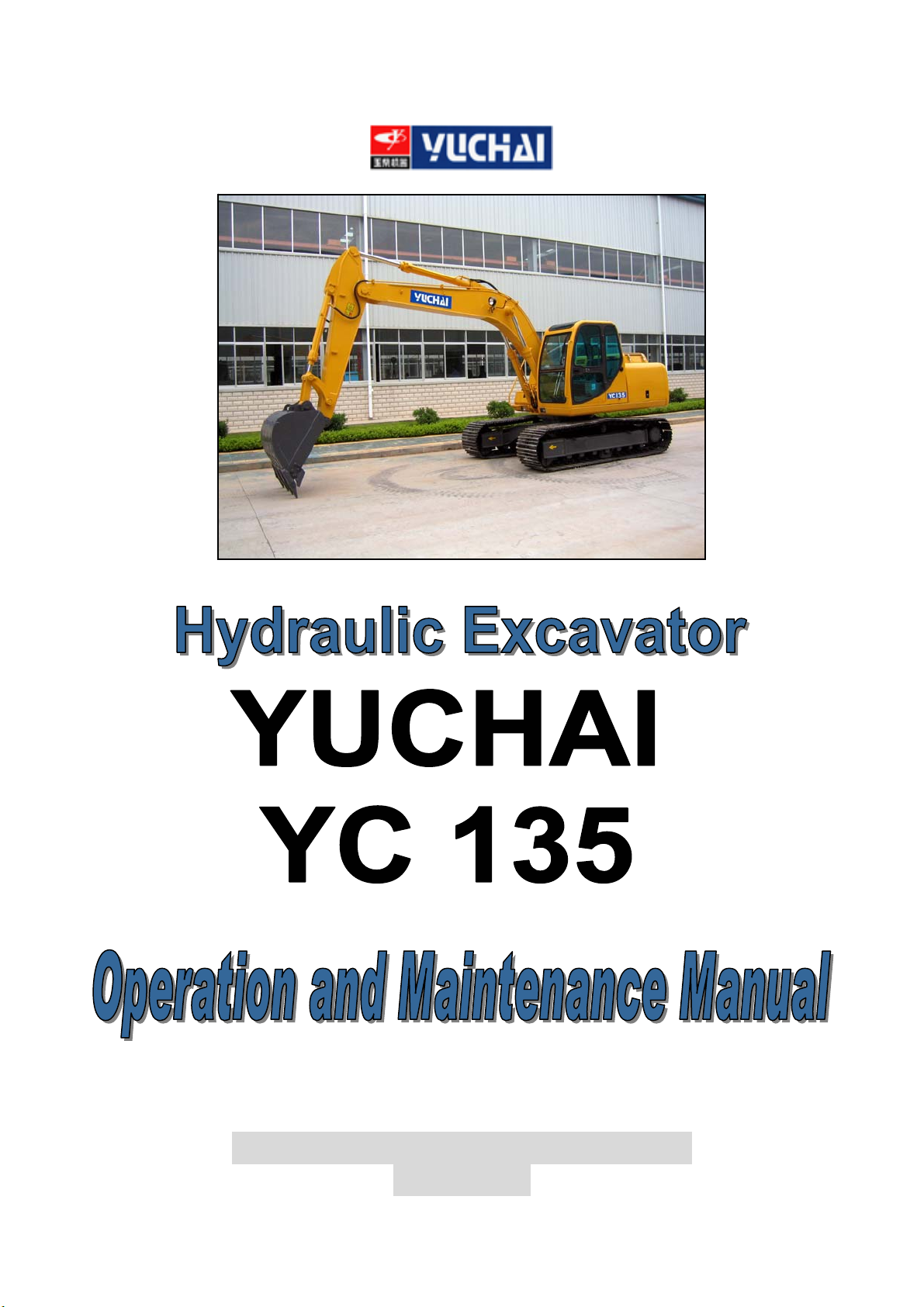

Yuchai YC135-7 Owner's Manual

Y

Y

Y

U

U

U

C

C

C

H

H

H

A

A

A

I

I

I

E

E

E

N

N

N

G

G

G

I

I

I

N

N

N

E

E

E

E

I

E

I

E

I

R

s

R

s

R

s

I

s

I

s

I

s

N

u

N

u

N

u

G

e

G

e

G

e

:

:

:

T

D

.

M

M

M

A

2

A

2

A

2

C

0

C

0

C

0

H

0

H

0

H

0

I

5

I

5

I

5

N

N

N

E

E

E

R

R

R

Y

Y

Y

C

C

C

O

O

O

.

.

.

L

L

L

T

T

D

D

.

.

ATTENTION!!!

A dangerous use of the machine may cause serious injure to the

operators and to the people near the working zone. So it is essential

that, who will use the machine, follows all is written in the manual.

The operators and the maintainers have to read this manual before to

perform any services on the machine. This manual must be kept on

board to allow to the operators further consultation and periodical

reading by who will use the machine.

Is absolutely forbidden use the machine inside tunnels, mines and

fields with slope that exceed 30 °.

Duplication, total or partial, with any device of this manual is

forbidden because it is exclusive property of the Yuchai Engineering

Machinery Co. Ltd.

3

4

INDEX

1. INTRODUCTION AND GENERAL INFORMATION ............................... 9

1.1 Machine serial number........................................................................................12

1.2 Yuchai engineering machinery co. ltd. data......................................................13

2. GENERAL PRECAUTION AND SAFETY MEASURES....................... 15

3. PRECAUTION AND SAFETY MEASURES DURING WORK.............. 23

3.1 Precautions before engine start.........................................................................23

3.2 Precaution when the machine is working..........................................................26

3.3 Transport precaution...........................................................................................37

3.4 Precaution when operate with battery...............................................................38

3.5 Pulling precaution................................................................................................39

4. MAINTENANCE PRECAUTIONS......................................................... 41

4.1 Precautions before staring maintenance...........................................................41

4.2 Precaution during maintenance .........................................................................44

5. MACHINE DESCRIPTION .................................................................... 49

5.1 Excavator main parts description ......................................................................49

5.2 Data sheet.............................................................................................................50

5.2.1. Transport blocked .........................................................................................51

5.3 Warning plates.....................................................................................................52

5.4 Identification plate...............................................................................................54

6. INSTRUMENT AND COMMAND DESCRIPTION ................................ 55

6.1 Operators seat description .................................................................................55

6.1.1. Lever and pedal ............................................................................................56

6.2 Instrument panel and switches...........................................................................

6.2.1. Instrument and Switches...............................................................................

6.2.2. Heating and air conditioning..........................................................................66

6.3 Fuses ....................................................................................................................

6.4 Operator seat........................................................................................................

