1

C

USTOMER

P

ROCUREMENT

S

PECIFICATION

FEATURES

ROM

Device

Z86C83 4 237 21 3.0V to 5.5V

Z86C84 4 237 17 3.0V to 5.5V

Note: * General-Purpose

28-Pin DIP, SOIC, and PLCC Packages

■

■

Clock Speed: 16 MHz

■

Three Expanded Register Groups

■

8-Channel, 8-Bit A/D Converter with Track and Hold,

and Unique R-Ladder A

■

Z86C84 has two 8-Bit D/A Converters with

Programmable Gain Stages, 3 µ s Settling Time

(KB)

RAM*

(Bytes)

GND

I/O

Lines

Offset Control

Voltage

Range

Z86C83/C84

®

Z8

MCU M

■

Six Vectored, Prioritized Interrupts from Six Different

Sources

■

Two Analog Comparator Inputs with Programmable

Interrupt Polarity

■

Two Programmable 8-Bit Timers, each with a 6-Bit

Programmable Prescaler

■

Auto Latch Mask Option for P00, P01, and P02

■

Power-On Reset (POR) Timer

■

Permanent Watch-Dog Timer (WDT) Mask Option

■

Software-Programmable Pull-Up Resistors

■

On-Chip Oscillator for Crystal, Resonator or LC

ICROCONTROLLERS

1

GENERAL DESCRIPTION

The Z86C83/C84 Consumer Controller Processors

™

(CCP

) are full-featured members of the CMOS Z8 microcontroller family offering a unique register-to-register architecture that avoids accumulator bottlenecks for higher

code efficiency than RISC processors.

The Z86C83/C84 are designed to be used in a wide variety

of embedded control applications, such as appliances,

process controls, keyboards, security systems, battery

chargers, and automotive modules.

For applications requiring powerful I/O capabilities, the

Z86C83/C84 devices can have up to 21/17 (C83/C84

respectively) pins dedicated to input and output. These

lines are grouped into three ports, and are configured by

software to provide digital/analog I/O timing and status

signals.

An on-chip, half-flash 8-bit ± 1/2 Least Significant Bit (LSB)

A/D converter can multiplex up to eight analog inputs.

DS96DZ80203 1

Unused analog inputs revert to standard digital I/O use.

Unique, programmable A

resistor ladder compresses the converter's dynamic range

for maximum effective 9-bit A/D resolution.

The Z86C84 has two 8-bit ± 1/2 LSB D/A converters. High

and low reference voltages provide precise control of the

output voltage range. Programmable gain for each D/A

converter provides a maximum effective 10-bit resolution

for many tasks.

On-chip 8-bit counter/timers with many user-selectable

modes simplify real-time tasks, such as counting, timing,

and generation of PWM signals.

The designer can prioritize six different maskable,

vectored, internal or external interrupts for efficient

interrupt handling and multitasking functions.

offset control of the A/D

GND

Z86C83/C84

®

Z8

MCU Microcontrollers

GENERAL DESCRIPTION (Continued)

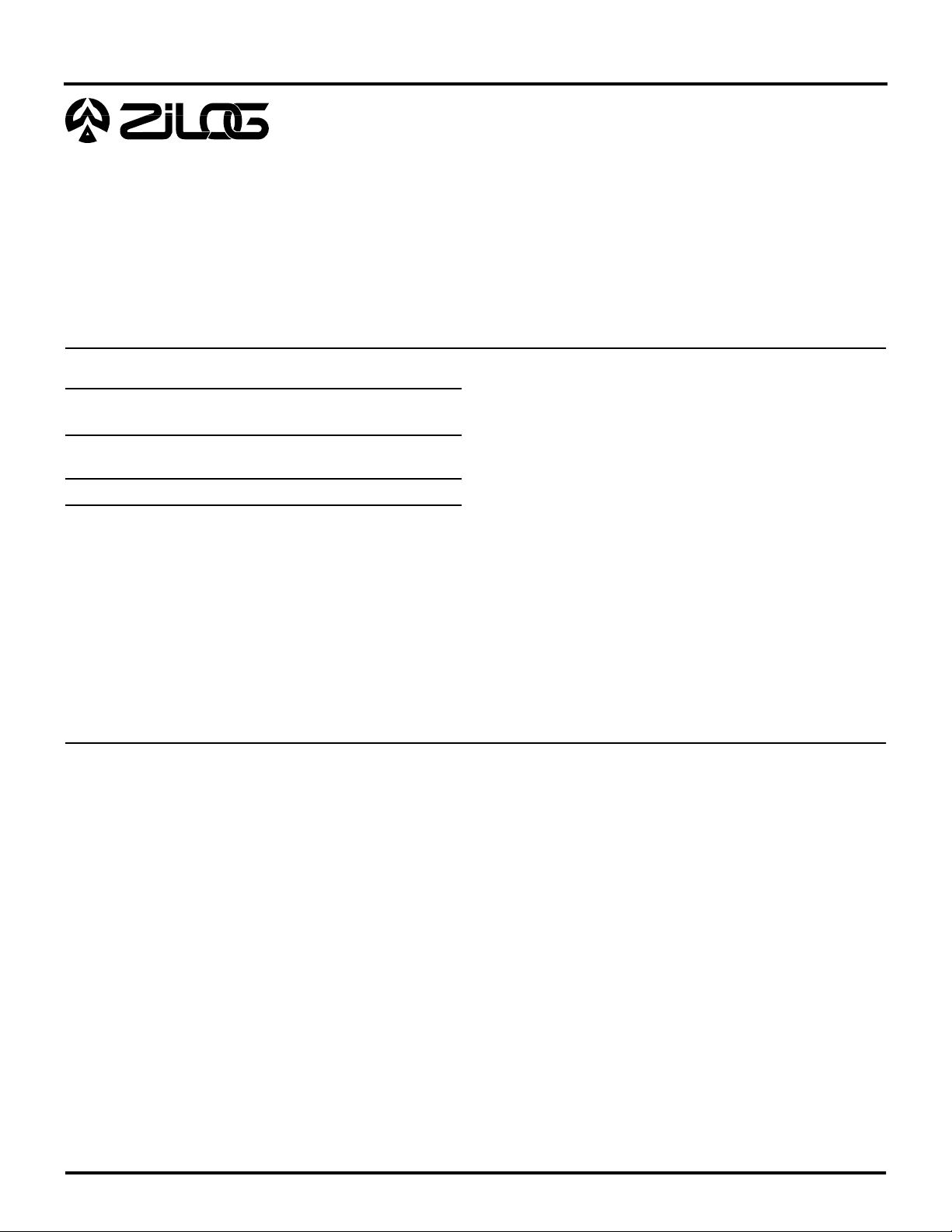

By means of an expanded register file, the designer has

access to additional control registers for configuring peripheral functions including the A/D and D/A converters,

counter/timers, and I/O port functions (Figure 1).

Notes: All Signals with a preceding front slash, "/", are

active Low, e.g., B//W (WORD is active Low); /B/W (BYTE

is active Low, only).

P00

P01

P02

P03†

P04†

P05†

P06†

VDHI **

VDL0 **

DAC1 **

DAC2 **

AC0/P20

AC1/P21

AC2/P22

AC3/P23

AC4/P24

AC5/P25

AC6/P26

AC7/P27

Port 0

**Dual

8-Bit

DAC

Port 2

Comparators

(2)

Register Bus

ROM

4K x 8

Internal Data Bus

Expanded

Register File

Power connections follow conventional descriptions

below:

Connection Circuit Device

Power V

Ground GND V

Register File

256 x 8-Bit

Internal

Address Bus

Register Bus

Expanded

Z8

®

Core

CC

Port 3

Machine

Timing

and

Instruction

Control

Power

V

CC

SS

P31

P32

P33

P34

P35

P36

XTAL 1/2

/RESET

VCC

GND

AVCC

AGND

8-Channel

8-Bit A/D

Counter/Timer

8-Bit (2)

Notes:

** Not available on Z86C83.

† Not available on Z86C84.

