Yuchai YC6A, YC6B, YC6J Service Manual

YC6A YC6B YC6J

YC6A YC6B YC6J Series Construction Engine

Operation & Maintenance Manual

Please read the Manual carefully before using.

Guangxi YuChai Machinery Co., Ltd.

00

June.2008

Foreword

YCA YC6B YC6J

This Instruction Manual introduces the YCA YC6B YC6J series construction engine about its structure and technical parameters, the technical specifications and data of its main accessories as well as the basics information on use and service. It also describes some common malfunctions and solutions.

YCA YC6B YC6J“ ”

Please read this manual carefully to understand and master the operation and maintenance requirements about YCA YC6B YC6J series construction engine prior to

putting the machine into operation and pay your particular attention to the Precautions for Safe Operation described below in order to enable the machine to bring its superior performance into full play and ensure its safe operation.

With continuous development and demand of the society, the engine will be uninterruptedly optimized and improved and its modified products will also be continuously increased. Except for especially great modifications in the design this manual will not be altered again. Therefore, after a certain period, there will be some discrepancies between the description in the manual and the actual engine, to which kindly ask our customers to pay due attention.

The manual gives a detailed description for the basic model engine only, and any modifications of it are not laid out to which we ask our customers to pay due attention and understand it well.

YuChai reserves the explanation right of this manual.

! Precautions for Safe Operation!

1.

Such parts as lubricating oil pressure sensing plug, water temperature sensing plug and alarm for too low lubricating oil pressure are very important. In case any failure, immediately replace it to ensure normal working of these parts, otherwise the crankshaft may be burned due to lack of the oil or the cylinder head may crack due to overheating resulted from lack of the water.

2.

After cleaning the oil filter or during the process of replacing filter gauze, reinstall the filter

only after refilling oil fully, and start the engine on idle running immediately after reinstallation; meantime, check if there is any sign of leakage to any filter. Correct the leaking filters or it may easily lead to crankshaft burn caused by oil shortage.

3. 3 5

Each time you start the vehicle, first start the engine on idle running for 3 to 5 minutes till the engine warms up and all gauges working in normal function, then start to move. Never put the vehicle to sudden acceleration from cold-start. For any dramatic speed-up on cold status will damage the instruments and their corresponding parts and components and accelerate the wear and tear of engine’s kinetic parts, consequently it will shorten the engine’s life cycle.

4. 3 5

Avoid any sudden stall and stop at high speed & high load status, the appropriate way is to gear down gradually and stop the vehicle after 3 5 minutes of engine idle running. Otherwise it will damage turbocharger and other moving parts and shorten engine service life consequently.

5.

Check often for the leakage and blockage of the intake piping and air cleaner to make them work normally. Do make adjustment or maintenance when there is leakage in the intake system and blockage in air cleaner, for they will damage the turbo-charger and cause the cylinder scoring, and will decrease the engine’s power at the same time , therefore maintain timely as the vehicle can be driven at pretty low speed .

6.

Start the engine on first gear, otherwise it may stop. 7.

Whenever the engine works abnormally, it shall be dealt with care. 8.

Don’t approach rotating components and directly touch the high temperature parts (such as exhaust pipe and turbocharger etc.) of the engine when you check it, don’t open the water tank cover immediately just after stop, for this may cause physical burn.

9. 50 60

Send the engine to a consignment technical service station of YuChai for run-in service

when it runs 50-60hour, or you will waive the warranty for this engine. 10.

Anti-freeze coolant shall be used in the cooling system; otherwise the consequent failure will not be included in the free warranty

11.

Customer is prohibited to insert or pull out the connectors. 12.

Water and any other cleaning agent are prohibited to use for washing and cleaning the engine.

13

Follow the instruction to drain water of fuel pre-filter, replace filter element assy. of pre-filter and filter element assy. of precision fuel filter.

14.

Make sure the ignition switch is turned off before dismounting and cutting off the battery.

15

Hoist and transport the engine in accordance with the precautions described on the outside the packaging case. The place for storage of the engine shall be well-ventilated, dry, clean and free of corrosive substances. See the mark on the package for preservation of the engine.

16.:

The basic information of the engine is on the nameplate, including: rated power, rated speed, series number, production date and implement standard. The nameplate of the engine is located at the top of the cylinder cover housing.

The engine type and ex-work number are printed on the platform in the middle of the cylinder lower margin.