6.4.1. Operator seat adjusting.................................................................................

6.4.2. Seat belt........................................................................................................

6.5 Cabin.....................................................................................................................68

6.5.1. Open / Close side door .................................................................................68

6.5.2. Front window opening...................................................................................69

6.5.3. Side window opening ....................................................................................70

6.5.4. Cab light........................................................................................................70

6.5.5. Emergency exit .............................................................................................70

60

60

66

67

67

68

7. STARTING MACHINE .......................................................................... 71

7.1 Check before start ...............................................................................................71

7.1.1. Check coolant, refill it....................................................................................

7.1.2. Check and replacing engine oil .....................................................................

7.1.3. Inspecting and adjusting the fan belt.............................................................72

7.1.4. Fuel level and refuelling ................................................................................73

5

71

72

7.1.5. Check hydraulic oil and refill .........................................................................73

7.1.6. Check air filter ...............................................................................................74

7.1.7. Check electrical circuit ..................................................................................75

7.2 Starting.................................................................................................................76

7.2.1. Precaution.....................................................................................................76

7.2.2. Engine starting ..............................................................................................76

7.2.3. Start engine in cold weather..........................................................................77

7.3 Operations and controls after starting...............................................................77

7.3.1. Engine heating ..............................................................................................

7.3.2. Instrument panel check.................................................................................

7.3.3. Safety lock lever check .................................................................................78

7.3.4. Noise and exhaust check..............................................................................78

77

78

8. MACHINE MOVING RULES................................................................. 79

8.1 Forward movement..............................................................................................

8.2 Backwards movement.........................................................................................80

8.3 Changing direction (steering).............................................................................

8.4 Machine stop and park........................................................................................

8.5 Swinging...............................................................................................................85

8.6 Forbidden movement and forbidden use ..........................................................86

8.7 Precaution for operating .....................................................................................89

8.8 Work possible using hydraulic excavator .........................................................92

8.8.1. Backhoe work ...............................................................................................92

8.8.2. Ditching work ................................................................................................93

8.8.3. Loading work.................................................................................................93

8.8.4. Operations in confined spaces......................................................................93

8.9 How to escape from mud ....................................................................................94

79

81

84

9. COLD WEATHER OPERATION........................................................... 96

9.1 Precaution for fuel, lubricants and coolant in low temperature ......................96

9.1.1. Fuel and lubricants........................................................................................

9.1.2. Coolant .........................................................................................................

9.1.3. Battery ..........................................................................................................

9.2 Engine starting in cold weather..........................................................................

9.3 Precaution at work end in cold weather ............................................................97

9.4 Cabin heater.........................................................................................................98

96

96

97

97

10. CHECK AFTER COMPLETION OF WORK ......................................... 99

11. USING RUBBER SHOES (ONLY FOR MACHINE WITH RUBBER

SHOES) ......................................................................................................

11.1 Rubber shoes guarantee...................................................................................

11.2 Precautions when using rubber shoes............................................................

101

101

102

12. TRANSPORTATION........................................................................... 105

12.1 Loading unloading work ...................................................................................105

12.2 Load precaution.................................................................................................107

12.3 Precaution for transportation ...........................................................................107

6

13. MACHINE TOWING............................................................................ 109

14. LONG TERM STORAGE .................................................................... 111

14.1 Before storage....................................................................................................111

14.2 During storage ...................................................................................................112

14.3 After storage.......................................................................................................112

15. STARTING MACHINE WITH JUMP-START CABLES (BATTERY

DISCHARGED!) .........................................................................................

113

15.1 Precaution for jump-start cable connection and staring................................

15.2 Precaution for jump-start cables disconnecting.............................................

15.3 Precaution for battery charging while it is onboard.......................................117

116

117

16. PHENOMENA THAT ARE NOT FAILURE......................................... 119

17. THE BUCKET ..................................................................................... 121

17.1 Bucket removing................................................................................................121

17.2 Bucket assembling............................................................................................123

18. MAINTENANCE.................................................................................. 125

18.1 Guides to maintenance .....................................................................................125

18.2 Controls table and maintenance schedule......................................................128

18.3 Maintenance during Breaking-in period ..........................................................129

18.4 Lubricants (oil and grease), coolant, fuel characteristics..............................130

18.4.1. Engine oil and hydraulic oil .........................................................................131

18.4.2. Fuel.............................................................................................................131

18.4.3. Coolant .......................................................................................................132

18.4.4. Grease ........................................................................................................132

18.4.5. Oil and fuel storage.....................................................................................132

18.5 Filter....................................................................................................................

18.6 Electrical wiring .................................................................................................134

18.7 Maintenance tools and torque list....................................................................

18.7.1. Needed tools for maintenance ....................................................................

18.7.2. Standard torque list.....................................................................................

133

135

135

136

19. PERIODICAL REPLACEMENT OF SAFETY CRITICAL PARTS...... 137

19.1 Daily checking or every 10 hours.....................................................................

19.1.1. General check.............................................................................................137

19.1.2. Check, Clean and Replace air filter.............................................................138

19.1.3. Check coolant level and pipe preservation..................................................139

19.1.4. Check bolt torque of the sprocket ...............................................................139

19.1.5. Checking and adjusting rubber shoes tension (for machine with rubber shoes

only) 139

19.1.6. Checking and adjusting steel track tension (for machine with steel track only)

146

19.2 Maintenance every 50 hours.............................................................................

19.2.1. Lubricating ..................................................................................................

19.2.2. Check electrolyte level ................................................................................150

19.3 Maintenance every 100 hours...........................................................................151

7

137

149

149

19.3.1. Cleaning fuel filter and water separator ......................................................151

19.3.2. Fan belt adjusting........................................................................................152

19.4 Maintenance every 200 hours...........................................................................153

19.4.1. Replacing oil engine and oil filter cartridge .................................................153

19.4.2. Check and refill oil in the sprocket ..............................................................155

19.4.3. Oil level in swing gear .................................................................................156

19.4.4. Cleaning water separator filter ....................................................................156

19.5 Maintenance every 400 hours...........................................................................158

19.5.1. Check intake pressure ................................................................................

19.5.2. Fuel filter cartridge replacement..................................................................

19.5.3. Check and clean radiator fins......................................................................159

19.5.4. Replacing the hydraulic oil return filter ........................................................160

19.5.5. Replacing pilot filter cartridge......................................................................161

19.5.6. Engine bolts supports tightening.................................................................

19.5.7. Replacing the air filter cartridge ..................................................................

19.5.8. Sprocket bolts fastening..............................................................................162

19.5.9. Oil level in the front idler .............................................................................163

19.6 Maintenance every 800 hours...........................................................................164

19.6.1. Cleaning and replacing cooling system.......................................................164

19.6.2. Replacing the hydraulic oil and cleaning the suction strainer......................166

19.6.3. Replacing the travel motor gear oil .............................................................168

19.6.4. Replacing swing system oil.........................................................................168

19.6.5. Check the engine valves clearance, adjusting them ...................................168

158

159

162

162

20. HYDRAULIC SCHEME....................................................................... 169

21. ELECTRICAL SCHEME ..................................................................... 171

22. TROUBLE SHOOTING....................................................................... 173

23. OPTIONAL ACCESSORIES............................................................... 177

23.1 Safety precaution...............................................................................................

177

24. NOTICE............................................................................................... 179

25. ANALYTIC INDEX .............................................................................. 181

8

1. INTRODUCTION AND GENERAL INFORMATION

This manual provide regulations and orientations which

will help you to use correctly your machine without any

risk.

