Page 1

IQ SENSOR NET

Power

!

O

K

MIQ/IC2

Operating Manual

ba76034e01 01/2012

IQ SENSOR NET Current input module

2 x 0/4 ... 20 mA

with power supply/isolator feed-in

Page 2

MIQ/IC2

Note

For the most recent version of the manual, please visit www.ysi.com

.

Contact YSI

1725 Brannum Lane

Yellow Springs, OH 45387 USA

Tel: +1 937-767-7241

800-765-4974

Email: environmental@ysi.com

Internet: www.ysi.com

Copyright © 2012 Xylem Inc.

2

ba76034e01 01/2012

Page 3

MIQ/IC2 List of contents

MIQ/IC2 - List of contents

1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.1 How to use this component operating manual . . . . . . . . 1-1

1.2 Feature s of the MIQ/IC 2 . . . . . . . . . . . . . . . . . . . . . . . . .1-2

2 Safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.1 Authorized use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2.2 General safety instructions . . . . . . . . . . . . . . . . . . . . . . .2-2

3 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.1 Scope o f de livery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.2 Installation in the IQ S

3.3 Connecting external meters to the current inputs . . . . .3-1

3.4 Instal la tion examples . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

ENSOR NET . . . . . . . . . . . . . . . . . 3-1

4 Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

5 What to do if ... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

6 Maintenance and cleaning . . . . . . . . . . . . . . . . . . . . . 6-1

6.1 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 -1

