Page 1

P1066584-001 Rev. A

Zebra® KR203

Kiosk Receipt Printer

Programming Manual

Page 2

TABLE OF CONTENTS

1 DESCRIPTION ...................................................................................... 6

1.1 Purpose ........................................................................................................... 6

1.2 Scope .............................................................................................................. 6

1.3 Document Format ............................................................................................. 6

2 USER INTERFACE ................................................................................ 7

2.1 User Interface Overview .................................................................................... 7

2.1.1 Application LED States................................................................................ 7

2.1.2 Application User Interface .......................................................................... 8

2.1.3 Additional UI Operations ............................................................................. 8

2.1.4 Bootware User Interface ........................................................................... 10

3 COMMANDS ........................................................................................ 11

3.1 Command Overview ........................................................................................ 11

3.2 General Notes on All Commands ...................................................................... 12

3.3 Enquiry Commands ......................................................................................... 12

3.3.1 Send status - <ESC><ENQ><1>.............................................................. 12

3.3.2 Send ack marker - <ESC><ACK><N1> .................................................... 12

3.3.3 Send information - <ESC><ENQ>c ........................................................... 13

3.3.4 Send sensor - <ESC><ENQ><5><N1> .................................................... 13

3.3.5 Send parameter - <ESC><ENQ>P<N1> ................................................... 14

3.3.6 Send all parameters - <ESC><ENQ>Q<N1> ............................................. 14

3.4 Graphics Commands ....................................................................................... 14

3.4.1 Print graphics line - <ESC>s<N1><N2>..<nX> ........................................ 14

3.5 Feed and Cut Commands ................................................................................ 15

3.5.1 Feed forward - <ESC>J<N1> ................................................................... 15

3.5.2 Feed backward - <ESC>j<N1> ................................................................. 15

3.5.3 Advance to TOF - <FF> ........................................................................... 15

3.5.4 Cut and present media - <RS><N1> ........................................................ 15

3.5.5 Cut media - <ESC><RS> ......................................................................... 16

3.5.6 Partial cut media - <US><N1> ................................................................. 16

3.5.7 Eject media - <ENQ> ............................................................................... 16

3.6 System Commands ......................................................................................... 17

3.6.1 Hard reset - <ESC>? ................................................................................ 17

3.6.2 Soft reset - <ESC>@ ............................................................................... 17

3.6.3 Set parameter in queue - <ESC>&p<N1><N2>..<NX> ............................. 17

3.6.4 Print test page - <ESC>P<N1> ................................................................ 17

3.6.5 Force print - <ESC>p ............................................................................... 18

3.6.6 Store parameters - <ESC>&<4><N1> ..................................................... 18

P1066584-001 KR203 KPL Programming Manual Page 2 of 58

Page 3

3.6.7

Recall parameters - <ESC>&F<N1> ......................................................... 18

3.6.8 Exit application - <ESC><255><n1> ........................................................ 19

3.6.9 Load application - <ESC><0><Application data> ...................................... 19

3.6.10 Calibrate Media - <ESC># ........................................................................ 20

3.6.11 Calibrate System - <ESC>g ...................................................................... 20

4 PARAMETERS ..................................................................................... 22

4.1 Parameters Overview ...................................................................................... 22

4.1.1 6 – Secondary burn time .......................................................................... 23

4.1.2 7 – Primary burn time .............................................................................. 23

4.1.3 8 – Max print speed ................................................................................. 24

4.1.4 9 – Presenter loop length ......................................................................... 24

4.1.5 31 – Presenter speed ............................................................................... 24

4.1.6 34 – Auto cut and present after FF ............................................................ 24

4.1.7 35 – TOF Synchronization ......................................................................... 24

4.1.8 37 – Page length ...................................................................................... 25

4.1.9 39 – TOF marker length ........................................................................... 25

4.1.10 40 – Garbage fil ter ................................................................................... 25

4.1.11 41 – TOF cut offset .................................................................................. 25

4.1.12 45 – Eject timeout.................................................................................... 26

4.1.13 46 – Cut position calibration ..................................................................... 26

4.1.14 47 – Wall compensation ........................................................................... 26

4.1.15 48 – Print width ....................................................................................... 26

4.1.16 49 – Advance before cut ........................................................................... 26

4.1.17 51 – TOF marker sensitivity ...................................................................... 27

4.1.18 53 – Lock parameters ............................................................................... 27

4.1.19 57 – System ............................................................................................ 27

4.1.20 58 – Out of paper level ............................................................................. 27

4.1.21 65 – Status mode ..................................................................................... 28

4.1.22 66 – Status protocol ................................................................................. 28

4.1.23 67 – Information Level ............................................................................. 28

4.1.24 68 – End of paper threshold ..................................................................... 29

4.1.25 69 – Installed guide width ........................................................................ 29

4.1.26 70 – Presenter PWM percentage ............................................................... 29

4.1.27 71 – EOP PWM percentage ....................................................................... 29

4.1.28 75 – Keepalive timeout ............................................................................. 29

4.1.29 80 – Compensation mode ......................................................................... 30

4.1.30 81 – 84 Compensation ............................................................................. 31

4.1.31 248 – Last reset reason ............................................................................ 31

4.1.32 249 – Power down count .......................................................................... 32

4.1.33 250 – Media length (m) ............................................................................ 32

4.1.34 251 – Number of cuts............................................................................... 32

4.1.35 252 & 253 – Page Erases .......................................................................... 32

P1066584-001 KR203 KPL Programming Manual Page 3 of 58

Page 4

4.1.36

254 – Uptime (s) ...................................................................................... 32

5 STATUS CODES .................................................................................. 33

5.1 Application Status Code Overview .................................................................... 33

5.2 Groups, Types and Reporting .......................................................................... 33

5.2.1 0 – Ok ..................................................................................................... 34

5.2.2 1 – Paper jam in presenter ....................................................................... 34

5.2.3 2 – Cutter Jam ......................................................................................... 34

5.2.4 3 – Out of paper ...................................................................................... 35

5.2.5 4 – Printhead lifted .................................................................................. 35

5.2.6 5 – Paper feed error ................................................................................. 35

5.2.7 6 – Head temperature error ...................................................................... 35

5.2.8 10 – Black mark not found ........................................................................ 35

5.2.9 11 – Black mark calibration error .............................................................. 36

5.2.10 12 – Index error ...................................................................................... 36

5.2.11 18 – Out of range .................................................................................... 36

5.2.12 19 – Paper low......................................................................................... 37

5.2.13 20 – Media in presenter ............................................................................ 37

5.2.14 40 – Printer entered USB bus .................................................................... 37

5.2.15 41 – Media guide detection error .............................................................. 37

5.2.16 42 – Media guide detection success .......................................................... 37

5.3 Bootware Status Code Overview ...................................................................... 38

5.3.1 0 – Ok ..................................................................................................... 38

5.3.2 13 – Checksum error ................................................................................ 38

5.3.3 14 – Wrong object type ............................................................................ 38

5.3.4 15 – Corrupt or missing application ........................................................... 39

5.3.5 21 – Boot/Application version mismatch .................................................... 39

5.3.6 22 – Wrong target ................................................................................... 39

5.3.7 23 – Tag system not found ....................................................................... 39

6 STATUS PROTOCOLS ......................................................................... 40

6.1 Status Protocol Overview ................................................................................ 40

6.2 XML Protocol .................................................................................................. 40

6.2.1 Header .................................................................................................... 41

6.2.2 Root Element ........................................................................................... 41

6.2.3 Send status block ..................................................................................... 42

6.2.4 Send ack marker ...................................................................................... 44

6.2.5 Send information ..................................................................................... 45

6.2.6 Send sensor ............................................................................................. 47

6.2.7 Send parameter ....................................................................................... 48

6.2.8 Send all parameters ................................................................................. 50

6.3 TTP Protocol ................................................................................................... 51

6.3.1 Send status ............................................................................................. 51

P1066584-001 KR203 KPL Programming Manual Page 4 of 58

Page 5

Version

Date

Author(s)

Description

A

11 June

First Release Version

6.3.2

Send ack marker ...................................................................................... 51

6.3.3 Send information ..................................................................................... 51

6.3.4 Send tags ................................................................................................ 51

6.3.5 Send sensor ............................................................................................. 51

6.3.6 Send parameter ....................................................................................... 51

6.3.7 Send all parameters ................................................................................. 51

7 TUTORIALS ......................................................................................... 52

7.1 Text on KR203 ............................................................................................... 52

7.1.1 Introduction............................................................................................. 52

7.1.2 Document Format .................................................................................... 52

7.1.3 Overview ................................................................................................. 52

7.1.4 Print graphics line .................................................................................... 53

7.2 Status from KR203 .......................................................................................... 54

7.2.1 Introduction............................................................................................. 54

7.2.2 Document Format .................................................................................... 54

7.2.3 Overview ................................................................................................. 54

7.2.4 Set up the printer..................................................................................... 54

7.2.5 Send status – <ESC><ENQ><1> .............................................................. 55

7.2.6 Send ACK marker – <ESC><ACK><N1> ................................................... 55

7.2.7 Monitoring when customer takes receipt.................................................... 57

7.2.8 Printing valuable vouchers ........................................................................ 57

7.2.9 Summary of commands used: ................................................................... 58

REVISION HISTORY

2013

P1066584-001 KR203 KPL Programming Manual Page 5 of 58

Page 6

1 Description

1.1 Purpose

This manual is for integrating KR203 into systems not using a printer driver supplied by Zebra

Technologies, for example embedded system using a proprietary controller and Operating

System.

