Page 1

3B SCIENTIFIC

Instruction manual

04/09 MC/CW

®

PHYSICS

3B Netlab™ U11310

Contents

1. Introduction

2. System requirements

3. CD-ROM contents

4. System set-up and installation

5. Experiment system

5.1. Measurement lab

(for your own experiments)

5.2. Experiments (instructions)

6. Administration and network set-up

7. Network applications

8. Support

1 Introduction

3B NETlab™ is a data collection and evaluation

program for the 3B NETlog

that can be incorporated into a network. Since it is

based on ActiveX technology, all its control elements can be integrated into web pages which can

be displayed and operated using Microsoft’s Internet Explorer browser.

The main function of the 3B NETlab

facilitate computer-aided experimentation for

educational purposes. To this end, instructions for

numerous experiments from the various areas of

physics are available in web-page form. A user can

navigate between pages just as on the internet and

can use controls connected to on-site equipment to

conduct all aspects of the procedures.

TM

(U11300) equipment

TM

program is to

1

Page 2

A measurement lab has been provided from which

all functions of the 3B NETlog™ equipment can be

operated. To evaluate the measured data, the program is equipped with a whole range of graphic

tools.

Thanks to its networking functionality, the

3B NETlab™ program is perfectly suited for application in schools and educational institutes. Instructors are able to monitor the progress of students

and the data they gather during experiments from

their own workstation. Similarly, students can follow experiments being demonstrated or carried out

by an instructor on their own monitor screens.

2 System requirements

2.1 System requirements

• Windows 98/ME/2000/XP

• Microsoft Internet Explorer 6 or later

• Intel Pentium III/AMD Athlon 600 MHz or

higher

• 128 MB RAM

• 50 MB hard-disk storage

• Monitor with 1024x768 resolution or higher

• USB connection

2.2 Additionally recommended

• Internet access

• Adobe Reader 7.0

• Adobe Flash Player

3 CD-ROM contents

• 3B NETlab™ software

• USB driver

• Instruction manual

4 System set-up and installation

4.1 System set-up:

In order to ensure flawless functioning of

3B NETlab™, it may be necessary to alter certain

settings for Microsoft’s Internet Explorer which are

connected to the execution guidelines for ActiveX

controls.

4.1.1 ActiveX controls:

An ActiveX control is a software program that cannot run independently. Rather, it is executed in a

container provided by a separate application. The

most prominent example of such an application is

Microsoft’s Internet Explorer with its capability to

display ActiveX controls on web pages. This is

mostly used for integrating multimedia content

(e.g. animations using Adobe's Flash Player). Since

ActiveX controls can provide any kind of functionality within programs regardless of the container,

this technology offers users far greater possibilities

(e.g. on Microsoft’s Windows Update website, where

updates can be installed into the operating system

via an ActiveX control). At the same time, however,

there are also certain dangers accompanying this

technology – for instance, risks due to dubious

websites which attempt to plant and execute harmful program code in the form of ActiveX control

elements onto the user’s computer. For this reason,

Internet Explorer is so configured that it requires by

default the explicit consent of a user before installing a control. A publisher or server can be verified

on the basis of a digital signature. If such a digital

signature is missing, any attempt by a website to

install code is ignored.

4.1.2 Security settings for Internet Explorer:

The 3B NETlab™ control is provided with a digital

signature and can thus be installed by Internet

Explorer without altering the default settings. As a

rule, it is only necessary to alter the settings

marked * to allow the program to run. However, if

a particularly restrictive security policy has been

instituted, then further modifications may be required.

Internet Explorer differentiates between various

security zones: “Internet”, “Local intranet”, “Trusted

sites” and “Restricted sites”. To modify the settings,

go to the “Tools” menu, select “Internet Options”

then click the “Security” tab.

Since the pages for 3B NETlab™ are present either

on the hard-disk of the local computer or on the

local network, it is likely that the zone that requires

new settings is the one called “Local intranet”.

If the standard level has been set to “Medium”,

“Medium-low”, or “Low”, no further steps are re-

quired. If not, set the following settings under

“Custom Level”.

• “Script ActiveX controls marked safe for script-

ing” – “Enable”

• “Run ActiveX controls and plugins” – “Enable”

• “Active scripting” – “Enable”

There is no specific zone for pages on the local

computer. In order to permit the execution of

ActiveX control elements, go to “Security” and activate the following option in the “Advanced” tab

(Windows XP only):

• “Allow active content to run in files on My

Computer” *

If you use a pop-up blocker, deactivate the blocker

when working with 3B NETlab™, since the system

works with pop-ups.

2

Page 3

4.2 Installation:

The following steps will guide you through the

installation of 3B NETlab™ for single-user operation. Installation on a network is described in chapter 7.

4.2.1 Driver installation

Before installing the 3B NETlab™ software, it is

important to install the USB driver:

• Connect 3B NETlog™ to the computer via the

USB cable.

