Yuchai DL165H Owner's Manual

SUNBEAR HEAVY EQUIPMENT

DL165 Skid Steer Loader

Owner's

and

Operator's

Manual

PUBLICATION NO. 16500

SEPTEMBER, 2009

SUNBEAR HEAVY EQUIPMENT LIABILTY WARRANTY

THE WARRANTY IS THE ONLY OBLIGATION OF SUNBEAR HEAVY EQUIPMENT OR A

SUNBEAR HEAVY EQUIPMENT DEALER TO THE PURCHASER OR ANYONE ELSE

CONCERNING A PRODUCT. IT'S USE OR PERFORMANCE OR ITS LOSS OF USE OR FAILURE

TO PERFORM. NEITHER SUNBEAR HEAVY EQUIPMENT NOR A IMPLIED REPRESENTATION,

WARRANTY OR AGREEMENT CONCERNING A PRODUCT, NEITHER SUNBEAR HEAVY

EQUIPMENT NOR A SUNBEAR HEAVY EQUIPMENT DEALER HAVE MADE OR WILL MAKE

ANY REPRESENTATION, WARRANTY OR AGREEMENT CONCERNING A PRODUCT'S

MERCHANTABILITY OR OTHER QUALITY, IT'S SUITABILITY FOR PURCHASER'S PURPOSE

(EVEN IF A PURCHASER HAS INFORMED SUNBEAR HEAVY EQUIPMENT OR A SUNBEAR

HEAVY EQUIPMENT DEALER OF THAT PURPOSE), IT'S DURABILITY, PERFORMANCE OR

OTHER CONDITION.

EVEN IF SUNBEAR HEAVY EQUIPMENT OR A SUNBEAR HEAVY EQUIPMENT DEALER WAS

ADVISED OF THE POSSIBILITY OF SUCH LOSS, NEITHER SUNBEAR HEAVY EQUIPMENT

NOR A SUNBEAR HEAVY EQUIPMENT DEALER WILL BE LIABLE TO PURCHASER OR

ANYONE ELSE FOR ANY INDIRECT, INCIDENTAL CONSEQUENTIAL, PUNITIVE, ECONOMIC,

COMMERCIAL, OR SPECIAL LOSS WHICH IN ANY WAY ASSOCIATED WITH A PRODUCT.

THIS INCLUDES ANY LOSS OF USE OR NON-PERFORMANCE OF A PRODUCT, ANY

REPLACEMENT RENTAL OR ACQUISITION COST, ANY LOSS OF REVENUE OR PROFITS,

ANY FAILURE TO REALIZE EXPECTED SAVINGS, ANY INTEREST COSTS, ANY IMPAIRMENT

OF OTHER PERSON.

PURCHASER MAY NOT ATTEMPT TO ENLARGE ITS RIGHTS UNDER THE WARRANTY BY

MAKING CLAIM, FOR INEMNITY, FOR BREACH OF CONTRACT, FOR BREACH OF

COLLATERAL WARRANTY, FOR A TORT (INCLUDING NEGLIGENCE, MISREPRESENTATION

OR STRICT LIABILITY) OR BY CLAIMING ANY OTHER CAUSE OF ACTION.

THE WARRANTY IS A CONDITION OF SALE OF THE PRODUCT TO THE PURCHSER AND WILL

THEREFORE APPLY EVEN IF THE PURCHASER ALLEGES THAT THERE IS A TOTAL FAILURE

OF THE PRODUCT.

WARRANTY DELIVERY: TWO (2) YEARS 1000HOURS (FOR ONLY SAMPLES).

N.B. Read and practice your Sunbear Heavy Equipment operating and servicing instructions.

Failure to do this may void the warranty.

PUBLICATION NO. 16500

SEPTEMBER, 2009

INDEX

1. SAFETY PRECAUTIONS

2. CONTROLS

2. 1 Instrument Panel

2. 2 Control Lever Handles

2. 3 Seat and Seat Belt

2. 4 Seat Bar

2. 5 Parking Brake

2. 6 Throttle Control

2. 7 Lift Arm Support

2. 8 Steering Control

2. 9 Auxiliary Controls

2. 10 Liftarm Control

2. 11 Quick - Tach

2. 12 Electrical Panel

3. OPERATION

3. 1 Starting Instructions

3. 2 Operating Procedure

3. 3 Filling From a Pile

3. 4 Digging with a Bucket

3. 5 Leveling and Backfilling

3. 6 Auxiliary Hydraulics

3. 7 Lifting

3. 8 Towing

3. 9 Securing and Transporting

3. 10 Lowering Lift Arms

3. 11 Accumulator

4. MAINTENANCE

4. 1 Preventive Maintenance Service Schedule

4. 2 Service Access

4. 3 Daily Service Checks

4. 4 50 Hour Service Check

4. 5 250 Hour Service Check

4. 6 Final Drive Maintenance

4. 7 Hydraulic / Hydrostatic System Maintenance

4. 8 Engine Maintenance

4. 9 Air Cleaner Maintenance

4. 10 Engine Cooling System

4. 11 Electrical System

4. 12 Tire Maintenance

4. 13 Trouble Shooting

4. 14 Hydraulic / Hydrostatic Circuit

4. 15 Special Tools

5. SPECIFICATIONS

5. 1 Loader Specifications

5. 2 Torque Specifications

5. 3 Decals

6. A TTACHMENTS AND BUCKETS

6. 1 SUNBEAR Approved Buckets and Attachments

WARNING

This warning indicates

hazards or unsafe

practices which COULD

result in severe personal

injury or death.

This warning indicates an

immediate hazard which

WILL result in severe

personal injury or death.

DANGER

Instructions are necessary

before operating or

servicing this machine.

Read the operators manual

and service decals on the

loader. Follow warnings and

instructions in this manual

when making repairs,

adjustments or servicing.

Check for correct operation

after adjustments and

repairs.

IMPORTANT

This notice shows

important procedures

which must be followed

to prevent damage to the

loader or attachment.

IMPORTANT

This warning indicates

hazards or unsafe

practices which COULD

result in minor personal

injury or product or

property damage.

CAUTION

FOREWORD

This book has been written to give the Owner / Operator necessary operating,

servicing and preventative maintenance instructions on the loader.

Read this manual completely and know the loader before operating or servicing it.

Do not do any service procedures that are not in the Operator•s manual.

Only service personnel that have had training in the service of this loader can do these

service procedures.

Reference Information

Write the correct information for your loaders in the spaces below. Always use these

numbers when referring to your loader.

Model No.

Serial No.

Dealer Name

Address

Phone

Throughout this manual the terms DANGER, WARNING and CAUTION are used to

indicate the degree of hazard in terms of personal safety. These words will be used in

conjunction with the Safety - Alert symbol, a triangle with an exclamation mark.

Throughout this manual, the term IMPORTANT is used

* To indicate that instructions are necessary before operating or servicing the

loader.

* To show important procedures which must be followed to prevent damage to

the loader or attachment.

5

1. SAFETY PRECAUTIONS

The following precautions are suggested to help prevent accidents.

A careful operator is the best operator. Most accidents can be avoided by observing certain precautions. Read and take the

following precautions before operating this loader to help prevent accidents. Equipment should be operated only by those

who are responsible and instructed to do so.

1. Read this manual carefully before using the loader.

Working with unfamiliar equipment can lead to accidents.

2. Do not allow anyone to ride on the loader with the

operator.

3. Make sure the seat bar is installed and functioning at all

times.

4. Never run the engine in a closed building without

adequate ventilation, as the exhaust fumes can cause

death.

5. Always fasten the seat belt around your waist before

starting the engine. Never fasten the seat belt behind you.

6. Never attempt to start the engine while standing beside

the unit unless as specified in this manual or under

specific service and backhoe operation procedures. Start

the engine only while sitting in the operator•s seat with

the seat belt fastened around you. Always check to make

certain that the seat cushion is secured to the frame.

7 Keep the operator•s area free of debris.

8. Never enter or leave the loader while the engine is

running. Always lower the lift arms down against the

frame, drop the attachment down to contact the ground,

set the parking brake and shut off the engine prior to

leaving the loader.

9. If the unit is equipped with a cab enclosure kit always

close the door prior to operating the loader lift arms.

10. Do not operate the loader unless all safety equipment,

shields, seat belt, seat bar, hydraulic controls, parking

brake, operator guard, and lift arm support are working

properly, as well as all safety and instruction decals are in

place.

OPERATING THE LOADER

1. Always drive the loader at speeds compatible with safety,

especially when operating over rough ground, crossing

ditches or when turning.

2. Avoid jerky turns, starts, stops, or reverses.

3. Use care when operating on steep grades to maintain

proper stability.

4. Do not turn the loader while the lift arms are in the

raised position.

5. Be careful when driving through door openings or under

overhead objects. Always make sure there is sufficient

clearance for the operator•s guard.

6. When travelling on public roads, know the local rules and

regulations and make sure your loader is equipped with

the proper safety equipment.

7. Always be sure of water, gas, sewage and electrical line

locations before you start to dig.

8. Watch out for overhead and underground high-voltage

electrical lines when operating the loader.

9. Park the loader on level ground where possible. If the

loader is to be parked on an incline, always lower the

attachment so it contacts the ground, set the parking brake

and block the wheels.

10. Do not leave the loader when it is in motion.

11. Do not dismount from the loader and leave the loader lift

arms raised, unless following specific service procedures.