6.2 Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1

7 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

8 Contact Information . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

8.1 Ordering & Technical Support . . . . . . . . . . . . . . . . . . . . 8-1

8.2 Service In fo rmation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

9 Lists . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

9.1 Explanation of the messages . . . . . . . . . . . . . . . . . . . . . 9-1

9.1.1 Error messages . . . . . . . . . . . . . . . . . . . . . . . . .9-1

9.1.2 Informative messages . . . . . . . . . . . . . . . . . . . .9-2

9.2 Status in fo . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-2

ba76034e01 01/2012

0 - 1

Page 4

List of contents MIQ/IC2

0 - 2

ba76034e01 01/2012

Page 5

MIQ/IC2 Overview

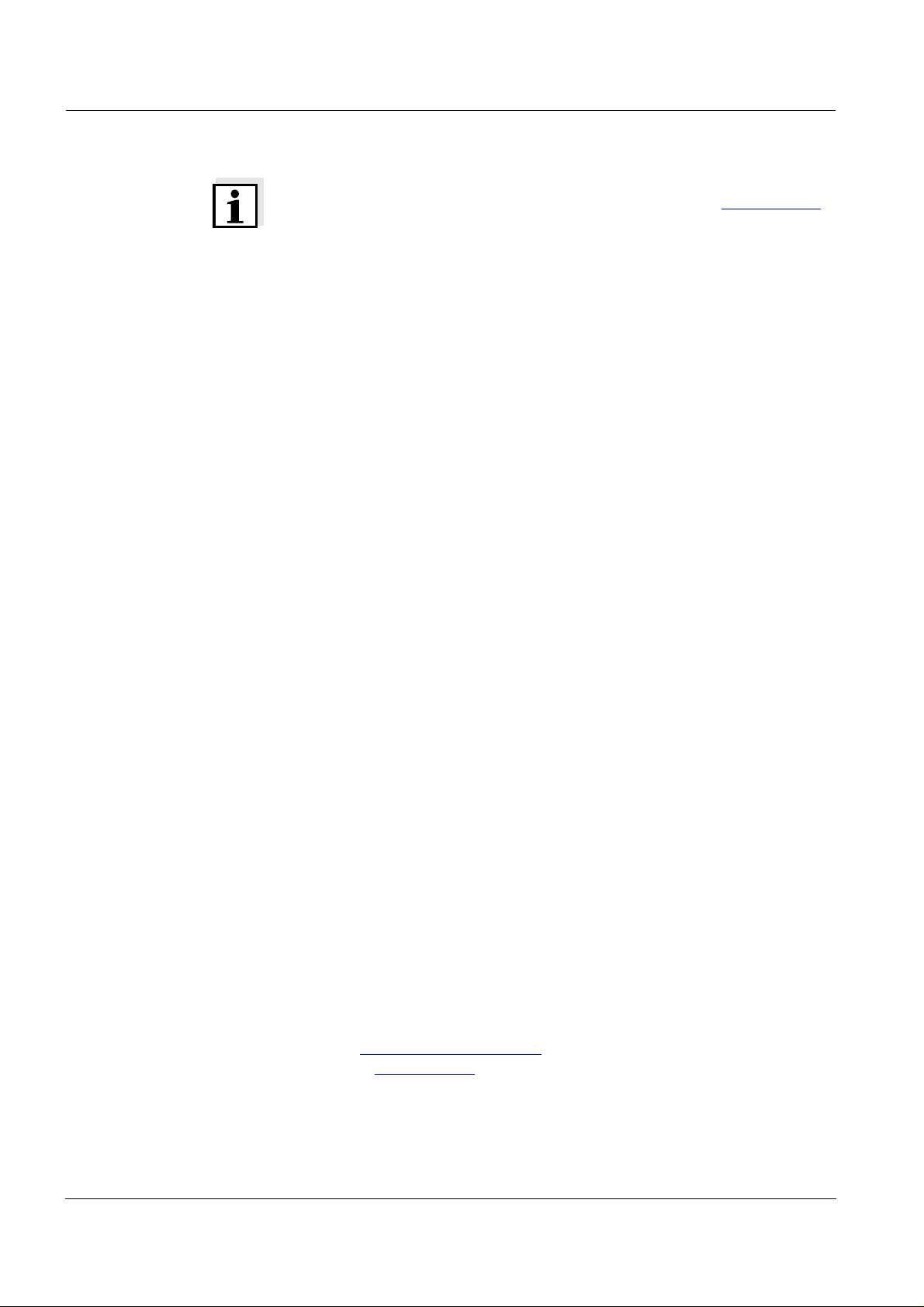

IQ Sensor Net Operating Manual

System

Operating

Manual

(Ring Binder)

IQ Sensor

Operating

Manual

MIQ Module

Operating

Manual

MIQ Terminal

Operating

Manual

Component Operating Manuals

1Overview

1.1 How to use this component operating manual

Structure of the

IQ S

ENSOR NET

operating manual

ba76034e01 01/2012

Fig. 1-1 Structure of the IQ SENSOR NET operating manual

The IQ SENSOR NET operating manual has a modular structure like the

IQ S

ENSOR NET itself. It consists of a system operating manual and the

operating manuals of all the components used.

Please file this component operat ing manual in to the ring binder of th e

system operating manual.

