Page 1

Operations Manual

®

EcoSense

DO200A

Dissolved Oxygen

and Temperature

English

Français

Español

Field/Lab

Instrument

Português

Page 2

WARRANTY

The EcoSense® DO200A Instrument is warranted for one year from date of

purchase by the end user against defects in materials and workmanship. DO200A

probes and cables are warranted for one year from date of purchase by the end

user against defects in material and workmanship. Within the warranty period, YSI

will repair or replace, at its sole discretion, free of charge, any product that YSI

determines to be covered by this warranty.

To exercise this warranty, write or call your local YSI representative, or contact YSI

Customer Service in Yellow Springs, Ohio. Send the product and proof of

purchase, transportation prepaid, to the Authorized Service Center selected by YSI.

Repair or replacement will be made and the product returned, transportation

prepaid. Repaired or replaced products are warranted for the balance of the

original warranty period, or at least 90 days from date of repair or replacement.

Limitation of Warranty

This Warranty does not apply to any YSI product damage or failure caused by: (i)

failure to install, operate or use the product in accordance with YSI’s written

instructions; (ii) abuse or misuse of the product; (iii) failure to maintain the product

in accordance with YSI’s written instructions or standard industry procedure; (iv)

any improper repairs to the product; (v) use by you of defective or improper

components or parts in servicing or repairing the product; or (vi) modification of

the product in any way not expressly authorized by YSI.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED OR

IMPLIED, INCLUDING ANY WARRANTY OF MERCHANTABILITY OR FITNESS FOR

A PARTICULAR PURPOSE. YSI’s LIABILITY UNDER THIS WARRANTY IS LIMITED TO

REPAIR OR REPLACEMENT OF THE PRODUCT, AND THIS SHALL BE YOUR SOLE

AND EXCLUSIVE REMEDY FOR ANY DEFECTIVE PRODUCT COVERED BY THIS

WARRANTY. IN NO EVENT SHALL YSI BE LIABLE FOR ANY SPECIAL, INDIRECT,

INCIDENTAL OR CONSEQUENTIAL DAMAGES RESULTING FROM ANY

DEFECTIVE PRODUCT COVERED BY THIS WARRANTY.

CONTACT INFORMATION

YSI

1725 Brannum Lane

Yellow Springs OH, 45387, USA

Tel: 800-897-4151 • 937-767-7241; Fax: 937-767-1058

E-mail : environmental@ysi.com

Web : www.ysi.com

1

Page 3

CONTENTS

WARRANTY ............................................................................................................ 1

CONTACT INFORMATION .................................................................................. 1

GENERAL INTRODUCTION ................................................................................. 3

INITIAL INSPECTION ............................................................................................ 3

PRECAUTIONS ...................................................................................................... 3

The Case ......................................................................................................... 3

The Probes (Field & Lab) ............................................................................... 3

PROBE PREPARATION ......................................................................................... 4

BATTERY INSTALLATION .................................................................................... 4

Battery Disposal ............................................................................................. 4

THE KEYPAD .......................................................................................................... 4

THE LCD DISPLAY ................................................................................................. 4

OPERATIONAL PROCEDURES ........................................................................... 5

MEASUREMENT MODES ..................................................................................... 5

SAVING, VIEWING AND DELETING DATA

.................................................... 5

CALIBRATION SET-UP .......................................................................................... 5

Requirements ................................................................................................. 5

Procedure ....................................................................................................... 5

PROBE MAINTENANCE ....................................................................................... 6

TROUBLESHOOTING ........................................................................................... 7

SPECIFICATIONS .................................................................................................. 7

CONVERSIONS ..................................................................................................... 7

RECOMMENDED SPARE PARTS LIST ................................................................ 7

2

Page 4

GENERAL INTRODUCTION

The DO200A is a precise tool that measures temperature and dissolved oxygen in % and

ppm (mg/L) .

This instrument has a waterproof IP67 case when the connector cap is installed. The keys are

highly reliable with tactile and audio feedback. This instrument uses one 9V battery. Recalibration is not required after turning the instrument off and on.

The front of the instrument has a large LCD that displays DO %, ppm, and temperature

simultaneously along with user prompts and mode indicators. The unit prompts the user

through calibration and measurement procedures.

The model DO200A field and lab probes use a polarographic electrode with convenient

screw-on cap membranes. The 200-4 and 200-10 field probes come with a built-in

temperature probe for automatic temperature compensation, as well as a stainless steel body

for added weight. The self stirring 200-BOD lab probe comes with a power supply and has

replaceable electrodes.

Other features include long battery life and high 50/60 Hz AC noise rejection. This instrument

is universal and user-friendly for field, industrial, and laboratory applications.

INITIAL INSPECTION

Carefully unpack the unit and accessories, and inspect for shipping damages. Compare

received parts with materials listed on the packing list. Notify YSI immediately of any damage

or missing parts. Save all packing materials until satisfactory operation is confirmed.

PRECAUTIONS

The Case

Though the instrument is housed in a water-proof IP67 case, DO NOT use it underwater. The

connector is not waterproof unless the cap is installed. In case of submersion without the cap

connected, follow these steps immediately:

1. Dry the connector if necessary. Rinse unit carefully with distilled water. After rinsing and

drying, inspect and clean connectors to remove all contaminants that may affect probe

connections.

2. Wait for unit and connectors to dry completely before resuming operation.

3. If the unit does not function correctly after steps 1 and 2, call YSI for possible repair or

replacement.

The Probes (Field & Lab)

1. Membranes last longer if properly installed and regularly maintained. Erratic readings

can result from damaged or fouled membranes or from large bubbles in the electrolyte

reservoir. If unstable readings or membrane damage occurs, replace both the

membrane cap and Oxygen Probe solution (O2 Probe Electrolyte). The average

membrane replacement interval is 4 to 8 weeks, although they may last longer if kept

clean. Harsh environments, such as wastewater, may require membrane replacement

every 2 to 4 weeks. Unstable readings may occur if membrane cap is coated with oxygen

consuming or producing organisms such as bacteria or algae.

2. Chlorine, sulfur dioxide, nitric oxide and nitrous oxide can affect readings by behaving

like oxygen at the probe.

3. Avoid substances that may damage probe materials such as concentrated acid, caustics

and strong solvents. Probe materials include Stainless steel, epoxy and ABS Plastic.

4. Keep the probe’s gold cathode clean and textured (when properly maintained it has a

matte finish). If it is tarnished (from contact with certain gases), or plated with silver (from

extended use with a loose or wrinkled membrane), then clean it, following the

instructions in “Probe Maintenance”.

3

Page 5

5. To prevent the membrane and electrolyte from drying out, store the field probe in the

A

calibration bottle with the moistened, clean sponge and the lab probe in a clean BOD

bottle with 1 inch of water to keep them in a saturated air environment.

PROBE PREPARATION

The DO200A probe ships with a dry, protective membrane. To install a new membrane cap

on the probe:

1. Unscrew probe membrane cap and discard.

2. Fill a new cap with Oxygen Probe Solution. If using the probe solution for the first time,

prepare it according to directions on the bottle.

3. Thread filled membrane cap onto sensor.

4. Allow sufficient warm-up time for initial use (10-15 min). During this time an “ovEr”

message may appear on the display. This is normal. After the warm up is complete the

message will disappear.

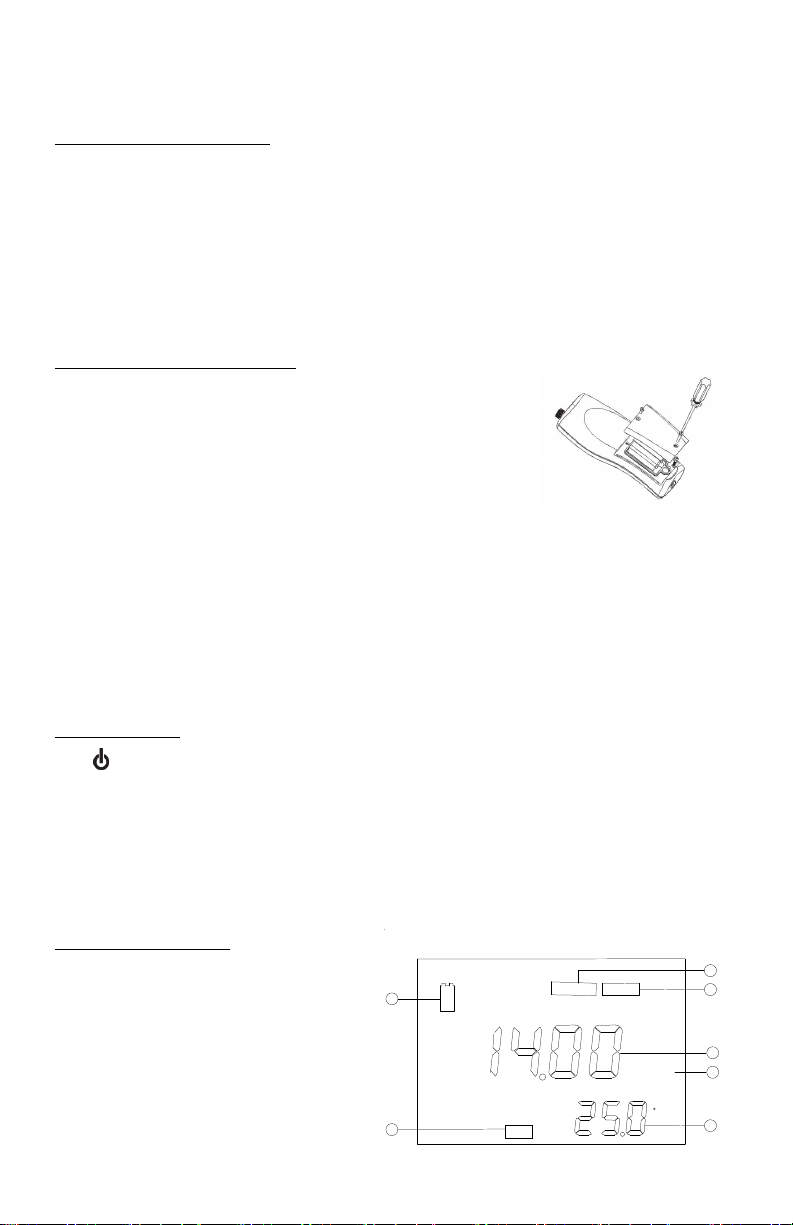

BATTERY INSTALLATION

An initial display of “LOW BAT” on the LCD indicates

approximately one hour of battery life for unit operation within

specifications. Replace battery when “LOW BAT” appears on

the LCD.