Always lower the lift arms down against the frame and

drop the attachment down to contact the ground.

12. Always be watchful of bystanders when operating the

loader.

13. Always carry the attachment low for maximum stability

and visibility.

14. Exercise extreme caution when operating the loader with

a raised attachment.

15. Never attempt to lift loads in excess of loader capacity.

16. Check that control lever functions are locked before

getting out of the operator•s seat.

17. Keep both hands on the control levers while the loader is

in motion.

MAINTENANCE

1. Stop the engine before performing any service on the

loader.

2. Never refuel the loader while smoking or with the engine

hot or running.

3. Replace all missing, illegible or damaged safety and

warning decals. See Section 5.3 for list.

4. Do not modify or alter, or permit anyone to modify or

alter this loader or any of its components or any loader

function.

5. Do not bypass the safety system. Consult your SUNBEAR

Equipment Dealer if your safety controls are

malfunctioning.

6. Do not make mechanical adjustments while the loader is

in motion or when the engine is running. However, if

minor engine adjustments must be made, securely block

the loader with the wheels clear of the ground, and use

extreme caution.

7. Do not attempt to repair or tighten hydraulic hoses when

the system is under pressure, when the engine is running

or when the lift arms are raised.

8. Do not get under the attachment or lift arms or reach

through the lift arms when they are raised.

9. Never attach the chains or ropes to the operator•s guard

for pulling purposes, as the loader can tip over.

10. Whenever servicing or replacing pins in cylinder ends,

buckets,

etc., always use a brass drift and a hammer.

Failure to do so could result in injury from flying metal

fragments.

11. Cooling system operates under pressure which is

controlled by the radiator cap. It is dangerous to remove

the cap while system is hot. Always turn cap slowly to the

first stop and allow the pressure to escape before

removing the cap entirely.

12. Keep the operator area free from debris.

13. For lifting and towing instructions, refer to Sections 3.7

and 3.8 of this manual.

To prevent personal

injury do not start the

engine unless you are in

the seat with the seat belt

fastened around you.

WARNING

To prevent personal

injury do not operate the

loader without lowering

the safety bar, fastening

the seat belt and keeping

feet on the cab floor.

WARNING

This engine is equipped

with glow plugs. Do not

use ether or any high

energy fuels to assist

starting.

IMPORTANT

C-359

6

1. SAFETY PRECAUTIONS

To avoid personal injury,

lower the lift arms, shut off

the engine, raise the seat bar

and cycle the hydraulics to

ensure they are locked.

Then, unlatch the seat belt

and exit the loader. Do not

enter or exit with the engine

running unless as specified

in this manual or under

specific service and backhoe

operating procedures.

WARNING

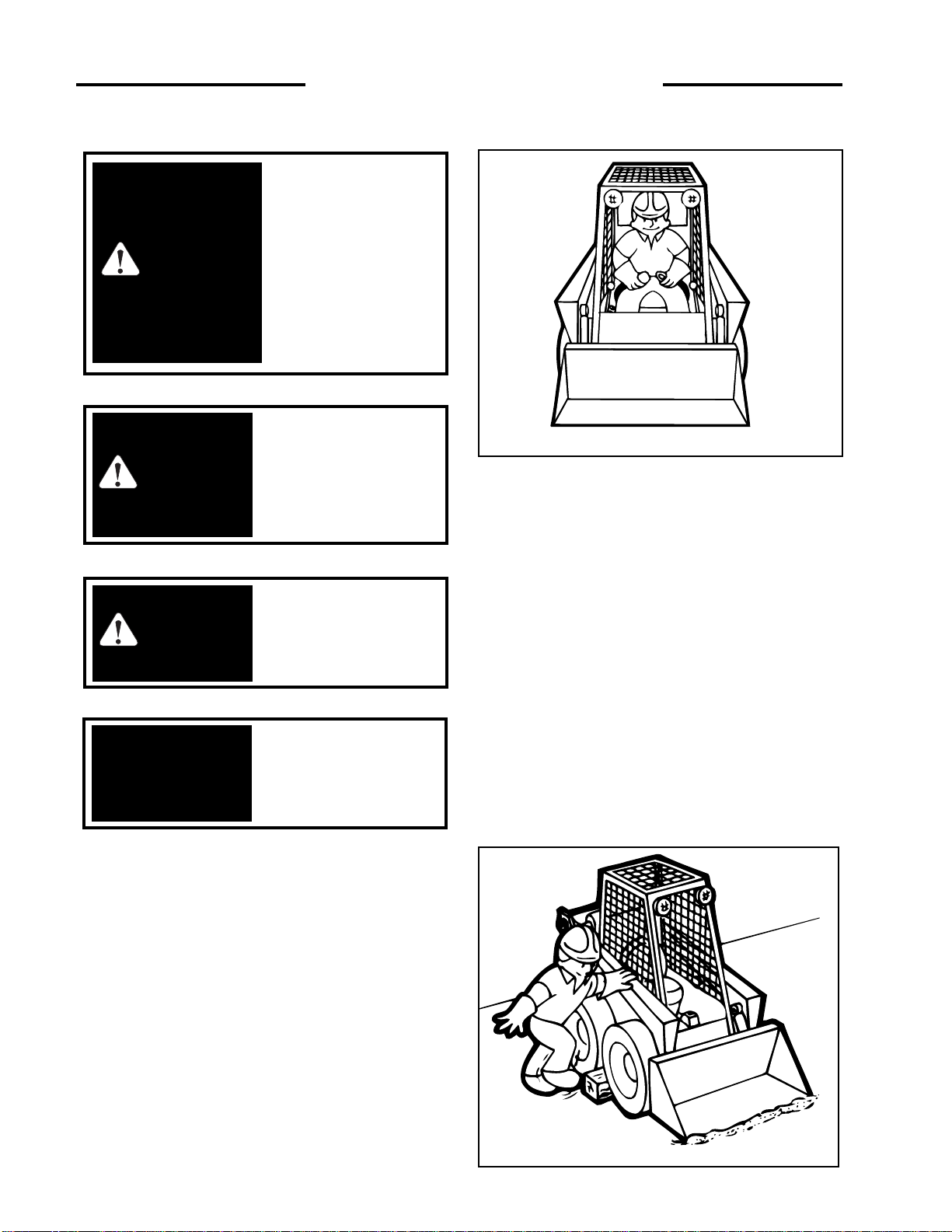

START SAFELY

1. Sit in the operator's seat and adjust it so you can operate

all of the controls properly.

2. Adjust the seat and fasten the seat belt. Cycle the

controls to make sure they are in the locked or neutral

position. Lower the seat bar.

3. Know the exact starting procedure for your machine.

See Section 3 for the manufacturer•s instructions for

starting.

PARK SAFELY

Select level ground whenever possible. If you must park

on a slope or incline, position the machine at right angles

to the slope. Lower the attachment to the ground, engage

the parking brake and block the wheels (C359).