18.

The safety warnings include user’s precaution, crankshaft steering/rotating danger and high temperature danger sticking on engine cover, clutch housing and cover on exhaust pipe respectively

19

Random documents are included in the package: user’s manual, parts list, tool list, certification and packing list. Please check after opening.

|

|

|

Content |

|

1 |

General introduction ................................................................................................... |

|

18 |

|

|

1.1 |

Product Feature ........................................................................................... |

|

18 |

1.2 Style number composition and its specific meaning |

|

|||

|

.......................................................................................................................................... |

|

|

18 |

|

1.3 |

Main application scope............................................................... |

19 |

|

2 Technical specification............................................................................................ |

|

20 |

||

|

2.1 |

Main specification (basic) ............................................................ |

20 |

|

|

2.2 |

Main technical parameter ..................................................................... |

|

35 |

3 |

................................................................................................. |

|

39 |

|

Primary Structures of Engine and working principle ................................................................. |

39 |

|||

|

3.1 |

Cylinder Block.................................................................................................. |

|

39 |

|

3.2 |

Cylinder Head and Valve Train....................................................... |

40 |

|

|

3.3 |

Crank-connecting Rod Mechanism..................................................... |

46 |

|

|

3.4 |

fuel system ................................................................................................ |

|

50 |

|

3.5 |

Lubrication System .................................................................................... |

|

58 |

|

3.6 |

Cooling System ............................................................................................ |

|

62 |

|

3.7 |

Start device, electrical system and instrument................ |

66 |

|

|

3.8 |

Turbocharger ................................................................................................... |

|

69 |

|

3.9 |

Steering pump................................................................................................. |

|

72 |

4 |

.................................................................................................... |

|

75 |

|

Operation and maintenance of engine...................................................................................... |

|

75 |

||

|

4.1 |

Operation of engine............................................................................... |

|

75 |

4.2 |

Engine Maintenance ...................................................................... |

79 |

|

5 |

.................................................................................................... |

82 |

|

Frequently-possible Troubles ......................................................................and Their Solution |

82 |

||

5.1 |

Engine ..........................................................................Fails to Start |

82 |

|

5.2 |

Insufficient ..............................................................power of Engine |

84 |

|

5.3 |

...................................................................................... |

86 |

|

Abnormal Noise during Running .......................................................................of Engine |

86 |

||

5.4 |

Black Smoke ........................................................from Exhaust Manifold |

87 |

|

5.5 |

........................................................................................................ |

|

88 |

White smoke and Blue Smoke ......................................................from Exhaust Manifold |

88 |

||

5.6 |

................................................... |

Abnormal lubricant pressure |

88 |

5.7 |

............................................................................................. |

90 |

|

Large Consumption of Lubricating ...............................................................................Oil |

90 |

||

5.8 |

Too high .........................................................water outlet temperature |