Figure 1. Z86C83/C84 Functional Block Diagram

2 DS96DZ80203

1

PIN DESCRIPTION

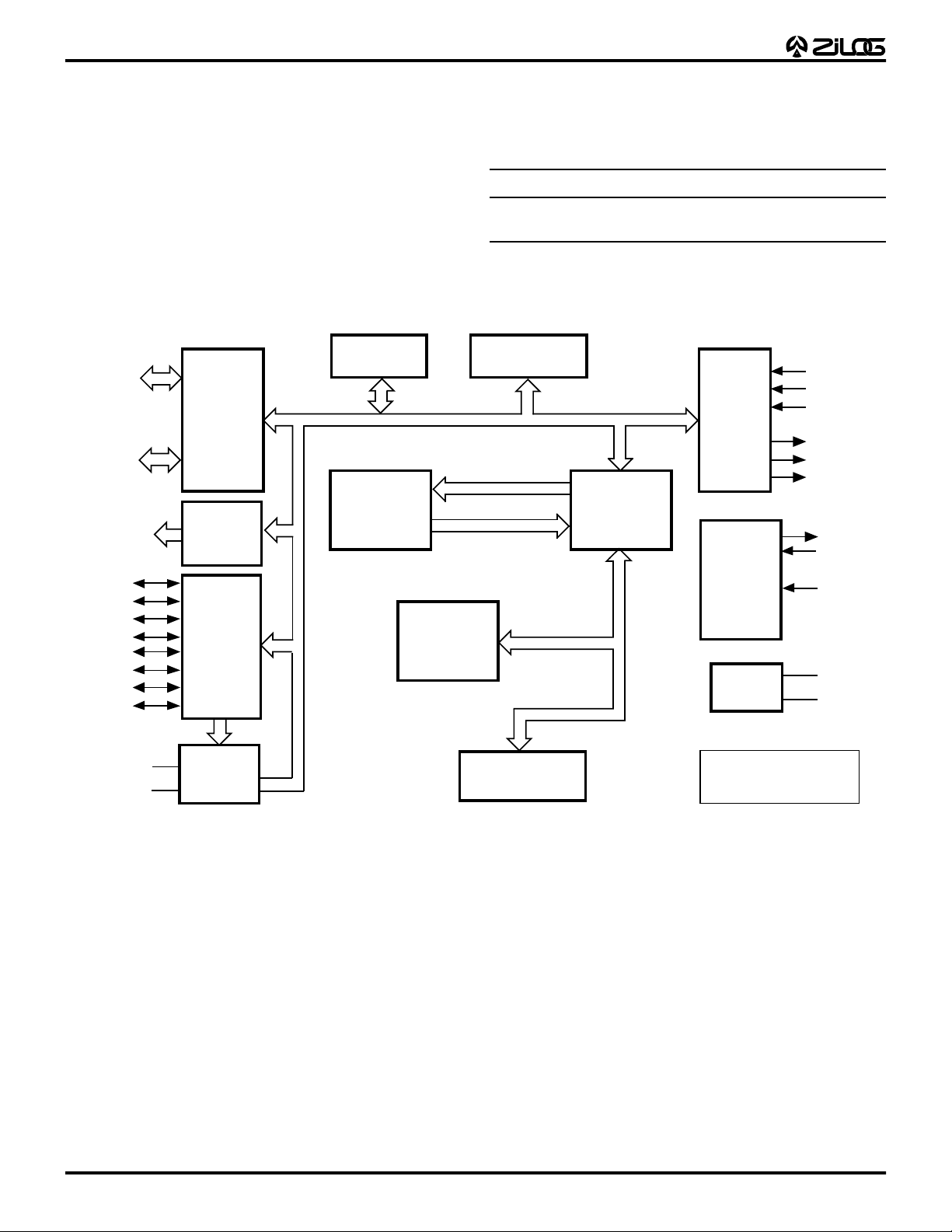

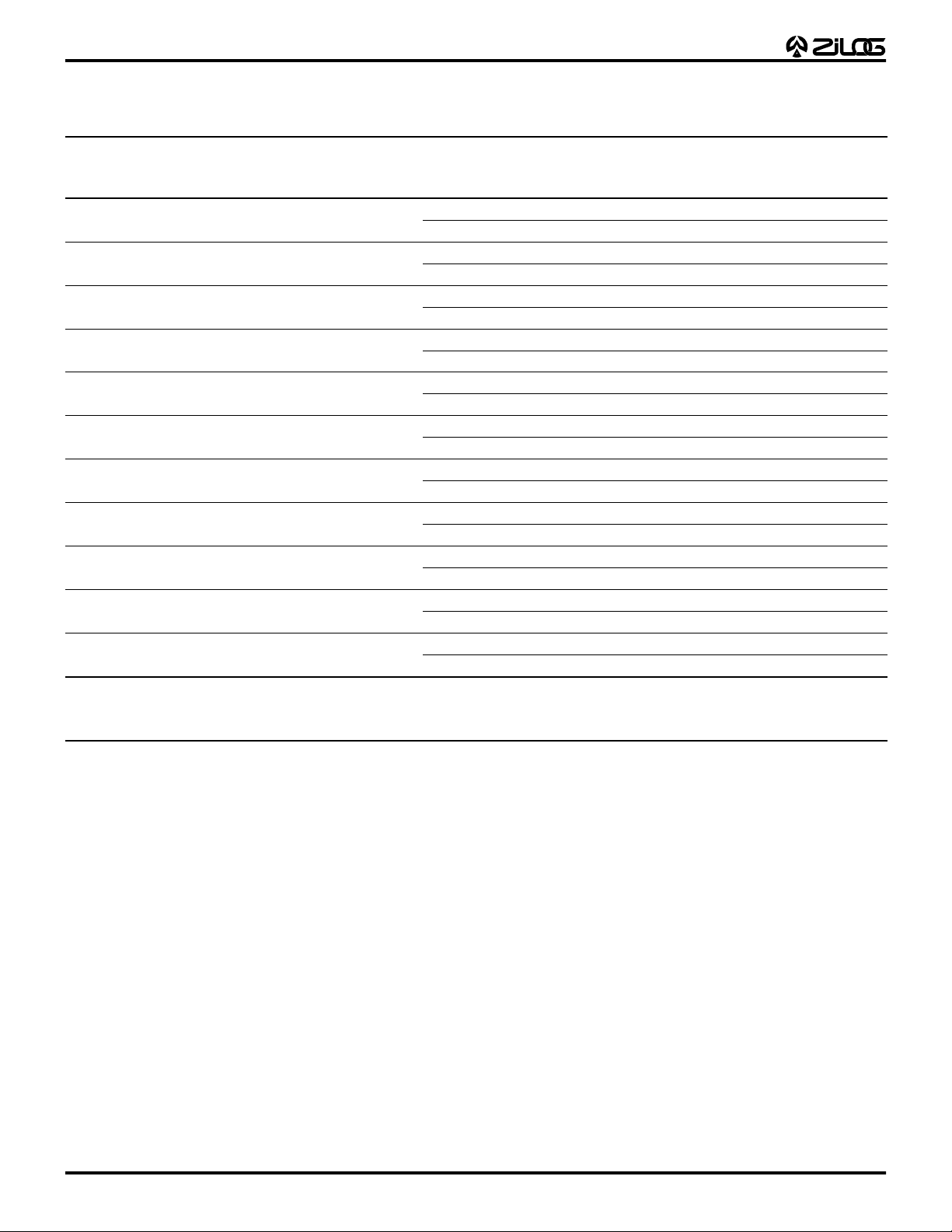

Table 1. Z86C83 28-Pin DIP, SOIC Pin Identification*

®

Z8

MCU Microcontrollers

Z86C83/C84

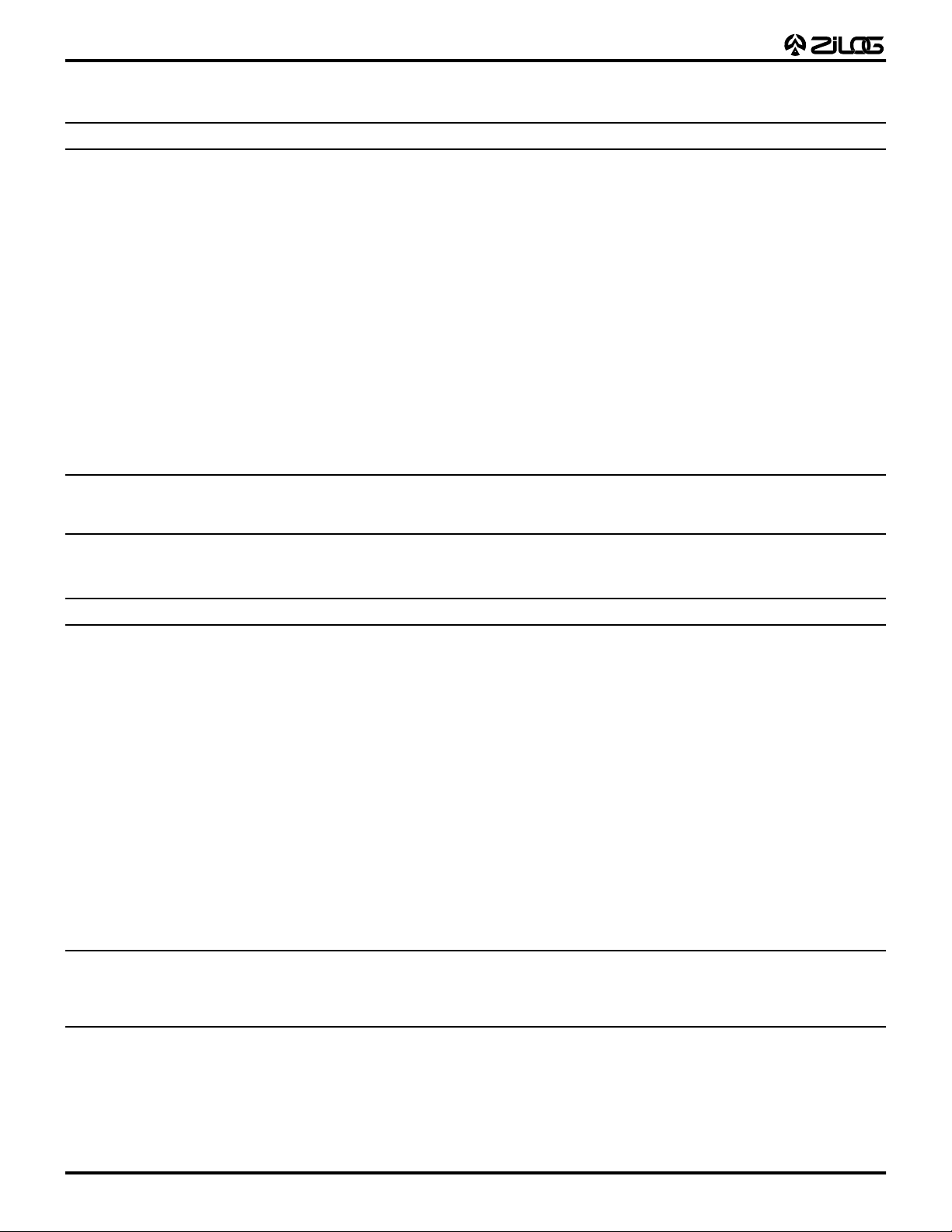

Table 2. Z86C84 28-Pin DIP, SOIC Pin Identification*

No Symbol Function Direction

1-7 P21-P27

or AC1-AC7

Port 2, Bit 1-7

Analog In 1-7

Input/Output

8 /RESET Reset Input

9 XTAL1 Oscillator Clock Input

10 XTAL2 Oscillator Clock Output

11 GND Ground

12 V

CC

Power

13-15 P31-P33 Port 3, Bits 1-3 Input

16 P34 Port 3, Bit 4 Output

17 P36 Port 3, Bit 6 Output

18 P35 Port 3, Bit 5 Output

19-25 P0-P06 Port 0, Bits 0-6 Input/Output

26 A

27 AV

GND

CC

28 P20

or AC0

Note:

* DIP and SOIC Pin Description and Configuration are identical.

Analog Ground

Analog Power

Port 2, Bit 0

Analog In 0

Input/Output

No Symbol Function Direction

1-7 P21-P27

or AC1-AC7

Port 2, Bit 1-7

Analog In 1-7

Input/Output

8 /RESET Reset Input

9 XTAL1 Oscillator Clock Input

10 XTAL2 Oscillator Clock Output

11 GND Ground

12 V

CC

Power

13-15 P31-P33 Port 3, Bits 1-3 Input

16 P34 Port 3, Bit 4 Output

17 P36 Port 3, Bit 6 Output

18 P35 Port 3, Bit 5 Output

19-21 P0-P02 Port 0, Bits 0-3 Input/Output

22 VDLO D/A Ref. Volt.,Low Input

23 VDHI D/A Ref. Volt.,High Input

24-25 DAC2-1 D/A Converter Output

26 A

27 AV

GND

CC

28 P20

or AC0

Note:

* DIP and SOIC Pin Description and Configuration are identical

Analog Ground

Analog Power

Port 2, Bit 0

Analog In 0

Input/Output

P21/AC1 P20/AC0

P22/AC2

P23/AC3

P24/AC4

P25/AC5

P26/AC6

P27/AC7

/RESET

XTAL1

XTAL2

GND

VCC

P31

P32

1

2

3

4

5

6

7

Z86C83

8

9

10 19

11

12

13

14 15

Standard Mode

28

27

26

25

24

23

22

21

20

18

17

16

AVCC

AGND

P06

P05

P04

P03

P02

P01

P00

P35

P36

P34

P33

Figure 2. Z86C83 28-Pin DIP and SOIC Pin

Configuration*

P21/AC1 P20/AC0

P22/AC2

P23/AC3

P24/AC4

P25/AC5

P26/AC6

P27/AC7

/RESET

XTAL1

XTAL2

GND

VCC

P31

P32

1

2

3

4

5

6

7

Z86C84

8

9

10 19

11

12

13

14 15

* Standard Mode

28

27

26

25

24

23

22

21

20

18

17

16

AVCC

AGND

DAC1

DAC2

VDHI

VDLO

P02

P01

P00

P35

P36

P34

P33

Figure 3. Z86C84 28-Pin DIP and SOIC Pin

Configuration*

DS96DZ80203 3

Z86C83/C84

3

0

®

Z8

MCU Microcontrollers

PIN DESCRIPTION (Continued)

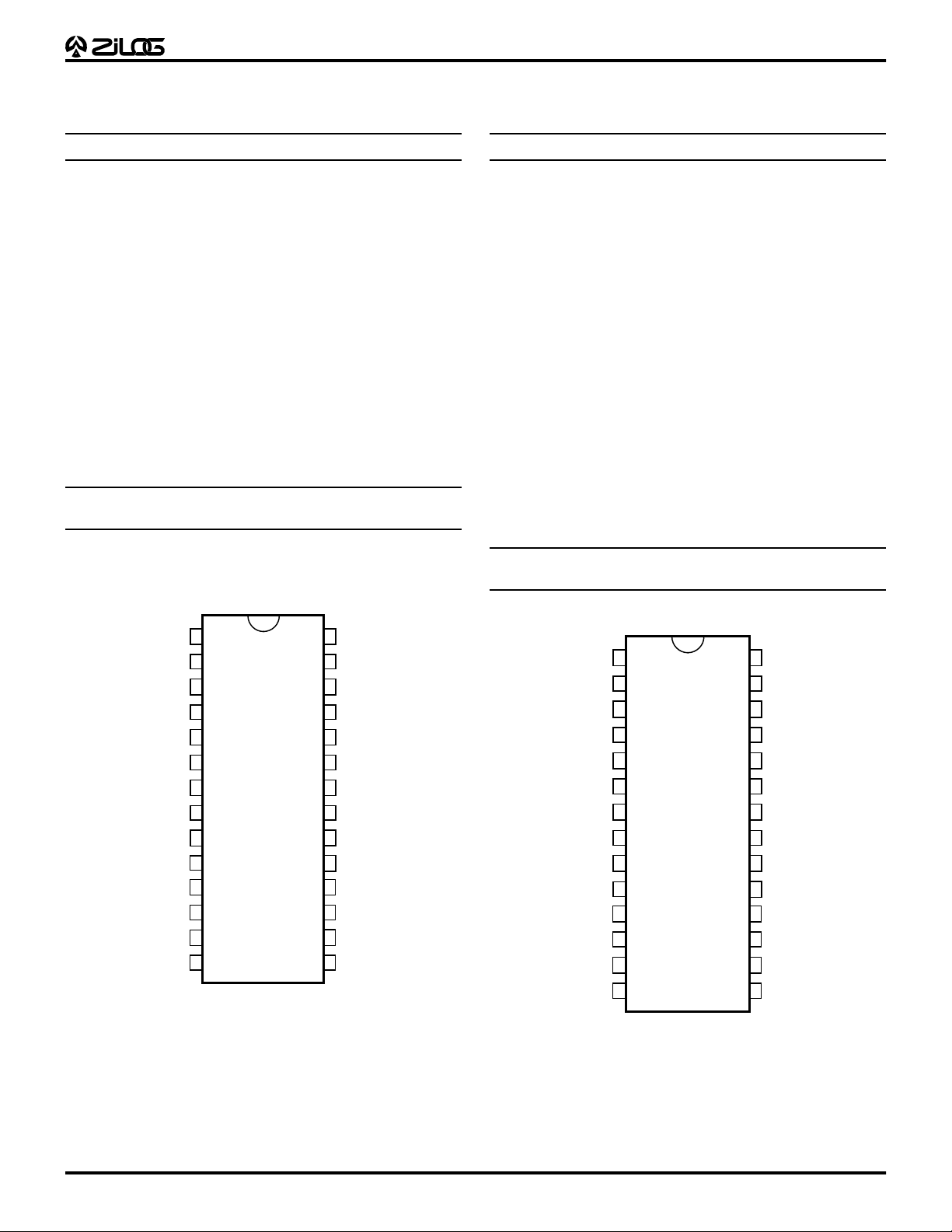

Table 3. Z86C83 28-Pin PLCC Pin Identification

No Symbol Function Direction

1-8 P20-P27

or AC0-AC7

Port 2, Bit 0-7

Analog In 0-7

Input/Output

9 /RESET Reset Input

10 XTAL1 Oscillator Clock Input

11 XTAL2 Oscillator Clock Output

12 GND Ground

13 V

CC

Power

14-16 P31-P33 Port 3, Bits 1-3 Input

17 P34 Port 3, Bit 4 Output

18 P36 Port 3, Bit 6 Output

19 P35 Port 3, Bit 5 Output

20-26 P00-P06 Port 0, Bits 0-6 Input/Output

27 A

28 AV

GND

CC

Analog Ground

Analog Power

Table 4. Z86C84 28-Pin PLCC Pin Identification

No Symbol Function Direction

1-8 P20-P27

or AC0-AC7

Port 2, Bit 0-7

Analog In 0-7

Input/Output

9 /RESET Reset Input

10 XTAL1 Oscillator Clock Input

11 XTAL2 Oscillator Clock Output

12 GND Ground

13 V

CC

Power

14-16 P31-P33 Port 3, Bits 1-3 Input

17 P34 Port 3, Bit 4 Output

18 P36 Port 3, Bit 6 Output

19 P35 Port 3, Bit 5 Output

20-22 P00-P02 Port 0, Bits 0-3 Input/Output

23 VDLO D/A Ref. Volt,Low Input

24 VDHI D/A Ref. Volt.,High Input/Output

25-26 DAC2-DAC1 D/A Converter Output

27 A

28 AV

GND

CC

Analog Ground

Analog Power

AGND

18171614 15

P34

P06

P36

25

24

23

22

21

20

P05

P04

P03

P02

P01

P00

P35

19

P24/AC4

P25/AC5

P26/AC6

P27/AC7

/RESET

XTAL1

XTAL2

10

11

5

6

7

8

9

P23/AC3

4

12

GND

P22/AC2

13

VCC

P20/AC0

P21/AC1

123

Z86C83

PLCC

P31

P32

AVCC

28 27 26

P33

Figure 4. Z86C83 28-Pin PLCC Pin Configuration

AGND

18171614 15

P34

DAC1

25

24

23

22

21

20

19

P36

DAC2

VDHI

VDLO

P02

P01

P00

P35

P24/AC4

P25/AC5

P26/AC6

P27/AC7

/RESET

XTAL1

XTAL2

10

11

AVCC

P23/AC

P22/AC2P21/AC1

4

5

6

7

8

9

13

12

VCC

GND

P20/AC

123

Z86C84

PLCC

P31

P32

28 27 26

P33

Figure 5. Z86C84 28-Pin PLCC Pin Configuration

4 DS96DZ80203

1

µ

µ

®

Z8

MCU Microcontrollers

Z86C83/C84

ABSOLUTE MAXIMUM RATINGS

Parameter Min Max Units

Ambient Temperature under Bias –40 +105 C

Storage Temperature –65 +150 C

Voltage on any Pin with Respect to V

Voltage on V

Pin with Respect to V

CC

Voltage on /RESET Pins with Respect to V

Total Power Dissipation 770 mW

Maximum Current out of V

Maximum Current into V

SS

CC

Maximum Current into an Input Pin [Note 3] –600 +600

Maximum Current into an Open-Drain Pin [Note 4] –600 +600

Maximum Output Current Sinked by Any I/O Pin 25 mA

Maximum Output Current Sourced by Any I/O Pin 25 mA

Notes:

1. This applies to all pins except XTAL and /RESET pins and where otherwise noted.

2. There is no input protection diode from pin to V

3. This excludes XTAL pins.

4. Device pin is not at an output Low state.

[Note 1] –0.6 +7 V

SS

SS

[Note 2] –0.6 V

SS

–0.3 +7 V

+1 V

CC

140 mA

125 mA

.

