Page 1

CR 3200

OPERATIONS MANUAL

Thermoreactor

Page 2

CR 3200

Note

For the most recent version of the manual, please visit www.ysi.com

.

Contact YSI

1725 Brannum Lane

Yellow Springs, OH 45387 USA

Tel: +1 937-767-7241

800-765-4974

Email: environmental@ysi.com

Internet: www.ysi.com

Copyright © 2012 Xylem Inc.

2

ba76120e01 08/2012

Page 3

CR 3200 Contents

CR 3200 - Contents

1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.1 Components of the thermoreactor . . . . . . . . . . . . . . . . . . 6

2 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1 Authorized use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.2 General safety instructions . . . . . . . . . . . . . . . . . . . . . . . . 8

3 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.1 Scope of delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.2 Initial commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4 Basic principles of operation . . . . . . . . . . . . . . . . . . . . 15

4.1 Operating and display elements . . . . . . . . . . . . . . . . . . . 15

4.1.1 Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.1.2 Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.1.3 Control lamps (LEDs) . . . . . . . . . . . . . . . . . . . . 17

4.2 Operating modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.1 Inserting the reaction cells . . . . . . . . . . . . . . . . . . . . . . . 19

5.2 Starting a temperature program . . . . . . . . . . . . . . . . . . . 19

5.3 Stopping a temperature program . . . . . . . . . . . . . . . . . . 21

5.4 Temperature test program . . . . . . . . . . . . . . . . . . . . . . . 21

5.4.1 Starting the temperature test program . . . . . . . 22

5.4.2 Downloading the test report to an external

printer/PC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.5 Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5.5.1 Editing a temperature program . . . . . . . . . . . . . 25

