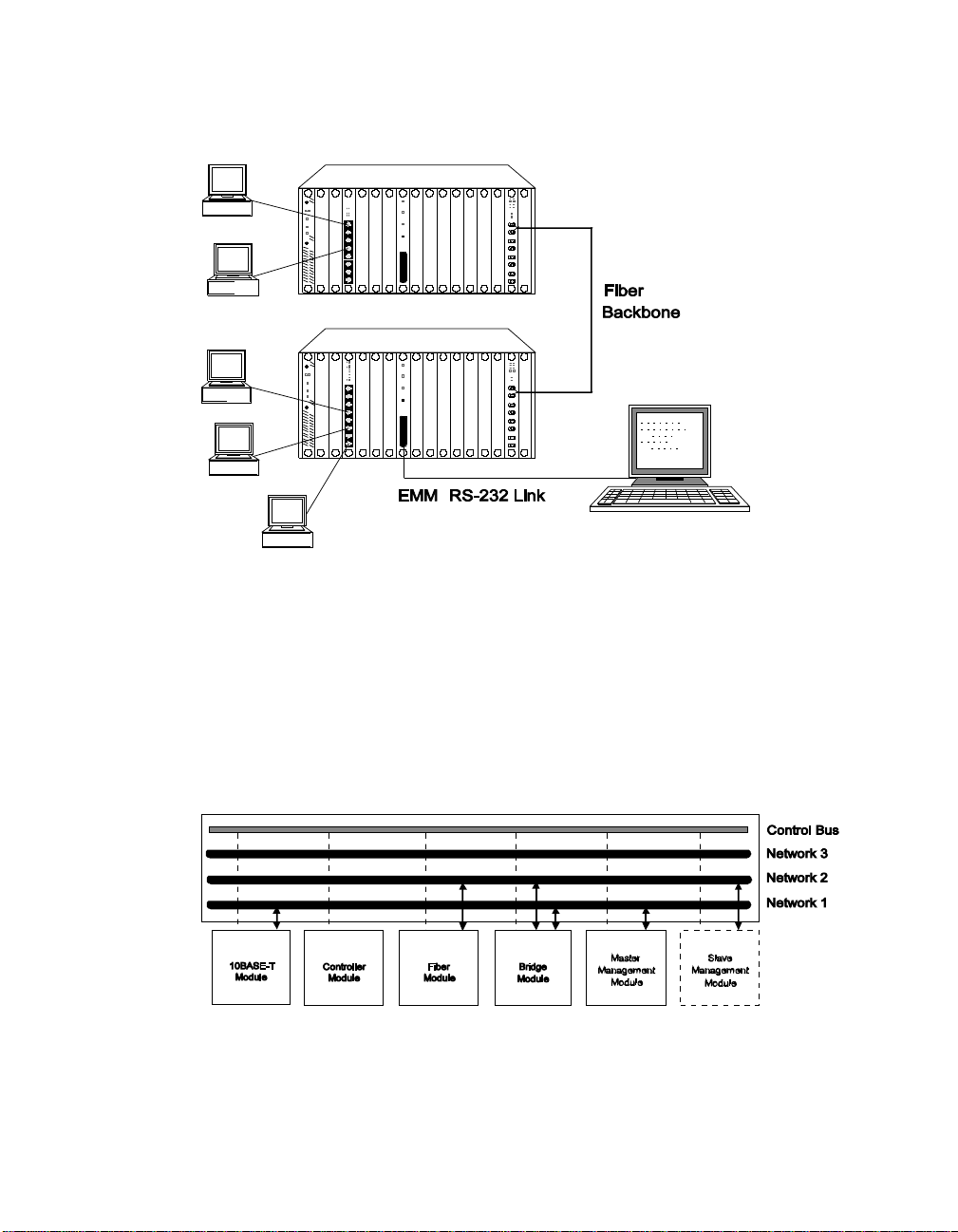

Figure 1-1 shows a typi cal im plementation of EMMs.

1 - 2 ONline Ethernet Management Module Installation and Operation Guide

Page 21

Figure 1-1. EMMs in Network Configuration

Theory of Operation

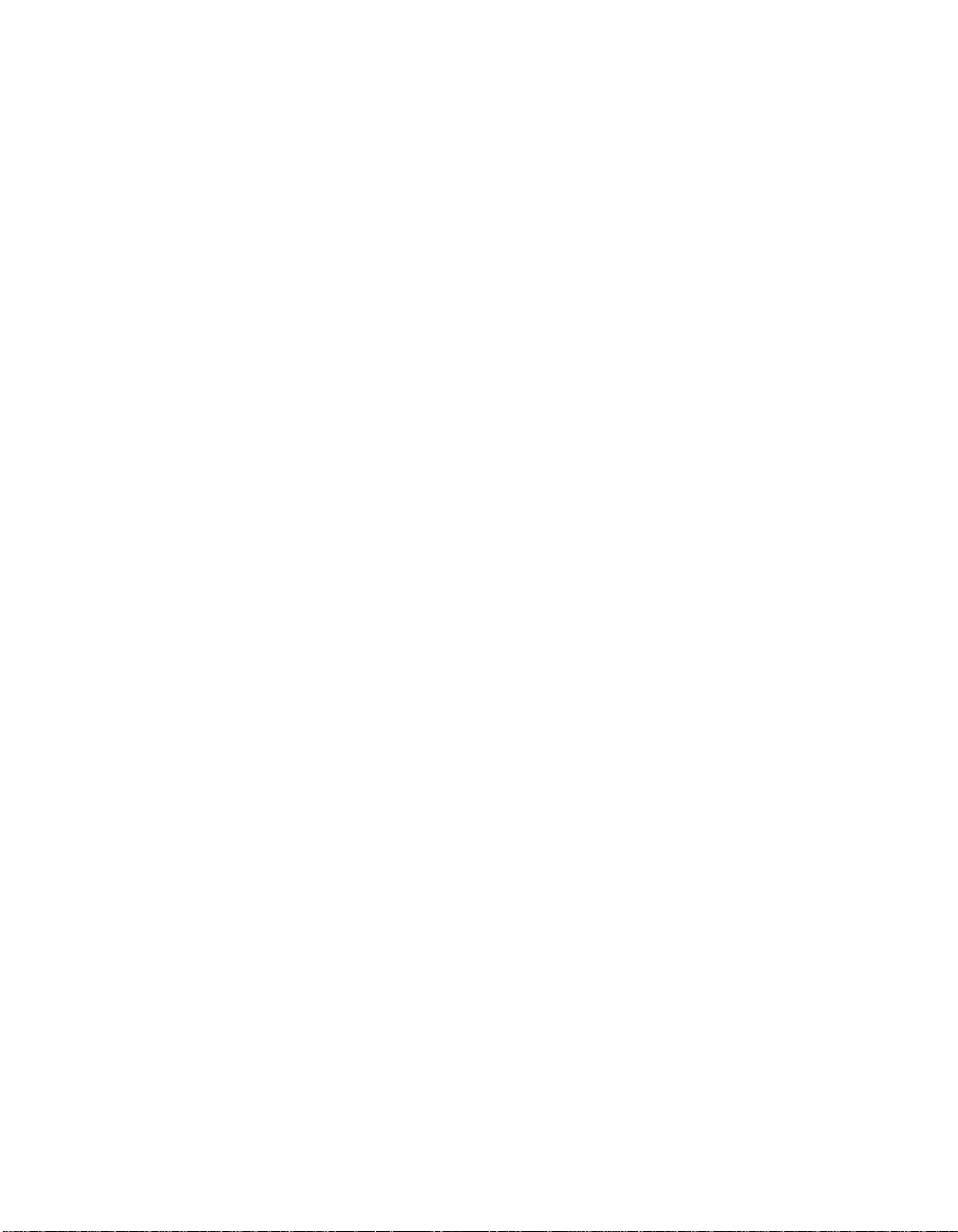

The EMM can be installed into any slot in the concentrator and

communicates with all other modules in the concentrator via a dedicated

control bus on the concentrator backplane as shown in Figure 1-2.