C - 360

7

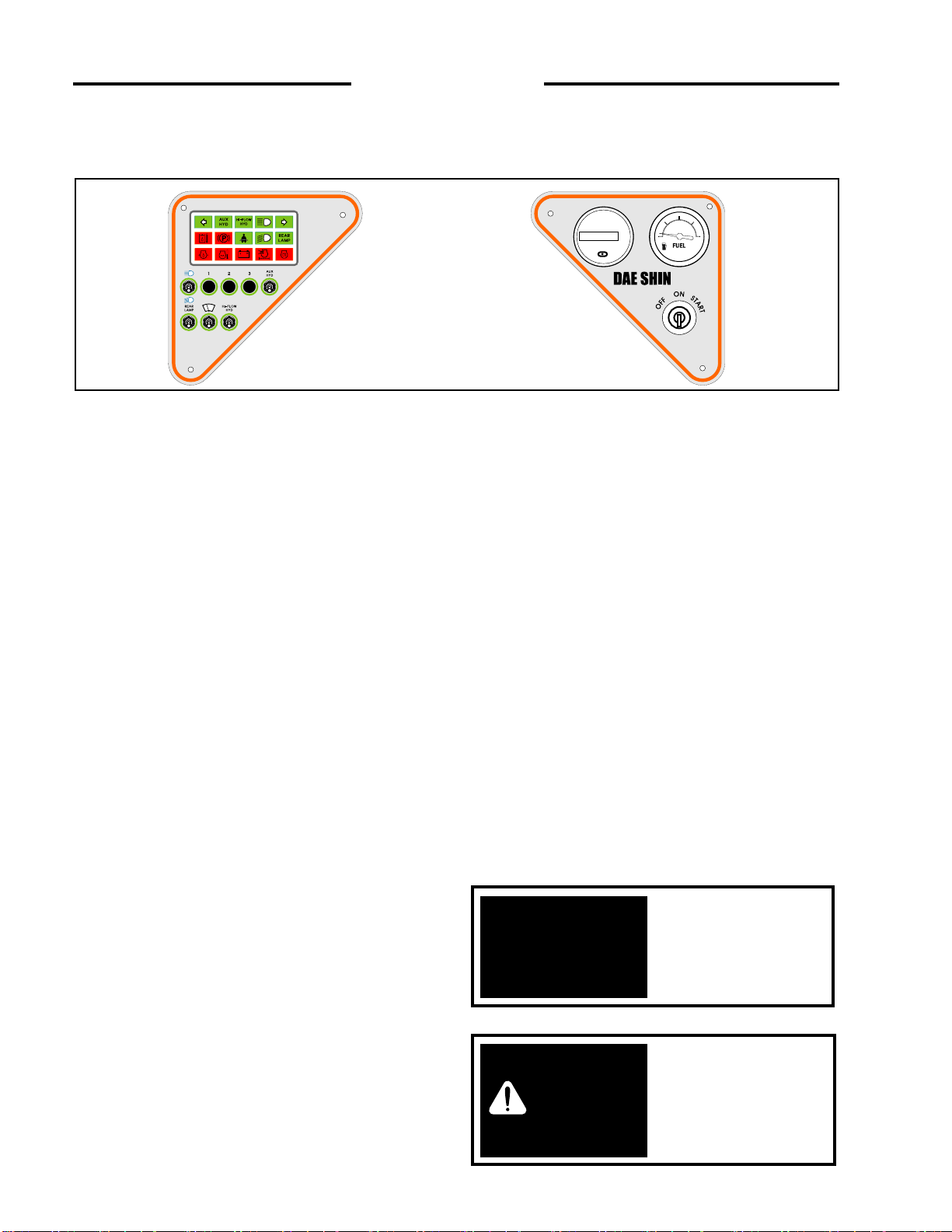

2. 1 Instrument Panel

2. 2 Control Lever Handles

2. 3 Seat and Seat Belt

2. 4 Seat Bar

2. 5 Parking Brake

2. 6 Throttle Control

2. 7 Lift Arm Support

2. 8 Steering Control

2. 9 Auxiliary Controls

2. 10 Liftarm Control

2. 11 Quick-Tach

2. 12 Electrical Panel

2. CONTROLS

2. CONTROLS

1. Left Signal Indicator Light: This light will

illuminate when the operator uses the optional left signal.

(Optional)

2. Auxiliary Front Indicator Light: This light will

illuminate when the loader auxiliary hydraulic front switch

is turned on. Light does not operate when lever switch is

depressed.

3. Hi-Flow Hydraulics Indicator: This light will

illuminate when the loader hi-flow hydraulics are in use.

(Optional)

4. Work Lights (Up) Indicator: The light will

illuminate when the loader work lights are turned on.

This will serve as a reminder to turn them OFF when the

loader is not in use.

5. Right Signal Indicator Light: This light will

illuminate when the operator uses the optional right signal.

(Optional)

6. Hydraulic Oil Temperature Indicator: This light

will illuminate when the oil temperature has exceeded

recommended levels. Shut off the engine immediately and

determine the cause.

7. Brake Light Indicator: The brake light will

illuminate when the parking brake is engaged.

8. Seat Belt Indicator Light: This light will illuminate

when the seat belt is unfastened.

9. Work Lights (Down) Indicator:

10. This light will

11.

The light will

illuminate when the loader work lights are turned on.

This will serve as a reminder to turn them OFF when the

loader is not in use.

14. Air Cleaner Indicator Light: This light will

illuminate when there is an obstruction in the intake or

when the air filter needs servicing. If this light illuminates,

stop the engine and service the cleaner.

8

2. CONTROLS

2.1 INSTRUMENT PANEL

K5250A

To prevent personal

injury do not start the

engine unless you are in

the seat with the seat belt

fastened around you.

WARNING

This engine is equipped

with glow plugs. Do not

use ether or any high

energy fuels to assist

starting.

IMPORTANT

1 2 3 4 5

1 2 3 4 5

6 7 8 9 10

6 7 8 9 10

11 12 13 14 15

11 12 13 14 15

16 17

HOURMETER

000032H

1/10

½

0 FULL

21 22

18 19 20

23

12. Coolant Temperature Indicator Light: This light

will illuminate if there is a rise in engine temperature. If

this occurs, shut of

f the engine immediately and determine

the cause.

13. Alternator Indicator Light: This light will

illuminate when the alternator is not producing sufficient

current.

15. Pre-heat Indicator Light: This light will illuminate

when the ignition key is turned counter clockwise to

activate the engine glow plugs.

16. Headlight Switch: This is a toggle switch. Push up

to turn the dipped beam lights on. These lights are located

on the front of the loader.

17. Auxiliary Hydraulics Front Switch: This switch

is a toggle switch. Push up to provide a continous flow of

oil to the quick couplers when using an attachment.

Work Lights (Back) Indicator:

illuminate when the loader Back light are turned on. This

will serve as a reminer to turn them OFF when the loader is

not in use.

Engine Oil Pressure Indicator:

This light will

illuminate when the engine loses lubrication pressure. Shut

off the engine immediately and determine the cause.

9

This switch is a toggle switch

Push up to turn the dipped beam lights on. This light are

located on the rear of the loader.