To replace battery, remove the two battery cover screws and

the

battery cover and o-ring. Replace the 9V battery. Replace the

battery cover and o-ring (be sure to align the o-ring correctly to

prevent a bad seal) and fasten the two battery cover screws for

Figure 1.

Battery Installation

the water-proof feature.

Battery Disposal

This instrument is powered by a 9 volt battery, which the user must remove and dispose of

when the batteries no longer power the instrument. Disposal requirements vary by country

and region, and users are expected to understand and follow the battery disposal

requirements for their specific locale.

THE KEYPAD

1. : Turns the unit on or off.

2. MODE: In normal operation, toggles display between Dissolved Oxygen in % air

saturation, Dissolved Oxygen in ppm (mg/L), Delete and Recall. In Calibration mode,

exits current calibration and displays the next calibration parameter.

3. CAL: In normal operation, changes the mode from Normal to Calibration. See

Calibration Set-up.

: In Calibration Set-up, press this key to save the current parameter to memory.

4.

5. and Keys: Increases or decreases the display value as desired.

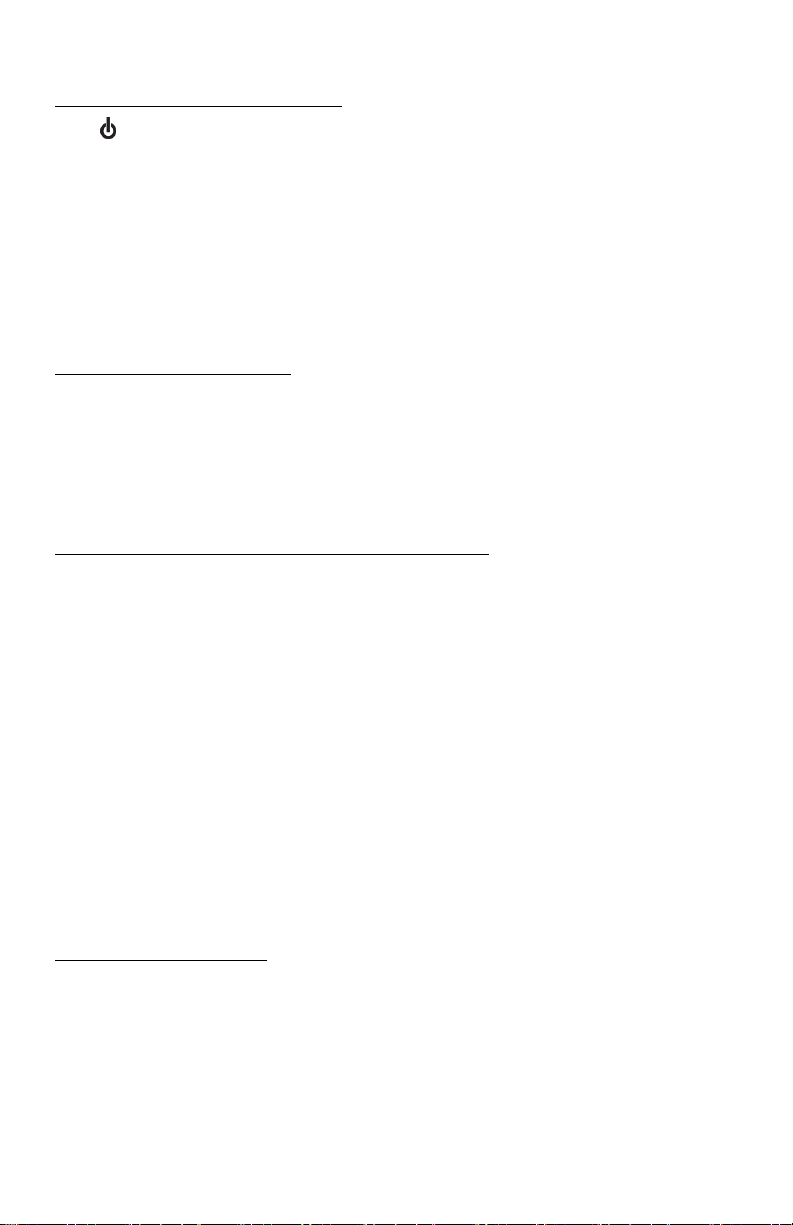

THE LCD DISPLAY

1. BAT: Low battery indicator.

2. CAL: Calibration mode indicator.

3. SAL ppt: Displays during calibration

when user is prompted for the

approximate salinity of the sample in

parts per thousand (ppt).

4. mBar: Displays during calibration to

prompt user for barometric pressure.

5. Main display for dissolved oxygen

values.

6. %/ppm: Unit indicators.

1

2

4

BAT

CAL

Figure2. LCD Display

SAL ppt

mBar

% ppm

C

3

4

5

6

7

Page 6

7. ºC: Temperature display.

OPERATIONAL PROCEDURES

Press to turn the unit on or off. The instrument will perform a self-diagnostic test, during

which an “ovEr” message may appear on the display. This is normal. After the warm up is

complete the message will disappear. After the self-diagnostic test completes, the

temperature displays in the lower right of the display, and the unit is ready for operation.

Immerse the probe into the sample solution. If possible, do not allow probe to touch any solid

object in the solution. Avoid air bubbles bursting on the membrane surface. When the unit is

not in use, turn it off to save battery life. The instrument has a 30 minute auto shut off feature

when not in use.

NOTE: During an oxygen measurement, the probe must be moved approximately 1/2 ft per

second to overcome the consumption of oxygen by the sensor. When using the 200-BOD lab

probe, however, simply use the probe’s self-stirring feature.

MEASUREMENT MODES

This unit provides three distinct measurements:

1. Temperature - Current solution temperature continually displays.

2. Dissolved Oxygen % - Measurement of oxygen in percent saturation.

3. Dissolved Oxygen ppm - Measurement of oxygen in ppm (mg/L).

Carefully observe the units displayed at the far side of the LCD to determine the desired

mode.

SAVING, VIEWING AND DELETING DATA

The DO200A can save 50 data records. When in measurement mode, press to save a

record. The instrument will confirm the saved data by displaying SAVE and the record

number for one second. “Full” is displayed when trying to save data and the memory is full.

To view saved data, press mode until RECALL is displayed and then press . Use the Up or

Down arrow keys to review different saved records. Press Mode to escape back to

measurement mode.

To delete data records, press Mode while in measurement mode until DELETE is displayed.

Press . “All” will be displayed and blinking. Press the Up or Down arrow key to switch

between delete ‘All’ or ‘Each’ options. Select either ‘All’ or ‘Each’ by pressing while that

option is displayed.

If ‘All’ is selected, all records will be deleted from memory and ‘None’ will be displayed. Press

Mode twice to return to the measurement mode.

If ‘Each’ is selected, the Up and Down arrow keys will allow you to scroll through the saved

data records. Press to delete the selected record. All records after the deleted record will

shift up to keep the records in sequential order. For example, if record 3 is deleted, record 4

will become record 3 and record 5 will become record 4. Press Mode twice to return to the

measurement mode.

CALIBRATION SET-UP

Requirements

1. The approximate pressure (in millibars [mBar]) of the location at the time of calibration.

2. The approximate salinity of the water to be analyzed. Fresh water has an approximate

salinity of zero parts per thousand (ppt). Seawater has an approximate salinity of 35 ppt.

Procedure

1. For the field probe, place 5-6 drops of clean water (tap, distilled, or deionized) into the

sponge inside the calibration bottle. Turn the bottle over and allow any excess water to

drain out of the bottle. The wet sponge creates a 100% water-saturated air environment

5

Page 7

for the probe, which is ideal for calibration, transport, and storage of the Model DO200A

probe. For calibration, the probe remains in a water saturated air atmosphere and is not

submersed.

For the lab probe, simply use the same bottle the probe is stored in with approximately

1 inch of water in the bottom. This creates a 100% water-saturated air environment for

the probe, which is ideal for calibration and storage of the Model 200-BOD probe. For

calibration, the probe remains in a water saturated air atmosphere and is not

submersed.

2. For the field probe, slide it into the calibration bottle. Be sure the membrane does not

touch the sponge.

3. Turn on the DO200A by pressing . Wait 10 to 15 minutes for the dissolved oxygen and

temperature readings to stabilize.

4. Press CAL.

5. The LCD prompts for the local pressure in mBar. Use the and keys to increase or

decrease the pressure value respectively. See the section titled ‘Conversions’ to convert

barometric pressure units to mBars.

6. When the proper pressure displays, press

lower right of the display. Once the value in the main display stabilizes, press

move to the salinity compensation procedure.

7. The display prompts for the approximate salinity of the water to be analyzed. Use the

and keys to increase or decrease the salinity compensation value to the value of your

sample (between 0 to 40 parts per thousand [ppt]). When the correct salinity displays,

.

press

8. The unit holds calibration even if it is powered off. However, it is recommended to check

calibration with each use and recalibrate as necessary to prevent drift. Dissolved oxygen

readings are only as good as the calibration.

once to view the calibration value in the

again to

PROBE MAINTENANCE

Clean the probe whenever it won’t calibrate or the readings are unstable and changing the

membrane does not solve either issue. On average, the probe should only be cleaned about

once or twice per year. To clean the probe, sand the electrodes according the directions

below. In addition to sanding, a chemical soak may be necessary (direction below). Always

sand the electrodes after performing a chemical soak.

