Page 1

®

ONline 17-Slot System

Concentrator Installation and

Operation Guide

Document Number 17-00417-3

Printed March 1995

Model Numbers: 5017C-LS

5017C

5017C with load sharing

3Com Co rporation

118 Turnpik e Road

Southborough, MA 01772-1886

U.S.A.

(508) 460-8900

FAX (508) 460-8950

Page 2

Federal Communications Commission

Notice

This equipment has been tested and found to comply with the

limits for a Class A digital device, pursuant to Part 15 of the FCC

Rules. These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in a

commercial environment. This equipment generates, uses, and can

radiate radio frequency energy and, if not installed and used in

accordance with the instruction manual, may cause harmful

interference to radio communications. Operation of this equipment

in a residential area is likely to cause harmful interference, in which

case you must correct the interference at your own expense.

Canadian Emissions Requirements

This Class A digital apparatus meets all requirements of the

Canadian Interference-Causing Equipment Regulations.

Cet appareil numérique de la classe A respecte toutes les exigences

du Règlement sur le matériel brouilleur du Canada.

VDE Class B Compliance

Hiermit wird bescheinigt, dass der 5017C und 5017C-LS in

Üebereinstimmung mit den Bestimmungen der Vfg 243/1991

funkentstöert ist.

Der Deutschen Bundespost wurde das Inverkehrbringen dieses

Geraetes angezeigt und die Berechtigung zur Üeberprüefung der

Serie auf Einhaltung der Bestimmungen eingeräeumt.

Einhaltung mit betreffenden Bestimmugen kommt darauf an, dass

geschirmte Ausfuehrungen gebraucht werden. Fuer die

Beschaffung richtiger Ausfuehrungen ist der Betreiber

verantwortlich.

This is to certify that the 5017C and 5017C-LS are shielded against

radio interference in accordance with the provisions of Vfg

243/1991.

The German Postal Services have been advised that this equipment

is being placed on the market and that they have been given the

right to inspect the series for compliance with regulations.

Compliance with applicable regulations depends on the use of

shielded cables. The user is responsible for procuring the

appropriate cables.

EN55022/CISPR22 Compliance

This equipment conforms to the Class A emissions limits for a

digital device as defined by EN55022 (CISPR22).

VCCI Class 1 Compliance

This equipment is in the 1st Class category (information equipment

to be used in commercial or industrial areas) and conforms to the

standards set by the Voluntary Control Council for Interference by

Information Technology Equipment aimed at preventing radio

interference in commercial or industrial areas.

Consequently, when the equipment is used in a residential area or

in an adjacent area, radio interference may be caused to radio and

TV receivers, and so on.

Read the instructions for correc t handling .

UK General Approval Statement

The ONcore Switching Hub, ONline System Concentrator, and

ONsemble StackSystem Hub are manufactured to the International

Safety Standard EN 60950 and are approved in the UK under the

General Approval Number NS/G/12345/J/100003 for indirect

connection to the public telecomm unication network.

Disclaimer

The information in this document is subject to change without

notice and should not be construed as a commitment by 3Com

Corporation. 3Com Corporation assumes no responsibility for any

errors that may appear in this document.

Copyright State me nt

©

1995 by Chipcom Corporation , a subsidiar y of 3Com

Corporation. Printed in U.S.A. All rights reserved. The information

contained herein is the exclusive and confidential property of

3Com Corporation. No part of this manual may be disclosed or

reproduced in whole or in part without permission from 3Com

Corporation.

Trademarks

Because of the nature of this material, numerous hardware and

software products are mentioned by name. In most, if not all

cases, these product names are claimed as tradem arks by the

companies that manufacture the products. It is not our intent to

claim these names or trademarks as our own.

Artel, Chipcom, Ethermodem, Galactica, ONcore, ORnet,

StarBridge, and TriChannel are registered trademarks of Chipcom

Corporation, a subsidiary of 3Com Corporation.

Chipcom OpenHub, G-Man, LANsentry, MultiProbe, ONdemand,

ONline, ONsemble, PowerRing, SL2000, SL3000, SL4000,

StackJack, StackSystem, and SwitchCentral are trademarks of

Chipcom Corporation, a subsidiary of 3Com Corporation.

ii ONline 17-Slot System Concentrator Installation and Operation Guide

Page 3

The Chipcom Multichannel Architecture Communications System is

registered under U.S. Patent Number 5,301,303.

UNIX is a registered trademark in the U.S.A. and other countries

licensed exclusively through X/Open Company, Ltd.

XNS is a trademark of Xerox Corporation.

DEC, DECnet, the Digital logo, DELNI, POLYCENTER, VAX, VT100,

and VT220 are trademarks of Digital Equipment Corporation.

3ComFacts, Ask 3Com, CardFacts, NetFacts, and CardBoard are

service marks of 3Com Corporation.

3Com, LANplex, BoundaryRouting, LanScanner, LinkBuilder,

NETBuilder, NETBuilderII, ParallelTasking, ViewBuilder, EtherDisk,

Etherl\Link, EtherLink Plus, EtherLink II, TokenLink, TokenLink Plus,

and TokenDisk are registered trademarks of 3Com Corporation.

3ComLaser Library, 3TECH, CacheCard, FDDILink, FMS, NetProbe,

SmartAgent, Star-Tek, and Transcend are trademarks of 3Com

Corporation.

CompuServe is a registered trademark of CompuServe, Inc.

3Com registered trademarks are registered in the United States,

and may or may not be registered in other countries. Other brand

and product names may be registered trademarks or trademarks of

their respective holders.

Restricted Rights

Use, duplication, or disclosure b y the G overnm ent is subject to

restrictions as set forth in subparagraph (c)(1) (ii) of the Rights in

Technical Data and Computer Software clause at

DFARS 252.227-7013.

Printed on recycle d paper.

ONline 17 -Slot System Concentrator Installation and Operation Guide iii

Page 4

iv ONline 17-Slot System Concentrator Installation and Operation Guide

Page 5

How to Use This Guide

Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiii

Structure of This Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiv

Docume nt Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

Related Documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

3Com Doc uments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xvii

Reference Documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xvii

Chapter 1 — Introduction

Introducing the ONline System Concentrator . . . . . . . . . . . . . . . . . . . . . . .1-1

Back Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

ONline System Concentrator Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

Modul ar Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5

TriChannel Architecture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6

Port-Switching Technology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6

Fault-Tolerance Capabilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-8

Backup Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-8

Load Sharing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-8

Backup Controller Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-9

Redun dant Cable Links . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-9

Backup Concentrator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-10

Hot Swa pping of Media Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-11

Synchronous Backplane . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-12

Contents

Chapter 2 — Installation and Troubleshooting

Contents of the S hipping B ox . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

FCC Regulations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

Site Se lection Consider ations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

ONline 17-Slot System Concentrator Installation and Operation Guide v

Page 6

Location Requirement s . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

Ventilation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

Power Requirem ents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

Rack Mount Installati on Require ments . . . . . . . . . . . . . . . . . . . . . . . . .2-5

Table Top Installation Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

Inst alling the Cable Tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-7

Cabl e Tray Rack Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-8

Cabl e Tray Table Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-10

Installing the ONline System Concentrator . . . . . . . . . . . . . . . . . . . . .2-11

Rack Mounting the ONline System Concentrator . . . . . . . . . . . . .2-11

Table Top Mounting the ONline Concentrator . . . . . . . . . . . . . . .2-13

Inst alling the Backup Power Supply (Optional) . . . . . . . . . . . . . . . . . .2-14

Selecting the Power Supp ly Voltage . . . . . . . . . . . . . . . . . . . . . . . . . .2-17

Inst alling ONline Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-19

Connecting Network Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-19

Power Up and Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-20

Fan Operation Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-21

Power Supply Operation Verification . . . . . . . . . . . . . . . . . . . . . .2-21

Technical Assistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-25

Where To G o F r om Here . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-26

Chapter 3 — Maintenance

Routine Maint enance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

Replacing the Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

Replacing the Fan Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-7

ONline Module Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-9

Other System Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-9

Appendix A — Specifications

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Environmental . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Mechanical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Power Source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Regulatory Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

vi ONline 17-Slot System Concentrator Installation and Operation Guide

Page 7

Appendix B — Slot Usage Chart

Appendix C — Technical Support

On-line Technical Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-1

Email Technical Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C- 2

World Wide Web Site . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-2

Support from Your Network Supplier . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-2

Support from 3Com . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-3

Returning Products for Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-4

Accessing the 3 Com MIB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-4

3Com Tec hnical Publicat ions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-5

Index

ONline 17-Slot System Concentrator Installation and Operation Guide vii

Page 8

viii ONline 17-Slot System Concentrator Installation and Operation Guide

Page 9

Figures

Figure 1-1. Multiple 17-Slot Concentrator Environment . . . . . . . . . . . .1-2

Figure 1-2. ONline System Concentrator Rear View . . . . . . . . . . . . . . .1-3

Figure 1-3. ONline System Concentrator Front View . . . . . . . . . . . . . . .1-4

Figure 1-4. Modular ONline Configuration . . . . . . . . . . . . . . . . . . . . . .1-5

Figure 1-5. ONline System Concentrator Using Multiple Networks . . . .1-7

Figure 1-6. Redunda nt Cable Lin k Configuration . . . . . . . . . . . . . . . .1-10

Figure 1-7. Backup Concentrator Configuration . . . . . . . . . . . . . . . . .1-11

Figure 2-1. ONline System Concentrator Shipping Box Contents . . . . . .2-2

Figure 2-2. Rack Mount Positions . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-9

Figure 2-3. Cable Tray Installation i n Rack . . . . . . . . . . . . . . . . . . . . .2-10

Figure 2-4. Attaching the Rack Mount Flanges . . . . . . . . . . . . . . . . . .2-12

Figure 2-5. Chassis Mounted in Rack . . . . . . . . . . . . . . . . . . . . . . . . .2-13

Figure 2-6. Removing Fan Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-14

Figure 2-7. U npluggi ng the Fan Unit . . . . . . . . . . . . . . . . . . . . . . . . .2-15

