Page 1

YSI incorporated

6200

Data Acquisition System

User’s Manual

Page 2

Table of Contents

Page

Section 1 Introduction

1.1 Description 1-1

1.2 General Specifications 1-2

1.3 How to Use this Manual 1-4

Section 2 Getting Started

2.1 Unpacking and Inspection 2-1

2.2 Installing EcoWatch DCP 2-2

2.3 Setting Up System Components f or Checkout 2-3

2.4 Setting Up a 6-Series Sonde for System Checkout 2-6

2.5 Configuring the System 6200 with EcoWatch DCP 2-11

2.6 Testing the 6200 DCP 2-16

2.7 Testing Sensor Function 2-19

2.8 Displaying Data in EcoWatch DCP 2-21

Section 3 Setting Up and Calibrating 6-Series Sondes

3.1 Introduction 3-1

3.2 Communicating with a Sonde 3-1

3.3 Connecting a Sonde to a Computer with EcoWatch DCP 3-3

3.4 Preparing the Sonde to Communicat e with the 6200 DCP 3-4

3.5 Installing and Calibrating Sonde Sensors 3-5

Section 4 Powering the Field Station

4.1 Introduction 4-1

4.2 General Wiring Information 4-1

4.3 Installing the Battery 4-4

4.4 Installing AC Power to the Field Station 4-5

4.5 Installing Solar Power to the Field Stat ion 4-7

Section 5 Connecting Sensors to the Field Station

5.1 Introduction 5-1

5.2 Connecting the MET Suite 5-2

5.3 Connecting the Rain Gauge 5-2

5.4 Connecting the Pyranometer 5-3

5.5 Connecting One Sonde 5-3

5.6 Connecting More Than One Sonde to a Field Station 5-4

Section 6 Communicating with the Field Station

6.1 Introduction 6-1

6.2 Installing RS232 Direct Communication Link 6-6

6.3 Installing RF Radio Communication Link 6-7

6.4 Installing Phone modem Communicat ion Link 6-9

6.5 Installing Cellular modem Comm unication Link 6-10

6.6 Setting Up Communication Paramet er s with EcoWatch DCP 6-11

3

Page 3

Section 7 Collecting Data with EcoWatch DCP

7.1 Introduction 7-1

7.2 Completing Field and Base System Setup 7-1

7.3 Verifying Field/Base Communication from the Field 7-3

7.4 Collecting Data with EcoWatch DCP 7-3

7.5 Reconfiguring Sensors and System with EcoWatch 7-11

7.6 Backing Up and Restoring DCP Configuration Files 7-14

Section 8 Reporting and Plotting Data with EcoWatch DCP

8.1 Introduction 8-1

8.2 Opening a Data File 8-1

8.3 Viewing Data 8-3

8.4 Changing Display Formats Using Setup 8-7

8.5 Changing Display Formats Using ‘Gr aph’ Funct ion 8-8

8.6 Save, Import, Export and Print Comm ands 8-9

8.7 Example of Customizing a Subset of SAMPLE.DAT 8-10

Section 9 Maintaining and Troubleshooting the System

9.1 Introduction 9-1

9.2 Routine Care and Maintenance 9-1

9.3 Troubleshooting 9-5

Appendix A Component Descriptions and Sensor Specifications

Appendix B Required Notice

Appendix C Warranty and Service Information

Appendix D Accessories

Appendix E Field Installation Examples

4

Page 4

Assistance

Help with this product can be obtained by contacting a YSI Factory Service Center.

United States

YSI Massachusetts

Repair Center

13 Atlantis Drive

Marion, MA 02738

Phone: 508 748-0366

Fax: 508 748-2543

Compliance

The 6200 Data Acquisition System meets the EN61326 Electronic Equipment for Measurement

and Control specification when connected 6-series sonde cabling is protected from RF induction

and industrial noise. The 6-series sondes may malfunction over the frequency range of 4.2 MHz

to 8.5 MHz at a level of 3 volts RF on the cable (see Appendix E).

The 6-series sonde must be fitted with the CE bead kit for the 6200 system to meet the Class B

emissions requirements.

The 6200 complies with EN61010 as manufactured.

1

Page 5

Safety Notes

The following type of safety notes are used throughout this manual. Familiarize yourself with

each of the notes and their meaning before using this product.

NOTE The NOTE is used to indicate a statement of company recommendation or

policy. A NOTE is not associated directly with a hazard or hazardous

situation, and it is not used in place of CAUTION or WARNING.

CAUTION! Used to indicate a hazard. It calls attention to a procedure that, if not

correctly performed, could result in damage or injury. Do not proceed

beyond a caution sign until the indicated conditions are fully understood

and met.

WARNING! Used to indicate a hazard. It calls attention to a procedure that, if not

correctly performed, could result in injury or loss of life. Do not proceed

beyond a caution sign until the indicated conditions are fully understood

and met.

General Safety Considerations

WARNING!

No operator serviceable parts inside. Refer ser vicing t o a YSI factory service center.

To prevent electrical shock, do not remove covers.

This is the instruction documentation symbol. The product is marked with this

symbol when it is necessary for the user to refer to instructions in this manual.

2

Page 6

YSI 6200 DAS USER Manual

Section 1

Introduction

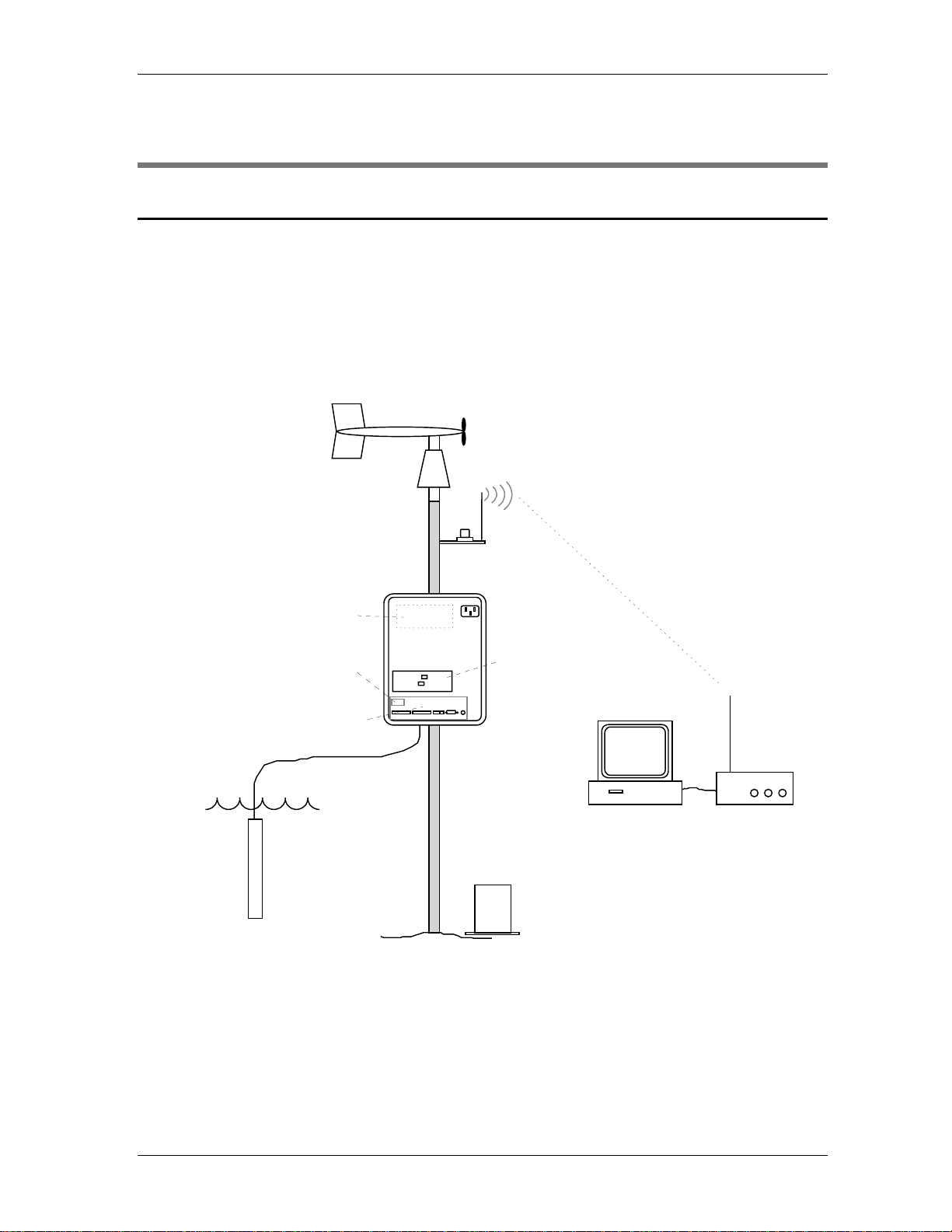

1.1 Description

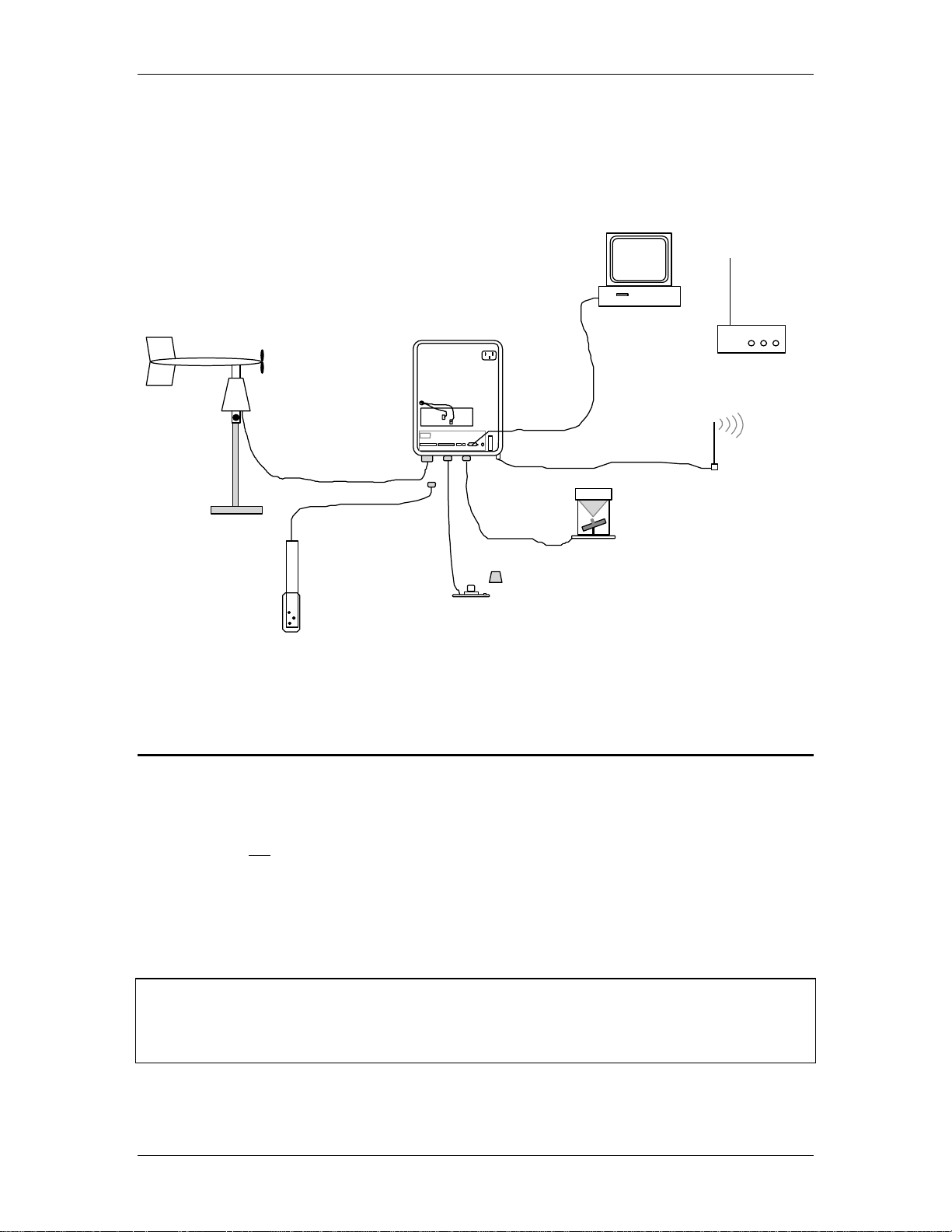

The 6200 Data Acquisition System (6200 DAS) with EcoWatch DCPä is an integrated hardware

and software package specifically designed to be a powerful, yet easy to configure, multiparameter

water quality and meteorological data collection platform with a graphical user interface.