Keep the manual easy to read to allow all operators to

read it periodically.

If the manual will miss or become unreadable, please ask

for a copy to YUCHAI ENGINEERING MACHINERY CO.

LTD.

If you sell the machine, deliver the manual to new owner.

Machine project improvement could cause changing on the machine without

manual updating. Check from YUCHAI ENGINEERING MACHINERY CO.

LTD. For the latest information about your machine o for any question about

information inside this manual.

GENERAL INFORMATION

• the improperly use and maintenance of the machine

may cause hazards e could cause serious injury or

death.

• Machine’s operators and maintainers have to read this

manual from the first to the last page, before to start

any work.

• Some action relative the machine’s functioning and

maintenance may cause serious injures if they aren’t

carried out likewise is described in this manual.

• Procedure and precaution described in this manual are

applicable only at the expected machine use. If you use

the machine for any different scope here mentioned but

doesn’t specifically forbidden, you have to be sure that

it is safe for you and all others.

• Never you can use the machine for any scope

specifically forbidden in this manual.

9

Most of the accident and injuries that happens in the factories, agricultural

firms, homes or on the roads are due to the lack of attention to any simple but

basic rule of caution and safety. For this reason, most of them could be

avoided: just forecast all predictable cause and act with the necessary

caution.

With any kind of machine, anyhow projected and assembled, it is impossible

to exclude an accident without negative interference on some essential

characteristics (accessibility, efficient working, etc.).

Pay attention to all warnings written on the followed chapters and to all

“PRECAUTION AND SAFETY MEASURES”.

An operator who pay attention at his work is the best guarantee against

injuries.

The most representative of the safety rule is:

Never clean, lubricate or make service if the machine or part of it are

working.

To avoid injuries read, comprehend and forward all precautions and warnings

written in this manual and on board.

To identify the safety message, they will be highlight with the follows symbols.

DANGER

This picture is used where a residual risk with concrete

possibility of permanent injury or death will remain. The

messages describe safety cautions which have to be taken

to avoid residual risk. The fail of comply with all is written

here can, also, damage the machine.

ATTENTION

This picture is used where a residual risk with concrete

possibility of moderate injury will remain.

This picture could be used also where the only residual

risk is to damage the machine.

10

The YUCHAI ENGINEERING MACHINERY CO. LTD. cannot predict each

circumstance which may cause a residual risk during work and/or

maintenance, therefore the safety messages written in the manual can not

include all safety precaution.

If you decide to make any action which is not specifically allowed o forbidden,

you must evaluate every consequence to the action in order to avoid

damages to people, machine or object around.

If the machine is used for a work which is not listed in this manual, the

YUCHAI ENGINEERING MACHINERY CO. LTD. will not assume any

responsibility about damage or injury to people and/or object.. All safety

aspect in those action are under user responsibility.

All forbidden action in this manual never have to be made

in any

circumstance.

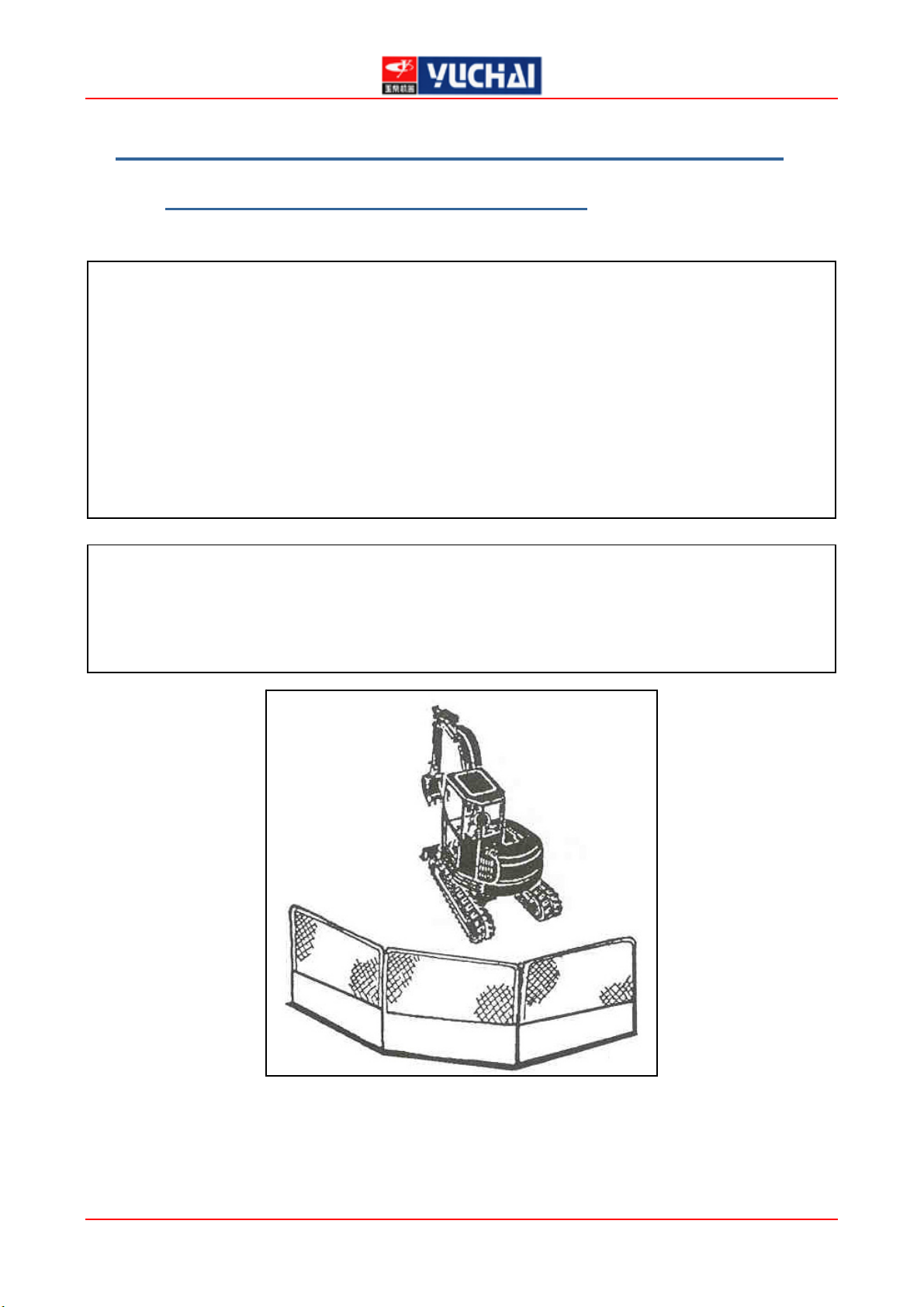

SPECIFIC USE:

This hydraulic excavator made by YUCHAI ENGINEERING MACHINERY CO.