1 - 1

Page 6

Overview MIQ/IC2

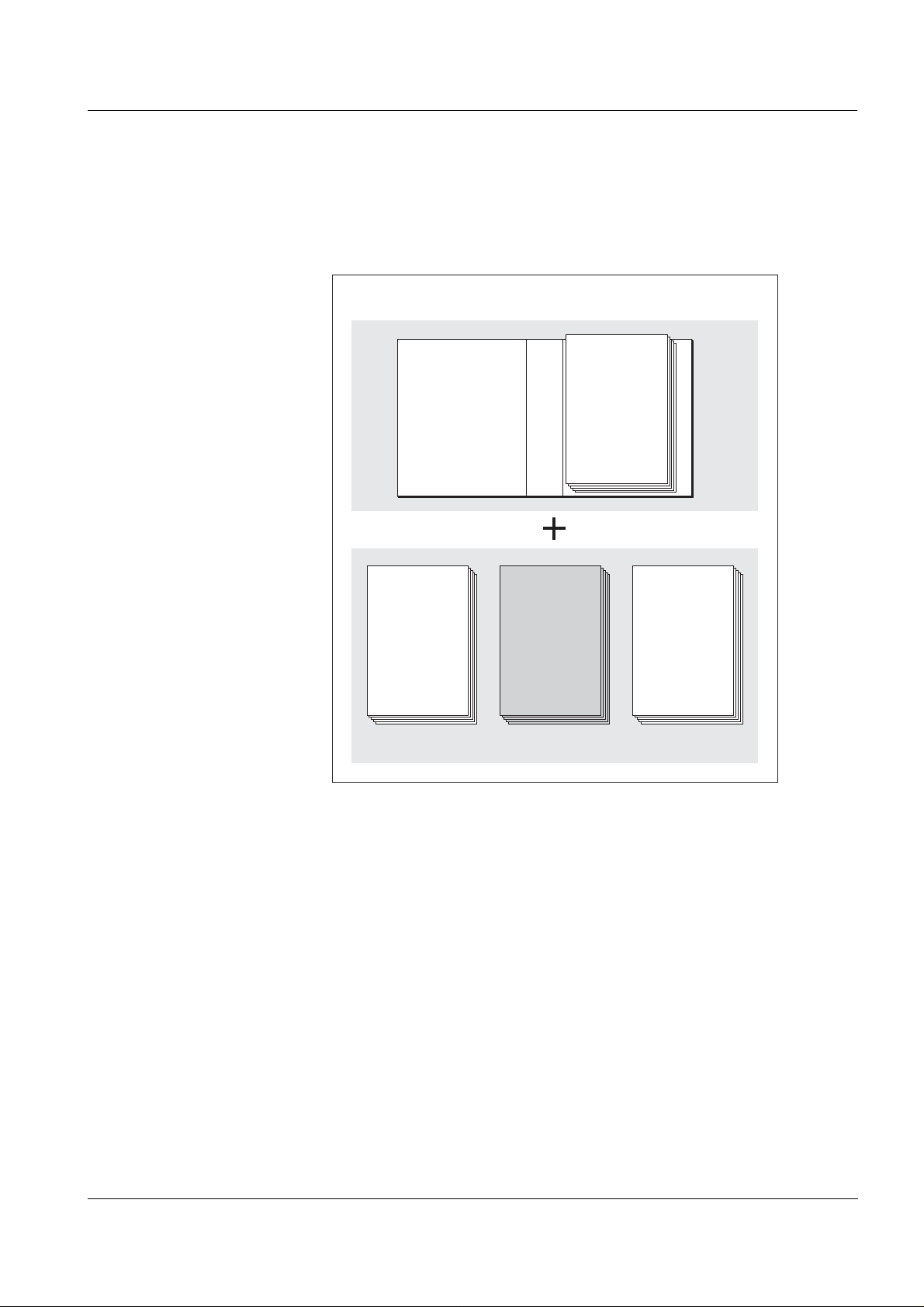

1.2 Features of the MIQ/IC2

General characteristics The MI Q/IC2 current input module provides two 0/4 ... 20 mA current

inputs for the IQ S

ters via their current output. Measured values of the external meters

can be displayed, recorded and processed like the measured values

from IQ S

ENSOR NET sensors.

Examples of external meters:

Measuring transmitters by YSI

Measuring transmitters by other manufactur ers

Measuring transmitters with explosion prot ection via a power sup-

ply/isolator

Analyzers

ENSOR NET and thus enables to connect external me-

1 - 2

Fig. 1-2 Connection of external meters to the IQ SENSOR NET

With the standard MIQ module housing, the MIQ/IC2 has the same

characteristics as all MIQ modules regarding stability, leakproofness

and weather resistance. It also pr ovides the same wide variety of inst allation options (stacked mounting, canopy mounting, tophat rail

mounting, etc.).

Terminal strip The MIQ/IC2 has the following electrical connections on the terminal

strip inside the housing:

2 x current input (0/4 ... 20 mA)

2 x SENSORNET connection

1 x power supply/isolator feed-in

ba76034e01 01/2012

Page 7

MIQ/IC2 Safety instructions

2 Safety instructions

This operating manual contains special instructions that must be

followed during the installation of the MIQ/IC2 cur rent input module.

Thus, it is essential for the operator to read this component operating

manual before carrying out any work with t he system. In addition to t his

manual, the S

manual must be followed.

Always keep this component operating manual together with the

system operating manual and all other component operating manuals

in the vicinity of the IQ S

AFETY chapter of the IQ SENSOR NET system operating

ENSOR NET system.

General safety

instructions

Other labels

Safety instructions in this operat ing manual are identified by the

warning symbol (triangle) in the left column. The signal word (e. g.

"Caution") indicates the level of danger:

Warning

indicates instructions that must be followed precisely in order to

prevent serious dangers to persons.