The computer reports that it has detected a new

hardware. Subsequently, the window of the hardware wizard opens:

• Insert the installation CD into the CD-ROM

drive of the computer.

Windows 2000:

• Select “Search for the best driver for your de-

vice”.

• Under search for driver files, select “CD-ROM

drives”. (If no driver can be found, select “Display other source locations”.)

Windows XP:

• Do not activate Windows Update.

• Select “Install software from specified loca-

tion”.

• Under “Browse”, specify the location of the

driver on the CD.

• A hardware message will state that the soft-

ware has failed to pass the Windows Logo Test.

You should nevertheless click “Proceed with installation”.

As an alternative, the folder containing the driver

file can be copied directly onto the computer from

the CD and can be installed from the hard disk.

4.2.1.1 Exception:

If the software for the U21800 CCD linear camera

and/or U21830 Spectrophotometer products has

already been installed onto the computer, follow

the instructions below:

• Connect 3B NETlog™ to the computer via the

USB cable.

The computer will not report that a new hardware

has been detected.

• Insert the installation CD into the CD-ROM

drive of the computer.

Windows 2000:

• System control panel -> System -> Hardware ->

open Device manager.

• Double-click USB controller.

• Double-click “ULICE USB Product”.

• Click Driver -> Update driver. (The wizard for

updating the device driver will start.)

• Select “Show all known drivers from list and

search for the suitable/appropriate driver”.

• Select “Drive” and then “Search” to establish

the path to the driver.

• Click “Yes” to confirm that the file should be

overwritten.

Windows XP:

• System control panel -> System -> Hardware ->

open Device manager.

• Double-click on USB controller.

• Double-click “ULICE USB Product”.

• Click Driver -> Update driver. (The hardware

assistant will start.)

• Do not activate Windows Update.

• Select “Install software from specific source”.

• Select “Do not search. Autodetect driver”.

• Select “Drive” and then “Search” to establish

the path to the driver.

• Click “Yes” to confirm that the file should be

overwritten.

• Click “Proceed with installation” when the

hardware message states that the software has

failed to pass the Windows Logo Test.

4.3 Software installation

1. Insert the Install CD into the CD-ROM

drive.

2. If the install program does not start auto-

matically, run “start.exe” from the root directory of the CD-ROM or right click the

CD-ROM drive icon and select “AutoPlay”.

3. Click “Install 3B NETlab™”.

4. A window appears in which you can select

a language by clicking on the respective

country flag. In response to the prompt

“Install 3B NETlab?”, click “Yes”.

5. Click “OK” to start the installation.

6. The program raises the question whether

the directory “C:\Programs\3BNETlab”

should be created, click “Yes”.

7. Enter a user name and password for the

instructor (or the program administrator).

Click “OK” to confirm.

8. The program files will then be installed.

3

Page 4

9. A window appears in which you can select

the experiments that are to be installed.

These experiments have been categorised

according to language and subject area. It

is possible to select either individual experiments or whole categories. Select the

required experiments/categories and click

“OK” to confirm.

10. The experiments will now be installed.

11. After completion of the installation, a

message box appears stating “Installation

completed successfully. Click OK to launch

program”. Click “OK” to confirm.

12. Internet Explorer will now be restarted

automatically and the program will be

loaded.

5 The experiment system

3B NETlab™ differentiates between two types of

experiments. On the one hand, it features a series

of experiment procedures covering various disciplines of physics. By following the instructions

therein, experiments can be conducted quickly and

purposefully using predefined settings. On the

other hand, the measurement lab lets you access

all settings and functions for the 3B NETlog™

equipment in order to conduct your own experiments.

Once the program has been started by either clicking the desktop icon or via the Start menu, a

prompt appears. You should now log in by entering

your user name and password. You can now select

from among the following items:

• Measurement lab

• Experiments

• Administration

Details for Administration are explained in chapter 6. The procedure after selecting either of the

first two items is very similar, since the measurement lab, in principle, also provides a set of instructions for experiments, the only difference

being that it leaves all options open. The steps

required for starting an experiment, managing the

experiment data and operating controls are thus

explained here using the measurement lab for all

examples. These then apply equally to the “Experi-

ments” option.

5.1 Measurement lab (for experiments of your

own design):

5.1.1 Starting, suspending, resuming and com-

pleting experiments:

5.1.1.1 Starting an experiment:

You can start the Measurement Lab by selecting

the corresponding item from the splash screen

then clicking “Continue”. You will now see a list

with the available data entries. A data entry or

record contains all the information on the status of

a particular experiment as well as the measurements made hitherto. To start a new experiment, it

is necessary to create a new data record.

1. Select “Create new data set” and click “Con-

tinue”.

2. Enter a name for the data record and click

“OK” to confirm.