Figure 2-8. Power Su pply Conne ctors . . . . . . . . . . . . . . . . . . . . . . . . .2-16

Figure 2-9. Installing the B ackup Power Supply . . . . . . . . . . . . . . . . .2-16

Figure 2-10. Inst alled Backup Powe r Supply . . . . . . . . . . . . . . . . . . . . .2-17

Figure 2-11. Setting the Voltage Selector Switch . . . . . . . . . . . . . . . . .2-18

Figure 2-12. Networ k Cable Connectio ns . . . . . . . . . . . . . . . . . . . . . . .2-20

Figure 3-1. Removing the Power Su pply . . . . . . . . . . . . . . . . . . . . . . . .3-3

Figure 3-2. U npluggi ng the Power Supply . . . . . . . . . . . . . . . . . . . . . .3-4

Figure 3-3. Power Supply Plugs in ONline System Concentrator . . . . . .3-5

Figure 3-4. Backup Power Supply Install ed . . . . . . . . . . . . . . . . . . . . . .3-6

Figure 3-5. Removing the Fan Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-7

Figure 3-6. U npluggi ng the Fan Unit . . . . . . . . . . . . . . . . . . . . . . . . . .3-8

Figure 3-7. Fan Unit Install ed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-9

ONline Ethernet 10BASE- FL Module Installation and O peration Guide ix

Page 10

x ONline Ethernet 10BASE-FL Module Installation and Operation Guide

Page 11

Tables

Table 2-1. Steps for Installing the ONline System Concentrator . . . . . .2-6

Table 2-2. Rack Mount Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-8

Table 2-3. Controller Module LEDs After Proper Power-Up . . . . . . . . .2-21

Table 2-4. Troubleshooting with Controller Module LEDs . . . . . . . . . .2-22

Table B-1. Concentrator Slot Usage Chart . . . . . . . . . . . . . . . . . . . . . .B-1

ONline Ethernet 10BASE- FL Module Installation and O peration Guide xi

Page 12

Page 13

How to Use This Guide

This guide explains how to install, operate, and manage the following

3Com ONli ne™ 17-Slot System Co ncentrators.

❑ 5017C

❑ 5017C with load sh aring

❑ 5017C-LS

Keep this guide near the ONline System Concentrator

Audience

This guide is intended for the following people at your site:

❑ Network manager or administrator

❑ Hardware installer

ONline 17-Slot System Concentrator Installation and Operation Guide xiii

Page 14

Structure of This Guide

This guide contains the following chapters:

Chapter 1, Introduction – Introduces the principal features of the ONline

System Concentrator and provides a front and rear view of the unit.

Chapter 2, Installation and Troubleshooting – Provides illustrated

procedures for installin g and verify ing the operation of the 17-Slo t ONline

System Concentrator.

Chapter 3, Maintenance – Describes how to order and replace

serviceable parts on the ONline Syste m Concentrator. These parts include

the power supply, backup power supply, and fan units.

Appendix A, Specifications – Provides product dimensions, power

requirements, and other specifications for the unit.

Appendix B, Slot Usage Chart – Provides a chart to record informatio n

about which modules are installed in the 17 concentrator slots.

Appendix C - Technical Support – Lists the various methods for

contacting the 3Com technical support organization and for accessing

other product support services.

Index

ONline 17-Slot System Concentrator Installation and Operation Guide xiv

Page 15

Document Conve ntions

The following document conventions are used in this manual:

Convention Indicates Example

Courier text User input In the Agent Information Form,

enter MIS in the New Contact

field.

System output After pressing the A pply

button, the sy stem displays

the message

Transmi tt in g da ta .

Bold command

string

Italic text in braces User-substituted

Capitalized text in

plain brackets

Italics Text emphasis,

Path names Before you begin, read the

identifiers

Keyboard entry

by the user

docu me nt titles

readme.txt file located in

/usr/snm/agents.

Use t he following command to

show port details:

SHOW PORT {

Type your password and press

[ENTER].

Ensure that you press the Apply

button after you add the new

search parameters.

slot

.all} VERBOSE

ONline 17-Slot System Concentrator Installation and Operation Guide xv

Page 16

Convention Indicates Example

Note: A Note. The

Caution: A Caution. A

Warning: A Warning. A

Related Docu me nts

This section provides information on supporting documentation, including:

❑ 3Com Documents

information is

important

condition may

damage

software or

hardware

condition may

threaten

personal safety

Note: Use STP lobe

cables for yo ur s yste m.

Caution: Do not put

your installation

diskettes on a

magnetic surface.

This may damage the

diskettes.

Warning: Wear eye

protec tion when

performing these

maintenance

procedures.

❑ Reference Documents

xvi ONline 17-Slot System Concentrator Installation and Operation Guide

Page 17

3Com Documents

The following documents provide additional information on 3Com

products:

17-Slot ONline System Concentrator Installation and Operation

Guide – Explains how to install, operate, and manage the 3Com ONline

17-Slot Syste m Concentrator (Models 5017 C-LS and 5017C with load

sharing) .

6-Slot ONline System Concentrator Installation and Operation

Guide – Explains how to install, operate, and m anage the 3Com ONline

6-Slot System Concentrator.

ONline To ken Ring Management Module User’s Guide – Explains how to

install, operate, and use the 3Com ONline Token Ring Management

Module.

ONline Management Commands Guide – Provides an alphabetized

reference resource describing all ONline management commands.

For a complete list of 3Com documents, contact your 3Com representative.

Reference Documents

The following documents supply related background information:

Case, J., Fedor, M., Scoffstall, M., an d J. Davin, The Simple Network

Management Protocol, RFC 1157, University of Tennessee at Knoxville,

Performance Systems International and the MIT Laboratory for Computer

Science, May 1990.

Rose, M., and K. McCloghrie , Structure and Identification of

Management Information for TCP/IP-based Internets, RFC 1155,

Performance Systems International and Hughes LAN Systems, May 1990.

ONline 17-Slot System Concentrator Installation and Operation Guide xvii

Page 18

Page 19

Introduction

1

This chapter briefly describes the cap abilities and operation of the 3Com

ONline™ System Concentrator. Chapter 2 provides important information

for installing modules and verifying their operation.

If you are uncertain about legal network configurations when using the

ONline System Concentrator, refer to the appropriate ONline media module

manual.

Introducing the ONline Sys tem Conc e ntrat or

The ONline System Concentrator is a modular, fault-tolerant pl atform for

facility networks. The concentra tor has a unique TriChannel® architecture

that allows it to run three network protocols concurrently. It is capable of

running Ethernet, Token Ring, and FDDI networks - all in the same

concentrator.

Ethernet connectivity is available on a variety of major cable types including:

❑ Fiber optic ca ble

❑ Unshielded and Shielded twisted pair wire

❑ Thin and Th ick coaxial cable

Introduction 1 - 1

Page 20

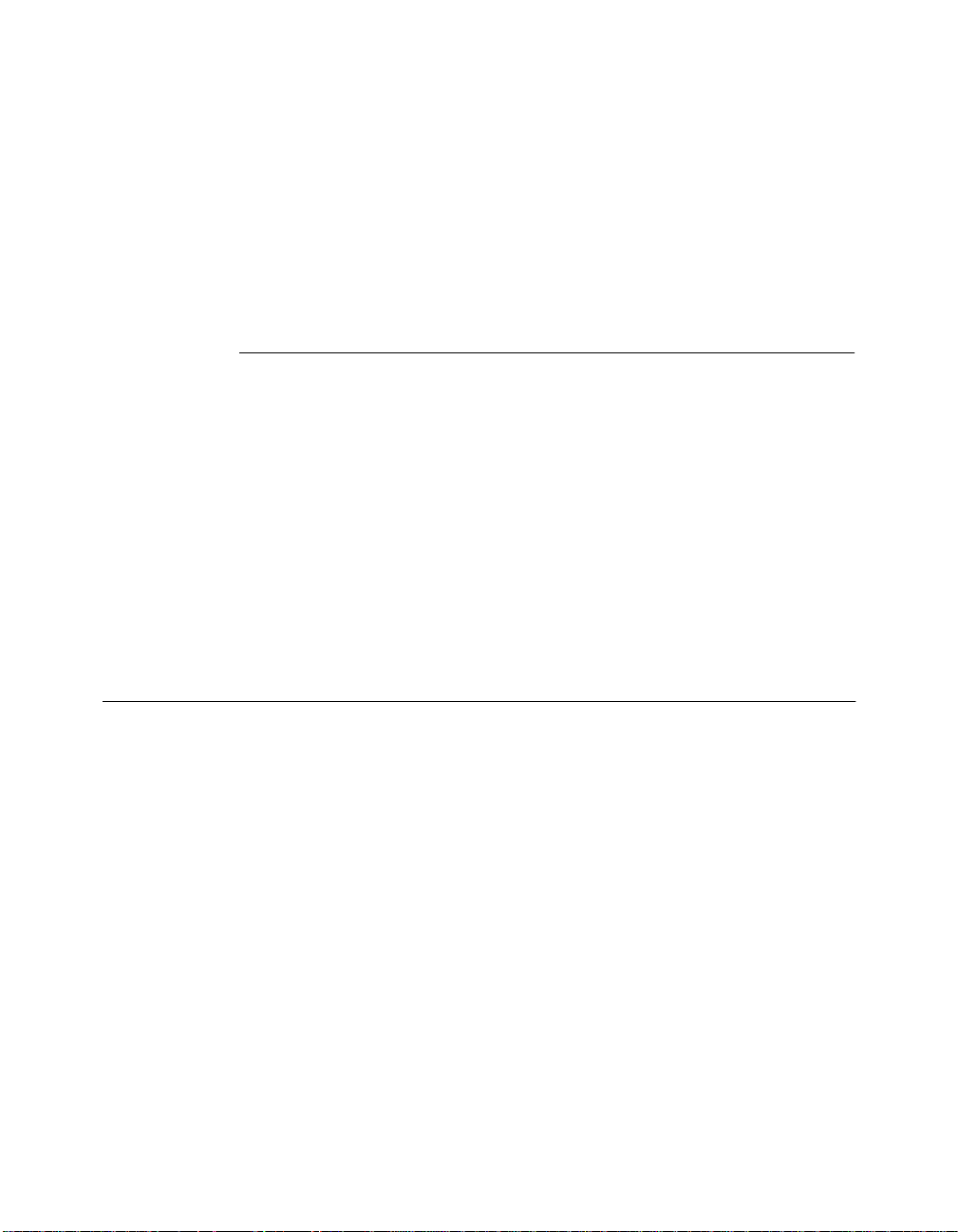

Figure 1-1 shows a mod el syst em that i nclud es ea ch of thes e cable t ypes. I n

this diagram, an ONline Ethernet Repeater Module is connected to a

10BASE5 segment via an AUI cable and a transceiver. Also shown is the

physical connection between an ONline Ethernet Fiber Module and a

10BASE2 segment, via a fibe r cable, fiber media access unit, and IEEE

repeater. Unshielded and shielded twisted pair connections to-the-desk are

also included in this sample configuration.