Information can be collected real-time or periodically from solid state memory. Combined with

YSI 6-series sondes and/or a variety of meteorological sensors, this system is intended for use in

research, assessment and regulatory compliance applications.

Wind Speed/Direction

Relative Humidity

Air Temperature

Radio

Antenna

Solar

Radiation

Radio Transceiver

Battery

(charged Solar or AC)

Computer with

EcoWatch DCP

Rain accumulation

Rain rate

Radio

Base Station

6200

Data Collection Platform

6-Series Sonde

Barometer

Water Temperature

Conductivity

Dissolved Oxygen

pH

ORP

Depth/Level

and more...

Figure 1.1 6200 DAS, Example Config uration

The system can be configured many ways, using a variety of sensors, communication modes and

power options. The sensors provide signals for both water quality and meteorological

measurement parameters. The meteorological sensors include wind speed and direction, relative

humidity, barometric pressure, rainfall rate and accumulation, air temperature and solar radiation.

YSI/Massachusetts 508.748.0366, Fax 508.748.2543 Page 1-1

Page 7

YSI 6200 DAS USER Manual

The water quality sensors include water temperature, conductivity, dissolved oxygen, pH, ORP,

depth/level, turbidity, nitrate, ammonia and chloride.

The system includes a field station (6200 DCP), which houses a powerful data logger and connects

to any of the water quality or meteorological sensors you choose. The data logger uses a 32-bit

â

microprocessor with up to 1 megabyte of data storage memory. Windows

-based EcoWatch DCP

software functions to interrogate the data logger and display real-time results in time stamped table

format. Alternatively, you may request data stored in the field station less frequently to conserve

power. The software also provides autoconfiguration capability during setup and calibration and

includes a powerful plotting package for further analysis of the recorded data.

There are four options for communication between the field station and the base station computer.

They are (1) direct link via RS-232 serial communication, (2) phone modem communication, (3)

cellular phone communication, and (4) UHF radio communication.

There are three options for powering the field station. They are (1) rechargeable lead acid battery

(12 volt, 12 Ah) mounted inside the NEMA 4X field station enclosure, (2) solar panel that charges

the battery described in 1 above, and (3) 100/120//220/230-240 V~, 50/60 Hz power. The battery

is installed in all versions. It is required in the solar setup and serves as a backup in the AC power

setup.

The 6200 DAS comes to you configured to your order, including all interface cables. You may

need to provide additional wiring and junction boxes if you are powering the field station with AC

power. You may need to provide mounting supports for the main enclosure and various

accessories, such as sensors, antennas and the like. Most of the mounting hardware you need

comes with the 6200 system, but some may not be appropriate for your particular mounting

configuration.

The 6200 DAS specifications are described below. You may refer to Appendix A for

specifications of specific sensors and accessories. In addition, the accessory manuals provided

with this manual package should be helpful.

1.2 General Specifications

Environmental

Operating Temperature -40 to 60oC (-40 to 140 oF)

Enclosure 33 x 38 x 15.2 cm (13 x 15 x 6 in), fiberglass

Enclosure Rating NEMA 4X

Pollution Degree II (per UL3101)

Installation Category III (per EN61010-1)

Data Acquisition

6200 DCP (standard) 64 KB RAM, 56 KB required for run-time memory

8 KB (logging memory)

Memory Options 256 KB, 200 KB (logging memory)

1 MB, 968 KB (logging memory)

YSI/Massachusetts 508.748.0366, Fax 508.748.2543 Page 1-2

Page 8

YSI 6200 DAS USER Manual

User-Interface

Software YSI EcoWatch DCPä featuring autoconfigurable sensors,

real-time data displays, powerful reporting and plotting options

Compatibility: Windows

â

3.1, 95, 98 and NT.

Computer Hardware Minimum: PC 386 (4 MB RAM, 4 MB hard disk space)

Recommended: PC 486DX or higher, (8 MB RAM, 4 MB hard

disk space)

Power Information

Battery Type Lead-acid, gel type, sealed (Power Sonic PS-12120 L)

Battery Rating 12 VDC, 5 A max current, 12 Ah capacity

Battery Fuse Type/Rating Type 3AG (fast blow), 5 amps, 32 volts

I/O Interface Fuse Type/Rating Type 3AG (slow blow), 5 amps, 32 volts

When applicable…

Line Power (nominal) 100/120//220/230-240 V~, 50/60 Hz, 0.8A//0.4A

Maximum Current 1.0 A @ 120 V~, 0.5 A @ 240 V~

AC Fuse Type/Rating for 100/120 V~ operation: Type 3AG (slow blow), 1.0 A @ 120 V

AC Fuse Type/Rating for 220/240 V~ operation: 5 x 20mm IEC127 (time delay), 0.5 A(T), 250 V

Fuses may be purchased from any YSI Factory Service Center.

Solar Panel 10 watt, 20 VDC (no load), 0.6 A max current

Electrical Safety CE (pending)

Communication Options

Direct cable 3 m (10 ft) RS-232 cable

Radio 2 watt, 2-way (no license required), 467.8 MHz

Telephone modem Hayes-compatible

Cellular modem Wireless phone modem, uses PSTN through cellular network

Connectors/Access

Power (AC or solar) 1/2” non-metallic, water tight conduit or feed through gland

AC, 3-prong male; Solar, 2-wire interface cable

Phone or direct 1/2” non-metallic, water tight conduit or feed through gland

Phone, standard 3-wire cable; Direct RS-232, DB-9 male

RF (radio or cellular) N-type

Sonde MS-8 pin with tethered cap

Meteorological Suite MS-17 pin with tethered cap

Rain Gauge MS-4 pin with tethered cap

Solar Radiation Sensor MS-5 pin with tethered cap

Ground Standard Ground Lug

Sensor Compatibility

Sonde Compatibility YSI 600, 600R, 600XL, 600XLM, 6820, 6920.

Met Suite (WS, WD, RH, AT) YSI MAZ6213, w/ 4.6 m (15 ft) cable

Met Suite (WS, WD, RH, AT) YSI MAZ6219, w/ 13.7 m (45 ft) cable

Pyranometer (solar radiation) YSI MAZ6214, w/ 3 m (10 ft) cable, leveling base

Pyranometer (solar radiation) YSI MAZ6212, w/ 3 m (10 ft) cable, leveling base, CE approved

Rain Gauge (tipping bucket) ISCO 674, w/ 4.6 m (15 ft) cable

Rain Gauge, with heater YSI MAZ6216, w/ 4.6 m (15 ft) cable (also requires AC power)

Barometer YSI MAZ6217, (located inside NEMA enclosure)

YSI/Massachusetts 508.748.0366, Fax 508.748.2543 Page 1-3

Page 9

YSI 6200 DAS USER Manual

1.3 How to Use this Manual

The 6200 DAS is a complex product that requires your understanding before y ou can successfully use

it; therefore, we strongly suggest that you perform the following steps to get y our sy stem set up

quickly and correctly in the field.

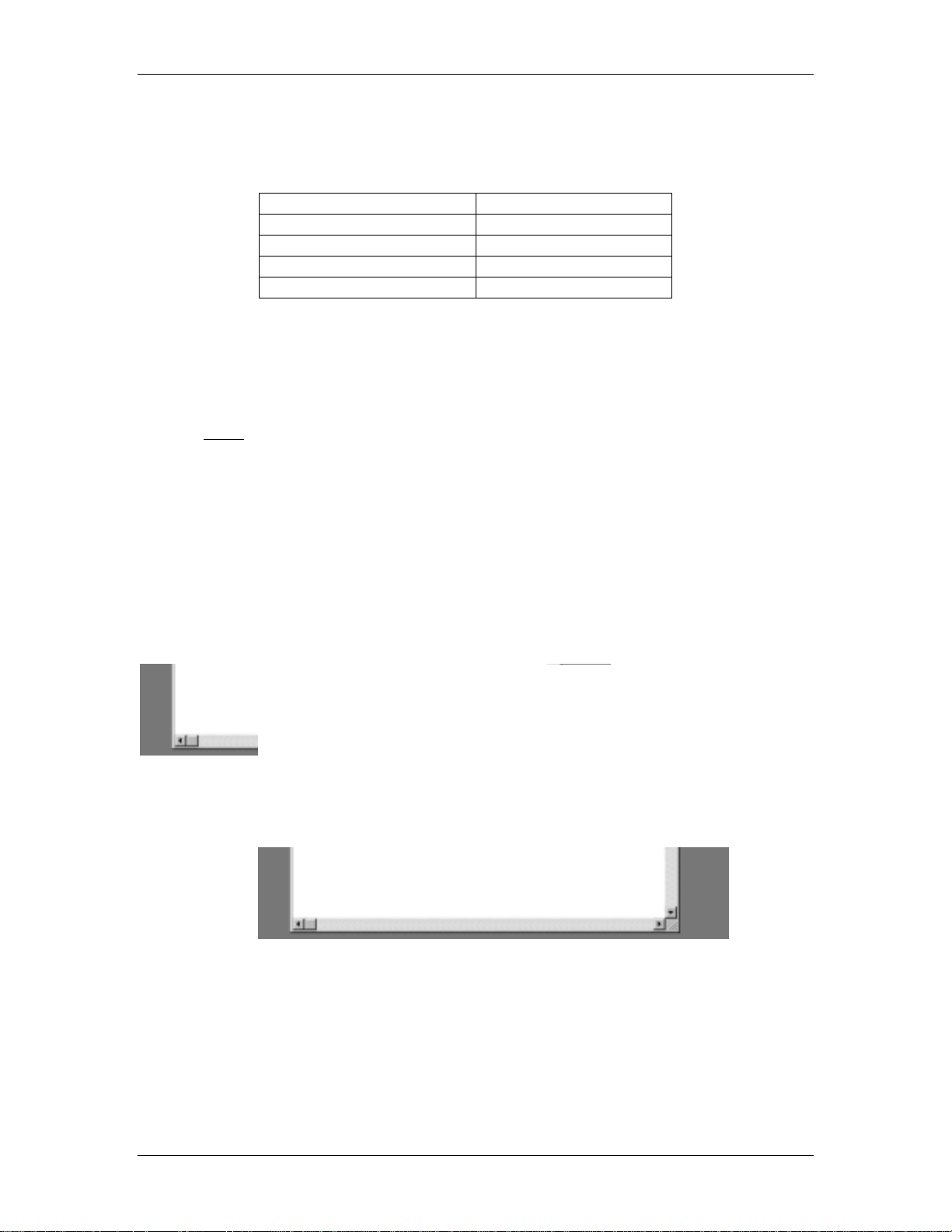

Part I Manual Sections to Read

Familiarize yourself with the 6200 DAS 2, Browse through manual

Unpack and setup sonde 3, Sonde Manual

Check out Communication Method 2, 6, 7

Plan out and prepare remote site 4, 5, See Appendix E for samples

Part II

Fully Calibrate Sonde 3, Sonde Manual

Prepare 6200 DCP for the field 7

Go to the field site and setup 4, 5, 6, 7

Verify that the system work s 7, 8

Section 2 Getting Started

After this section you should be familiar with the 6200 DCP, the EcoWatch DC P userinterface software, and the sensors. This “in lab” setup should give you a basic

understanding of the system. The mo re detailed inform ation found in the other sections

is necessary for the installation and day-to- day operation of the system.