A new measurement lab window then opens. Before dealing with the controls featured in the

measurement lab and the experiments themselves,

further explanation is required on how to proceed

with the data records.

5.1.1.2 Suspending and resuming an experiment;

importing, exporting and deleting data records:

It is possible to suspend the experiment at any time

that no actual measurement is being made.

1. Simply close the experiment window. The

program will then return to the main window.

2. Click “Back”.

The data record you created now appears in the

list. The status “executable” indicates that it is

possible to resume the corresponding experiment

by selecting the item “Open selected data set”.

Furthermore, options for deleting, exporting and

importing data records are also provided.

To export a data record set, it is necessary to specify a directory in which system components as well

as experiment data can be copied so that the experiment can be resumed from this location.

5.1.1.3 Concluding an experiment:

As soon as the first measurement has been concluded in the course of an experiment, a button

“Finish the experiment” appears in the top left hand

corner of the window.

1. Click the button to deactivate all measure-

ment functions.

2. Close the experiment window.

3. Click “Back” in the main window.

The data record is now marked is now marked

“Finished” and can be opened only for viewing.

4

Page 5

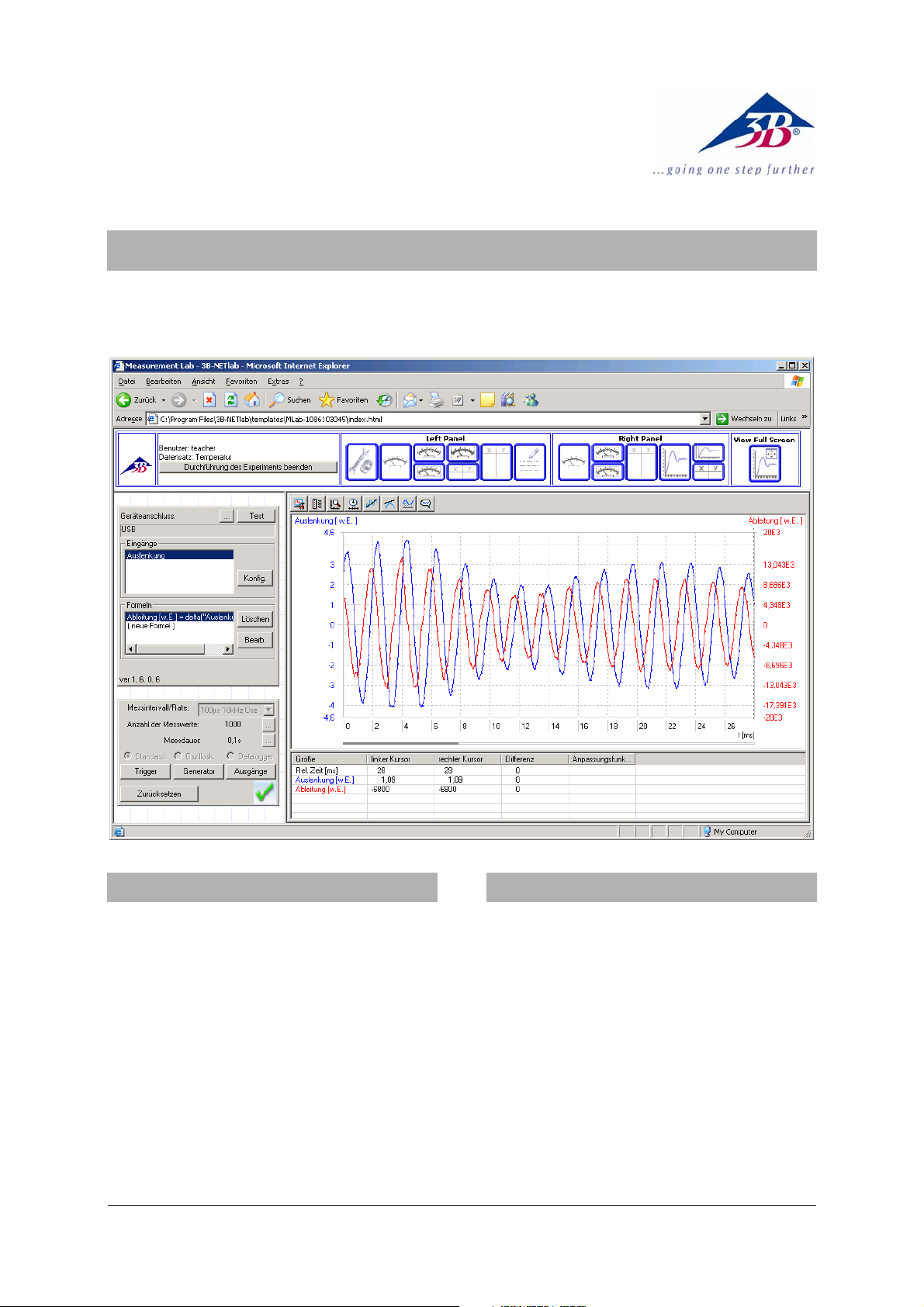

5.1.2 Measurement functions:

5.1.2.1 Establishing and testing a connection:

In the first row of the upper left hand control panel

(Input control panel) in the measurement lab window, it is possible to enter the name of the connection by which the 3B NETlog™ is linked to the computer by using the “…” button. This setting need

only be modified in exceptional cases. Normally, it

is set to “USB”. By clicking the “Test” button, the

connection can be tested and the result is displayed after a brief pause.