1. Turn unit off, or disconnect probe.

2. Remove membrane cap and rinse the probe with clean water (tap, distilled, or

deionized).

3. Obtain either:

14 % lab strength ammonium hydroxide and soak for 2-3 minutes

4. Rinse ammonium hydroxide/ammonia completely from probe.

5. Use sandpaper (400 grit wet/dry, supplied with 5238 kit and with the 5908 membrane

6. Install a new membrane cap.

Never use chemicals or abrasives not recommended by YSI.

3% household cleaning strength ammonia and soak overnight (8-12 hours)

kit) to buff (wet sand) excess deposits from probe. Perform a circular sand on the gold

cathode (tip) and also wrap the sand paper around the silver anode (shaft) and twist.

Rinse with clean water (tap, distilled, or deionized).

6

Page 8

TROUBLESHOOTING

Y

Y

Main Display reads: Possible Solutions:

“ovEr” or “undr”

Check membrane and electrolyte solution.

Clean anode and cathode.

Return product for service.

Secondary Display reads: Possible Solutions:

“undr”

“ovEr”

Heat the sample to above –6.0 °C

Return product for service.

Cool sample to below 46.0 °C

Return product for service

SPECIFICATIONS

Display Range Accuracy Resolution

Dissolved O2

(ppm or mg/L)

Dissolved O2

% air-sat

Temperature °C -6.0 to 46.0 °C

Pressure Compensation 600 to 1100 mBar (450 to 825 mmHg)

Salinity Compensation From 0.0 to 40.0 ppt

ATC Probe

Calibration Backup

Audio Feedback

Power Source One 9V battery

Operating Temperature

Instrument Casing Waterproof IP 67

Weight (with battery) 270 grams (.61 lbs)

Dimensions (L x W x D) 18.7 cm x 7.6 cm x 3.8 cm (7.3 in x 3 in x 1.5 in)

0 to 20.00 ppm (mg/L) ±2 % of the reading or ±2% air

0 to 200.0 % ±2% of the reading or ±0.2 ppm,

21 to 115 °F

saturation, whichever is greater

whichever is greater.

±0.3 °C ±1 digit 0.1 °C

Thermistor, 10K, at 25C

es

es, on all keys

0 to 50C (32 to

122 °F)

0.01 mg/L

0.1 %

CONVERSIONS

To Convert: Multiply by:

Inches of Hg to mBar 33.864

Inches of Hg to mmHg 25.4

mmHg to mBar 1.333

RECOMMENDED SPARE PARTS LIST

PART # DESCRIPTION

200-4 4 meter (approx. 13 feet) probe and cable assembly

200-10 10 meter (approx. 33 feet) probe and cable assembly

200-BOD Self-stirring BOD lab probe and cable assembly with power supply

485 DO carrying case, soft sided

606036 DO carrying case, hard sided

5908 Membrane kit, 1.25 mil PE (605306), six cap membranes and KCl solution

Item #606035REF

Revision A; July 2012

For the latest version of this manual, visit www.ysi.com

7

Page 9

GARANTIE

L’appareil EcoSense® DO200A est garanti pour une période d’un an, à compter de la date

d’achat par l’utilisateur final, contre tout défaut matériel et de fabrication. Les sondes et les

câbles de DO200A sont garantis pour une période d’un an, à compter de la date d’achat par

l’utilisateur final, contre tout défaut matériel et de fabrication. Pendant la période de garantie,

YSI s’engage à réparer ou à remplacer, gratuitement et à sa discrétion, tout produit qu’YSI

peut établir comme étant couvert par la garantie.

Pour faire valoir cette garantie, écrivez ou appelez votre représentant YSI ou contactez le

Service clientèle d’YSI à Yellow Springs, Ohio, États-Unis. Envoyez le produit et son justificatif

d’achat en port payé au Centre de service homologué sélectionné par YSI. La réparation ou le

remplacement seront effectués et le produit vous sera retourné en port payé. Les produits

réparés ou remplacés sont garantis jusqu’à expiration de la période de garantie originale ou

au moins 90 jours à compter de la date de réparation ou de remplacement.

Limitation de garantie

Cette garantie ne s’applique pas aux produits YSI endommagés ou présentant des

dysfonctionnements pour les raisons suivantes : (i) installation, exploitation ou utilisation du

produit d’une façon non conforme aux instructions écrites d’YSI ; (ii) abus ou mésusage du

produit ; (iii) manquement à l’entretien du produit conformément aux instructions écrites

d’YSI ou aux procédures industrielles normales ; (iv) réparation non conforme du produit ; (v)

utilisation par vous de pièces ou de composants défectueux ou non conformes lors de

l’entretien ou de la réparation du produit ; ou, (vi) modification du produit d’une façon non

expressément autorisée par YSI.

CETTE GARANTIE REMPLACE TOUTES LES AUTRES GARANTIES, EXPRESSES OU INDUITES,

Y COMPRIS LES GARANTIES DE COMMERCIABILITÉ OU D’ADAPTATION À UN USAGE

PARTICULIER. LA RESPONSABILITÉ D’YSI SELON LES TERMES DE CETTE GARANTIE SE

LIMITE À LA RÉPARATION OU AU REMPLACEMENT DU PRODUIT, CONSTITUANT VOTRE

SEUL ET UNIQUE RECOURS POUR TOUT PRODUIT DÉFECTUEUX COUVERT PAR CETTE

GARANTIE. YSI NE POURRA EN AUCUN CAS ÊTRE TENU RESPONSABLE DE DOMMAGES

SPÉCIAUX, INDIRECTS, ACCIDENTELS OU CONSÉCUTIFS RÉSULTANT DE L’UTILISATION DE

TOUT PRODUIT DÉFECTUEUX COUVERT PAR CETTE GARANTIE.

COMMENT NOUS CONTACTER

YSI

1725 Brannum Lane

Yellow Springs OH, 45387, États-Unis

800-897-4151 • 937-767-7241 • Télécopie : 937-767-1058

E-mail : environmental@ysi.com

Web : www.ysi.com

1

Page 10

TABLE DES MATIÈRES

GARANTIE .............................................................................................................. 1

TABLE DES MATIÈRES ......................................................................................... 2

INFORMATIONS GÉNÉRALES ............................................................................ 3

INSPECTION INITIALE .......................................................................................... 3

PRÉCAUTIONS ...................................................................................................... 3

PRÉPARATION DE LA SONDE ............................................................................ 4

INSTALLATION DE LA PILE ................................................................................. 4

CLAVIER ................................................................................................................. 4

ÉCRAN À CRISTAUX LIQUIDES .......................................................................... 5

PROCÉDURES D’UTILISATION ........................................................................... 5

MODES DE MESURE ............................................................................................ 5

ENREGISTREMENT, AFFICHAGE ET SUPPRESSION DES DONNÉES ........... 5

CONFIGURATION DE L’ÉTALONNAGE ............................................................ 6

ENTRETIEN DE LA SONDE .................................................................................. 7

DÉPANNAGE ......................................................................................................... 7

SPÉCIFICATIONS .................................................................................................. 8

CONVERSIONS ..................................................................................................... 8

LISTE DES PIÈCES DÉTACHÉES RECOMMANDÉES ........................................ 8

2

Page 11

INFORMATIONS GÉNÉRALES

L’ DO200A est un outil de précision mesurant l’oxygène dissous en pourcentage, ppm (mg/l)

ainsi que sa température. Un microprocesseur incorporé stocke, calcule et compense tous les

paramètres relatifs aux déterminations liées à l’oxygène dissous, y compris les

caractéristiques de température des électrodes de détection de l’oxygène dissous.

Cet appareil est étanche (IP67) uniquement lorsque le capuchon recouvre le connecteur est

branché. Les touches mécaniques sont très fiables et fournissent une réaction tactile et

sonore. Cet appareil utilise une pile de 9 V. Aucun réétalonnage n'est nécessaire lorsque

l'alimentation électrique est rétablie

L’avant de l’appareil dispose d’un écran à cristaux liquides affichant simultanément le

pourcentage, les mg/l et la température de l’oxygène dissous, ainsi que les invites destinées à

l’utilisateur et les indicateurs de mode. L’appareil émet des invites destinées à l’utilisateur lors

des procédures d’étalonnage et de mesure.

Le modèle de sonde de terrain et de laboratoire DO200A utilise une électrode

polarographique disposant de capuchons à membrane vissables. Les sondes de terrain 200-4

et 200-10 sont équipées d’une sonde de température incorporée permettant la

compensation automatique de la température, ainsi que d’un corps en acier inoxydable qui

en augmente la masse. La sonde de laboratoire 200-BOD est équipée d’un bloc

d’alimentation électrique et comporte des électrodes remplaçables auto-agitées.

Parmi les autres caractéristiques, on notera la longue durée de vie des piles et une

élimination du bruit élevée de 50/60 Hz c.a. Cet appareil est convivial et particulièrement

souple dans les applications sur le terrain, industrielles et en laboratoire.

INSPECTION INITIALE

Déballez soigneusement l’appareil et les accessoires et vérifiez qu’ils n’ont pas été

endommagés lors de l’expédition. Comparez les pièces reçues aux matériaux répertoriés

dans le bordereau d’emballage. Notifiez immédiatement YSI s’il s’avère que des pièces sont

endommagées ou manquantes. Mettez de côté les matériaux d’emballage jusqu’à ce que le

fonctionnement correct de l’appareil soit confirmé.

