Page 1

YSI i n c o r p o r a t e d

YSI MODEL 6500

Environmental Process Monitor

Operations Manual

Page 2

Page 3

CONTENTS

Page

Section 1 INTRODUCTION 1

1.1 6500 Monitor Features 1

1.2 How to Use This Manual 2

Section 2 INSTALLATION 3

2.1 Unpacking and Inspection 3

2.2 Selecting an Installation Location 3

2.3 Installing the Sonde 7

2.4 Installing the 6500 Monitor 9

2.5 Wiring Instructions 11

2.5.1 Sonde Connections 11

2.5.2 AC Power Connections 13

2.5.3 Relays and Output Wiring 14

2.5.4 Grounding Information 15

2.5.5 Safety Issues 15

2.5.6 Lightning and Surge Protection 15

2.6 Sealants, Desiccant and Securing the Monitor 16

2.7 Installation Check List 17

Section 3 SYSTEM SETUP 19

3.1 System Configuration 19

3.2 6-Series Sonde Setup 20

3.3 6500 Monitor Setup 23

3.3.1 Calibration setup 24

3.3.2 Display setup 26

3.3.3 Relays 29

3.3.4 4-20 mA channel setup 31

3.3.5 Modbus Setup 32

3.3.6 Change Sonde Address 33

3.3.7 System Status 35

Section 4 CALIBRATION 37

4.1 General Calibration Tips 37

4.2 Field Calibration Using the 6500 Monitor 40

4.3 6500 calibration Warning and Error Messages 42

Section 5 PROPER USE AND CARE OF THE 6500 MONITOR SYSTEM 43

5.1 Deciding How to Use Your Monitoring System 43

5.2 Quality Assurance 47

5.2.1 Sonde Maintenance and Deployment Site 48

5.2.2 Calibration Checks 49

5.2.3 Recommended Quality Assurance Protocol 49

5.2.4 Recommended Monthly Maintenance of DO Probe 51

5.2.5 Recommended Cleaning of the 6500 Enclosure 52

i

Page 4

Section 6 TROUBLESHOOTING 53

6.1 Communication Problems 53

6.2 6500 Menu Choice Problems 55

6.3 Calibration Error Messages 56

6.4 Sensor Accuracy and Repeatability Problems 56

6.5 Alarm Function Problems 57

6.6 4-20 mA Loop Output Problems 58

Section 7 WARRANTY AND SERVICE INFORMATION 59

Appendix A SPECIFICATIONS 63

Appendix B HEALTH AND SAFETY 65

Appendix C REQUIRED NOTICE 73

Appendix D ACCESSORIES 75

Appendix E SOLUBILITY AND PRESSURE/ALTITUDE TABLES 99

Appendix F ADVANCED CALIBRATION SETUP 103

Appendix G INDEX 105

ii

Page 5

SECTION 1 INTRODUCTION

L

A

A

The 6500 Environmental Process Monitor is designed for configuration with YSI 6-Series

sonde(s) to measure up to fifteen water quality parameters. All sensors that perform the parameter

measurements are located on the 6-Series sonde, which is submersed and secured in the medium.

Conversion of the sensor signals from analog to digital is performed by microprocessor based

electronics located in the 6-Series sonde interior. The signals are transmitted via cabling to the

6500 Environmental Process Monitor using SDI-12 protocol.

The 6500 Environmental Process Monitor can be used for a wide variety of sampling and

monitoring applications, including, monitoring at either municipal or industrial wastewater

treatment plants, drinking water intake, source water, and a variety of other applications. Other

municipal and industrial process applications encompass a wide range of matrices (e.g., influent

and aeration basins) and the overall performance of the 6-Series sonde is typically site-specific,

particularly with regard to fouling of the sensors. In addition, the industrial end-user should be

aware of potential incompatibility of their process environment with the operating range and/or

the construction materials of the sonde body and the sensors.

1.1 6500 MONITOR FEATURES

Water quality parameter data can be viewed on the liquid crystal display (LCD) of the 6500

Monitor. Additionally, the 6500 Monitor contains 8 x 4-20 mA loop outputs that can be assigned

to the various parameters. The 4-20 mA loop outputs provide the means for logging parameter

data either (1) by direct recording of the loop outputs with a data logging device or (2) by

interfacing the loop outputs with a SCADA system. A set of 4 relays is also present that can be

activated by pre-set limit values. The relays are intended to drive alarm indicators, such as lamps,

horns or automatic phone dialer systems.

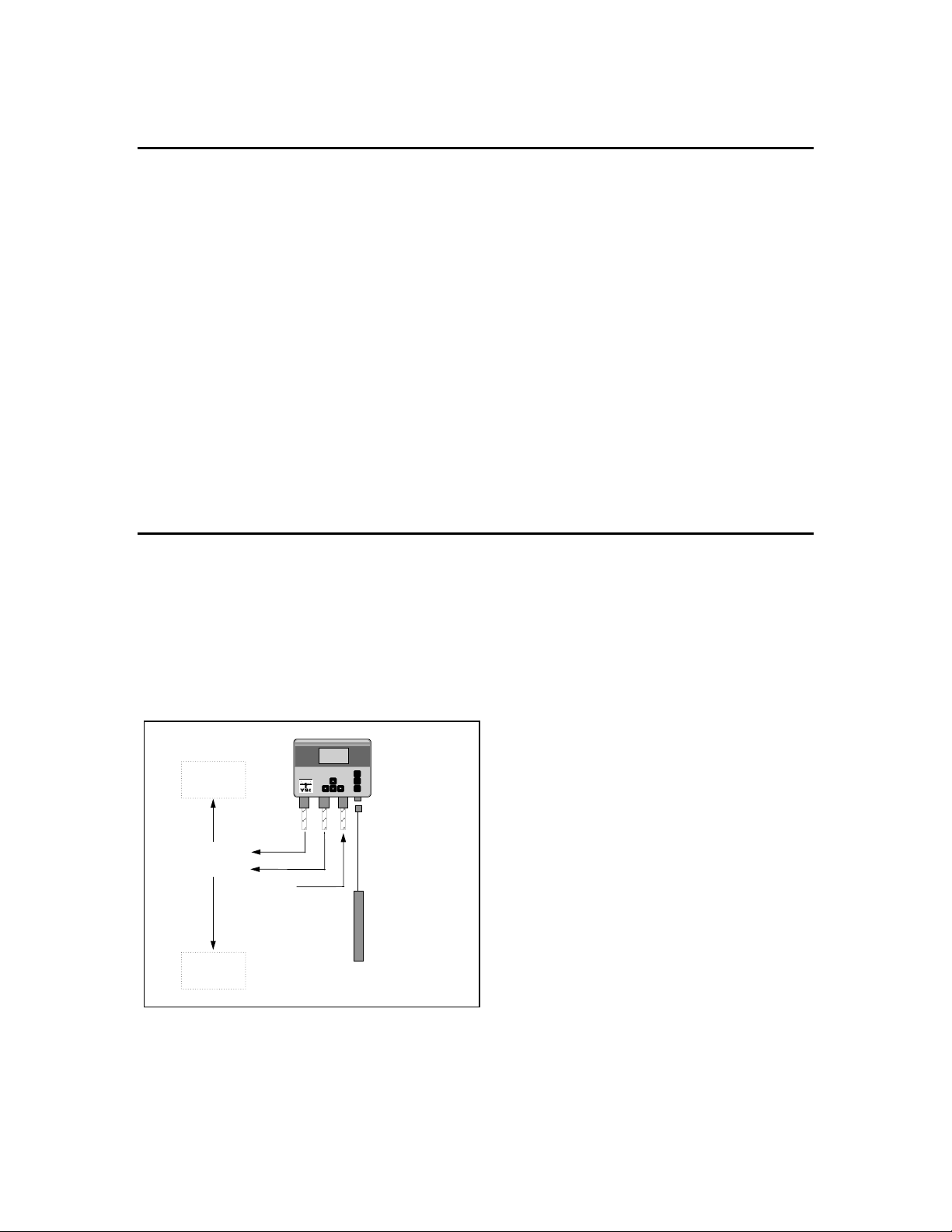

System set-up, including calibration of the 6-

21.2 Temp

6500

6500

ENVIRON MENTALENVIRON MENTA

7.35 DO

MONITORINGMONITORING

SYSTEM

SYSTEM

6.53 pH

Esc

SCADA

4-20 mA out

Relay output

C power in

larms

Cal

Enter

Sonde cable

w/ MS-8

Sonde

Effluent Stream

Monitor is accomplished with a watertight connector located on the bottom panel of the 6500

Monitor. There are two means to connect the 6-Series Sonde to the 6500 Monitor. The sonde

may be connected directly via the sonde cable, or if the sonde is not

6500 Monitor installation, an optional YSI #6508 Junction Box may be used with customersupplied cabling.

Series Sonde sensors, can be performed at the

site with the 6500 Monitor front panel keys

and LCD or in the laboratory with a personal

computer or a YSI 610 Display/Logger.

Ports for up to three non-metallic watertight

conduit fittings are located on the 6500

Monitor bottom panel and provide the means

for connecting the AC power input, the 4-20

mA loop outputs and the relay output

conductors via conduit to the I/O plate located

within the 6500 Monitor enclosure.

Connection of the 6-Series Sonde to the 6500

located in the vicinity of the

Page 6

Introduction Section 1

With the optional Breakout Box (YSI #6504), the 6500 Environmental Process Monitor can be

used with multiple sondes. The 6500 Monitor is designed for indoor or outdoor use, and features

a watertight enclosure. An optional weather shield (YSI # 6505) is also available. Other optional

accessories include several different mounting kits for the sondes and 6500 Monitor. See

Appendix D, Accessories, for more information.

1.2 HOW TO USE THIS MANUAL

The manual is organized to let you quickly understand how to install and operate the 6500 Monitor

system. However, it cannot be stressed too strongly that informed and safe operation is more than

just knowing which buttons to push. An understanding of the principles of operation, installation,

calibration techniques, system setup and maintenance is necessary to obtain accurate and meaningful

results. Before you begin to use the 6500 Environmental Process Monitor, it is strongly

recommended that you thoroughly read and understand the YSI 6-Series Sonde Manual. The sonde

manual will be referenced in several parts of the 6500 Manual. Before using the sonde with the 6500

Monitor, you must:

9 Install the dissolved oxygen membrane

9 Install the probes

9 Learn how to access sonde software

9 Calibrate the sensors

9 Learn how to take readings

If you are using multiple sondes, each sonde must have a different address (name) and each sonde

must be named separately. Assigning the names are done by accessing the sonde software and

entering System Setup from the Main Menu. From the System Setup, then enter SDI-12 Address. A

character (0-9 and A-F) may be assigned to each sonde that you are using, but each sonde

have a different name. For more information about the other functions of the System Setup, see the

6-Series Sonde Operations Manual, Section 2.

Included with this manual is a laminated Field Operation Guide that allows quick and convenient

reference to 6500 operation, maintenance and troubleshooting at the installation site. This guide

references sections of the basic manual when more detailed information is needed.

MUST

YSI Incorporated 6500 Environmental Process Monitor 2

Page 7

SECTION 2 INSTALLATION

2.1 UNPACKING AND INSPECTION

Inspect the outside of the shipping carton for damage. If damage is detected, contact the carrier

immediately. Remove the instrument from the shipping container. Be careful not to discard any

parts or supplies. Confirm that all items on the packing list are present. Inspect all assemblies

and components for damage. The basic 6500 Environmental Process Monitor is shipped with the

following major components.

6500 Monitor and mounting hardware

6506 Desiccant Kit

065926 Conduit Fittings (3)

065921 Industrial Encapsulant (sealer for conduit fittings)

065927 Knockout Plugs (2)

065902 Operations Manual

065979 Field Operation Guide

If you ordered a 6-Series Sonde and/or reagents, these may be shipped separately. For optional

accessories information see Appendix D, Accessories.

If any parts are damaged or missing, contact your factory representative immediately. If you do

not know from which dealer your 6500 Environmental Process Monitor was purchased, refer to

Section 7, Warranty and Service Information. Check the monitor for any obvious external

damage.

Save the original packing cartons and materials. Carriers typically require proof of damage due

to mishandling. Also, if it is necessary to return the monitor, you should pack the equipment in

the same manner it was received. Once the system is installed and working, maintaining original

cartons and packing material is less critical.

If the monitor, sonde and associated components match the packing list and the components

appear to be in satisfactory condition, proceed to the installation sections below.

WARNING!

To avoid severe personal injury or damage to the equipment, installation, operation and service

should be performed by qualified personnel who are thoroughly familiar with the entire contents

of this manual.

2.2 SELECTING AN INSTALLATION LOCATION

The 6500 Monitoring System is an on-line continuous measurement tool that can provide

valuable insight into your facility’s operation and performance. As with any instrument of this

type, proper installation is the first important step to ensure you are provided with reliable

performance and accurate data. Installation of the monitor and sonde should be carefully planned

in advance to obtain the most effective and accurate utilization of the equipment.

Page 8

Installation Section 2

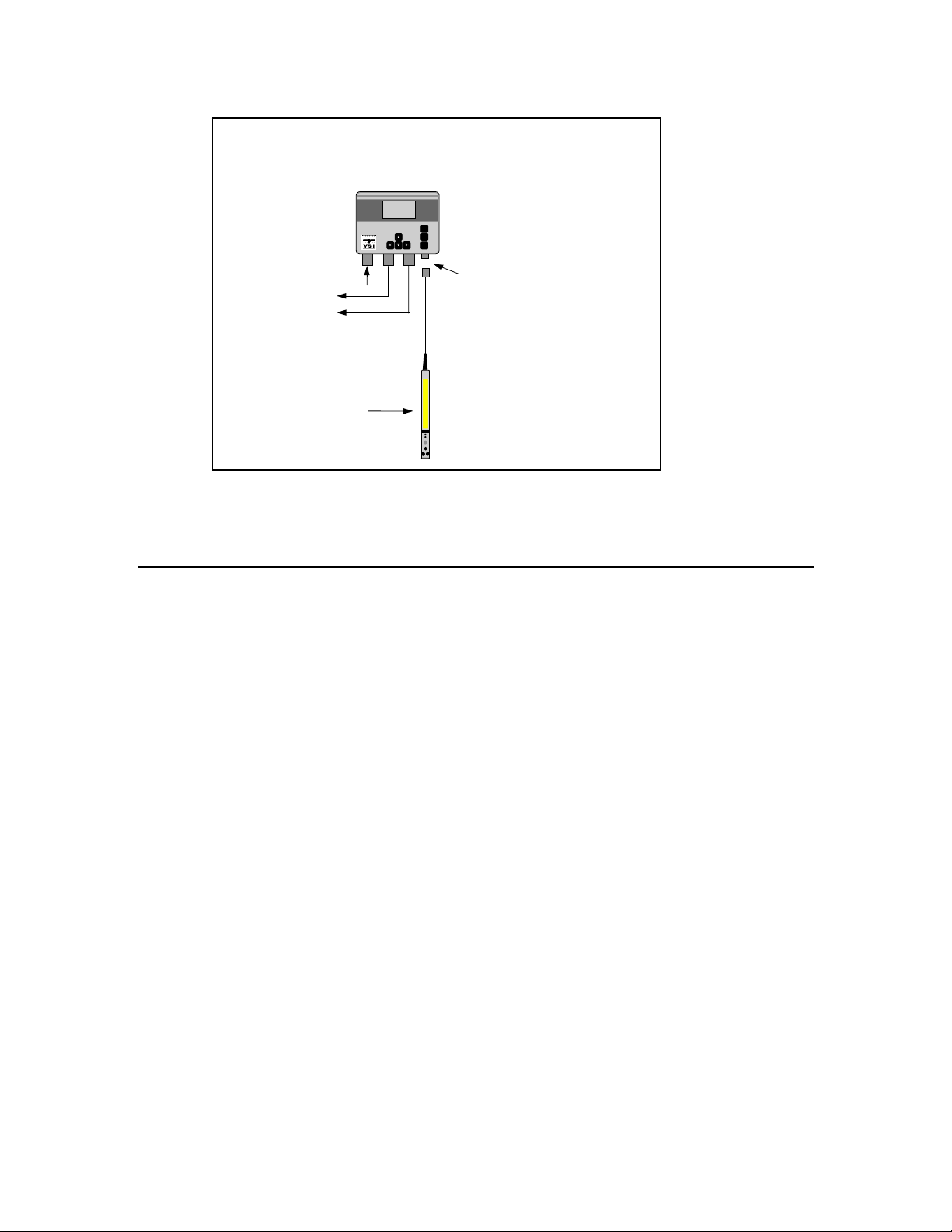

Two major components make up the 6500 Environmental Monitoring System: the 6500 Monitor

and the 6-Series Sonde that contains the sensors. The sonde is a multi-parameter sensor device

that must be placed in a representative sampling location to monitor desired water quality

parameters in the flow stream. Since the 6500 Monitor may be located considerable distance

from the sonde, a specialized Breakout box and/or Junction Box may be required for your