5.1.2.2 Selection of inputs:

Selection of the inputs required for measurements

can also be carried out in the top left control panel.

Clicking “Select” opens a dialog box, in which the

desired inputs can be specified. The following options are available:

Analog input A: used for measuring voltage, current or other quantities in conjunction with a sensor box which can be connected via the input at

the side.

Analog input B: used for measuring voltage or

other quantities in conjunction with a sensor box

which can be connected via the input at the side.

Digital inputs: the four digital inputs of the

3B NETlog™ unit are integrated together in an 8-pin

mini DIN connector on the right and designated A,

B, C and D. It is possible to interpret the inputs in

any of the following ways:

• As individual signals (A, B, C or D)

• An OR of all four signals (1 if at least one of the

signals is HIGH)

• The binary number represented by the signals

(“D/A conversion”, 1•A + 2•B + 3•C + 4•D)

Manual input: by selecting this input type it is

possible to enter a value into the data record

manually.

Time: a pulse signal at any of the digital or analog

inputs can be processed to determine information

about the pulse with regard to its timing. A value is

recorded for every pulse.

• Pulse time: elapsed time from the beginning of

the measurement to the rising edge of the current pulse.

0

t

• Puls duration: elapsed time between the rising

edge and the falling edge of the current pulse.

t

• Pulse distance (- +): elapsed time between the

falling edge of the previous pulse and the rising edge of the current pulse.

t

• Pulse distance (+ +): elapsed time between the

rising edge of the previous pulse and the rising

edge of the current pulse.

t

Frequency: measures the mean frequency or duration of a periodic signal at an analog or digital

input over an interval specified by the user (the

start and end of the interval are specified by activating a button.)

5.1.2.3 Configuration of inputs:

The selected inputs appear in a list at the top of the

control panel. In order to configure a specific input, select it and click “Config”. A dialog box appears which provides various options depending on

the selection:

Analog inputs:

• Symbol/Name and description: this makes it

possible to rename an input (e.g. corresponding to the quantity which will be measured)

and also allows a description to be entered, if

needed, that should follow a semicolon.

• Input mode: selects between sensor (for use

with an external sensor box), DC voltage (VDC),

rms AC voltage (VAC), DC current (IDC, analog

input A only) and rms AC current (IAC, analog

input A only) measuring modes.

• Input range: selection of input range (measur-

ing range)

• Use prefix for displaying values: this makes it

possible to display measured values, large or

small, with prefices in front of the unit instead

of expressing them in powers of 10.

Digital inputs:

• Input mode: selects between displaying the

signal for a single input (digital signal A, digital

signal B, …), the result of ORing all four signals

(arbitrary digital signal) or the binary number

represented by the four signals (D/A conversion, MSB: D).

Time/frequency:

• Input mode: selects the input where the pulse

signal is to be measured. The following selections are possible: digital input A, an OR of two

5

Page 6

or more digital inputs (A, B), (A, B, C), (A, B, C,

D) or either of the analog inputs. If the analog

inputs are selected, an additional check box

appears for setting a comparator threshold

(see below).

• Input range:

Digital inputs: assigns logical states to physical

input signals. “Uninterrupted = 1” means that

high voltage (>3.8 V) at the input corresponds

to a logical 1 and low voltage at the input

(<0.3 V) corresponds to a logical 0. The relation

is reversed if “Uninterrupted = 0”. This notation is derived from the status of a light barrier

associated with the digital input.

Analog inputs: (see above)

• Comp. level: sets a threshold voltage, specified

as a percentage of the upper limit of the input

range. The threshold voltage denotes the point

of transition between the two logical states.

By using the data conversion table on the right

hand side, it is possible to define how you want a

value to be displayed in relation to the actual signal. This relation is described by means of a table

consisting of pairs of values. Enter pairs of values

for the measured value and the value to be displayed starting from the bottom and working up.

Enter the unit for the new value in the “Results”

box. During subsequent measurements, instead of

the directly measured value the value displayed

will be converted with the help of the table. Values

between the entries in the table will be interpolated assuming a linear gradient between entries.

5.1.3 Formulas:

Underneath the input control panel is another

panel in which it is possible to enter formulae that

are based on the measured values. This function is

mostly used when the values of a particular quantity are to be displayed together with the measured

values. The quantity to be displayed is a function of

the measured quantity, i.e. its values can be calculated directly from the measurements.