PRÉCAUTIONS

Boîtier

L'appareil est en effet protégé par un boîtier étanche IP67, mais NE doit PAS être utilisé sous

l'eau. Le connecteur n’est pas étanche, sauf si le capuchon le recouvre. En cas d’immersion

sans capuchon, suivre immédiatement les étapes suivantes:

1. Séchez le connecteur, le cas échéant, et remplacez la sonde d’oxygène dissous. Rincez

soigneusement l’appareil avec de l’eau distillée. Après le rinçage et le séchage,

inspectez et nettoyez les connecteurs en vue d’éliminer tout contaminant pouvant

affecter les connexions de la sonde.

2. Attendez que l’appareil et la sonde soient parfaitement secs avant de reprendre les

opérations.

3. Si l’appareil ne fonctionne pas correctement après les étapes 1 et 2, appelez YSI en vue

d’une réparation ou d’un remplacement éventuels.

Les sondes (de terrain et de laboratoire)

1. Les membranes durent plus longtemps si elles sont correctement installées et

entretenues régulièrement. Des membranes endommagées ou sales et des grosses

bulles dans le réservoir d’électrolyte peuvent entraîner des lectures incohérentes. Si les

lectures sont instables ou la membrane endommagée, remplacez le capuchon à

membrane et la solution de la sonde à oxygène (également appelée « Électrolyte de

sondage d’oxygènométrie », chlorure de potassium ou solution KCl). Les intervalles de

remplacement sont habituellement de 4 à 8 semaines, bien qu’ils puissent se prolonger

s’ils sont conservés en bon état de propreté. Les milieux particulièrement difficiles, tels

que les eaux usées, peuvent exiger que la membrane soit remplacée toutes les 2 à 4

semaines. Des lectures instables peuvent avoir lieu si le capuchon à membrane est

3

Page 12

recouvert d’organismes consommant ou évoluant dans l’oxygène, tels que des bactéries

ou des algues.

2. Le chlore, l’anhydride sulfureux, le monoxyde d’azote et l’oxyde nitreux peuvent affecter

les lectures en se comportant comme de l’oxygène au niveau de la sonde.

3. Évitez les produits pouvant endommager les matériaux de la sonde, tels que l’acide

concentré et les solvants puissants et caustiques. Les matériaux de la sonde comportent

de l’acier inoxydable, de l’adhésif époxyde et du plastique ABS.

4. Gardez la cathode dorée de la sonde en bon état de propreté et texturée (lorsqu’elle est

correctement entretenue, elle présente un fini mat). Si elle se ternit (après être entrée en

contact avec certains gaz) ou présente un aspect argenté (en raison d’une utilisation

prolongée avec une membrane lâche ou plissée), nettoyez-la en suivant les instructions

de la section « Entretien de la sonde ».

5. Pour éviter que la membrane et l’électrode se dessèchent, stockez la sonde de terrain

dans la bouteille d’étalonnage avec l’éponge humide et la sonde de laboratoire dans un

flacon BOD avec 2,5 cm (1 po) d’eau pour les conserver dans un milieu saturé.

PRÉPARATION DE LA SONDE

La sonde DO200A est fournie avec une membrane protectrice sèche. Pour installer un

nouveau capuchon à membrane sur la sonde :

1. Dévissez le capuchon à membrane de la sonde et jetez-le.

2. Remplissez un nouveau capuchon de solution de sondage d’oxygénométrie. Effectuez la

préparation conformément aux instructions de la bouteille de solution.

3. Enfilez le capuchon à membrane rempli sur le capteur.

4. Laissez l’ensemble se réchauffer suffisamment longtemps lors de la première utilisation

(10 à 15 minutes). Il se peut que le message « ovEr » s’affiche pendant ce temps sur

l’écran. Cette condition est normale. Le message disparaîtra une fois le chauffage

terminé.

INSTALLATION DE LA PILE

Lorsque l’écran à cristaux liquides affiche pour la première fois

« LOW BAT », il reste environ une heure de fonctionnement sur pile

selon les spécifications. Remplacez la pile lorsque l’indication « LOW

BAT » s’affiche sur l’écran.

Pour remplacer la pile, enlevez les deux vis du compartiment ainsi

que le couvercle et le joint torique. Remplacez la pile de 9 V.

Replacez le couvercle et le joint torique (veillez à aligner le joint

correctement afin d’assurer une bonne étanchéité) et revissez les

deux vis du compartiment pour conserver une bonne résistance aux

éclaboussures.

Figure 1.

Installation de la

pile

Mise au rebut des piles

L’appareil est alimenté par des piles alcalines que l’utilisateur doit retirer et jeter lorsque les

piles n’alimentent plus l’appareil. Les exigences concernant la mise au rebut sont différentes

en fonction du pays et de la région, et il est attendu de l’utilisateur qu’il comprenne et suive

les règlements spécifiques à sa juridiction concernant la mise au rebut des piles.

CLAVIER

1. : Met l’appareil hors ou sous tension.

2. MODE : Défilement de l’affichage en service normal : oxygène dissous en pourcentage

de saturation de l'air, oxygène dissous en ppm (mg/l), Supprimer, Rappeler. En mode

d'étalonnage, quitte l'étalonnage actuel et affiche le paramètre d'étalonnage suivant.

3. CAL : En fonctionnement normal, passe du mode Normal au mode Étalonnage

(Calibration). Voir la section Configuration de l’étalonnage.

: Lors de la configuration de l’étalonnage, appuyez sur cette touche pour enregistrer

4.

le paramètre actuel en mémoire.

5. Touches et : Augmentent ou diminuent la valeur affichée, comme voulu.

4

Page 13

ÉCRAN À CRISTAUX LIQUIDES

A

1. BAT : Indicateur de pile déchargée.

2. CAL : Indicateur de mode

d’étalonnage (Calibration).

3. SAL ppt : S’affiche lors de

3

1

BAT

SAL ppt

mBar

4

l’étalonnage pour inviter l’utilisateur à

indiquer la salinité approximative de

l’échantillon, exprimée en parties par

millier (ppt).

4. mBar : S’affiche lors de l’étalonnage

pour inviter l’utilisateur à indiquer la

pression barométrique.

5. Affichage principal des valeurs de

l’oxygène dissous.

2

CAL

Figure 2. Écran à cristaux liquides

% ppm

5

6

C

7

6. %/ppm : Indicateurs d’unité.

7. ºC : Affichage de la température.

PROCÉDURES D’UTILISATION

Appuyez sur pour mettre l’appareil hors ou sous tension. L’appareil exécutera un test

d’autodiagnostic pendant lequel le message « ovEr » peut s’afficher sur l’écran. Cette

condition est normale. Le message disparaîtra une fois le chauffage terminé. Une fois que le

test d’autodiagnostic est terminé, la température s’affiche dans la partie inférieure droite de

l’écran et l’appareil est prêt à être utilisé. Plongez la sonde à mi-hauteur dans la solution de

l’échantillon. Si possible, ne laissez pas la sonde toucher un objet quelconque dans la

solution. Ne laissez aucune bulle se former autour de la sonde. Lorsque l’appareil n’est pas

utilisé, mettez-le hors tension pour économiser la pile. L’appareil s’éteint automatiquement

s’il n’est pas utilisé après 30 minutes.

REMARQUE : Lors de la mesure de l’oxygène, la sonde doit être déplacée d’environ 15 cm

(1/2 pied) par seconde pour compenser la consommation d’oxygène inhérente du capteur.

Cependant, avec une sonde de laboratoire 200-BOD, utilisez simplement la fonction d’autoagitation des sondes.

MODES DE MESURE

Cet appareil permet trois mesures distinctes :

1. Temperature (Température) – La température actuelle de la solution s’affiche

constamment.

2. Dissolved Oxygen % (Pourcentage d’oxygène dissous) – Mesure de l’oxygène en

pourcentage de la saturation.

3. Dissolved Oxygen ppm (Mg/l d’oxygène dissous) – Mesure de l’oxygène en ppm

(mg/l).

Observez soigneusement les unités affichées à l’extrémité de l’écran à cristaux liquides pour

déterminer le mode voulu.

ENREGISTREMENT, AFFICHAGE ET SUPPRESSION DES DONNÉES

Le DO200A enregistre jusqu’à 50 jeux de données. En mode de mesure, appuyez sur pour

enregistrer un jeu. L’appareil confirmera l'enregistrement des données en affichant pendant

une seconde SAVE (Enregistrer) et le numéro du jeu. Si la mémoire est pleine, l’appareil

affiche « Full » (Pleine) lorsque vous essayez d’enregistrer des données.

Pour afficher des données enregistrées, appuyez sur Mode jusqu’à ce que RECALL (Rappeler)

s’affiche, puis appuyez sur. Parcourez alors les jeux enregistrés à l’aide des touches de

déplacement vers le haut ou vers le bas. Appuyez sur Mode pour revenir au mode de

mesure.

Pour supprimer des jeux de données, appuyez sur Mode en mode de mesure jusqu’à ce que

DELETE (Supprimer) s'affiche. Appuyez sur. « All » (Tous) s’affiche et clignote. À l’aide des

5

Page 14

touches de déplacement vers le haut ou vers le bas, passez de All (Tous) à Each (Chaque).

Appuyez sur pour valider l'option affichée (All ou Each).

Si vous choisissez All, tous les jeux seront supprimés de la mémoire et None (Aucun) sera

affiché. Appuyez deux fois sur Mode pour revenir au mode de mesure. Si vous sélectionnez

Each, faites défiler les jeux de données enregistrés avec les touches de déplacement vers le

haut ou vers le bas. Appuyez sur pour supprimer le jeu sélectionné. La suppression d’un

jeu modifie le classement des jeux suivants, de manière à garder les jeux en suite ordonnée.

Par exemple, si le jeu 3 est supprimé, le jeu 4 deviendra le jeu 3, le jeu 5 deviendra le no 4,

etc. Appuyez sur Mode pour revenir au mode de mesure

CONFIGURATION DE L’ÉTALONNAGE

Exigences Préalables

1. La pression barométrique réelle approximative (exprimée en millibars [mBar]) au

moment de l’étalonnage.