Figure 1-2. Ethernet Management Module Communication in the

ONline System Concentrator

Introduction 1 - 3

Page 22

Like media modules installed in the ONline System Concentrator , the EMM

is assigned to a network on the concentrator backplane. The configuration

and fault-detection capability of the EMM is protocol-independent an d

enables you to configure all Ethern et modules as well as Token Ring and

FDDI modules. In addition, via the Control Bus, the EMM can configure and

check status on all modules in the concentrator , even if they are assigned to

different networks or are isolated.

If you have modules assigned to different Ether net networks in a

concentrator, you should use multiple EMMs to track statistics on the

individual networks. For configuration management, however, only one

EMM in the concent rator can be the master EMM - all other EM Ms are

considered slaves.

A slave EMM can collect statistics and listen to traffic on the network to

which it is assigned. Since the slave does not have contro l of the Control

Bus, it cannot configure modules or detect faults. The slave module will

take over as master if the master EMM fails, thus providing fault tolerance

for your concentrator management. The administrator assigns a mastership

priority level between 1 and 10 to each EMM.

Since all EMMs are factory set with a priority level 10, the first EMM you

install will automatically become the master for that concentrator . All other

EMMs you install should have their mastership priority changed to a lower

value so as not to conflict with the first EMM.

1 - 4 ONline Ethernet Management Module Installation and Operation Guide

Page 23

Complete ONline Control

When you install an EMM into a concentrator for the first time and it

becomes master , it automatically learns a nd saves the configurations of all

existing modules and their ports. The EMM provides the following features

that maximize security and minimize the risk of losing module and port

configuration settings:

❑ All known modules installed in an ONline System Concentrator after

an EMM has been installed will have all ports disabled to prevent

unapproved connections and will be set to the network setting of

isolated. The one exception is when a module is unknown to the

EMM, in whi ch case it will be configured off its dip switch settings.

❑ If you remove any module from the concentrator and then reinstall it,

or another module of the same type in the original slot, the EMM will

automatically configure it as it was as of the last save.

❑ If you replace an EMM with another EMM, the new EMM

automatically learns the module and port configurations. However,

you will need to configure the new EMM to the proper terminal and

device settings.

ONline Ethernet Management Module Versions

There are three versions of the ONline Ethernet Management Module:

Starter (5101M-MGTS), Basic (5101M-MGTB), and Advanced (5101M-MGTA).

The following paragraphs explain the differences between these three

versions.

The EMM Starter Version

The EMM Starter includes all of the functions of the Basic soft ware, with

the following exception:

❑ Can only manage modules that are assigned to the same network as

the EMM

Introduction 1 - 5

Page 24

The EMM Basic Version

The EMM Basic provides:

❑ Local inband softw are upgrades using TFT P (Trivial File Transfer

Protocol) in mai ntenance mode

❑ SNMP support

❑ Out-of-band software upgrade

❑ Modem support (up to 9600 baud)

❑ Master/slave network managem ent

❑ Automatic statistics reporting

❑ Telnet support for remotely managing the EMM via inband

connection

The EMM Advanced Version

The EMM Advanced includes all of the functions of the Basic software plus

the following features:

❑ Local and remote inband software upgrades using TFTP

❑ Enhanced security through MA C address tracking per port

❑ Cross-module redundancy (ability to set port redundancy using

different modules )

❑ The ability to receive traps from othe r SNMP agents

1 - 6 ONline Ethernet Management Module Installation and Operation Guide

Page 25

Network Management Access

The EMM provides several ways to access networ k management. For

inband management, the EMM provid es built-in SNMP (Simple N et work

Management Protocol) agent, the de facto industry standard for network

management. The agent will let you manage EMMs through SNMP-based

network management solutions.

For out-of-band management, you can connect an ASCII terminal to the

RS-232 port on the module faceplate and manage the EMM using the

command-lin e in terface. You also have the flexibility to use Telnet for

inband management using the same extensive command-line interface.

The EMM also provides the Rem ote_login and Telnet features.

Remote_login is based on the 3Com proprietary proto col, RCP (Remote

Character Protocol). Telnet support is based on a fully compliant TCP /IP

stack.

Network Management Functio ns

The EMM provides management and control capabilities in six major areas:

❑ Configurations - When logged in under the administrator password,

you can configure the EMM, Ethernet network, modules, ports, and

terminal settings.

❑ Fault, Performance, and T raffic Statistics Monitoring - T ypical terminal

management systems only report statistics when you request them.

Y ou can configure the EMM to continuously monitor and report key

statistics by invoking the MONITOR command. The statistics on the

screen are updated periodically to give a snapshot of the network.

❑ Security Control - The EMM provides two important security features

that prevent unauthorized access to devices on the network address-to-port security and a two-level password protection feature.

Introduction 1 - 7

Page 26

❑ SNMP S up po r t - SNMP (Simple Network Management Protocol) is a

protocol defined by the Internet com munity. The EMM acts as an

agent i n a n S NMP managed environment r e sponding t o S NMP

requests and generating SNMP traps.

❑ Inband and Out-of-Band Download - The EMM provides both inband

and out-of-band dow nlo ad features. An inb and download is

performed via TFTP (Trivial File Transfer Protoco l ). The out-o f-band

download is performed using Xmodem software and a connection to

the RS-232 serial port on the front panel of the EMM.

❑ Telnet Support - The T elnet command enables you to log in remotely

to any EMM on the network and manage it from a remote EMM.

You can also manage an EMM from a workstation with Telnet

support.

ONline Backp l ane Architec tu re

The 3Com unique backplane architecture provides you with the power and

flexibility to create multiple Ethernet, Token Ring, FDDI networks in one

ONline System Concentrator. This backplane architecture allows th e

following networks to run in a single ONline System Conc en trator:

❑ three separate Ethernet networ ks and one isolated network

❑ seven backplane Token Ring networks and one isolated network

❑ four FDDI networks and one isolated network

Figure 1-3 illustrates how Ethernet, T oken Ring, and FDDI networks coexist

on the concentrator backplane. Note in Figure 1-3 that Ethernet networks

and paths correspond. That is, Ethernet_1 network is always allocated to

Ethernet path 1, Ethernet_2 network is always allocated to Ethernet path 2,

and Ethernet_3 network is always allocated to Ethernet path 3.

1 - 8 ONline Ethernet Management Module Installation and Operation Guide

Page 27

This is not true for Token Ring and FDDI networks and paths. There are 7

available Token Ring networks and 15 Token Ring paths. For FDDI, there

are 4 available FDDI networks and 8 FDDI paths. When you a s sign a

module or port to a network, the master management module dynamically

allocates the best possible path currently available for your configuration.