Caution

indicates instructions that must be followed precisely in order to

avoid slight injuries or damage to the instrument or the

environment.

Note

This symbol indicates instructions that describe special features.

Note

indicates cross-references to other documents, e.g. operating manuals.

ba76034e01 01/2012

2 - 1

Page 8

Safety instructions MIQ/IC2

2.1 Authorized use

The authorized use of the MIQ/IC2 consists of the provision of two

0/4 ... 20 mA current inputs for the IQ S

ENSOR NET.

Please keep to the technical specifications according to chapter 7

T

ECHNICAL DATA. Only operation according to the i nstructions in this

operating manual is authorized.

Any other use is considered to be unauthorized. Unauthorized use

invalidates any claims with regard to the guar antee.

2.2 General safety instructions

The MIQ/IC2 is constructed and inspected according to the relevant

guidelines and norms for electronic instruments (see chapter 7

T

ECHNICAL DATA).

It left the factory in a safe and secure technical condition.

Function and

operational safety

The failure-free function and operational safety of the MIQ/IC2 is only

guaranteed if the generally applicabl e safety measures and the special

safety instructions in this oper ating manual ar e foll owed during i ts use.

The failure-free function and operational safety of the MIQ/IC2 is only

guaranteed under the environmental conditions that a re speci fied in

chapter 7 T

ECHNICAL DATA.

Safe operation If safe operation is no longer possible, the MIQ/IC2 must be taken out

of operation and secured against inadvertent operation.

Safe operation is no longer possible if the MIQ/IC2:

has been damaged in transport

has been stored under adverse conditions for a lengthy period of

time

is visibly damaged

no longer operates as described in this manual.

If you are in any doubt, contact the supplier of your MIQ/IC2.

2 - 2

ba76034e01 01/2012

Page 9

MIQ/IC2 Installation

3 Installation

3.1 Scope of delivery

The scope of delivery of the MIQ/IC2 is listed in the INSTALLATION

chapter of the system operating manual.

3.2 Installation in the IQ SENSOR NET

The IQ SENSOR NET provides a number of options to integrate the MIQ/

IC2 mechanically and electrically in the system (stacked mounting,

distributed mounting, etc.). The various types of installation are

described in detail in the I

manual.

NSTALLATION chapter of the system operat ing

Software requirements

of the IQ S

ENSOR NET

Software requirements for the settings of Unit and Measured parame-

ter:

Controller from version 2.58

Terminal from version 2.55

When using older software versions, i t is not possi ble to enter t exts for

the settings of Unit and Measured parameter. The measured value

display displays the numerical value of the correl ated measured value

without designation.

Note

It is possible to update the so ftware if your componen ts have older software versions. Contact the YSI service depar tment.

3.3 Connecting external meters to the current inputs Warning

If external electrical cir cuits that are subject to the danger of physical contact are incorrectly connect ed to the current inputs, ther e

may be a danger of life threatening electric shock. Electrica l circuits are regarded to be subject to the danger of physical contact

when there are voltages higher than the Safety Extra Low Voltage

(SELV).

General installation

instructions

ba76034e01 01/2012

Observe the following instructions when att aching connect ing wir es to

the terminal strip:

Shorten all the wires used to the length required for the installation.

Fit all wire ends with wire end sleeves before connecting them to the

terminal stri p .

3 - 1

Page 10

Installation MIQ/IC2

1

3

2

SENSORNET 2

SENSORNET 1

ON

OFF

X6

RED

RED

SN TERMINATOR

SHIELD

GREEN

SHIELD

GREEN

X5

X4

X3

X2

X1

X8

X9

X7

X11

X12

X10

24V

0/4...20mA0/4...20mA

Current

Input 1

Supply

max

240 mA

Current

Input 2

+ REC 1-+ REC 2 -

+ Power -

Any wires that are not used a nd project int o the housing must be cut

off as closely as possible to the cable gland.

Materials required Wire end sleeves, suitabl e for the connecting wires, with suitable

crimping tool

Cable gland with sealing ring (scope of delivery of the MIQ/IC2)

Tools Cable stripping knife

Wire stripper

Phillips screw driver

Small screw driv e r

Connecting lines to the

terminal strip

1 Open the module.

2 Open the dummy screw fitting under the required input. Keep

the dummy screw fitting for possible later modifications.