CC

A

A

)

Notice:

Stresses greater than those listed under Absolute

Maximum Ratings may cause permanent damage to the

device. This is a stress rating only; functional operation of

the device at any condition above those indicated in the

operational sections of these specifications is not implied.

Exposure to absolute maximum rating conditions for an

extended period may affect device reliability.

STANDARD TEST CONDITIONS

The characteristics listed below apply for standard test

conditions as noted. All voltages are referenced to

Ground. Positive current flows into the referenced pin

(Figure 6).

Total power dissipation should not exceed 770 mW for the

package. Power dissipation is calculated as follows:

Total Power Dissipation = V

x [ I

CC

– (sum of I

CC

+ sum of [ (V

+ sum of (V

CC

– V

0L

x I

OH

OH

) x I

0L

) ]

OH

]

From Output

Under Test

I

150 pF

Figure 6. Test Load Diagram

V

SPECIFICATION

DD

V

= 3.0V to 5.5V

DD

DS96DZ80203 5

Z86C83/C84

®

Z8

MCU Microcontrollers

CAPACITANCE

TA = 25°C, VCC = GND = 0V, f = 1.0 MHz, unmeasured pins returned to GND.

Parameter Min Max

Input capacitance 0 20 pF

Output capacitance 0 20pF

I/O capacitance 0 20 pF

6 DS96DZ80203

1

DC ELECTRICAL CHARACTERISTICS

Z86C83/C84

Z8® MCU Microcontrollers

Sym Parameter

V

Clock Input High

CH

Voltage

= 0° C

T

V

CC

A

to +70°C

Note 3

3.0V 0.7 VCCVCC+0.3 0.7 VCCVCC+0.3 1.3 V Driven by External Clock

5.5V 0.7 V

CCVCC

+0.3 0.7 VCCVCC+0.3 2.5 V Driven by External Clock

TA = –40°C

to +105°C

Typical

[13]

@ 25°C Units Conditions NotesMin Max Min Max

Generator

Generator

V

Clock Input Low

CL

Voltage

3.0V GND-0.3 0.2 VCCGND-0.3 0.2 V

5.5V GND-0.3 0.2 V

GND-0.3 0.2 V

CC

0.7 V Driven by External Clock

CC

Generator

1.5 V Driven by External Clock

CC

Generator

V

Input High Voltage 3.0V 0.7 VCCVCC+0.3 0.7 VCCVCC+0.3 1.3 V

IH

5.5V 0.7 V

Input Low Voltage 3.0V GND-0.3 0.2 VCCGND-0.3 0.2 V

V

IL

CCVCC

5.5V GND-0.3 0.2 V

V

Output High

OH1

Voltage

Output Low

V

OL1

Voltage

Output Low

V

OL2

Voltage

Reset Input High

V

RH

Voltage

V

Reset Input Low

Rl

Voltage

Comparator Input

V

OFFSET

3.0V VCC-0.4 VCC-0.4 3.1 V IOH = -2.0 mA 8

5.5V V

-0.4 VCC-0.4 4.8 V IOH = -2.0 mA 8

CC

3.0V 0.6 0.6 0.2 V IOL = +4.0 mA 8

5.5V 0.4 0.4 0.1 V I

3.0V 1.2 1.2 0.3 V IOL = +6 mA 8

5.5V 1.2 1.2 0.3 V I

3.0V .8 V

5.5V .8 V

CC

CC

3.0V GND-0.3 0.2 VCCGND-0.3 0.2 V

5.5V GND-0.3 0.2 V

3.0V 25 25 10 mV 10

+0.3 0.7 VCCVCC+0.3 2.5 V

0.7 V

CC

CC

V

CC

V

CC

CC

GND-0.3 0.2 V

.8 V

.8 V

CC

CC

V

V

GND-0.3 0.2 V

CC

CC

CC

CC

CC

1.5 V

1.5 V

2.1 V

1.1 V

1.7 V

= +4.0 mA 8

OL

= +12 mA 8

OL

Offset

Voltage 5.5V 25 25 10 mV 10

I

Input Leakage 3.0V -1 1 -1 2 <1 µAVIN = OV, V

IL

5.5V -1 1 -1 2 <1 µAVIN = OV, V

I

Output Leakage 3.0V -1 1 -1 2 <1 µAVIN = OV, V

OL

5.5V -1 1 -1 2 <1 µAVIN = OV, V

I

Reset Input

IR

Current

I

Supply Current 3.0V 20 20 7 mA @ 16 MHz 4, 15

CC

3.0V -130 -130 -25 µA

5.5V -180 -180 -40 µA

CC

CC

CC

CC

5.5V 25 25 20 mA @ 16 MHz 4, 15

5.0V 7 7 3 mA @ 3.58 MHz 4, 15

5.0V 10 10 5 mA @ 8 MHz 4, 15

I

Standby Current 3.0V 4.5 4.5 2.0 mA HALT Mode VIN = OV, VCC @ 16

CC1

4

MHz

5.5V 8 8 3.7 mA HALT Mode VIN = OV, VCC @ 16

4

MHz

3.0V 3.4 3.4 1.5 mA

5.5V 7.0 7.0 2.9 mA

Clock Divide-by-16 @ 16 MHz

Clock Divide-by-16 @ 16 MHz

4

4

DS96DZ80203 7

Z86C83/C84

Z8® MCU Microcontrollers

= 0° C

T

V

Sym Parameter

I

Standby Current 3.0V 8 15 1 µA STOP Mode VIN = OV,

CC2

CC

Note 3

A

to +70°C

5.5V 10 20 2 µA STOP Mode V

3.0V 500 600 310 µA STOP Mode V

5.5V 800 1000 600 µA STOP Mode V

V

Input Common

ICR

3.0 0 VCC-1.0V 0 VCC-1.5V V 10

TA = –40°C

to +105°C

Typical

[13]

@ 25°C Units Conditions NotesMin Max Min Max

WDT is not Running

V

CC

= OV,

WDT is not Running

V

CC

WDT is Running

V

CC

WDT is Running

V

CC

IN

= OV,

IN

= OV,

IN

Mode

Voltage Range 5.5 0 V

I

Auto Latch Low

ALL

Current

Auto Latch High

I

ALH

Current

VCC Low-Voltage

V

LV

3.0V 8 10 5 µA OV < VIN < V

5.5V 15 20 11 µA OV < V

3.0V -5 -7 -3 µA OV < VIN < V

5.5V -8 -10 -6 µA OV < V

2.0 3.3 2.2 3.6 3.0 V 2 MHz max Int. CLK Freq. 7

-1.0V 0 VCC-1.5V V 10

CC

CC

< V

IN

CC

CC

< V

IN

CC

Protection V oltage

Notes:

1. I

CC1

Typical Max Unit Freq

Clock-Driven 0.3 mA 5 mA 8 MHz

2. GND = 0V.

3. 3.0V VCC voltage specification guarantees 3.3V ±0.3V, and 5.5V VCC voltage specification guarantees 5.0V ±0.5V.

4. All outputs unloaded, I/O pins floating, inputs at rail.

5. CL1 = CL2 = 100 pF.

6. Same as note [4] except inputs at V

.

CC

7. The VLV increases as the temperature decreases.

8. Standard Mode (not Low EMI).

9. Auto Latch (mask option) selected.

10. For analog comparator, inputs when analog comparators are enabled.

11. Clock must be forced Low, when XTAL 1 is clock-driven and XTAL2 is floating.

12. Excludes clock pins.

13. Typicals are at V

= 5.0V and 3.3V.

CC

14. Internal RC selected.

15. Combined Digital and Analog V

supply current.

CC

6,11,15

6,11,15

6,11,14,

15

6,11,14,

15

9

9

9

9

8 DS96DZ80203

1

AC ELECTRICAL CHARACTERISTICS

Additional Timing Diagram

Z86C83/C84

Z8® MCU Microcontrollers

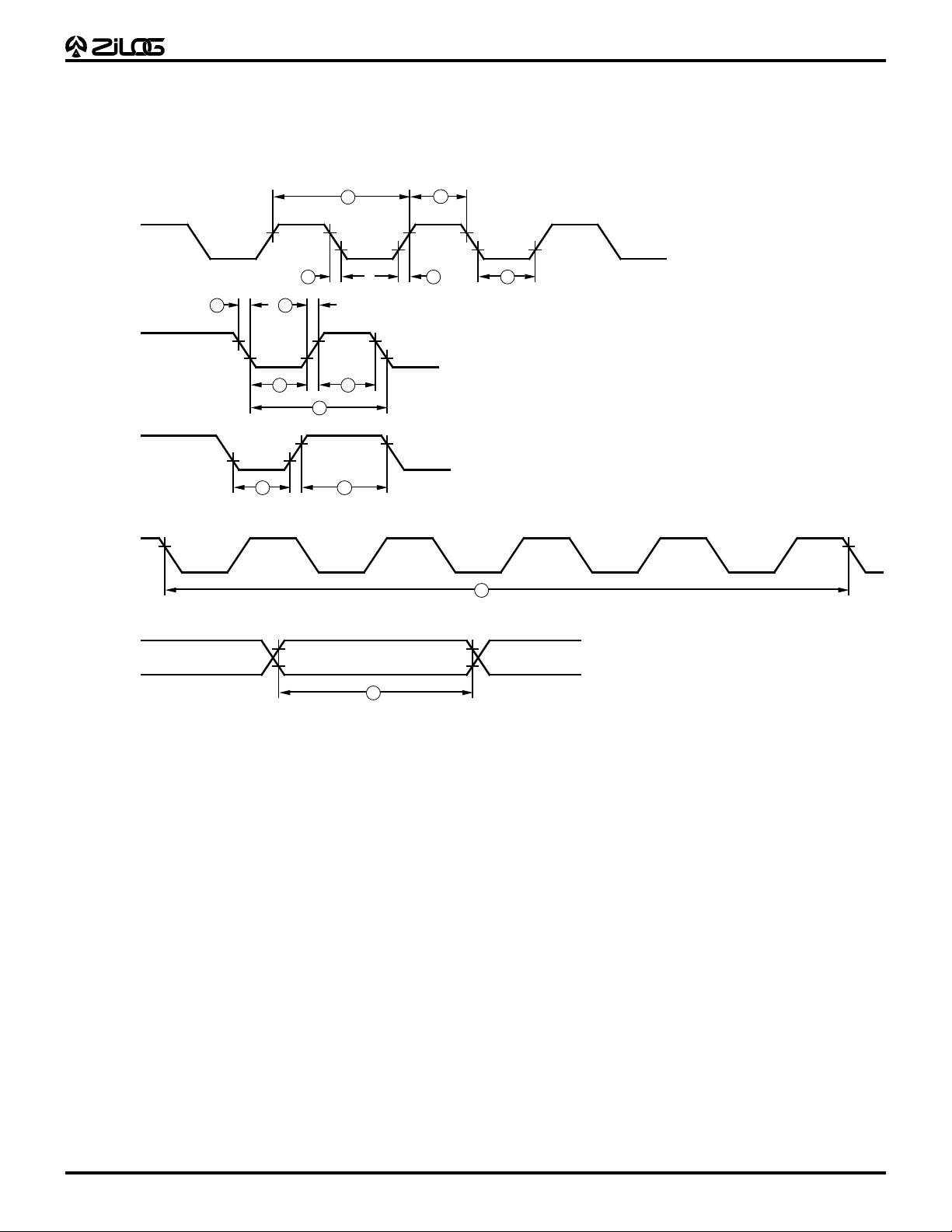

Clock

T

IN

IRQ

N

Clock

Setup

Stop-Mode

Recovery

Source

7 7

8

1

2 2 3

4

5

6

9

3

11

10

Figure 7. Additional Timing

DS96DZ80203 9

Z86C83/C84

Z8® MCU Microcontrollers

AC ELECTRICAL CHARACTERISTICS (Continued)

Additional Timing Table (SCLK/TCLK = XTAL/2)

No Symbol Parameter

1 TpC Input Clock Period

2 TrC,TfC Clock Input Rise & Fall

Times

3 TwC Input Clock Width

4 TwTinL Timer Input Low Width

5 TwTinH Timer Input High Width

6 TpTin Timer Input Period

7 TrTin, Timer Input Rise & Fall

Timer

TfTin

8A TwIL Int. Request Low Time

8B TwIL Int. Request Low Time

9 TwIH Int. Request Input High

Time

10 Twsm STOP-Mode Recovery

Width Spec

11 Tost Oscillator Startup Time

12 Twdt Watch-Dog Timer Delay

Time

T

13

Notes:

POR

1. Timing Reference uses 0.7 V

2. Interrupt request via Port 3 (P31-P33).

3. Interrupt request via Port 3 (P30).

4. SMR-D5 = 0.

5. The V

Power On Reset Delay

for a logic 1 and 0.2 VCC for a logic 0.

CC

voltage specification of 3.0V guarantees 3.3V ±0.3V, and the VCC voltage specification of 5.5V guarantees 5.0V ±0.5V.