Figure 1-1. Multiple 17-Slot Concentrator Enviro nment

Network segments attach to the concentrator through media modules you

install into the chassis. The ONline Controller Module, which provides

re-timing and re-transmission of received signals, must be installed in one of

the concentrator's seventeen slots. The remaining sixteen slots can be

configured with any combination of media modules.

1 - 2 ONline 17-Slot System Concentrator Installation and Operation Guide

Page 21

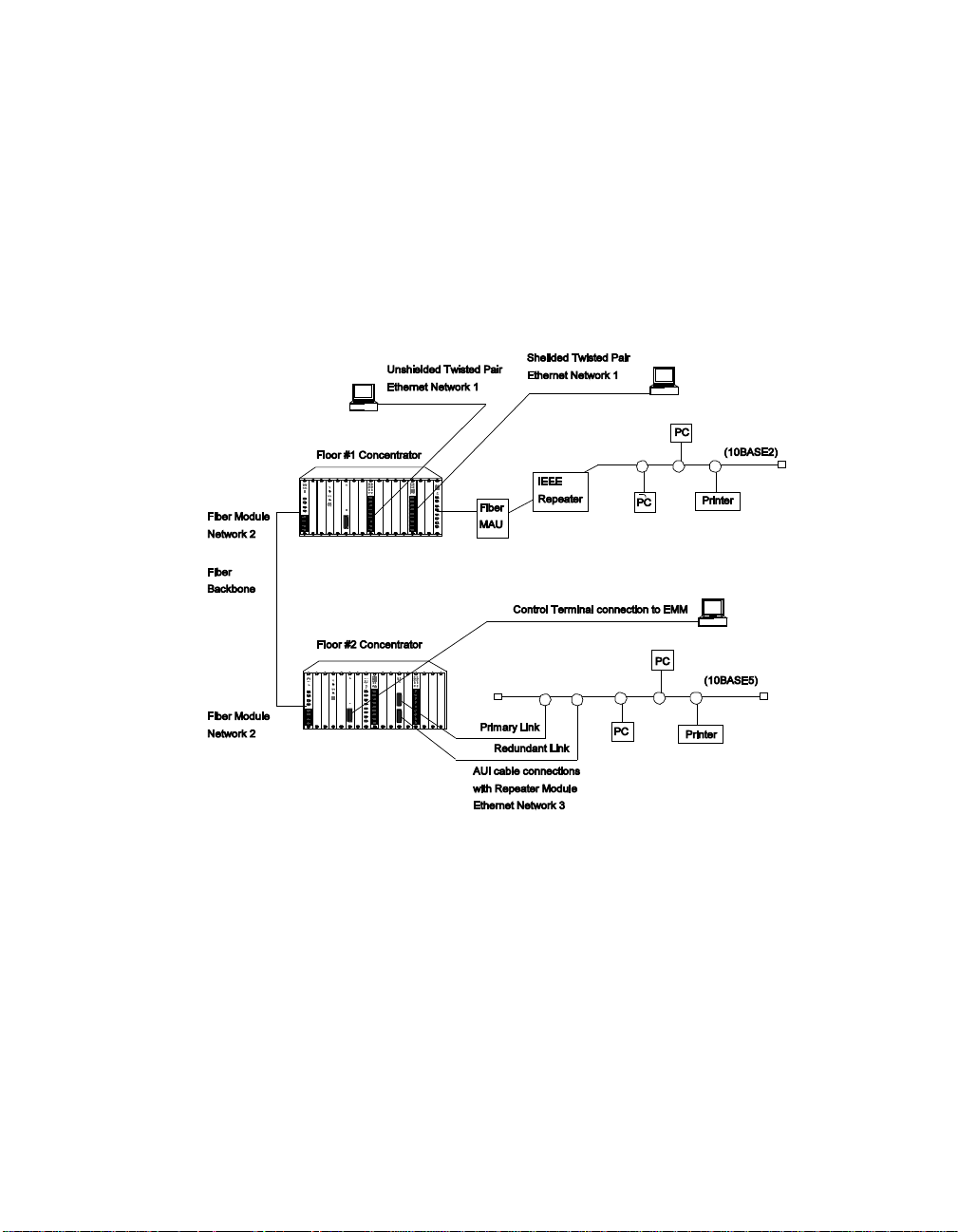

Back Panel

A power supp ly and DC fan unit are installed when you receive your

concentrator. There is an On/O ff switch on the power supply. The power

supply should be powered down when you install or remove it. Note that

there is no need to power down the concentrator for installation or

removal of the media modules. Add itionally, you can repl ace the fan unit

with an optional backup power supply to provide power redundancy.

Figure 1-2. ONline System Concentrator Rear View

Front Panel

The concentrator is shipped with 15 blank faceplates and two empty slots.

The two slots are left empty because you must install the ONline Controller

Module and a t least one media module for the concentrator to be

functional. As you add media modules to your unit, remove blank

faceplates to provide additional slots for the new modules.

Introduction 1 - 3

Page 22

Figure 1-3. ONline System Co ncentrator Front View

A cable tray is provided with the concentrator so that c ables you attach to

the media m odules can be run under the unit and out the back − where

they will not be in the way. A rack mount kit is also provided for the

concentrator and for the cable tray so you can rack mount the enti re unit.

ONline System Concentrator Features

This section describes the major features of the ONline System

Concentrator. The features include:

❑ Modular Desi gn

❑ TriChannel® Architecture

❑ Port-Switching Technology

❑ Fault-Tolerance Capabiliti es

❑ Hot Swapping of Media Modules

❑ Synchronous Backplane

1 - 4 ONline 17-Slot System Concentrator Installation and Operation Guide

Page 23

Modular Design

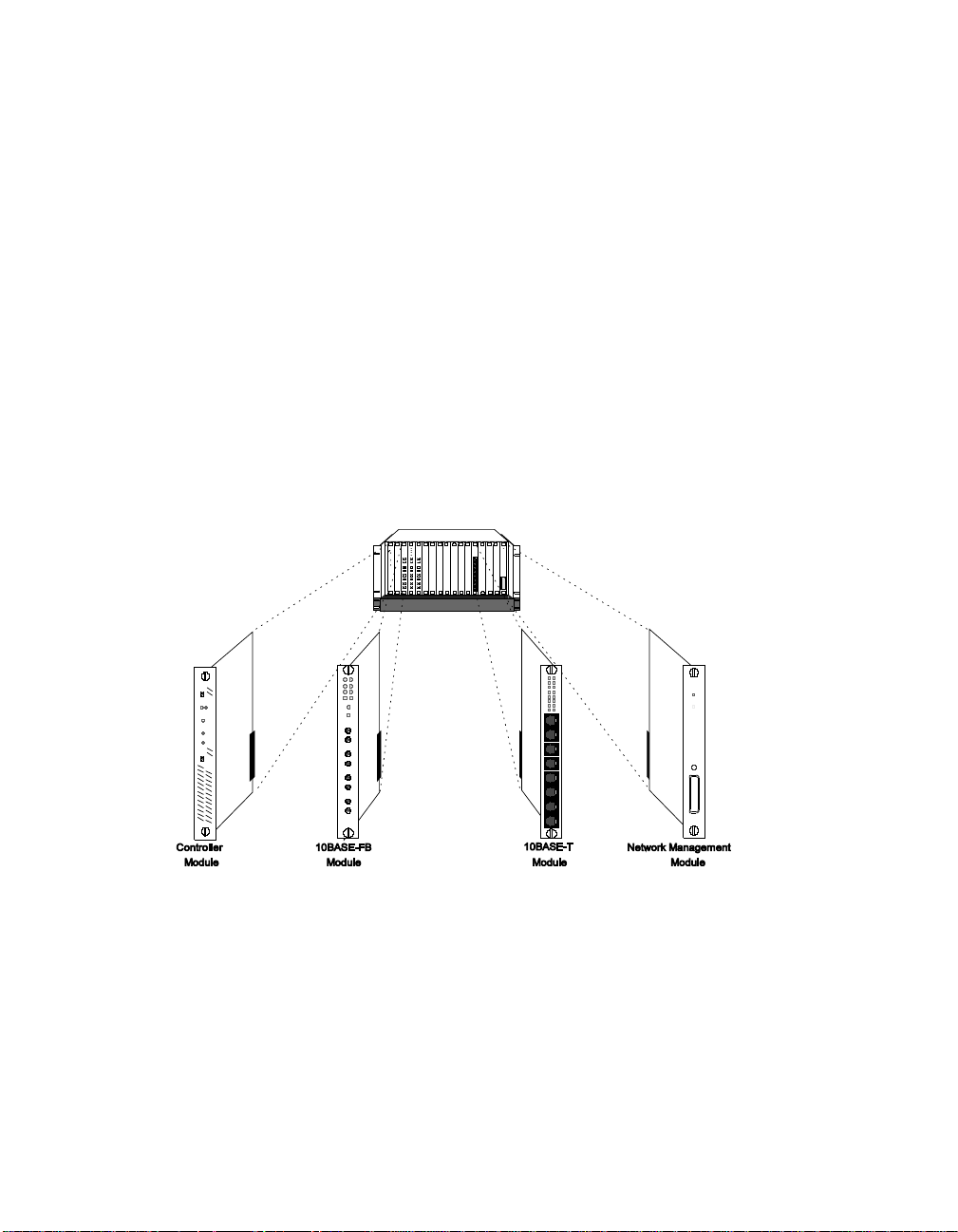

The ONline Concentrator's modular design lets you add different media

modules (such as fiber, twisted pair, and coaxial) in any combination to

connect different types of media segments. A possible configuration is

shown in Figure 1-4. You can link segments of different protocols using

Token Ring, FDDI, bridging and routing modules.