Section 3 Setting Up a 6-Series Sonde

If you are using a 6-Series sonde with your system this section provides basic

information related using a Sonde with this package.

Section 4 Powering the Field Station

Section 5 Connecting Sensors to the Field Station

Section 6 Communicating with the Field Station

Section 7 Collecting Data with EcoWatch DCP

This section needs to be read to properly configure the data collection platform. It

includes power management strategies, and how to upload reading s from the data

collection platform.

Section 8 Reporting and Plotting Data with EcoWatch DCP

Section 9 Maintaining and Troubleshooting the System

Throughout this manual the phrase 6200 DAS (Data Acquisition System) refers to the entire 6200

package you have purchased, including the field station, communications methods, and EcoWatch

DCP software. The phrase 6200 DCP (Data Collection Platform) and field s t a t i o n are used

interchangeably and refer to the remote site setup. The phrase base station refers to the office/lab

setup which includes your PC and communication m ethod.

YSI/Massachusetts 508.748.0366, Fax 508.748.2543 Page 1-4

Page 10

YSI 6200 DAS USER Manual

Section 2

Getting Started

2.1 Unpacking and Inspection

Inspect the outside of the shipping carton(s) for damage. If damage is detected, contact the

carrier immediately. Remove the instrument from the shipping container. Be careful not to

discard any parts or supplies. Confirm that all items on the packing list are present. Inspect all

assemblies and components for damage. The basic 6200 DAS is shipped with the following

major components. Some differences may occur based on the configuration you ordered.

❑ Data Collection Platform with barometer, communication and power accessories installed

❑ Battery for powering remote station (packed separately)

❑ Meteorological Suite (WS, WD, RH, AT) with 4.6 m cable, or 13.7 m cable

❑ Pyranometer (3 m cable) or Pyranometer with CE approval (3 m cable)

❑ Rain Gauge, ISCO 674 (4.6 m cable) or Rain Gauge with heating element (4.6 m cable)

❑ Sonde with appropriate sensors, cables, adapters and reagents

❑ Antennas (if applicable)

❑ Radio Base Station (if applicable)

If you ordered a sonde with reagents, the reagents may be shipped separately. See Appendix D

for a complete list of accessories.

If any parts are damaged or missing, contact your factory representative immediately. If you do

not know from which dealer your 6200 DAS was purchased, contact YSI/Massachusetts. See

phone/fax information below in the footer.

Save the original packing cartons and packing materials. Carriers typically require proof of

damage due to mishandling. Also, if it is necessary to return any parts, you should pack the

equipment in the same manner it was received. Maintaining original cartons and packing

material is less critical once the system is installed and working

If the 6200 DAS components match the packing list and the components appear to be in

satisfactory condition, proceed to the sections below.

WARNING!

To avoid severe personal injury or damage to the equipment...installation,

operation and service should be performed by qualified personnel who

are thoroughly familiar with the entir e cont ents of this manual.

The 6200 Data Acquisition System with EcoWatch DCPä is an integrated hardware and

software package. Most of the hardware will be installed in the field. We will refer to this as the

“field” location. The “base” location will refer to the site where the radio base station or modem

connects to the computer loaded with EcoWatch DCP. We strongly recommend that you

assemble the system “in-house” and functionally test it prior to beginning the field

YSI/Massachusetts 508.748.0366, Fax 508.748.2543 Page 2-1

Page 11

YSI 6200 DAS USER Manual

installation of the system. The next few pages of the manual describe the checkout installation.

You need not use the final mounting hardware to perform this test, however, this is a good time

to review your installation plan for your field site.

2.2 Installing EcoWatch DCP

Choose a computer with these minimum requirements: 386 processor with 4 MB of RAM, at

least one COM port and Windows

you will need at least 4 MB of available hard disk space. Although these minimum requirements

work, we recommend a 486DX processor with 8 MB of RAM and 2 COM ports. The EcoWatch

DCP software is also fully compatible with the Pentium

Windows NT

Windows 98

To install on Windows 3.1:

â

. The system has also been designed and tested with current beta versions of

â

.

Insert Disk 1 into your 3.5” drive. From Program Manager, click on File, then

choose Run. In the box labeled Command Line type in “a:\setup.exe” then click on

OK. If the disk is in drive B, change the command to “b:\setup.exe”. Follow the

instructions and prompts on the screen to complete software installation. Once complete,

store your disks in a safe place in the event you need to reload the software at a later

date.

To install on a Windows 95 or NT machine:

Insert Disk 1 into the proper drive, then click on Start at the bottom left of the screen,

then Run from the submenu. In the box type in “a:\setup.exe” then click on OK. If the

disk is in drive B, change the command to “b:\setup.exe”. Follow the instructions and

prompts on the screen to complete software installation. Once complete, store your disks

in a safe place in the event you need to reload the software at a later date.

When you double click on the EcoWatch DCP icon, the main screen will display a window with

menu bar and icons similar to the one shown below. Below is a Windows 95 illustration.

Windows 3.1 will look slightly different, but not be functionally different.

â

3.1. A 3.5” disk drive is needed to load EcoWatch DCP, and

â

processor and Windows 95â and

There are limits to what you can do with EcoWatch DCP at this time, so you should now turn

your attention to making hardware connections. If part of your 6200 DAS includes a sonde, your

first use of EcoWatch DCP software will be to communicate with the sonde to set sensors and

report parameters and to calibrate the sonde. This is described below in Section 2.4.

YSI/Massachusetts 508.748.0366, Fax 508.748.2543 Page 2-2

Page 12

YSI 6200 DAS USER Manual

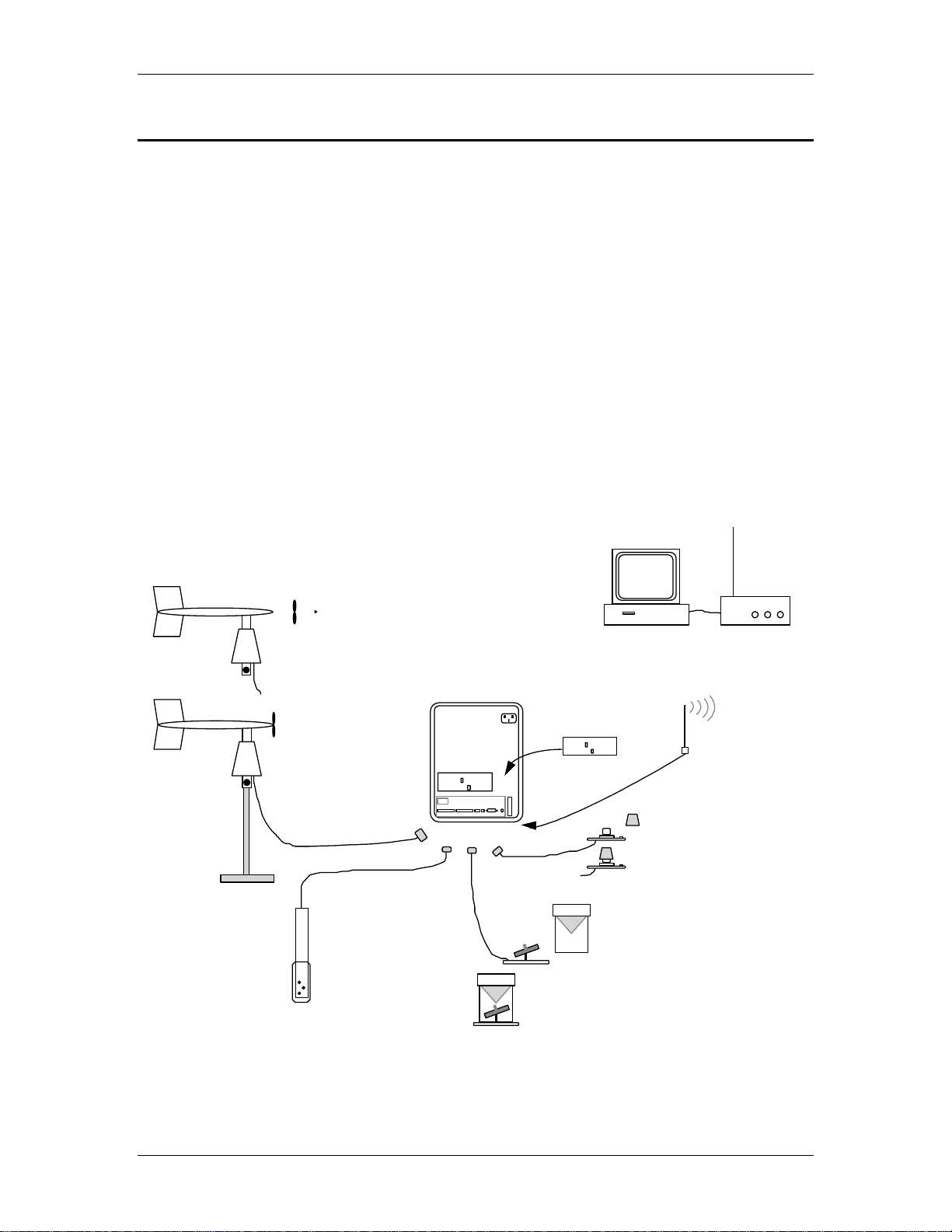

2.3 Setting Up System Components for Checkout

In this section you will find instructions for checkout installation of your entire system in the

laboratory or other temporary location of your choice. Field station and base station components

will be in the same room for this initial setup and checkout procedure. Your setup may differ

from the one described below since the 6200 DAS was ordered to your specification. Many

steps are common to all setups, therefore simply skip sensor, communication and power setup

instructions that are not relevant to your system. Section 5 will go into more details about setting

up each sensor in the field.

The example 6200 DAS described below contains all of the standard meteorological sensors and

one sonde with the most common water quality sensors. Initially we will use a “Direct Link”

(RS-232) communication option and battery power to set up and check out the system in the

laboratory. If a radio transmitter has been installed in the 6200 DCP enclosure, then it is very

important to install the radio antenna. For this reason the radio and antenna have been shown in

the diagram below. Begin by studying this diagram, then follow the step-by-step assembly and

connection instructions. If your system includes a 6-series sonde, you may want to refer ahead to

Section 2.4 for initial setup information.