CC

V

CC

Note 6

3.0V 83 DC 62.5 DC 83 DC 62.5 DC ns 1

5.5V 83 DC 62.5 DC 83 DC 62.5 DC ns 1

3.0V 15 15 15 15 ns 1

5.5V 15 15 15 15 ns 1

3.0V 41 31 41 31 ns 1

5.5V 41 31 41 31 ns 1

3.0V 100 100 100 100 ns 1

5.5V 70 70 70 70 ns 1

3.0V 5TpC 5TpC 5TpC 5TpC 1

5.5V 5TpC 5TpC 5TpC 5TpC 1

3.0V 8TpC 8TpC 8TpC 8TpC 1

5.5V 8TpC 8TpC 8TpC 8TpC 1

3.0V 100 100 100 100 ns 1

5.5V 100 100 100 100 ns 1

3.0V 100 100 100 100 ns 1,2

5.5V 70 70 70 70 ns 1,2

3.0V 5TpC 5TpC 5TpC 5TpC 1,3

5.5V 5TpC 5TpC 5TpC 5TpC 1,3

3.0V 5TpC 5TpC 5TpC 5TpC 1,2

5.5V 5TpC 5TpC 5TpC 5TpC 1,2

3.0V 12 12 12 12 ns

5.5V 12 12 12 12 ns

3.0V 5TpC 5TpC 5TpC 5TpC 4

5.5V 5TpC 5TpC 5TpC 5TpC 4

3.0V

3.0V 12.5 12.5 12.5 12.5 ms 0

3.0V 25 25 25 25 ms 1

3.0V 100 100 100 100 ms 1

3.0V 7 24 7 25 7 24 7 25 ms

5.5V 3 13 3 14 3 13 3 14 ms

TA = 0°C to +70°CT

12 MHz 16 MHz 12 MHz 16 MHz

Min Max Min Max Min Max Min Max

6.25 6.25 6.25 6.25

= –40°C to +105°C

A

WDTMR

Units Notes

Reg. D1

ms 0

D0

0

1

0

1

10 DS96DZ80203

Z86C83/C84

Z8® MCU Microcontrollers

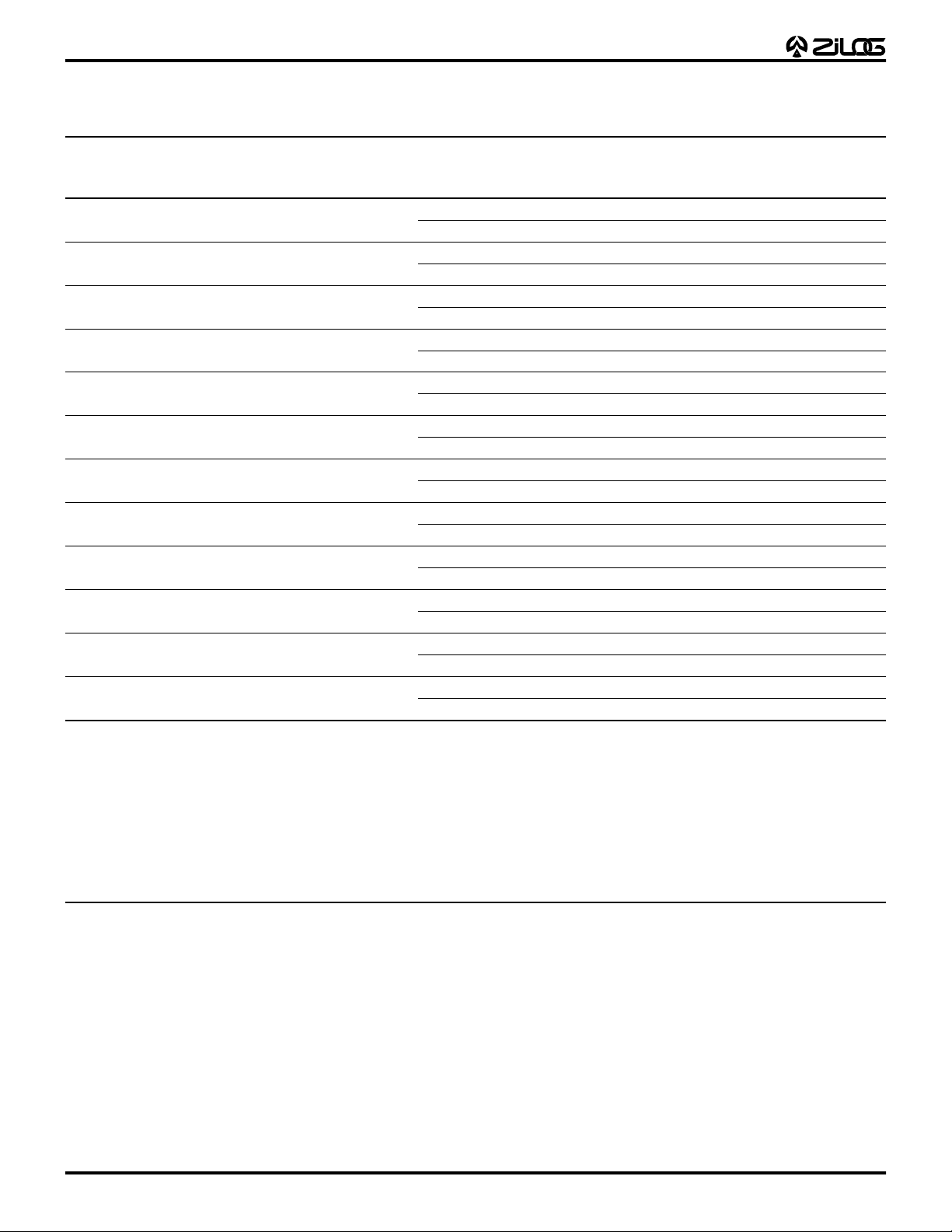

AC ELECTRICAL CHARACTERISTICS (Continued)

Additional Timing Table (Divide-By-One Mode, SCLK/TCLK = XTAL)

T

= 0°C to +70°CTA = –40°C to +105°C

V

No Symbol Parameter

Note 6

1 TpC Input Clock Period 3.0V 250 DC 250 DC ns 1,7,8

5.5V 250 DC 250 DC ns 1,7,8

2 TrC,TfC Clock Input Rise & Fall Times 3.0V 25 25 ns 1,7,8

5.5V 25 25 ns 1,7,8

3 TwC Input Clock Width 3.0V 125 125 ns 1,7,8

5.5V 125 125 ns 1,7,8

4 TwTinL Timer Input Low Width 3.0V 100 100 ns 1,7,8

5.5V 70 70 ns 1,7,8

5 TwTinH Timer Input High Width 3.0V 3TpC 3TpC 1,7,8

5.5V 3TpC 3TpC 1,7,8

6 TpTin Timer Input Period 3.0V 4TpC 4TpC 1,7,8

5.5V 4TpC 4TpC 1,7,8

7 TrTin, Timer Input Rise & Fall Timer 3.0V 100 100 ns 1,7,8

TfTin 5.5V 100 100 ns 1,7,8

8A TwIL Int. Request Low Time 3.0V 100 100 ns 1,2,7,8

5.5V 70 70 ns 1,2,7,8

8B TwIL Int. Request Low Time 3.0V 3TpC 3TpC 1,3,7,8

5.5V 3TpC 3TpC 1,3,7,8

9 TwIH Int. Request Input High Time 3.0V 3TpC 3TpC 1,2,7,8

5.5V 3TpC 2TpC 1,2,7,8

10 Twsm STOP-Mode Recovery Width Spec 3.0V 12 12 ns 4,8

5.5V 12 12 ns 4,8

11 Tost Oscillator Startup Time 3.0V 5TpC 5TpC 4,8,9

5.5V 5TpC 5TpC 4,8,9

Notes:

1. Timing Reference uses 0.7 V

2. Interrupt request via Port 3 (P33-P31).

3. Interrupt request via Port 3 (P30).

4. SMR-D5 = 1, POR STOP mode delay is on.

5. Reg. WDTMR.

6. The V

7. SMR D1 = 0.

8. Maximum frequency for internal system clock is 4 MHz when using XTAL divide-by-one mode.

9. For XTAL and LC oscillator, and for oscillator driven by clock driver.

voltage specification of 3.0V guarantees 3.3V ±0.3V, and the V

CC

for a logic 1 and 0.2 VCC for a logic 0.

CC

A

cc

4 MHz 4 MHz

Min Max Min Max

voltage specification of 5.5V guarantees 5.0V ±0.5V.

CC

Units Notes

11 DS96DZ80203

Z86C83/C84

Z8® MCU Microcontrollers

AC ELECTRICAL CHARACTERISTICS

Handshake Timing Diagrams

Data In

/DAV

(Input)

RDY

(Output)

Data Out

Data In Valid

1 2

3

4 5 6

7

Next Data In Valid

Delayed DAV

Delayed RDY

Figure 8. Input Handshake Timing

Data Out Valid

Next Data Out Valid

/DAV

(Output)

RDY

(Input)

8 9

10

Figure 9. Output Handshake Timing

Delayed DAV

11

Delayed RDY

12 DS96DZ80203

Z86C83/C84

Z8® MCU Microcontrollers

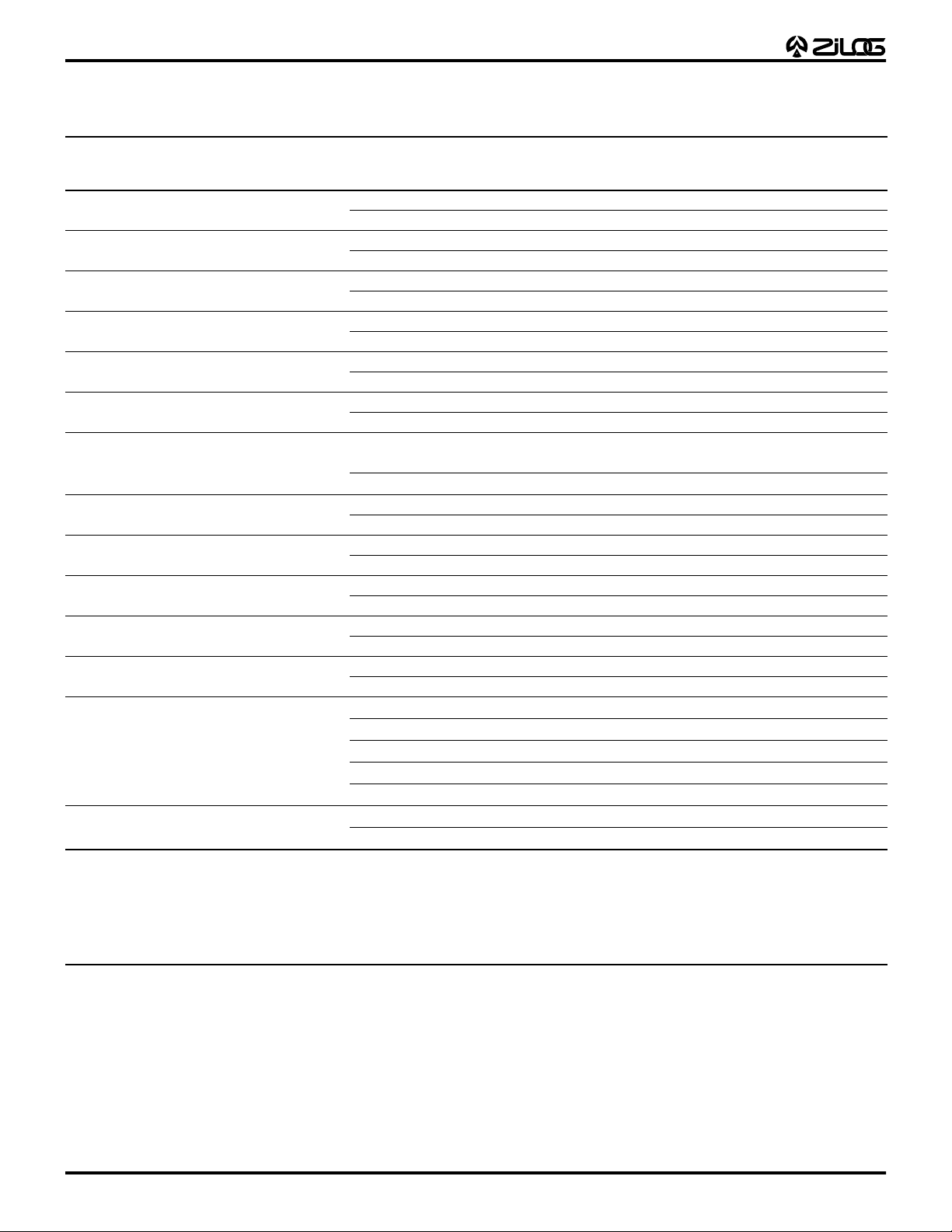

AC ELECTRICAL CHARACTERISTICS (Continued)

Handshake Timing Table

T

= 0°C to +70°CTA = –40°C to +105°C

V

CC

No Symbol Parameter

Note1,2

1 TsDI(DAV) Data In Setup Time 3.0V 0 0 0 0 IN

5.5V 0 0 0 0 IN

2 ThDI(DAV) Data In Hold Time 3.0V 160 160 160 160 IN

5.5V 115 115 115 115 IN

3 TwDAV Data Available Width 3.0V 155 155 155 155 IN

5.5V 110 110 110 110 IN

4 TdDAVI(RDY) DAV Fall to RDY Fall Delay 3.0V 160 160 160 160 IN

5.5V 115 115 115 115 IN

5 TdDAVId(RDY) DAV Rise to RDY Rise Delay 3.0V 120 120 120 120 IN

5.5V 80 80 80 80 IN

6 TdRDY0(DAV) RDY Rise to DAV Fall Delay 3.0V 0 0 0 0 IN

5.5V 0 0 0 0 IN

7 TdD0(DAV) Data Out to DAV Fall Delay 3.0V 42 31 42 31 OUT

5.5V 42 31 42 31 OUT

8 TdDAV0(RDY) DAV Fall to RDY Fall Delay 3.0V 0 0 0 0 OUT

5.5V 0 0 0 0 OUT

9 TdRDY0(DAV) RDY Fall to DAV Rise Delay 3.0V 160 160 160 160 OUT

5.5V 115 115 115 115 OUT

10 TwRDY RDY Width 3.0V 110 110 110 110 OUT

5.5V 80 80 80 80 OUT

11 TdRDY0d(DAV) RDY Rise to DAV Fall Delay 3.0V 110 110 110 110 OUT

5.5V 80 80 80 80 OUT

Notes:

1. Timing Reference uses 0.7 V

2. The V

voltage specification of 3.0V guarantees 3.3V ±0.3V and the VCC voltage specification of 5.5V guarantees 5.0V ±0.5V.