3 - 2

Fig. 3-1 Terminal strip MIQ/IC2

3 Screw the cable gland (pos. 1 in Fi g. 3-1) with the sealing ring

(pos. 2) into the module housing.

ba76034e01 01/2012

Page 11

MIQ/IC2 Installation

4 Loosen the coupling ring (pos. 3 in Fig. 3-1).

5 Feed the line through the cable gland in the module housing.

6 Connect the wi res to t he termi nal stri p. Whil e doi ng so, pay at-

tention to the specifications on the label located under the terminal strip.

7 Tighten the coupling ring (pos. 3 in Fig. 3-1).

Note

No free wires must be allowed to project into the housing. Otherwise

there is the risk of malfunction. Always cut of f any wires that are not i n

use as closely as possible to the cable gland.

8 Close the module.

ba76034e01 01/2012

3 - 3

Page 12

Installation MIQ/IC2

3.4 Installation examples

The following installation examples demonstrate the basi c application

of the MIQ/IC2.

Note

For installation, please always observe the installation and operating

manuals of the external meters.

Connecting external

meters directly

The current outputs of external measur ing systems can be direct ly connected to the current inputs of the MIQ/IC2 module.

If the connection data of t he external meter is suitable, it i s also possible

to supply the external meter with power by the power supply/isolator

feed-in on the MIQ/IC2 module.

3 - 4

Fig. 3-2 Connection diagram for the conn ection of external measuring s ystems to the

MIQ/IC2 module

ba76034e01 01/2012

Page 13

MIQ/IC2 Installation

IQ Sensor Net

2 x Power supply/isolator

Potentially

explosive area,

zone 1 / zone 2

4 … 20 mA

4 … 20 mA 4 … 20 mA

4 … 20 mA

Feed-in

1

5

7

3

4 8

11

12

11

12

+

+

+

+

Meter 1

Meter 2

+

5

+

1

7

3

4 8

MIQ/IC2

- +

X7 X8

X9

X10

X11

X12

+

+

Connecting external

meters via a power sup-

ply/isolator

The current outputs of external meters c an be directly connected to the

current inputs of the MIQ/IC2 module vi a a power su pply/i solato r. Connecting via a power supply/isolator is necessary for measurements in

potentially explosive areas, for example.

If the connection data of the power supply/ isolators is su itable, it is possible to supply up to two power suppl y/isolators with power vi a the feedin connector on the MIQ/IC2 module.

ba76034e01 01/2012

Fig. 3-3 Connection diagram for the connection of external meters situated in

potentially explosive areas to the MIQ/IC2 module

Warning

In potentially explosive areas, inst ruments may be install ed, commissioned and operated by specialist electricians only, and according to the relevant regulations and the instructions in the

relevant operating manuals.

3 - 5

Page 14

Installation MIQ/IC2

3 - 6

ba76034e01 01/2012

Page 15

MIQ/IC2 Settings

Active measured

current value at

the 0/4 ... 20 mA

current input

Correlated

measured value

(display value)

with Measured

parameter and

Unit

4 Settings

Overview The MIQ/IC2 module provides two 0/4 ... 20 mA current inputs for the

IQ S

ENSOR NET. Each current input appears in the measured value

display, the Edit list of sensors over view and the Settings of sensors

and diff. sensors menu.

Each current input is treated like a sensor ("current sensor") by the

IQ S

ENSOR NET and has a separate setting menu.

On initial commissioning, only current input 1 is registered on the

IQ S

ENSOR NET. The measured value display indicat es the value of the

current at current input 1 in mA.

The correlated measured value (display val ue) is displayed without any

designation of Unit and Measured parameter and, in the delivery

condition, is identical with the current value (default setting).

After the display values at the measuring range limits have been set

and the Unit and Measured parameter have been specified, the correlated measured value corresponds to the measured value of the sensor, e.g. of a DO sensor:

ba76034e01 01/2012

Fig. 4-1 Example: correlated measured value of a DO sensor

Activate current input 2 in the Settings of sensors and diff. sensors

menu of current input 1. The setting menus of both current inputs are

identical except for the activation of current input 2.