5.5.2 Setting the display contrast . . . . . . . . . . . . . . . . 26

5.5.3 Setting the timer for the reaction time . . . . . . . . 26

6 Maintenance, cleaning, disposal . . . . . . . . . . . . . . . . . 29

6.1 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

6.2 Exchanging the fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

6.3 Cleaning the enclosure . . . . . . . . . . . . . . . . . . . . . . . . . 30

6.4 Cleaning the thermoblock of spilled cell contents . . . . . 30

6.5 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

ba76120e01 08/2012

7 What to do if... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

3

Page 4

Contents CR 3200

8 Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

9 Accessories/Options . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

10 Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

11 Contact Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

11.1 Ordering & Technical Support . . . . . . . . . . . . . . . . . . . . 39

11.2 Service Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

4

ba76120e01 08/2012

Page 5

CR 3200 Overview

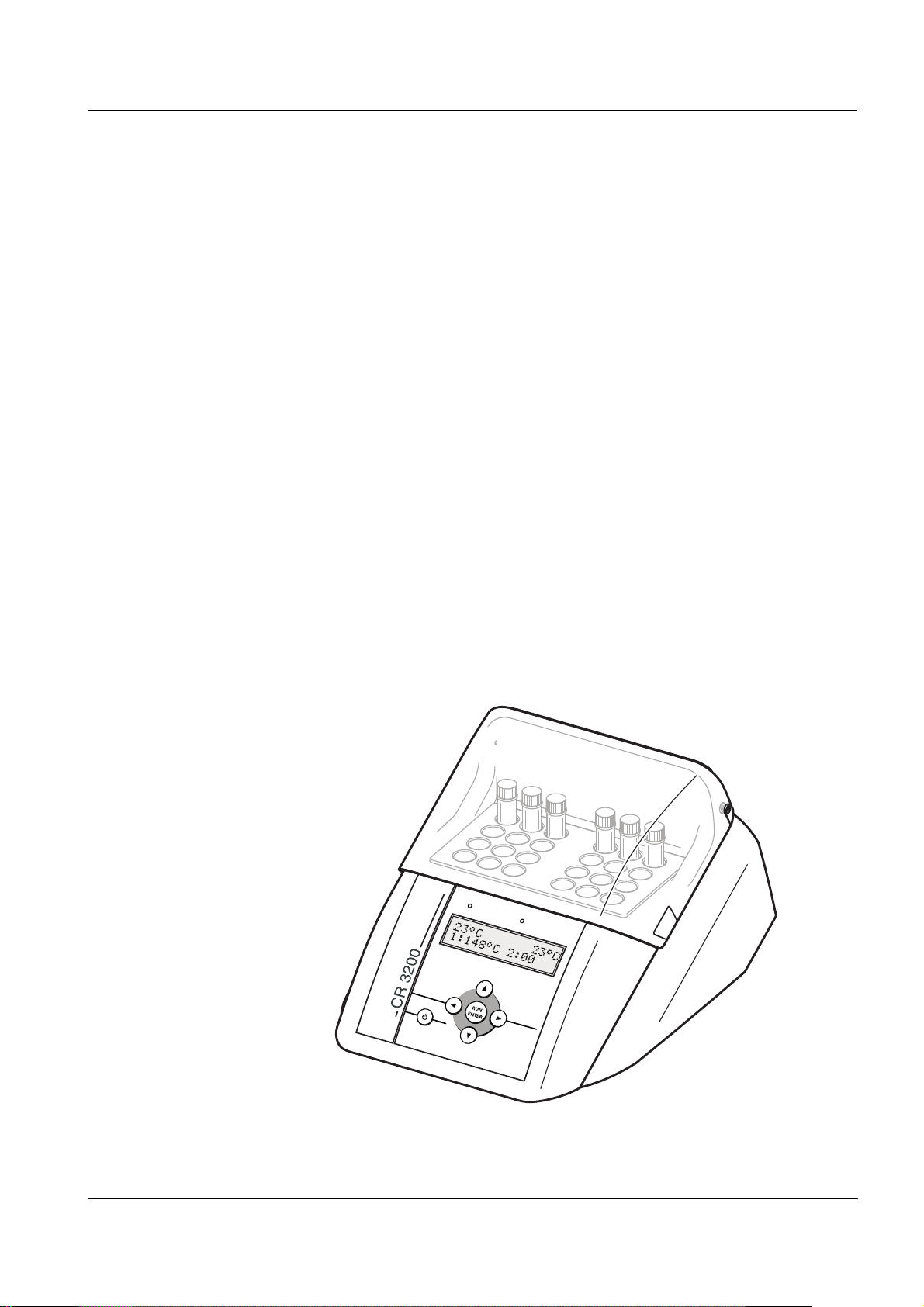

1Overview

The thermoreactor CR 3200 is a dry temperature control device for

laboratory use. It facilitates and secures the digestion using reaction

cells.

The thermoreactor has 8 fixed temperature programs.

1: 148 °C for 120 minutes

2: 120 °C for 30 minutes

3: 120 °C for 60 minutes

4: 120 °C for 120 minutes

5: 100 °C for 60 minutes

6: 148 °C for 20 minutes

7: 150 °C for 120 minutes

8: 100 °C for 30 minutes

8 more temperature programs can be set up freely. The reaction

temperature can be adjusted from room temperature to 170 °C, the

heating time from 0 to 180 min.

The thermoreactor takes 24 reaction cells with an outer diameter of

16 mm.

ba76120e01 08/2012

5

Page 6

Overview CR 3200

1

2

3

4

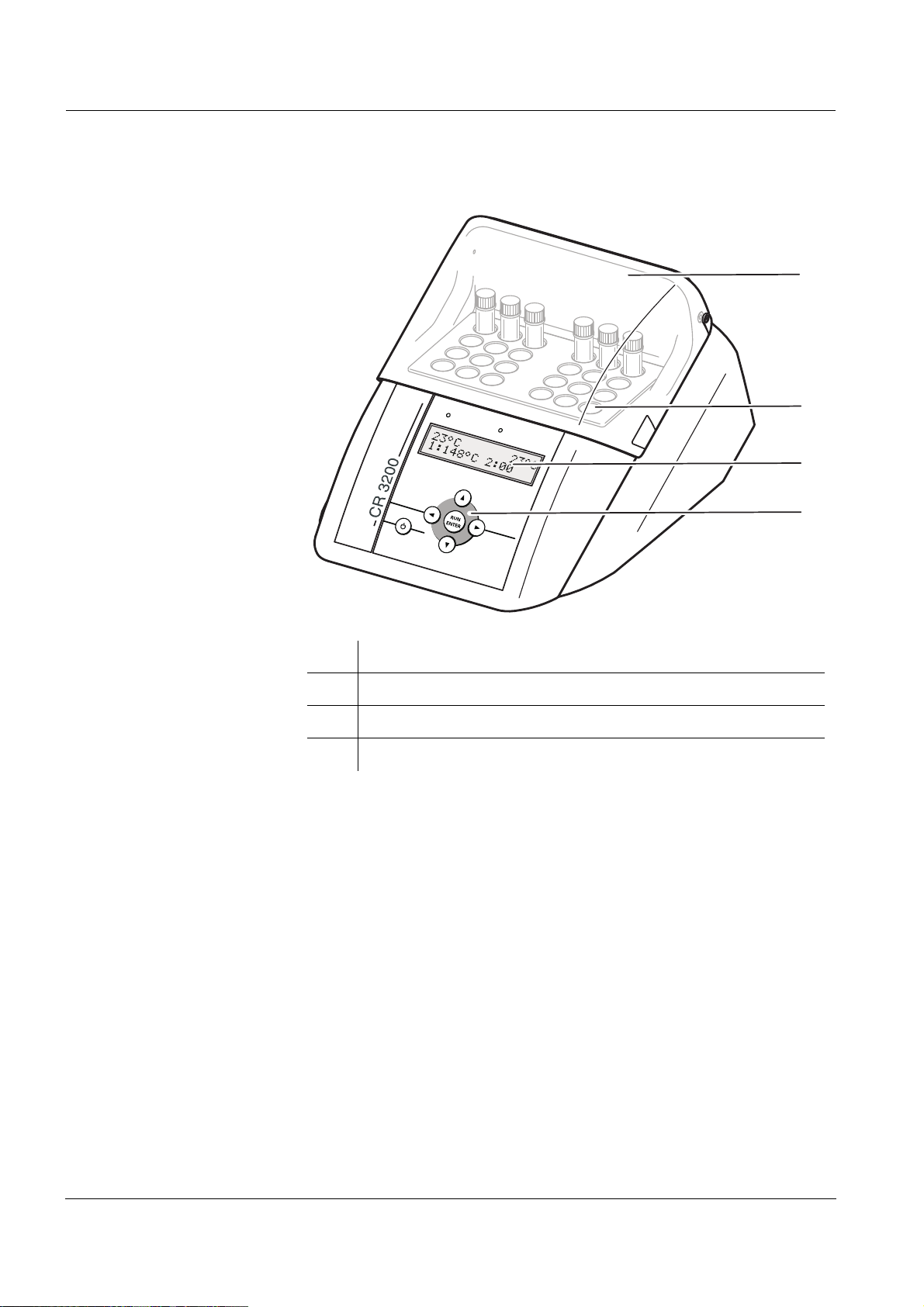

1.1 Components of the thermoreactor

1 Protection cover

2 Thermoblock with cell shafts

3 Display

4 Keypad

6

ba76120e01 08/2012

Page 7

CR 3200 Safety

2 Safety

This operating manual contains basic instructions that you must follow

during the commissioning, operation and maintenance of the

thermoreactor. Consequently, all responsible personnel must read this

operating manual before working with the thermoreactor. The operating

manual must always be available within the vicinity of the

thermoreactor.