Following Figure 1-3 are T able 1-1, T able 1-2, and T able 1-3, which provide

reference tables for configuring Ethernet, Token Ring, and FDDI networks

in one concentrator . These tables define which networks paths are

removed when certain network paths are used. Refer to these charts to

determine the n um ber and types of different protocol combinations yo u

can have in one concentrator.

Y ou may want to issue the SHOW NETWORK P A THS command before and

after you configure networks to modules or ports to display which network

paths are in use.

TR1 TR2

FDDI 1

TR7 TR8

FDDI 4

TR13 TR15 TR14

*TR12 overlays part of FDDI 6, but it does not affect the Ethernet 2 path.

TR3

FDDI 17

TR4

FDDI 2

TR9

FDDI 5

FDDI 18

TR5

TR10

TR6

FDDI 3

TR11

FDDI 6

TR12*

Ethernet 1

Ethern et 2

Ethernet 3

Figure 1-3. Tr iChannel Backplane Architecture Assignments

Introduction 1 - 9

ONline

Backplane

Page 28

As shown in T able 1-1, Ethernet_3 is the best Ethernet network selection to

use in a mixed protocol environment because it affects the least amount of

Token Ring and FDDI network paths.

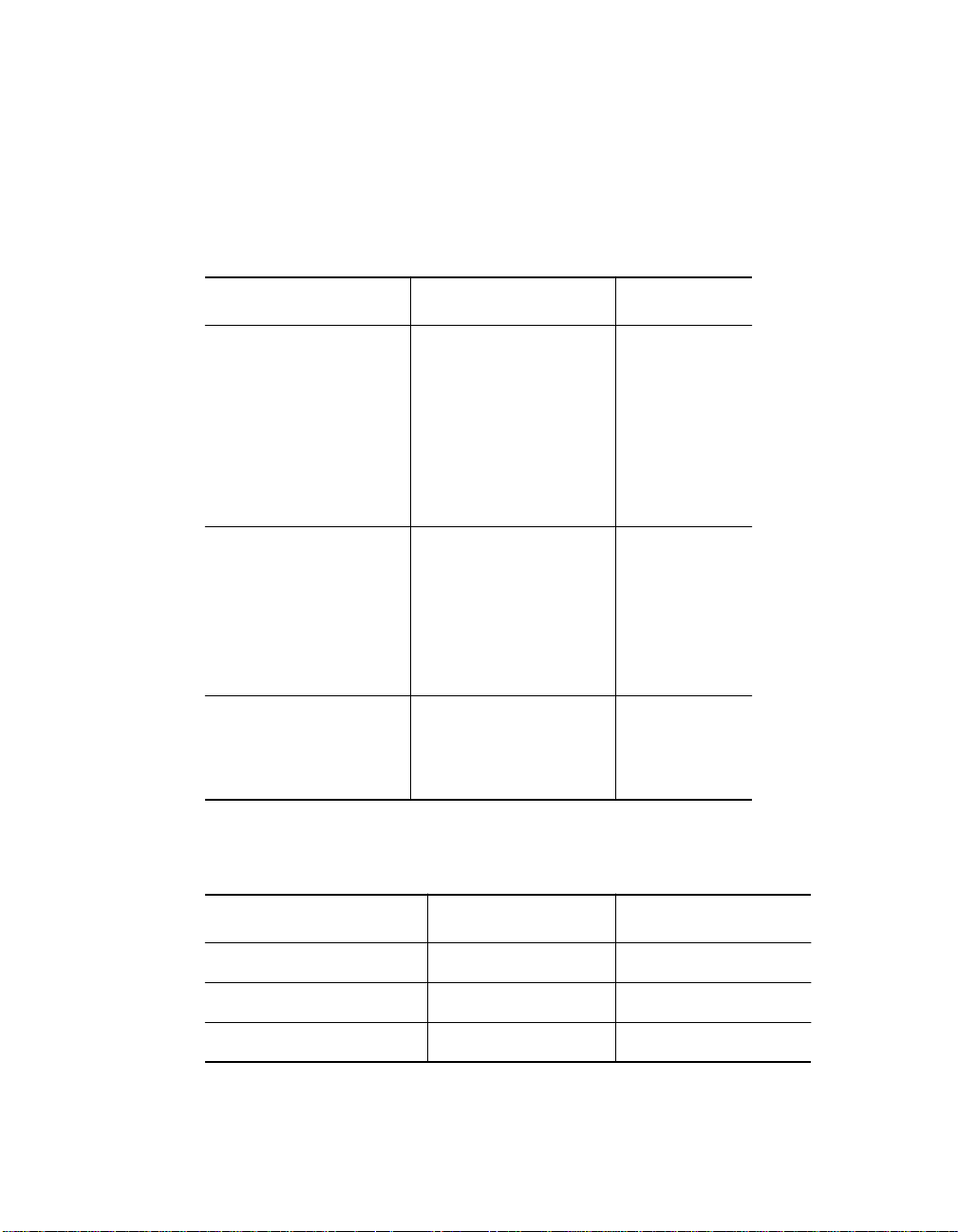

Table 1-1. Ethernet Backplane Combination Reference Chart

Ethern et Paths Token Ring Paths FDDI Paths

Ethernet 1 removes Token Ring 1

Token Ring 2

Token Ring 3

FDDI 1

FDDI 2

FDDI 3

Token Ring 4

Token Ring 5

Token Ring 6

Ethernet 2 removes Token Ring 7

Token Ring 8

Token Ring 9

FDDI 4

FDDI 5

FDDI 6

Token Ring 10

Token Ring 11

Ethernet 3 removes Token Ring 13

Token Ring 14

FDDI 7

FDDI 8

Token Ring 15

Table 1-2. Token Ring Backplane Combination Reference

Chart

Token Ring Paths Ethernet Paths FDDI Paths

Token Ring 1 removes Ethernet 1 FDDI 1

Token Ring 2 removes Ethernet 1 FDDI 1

Token Ring 3 removes Ethernet 1 FDDI 1 and FDDI 2

1 - 10 ONline Ethernet Management Module Installation and Operation Guide

Page 29

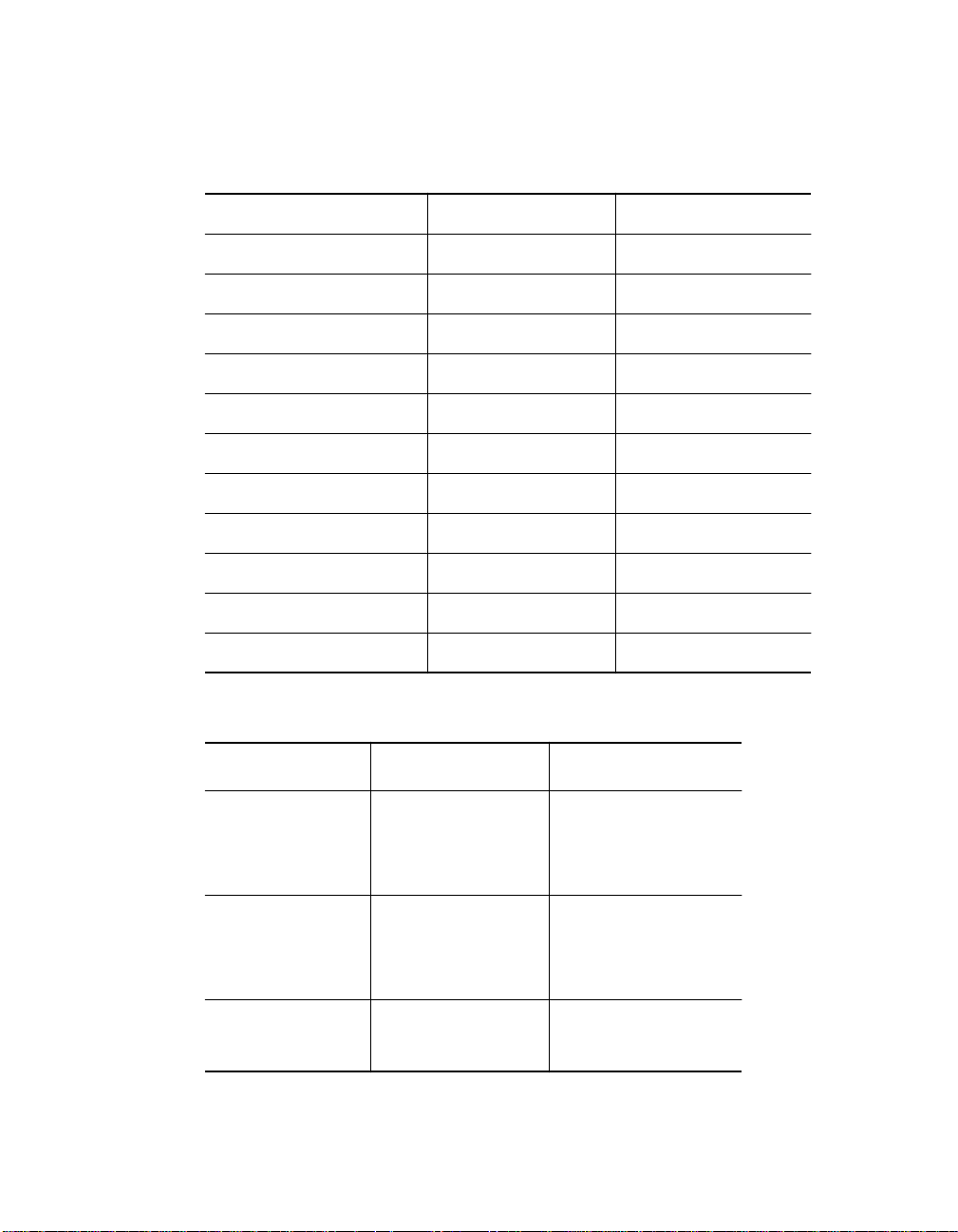

Table 1-2. Token Ring Backplane Combination Reference

Chart (Continued)

Token Ring 4 removes Ethernet 1 FDDI 2

Token Ring 5 removes Ethernet 1 FDDI 2 and FDDI 3

Token Ring 6 removes Ethernet 1 FDDI 3

Token Ring 7 removes Ethernet 2 FDDI 4

Token Ring 8 removes Ethernet 2 FDDI 4 and FDDI 5

Token Ring 9 removes Ethernet 2 FDDI 5

Token Ring 10 removes Ethernet 2 FDDI 5 and FDDI 6

T oken Ring 11 removes Ethernet 2 FDDI 6

T oken Ring 12 removes FDDI 6

T oken Ring 13 removes Ethernet 3

T oken Ring 14 removes Ethernet 3 FDDI 8

Token Ring 15 removes Ethernet 3 FDDI 7 and FDDI 8

Table 1-3. FDDI Backplane Combination Reference Chart

FDDI Paths Ethernet Paths Token Ring Paths

FDDI 1 removes Ethernet 1 Token Ring 1

Token Ring 2

Token Ring 3

FDDI 2 removes Ethernet 1 Token Ring 3

Token Ring 4

Token Ring 5

FDDI 3 removes Ethernet 1 Token Ring 5

Token Ring 6

Introduction 1 - 11

Page 30

Table 1-3. FDDI Backplane Combination Reference Chart

FDDI 4 removes Ethernet 2 Token Ring 7

FDDI 5 removes Ethernet 2 Token Ring 8

FDDI 6 removes Ethernet 2 Token Ring 10

FDDI 7 removes Ethernet 3 Token Ring 15

FDDI 8 removes Ethernet 3 Token Ring 14

Where To Go From Here

Token Ring 8

Token Ring 9

Token Ring 10

Token Ring 11

Token Ring 12

Token Ring 15

This chapter presented an overview of the ONline Ethernet Management