If the physical input current range is exceeded, OFL is displayed

(measuring range exceeded or undercut).

Note

The general operating principles are given in the system operating

manual or in the component operating manual of the terminal components.

4 - 1

Page 16

Settings MIQ/IC2

Settings The following settings can be made for the sensor (default settings are

marked in bold):

Menu item Possible settings Explanations

Measuring mode REC Measurement of the current at the

0/4 ... 20 mA current inputs

Measuring range 0..20 mA

4..20 mA

Decimal places none

1 (.0)

2 (.00)

3 (.000)

Display value (0/4 mA) depending on the setting of

the Decimal places:

Display value (20 mA)

-9999 ... 20 ... 99999

-99.9 ... 20.0 ... 999.9

-9.99 ... 20.00 ... 99.99

0.000 ... 2.000 ... 9.999

Error detection >= Error threshold

<= Error threshold

Two measuring ranges can be selected.

The setting should agree with the output

range of the external sensor.

Display accuracy of the correlated measured value (display value).

The setting of the Decimal places affects

the maximum limits of the correlated measured value (see settings of displa y value).

Lower and upper limit of the measuring

range for the displayed, correlated measured value.

The maximum measuring range limits to

be set depend on the setting of the

Decimal places.

Specification whether an invalid measur ed

value ("----") is displ ayed if the current li mit

value (Error threshold) is exceeded or un-

dercut.

Error thresh o ld 0.5 ... 20.5 ... 21.5 mA Current limit value. If it is reached and ex-

ceeded or undercut, an error should be

displayed (see setting of Error detection).

Display indications for diff erent settings of

Measuring range, Error threshold and Error detection:

Fig. 4-2 Measuring range 0... 20 mA, Error detection >= Error threshold (IF),

= 20.5 mA

I

F

4 - 2

ba76034e01 01/2012

Page 17

MIQ/IC2 Settings

Fig. 4-3 Measuring range: 4 ... 20 mA, Error detection >= Error threshold (IF);

= 20.5 mA

I

F

Fig. 4-4 Measuring range: 4 ... 20 mA, Error detection <= Error threshold (IF)

= 3.5 mA

I

F

Menu item Possible settings Explanations

Unit ..... Entry of texts for Unit and Measured para-

meter. The texts entered appear in the

Measured parameter .....

measured value display next to the measured value.

The text is entered with

d and g

(see system operating manual)

e.g. Unit = mg/l

e.g. Measured parameter = O2

MIQ/IC2 REC2

(in the setting menu of

active

inactive

Activate or deactivate current input 2

current input 1 only)

Save and quit The system confirms the saving of the set-

tings and the display switches to the next

higher level.

Quit The display switches to the next higher

level without saving the new settings.

Carrying out settings

1 Switch to the measured value display with m.

ba76034e01 01/2012

2 Open the Settings menu with

s.

3 Select and conf irm the menu item Settings of sensors and diff.

sensors -> column Measuring range with

4 Select an entry with

d.

d and g.

4 - 3

Page 18

Settings MIQ/IC2

Fig. 4-5 140 - Settings of sensors and diff. sensors

5 Confirm the selection with g.

The settings of the sensor are displayed.

4 - 4

Fig. 4-6 140 - Settings of sensors and diff. sensors

6 Make the sensor settings with d and confirm each of them

with

g.

7 Select the Save and quit menu item with

d and confirm with

g. The new settings are stored in the sensor.

ba76034e01 01/2012

Page 19

MIQ/IC2 What to do if ...

5 What to do if ...

No measured value

Cause Remedy

– MIQ/IC2 not connected – Connect the MIQ/IC2

– Unknown – Look in the log book

Measurement provi des

implausible measured

values

Display of OFL

Cause Remedy

– Unsuitable settings of:

– Measuring range,

– Adjust the setting s in the setting

menu of the MIQ/IC2

– Display value (0/4 mA),

– Display value (20 mA)