Target group The thermoreactor was developed for use in the laboratory. Thus, we

assume that, as a result of their professional training and experience,

the operators will know the necessary safety precautions to take when

handling chemicals.

General safety

instructions

Other labels

The individual chapters of this operating manual use the following

safety labels to indicate different levels of danger:

Warning

indicates instructions that must be followed precisely in order to

prevent serious dangers to persons.

Caution

indicates instructions that must be followed precisely in order to

avoid slight injuries or damage to the instrument or the environment.

Note

indicates notes that draw your attention to special features.

Note

indicates cross-references to other documents, e.g. application

reports.

ba76120e01 08/2012

7

Page 8

Safety CR 3200

2.1 Authorized use

The authorized use of the thermoreactor is exclusively the heating of

samples in cells in a laboratory. The technical specifications as given

in chapter 8 T

ECHNICAL DATA must be observed. Only the operation and

running of the measuring instrument according to the instructions given

in this operating manual is authorized. Any other use is considered

unauthorized.

2.2 General safety instructions

This thermoreactor is constructed and tested in compliance with the EN

61010 safety regulations for electronic measuring instruments. It left

the factory in a safe and secure technical condition.

Function and operating

safety

The smooth functioning and operational safety of the thermoreactor

can only be guaranteed if the generally applicable safety measures and

the specific safety instructions in this operating manual are followed

during operation.

The smooth functioning and operational safety of the thermoreactor

can only be guaranteed under the environmental and electrical

operating conditions that are specified in chapter 8 T

ECHNICAL DATA.

If the thermoreactor was transported from a cold environment to a

warm environment, the formation of condensate can impair the

functioning of the measuring system. In this event, wait until the

temperature of the thermoreactor reaches room temperature before

putting the thermoreactor back into operation.

Caution

The thermoreactor is only allowed to be opened by personnel authorized by.

8

ba76120e01 08/2012

Page 9

CR 3200 Safety

Safe operation If safe operation is no longer possible, the thermoreactor must be taken

out of service and secured against inadvertent operation. Safe

operation is no longer possible if the thermoreactor

has been damaged in transport

has been stored under adverse conditions for a lengthy period of

time

is visibly damaged

no longer operates as described in this manual.

If you are in any doubt, please contact the supplier of the

thermoreactor.

Obligations of the

purchaser

The purchaser of this thermoreactor must ensure that the following

laws and guidelines are observed when using dangerous substances:

EEC directives for protective labor legislation

National protective labor legislation

Safety regulations

Safety datasheets of the chemical manufacturers.

ba76120e01 08/2012

9

Page 10

Safety CR 3200

10

ba76120e01 08/2012

Page 11

CR 3200 Commissioning

3 Commissioning

3.1 Scope of delivery

Thermoreactor CR 3200

Connection cable for mains connection

Operating manual

Warning

Always keep the original packing including the inner packing. If

you have to transport the instrument, the packing protects the instrument optimally from hard shocks.

The original packing is also required for the appropriate return

transport of the instrument if it has to be repaired.

Please note that the warranty does not cover damage caused by

inappropriate transport.