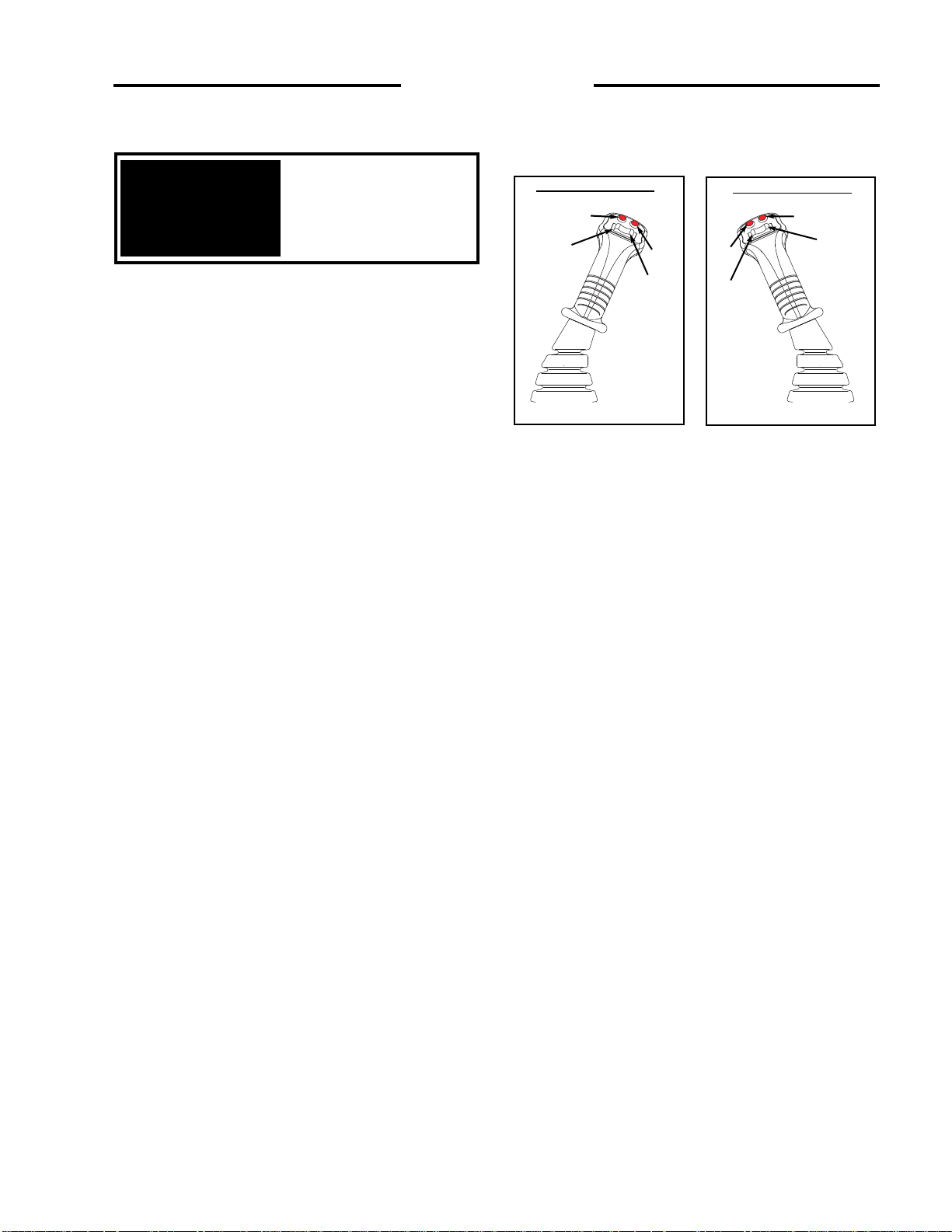

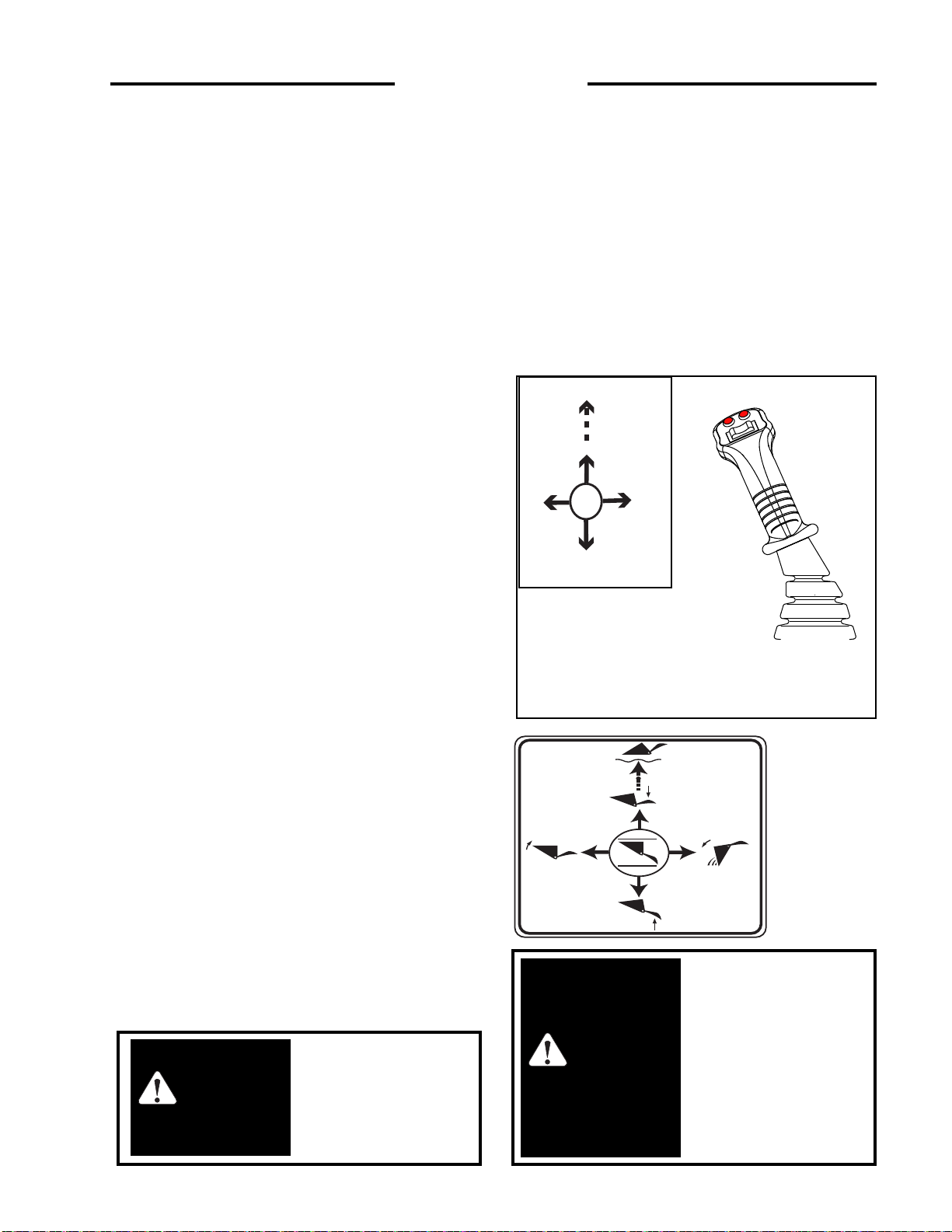

2.2 CONTROL LEVER HANDLES

1. Spare

2. Spare

3, 4. Right / Left Direction Indicator (optional)

5. Horn

6. Spare

8. Auxiliary Hydraulic Switch

The left hand control lever is for moving the loader

forward and reverse. Pushing the lever forward will cause

the loader to move forward, and pulling the lever back

towards the operator will cause the loader to move in

reverse. This lever also operates hydraulic functions (refer

to section 2.8 for instructions).

The right hand control lever controls the lift arms and

bucket tilt. Pushing the lever forward will cause the lift

arms to raise, while pulling the lever back towards the

operator will cause the lift arms to lower. Moving the

control lever to the left and right will tilt and untilt the

bucket. Refer to section 2.10 for detailed operating

instructions of this lever.

Ensure liftarm brace is

properly stowed before

raising or lowering lift

arms

IMPORTANT

2. CONTROLS

LH Control Handle

RH Control Handle

1

3

2

4

5

6

8

7

Fig. 2.2A

C3933

18. Back Light Switch:

19. Door Window Wiper Switch: This switch is a toggle

switch. Push up to turn the wiper on.

20. Hi-Flow Hydraulic Switch: This switch is a toggle

switch. Push up to turn the Hi-Flow hydraulics on. (Not

available on all models)

21. Hour Meter: The hour meter records the number of

engine operating hours and has a total of 99999.9 hours.

22. Fuel Gauge: The fuel gauge indicates the quantity of

fuel remaining in the fuel tank.

23. Ignition Switch: The ignition switch is a three (3)

position switch: 'OFF', 'ON', 'RUN' and 'START'. Turn the

Turn the key counter clockwise to engage engine 'PREHEAT'. Turn the key clockwise to the 'START' position,

this engages the starter The key will be in the 'RUN' position

when released. Turn the key to 'OFF' to shut off the engine

and remove the key.

C3015

Fig. 2.2B

2. CONTROLS

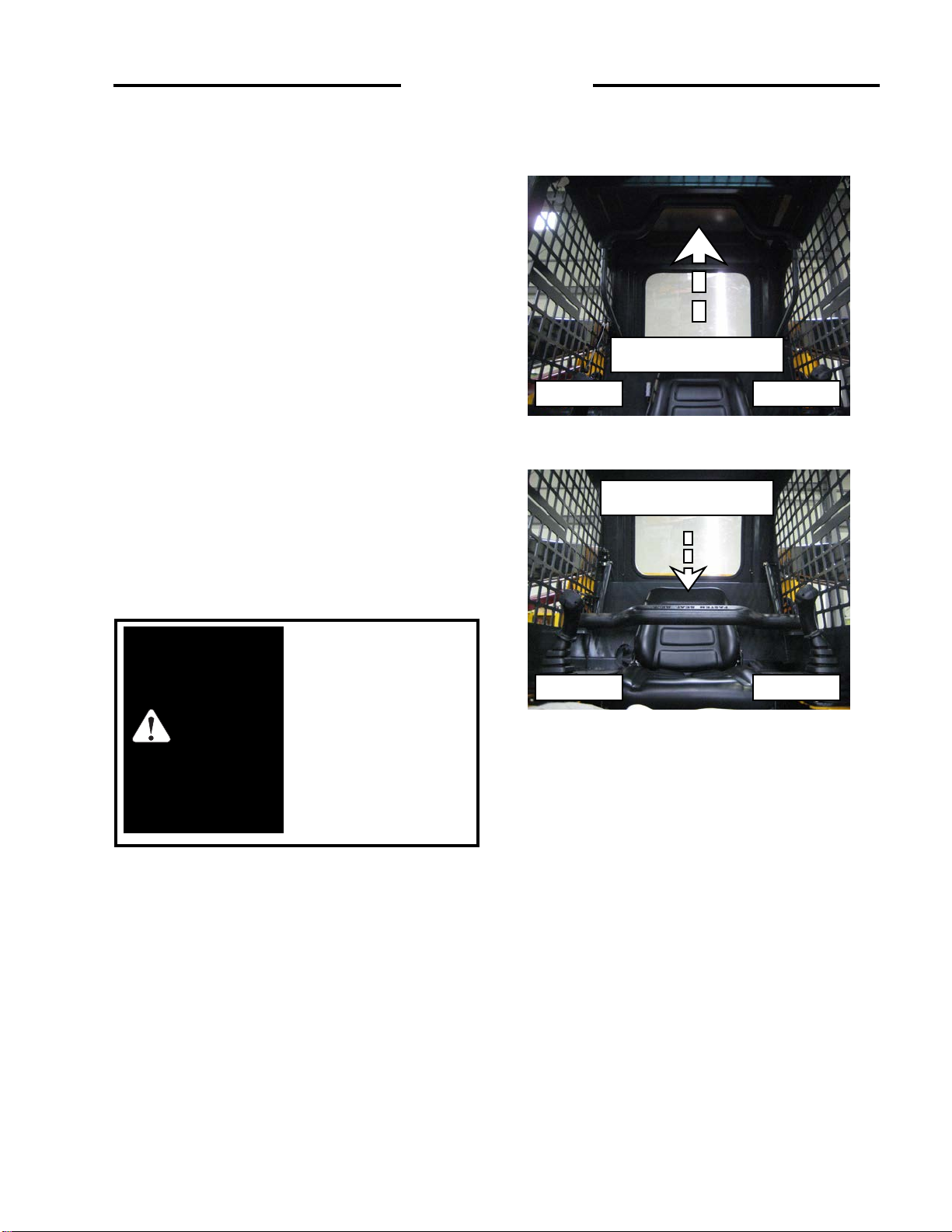

2.3 SEATAND SEAT BELT

The seat can be adjusted forward or back for operator

comfort (Fig. 2.3A)

For your safety the loader is equipped with a seat belt.

Before starting the loader adjust and fasten the seat belt

(Fig. 2.3B) around you. The seat and seat belt also have

integrated safety lock switches whereby the operator must

be seated in the seat with the seat belt securely fastened

and seat bar lowered before the loader hydraulics can be

operated.

To prevent personal

injury do not start the

engine unless you are in

the seat with the seat belt

fastened around you.

WARNING

Fig. 2.3B

C2698

Fig. 2. 3A

C2699

Release

10

11

2. 4 SEAT BAR

For operator protection the loader is equipped with a seat

bar.

The loader must be started with the operator seated in the

loader and the seat bar in the up position. To raise the seat

bar, lift up on the bar (Fig. 2.4A). In the up position, the

seat bar activates the parking brake and locks out the

functions of the control levers including the auxiliary

hydraulics.