• In order to enter a new formula, select “(New

Formula)” from the list and click “Edit”. .

• In the dialog box which appears, enter the

name of the value to be calculated in the

“Formula name” field and the corresponding

unit in “Formula unit”.

• To define the formula, use variables and func-

tions from the two lists that are provided by

double clicking the “Formula text” field. Note:

the term representing the measured values is

entered in the formula in inverted commas.

The check box “Use prefix” makes it possible to

display formula values using prefices instead of

expressing them in powers of 10.

After clicking “OK” to confirm the entries, the formula name is added to the list. When this is se-

lected, the formula can be edited or deleted by

means of the corresponding buttons.

5.1.4 Control of measurements:

After selecting inputs and entering formulae, click

“Inputs OK” on the input control panel to confirm

the entries. You can now proceed with adjusting

settings for recording measurements via the control

panel underneath (Measurement control panel).

Various logging/recording modes can be implemented depending on the selection and configuration of the inputs. First of all, however, it is important to define the recording speed (sampling rate)

in the field “Sampling rate”. The entries set the

interval between two recordings or, in some cases,

the corresponding frequency. AC current or voltage

measurements, i.e. measurements of root mean

square values, or measurements involving several

sensors can only be carried out in a slow mode

(interval >

0.5 s).

The final option is for manual mode (“manual

sampling”), in which recording of a measurement

is triggered by clicking a button.

The following three recording modes are available:

Recorder: a pre-defined number of measurements

are carried out. This number can be specified directly via the field “Number of measurements” or

indirectly via the duration of the measurement (set

using the adjacent “…” button). At a sampling rate

of 100 Hz or less, the measured values are output

in real time as the measurements are made. In

high-speed mode (>100 Hz), the data is first stored

in the internal memory of the equipment and read

out after measurements have been completed. It is

possible to view the measured values in various

ways, e.g. as a graph or in tabular form.

Oscillosc.: the measurements are recorded over

time and displayed as a curve. After each sweep

from left to right, the old curve is replaced by a

new one. Unlike standard mode, in oscilloscope

mode only the last 128 measurements can be

viewed or stored. Since a new trace is recorded only

a few times per second, at high-speeds oscilloscope

mode only displays samples of the overall signal

waveform. However, the advantage over standard

mode is that, even in high-speed mode, it is possible to observe measurements in “real time”.

Datalogger: it is also possible to record measurements offline using 3B NETlog™, without being

connected to the computer. The necessary configuration can be selected on the equipment itself or

conveniently using this function in 3B NETlab™.

After completing measurements, once the device is

connected to the computer again, the data can be

read out via the same function.

Use the “Trigger” button to open a dialog box that

defines the trigger conditions that initiate recording in standard mode.

6

Page 7

• Activate the inputs which are to be triggered at

the left of the box.

• In the middle of the box you can select

whether the trigger should occur when the signal crosses the threshold rising or falling.

• Trigger thresholds for the analog inputs can be

set on the right (as a percentage of the upper

limit of the input range).

5.1.5 Conducting measurements:

When all settings have been carried out, confirm

and click “Parameters OK”. You can now start

measuring by clicking “Start”.

5.1.5.1 Standard mode:

• If manual recording mode has been selected,

you can make a measurement simply by clicking “Sample”. At high -speeds a bar appears

showing the progress of the measurements being conducted. The display of measured values

is dealt with in section 6.1.8 “Evaluation”.

• Measurements can be stopped before they

have finished by clicking “Finish”. If this is not

done, measurements continue to be made until the desired number of values has been recorded. After that it is possible to carry out an

evaluation.

• In order to start new measurements, first click

“Reset”. You will first be given the chance to

save the current recorded values in a new data

record. Thereafter, you can begin conducting

new measurements. In case any parameters

need to be changed, click “Change settings” in

order to return to the choice of inputs. Your

saved settings will not be overwritten by doing

this.

5.1.5.2 Oscilloscope:

A new window opens, consisting of the oscilloscope

display and control panel. It is possible to adjust

the sampling rate and the input range by moving

the corresponding sliders during measurements. In

addition, a trigger is provided which initiates the

recording of the measurements when the threshold

has been crossed. The first slider, marked “Trigger”

in the control panel, is used for selecting the trigger

input. The second slider determines in which direction the threshold has to be crossed. The third

slider sets the threshold itself, specified as a percentage value of the top limit of the input range.

The “Sampling” control panel allows you to choose

between “Single” and “Continuous” modes. If “Sin-

gle” has been selected, the recording of measurements begins when you click “Start” and ends after

one sweep. In this manner, it is possible to trace

rare events as soon as they cause a trigger without

their being immediately overwritten.