ba76120e01 08/2012

11

Page 12

Commissioning CR 3200

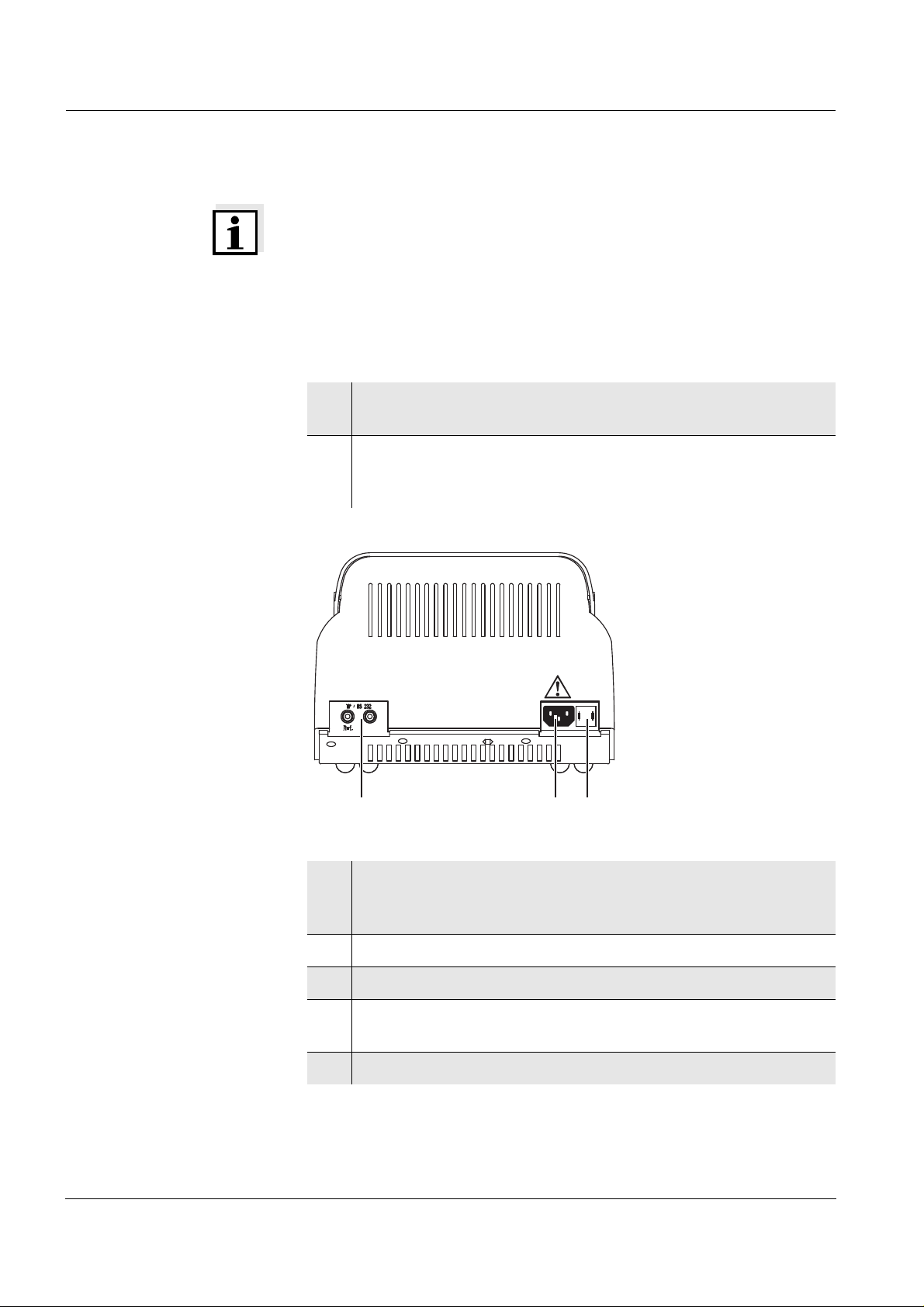

231

3.2 Initial commissioning

Note

The thermoreactor works at an ambient temperature of +5 °C to

+40 °C. When the thermoreactor was transported from a cold

environment to a warm environment, condensate may occur and cause

a malfunction. Wait until the thermoreactor has adjusted to the new

environmental conditions before putting it into operation again (see

also chapter 8 T

ECHNICAL DATA).

Setting up the

thermoreactor

Adjusting the mains

voltage

1 Place the thermoreactor firmly onto a heat-resistant

underground.

2 Make sure that there is enough space between the

thermoreactor and other instruments or devices that are heatsensitive.

12

3 Check whether the arrow on the housing points to the mains

voltage (115 or 230 V) given on the fuse holder (3) that is

provided by the mains.

4 If the wrong mains voltage is set, perform steps 5 to 7.

5 Pull out the fuse holder (3).

6 Turn the fuse holder (3) so that the arrow on the housing points

to the mains voltage (115 or 230 V) provided by the mains.