Every concentrator requires one Controller Module that controls

communications between all modules. In addition, a Network

Management Module provides sophisticated monitoring and control of the

modules in the concentrator. As a rack-mounted unit, the ONline

Concentrator can be connected to patch panels to simplify and manage

your network cables.

Figure 1-4. Mod u lar ONline Config u ration

Introduction 1 - 5

Page 24

TriChannel Architecture

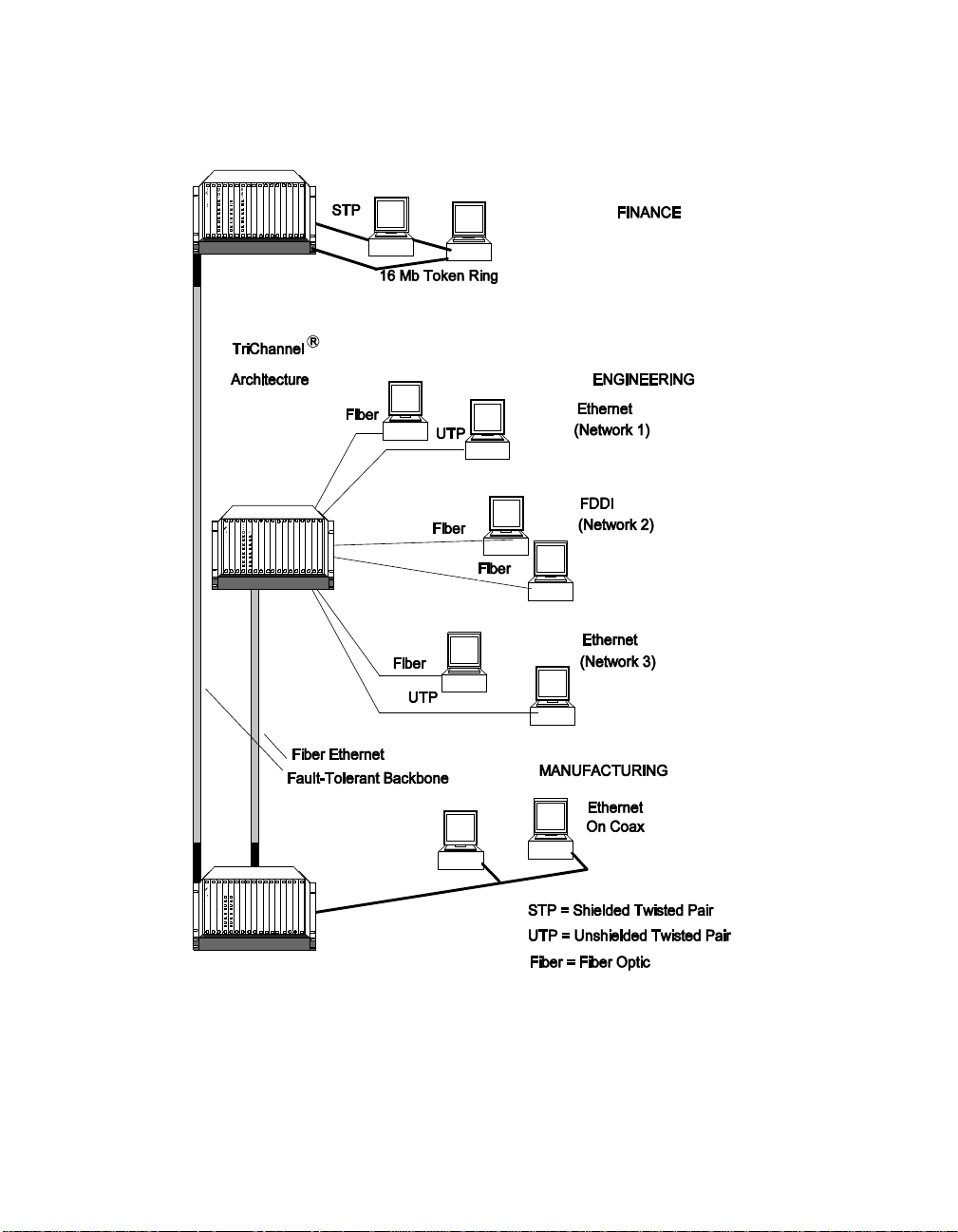

The ONline System Concentrator's TriChannel architecture lets you run

Ethernet, Token Ring, and FDDI networks, al l in the same concentrator.

This allows a single ONline unit to do the work of three conventional hubs.

You can also run multiple Ethernet networks or mixture of Ethernet, Token

Ring, and FDDI networks in any combination you want. This architecture is

shown in Figure 1-5.

Any module you add to the concentrator can be assigned to any of three

networks on its backpl ane and can be easily moved to another backplane

network using either an on-board dip switch or remote network

management.

Additionally, any module can be set to “isolated” mode whereby it acts as

an isolated network - not connected to the concentrator backplane. This

mode lets you isolate users from the main network. This can be useful for

security or as a temporary situa tion to preve nt traffic from c ontaminating

the network (for example, if some users are conducting network tests or

running at very high loads.)

Port-Switching Technology

Available port-switching modules allow you to assign any port to any

backplane network using a network management command. This allows

you to perform moves, adds, and changes at the network console, saving

costly and time-consuming trips to the wiring closet. It also allows you to

get additional bandwidth on demand by switching users to lower volume

networks during peak traffic periods.

1 - 6 ONline 17-Slot System Concentrator Installation and Operation Guide

Page 25

Figure 1-5. ON line System Co ncentrator Using Multiple Networks

Introduction 1 - 7

Page 26

Fault-Tolerance Capabilities

The ONline System Concentrator provides fault tolerance through

redundant features, such as an optional backup power supply, backup

controller module, redundant cable links , and backup concentrator

capability.

Backup Power Supply

An optional second power supply can be used to backup the primary

power supply in case of a power failure. Should the primary power supply

fail, the backup power supply takes over automatically. In addition, once a

backup power supply has been installed, you ca n replace a faile d primary

power supp ly without shutting down the system.

Load Sharing

The load-sharing func tion provi des uninterrupted power to modules

installed in a concentrator with two power supplies. If the active power

supply fails, the concentrator automatically switches to the other power

supply without interrupting the network.

The following ONline 17-Slot System Concentrators have load-sharing

capability:

❑ Model 5017C-LS

❑ Model 5017C with load-sharing upgrade

To determine if your model 5017C concentrator has load-sharing hardware,

check the rear of the concentrator chassis for a label reading “Upgraded

w/30-0 286.” If this label is present, the concentrator has received the

load-sharing upgrade.

In order for load shari ng to work, the Fault-Tolerant Controller Module

model 5000M-RCLS must be installed. This co ntroller monitors the

concentrator's load-sharing function.

1 - 8 ONline 17-Slot System Concentrator Installation and Operation Guide

Page 27

Backup Controller Module

The controller is vital to the system because it performs important functions

including:

❑ synchronizing all modules

❑ monitoring concentrator conditions (temperature, power supply

status, etc.)

❑ recognizing failures

❑ clocking and timing to the ONline Concentrator backplane

By using two 3Com Fault-Tolerant Controller Modules (5000M-RCLS) in

your concentrator you can protect these critica l tasks if a controller fails.

Note: You cannot use the 5000M-RCTL or 5000M-CTL controller

in a load-sharing conc entrator (Model 5017C-LS or Model

5017C with load-sharing upgrade).

Redundant Cable Links

Cable breaks or failures are the most common problem in any network.

Using the ONline Ethernet Fiber Module in your ONline System

Concentrator enables you to implement full cable redundancy for your

network's backbone. Thereafter, if one port should fail, or if a cable is

disconnected or cut, the b ackup port will take over in 100 milliseconds. A

sample redundant network connection is shown in Figure 1-6.

Introduction 1 - 9

Page 28

Figure 1-6. Redundant Cable Link Configuration

Backup Concentrator

A second concentrator or 3Com Fiber Ethernet Star Coupler may be used

to backup the primary concentrator in a star-wired network. This provides

full fault t olerance for a backbone c able plant.

1 - 10 ONline 17-Slot System Concentrator Installation and Operation Guide

Page 29

Figure 1-7. Backup Concentrator Configuration

Hot Swapping of Media Modules

Media modules can be added, removed, and reconfigured without

powering down the ONlin e System Conc entrator or affecting the rest of

the network. This means that you can add entire new segments or make

minor system adjustments during normal working hours withou t

interrupting the entire system.

Introduction 1 - 11

Page 30

Synchronous Backplane

The ONline System Concentrator backplane is designed with all passive

components to achieve the maximum reliability. The synchron ous

backplane allows the concentrator to be connected (using the 3Com

ONline Fiber Module) without the need for internal repeaters. This avoids

the limitations of the Ethernet four-repeater rule and lets you connect up to

23 concentrators serially, without the need for an intervening repeater or

bridge.

1 - 12 ONline 17-Slot System Concentrator Installation and Operation Guide

Page 31

2

This chapter describes how to install the ONline System Concentrator, how

to install ONline modules, and how to install the optional backup power

supply into y our ONline uni t.

Warning: Do not turn the concentrator's power supply switch on until

Installation and

Troubleshooting

you are instructed to do so in the following procedures.

The information and procedure s contained in this chapter

are to be used only by service personnel to install and

maintain the ONline 17-Slot System Concentrator.