– Current value at the current

input or output of an instru-

ment (e.g. measuring trans-

mitter, power supply/isolator,

– Change the settings of the

external m et e rs as necessary

– Adjust the setting s in the setting

menu of the MIQ/IC2

MIQ/IC2 etc.) does not agree

with the nominal value

– Calibration is not up-to-date – Calibrate the external meter

Cause Remedy

– Allowed signal range excee-

ded or undercut

– Operate the 0/4 ... 20 mA cur-

rent inputs of the MIQ/IC2 in the

allowed current range only (see

chapter 7 T

ECHNICAL DATA)

ba76034e01 01/2012

5 - 1

Page 20

What to do if ... MIQ/IC2

5 - 2

ba76034e01 01/2012

Page 21

MIQ/IC2 Maintenance and cleaning

6 Maintenance and cleaning

6.1 Maintenance

The MIQ/IC2 requires no special maintenance. The general maintenance of IQ S

IQ S

ENSOR NET system operating manual.

6.2 Cleaning

The cleaning of IQ SENSOR NET components is described in the

IQ S

ENSOR NET system operating manual.

ENSOR NET components is described in the

ba76034e01 01/2012

6 - 1

Page 22

Maintenance and cleaning MIQ/IC2

6 - 2

ba76034e01 01/2012

Page 23

MIQ/IC2 Technical data

7 Technical data

Note

Electrical data

General technical data on MIQ modules are given in the T

DATA chapter of the IQ SENSOR NET system operating manual.

Nominal voltage Max. 24 VDC via the IQ SENSOR NET (for

details, see the T

the IQ S

ENSOR NET system operating

ECHNICAL DATA chapter of

manual)

Power consumption 0.2 ... 4.6 W

0.2 W: without supplying any power supply/

isolator

≤ 2.4 W: with one power supply/isolator

≤ 4.6 W: with two power supply/isolators

ECHNICAL

Instrument safety

Terminal connections

Protective class III

Applicable norms – EN 61010-1

– UL 3111-1

– CAN/CSA C22.2 No. 1010.1

IQ SENSOR NET connections

2

Additional connectable SENSORNET terminator (terminating resistor)

Current inputs

2

(0/4 ... 20 mA)

Connector for power

1

supply/isolator

Terminal type Screw-type terminal strip, accessible by

opening the lid

Terminal ranges Solid wires: 0.2 ... 4.0 mm

2

AWG 24 ... 12

2

2

Line cross-section of cables carrying mains volt-

Flexible wires: 0.2 ... 2.5 mm

Europe: 1.5 ... 4.0 m m

USA: AWG 14 ... 12

age

ba76034e01 01/2012

Cable feeds 4 cable glands M16 x 1.5 on the underside

of the module

7 - 1

Page 24

Technical data MIQ/IC2

Current inputs

Measuring channels 2

Physically separated from the

IQ S

ENSOR NET

Physical input current

range

0.0 ... 22.5 mA

If this range is exceeded, the input switches

itself off for approx. one minute as a protective measure

Allowed signal ranges 0 ... 20 mA: 0.0 mA ≤ I ≤ 20.2 mA

4 ... 20 mA: 3.8 mA ≤ I ≤ 20.2 mA

Undefined signal ranges

Display of OFL

(range within the physi-

At the lower end of the signal range

(with signal range 4 ... 20mA only):

I

Error threshold

< I < 3.8 mA

cal input current range

but outside of the allowed signal range)

Error signal ranges

Display of "- ---"

At the upper end of the signal range

(with signal range 0/4 ... 20mA only):

20.2 mA < I < I

Error threshold

Error detection <= Error threshold:

0.0 mA ≤ I ≤ I

Error threshold

(corresponding to

setting of Error detec-

tion)

Error detection >= Error threshold:

I

Error threshold

≤ I ≤ 22.5 mA

Feed-in

(power supply/isolator)

Allowed common-mode

10 VDC, 20 VAC

difference between the

measuring channels

Measuring uncertainty

< 0.2 % of the measured value ± 0.01 mA

(precision)

Load max. 250 Ohm

Electrical data 20.5 - 24 V

Output current max. 240 mA,

permanently short-circuit proof

Requirement or monitor-

ing of the supply voltage

(only applies if a power

supply/isolator is connected)

21.5 ... 24 V

different from the IQ S

monitoring (see system operating manual)

The voltage monitoring values are automat-

ically changed when a power supply/is olator

is connected.