7 Push the fuse holder (3) in completely.

ba76120e01 08/2012

Page 13

CR 3200 Commissioning

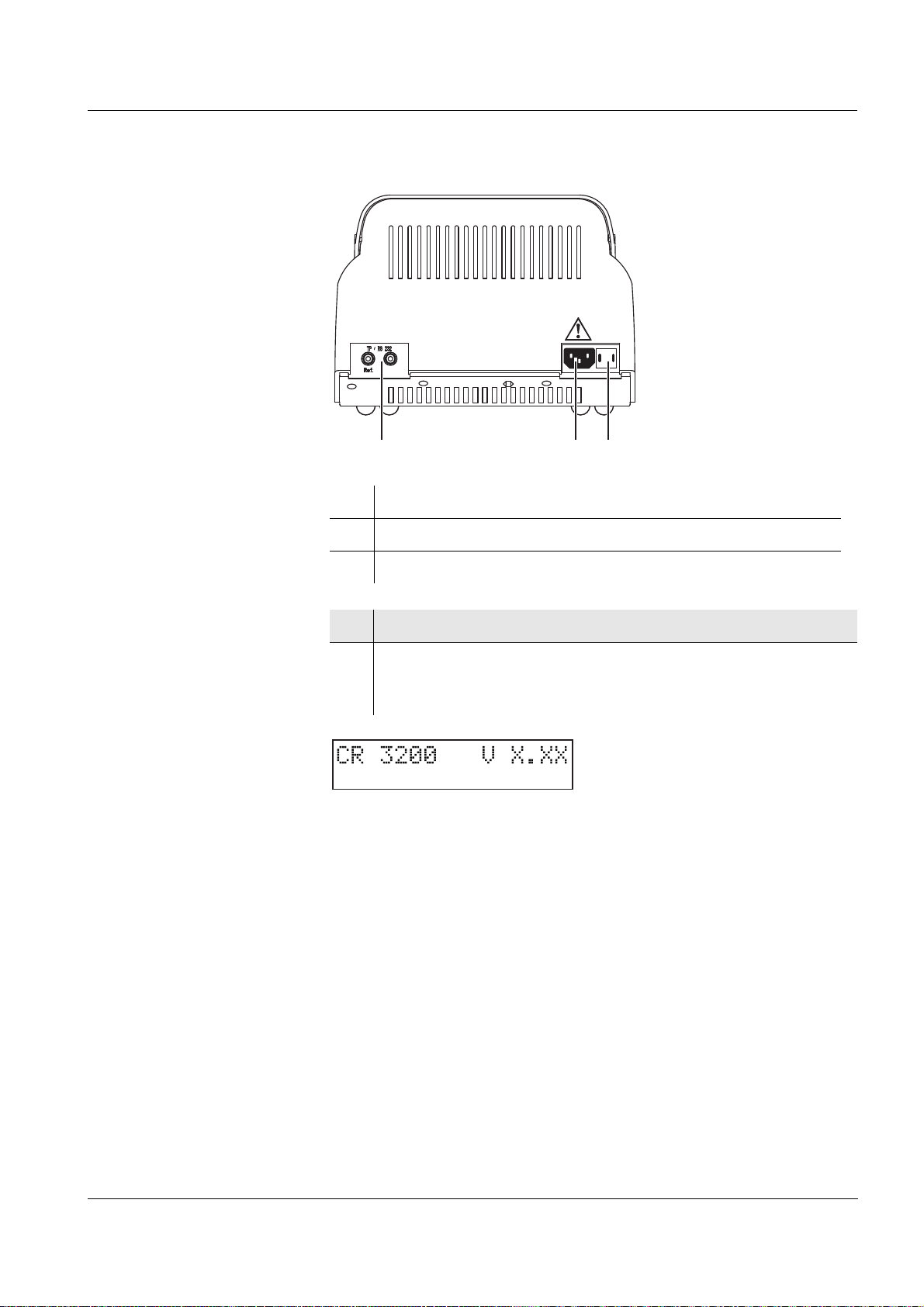

231

Connecting the mains

cable

1 Socket for temperature probe or PC

2 Socket for mains plug

3 Fuse holder

8 Connect the mains cable to the socket 2 on the thermoreactor.

9 Connect the mains cable to an easily available mains socket.

The thermoreactor is now in the Standby mode.

The display shows the name of the instrument.

The thermoreactor is ready for operation.

ba76120e01 08/2012

13

Page 14

Commissioning CR 3200

14

ba76120e01 08/2012

Page 15

CR 3200 Basic principles of operation

4 Basic principles of operation

This chapter provides you with basic information on how to operate the

thermoreactor.

4.1 Operating and display elements

Using the six keys of the keypad (see section 4.1.1) you control the

thermoreactor.

Temperature values, available temperature programs or settings can

be viewed in the display (see section 4.1.2).

The control lamps above the operating panel are assigned to the

thermoblock. Their color (red or green) and their state (flashing or

illuminated) show the current operating state of the thermoreactor (see

section 4.1.3).

ba76120e01 08/2012

15

Page 16

Basic principles of operation CR 3200

4.1.1 Keys

Key Meaning

e

g

ge

4 6

8 2

On/off switch

Making or confirming a selection

or

Starting the timer for the reaction time (active

temperature program).

Keep g depressed and simultaneously press e:

Changing to the SETUP menu from the Standby mode

Changing between the temperature setting and the

reaction time setting (in the SETUP menu)

or

Canceling the active temperature program

Selecting the temperature program (program

selection)

or

Changing settings and switching between settings

(SETUP)

Starting the scrolling through settings by keeping the

key depressed

16

ba76120e01 08/2012

Page 17

CR 3200 Basic principles of operation

1

2

3

4

23°C 23°C

1:148°C 2:00

1

4.1.2 Display

Example: Program selection

1 Temperature in the thermoblock

2 Number of the temperature program

3 Specified temperature

4 Reaction time in hours and minutes

4.1.3 Control lamps (LEDs)

The control lamps above the operating panel are assigned to the

thermoblock and indicate the current operating state.

LED flashes is illuminated

green Program selection

red active temperature

program:

heating period or cooling

period

red and

green

If the control lamps are off the thermoreactor is in the Standby mode.

active temperature

program:

program canceling

selected

active temperature program:

reaction temperature reached

ba76120e01 08/2012

17

Page 18

Basic principles of operation CR 3200

4.2 Operating modes

The thermoreactor has three operating modes:

Standby

The display shows the model and version number of the

thermoreactor.

Using the g and e keys simultaneously takes you to the SETUP

menu. There you can:

– Edit the 8 temperature programs and the temperature test

program (setting the temperature and reaction time for the

programs 9 to 16 and T, see section 5.5.1)

– Set the display contrast (CONTRAST:0 to 9, see section 5.5.2)

– Activate a manual confirmation before the timer for the reaction

time is started (START TIMER:MAN. or AUTO, see section

5.5.3)

Program selection

After switching on with e the display shows the current

temperature value for the thermoblock. The second display line

shows the temperature programs and the temperature test program

to be selected if a reaction time of at least one minute has been set

(see section 5.5.1). The control lamps above he display light up

green.

Active temperature program

The display shows the current temperature value for the

thermoblock. The control lamps above the display light up or flash

red.

18

ba76120e01 08/2012

Page 19

CR 3200 Operation

23°C 23°C

4:120°C 2:00

5 Operation

5.1 Inserting the reaction cells

The reaction cells can either be inserted at room temperature or when

the thermoreactor has been preheated.

Caution

When dealing with chemicals always follow the safety data sheets

and the regulations for prevention of accidents.

Caution

Observe the analysis specifications of the test sets used.

Warning

The thermoblock can become very hot (170 °C).

There is danger of burning when the thermoblock is heated up.

Note

When cold reaction cells are inserted in the preheated thermoblock it

can cool down by approx. 3 °C.

1 Insert the filled reaction cells in the cell shafts.

2 Close the protection cover.

5.2 Starting a temperature program

1 Switch the thermoreactor on with e.

2 Select a temperature program with 8 2.

You can select from 8 predefined temperature programs and a

temperature test program (see section 5.5.1).

ba76120e01 08/2012

19

Page 20

Operation CR 3200

3 Start the displayed temperature program with g.

The control lamps for the thermoblock flash red.

The nominal reaction time (in hours and minutes) appears on

the display.

Note

The reaction temperature is reached when the temperature in the

thermoblock is in a range of ± 1 °C around the adjusted temperature

for two minutes constantly. The control lamps of the thermoblock will

then light up red.

Sequence with

automatic timer

Sequence with manual

timer

If the start of the timer for the reaction time has been set to automatic

in the SETUP menu (START TIMER:AUTO see section 5.5.3), the

reaction time automatically starts after the reaction temperature has

been achieved. The reaction temperature is kept constant during the

reaction time.