Contents of the Shipping Box

The ONline System Concentrator is a chassis that enables installation of

media modules for network connection. The unit is shipped complete with

the following parts:

❑ Chassis containing:

– singl e power supply

– fan unit

Installation and Troubleshooting 2 - 1

Page 32

– 15 blank faceplates

❑ Chassis rack mount kit

❑ Cable tray with rack mount kit

❑ ONline Fault-Tolerant Controller Module and ONline Fault-Tolerant

Controller Module Ins tallation Guide

❑ Power cord

❑ This ONline System Concentrator Installation and Operation Guide

The pow er cord and hardware items are shown in Figure 2-1.

ONline System

Power Cord

Cable Tray

Rack

Mount Kit

Concentrator

Rack Mount

Controller

Figure 2-1. ONline System Concentrator Shipping Box Contents

2 - 2 ONline 17-Slot System Concentrator Installation and Operation Guide

Page 33

If an y o f t h es e it ems are d amaged or mi ssing, c on ta ct your l oc al s up plier or

a 3Com se rvice representative.

3Com suggests you keep the carton and anti-static shielding ba g in which

your unit was shipped in case you later want to repackage the unit for

storage or shipment.

We also suggest that you record the serial number of your Controller

Module. We have provided a log for this and other information specific to

modules under the Slot Usage Char t in Appendix B nea r the end of this

manual.

FCC Regulations

FCC regulations require that blank faceplates cover slots that are not being

used. To comply with this regulation, the concentrator is shippe d with 15

blank faceplates and two empty slots. These two slots are left empty

becau se t he ONl in e Con tro ller Modu le an d at l ea st one media modu le mu st

be installed for the concentrator to be functional.

Caution: Do not turn the concentrator's power supply switch on

until you have:

❑ verified tha t the selected site meets the installation requirements

outlined in the following pages

❑ completed each of the steps outlined in Table 2-1.

– Be sure to verify that the correct voltage level has been

selected. An improper setting may damage the power

supply.

Installation and Troubleshooting 2 - 3

Page 34

Site Selecti on Considerations

The concentrator can be placed almost anywhere within your company,

including offices and computer rooms. In general, we recommend

installation in a wiring closet. The unit has been designed for rac k

mounting and come s with all the necessary hardware.

Location Requirements

The area where you install the ONline System Concentrator must meet the

following conditions:

❑ Temperature b etween 0° to 50° C (32° to 122° F)

❑ Relative humidity less than 95%, non-condensing

❑ AC power source withi n 6 feet (2 meters). Note that for installation

to have true backup power, two independent AC power sources are

required

❑ The tabl e or rac k wh er e the un it i s in st a ll ed sho ul d b e le ve l and n ot i n

direct sunlight or in an excessively dusty location

Ventilation

The concentrator fan units draw air in through the front and bottom of the

chassis and exhausts air out the back. Make sure there are at least 6 inches

(15 centimeters) between the fan vents at the back of the unit and the

nearest surface to allow adequate airflow for cooling. This minimum

distance is also required for access to the rear of the unit for maintenance.

The cable tray that comes standard with the concentrator helps prevent a

tangle of cables at the front of the concentrator and also permits the

required airflow to the unit. Make sure the cable tray is installed below the

unit correctly before installing the concentrator.

2 - 4 ONline 17-Slot System Concentrator Installation and Operation Guide

Page 35

Caution: The concentrator should have two fans running at all

times to cool the unit properly. You should therefore

have: (A) a power supply (with b uil t-in fan) and a fan

unit installed or (B) two power supplies installed.

Power Requirements

3Com recommends using a 15 ampere electrical wire (branch circuit) to

supply power to the concentrator. This circuit must be grounded to a

safety ground (protected earth ground), not to neutral that carries current

back to the transformer. Do not use the electrical conduit pipe as the only

means of grounding.

Rack Mount Installation Requirements

For rack mount installation of the ONline System Concentrator you need a

standard nineteen-inch EIA config ured rack. The rack and its environment

also should meet the following specifications:

❑ If the rack has an open back and sides:

– the rack must be bolted to the floor

– the top of the rack may need to be braced to the wall

❑ the rack must be grounded

❑ there must be 10.5" (26.7 cm) (6U) of vertical space in the rack for

each 17-slot concentrator

❑ the unit location in the rack must be less than 6 feet (2 meters) from

the nearest AC outlet

❑ patch panels should already be installed in the rack for easier cable

management

Installation and Troubleshooting 2 - 5

Page 36

Table Top Installation Requirements

For table top or shelf mount installation of the ONline System Concentrator

you must make sure the table or shelf can suppo rt 100 pounds (45 kg) for

a fully loaded 17-slot conc entrator. (The concentrator itself, fully loaded

and with cable tray, weighs almost 75 pounds/34 kilograms.) The

table/shelf als o must be less than 6 feet (2 me ters) from the ne arest AC

outlet.

To ensure proper airflow to the un it, you should leave at least 1.75"

(4.45cm) of space below the concentrator (provided by the installed rubber

feet) and by installing the cable tray below the concentrator.

Installation

Table 2-1 prov id es a qui ck d es cr ipt i on of th e s tep s yo u m ust f ol lo w to i ns tall

the ONline System Concentrator as well as reference to the section in this

manual where the step is described. It is important that you perform the

steps in the order ind icated, noting that Step 3 is optional.

Table 2-1 . Steps for Installing the ONline System Concentrator

Step Action Section

1 Install the cable tray into a

rack or place it on a table

top.

2 Install the concentrator unit

into a rack or place it on a

table top.

3 Install the backup power

supply in the concentrator.

2 - 6 ONline 17-Slot System Concentrator Installation and Operation Guide

“Installing the Cable Tray”

“Installing the ONline System

Concentrator”

“Installing the Backup Power

Supply (Optional)”

Page 37

Table 2-1 . Steps for Installing the ONline System Concentrator

(Continued)

4 Set up the power supply. “Selecting the Power Supply

Voltage”

5 Install the ONline Controller

Module in the concentrator.

6 Inst all media modules in the

concentrator.

7 Connect the network

cables to the media

modules.

8 Power up all network

devices and verify the

installation.

Installing the Cable Tray

The cable tray that comes standard with the concentrator helps to manage

the cables that run from the front of the unit so they are fed under the unit

and out through the back. The tray also provides the required space

between the bottom of the unit and the next device in the rack (or the top

of the table) so there is adequate air flow to cool the unit.

“Installing ONline Modules”

“Installing ONline Modules”

“Connecting Network Cables”

“Power Up and Verification”

Caution: If you choose not to use the c able tray beneath your

unit, you must ensure that 1 3/4" (4.45 cm) of space is

open below the ONline unit to ensure adequate

incoming airflow (provided by the installed feet).

Installation and Troubleshooting 2 - 7

Page 38

Cable Tray Rack Mounting

To install the concentrator in a rack , first install the cable tray and then

install the concentrator above the tray. The cable tray can be mounted in

four separate configurations in your rack depending on your preference.

The options are described in Table 2-2 and shown in Figure 2-2.

Table 2-2. Rack Mount Settings

Option Rack Setting Function

1 Flush Mount Flush mounts the unit to the front of

the rack.

2 1/2" Recess Recesses the unit 1/2" (1 .3 cm) from

the front of the rack.

3 2 1/8" Recess Recesses the unit 2 1/8" (5.4 cm) in

a rack.

4 2 3/4" Rec ess Recesses the unit 2 3/4" (7.0 cm) in a

rack.

Note: The ONline System Concentrator is 18.3" (46.5 cm) deep.

Some shallow rack cabinets may only allow you to flush

mount the unit. In addition, make sure you mount the unit

so that cables connected to the media modules hav e

enough room to bend (especially important for fiber

cables).

2 - 8 ONline 17-Slot System Concentrator Installation and Operation Guide

Page 39

Figure 2-2. Rack Mount Po sitions

Follow the steps below to mount the cable tray in yo ur rack:

1. Attach the two rack mount flanges to the cable tray in the position

you want as shown in Fi gure 2-2 using th e eight (8) provided 8-32 x

1/4" flathead screws - four per side.

Note: You must tighte n the screws completely to be fl ush

with the rack mount flanges so the tray will fit in the

rack.

2. Select a vacant position in the rack that is at least 10.5 inches (26.7

cm) from the top of the rack or the next higher unit in the rack.

3. Install the provided clip nuts onto the front of the rack where you

want to attach the tray.

Installation and Troubleshooting 2 - 9

Page 40

Note: The function of the clip is to hold the nut in place behind

the rail. Be sure to install the clip onto the rail so that the

nut is centered behind the hole through which you plan to

insert the screw.

4. Place the tray in the rack and attach to the clip nuts through the front

of the rack using the four (4) 10-32 x 5/8" truss-head screw s and as

shown in Figure 2-3.

Figure 2-3. Cable Tray Installation in Rack

Cable Tray Table Mounting

To install the concentrator on a table top or on a shelf, place the cable tray

on the surface first and then place the concentrator on top of the tray.

Note that the four rubber feet must be installed on the concentrator before

it is placed on the table top or on top of the cable tray. The feet fit into the

four holes in the cable tray, which prevents the concentrator from moving.

2 - 10 ONline 17-Slot System Concentrator Installation and Operation Guide

Page 41

Installing the ONline System Concentrator

The ONline System Concentrator can be placed on top of a table or a shelf,

or mounted in a rack. Make sure the cable tray has been install ed first on

the table or in the rack (or that 1 3/4" (4.5 cm) of vertical space has been

provided below the unit for air flow) an d that the loc ation meets all the

environmental considerations specified earlier in this chapter.

Caution: 3Com recommends that two people install the unit

since it weighs 38 lbs (17 kg) with one power supply

and 46 lbs (24 kg) with the backup po wer supply

installed.

3Com also recommends installing the backup power supply

prior to rack mounting the unit (see the section titled

Installing the Backup Power Supply later in this chapter). In

some rack cabinets, the rear of the c abinet may interfere

with installation or removal of the power supply and fan.

Rack Mounting the ONline System Concentrator

The ONline System Concentrator can be mounted in four different

configurations in the rack. Use the same rack settings for both the cable

tray and the concentrator. If you are not installing the cable tra y in the

rack, you should select the concentrator mount setting at this time. Refer

to Table 2-2 and Figure 2-2 in the “Cable Tray Rack Mounting” section for

specifics about the four mounting settings.

Follow the steps below to mount the concentrator in your rack:

1. Attach the two rack mount flanges to the ONline concentrator unit in

the position you want as shown in Figure 2-4 using the eight (8)

provided 8-32 x 1/4" flathead screws - four per side.

Installation and Troubleshooting 2 - 11

Page 42

Caution: You must use the supplied 8-32 x 1/4" screws to attach

the rack mount flanges. A longer screw may extend

too far into the ONline chassis and disrupt the

installation of modules.

Figure 2-4 . A ttaching the Rack Mount Flanges

2. Install the provided clip nuts onto the front of the rack where you

want to attach the unit. See Figure 2-3 for proper orientation.

3. Slide the unit in the rack above the installed cable tray until the rack

mount flanges seat flush to the front of the rack.

Caution: While mounting the concentrator, do not leave the unit

resting on the mounted ca ble tray since the c able tray

rack mounts may not support a fully-loaded

concentrator.

4. Secure th e unit to the rack with the four (4) 10-32 x 5/8" truss-head

screws as shown in Figure 2-5.

2 - 12 ONline 17-Slot System Concentrator Installation and Operation Guide

Page 43

Figure 2-5. Chassi s Mounted i n Rack

Table Top Mounting the ONline Concentrator

You can set the ONline Concentrator directly on a table top or shelf that

can support at least 100 pounds (45 kg). A fully load ed concentrator

weigh s ab out 75 l bs ( 3 4 k g) . 3C om reco mme nd s yo u s et t he u nit on top of

the ONline cable tray as the cable tray provides a central area for cable

management and provides the required 1 3/4" (4.5 cm) of clearance for

sufficient air flow. Regardless of whether the cable tray is used or not, the

four (4) rubber feet must remain on the bottom of the unit.

If the cable tray is used, place the ONline unit on top of the cable tray and

insert the rubber feet from the unit into the holes in the cable tray, which

stabilizes the unit on the tray.

If the cable tray is not used, place the unit on the table or shelf.

Installation and Troubleshooting 2 - 13

Page 44

Installing the Backup Power Supply (Optional)

Install the backup power supp ly in the ONline System Concentrator (if

ordered). This power sup ply provides p ower redundancy if the primary

power supp ly should fail. Skip this section if you do not have a backup

power supply.

To install the backup power supply, you must first remove the fan unit from

the power supply slot in the back of the unit. Follow the steps below to

install the backup power supply:

1. Remove and save the four screws that attach the fan unit to the rear

of the concentrator as shown in Figure 2-6.

Figure 2-6. Removing Fan Unit

2. Carefully remove the fan unit and disconnec t the fan unit wiring

harness from the connector inside the base of the ONline u nit as

shown in Figure 2-7. Save this fa n unit in case a power s u pp ly s h ou ld

fail at a later ti me and you need to reinstall the fan unit.

2 - 14 ONline 17-Slot System Concentrator Installation and Operation Guide

Page 45

Figure 2-7. Unplugging the Fan Unit

Before you install the new power supply, chec k the label on the inside of

the power supply bay that explains where each of the seven power leads

from the power supply are connected in the concentrator chassis.

Power leads labeled P7, P8, and P9 fit in the back three raised connectors

and they are “keyed” so they can be inserted only in the correct

connector and only in one direction. Power leads labeled P10, P11, P12,

and P13 fit in the front four recessed connectors and can be ins erted in

only one direction. These connectors are shown in Figure 2-8.

Installation and Troubleshooting 2 - 15

Page 46

Figure 2-8. Power Supply Conne ct ors

3. Hold the backup power supply in one hand while using your other

hand to plug in the seven (7) le ads from the power supply as shown

in Figure 2 -9.

Figure 2-9. Installing the Backup Power Supply

2 - 16 ONline 17-Slot System Concentrator Installation and Operation Guide

Page 47

4. Make sure the cable is pushed up to the right side and then slide the

power supply into the b ack of the concentrator as shown in

Figure 2-10. Then fasten with the four (4) s crews you removed

earlier from th e fan unit.

Figure 2-10. Installed Backup Power Supply

Selecting the Power Supply Voltage

Before you plug in the power cord to the power connector on the power

supply (and to the backup pow er supply, if you have one), you must verify

that the voltage selector is correctly set for your country line voltage.

Caution: An incorrect voltage setting can damage the power

supply.

1. Set the power switch to the Off (O) position.

Installation and Troubleshooting 2 - 17

Page 48

2. Use a flat-blade screwdriver to move the voltage selector switch so

the setting that is appropriate for your country's line voltage is

showing: 100/120 Volts or 220/240 Volts, as shown in Figure 2-11.

Figure 2-11 . Setting the Voltage Selector Switch

3. Plug in the power cord to the power conn ector on the ba ck of the

concentrator and connect the other end to an outlet. If you installed

a backup power supply, make sure that power cord is connected to

an outlet on an independent circ uit from that used for the primary

power supp ly.

The power receptacle on the concentrator is an approved IEC

connec tor. Make sur e the power cord you u se is appr opr iat e for you r

country line voltage:

❑ For 100/120 Volt operation, use only a power cord rated for 10

Amps, 125 Volts.

❑ For 220/240 Volt op eration, use only use a power cord rated for

10 Amps, 250 Volts.

2 - 18 ONline 17-Slot System Concentrator Installation and Operation Guide

Page 49

Warning: DO NOT use a 3-to-2 pronged adapter at the outlet since

this may result in elec trical shock and does not provide

adequate grounding.

Installing ONline Modules

Warning: Only service personnel should install ONline modules.

Install the ONline Controller Module in the concentrator as described in the

ONline Controller Module Installation Guide provide d with the Controller

Module.

Install any ONline media modules in the ONline System C oncentrator as

described in the manual provided with each module. Note that you do not

need to turn off the concentrator when installing additional modules to

your co nce n trator.

Use the chart in Append ix B to label the location of each module in the

concentrator. At least one m edia module must be installed along with the

Controller Module to m ake the conc entrator functional.

Connecting Network Cables

Connect the network cables betw een conce ntrators, patch panels , and

transceivers.

Installation and Troubleshooting 2 - 19

Page 50

Figure 2-12. Network Cable Connections

Power Up and Verification

This section tells how to power up the concentrator and verify that it is

working correctly.

Switch the power supply O n/Off switch to the On (|) pos ition .

The Power Supply LED(s) on the ONline Controller Module light when the

unit is powered up correctly. The verification procedure i s split into the

following areas:

❑ fan operation

❑ power supply operation

❑ netwo rk operation

2 - 20 ONline 17-Slot System Concentrator Installation and Operation Guide

Page 51

Fan Operation Verification

To verify that the fan unit and the power sup ply fan are functio ning

correctly you need to visually inspect the fan unit(s) on the rear of the

concentrator to make sure they are turning and that nothing is blocking

their path.

Power Supply Operation Verification

Verify that the LEDs on the Controller Module appear as defined in

Table 2-3 to check the operation of the power supply.

Table 2-3. Controller Module LEDs After Proper Power-Up

LED Proper State

Primary Power On.

Backup Power On. A backup power supply is installed.

Off. No backup power supply is installed.

Temperature (TEMP) Off.

Installation and Troubleshooting 2 - 21

Page 52

If any of these LEDs are not lit as shown in this chart, refer to Table 2-4 to

troubleshoot the problem.

Table 2-4. Troubleshooting with Controlle r Module LEDs

LED State

Primary

Power

Off The Primary

Steady

Blinking

Possible

Problem

Power LED is

broken.

The primary

power supply

is not properly

installed.

The primary

power supply

has failed.

Troubleshooting

Suggestions

Press the LED Test button

to verify that the LED is

working properly.

Reinsta ll the primary

power supply and turn it

on.

Verify that the outle t is

supplying power.

Verify that the voltage

selection switch is set to

the correct position for

your country's line

voltage.

Verify that the power

cord is plugged in at

both ends and that the

cord is appropriate for

your country's line

voltage.

Verify that the power

switch is turned on.

Replace the power

supply.

2 - 22 ONline 17-Slot System Concentrator Installation and Operation Guide

Page 53

Table 2-4. Troubleshooting with Controlle r Module LEDs

(Continued)

LED State

Primary

Power

(cont.)

Steady

blinking

(cont.)

Two blinks,

then a pause

(in unison

with Backup

Power LED)

Possible

Problem

The primary

power supply

is not properly

installed.

The pow er

load-sharing

hardware is in

an error state.

Troubleshooting

Suggestions

Reinsta ll the primary

power supply and turn it

on.

If a management mod ule

is installed, the

concentrator should

recover automatically

from this condition. If it

doesn't, reset the

concentrator using the

RESET CONCEN TRATOR

command. If this fails to

correct the condition,

turn both power

supplies OFF, then ON

again.

If a management mod ule

is not installed, turn both

power su ppli es OFF, then

ON agai n.

Backup

Power

Off The Backup

Power LED is

broken.

The backup

power supply

is not properly

installed.

Installation and Troubleshooting 2 - 23

Press the LED Test button

to verify that the LED is

working properly.

Reinsta ll the backup

power supply and turn it

on.

Page 54

Table 2-4. Troubleshooting with Controlle r Module LEDs

(Continued)

LED State

Backup

Power

(cont.)

Temp Blinking The

Steady

blinking

(cont.)

Two blinks,

then a pause

(in unison

with Primary

Power LED)

The backup

power supply

has failed.

The backup

power supply

is not properly

installed.

The pow er

load-sharing

hardware is in

an error state.

temperature in

the

concentrator is

too high.

Possible

Problem

Troubleshooting

Suggestions

See Prima ry Power LED

suggestions for same

State and Possible

Problem (above).

Reinsta ll the backup

power supply and turn it

on.

See Primary Power LED

suggestions for same

State and Possible

Problem (above).