2. La salinité approximative de l’eau devant être analysée. L’eau douce a une salinité

approximative de zero ppt. L’eau de mer a une salinité approximative de 35 ppt.

Procédure

1. Avec la sonde de terrain, déposez 5 ou 6 gouttes d’eau propre (courante, distillée ou

désionisée) sur l’éponge, à l’intérieur de la bouteille d’étalonnage. Renversez la bouteille

et laissez toute eau en excès s’écouler hors de la bouteille. L’éponge humide permet

d’obtenir un milieu atmosphérique saturé à 100 % d’humidité pour la sonde, ce qui est

optimal pour l’étalonnage et le stockage de la sonde du modèle DO200A. Pour

l’étalonnage, la sonde reste dans une atmosphère saturée d’humidité et n’est pas

immergée.

Avec la sonde de laboratoire, utilisez simplement la bouteille de stockage de la sonde

avec environ 2,5 cm (1 po) d’eau au fond. Cela permet d’obtenir un milieu

atmosphérique saturé à 100 % d’humidité pour la sonde, ce qui est optimal pour

l’étalonnage et le stockage de la sonde du modèle 200-BOD. Pour l’étalonnage, la

sonde reste dans une atmosphère saturée d’humidité et n’est pas immergée.

2. Avec la sonde de terrain, glissez-la dans la bouteille d’étalonnage. Veillez à ce que la

membrane ne touche pas l’éponge.

3. Mettez le modèle DO200A sous tension en appuyant sur . Attendez 10 à 15 minutes

que les lectures de l’oxygène dissous et de la température se stabilisent.

4. Appuyez sur CAL.

5. L’écran vous invite à indiquer la pression atmosphérique locale, exprimée en mBar.

Utilisez les touches et , respectivement, pour augmenter ou diminuer la valeur de la

pression. Reportez-vous à la section intitulée « Conversions » pour convertir les unités de

pression barométriques en mBar.

6. Lorsque la pression voulue est affichée, appuyez une fois sur

d’étalonnage dans la partie inférieure droite de l’écran. Une fois que la valeur affichée

dans l’écran principal se stabilise, appuyez à nouveau sur

de compensation de la salinité.

7. L’écran vous invite à indiquer la salinité approximative de l’eau devant être analysée.

Utilisez les touches et pour augmenter ou diminuer la valeur de compensation de la

salinité afin qu’elle corresponde à la valeur de l’échantillon (entre 0 et 40 parties par

millier [ppt]). Une fois que la salinité correcte est affichée, appuyez sur

8. L’appareil retient l’étalonnage même s’il est mis hors tension. Cependant, nous vous

recommandons de vérifier l’étalonnage à chaque utilisation et de réaliser un nouvel

étalonnage, le cas échéant, afin d’éviter toute déviation. La validité des lectures

d’oxygène dissous dépend d’un bon étalonnage.

pour afficher la valeur

pour passer à la procédure

.

6

Page 15

ENTRETIEN DE LA SONDE

Pour nettoyer les sondes, utilisez le kit YSI de reconditionnement de sonde (YSI Probe

Reconditioning kit) (numéro de référence 5238). Avec la sonde de laboratoire, utilisez le

disque abrasif fourni dans le kit de membrane 5908 et suivez les consignes de nettoyage

décrites dans le manuel de la sonde 200-BOD concernant le ponçage. En plus du kit de

reconditionnement et du disque abrasif fourni dans le kit de membrane 5908, un nettoyage

chimique peut s’avérer utile. Pour effectuer un nettoyage chimique de la sonde, trempez-la

dans de l’ammoniaque.

1. Enlevez le capuchon à membrane et rincez la sonde avec de l’eau propre (courante,

distillée ou désionisée).

2. Mettez l’appareil hors tension ou déconnectez la sonde.

3. Obtenez soit :

de l’ammoniaque de laboratoire à 14 % et laissez tremper la sonde 2 ou 3 minutes

de l’ammoniaque de nettoyage domestique à 3 % et laissez tremper la sonde de 8

à 12 heures.

4. Rincez la sonde de toute trace d’ammoniaque.

5. Utilisez le papier de verre (n° 400 sec/mouillé, fourni avec le kit 5238 et avec le kit de

membrane 5908) pour poncer à l’eau la sonde et éliminer tout dépôt restant.

6. Installez un nouveau capuchon à membrane.

N’utilisez jamais de produits chimiques ou abrasifs non recommandés par YSI.

DÉPANNAGE

L’écran principal affiche : Solutions possibles :

« ovEr » ou « undr »

L’écran secondaire affiche : Solutions possibles :

« undr »

« ovEr »

Vérifiez la membrane et la solution d’électrolyte.

Nettoyez l’anode et la cathode.

Retournez le produit au centre de service.

Réchauffez l’échantillon pour que sa température soit

supérieure à -6,0 °C

Retournez le produit au centre de service.

Refroidissez l’échantillon pour que sa température

soit inférieure à 46,0 °C

Retournez le produit au centre de service.

7

Page 16

SPÉCIFICATIONS

Affichage Fourchette Précision Résolution

Oxygène dissous

(ppm ou mg/l)

Oxygène

dissous,

pourcentage de

la saturation

de l’air

Température °C

(°F)

Compensation de la pression 600 à 1100 mBar (450 à 825 mmHg)

Compensation de la salinité

Sonde CAT

0 à 20,00 ppm (mg/l) Le plus grand de ±2 % de la

0 à 200,0 % Le plus grand de ±2% de la

-6,0 à 46,0 °C

(21 à 115 °F)

De 0,0 à 40,0 x 10

lecture ou ±2 % de la saturation

lecture ou ±0,2 ppm (mg/l)

de l’air

±0,3 °C ±1 chiffre 0,1 °C

-3

Thermistor, 10 K, à 25 C

0,01 mg/l

0,1 %

Sauvegarde de l’étalonnage Oui

Touches sonores Oui, toutes les touches

Source d’alimentation Une pile de 9 V

Température de

0 à 50 °C (32 à 122 °F)

fonctionnement

Boîtier de l’appareil

Étanche, norme IP 67

Poids (avec pile) 270 g (0,61 de livre)

Dimensions (L x P x H) 18.7 cm x 7.6 cm x 3.8 cm (7,4 po x 3 po x 1,5 po)

CONVERSIONS

Pour convertir : Multiplier par :

Pouces de mercure en mBar 33,864

Pouces de mercure en mmHg 25,4

mmHg en mBar 1,333

LISTE DES PIÈCES DÉTACHÉES RECOMMANDÉES

N° RÉF. DESCRIPTION

200-4 Assemblage, câble de 4 mètres (environ 13 pieds) et sonde

200-10 Assemblage, câble de 10 mètres (environ 33 pieds) et sonde

200-BOD Sonde BOD de laboratoire auto-agitante et câblage avec bloc d’alimentation

606036 Sacoche de transport DO, flancs durs

5908

485 Sacoche de transport de l’appareil, souple

Kit de membrane, PE de 31,75 μm (1,25 millième de pouce) d’épaisseur

(605306), six capuchons à membrane et solution KCl

Article n° 606035REF

Révision A ; Juillet 2012

Pour la dernière version de ce manuel, visite www.ysi.com

8

Page 17

GARANTÍA

El medidor EcoSense® DO200A tiene un año de garantía contra defectos de materiales y

fabricación, contado a partir de la fecha de compra por el usuario final. Las sondas y cables

del medidor DO200A tienen un año de garantía contra defectos de materiales y fabricación,

contado a partir de la fecha de compra por el usuario final. Durante el período de garantía,

YSI reparará o reemplazará, según su criterio, sin coste alguno, cualquier producto que YSI

determine que está cubierto por esta garantía.

Para hacer valer esta garantía, escriba o llame al representante local de YSI, o comuníquese

con el Servicio de atención al cliente de YSI en Yellow Springs, Ohio, EE.UU. Envíe el

producto y la factura de compra, con el flete prepagado, al centro de servicio técnico

autorizado seleccionado por YSI. Se realizará la reparación necesaria o el reemplazo y el

producto será enviado de vuelta, con el flete prepagado. Los productos reparados o

reemplazados se garantizan durante el resto del período de la garantía original, o al menos

durante 90 días contados a partir de la fecha de reparación o reemplazo.

Limitación de la garantía

Esta garantía no tendrá validez en caso de daños o fallos en el producto de YSI debido a lo

siguiente: (i) la instalación, funcionamiento o utilización del producto de manera contraria a

las instrucciones escritas suministradas por YSI; (ii) abuso o uso inadecuado del producto; (iii)

falta de mantenimiento del producto de acuerdo con las instrucciones escritas suministradas

por YSI o con los procedimientos estándar de la industria; (iv) cualquier reparación indebida

realizada en el producto; (v) utilización por parte del usuario de componentes o repuestos

defectuosos o inadecuados para el mantenimiento o reparación del producto; o (vi)

cualquier modificación del producto no autorizada de manera expresa por YSI.

ESTA GARANTÍA SE OTORGA EN LUGAR DE CUALQUIER OTRA GARANTÍA, EXPLÍCITA O

IMPLÍCITA, LO QUE INCLUYE TODA GARANTÍA DE COMERCIALIZACIÓN O IDONEIDAD

PARA UN PROPÓSITO ESPECÍFICO. DE CONFORMIDAD CON ESTA GARANTÍA, LA

RESPONSABILIDAD DE YSI SE LIMITA A LA REPARACIÓN O REEMPLAZO DEL PRODUCTO,

LO CUAL SERÁ LA SOLUCIÓN ÚNICA Y EXCLUSIVA QUE TENDRÁ EL COMPRADOR POR

CUALQUIER PRODUCTO DEFECTUOSO CUBIERTO POR ESTA GARANTÍA. EN NINGÚN

CASO, YSI SERÁ RESPONSABLE POR NINGÚN DAÑO CUANTIFICABLE, INDIRECTO,

INCIDENTAL O CONSIGUIENTE QUE RESULTARA DE ALGÚN PRODUCTO DEFECTUOSO

CUBIERTO POR ESTA GARANTÍA.