1.2 Scope

This document covers the command set, settings and user interface of the KR203 kiosk

printer.

1.3 Document Format

In this document, binary data is represented in Zebra Toolbox format, which interprets data

within < and > symbols as binary data. Standard ASCII names such as <ESC> and <ENQ>

are converted to their equivalent binary values by Toolbox. Numbers such as <5> are sent

directly as binary d ata to the printer. Anything not appearing in bracket s, such as the & in

<ESC>&<4> is sent directly as ASCII text to the printer. See Toolbox help for more

information.

When values are specified in the format <N1 2> the space and the 2 indicate that the val ue

is a 16-bit value. Similarly, <N1 4> specifies that it is a 32-bit value.

P1066584-001 KR203 KPL Programming Manual Page 6 of 58

Page 7

Status LED State

Definition

Solid Yellow

Starting up. Present for about 100ms at first power on. If the solid

yellow stays, the printer failed RAM test and cannot start.

Solid Green

Printer OK

Flashing Red

Printer has detected a severe error. The patt ern of flashing signals

the error. See below for error table.

Flashing or Flickering

Green

Printer is receiving data.

Flash Pattern

Definition

* _ * _

Paper jam in presenter, Error Code 1

* * _ * * _

Cutter jam, Error Code 2

* * * _ * * * _

Out of paper, Error Code 3

* * * * _ * * * * _

Printhead lifted, Error Code 4

* * * * * _ * * * * * _

Paper feed error, Error Code 5

Amber On and Off

Head temperature error, Error Code 6

2 User Interface

2.1 User Interface Overview

The KR203 printer adapts the standard Zebra user interface used on the GX series desktop

products with a couple modifications and extensions. The printe r has four LEDs, two on each

side. The LEDs are labeled Power and Status. There is also a button labeled Feed on each

side.

The user interface is the same on each side. Neither the buttons nor the LEDs are individually

addressable.

The Power LED is green and is always on when 24V is applied to the unit. The Power LED

monitors only the 24V system.

The Status LED displays the current printer status. This LED is bi-col or, and can signal green,

red and yellow. The followi ng table explains the LED states when the feed button is not

pressed.

The KR203 printer has two pieces of software, a bootware and an application.

2.1.1 Application LED States

When the printer is flashing red the following error states can be signaled:

The lowest number error is always reported with the exception of error 4, head open. If the

head is open and the paper is out, the head open will be reported. All errors can be cleared

by the conditions causing them being removed, except cutter jam, which requires a power

cycle or reset command to be issued.

In addition “Paper jam in presenter” will clear automatically when the paper is removed from

the presenter, and “Head temperature error” will clear when the head cools sufficiently. See

“Status Codes” for more information.

P1066584-001 KR203 KPL Programming Manual Page 7 of 58

Page 8

While Button

Held

Meaning

Solid Green

Appears for 2 seconds, release during this time for a feed, cut and

present. Equivalent to command sequence <RS><0>.

One Flash,

then Solid Green

Release during this time to print the internal self test page. Equivalent

to command sequence <ESC>P<0>

Two Flashes,

Performs media guide detection, cutter calibration, and paper/TOF

sequence <ESC>g.

Three Flashes,

then Solid Green

Performs simulated USB cable disconnect and reconnect causing a

USB plug and play event to occur. No equivalent command.

Four Flashes,

Defaults all printer settings except “EOP Threshold”, and then

perform the calibration and resets all settings.

Five Flashes,

Prints a 50% grey pattern, cuts and ejects it; prints diagonal line

<ESC>P<4><ESC>P<5>

LED Off

Occurs if you continue to hold button beyond five flashes, releasing

button during this t ime does nothing.

Media Present

Meaning

Yes

Advances the media to the next mark in mark mode or the minimum

mode and then cuts media and presents minimum amount.

No

Prepares the printer for auto-load operation.

2.1.2 Application User Interface

The user interface is accessed via the feed button. To use the user interface, press and hold

the feed button. As soon as you depress the but ton, the user interface activates and signals

this by displaying a solid green LED on the status indicator.

The user interface can be accessed when the application is in an idle state, including while an

error has occurred. It cannot be accessed while the printer is already printing.

The function of the UI is dependent on how long the feed button is held. Continuing to hold

the button beyond a given entry in the t able proceeds to the next entry in the table.

then Solid Green

then Solid Green

then Solid green

calibration. Must be started with paper out or error is signaled, see

“Media Guide Detection” for more information. Equivalent to command

performs a media calibration. <ESC>&F<0> is similar but does not

pattern, cuts and presents it. Equivalent to command sequence

2.1.3 Additional UI Operations

In addition to the above items, the printer performs the following tasks:

When the printhead transitions from open to close the following operat ions occur :

amount of media required to maintain media control in continuous

2.1.3.1 Head Close Presenter Clearing

When the printhead is closed, the printer will attempt to clear the presenter if it detects

media is present at it and there is no media at the end of paper sensor. This is in preparation

for calibration. The calibration routine also does this check independently when media is

inserted.

2.1.3.2 Auto Load Operation (Calibration)

When the printer either starts up with no media present or the head is closed and no media

is detected, the printer prepares to auto load media. It also occurs after the defaulting as part

of the 4-flash operation.

P1066584-001 KR203 KPL Programming Manual Page 8 of 58

Page 9

Reasons For Calibrat ion Failure

Media is pulled out during 1 second start delay.

Head is opened at any time during operation.

In mark mode, printer fails to detect a the first mark within 625mm.

In plain paper mode if the white level of the media varies excessively and cannot be

stabilized within 625mm.

If entire calibration process does not complete within 1250mm.

If any printing has occurred since the last cut (On ly when used as a command)

If the printer detects media in the presenter and is unable to clear it

Parameter No.

Description

35

TOF synchronization

37

Page length

39

TOF marker length

40

Garbage filter

51

TOF marker sensitivity

58

Out of paper level

70

Presenter PWM percentage

When media is inserted into the rear of the printer, it is detected by the active media sensor,

and after a 1 second delay the printer begins to accept the media into the printer, and the

printer will perform a media calibration.

During the one second delay, presenter calibration is performed, so it is important to ensure

no media is present in the presenter when starting a calibration or media load. The firmware

ensures this by attempting to clear the presenter if it detects media present at it when media

is detected at the EOP sensor.

This media calibration occurs when the printer is both continuous and mark mode. In mark

mode, it requires two full forms to complete the calibration. The calibration type depends on

the “TOF Synchro nization ” paramete r. Calibration can fail for the following reasons:

When calibration fails, the media will be cut and ejected, and no error is signaled on the LED,

although a “Black mark calibration error” is reported to the host. If calibration succeeds,

calibration settings are stored. The “Black mark calibration error” is only reported if there are

no other severe errors active.

The following parameters are stored on a successful calibration:

2.1.3.3 Manual Media Loading

Media can also be loaded by opening the printhead, placing media under the printhead and

then closing the printhead. When this happens, no calibration occurs and previous calibration

settings are used. The printer will feed media the minimum amount, move to cut position, cut

and eject the media.

2.1.3.4 Media Guide Detection

When the media guide is changed, the printer will signal media present even when none is.

You must instruct the printer to detect the sensor it should use. This is accomplished with the

two flash function.

This process must be done without media in the printer. If the process is attempted with

media in the printer a “Media guide detection error” (Code 41) occurs. Upon successful

detection of the guide, guide settings are stored, and a “Media guide detection success”

(Code 42) message occurs. The “End of paper threshold” (Parameter 68) is captured during

guide detection along with the read only “Installed guide width” (Parameter 69).

P1066584-001 KR203 KPL Programming Manual Page 9 of 58

Page 10

Status LED State

Meaning

Rapid Flash Yellow

Firmware missing or corrupt

Fading in and out green

Bootware OK

Alternating Green-Red

Installing application – Do Not power off

Solid Off

Installing bootware – Do Not power off

2.1.3.5 Startup Behavior

The printer must ensure that at startup the printer is in a known state. When the printer is

powered on, it will make a small click to signal it has become ready.

2.1.3.6 Additional Notification

When settings are stored to flash with the <ESC>&<4> command, a small click will be made

to signal the storage.

2.1.4 Bootware User Interf ace

When the bootware is in error, holding the feed button down will signal the error condition:

Force entry into boot mode b y powering on the printer while holdi ng the feed button and

having the printhead open. Exit boot mode from a “Bootware OK” state by pressing and

holding the feed button for 10 seconds.