90 |

|

5.9 |

.......................Malfunction and Solution of Turbocharger |

91 |

|

5.10 ................................Malfunction and Solution of Clutch |

92 |

||

5.11 ............................................................. |

Shut - off automatically |

92 |

|

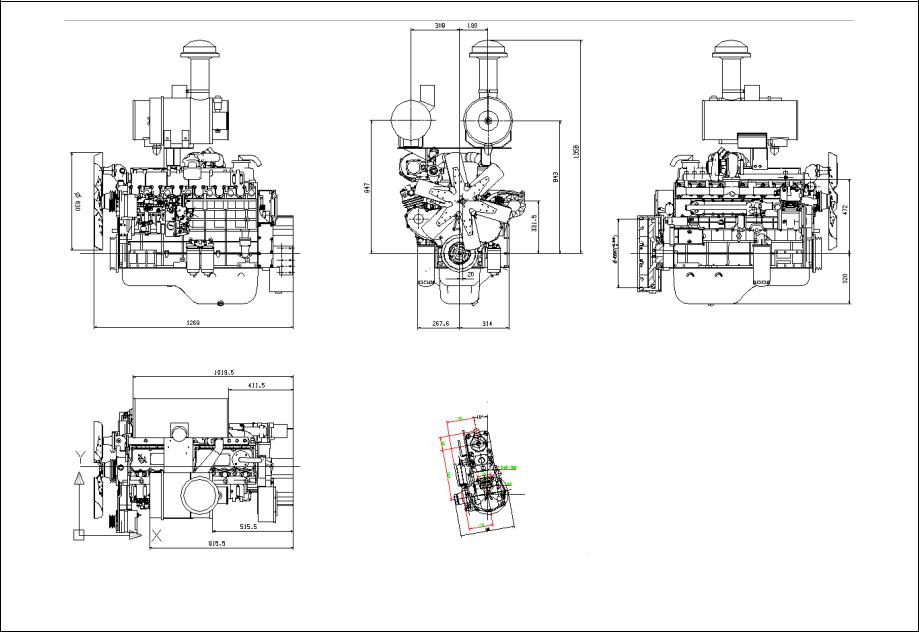

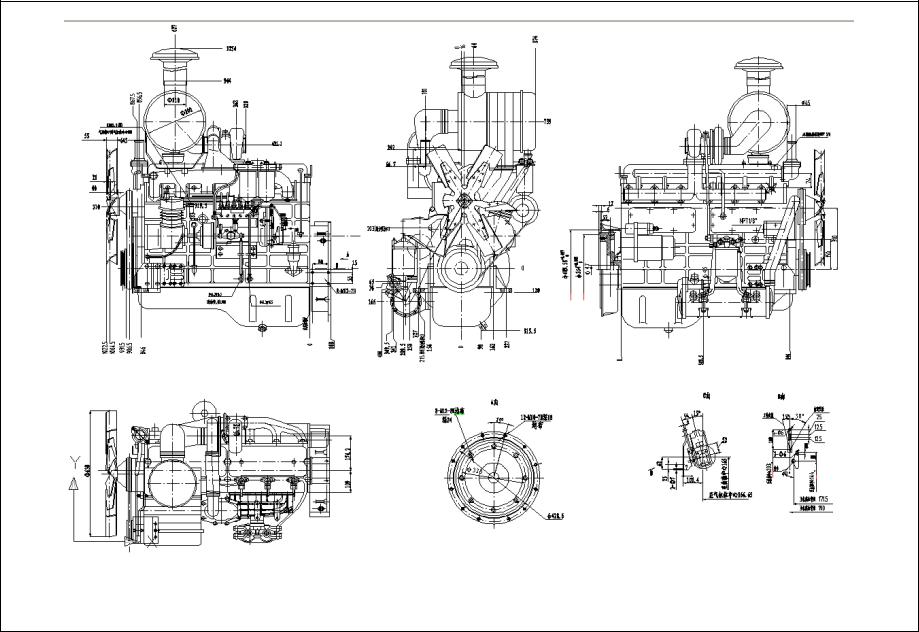

1 YC6A

Fig 1 Assembly Layout for YC6A Diesel Engine (may differ from the practical configuration)

2 YC6B

Fig 2 Assembly Layout for YC6B Diesel Engine (non-Turbocharged) (may differ from the practical configuration)

3 YC6B

Fig 3 Assembly Layout for YC6B Diesel Engine (Turbocharged) (may differ from the practical configuration)

4 YC6J

Fig 4 Assembly Layout for YC6J Diesel Engine (may differ from the practical configuration)

YC6A A8700

YC6A series construction engine (A8700) external characteristic

curve

13

YC6B B8C00 B9C00

YC6B series construction non-Turbocharged engine B8C00 B9C00 external characteristic curve

14

YC6B B7700

YC6B series construction Turbocharged engine B7700 external characteristic curve

15

YC6J J8000

YC6J series construction engine (J8000) external characteristic

curve

16

1General introduction

1.1 Product Feature

YC6A YC6B YC6J ,,

YC6A YC6B YC6J series engines are developed by Yuchai with advantages of reliability, fuel consumption saving and strong power. It is ideal power for construction.

1.2

Model number composition and its specific meaning

The product style number is consisted of Arabic numbers and capital English letters, and the specific meaning is as follows:

17

Turbocharged

1.3 Main application scope

-15 40 2000-15 40 2500

The engine could work normally under temperature of -15 40 and at the height above sea-level of lower than 2000 m. it is forbidden to work in the water or in the fire. When the engine needs to work at temperature lower than -15 or higher than 40 , at the at the height above sea-level of higher than 2500 m, the user should consults YuChai Technical Dept. and Service Dept. to adopt effective measure or replace special engine to ensure the normal working.