The oscilloscope window can be closed by clicking

either of the buttons “Abort” or “Finish and Store

Data”. If you click the latter, the measurements

most recently recorded (128 samples) remain displayed in the display mode selected at the top, just

as in standard mode, and are available for evaluation.

5.1.5.3 Datalogger:

In this mode, no measurements are actually begun

after you click “Start”. Instead, a selection window

appears.

Setup: writes the configuration of the inputs and

the sampling rate to the equipment. Once a message has been received acknowledging that the

data has been stored, the equipment can be disconnected from the computer and can be used as a

portable device for measurements. Additional

information is available in the 3B NETlog™ instruction manual.

Readout: this opens a second selection window.

Click “Readout” to read data from the internal

memory of the 3B NETlog™ device. “Previous data”

calls up the most recently recorded data. A list

containing the available data records appears, from

which it is possible to select one set of records and

download it by clicking “OK”. Note: the maximum

number of samples read out is no greater than the

value that was specified under “Number of samples”

in the measurement control panel.

5.1.6 Generator:

5.1.6.1 Constant signals and digital pulses

In the course of the measurement process voltage

signals can be output from the analog outputs and

logical signals from the digital outputs. The “Out-

puts” button accesses a menu where you can enter

values for constant voltage at the analog outputs.

For digital outputs, it is possible to choose between

the following options:

0: During the entire measurement process, the

digital output is set to “logical 0” (0 V).

1 permanent:

during the entire measurement

process, the digital output is set to “logical 1” (5 V).

1 with delay: the digital output switches to “logi-

cal 1” shortly after the measurement process has

been started.

Pulse with delay: the digital input sends a pulse

shortly after the measurement process has started.

In order to activate the analog outputs, turn on the

check box “Analog outputs ON”.

5.1.7 Signals varying over time (Function genera-

tor):

It is possible to use the function generator to generate time-variant periodic signals at the analog

outputs using the “Generator” button. The sample

rate for the generator is always equal to the sampling rate of the measurement. If manual recording

has been selected, then the sampling rate of the

7

Page 8

generator can be set in the corresponding input

box of the “Sampling” panel. Next to this is the

check box “Generator enabled” that enables the

function generator.

The type of signal can be defined separately for

Channel A and Channel B by selecting the corresponding output. Clicking “Predefined” opens a

dialog box in which one of the following predefined signal waveforms can be selected: “Sine”,

“Rectangle”, “Triangle” and “Flat”. The parameters

are also modified according to the selected type of

signal. Click “OK” to confirm the entries. The specified signal is then displayed in a graphic.

It is possible to use the mouse to plot arbitrary

signal types on the graph. Move the cursor to the

left edge, press the left mouse button, draw the

desired signal with the cursor and release the

mouse button after you have finished.

The period and frequency of a repeating signal are

displayed above the graphic.

If the same signal is to be output to both outputs,

set the signal for output A and click “Copy from A”

under “Channel B” (or vice versa).

Note that the function generator is not working in

the oscilloscope mode.

5.1.8 Evaluation:

5.1.8.1 Display of measurements:

After any measurement in standard or oscilloscope

mode, the data can be viewed in various forms. It is

possible to change the display at any given time by

simply clicking the corresponding icons at the top

edge of the screen.

Dial: the current value is displayed on a

dial as on an analog multimeter. This

representation is useful at slow speeds or

in manual mode because the currently

valid measurement can be displayed in

real time.

Dual display: the values of two inputs

are displayed simultaneously.

Table: a table containing the measured

values is displayed

Selects the columns to be displayed

Copies the selected measured data

records to the clipboard

Manual entry of values in the se-

lected cells

Deletes all manually entered values

Graph: the measured values are plotted

on a graph. The next section deals with

the functions available for the graphical

display.

Table and pointer: see above

Graph and table: see above

Notes: This allows you to enter com-

ments describing the measurements.

Settings: once a display setting for the

left-hand side of the screen has been

configured, clicking this icon allows the

control fields to be reopened for modification.

5.1.8.2 Graphical display:

In a graphical display, the data for each digital

input is displayed in a different colour with a legend underneath. The parameters for the x-axis are

entered in the first row.

The graph provides two cursors represented by

vertical dotted lines that can be moved along the xaxis. Just move the mouse close to one of these

cursors, press the left mouse button and move the

cursor to the requisite position, releasing the cursor

when it is correctly placed. The coordinates of the

cursor are displayed in the row containing the

legend for the x-axis. Beneath that, the individual

measurements are contained in the rows corresponding to the y-axis, i.e. the y coordinates for the

selected curve at the cursor position.

The right mouse button is used for zooming. A

context menu appears which provide the possibility

of zooming in or out of the x-axis, the y-axis or

both of the axes. It is possible to highlight sections

by keeping the right mouse button pressed and

dragging the mouse, thereby enclosing the relevant

section in a rectangle. The contents highlighted

within this rectangle can be magnified to fill the

entire screen by selecting “Zoom into selected win-

dow”. The visible section of the graph can be

shifted by dragging the axis legend with the left

mouse button.