P1066584-001 KR203 KPL Programming Manual Page 10 of 58

Page 11

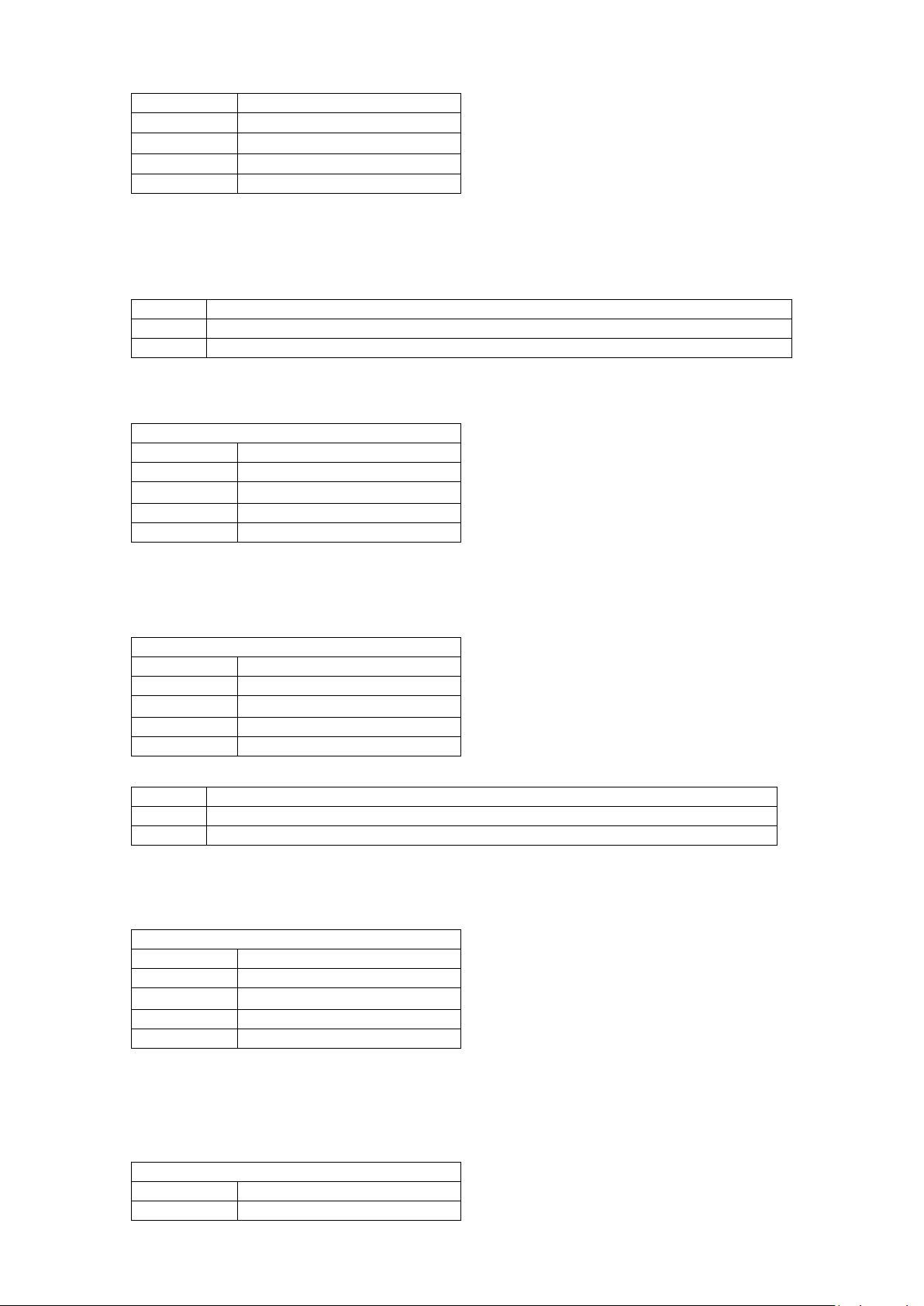

Command

Modes

Category

Description

Page

<ESC><ENQ><1>

A & B

Enquiry

Send status

12

<ESC><ACK>

A

Enquiry

Send ack marker

12

<ESC><ENQ>c

A & B

Enquiry

Send information

13

<ESC><ENQ><5>

A

Enquiry

Send sensor

13

<ESC><ENQ>P

A

Enquiry

Send parameter

14

<ESC><ENQ>Q

A

Enquiry

Send all parameters

14

Print uncompressed graphics

line

<ESC>J

A

Feed

Feed forward

15

<ESC>j

A

Feed

Feed backward

15

<FF>

A

Feed

Advance to TOF

15

<RS>

A

Feed

Cut and present media

15

<ESC><RS>

A

Feed

Cut media

16

<US>

A

Feed

Partial cut media

16

<ENQ>

A

Feed

Eject media

16

<ESC>?

A & B

System

Hard reset

17

<ESC>@

A

System

Soft reset

17

<ESC>&p

A

System

Set parameter in queue

17

<ESC>P

A

System

Print test page

17

<ESC>p

A

System

Force print

18

<ESC>&<4>

A

System

Store parameters

18

<ESC>&F

A

System

Recall parameters

18

<ESC><255>

A

System

Exit application

19

<ESC><0>

B

System

Load application

19

<ESC>#

A

System

Calibrate Media

20

<ESC>g

A

System

Calibrate System

20

3 Commands

3.1 Command Overview

The following is a table of all commands implemented in the KR203 Kiosk printer.

The Mode field indicates what modes the command is available in, A indicates it is available in

the Application; B indicates it is availa b le in Bootware.

<ESC>s A Graphics

14

P1066584-001 KR203 KPL Programming Manual Page 11 of 58

Page 12

Quick Command Facts

Name

Send status

Modes

Application and Boot

Parameters

None

Type

Enquiry

Execution

Immediate

Quick Command Facts

Name

Send ack marker

Modes

Application

Parameters

N1

Marker Number

0-255

Type

Enquiry

Execution

Synchronized, Initiate

3.2 General Notes on All Commands

Once transmission begins, a complete command must be received by the printer within 5

seconds. If the complete command is not received, the printer will automatically reset.

Commands marked “Immediate” will always operate as soon as they are parsed, regardless

of if there is any error conditions present.

Commands marked as “Synchronized” are placed into the printers command queue when

they are received.

Commands marked “Initiate” cause processing on the command queue to start as soon as

they are received by the printer.

Note that when any Severe error occurs, “Synchronized” commands that were present in the

print queue are not executed and are deleted. Some commands (such as Send ack marker)

do special things when they are deleted from the queue in this way. See individual

commands for more details.

Some of the parameters reference trays which are folders to store parameter data in. The

available trays are:

0 which is the current temporary values (these value s will be deleted during a power cycle)

1 which are the stored values (these values will rema in after a power cycle)

255 which are the default values of the firmware version loaded into the printer

3.3 Enquiry Commands

For all Enquiry commands, the status will be returned in the format selected by the “Status

protocol” parameter (number 66). The contents of the returned data vary based on the

selected protocol. See the “Status protocol” parameter, specifically the “Send Status” section

of the selected protocol.

3.3.1 Send status - <ESC><ENQ><1>

This command instructs the printer t o return its

current status to the host.

3.3.2 Send ack marker - <ESC><ACK><N1>

This command instructs the printer t o return an

ack marker to the host.

An ack marker is a marker that is returned to the

host when all the commands in the command

queue have been executed up to the point at

which the command was received. Executed

means physically printed in the case of motor or

feed commands, not just received by the printer.

N1 specifies the marker number to return. Resending the same marker will cause the same

marker to be returned twice.

P1066584-001 KR203 KPL Programming Manual Page 12 of 58

Page 13

Number

Name

Range

Description

0

Returns information on all available sensors

1

End of paper selected

0,1

Determines if paper is out at the selected

paper sensor

2

Top of form

0,1

Determines if the paper is currently at top of

form position

5

Paper at presenter

0,1

Determines if there is paper present under the

presenter sensor

9

Printhead temperature (C)

-57..122

Determines the printhead temperature in

degrees Celsius

10

Environment temperature (C)

-60..127

Not implemented on KR203 printer.

11

Head down

0,1

Determines if the printhead is in the down and

locked position

12

Cutter home

0,1

Determines if the cutter is in home position

13

Paper low

0..2

Determines if paper is detected at the paper

connected.

14

24V level (V)

0..50

Determines the voltage of the 24v supply

below 18 volts.

15

Media width

60,80

Determines the sensed guide width. Set during

guide width” setting.

16

FF button

0,1

Determines if the feed button is depressed.

individually addressable.

17

Pull detect

0,1

Determines if the presenter feed motor is

be active during print.

Quick Command Facts

Name

Send information

Modes

Application & Boot

Parameters

None

Type

Enquiry

Execution

Immediate

Quick Command Facts

Name

Send sensor

Modes

Application

Parameters

N1

Sensor Number,

or 0 for all.

Type

Enquiry

Execution

Immediate

The contents of the returned data vary based on the selected protocol. See the “Status

protocol” parameter, specifically the “Send ack marker” section of the selected protocol. If

the protocol supports it, the marker can either be positive, meaning all commands up to this

point were executed, or negative, ind icating that an error occurred on a command executed

before this point.

3.3.3 Send info r m ation - <ESC><ENQ>c

This command instructs the printer t o return

system information to the host.

See the “Status protocol” parameter, specifically

the “Send information” section of the selected

protocol.

NOTE! – This command takes several seconds to execute if information level setting in

parameter n67 is set to High.

3.3.4 Send sensor - <ESC><ENQ><5><N1>

This command instructs the printer to information

about a sensor to the host.

A value of zero indicates a negative “NO” for the

sensor. A value of one indicates a positive “YES”

for the sensor.

Table of Sensor Numbers:

P1066584-001 KR203 KPL Programming Manual Page 13 of 58

low sensor. The result is 2 if no sensor is

running into the printer. Printer will reset

calibration, and the same as the “Installed

The two feed buttons are ganged and not

currently sensing motion. Note that this may

Page 14

Number

Name

Range

Description

18

End of paper 80mm

0,1

Determines if paper is out at the 80mm sensor

guide.

19

End of paper 60mm

0,1

Determines if paper is out at the 60mm sensor

guide.