MET Suite

Wind Speed/Direction

Relative Humidity

Air Temperature

6200 DAS Components

(Phone Mo de m)

Radio Tra ns ceiver

(or Cel lu l a r Mo dem)

Data Collection

Platform

Barometer

makeshift

support

6-Series Sonde

Water Tempe rat ure

Conductivity

Dissolved Oxyg en

pH

Rain Ga uge

Rain accumulation

Rain rate

Figure 2.1 Lab Setup for Checking Out the 6200 DAS

Computer with

EcoWat c h DCP

AC Power

Battery

Desiccant Pack

Radio

Base St ation

Radio

Antenna

Pyranometer

Solar Radiation

YSI/Massachusetts 508.748.0366, Fax 508.748.2543 Page 2-3

Page 13

YSI 6200 DAS USER Manual

Assuming that all shipping cartons have been opened and the equipment has been initially

checked for damage, proceed by doing the following.

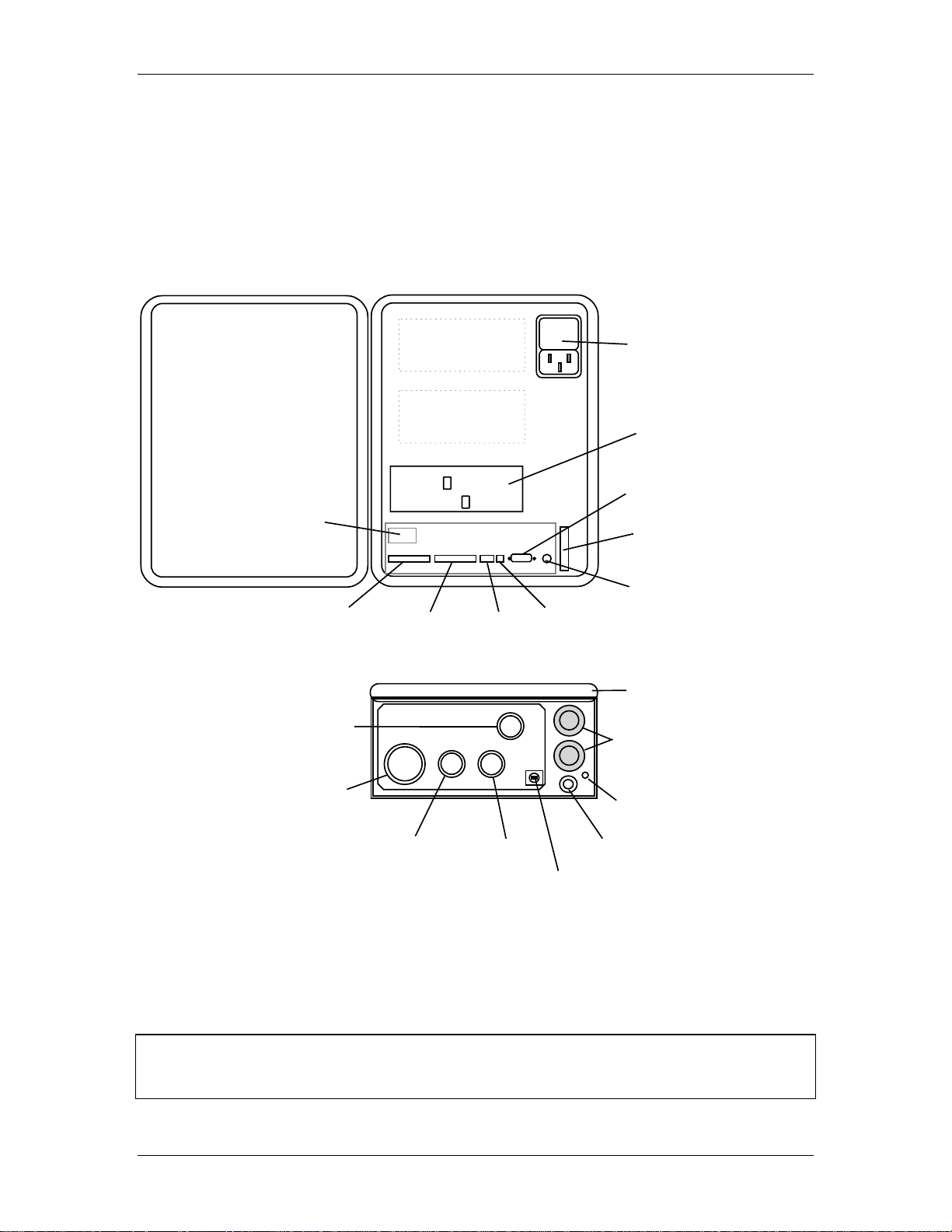

1. Place the 6200 Data Collection Platform enclosure on a work surface, leaving space for

accessories to be laid out and connected. Position the enclosure so that the bottom (connector

ports) faces toward you. Next open the hinged cover, by releasing the two latches on the right

side. Refer to the diagram below, and remember that the diagram may differ slightly from your

unit based on the components you ordered.

Barometer

Analog Inputs

6-Series Sonde

Met Suite

Phone Modem

Radio or

Cell Modem

Digital I/O

bottom view of enclosure

Phone Solar Power In

AC Power In

Battery

COM Port

Desiccant Pack

Fuse

Front Cover

Conduit Fittings for AC,

solar, and phone lines

Barometer Vent

Rain Gauge

Pyranometer

Grounding Terminal

Antenna or RF cable port

Figure 2.2 6200 Data Collection Platf or m, Component and Connector Layout

2. If a radio is installed in the 6200 DCP enclosure, you should locate the field antenna that you

ordered and connect it to the antenna connector on the bottom of the enclosure.

CAUTION!

To avoid permanent damag e to the radio transceiver, connect the antenna befor e

powering the 6200 DCP or the radio base unit.

YSI/Massachusetts 508.748.0366, Fax 508.748.2543 Page 2-4

Page 14

YSI 6200 DAS USER Manual

3. Unpack the battery and insert it into the battery slot (see Section 4.3 for details). The battery

connectors are different sizes. Connect the leads, red to positive and blue to negative. After the

battery is connected, the 6200 DCP should beep for a few seconds as it boots up. The battery

was charged at the factory and should function without problem for this test. Later we will check

the battery voltage with EcoWatch DCP software.

4. For proper testing of the Meteorological Suite sensors, you should construct a makeshift

support or stand for this accessory. A 2” (5 cm) diameter rigid pipe secured to a base works

well. (refer to Figure 2.1) Remove the Meteorological Suite main assembly from its packing

carton. The propeller has been packed separately in the same carton. Remove the propeller, and

use the finger-nut attached to the main shaft to secure the propeller to the main assembly. The

molded lettering on the propeller should face out or away from the main assembly. Hold the

front cone and slightly rotate the propeller to insure that it drops into the “cross” shaped channel

on the cone. Finally tighten the knob on the main assembly with your fingers. Do not use

excessive force. Connect this sensor to the 6200 DCP.

5. Remove the Rain Gauge from the packing carton. There is no assembly required. You may

want to remove the lid, which is an assembly containing a screen or grid and funnel. In order to

functionally test the rain gauge in the lab, the tipping buckets need to be accessible. In the ISCO

model, unlatch the base and gently remove the cylinder/funnel assembly. In the model

containing a heating element, remove the lid/funnel by lifting it off. Connect this sensor to the

6200 DCP.

6. Remove the pyranometer from its packing carton and place it on a flat surface near the 6200

DCP. Locate the certificate and save this document. It contains a calibration constant that must

be entered during the sensor setup routine in EcoWatch DCP. To perform the functional test you

will need to remove the plastic cap that protects the light sensing surface. Also note that a small

bubble level is permanently installed in the base of this unit. During field installation, this

bubble should be used for proper installation. Absolute “level” is not critical during this initial

setup. Connect this sensor to the 6200 DCP.

7. Remove the 6-series sonde from its packing carton. There are several models of sondes that

can be used with the 6200 DAS. Refer to Section 2.4 in this manual for a basic checkout setup.

Note that this is not the complete setup and calibration procedure you would use for deployment

of the sonde at a field station. EcoWatch DCP contains a menu related to sonde communication.

More information for setup of the sonde is located in Section 3. Wait until section 2.4 to connect

this sensor.

8. There are several options that you may use to initially establish a communication link

between the data collection platform and the PC-based EcoWatch DCP software. The simplest

link at this point is the “Direct Link” using the RS-232 cable provided. Plug one end of this

cable into the DB-9 COM port of the 6200 DCP and the other end to a COM port of the PC

loaded with EcoWatch DCP.

Naturally, you will want to functionally check the 2-way radio link, the cellular modem link,

and/or the phone modem link. Refer to Sections 6 and 7 for more information. For now,

YSI/Massachusetts 508.748.0366, Fax 508.748.2543 Page 2-5

Page 15

YSI 6200 DAS USER Manual

however, use the direct link to functionally check your sensors, power source, and DCP in this

laboratory setup.

Your setup as described above should now appear similar to the diagram below. Note that the

Radio Base Station is not connected to the system at this point, as it will be checked later.

Direct Link Initial Checkout

MET Suite

Wind Speed/Direction

Relative Humidity

Air Temper ature

makeshift

support

Radio Transceiver

(or Cellular Modem)

(Phone Mode m)

Dat a Col le c tion

Platform

Barometer

AC

Power In

Battery

Computer with

EcoWatch DCP

RS-232

Cable

Radio

Antenna

Rain Gauge

Rain accumulation

Rain rate

Radio

Base Statio n

6-Se r ie s Sond e

Water Temperature

Conductivity

Dissol ved Ox ygen

pH

* Sonde co nnects to MS-8 once calibrated.

*Remove cover to activate tipping buckets.

Pyranometer

Solar Radiation

Figure 2.3 Setup and Checkout Configuration with Direct Link RS-232 (no radio)

2.4 Setting Up a 6-Series Sonde for Checkout

If a 6-series sonde is not part of the system you ordered, proceed to Section 2.5.

Below is the procedure to unpack and set up a 6-Series sonde for 6200 DCP checkout. The

procedure does not include calibration of the sonde sensors. Other than temperature, the

readings may seem unrealistic at this time. The objective is to familiarize you with specific

sensor setup protocols, not to obtain accurate data.

For many sonde models you must physically install some of the sensors into the sonde bulkhead.

You should refer to the sonde manual for details so not to damage the sensors.

CAUTION!

To avoid permanent damag e to the sonde, do not submerse the sonde in water during

this initial checkout.

YSI/Massachusetts 508.748.0366, Fax 508.748.2543 Page 2-6

Page 16

YSI 6200 DAS USER Manual

When you remove the sonde from the shipping container, you

will see that a probe guard protects the sensors. Unscrew the

guard to determine the sensors installed. After checking

and/or installing sensors, place the probe guard back in place

to protect the sensors.

Sensors shown in this example are temperature, conductivity,

dissolved oxygen and pH. It is important to know what

sensors are installed for the purpose of correctly assigning

sensors during setup.