INFORMACIÓN DE CONTACTO

YSI

1725 Brannum Lane

Yellow Springs OH, 45387, EE.UU.

800-897-4151 o 937-767-7241; Fax: 937-767-1058

Correo electrónico: environmental@ysi.com

Página en Internet: www.ysi.com

1

Page 18

CONTENIDO

GARANTÍA ............................................................................................................. 1

INFORMACIÓN DE CONTACTO ........................................................................ 1

PRESENTACIÓN GENERAL ................................................................................. 3

INSPECCIÓN INICIAL ........................................................................................... 3

PRECAUCIONES ................................................................................................... 3

PREPARACIÓN DE LA SONDA ........................................................................... 4

INSTALACIÓN DE LA PILA .................................................................................. 4

TECLAS ................................................................................................................... 4

PANTALLA DE CRISTAL LÍQUIDO ...................................................................... 5

INSTRUCCIONES DE FUNCIONAMIENTO ....................................................... 5

MODOS DE MEDICIÓN ....................................................................................... 5

CÓMO GUARDAR, VER Y BORRAR DATOS

AJUSTE DE LA CALIBRACIÓN ............................................................................ 6

MANTENIMIENTO DE LA SONDA ..................................................................... 7

LOCALIZACIÓN DE FALLOS ............................................................................... 7

ESPECIFICACIONES ............................................................................................. 7

CONVERSIONES ................................................................................................... 8

LISTA DE REPUESTOS RECOMENDADOS ....................................................... 8

.................................................. 5

2

Page 19

PRESENTACIÓN GENERAL

El medidor DO200A es un instrumento de precisión que mide el oxígeno disuelto

mostrándolo en porcentajes y en ppm (mg/L), y también mide la temperatura. Tiene un

microprocesador integrado que almacena, calcula y realiza la compensación de todos los

parámetros relacionados con la determinación del oxígeno disuelto, incluso, las

características de temperatura del electrodo de oxígeno disuelto.

Cuando está instalados la tapa conectora, el instrumento es a prueba de agua (IP67). Las

teclas de contacto mecánico son muy confiables y al pulsarlas proporcionan una respuesta

táctil y audible. Este instrumento utiliza una pila de 9 voltios. No requiere nueva calibración

cuando se restablece la corriente

La parte delantera del instrumento tiene una pantalla grande de cristal líquido que muestra

simultáneamente el oxígeno disuelto en valor porcentual, en partes por millón (ppm) y la

temperatura, junto con las indicaciones para el usuario y los indicadores del modo de

funcionamiento. La unidad orienta al usuario durante los procedimientos de calibración y

medición.

Las sondas de campo y de laboratorio modelo DO200A utilizan un electrodo polarográfico

con cápsulas prácticas de membrana enroscables. Las sondas de campo 200-4 y 200-10

cuentan con una sonda integrada para temperatura que realiza la compensación automática

de la temperatura, así como una estructura de acero inoxidable que proporciona más peso.

La sonda de laboratorio 200-BOD cuenta con alimentación de corriente e incluye

autoagitación y electrodos reemplazables.

Otras características incluyen una pila de larga duración y un mecanismo de eliminación de

ruido de 50/60 Hz CA. Este medidor es universal y fácil de usar en aplicaciones

industriales y de laboratorio.

.

in situ

,

INSPECCIÓN INICIAL

Saque la unidad de su embalaje con cuidado y verifique que no haya sufrido daños durante

el envío. Compare las piezas recibidas con los materiales enumerados en la lista de embalaje.

Notifique inmediatamente a YSI en caso de que haya piezas faltantes o dañadas. Guarde

todos los materiales de embalaje hasta que confirme que la unidad funciona

satisfactoriamente.

PRECAUCIONES

Estuche

Aunque el instrumento se encuentra en un estuche IP67 a prueba de agua, NO lo utilice bajo

agua. El conector no es a prueba de agua a menos que la tapa estén instalados. En caso de

sumergirlo sin la tapa o cable conectado, siga estos pasos inmediatamente.

1. Seque el conector, si es necesario, y cambie la sonda de oxígeno disuelto. Enjuague la

unidad cuidadosamente con agua destilada. Después del enjuague y secado, revise y

limpie los conectores para eliminar cualquier contaminante que pueda afectar las

conexiones de la sonda.

2. Espere hasta que la unidad y la sonda se sequen por completo antes de reanudar el

funcionamiento.

3. Si la unidad no funciona correctamente después de realizar los pasos 1 y 2,

comuníquese con YSI para su posible reparación o reemplazo (consulte la garantía).

Sondas (Campo y laboratorio)

1. Las membranas durarán más tiempo si se instalan correctamente y se les hace

mantenimiento con frecuencia. Pueden producirse lecturas erráticas si las membranas

están dañadas o sucias o si hay burbujas grandes en el depósito del electrólito. Si se

producen lecturas inestables o daños en la membrana, cambie tanto la cápsula de la

membrana como la solución de la sonda de oxígeno (también llamada “electrólito de la

sonda de O2”, cloruro potásico o solución KCl). En promedio, estos cambios deben

3

Page 20

hacerse cada 4 a 8 semanas, aunque la cápsula y la solución pueden durar más tiempo

si se mantienen limpias. En ambientes arduos, por ejemplo, en aguas residuales, puede

ser necesario cambiar la membrana cada 2 a 4 semanas. Pueden producirse lecturas

inestables si la cápsula de la membrana está recubierta de microorganismos que

consuman o transformen oxígeno, como las bacterias y las algas.

2. El cloro, el dióxido de azufre, el óxido nítrico y el óxido nitroso pueden afectar las

lecturas, ya que se comportan de manera similar al oxígeno en la sonda.

3. Evite las sustancias que puedan dañar los materiales de la sonda, tales como ácidos

concentrados, cáusticos y solventes fuertes. Los materiales de la sonda incluyen acero

inoxidable, epoxia y copolímeros acrilonitrilo, butadieno y estireno (ABS).

4. Mantenga el cátodo de oro de la sonda limpio y con la misma textura (cuando el

mantenimiento es adecuado, el acabado es mate). Si está manchado (por el contacto

con ciertos gases) o recubierto de plata (debido al uso prolongado con la membrana

floja o arrugada), deberá limpiarlo según las instrucciones de la sección “Mantenimiento

de la sonda”.

5. Para evitar que la membrana y el electrólito se sequen, almacene la sonda de campo en

la botella de calibración con la esponja húmeda y la sonda de laboratorio en una botella

BOD con 2,5 cm (1 pulgada) de agua para mantenerlas en un ambiente saturado de

aire.

PREPARACIÓN DE LA SONDA

La sonda del YSI DO200A viene con una membrana protectora seca. Instrucciones para

instalar una cápsula nueva en la membrana de la sonda:

1. Desenrosque la cápsula de la membrana de la sonda y deséchela.

2. Llene una nueva cápsula con solución para sondas de oxígeno. Prepare la solución de

acuerdo con las instrucciones de la botella.

3. Enrosque la cápsula llena en el sensor.

4. Deje que la solución se caliente antes de utilizarla por primera vez (de 10 a 15 minutos).

Durante este tiempo puede aparecer un mensaje “ovEr” en la pantalla. Esto es normal. El

mensaje desaparecerá cuando se haya completado el calentamiento.

INSTALACIÓN DE LA PILA

En la pantalla de cristal líquido aparecerá el mensaje de “LOW BAT”

(pila descargada) para indicar que queda aproximadamente una

hora de carga de la pila para el funcionamiento de la unidad según

las especificaciones. Cambie la pila cuando aparezca el mensaje

“LOW BAT” en la pantalla de cristal líquido.

Para cambiar la pila, saque los dos tornillos de la tapa y luego

retire la tapa y el aro tórico. Coloque una nueva pila de 9 voltios.

Vuelva a colocar la tapa y el aro tórico (asegúrese de alinear este

aro correctamente para garantizar un buen sellado) y ajuste los

dos tornillos de la tapa para que funcione la protección contra salpicaduras.

Figura 1.

Instalación de la batería

Eliminación de las pilas

Este instrumento funciona con pilas alcalinas que el usuario debe extraer y desechar cuando

ya no funcionen. Los requisitos de desechado varían según el país y la región, y se espera

que los usuarios entiendan y sigan los requisitos de desechado de pilas para su área

específica.

TECLAS

1. : Para encender y apagar la unidad.

2. MODE (MODO): Durante el funcionamiento normal, hace que la pantalla muestre

alternadamente el oxígeno disuelto en un porcentaje de aire saturado y en ppm (mg/L),

Borrar y Recordar. En el modo Calibración, sale de la calibración actual y muestra el

siguiente parámetro de calibración.

4

Page 21

3. CAL: Durante el funcionamiento normal, cambia el modo de Normal a Calibration

A

(Calibración). Consulte la sección “Ajuste de la calibración”.

4.

: En el ajuste de la calibración, pulse esta tecla para guardar en la memoria el

parámetro actual.

5. Teclas y : Para aumentar o disminuir el valor que aparece en la pantalla como sea

conveniente.

PANTALLA DE CRISTAL LÍQUIDO

1. BAT: Indicador de pila descargada.

2. CAL: Indicador del modo de

calibración.

3. SAL ppt: Aparece durante la

calibración cuando se pide al usuario

la salinidad aproximada de la muestra

en partes por millar (ppt).

4. mBar: Aparece durante la calibración

para pedir al usuario la presión

barométrica.

5. Pantalla principal que muestra los valores

del oxígeno disuelto.

6. %/ppm: Indicadores de la unidad.

7. ºC: Indicador de la temperatura.