CC

for a logic 1 and 0.2 VCC for a logic 0.

CC

A

12 MHz 16 MHz 12 MHz 16 MHz

Min Max Min Max Min Max Min Max

Data

Direction

13 DS96DZ80203

Z86C83/C84

Z8® MCU Microcontrollers

Table 5. D/A Converter Electrical Characteristics

VCC = 3.3V ± 10%

Parameter Minimum Typical Maximum Units

Resolution 8 Bits

Integral non-linearity 0.25 1 LSB

Differential non-linearity 0.25 0.5 LSB

Setting time, 1/2 LSB 1.5 3.0 µsec

Zero Error at 25°C1020mV

Full Scale error at 25°C 0.25 0.5 LSB

Supply Range 3.0 3.3 3.6 Volts

Power dissipation, no load 10 mW

Ref Input resistance 2K 4K 10K Ohms

Output noise voltage 50 µVp-p

VDHI

range at 3 volts 1.5 1.8 2.1 Volts

VDLO range at 3 volts 0.2 0.5 0.8 Volts

VDHI–VDLO, at 3 volts 1.3 1.6 1.9 Volts

Capacitive output load, CL 20 pF

Resistive output load, RL 50K Ohms

Output slew rate 1.0 3.0 V/µsec

Notes:

Voltage: 3.0V to 3.6V

Temp: 0–70°C

Table 6. D/A Converter Electrical Characteristics

VCC = 5.0V ±10%

Parameter Minimum Typical Maximum Units

Resolution 8 Bits

Integral non-linearity 0.25 1 LSB

Differential non-linearity 0.25 0.5 LSB

Setting time, 1/2 LSB 1.5 3.0† µsec

Zero Error at 25°C1020mV

Full Scale error at 25°C 1 2 % FSR

Supply Range 4.5 5.0 5.5 Volts

Power dissipation, no load 50 85 mW

Ref Input resistance 2K 4K 10K Ohms

Output noise voltage 50 µVp-p

VDHI range at 5 volts 2.6 3.5 Volts

VDLO range at 5V volts 0.8 1.7 Volts

VDHI–VDLO, at 5V volts 0.9 2.7 Volts

Capacitive output load, CL 30 pF

Resistive output load, RL 20K Ohms

Output slew rate 1.0 3.0 V/µsec

Notes:

Voltage: 4.5V - 5.5V

Temp: 0-70°C

† The C84 Emulator has maximum setting time of 20 µsec. (10 µsec. typical).

14 DS96DZ80203

Z86C83/C84

Z8® MCU Microcontrollers

AC ELECTRICAL CHARACTERISTICS (Continued)

Table 7. A/D Converter Electrical Characteristics

VCC = 3.3V ± 10%

Parameter Minimum Typical Maximum Units

Resolution 8 Bits

Integral non-linearity 0.5 1 LSB

Differential non-linearity 0.5 1 LSB

Zero Error at 25°C 5.0 mV

Supply Range 3.0 3.3 3.6 Volts

Power dissipation, no load 20 40 mW

Clock frequency 24 MHz

Input voltage range VA

LO

VA

HI

Conversion time 4.3 35 X SCLK µsec

Input capacitance on ANA 25 40 pF

VAHI range VA

range AN

VA

LO

VAHI -–VA

Notes:

Voltage: 3.0V to 3.6V

Temp: 0-70°C

SCLK = System Clock on Bus Speed.

LO

+2.5 AV

LO

GND

AVCC–2.5 Volts

2.5 AV

CC

CC

Volts

Volts

Volts

Table 8. A/D Converter Electrical Characteristics

VCC = 5.0V ±10%

Parameter Minimum Typical Maximum Units

Resolution 8 Bits

Integral non-linearity 0.5 1 LSB

Differential non-linearity 0.5 1 LSB

Zero Error at 25°C 45 mV

Supply Range 4.5 5.0 5.5 Volts

Power dissipation, no load 50 85 mW

Clock frequency 33 MHz

Input voltage range VA

LO

VA

HI

Volts

Conversion time 4.3 35 X SCLK µsec

Input capacitance on ANA 25 40 pF

VAHI range VA

VALO range AN

-–VA

VA

HI

Notes:

Voltage: 4.5V –5.5V

Temp: 0-70°C

Conversion time is defined as the time from initiation of A-D conversion to storage of the digital result in the ADR register.

SCLK = System Clock on Bus Speed.

LO

+2.5 AV

LO

GND

AVCC–2.5 Volts

2.5 AV

CC

CC

Volts

Volts

15 DS96DZ80203

Z86C83/C84

Z8® MCU Microcontrollers

PIN FUNCTIONS

Application Precaution

The production test-mode environment may be enabled

accidentally during normal operation if

surges above V

occur on the /RESET pin.

cc

Recommendations for dampening voltage surges in both

test and OTP mode include the following:

■ Using a clamping diode to /RESET

■ Adding a capacitor to the affected pin

XTAL1.

Crystal 1

(time-based input). This pin connects a

parallel-resonant crystal, ceramic resonator, LC network

or an external single-phase clock to the on-chip oscillator

input.

XTAL2.

Crystal 2

(time-based output). This pin connects a

parallel-resonant crystal, ceramic resonator, LC network to

the on-chip oscillator output.

Port 0 P00-P06.

Z86C84).

Port 0 is a 7-bit, bidirectional, CMOS-compatible

(P03-P06 is not available on the

I/O port. These seven I/O lines can be nibble

programmable as P00-P03 input/output and P04-P06

input/output, separately (Figure 10). All input buffers are

Schmitt-triggered and output drivers are push-pull. There

is a ROM mask option to enable 100K (±40%) pull-up

resistors to Port 0, P00 to P02.

excessive noise

Port 2 (P27-P20) Port 2 is an 8-bit, bi-directional, CMOS-

compatible I/O port and an 8-channel muxed input to the

8-bit ADC. When configured as a digital input, by

programming the Port2 Mode register, the Port 2 register

can be evaluated to read digital data applied to Port 2, or

the ADC result register can be read to evaluate the analog

signals applied to Port 2 after configuring the ADC Control

Registers. The direction of each of the eight Port 2 I/O lines

can be configured individually (Figure 11).

In addition, all four versions of the device provide the

capability of connecting 10K (±20%) pull-up resistors to

each of the Port 2 I/O lines individually. The pull-ups are

connected when activated through software control of

P2RES register (Figure 67) when the corresponding Port

2 pin is configured to be an input. The pull-up resistor of a

Port 2 I/O line is automatically disabled when the

corresponding I/O is an output, regardless of the state of

the corresponding P2RES bit value.

Note: The Z86C83/C84 Emulator does not emulate the

P2RES Register. Selection of the pull-ups are done via

jumper settings on the emulator.

Port 0 Auto Latch.

(Auto Latch Mask Option available

only on P00-P02. P03-P06 has the Auto Latches

permanently enabled.)

The Auto Latch provides valid

CMOS Levels when P00-P06 (P00-P02 on C84) are

selected as inputs and not externally driven. It is

impossible to determine if a non-driven input is 1 or 0,

however; the Auto Latch will sense the input condition and

drive a valid CMOS level, thereby eliminating a floating

mode that could cause excessive current. (Auto Latch is a

ROM mask option for the Z86C83, Z86C84).

16 DS96DZ80203

Z86C83/C84

Z8® MCU Microcontrollers

PIN FUNCTIONS (Continued)

Port 0 (I/O)

/OEN

Out

In

1.5 2.3 Hysteresis

R 500 kΩ

100K

ROM Mask Pull-Up Option

(P00-P02 only)

Pad

Notes:

Auto Latch

C83/E83: P00-P02 Mask Option

P03-P06 Permanent

C84/E84: P00 - P02 Mask Option

Figure 10. Port 0 Configuration

17 DS96DZ80203

Z86C83/C84

Z8® MCU Microcontrollers

P27

P26

P25

/OEN

/C83

/C84

/E84

Data

P24

P23

P22

P21

P20

Input_en

Select from

P2RES

Port 2 (I/O)

10K

Pad

P2

Analog Mux

ADC

ADC0 (Bits 7, 6, 5)

Figure 11. Port 2 Configuration

18 DS96DZ80203

Z86C83/C84

Z8® MCU Microcontrollers

PIN FUNCTIONS (Continued)

Port 3 (P37-P30). Port 3 is a 6-bit, CMOS-compatible

port, with three fixed inputs (P33-P31) and three fixed

outputs (P34-P36), configured under software control for

Input/Output, Counter/Timers, interrupt, and port

handshake. P31, P32, and P33 are standard CMOS inputs

(no Auto Latches). Pins P34, P35, and P36 are push-pull

output lines (Figure 11). Low EMI output buffers can be

globally programmed by the software.

Two on-board comparators can process analog signals on

P31 and P32 with reference to the voltage on P33. The

analog function is enabled by programming Port 3 Mode

Register (P3M bit 1). For Interrupt functions, Port 3, pin 3

is falling-edge interrupt input. P31 and P32 are

programmable as rising, falling, or both edge triggered

interrupts (IRQ register bits 6 and bit 7). P33 is the

comparator reference voltage input when in Analog Mode.

Access to Counter/Timers 1 is made through P31 (T

P36 (T

). Handshake lines for Ports 0 and 2 are available

OUT

) and

IN

on P31/P36 and P32/P35 (Table 9).

Port 3 also provides the following control functions:

handshake for Ports 0 and 2 (/DAV and RDY); three

external interrupt request signals (IRQ2-IRQ0); timer input

and output signals (TIN and T

OUT

).

Table 9. Port 3 Pin Assignments

Pin I/O CTC1 Analog Int. P0 HS P2 HS

P31 IN T

AN1 IRQ2 D/R

IN

P32 IN AN2 IRQ0 D/R

P33 IN REF IRQ1

P34 OUT AN1-OUT

P35 OUT R/D

P36 OUT T

Notes:

HS = Handshake Signals

D = /DAV

R = RDY

OUT

R/D

Auto Latch. The Auto-Latch instruction puts valid CMOS

levels on all CMOS inputs (except P33-P31) that are not

externally driven. Whether this level is 0 or 1, cannot be

determined. A valid CMOS level, rather than a floating

node, reduces excessive supply current flow in the input

buffer.

Notes:

1. Deletion of Port Auto Latches is available as a ROM

mask option. The Auto Latch Delete option is selected

by the customer when the ROM code is submitted.

2. Ports 03, 04, 05, 07 have permanently enabled Auto

Latches.

Comparator Inputs. Port 3, P31 and P32, each have a

comparator front end. The comparator reference voltage,

P33, is common to both comparators. In analog mode, the

P33 input functions as a reference voltage to the

comparators. In Analog Mode, the internal P33 register

and its corresponding IRQ1 is connected to the Stop-Mode

Recovery source selected by the SMR register. In this

mode, any of the Stop-Mode Recovery sources are used

to toggle the P33 bit or generate IRQ1. In Digital Mode,

P33 can be used as a Port 3 register input or IRQ1 source.

P34 outputs the comparator outputs by software

programming the PCON Register bit D0 to 1.

19 DS96DZ80203

Z86C83/C84

Z8® MCU Microcontrollers

P36

P35

Z86C83/C84

P31 (AN1)

P32 (AN2)

P33 (REF)

P34

P33

P32

P31

+

-

+

-

Port 3

R247 = P3M

DIG.

AN

D1

Port 3 (I/O)

1 = Analog

0 = Digital

IRQ2, T

, P31 Data Latch

IN

IRQ0, P32 Data Latch

From Stop-Mode Recovery

IRQ1, P33 Data Latch

Source

Figure 12. Port 3 Input Configuration

20 DS96DZ80203

Z86C83/C84

Z8® MCU Microcontrollers

PIN FUNCTIONS (Continued)

Port Configuration Register (PCON). The PCON con-

figures the ports individually for comparator output on Port

3. The PCON Register is located in the Expanded Register

File at Bank F, location 00 (Figure 13).

Bit 0 multiplexes comparator AN1 Output at P34. A "1" in

this location brings the comparator output to P34

PCON (F) 00

D7 D6 D5 D4 D3 D2 D1 D0

(Figure 14), and a "0" puts P34 into its standard I/O

configuration.

Note: Only comparator output AN1 is multiplexed to a

Port 3 output. Comparator AN2 output is not connected to

any pins. Note that the PCON Register is reset upon the

occurrence of a WDT RESET (not in Stop Mode), and

Power-On Reset (POR).

Comparator

Output Port 3

0 P34 Standard Output

*

1 P34 Comparator Output

Reserved (Must be 1.)

0 Port 0 Open-Drain

1 Port 0 Push-Pull*

P31

Figure 13. Port Configuration Register (PCON) (Write-Only)

P34 OUT

REF (P33)

Reserved (Must be 1.)

* Default setting from Stop-Mode Recovery,

Power-On Reset, and any WDT Reset.

Normal

0 P34 Standard Output

1 P34 Comparator Output

Reset Condition

*

*

+

-

AN1

PCON

D0

P34

PAD

Figure 14. Port 3 P34 Output Configuration

21 DS96DZ80203

Z86C83/C84

Z8® MCU Microcontrollers

FUNCTIONAL DESCRIPTION

RESET.

(Input, Active Low)

. This pin initializes the MCU.

Reset is accomplished either through Power-On Reset

(POR), Watch-Dog Timer (WDT) Reset, or external reset.

During POR, and WDT Reset, the internally generated

reset is driving the reset pin Low for the POR time.

Any

devices driving the reset line must be open-drain to

avoid damage from a possible conflict during reset

conditions.

Pull-up is provided internally.

After the POR time, /RESET is a Schmitt-triggered input.

After the reset is detected, an internal RST signal is

latched and held for an internal register count of 18

external clocks, or for the duration of the external reset,

whichever is longer. Program execution begins at location

000C (hex), 5-10 TpC cycles after the RST is released. For

POR, the reset output time is T

POR

.