Quick Command Facts

Name

Send parameter

Modes

Application

Parameters

N1

Parameter

number

Type

Enquiry

Execution

Immediate

Quick Command Facts

Name

Send all parameters

Modes

Application

Parameters

N1

Tray Number

Type

Enquiry

Execution

Immediate

Quick Command Facts

Name

Print uncompressed graphics

line

Modes

Application

Parameters

N1

Data Size

N2…NX

Data

Type

Graphics

Execution

Synchronized

on the printer, regardless of the selected

on the printer, regardless of the selected

Specifying an inva lid sensor number for N1 will result in an “Index error”.

3.3.5 Send para meter - <ESC><ENQ>P<N1>

This command instructs the printer t o return a

parameter settings value.

N1 specifies the parameter number to return.

Specifying an invalid parameter number for N1

will result in an “Index error”.

For a list of available parameters see the “Parameters” section.

3.3.6 Send all parameters - <ESC><ENQ>Q<N1>

This command instructs t he printer to return all

parameters for a given tray value.

N1 specifies the tray to return.

The available trays are 0 which is the current

temporary values, tray 1 which are the stored

values and 255 which are the default values. Specifying a value for N1 other than these

values will result in an “Index error”.

3.4 Graphics Commands

3.4.1 Print graphics line - <ESC>s<N1><N2>..<nX>

This command sends a graphics stream to

the printer.

N1 specifies the stream size, which is the

number of bytes fron N2 to nX.

N2 specifies the graphic data to transmit to

the printer in raw binary format.

Any line for which less data than the current print width is specified, the remainder of the line

will be filled with blank dots. Excess data beyond the print width specified for a line will be

ignored.

When printing graphic lines, the print speed is deter mined by the burn time s ettings and the

compensation systems. The printer will drop speed when this occurs. Feed media commands

always moves media at the selected speed, so the rapid change between feed speed and

print speed can reduce print quality.

P1066584-001 KR203 KPL Programming Manual Page 14 of 58

Page 15

Quick Command Facts

Name

Feed forward

Modes

Application

Parameters

N1

Amount

Type

Feed

Execution

Synchronized

Quick Command Facts

Name

Feed backward

Modes

Application

Parameters

N1

Amount

Type

Feed

Execution

Synchronized

Quick Command Facts

Name

Advance to TOF

Modes

Application

Parameters

None

Type

Feed

Execution

Synchronized, Initiate

Quick Command Facts

Name

Cut and present media

Modes

Application

Parameters

N1

Present Amount

Type

Feed

Execution

Synchronized, Initiate

N1 Value

Amount Presented

0

50mm

1-254

1-254mm respectively

255

Entire page lengt h minus

20mm.

3.5 Feed and Cut Commands

3.5.1 Feed forward - <ESC>J<N1>

This command feeds media forward, i.e.

feeds without printing.

N1 specifies the amount to feed in motor

steps. There are approximately 8 steps per

mm.

The media feed always occurs at the selected print speed.

3.5.2 Feed backward - <ESC>j<N1>

This command feeds media backward.

N1 specifies the amount to feed in motor

steps. There are approximately 8 steps per

mm.

The media feed always occurs at the

selected print speed.

Note that it is possible to back the media out of the printer. A reverse operation at the start

of a page should ne ver exceed 7mm, or a N1 value of 56.

3.5.3 Advance to TOF - <FF>

This command feeds media to the next top

of form. The top of form position is either

when the next mark i s detected when “TOF

Synchronization” is enabled, or the “Page

Length” when in continuous mode.

If the setting “Auto Cut After TOF” is

enabled, a cut occurs after the movement, and the cut media is presented the default

amount (50mm).

3.5.4 Cut and present media - <RS><N1>

This command feeds media to the next top

of form. The top of form position is either

when the next mark i s detected when “TOF

Synchronization” is enabled, or the “Page

Length” when in continuous mode, and then

cuts the media.

The media is then presented based on the amount specified by N1:

The first time media is presented, the

parameter “Wall Compensation” is added to

the present amount.

Subsequent presentations do not have this

addition performed.

P1066584-001 KR203 KPL Programming Manual Page 15 of 58

Page 16

Quick Command Facts

Name

Cut media

Modes

Application

Parameters

None

Type

Feed

Execution

Synchronized, Initiate

Quick Command Facts

Name

Partial cut media

Modes

Application

Parameters

N1

Amount to leave

uncut in MM

Type

Feed

Execution

Synchronized, Initiate

Quick Command Facts

Name

Eject media

Modes

Application

Parameters

None

Type

Feed

Execution

Synchronized, Initiate

It is important to note that no presenting operation can cause the media to be completely

ejected from the printer. Only an eject command can completely remove the paper from the

printer. This cut is affected by the “Auto advance before cut” setting.

3.5.5 Cut m ed i a - <ESC><RS>

This command feeds media to the next top

of form. The top of form position is either

when the next mark i s detected when “TOF

Synchronization” is enabled, or the “Page

Length” when in continuous mode, and then

cuts the media.

No present operation occurs when using this command so a “Present media” command must

then be performed to present the media to the customer. This cut is affected by the “Auto

advance before cut” setting.

3.5.6 Partial cut media - <US><N1>

This command feeds media to the next top

of form. The top of form position is either

when the next mar k i s detected when “TOF

Synchronization” is enabled, or the “Page

Length” when in continuous mode, and then

partially cuts the media. The value specified

by N1 determines how much media is left

uncut in millimeters.

The amount specified is generally only accurate to 10mm increments, and has a range of 10-

60mm. Values above 60 result in no cut, a value of 0 results in a full cut, and is identical to

the <ESC><RS> command.

Note that if a partial cut fails, a full cut may occur in the process of trying to resolve the

error, but the customer will still be able to get both of their receipts, just fully separated.

A complete cut operation must be performed before the media can be ejected. This cut is

affected by the “Auto advance before cut” setting.

3.5.7 Eject media - <ENQ>

P1066584-001 KR203 KPL Programming Manual Page 16 of 58

This command completely ejects a cut piece

of media from the presenter.

This command does nothing if the media has

not been cut yet.

Page 17

Quick Command Facts

Name

Hard reset

Modes

Application & Boot

Parameters

None

Type

System

Execution

Immediate

Quick Command Facts

Name

Soft reset

Modes

Application

Parameters

None

Type

System

Execution

Immediate

Quick Command Facts

Name

Set parameter in queue

Modes

Application

Parameters

N1

Parameter Number

N2…NX

Parameter Value

Type

System

Execution

Synchronized

Quick Command Facts

Name

Print test page

Modes

Application

Parameters

N1

Type of page

Type

System

Execution

Asynchronous, Initiate

3.6 System Commands

3.6.1 Ha rd reset - <ESC>?

3.6.2 So f t reset - <ESC>@

This command performs a hard printer reset.

This is equivalent to a power cycle.

When in the bootware, this command is

used to exit the bootware and start

execution of the application, provided a valid

application is installed.

This command performs a software reset of

the printer. A software reset resets all

communication interfaces, and emp ties all

queues and buffers.

3.6.3 Set parameter in queue - <ESC>&p<N1><N2>..<NX>

different sizes in the KR203, so it is critical to send the proper number of bytes for a given

setting.

If N1 is an invalid parameter number, an “Index error” will occur. If the value specified by

N2..NX is outside the valid range for parameter N1, an “Out of range” will occur.

For a list of available parameters see the “Parameters” section.

This command just loads the setting into the operating parameters; to store them, use