2 Technical specification

2.1 Main specification (basic)

1 1 YC6A

Table 1-1 Main technical parameters of YC6A engine

|

|

|

|

|

Technical specification |

|

|

|

|

|

|

18

No. |

Name |

|

A8900 |

|

A8700 |

|

|

|

|

|

|

1 |

Model |

|

YC6A180Z-T11 |

|

YC6A190Z-T10 |

|

|

|

|

|

|

2 |

|

|

|

||

Type |

|

Vertical in-line, water-cooling, 4-stroke |

|||

|

|

||||

|

|

|

|

||

3 |

|

|

Turbocharged |

||

Air intake way |

|

|

|

||

|

|

|

|

||

4 |

|

|

ω Direct injection tube sinking ω combustion |

||

Combustion type |

|

chamber |

|||

|

|

||||

|

|

|

|

|

|

5 |

Cylinder |

|

6 |

||

number |

|

|

|||

|

|

|

|

|

|

6 |

|

mm |

|

108 |

|

Cylinder diameter |

|

||||

|

|

|

|

||

7 |

|

mm |

|

132 |

|

Piston stroke (mm) |

|

||||

|

|

|

|

||

|

L |

|

|

|

|

8 |

Total piston |

|

|

7.252 |

|

|

displacement |

|

|

|

|

|

|

|

|

|

|

9 |

Compression |

|

17:1 |

||

ratio |

|

|

|||

|

|

|

|

|

|

10 |

Cylinder |

|

Wet |

||

|

sleeve type |

|

|

|

|

|

|

|

|

||

11 |

kW |

130 |

|

140 |

|

|

Rated power (kW) |

|

|

|

|

|

|

|

|

|

|

|

|

r/min |

|

|

|

12 |

Rated rotation |

2300 |

|

2300 |

|

|

speed(r/min) |

|

|

|

|

13 |

|

N·m |

670 |

|

690 |

|

Max. torque(N·m) |

|

|

|

|

|

r/min |

|

|

|

|

14 |

Speed at max torque |

1500 1700 |

|

1500 1800 |

|

|

(r/min) |

|

|

|

|

|

|

|

|

|

|

19

|

|

|

|

|

|

|

|

|

|

g/kW·h Fuel |

|

|

|

|

|

|

|

15 |

consumption rate at |

|

|

|

≤240 |

|||

|

rated working |

|

|

|

|

|

|

|

|

condition |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

16 |

Fuel |

|

|

|

≤225 |

|||

|

consumption rate at |

|

|

|

|

|

|

|

|

max torque g/kW·h |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Name |

|

|

|

Technical specification |

|||

No. |

|

A8900 |

|

|

|

A8700 |

||

|

|

GB 252-2000 0 10 , |

||||||

|

|

Summer: GB 252-2000 top grade or first rater 0 #, 10 # light |

||||||

|

Diesel oil |

diesel oil |

|

|

|

|

|

|

17 |

GB 252-2000 0 -10 -20 -35 |

|||||||

brand |

||||||||

|

|

|

|

|||||

|

|

|

|

|||||

|

|

Winter: GB 252-2000 top grade or first rater 0 #,-10 #, -20 #, -35 |

||||||

|

|

|

|

# light diesel oil |

||||

|

|

|

|

|

|

|

|

|

|

Max. |

|

|

|

|

|

|

|

18 |

rotation speed with |

≤2530 |

|

|

|

≤2540 |

||

|

no load r/min |

|

|

|

|

|

|

|

|

Min. |

|

|

|

|

|

|

|

19 |

rotation speed with |

|

|

|

700 750 |

|||

|

no load r/min |

|

|

|

|

|

|

|

|

|

|

|

|

||||

20 |

Working |

|

|

1—5—3—6—2—4 |

||||

|

order |

|

|

|

|

|

|

|

|

Oil |

|

|

|

|

|

|

|

21 |

fuel consumption |

|

|

|

≤0.5 |

|||

|

ratio |

|

|

|

|

|

|

|

20

|

|

CD40 CD15W—40 CD10W—30 |

|

|

|

GB 11122-2006 CD |

|

22 |

Oil brand |

Summer: CD40 CD15W—40, Winter: CD10W—30 or other |

|

diesel oil with grade not below CD grade of GB 11122-2006 |

|||

|

|

||

|

|

corresponding with the environment |

|

|

|

|

|

|

( |

|

|

|

) |

|

|

23 |

Crankshaft rotation |

Anticlockwise |

|

|

direction (face to |

|

|

|

power output end) |

|

|

|

|

|

|

|

( |

|

|

|

) °CA Fuel |

|

|

24 |

supply advance |

12±1 |

|

angle (Top dead |

|||

|

|

||

|

point front crankshaft |

|

|

|

corner ) °CA |

|

|

25 |

Fuel |

KBEL-P023A |

|

|

injector type |

|

|

|

|

|

|

26 |

Fuel |

DSLA147P008 |

|

|

nozzle type |

|

|

|

|

|

|

|

|

|

|

27 |

Fuel injector opening |

25 26 |

|

|

pressure MPa |

|

|

|

|

|

|

|

FSN |

|

|

28 |

Exhaust smoke level |

≤3.0 |

|

|

(FSN) |

|

|

|

LwdB(A) |

|

|

29 |

Limit of noise |

≤115 |

|

|

LwdB(A) |

|

|

|

|

|

|

30 |

Compressing |

≥2.5 |

|

pressure |

|||

|

|

||

|

(n≥200r/min) MPa |

|

|

|

|

|

21

31 |

|

|

|

|

|

|

|

||||

|

Lubricating method |

|

Pressure lubricating and splattering lubricating combined |

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

32 |

|

|

|

|

|

|

Electrical starting |

||||

|

Starting method |

|

|

|

|

|

|

|

|

||

|

|

L |

|

|

|

|

|

|

|

|

|

33 |

Capacity of engine |