Module and its co ntrol capabilities. The next chapter, Unpacking and

Installing the Module, explains how you install the module into your

concentrator.

1 - 12 ONline Ethernet Management Module Installation and Operation Guide

Page 31

Unpacking and

Installing the Module

2

This chapter describes the precautionary, unpacking, and installation

procedures for the ONline Ethernet Man agement Module (EMM). It also

describes the module's front panel LEDs, Reset Button, and RS-232 serial

port connector . After you install the module, follow the steps in Chapter 3

to configure the module for proper operation.

Precautionary Procedures

Electrostatic discharge (ESD) can damage the static-sensitive devices on

circuit boards. T o avoid this kind of damage, use the following precautions

when han dling the EMM:

❑ Do not remove the board from its anti-static shielding bag until you

are ready to insert it into the concentrator.

❑ Use proper grounding techniques when inspecting and installing the

EMM. These techniques include using a foot strap and grounded mat

or wearing a grounded static discharge wrist strap. An alternate

method is to touch a grounded rack or other source of ground before

you handle th e EMM.

Unpacking and Installing the Modul e 2 - 1

Page 32

Unpacking Procedure

Use the following procedure when unpacking the EMM:

1. Verify that the EMM is the correct model by matching the model

number listed on the side of the shipping carton to the model

number you ordered (5101M-MGTB, 5101M-MGTA, or

5101M-MGTS).

Note that the product model number printed on the shipping box

differs from the model number on the product. The model number

on the shipping box contains the prefix ’3C9’.

2. Remove the module, in its anti-static bag, from the shipping carton.

3. Remove the module from the anti-static shielding bag and inspect it

for damage. Always handle the m odule by the faceplate being

careful not to tou ch the components.

4. If the module appears to be damaged, replace it in the anti-static

shielding bag, return it to the shipping carton and contact your local

supplier .

We suggest you keep the shipping carton and anti-static shielding bag in

which your module was shipped in case you later want to repackage the

module for storage or shipment.

We also suggest that you record the serial number of your EMM. A log for

this and other information specific to your modules under the Slot Usage

Chart in Appendix B of the ONline System Co ncentrator Installation and

Operation Guide.

2 - 2 ONline Ethernet Management Module Installation and Operation Guide

Page 33

Installatio n Procedures

For a new installation where you have received a new ONline System

Concentrator and all the modules, the following steps must be performed

prior to installin g the EMM:

❑ Install the concentrator in its location (rack, table, etc.) referring to

the instructions in the ONline System Concentrator Installation and

Operation Guide.

❑ Remove blank panels on the concentrators to expose empty slots for

the Controller Module, EMM, and ONline modules.

❑ Install the Con troller Module and ONlin e m odules into the board

guides at the top and bottom of the slots and slide them into the

concentrator. Make sure the connectors are firmly seated in the

backplane of the co ncentrator.