When down (Fig. 2.4B), the seat bar releases the park

brake and the hydraulic controls of the lift, tilt and

auxiliary hydraulic circuits.

Before exiting the loader always check the controls by

cycling them to ensure that they are in the neutral position.

2. CONTROLS

To avoid personal injury,

lower the lift arms, shut off

the engine, raise the seat bar

and cycle the hydraulics to

ensure they are locked. Then,

unlatch the seat belt and exit

the loader. Do not enter or

exit with the engine running

unless as specified in this

manual or under specific

service and backhoe

operating procedures.

WARNING

C5295

C5288

SeatBarUp

Fig. 2. 4A

SeatBarDown

Fig. 2. 4B

12

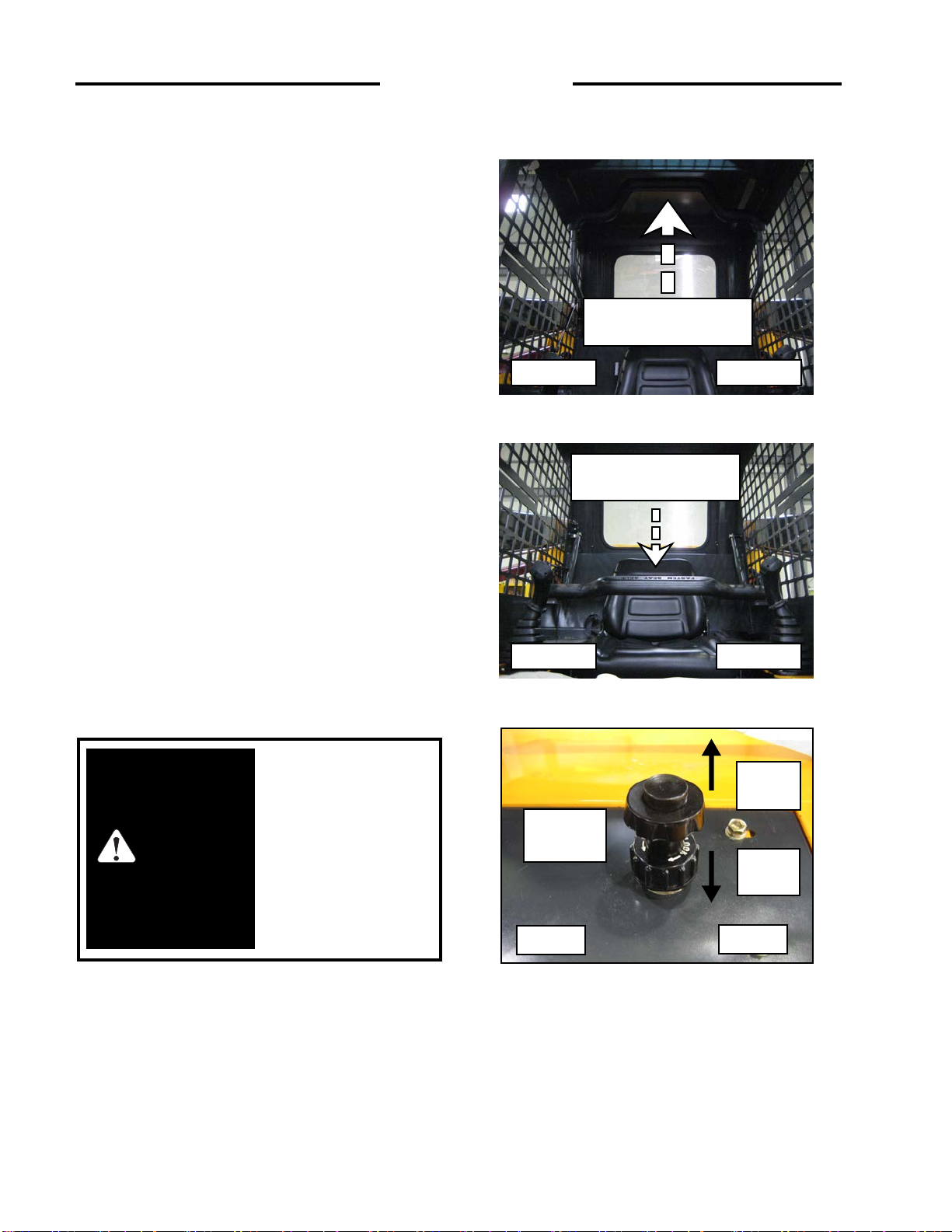

2. 5 PARKING BRAKE

The loader is equipped with park brakes, located inside the

torque motor. The brakes are activated and de-activated

by the seat bar, via charge pressure. When the seat bar is

in the up position, the brake is activated (Fig. 2.5A). When

the seat bar is in the down position, the brake is off (Fig.

2.5B).

The loader has a parking brake indication light to warn that

the brake is engaged. When the seat bar is in the down

position, activation of the emergency break can be carried

out by pushing on the button, located on the ROPS, in

front of the left hand control lever handle.

2. 6 THROTTLE CONTROL

The diesel engine throttle control is located on the left

hand side of the loader behind the control lever (Fig. 2.6).

Engine start and stop are controlled electrically by the

ignition key.

Before shutting off the engine, return the throttle control

to idle position and allow the engine to cool at least 2

minutes.

Pushing the lever full forward increases the engine speed

to maximum high idle. Pulling the lever back decreases

the engine RPM.

The engine should always be operated at full speed and

the loader travel speed controlled with the steering

control lever (See Section 2.8)

.

To avoid personal injury,

lower the lift arms, shut off

the engine, raise the seat bar

and cycle the hydraulics to

ensure they are locked.

Then, unlatch the seat belt

and exit the loader. Do not

enter or exit with the engine

running unless as specified

in this manual or under

specific service and backhoe

operating procedures.

WARNING

2. CONTROLS

Seat Bar Up

(ParkingBrakeon)

C5295 Fig.2.5A

Seat Bar Down

(ParkingBrakeoff)

C3776 Fig.2.5B

Throttle

Control

C5297

High

Speed

Low

Speed

Fig.2.6

13

2. 7 LIFT ARM SUPPORT

For safety while performing regular service or

maintenance work the loader is equipped with a liftarm

support.

The liftarm support, when engaged, prevents the liftarms

from dropping if hydraulic pressure is relieved or the right

hand control lever is accidentally cycled.

To operate the liftarm support, remove attachment and

park on level ground. Lower the liftarms to the ground and

stop the engine. Exit the machine and remove pin that

holds the liftarm support in stored positon(Fig. 2.7A).

Lower the liftarm support to rest on the lift cylinder(Fig.

2.7B). Re-enter the machine and re-assume proper

operating positon with the seat belt fastened and start the

engine. Slowly raise the liftarms until the support falls

onto the cylinder rod. Slowly lower the liftarms until

support restricts movement. Stop the engine.

T o remove the liftarm support, enter the loader and assume

proper operating position with the seat belt fastened and

start the engine, slowly raise the liftarms until the support

is free, have a helper pin the support into its stored positon,

lower the liftarms to the ground and shut off the engine

before exiting the loader.

2. 8 STEERING CONTROL LEVER

The left control lever controls speed, direction and turning

of the loader. Loader speed is controlled by the amount the

lever is moved from the centre or neutral position. (Fig.

2.8A) The further away from neutral, the faster the travel

speed. For maximum power and slow travel speed move

the control lever only a small amount.

T o drive the loader forward in a straight line, move the left

control lever forward from the neutral position (Fig.

2.8A).

To drive the loader in reverse in a straight line, move the

left control lever back from the neutral position (Fig.

2.8A).

The loader is turned by moving the left control lever to the

side. To turn right while in forward or reverse travel, ease

the control lever to the right. To stop turning, return the

lever to a center position. To turn left while in forward or

reverse travel, ease the lever to the left from the neutral

position. To stop turning, return the lever to a center

position (Fig. 2.8A).

For the loader to turn or "skid-steer" within its own length,

move the lever to the left or the right from the neutral

position. This causes the wheels on one side to turn

forward and the wheels on the other side to reverse turning

the loader (Fig. 2.8A).

2. CONTROLS

C5298

Fig. 2.7A

C5416

Fig. 2.8A

Liftarm Support,

Stored Position

Pin

Fig. 2. 7B

C 5299

Liftarm Support

Resting On Cylinder

C5415

Ensure liftarm brace is

properly stowed before

raising or lowering lift

arms

IMPORTANT

Forward Reverse

LeftTurn RightTurn

Forward

Left

Turn

N

Reverse

Right

Turn

14

2. CONTROLS

C5254

Fig. 2.9B

C5416

Fig. 2.9A

C5255

Fig. 2.9C

2.9 ELECTRIC SOLENOID

AUXILIARY CONTROLS

Auxiliary hydraulics (solenoid operated - standard) will

only operate with the seat bar down.

A switch located on the R.H. steering control lever (Fig.

2.8A) is used to engage the loader's auxiliary hydraulic

circuit to power attachments such as post hole augers,

sweepers, etc. Pressing and holding the switch in position

1 (fig. 2.8A) provides hydraulic flow to the female quick

connect coupling located at the front of the lift arms (fig.

2.8C). Releasing the switch returns the auxiliary hydraulic

circuit to neutral, stopping the hydraulic flow.