<ESC>&<4><1>

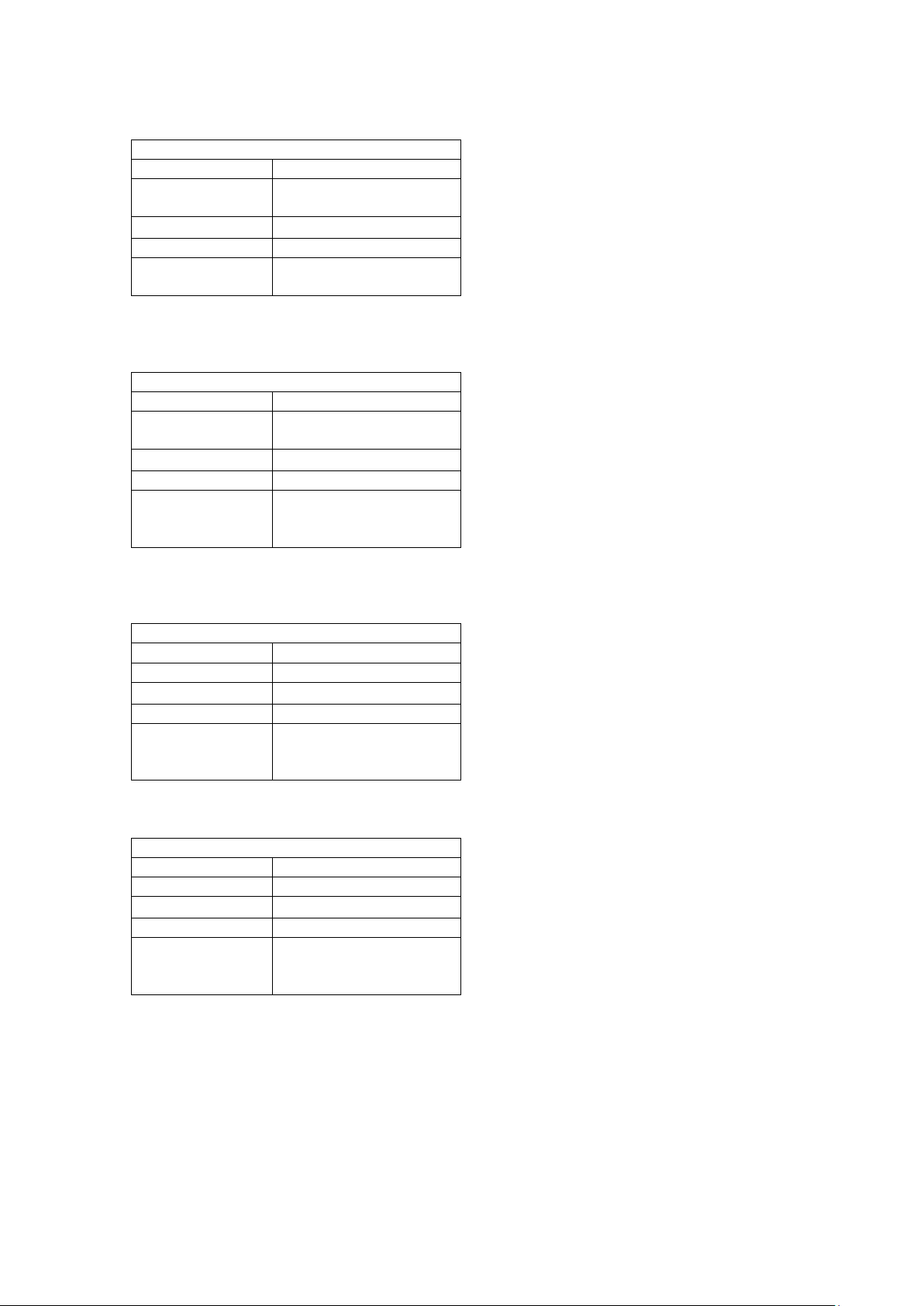

3.6.4 Print test page - <ESC>P<N1>

value for N1 will result in an “Index error”.

The execution of this command is Asynchronous, meaning that while it will be executed in

queue order; commands around it may also be executed at the same time. For this reason,

when executing these commands, other printing commands should not be executed; however

additional test pages can be executed.

P1066584-001 KR203 KPL Programming Manual Page 17 of 58

This command sets a parameter in the

printer. Parameters control all system

options in the printer.

N1 specifies the parameter number to set.

N2 to NX specifies a binary value to set the

parameter to. Different parameters are

This command instructs the printer to print a

built in test page.

N1 specifies the type of page to print. See

the table below for more details. Each print

is followed by a move to cut position, and a

cut and default eject. Specifying an invalid

Page 18

N1 Value

Page Description

Continuous Mode Length

0

Self test page – Displays logo and firmware

version number

92mm

3

25% staggered dot page

177mm of printing, 190mm

total

4

50% 1-dot page

177mm of printing, 190mm

total

5

2-bit rotating pattern page

177mm of printing, 190mm

total

6

50% 2-dot page

177mm of printing, 190mm

total

7

Density pattern page

152mm of printing, 165mm

total

Quick Command Facts

Name

Force print

Modes

Application

Parameters

None

Type

System

Execution

Immediate, Initiate

Quick Command Facts

Name

Store parameters

Modes

Application

Parameters

N1

Tray to store

parameters in

Type

System

Execution

Immediate

Quick Command Facts

Name

Recall parameters

Modes

Application

Parameters

N1

Tray to load

parameters from

Type

System

Execution

Immediate

When “TOF Synchronization” is enabled, after the page is completed, the printer will advance

to the next mark, then cut and eject.

3.6.5 Force print - <ESC>p

This command forces all items in the

printer’s queue to be executed immediately

upon receipt of this command.

Note that when there is a severe error, the

queue is emptied, so sending this command

during a severe error has no effect.

3.6.6 St ore parameters - <ESC>&<4><N1>

This command instructs the printer to store

the current operating parameters in flash,

making them the power on settings.

N1 specifies the tray to store the parameters

in. Tray 1 is the only t ray present on the

KR203. Specifying an invalid tray will result

in an “Index error ”.

After execution of this command is complete, the printer will make a small click noise to give

the user acknowledgement that the save has occurred.

Note that parameters set with <ESC>&p as well as any temporary parameters send by an

installed driver will be stored via this command.

3.6.7 Recall parameters - <ESC>&F<N1>

This command instructs the printer to load

the current operating parameters from the

specified tray.

N1 specifies the tray to load the parameters

from.

On the KR203, tray 1 holds the parameter

values stored in flash, and tray 255 holds the factory defaul t values. Specifying any other

value will result in an “Index error”.

P1066584-001 KR203 KPL Programming Manual Page 18 of 58

Page 19

Quick Command Facts

Name

Exit application

Modes

Application

Parameters

Boot or application PID

Type

System

Execution

Immediate

Quick Command Facts

Name

Load application

Modes

Boot

Parameters

Components of application

file

Type

System

Execution

Immediate, Initiate

This command just loads the specified set into the operating parameters; to store them, use

<ESC>&<4><1>.

3.6.8 Exit application - <ESC><255><n1>

This command exits the application and

enters the bootware. When the application is

terminated all data present in that session is

lost.

When this command is issued, the printer

will leave the USB bus and return as either

the same or a different device.

If n1=0, the boot loader w i ll return with the boot loader USB ID (PID = 0x0 0B 4)

If n1=1, the boot loader w i ll return with the firmware’s USB ID (P ID = 0x0 0B3)

You should use interactive polling to ensure you entered boot mode successfully.

To exit the boot and start the application, use the <ESC>? co mmand.

3.6.9 Load application - <ESC><0><Application data>

The sequence for firmware (application) update has to be interactive:

1) Send: <ESC><255><0> or <ESC><255><1>

If you use 0, the boot loader will come up with a boot loader USB ID string. If you use 1,

it will come up with the firmware’s ID string and you should use interactive polling to

ensure you entered boot mode successfully. In W indows 7 and above it is best to use 1

as a change of identity requires a new driver and administrative rights to load.

2) Wait for the USB Device to leave the bus and then reenter.

3) Send: <ESC><0><firmware file>

4) Verify load complete and successful.

5) <ESC>? Reset printer to exit the boot.

6) Wait for the USB device to re-appear.

7) Verify update.

This command instructs the bootware that it

should load a new application.

When this command is issued, an application

file is to follow.

The first four bytes of the application file is

the file size, and the boot first checks to

make sure the new application will fit between the boot and the flash disks. If it does not, a

“Boot/Application version mismatch” error occurs.

Next, the application is checked to ensure it is a n ap p lication file, this is accomplished via the

tagging mechanism in the firmware files. If the file is not detected to be an application file a

“Wrong object type” error occurs.

P1066584-001 KR203 KPL Programming Manual Page 19 of 58

Page 20

Quick Command Facts

Name

Calibrate Media

Modes

Application

Parameters

None

Type

System

Execution

Synchronized, Initiate

Quick Command Facts

Name

Perform System Calibration

Modes

Application

Parameters

None

Type

System

Execution

Immediate

The printer must have been previously programmed with tags in order to load any file,

application or bootware. If the current bootware cannot find the system tags on the printer’s

flash disk, or if the bootware cannot find any tag entries in the first 2k of the application file,

a “Tag system not found” error occurs.

Next it is checked for compatibility with this specifi c controlled PCB. If the bootware file is not

detected as being compatible with this board, a “Wrong target” error occurs.

As the application is received by the printer, it is burned directly to flash memory.

After the entire application has been received and flashed to the application flash space, a

checksum is then received by the printer, which is the final four bytes of the application file.

If the checksum pr ovided and the checksum of the data in flash do not match, a “Checksum

error” occurs.

After a successful load, there is a single 50ms writ e operation to the boot area to inform it

where the new application starts in memory. If the printer is powered off during the

application, the printer might not be recoverable.

After successful load, the printer remains in the bootware. To exit the bootware, issue an

<ESC>?.

3.6.10 Calibrate Media - <ESC>#

This command instructs the printer to

perform a media calibration.

Media calibration can be done for both

continuous and mark based media, and the

type of calibration performed is based on the

option selected by the “TOF

Synchronization” p arameter. See more details in the user interface section for what occurs

during calibration.

The media calibration process must begin with n o other print in progress. If it is attempted

while there is a print out in progress, the printer will cut and eject the page, and signal a

“Black mark calibration error”.

Sending this command multiple times will only cause one calibration until the calibration

which is active is complete.

3.6.11 Calibrate System - <ESC>g

This command instructs the printer t o select

media guide, and calibrate cutter and media,

If TOF synchronization if enabled through

parameter n35, the printer will be calibrated

for the TOF media loaded.

System calibration triggered with this

command is the same as holding the Feed button pressed until two blinks.

In order to start this process, no media must be present under the platen or under the

presenter sensor, the printhead must be closed, and no cutter jam must exist.

If these conditions are not met, a “System calibration error” occurs. If the calibration is

successful, a “System calibration success” occurs.

P1066584-001 KR203 KPL Programming Manual Page 20 of 58

Page 21

This command also calibrates the cutter, so it is normal that as part of its execution 3 cuts

occur. If the cutter calibration cannot compete successfully, a “Cutter jam” error occurs.