A row of icons is located above the graph. The

following sections explain their function:

Setup display: (connecting lines, grids, data

points, etc.)

Select inputs/formulas to be displayed: also

for assigning what is to be on the x-axis. The x-axis

8

Page 9

can also be assigned to one of the measured values

(x-y display).

Modify scale range: use “Autoscaling” to

scale the highlighted axis so that it is possible to

view all data. “Manual scaling” opens a dialog box

in which the limits of the visible intervals can be

entered manually.

Modify time scale range: (exception: in x-y

mode, both of the axes are set in the dialog box

described above)

Fit to a function (Fit): for further information

see the following section

Calculate tangent: if this icon is activated,

then a tangent is drawn to the displayed curve

from the last cursor to be moved If several curves

are visible, then it is necessary to select one of the

curves in a selection window before proceeding.

The section of the axis and the gradient of the

tangent are displayed in the upper left of the

graph.

Calculate integral: when this icon is activated, it is possible to calculate the integral of the

highlighted (or the only visible) data curve within

limits defined by the cursors. In graphical terms

this corresponds to the area below the respective

curve (which is shaded). Any areas below the x-axis

are considered negative.

Edit text labels: activating this icon allows us

to create a text field and position it on the graph.

5.1.8.3 Fitting to a function (Fit):

Proceed as described in the following to fit a function to a data curve:

• Click the icon for the graph. A dialog box

for fitting the function will open.

• On the left, select the desired data.

• Click “Edit fit function for selected quantity”.

A window appears in which the section of the

curve that was highlighted earlier by the cursors is drawn (preview) and a list of functions is

presented.

• Select the desired function from the list or

define a unique function by means of “Edit the

user formula”. (See section 6.1.3 “Formulas”. It

is possible to use six parameters from A to F.

The independent variable appears last in the

list.) The equation (strictly speaking, the right

hand side of the algebraic equation) of the

chosen function is displayed above the list.

• Specify the parameters for the initial values on

the right hand side. This is not always necessary. Sometimes, however, the preset initial

values are not helpful. Click “Draw” to plot the

function with the specified parameters in the

preview.

• In addition to the input fields for the initial

values, activating the check box can cause the

parameter values to remain constant during

the fitting of the function.

• Click “Try to fit”. The result is displayed in the

preview. The correlation coefficient R

2

is output

above the control panel labelled “Parameters”.

• After clicking “OK” and exiting the window for

fitting the function, the fit function is also plotted on the graph.

An existing fit function can be edited in the same

way. In order to display or hide a fit function, open

the dialog field for setting a fit function and, after

highlighting the relevant data set, click the corresponding icon.

5.2 Experiments (according to the instructions):

The only difference between experimenting according to instructions and experimenting with the

measurement lab is that the control panels have

been incorporated and pre-configured in the experiment procedure. Usually, only those measurement functions which are significant are activated.

In this way, even users little accustomed to the

functions of 3B NETlog™ are able to perform experiments easily. To begin an experiment, proceed

from the splash screen as follows:

• Select “Experiments” and click “Continue”.

• Choose “Perform/browse an experiment” and

click “Continue”.

• Select an experiment from the list and click

“Continue”. The experiment which is now visible is recognised by the measurement laboratory. This is where the data pertaining to the

selected experiment are administered. Subsequently proceed as explained in section 6.1.1.1

“”.

6 Administration and network set-up

The functions of 3B NETlab™ described in the following section support its operation within a network. After installation, no administrative intervention is required for single-user operation. Owing to

the innumerable ways of implementing a network

and the corresponding differences in configuration

associated with that, it is not possible to explain

the various steps in detail within the scope of this

chapter. Administrator rights are essential for setting up a network.

The network functionality makes it possible for

instructors to observe students’ experiments from

their own computer while they are being conducted and also to view the recorded readings.

Likewise, instructors can also conduct an experi-

9

Page 10

ment at their own computer while students observe at their terminals.

Communication is conducted entirely via Windows

file sharing. No additional TCP connections need to

be set up. The supervisor can regularly access and

read a data file shared by the computer where the

experiment is being conducted. The data is thus

accessible from the supervisors’ controls after only

a very brief delay. At the same time however, supervisors are not restricted to viewing those pages

or controls currently being used by students performing the experiments. A supervisor can, for

instance, check the individual numbers in a table

while the student performing the experiment is

conducting an analysis of them in a graph.

6.1 Network installation:

Installation on an instructor’s computer is carried

out as in the single-user installation procedure, but

subsequently the instructor’s computer is set up as

a server.

• Select “Administration” from the splash screen

and click “Continue”.

• Select “Adm. the teacher's server and student's

computers” and click “Continue”.