|

|

|

|

17~20 |

|

|

|||

|

oil (L) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Diesel |

|

|

|

|

|

|

|

|

||

34 |

engine net weight |

|

|

|

|

700 |

|

|

|||

|

kg |

|

|

|

|

|

|

|

|

|

|

|

|

× × |

|

|

|

|

|

|

|

|

|

|

mm |

|

|

|

|

|

|

|

|

|

|

35 |

Overall dimension |

|

|

|

|

1234×800×1100 |

|

||||

|

(length × width× |

|

|

|

|

|

|

|

|

||

|

height) (mm) |

|

|

|

|

|

|

|

|

|

|

|

1 2 |

YC6B |

|||||||||

Table 1-2 YC6B (non-Turbocharged) series engine main technical parameter |

|||||||||||

|

|

|

|

|

|

|

|

Technical specification |

|||

No. |

Name |

|

|

|

|

|

|

|

|

|

|

|

|

|

B8W00 |

|

B9C00 |

|

B9D00 |

B8Q00 |

B8C00 |

||

1 |

Model |

|

|

YC6B120-T1 |

|

YC6B125-T1 |

|

YC6B125-T1 |

YC6B105-K |

YC6B125-K |

|

|

|

|

|

|

|

|

|

|

|

|

|

2 |

Type |

|

|

|

|

|

|

||||

|

|

|

|

|

Vertical in-line, water-cooling, 4-stroke |

||||||

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Natural air intake |

||||

3 |

|

|

|

|

|

|

|||||

Air intake way |

|

|

|

|

Turbocharged |

||||||

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

4 |

Type of |

|

|

|

|

|

ω |

||||

combustion |

|

|

|

Direct injection type tube sinking ω combustion chamber |

|||||||

|

|

|

|

||||||||

|

chamber |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

22

5 |

|

|

|

|

|

6 |

|

|

Cylinder NO. |

|

|

|

|

|

|||

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

mm |

|

|

|

|

|

|

6 |

Cylinder diameter |

|

|

|

108 |

|

|

|

|

(mm) |

|

|

|

|

|

|

|

7 |

|

mm |

|

|

|

125 |

|

|

Piston stroke (mm) |

|

|

|

|

|

|||

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

L |

|

|

|

|

|

|

|

8 |

Total piston |

|

|

|

|

6.871 |

|

|

|

displacement |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

9 |

|

|

|

|

|

17.5:1 |

|

|

Compression ratio |

|

|

|

|

|

|||

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

10 |

Cylinder sleeve |

|

|

|

Wet |

|

|

|

|

type |

|

|

|

|

|

|

|

11 |

|

kW |

85 |

|

92 |

92 |

75 |

92 |

|

Rated power (kW) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

r/min |

|

|

|

|

|

|

12 |

Rated rotation |

2000 |

|

2200 |

2300 |

1700 |

2200 |

|

|

speed(r/min) |

|

|

|

|

|

|

|

13 |

|

N·m |

|

463 |

450 |

460 |

463 |

|

|

Max. torque(N·m) |

|

|

|

|

|

|

|

|

|

|

|

|

|

1300 |

1400 |

|

14 |

r/min Speed at |

|

|

1400 1600 |

|

|||

|

|

|

1400 |

1600 |

||||

|

max torque (r/min) |

|

|

|

|

|||

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

g/kW·h Fuel |

|

|

|

|

|

|

|

15 |

consumption rate |

|

|

|

≤240 |

|

|

|

at rated working |

|

|

|

|

|

|||

|

|

|

|

|

|

|

||

|

condition |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

23

|

|

|

|

|

|

|

|

|

|

||

|

Fuel |

|

|

|

|

|

|

|

|

||

16 |

consumption rate |

|

|

|

|

≤235 |

|

|

|

||

|

at max torque |

|

|

|

|

|

|

|

|

||

|

g/kW·h |

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

||||

|

|

|

GB 252-2000 0 10 , |

||||||||

|

|

|

Summer: GB 252-2000 top grade or firstrater 0 #, 10 # light diesel |

||||||||

|

|

oil |

|

|

|

|

|

|

|

||

17 |

GB 252-2000 0 -10 -20 -35 |

||||||||||

Diesel oil brand |

|||||||||||

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

||||

|

|

|

Winter: GB 252-2000 top grade or firstrater 0 #,-10 #, -20 #, -35 # |

||||||||

|

|

|

|

|

|

|

light diesel oil |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

||

18 |

Max. rotation |

≤2200 |

|

|

2420 |

≤2530 |

1870±20 |

|

2420 |

||

speed |

with no |

|

|

2464 |

|

2464 |

|||||

|

|

|

|

|

|

|

|||||

|

load r/min |

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

||

|

Min. |

|

|

|

|

|

|

|

|

||

19 |

rotation speed |

|

|

|

|

700 750 |

|

|

|

||

|

with no load r/min |

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|||||

20 |

Working |

|

|

|

1—5—3—6—2—4 |

|

|||||

|

order |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1-2 Table 1-2 (continued) |