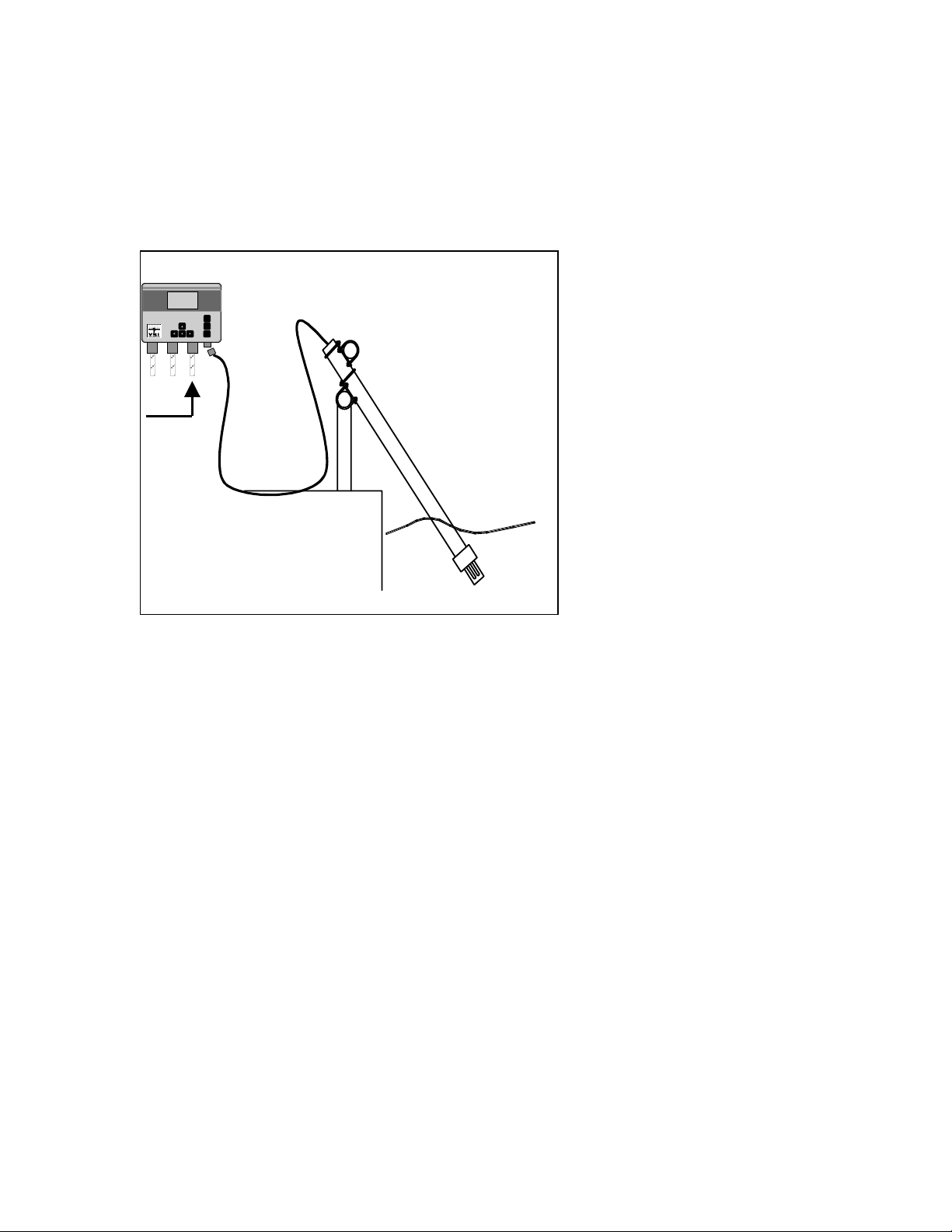

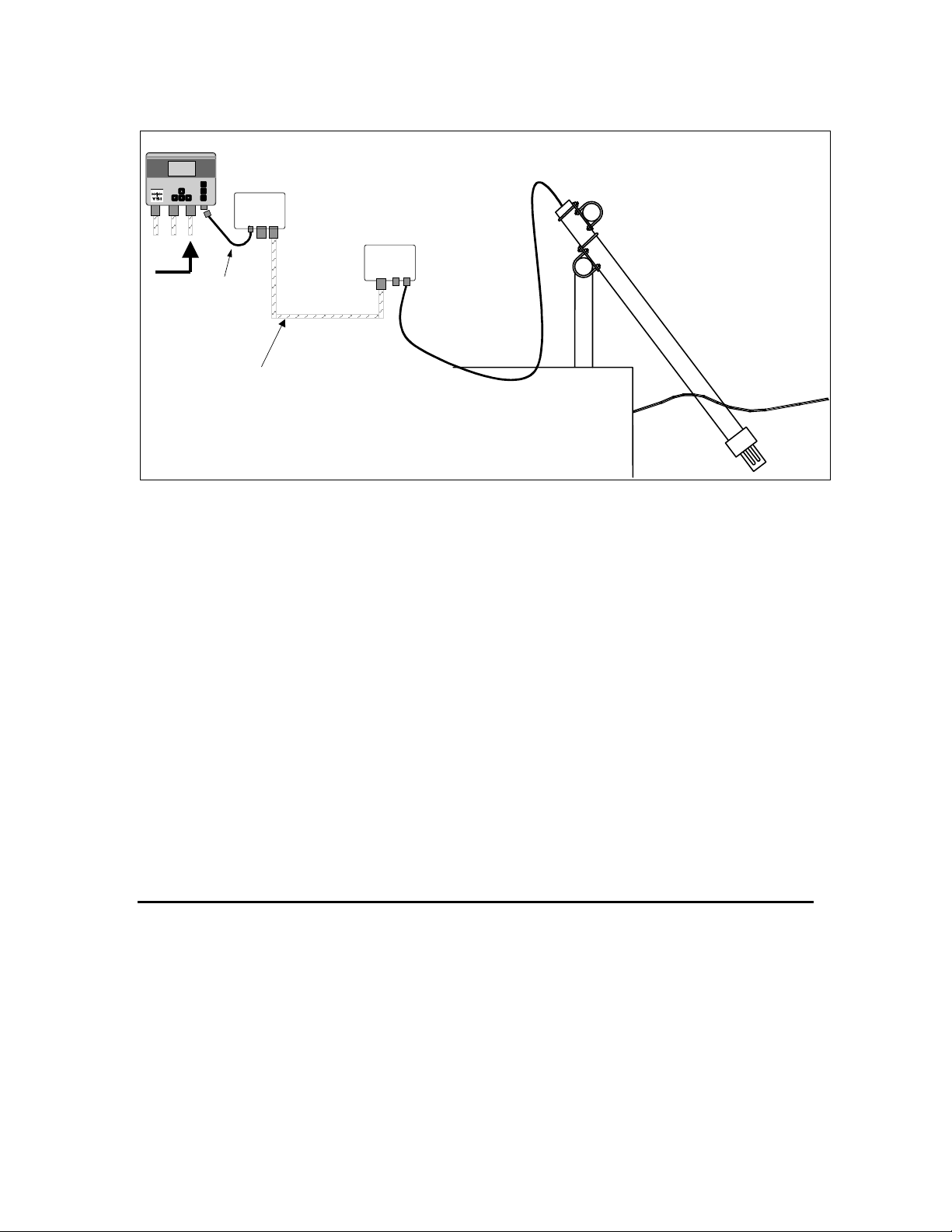

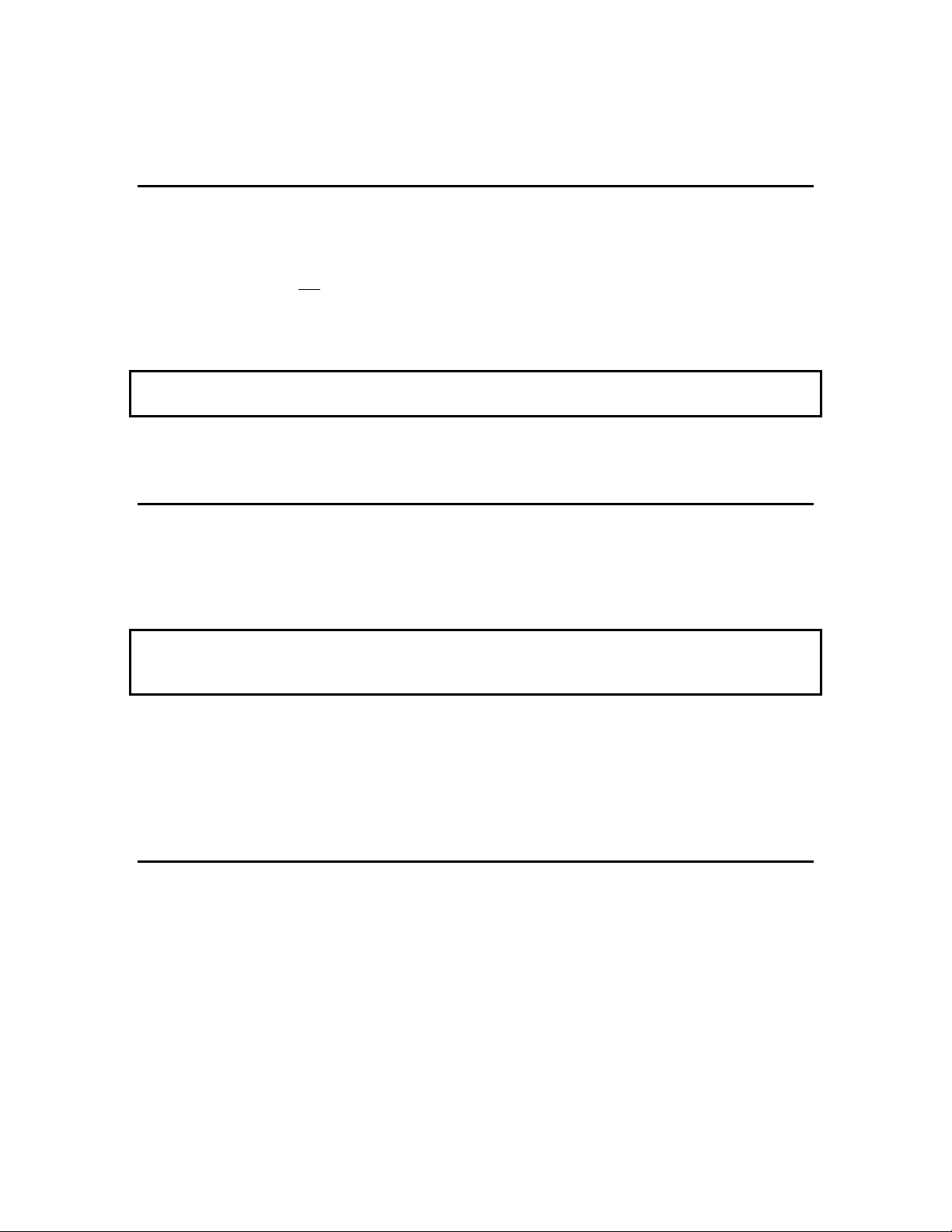

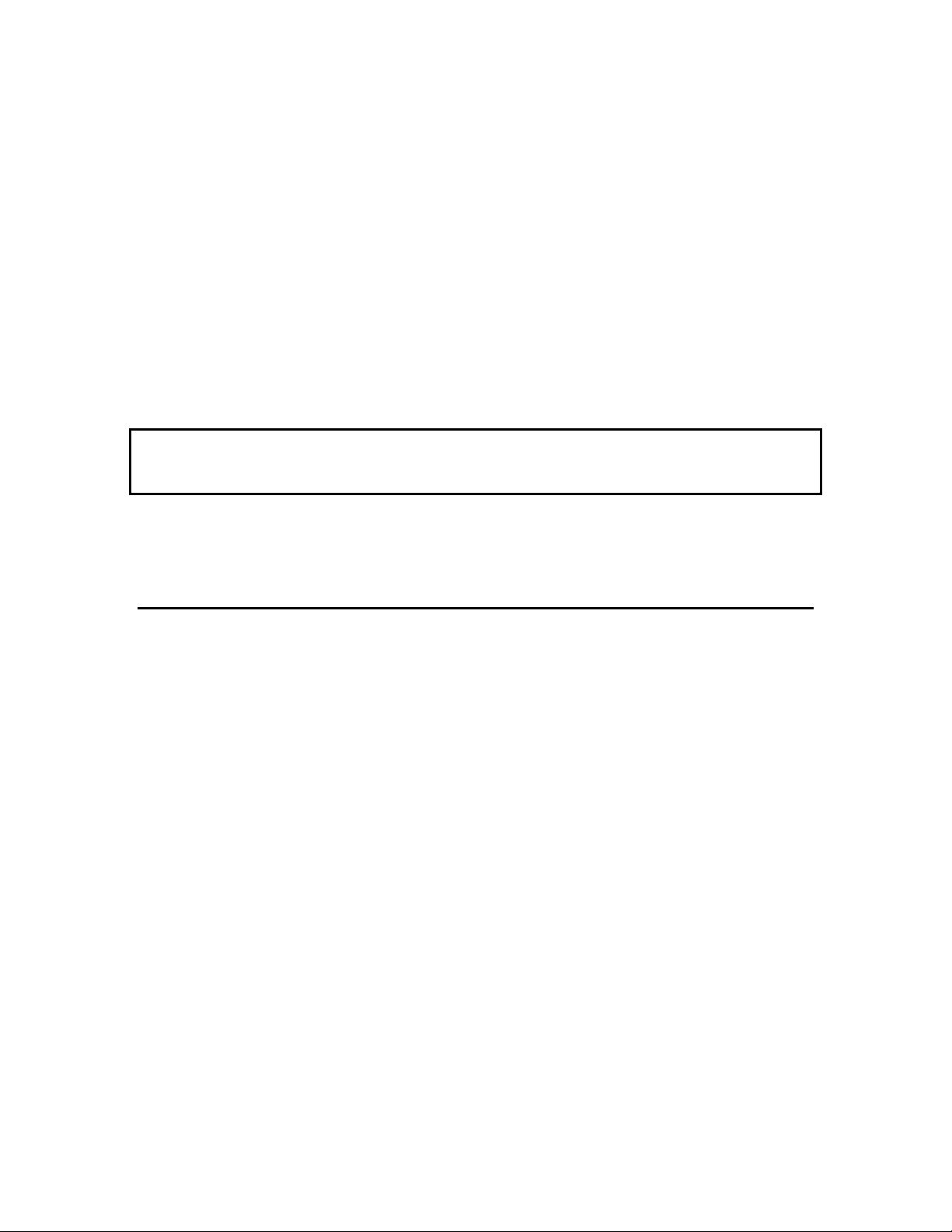

installation, see Appendix D for Accessories information. See Figures 2 and 3 for diagrams of

the two most common installation configurations.

CHOOSING A SONDE LOCATION

The sonde installation will be determined by the site necessary to obtain water quality readings

which are representative of the bulk flow stream. A suitable location should take a number of

physical and chemical factors into consideration:

9 The sonde must be located in the flow stream where level fluctuations will not expose the

sensing probes to the atmosphere. The sonde sensors must remain submersed at all times

during the monitoring.

9 The sonde must be placed in a well mixed, free flowing area of the process stream. The flow

stream should be representative of the process flow being monitored. For example, if effluent

flow is being analyzed,

extended detention time of the effluent desired for monitoring.

9 Ideally, the sonde should be placed at least three (3) feet away from the sidewall and at least

two (2) feet submersed. For most flow channels, midstream and mid-depth would be the

most representative area for the sonde location.