After the reaction time has expired the control lamps flash red.

The temperature program is finished.

The thermoreactor is in the program selection mode.

As soon as the thermoblock has cooled down to under 50°C, the

control lamps switch themselves off.

If the start of the timer for the reaction time has been set to manual in

the SETUP menu (START TIMER:MAN. see section 5.5.3), an S is

displayed in front of the nominal reaction time. With this setting the

thermoreactor controls the temperature until the timer for the reaction

time is started by pressing g.

4 Start the timer for the reaction time with g. The S in front of

the reaction time disappears.

20

The reaction temperature is kept constant during the reaction time.

The control lamps of the thermoblock will then light up red.

After the reaction time has expired the control lamps flash red.

Additionally, an acoustic signal sounds.

5 Using g confirm the end of the reaction time for each

thermoblock.

The temperature program is finished.

The acoustic signal is finished.

ba76120e01 08/2012

Page 21

CR 3200 Operation

The thermoreactor is in the program selection mode.

As soon as the thermoblock has cooled down to under 50°C, the

control lamps switch themselves off.

5.3 Stopping a temperature program

You can terminate a running program at any time.

1 Using 4 6, terminate the running temperature program.

The control lamp for the thermoblock flashes red/green.

The safety query STOP? is displayed.

2 Using g confirm the safety query STOP?.

The temperature program is finished.

The control lamps of the thermoblock will then light up green.

or:

Using 4 6, leave STOP?.

The query STOP? disappears from the display. The

temperature program is continued.

Note

While STOP? is displayed the temperature program goes on running.

As soon as a section of the temperature program is finished (e.g. after

the end of the heating period or after the end of the reaction time), the

STOP? display is overwritten.

5.4 Temperature test program

With the temperature test program, you can check the temperature in

the thermoblock with the aid of an external temperature probe that is

available as an accessory (see chapter 9 A

While the temperature test program is active, the display shows the

current temperature of the thermoblock and at the same time the

measured temperature value of the external temperature probe.

The thermoreactor functions correctly if the temperature of the external

temperature probe does not deviate from the nominal temperature

value by more than 2 °C.

If the deviations from the nominal value are greater, further measures

can be necessary (see chapter 7 W

HAT TO DO IF...).

CCESSORIES/OPTIONS).

ba76120e01 08/2012

21

Page 22

Operation CR 3200

Note

The external temperature probe has the same accuracy as the internal

temperature sensor.

5.4.1 Starting the temperature test program

Note

All other temperature programs are blocked while the temperature test

program runs.

1 Connect the external temperature probe to the socket at the

thermoreactor (see chapter 3 C

OMMISSIONING).

2 Insert the external temperature probe in a cell shaft.

3 Switch the thermoreactor on with e.

4 Using 8 2, select the temperature test program T.

5 Using g start the temperature test program T.

The first display line shows the nominal measuring time and the

temperature of the thermoblock. The second display line shows the

temperature of the external temperature probe. After the nominal

temperature has been reached, the measuring time is counted down in

the second display line.

During the temperature regulation phase, the thermoreactor saves the

measured temperature values of the external temperature probe in a

test report every 60 seconds.

As soon as the temperature test is finished, "PRINT" appears on the

display.

22

You can now output the measuring data of the temperature test to a PC

or printer.

You have the following options now:

Connect the thermoreactor with a PC and transmit the test report to

ba76120e01 08/2012

Page 23

CR 3200 Operation

CR 3200 V.X.XX

Tref = 148 C

1: Tblock = 147.5 C

2: Tblock = 147.6 C

3: Tblock = 147.7 C

. . .

. . .

a terminal program (see section 5.4.2).

Connect the thermoreactor with a printer and download the test

report to the printer (see section 5.4.2).

Leave the temperature test program with g.

The test report in the thermoreactor is erased in any case at the end.

5.4.2 Downloading the test report to an external printer/PC

To transmit the temperature test report to a printer or PC, a printer

cable or PC cable is required (see chapter 9 A

CCESSORIES/OPTIONS).

You can record the test report with the aid of a so-called terminal

program on the PC side.

Generally, a terminal program serves to establish a connection to a

meter at a data interface and to communicate with the meter via a

console on the display. A terminal program usually offers the possibility

to save the contents of the console in a text file or print it. If the terminal

program is connected to the thermoreactor, it can receive the

temperature test report and display it on the console.

Sample report

Downloading the test

report

Terminal programs are available by different manufacturers for

different operating systems. The "HyperTerminal" terminal program is

included in Windows (versions 95 to XP). It is in the program menu

under Accessories.

More detailed information can be taken from the user information of the

terminal program.

Precondition:

The temperature test is finished and PRINT is displayed (see page 5-

22).

1 Disconnect the external temperature probe from the

thermoreactor.

ba76120e01 08/2012

Note

When connecting the PC or printer cable observe the cable poling.

Data transmission is possible with the correct poling only.

23

Page 24

Operation CR 3200

1 Ref

2 TxD

Socket assignment

2 Connect the thermoreactor to the PC or printer. (Cable see

chapter 9 A

CCESSORIES/OPTIONS). To do so:

plug the reference plug (unmarked) in the "Ref" socket (1).

plug the signal plug (marked by a red ring) in the socket (2).

3 Start the terminal program on the PC.

4 Set the following transmission data in the terminal program:

Baud rate 4800

Handshake none

Parity none

Data bits 8

Stop bits 1

Record none

5 Start the data transmission with g.

After the transmission is finished the test report is deleted in

the thermoreactor.