Pressing and holding the switch in position 2 (fig. 2.8A)

provides hydraulic flow to the male quick connect

coupling located at the front of the lift arms (fig. 2.8C).

releasing the switch returns the auxiliary hydraulic circuit

to neutral, stopping hydraulic flow.

For continuous flow to the auxiliary hydraulic circuit, a

toggle switch is located on the L.H. instrument panel (fig.

2.8B). Placing the switch in the "ON" position provides

continuous hydraulic flow to the female quick connect

coupling located at the front of the lift arms (fig. 2.8C). To

stop hydraulic flow to the auxiliary hydraulic circuit,

return the switch to the "OFF" position (fig. 2.8B). When

the switch on the instrument panel is in the "ON" position,

the switch located in the L.H. control lever is not operable.

NOTE: See Section 2.2 for information on the control

handles.

AUXILIARY HYDRAULIC CONTROL

1

2

NEUTRAL

TOGGLE

SWITCH

To avoid personal injury,

lower the lift arms, shut off

the engine, raise the seat bar

and cycle the controls to

ensure they are locked.

Then, unlatch the seat belt

and exit the loader. Do not

enter or exit with the engine

running unless as specified

in this manual or under

specific service and backhoe

operating procedures.

WARNING

Female Quick Coupling

Male Quick Coupling

ROPSSIDESEATSIDE

15

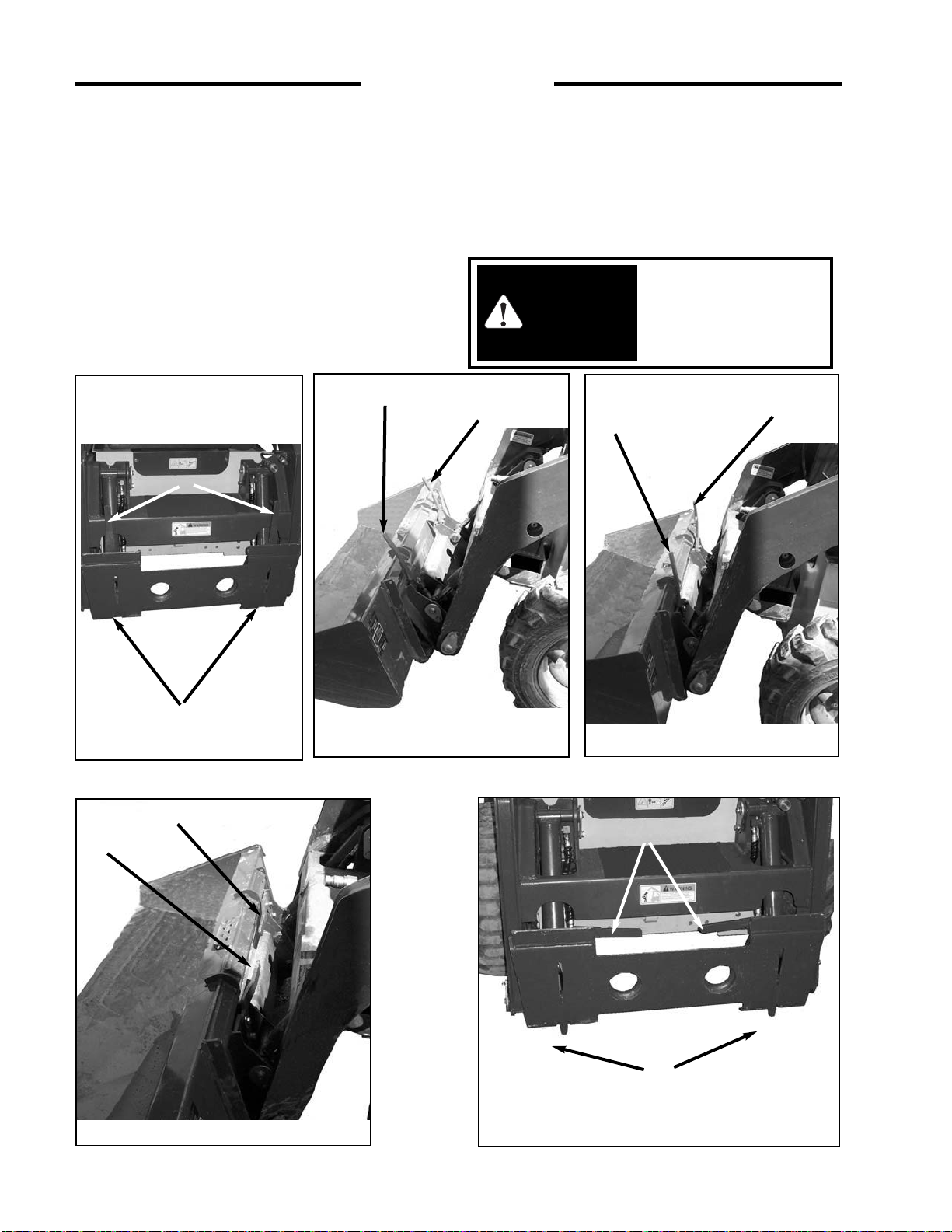

2. 10 LIFTARM CONTROLS

The right hand control lever (Fig. 2.10) operates the

loader•s liftarm and bucket hydraulic system. Refer to

section 2.8 for instructions on steering control.

When the control lever is in the neutral position, the lift

and tilt functions are static, the work attachment position

should not change unless the control lever is moved. If the

work attachment does move, service to hydraulic controls

is required.

Having the control lever in the neutral position does not

affect auxiliary hydraulics. Auxiliary hydraulics are

controlled separately and will continue to operate with the

control lever in the neutral position.

FLOAT (A)- Pushing the control lever all the way forward

will lock the lever in liftarm float detent. This float

position allows the work attachment to follow the contour

of the ground. Lever will remain locked in float position

until it is pulled out of float position.

LOWER (B)- To lower the liftarm, push the control lever

straight forward from the neutral position, the control lever

will return to the neutral position when released.

NEUTRAL (N)- Neutral (hold) position, lift and tilt

functions are static. Liftarms should hold their position.

RAISE(D)- Pulling the control lever back from the neutral

position will raise the liftarms, releasing the control lever

will allow it to return to the neutral position.

TILT BACK (E)- Moving the control lever to the left will

tilt the work attachment back (roll back bucket), releasing

the control lever will allow it to return to a neutral position.

TILT FORWARD (F)- Moving the control lever to the

right will tilt the work attachment forward (dump bucket),

releasing the control lever will allow it to return to a

neutral position.

By moving the control lever between two positons, both

functions can be done at the same time.

- Move the lever diagonally between lower and tilt forward

(B-F) to do both at the same time (lower and roll the work

attachment forward).

-Move the lever diagonally between raise and tilt back (DE) to do both at the same time (raise and roll the work

attachment back).

-Move the lever diagonally between raise and tilt forward

(D-F) to do both at the same time (raise and tilt the work

attachment forward).

-Move the lever diagonally between lower and tilt back

(B-E) to do both at the same time (lower and tilt the work

attachment back).

2. CONTROLS

To prevent personal

injury do not operate the

loader without lowering

the safety bar, fastening

the seat belt and keeping

feet on the cab floor.

WARNING

To avoid personal injury,

lower the lift arms, shut

off the engine, raise the

seat bar and cycle the

hydraulics to ensure they

are locked. Then unlatch

the seat belt and exit the

loader. Do not enter or

exit with the engine

running unless as

specified in this manual

or under specific service

and backhoe operating

procedures.