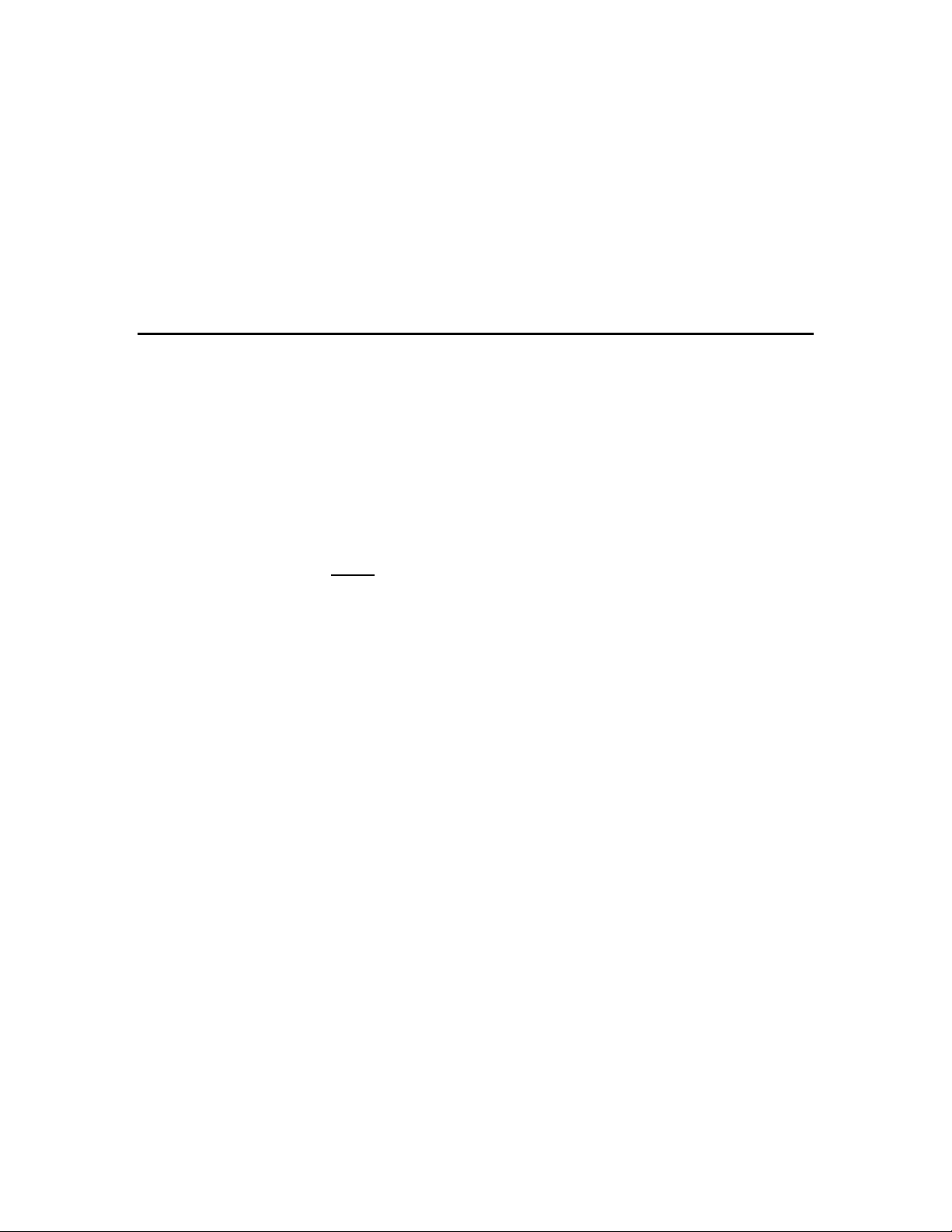

9 Ideally, the sonde should be placed at an angle within 45

flow direction (see Figure 1). This location will provide for the least stress on the support

arm holding the sonde while minimizing opportunity to collect debris. Placement against the

flow stream or perpendicular to the flow stream also provides accurate monitoring, but

inspection and cleaning may be required more frequently due to increased collection of

debris.

do not place the sonde ahead of a tank or an area that provides for

0

of vertical and directed with the

YSI Incorporated 6500 Environmental Process Monitor 4

Page 9

Installation Section 2

Not

Figure 1 Sonde orientation

to

scale.

drawn

Sonde

Stream

If the sonde is to be utilized in monitoring for results of chemical feeds and resulting chemical

reactions, sufficient downstream mixing and reaction time should be provided prior to insertion of

the sonde for monitoring. If pH adjustment is necessary, the sonde location should provide for

sufficient mixing and reaction time upstream of the location. Thus, if you question the ideal

location for monitoring, check your installation by manually testing upstream and downstream of

the sondes proposed location. It may prove that you can utilize “less-than-ideal” sonde location

in the flow stream, but take advantage of the location supports for mounting, proximity to the

monitor or other factors that may facilitate the installation.

The flow stream should be as free as possible of debris (e.g., algae) which could collect on the

sonde and cause erroneous readings.

Remember that this is an on-line device that is measuring actual conditions in real time.

Composite sampling for pH, for example, will not match on-line monitoring. Therefore, pH

values recorded by the chart recorder and/or plant control system connected to the 6500

Environmental Monitoring System cannot be averaged to equal the pH of the composite sample.

CHOOSING A MONITOR LOCATION

The sonde is a primary device that measures conditions in the flow stream and transmits a low

voltage signal to the 6500 Monitor. The sonde is attached to a cable that is equipped with a

“military grade” watertight connection to the monitor or optional breakout box.

Several optional accessories are available from YSI to make the 6500 Monitor extremely

versatile. The YSI #6502 Breakout Box is an enclosure for the connections interface between the

sonde cable(s) and customer supplied wiring and conduit which enables the sensor connection to

the monitor to be extended up to 250 feet. The YSI #6503 Breakout Box is the same as #6502,

but is also CE compliant for European users. The YSI #6504 Breakout Box is similar to the above

description, but can also handle two sondes. These Breakout Boxes makes it possible to install the

monitor in a location and environment different than the sonde(s). A YSI #6508 Junction Box is

also needed if the 6500 Monitor is installed with multiple sondes, or if a single sonde is farther

than 6 feet away.

YSI Incorporated 6500 Environmental Process Monitor 5

Page 10

Installation Section 2

SYSTEM

N

Note: The 6500 Monitor is provided with a weatherproof enclosure that will withstand most

environmental conditions with no compromise to system performance. An optional Weather

Shield (YSI #6505) is available for added protection from the elements.

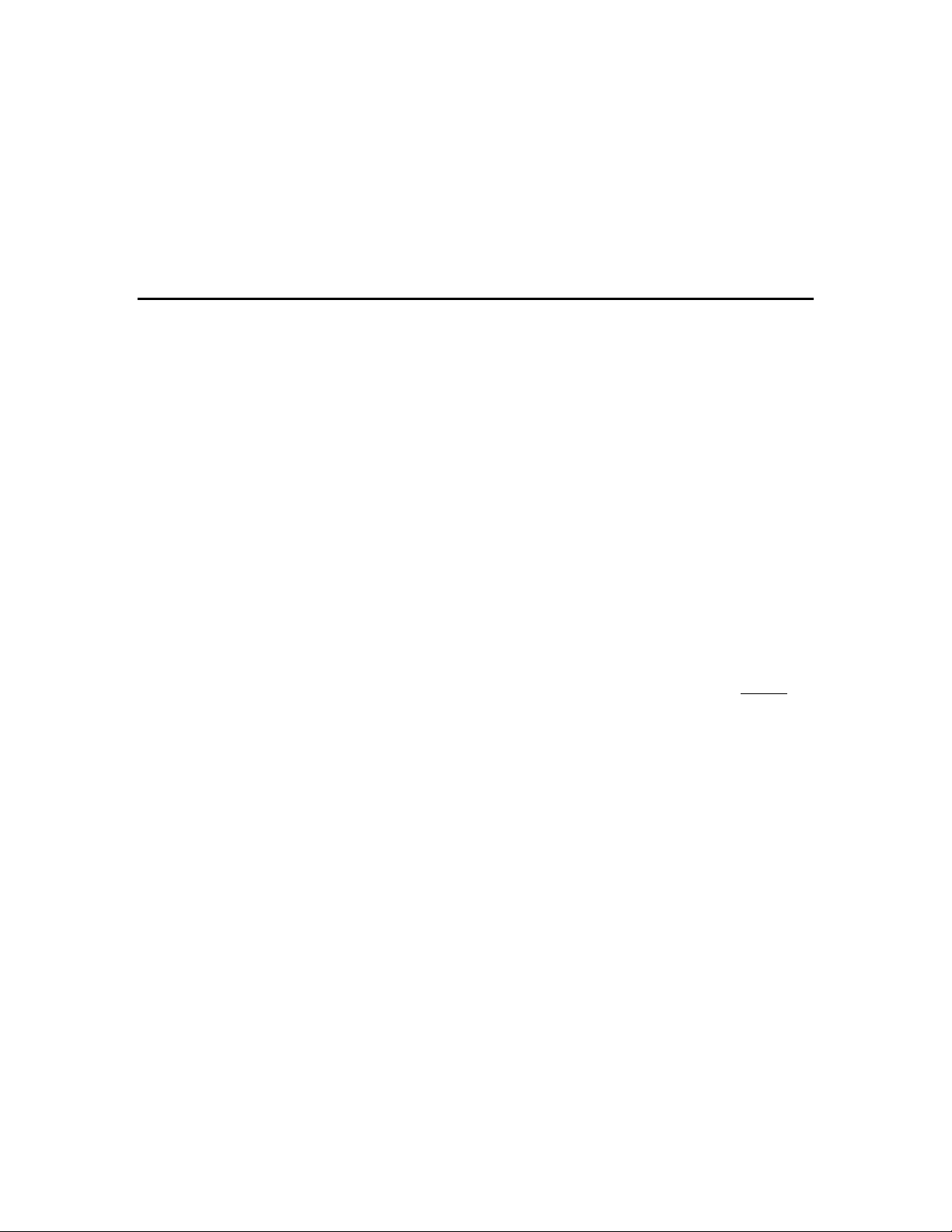

Figure 2 Monitor installed using sonde cable

6500 Monitor

21.2 Temp

6500

6500

ENVIRONM ENTALENVIRONMENTAL

7.35 DO

MONITORING

MONITORING

SYSTEM

6.53 pH

Esc

Cal

Enter

AC

Sonde

ot drawn to scale.

Stream

Locating the monitor near the sonde will have advantages since in-situ (on-line) calibration can

be more easily facilitated under this arrangement. For example, a recently calibrated, hand-held

dissolved oxygen meter and probe can be placed next to the sonde and readings compared

between the monitor and the hand-held meter. In addition, operator checks to verify accuracy and

determine the frequency of calibration for water quality measurement in the flow stream can be

easily carried out with a variety of hand-held manual readings at the time of inspection by the

operator if the monitor is conveniently located.

Two sondes, #6920 and #600XLM, have logging capability. These two sondes are able to store

recorded data into their memory, which then can be downloaded into a PC or Display/Logger. If

the 6500 cannot be connected to a system such as a SCADA, data can still be recorded using one

of these two sondes. The 6500 itself does not record data; it only displays real-time monitoring.

YSI Incorporated 6500 Environmental Process Monitor 6

Page 11

Installation Section 2

SYSTEM

N

Figure 3 Remote location of monitor relative to sonde

6500 Monitor

21.2 Temp

6500

6500

ENVIRONMENTALENVIRONMENTAL

7.35 DO

MONITORING

MONITORING

SYSTEM

6.53 pH

Esc

Cal

Enter

6508

Junction Box

Breakout Box

AC

6507

6’ Patch cable

w/ MS-8

Conduit &

customer-supplied

3-conductor cable

250’ Maximu m

ot drawn to scale.

sonde cable

w/ MS-8

Sonde

Stream

YSI also provides a means for convenient and accurate bench calibration of the sonde. Refer to

the Sonde Manual for bench calibration procedures. Bench calibration allows the operator to

easily disconnect the sonde from the monitor and then reconnect the sonde to a laboratory

computer or terminal device (YSI 610 display/logger). Under this protocol, the sonde can be

fully checked in a user-friendly environment, recalibrated and then redeployed. If the sonde is

equipped with a bulkhead connector rather than an integral cable, bench calibration is used.

If locating the monitor near the sonde is not possible due to environmental conditions and/or

accessibility, bench calibration provides a very good alternative to on-line calibration.

Although the monitor is suitable for outdoor use, it should be located in an area where

temperature extremes, vibrations, electromagnetic and radio frequency interference are minimal.

Select an installation location that is at least two (2) feet from any high voltage conduit. Avoid

mounting on severely vibrating structures. Be sure the monitor can be fully opened and serviced

at its installed location by maintenance personnel. Be sure the site has easy access for operating

personnel.

2.3 INSTALLING THE SONDE

After you have chosen suitable sites for the monitor and sonde, proceed with the installation as

described below.

Avoid routing sonde cabling near wiring associated with rotating machinery and/or equipment

involving electrical switching or regulation. Consider placing sonde cabling in grounded metallic

conduit if unstable readings appear due to electromagnetic interference.

YSI Incorporated 6500 Environmental Process Monitor 7

Page 12

Installation Section 2

L

L

A

A

RAIL MOUNT OPTION

The sonde can be mounted in a number of different configurations, but a rail mount with a

fabricated bracket is recommended. A rail mount kit is also available from YSI, #6511 for 600

series sondes, and 6512 for 6820/6920 sondes. See Appendix D, Accessories for more

information.

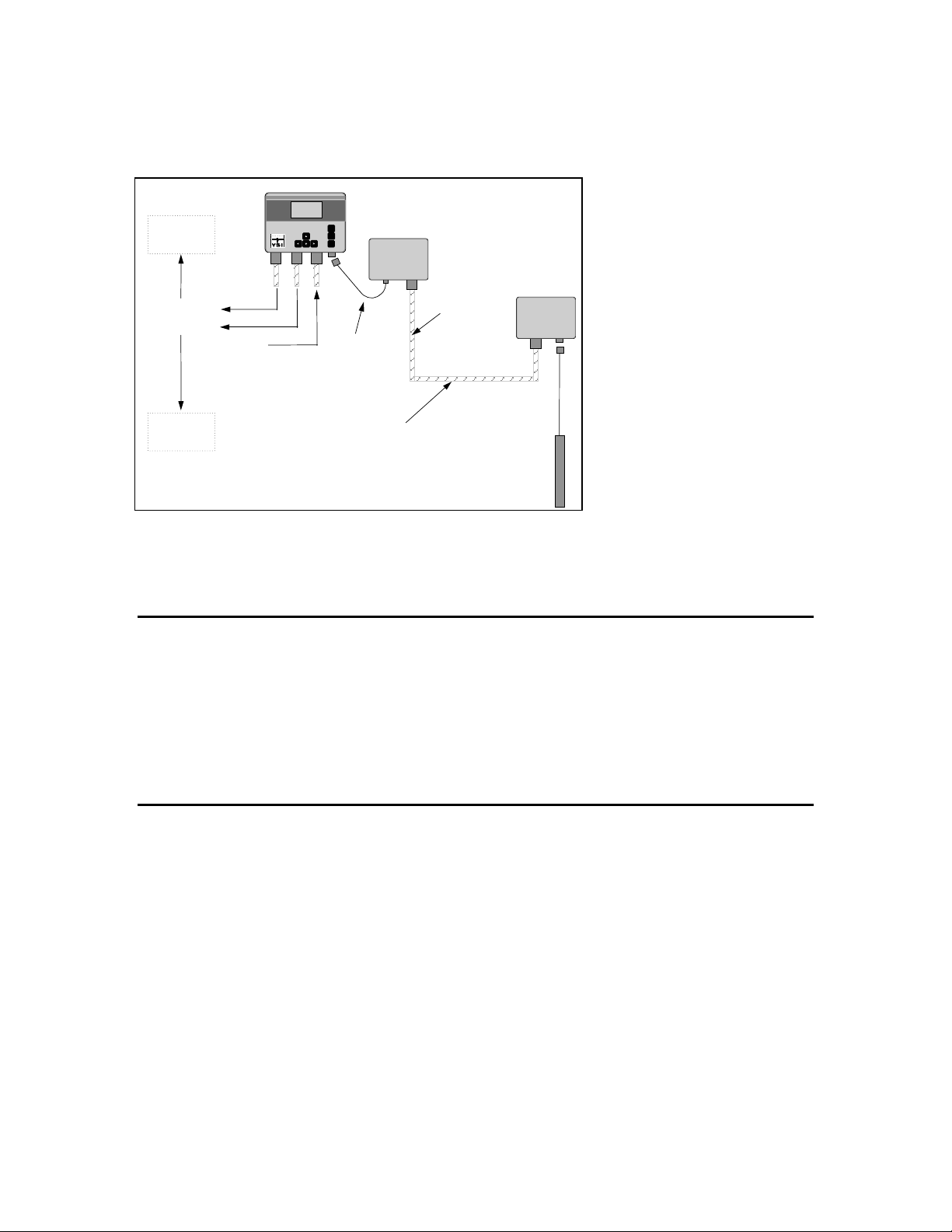

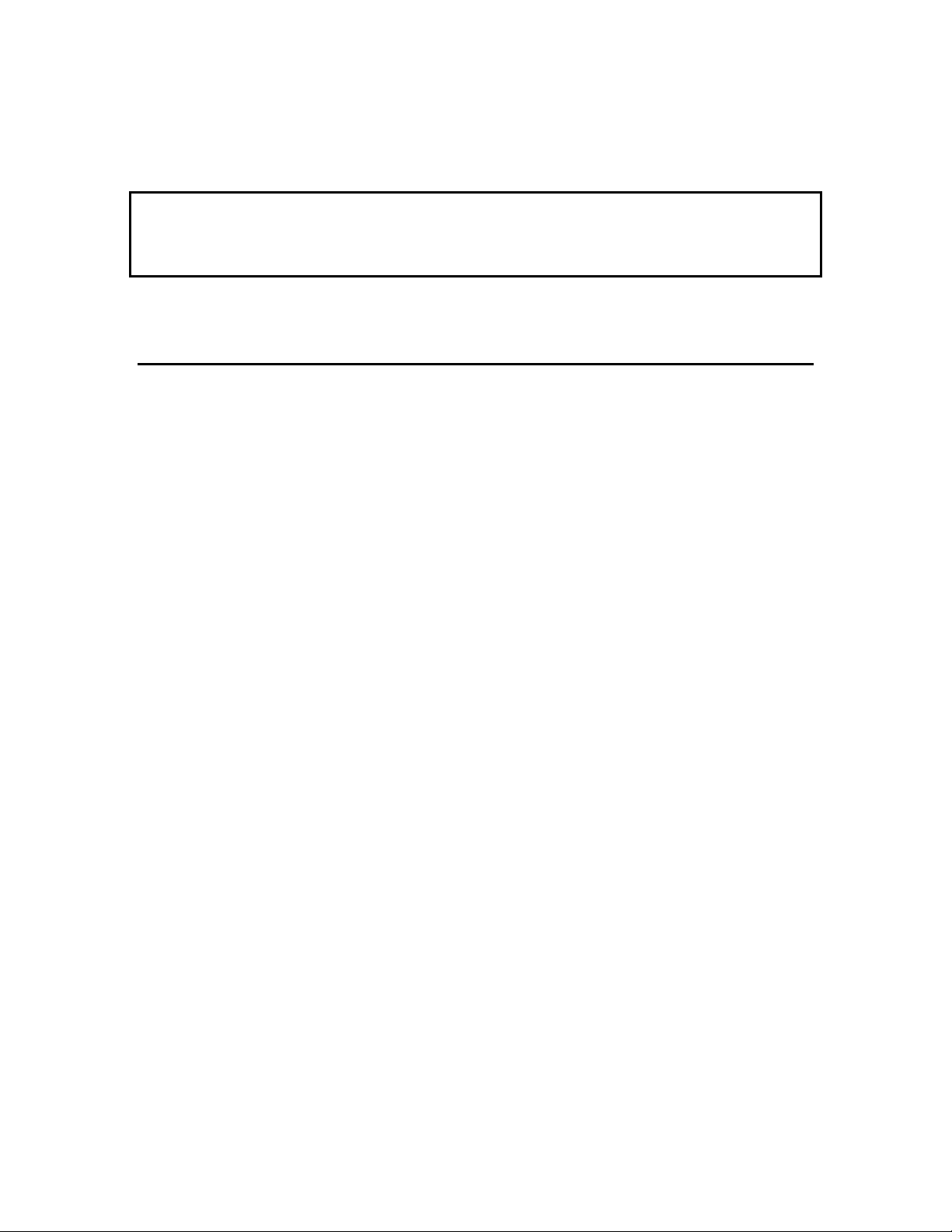

Figures 4 and 5 show the two common connection layouts and short and long-range wiring of the

monitor to the sonde.