Upon successful calibration of the media guide, “End of paper threshold”, “Installed guide

width”, “Cutter calibration” and “Presenter threshold” are stored to flash.

P1066584-001 KR203 KPL Programming Manual Page 21 of 58

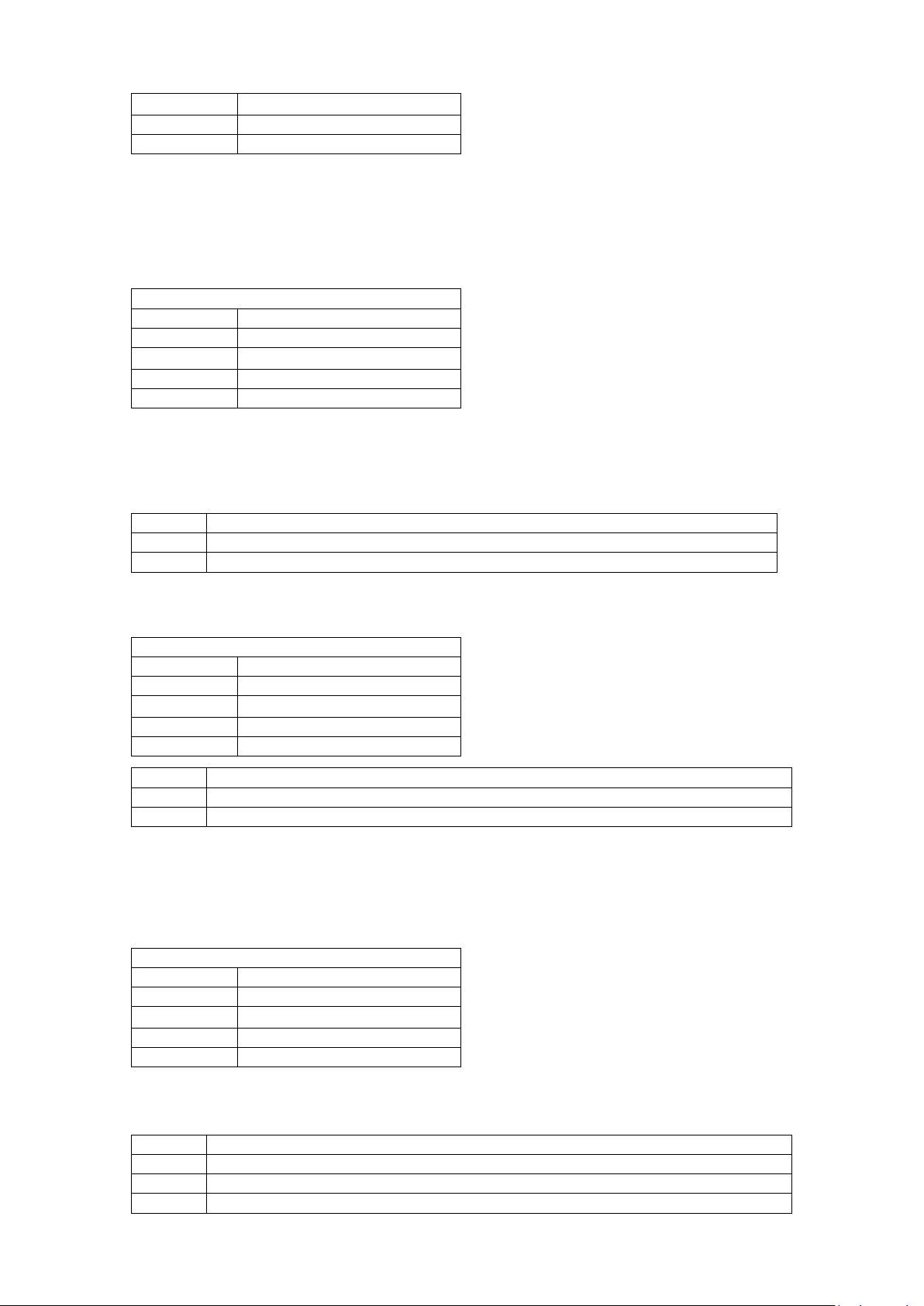

Page 22

Number

Name

Range

Default

Size

Attributes

6

Secondary burn time

10..900

130

2

None

7

Primary burn time

10..2600

560

2

None

8

Max print speed

50..175

152

1

None

9

Presenter loop length

0,80..600

400

2

None

31

Presenter speed

50..450

300

2

None

34

Auto cut and present after FF

0..1

0

1

None

35

TOF synchronization

0..1

0

1

None

37

Page length

11..600

85

2

None

39

TOF marker length

1..30

5

1

None

40

Garbage filter

1..15

1

1

None

41

TOF cut offset

0..255

0

1

None

45

Eject Timeout

0..600

0

2

None

46

Cut position calibration

-127..127

0

1

None

47

Wall Compensation

0..600

0

2

None

48

Print width

0,20..80

0

1

None

49

Advance before cut

0..1

1

1

None

51

TOF marker sensitivity

0..255

120

1

None

53

Lock parameters

0..1

0

1

None

57

System

0..255

255

1

None

58

Out of paper level

0..255

0

1

None

65

Status mode

0,1,3

3

1

None

66

Status protocol

0..1

1

1

None

67

Information level

10,20,30

10

1

None

68

End of paper threshold

0..235

60

1

None

69

Installed guide width

60,80

80

1

Read Only

70

Presenter PWM percentage

0..100

100

1

None

71

EOP PWM percentage

0..100

100

1

None

75

Keepalive timeout

0..65535

0

2

None

80

Compensation mode

0..255

255

1

None

81

Compensation curve knee

1..1000

88

2

None

82

Compensation curve divisor

1..10000

1000

2

None

83

Compensation slope

1..1000

610

2

None

84

Compensation Y-intercept

1..10000

1481

2

None

248

Last reset reason

10,20,30,40,50,60,70

10

1

Read Only

249

Power down count

(All values valid)

0

4

Read Only

250

Media length (m)

(All values valid)

0

4

Read Only

251

Number of cuts

(All values valid)

0

4

Read Only

252

MIFS low page erases

(All values valid)

0

4

Read Only

253

MIFS high page erases

(All values valid)

0

4

Read Only

254

Uptime (s)

(All values valid)

0

4

Read Only

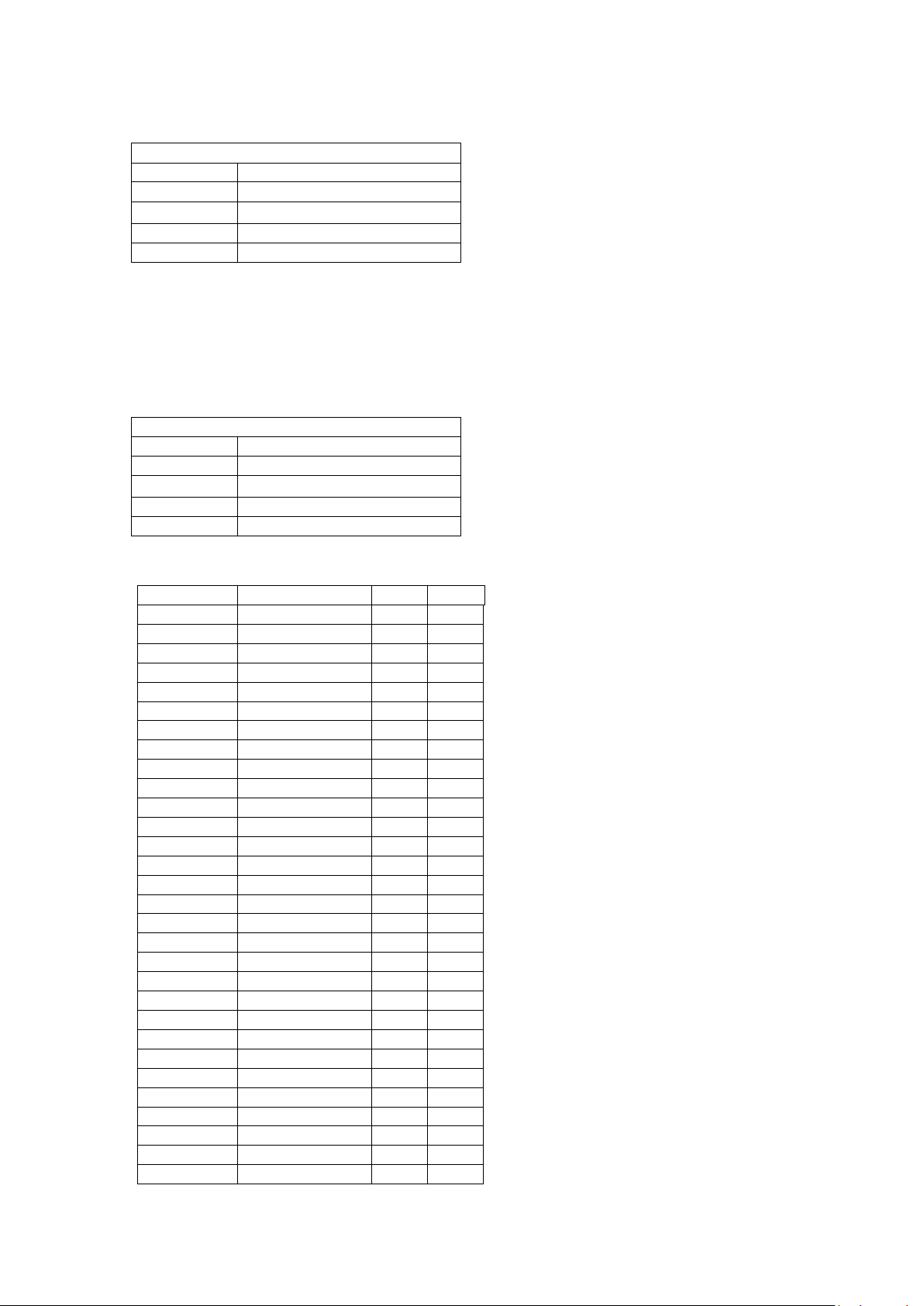

4 Parameters

4.1 Parameters Overview

The following is a table of all parameters implemented in the KR203 Kiosk printer.