WARNING

C5413

Fig. 2.10

C5325

C5414

A

B

E

N

D

F

16

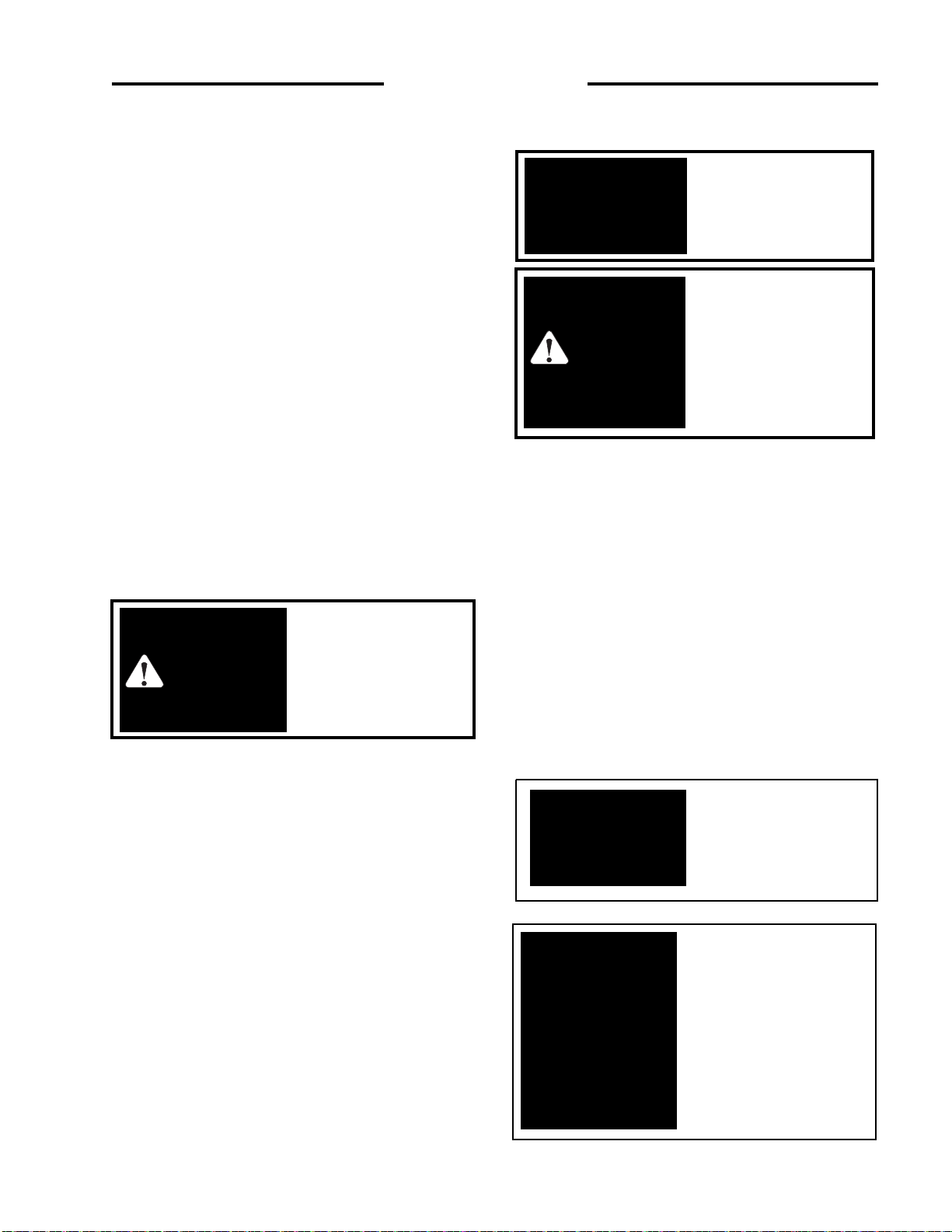

2.11 QUICK - TACH

The quick-tach, which is standard equipment, allows

changing from one attachment to another quickly without

having to remove bolt or pins.

To operate, (Fig. 2.11A), lift the locking lever (1) up to

completely retract the locking pins (2). Tilt the quick - tach

frame forward (Fig. 2.11B) with the bucket tilt cylinders and

drive into the attachment. Retract the bucket tilt cylinders

(Fig. 2.11C) which will line up the bottom of the attachment

with the quick - tach lock pins. Shut off the engine.

Push the locking lever (1) fully down (Fig. 2.11D) extending

the lock pins (Fig. 2.11E item 2) through the attachment and

securing the attachment.

Before operating the attachment check that the locking pins

are correctly engaged.

After hooking up the

attachment check to be

sure pins and locking

levers are correctly

engaged.

WARNING

C5359

C5410

Fig. 2.11B

Fig. 2.11A

C5412

C 5357

Fig. 2.11E

1

1

2

Fig. 2.11D

1

C5411

Fig. 2.11C

1

1

1

1

2

1

2. CONTROLS

17

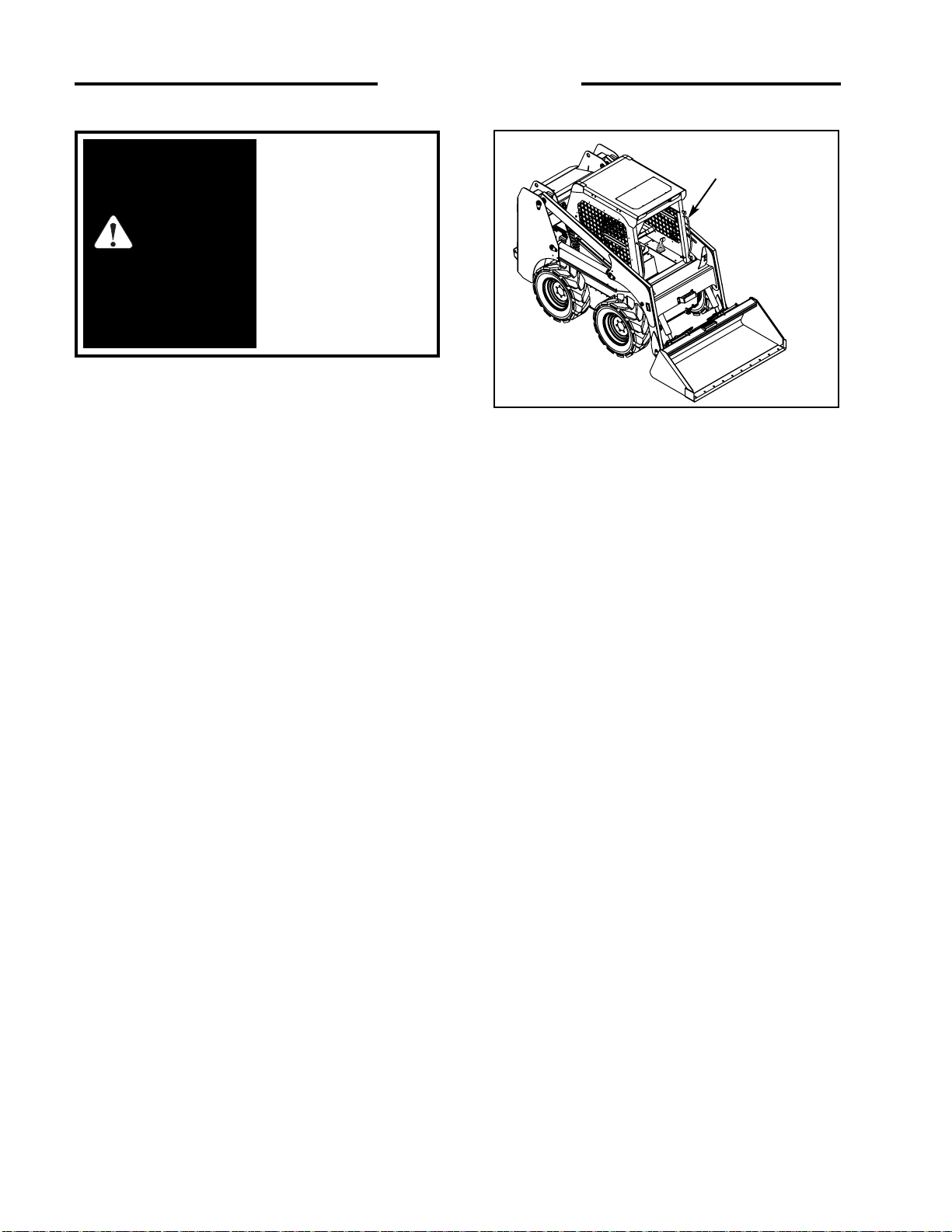

2.12 ELECTRICAL PANEL

The loader is equipped with a 12 volt, negative ground

electrical system. The fuse and relay panel is located in the

engine compartment on the underside of the engine cover.

The panel consists of the following(Fig.2.12):

1. Engine Pre-Heater Relay.

2. Starter Relay.

3. Fuse Panel.

4. Turn Signal Flasher (optional)

5. Head Lamp. (20A)

FUSE PANEL (3)

6. Rear Lamp. (10A)

7. Wiper (15A)(Optional)

9. Front Horn. (10A)

10. Cigar Jack. (15A)

11. Aux, Hyd, Solenoid. (10A)

12. Alternator Light. (10A)

13. Brake Valve Solenoid. (10A)

14. Shut Down. (15A)

2. CONTROLS

Fig 2.12

8. Back up Alram. (10A)

C5256

18

3. OPERATION

3. 1 Starting Instructions

1. Pre-Starting Inspection

2. Starting Procedure

3. Shut-Off Procedure

3. 2 Operating Procedures

3. 3 Filling From a Pile

3. 4 Digging With a Bucket

3. 5 Leveling and Backfilling

3. 6 Auxiliary Hydraulics

3. 7 Lifting

3. 8 Towing

3. 9 Securing and Transporting

3. 10 Lowering Lift Arms

3. 11 Accumulator

3. OPERATION

19

3.1 STARTING INSTRUCTIONS

1. Pre-Starting Inspection

Before starting the loader complete the following inspection:

(1) Check the hydraulic oil level, engine oil level, engine

coolant level and fuel supply.

(2) Check for fuel, oil and hydraulic leaks.

(3) Check lights, battery level and cables.

(4) Check tire pressure:

10.00 x 16.5 . . . . 40 - 45 PSI (276 - 310 kPa)

(5) Check wheel nut torque 100 - 110 ft. lbs. (13.8 - 15.2

kgm) (136- 149 Nm).

(6) Lubricate all grease fittings.

(7) Check the condition and operation of all safety decals

and equipment … Ensure all shields and safety screens

are in place. If necessary repair or replace before

starting.

For complete daily servicing refer to section 4. 3.

2. Starting Procedure

1. Ensure the seat bar is in the UPposition and the control

levers are in neutral.

2. Adjust and fasten the seat belt securely around you.

3. Place the throttle control in idle position.

4. Turn the ignition key counter clockwise to activate the

glow plugs. Both the alternator and engine oil pressure

warning lights should be on. Use chart for correct pre-

heat times.