Figure 4 Direct connection

21.2 Temp

6500

6500

7.35 DO

ENVIRON MENTA

ENVIRON MENTA

MONITORING

MONITORING

SYSTEMSYSTEM

6.53 pH

Esc

SCADA

Cal

Enter

4-20 mA out

sonde cable

Relay output

C power in

Sonde

Stream

larms

w/ MS-8

YSI Incorporated 6500 Environmental Process Monitor 8

Page 13

Installation Section 2

L

L

A

A

Figure 5 Sonde installed distant from the 6500 Monitor

SCADA

6500

6500

ENVIRONMENTA

ENVIRON MENTA

MONITORING

MONITORING

SYSTEM

SYSTEM

21.2 Temp

7.35 DO

6.53 pH

Esc

Cal

Enter

6508

Junction

Box

4-20 mA out

Relay output

larms

C power in

6507

6’ Patch cable

w/ MS-8

customer-supplied

3-conductor cable

conduit

Breakout

up to 250 ‘

sonde cable

w/ MS-8

Sonde

Stream

2.4 INSTALLING THE 6500 MONITOR

The 6500 Monitor should be located within 250-ft (75 m) of the sonde. The distance limit is

based on noise tolerance of the SDI-12 communication protocol. If you choose to install the

monitor more than the length of the sonde cable away from the sonde, additional hardware and

wiring will be necessary. A rail mount kit #6509, and panel mount kit # 6510 are also available

for the 6500 Monitor. See Appendix D, Accessories, for more information.

WALL MOUNTING OPTION

Although the monitor is designed for outdoor deployment, some operators may prefer the

convenience of reading the monitor under shelter, for example, inside a nearby building. Figure 4

shows this indoor type of installation. Wall-mounting the 6500 Monitor is a simple process using

the enclosed mounting hardware.

YSI Incorporated 6500 Environmental Process Monitor 9

Page 14

Installation Section 2

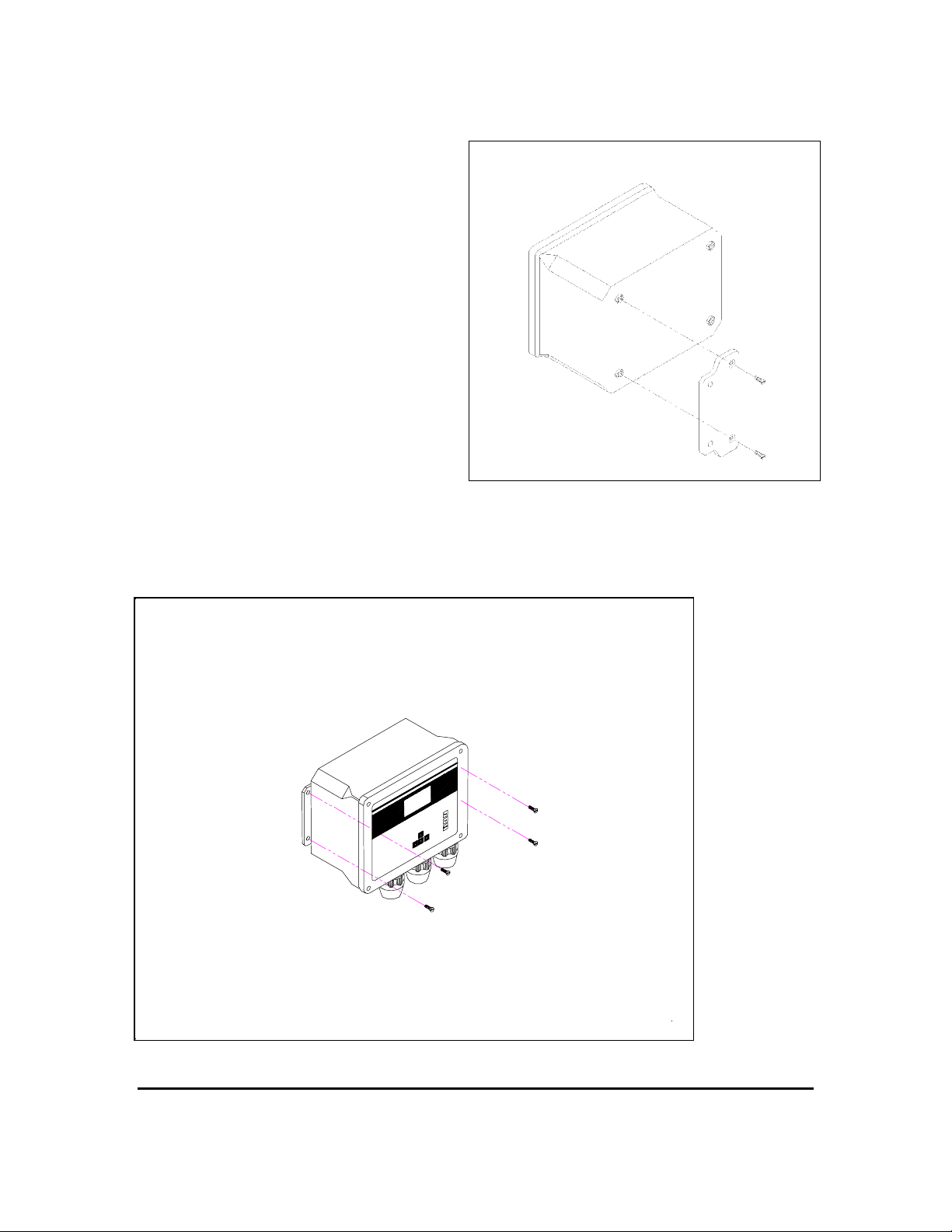

Figure 6 Attaching the Mounting Brackets

The following steps should be followed when

wall mounting the 6500 Monitor.

1. Loosely fasten the mounting brackets

(included) to the back of the 6500

Monitor with the mounting screws

provided as shown in Figure 6.

2. Tighten the screws, securing the

brackets to the Monitor.

3. Loosely fasten the 6500 Monitor to

the mounting surface with the

mounting screws provided as shown

in Figure 7.

4. Tighten the screws, securing the Monitor to the surface.

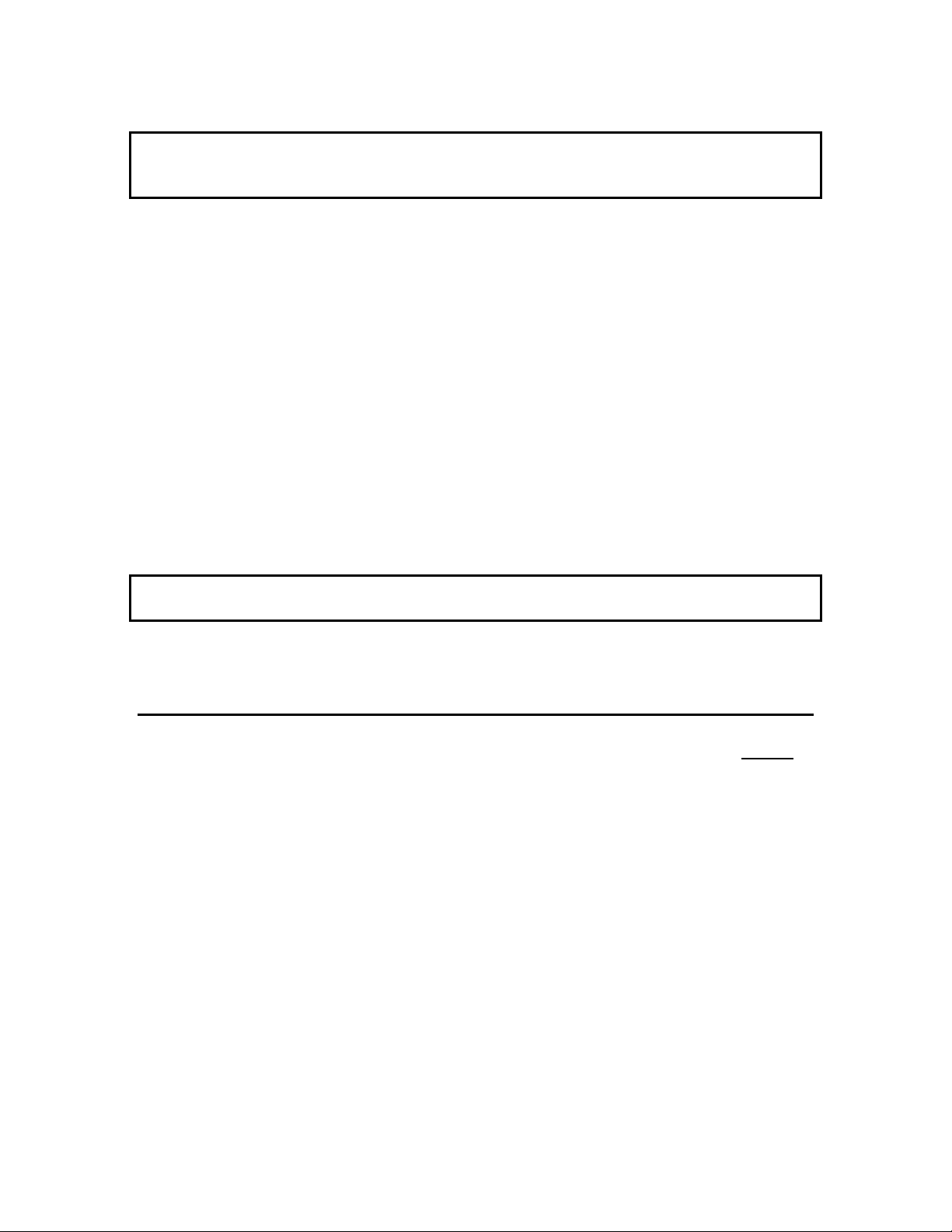

Figure 7 Securing the screws to the mounting surface

Wall Mount

2.5 WIRING INSTRUCTIONS

YSI Incorporated 6500 Environmental Process Monitor 10

Page 15

Installation Section 2

WARNING!

A qualified electrician should perform wiring.

Do not make connections while power is applied. Disconnect power before proceeding.

This particular phase of the installation will vary considerably depending on the distance between

the sonde and monitor and on which outputs you use in your particular configuration. In the

simplest configuration in which the sonde is connected using the sonde cable and neither the relay

outputs nor the 4-20 mA current loop outputs are used, only AC power wiring is required. The

sonde connects to the monitor by the MS-8 sonde cable connector, which is pre-wired. The end

connection of the cable is a military-style 8-pin connector (MS-8). If, however, the monitor is

more than the length of the sonde cable away from the sonde and either of the outputs is wired to

alarms or a SCADA system, additional wiring is required. Below are wiring instructions for all

parts of the 6500 Environmental Process Monitoring system.

The 6500 Monitor has one MS-8 connector and three conduit openings in the bottom of the

monitor housing which will accommodate ¾ inch conduit fittings. From a front view, the 2

conduit openings on the left are for the four relay outputs and the eight 4-20 mA outputs. The

conduit opening on the right should be used for the AC power supply cable. The MS-8 connector

is used to interface with the sonde cable in the close range system layout, or in the long distance

wiring layout, the optionally-supplied 6 foot (1.8 m) patch cable (YSI #6507) to the #6508

Junction Box. Refer back to Figure 3 to review the configuration options.

IMPORTANT!

It is essential that all sensor wiring be run in a separate conduit from power wiring.

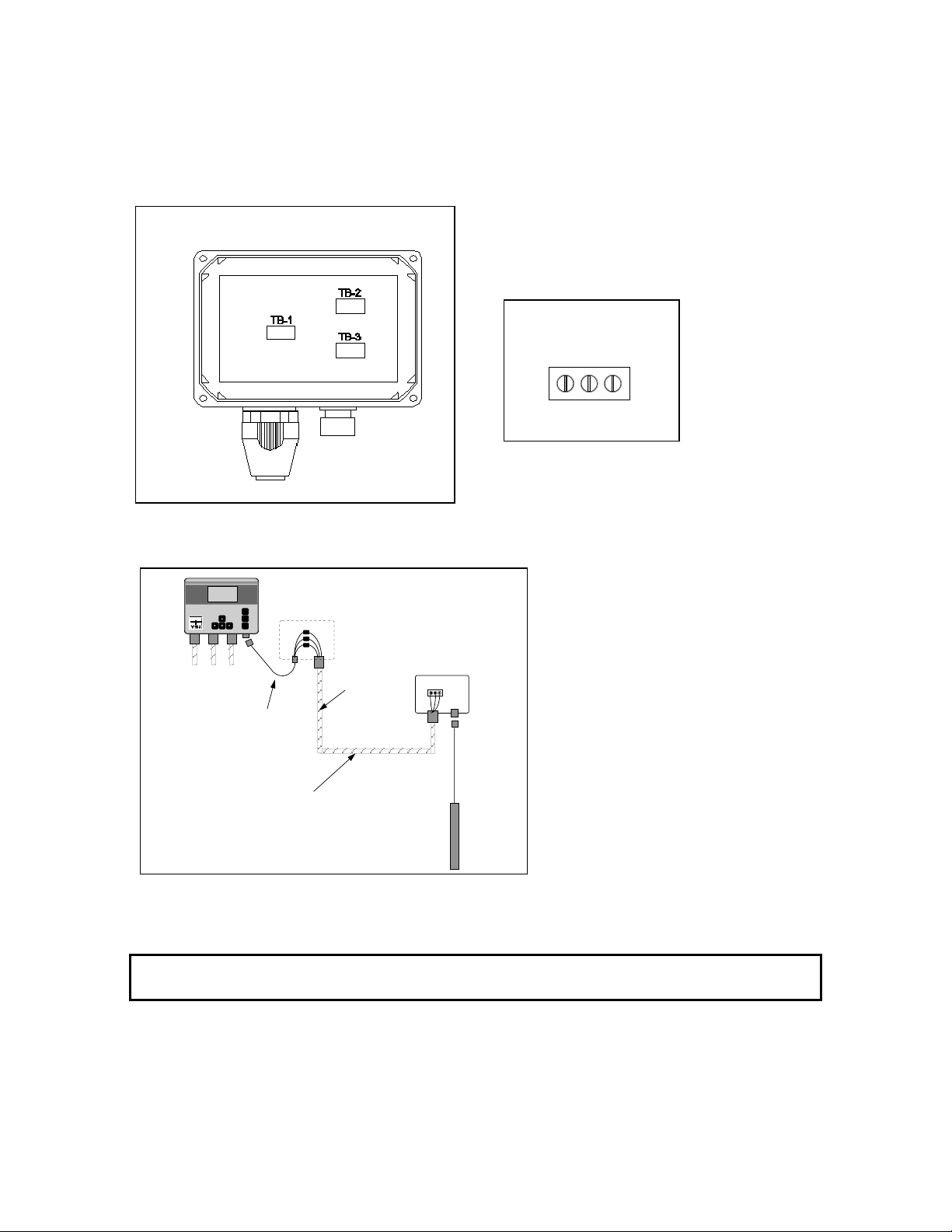

2.5.1 SONDE CABLE CONNECTIONS (SDI-12

COMMUNICATIONS LINK)

The sonde is equipped with a detachable or non-detachable cable. This connector plugs

into the 6500 Monitor when the 6500 Monitor is within range of the sonde cable. This

configuration is shown in Figure 2.

In remote sonde installations the 6500 Monitor uses a standard MS-8 connection to interface with

the 6-ft (1.8 m) Patch Cable (YSI #6507) that will run to the #6508 Junction Box. The customer

is advised to supply rigid conduit and 18 AWG or heavier shielded multi-conductor cable to

connect between the local junction box and the remote 6502 Breakout Box at the sonde

installation site. The cable from the Junction Box should be landed to TB-1 in the Breakout Box.

The MS-8 connector for sonde hookup is pre-wired to TB-2 and TB-3.

directly

YSI Incorporated 6500 Environmental Process Monitor 11

Page 16

Installation Section 2

L

3

2

2

SDI

The 6507 Patch Cable is pre-wired. The conductor color code is: Red +12 VDC

Black Common

Purple SDI-12

6502, Front Cover Removed

Figure 8

Connector TB-1

detail

6500

6500

ENVIRONMENTALENVIRONMENTA

MONITORINGMONITORING

SYSTEMSYSTEM

21.2 Temp

7.35 DO

6.53 pH

+12 VDC

GND

SDI-12

TB-1

132

MS-8 to sonde

3/4” conduit to jct box

6508

Junction

Esc

Cal

Enter

Box

Breakout

+1

VDC

-

12

w/ MS-8

Sonde

GND

TB-1

1

6507

6’ Patch cable

w/ MS-8

customer-supplied

3-conductor cable

conduit

up to 250 ‘

sonde cable

Stream

IMPORTANT!

GND on TB-1 is for signal common only. Do not connect to earth ground.

YSI Incorporated 6500 Environmental Process Monitor 12

Page 17

Installation Section 2

A

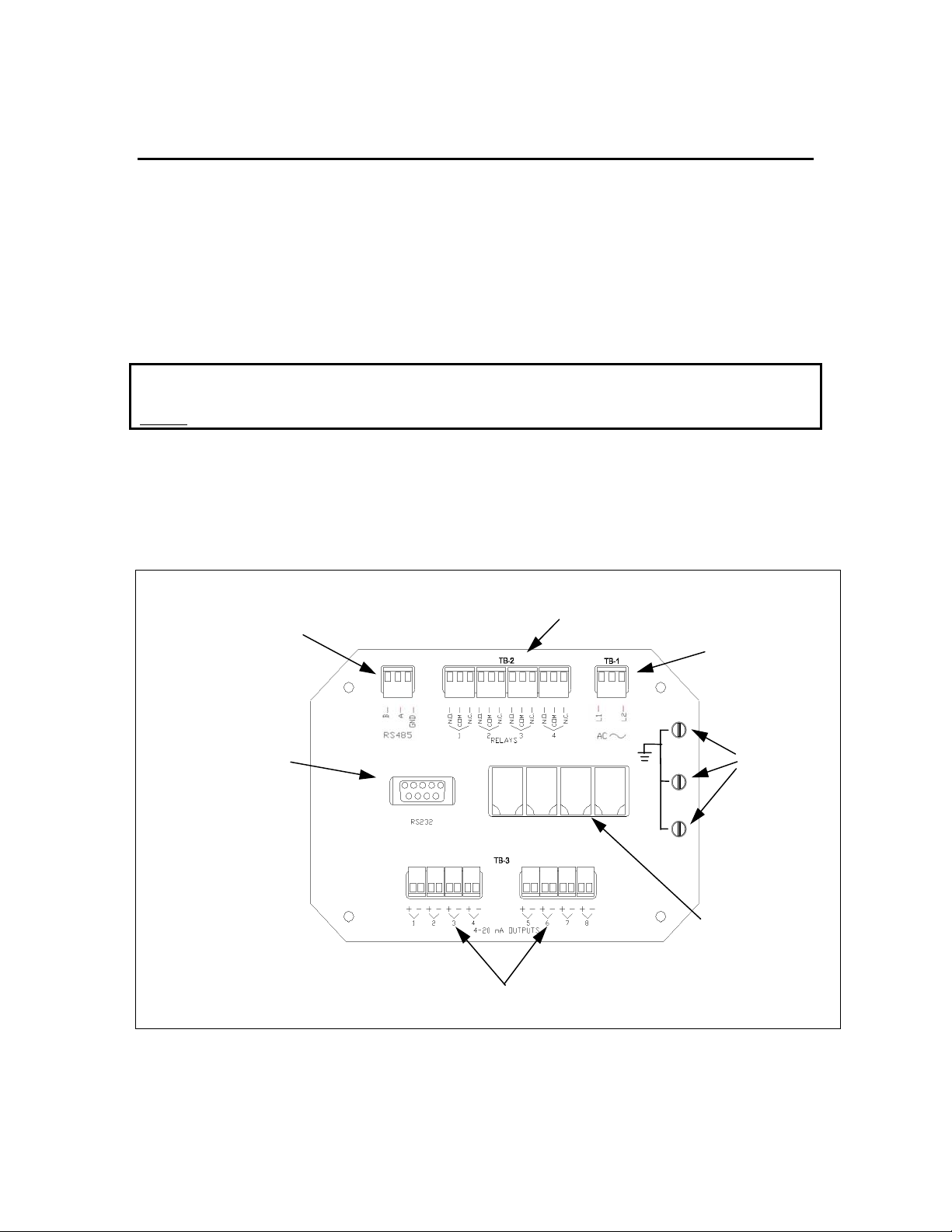

2.5.2 AC POWER INPUT WIRING

The 6500 Monitor has a switching power supply and can operate on 100 to 240 VAC power.

When you remove the front panel of the 6500 Monitor, take care not to drop the cover since it is

not hinged to the Monitor. Refer to figure 8 for power installation.

Connect AC power to TB1-1, L1 and L2. Connect ground wire to one of the three 10-32

grounding screws using a lug (not provided). To meet compliance with UL3010, EN61010 and

CSA1010, install a power switch on the AC load line external to the 6500 Monitor (Note: AC

on/off power switch is not included with the 6500 Monitor package).

CAUTION!

The sensitivity and stability of the monitor will be impaired if the input wiring is not grounded.

Do not apply power to the Monitor until all electrical connections are verified and secure.

Figure 10 6500 Terminal Connections (6500 Cover Removed)

RS485 for

Modbus

RS232 for Modbus and

software upgrades

B-A-

G

N

8-pin connectors (2)

for 4-20 mA outputs

Single 12-pin connector

for relay outputs

C Power

connector

L1 L2

Grounding

Screws (10-32)

Relays (4)...

soldered to PCB

YSI Incorporated 6500 Environmental Process Monitor 13

Page 18

Installation Section 2

Use the following precautions from UL 508 as a guide to safety for personnel and property.

¾ AC connections and grounding must be in compliance with UL 508 and/or local electrical

codes.

¾ The metal stiffener provides support and proper electrical continuity between conduit fittings.

¾ This type 4/4X enclosure requires a conduit hub or equivalent that provides watertight

connection, REF UL 508-26.10.

¾ Watertight fittings/hubs that comply with the requirements of UL 514B are to be used.

¾ Conduit hubs are to be connected to the conduit before the hub is connected to the enclosure,

REF UL 508.26.10.

¾ If the metal support plate is not used, plastic fittings must be used to prevent structural

damage to the Monitor. Also, the appropriate grounding lug and AWG conductor must be

used with the plastic fittings. When using plastic connectors and non-metallic liquid-tight

conduit note that the maximum conduit run length is 6 feet, REF NEC351-23-b3.

2.5.3 RELAY OUTPUT WIRING

The four (4) output relay connections are made to terminals 1 through 12 of TB-2. Relays may be

wired normally open (N.O.) or normally closed (N.C.). Use appropriate wire in terms of gauge

and insulation to adequately handle the voltage and current being switched by the relays. See

Appendix A, Specifications, for relay specifications. Do not use power at TB-1 as a source for

any of the relays in the 6500 system. Remember that relays are intended to activate alarms,

phone dialers and similar devices. The relays are

4-20 MA CURRENT LOOP OUTPUT WIRING

The eight (8) 4-20 mA current output connections are made to TB3-1 through TB3-16. Use

Belden cable #8164 (4-conductor), #8168 (8-conductor) or equivalent between the 6500 Monitor

and the SCADA or recorder site.

RS232 AND RS485 TERMINALS

The RS232 port is used for 6500 Monitor software updates and optional Modbus interface. The

RS485 port can also be used for an optional Modbus interface. Neither of these connectors is

involved in the installation of the 6500 system.

not intended to switch heavy loads.

YSI Incorporated 6500 Environmental Process Monitor 14

Page 19

Installation Section 2

2.5.4 GROUNDING INFORMATION

This section contains important installation information regarding grounding of the 6500 Monitor

and 6-Series Sonde. The sonde is powered by the 6500 Monitor or by batteries (depending on

which sonde you have chosen) and will be operated with a “floating” ground reference. This

requires that the sonde

cause a “ground loop”; i.e. one conductor of the sonde output grounded common to both the

sonde and the meter. Grounding the sonde will cause significant performance problems with the

sensors and likely result in erroneous readings.

not be individually grounded. Grounding the sonde individually will

IMPORTANT!

Do not ground the sonde body.

2.5.5 SAFETY ISSUES

The electrical system must be grounded to avoid possible electrical shock or damage to the

equipment.

WARNING!

Turn off all power and assure power “lockout” before servicing to avoid contact with electrically

powered circuits.

To avoid possible electrical shock, do not touch other circuit components when making

adjustments to the 6500 Monitor circuit board. Disconnect external power to the unit before

connecting or disconnecting wiring.

2.5.6 LIGHTNING AND SURGE PROTECTION

Surge protectors are strongly recommended to protect from secondary surges and lightning on

outdoor installations.

Surge suppression devices should be located on the AC line supplying power to the 6500 Monitor

and any signal lines connecting the 6500 Monitor to alarms, a SCADA or other data collecting

device.

AC line voltage surge suppressors protect field equipment on any AC line to ground from damage

due to electrical transients induced in the interconnecting power lines from lightning discharges

and other high voltage surges. The unit should include noise filtering, common mode and normal

YSI Incorporated 6500 Environmental Process Monitor 15

Page 20

Installation Section 2

mode suppression and nanosecond reaction time. Surge suppressors should be internally fused to

remove the load if the unit is overloaded or the internal protection fails.

Signal line suppressors protect 4-20 mA DC current loops, low voltage signals and relay outputs

from damage due to electrical transients induced in the signal lines from lightning discharges or

nearby electrical devices. Signal line suppressors should be installed at each end of an analog

loop. Relay outputs should be protected at the receiver end. Signal line suppressors should

consist of a three-element gas tube followed by metal oxide varistors and suppressor diodes. The

protective elements should be matched such that high-energy surge voltages trigger the gas surge

arrester, while low energy or surge voltages affect the MOV’s and suppressor diodes.

Lightning protection devices should be located as close to the sonde and monitor as possible and

wired in accordance with the National Electric Code in approved watertight enclosures. If the

distance between the sonde and the 6500 Monitor is less than 100 feet, only one protector per line

is needed, otherwise lightning protection should be installed at both ends of the wiring runs.

IMPORTANT NOTICE

This or any other installation procedure can not protect against a direct lightning strike. YSI

Incorporated cannot accept liability for damage due to lightning or secondary surges.

2.6 SEALANTS, DESICCANTS AND SECURING THE MONITOR

Since the 6500 Monitor, Breakout Box(s) and/or Junctions Box will likely be subjected to

environmental conditions that promote formation of condensation, it is very important to follow

the instructions below before securing the cover to your unit(s). This will prevent damage to the

electronic components within the Monitor and extend the life of the monitoring system.

Enclosed with shipment of every 6500 Environmental Monitoring System is industrial

encapsulant (conduit sealer), in a cartridge for your convenience. After all wiring is complete

apply the sealant to the conduit openings from the inside of the 6500 Monitor, Breakout Box

and/or Junction Box if applicable. This will help prevent moisture from entering the inside of the

6500 Monitor from conduit that was used for AC power cable or signal cables.

Note: If any of the conduit fittings were not used in the installation, remove the fitting and

replace with a 3/4” knockout plug provided with the unit. Two knockout plugs are provided.

Also enclosed with the 6500 Monitor is a box of desiccant packs. After all wiring is completed

and sealant applied, place two desiccant packs inside, near the bottom right of the Monitor before

securing the cover. This desiccant will consume any moisture captured during the closure to

provide a low humidity environment within the Monitor.

To complete the installation secure the cover of the 6500 Monitor using the four mounting screws

that you removed while doing the wiring operations. Note that the cover contains a captured

rubber gasket that provides the weatherproofing. Make certain that the gasket is in place and not

damaged. Check to make certain that the large blue ribbon cable is not trapped in the gasket

YSI Incorporated 6500 Environmental Process Monitor 16

Page 21

Installation Section 2

channel before inserting the screws. When securing the screws, take care not to cross thread.

The screws are stainless steel, and the receiving threads are brass. Do not over-tighten!

IMPORTANT!

Anytime the 6500 cover is removed, replace the desiccant packs with new packs.

Anytime the 6500 front panel is removed, place it on top of the 6500 Monitor

or secure it so that the blue ribbon cable does not bear the weight of the cover.

2.7 INSTALLATION CHECK LIST

9 Inspect packaging for damage

9 Verify that all components are included

9 Determine optimum mounting location for 6-Series Sonde based on process parameters being

measured

9 Determine optimum mounting location for 6500 Monitor

9 Determine preferred sonde location and fabricate mounting plate if necessary

9 Mount the sonde

9 Determine preferred monitor mounting location

9 If monitor is not located near sonde, mount junction box for the patch cable near the monitor

9 If monitor is not located near sonde, mount breakout box near the sonde deployment site

9 Make wiring connections for sonde

9 Make wiring connections for relays

9 Make wiring connections for 4-20 mA loops

9 Make wiring connections for AC power, including an AC power switch external to the unit

9 Apply industrial capsulant to conduit fittings

9 Insert desiccant pack(s) into 6500 Monitor

9 Reinstall front cover to 6500 and, if necessary, the 6502, 6504 or 6508

9 Verify that all wiring connections are secure and that the sonde is properly located in the flow

stream

9 Recheck grounding and surge protection installations

9 Connect calibrated sonde to mounting fixture and place in stream

9 Connect sonde cable to 6500 or 6502 or 6504

9 Allow sonde circuitry and sensors to warm up for several minutes before checking readings

YSI Incorporated 6500 Environmental Process Monitor 17

Page 22

Installation Section 2

YSI Incorporated 6500 Environmental Process Monitor 18

Page 23

SECTION 3 SYSTEM SETUP

This section is designed to quickly familiarize you with the hardware and software components of

the 6500 Monitor, the 6-Series Sonde and the overall system. You will learn about cable

connections and basic communication between the 6-Series Sonde and the 6500 Monitor.

Diagrams, menu flow charts and basic written instructions will guide you through basic hardware

and software setup. For the first time user, we encourage the reading and understanding of the 6Series Sonde Operations Manual, with regard to the specific sonde that you own, before

proceeding with the 6500 Monitor setup.

Before you begin 6500 Monitor Setup, you must setup the sondes:

9 Install the dissolved oxygen membrane

9 Install the sonde’s probes

9 Learn how to access sonde software

9 Calibrate the sonde sensors

9 Learn how to take readings with the sonde

These instructions are in the 6-Series Sonde Operations Manual, which was provided with your

sonde, Section 2.

Successful completion of the above list is essential for you to continue on to Section 3 of the 6500

Environmental Process Monitor Operations Manual.

3.1 SYSTEM CONFIGURATION

The most common configuration for the system which you have purchased involves direct

interaction of the 6500 Monitor with the 6-Series Sonde, but there are also ways in which you

may configure the 6-Series Sonde with various computers or handheld data displays. The latter

configurations are primarily used when setting up and calibrating your sensors in the laboratory.

If you calibrate your sensors in the laboratory while the sonde is disconnected from the 6500

Monitor, you should make certain that you have all of the components you need to make your

system work. See your sonde manual for other possible configurations.

Page 24

System Setup Section 3

A

Sonde to 6500 Monitor

21.2 Temp

6500

6500

7.35 DO

ENVIRONMEN TAL

ENVIRONMENTAL

MONITORINGMONITORING

6.53 pH

SYSTEM

SYSTEM

Esc

Cal

Enter

C power in

4-20 mA out

Relay output

Sonde

MS-8

You will need...

T

Sonde and cable

T

60

0

6500 Monitor

T

AC Power

T

Mounting Hardware

3.2 6-SERIES SONDE SETUP

The 6-Series Sonde contains a powerful computer that allows the sonde to be configured for use

with the 6500 Monitor. It is important to remember that the sonde setup information and

calibration data are stored in the 6-Series Sonde and not in the 6500 Environmental Process

Monitor. With this in mind, the following sections are designed to assure proper setup of the 6Series Sonde software prior to deployment. This can be accomplished by two different methods:

1. Interface of the 6-Series Sonde with the 6500 Monitor via the matching MS-8

connectors on the sonde cable and the 6500 enclosure. To carry out this procedure,

the 6500 Environmental Process Monitor must be installed in its permanent location

with AC line power properly installed as described by local electrical codes.