LTD. is drawing and realized to be used for followed jobs:

• Excavator jobs (ditches and/or canals, foundation excavation, etc.);

• Loading jobs.

The YUCHAI ENGINEERING MACHINERY CO. LTD. deny liability for

possible damage to people and/or object due to different use from those

above mentioned or anyway do not specifically mentioned in this

manual.

MACHINE RUNNING IN PERIOD:

Your machine has been regulated and checked by YUCHAI ENGINEERING

MACHINERY CO. LTD. Anyway, start with hard jobs and critical condition

may have a negative influence on the machine’s performance and reduce the

lifetime.

Be sure to respect the running in period for the first 100 hours (like is showed

on the hours meter).

During the running in period:

• do run the engine at the low idling speed for 5 minutes before start work;

• avoid jobs with heavy load or high speed;

• avoid starts, braking, manoeuvres and unexpected stop except for

emergency.

11

1.1 MACHINE SERIAL NUMBER

Fill the serial number of your machine into the followed form. If you need

assistance please contact the YUCHAI ENGINEERING MACHINERY CO.

LTD. service, then specify model kind and serial number of you machine.

KIND/MODEL:

REGISTRATION No.:

The plate where is written the machine registration number is installed on

front side.

KIND/MODEL:

REGISTRATION No.:

HYDRAULIC MOTORS KIND AND REGISTRATION NUMBER

MODEL:

REGISTRATION No.:

MODEL:

REGISTRATION No.:

MACHINE KIND AND REGISTRATION NUMBER

ENGINE KIND AND REGISTRATION NUMBER

TRAVELLING ENGINE

ROTATING ENGINE

12

1.2 YUCHAI ENGINEERING MACHINERY CO. LTD. DATA

YUCHAI ENGINEERING MACHINERY CO. LTD.

Manufacturing Base:

168 Tianqiao Road, Yulin, Guangxi, 537005 P.R. China

Export Department Office:

36 Cuizhu Road, Guilin, Guangxi, 541002 P.R. China

Tel: 0086-773-5588521 5588522 5588523

Fax: 0086-773-5588530

E-mail: export@yuchai-excavator.com

Web-site: www.yuchai-excavator.com

YUCHAI EUROPE:

Address: V. Del Fonditore, 14 40138 Bologna, Italy

Tel:0039

Fax:0039

E-mail: europe@yuchai-excavator.com

13

14

2. GENERAL PRECAUTION AND SAFETY MEASURES

FOLLOWS THE SAFETY REGULATIONS

• ONLY trained, qualified, and authorized operator can drive the machine

and make maintenance.

• Follow all safety regulations, precaution and instruction written in this

manual when you use or make service on the machine.

• When you work with a person who assigned to working zone traffic, be

sure that he understand all hand signal used.

SAFETY CHARACTERISTICS

• Be sure that all protections and cover will be on their correct position. If

the protections or cover are damaged they must be repaired and/or

replaced.

• Use correctly all safety system and device installed on the machine, like

the lock lever and the seat belt.

• NEVER remove any safety system and/or devices.

• Be sure that they will remain EVER in good condition.

• Unexpected use of the safety system and/or devices may cause serious

injuries or death.

NON ALLOWED MODIFICATION

• Each modify made without YUCHAI ENGINEERING MACHINERY CO.

LTD. authorization may cause risk.

• YUCHAI ENGINEERING MACHINERY CO. LTD. deny liability for

possible injures or damage to people or objects due to non allowed

modification.