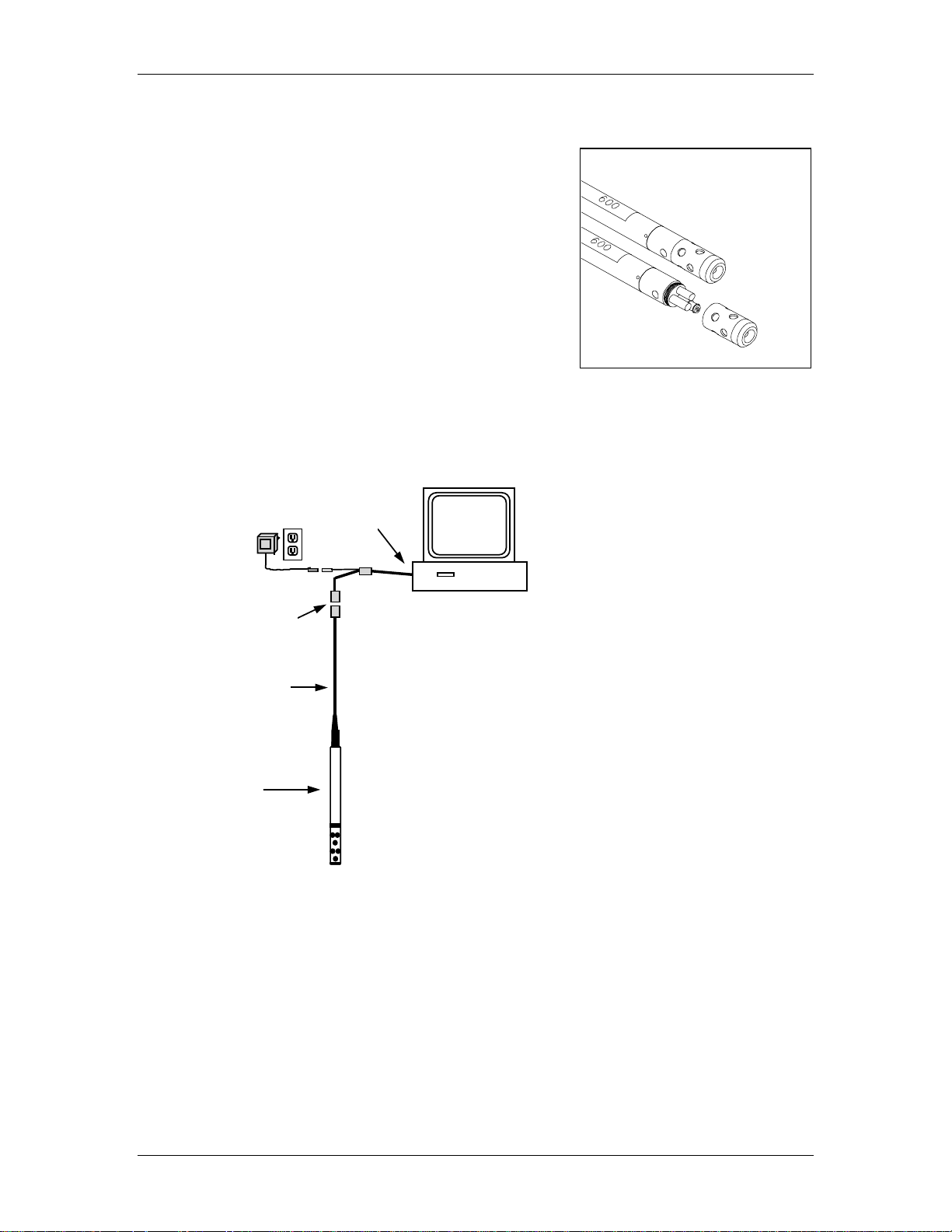

Figure 2.4 600 Sonde, Probe Guard Removed

In order to setup your sonde, you must connect the sonde to your PC and communicate through

EcoWatch DCP. The diagram below helps describe this connection.

In addition to the sonde, you need a

cable. The cable may be a field

cable permanently attached to the

sonde or you may need to connect a

separate field or cal cable to the

bulkhead connector of the sonde.

Regardless of the type, the cable

Power Supply

6037: 220 VAC

6038: 110 VAC

MS-8

DB-9

6095B

Adapter

Computer with

EcoWatch DCP

terminates in an MS-8 connector.

Cable

Many sondes also require power in

order to communicate with the PCbased software. A 6095B Adapter

and a 6038 (or 6037) Power Supply

600

600 Sonde

may be needed to make the

connection. The PC-end of the

adapter is a DB-9 which is a typical

COM port connector. If your PC

has a DB-25 connector, you will

need another adapter (25 to 9 pin).

Figure 2.5 Sonde to PC Connection

Identify your COM port, for example, COM 1, COM 2, etc. You need this information to

establish communication between the sonde and EcoWatch DCP. If your COM port is not

clearly marked, assume that it is COM1 for now. You can reconfigure for COM2 (or other COM

port) if communication is not established during setup.

YSI/Massachusetts 508.748.0366, Fax 508.748.2543 Page 2-7

Page 17

YSI 6200 DAS USER Manual

You should now open the EcoWatch DCP program. If you have not installed it yet refer to

Section 2.2, Installing EcoWatch DCP. Click on the Comm top line menu, then Settings…

Verify that the settings match the table.

Baud 9600

Data 8 bits

Parity None

Protocol Kermit

Handshaking XonXoff

Once complete with this window click on OK.

Now return to top line menu and click on Comm, then choose Sonde from the submenu. Select

your COM port and press OK. You will now see a window labeled Sonde – COM1.

The # sign should appear (see below). Type in “menu”. When you press Enter, you will enter

the main sonde menu. It will appear similar to the screen below. Any difference is related to the

model of sonde you are using.

If you are unable to establish interaction with the sonde, make sure that the cable is properly

connected, power is applied (e.g., 6038 Power Supply or other 12 VDC source), and that the

COM port settings are set correctly. If you were unsure of your COM port number, reassign

another port number and repeat the steps above.

YSI/Massachusetts 508.748.0366, Fax 508.748.2543 Page 2-8

Page 18

YSI 6200 DAS USER Manual

The sonde software is menu-driven. Select a function by typing its corresponding number or

character. It is not necessary to press Enter after a number/character selection. Use the 0 or Esc

key to return to a previous menu. The mouse does not interact with the sonde menus.

NOTE

If a single keystroke yields no response on the screen, press the key again. You should

now see a reaction. This occurs when a key is not pressed for a period of time sending

the sonde into a “sleep mode”. The f ir s t pr ess of any key “wakes” up the sonde and the

second press activates the command.

In order to properly assign sensors and parameters for the sonde, follow the step-by-step

instructions below. You need not fully understand each submenu at this time, but you should

configure your sonde menu to appear very similar to the screens shown below. The illustrations

below may differ some from your screens, since sonde menus vary somewhat from model to

model.

1. From Main menu press 3-System, then 1-Comm setup. This allows you to confirm baud

rate at 9600, which is the default value. Refer to the screens below. Note also that the SDI-12

address of the sonde is 0 by default. You may assign any character between 0 and F to provide a

specific address for your sonde. This will be of particular importance in multi-sonde applications

involving the 6200 DAS. For now, maintain the “0” address designation. Press 0 to return to

previous menus until you return to Main.

-----------------Main----------------1-Run 4-Report

2-Calibrate 5-Sensor

3-System 6-Advanced

-----------System-setup-----------------

Select Option (0 for previous menu):

1-Comm setup

2-Page length=25

3-Instrument ID

4-SDI-12 address=0

Select Option (0 for previous menu):

--------------Comm-setup-------------1-(*)Auto baud 5-( )2400 baud

2-( )300 baud 6-( )4800 baud

3-( )600 baud 7-(*)9600 baud

4-( )1200 baud

Select Option (0 for previous menu):

2. From Main menu press 5-Sensor, to enter the menu that allows you to assign installed

sensors. In the example we are selecting four sensors which were shown earlier in Figure 2.4.

To change an assignment press the number of the sensor. The * indicates that the sensor is

activated. After assigning sensors press 0 to return to Main.

YSI/Massachusetts 508.748.0366, Fax 508.748.2543 Page 2-9

Page 19

YSI 6200 DAS USER Manual

-----------------Main----------------1-Run 4-Report

2-Calibrate 5-Sensor

3-System 6-Advanced

Select Option (0 for previous menu):

------------Sensors enabled------------1-(*)Temperature 5-(*)ISE1 pH

2-(*)Conductivity 6-( )ISE2 NONE

3-(*)Dissolved Oxy 7-( )ISE3 NONE

4-( )Pressure-Abs

Select Option (0 for previous menu):

3. From Main menu press 4-Report, to enter the menu that allows you to assign the parameters

and the units of your choice. In the example we select five parameters...one temperature, one

conductivity, one pH and two for DO. After assigning parameters press 0 to return to Main.

-----------------Main----------------1-Run 4-Report

2-Calibrate 5-Sensor

3-System 6-Advanced

Select Option (0 for previous menu):

--------------Report setup------------1-(*)Temp C A-( )Resist Ohm*cm

2-( )Temp F B-( )TDS g/L

3-( )Temp K C-( )TDS Kg/L

4-( )SpCond mS/cm D-( )Sal ppt

5-(*)SpCond uS/cm E-(*)DOsat %

6-( )Cond mS/cm F-(*)DO mg/L

7-( )Cond uS/cm G-( )DOchrg

8-( )Resist MOhm*cm H-(*)pH

9-( )Resist KOhm*cm I-( )pH mV

Select Option (0 for previous menu):

4. From Main menu press 6-Advanced, then 2-Setup. Verify that the screen below matches

what you see. It is very important that the Auto sleep options are activated, especially when the

sonde is being set up for deployment. For more details see Section 3 and your sonde manual.

----------------Advanced--------------1-Cal Constants 3-Sensor

2-Setup 4-Data Filter

Select Option (0 for previous menu):

-------------Advanced setup-----------1-(*)VT emulation

2-( )Power up to Menu

3-( )Power up to Run

4-( )Comma Radix

5-(*)Auto sleep RS232

6-(*)Auto sleep SDI12

7-( )Multi SDI12

Select Option (0 for previous menu):

Press 0’s to return to the statement that asks you to press Y or N to exit the sonde menu. Press Y

to exit the sonde menu. Close the Sonde-COM1 window and disconnect the adapters and cables.

Now you should connect the 6-series sonde to the 6200 DCP.

YSI/Massachusetts 508.748.0366, Fax 508.748.2543 Page 2-10

Page 20

YSI 6200 DAS USER Manual

2.5 Configuring the 6200 DCP using EcoWatch DCP

All sensors connect to the 6200 DCP (Data Collection Platform). The DCP electronics

physically reside inside the NEMA 4X enclosure. You should now have all of your sensors

connected and a “direct link” RS-232 cable running from the 6200 DCP a COM port on your PC

(COM1 in our example). You should have an antenna or RF cable connected to the antenna

connector on the 6200 enclosure and you should have installed the battery and connected the

power leads to positive and negative terminals. You are now ready to create a file, configure the

data collection platform, and begin collecting data using EcoWatch DCP. Follow the step-bystep instructions below to proceed.

Start by opening EcoWatch DCP, if it is not already running.

From the main screen click on the top line menu labeled 6200, then click on New... to bring up

the screen titled “Save 6200 DCP Configuration File As” Type in a filename of your choice (8

character maximum).

In the figure below the filename “checkout.s62” has been entered. Actually three

configuration files (.s62, .zcf, .ini) will be opened and saved in the location shown

(c:\ecowwin\sys6200). You have the option to direct the .s62 file to a location of your choice,

but we recommend that you accept the default path. Click on OK to proceed.

YSI/Massachusetts 508.748.0366, Fax 508.748.2543 Page 2-11

Page 21

YSI 6200 DAS USER Manual

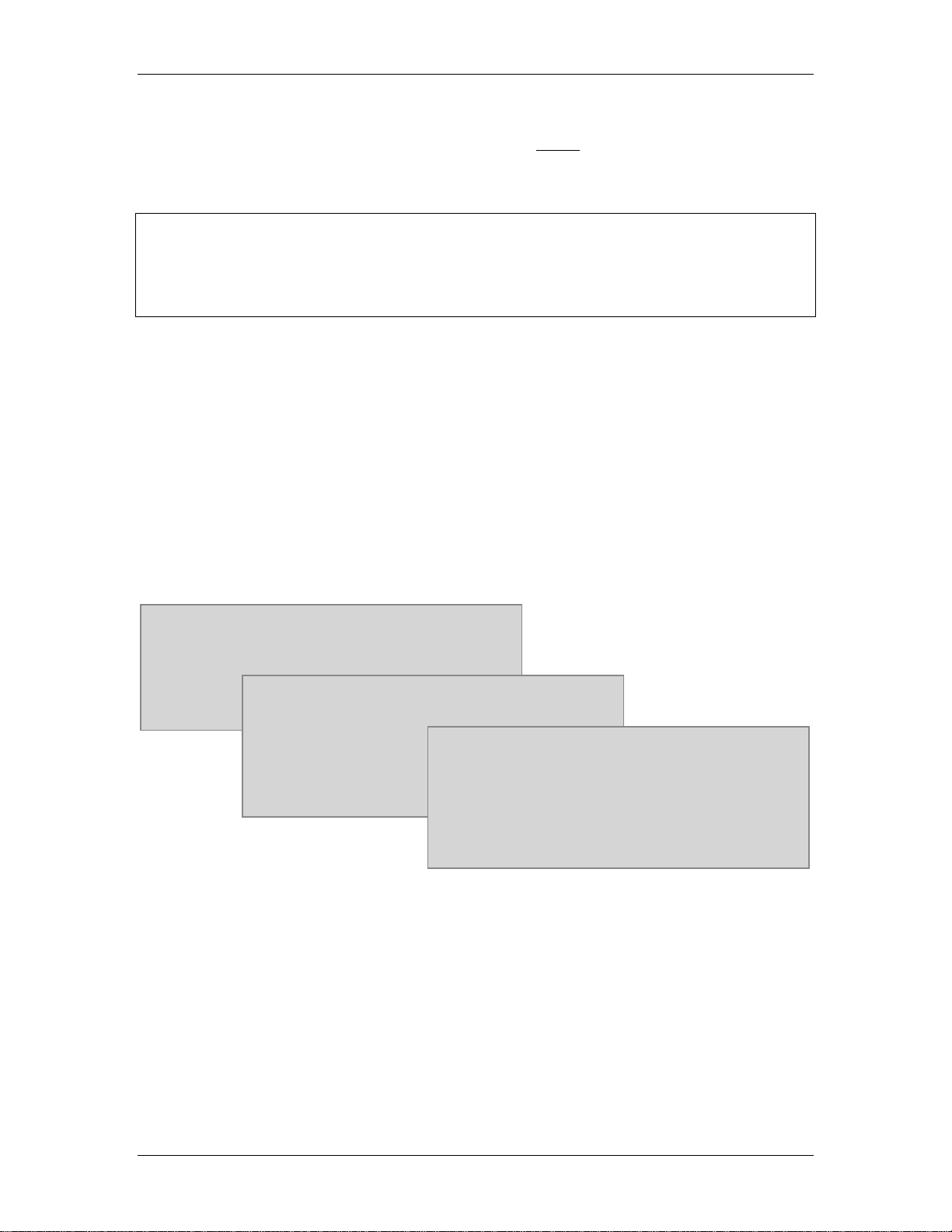

Once you click on OK several status screens will appear indicating that EcoWatch DCP is

attempting to detect the 6200 DCP and its sensors. The screens are part of an autoconfiguration

routine that searches for SDI-12 sensors (sondes) and MET sensors (meteorological sensors).

The screens are titled “6200 DCP ConfigWizard”. An example below shows that a sonde with

SDI-12 Address 0 has been detected after scanning addresses 0 to 8. EcoWatch DCP searches

from Addresses 0 to 9, by default. The sonde with the address of 0 will be the only address

detected in your checkout procedure.

YSI/Massachusetts 508.748.0366, Fax 508.748.2543 Page 2-12

Page 22

YSI 6200 DAS USER Manual

After completing the scan of SDI-12 sensors, the software switches to a ConfigWizard screen

that shows the status of the scan of meteorological sensors. If a MET sensor requires entry of a

calibration constant, a screen appears. Only the solar radiation sensor and barometer sensor

require a calibration constant, which is provided in the sensor literature or included in the back of

the manual. Each time you make a New 6200 file you will need to enter these calibration

constants. A good place to save these calibration constants is with the manual. Below you see

the MET status window and the screen for entering the calibration constants for the solar

radiation sensor (pyranometer) and the barometer.

Enter the numbers from the certificates, then click on Next and proceed to the next screen in

ConfigWizard.

YSI/Massachusetts 508.748.0366, Fax 508.748.2543 Page 2-13

Page 23

YSI 6200 DAS USER Manual

The next choice relates to the communication option that you will be using for this particular file.

For example, if you ordered a system with a 2-way radio, click on the appropriate circle.

Remember that even though you may be “directly” communicating with the 6200 DCP field

station during configuration, you must choose the mode of communication you will use for field

installation.

In our laboratory setup and checkout procedure we will be initially communicating directly via

RS-232 cable. Therefore the default choice shown below is correct. Click on Next to proceed.

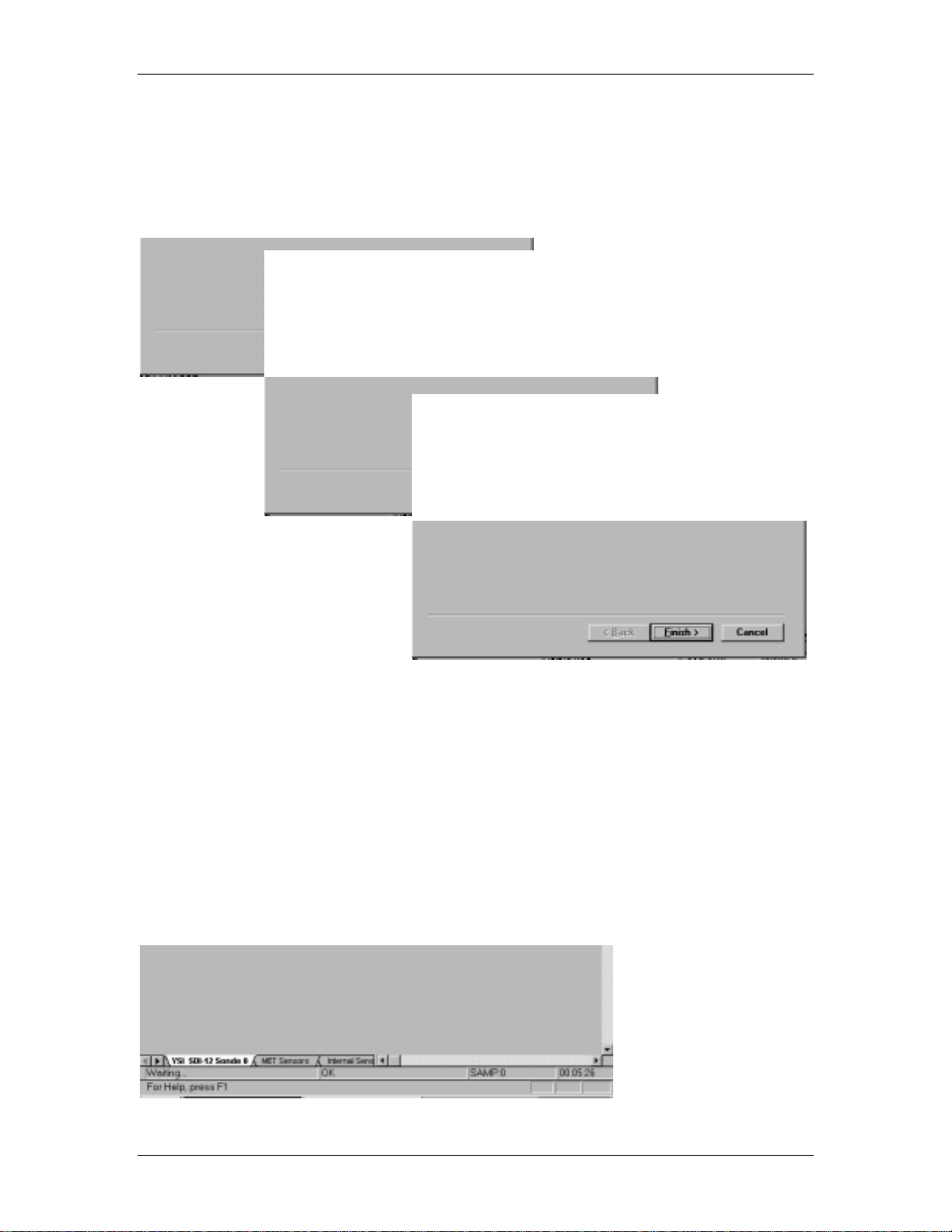

EcoWatch DCP now completes its configuration of the 6200 DCP. See the example screens

below.

YSI/Massachusetts 508.748.0366, Fax 508.748.2543 Page 2-14

Page 24

YSI 6200 DAS USER Manual

The last step EcoWatch DCP will do is to reboot the 6200 DCP, and you should hear a long

beep. After you click on Finish, a report form similar to the one shown below appears on the

screen.

YSI/Massachusetts 508.748.0366, Fax 508.748.2543 Page 2-15

Page 25

YSI 6200 DAS USER Manual

2.6 Testing the 6200 DCP

At this point you have connected the 6200 DCP components, installed EcoWatch DCP and run

the ConfigWizard. You are ready to begin collecting data and display it on EcoWatch DCP. In

order to perform a test that provides data in a timely manner for testing, click on 6200, then

6200 DCP Setup. The following screen should appear.

Click on System… to open the window related to system settings. A message will appear to

alert you that any data remaining in memory in the 6200 DCP will be erased if system settings

are changed. This does not mean that data already uploaded to EcoWatch DCP will be lost. See

Section 7 for more details on the consequences of changing system or sensor settings.

Click on Yes to continue and notice that there are two “folders”, Site/Timing and

Communication/Power. Site/Timing will appear first and the Description box will be

highlighted. By default, it reads <noname100>. The number 100 is the number EcoWatch

DCP has assigned this field station, and may be any number between 100 and 999 since this

value increments each time a new field station is setup. You may type in a description of your

choice or you may tab to the next box, thereby accepting the default description. The next box is

Sample Interval, that is the time that elapses between samples being logged to the data

collection platform (DCP). The default value is 15 (minutes). Do not confuse this with

YSI/Massachusetts 508.748.0366, Fax 508.748.2543 Page 2-16

Page 26

YSI 6200 DAS USER Manual

EcoWatch DCP interrogation timing. Even when EcoWatch DCP is not running, the DCP

continues to log data to its memory once it has been configured.

The next selection gives you the choice of interrogating the DCP at the same rate as the sample

interval or, alternatively, choosing some number of minutes independent of the DCP sample

interval. For the 6200 Test, set the interrogation schedule to “Same as Sample Interval” by

clicking on the box just to the left of this choice. Also change the Sample Interval to 2 or 3

minutes during the checkout routine in order to collect readings more quickly.

1

Now click on the Communication/Power folder and verify that communication is Direct

Connect to PC and the COM port agrees with the serial port to which you are connected

(COM1 in our example screen). The power option should be Battery. The information related

to MODEM communications is not relevant at this point.

YSI/Massachusetts 508.748.0366, Fax 508.748.2543 Page 2-17

Page 27

YSI 6200 DAS USER Manual

Click on OK to exit the menu and return to the main EcoWatch DCP menu screen. A window

appears momentarily, displaying the message Programming 6200...Please Wait. When

EcoWatch DCP is done downloading the new configuration it will reboot the 6200 DCP. You

should hear a long beep from the 6200 DCP as it starts up again.

Once the main menu appears, click on 6200 to pull down the menu and click on Interrogate

Now. Any data that has been collected by the DCP will appear. If readings do not appear

initially, you will need to wait as much time as the sample interval you chose above. A

countdown timer in the lower right corner of the window will give you the time to next

interrogation.

Below you see readings that have been uploaded to EcoWatch DCP from the 6200 DCP. Up to

seven lines of data may be displayed at one time, the bottom line being the most current. Note

that there are three separate display “sheets”. Simply click on the sheet label near the bottom of

each window to view readings from YSI SDI-12 Sonde 0, MET Sensors, or Internal Sensors.

You can not display all sensor readings in one window simultaneously.

YSI/Massachusetts 508.748.0366, Fax 508.748.2543 Page 2-18

Page 28

YSI 6200 DAS USER Manual

If you have difficulty viewing the readings on a sheet, you have two options. One...click and

hold on a vertical line that separates description headers. While holding the mouse button down

you can resize the column width. Two...Click on 6200, Data Table Setup, Font/Color...

The default font/size is Arial/11. Change this to suit your needs. For example, changing the size

from 11 to 9 will fit more information on one screen without the need to scroll.

2.7 Testing Sensor Function

Now that you are able to view readings, you may wish to perform some preliminary tests of

sensor function. As you have seen some readings display 0.000 in the checkout testing. For

example, rain fall and accumulation, wind speed and direction and solar radiation probably have

zero readings. Here are some quick tests you can perform.

For wind speed/direction locate the plastic arrow protruding from the MET Suite head assembly.

Rotate the MET head assembly on the support so that the arrow points north (0 degrees). East

would be 90, south 180 and west 270 degrees. Direction will not be displayed unless there is

measurable wind speed. To check wind speed set up a small fan to provide continuous air

motion in front of the propeller. During interrogation of the 6200 DCP, EcoWatch DCP will

upload readings showing wind speed and direction. In the example below the wind speed is

about 5.4 mph and the direction is 0

For rain rate/accumulation testing, remove the top assembly of the rain gauge to locate the

tipping buckets. Carefully tip the buckets from one position to the other 5 to 10 times in

YSI/Massachusetts 508.748.0366, Fax 508.748.2543 Page 2-19

°

, which is due north.

Page 29

YSI 6200 DAS USER Manual

succession. During the next sampling period, a rain fall between 0.05 and 0.10 inch should

appear after interrogation. A rain rate, calculated based on accumulation per unit time also

appears. For example, an accumulation of 0.06 inches in 15 minutes translates to a rate of 0.24

in/hour (4 15-minute intervals per hour, or 4 x 0.06).

For solar radiation remove the cap/dust cover and expose the sensor to natural light during the

test period.

Other sensors should be producing values that indicate functionality. For example, the sonde

temperature value should approximate room temperature. Relative humidity should be realistic

for your room conditions. Barometric pressure should approximate a reading uncorrected for sea

level. That means if you are not at sea level, altitude will cause a discrepancy between your

reading and the local weather bureau’s reading. If possible, use a calibrated laboratory barometer

to check for accuracy.

YSI/Massachusetts 508.748.0366, Fax 508.748.2543 Page 2-20

Page 30

YSI 6200 DAS USER Manual

2.8 Displaying Data in EcoWatch DCP

After you have uploaded several sets of readings into EcoWatch DCP, close the 6200 file by

choosing 6200, then Close.

Data files in EcoWatch DCP have a “.DAT” extension, unlike the 6200 DCP files which have

“.S62” extension. There is one data file generated for each set of sensors (SDI-12 Sonde, MET

and Internal). Each data file contains encrypted information related to time and identity of the

file. Using the data file below as an example (1077BM00.DAT), note the following...

107 The field station number, assigned by EcoWatch, and incremented with each new field

station.

7 The last number of the year, for example, 1997

B The month of the year where 1=January, 2=February and so on to 9=September

A=October, B=November and C=December

M Type of sensor where S=SDI-12 sonde, M=MET, I=Internal (eg, battery voltage)

0 SDI-12 Sonde Address, for example, Sonde Address 0 as shown above

0 Number indicating the set of data opened for a given record, 0=initial set.

If you change a report parameter or measurement unit for a file, the number increments

to 1, 2, 3… a, b, c… and so on.

Use the File command on the top level menu of EcoWatch DCP, then Open. Select the drive

and subdirectory where the data files are located, usually c:\ecowwin\data. Highlight or click on

the data file of the field station number and sensor type you wish to observe, then click OK.

Below you see meteorological data for record 107 collected on November 18, 1997. Readings

were collected every 2 minutes as part of a checkout procedure. Note the wind and rain events

on the graph. By default, EcoWatch DCP opens the data file in graphical format with one

parameter per graph. Autoscaling defines the upper and lower limits.

There are many options for displaying, reporting, and generally customizing the data in

EcoWatch DCP. This is discussed in detail in Section 7. The objective of this section is for you

to become generally familiar with this plotting/reporting software.

If you hold down the right mouse button you can scan through the data and show the actual

readings correlating events with times. See the example below, which shows wind

speed/direction events on the left side of the graph. We created these events in the 6200 DCP

checkout procedure by spinning the propeller during the sensor reading period. Note that the

wind speed/direction is zero for all other times.

To observe actual data records, click View, Data Table from the pull-down menus. After a

while you will learn to use the icons and variety of other techniques for viewing, plotting and

reporting data.

YSI/Massachusetts 508.748.0366, Fax 508.748.2543 Page 2-21

Page 31

YSI 6200 DAS USER Manual

This completes the Getting Started section of the manual. You should now take time to become

thoroughly informed about the 6200 DAS by reading all sections of the manual that pertain to the

specific system you have received. Not all sections apply since there are a number of

communication, power and sensor options.

IMPORTANT! Before continuing, remember that the DCP continues to collect data from the

sensors at whatever interval you set (e.g., every 2 minutes). The DCP will continue collecting

data at this rate until the battery runs down to an unusable level or until you reconfigure the DCP

to collect at a different interval. We recommend that you return to the 6200 menu, Open the

file checkout.s62 (or other name that you assigned) and from the 6200 menu, 6200 DCP

Setup, System… submenu and change the Sample Interval to a larger number (60 minutes

or more). This change conserves power and will help extend the life of some of the sensors (DO,

for example). If the battery power level drops too low, the 6200 will automatically turn off.

YSI/Massachusetts 508.748.0366, Fax 508.748.2543 Page 2-22

Page 32

YSI 6200 DAS USER Manual

Section 3

Setting Up a 6-Series Sonde

3.1 Introduction

This section is designed to familiarize you with the settings a 6-Series Sonde must have to w ork

with the 6200 DAS. It will also describe how to access the sonde m enus throug h EcoWatch D CP.

You should refer to the sonde user manual provided with each sonde to learn mo re about setup and

calibration of your particular sonde model.

By the end of Section 3 you will have...

♦ Connected your sonde to the PC and verified communication

♦ Prepared the sonde to communicate with the 6200 DCP

♦ Enabled the sensors, selected appropriate report parameters and calibrated the activated sensors

for field deployment

Successful completion of the above list is essential before you deploy a sonde in the field. If you

read Section 2 Getting Started, some of the following information will be redundant. However, in

the previous section the main objective was to check out the 6200 DCP. In this section the focus

turns to proper setup of the sonde for field deployment.

3.2 Communicating with a Sonde

The most common configuration for communicating with your 6-Series sonde will be through a

PC loaded with EcoWatch DCP software. You also have the option to use the YSI 610-D or 610DM handheld display. The 610 has a communication mode which allows you to configure

parameters, display readings and calibrate sondes. The 610 is also battery-powered and waterresistant, which makes it very useful for sonde calibration performed at a field station, especially

when AC power is unavailable.

Below are hardware illustrations and lists of parts required for both PC and 610 configurations.

For the purpose of describing sonde setup and calibration we will need a PC with EcoWatch

DCP and encourage you to perform this in the laboratory or similar location. If you choose to

use a 610 for calibration, refer to the manual provided with the 610. Note that when accessing

the sonde software with either PC or 610, the menus are virtually identical.

EcoWatch DCP is designed to allow you to fully control the 6200 DCP field station. It also has

all of the functionality of standard EcoWatch which includes a terminal for setting up and

calibrating a sonde. Some features of a sonde can be set through EcoWatch DCP such as turning

sensors on or off and determining what parameters to report. However, calibrating the sonde can

not be done through the 6200 DCP. You will need to either bring the sonde into the lab or use a

610 in the field for calibration.

YSI/Massachusetts 508.748.0366, Fax 508.748.2543 Page 3-1

Page 33

YSI 6200 DAS USER Manual

Y

6-Series So nde to Lab Compute r

DB-9

Power Supply

6037: 220 VAC

6038: 110 VAC

MS-8

6095B

Adapter

Cable

60

6-Series Sonde

You will need...

❑

6-Series Sonde

❑

Computer with Com Port

❑

Power Supply

❑

6095B MS-8/DB-9 Adapter

❑

DB-9 to DB-25 Adapter may

be needed at Com Port

6-Series So nde to 610 Display/Logger

6098 MS-8 Adapter

Environmental

Monitoring

SI

MS-8

Cable

6-Series Sonde

Systems

610-DM

600

610-D or 610-DM

You will need...

❑

6-Series Sonde

❑

610-D Displayor

❑

610-DM Display/Logger

❑

6098 MS-8 Adapter for 610

YSI 610’s operate on rechargeable batteries.

Each 610 comes with a 110 VAC Wall Socket Charger Unit.

YSI/Massachusetts 508.748.0366, Fax 508.748.2543 Page 3-2

Page 34

YSI 6200 DAS USER Manual

3.3 Connecting a Sonde to a Computer with EcoWatch DCP

In order to assign sonde sensors, report parameters, sonde address and various “advanced”

parameters, you will need to connect the sonde to your PC (or 610) and communicate through

EcoWatch DCP. The diagram below helps describe this connection.