|

||||||

|

|

|

|

|

|

|

|

||||

|

|

Name |

|

|

|

Technical specification |

|

||||

No. |

|

|

|

|

|

|

|

|

|||

B8W00 |

|

|

B9C00 |

B9D00 |

B8Q00 |

|

B8C00 |

||||

|

|

|

|

|

|||||||

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

||

21 |

Oil fuel |

|

|

|

|

≤0.5 |

|

|

|

||

consumption |

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|||

|

ratio |

|

|

|

|

|

|

|

|

|

|

24

|

|

CD40 CD15W—40 CD10W—30 |

|

|

|

GB 11122-2006 CD |

|

22 |

|

Summer: CD40 CD15W—40, Winter: CD10W—30 or other |

|

|

Oil brand |

diesel oil with grade not below CD grade of GB 11122-2006 |

|

|

|

||

|

|

corresponding with the environment |

|

|

|

|

|

|

( |

|

|

|

) |

|

|

23 |

Crankshaft rotation |

Anticlockwise |

|

|

direction (face to |

|

|

|

power output end) |

|

|

|

|

|

|

|

( |

|

|

|

) °CA |

|

|

|

Fuel supply |

|

|

24 |

advance angle |

13±2 |

|

|

(Top dead point |

|

|

|

front crankshaft |

|

|

|

corner ) °CA |

|

|

|

|

|

|

25 |

Fuel |

CKBL68S001/PF68S35 |

|

|

injector type |

|

|

|

|

|

|

26 |

Fuel |

CDLLA147S071/DSLA147S071 |

|

|

nozzle type |

|

|

|

|

|

|

|

|

|

|

27 |

Fuel injector |

23 24 |

|

opening pressure |

|||

|

|

||

|

MPa |

|

|

|

|

|

|

|

FSN |

|

|

28 |

Exhaust smoke |

≤3.5 |

|

|

level (FSN) |

|

|

|

|

|

25

|

LwdB(A) |

|

|

29 |

Limit of noise |

≤115 |

|

|

LwdB(A) |

|

|

|

|

|

|

|

Compressing |

|

|

30 |

pressure |

|

≥2.5 |

|

(n≥200r/min) |

|

|

|

MPa |

|

|

31 |

|

|

|

|

Lubricating method |

Pressure lubricating and splattering lubricating combined |

|

32 |

|

|

Electrical starting |

|

Starting method |

|

|

|

|

L |

|

33 |

Capacity of engine |

15~18 |

|

|

oil (L) |

|

|

|

|

|

|

34 |

Diesel engine net |

650 |

|

|

weight |

kg |

|

|

|

|

|

|

|

× |

|

|

× |

mm |

|

35 |

Overall dimension |

1133×725×889 |

|

|

(length × width× |

|

|

|

height) (mm) |

|

|

|

|

|

|

1 3 YC6B

Table 1-3 YC6B (Turbocharged) series engine main technical parameters

|

|

|

|

|

|

|

Technical specification |

|||

No. |

Name |

|

B7700 |

|

|

B9A00 |

|

B9F00 |

B9K00 |

|

|

|

|

|

|

|

|

|

|||

1 |

Model |

|

YC6B160Z- |

YC6B140Z-T1 |

|

YC6B150Z-T1 |

YC6B150Z-T1 |

|||

|

|

|

|

|

|

|

|

|

||

2 |

Type |

|

|

|

|

|

|

|||

|

|

Vertical in-line, water-cooling, 4-stroke |

||||||||

|

|

|

|

|||||||

3 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

Air intake way |

|

|

|

|

Turbocharged |

|

||||

|

|

|

|

|

|

|||||

26

|

Type of |

ω Direct injection type tube sinking ω |

|||||||||||||

4 |

combustion |

|

|||||||||||||

|

|

|

|

|

combustion chamber |

|

|

|

|||||||

|

chamber |

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

5 |

|

|

|

|

|

|

|

|

6 |

|

|

|

|

|

|

Cylinder NO. |

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

mm |

|

|

|