24

ba76120e01 08/2012

Page 25

CR 3200 Operation

5.5 Settings

5.5.1 Editing a temperature program

The temperature programs 1 to 8 are installed permanently and cannot

be changed.

The temperature programs 9 to 16 and the temperature test program

can be edited according to individual requirements.

Note

For the temperature test program, a TFK CR external temperature

probe is required (available as an accessory, see chapter 9

CCESSORIES/OPTIONS).

A

1 Switch to the Standby mode.

2 Keep the g key depressed while you press e to sw itch to th e

SETUP menu.

SETUP and, in the second line, an editable parameter are

displayed.

3 Using 8 2 select a temperature program no. 9 to 16 or the

temperature test program.

4 Using g edit the selected temperature program.

The two parameters, temperature and time, are displayed.

The editing is marked on the display by *.

The selected parameter is marked by an arrow < or >.

5 Using 8 2 change the parameter (e.g. temperature ).

6 Using 4 6 switch to the other parameter.

ba76120e01 08/2012

7 Using 8 2 change the parameter (e.g. reaction time ).

8 Using g confirm the changes.

The marking on the display (*) disappears.

25

Page 26

Operation CR 3200

9 Using e leave the SETUP menu.

The changes are stored.

The thermoreactor is switched on (operation mode: program

selection).

5.5.2 Setting the display contrast

The display contrast can be set in 10 steps.

1 Switch to the Standby mode.

2 Keep the g key depressed while you press e to switch to the

SETUP menu.

SETUP and, in the second line, an editable parameter are

displayed.

3 Using 8 2 select CONTRAST.

4 Using g edit the contrast setting.

The editing is marked on the display by*.

5 Using 8 2 set the contrast from 0 to 9.

6 Using g confirm the changes.

The marking on the display (*) disappears.

7 Using e leave the SETUP menu.

The changes are stored.

The thermoreactor is switched on (operation mode: program

selection).

26

5.5.3 Setting the timer for the reaction time

After the start of a temperature program the thermoblock starts heating

up. Depending on the setting, the timer for the reaction time starts

automatically after the reaction temperature has been reached or only

after confirmation by keypressing.

ba76120e01 08/2012

Page 27

CR 3200 Operation

With the setting START TIMER:AUTO the timer for the reaction time

starts immediately after the reaction temperature has been reached.

With the setting START TIMER:MAN. the timer for the reaction time

starts after confirmation by keypressing only.

1 Switch to the Standby mode.

2 Keep the g key depressed while you press e to sw itch to th e

SETUP menu.

SETUP and, in the second line, an editable parameter or a

temperature program are displayed.

3 Using 8 2 select START TIMER.

4 Using g set the start of the timer for the reaction time.

The editing is marked on the display by *.

5 Using 8 2 select MAN. or AUTO.

6 Using g confirm the changes.

The marking on the display (*) disappears.

7 Using e leave the SETUP menu.

The changes are stored.

The thermoreactor is switched on (operation mode: program

selection).

ba76120e01 08/2012

27

Page 28

Operation CR 3200

28

ba76120e01 08/2012

Page 29

CR 3200 Maintenance, cleaning, disposal

231

6 Maintenance, cleaning, disposal

6.1 Maintenance

The CR 3200 thermoreactor is maintenance-free.

6.2 Exchanging the fuses

1 Disconnect the line power cable from the thermoreactor.

2 Pull out the fuse holder (3).

3 Exchange one or both fuses (6.3 AT).

4 Turn the fusion holder (3) so that the arrow on the housing

points to the line voltage (115 or 230 V) provided by the power

line.

5 Push the fusion holder (3) completely in.

ba76120e01 08/2012

29

Page 30

Maintenance, cleaning, disposal CR 3200

6.3 Cleaning the enclosure

Wipe the thermoreactor with a damp cloth.

Caution

The housing is made of synthetic material. Thus, avoid contact

with acetone or detergents that contain solvents. Remove any

splashes immediately.

6.4 Cleaning the thermoblock of spilled cell contents

If liquid penetrated a thermoblock (e.g. from a cell), clean the

thermoblock as follows:

Warning

Cells can contain poisonous or corrosive substances. If the content has been set free observe the danger notes on the cell. If necessary take the corresponding protective measures (protective

goggles, protective gloves etc.).

Warning

The thermoblock can become very hot (170 °C). There is danger

of burning when the thermoblock is heated up.

1 Switch off the thermoreactor and disconnect the power plug.

2 Allow the thermoreactor to cool down.

3 Unscrew the cover plate on top of the thermoblocks.

4 Clean the cover plate, block surfaces and borings with a damp

cloth.

5 Screw on the cover plate again.

Note

Discoloration that remains on the thermoblock and cover plate does not

affect the functioning of the thermoreactor.

6.5 Disposal

Dispose of the thermoreactor as electronic waste at an appropriate

collection point. It is illegal to dispose of the thermoreactor in household

refuse.

30

ba76120e01 08/2012

Page 31

CR 3200 What to do if...