• Select “Define/modify the teacher's

server” and click “Continue”.

• In the dialog box, a path is displayed which

must now be shared for all network users to

have read access. For NTFS data systems, make

sure that the necessary authorisation is

granted.

• Enter the network address of the share. Click

“OK” to confirm.

A message appears which explains how to proceed.

Among others, the URL for the installation of the

3B NETlab™ students’ version is specified. The following steps must be carried out on each student’s

computer. While carrying out these steps, make

sure to observe the notes on security settings, as

described in section 4.1.2.

• Enter the installation URL in Internet Explorer.

• An installation prompt appears for the ActiveX

control element “3BNETlab” which you should

accept.

• The installation routine for the students’ ver-

sion begins. Confirm the creation of a program

directory.

• A message appears in which the path is speci-

fied. This must be shared in order to grant the

instructor full access. Make sure the relevant

authorisation is provided for NTFS file systems.

After confirming this message, the program is concluded. It is now important that the server can

detect the student computers. To test this:

• Go to “Administration” and select the item

“Define a new student's computer”. Click

“Continue”.

• Enter a name and the network address of the

supervisor share on the student’s computer.

Click “OK” to confirm.

6.2 User identification for students:

A separate user ID can be set up for each individual

student. The advantage of this is that after logging

on for each experiment, only that particular student’s data are listed. In this way, any confusion

which may arise on account of multiple students

working simultaneously is avoided. Also, experimental results are always ascribed to a particular

student. This simplifies the task of monitoring for

the supervisor.

6.2.1 Setting up user identification for students:

After the installation of the network, students must

be granted user identification in order to run the

program.

• From “Adm. the teacher's server and

student's computers” click “Back” to return

to the previous page.

• Select “Students” and click “Continue”.

• Select “Create new student entry” and click

“Continue”.

• From the list, select the computer on which the

user ID is to be created and click “Continue”.

• Enter a user name for the student.

• Select a user group. If necessary, click “Create

a new group of students”.

• Enter a password. Click “OK” to confirm.

6.2.2 Changing students’ user identification:

• Go to “Students” and select “Edit an existing

student entry”.

• From the list of students’ entries, select an

entry then click “Modify” and “Continue”.

• A dialog box appears where it is possible to

change the group and, if required, the password of the student.

6.2.3 Deleting students’ user identification:

• Go to “Students” and select “Edit an existing

student entry”.

• From the list of students’ entries, select an

entry then click “Delete” and “Continue”.

6.3 User identification for teachers:

6.3.1 Setting up user identification for teachers:

It is also possible to set up an individual user identification for each teacher.

10

Page 11

Go to “Administration”. Select “Administrate

•

the teachers' list” and click “Continue”.

• Select “Create a new teacher entry” and

click “Continue”.

• Enter a user name and password, click “OK” to

confirm.

6.3.2 Changing your own password:

Any teacher can only change his/her own password.

• Go to “Administration”. Select “Administrate

the teachers' list” and click “Continue”.

• Select “Edit current teacher entry” and click

“Continue”.

• Activate the “Change” check box in the field

labelled “Password”.

• Enter a new password. Click “OK” to confirm.

7 Network applications

This chapter describes functions which can only be

used in the network.

7.1 Teachers monitoring experiments con-

ducted by students:

Experiments conducted by students can be monitored at any time by the instructor. Even after

completion of the experiment, it is still possible to

refer to and consult the data.

• Select “Administration” on the splash screen

and click “Continue”.

• Select “Student” and click “Continue”.

• Select “Watch a student’s experiment” and

click “Continue”.

• From the list, select a particular student whose

experiment you wish to monitor and click

“Continue”.

• From the list, select the data sets you wish to

see. The “Date/time” column specifies the time

the data set was created.

• Click “Browse”. The experiment window will

open. However, the control elements are deactivated. Therefore, it is not possible to take

control of the experiment.

While monitoring an experiment, it is possible to

change the display or navigate on the page independently, without interfering with the participating student(s). The evaluation functions of the

graph display may also be used.

To exit the experiment, simply close the window

and click “Back” to return to the main window.

7.2 Students observing experiments conducted

by teachers:

It is possible for the students to observe experiments conducted and demonstrated by the instructors.

• Select “Watch the teacher's experiment”

on the splash screen and click “Continue”.

• From the list, select the data sets you wish to

see. The “Date/time” column specifies the time

the data set was created.

• Select “Browse”.

The experiment window will open. It provides the

same range of options as described under section 7.1 “Teachers monitoring experiments conducted by students”.

8 Support

If you have any queries and/or suggestions, please

feel free to contact our support team:

Email: support@3bnetlab.com

3B Scientific GmbH • Rudorffweg 8 • 21031 Hamburg • Germany • www.3bscientific.com

Subject to technical amendments

© Copyright 2009 3B Scientific GmbH

Page 12

Loading...

Loading...