|

|

|

|

|

|

|

|

|

|

6 |

Cylinder diameter |

|

|

|

|

|

|

108 |

|

|

|

|

|

||

|

(mm) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

7 |

|

mm |

|

|

|

|

|

|

125 |

|

|

|

|

|

|

Piston stroke (mm) |

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

L |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

8 |

Total piston |

|

|

|

|

|

|

|

6.871 |

|

|

|

|

|

|

|

displacement |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

9 |

|

|

|

|

|

|

|

|

17.5:1 |

|

|

|

|

|

|

Compression ratio |

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

10 |

|

|

|

|

|

|

|

Wet |

|

|

|

|

|

||

|

Cylinder sleeve |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

11 |

|

kW |

115 |

102 |

|

110 |

110 |

||||||||

|

Rated power (kW) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

r/min |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

12 |

Rated rotation |

2200 |

2000 |

|

2000 |

2100 |

|||||||||

|

speed(r/min) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

13 |

|

N·m |

560 |

550 |

|

550 |

550 |

||||||||

|

Max. torque(N·m) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

14 |

r/min |

|

1400 |

|

1600 |

1400 |

|

1600 |

|

1400 |

|

1600 |

1400 |

|

1600 |

|

Speed at max |

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

torque (r/min) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

27

|

|

|

|

|

|

|

|

|

|

g/kW·h |

|

|

|

|

|

|

|

15 |

Fuel consumption |

|

|

≤230 |

|

|||

|

rate at rated |

|

|

|

|

|

|

|

|

working condition |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

g/kW·h |

|

|

|

|

|

|

|

16 |

Fuel consumption |

|

|

≤225 |

|

|||

|

rate at max torque |

|

|

|

|

|

|

|

|

g/kW·h |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

GB 252-2000 0 10 , |

|||||

|

|

|

Summer: GB 252-2000 top grade or firstrater 0 #, 10 # light diesel |

|||||

|

Diesel oil |

oil |

|

|

|

|

|

|

17 |

GB 252-2000 0 -10 -20 -35 |

|||||||

brand |

|

|

|

|

|

|||

|

|

|

|

|

||||

|

|

|

Winter: GB 252-2000 top grade or firstrater 0 #,-10 #, -20 #, -35 # |

|||||

|

|

|

|

light diesel oil |

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

18 |

Max. rotation |

≤2420 |

≤2160 |

|

≤2200 |

|

≤2310 |

|

speed |

with no |

|

|

|||||

|

|

|

|

|

|

|

||

|

load r/min r/min |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Min. |

|

|

|

|

|

|

|

19 |

rotation speed |

|

|

700 750 |

|

|||

|

with no load r/min |

|

|

|

|

|

|

|

20 |

Working |

|

1—5—3—6—2—4 |

|

||||

|

order |

|

|

|

|

|

|

|

|

|

|

1-3 Table 1-3(continued) |

|

||||

|

|

|

|

|

|

|

||

|

|

Name |

|

|

Technical specification |

|

||

No. |

|

|

|

|

|

|

||

B7700 |

B9A00 |

|

B9F00 |

|

B9K00 |

|||

|

|

|

|

|||||

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

21 |

Oil fuel |

|

|

≤0.5 |

|

|||

consumption |