P-P

ENSOR NET voltage

7 - 2

ba76034e01 01/2012

Page 25

MIQ/IC2 Contact Information

8 Contact Information

8.1 Ordering & Technical Support

Telephone

Fax

: (937) 767-1058

Email

Mail: YSI Incorporated

Internet

When placing an order please have the following information availabl e:

YSI account number (if available) Name and Phone Number

Model number or brief description Billing and shipping address

Quantity Purchase Order or Credit Card

: (800) 897-4151

(937) 767-7241

Monday through Friday, 8:00 AM to 5:00 PM ET

: environmental@ysi.com

1725 Brannum Lane

Yellow Springs, OH 45387

USA

: www.ysi.com

8.2 Service Information

YSI has authorized service centers throughout the United States and

Internationally. For the neares t ser vice center inf ormati on, please vi si t

www.ysi.com

directly at 800-897-4151.

When returning a product for service , i nclude the Product Retur n f orm

with cleaning certification. Th e form must be completely fil led out for an

YSI Service Center to accept the instrument for service. The Product

Return form may be downloaded at www.ysi.com

‘Support‘ tab.

and click ‘Support’ or contact YSI Technical Support

and clicking on the

ba76034e01 01/2012

8 - 1

Page 26

Contact Information MIQ/IC2

8 - 2

ba76034e01 01/2012

Page 27

MIQ/IC2 Lists

9Lists

9.1 Explanation of the messages

In this chapter you will fi nd a lis t with all the mess age codes and cor responding message texts that may occur in the log book of the

IQ S

ENSOR NET system for the MIQ/IC2 current input module.

Note

Information about

Contents and structure of the log book and

Structure of the message code

can be found in the L

operating manual.

Note

All message codes of the MIQ/IC2 current input module end with the

number "381" (current input 1) or "382" (cur rent input 2).

9.1.1 Error messages

Message code Message text

EA9381

EA9382

Input current in undefined range

* Check settings and, if necessary, change them

* Check installation

* Check connected measuring system

* Check the MIQ/IC2

EAA381

EAA382

An error was reported

* Check settings and, if necessary, change them

* Check installation

* Check connected measuring system

* Check the MIQ/IC2

OG BOOK chapter of the IQ SENSOR NET system

EI1381 Operational voltage too low

* Check installation and cable lengths,

Follow installation instructions

* Power unit(s) overloaded, add power unit(s)

* Check terminal and module connections

* Defective components, replace components

EI2381 Operational voltage too low, no operation possible

* Check installation and cable lengths,

Follow installation instructions

* Power unit(s) overloaded, add power unit(s)

* Check terminal and module connections

* Defective components, replace components

ba76034e01 01/2012

9 - 1

Page 28

Lists MIQ/IC2

Message code Message text

ES1381 Component hardware defective

* Contact service

9.1.2 Informative messages

The MIQ/IC2 current input module does not send any info messages.

9.2 Status info

The status info is a coded piece of i nformat ion on the c urrent status of

a sensor. Each sensor sends this status info to the controller. The status info of sensors consists of 32 bits, each of whi ch can have the value

0 or 1.

General structure of the

status info

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 (general)

0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 (internal)

16 17 1 8 1 9 2 0 2 1 22 2 3 24 25 26 27 28 29 30 31

The bits 0 - 15 are reserved for general information.

The bits 16 - 21 are reserved for internal service information.

The status info can be obtained as follows:

via a manual query in the menu, Einstellungen/Settings/Service/

Liste aller Teilnehmer (see system operating manual)

via an automatic query

– of a superior process control (e. g. when connected to the Profi-

bus)

– of the IQ Data Server (see IQ S

ENSOR NET Software Pack ope-

rating manual)

Note

The evaluation of the status inf o, e. g. in the c ase of an automati c query, has to be made individually for each bit.

9 - 2

MIQ/IC2

status info

Status bit Explanation

Bit 0 Component hardware defective

Bit 1-31 -

ba76034e01 01/2012

Page 29

Page 30

1725 Brannum Lane

Yellow Springs, Ohio 45387 USA

+1 937-767-7241

800-765-4974 (US)

FAX (937) 767-1058

Email: environmental@ysi.com

Internet: www.ysi.com

Loading...

Loading...