Program Memory. C83/C84 can address up to 4 KB of

internal Program Memory (Figure 15). The first 12 bytes of

program memory are reserved for the interrupt vectors.

These locations contain six 16-bit vectors that correspond

to the six available interrupts. Bytes 13 to 4095 consist of

on-chip, mask-programmed ROM.

ROM Protect. The 4 KB of Program Memory is mask

programmable. A ROM protect feature will prevent

dumping of the ROM contents from an external program

outside the ROM.

Expanded Register File. The register file has been

expanded to allow for additional system control registers

and for mapping of additional peripheral devices and

input/output ports into the register address area. The Z8

register address space R0 through R15 is implemented as

16 groups of 16 registers per group (Figure 16). These

register banks are known as the Expanded Register File

(ERF). Bits 3-0 of the Register Pointer (RP) select the

active ERF bank. Bits 7-4 of register RP select the working

register group (Figure 17). Four system configuration

registers reside in the ERF address space in Bank F and

eight registers reside in Bank C. The rest of the ERF

addressing space is not physically implemented, and is

open for future expansion.

Note: When using Zilog's Cross Assembler version 2.1 or

earlier, use the LD RP, #0X instruction rather than the SRP

#0X instruction to access the ERF.

2048/4096

Location of

First Byte of

On-Chip

ROM

Instruction

Executed

After RESET

Interrupt

Vector

(Lower Byte)

Interrupt

Vector

12

11

10

IRQ5

IRQ5

9

8

7

6

5

4

3

IRQ4

IRQ4

IRQ3

IRQ3

IRQ2

IRQ2

IRQ1

(Upper Byte)

2

1

0

IRQ1

IRQ0

IRQ0

Figure 15. Program Memory Map

22 DS96DZ80203

Z86C83/C84

Z8® MCU Microcontrollers

FUNCTIONAL DESCRIPTION (Continued)

\

101

UUUU00

RESET CONDITION

U

U

UUU 0 1

00100000

1

1

1

1

1

1

1

1

RESET CONDITION

UUUUUUU

UUUUUU0

U

U

UUU

U

UU

UU

UUU0U

UUU1U

UUUUUU

UUUUUUUUU1U

UUU

UUU

U

UUU

0

0

000

0UUU

UUUU

0

0

0

UUUUUUU

1U0

U

0000

0

000UUU

0

00

0

0

U

U

UUUUUU

UUUUUU

UUUUUU

U

UUU

Reserved

WDTMR

STANDARD CONTROL REGISTERS

®

Z8

(F) 0F

REGISTER**

EXPANDED REG. GROUP (F)

*

(F) 0E

SMR2

Reserved

Reserved

SMR

(F) 0D

(F) 0C

(F) 0A

(F) 0B

†

REGISTER POINTER

6543210

7

Reserved

Reserved

Reserved

Reserved

(F) 09

(F) 08

(F) 07

(F) 06

Group Pointer

Expanded Register

Z8 Register File**

Group Pointer

Working Register

Reserved

(F) 05

FF

FO

Reserved

(F) 04

Reserved

(F) 03

Reserved

(F) 02

Reserved

(F) 01

PCON

(F) 00

*

ADR1

Reserved

Reserved

(C) 0E

(C) 0D

Reserved

Reserved

(C) 0C

(C) 0B

EXPANDED REG. GROUP (C)

REGISTER

Reserved

(C) 0F

Reserved

Reserved

RESET CONDITION

7F

0F

00

EXPANDED REG. GROUP (0)

REGISTER**

ADC1

(C) 09

(C) 0A

*

UU

UUUUUU

U1 1 1U U

UU

P3

P2

(0) 03

(0) 02

*

*

*

U

UUU

UU

UU

(0) 01 P1

ADC0

(C) 08

*

UU

UUU

U

U

U

P0

(0) 00

DAC2

(C) 07

*

DAC1

(C) 06

*

DACR1

DACR2

(C) 04

(C) 05

*

*

P2RES

(C) 03

*

Reserved

Reserved

(C) 02

(C) 01

Reserved

(C) 00

T1

TMR

U

UU

U

UU

U

UU

UUUU

UUU

Reserved

F0

0

00

00

000000

U

0

0

0U

U = Unknown

Notes:

* Will not be reset with a Stop--Mode Recovery

** All addresses are in Hexadecimal

† Will not be reset with a Stop-Mode Recovery, except Bit 0.

GPR

SPL

RP

FFFEFDFCFBFAF9

REGISTER**

0

0

0

D0

D3 D2 D1

D5 D4

RESET CONDITION

D7 D6

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

FLAGS

U

U

U

U

U

U

U

U

IMR

IRQ

U0U

U0U

U0U

U0U

0

U

0

U

U0U

0

0

IPR

P01M

P3M

P2M

P0T0P1

F7

1

1

1

0

0

F5F4F3F2F1

F6

*

*

0

1

0

1

0

1

0

1

0

1

0

1

0

1

1

0

U

U

U

UU

UUU

U

UUUUU

UU

F8

0

U

U

0

1

U

Figure 16. Expanded Register File Architecture

23 DS96DZ80203

Z86C83/C84

Z8® MCU Microcontrollers

RPR253

D7 D6 D5 D4 D3 D2 D1 D0

Note: Default Setting After Reset = 00000000

Expanded Register Group

Working Register Group

r7 r6 r5 r4

The upper nibble of the register file address

provided by the register pointer specifies

the active working-register group.

FF

F0

r3 r2 r1 r0

R253

(Register Pointer)

R15 to R0

Figure 17. Register Pointer Register

Register File. The Register File consists of three I/O port

registers, 237 general-purpose registers, 15 control and

status registers, and four system configuration registers in

the Expanded Register Group (Figure 16). The

instructions can access registers directly or indirectly

through an 8-bit address field. This allows a short 4-bit

register address using the Register Pointer (Figure 18). In

the 4-bit mode, the Register File is divided into 16 working

register groups, each occupying 16 continuous locations.

The Register Pointer addresses the starting location of the

active working-register group.

Note: Register Bank E0-EF is only accessed through

working registers and indirect addressing modes.

CAUTION: D4 of Control Register P01M (R251) must

be 0.

7F

70

6F

60

5F

50

4F

40

3F

30

2F

20

1F

10

0F

00

* Expanded Register File Bank (0) is selected

in this figure by handling bits D3 to D0 as "0"

in Register R253 (RP).

Specified Working

Register Group

Register Group 1

Register Group 0*

I/O Ports*

Figure 18. Register Pointer

The lower nibble

of the register

file address

provided by the

instruction points

to the specified

register.

R15 to R0

R15 to R4*

R3 to R0*

R254. The C83/C84 has one extra general-purpose

register located at FEH (R254). It is set to 00H after any

reset.

Stack. The C83/C84 has an 8-bit Stack Pointer (R255)

used for the internal stack that resides within the 236

general-purpose registers. Register R254 cannot be used

for stack.

General-Purpose Registers (GPR). These registers are

undefined after the device is powered up. The registers

keep their last value after any reset, as long as the reset

occurs in the V

voltage-specified operating range. It will

CC

not keep its last state from a VLV reset if the VCC drops below

RAM Protect. The upper portion of the RAM’s address

spaces %80F to %EF (excluding the control registers) are

protected from reading and writing. The RAM Protect bit

option is mask-programmable and is selected by the

customer when the ROM code is submitted. After the mask

option is selected, the user activates this feature from the

internal ROM code to turn off/on the RAM Protect by

loading either a 0 or 1 into the Interrupt Mask (IMR)

register, bit D6. A 1 in D6 enables RAM Protect.

1.8V. This includes Register R254.

Note: Register Bank E0-EF is only accessed through

working register and indirect addressing modes.

24 DS96DZ80203

Z86C83/C84

Z8® MCU Microcontrollers

FUNCTIONAL DESCRIPTION (Continued)

Counter/Timers. There are two 8-bit programmable

counter/timers (T0-T1), each driven by its own 6-bit

programmable prescaler. The T1 prescaler is driven by

internal or external clock sources; however, the T0

prescaler is driven by the internal clock only (Figure 19).

The 6-bit prescalers can divide the input frequency of the

clock source by any integer number from 1 to 64. Each

prescaler drives its counter, which decrements the value

(1 to 256) that has been loaded into the counter. When the

counter reaches the end of the count, a timer interrupt

request, IRQ4 (T0) or IRQ5 (T1), is generated.

The counters can be programmed to start, stop, restart to

continue, or restart from the initial value. The counters can

OSC

D1 (SMR)

Write Write Read

÷2

Initial Value

D0 (SMR)

also be programmed to stop upon reaching zero (single

pass mode) or to automatically reload the initial value and

continue counting (modulo-n continuous mode).

The counters,

but not the prescalers

, are read at any

time without disturbing their value or count mode. The

clock source for T1 is user-definable and is either the

internal microprocessor clock divide-by-four, or an

external signal input through Port 3. The Timer Mode

register configures the external timer input (P31) as an

external clock, a trigger input that can be retriggerable or

non-retriggerable, or as a gate input for the internal clock.

The counter/timers can be cascaded by connecting the T0

output to the input of T1. T

Mode is enabled by setting

IN

R243 PRE1 Bit D1 to 0.

Internal Data Bus

PRE0

Register

T0

Initial Value

Register

T0

Current Value

Register

÷16

Clock

Logic

TIN P31

Internal

Clock

External Clock

÷4

Internal Clock

Gated Clock

Triggered Clock

Figure 19. Counter/Timer Block Diagram

÷4

Write Write Read

6-Bit

Down

Counter

6-Bit

Down

Counter

PRE1

Initial Value

Register

8-bit

Down

Counter

8-Bit

Down

Counter

T1

Initial Value

Register

Internal Data Bus

÷2

Current Value

Register

IRQ4

TOUT

P36

IRQ5

T1

25 DS96DZ80203

Z86C83/C84

Z8® MCU Microcontrollers

Interrupts. The Z8 has six different interrupts from six

different sources. These interrupts are maskable,

prioritized (Figure 20) and the six sources are divided as

follows: four sources are claimed by Port 3 lines P33-P30,

and two in counter/timers (Table 10). The Interrupt Mask

Register globally or individually enables or disables the six

interrupt requests.

IRQ1, 3, 4, 5

When more than one interrupt is pending, priorities are

resolved by a programmable priority encoder that is

controlled by the Interrupt Priority register. An interrupt

machine cycle is activated when an interrupt request is

granted. This action disables all subsequent interrupts,

saves the Program Counter and Status Flags, and then

branches to the program memory vector location reserved

for that interrupt.

IRQ0 IRQ2

Interrupt

Edge

Select

IRQ

IRQ (D6, D7)

IMR

6

Global

Interrupt

Enable

Interrupt

Request

IPR

PRIORITY

LOGIC

Vector Select

Figure 20. Interrupt Block Diagram

Table 10. Interrupt Types, Sources, and Vectors

Name Source Vector Location Comments

IRQ0 /DAV0, IRQ0 0, 1 External (P32), Rise/ Fall Edge Triggered

IRQ1, IRQ1 2, 3 External (P33), Fall Edge Triggered

IRQ2 /DAV2, IRQ2, T

IN

4, 5 External (P31), Rise /Fall Edge Triggered

IRQ3 IRQ3 6, 7 By User Software

IRQ4 T0 8, 9 Internal

IRQ5 T1 10, 11 Internal

26 DS96DZ80203

Z86C83/C84

Z8® MCU Microcontrollers

FUNCTIONAL DESCRIPTION (Continued)

All Z8 interrupts are vectored through locations in the

program memory. This memory location and the next byte

contain the 16-bit address of the interrupt service routine

for that particular interrupt request. To accommodate

polled interrupt systems, interrupt inputs are masked and

the Interrupt Request register is polled to determine which

of the interrupt requests need service.

An interrupt resulting from AN1 is mapped into IRQ2, and

an interrupt from AN2 is mapped into IRQ0. Interrupts

IRQ2 and IRQ0 may be rising, falling, or both edge

triggered, and are programmable by the user. The

software may poll to identify the state of the pin.

Programming bits for the Interrupt Edge Select is located

in the IRQ Register (R250), bits D7 and D6. The

configuration is shown in Table 11.

Table 11. IRQ Register

IRQ Interrupt Edge

D7 D6 P31 P32

00 F F

01 F R

10 R F

1 1 R/F R/F

Notes:

F = Falling Edge

R = Rising Edge

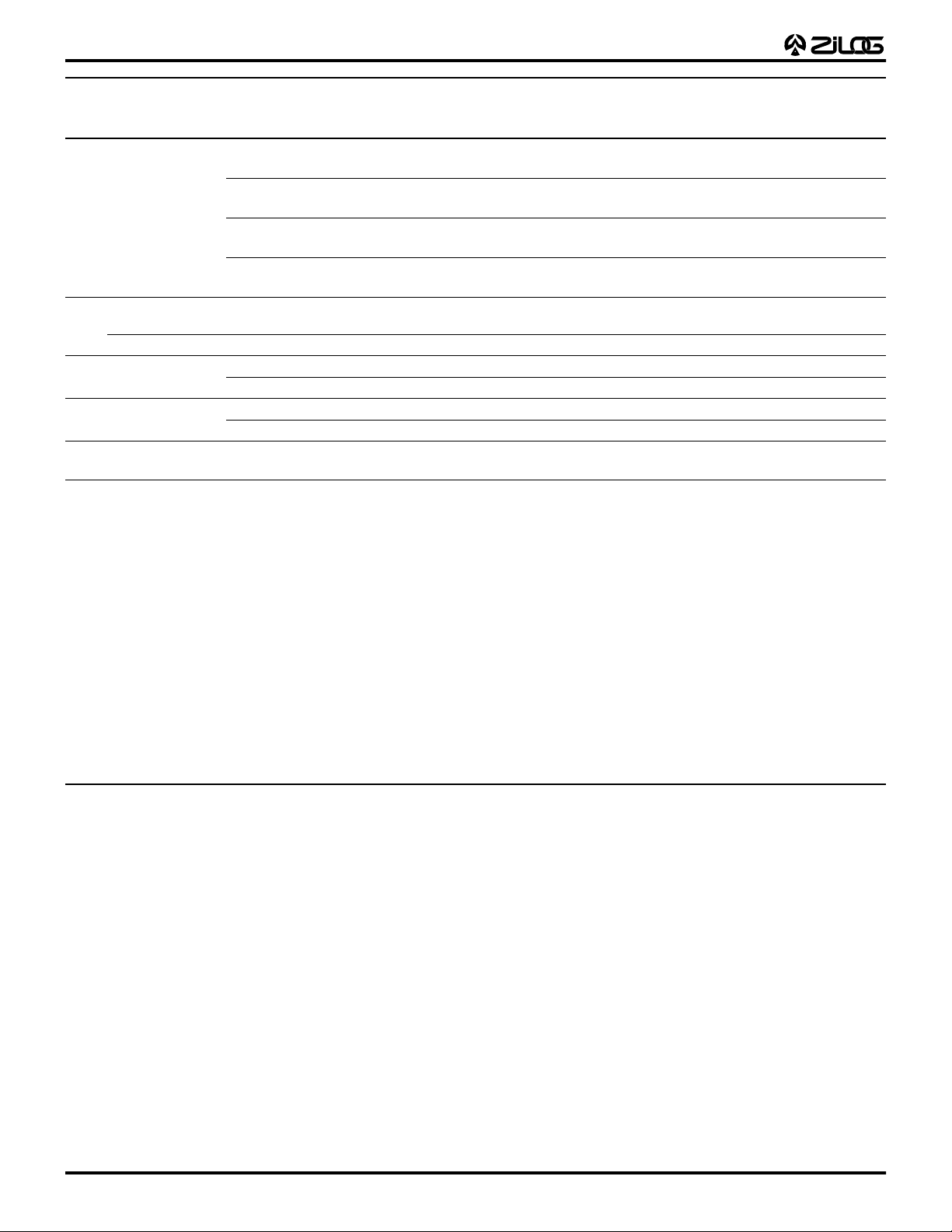

Clock. The Z8 on-chip oscillator has a high-gain, parallelresonant amplifier for connection to a crystal, LC, RC,

ceramic resonator, or any suitable external clock source

(XTAL1 = Input, XTAL2 = Output). The crystal should be

AT cut, 16 MHz max., with a series resistance (RS) of less

than or equal to 100 Ohms when clocking from 1 MHz to

16 MHz.

The crystal should be connected across XTAL1 and

XTAL2 using the vendor's recommended capacitor values

from each pin directly to the device Ground pin to reduce

Ground noise injection into the oscillator.

Note: For better noise immunity, the capacitors should be

tied directly to the device Ground pin (V

).

SS

XTAL1

C1

VSS* *

XTAL2

C2

VSS* *

Ceramic Resonator or

Crystal

C1, C2 = 47 pF TYP *

f = 8 MHz

* Preliminary value including pin parasitics

* * Device ground pin

VSS* *

VSS* *

C1

C2

LC

C1, C2 = 22 pF

L = 130 uH *

f = 3 MHz *

L

XTAL1

XTAL2

XTAL1

XTAL2

External Clock

Figure 21. Oscillator Configuration

27 DS96DZ80203

Z86C83/C84

Z8® MCU Microcontrollers

Analog-to-Digital Converter

The Analog-to-Digital (ADC) is an 8-bit half flash converter

that uses two reference resistor ladders for its upper 4 bits

(MSBs) and lower 4 bits (LSBs) conversion. Two reference

voltage pins, AVCC and A

reference voltage supplies. During the sampling period

from one of the eight channel inputs, the converter is also

being auto-zeroed before starting the conversion. The

conversion time is dependent on the internal clock

frequency. The minimum conversion time is 35 X

SCLK(see Figure 22).

The ADC is controlled by the Z8® and its three registers

(two Control and one Result) are mapped into the

Extended Register File. A conversion can be initiated by

writing to the ADC Control Register 0 after the ADC

Control Register 1 is configured.

The start command is implemented in such a way as to

begin a conversion at any time, if a conversion is in

progress and a new start command is received, then the

conversion in progress will be aborted and a new

conversion will be initiated. This allows the programmed

values to be changed without affecting a conversion-in-

, are provided for external

GND

progress. The new values will take effect only after a new

start command is received.

The ADC can be disabled (for low power) or enabled by a

Control Register bit.

Though the ADC will function for a smaller input voltage

and voltage reference, the noise and offsets remain

constant over the specified electrical range. The errors of

the converter will increase and the conversion time may

also take slightly longer due to smaller input signals.

ADC Calibration Offset

Specially matched resistors are program-enabled to allow

35.0 percent or 50 percent offset from A

selectively enable these resistors to offset the A

percent (2.5V to 5V) or 50 percent (1.75V to 5V) thereby

allowing the 8-bit ADC across a narrower voltage range.

This will allow significant resolution improvement within

the reduced voltage range.

Note: The AV

must be the same value as VCC and A

CC

must be the same value as GND.

. They may

GND

by 35.0

GND

GND

EXT

Start

A/D

Control

88

8

Reg.

ADC0

A/D

Result

Reg.

8

ADR1

A/D

Control

Reg.

ADC1

Converter

Vref +

A/D

Converter

Vref GND

Selected

Channel

Vcc

Sample

and

Hold

4

ADC Register

9

D4, D5

AV

CC

A

GND

Calibration Offset

Figure 22. ADC Architecture

28 DS96DZ80203

Z86C83/C84

Z8® MCU Microcontrollers

FUNCTIONAL DESCRIPTION (Continued)

ADC0 (A) Bank C, Register 8

D7 D6 D5 D4 D3 D2 D1 D0

CSEL0

CSEL1

CSEL2

SCAN

0 = No action. *

1 = Convert, then stop.

AIN/Input/Output Control

0 = No action *

1 = Enable selected channel

(D

on associated Port 20-27

Must be D7 = 0

* Default After Reset

D6 = 0

D5 = 1

Figure 23. ADC Control Register 0 (Read/Write)

2,D1,D0

) as analog input

ADE (bit 7). A zero disables any A/D conversions or

accessing any ADC registers except writing to ADE bit. A

one Enables all ADC accesses. ADC result register is

shown in Figure 25.

ADR Bank C, Register A

D7 D6 D5 D4 D3 D2 D1 D0

Data

Figure 25. Result Register (Read-Only)

SCAN

0 No action*

1 Convert channel then stop

Channel Select (bits 2, 1, 0).

CSEL2 CSEL1 CSEL0 Channel

0 0 0 0 (P20)*

0 0 1 1 (P21)

0 1 0 2 (P22)

0 1 1 3 (P23)

1 0 0 4 (P24)

1 0 1 5 (P25)

1 1 0 6 (P26)

1 1 1 7 (P27)

Note: *The desired P2 bit must be set equal 1 to allow Port bit

ias ADC input.

ADC1 Bank C, Register 9

D7 D6 D5 D4 D3 D2 D1 D0

Reg F

Reg E

Reg D

Reg C

Reg B

Reg A

Reg 9

AD Result 1

AD Control 1

Reg 8 AD Control 0

Reg 7

Reg 6

Reg 5

Reg 4

Reg 3

Reg 2

Reg 1

Reg 0

Figure 26. Bank C

These registers

can be accessed.

Must be 0.

D5 D4

0 0 50 % AGND Offset

1 0 35% AGND Offset

0 1 Reserved

1 1 No Offset

Reserved (Must be 1.)

ADE

0 Disable*

1 Enable

Figure 24. ADC Control Register 1 (Read/Write)

29 DS96DZ80203

Z86C83/C84

Z8® MCU Microcontrollers

Figure 27 shows the input circuit of the ADC. When

conversion starts the analog input voltage is connected to

the MSB and LSB flash converter inputs as shown in the

Input Impedance CKT diagram. Effectively, shunting 31

parallel internal resistance of the analog switches and

simultaneously charging 31 parallel 0.5 pF capacitors,

which is equivalent to seeing a 400 Ohms input impedance

CMOS Switch

on Resistance

2 - 5 k Ω

V Ref

R Source

V Ref

C Parasitic

in parallel with a 16 pF capacitor. Other input stray

capacitance adds about 10 pF to the input load. For input

source resistances up to 2 kOhms can be used under

normal operating condition without any degradation of the

input settling time. For larger input source resistance,

longer conversion cycle time may be required to

compensate the input settling time problem.

C .5 pF

31 CMOS Digital

C .5 pF

Comparators

V Ref

Figure 27. Input Impedance of ADC

Typical Z8 A/D Conversion Sequence

1. Set the register pointer to Extended Bank (C),that is,

SRP #%0C instruction.

2. Next, set ADE flag by loading ADC1 Control Register

Bank (C) Register 9, bit 7. Also, load bits 0-4 of this

same register to select a AVCC or A

precision voltage divider connected to the A/D

resistive ladder can offset conversion dynamic range

to specified limits within the AV

loading Bank (C) Register 9, bits 0-4, with the

appropriate value it is possible to select from these

groups:

a. No Offset. The Converter Dynamic range is from

0V to 5.0V for AVCC = 5.0V.

offset value. A

GND

and A

CC

limits. By

GND

C .5 pF

3. Select one of the eight A/D inputs for conversion by

loading Bank (C) Register 8 with the desired attributes:

Bits 0 - 2 select an A/D input, bits 3 and 4 select A/D

conversion (or digital port I/O).

4. Set Bank (C) Register 8, bit 3 to enable A/D

conversion. (This flag can be set concurrently with

step 3.) This flag is automatically reset when the A/D

conversion is completed, so a bit test can be

performed to determine A/D readiness if necessary.

5. Read the A/D result in Bank (C) Register A. Please

note that the A/D result is not valid (indeterminate)

unless ADE flag (Register 9, bit 7) was previously set,

otherwise A/D converter output is tri-stated.

b. 35 Percent A

Offset. The Converter Dynamic

GND

range is 1.75V - 5.0V for AVCC = 5.0V.

c. 50 Percent A

Offset. The Converter Dynamic

GND

range is 2.5V - 5.0V for AVCC = 5.0V.

30 DS96DZ80203

Z86C83/C84

Z8® MCU Microcontrollers

FUNCTIONAL DESCRIPTION (Continued)

Digital-to-Analog Converters

The Z86C84 has two Digital-to-Analog Converters

(DACs). Each DAC is an 8-bit resistor string, with a

programmable 0.25X, 0.5X, or 1X gain output buffer. The

DAC output voltage settles after the internal data is latched

into the DAC Data register. The top and bottom ends of the

resistor ladder are register-selected to be connected to

either the analog supply rails, AVCC and A

externally-provided reference voltages, VDHI and VDLO.

External references are recommended to explicitly set the

DAC output limits. Since the gain stage cannot drive to the

, or two

GND

supply rails, VDHI and VDLO must be within ranges shown

in the specifications. If either reference approaches the

analog supply rails, the output will be unable to span the

reference voltage range. The externally provided

reference voltages should not exceed the supply voltages.

The DAC outputs are latch-up protected and can drive

output loads (Figure 28).

Note: The AVCC must be the same value as VCC and A

must be the same value as GND

VDHI

GND

PAD

Data

Bus

AVCC

8

8

DACn

Data

Register

DACRn

Control

Register

(n = 1 or 2)

8

Figure 28. DAC Block Diagram

High

8-Bit

Resistor

Ladder

Low

Note:

* DACRn Control Register Bits

Analog

+

-

AGND

Programmable

Gain

* Bits 0, 1

DAC1

or

DAC2

PAD

PAD

VDLO

31 DS96DZ80203

Z86C83/C84

Z8® MCU Microcontrollers

The D/A conversion for DAC1 is driven by writing 8-bit data

to the DAC1 data register (Bank C, Register 06H). The

D/A conversion for DAC 2 is controlled by the DAC2 data

register (Bank C, Register 07H). Each DAC data register

is initialized to midrange 80H on power-up.

There are two DAC control registers: DACR1 (Bank C,

Register 04H) for DAC1, and DACR2 (Bank C, Register

05H) for DAC2. Control register bits 0 and 1 set the DAC

gain. When DAC data is 80H, the DAC output is constant

for any gain setting (Figure 29 and Figure 31).

DACR1 Bank C, Register 4

D7 D6 D5 D4 D3 D2 D1 D0

DACR2 Bank C, Register 5

D7 D6 D5 D4 D3 D2 D1 D0

DAC2 Gain

0 0 1 X

0 1 1/2 X

1 0 1 Not Used

1 1 1/4 X

DAC2 Enable

0 Disable

1 Enable

Reserved (Must be 0)

Figure 31. D/A 2 Control Register

Figure 29. D/A 1 Control Register

DAC1 Bank C, Register 6

D7 D6 D5 D4 D3 D2 D1 D0

0 = Low Level

1 = High Level

Figure 30. D/A 1 Data Register

DAC1 Gain

0 0 1 X

0 1 1/2 X

1 0 1 Not Used

1 1 1/4 X

DAC1 Enable

0 Disable

1 Enable

Reserved (Must be 0)

AC2 Bank C, Register 7

D7 D6 D5 D4 D3 D2 D1 D0

= Low Level

= High Level

Figure 32. D/A 2 Data Register

32 DS96DZ80203

Z86C83/C84

Z8® MCU Microcontrollers

FUNCTIONAL DESCRIPTION (Continued)

DAC Output in Volts

3.5V

VDHI

2% accuracy

2.15

1.7

1.26

.8VDLO

1/4X

1/2X

0 80H

Notes:

Vcc = 5.0V ±10%

VDHI = 3.5V

VDLO = 0.8V

1X

3.5

3.05

2.6

2.15

FFH

DAC Data Register Value

Figure 33. Gain Control on DAC

Power-On Reset (POR). A timer circuit clocked by a

dedicated on-board RC oscillator or by the XTAL oscillator

is used for the POR timer function. The POR time allows

VCC and the oscillator circuit to stabilize before instruction

execution begins. The POR timer circuit is a one-shot timer

triggered by one of three conditions:

■ Power Fail to Power OK Status

■ Stop-Mode Recovery (If D5 of SMR Register = 1)

■ WDT Time-Out (Including from Stop Mode)

The POR time is T

minimum. Bit 5 of the STOP Mode

POR

Register determines whether the POR timer is bypassed

after Stop-Mode Recovery (typical for external clock, and

RC/LC oscillators with fast start up time).

HALT. Turns off the internal CPU clock but not the XTAL

oscillation. The counter/timers and external interrupts

IRQ0, IRQ1, and IRQ2 remain active. The device is

recovered by interrupts, either externally or internally

generated (a POR or a WDT time-out). An interrupt

request must be executed (enabled) to exit HALT mode.

After the interrupt service routine, the program continues

from the instruction after the HALT. In case of a POR or a

WDT time-out, program execution will restart at address

000CH.

STOP. This instruction turns off the internal clock and

external crystal oscillation and reduces the standby

current to 10 µA (typical) or less. The STOP mode is

terminated by a reset of either WDT time-out, POR, or

Stop-Mode Recovery. This causes the processor to restart

the application program at address 000CH.

33 DS96DZ80203

Z86C83/C84

Z8® MCU Microcontrollers

In order to enter STOP (or HALT) mode, it is necessary to

first flush the instruction pipeline to avoid suspending

execution in mid-instruction. To do this, the user must

execute a NOP (opcode = FFH) immediately before the

appropriate sleep instruction, that is,

FF NOP ; clear the pipeline

6F STOP ; enter STOP mode

or

FF NOP ; clear the pipeline

7F HALT ; enter HALT mode

STOP-Mode Recovery (SMR) Register. This register selects the clock divide value and determines the mode of

STOP-Mode Recovery (Figure 34 and Figure 35). All bits

are Write-Only, except bit 7, which is Read-Only. Bit 7 is a

flag bit that is hardware set on the condition of STOP recovery and reset by a power-on cycle. Bit 6 controls whether a low level or a high level is required from the recovery

source. Bit 5 controls the reset delay after recovery. Bits 2,

3, and 4, or the SMR Register, specify the source of the

STOP-Mode Recovery signal. Bits 0 and 1 determine the

timeout period of the WDT. The SMR Register is located in

Bank F of the Expanded Register Group at address 0BH.

When the Stop-Mode Recovery sources are selected in

this register, then SMR2 Register bits D0,D1 must be set

to 0.

SMR (FH) 0B

D7 D6 D5 D4 D3 D2 D1 D0

SCLK/TCLK Divide-by-16

0 OFF* *

1 ON

External Clock Divide-by-2

0 SCLK/TCLK = XTAL/2*

1 SCLK/TCLK = XTAL

Stop-Mode Recovery Source

000 POR Only and/or External Reset*

001 Reserved

010 P31

011 P32

100 P33

101 P27

110 P2 NOR 0-3

111 P2 NOR 0-7

Stop Delay

0 OFF

1 ON

*

Stop Recovery Level

0 Low *

1 High

Stop Flag (Read-Only)

0 POR

Note: Not used in conjunction with SMR2

Source

* Default Setting After RESET

** Default setting after RESET and

Stop-Mode Recovery

*

1 Stop Recovery

SMR2 (0F) DH

D7 D6 D5 D4 D3 D2 D1 D0

Stop-Mode Recovery Source 2

00 POR only*

01 AND P20,P21,P22,P23

10 AND P20,P21,P22,P23,

P24,P25,P26,P27

Reserved (Must be 0)

Note: Not used in conjunction with SMR Source

Figure 35. Stop-Mode Recovery Register 2

([0F] DH: Write-Only)

SCLK/TCLK Divide-by-16 Select (D0). D0 of the SMR

controls a divide-by-16 prescaler of SCLK/TCLK. The

control selectively reduces device power consumption

during normal processor execution (SCLK control) and/or

HALT mode (where TCLK sources counter/timers and

interrupt logic). This bit is reset to D0 = 0 after a Stop-Mode

Recovery, WDT Timeout, and POR.

External Clock Divide-by-Two (D1). This bit can eliminate the oscillator divide-by-two circuitry. When this bit is

0, the System Clock (SCLK) and Timer Clock (TCLK) are

equal to the external clock frequency divided by two. The

SCLK/TCLK is equal to the external clock frequency when

this bit is set (D1=1). Using this bit together with D7 of

PCON further helps lower EMI (that is, D7 (PCON) = 0, D1

(SMR) = 1). The default setting is zero. Maximum external

clock frequency is 4 MHz when SMR Bit D1 = 1 where

SCLK/TCLK = XTAL.

OSC

SMR, D1

2

÷

SCLK

16

÷

SMR, D0

TCLK

Figure 34. STOP-Mode Recovery Register (Write-

Only Except Bit D7, Which Is Read-Only)

Figure 36. SCLK Circuit

34 DS96DZ80203

Z86C83/C84

Z8® MCU Microcontrollers

FUNCTIONAL DESCRIPTION (Continued)

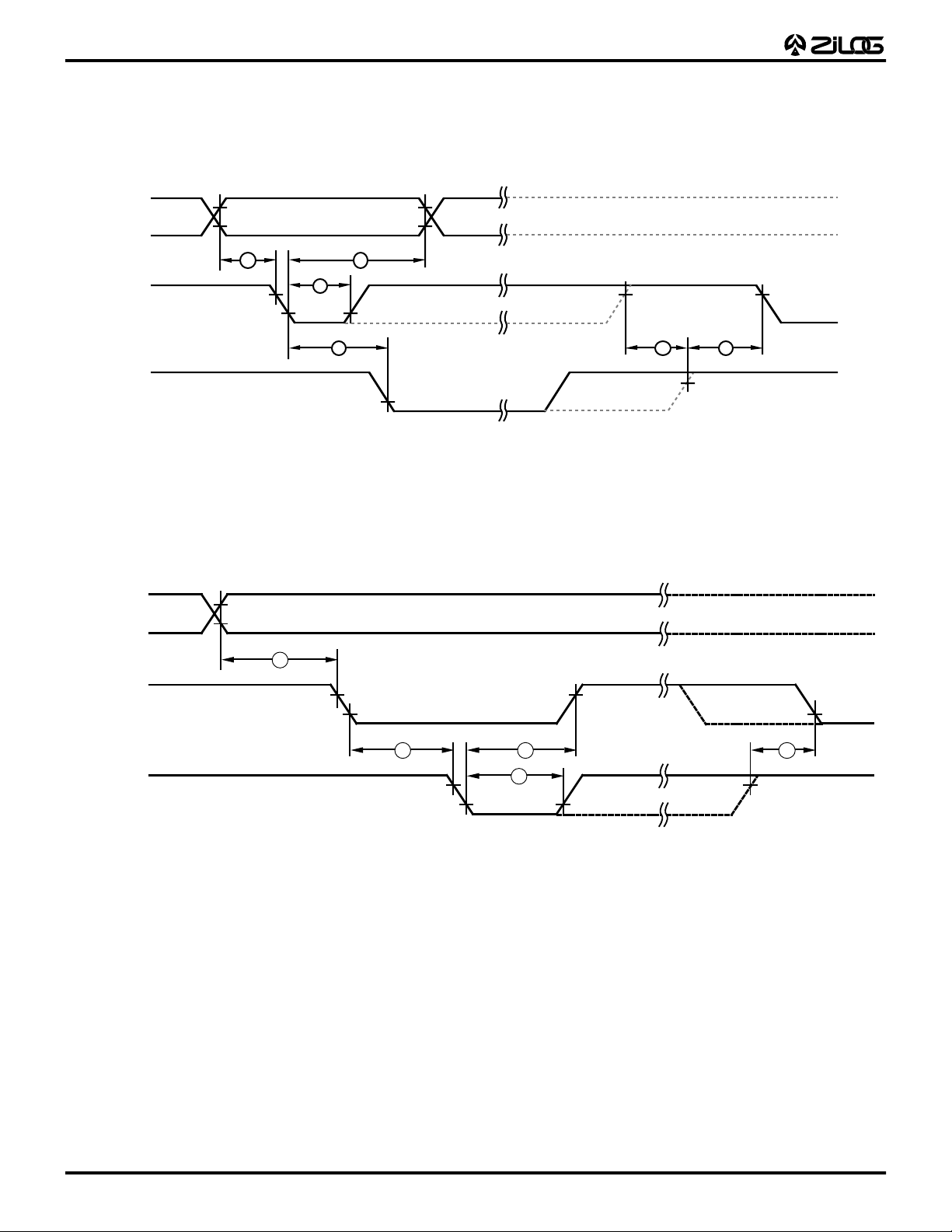

STOP-Mode Recovery Source (D2, D3, and D4).

These three bits of the SMR register specify the wake-up

source of the STOP recovery (Figure 37 and Table 12).

When the STOP-Mode Recovery Sources are selected in

this register then SMR2 register bits D0,D1 must be set to

zero. P33-P31 cannot wake up from Stop Mode if the input

lines are configured as analog inputs to the Analog

comparator or Analog-to-Digital Converter since the

Analog Comparator’s are powered down in Stop Mode.

Note: If the Port 2 pin is configured as an output, this

output level will be read by the SMR circuitry.

Table 12. STOP-Mode Recovery Source

SMR:432 Operation

D4 D3 D2 Description of Action

0 0 0 POR and/or external reset recovery

0 0 1 Reserved

0 1 0 P31 transition (not in Analog Mode)

0 1 1 P32 transition (not in Analog Mode)

1 0 0 P33 transition (not in Analog Mode)

1 0 1 P27 transition

1 1 0 Logical NOR of P20 through P23

1 1 1 Logical NOR of P20 through P27

STOP-Mode Recovery Delay Select (D5). This bit, if

High, enables the T

/RESET delay after Stop-Mode

POR

Recovery. The default configuration of this bit is "1". A

POR or WDT reset will override the selection and cause

the reset delay to occur.

STOP-Mode Recovery Edge Select (D6). A "1" in this bit

position indicates that a high level on the output to the

exclusive Or-Gate input from the selected recovery source

wakes the Z86C83/C84 from STOP mode. A "0" indicates

low-level recovery. The default is 0 on POR. This bit is

used for either SMR or SMR2.

Cold or Warm Start (D7). This bit is set by the device

upon entering STOP mode. A 0 in this bit (cold) indicates

that the device resets by POR/WDT reset. A "1" in this bit

(warm) indicates that the device awakens by a Stop-Mode

Recovery source.

Note: A WDT reset out of Stop Mode will also set this bit

to a "1."

STOP-Mode Recovery Register 2 (SMR2). This register

contains additional Stop-Mode Recovery sources. When

the Stop-Mode Recovery sources are selected in this

register then SMR Register Bits D2, D3, and D4 must be 0.

Table 13. Stop-Mode Recovery Source

SMR:10 Operation

D1 D0 Description of Action

0 0 SMR2 disables source

0 1 Logical AND of P20 through P23

1 0 Logical AND of P20 through P27

35 DS96DZ80203

Z86C83/C84

Z8® MCU Microcontrollers

SMR D4 D3 D2

0 0 0

VDD

SMR SMR SMRD4 D3 D2

P31

P32

Stop-Mode Recovery Edge

Select (SMR)

P33 From Pads

0 0 1

0 1 0

0 1 1

P33 P27

D4 D3 D2

1 0 0

D4 D3 D2

1 0 1

P20

P23

P20

P23

SMR2 SMR2D1 D0

1 1

SMR SMRD4 D3 D2

1 1 0

P20

P27

D1 D0

1 1

P20

P27

D4 D3 D2

1 1 1

To POR

RESET

To P33 Data

Latch and IRQ1

MUX

Digital/Analog Mode

Select (P3M)

Figure 37. STOP-Mode Recovery Source

36 DS96DZ80203

Z86C83/C84

Z8® MCU Microcontrollers

FUNCTIONAL DESCRIPTION (Continued)

Watch-Dog Timer Mode Register (WDTMR). The WDT

is a retriggerable one-shot timer that resets the Z8 if it

reaches its terminal count. The WDT is initially enabled by

executing the WDT instruction and refreshed on

subsequent executions of the WDT instruction. The WDT

circuit is driven by an on-board RC oscillator or external

oscillator from the XTAL1 pin. The POR clock source is

selected with bit 4 of the WDT register (Figure 38).

WDT instruction affects the Z (Zero), S (Sign), and V

(Overflow) flags. The WDTMR must be written to within 64

internal system clocks. After that, the WDTMR is write

protected.

Note: WDT time-out while in Stop-Mode will not reset

SMR, PCON, WDTMR, P2M, P3M, Ports 2 and 3 Data

Registers, but will cause the reset delay to occur.

/RESET

Clear

CLK

The Power-On Reset (POR) clock source is selected with

bit 4 of the WDTMR. Bits 0 and 1 control a tap circuit that

determines the time-out period. Bit 2 determines whether

the WDT is active during HALT and bit 3 determines WDT

activity during STOP. If bits 3 and 4 of this register are both

set to "1," the WDT is only driven by the external clock

during STOP mode. This feature makes it possible to wake

up from STOP mode from an internal source. Bits 5

through 7 of the WDTMR are reserved (Figure 39). This

register is accessible only during the first 64 processor

cycles (64 SCLKs) from the execution of the first

instruction after Power-On-Reset, Watch-Dog Reset or a

Stop-Mode Recovery. After this point, the register cannot

be modified by any means, intentional or otherwise. The

WDTMR cannot be read and is located in Bank F of the

Expanded Register group at address location 0FH.

18 Clock RESET

Generator

RESET

WDT Select

(WDTMR)

CK Source

(WDTMR)

VCC

3.0V REF.

WDT

From Stop

Mode

Recovery

Source

Select

XTAL

12 ns Glitch Filter

Stop Delay

Select (SMR D5)

RC

OSC.

3.0V Operating

Voltage Det.

+

-

Internal

RESET

WDT TAP SELECT

M

U

X

128 SCLK

POR

CK CLR

128

256

512

SCLK

SCLK

WDT/POR Counter Chain

SCLK

2048

SCLK

Figure 38. Resets and WDT

37 DS96DZ80203

Z86C83/C84

Z8® MCU Microcontrollers

WDTMR (F) 0F

D7 D6 D5 D4 D3 D2 D1 D0

WDT TAP

00 256 SCLK

01 512 SCLK *

10 1024 SCLK

11 4096 SCLK

WDT During HALT

0 OFF

*

1 ON

WDT During STOP

0 OFF

1 ON

*

XTAL1/INT RC Select for WDT

0 On-Board RC

1 XTAL

* Default setting after RESET

† XTAL=SCLK/TCLK shown

Reserved (Must be 0)

Figure 39. Watch-Dog Timer Mode Register

(Write Only)

Notes:

1. If WDT is permanently selected (always ON mode),

the WDT will continue to run even if set not to run in