15

A

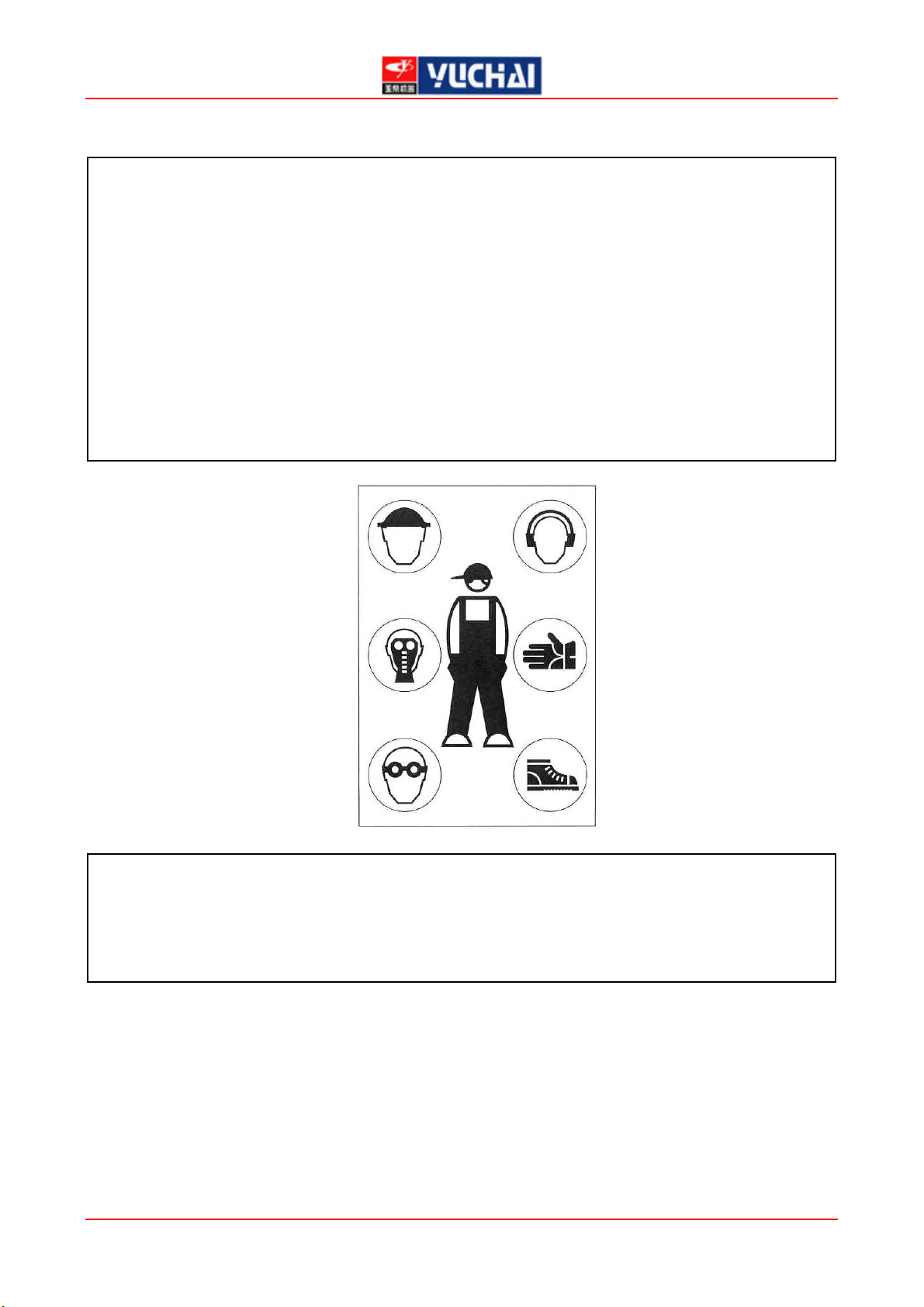

CLOTHES AND INDIVIDUAL PROTECTION DEVICES

• Avoid swirling clothes, jewels and streaming hair. They could trap

themselves on the lever or floating part and cause serious injures.

lso

do not wear oiled clothes because they are flammable.

When drive or make service on the machine, wear a tight cap, protective

eyeglass, safety shoes, filter mask, and heavy gloves. Wear always

safety glasses, hard hat and heavy gloves if your job entails metal flakes

or tiny materials, specially when you are hammering a hinge or are

cleaning the air filter with compressed air. Also make sure that nobody

stand close the machine.

• In order that the machine work in total safety is necessary the full

operator’s attention. Do not wear headphones for radio or music during

work.

16

INDIVIDUAL PROTECTION DEVICES (IPD)

If you do not follow these safety precautions it may cause

severe accident.