For any parameter, if the value specified is not in the range, an “Out of range” error occurs.

P1066584-001 KR203 KPL Programming Manual Page 22 of 58

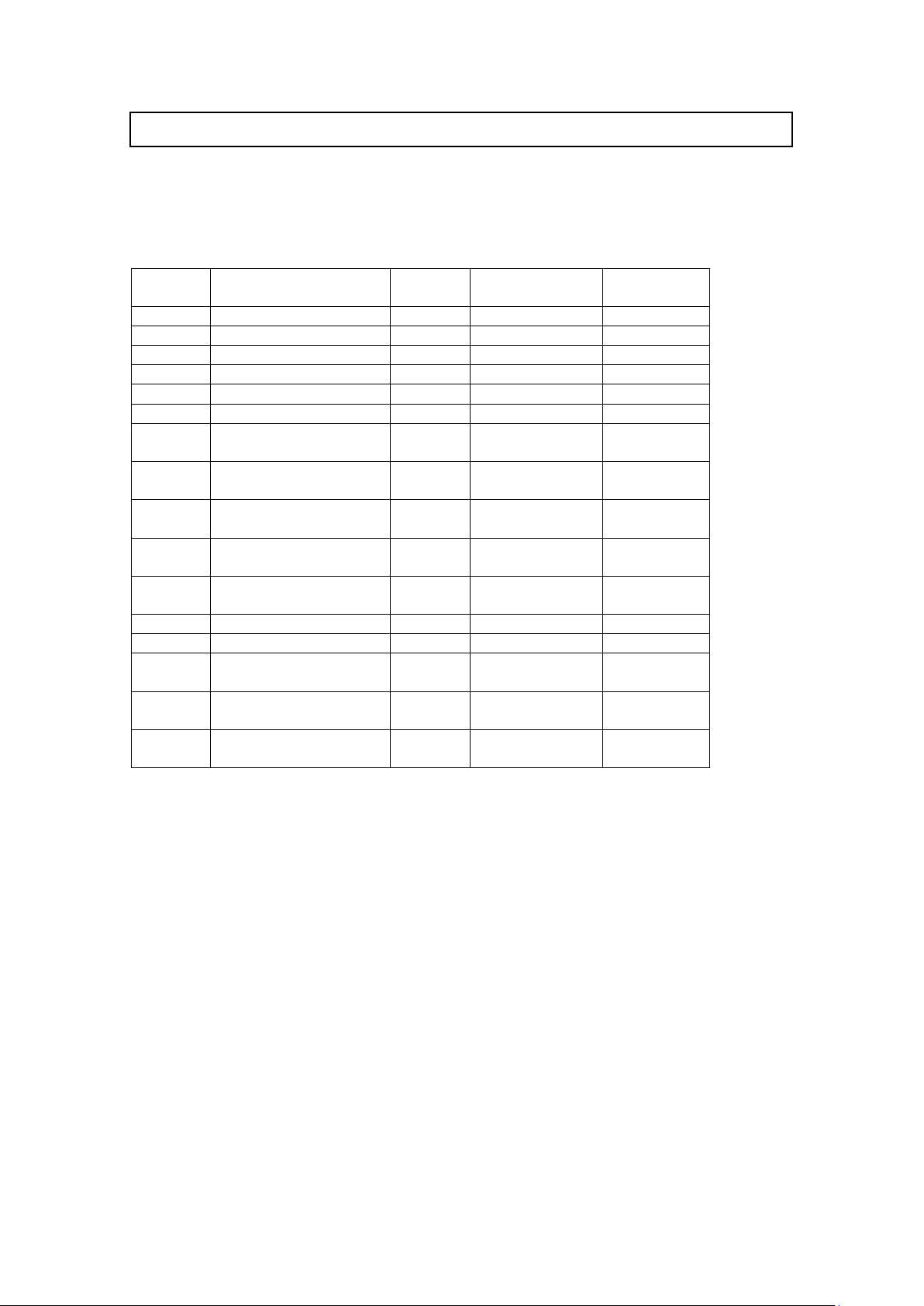

Page 23

Darkness

Total burn time

N6

N7

5%

33

6

28

10%

67

12

55

15%

100

18

82

20%

133

24

110

25%

167

30

137

30%

200

36

164

35%

233

42

192

40%

267

48

219

45%

300

54

246

50%

333

60

274

55%

367

66

301

60%

400

72

328

65%

433

78

356

70%

467

84

383

75%

500

90

410

80%

533

96

438

85%

567

102

465

90%

600

108

492

95%

633

114

520

100%

667

120

546

105%

700

126

574

110%

733

132

602

115%

767

138

629

120%

800

144

656

125%

833

150

684

130%

867

156

711

135%

900

162

738

140%

933

168

766

145%

967

174

793

150%

1000

180

820

Parameter Facts

Number

6

Name

Secondary burn time

Range

10..900

Size

Unsigned 16-bit

Default

120 (µS)

Parameter Facts

Number

7

Name

Primary burn time

Range

10..2600

Size

Unsigned 16-bit

Default

546(µS)

4.1.1 6 – Second ary burn time

When “Compensation mode” bit 2 is

enabled, this is the amount of time spent

burning the history control dot line during

printing, it is ignored otherwise.

History lines give extra burn time to pixels

which have been off in order to improve

print darkness on those dots.

The time is specified in microseconds. Note that setting this val ue to a high number can

reduce print speed.

4.1.2 7 – Primary b urn t ime

T is the amount of time spent burning the

dot line during printing.

The time is specified in microseconds. Note

that setting this value to a high numbe r can

reduce print speed.

Using very large values ca n reduc e printhead life. Generally there is no reason to set this

above 1000.

P1066584-001 KR203 KPL Programming Manual Page 23 of 58

Page 24

Parameter Facts

Number

8

Name

Max print speed

Range

50..175

Size

Unsigned 8-bit

Default

152 (mm/s)

Parameter Facts

Number

9

Name

Presenter loop length

Range

0,80..600

Size

Unsigned 16-bit

Default

400 (mm)

Parameter Facts

Number

31

Name

Presenter speed

Range

50..450

Size

Unsigned 16-bit

Default

300 (mm/s)

Parameter Facts

Number

31

Name

Auto cut and present after FF

Range

0..1

Size

Unsigned 8-bit

Default

0 (Disabled)

Parameter Facts

Number

35

Name

TOF Synchronizatio n

Range

0..1

Size

Unsigned 8-bit

Default

0 (Disabled)

4.1.3 8 – Max print speed

This parameter specifies the maximum print

speed. This speed is used as the feed speed.

The value specified is in millimeters per

second. It is not advised to set this value

less than 75 or over 152.

4.1.4 9 – Presenter loop length

This parameter specifies the maximum

media length stored in the presenter loop

during printing. Once this much media is

stored in the loop, it begins feeding out as

more is printed.

The value specified is in millimeters. A value

of zero indicates no loop. Note that because of gearing differences in the motors, the size of

the loop will slowly increase as more printing occurs, even if the loop is disabled.

4.1.5 31 – Presenter speed

This parameter specifies the speed the

presenter moves media at when presenting

and ejecting. It does not control the speed

when maintaining t he height of the loop.

The value specified is in millimeters per

second.

4.1.6 34 – Auto cut and present after FF

This parameter specifies whether or not the

printer automatically cuts and presents after

an <FF> command.

A value of zero performs no cut after <FF>,

a value of 1 causes a cut and default present

to occur after <F F>, equivalent to an

<RS><0>

4.1.7 35 – T OF Sync hr onization

This parameter specifies whether the printer

should sync to TOF (Black) marks or not.

A value of 0 places the printer in continuous

mode.

A value of 1 places the printer in TOF

synchronization mode.

If you attempt to use mark media in continuous mode, normal ope ration occurs unless the

marks are larger than the value specified by “TOF marker length”. If this is the case, media

out may be signaled when a mark is encountered.

P1066584-001 KR203 KPL Programming Manual Page 24 of 58

Page 25

Value

Result

0

Continuous Mode

1

TOF Synchronization Mode

Parameter Facts

Number

37

Name

Page length

Range

11..600

Size

Unsigned 16-bit

Default

92 (mm)

Parameter Facts

Number

39

Name

TOF marker length

Range

1..30

Size

Unsigned 8-bit

Default

5 (mm)

Parameter Facts

Number

40

Name

Garbage filter

Range

1..15

Size

Unsigned 8-bit

Default

1 (mm)

Parameter Facts

Number

41

Name

TOF cut offset

Range

0..255

If you attempt to use continuous media in mark mode, at the end of each page, the printer

will feed media for twice the “Page length” searching for the mark. If it is not found, a “Black

mark not found” error occu rs.

4.1.8 37 – Page length

This parameter specifies the length of a

page.