1

2

BAT

SAL ppt

CAL

Figura 2. Pantalla de cristal líquido

mBar

% ppm

3

4

5

6

C

7

INSTRUCCIONES DE FUNCIONAMIENTO

Pulse la tecla para encender y apagar la unidad. El instrumento llevará a cabo una prueba

de autodiagnóstico, durante la cual puede aparecer un mensaje “ovEr” en la pantalla. Esto es

normal. El mensaje desaparecerá cuando se haya completado el calentamiento. Después de

completar la prueba de autodiagnóstico, aparecerá la temperatura en la parte inferior

derecha de la pantalla y la unidad estará lista para funcionar. Sumerja la sonda hasta la mitad

en la solución de muestra. A ser posible, no permita que la sonda haga contacto con ningún

objeto sólido en la solución. No permita que haya burbujas alrededor de la sonda. Cuando la

unidad no esté en uso, apáguela para ahorrar carga de la pila. El instrumento tiene una

función de apagado automático a los 30 minutos cuando no está en uso.

NOTA: Durante la medición de oxígeno, se debe mover la sonda unos 15 cm (1/2 pie) por

segundo para contrarrestar el consumo de oxígeno que hace el sensor. Sin embargo, cuando

se usa la sonda de laboratorio 200-BOD, utilice simplemente la característica de

autoagitación.

MODOS DE MEDICIÓN

Esta unidad realiza tres mediciones distintas:

1. Temperatura: la pantalla muestra constantemente la temperatura actual de la solución.

2. % de oxígeno disuelto: medición del oxígeno en porcentaje de saturación.

3. Oxígeno disuelto en ppm: medición del oxígeno en ppm (mg/L).

Observe detenidamente las unidades mostradas en el extremo de la pantalla de cristal

líquido para determinar el modo deseado.

CÓMO GUARDAR, VER Y BORRAR DATOS

El DO200A puede almacenar 50 registros de datos. Cuando esté en modo de medición,

para guardar un registro. El instrumento confirmará los datos guardados

pulse

indicando SAVE (guardar) y el número de registro durante un segundo. Se muestra “Full”

(llena) cuando se intenta guardar datos y la memoria está llena.

Para ver los datos guardados, pulse “mode” (modo) hasta que se muestre RECALL

(recordar) y luego pulse

diferentes registros guardados. Pulse “Mode” (modo) para volver al modo de medición.

. Use las teclas de flecha hacia arriba y abajo para revisar

5

Page 22

Para borrar los registros de datos, pulse “Mode” (modo) mientras está en el modo de

medición hasta que se muestre DELETE (borrar). Pulse

parpadeando. Pulse la flecha hacia arriba y hacia abajo para cambiar entre las opciones

para borrar “All” (todo) o “Each” (cada uno). Seleccione “All” o “Each” presionando

mientras se muestra esa opción.

Si está seleccionado “All” (todo), se borrarán todos los registros de la memoria y se

mostrará “None” (ninguno). Pulse “Mode” (modo) dos veces para volver al modo de

medición. Si se selecciona “Each” (cada uno), las flechas hacia arriba y hacia abajo le

permitirán desplazarse a través de los registros de datos guardados. Pulse

el registro seleccionado. Todos los registros después del registro borrado pasarán hacia

arriba para mantener los registros en orden secuencial. Por ejemplo, si se borra el

registro 3, el registro 4 se volverá el 3 y el 5 se volverá el registro 4. Pulse “Mode” (modo)

dos veces para volver al modo de medición

.

. Se mostrará “All” (todo)

para borrar

AJUSTE DE LA CALIBRACIÓN

Requisitos

1. La presión barométrica aproximada verdadera (en milibares [mBar]) en el momento de

la calibración.

2. La salinidad aproximada del agua que se analizará. El agua dulce tiene

aproximadamente cero de salinidad. El agua de mar tiene una salinidad aproximada de

35 partes por millar (ppt).

Procedimiento

1. Para la sonda de campo, ponga 5 ó 6 gotas de agua limpia (de grifo, destilada o

desionizada) en la esponja que se encuentra dentro de la botella de calibración. Dé

vuelta a la botella y permita que se vacíe todo el exceso de agua que tenga dentro. La

esponja humedecida crea para la sonda un ambiente de aire con 100 % de saturación

de agua, el cual es ideal para la calibración, transporte y almacenamiento de la sonda

modelo DO200A. Para la calibración, la sonda permanece en una atmósfera de aire

saturada de agua y no sumergida.

Para la sonda de laboratorio, utilice simplemente la misma botella en que se almacena

la sonda con aproximadamente 2,5 cm (1 pulgada) de agua en el fondo. Esto crea para

la sonda un ambiente de aire con 100 % de saturación de agua, el cual es ideal para la

calibración y el almacenamiento de la sonda modelo 200-BOD. Para la calibración, la

sonda permanece en una atmósfera de aire saturada de agua y no sumergida.

2. Deslice la sonda de campo hacia el interior de la botella de calibración. Asegúrese de

que la membrana no haga contacto con la esponja.

3. Pulse la tecla para encender la unidad DO200A. Espere entre 10 y 15 minutos para

que se estabilicen las lecturas del oxígeno disuelto y de la temperatura.

4. Pulse la tecla CAL.

5. La pantalla de cristal líquido le pedirá la presión local expresada en mBar. Con las

teclas y aumente o disminuya, respectivamente, el valor de la presión. Vea la sección

titulada “Conversiones” para convertir las unidades de presión barométrica a milibares.

6. Cuando aparezca en pantalla la presión correcta, pulse la tecla

valor de calibración en la parte inferior derecha de la pantalla. Una vez que el valor en la

pantalla se estabilice, pulse la tecla

compensación de salinidad.

7. La pantalla le pedirá la salinidad aproximada del agua que se analizará. Con las

teclas y aumente o disminuya el valor de compensación de la salinidad de la

muestra (entre 0 y 40 partes por millar [ppt]). Cuando aparezca la salinidad correcta,

pulse la tecla

8. La calibración queda registrada aun cuando la unidad se apague. No obstante, se

recomienda verificar la calibración en cada uso y recalibrar si es necesario para evitar el

desplazamiento. La lectura del oxígeno disuelto sólo es precisa cuando la calibración

también lo es.

.

nuevamente para pasar al procedimiento de

6

una vez para ver el

Page 23

í

MANTENIMIENTO DE LA SONDA

Para limpiar las sondas, utilice el juego de reacondicionamiento de sonda de YSI (número de

componente 5238), para la sonda de campo. Para la sonda de laboratorio, utilice el disco de

lijado incluido en el juego de membranas 5908 y siga las instrucciones de limpieza descritas

en el manual de la sonda 200-BOD con respecto al lijado. Además de utilizar este juego y el

disco de lijado con su juego de membranas 5908, se le puede hacer una limpieza química.

Para limpiar los electrodos químicamente, prepare una solución de remojo con hidróxido de

amonio.

1. Quite la cápsula de la membrana y enjuague la sonda con agua limpia (de grifo,

destilada o desmineralizada).

2. Apague la unidad y desconecte la sonda.

3. Utilice uno de los siguientes métodos:

Hidróxido de amonio al 14 % de concentración para uso en laboratorios y remoje la

sonda durante 2 ó 3 minutos.

Amoníaco al 3 % de concentración para uso doméstico y ponga la sonda en remojo

de un día para otro (de 8 a 12 horas).

4. Enjuague el hidróxido de amonio o el amoníaco de la sonda.

5. Con papel de lija (de grano 400 para superficies húmedas y secas, incluido con el juego

5238 y con el juego de membranas 5908) elimine (lijado en húmedo) cualquier exceso

depositado en la sonda.

6. Instale una nueva cápsula en la membrana.

Nunca utilice productos químicos ni abrasivos que no estén recomendados por YSI.

LOCALIZACIÓN DE FALLOS

La pantalla principal

muestra:

“ovEr” o “undr”

La pantalla secundaria

muestra:

“undr”

“ovEr”

Revise la membrana y la solución de electrólitos.

Limpie el ánodo y el cátodo.

Envíe el producto al servicio técnico.

Caliente la muestra hasta una temperatura mayor a -6,0 °C.

Envíe el producto al servicio técnico.

Enfríe la muestra hasta una temperatura menor a 46,0° C.

Envíe el producto al servicio técnico.

Posibles soluciones:

Posibles soluciones:

ESPECIFICACIONES

Pantalla Escala Precisión Resolución

O2 disuelto

(ppm o mg/L)

O2 disuelto

% de sat de aire

Temperatura en

°C (°F)

Compensación de la presión 600 a 1100 mBar (450 a 825 mmHg)

Compensación de la salinidad De 0,0 a 40,0 ppt

Sonda ATC

Respaldo de la calibración S

0 a 20,00 ppm (mg/L) ±2 % de la lectura o ±2 % de

0 a 200,0 % ±2 % de la lectura o ±0,2 ppm,

-6,0 a 46,0° C

(21 a 115° F)

saturación del aire, lo que sea

lo que sea mayor

±0,3° C ±1 cifra

Termistor, 10K, a 25 C

7

0,01 mg/L

mayor

0,1 %

0,1° C

Page 24

Respuesta audible Sí, en todas las teclas

Fuente de corriente Una pila de 9 voltios

Temperatura de

0 a 50 C (32 a 122

° F)

funcionamiento

Estuche del medidor

IP 67, A prueba de agua

Peso (con la pila) 270 gramos (0,61 libras)

.