❑ Fasten the spring-loaded screws on the front panels of the modules

to the concentrator with your fingers (do not overtighten).

❑ Plug the power cord into an outlet and verify that all modules come

up in their default state. Optionally , press the LED Test button on the

Controller Module to ver ify that all LEDs are functional.

Installing the EMM into an existing installation does not require you to

power down the concentrator . The EMM, like all other ONline modules, has

the ability to be “hot swapped,” meaning that you can install the module

into any open slot and remove it with the concentrator in an operating

state. Use the following procedure if you are installing the EMM into an

existing installation.

1. Install the EMM into the board guides at the top and bottom of the

empty slot and slide it into the concentrator as shown in Figure 2-1.

Make sure the connector is firmly seated in the backplane of the

concentrator.

Unpacking and Installing the Modul e 2 - 3

Page 34

Wait for the Status LED and Master Mgt Module LED to light solid

green. At this point the EMM will learn the default module and port

settings for all modules installed in the concentrator.

Figure 2-1. Installing the Ethernet Management Module

2. Fasten the spring-loaded screws on the front panel of the EMM

faceplate to the concentrator with your fingers (do not overtighten).

3. If a terminal (out-of-band) connection is desired, verify that the

terminal meets the factory defaults of the EMM or you will not be

able to communicate with the module. The default EMM settings are:

– 9600 baud

– 8 data bits

– No parity

– 2 stop bits

4. Attach one end of an RS-232 cable to the RS-232 serial port connector

on the front of the EMM . Loop the cable through the concentrator

cable tray (if installed) and attach the other end to the RS-232 serial

port connector on a terminal or personal computer as shown in

Figure 2-2.

2 - 4 ONline Ethernet Management Module Installation and Operation Guide

Page 35

Figure 2-2. Installed EMM Connected to a Terminal

The RS-232 cable can be a maximum of 50 ft. in length. There are several

legal RS-232 cable configurations available depending on your installation.

Refer to Appendix B for more information on the exact RS-232 cable that

you need for your installation.

If you want to connect another type of device to the EMM, you can change

the factory default terminal settings of the EMM as described at the

beginning of Chapter 3.

Verifying Operation

This section explains how to v erify module functionality.

1. The Status LED on the m odule should light and t he Master Mgt

Module LED should light if this is the master EMM (or the only

management module in the con centrator).

Unpacking and Installing the Modul e 2 - 5

Page 36

2. The following message should display on the terminal screen once

the module is installed properly and the RS-232 connection is made:

Ethernet Management Module (v4 .00), Copyright (c) 1993

Chipcom Corporation

The EMM Front Panel

The EMM has three LEDs on the front panel that indicate the status of the

module, one button to reset the module, and one RS-232 serial port

connector used to connect the EMM to a terminal or modem. Figure 2-3

shows the features of the EMM faceplate and T able 2-1 describes the LEDs.

Figure 2-3. Ethernet Management Module Faceplate

2 - 6 ONline Ethernet Management Module Installation and Operation Guide

Page 37

T able 2-1. Interpretation of the Ethernet Management Module LEDs

LED Name Color State Indicates

Status Green Off Power off

On Power on

Blinking Error

Master Mgt

Module

Download in

Progress

Green Off EMM is a slave

On EMM is a master

Yellow Off Not downloading

On Downloading n ew

software to EMM flash

EPROM

Status LED

The Status LED displays a steady green glow to indicate that power is being

provided to the EMM and that the EMM is working proper ly. This LED

blinks when an error occurs during operation or if an error is found when

diagnostics are performed during a reboot. Refer to Chapter 4,

Troubleshootin g, for a description of the error codes.

Master Mgt Module LED

The Master Mgt Module LED displays a steady green glow if this EMM is

the master management module in the concentrator. It also displays a

green glow while a mastership election is in progress and during initial

installation. The LED is off when the EMM is a slave.

Unpacking and Installing the Modul e 2 - 7

Page 38

Download in Progress LED

The Download in Progress LED displays a steady yellow glow when

software is being downloaded to the Flash EPROM on the EMM. See

Chapter 5, Software Download Instructions, for details on downloading

new software.

Note that you need the Firmware Distribution Kit3Com Firmware

Distribution Kit (part number 5000-FDK) to initiate the download of new

software provided in the Update Distribution Kit (part number

5101M-UDKx-x.xx) .

Reset Button

The Reset Button resets the EMM and executes self-test diagnostic routines

(network traffic is not affected). You should press this button only w hen

you suspect problems with the EMM. The Reset Button is recessed to

prevent an accidental reset, yet you can access it with a pen tip or a small

screwdriver.

When the EMM is reset, it will come up under the last saved configuration

parameters. Pushing this button has the same effect as issuing the RESET

DEVICE command with one exception. Pushing the Reset button will cause

any unsaved changes to be lost. Issuing the RESET command on an EMM

after changes have been made but not saved causes a messa ge to display

warning you that unsaved changes exist. The RESET command aborts and

cannot be executed until the SAVE command is issued.

RS-232 Serial Port

The 25-pin (DB-25) RS-232 serial port is a DTE male connector used to

connect the EMM to a terminal or modem so you can enter management

commands and do wnload new software.

2 - 8 ONline Ethernet Management Module Installation and Operation Guide

Page 39

Where to go From Here

This chapter covered installation procedures for installing the EMM into a

concentrator. Also provided were descriptions of the EMM front panel

LEDs, RS-232 port, and the Reset Button. Now you are ready to set up your

terminal for c om m unication wit h the EMM and configure the EMM to

begin managing your Ethernet network as explained in Chapter 3. If you

encountered any problems with installing the module or the operation of

the LEDs, refer to Chapter 4, Troubleshooting.

Unpacking and Installing the Modul e 2 - 9

Page 40

Page 41

3

Startup and

Management Functions

This chapter describes how to configure the EMM once you have

completed the installation procedures outlined in Chapter 2. Included in this

chapter is a quick reference chart for getting started. The remainder of this

chapter is organized into the following sections:

❑ Configuring the Terminal

❑ Config uring the EMM

❑ Configuring SNMP Values

❑ Configuring Modules and Ports

❑ Configuring Address-to-Port Security

❑ Establishing Remote Logins

❑ Monito ring With SHOW Commands

The commands necessary to configure the EMM for operation are provided

in this chapter. The EMM supports similar command conventions and

keystroke functions as other ONline management d ev ices. Refer to th e

ONline Management Commands Guide (17-00403) for complete

information on all ONline management commands and command

conventions.

Startup and Management Functions 3 - 1

Page 42

Quick Reference for Getting Started

Table 3-1 outlines the steps and commands necessary to configure your

EMM. The procedures and command examples are explained further

throughout this chapter. If you are familiar with these instructions, you may

want to use this table as a checklist.

Table 3-1. Quick Reference for Getting Started

Procedure Command

1. Configure your terminal to

default

EMM communication settings

❑ Configure EMM Te rminal

Settings

2. Configure the EMM

❑ Concentrator Configuration

❑ Device Configuration (EMM)

SNMP Configuration SET COMMUNITY

Refer to your terminal v endor's

documentation

SET TERMINAL HANGUP

SET TERMINAL PROMPT

SET TERMINAL TIMEO UT

SET CONCENTRATOR PLATFORM

SET CLOCK

SET DEVICE CONTACT

SET DEVICE DIAGNOSTICS

SET DEVICE LOCA TION

SET DEVICE NAME

SET DEVICE P ASSWORD

SET DEVICE DEFAULT_GATEWAY

SET DEVICE IP_ADDRESS

SET DEVI CE SUB NET_MASK

SETALERT

SET DEVICE TRAP_RECEIVE

(Advanced EMM only)

3 - 2 ONline Ethernet Management Module Installation and Operation Guide

Page 43

Table 3-1. Quick Reference for Getting Started (C ontinued)

Procedure Command

3. Module Configuration SET MODULE

MASTERSHIP_PRIORITY

SET MODU LE NET WORK

SET MODULE RING_SPEED

4. Port Configuration SET PORT

SET PORT MODE

SET SECURITY PORT (Advanced

EMM only)

5. Save All Configuration Values SA VE ALL

6. Monitor the Network and

Device with SHOW commands

❑ Device Information

Module Information

Port Information

Concentrator Information

Counter Statistics

❑ EMM Traffic Statistics

SHOW DEVICE

SHOW MODULE

SHOW PORT

SHOW CONCENTRATOR

SHOW COUNTER MODULE

SHOW COUNTER PORT

SHOW COUNTER NETWORK

Saving and Reverting Config ura tio n Values

When you make configuration changes using the SET c ommand, t hey ar e

effective immediately but are not saved permanently. To s ave comma nds

permanently, use the SA VE command. Only saved values are in effect upon

reset of the EMM or the concentrator. You can issue the SAVE ALL

command to save all current concentrator configuration values previously

established by the SET command for all cat egories. Or you may issue a

specific SAVE command to save the configurations of only one group.

Startup and Management Functions 3 - 3

Page 44

Use the REVERT command to restore the c onfiguration values in effect at

the time of the last save. Any unsaved changes made using th e S ET

command are lost. The REVERT and SAVE commands support the same

configuration groups as defined below.

❑ Alert

❑ All

❑ Community

❑ Concentrator

❑ Device

❑ Security

❑ Module_Port

❑ Te rminal

❑ TFTP

Configuring the Terminal

The terminal that attaches to the serial port on the EMM must be

configured to the same parameter settings as the EMM so the terminal and

EMM can communicate. These settings include baud rate, data bits, parity ,

and stop bits. Initially , the terminal settings must match the factory default

settings of the EMM as specified in Table 3-2 . Consult the user's guide

shipped with your computer terminal for instructions on how to set these

values

3 - 4 ONline Ethernet Management Module Installation and Operation Guide

Page 45

.

Table 3-2. EMM Terminal Parameter Options and Factory Defaults

Parameter Options Factory Defa ult

Baud 300, 1200, 2400, 4800, 9600 9600

Data_bits 7 or 8 8

Parity odd, even, or none none

Stop_bits 1 or 2 2

Once you have configured your terminal to match the factory defaults of

the EMM, press [ENTER] and the following greeting is displayed:

Ethernet Management Module (v4.00) Copyri ght (c) 1993 Chipcom Corporation

Press [ENTER] again and the EMM prompts you for a password. Enter the

password and then press [ENTER] (the default password is a null string).

The following greeting and the default management prompt is displayed:

Welcome to system administrator service on ONline.

ONline>

You are now logged in as the administrator with full access to all

commands. Once terminal setti ngs are complete, yo u can configure the

ONline System Concentrator , the newly installed EMM, and all other ONline

modules residing in the concentrator.

When you are done using the EMM, save all changes, and then log out of

the system using the LOGOUT co mmand. Provided you have saved all

changes before issuing this command, you are logged out of the system

and the following message displays:

ONline> logout [ENTER]

Bye

Startup and Management Functions 3 - 5

Page 46

If you have made configuration changes and you have not saved those

changes, the LOGOUT command prom pts you as follows:

ONline> logout [ENTER]

WARNING: Save unsaved changes before logout.

You must either SAVE or REVERT any changes you made to the system

before you can successfully log out. Re-issue the LOGOUT command to log

out of the system once you have saved or reverted.

Optional Termina l Settings

The EMM provides three additional terminal management commands that

allow you to customize your term inal connection:

❑ terminal hangup

❑ terminal prompt

❑ terminal timeout v alue

These terminal settings are discussed in the following paragraphs. Also

included in this section is the procedure to change the terminal's setting if

you need to connect another device to the EMM that runs at a slower baud

rate or different parity or data bits values than the factory settings.

Setting Terminal Hangup

If you use a modem connection to the EMM, you may want to use the SET

TERMINAL HANGUP command to specify that the modem automatically

hang up the connection to the terminal when you log out of the EMM. The

factory default is disable, which means the modem will not automatically

hang up when y ou log out of the connection. If you fail to hang up the

modem connection, an unautho rized user may pick up the last lo gin

session.

Use the SET TERMINAL HANGUP command as shown to automatically

hang up the modem connection once you log out of the EMM:

ONline> set terminal hangup enable [ENTER]

3 - 6 ONline Ethernet Management Module Installation and Operation Guide

Page 47

Setting Terminal Prompt

It is a good idea to customize the management prompt for each EMM. This

will remind you of the EMM to which you are connected in the case where

you are logged into a remote EMM. The d efault management prompt is

“ONline>” for all Hems. Use the SET TERMINAL PROMPT command as

shown to customize your management prompt. 3Com recommends that

you use the same identification to specify the terminal prompt and device

name for your EMM.

ONline> set terminal prompt NEW PROMPT> [ENTER]

Setting Terminal Timeout

For optimum security, you should set the terminal timeout value to specify

the amount o f time you want yo ur terminal to remain active during the

absence of any keyboard activity. This feature is useful for keeping

unauthorized users off the system if you leave your terminal without

logging off. Once timeout has been set, the terminal will automatically log

you off the system if there is no terminal (keyboard) activity for the period

of time you have specified.

The default timeout value is 0, which means that no timeout has been set you will never be logged off automatically. Use the SET TERMINAL

TIMEOUT command as shown to set the timeou t period. Note that the

value specified is in minutes.

ONline> set terminal timeout 10 [ENTER]

Configuring the EMM

This section describes the commands necessary for startup and

management of your concentrator and EMM. You need to define the

following setting s for your EMM :

❑ Passwords

❑ EMM Name

Startup and Management Functions 3 - 7

Page 48

❑ Diagnostics

❑ Contact Nam e and Location

Use the following command to set the EMM' s internal clock .

ONline> set clock 5:53 93/03/6 Saturday [ENTER]

Use the following command to define the concentrator platform for your

EMM.

ONline> set concentrator platform {5006C} [ENTER]

{5017C}

{5006C-FT}

Note: Use the 5006C designation for all 6-slot concentrators.

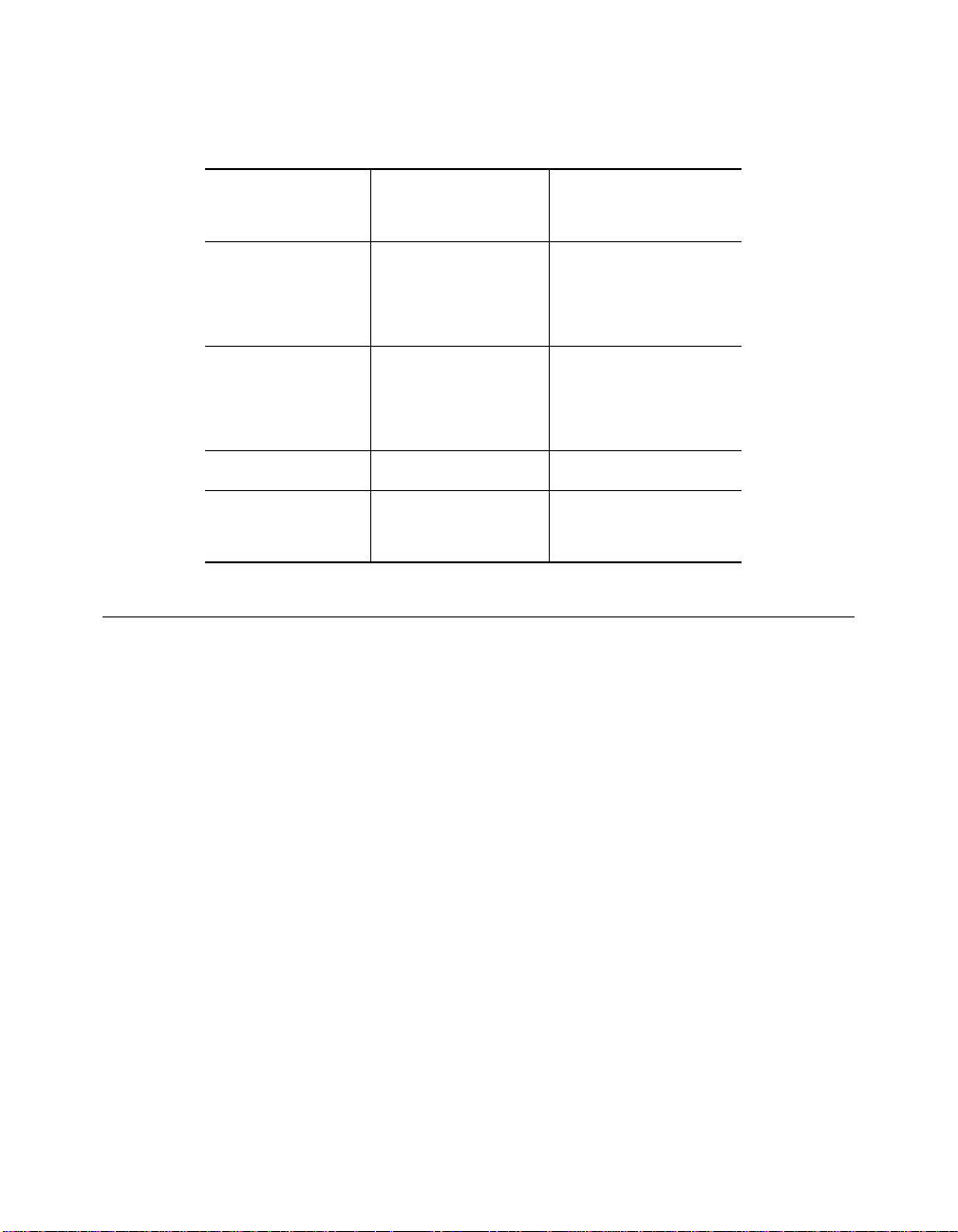

Figure 3-1, Figure 3-2, and Figure 3-3 show an ONline 17-Slot System

Concentrator, an ONline 6-Slot System Concentrator , and an ONline 6-Slot

System Concentrator with Integrated Controller , respectively . As the names

imply , there are 17 available slots (numbered from left to right) on the large

concentrator and 6 slots (numbered top to bottom) on the smaller

concentrators.

SLOT

2 3 4 5 6 7

1

8910 11

12 13 141516 17

Figure 3-1. The 17-Slot ONline System Concentrator

3 - 8 ONline Ethernet Management Module Installation and Operation Guide

Page 49

1

2

3

4

5

6

Figure 3-2. The 6-Slot ONline System Concentrator

1

2

3

4

5

6

Figure 3-3. The 6-Slot ONlin e System Concentrator w ith Integrated

Controller

Setting Device Password

The EMM provides two levels of password protection to protect against

unauthorized access to the EMM console and possible network tampering.

❑ Administrator. The administrator password provide s acce ss to all

EMM commands.

❑ User. The user password allows limited access to EMM commands

enabling status and configuration displays only.

Startup and Management Functions 3 - 9

Page 50

Both the administrator and the user password can be a maximum of 15

characters in length. Note that you must enter a password within 10

seconds following the display of the Password: prompt, or the terminal will

display “Timeout.” If this happen s, press [CTRL] [R] to redisplay the SET

DEVICE P ASSWORD command. The new passwords you set go into effect

immediately , but you must issue the SAVE DEVICE (or SAVE ALL) command

to save the new passwords.

Establishing the Administrator Password

Use the following command to establish the administrator password.

ONline> set device password administrator [ENTER]

Enter cu rrent administrator password: {old password} [ENTER]

New pass word: {new password} [ENTER]

Verify: {new password} [ENTER]

Note: For security purposes, the values you enter in the password

fields are not displayed on the screen.

Y ou do not need to use the new administrator password until the next time

you log in to the EMM.

As EMM administrator, you can conf igure the following:

❑ Device - This includes naming the EMM, establishing passwords,

setting mastership priority , setting SNMP Values, as well as providing

location and contact information.

❑ Modules - The EMM can assign each module in the ONline System

Concentrator to one of the available networ ks or i solate it (not

connect that module to any network). Reconfiguration of network

assignments can be done at any time, witho ut removing a module

from the concentrator or disrupting other configuration settings. If a

module is removed from the concentrator slot and replaced with the

same module ty pe in the same slot, the new module will be

configured to the settings of the previous module installed in that

slot.

3 - 10 ONline Ethernet Management Module Installation and Operation Guide

Page 51

❑ Ports - The EMM can assign each port on a per-port switching ONline

module to one of the available networks. Reconfiguration of network

assignments can be done at any time, without removing the module

from the concentrator or disrupting other configuration settings.

❑ Override Control - The EMM can overr ide all ONline module d ip

switch set ting s .

❑ Terminal - EMM terminal configuration values can be modified to

meet your particular application requirements.

❑ Security - The EMM address-to-port security feature enables you to

assign a maximum of four MAC addresses to a port. Whenever a

device assignment is changed, the EMM is alerted to the change in

MAC Address, sends a trap to the designated workstation, and

automatically disables that port.

❑ Fault Tolerance - The EMM can assign the ports of some modules

(e.g., Fiber Module, 10BASE-T Module) as redundant pairs in order to

provide fault-toleran t links between concentrators or between

devices (when using Fault-To lerant Transceivers).

Establishing the User Password

Use the following command to establish a user p assword. Note that you

must be logged in as administrator to change the user password. The

default user password is [ENTER].

ONline> set device passw ord user [ENTER]

Enter current administrator password: {administra tor password} [ENTER]

New passwo rd: {new use r p assword} [ENTER]

Verify: {new use r password} [ENTER]

Startup and Management Functions 3 - 11

Page 52

Assigning an EMM Name

To make identification of your EMMs easier, 3Com recommends that you

assign a unique name to each EMM. Y ou can then use this name instead of

the IP address or MAC address to refer to a particular EMM. Use the SET

DEVI CE NAME co mmand a s shown t o ass ign a un ique na me to yo ur EMM.

The EMM name can be a maximum of 31 characters.