Verify tha t the fan units

are working and nothing

is blocking airflow from

the front and bottom of

the concentrator.

Active Off The module is

in standby

mode.

2 - 24 ONline 17-Slot System Concentrator Installation and Operation Guide

Verify at least 1 3/4"of

space below the

concentrator for proper

air flow.

Lower the temperature in

the room.

Verify tha t the Standby

LED is illuminated.

Page 55

Table 2-4. Troubleshooting with Controlle r Module LEDs

(Continued)

LED State

Standby Off The mod ule is

Blin king There is a

Possible

Problem

The Active LE D

is broken.

in active mode.

The Stand by

LED is broken.

hardware

failure in the

Standby

module.

Troubleshooting

Suggestions

Press the LED Test button

to see if the LED is

working.

Verify that the Active LED

is illuminated.

Press the LED Test button

to see if the LED is

working.

Reset the module. If this

action does not correct

the probl em, install the

module in another slot.

If necessary, replace the

module and contact

3Com Customer

Support Organiza tion.

See Technical A s sis ta nc e

to follow.

Technical As sist anc e

You can receive assistance for installing and troubleshooting the 17-Slot

concentrator by calling your dealer or 3Com Customer Support. Be

prepared to supply a representative with th e following information:

❑ a description of the problem

❑ the steps you have taken to try and correct the problem

Installation and Troubleshooting 2 - 25

Page 56

❑ the configuration of your concentrator

❑ the screen information reporting the SHOW DEVICE command (if you

have an ONline management module installed in the concentrator)

Refer to Ap pendix C for in structions how to contac t Technical

Support for your product.

Where To Go From Here

Once you have made the necessary concentrator connections, and have

verified that communication has been established between all segments

connected to the concentrator, no further installation procedures are

required. Chap ter 3, Maintenance, discusses what to do in the event that

the fan unit or power supply needs to be repla ced.

2 - 26 ONline 17-Slot System Concentrator Installation and Operation Guide

Page 57

3

This chapter describes routine maintenance designed to keep your ONline

System Conce ntrator working at its best . It also explains how to replace a

failed power supply o r fan unit.

This chapte r explains the fo ll owing maintenance procedures:

Maintenance

❑ Routine Maintenance

❑ Power Supply Replacement

❑ Fan Unit Replacement

❑ ONline Module Maintenance

❑ Other System Components

Warning: There are no serviceable parts on either the power supply

or the fan unit. If either of these parts fail, remove them as

described in this chapter and return them to your reseller or

to 3Com Corporation. You sho uld keep replacemen t

power supply and fan units at your site so they are available

if needed.

Maintenance 3 - 1

Page 58

Routine Maintenance

You should inspect your equipment to make sure that all of the following

are true:

❑ all the blank faceplates are on

❑ the fans are running

❑ there are no obstructions to the ventilation on the concentrator

❑ the ONline Controller Module and media module LEDs are registering

correctly

Replacing the Powe r Supp ly

Both the primary and backup power supplies in the ONline System

Concentrator are removed and installed in exactly the same manner. If a

power supply should fail and switch over automatically to the backup

power supply (optional) you can replace the failed power supply while the

unit is operating - without disrupting network operation.

Caution: Improper installation of the power supply could

damage the power supply.

Follow the steps below to replace a power supply unit:

1. Switch Off the failed power supply, then unplug the power cord from

both the wall and from the back of the power supply.

2. Remove and save the four screws that attach the power supply to the

rear of the concentrator as shown in Figure 3-1.

3 - 2 ONline 17-Slot System Concentrator Installation and Operation Guide

Page 59

Figure 3-1. Removing the Power Supply

3. Carefully pull the power supply out from the concentrator and

disconnect the seven (7) power leads from the conne cto rs inside the

base of the ONline unit as shown in Figure 3-2.

Maintenance 3 - 3

Page 60

Figure 3-2. Unplugging the Power Supply

Note: Before you install the new power supply, check the label on

the inside of the power supply bay that explains where

each of the seven power leads from the power supply are

connected in the concentrator chassis.

Power leads labeled P7, P8, and P9 fit in the back three

raised connectors and they are “keyed” so they can be

inserted only in the correct connector and only in one

direction. Power leads labeled P10, P11, P12, and P13 fit in

the front four recessed connectors and can be inserted in

only one direction.

4. Pick up the new power sup ply and plug in the seven (7) power leads

from the power supply as shown in Figure 3-3.

3 - 4 ONline 17-Slot System Concentrator Installation and Operation Guide

Page 61

Figure 3-3. Power Supply Plugs in ONline System Concentrator

5. Make sure the cable is pushed up to the right side and slide the

power supply into the back of the concentrator and fasten it with the

four (4) screws you removed from the defective unit as shown in

Figure 3-4.

Maintenance 3 - 5

Page 62

Figure 3-4. Backup Power Supply Installed

6. Set the voltage selection switch on the back of the new power supply

to the same setting as the old power supply (or as explained in the

“Selecting the Power Supply Voltage” section in Chapter 2) and turn

the power swit ch to the Off (0) position.

7. Plug in the power cord to the powe r supply and to the wall outlet,

then turn the power switch to the On (|) position.

8. Check the power supply LEDs on the controller module to verify that

the new power supply is working correctly. Make sure the fan on the

power supply is running.

3 - 6 ONline 17-Slot System Concentrator Installation and Operation Guide

Page 63

Replacing the Fan Unit

A fan installed in either the left or right bays is removed or installed in

exactly the same manner as the power supply. Follow the steps below to

replace a fan unit:

Caution: The concentrator must have two fans running at all

times to cool the unit. This is achieved through the

power supply fan and the fan uni t that come standard

with the concentrator, or by having two power supplies

installed.

1. Remo ve and save the four screws that attach the fan to the rear of

the concentrator as sh own in Figure 3-5.

Figure 3-5. Remov ing the Fan Unit

Maintenance 3 - 7

Page 64

2. Carefully pull the fan unit out from the concentrator and disconnect

the wiring harness from the plug inside the base of the ONline unit as

shown in Figure 3-6.

Figure 3-6. Unplugging the Fan Unit

3. Pick up the new fan unit and plug the fan power lead in the same

connector in the base of the ONline unit from which you removed

the old fan (plug P0).

4. Slide the new fan unit into the back of the concentrator and fasten it

to the unit with the four (4) screw s you removed fro m the defective

unit as shown in Figure3-7.

3 - 8 ONline 17-Slot System Concentrator Installation and Operation Guide

Page 65

Figure 3-7. Fan Unit Installed

ONline Module Maintenance

Refer to the ONline installation guides that come with the modules for

installation and operation i nformation.

Other System Components

For maintenance other than hot swap of power supply, fan, and modules

described previously in this section, the following applies:

Caution: This unit may have one or two power supply cords.

Disconnect all power supply cords before servicing to

avoid electrical shock.

Maintenance 3 - 9

Page 66

Vorsicht: Dieses gerät hat eine oder zwei netzverbindungen. Vor

wartung des gerätes alle netzstecker ziehen um

elektroschock zu vermeiden.

3 - 10 ONline 17-Slot System Concentrator Installation and Operation Guide

Page 67

A

General

Network Protocols Sup ported:

Ethernet/IEEE 802.3 over various media

IEEE 802.5 Token Ring over various media

ANSI FDDI

Environmental

Operating te mp erature: 0° to 50° C (32° to 122° F)

Specifications

Storage temperature: -30° to 65° C (-22° to 149° F)

Operating humidity: less than 95%, non-condensing

Specifications A - 1

Page 68

Mechanical

Dimensions: 17.5"W x 18.3"D x 8.75"H (44.5 cm x 46.5 cm x 22.2 cm)

Weight: unloaded, with one power supply: 38 lb. (17 kg.)

Power So urce

90-132 VAC, 6 Amps

180-264 VAC, 3 Amps, 47-63 Hz

325 Watts

1700 BTU/hr

unloaded, with two power supplies: 46 lb. (21 kg.)

loaded, with two power supplies: 75 lb. (34 kg.)

Regulatory Compliance

Safety: UL, CSA, and TUV certified.

Emissions: FCC/A, VDE/B, and VCCI/1 certified.

A - 2 ONline 17-Slot System Concentrator Installation and Operation Guide

Page 69

Accessories

Cable Management Tray (5000CT): 17.5"W x 18.3"D x 1.75"H

Rack-Mount Kit (5017RM): 2.5 lb. (1.2 kg.)

Backup Power Supply (5017PS-325): 8 lb. (3.6 kg.)

Front Cover Panel (5017FC): .5 lb. (.23 kg.)

(44.5 cm x 46.5 cm x 4.5 cm)

8 lb. (3.6 kg.)

Specifications A - 3

Page 70

Page 71

B

Slot Usage Chart

The ONline System Concentrator has seventeen slots, sixteen of which are

available slots for installing media modules (one slot is occupied by the

ONline Controller Module). The slot on the far le ft is slot numb er 1 and

runs to slot 17 on the far right. Use the chart on the next two pages to

keep track of the following:

❑ which module is installed in each slot

❑ which network (channel) each module is set for (or if it is isolated)

❑ any general remarks, such as module serial number or module

specific configuration settings

Store any oth er information on this chart tha t you think wi ll be helpful

when ad ding new modu les or when di ag nosing network que stions.