|

|

|

|||||

|

|

|

|

|

|

|

||

|

ratio |

|

|

|

|

|

|

|

28

|

|

CD40 CD15W—40 CD10W—30 |

|

22 |

Oil |

GB 11122-2006 CD Summer: CD40 |

|

CD15W—40, Winter: CD10W—30 or other diesel oil with grade |

|||

|

brand |

||

|

|

not below CD grade of GB 11122-2006 corresponding with the |

|

|

|

|

|

|

( |

|

|

|

) |

|

|

23 |

Crankshaft rotation |

Anticlockwise |

|

|

direction (face to |

|

|

|

power output end) |

|

|

|

( |

|

|

|

) °CA |

|

|

|

Fuel supply |

|

|

24 |

advance angle |

13±2 |

|

|

(Top dead point |

|

|

|

front crankshaft |

|

|

|

corner ) °CA |

|

|

|

|

|

|

25` |

Fuel |

CKBL68S001/PF68S35 |

|

|

injector type |

|

|

26 |

Fuel |

CDLLA147S071/DSLA147S071 |

|

|

nozzle type |

|

|

|

|

|

|

|

|

|

|

27 |

Fuel injector |

23 24 |

|

opening pressure |

|||

|

|

||

|

MPa |

|

|

|

FSN |

|

|

28 |

Exhaust smoke |

≤3.5 |

|

|

level (FSN) |

|

|

|

|

|

|

|

LwdB(A) |

|

|

29 |

Limit of noise |

≤115 |

|

|

LwdB(A) |

|

|

|

|

|

|

|

Compressing |

|

|

30 |

pressure |

≥2.5 |

|

|

(n≥200r/min) |

|

|

|

MPa |

|

29

31 |

|

|

Pressure lubricating and splattering |

||||||||

|

Lubricating method |

|

|

lubricating combined |

|

|

|||||

32 |

|

|

|

|

Electrical starting |

|

|

||||

|

Starting method |

|

|

|

|

|

|

|

|

||

|

|

L |

|

|

|

|

|

|

|

|

|

33 |

Capacity of engine |

|

|

|

17~19 |

|

|

|

|||

|

oil (L) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

||

34 |

Diesel engine net |

|

|

|

650 |

|

|

|

|||

|

weight kg |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

× |

|

|

|

|

|

|

|

|

|

|

× |

mm |

|

|

|

|

|

|

|

|

|

35 |

Overall dimension |

|

|

1133×725×889 |

|

|

|

||||

|

(length × width× |

|

|

|

|

|

|

|

|

||

|

height) (mm) |

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

||

1 4 |

YC6J |

|

|

|

|

|

|

|

|||

Table 1-4 YC6J series engine main technical |

parameter |

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

Technical specification |

|||||

No. |

Name |

|

|

|

|

|

|

|

|

|

|

|

J8400 |

|

J8500 |

|

J8000 |

|

J7M00 |

||||

|

|

|

|

|

|

|

|||||

1 |

Model |

YC6J120-T1 |

YC6J120-T10 |

YC6J125Z-T2 |

YC6J145Z-T2 |

||||||

|

|

|

|

|

|

|

|

|

|||

2 |

Type |

|

|

|

|

||||||

Vertical in-line, water-cooling, 4-stroke |

|||||||||||

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

3 |

Air intake way |

Natural air intake |

|

Turbocharged |

|||||||

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

||

|

Type |

|

|

ω |

|

|

|||||

4 |

of combustion |

|

|

|

|

||||||

Direct injection type tube sinking ω combustion chamber |

|||||||||||

|

chamber |

|

|||||||||

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

||

5 |

Cylinder |

|

|

|

6 |

|

|

|

|||

NO. |

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

30

Loading...

Loading...