2. Interface of the 6-Series Sonde with a laboratory computer or 610 display/logger. If

a computer is selected for setup, you must employ a YSI #6095B DB-9 to MS-8

adapter and a YSI #6038 external power supply with MS-4 connector that plugs into

any 110 VAC outlet. If your sonde does not have an integral cable, it will require a

#6067B calibration cable. All of these accessories are optional and must be ordered

separately. After using this method to calibrate the sonde, proceed to section 3.3,

6500 Monitor Setup, in this manual.

Method 2 (above) is recommended. However, either method will result in identical setup of the

6-Series software. Instructions for the sonde calibration in a laboratory set-up are found in the 6Series sonde manual. Choose only one of the two methods for calibration.

When installation of the 6500 Monitor is complete and power is supplied, connect the 6-Series

Sonde to the 6500 Monitor via the matching MS-8 connectors. When power is applied to the

YSI Incorporated 6500 Environmental Process Monitor 20

Page 25

System Setup Section 3

6500 Monitor, a “YSI” display will momentarily appear on the 6500 screen followed by display

of actual parameter readings.

6500

6500

ENVIRONMENT AL

ENVIRONMENTAL

MONITORING

MONITORING

SYSTEM

SYSTEM

7.35 DO

6.53 pH

Esc

Cal

Enter

Multiple sondes may be attached to the 6500 Monitor using the optional 6504 Breakout Box. See

Appendix D, Accessories, for more details.

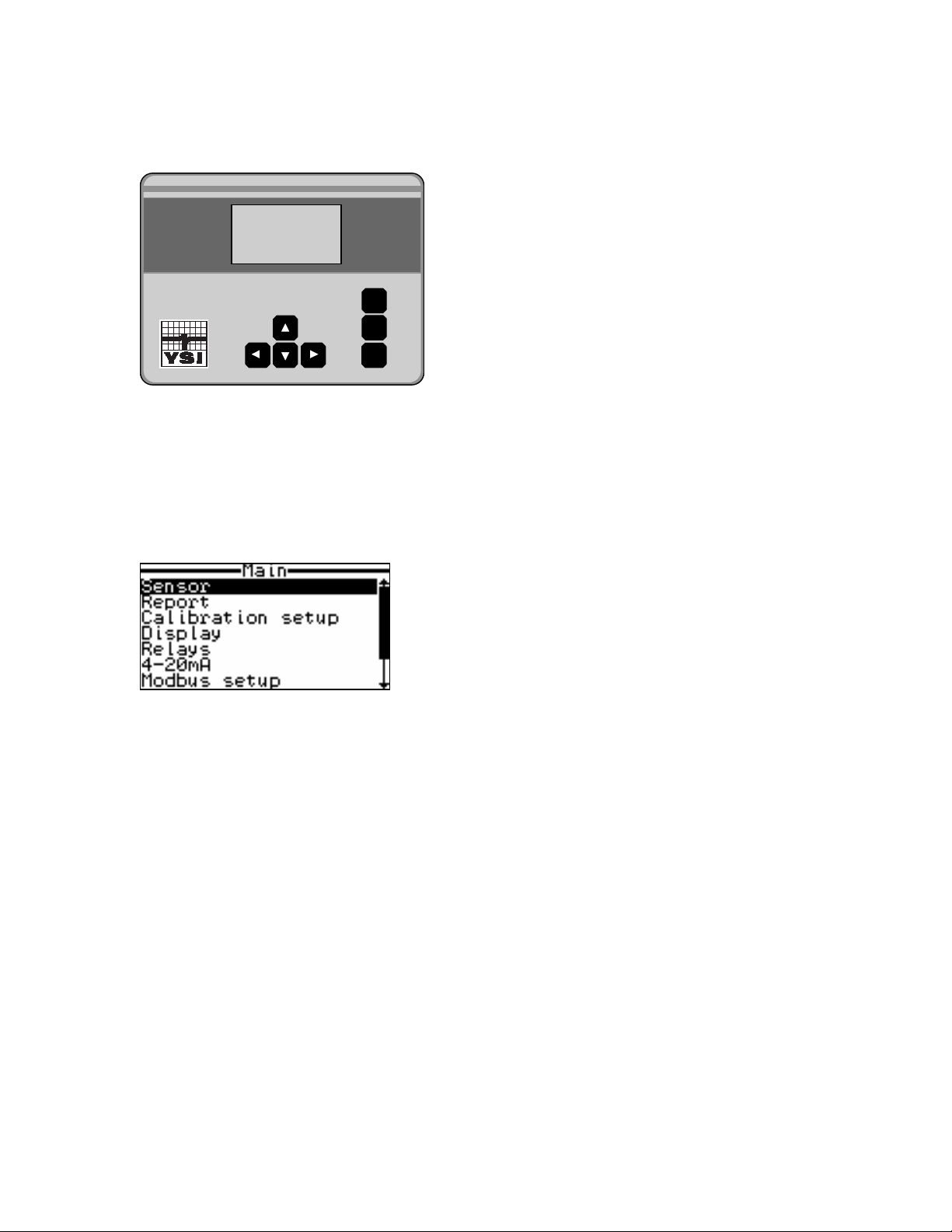

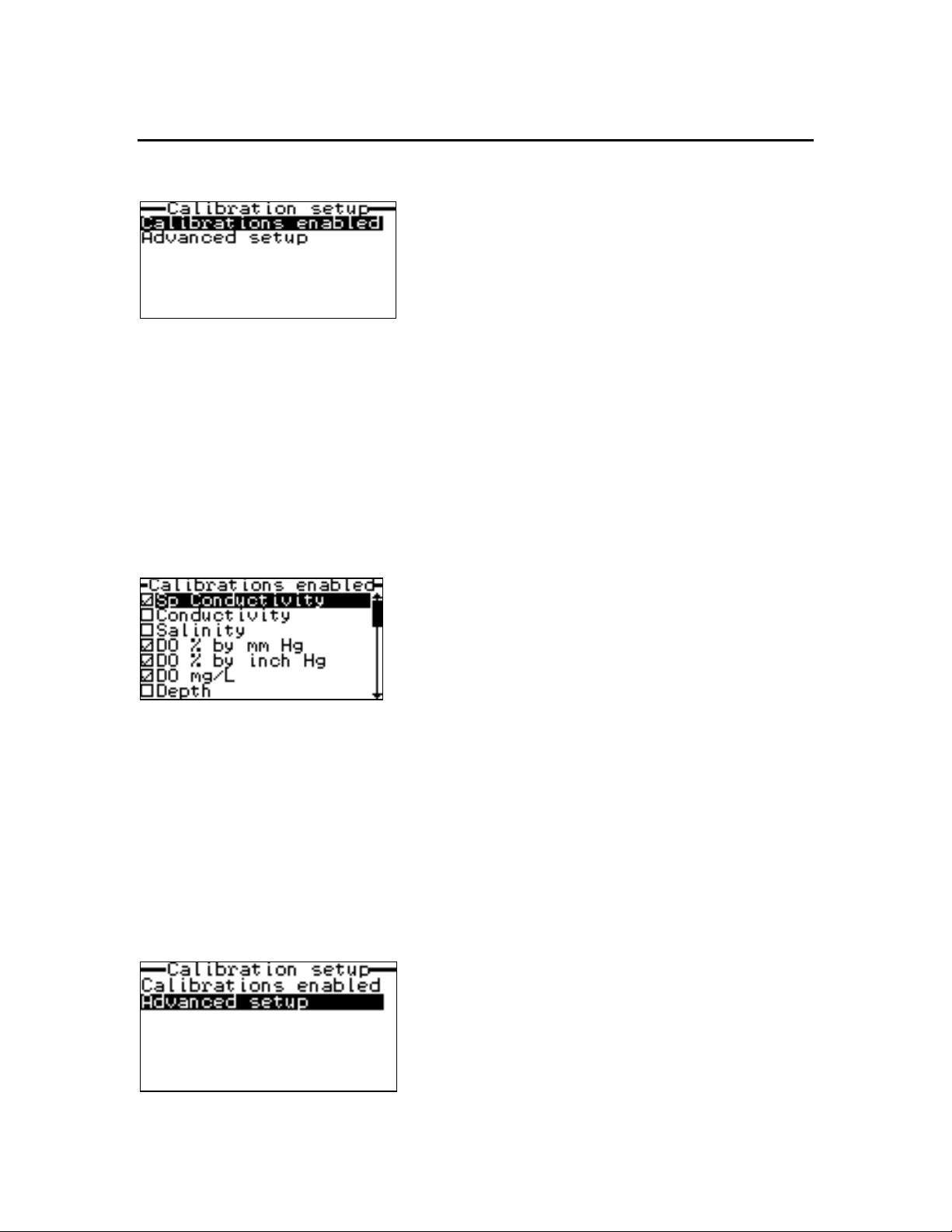

Setup of both the sonde and monitor is achieved through use of the Main menu associated with

the 6500 software. The Main menu is accessed by simultaneously pressing the Esc and Enter

keys for 1 second after the parameter display is active. The Main menu contains the submenu

options as shown in the following display.

21.2 Temp

Use the ↑↓ arrow keys to highlight the submenu options. Press Enter to select a highlighted

option.

YSI Incorporated 6500 Environmental Process Monitor 21

Page 26

System Setup Section 3

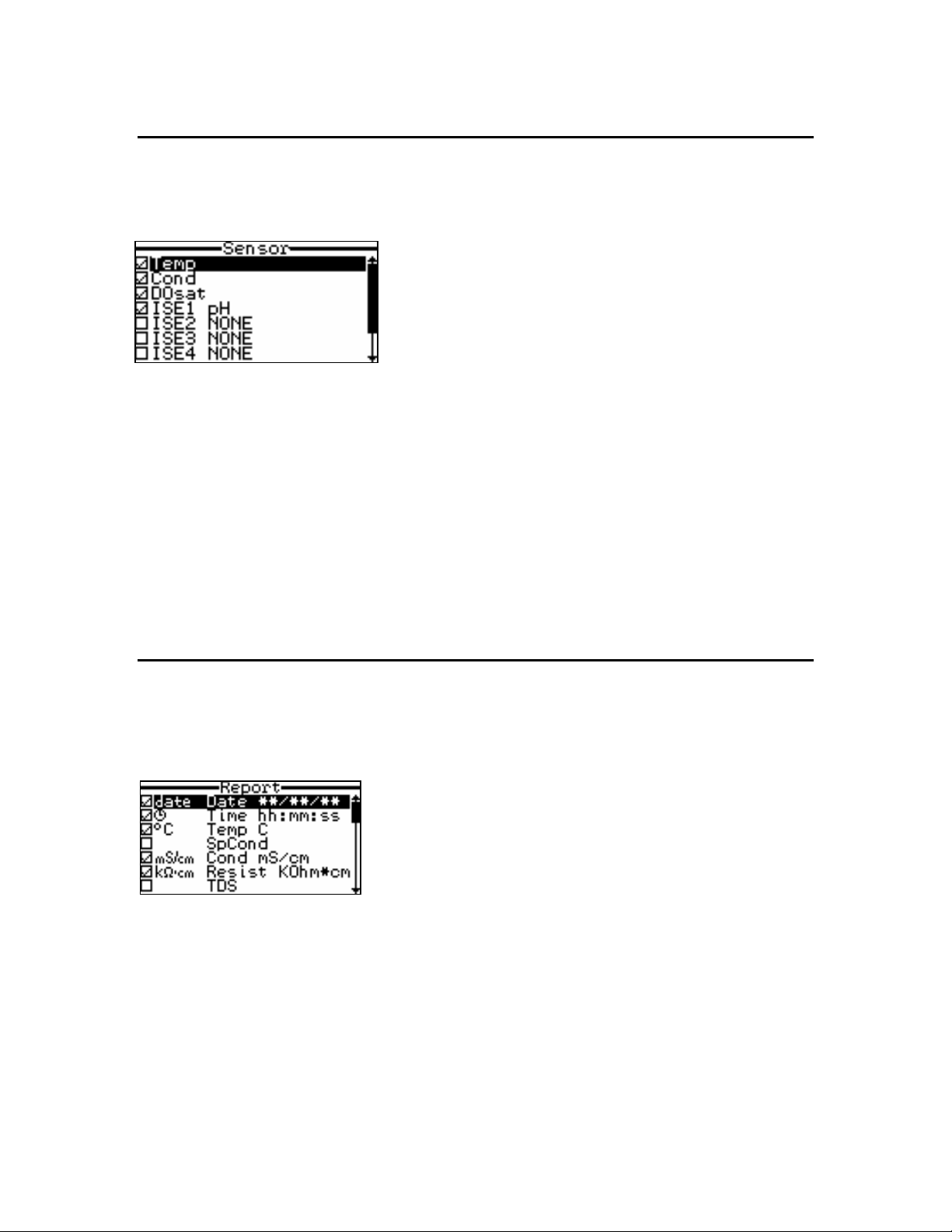

SENSOR

The first step that should be taken in setting up the sonde is to enable the proper sensors. This is

accomplished by highlighting the Sensor selection and pressing Enter. The following display will

appear.

The Sensor Menu allows the user to enable or disable any of the available sensors. Selected

sensors have a check mark next to them. Using the ↑↓ arrows to highlight items, the Enter key

will toggle selections on and off. When an item is selected, it is enabled and will be functional

when the system is activated. When a sensor is activated, this parameter and some of the

calculated parameters associated with the sensor will also automatically appear in the Report

function described below.

In the above example, the temperature, conductivity, dissolved oxygen, and pH sensors are

activated. ISE2, ISE3, and ISE4 are shown. ISE5, depth and turbidity can be found by scrolling

down the display.

REPORT

After the appropriate sensors are enabled, press Esc to return to the Main menu and then highlight

the Report selection and press Enter. The Report menu is used to select the displayed parameters

and units of measure. The following screen will be displayed.

The Report menu allows the user to configure the 6500 display readouts. A list of the possible

parameters and the currently selected units for each parameter will appear. The user can select a

displayed parameter using the ↑↓ arrows to highlight. When the desired parameter is highlighted,

the user can press Enter to display the Select Units menu for the specified parameter. The

following screen will be displayed.

YSI Incorporated 6500 Environmental Process Monitor 22

Page 27

System Setup Section 3

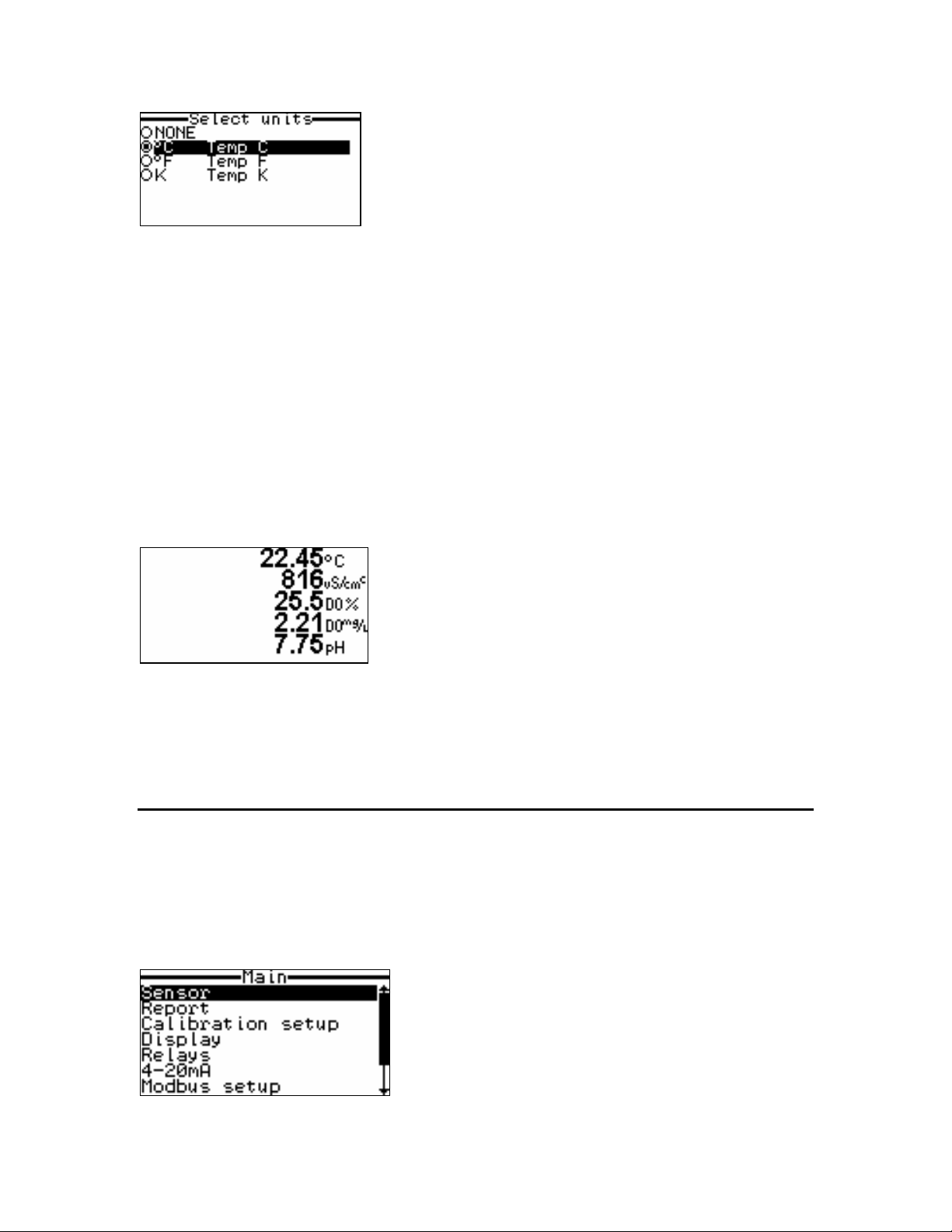

In the above example, the temperature parameter has been selected. The user can select a

displayed unit using the ↑↓ arrows to highlight. If the user selects NONE, the temperature

parameter will not appear in the report. When the desired selection has been made, press enter to

activate the change. In this example, temperature in degrees Celsius has been designated for

display and will appear on the display when the 6500 Monitor is in the Run mode. The main

report menu will then reappear and reflect the change just made. Although not shown, unit

changes to other parameters (conductivity, specific conductance, resistivity, TDS, depth, volume)

can be made by using the arrow keys to scroll downward to display these selections and the Enter

key to activate the Select Units menu. The appropriate unit selections can then be made.

After you have chosen the appropriate sensors and report parameters associated with your 6Series Sonde, it is now configured properly for display of the desired parameters in the Run mode

of the 6500 Monitor. To assure that everything is correct, press Esc until the Run display (similar

to that shown below) appears on the 6500 screen.

If you are connecting multiple sondes to your 6500 Monitor, please see section 3.3.6 for

instruction on multiple sonde configuration.

3.3 6500 MONITOR SETUP

After proper setup of your 6-Series Sonde, you must configure the options offered with the 6500

Monitor. It is not required that the sonde be attached to the monitor to implement this setup

procedure.

With ac line power applied to the 6500 Monitor, press the Esc and Enter keys simultaneously for

1 second to display the Main 6500 menu on the monitor display.

YSI Incorporated 6500 Environmental Process Monitor 23

Page 28

System Setup Section 3

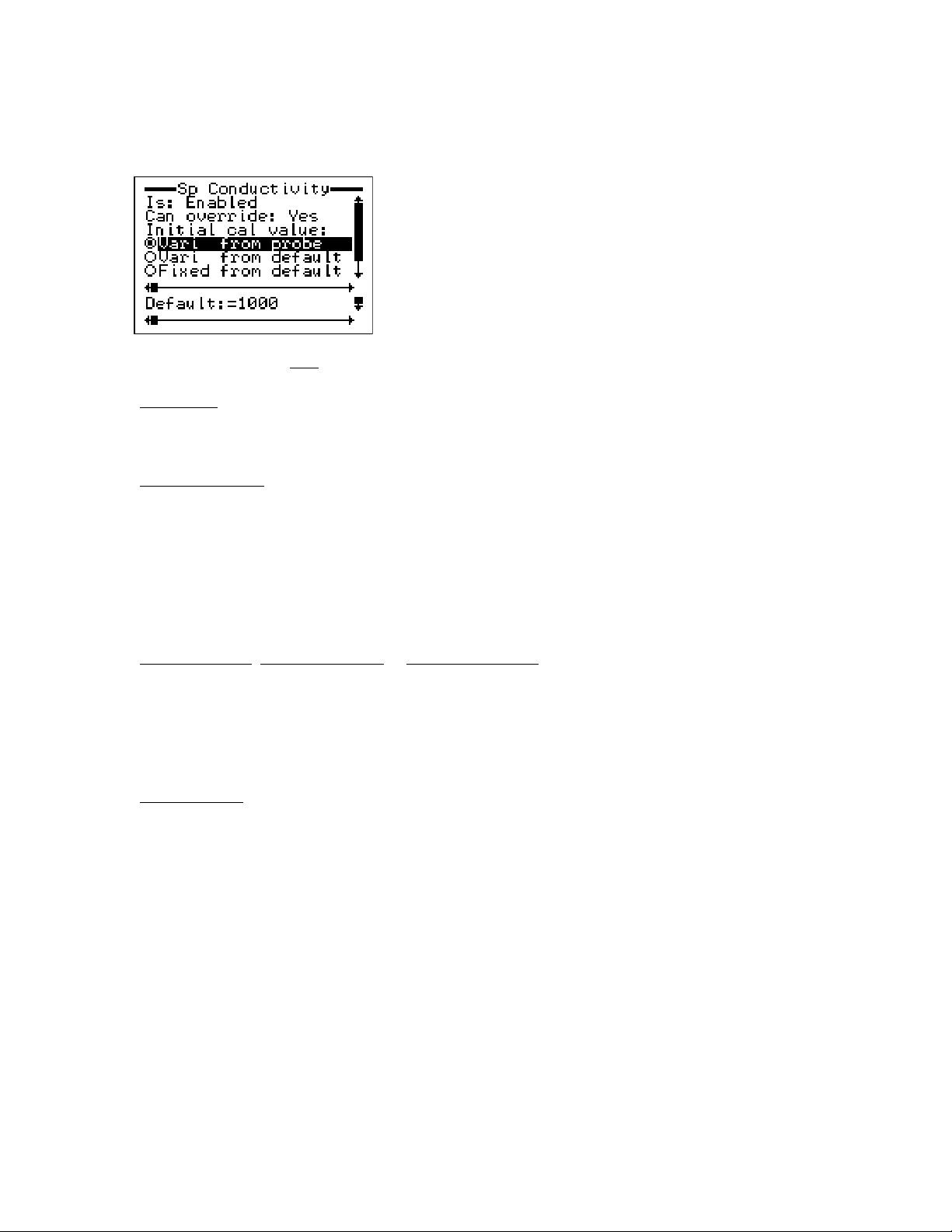

3.3.1 CALIBRATION SETUP

Highlight the Calibration setup selection and press Enter. The following screen will be displayed.

The Calibration Setup submenu presents two items:

(1) Calibrations enabled is a list of all possible sensor calibrations that can either be enabled or

disabled with regard to calibration from the Run mode.

(2) Advanced setup is a selection that allows the user to choose whether calibration errors can be

overridden and defines the default calibration value that will appear on the display during the

calibration protocol.

Highlight the Calibration enabled selection, press Enter, and the following screen will be

displayed.

Once a calibration is selected as indicated by the check mark, that sensor may be calibrated using

the Cal key during the Run mode. The user can select and deselect items using the ↑↓ arrows to

highlight and press Enter to toggle selections on and off.

In the example shown above, the parameters specific conductance, DO % air saturation, DO mg/L

(dissolved oxygen in mg/L concentration units) can be calibrated during the Run mode of the

6500. This selection will NOT allow calibration of conductivity or salinity even if these readings

appear on the display.

Press Esc to return to the Calibrate setup menu.

YSI Incorporated 6500 Environmental Process Monitor 24

Page 29

System Setup Section 3

Next highlight the Advanced setup selection, press Enter, and a display similar to the following

for specific conductance will appear.

You need to consider

four options within this menu.

Is: Enabled. This determines whether or not the calibration of this parameter is enabled (allowed)

from the Run mode of the 6500 display. Highlight the selection “Is: Enabled”. Press Enter to

toggle back and forth between “Is: Enable” and “Is: Disabled”. Select the desired option.

Can override: Yes. This determines whether or not an error message can be overridden if it

occurs during the calibration procedure. Highlight the “Can override: Yes” selection. Press Enter

to toggle back and forth between “Can override: Yes” and “Can override: No”. Select the desired

option. Remember that a calibration error message usually implies a significant malfunction of

the 6-Series Sonde sensor that in turn indicates that service to that sensor is required if accurate

readings are to be obtained. Therefore, it is usually proper to select the “No” option with regard

to this selection. There are occasions when the user is aware that the error message is due to

special circumstances and thus the “Yes” option is appropriate, but these are rare.

Vari from Probe, Vari from Default or Fixed from Default. The software allows you to choose

only one of these three choices. During setup choose “Vari from Probe”. This is the default

parameter value that appears on the 6500 display when the calibration procedure is initiated.

With this selection, the current reading of the parameter will be displayed on calibration startup

and this value can be varied from the 6500 keyboard to reflect the true value. For more detailed

information on these choices, see Appendix F, Advanced Calibration Setup.

Default = 1000. The value of the default calibration value for this parameter is only needed if

you choose one of the default choices above. If you choose “Vari from Probe”, you need not set

a value here.

A calibration setup display for each activated parameter, except temperature that requires no

periodic calibration, is accessible after the Advanced setup selection is made from the Calibrate

setup menu. To view other parameters, use the right and left arrow keys to scroll horizontally

between parameters using the scroll bar at the bottom of the screen (see screen above). Use the

descriptions above to set each of the 4 options for these other parameters.

After configuring your sensor calibrations as described above, press Esc to return to the Main

menu.

YSI Incorporated 6500 Environmental Process Monitor 25

Page 30

System Setup Section 3

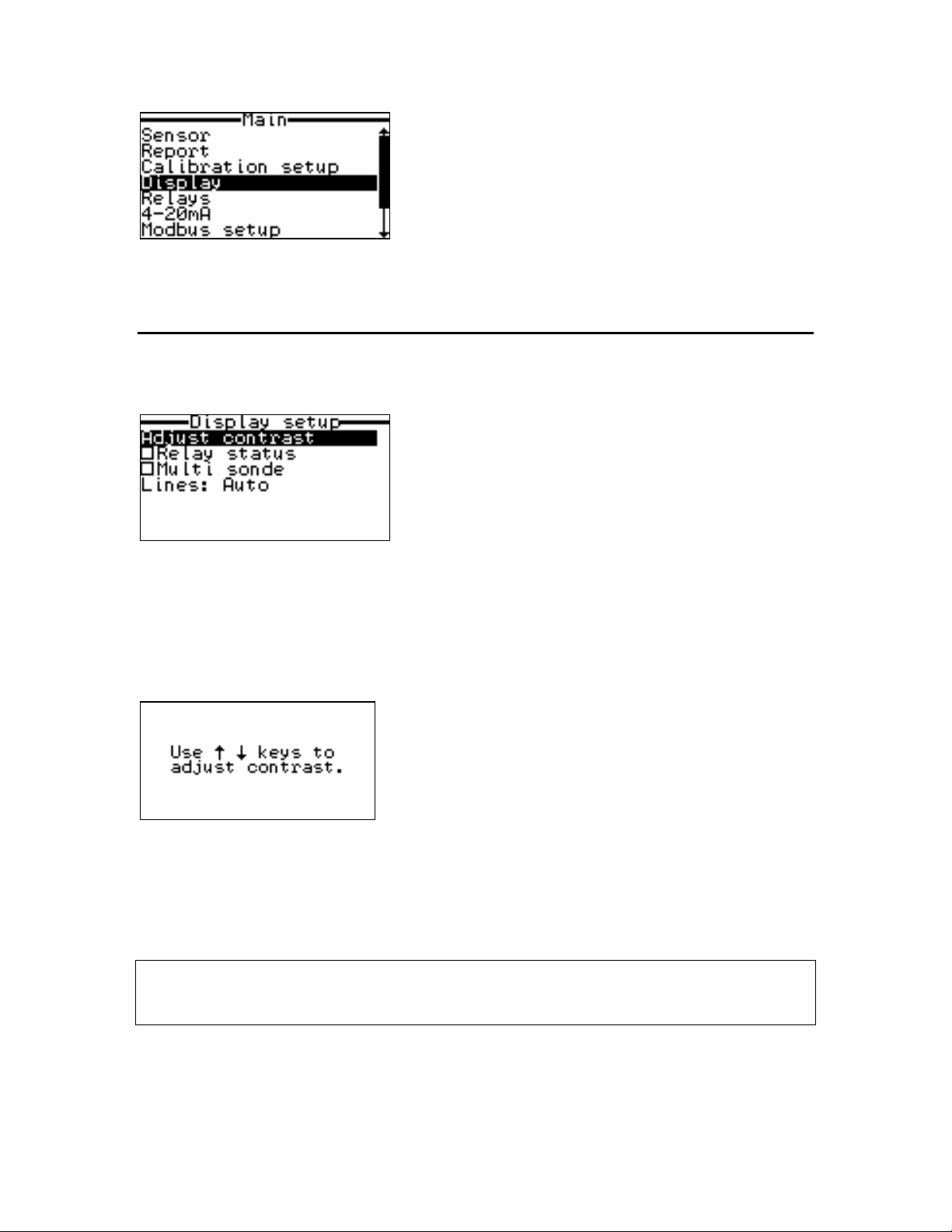

3.3.2 DISPLAY SETUP

Now highlight the Display selection from the Main menu and press Enter. The following screen

will appear.

The Display menu contains options concerning the visual display of the 6500 Monitor. Use the

↑↓ arrows to highlight the desired display feature. Press Enter to select the feature.

First, highlight the Adjust contrast selection. This option allows the user to select the optimal

screen contrast for the existing light conditions. Press Enter to access the Adjust contrast feature

and the following display will appear.

Using the ↑↓ arrows, select the desired screen contrast. Then press Esc to return to the Display

menu.

Tip: There is an alternate Adjust contrast feature. From the Run display screen, press and hold

the Cal key while using the ↑↓ arrow keys to change contrast. This may be especially useful if

bright sun or low light conditions make the display screen difficult or impossible to read.

Now highlight Relay status. This feature can be enabled and disabled by toggling the Enter key.

If enabled a check mark will appear in the box and the display in the Run mode will contain a bar

YSI Incorporated 6500 Environmental Process Monitor 26

Page 31

System Setup Section 3

at the bottom of the screen with symbols that indicate whether the relays are presently active as

defined by the current sensor value. An example is shown in the following Run screen.

If a relay is active, the symbol will be spinning as is simulated above for relays 2 and 4. If the

relay is inactive, the symbols will be stationary as shown above for relays 1 and 3.

If the overall feature is disabled in the Display mode (no checkmark in the box), then no relay

display will appear on the Run display screen. However, if relays are being controlled by the

6500 system, it is usually a good idea to activate this feature during setup. After making your

choice, press Esc to return to the Display menu.

Now highlight the Lines selection and press Enter. The following screen will be displayed.

Four selections are possible from the Display setup menu: Auto, 2, 3 and 4 lines per screen.

Highlight the desired item with the up and down arrow keys and press Enter to toggle it on. Only

one choice is allowed.

If you select one of the numbered options, then

only that number of parameters will appear

simultaneously on the screen during the Run mode. However, it is always possible to view the

non-displayed parameters by scrolling up or down with the arrow keys while viewing the Run

display screen. The lower the number, the larger the character size will be for the displayed

parameters; the larger the number, the smaller the size. If “Auto” is selected, all parameters will

be displayed simultaneously, but with a character size that is inversely proportional to the number

of items displayed. It is usually prudent to make a selection, then press Esc to return to the Run

mode and view the results of your choice. You can then re-enter the Display setup menu, vary

the choice, return to the Run mode and assess the new selection until your preference is

established.

YSI Incorporated 6500 Environmental Process Monitor 27

Page 32

System Setup Section 3

If you are using more than one sonde with your 6500 Monitor, you can choose how many sondes

you would like to view on the 6500 Monitor screen simultaneously by selecting the Multi-sonde

option as shown below.

Once selected, two additional options appear as shown.

You will now want to select the number of lines (displayed parameters) which will be shown

simultaneously on the 6500 Monitor during the run mode. Highlight Lines per Sonde and press

Enter. This selection is identical to that described above for use of the 6500 with a single sonde.

The chosen number of Lines per Sonde will be applied to the output of all of the displayed

sondes.

Highlight the desired setting, press Enter to select it, and then press Esc to return to the Display

menu.

Next, you will want to select the number of sondes per screen you wish to view. Highlight

Sondes per screen and press Enter.

If you have more than one sonde connected, you can choose to view 1,2, or 4 sondes per screen.

Highlight the desired setting and press Enter to select it. If you choose “1 sonde/screen”, you can

still view the data by scrolling right and left to view the other sondes connected. If you have

three sondes connected, you can choose “4 sondes/screen” to view all of the sondes on the screen.

One section will appear blank.

After your have configured your display as desired, press Esc to return to the Main menu.

YSI Incorporated 6500 Environmental Process Monitor 28

Page 33

System Setup Section 3

3.3.3 RELAYS

If you do not choose to use the 6500 Relay function, proceed to the next section, 3.3.4 4-20 mA

channel set-up.

Highlight the Relays option, press Enter and the following display will appear.

The Relays menu allows the user to set up the

relays on and off. If a relay is active, it might trigger an alarm indicating a problem in the

stream. For example, if a relay were configured as described below to activate when the pH falls

below 7.00, the alarm (flashing light, buzzer, etc.) attached to the relay would be enabled as long

as the pH was below 7. If the pH returned above the set value, the alarm would again be

disabled.

To set up the relays, highlight the Configure Relays selection and press Enter to activate the

following display in which no relay activation has taken place.

logic and levels for turning the four available

Now highlight the “1” selection and press Enter to display the setup options.

First highlight the “Para:” selection and then press Enter to choose the parameter with which the

first relay will be associated from the displayed list. Highlight the desired parameter, in the

example shown below temperature in degrees Celsius, and press Enter. Then press Esc to return

to the above menu.

YSI Incorporated 6500 Environmental Process Monitor 29

Page 34

System Setup Section 3

Now highlight the “Is:” selection and use the Enter key to toggle between “above” and “below”.

When the proper selection has been made, press Enter to confirm it (“above” in the example”).

Next highlight the “Set point=“ selection and press Enter. Use the up and down arrows on the

keyboard to adjust the parameter value to the point where the relay will be activated (18 C in the

example) and press Enter to confirm the selection. With the above setup, the first relay will be

enabled (and its associated alarm will be active) whenever the temperature is above 18 C.

The “Hysteresis” (dead band) serves to eliminate relay “chatter” around the set point.

To set up the remaining three available relays, scroll horizontally with the right and left arrows in

the screen shown directly above to access the Relay setup menu for the additional menus and then

configure them from this display as described above. Press Esc to return to the Configure Relays

menu as shown below. Conditions are now set for all four relays.

In the above example, Relay 1 will be enabled if the temperature is above 18 C, Relay 2 will be

enabled if DO is less than 5.00 mg/L, Relay 3 will be enabled if specific conductance is greater

than 2 mS/cm, and Relay 4 will be enabled if the pH is less than 7.00.

After the relays have been set as desired, press Esc to return to the Main menu.

3.3.4 4-20 MA CHANNEL SETUP

YSI Incorporated 6500 Environmental Process Monitor 30

Page 35

System Setup Section 3

If you do not choose to use the 6500 4-20 mA function, proceed to the next section. To enter the

4-20 menu press Enter after highlighting “4-20 mA”, then choose “Configure 4-20mA” and

press Enter again.

If you will be transmitting data from the sonde via your 6500 to a SCADA system or other analog

data collection device in the form of 4-20 mA signals, you will need to set the limits of this

output for any or all of the eight available channels. To do so, highlight the “4-20mA” selection

and press Enter. The following display will appear.

Now highlight the desired channel and press Enter to activate the display of the specific channel

of interest. Channel 1 is shown below.

First, choose the parameter which will be associated with the selected 4-20 mA channel by

highlighting the “Para:” selection and pressing Enter to display a list of available parameters.

Using the up and down arrow keys, select the desired parameter and then press Enter to confirm

the selection (temperature in degrees Celsius in the example).

Next, highlight the “4mA level=“ selection and press Enter. Using the arrow keys, enter the

desired value for the low limit of the range and press Enter to confirm the value (0 C in the

example). Press Esc to return to the above menu.

Finally, highlight the “20mA level=“ selection and enter the desired value for the high limit of the

range using the arrow keys. Press Enter to confirm the value (30 C in the example).

Other 4-20 mA channels can be activated (and then set up) by scrolling horizontally in the above

menu using the right and left arrow keys. Alternatively, you may return to the Channel menu,

highlight the desired channel number (see below), and set up the limits as described above.

Channel 1 Set Channels 1-4 Set

YSI Incorporated 6500 Environmental Process Monitor 31

Page 36

System Setup Section 3

After the 4-20 mA channels have been configured to your specifications, press Esc to return to

the Main menu.

3.3.5 MODBUS SETUP

Please see section 5.1 for a more complete description of the Modbus system implementation.

To begin setup of the Modbus, highlight the Modbus setup option on the Main menu and press

Enter.

The following screen will appear.

Use the arrow keys to highlight Base address and press Enter to select it. This will activate a

cursor which is used to change the 6500 Modbus base address. To increment the address, use the

↑↓ arrow keys. When the desired addressed is reached, press Enter to set it.

Now highlight Hardware and press Enter to select it. The following submenu will appear.

YSI Incorporated 6500 Environmental Process Monitor 32

Page 37

System Setup Section 3

Highlight the desired setting and press Enter to select it.

All of the listed Modbus parameters must be set to match those specified in your Modbus

configuration for successful system implementation. Most parameters have a submenu of

available settings. Change any other necessary Modbus settings in the same fashion.

After your have configured the Modbus setup as desired, check the “Enable Modbus” option to

activate the Modbus system by pressing Enter. Modbus will not work unless this option is

checked.

NOTE: This Enable Modbus function must be off in order to update the code on a 6500.

Press Esc to return to the Main menu.

3.3.6 CHANGE SONDE ADDRESS

Each sonde you connect to the 6500 Monitor has its own unique SDI-12 address. This address is

used by the sonde to identify itself to the 6500 Monitor. When multiple sondes are connected, it

is necessary that each sonde have its own unique address.

To change the SDI-12 address of a sonde, select the “Change sonde address” option in the Main

menu.

When selected, the SDI-12 addresses of any sondes connected will be shown.

YSI Incorporated 6500 Environmental Process Monitor 33

Page 38

System Setup Section 3

To change an SDI-12 addresses, highlight the current SDI-12 address of the sonde you wish to

change and press Enter to select it. A new screen showing available new addresses will be

displayed.

Choose the desired address and press Enter to select it. The 6500 Monitor will then display a

confirmation choice verify that your selection was correct.

The current active choice will flash. Verify your choice is correct and use the arrow keys to

highlight “yes” or “no”. Then press Enter when you have made your choice. If “yes” is selected,

the 6500 Monitor will update your sonde’s SDI-12 address and return to the main menu. If “no”

is selected, the 6500 Monitor will return to the main menu, but will not update your sonde’s SDI12 address.

3.3.7 SYSTEM STATUS

This item allows the user to determine the current version of the 6500 Monitor software and is

also intended for future feature enhancements for the 6500.

Highlight the System status selection and press Enter to produce the following display.

YSI Incorporated 6500 Environmental Process Monitor 34

Page 39

System Setup Section 3

Note that the current software version and date are shown in the first entry. This information will

be useful when contacting authorized service personnel for advice on the capabilities of your

system.

The second entry in the System status menu is “Wiper Interval”. If your sonde is equipped with a

YSI #6026 turbidity sensor, highlight the Wiper Interval, press enter, and use the arrow keys to

set the number of minutes between wiper activation cycles. The frequency of activation will be

dependent on the fouling present in your application. In most cases, a wiper interval of five

minutes will be appropriate.

YSI Incorporated 6500 Environmental Process Monitor 35

Page 40

SECTION 4 CALIBRATION

In this section, you will learn how to calibrate the 6-Series Sonde sensors using the 6500 Monitor

(field calibration) as the interface device. You will also learn how to view your data on a

computer display.

MULTIPLE SONDE CALIBRATION

If you are using multiple sondes with the 6500 Monitor, each sonde must be calibrated separately.

To calibrate each sonde, first make sure that the name of the sonde is highlighted, as in the figure

below. Follow the calibration procedures in this section, then highlight the name of the second

sonde, and proceed.

If you choose to calibrate using a laboratory computer, instructions can be found in your 6-series

sonde Operations Manual. Remember that the YSI-supplied PC6000 software should be installed

on your computer. PC6000 software is provided with the 6-Series sonde and is found on a disk in

the back of your Sonde Operations Manual. Information about how to calibrate your sonde using

a computer or YSI 610 Display/Logger, can also be found in the YSI 6-Series Operations

Manual.

4.1 GENERAL CALIBRATION TIPS

Your YSI 6-Series sonde will provide accurate sensor readings to the 6500 Monitor only if it is

calibrated properly! Thus, a complete understanding of the procedures in this section of the

manual is extremely important. The calibration of the sensors, whether carried out with the

sonde interfaced to a computer or the 6500 Monitor, is not difficult, but does require proper

attention to detail. The key is to follow the recommended procedures in general and, more

specifically, to

several weeks between recoveries for maintenance and therefore a few extra minutes during

calibration is not significant in the overall timeframe of its use. After several deployments, you

should be able to complete calibration of all sensors within 30 minutes, but it might take

somewhat longer until you are familiar with the software prompts and the protocols. The extra

time expended during initial calibration to “get it right” will be well worth the effort.

HEALTH AND SAFETY

WARNING: Reagents that are used to calibrate and check this instrument may be hazardous to your

health. Take a moment to review health and safety information in Appendix A of this manual.

Some calibration standard solutions may require special handling.

take your time during calibrations. Remember that the sonde will be deployed for

Page 41

Laboratory and Field Calibration Section 4

CONTAINERS NEEDED TO CALIBRATE A SONDE

The calibration cup that comes with your sonde serves as a calibration chamber for all calibrations.

You need to visually observe the turbidity calibration to insure that no air bubbles are trapped near

the optics and that standards are homogeneous. If you are using the 6026 “wiping” turbidity probe,

you should visually verify proper movement of the wiper mechanism. Turbidity must be calibrated

with the probe guard on the sonde.

Instead of the calibration cup, you may use laboratory glassware to perform calibrations. If you do

not use a calibration cup that is designed for the sonde, you are cautioned to do the following:

T Perform all calibrations with the Probe Guard installed. This protects the probes from possible

physical damage.

T Use a ring stand and clamp to secure the sonde body to prevent the sonde from falling over.

Much laboratory glassware has convex bottoms.

T Insure that all sensors are immersed in calibration solutions. Many of the calibrations factor in

readings from other probes (e.g., temperature probe). The top vent hole of the conductivity

sensor must also be immersed during calibrations.

TIPS FOR GOOD CALIBRATIONS

1. If you use the Calibration Cup for dissolved oxygen (DO) calibration,

make certain to loosen the seal to allow pressure equilibration before

calibration. The DO calibration is a water-saturated air calibration.

2. The key to successful calibration is to insure that the sensors are

completely submersed when calibration values are entered. Use

recommended volumes when performing calibrations.

3. For maximum accuracy, use a small amount of previously used

calibration solution to pre-rinse the sonde. You may wish to save old

calibration standards for this purpose.

4. Fill a bucket with ambient temperature water to rinse the sonde between

calibration solutions.

5. Have several clean, absorbent paper towels or cotton cloths available to

dry the sonde between rinses and calibration solutions. Shake the excess

rinse water off of the sonde, especially when the probe guard is installed.

Dry off the outside of the sonde and probe guard. Making sure that the

sonde is dry reduces carry-over contamination of calibrator solutions and

increases the accuracy of the calibration.

YSI Incorporated 6500 Environmental Process Monitor 38

Page 42

Laboratory and Field Calibration Section 4

6. You do not need to remove the probe guard to rinse and dry the probes

between calibration solutions. The inaccuracy resulting from simply

rinsing the probe compartment and drying the outside of the sonde is

minimal.

7. For the 600R, 600XL and 600XLM, remove the stainless steel weight

from the bottom of the sonde by turning the weight counterclockwise.

When the weight is removed, the calibration solutions have access to the

sensors while displacing a minimal amount of fluid in the calibration

cup. This also reduces the amount of liquid that is carried between

calibrations.

8. Make certain that port plugs are installed in all ports where probes are

not installed. It is extremely important to keep these electrical

connectors dry.

RECOMMENDED VOLUMES FOR USE WITH THE CALIBRATION CUP

Follow these instructions to use the calibration cup for calibration procedures

Ensure that a gasket is installed in the gasket groove of the calibration cup bottom cap, and

that the bottom cap is securely tightened. Note: Do not over-tighten as this could cause

damage to the threaded portions of the bottom cap and tube.

Remove the probe guard, if it is installed.

Remove the o-ring, if installed, from the sonde.

Inspect the installed gasket on the sonde for obvious defects and if necessary, replace it with

the extra gasket, supplied.

Screw cup assembly into place on the threaded end of sonde and securely tighten. Note: Do

not over tighten as this could cause damage to the threaded portions of the bottom cap and

tube.

Sonde calibration can be accomplished with the sonde upright or upside down. A separate

clamp and stand, such as a ring stand, is required to support the sonde in the inverted

position.

To calibrate, follow the procedures in the next section, Calibration Procedures. The

approximate volumes of the reagents are specified below for both the upright and upside

down orientations.

When using the Transport/Calibration Cup for dissolved oxygen calibration, make certain that the

vessel is vented to the atmosphere by loosening the bottom cap or cup assembly, depending on

orientation, and that approximately 1/8” of water is present in the cup.

Table 1

YSI Incorporated 6500 Environmental Process Monitor 39

Page 43

Laboratory and Field Calibration Section 4

6820 and 6920 Sondes

Conductivity 200ml 200ml

pH/ORP 100ml 250ml

ISE 125ml 275ml

Turbidity 25ml N/A

Table 2

600R, 600XL and 600XLM Upright Upside Down

Conductivity 50ml 50ml

pH/ORP 25ml 50ml

Upright Upside Down

4.2 FIELD CALIBRATION USING THE 6500 MONITOR

The 6-Series Sonde can be calibrated in the field using the 6500 Monitor display. Calibration is

performed from the 6500 Run mode (displayed readings mode) utilizing the Cal key on the face

of the 6500 Monitor front panel.

NOTE: Calibration for a specific sensor can

function has been turned on for that sensor. Refer to Section 3.3, 6500 Monitor Setup if you need

instructions for calibrate enable.

To calibrate 6-Series sensors using the 6500 Monitor, simply push the Cal button while in Run

mode. The Run display will be modified to mask out any parameters that have not been enabled

for user calibration. Select the appropriate enabled parameter for calibration using the ↑↓ to

highlight the selection and press Enter to confirm the selection. The display will prompt the user

through the calibration routine as described below.

Prior to beginning the calibration protocol described below for, attach the sonde to the 6500

Monitor via the matching MS-8 connectors and allow the unit to run for 10-15 minutes to allow

the sensors to stabilize.

The instructions for calibration of the conductivity sensors is detailed below as an example of

how to calibrate your 6-series sonde with using the 6500 Monitor. For all of the other calibration

instructions for the sonde, refer to the 6-Series Sonde Operations Manual, Section 2.

only be accomplished after the Calibrate Enable

CONDUCTIVITY

Place the correct amount of conductivity standard in a clean dry calibration cup (see Table 1

above) and carefully immerse the entire sonde in the solution making certain the vent hole on the

side of the sonde is covered with reagent. Rotate the sonde back and forth and move it up and

down to make certain that all bubbles have been displaced from the conductivity cell.

From the 6500 Run display, press the Cal key and the following Calibration display will appear.

YSI Incorporated 6500 Environmental Process Monitor 40

Page 44

Laboratory and Field Calibration Section 4

Use the arrow keys to highlight the output line for specific conductance as shown above. Press

Enter and the following display will be shown.

Using this display, you will now be required to input the ACTUAL value of your conductivity

standard. First use the right and left keyboard arrow keys to highlight the digits of the display

which your wish to vary. Then use the up and down keyboard arrows to increment this digit the

higher or lower values, respectively, until the desired value is shown. Proceed to additional digits

and make variations as required. When the displayed value is correct, press the Enter key and the

following screen will be shown.

This display allows you to view in REAL TIME the actual specific conductance values from your

probe. At this point you also have the option of aborting the calibration completely to return to

the Run display by highlighting the

entered the wrong value for your standard, highlight

Abort selection and pressing Enter. If you inadvertently

Redo and press Enter. You may reenter your

numerical calibration value at this point.

If you have made no mistakes in value entry, make certain that the

Cal selection is highlighted,

watch the readings in real time and when they are stable for approximately 30 seconds, press the

Enter key to confirm the calibration. The following screen will appear indicating that your

calibration was successful.

YSI Incorporated 6500 Environmental Process Monitor 41

Page 45

Laboratory and Field Calibration Section 4

Now simply press the Enter key to return to the Calibration display and proceed to calibration of

the other sensors using the same basic procedures as described above for specific conductance.

4.3 6500 CALIBRATION WARNING AND ERROR MESSAGES

When you calibrate the 6-Series Sonde sensors with the 6500 Monitor, you may occasionally

encounter an error message display similar to those shown below when attempting to confirm a

calibration value. The examples below show two “alert” categories, a warning and an error.

Warning messages can be overridden, while error messages can not be overridden. Examples are

shown below.

If any of these messages occur, it is usually due to one of three causes: (1) a contaminated standard,

(2) improper implementation of the recommended calibration procedure (e.g., not imme rsing the

sonde completely in the standard), or (3) a malfunctioning sensor. If you encounter a warning or

error message, first begin the calibration procedure again. Be certain that the value you enter for the

calibration standard is correct, that your calibration standard has not been contaminated (use a new

standard if necessary), and that you have followed the suggested calibration procedure for each

sensor as outlined below.

If you still encounter a calibration error message, contact YSI-authorized service for advice. You

can “override” a calibration warning, but you should not do this unless you have additional

knowledge regarding the cause of the message. Also see Section 7, of the sonde manual for more