Dimensiones (anc x prof x alt)

18.7 cm x 7.6 cm x 3.8 cm (7,37 pulg

pulg.)

x 3 pulg.x 1,5

CONVERSIONES

Para convertir: Multiplique por:

Pulgadas de Hg a mBar 33,864

Pulgadas de Hg a mmHg 25,4

mmHg a mBar 1,333

LISTA DE REPUESTOS RECOMENDADOS

o

PIEZA N

200-10 Conjunto de sonda de 10 metros (aproximadamente 33 pies) y cables

200-BOD Conjunto de sonda de laboratorio BOD con autoagitación y cables con

606036 Estuche portátil para oxígeno disuelto, de lados rígidos

DESCRIPCIÓN

200-4 Conjunto de sonda de 4 metros (aproximadamente 13 pies) y cables

alimentación de corriente

5908 Conjunto de membranas, 31,75 μm (1,25 mil) PE (605306), seis membranas

con cápsula y solución KCI

485 Estuche portátil para medidor, no rígido

Artículo N

Revisión A • Julio de 2012

Para la versión más reciente de este manual, visite www.ysi.com

o

606035REF

8

Page 25

GARANTIA

O instrumento DO200A da YSI tem uma garantia durante um período de um ano

válido a partir da data de compra pelo utilizador final contra defeitos de material e

mão-de-obra. As sondas e cabos de oxigénio dissolvido têm uma garantia durante um

período de um ano a partir da data de compra pelo utilizador final contra defeitos

de material e mão-de-obra. Durante o período da garantia, a YSI reparará ou

substituirá, sob sua discrição, gratuitamente, qualquer produto que determine como

estando abrangido pelos termos desta garantia.

Para exercer os termos desta garantia, escreva ou contacte o representante local da YSI

ou o Serviço de Apoio ao Cliente da YSI. Envie o produto e prova de compra, por

transporte pré-pago para o Centro de Assistência Autorizado seleccionado pela YSI. A

reparação ou substituição será efectuada e o produto devolvido, sendo o transporte

pré-pago. Os produtos reparados ou substituídos têm uma garantia que cobre o

período restante do período original da garantia ou de pelo menos 90 dias a partir da

data da reparação ou substituição.

Limitação da garantia

Esta Garantia não se aplica a quaisquer danos ou falhas/avarias dos produtos da YSI

provocados por: (i) falha em instalar, operar ou utilizar o produto de acordo com as

instruções escritas da YSI; (ii) abuso ou uso indevido do produto; (iii) falha em manter o

produto de acordo com as instruções escritas da YSI ou procedimento padrão da

indústria; (iv) quaisquer reparações indevidas no produto; (v) uso por parte do utilizador

de quaisquer componentes ou peças defeituosos ou indevidos nas tarefas de assistência

ou reparação do produto; ou (vi) modificação do produto de qualquer maneira não

expressamente autorizada pela YSI

ESTA GARANTIA SUBSTITUI TODAS AS DEMAIS GARANTIAS, EXPRESSAS OU

IMPLICÍTAS, INCLUINDO QUALQUER GARANTIA DE COMERCIALIZAÇÃO OU

ADEQUAÇÃO/APTIDÃO PARA UM DETERMINADO OBJECTIVO. A

RESPONSABILIDADE CIVIL DA YSI AO ABRIGO DOS TERMOS DESTA GARANTIA

ENCONTRA-SE LIMITADA À REPARAÇÃO OU SUBSTITUIÇÃO DO PRODUTO, E ESTA

SERÁ A SUA ÚNICA E EXCLUSIVA SOLUÇÃO PARA QUAISQUER PRODUTO

DEFEITUOSOS ABRANGIDOS PELOS TERMOS DESTA GARANTIA. EM CASO ALGUM,

SERÁ A YSI RESPONSÁVEL POR QUAISQUER DANOS ESPECIAIS, INDIRECTOS,

ACIDENTAIS OU CONSEQUENTES RESULTANTES DA COBERTURA DE QUAISQUER

PRODUTOS DEFEITUOSOS POR ESTA GARANTIA.

.

INFORMAÇÃO DE CONTACTO

YSI

1725 Brannum Lane

Yellow Springs, OH 45387, EUA

800-897-4151 • +1 937-767-7241 • Fax: 937-767-1058

Email correio: environmental@ysi.com

Internet: www.ysi.com

1

Page 26

ÍNDICE

GARANTIA

INFORMAÇÃO DE CONTACTO ....................................................................................... 1

ÍNDICE .................................................................................................................................. 2

INTRODUÇÃO GERAL

INSPECÇÃO INICIAL

PRECAUÇÕES

PREPARAÇÃO DA SONDA

INSTALAÇÃO DA PILHA

O TECLADO

O ECRÃ LCD

PROCEDIMENTOS OPERACIONAIS

MODOS DE MEDIÇÃO

GUARDAR, VISUALIZAR E ELIMINAR DADOS

CONFIGURAÇÃO DA CALIBRAÇÃO

MANUTENÇÃO DA SONDA

RESOLUÇÃO DE PROBLEMAS

ESPECIFICAÇÕES

CONVERSÕES

LISTA DE PEÇAS SOBRESSALENTES RECOMENDADAS

........................................................................................................................... 1

...................................................................................................... 3

......................................................................................................... 3

.................................................................................................................... 3

O Invólucro

A Sonda

Descarte da pilha ........................................................................................................ 4

Requisitos

Procedimento

.................................................................................................................. 3

........................................................................................................................ 3

............................................................................................. 4

................................................................................................... 4

....................................................................................................................... 4

....................................................................................................................... 5

............................................................................. 5

..................................................................................................... 5

............................................................................ 6

.................................................................................................................... 6

............................................................................................................. 6

........................................................................................... 6

....................................................................................... 7

.............................................................................................................. 7

................................................................................................................... 7

............................................................. 5

......................................... 8

2

Page 27

INTRODUÇÃO GERAL

O instrumento DO200A da YSI é uma ferramenta precisa que mede o oxigénio dissolvido em

% e ppm (mg/L) e a temperatura. Um microprocessador integrado armazena, calcula e

compensa todos os parâmetros relacionados com as determinações do OD, incluindo as

características do eléctrodo OD e da temperatura.

Este instrumento tem um invólucro IP67 impermeável quando a tampa do conector estivere

instalado.

usa uma pilha de 9V. Não é necessário efectuar uma nova calibração ao restaurar a energia.

A frente do instrumento tem um ecrã LCD de grande dimensão que apresenta os valores da

% do OD e a temperatura simultaneamente a par dos comandos para o utilizador e

indicadores do modo. A unidade apresenta os comandos para o utilizador através dos

procedimentos de calibração e medição.

O instrumento de medição do OD da YSI usa um eléctrodo polarográfico com membranas

de tampa de rosca convenientes. A sonda é fornecida com uma sonda de temperatura

integrada para uma compensação automática da temperatura bem como um corpo de aço

inoxidável para peso adicional.

Outras funções incluem uma duração prolongada da pilha e elevada rejeição do ruído de

50/60 Hz CA. Este instrumento é universal e fácil de utilizar, para aplicações no terreno,

industriais e laboratoriais.

As teclas são altamente fiáveis com um feedback táctil e áudio. Este instrumento

INSPECÇÃO INICIAL

Desempacote cuidadosamente a unidade e os acessórios e inspeccione-os com vista a

detectar danos de envio.

empacotamento. Notifique a YSI imediatamente de quaisquer danos ou peças em falta.

Guarde todos os materiais da embalagem até a operação satisfatória ser confirmada.

Compare as peças recebidas com os materiais listados na lista de

PRECAUÇÕES

O Invólucro

NÃO use o instrumento de medição do oxigénio dissolvido debaixo de água embora ele se

encontre alojado num invólucro IP67 impermeável. O conector não é impermeável excepto

caso a tampa esteja instalado. Se o instrumento for submerso sem a tampa ligado, cumpra os

seguintes passos prontamente:

1. Seque o conector se necessário, e substitua a sonda do OD. Enxagúe a unidade

cuidadosamente com água destilada. Após o enxaguamento e secagem, inspeccione e

limpe os conectores para remover todas as substâncias contaminantes que possam

afectar as ligações da sonda.

2. Aguarde até a unidade e sonda estarem completamente secas antes de retomar a

operação.

3. Contacte a YSI para fins de possível reparação ou substituição (consultar a Garantia) se a

unidade não funcionar correctamente após os passos 1 e 2.

A Sonda

1. As membranas duram mais tempo se forem devidamente instaladas e for efectuada

uma manutenção regular. Podem ocorrer leituras erráticas resultantes de membranas

danificadas ou sujas ou devido a bolhas de grande dimensão no reservatório dos

electrólitos. Se ocorrerem leituras instáveis ou danos na membrana, substitua a tampa

da membrana e solução da sonda de oxigénio (também designada como “Electrólito

da sonda de O2”, cloreto de potássio ou solução KCI). O intervalo de substituição

médio das membranas é de 4 a 8 semanas, embora possam durar mais tempo se

forem mantidas limpas. Ambientes abrasivos, como águas residuais, podem exigir a

substituição da membrana a cada 2 a 4 semanas. Podem ocorrer leituras instáveis se a

tampa da membrana estiver revestida com organismos consumidores de oxigénio ou

que desenvolvam com organismos, como bactérias ou algas.

3

Page 28

2. Cloreto, dióxido de enxofre, óxido nítrico e óxido nitroso podem afectar as leituras e

comportam-se como oxigénio na sonda.

3. Evite substâncias que possam danificar os materiais da sonda, como ácido concentrado,

substâncias caústicas e solventes fortes. Os materiais da sonda incluem aço inoxidável,

époxi e plástico ABS.

4. Mantenha o cátodo de ouro da sonda limpo e texturado (quando devidamente mantido

tem um acabamento mate). Se estiver manchado (devido ao contacto com

determinados gases) ou revestido com prata (devido a uso extensivo ou membrana

enrugada), deve-o limpar, cumprindo as instruções fornecidas na secção “Manutenção

da sonda”.

5. Para impedir que a membrana e os electrólitos sequem, armazene a sonda na garrafa

de calibração com a esponja humedecida.

PREPARAÇÃO DA SONDA

A sonda do OD é fornecida com uma membrana seca e protectora. Para instalar uma nova

tampa da membrana na sonda: