General

Maintenance

Requirements

for

Surgical

Microscopes

About

This

Manual

Regular

inspection

performance

tenance

formance

If

you

authorized

intervals

of

have

any

ZEISS

and

of

the

system

specified

your

surgical

questions,

dealer.

maintenance

on

an

ongoing

in

this

manual

microscope.

please

contact

is

required

General

basis.

ensures

your

local

Maintenance

to

ensure

high

Compliance

consistent

ZEISS

Service

Requirements

quality

with

and

reliable

team

the

and

main-

per-

or

an

Manufacturer

Copyright

Carl

Zeiss

Meditec

Goeschwitzer

07745

Germany

Subject

technical

©

All

permissible.

use.

vented.

Jena

to

Carl

Zeiss

rights

Access

changes

development.

Meditec

reserved.

However,

to

AG

Strasse

in

AG

Reprints

this

data

51-52

design

Printed

2013

this

manual

by

third

Fax: + 49

E-Mail:

Internet:

and

scope

of

Germany.

in

and

reproductions,

may

be

parties

is

(0)

7364 - 20

surgical@meditec.zeiss.com

www.meditec.zeiss.com

delivery

and

as

including

digitized

not

and

permissible

4823

a

result

excerpts,

archived

and

for

must

of

ongoing

are

not

internal

be

pre-

Page

2

Version

G-30-1854-en

2.2

General

Maintenance

Requirements

Maintenance

intervals

Regular

operation

following

The

which

This

able

formance

intervals

only

is

on

maintenance

Much

know-how.

only

may

Please

notice

you

If

use

for

no

must

ZEISS

local

Regardless

are

ment

preventive

of

the

table

they

general

a

system,

your

is

It

performed

be

contact

that

your

these

of

during

the

longer

service

the

of

use

obligated

maintenance

system.

the

lists

be

must

overview.

maintenance

the

not

work

frequently

local

maintenance

your

system

the

partner.

maintenance

to

necessary

authorized

by

ZEISS

own

does

system.

perform

required

is

relevant

maintenance

performed.

components

If

detailed

here

to

service

service

activities.

according

tests

correspond

not

shut

Please

listed,

work

recurrent

ensure

to

reliable

activities

listed

are

applicable.

not

described

open

is

requires

system

the

system-specific

staff.

representative

to

to

system

the

users

in

tests

in

microscope's

the

acceptance

the

down

medical

of

accordance

and

which

this

for

time

due

and

electrical

with

consistent

and

shows

not

are

expert

which

work

the

for

instructions

criteria,

contact

equip-

62353.

IEC

at

avail-

per-

you

your

Version

G-30-1854-en

2.2

Page

3

General

Maintenance

Requirements

Prior

Brakes

to

each

Illumination

use

;

・

Electrical

—

—

The

without

=

The

—

The

*

Visual

—

The

—

Backup

*

Exchange

have

+

Exchange

.

and

Brakes

unlock

braking

any

friction

locking

inspection

service

lamp

the

been

exceeded.

the

mechanical

completely

force

holds

change

brakes

tabs

and

hours

is

lamp

xenon

of

can

of

the

function

of

the

available

if

it

is

bulb

function

when

the

microscope

position.

be

set

to

casters

prevent

test

lamp

are

and

ready

defective

after

max.

test

release

move

within

for

or

when

500 h or

buttons

securely

smoothly

the

the

use.

the

are

in

and

system

permissible

maximum

max. 6 months.

pressed.

balanced

without

from

rolling

range.

service

state

play.

away.

hours

Every

E

12

months

Documentation

cation

Controls

labels

and

identifi- ・ Visual

・

inspection

—

Manuals

plete

Visual

inspection

—

Optical

in

the

—

Emergency

—

The

—

Electrical

. , ;

and

identification

and

legible.

and

and acoustic

respective

backup

buttons

are

connections

function

signals

operating

systems

smooth

and

and

labels

are

available,

test

are

functional

mode.

(e.g.

second

without

insulation

play.

are

undamaged,

and

react

on

lamp)

are

functional.

undamaged.

com-

activation

or

Page

4

Version

G-30-1854-en

2.2

General

|

Light

Stand

Casters

Maintenance

guide

column

Requirements

Visual

inspection

The

—

—

The

Visual

inspection

The

—

column

—

The

Visual

—

The

The

—

—

Rotary

sheathing

field

of

view

and

column

motion

inspection

casters

running

is

connection.

of

and

are

surface

and

rolling

light

the

of

is

illuminated

function

securely

the

positioned

lifting

function

properly

the

of

motions

without

is

guide

homogeneously.

test

without

column

is

test

mounted

casters

are

on

unblocked.

kink

mechanical

jolt-free.

the

stand.

display

not

does

dents.

or

play

any

the

in

damages.

Fan

of

the

Microscope

Zoom

and

illumination

focus

system

Locking

—

tem

Function

—

The

—

Vacuum

—

The

Clean

the

Function

—

The

Clean

the

Function

—

The

—

The

Function

-

The

tabs

from

rolling

test

fan

runs

capacity

fan

is

free

fan.

test

fan’s

filter

fan’s

filter

test

optical

field

zoom

image

of

test

system

properly

and

brakes

are

away.

inconspicuously.

is

noticeable

from

dust

and

is

free

from

dust

or

exchange

is

clear.

view

is

fully

illuminated.

runs

smoothly

(paper

lint.

and

lint.

it

if

necessary.

and

mounted

and

test).

jolt-free.

prevent

the

sys-

Version

2.2

G-30-1854-en

Zoom

—

smoothly.

and

focus

can

adjusted

be

manually

to

be

jolt-free

and

run

Page

5

Objective

other

the

lens,

accessories

microscope

tube

and

mounted

(camera,

to

*

Visual

—

inspection

Additional

and

parts

function

are

attached

test

properly

General

and

without

Maintenance

play.

Requirements

etc.):

Cables,

Foot

control

Monitor

connectors

panel

*

。

*

—

Knurled

Handgrips

ー

properly

Visual

—

—

—

—

inspection

Insulation

Fuses

the

Cables

Cables

through

—

The

canted.

Visual

—

—

—

inspection and

The

Buttons

properly.

The

plete.

Visual

inspection

screws

attached.

are

specifications

with

with

other

strain

are

other

and

function

and

and

connectors

installed

and

and

and

in

without

without

devices.

relief

device

function

housing

dust

and

and

is

undamaged.

switches

spray

and

function

available,

removable

undamaged

test

on

the

undamaged.

the

user

manual.

ducts

ducts

of

the

cables

test

as

well

as

water

protection

test

microscope

system

The

are

free

from

are

protected

functions

the

joystick

device

and

firmly

components

and

cables

fuse

value

dents

against

properly

move

is

undamaged

tightened.

are

are

undamaged.

corresponds

and

damage.

shearing,

and

freely

and

and

to

e.g.

is

not

function

com-

Gas

Page

pressure

6

spring

—

—

・

Function

—

—

The

housing

Image

Movement

The

quality

test

gas

is

undamaged.

is

OK.

of

the

pressure

No

gas

pressure

spring

noticeable

is

not

color

spring

operated

tinge.

is

homogeneous

in

the

limit

and

range.

G-30-1854-en

jolt-free.

Version

2.2

General

Maintenance

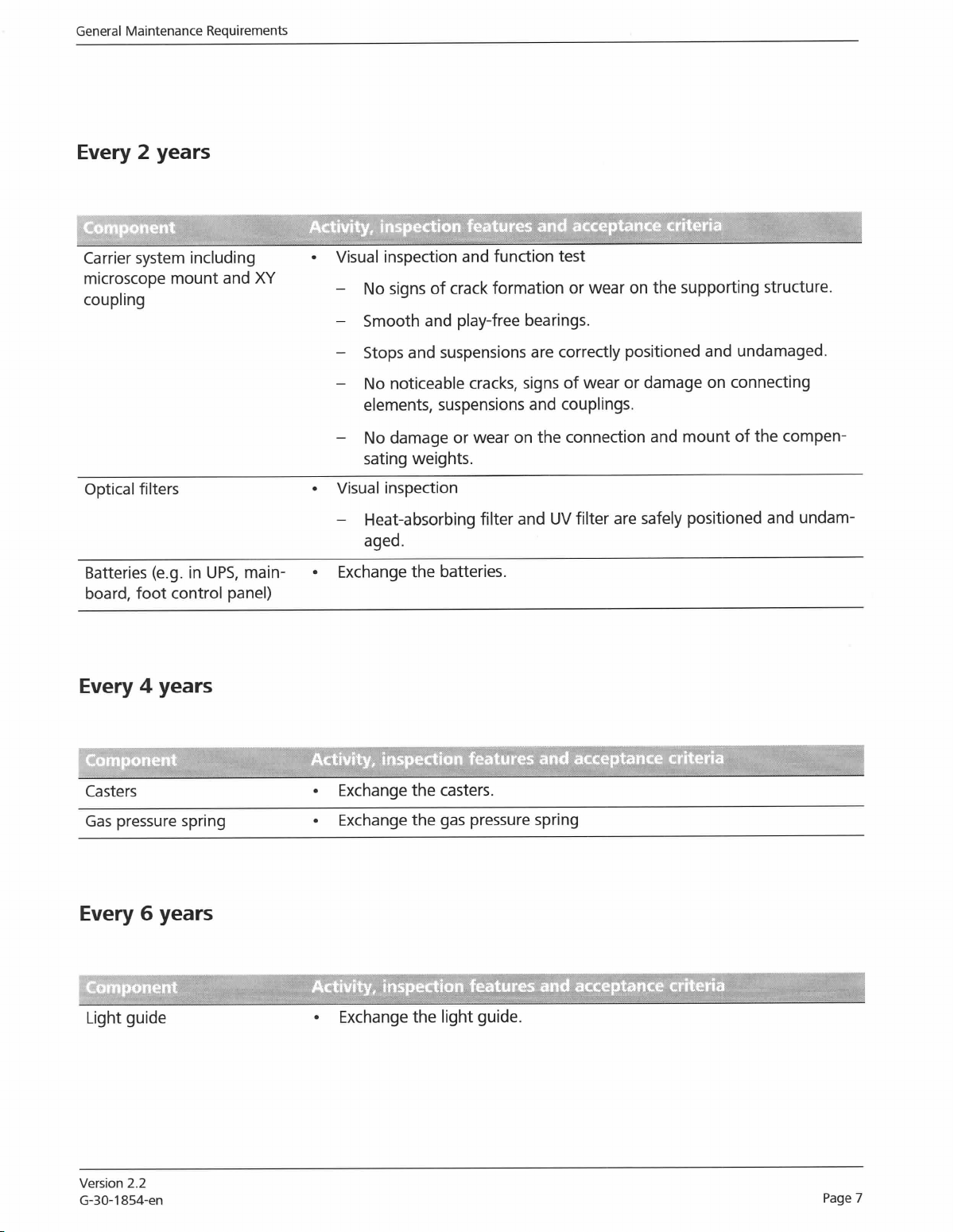

Every 2 years

Requirements

Carrier

microscope

system

mount

including

coupling

Optical

Batteries

board,

filters

(e.g.

in

foot

control

Every 4 years

and

UPS,

panel)

XY

main-

・

Visual

—

—

—

—

—

。

Visual

—

・

Exchange

inspection

No

signs

Smooth

Stops

and

No

noticeable

elements,

No

damage

sating

weights.

and

of

crack

and

play-free

suspensions

cracks,

suspensions

or

wear

inspection

Heat-absorbing

filter

aged.

the

batteries.

function

formation

test

or

bearings.

are

correctly

signs

of

and couplings.

on

the

connection

and

UV

wear

wear

or

filter

are

on

the

supporting

positioned

damage

and

mount

safely

positioned

and

undamaged.

on

connecting

of

the

structure.

compen-

and

undam-

Casters

Gas

pressure

Every 6 years

Light

guide

Version

2.2

G-30-1854-en

spring

‧

Exchange

・

Exchange

。

Exchange

the

casters.

the

gas

the

light

pressure

guide.

spring

Page

7

General

Maintenance

Requirements

Page

Version

2.2

8

G-30-1854-en

General

Maintenance

Requirements

(Blank

page,

for

your

notes...)

Version

2.2

G-30-1854-en

Page

9

Loading...

Loading...