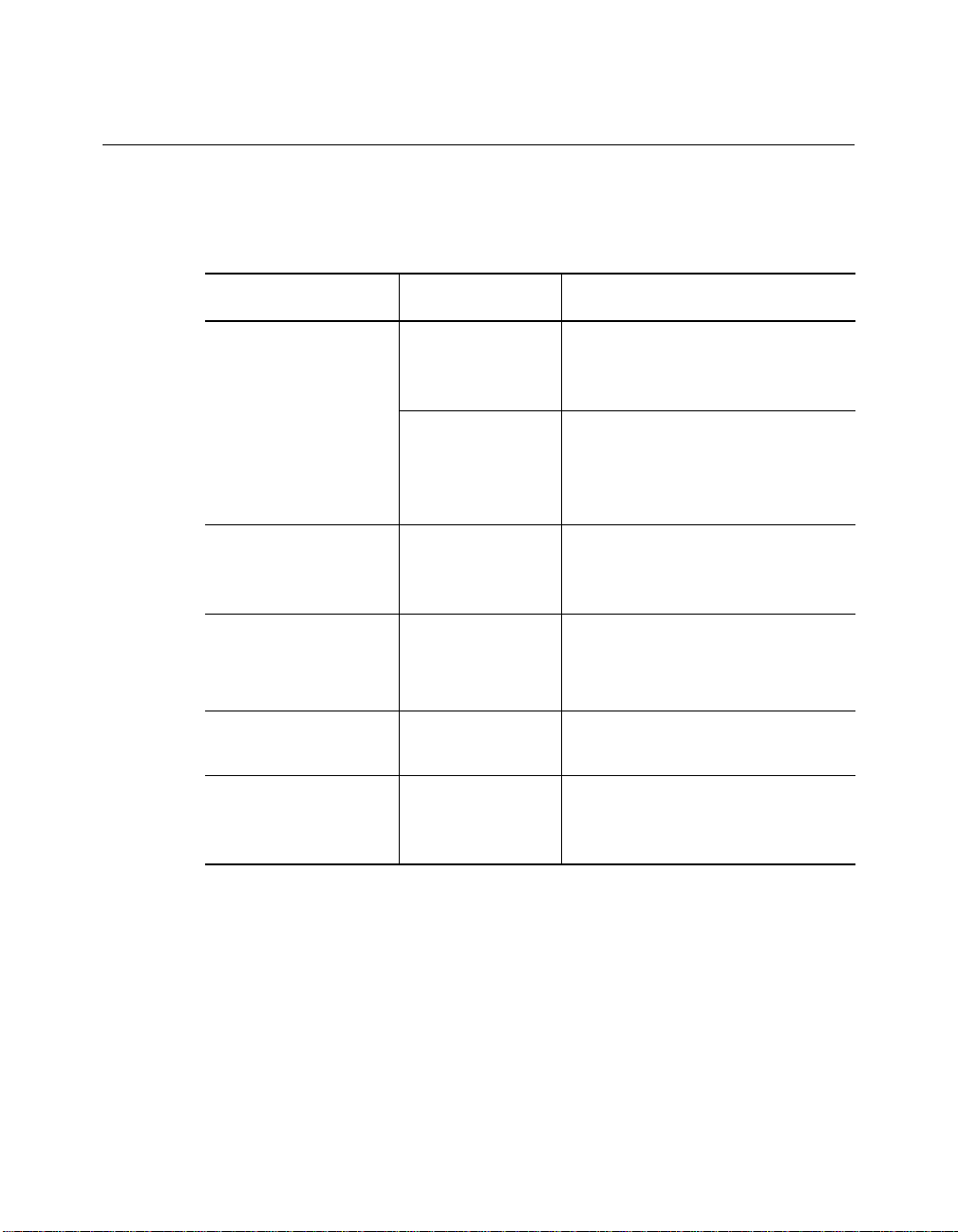

Table B-1. Concentrator Slot Usage Chart

Slot

1

2

Module

Type

Network

or Isolated)

(#

Remarks

Slot Usage Chart B - 1

Page 72

Table B-1. Concentrator Slot Usage Chart (Continued)

Slot

3

4

5

6

7

8

Module

Type

Network

or Isolated)

(#

Remarks

9

10

11

12

B - 2 ONline 17-Slot System Concentrator Installation and Operation Guide

Page 73

Table B-1. Concentrator Slot Usage Chart (Continued)

Slot

Module

Type

Network

or Isolated)

(#

Remarks

13

14

15

16

17

Slot Usage Chart B - 3

Page 74

Page 75

Technical Support

C

3Com provides easy access to technical support information through a

variety of services. This appendix describes the following services:

❑ On-line Technical Services

❑ Support from Your Network Supplier

❑ Support from 3Com

❑ Returning Products for Repair

On-line Technical Support

3Com offers worldwide product support through the followin g on-line

systems:

❑ Email Technical Se rvice

❑ World Wide Web Site

Technical Suppo rt C - 1

Page 76

Email Technical Support

You can contact the Integrated Systems Division (formerly Chipcom) on the

Internet for technical support using the e-mail address

techsupp@chipcom.com.

World Wide Web Site

You can ac cess the latest networking information on the 3Com World

Wide Web site by entering our URL into your Internet browser:

http://www.3Com.com/

This service features news and information about 3Com products,

customer serv ic e and support, the 3Com latest news releases , selected

articles from 3TECH™, the 3Com award-winning technical journal, and

more.

You can contact the Integrated System s Division o n the World Wide Web

by entering our URL into your Internet browser:

http://www.chipcom.com/

There are li nks between both WWW page s to view informatio n from all

3Com divisions.

Support from Your Network Supplier

If additional assistance is required, contact your network supplier. Many

suppliers are authorized 3Com service partners who are qualified to provide

a variety of services, including network planning, installation, hardware

maintenance, application training, and support services.

C - 2 ONline 17_Slot System Concentrator Installation and Operation Guide

Page 77

When you contact your network supplier for assistance, have the following

information ready:

❑ Diagnostic error messages

❑ A list of system hardware and software, including revision levels

❑ Details about recent configuration changes, if applicable

If you are unable to contact your network supplier, see the following

section on how to co ntact 3Com.

Support from 3Com

If you are unable to receiv e support from your network supplier, technical

support contracts are a va il able from 3Co m.

For direct access to customer service for Integrated Systems Division

products (formerly Chipco m) in:

❑ U.S.A. and Canada - call (800) 724-2447

❑ Asia Pacific - call (508) 787-5151

❑ Europe - Refer to table below

Country Telephone Number Co untry Telephone Number

Belgium 0800 71429 Netherlands 06 0227788

Denmark 800 17309 Norway 800 11376

Finland 0800 113153 Spain 900 983125

France 05 917959 Sweden 020 795482

Germany 0130 82 1502 U.K. 0800 966197

Ireland 1 800 553117 U.S. 800 876-3266

Italy 1678 79489

Technical Suppo rt C - 3

Page 78

For access to customer service for all 3 Com products, call (800) 876-3266.

You can also contact the Integrated Systems Division (ISD) on the Internet

by using the e-mail address techsupp@chipcom.com.

Returning Produc ts for R epair

A product sent directly to 3Com for repair must first be assigned a Return

Materials Authorization (RMA) number. A product sent to 3Com without

an RMA number will be returned to the sender unopened, at the sender’s

expense.

To obtain an RMA number for Integrated Systems Division products

(formerly Chipcom ), use the following numbers .

Country Telephon e Number Fax Number

U.S. and Canad a (800) 724-2447 (508) 787-34 00

Europe (44) (1442) 275860 No Fax

Asia Pacific (508) 787-5296 (508) 787-3400

Accessing the 3Com MIB

The 3Com Management Information Base (MIB) for the Integrated Systems

Division desc ribes commands that enable you to manage 3Com

SNMP-based products. The MIB is available over the Internet on an

anonymous FTP server. Updates to these MIBs are released as new 3Com

products are introd uced.

To access Internet versions:

1. FTP to ftp.chipcom.com (151.104.9.65).

2. Enter the login name anonymous.

C - 4 ONline 17_Slot System Concentrator Installation and Operation Guide

Page 79

3. Enter your full Internet e-mail address as the password

(for example, jdoe@company.com).

4. Change to the mib or schema directory using the cd /pub /mibs or

cd /pub/ mi bs /s ch em as command.

5. To view the 3Com MIB, OID, or schema entries, enter the dir

command.

❑ To pause the display, press [CTRL-S].

❑ To continue the display, press [CTRL-Q].

6. Copy the MIB, OID, or schema files to your current directory using the

appropriate command (for example, get chipcom. mi b).

7. To exit the FTP session, invoke the quit command.

3Com Technical Publications

If you have comments or questions on 3Com Integrated Systems Division

Techn ical Pu blic at ions docu me nts, p le ase cont act t he T ech nica l Pu bl icat ion s

group by FAX (508) 229-1551.

Technical Suppo rt C - 5

Page 80

Page 81

Index

Numerics

3Com Bulletin Board Service (3ComBBS), C-3

A

Audience of Manua l, xiii

B

Back Panel, 1-3

Backup Power Supply

Installing

bulletin board ser vice , C-3

, 2-14

C

Cable Tr a y

Installing

Rack Mount i ng , 2-8

Table Top Mount, 2-10

Cable Types, 1-1

Concentrat or Features, 1-4

, 2-7

E

Environment a l Co ndi tio ns, 2-4

F

Fan Unit

Removing

Replacing, 3-7

Fault Toleran c e, 1-8

FCC notic e, ii

, 2-14

Front Panel, 1-3

H

Hot Swap pi ng Mod ule s, 1-11

I

Installation, 2-1

Introduction, 1-1

L

Load Sharing, 1-8

M

Maintenance, 3-1

Modules, 3-9

MIB, C-4

Modul es, insta l ling, 2-19

N

Network Pr ot ocols Suppor t ed, A-1

network supplier suppo rt, C-2

O

on-line technical services, C-1

P

Passive D esi gn, 1-12

Power Requirements , 2-5

Index 1

Page 82

Power Supply

Load Shar in g

Replacing, 3-2

, 1-8

Q

Quick Insta llation, 2-6

R

Rack Mount i ng , 2-11

Preparation, 2-5

Regulat o ry Co mp li an ce, A-2

returning product s for re pair, C-4

Rubb er Feet, Installing, 2-13

S

Shipping Cont ents, 2-1

Slot Usage Chart, B-1

SNMP Comma nds, C-4

Specifications

Environmental

General, A-1

Mechanical, A-2

, A-1

T

Table Top Installation, 2-13

Airflow, 2-6

Preparat ion, 2-6

technical support, C-1

TriChannel Architecture, 1-1, 1-6

V

VDE compliance, ii

Ventilation, 2-4

Verifying Opera tio n, 2-20

Voltage Selection, 2-17

2 Index

Loading...

Loading...