Glow Plug Pre-Heat Times

Ambient Temperature Preheat Time

0 C(32 F) and Above 10 Seconds

-18 C(0 F) to 0 C(32 F) 30 Seconds

-23 C(-10F) to -18C(0 F) 60 Seconds

-29 C(-20 F) to -23 C(-10 F) 120 Seconds

5. Turn the key clockwise to start position to engage the

starter. Do not crank the starter for more than 30

seconds. If the engine fails to start turn the key to off

position, wait one minute, and repeat the procedure. If

engine does not start after three attempts, check the

fuel suppply system. The absence of blue or white

smoke during cranking indicates that no fuel is being

delivered.

6. When the engine has started the engine oil pressure

and alternator warning lights should go out. If they

t, shut - off the engine immediately and determine

cause.

7. Allow the engine to warm up for five minutes before

operating. When ready to operate, lower the seat bar

and advance the throttle to full on position.

This engine is equipped

with glow plugs. Do not

use ether or any high

energy fuels to assist

starting.

Overvoltage (14 volts or

greater) will immediately

destroy the glow plugs.

Do not apply overvoltage

to the starting circuit at

any time. If boosting,

use a battery of equal

voltage to the loader and

connect it in

parallel,positive to

positive, negative to

negative.

Limit preheating to

recommended preheat

times; longer periods can

ruin the glow plugs.

IMPORTANT

IMPORTANT

IMPORTANT

3. OPERATION

To avoid personal injury

do not start the engine

unless you are in the seat

with the seat belt

fastened around you,

unless as specified in this

manual or under specific

service and backhoe

operating procedures

.

WARNING

To prevent personal

injury do not operate the

loader without lowering

the safety bar, fastening

the seat belt and keeping

feet on the cab floor.

WARNING

don'

WARNING

To avoid personal injury,

lower the lift arms, shut off

the engine, raise the seat bar

and cycle the hydraulic

controls to ensure they are

locked. Then, unlatch the seat

belt and exit the loader. Do

not enter or exit with the

engine running unless as

specified in this manual or

under specific service and

backhoe operating

procedures.

3. Shut-Off Procedure

(1) Select level ground whenever possible. If you must park on

a slope or incline, position the machine at right angles to the

slope. Lower the attachment to the ground, engage the

parking brake and bloke the wheels.

(2) Lower the lift arms and ground the attachment.

(3) Return auxiliary hydraulics to neutral or OFF position.

(4) Return the throttle control to idle position. If the engine is

hot allow it to idle until normal, at least 2 minutes.

(5) Never enter or exit the loader when the engine is running.

(6) Raise the seat bar to apply the park brake. Turn the ignition

switch to the OFF position, remove the key, unfasten the

seat belt, and ensure the hydraulic controls are locked by

rocking them.

3. OPERATION

3. 2 OPERATINGPROCEDURES

1. When learning to use the loader, operate at a slow rate.

2. Take advantage of the efficient operation of the loader.

Keep the travel distance as short as possible. Keep the work

area small so the cycle time is short.

3. Keep the work area as level as possible.

4. Decrease cycle time by "Skid" turning (See Section 2.8A)

rather than a go backward-go forward turn.

5. Fill the bucket to rated capacity . Turning is easier with a full

load than with a partial load. Keep the loaded bucket close

to the ground when transporting.

6. Tilt the bucket as you raise the lift arms or drive up a slope.

This will prevent material from falling off the back of the

bucket.

7. Do not drive across a slope. Always go up or down a slope

with the heavy end of the loader pointing up towards the top

of the slope.

C5363

20

Handle

Fig. 3.3

21

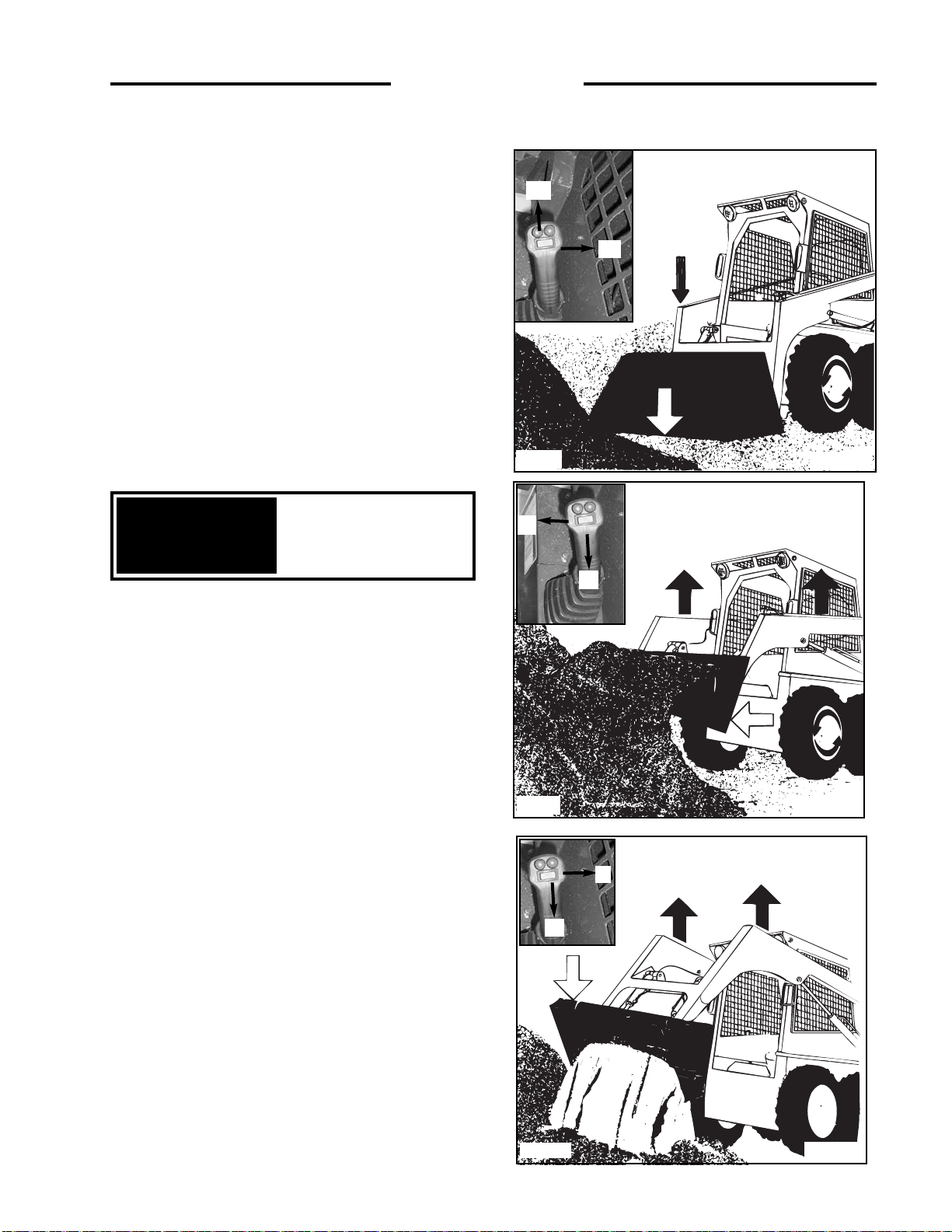

3. 3 FILLING FROM A PILE

Fig. 3.3A--Push ahead on the right hand control lever (1) and

lower the lift arms completely down. Push to the right on the

right hand control lever (2) and place the cutting edge of the

bucket on the ground.

Fig. 3.3B--Push ahead on left hand lever to drive the loader

forward slowly into the pile. As the bucket begins to fill pull

to the left on the right hand lever (3) to raise the front of the

bucket and pull back on the right hand lever (4) to raise the

lift arms. When the bucket is full back away from the pile.

Fig. 3.3C--To dump the bucket pull back on the right hand

control lever (4) to raise the lift arms, push to the right small

amounts as the lift arms are raising to stop material from

falling off the back of the bucket. When the bucket is at the

correct height for dumping, push to the right on the right hand

lever (2) to empty the bucket.

Always let the engine

warm completely before

you begin operation each

day.

IMPORTANT

3. OPERATION

Fig. 3.3A

C5303

Fig. 3.3C

C5304

C5305

1

2

3

2

4

4

Fig. 3.3B

22

3. 4 DIGGING WITH A BUCKET

Fig. 3.4D--Push ahead on the right hand control lever (1) and

lower the lift arms completely down. Push to the right on the

right hand lever (2) and place the cutting edge of the bucket

on the ground. Drive the loader forward at a slow rate and

continue to tilt the bucket down until it enters the ground.

Fig. 3.4E--Pull to the left on the right hand lever (3) to raise

bucket edge to increase traction and keep an even digging

depth.

Fig. 3.4F--Continue to drive forward until the bucket is full.

When digging in hard ground, it is easier to raise (3) and

lower (2) the bucket cutting edge with the right hand control

lever while slowly driving forward. When the bucket is full,

pull to the left on the right hand control lever (3) to roll back

the bucket.

To avoid personal injury:

When starting or

operating loader in an

enclosed area make sure

there is enough

ventilation. Exhaust

fumes can kill.

WARNING

3. OPERATION

Fig. 3.4D

To prevent personal

injury always carry the

load low.

WARNING

Fig. 3.4E

C5306

C5307

Fig. 3. 4F

To prevent personal

injury, ensure that the

bucket with the proper

rated capacity is being

used for the job you are

doing.

WARNING

1

2

3

3

2

C5308

Loading...

Loading...