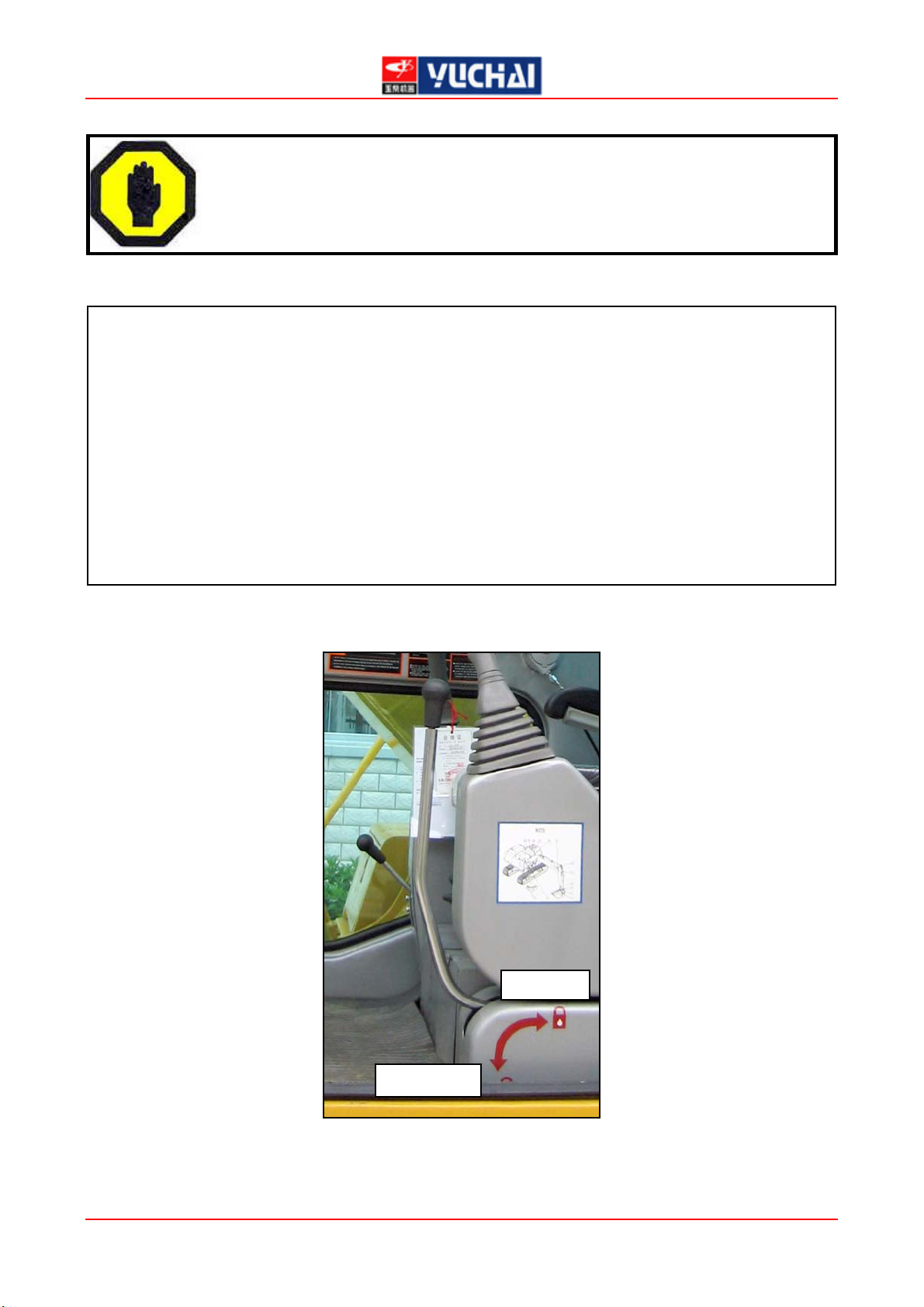

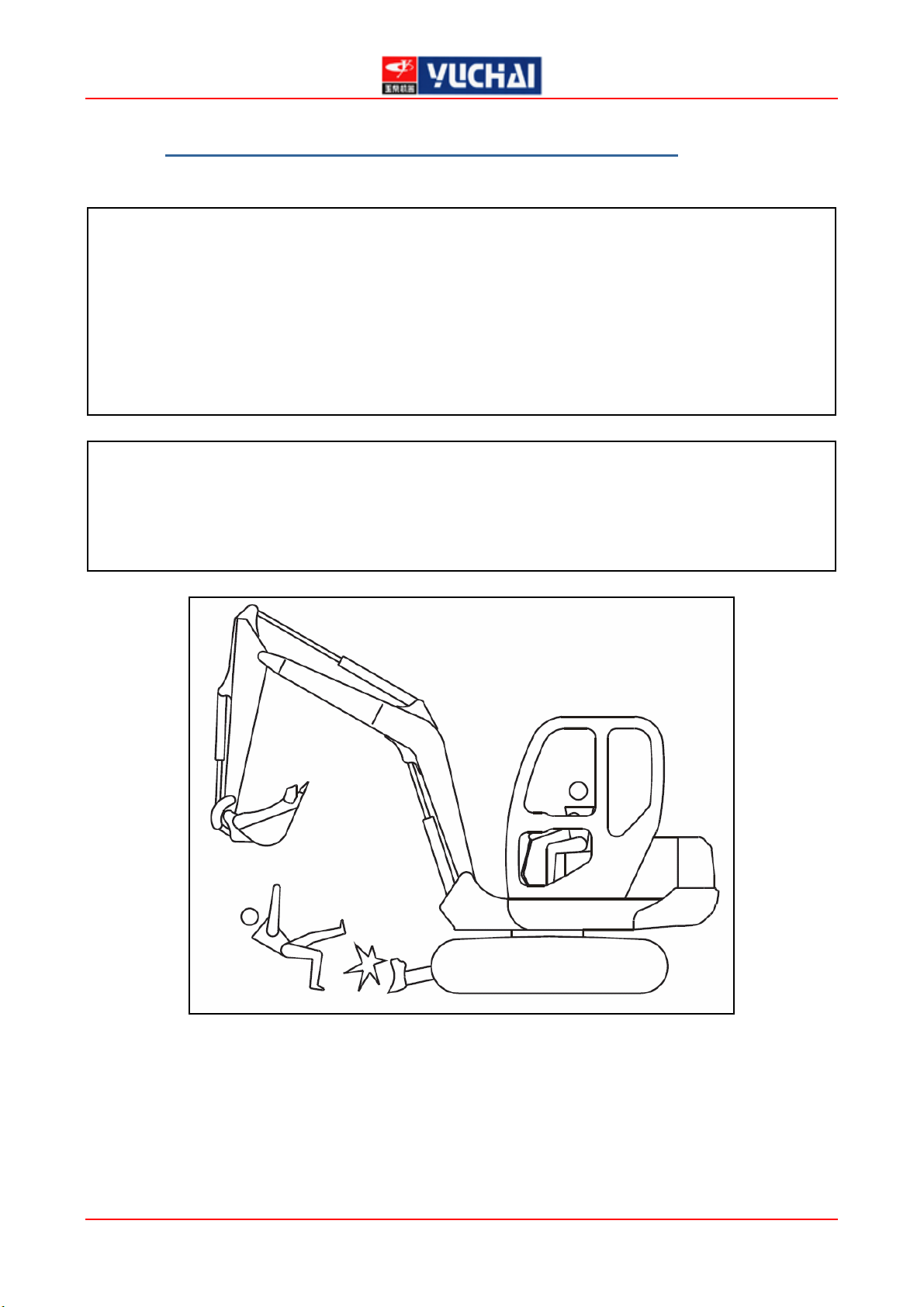

SET THE SAFETY LOCK LEVER BEFORE LEAVING THE SEAT

• When you are leaving the operator’s seat, set the safety lock lever

securely to the lock position. If any controls should be touched

accidentally when the safety lock lever has not be locked, the machine

will move suddenly and cause severe injury or death.

• When you are leaving the operator’s seat, low the bucket on the ground

(see paragraph “MACHINE STOP AND PARK”) then set the safety lock

lever in lock position. Then turn off the engine and lock the cabin door (if

your machine has a cabin). Take off the start key and keep it always with

you.

Lock

Unlock

17

MOUNTING AND DISMOUNTING FROM THE MACHINE

• NEVER jump on or off the machine.

• NEVER attempt to mount or dismount from a moving machine.

• When mounting or dismounting the cab, always face the access system

and maintain the contact with hand holds and steps while getting on or off

the machine.

• Never use the safety lock lever or control levers as hand holds.

• Always maintain three contact with hand holds and steps.

• Always clean out oil or mud from hand holds and steps. If they are

damaged then repair them, also close every bolt slackened.

• NEVER climb on the engine bonnet. It can put you in danger.

18

OIL AND FUEL FIRE PREVENTION

• Fuel, oil and antifreeze liquid may burst into flames if become in touch

with a flame. Specially, the fuel can be very DANGEROUS because it is

highly FLAMMABLE.

• Keep the flammable liquids off from the free flames.

• Turn off the engine and do not smoke while refuelling.

• Screw down as well the oil and fuel top.

• Fuel and oil refuelling must be done in well aired place.

• Take shelter oil and fuel and keep them out of reach of unauthorized

people.

PREVENT ASBESTOS INHALATION HAZARD

Asbestos inhalation may cause lungs cancer.

If asbestos fibres are in your working area, follow these rules:

• NEVER use compressed air to clean anything.

• Use water to keep down the dust.

• If possible, work with blow wind from your rear.

• If possible, use a mouth-mask approved.

19

PRECAUTION WITH HIGH TEMPERATURE WORK

• The engine, muffler, radiator, hydraulic lines, sliding parts and many other

parts of the machine are hot and under pressure directly after the engine

is stopped. Touching these parts will cause burns so wait for the

temperature drop before oil, fuel and water screw cap opening.

• To avoid hot water splash out:

1. turn off the engine;

2. waiting for the water temperature drop;

3. slowly open the screw cap to reduce the internal pressure.

• To avoid hot oil splash out:

1. turn off the engine;

2. waiting for the oil temperature drop;

3. slowly open the screw cap to reduce the internal pressure.

20

PREVENT CUTTING AND/OR CRUSHING

• do not put you hands, arms or other body parts between moving parts.

I.e. between work equipment and machine body or between cylinder and

moving parts or between upper structure and undercarriage or tracks. If

the work equipment is moving, the free space around it is changeable it

may cause severe injure or death.

FIRE EXTINGUISHER AND FIRST AID KIT

• Make sure that fire extinguisher is on board and where it is located and

make sure you are able to use it.

• Make sure that first aid kit is on board.

• Known how to do in case of fire.

• Make sure to know all phone number to contact emergency assistance

and first aid help.