7 What to do if...

There is nothing on the

display

Bars are displayed

instead of the

temperature (-°C)

Cause Remedy

– The power supply is

interrupted

Cause Remedy

– With an active

temperature test program:

the signal of the external

temperature probe was

not recognized

– In the program selection

mode: internal

temperature probe

defective

– Check mains cable and

connections

– Exchange the fuses

– Repair by service department

– Connect the temperature

probe

– Repair by service department

– Repair by service department

Temperature deviation

during the temperature

test program

Cuvette emptied /

thermoblock

contaminated

Cause Remedy

– Bad thermal contact

between the external

temperature probe and the

thermoblock

Cause Remedy

– e. g. leaking cuvette – see section 6.4

– Use original accessories only

– Close the protection cover

during the temperature test

– Contact the service

department

ba76120e01 08/2012

31

Page 32

What to do if... CR 3200

32

ba76120e01 08/2012

Page 33

CR 3200 Technical Data

8Technical Data

Reactor type Dry temperature control device

with safety cover

Cell shafts 2 x 12 cell shafts for reaction

cells 16 ± 0.2 mm

Reaction time setting 20 min, 30 min, 60 min, 120 min

(via fixed programs)

8 freely adjustable programs:

0...180 min

Temperature setting 100 °C, 120 °C, 148 °C, 150 °C

via fixed programs

and 8 freely adjustable

programs:

Room temperature ...170 °C

Controlling accuracy ± 1 °C ± 1 Digit

Temperature stability ± 0.5 K

Overtemperature protection 190 °C ± 5 °C

Heating time (with empty

thermoblock) from 25 °C to

Temperature of the enclose at

an environmental temperature

of 25 °C

Output unidirectional RS232 interface

Power supply 230 VAC 50 Hz ± 15 %

100 °C approx. 5 min

120 °C approx. 7 min

148 °C approx. 10 min

< 30 °C with a block temperature

of 148 °C

with 2 banana sockets for:

external temperature probe

or

PC cable

115 VAC 60 Hz ± 15 %

Power consumption: 560 W

Fuses 2 x 6.3 AT

ba76120e01 08/2012

Enclosure PC ABS, recyclable, high

temperature resistant

Protective class I according to DIN VDE 0700

part 1/11.90

33

Page 34

Technical Data CR 3200

Insulation group Insulation group: B according to

DIN VDE 0110/11.72

Overvoltage category II

Protection IP 20 according to DIN 40050

Ambient temperature Storage -25 °C to +65 °C

Operation +5 °C to +40 °C

Climatic class 2 according to VDI/VDE 3540

Relative humidity:

Yearly mean: < 75 %

30 days /year: 95 %

Other days: 85 %

Light dew: yes

EMC EN61326

FCC Class A

Test certificates cETLus, CE

Dimensions D x W x H: 312 x 255 x 185 mm

Weight: 4kg

Safety standards EN61010

UL3101

CAN/CSA C22.2-1010

EN61010-2-010

IEC-CAN/CSA C22.2-

1010.2.010

34

ba76120e01 08/2012

Page 35

CR 3200 Accessories/Options

9 Accessories/Options

Designation Accessory

TFK CR External temperature probe for the monitoring

of test equipment of the CR 3200 and CR 4200

thermoreactors

AK CR/PC PC cable for thermoreactors, CR 3200 and

ba76120e01 08/2012

35

Page 36

Accessories/Options CR 3200

36

ba76120e01 08/2012

Page 37

CR 3200 Index

10 Index

A

Authorized use ...........................................8

C

Commissioning ........................................11

Components of the thermoreactor ...............6

Control lamps (LEDs) ...............................17

D

Display ....................................................17

F

Fuses ......................................................29

K

Keys .......................................................16

M

Maintenance ............................................29

Temperature test program

starting

Trouble shooting ..................................... 31

.............................................. 22

W

What to do if... ........................................ 31

O

Operating and display elements ................15

Operating modes .....................................18

Operating safety ........................................8

Outputting data to a PC ............................23

Outputting data to a printer .......................23

P

PC ..........................................................23

Program selection ....................................18

S

Safety measures ........................................7

Scope of delivery .....................................11

Setting the display contrast .......................26

Standby ..................................................18

T

Temperature program

editing

starting ..............................................19

stopping .............................................21

Temperature program active .....................18

...............................................25

ba76120e01 08/2012

37

Page 38

Index CR 3200

38

ba76120e01 08/2012

Page 39

CR 3200 Contact Information

11 Contact Information

11.1 Ordering & Technical Support

Telephone

Fax

: (937) 767-1058

Email

Mail: YSI Incorporated

Internet

When placing an order please have the following information available:

YSI account number (if available) Name and Phone Number

Model number or brief description Billing and shipping address

Quantity Purchase Order or Credit Card

: (800) 897-4151

(937) 767-7241

Monday through Friday, 8:00 AM to 5:00 PM ET

: environmental@ysi.com

1725 Brannum Lane

Yellow Springs, OH 45387

USA

: www.ysi.com

11.2 Service Information

YSI has authorized service centers throughout the United States and

Internationally. For the nearest service center information, please visit

www.ysi.com

directly at 800-897-4151.

When returning a product for service, include the Product Return form

with cleaning certification. The form must be completely filled out for an

YSI Service Center to accept the instrument for service. The Product

Return form may be downloaded at www.ysi.com

‘Support‘ tab.

and click ‘Support’ or contact YSI Technical Support

and clicking on the

ba76120e01 08/2012

39

Page 40

Contact Information CR 3200

40

ba76120e01 08/2012

Page 41

Page 42

Xylem

1) The tissue in plants that brings water upward from the roots;

2) a leading global water technology company.

We’re 12,500 people unified in a common purpose: creating innovative solutions

to meet our world’s water needs. Developing new technologies that will improve

the way water is used, conserved, and re-used in the future is central to our work.

We move, treat, analyze, and return water to the environment, and we help people

use water efficiently, in their homes, buildings, factories and farms. In more than

150 countries, we have strong, long-standing relationships with customers who

know us for our powerful combination of leading product brands and applications

expertise, backed by a legacy of innovation.

YSI

1725 Brannum Lane

Yellow Springs, OH 45387

Tel: +1 937-767-7241; 800-765-4974

Fax: +1 937-767-1058

Email: environmental@ysi.com

Web: www.ysi.com

©Xylem Inc, October 2012

Loading...

Loading...