ONline> set device name EMM3 [ENTER]

3Com recommen ds that you use the same identification to specify the

terminal prompt an d the device name for your EMM.

Setting Device Diagnostics

When the EMM is reset (or rebooted) using the factory default settings, the

module performs a full diagnostic check of itself and t hen sets all the

modules to the approp riate settings. You have the option to disable the

diagnostics if you want the EMM to boot up faster. Use the SET DEVICE

DIAGNOSTICS command as shown to bypass the diagnostics.

ONline> set device diagnostics disable [ENTER]

Assigning a Contact Name and Location

The EMM enables you to enter the name of an appropriate service contact

and the concentrator location. Use the SET DEVICE LOCATION and SET

DEVICE CONT ACT commands as shown to identify the location of the EMM

and the name of the person responsible for EMM operation. These

commands allow you to enter one line of free format text up to 78

alphanumeric characters in length. Note that you must enter the line of text

within 15 seconds of receiving the prompt or the com m and will timeout.

ONline> set device location [ENTER]

ONline> set device contact [ENTER]

3 - 12 ONline Ethernet Management Module Installation and Operation Guide

Page 53

Configuring SNMP Values

SNMP (Simple Network Management Protocol) is a protocol defined by the

Internet co m munity. All TCP/IP-ty pe traffic is encapsulated in Ethernet

frames. The EMM supports SNMP by responding to SNMP requests and

generating SNMP traps. An EMM acts as an agent in an SNMP- managed

environment, enabling you to configure your EMM and all modules in the

concentrator through SNMP. It has a community table that can contain up

to 10 IP addresses.

An IP Address entry in a community table may have one of the following

attributes assigned:

– read-only allows the specified IP address to re ad SNMP

variables via the SNMP GET command

– read-write allows the specified IP address to read and

write SNMP variables via the SNMP GET and SNMP SET

commands, respectively

– trap sends a trap to the specified IP address when an

SNMP variable is changed

– read-trap allows the specified IP address to read SNMP

variables and receive traps

– all (rea d-write, and trap) allows the specified IP address

to read SNMP variables, change the variables via the SNMP

SET command and receive traps wh enever an SNMP

variable is changed.

– oldtrap access means that the IP Address you specify will

receive alerts from the EMM based on the 3Com MIB I.

– read_oldtrap access means that the IP Address you

specify can display information about the EMM and it will

receive alerts based on the 3Com MIB I.

– oldall access means that the IP Address you specify has

read_write and trap access to the EMM based on the

3Com MIB I.

Startup and Management Functions 3 - 13

Page 54

Note: When you use the IP Address entry of all, you cannot use

trap, read_trap, or all access.

The three “old” trap options should be used when sending traps to

workstations using the 3Com MIB I variables. All the non-”old" trap options

should be used when sending traps to workstations using the 3Com MIB II

variables.

An EMM sends alarms to those IP addresses in the community table having

either trap, read-trap, or all attributes. The EMM and all modules in the

concentrator can be configured via SNMP from stations having IP addresses

with either read-write or all attributes. Finally, the EMM can be monitored

from stations having IP addresses with read-only , read-write, read-trap, or

all attributes.

An EMM can receive SNMP alarm s from SNMP devices on the net work

(including its elf) once the EMM's IP address and accompanying attributes

have been added to the community table of the SNMP device generating

the alarms, and the SET ALERT feature is enabled.

For example, if a major fault co ndition causes a port to be disabled, an

SNMP alarm is generated and displays to the terminal or workstation. This

feature enables you to analyze network information simply by accessing a

single EMM instead of having to be at the network management

workstation.

If you plan to manage your concentrator through an SNMP workstation,

you must set the following attributes for th e EMM:

❑ IP Address

❑ Community Table

❑ Alerts

❑ Subnetwork Mask

❑ Trap Receive

❑ Default Gateway

3 - 14 ONline Ethernet Management Module Installation and Operation Guide

Page 55

Assigning IP Addresses

T o run SNMP properly , every device on your network must have a unique IP

address. Use the SET DEVICE IP_ADDRESS command as shown to assign an

IP address for the EMM on network 1. Note that you can set separate IP

addresses for each of the ind ividual networks on the concentrator

backplane.

ONline> set device ip_address 195.36.58.27 network_1 [ENTER]

Creating a Community Table

The community table defines which SNMP stations on the network can

access information from the EMM and which station(s) will receive a trap

from the EMM when the EMM detects an error . For example, the following

command adds a community name of NCS with IP Address 195.36.58.217

to have read_write access:

ONline> set community NCS 195.36.58.217 read_write [ENTER]

Note that community entry names are case-sensitive. For example NCS and

ncs are different community names. Use the SHOW COMMU NI TY

command to view existing community entries.

Configuring the Alert Setting

The SET ALERT command enables or disables the feature used to send an

alert to the management workstation. The following command enables the

alert feature. Therefore, when a configuration chan ge i s mad e to the

concentrator via SNMP, an alert will be sent to the management

workstation.

ONline> set alert change enable [ENTER]

Refer to the SET ALERT command in the ONline Management Commands

Guide for information on the different types of alerts available through this

command.

Startup and Management Functions 3 - 15

Page 56

Setting a Subnetwork Mask

The subnetwork mask is specific to each type of Internet class. Generally,

the subnetwork mask is a group of common characters appearing on the

left side of an IP Address (called the Network ID), while the host address is

the group of unique characters appearing on the right side of an IP

Address. For example, to set the subnetwork mask for a class C address

without subnetworks, enter the following command:

ONline> set device subnet_mask FF.FF.FF.00 all [ENTER]

The subnetwork mask for a class B device without subnetworks would be

set using the following command:

ONline> set device subnet_mask FF.FF.0.0 ne twork_1 [ENTER]

Note that you can set separate subnetwork masks for each of the individual

networks on the co ncentrator backplane, or the same subnetwor k mask

for all of the networks on the concentrator backplane.

Defining the Default Gateway

The default gateway is the IP Address of the gateway that receives and

forwards packets whose addresses are unknown to the local network. The

default gateway is useful when sending EMM alert packets to a

management workstation on a different network. For example, the

following command specifies that the gateway with address 195.3.6.58 is

to become the default gateway:

ONline> set device default_gateway 195.3.6.58 all [ENTER]

Note that you can set separate default gateways for each of the individual

networks on the concentrator backplane, or the same default gateway for

all of the networks on t he concentrator backplane.

3 - 16 ONline Ethernet Management Module Installation and Operation Guide

Page 57

Enabling Trap Receiv e

The Advanced version of EMM software provides you wi th the ability to set

the EMM as a trap receiver . As a trap r eceiver , the EMM receives traps from

other SNMP devices that have the EMM's IP address in their community

table.

Use the following command to enable an EMM to function as the trap

receiver for other SNMP devices on the network.

ONline> set device trap_receive enable [ENTER]

Note: You must add the EMM's IP Address to a device's

community table in order for that device to be able to send

traps to the EMM.

Configuring Modules and Ports

This section describes how to assign the EMM and media modules to an

Ethernet network and how to configu re ports. Also discussed is the

importance of settin g the appropriate m astership priority l evel for your

EMM. Appendix B of the ONline System Concentrator Installation and

Operation Guide provides a chart to r ecord the values you se t for modules

in your concentrator.

Assigning Module Networks

Modules assigned to the same network form a segment. Modules assigned