21

ACCESSORIES PRECAUTION

• When you will use an optional accessory, first read the accessory’s

operating manual and follow the instruction written in it.

• NEVER use accessories listed in this operating manual or do not

authorized from YUCHAI ENGINEERING MACHINERY CO. LTD.. The

non authorized accessories use may cause safety hazards and may have

a negative influence on the machine’s performance and reduce the

lifetime.

• Each possible injury, accident or machine bad working due to use

of the unauthorized accessory, will not be responsibility of the

YUCHAI ENGINEERING MACHINERY CO. LTD.

PAY ATTENTION DO NOT CRASH THE CABIN GLASS

If the cabin glass is damaged, it is dangerous use the machine. Always

change the broken glass immediately.

22

3. PRECAUTION AND SAFETY MEASURES DURING WORK

3.1 PRECAUTIONS BEFORE ENGINE START

WORKING AREA SAFETY

• Before turning on the engine check the working area, evaluate if there are

abnormal condition which cause hazardous.

• Before turning on the engine check the ground condition in the working

area. Choose the best working method.

• Before start work, reduce the ground slope.

• Before start work under water or run through a river, check the depth and

the water flow. NEVER immerse the machine in water if the depth exceed

the allowed level.

• If your work is on the road or near people passing, put a rigid repair to

protect people and object also appoint a person to control the working

zone.

23

• If you know that water pipe, gas pipe or electrical line were been lay

underground you have to contact the owner society to identify correctly

the position. Pay attention: do not cut off the pipes.

FIRE PREVENTION

• Remove wood splinter, leaves, paper and any flammable materials

accumulated into the engine compartment. They may cause fire.

• Check if there are fuel, lubricant oil and/or hydraulic oil leakage. Use a

clean sheet to dry oil, fuel excess or other flammable liquids escaped.

• Make sure that there is a fire extinguisher and that it works.

INSIDE THE CABIN

• Do not leave tools or spare parts on the cabin floor. They may damage or

break the levers or instrument panel. Put them always into the tool box.

• Keep clean: cabin floor, instrument panel, steps, hands hold. Remove oil,

grease and dirt accumulation.

24

CLOSED WORKING ZONE VENTILATION

• If it necessary turn on the engine inside a room, provide to adequate

ventilation. Exhaust gas can KILL.

LIGHT AND WINDOWS PRECAUTION

• Clean out the windows and lights. Make sure to see well!

• Check if the headlamp are correctly installed for the job to do. Check if

they work properly.

25

3.2 PRECAUTION WHEN THE MACHINE IS WORKING

WHEN TURN OF THE ENGINE

• before start work, walk around your machine to verify that no people or

object are in the working zone.

• NEVER start the machine if any plate is put on the instrument panel.

• Play the horn before turn on the engine.

• Turn on and drive your machine from the operator’s seat only, and after

have fastened your seat belt.

• Do not allow anyone to ride on any part of the machine at any time while

travelling.

• Do not allow anyone to be on any part of the machine while operating.

26

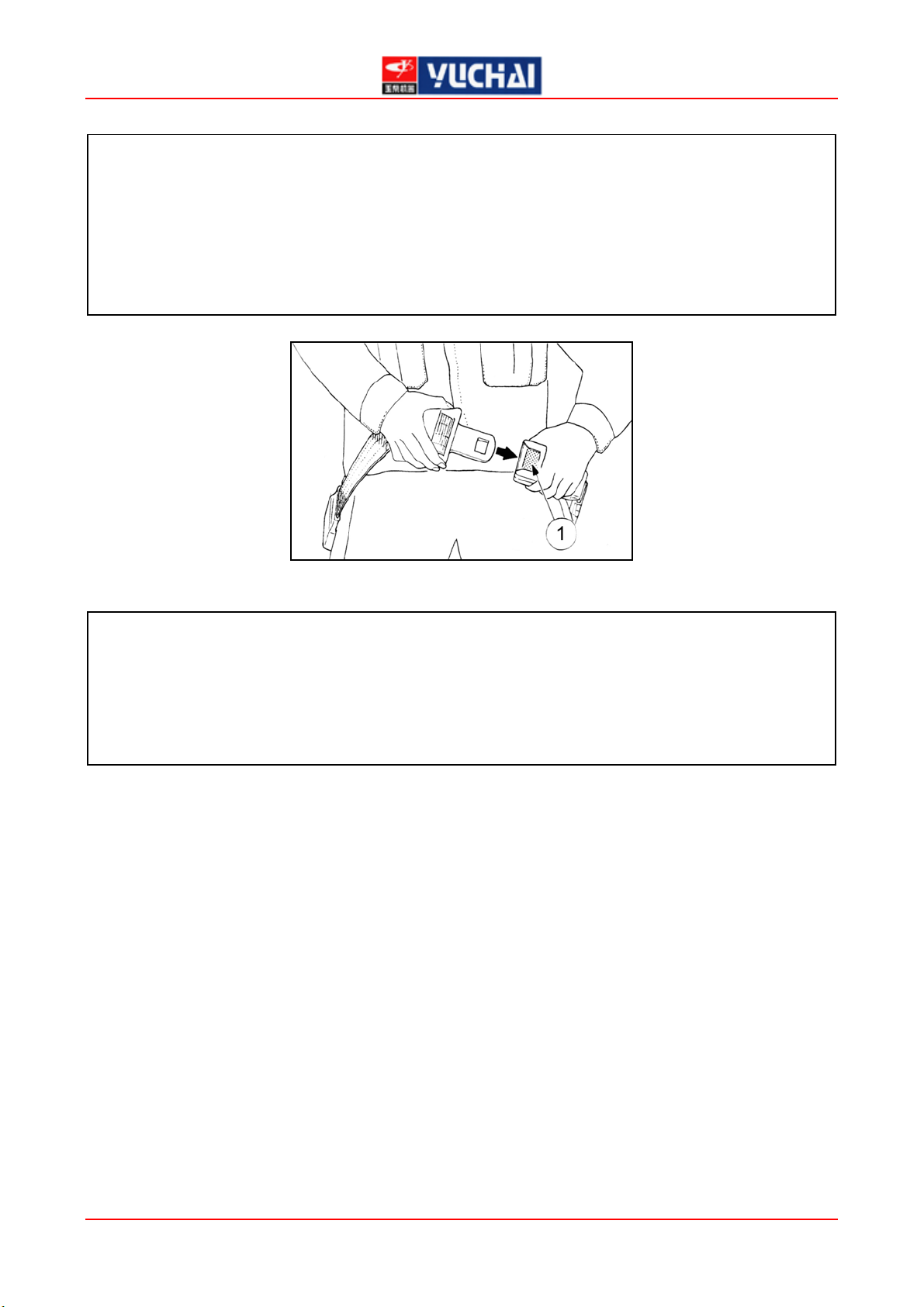

• Before start work, check the seat belt. If any part is damaged or worn,

change the seat belt.