When “TOF Synchronization” is enabled,

twice this value is the length of media that

will be fed searching for the next valid mark

to cut at.

When it is disabled, this represents the minimum page length that the pri nter will produce.

This setting is set automatically during a calibration when “TOF Synchronizat ion” is enab led .

Page length is always resolved jus t before a cut operation.

Generally speaking, the printer will always regard this setting when making any cut. Note that

during startup, the printer may cut without regard to this setting. This is by design and

needed to avoid a paper jam at startup.

4.1.9 39 – TOF marker length

This parameter specifies the maximum

length of a mark, and is measured in

millimeters.

If a mark is longer than this value plus 5mm,

a media out condition is signaled.

This setting is set automatically during a calibration when the calibration was started while

“TOF Synchronization” is enabled.

4.1.10 40 – Garbage filter

This parameter specifies how big a mark

must be to be detected as a mark.

If a mark is shorter than this, it is ignored.

This setting is set automatically during a

calibration when the calibration was started

while “TOF Synchronization” is enabled.

4.1.11 41 – TOF cut offset

P1066584-001 KR203 KPL Programming Manual Page 25 of 58

Page 26

Size

Unsigned 8-bit

Default

0 (mm)

Parameter Facts

Number

45

Name

Eject timeout

Range

0..600

Size

Unsigned 16-bit

Default

0 (Seconds)

Parameter Facts

Number

46

Name

Cut position calibration

Range

-127..127

Size

Signed 8-bit

Default

0 (steps)

Parameter Facts

Number

47

Name

Wall Compensation

Range

0..600

Size

Unsigned 16-bit

Default

0 (mm)

Parameter Facts

Number

48

Name

Print width

Range

0,20..80

Size

Unsigned 8-bit

Default

0 (automatic based on n69)

Parameter Facts

This parameter specifies how much media

should be fed once a mark is detected

before media is considered to be in cut

position. It has no effect when “TOF Synchronization” is not enabled.

Note that additional marks can be found in the interim and this will have no effect on the

operation, and may desynchronize the mark system.

4.1.12 45 – Eject timeout

This parameter specifies how long the

printer waits after a present operation

occurs before it automatically ejects the

page.

If this value is set to zero, no eject will

occur. Note that the time is measured from

the completion of the first present operation.

4.1.13 46 – Cut position calibration

This parameter is used to set how many

steps the cut position is to be modified by.

Note that this is a signed 8 bit value.

Negative values will cause the printer to cut

sooner than default position. Note that the

adjustment will never result in a reverse

feed.

4.1.14 47 – Wall compensation

This parameter is used to set the t hickness

of the kiosk wall. This value is added to the

first present operation of any printed page

as an additional feed. It only applies to the

first present operation of a given page,

subsequent feeds will be at their actual

values.

Note that the presenter will never lose control of the media with a present operation. Eject

cannot occur using present commands.

4.1.15 48 – Print width

This parameter is used to set the desired

print width output. This setting overrides

setting 69, “Installed guide width” and

instructs the system to print in the specified

width in millimeters.

The print window will always be centered.

If this value is 0, the value is based on “Installed guide width” and is 54 if a narrow guide is

detected and 72 if a wide guide is detected.

4.1.16 49 – Advance before cut

P1066584-001 KR203 KPL Programming Manual Page 26 of 58

Page 27

Value

Result

0

Do not advance before cut

1

Advance before cut

Value

Result

0

Do not lock parameters

1

Lock parameters

Number

49

Name

Advance before cut

Range

0..1

Size

Unsigned 8-bit

Default

1 (Enabled)

Parameter Facts

Number

51

Name

TOF marker sensitivity

Range

0..255

Size

Unsigned 8-bit

Default

122 (AD Steps)

Parameter Facts

Number

53

Name

Lock parameters

Range

0..1

Size

Unsigned 8-bit

Default

0 (Unlocked)

Parameter Facts

Number

57

Name

System

Range

0..255

Size

Unsigned 8-bit

Default

255

Parameter Facts

Number

58

Name

Out of paper level

If this parameter is set to 1, meaning it is

enabled, the printer will feed the print line to

cutter distance before it tries to move to cut

position. A value of zero means no motion

occurs, which means that part of the

previous page will appear on the top of the

next page.

Because the print line to cutter distance is less than the EOP sensor to print line distance, this

should never cause an extra form to be fed when “TOF synchronization” is enabled.

4.1.17 51 – TOF marker sensitivity

This setting determines what level the

selected EOP sensor must see before it

starts evaluating whether or not a detected

mark is valid. This is a detection done prior

to the garbage filter detection.

This is set during media calibration when

“TOF synchronization” is enabled.

4.1.18 53 – Lock parameters

This value specifies if parameters can be

changed using the <ESC>&p command.

When set to 1, setti ng any parameter other

than this one results in an “Index err or”.

Note that the “Recall parameters” command

overrides this setting.

4.1.19 57 – System

The System parameter is a bit field that will

control up to eight system components in

the printer. Bits 0-6 are unspecified and

should always remain set to 1.

Bit7 1: default. One PC /one KR203 USB

driver instance regardless of USB port used;

0: each USB port has its own KR203 USB driver instance.

4.1.20 58 – Out of paper level

P1066584-001 KR203 KPL Programming Manual Page 27 of 58

Page 28

Value

Result

0

No active status reporting

3

Report active status to USB port

Value

Result

0

TTP Reporting

1

XML Reporting

Value

Result

10

Minimum Information Level

20

Medium Information Level

30

Maximum Information Level

Range

0..255

Size

Unsigned 8-bit

Default

0

Parameter Facts

Number

65

Name

Status mode

Range

0 and 3

Size

Unsigned 8-bit

Default

3 (Active to USB)

Parameter Facts

Number

66

Name

Status protocol

Range

0..1

Size

Unsigned 8-bit

Default

1 (XML Reporting)

Parameter Facts

Number

67

Name

Information Level

Range

10,20,30

Size

Unsigned 8-bit

Default

30 (Maximum information)

This parameter is not currently used and is

set during calibration.

4.1.21 65 – Status mode

This setting determines the status reporting

behavior of the KR203.

When set to 3, the printer will actively report

status changes. These responses are

equivalent to the responses generated by

<ESC><ENQ><1>. The reporting format

will vary based on the value of “Status protocol” (parameter 66).

These requests will be generated automatically, without an enquiry. For a list of the codes

generated, see “Status codes”.

4.1.22 66 – Status protocol

This setting determines the status reporting

protocol of the KR203 printer.

All data that is returned by the printer will be

in a format supported by the specified

protocol.

For a detailed reference of the responses of each protocol, see the “Status protocols” section.

4.1.23 67 – Information Level

This setting determines the amount of

information to be reported when using the

“XML Reporting” option as selected by the

“Status protoco l” setting.

It only applies to the “XML Reporting”

option, and does nothing when any other

protocol is enabled.

P1066584-001 KR203 KPL Programming Manual Page 28 of 58

Page 29

Value

Result

60

60 (or 58mm) guide installed

80

80 (or 82.5mm) guide installed

Parameter Facts

Number

68

Name

End of paper thresho ld

Range

0..255

Size

Unsigned 8-bit

Default

60 (AD Steps)

Parameter Facts

Number

69

Name

Installed guide width

Range

60,80

Size

Unsigned 8-bit, read on ly

Default

80 (or 82.5mm)

Parameter Facts

Number

70

Name

Presenter PWM percentage

Range

0..100

Size

Unsigned 8-bit

Default

100 (percent)

Parameter Facts

Number

71

Name

EOP PWM percentage

Range

0..100

Size

Unsigned 8-bit

Default

100 (percent)

Parameter Facts

Number

75

For a detailed reference of the responses at each information level, see the “Status protocols”

section.

4.1.24 68 – End of paper threshold

This setting determines the thresholds for

the EOP sensor to determine if the printer is

out of paper. This is in addition to the

detection system afforded by the mark

detection system (which is if the mark length

is greater than “TOF marker length” plus

5mm).

This value is set after a successful media guide calibr ation.

4.1.25 69 – Installed guide width

This setting instructs the system which EOP

sensor to use, either the sensor for wide

guides or the sensor for narrow guides.

This value is set after a successful media

guide calibration.

4.1.26 70 – Presenter PWM percentage

This setting instructs the system what

amount of time the LED should be turne d on

per cycle. 100% is equal to full on, 0% is

equal to full off. This setting controls the

presenter sensor’s PWM.

This value is set after a successful media

calibration, regardless of the “TOF Synchronization” setting. This parameter should not be

manually set.

4.1.27 71 – EOP PWM percentage

This setting instructs the system what

amount of time the LED should be turne d on

per cycle. 100% is equal to full on, 0% is

equal to full off. This setting controls both

EOP sensor’s PWM.

This parameter should not be manually set.

4.1.28 75 – Keepalive timeout

P1066584-001 KR203 KPL Programming Manual Page 29 of 58

Page 30

Bit Number

Value to Add

Definition

0 1 Enable Thermal Compensation

Decreases burn time based on head temperature.

1 2 Enable Speed Compensation

Increases or decreases burn time based on print speed.

2 4 Enable Secondary Burn

Enables the history system, and burns history lines at the “Secondary burn time” time

Name

Keepalive timeout

Range

0..65535

Size

Unsigned 8-bit

Default

60

Parameter Facts

Number

80

Name

Compensation mode

Range

0..255