• Before start work, sit down on the operator seat and fast the seat belt.

• Stand on the seat with the seat belt fastened all the time, during work, to

reduce injury if case of accident.

CHECK THE POSITION OF THE TRACKS BEFORE TRAVELLING

• Before operating the travel levers, check to make sure that the dozer

blade is to the front of the operator’s seat. BE AWARE that when the

dozer blade is to the rear the travel lavers operate in the opposite

direction to when the dozer blade in the front.

27

A

BEFORE GO TO THE REVERSE MOTION OR SWING, BE SURE THAT

NOBODY IS AROUND THE WORKING ZONE

• In dangerous zone o where there is incomplete view, put always a signal.

• Make sure that nobody is inside the radius swing or rear the machine.

• Before start motion, play the horn to warn people standing or walking

around the machine.

• There are blind spots to the rear of the machine, so swing the cab around

before backing up to check that the area is safe and clear.

MOTION PRECAUTION

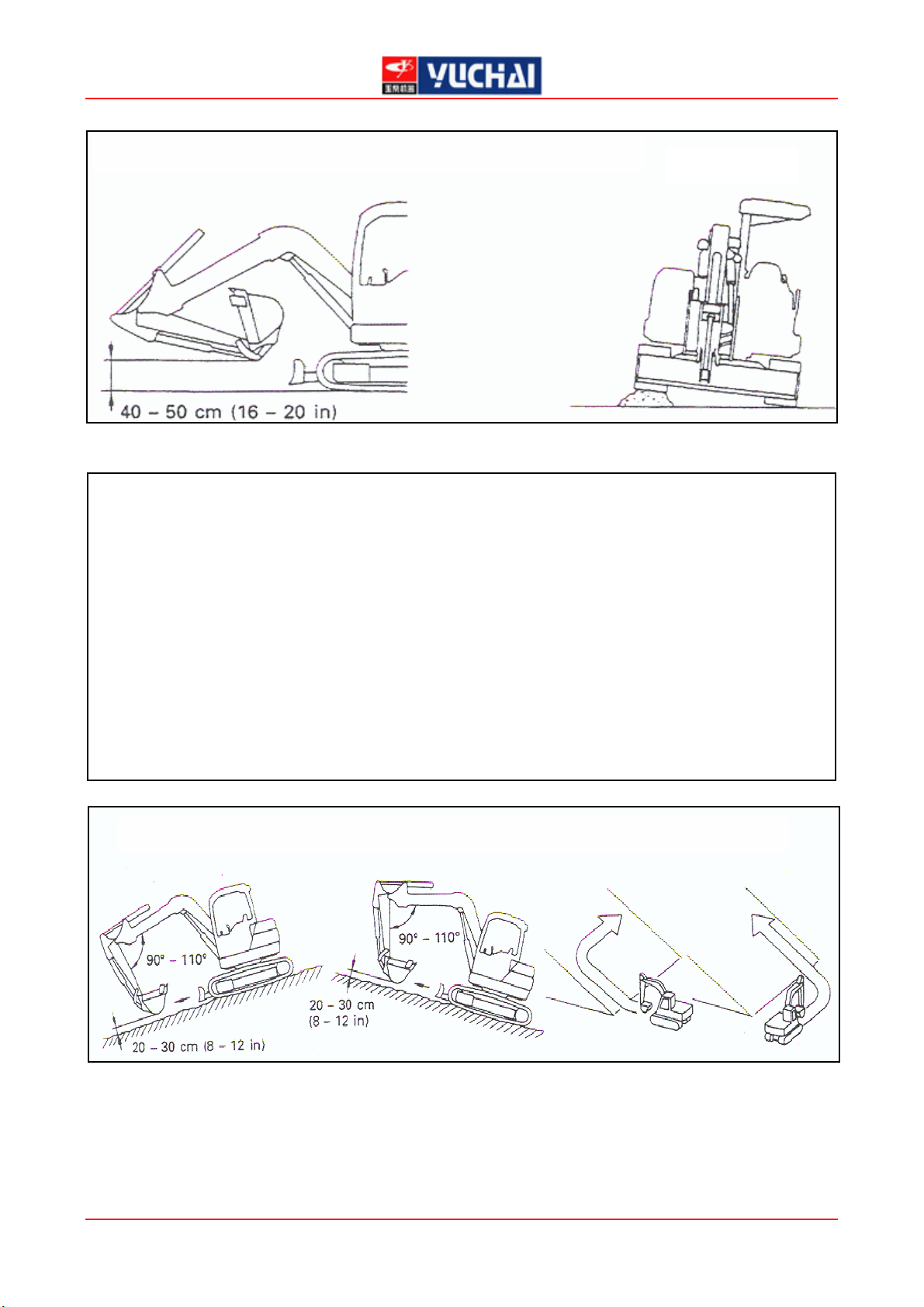

• Travel with the dozer blade folded as shown on the diagram and the

bucket raised 40 ÷ 50 cm. from the ground.

• Do not slew (swing) while travelling. If you must operate the hoe

attachment while travelling, operate at speeds slow enough so you have

complete control at all times.

• On uneven ground, travel at low speed and avoid accelerating, stopping

or changing directions abruptly.

•

void crossing over obstacles whenever possible. If you must do so,

keep the hoe attachment close to the ground and travel slowly. Never

cross obstacles if they will seriously tilt the machine (to an angle of 10° or

greater).

28

Motion Position

WRONG!

TRAVELLING ON SLOPES

• Motion up and down the hill with severe slope (greater then 30°) IS

FORBIDDEN. Great slope may cause machine roll over or slide.

• When travelling on slopes or grades, lower the bucket to a height from 20

to 30 cm off the ground. In emergencies, lower the bucket to the ground

and stop the machine.

• Do not change directions or cross slopes sideways. First return to a flat

surface then redirect the machine.

• On grass, dead leaves, wet metal or frozen surfaces, the machine may

slide sideways even on very gentle slopes. Make sure the machine never

faces sideways with respect to the slopes.

Downhill Uphill WRONG CORRECT

29

FORBIDDEN OPERATION

• Never undercut a high bank. Be particularly alert for the possibility of a

cave-in.

• Do not operate in places where there is a danger of falling rocks.

WRONG

WRONG

FORBIDDEN OPERATION

• Do not extend or move back the hydraulic cylinders for all them length,

keep a small distance.

• Do not undercut when the trucks are not leant on the ground, otherwise

you may damage the machine.

• Keep machine well back from the edge of an excavation. Avoid

undercutting the machine.

30

Loading...

Loading...