In addition to the sonde, you need a

cable. The cable may be a field cable

permanently attached to the sonde or

you may need to connect a separate

field or cal cable to the bulkhead

connector.

Regardless of the type, the cable

Power Supply

6037: 220 VAC

6038: 110 VAC

MS-8

DB-9

6095B

Adapter

Computer with

EcoWatch DCP

terminates in an MS-8 connector.

Cable

Many sondes also requires power in

order to communicate with the PCbased software. A 6095B Adapter

and a 6038 (or 6037) Power Supply

600

6-Series Sonde

are required to make the connection.

The PC-end of the adapter is a DB-9

which is a typical COM port

connector. If your PC has a DB-25

connector, you will need another

adapter (25 to 9 pin).

Figure 3.1 Sonde to PC Connection

Identify your PC COM port, for example, COM 1, COM 2, etc. You need this information to

establish communication between the sonde and EcoWatch DCP. If your COM port is not

clearly marked, assume that it is COM1 for now. You can reconfigure for COM2 (or other COM

port) if communication is not established during setup.

Following the diagrams and information above connect your sonde to your PC.

Run the EcoWatch DCP program. Click on Comm, then choose Sonde from the pull-down

menu. Verify the COM port selection and click OK to open a new window labeled Sonde -

COM2.

At the # sign type in “menu”. When you press Enter, you will enter the main sonde menu. It

will appear similar to the screen below. Any difference is related to the model of sonde you are

using.

YSI/Massachusetts 508.748.0366, Fax 508.748.2543 Page 3-3

Page 35

YSI 6200 DAS USER Manual

If you are unable to establish interaction with the sonde, make sure that the cable is properly

connected, power is applied (e.g., 6038 Power Supply or other 12 VDC source), and that the

COM port is set correctly. If you were unsure of your COM port number, reassign another port

number and repeat the steps above.

3.4 Preparing the Sonde to Communicate with the 6200 DCP

The sonde software is menu-driven. Select a function by typing its corresponding number or

character. It is not necessary to press Enter after a number/character selection. Use the 0 or Esc

key to return to a previous menu. The mouse does not interact with the sonde menus.

Note: If a single k eystr oke yields no response on the screen, press the key again. You

should now see a reaction. This occurs when a key is not pressed for a period of time

sending the sonde into a “sleep mode”. The first press of the key “wakes” up the sonde

and the second press activates the command.

In order to properly assign sensors and parameters for the sonde, follow the step-by-step

instructions below. The illustrations and numbers may differ some from your screens, since

sonde menus vary somewhat from model to model.

YSI/Massachusetts 508.748.0366, Fax 508.748.2543 Page 3-4

Page 36

YSI 6200 DAS USER Manual

To communicate with the 6200 DCP the sonde needs to have these three items setup properly:

1. Communication at 9600 baud with Auto baud

2. A unique SDI-12 address

3. The SDI-12 autosleep function on

From Main menu press 3-System, then 1-Comm setup.

1-Comm setup allows you to confirm the baud rate at 9600, which is the default value. You

should also confirm that the Auto baud has a (*). This assures that the sonde will work properly

with a 610. Press 0 to return to the previous menu System setup.

4-SDI-12 address of the sonde is 0 by default. You may assign any character between 0 - 9

and A - F to provide a specific address for your sonde. This is of particular importance in multisonde applications involving the 6200 DAS. If you are deploying multiple sondes then they each

must have a unique address. Usually, you would start with 0, then make the next sonde 1, then

the next sonde 2… and so on. Up to 16 sondes can be connected to one 6200 DCP. Press 0 to

return to previous menus until you return to Main.

-----------------Main----------------1-Run 4-Report

2-Calibrate 5-Sensor

3-System 6-Advanced

-----------System-setup-----------------

Select Option (0 for previous menu):

1-Comm setup

2-Page length=25

3-Instrument ID

4-SDI-12 address=0

Select Option (0 for previous menu):

--------------Comm-setup-------------1-(*)Auto baud 5-( )2400 baud

2-( )300 baud 6-( )4800 baud

3-( )600 baud 7-(*)9600 baud

4-( )1200 baud

Select Option (0 for previous menu):

YSI/Massachusetts 508.748.0366, Fax 508.748.2543 Page 3-5

Page 37

YSI 6200 DAS USER Manual

From Main menu press 6-Advanced, then 2-Setup. Verify that the screens below matches

what you see. It is very important that the Auto sleep options are activated, especially when the

sonde is being set up for deployment. For more details see your sonde manual.

----------------Advanced--------------1-Cal Constants 3-Sensor

2-Setup 4-Data Filter

Select Option (0 for previous menu):

-------------Advanced setup-----------1-(*)VT emulation

2-( )Power up to Menu

3-( )Power up to Run

4-( )Comma Radix

5-(*)Auto sleep RS232

6-(*)Auto sleep SDI12

7-( )Multi SDI12

Select Option (0 for previous menu):

Now press 0 twice to return to the Main menu.

3.5 Installing and Calibratin g Sonde Sensors

You are now ready to calibrate your 6-Series Sonde. Refer to the calibration and setup sections

in your users manual that comes with your sonde.

General Calibration Tips

Your YSI 6-Series Sonde will prov ide accurate sensor readings when used with the 6200 DAS only

if it is calibrated properly! Thus, a complete understanding of the procedures is required. The

calibration of the sensors is not difficult, but does require proper attention to detail. The key is to

follow the recommended procedures in general and, m o re specifically , to tak e y our time during

calibrations. Remember that the sonde will be deploy ed for sev eral w eek s betw een recov eries for

maintenance and, therefore, a few extra minutes during calibration is not sig nificant in the ov erall

timeframe of its use. After several deploy ments, you should be able to complete calibration of all

sensors within 30 minutes, but it might tak e somewhat longer until you becom e fam iliar w ith the

software prompts and the protocols. The extra time expended during initial calibration to “g et it

right” will be well worth the effort.

NOTE: The barometer reading from the 6200 DAS (if installed) is not corrected for sea level. You

may use this value if the calibration constant was entered when the system was setup. Barometer

readings which appear in meteorological reports are generally corrected to sea level. If you are not

at sea level, you must “uncorrect” these readings before entering them in the calibration procedure.

YSI/Massachusetts 508.748.0366, Fax 508.748.2543 Page 3-6

Page 38

YSI 6200 DAS USER Manual

Section 4

Powering the Field Station

4.1 Introduction

There are three options for powering the field station. All involve using a rechargeable lead acid

battery (12 volt, 12 Amp Hour) that is mounted inside the 6200 DCP (field station).

One option is to use the battery as the sole source of power. A fully charged battery lasts from a

few days to a few weeks, depending on the number and type of sensors and the mode and

frequency of communication. The battery is easy to remove, requiring no tools. Low batteries

may be recharged using a P/N 6254 Charger. One approach to powering would be to use two

batteries and periodically swap out one for the other, recharging the low battery at the Lab or

office.

A second option is to use AC power, which continuously recharges the battery. When you order

the AC Power Option, a power module is installed in the interface plate inside the enclosure.

The module contains a 3-prong male receptacle, voltage selector and fuse compartment. A

power cable (provided) plugs into the receptacle and is used in both setup and permanent

installation procedures to provide AC power. Predrilled holes in the bottom of the NEMA

enclosure are designed for use with standard conduit fittings. Cabling may be routed through ½”

conduit to interface the charging circuit with the AC power source.

A third option is to use a solar panel (10 watt rating) with the field station. This unit is designed

for use in a nominal 12 VDC system. The 6200 DCP uses the solar energy to power the board

and recharge the battery for continuous operation. A dedicated 2-conductor receptacle and plug

are installed inside the NEMA enclosure for easy access to connect the solar cable to the 6200

DCP. Cabling may be routed through conduit or a feed-through gland to interface the power

circuit with the solar panels.

4.2 General Wiring Information

WARNING!

Wiring should be per formed by a qualified electrician.

Do not make connections while power is applied. Disconnect power before proceeding.

This part of the installation of the 6200 DCP will vary considerably depending on the installation

setup you have chosen. Refer to Appendix E if you have not determined your installation setup.

Refer to sections below for specific power options and read thoroughly all general wiring

instructions before proceeding with the installation.

YSI Massachusetts 508.748.0366, Fax 508.748.2543 Page 4-1

Page 39

YSI 6200 DAS USER Manual

Connections and Routing...

All of the standard sensors (water quality and meteorological) have pre-wired waterproof

connectors on the bottom of the 6200 DCP. See Figure 4.1 to locate specific connector sites. In

addition, there are two holes (0.875 in or 22 mm) in the bottom of the enclosure for use with

conduit fittings or feed-through glands. These holes are plugged with NEMA 4X rated seals.

One of the two holes should be used for power lines in the options involving AC or solar power.

The second hole may be used for a phone line, direct serial cable, or for non-standard sensors

that must be wired to the expansion terminal block inside the enclosure. We do not recommend

that you route power cables and sensor cables through the same conduit hole.

Grounding...

Although there are several options related to powering your 6200 DCP field station, you should

properly ground the 6200 DCP. Refer to Figure 4.1 to locate the earth ground connector. We

recommend #6 standard copper wire connected to a 6’ grounding rod to earth ground your DCP,

however refer to your local wiring codes to insure proper grounding installation.

DCP Enclosure

Front Cover

bottom view of en c los ure

Front C o ver

6-Ser ies Sonde

MET Suite

Pyranometer

Earth Ground

Connector

Rain Gauge

Conduit Fittings for AC,

solar, and pho n e lines

Barome te r Vent

RF (N -T ype)

Figure 4.1 6200 DCP, Bottom View

In addition to the ground connector, notice the four MS waterproof connectors for the sensors,

including the 6-Series Sonde connector. If you are installing sondes at your field station, note

that the sondes are powered by the 6200 DCP and are operated with a “floating” ground. This

requires that the sonde not be individually grounded. Grounding the sonde individually will

cause a “ground loop”, i.e., one conductor of the sonde output grounded common to both the

sonde and the DCP circuitry. Grounding the sonde will cause significant performance problems

with the sensors and will likely result in erroneous readings.

CAUTION!

Do not ground the sonde body.

YSI Massachusetts 508.748.0366, Fax 508.748.2543 Page 4-2

Page 40

YSI 6200 DAS USER Manual

Lightning and Surge Protection...

The standard 6200 DCP has full isolation and lightning protection on all external connections

and standard internals such as telephone connection, DB-9 serial communications port and the

solar charger. You may purchase a factory-installed option that provides full isolation and

lightning protection on the expansion terminal block, which is not provided on the standard unit.

See Appendix D, Accessories. To insure maximum protection route grounding wire from the

6200 DCP to the grounding rod by the shortest possible distance.

For additional protection you should install a surge protection device on any AC line supplying

power to the 6200 DCP. AC line voltage suppressers protect field equipment on any AC line

from damage due to electrical transients induced in the interconnecting power lines, from

lightning discharges, and other high voltage surges. The unit should include noise filtering,

common mode and normal mode suppression, and nanosecond reaction time. Surge suppressers

should be internally fused to remove the load if the unit is overloaded or the internal protection

fails.

Lightning protection devices should be located as close to the 6200 DCP as possible and wired in

accordance with local codes in approved watertight enclosures.

NOTE

This or any other installation procedure can not prot ect against a direct lightning strike.

YSI can not accept liability for damage due to lightning or secondary surges.

Safety Issues...

To avoid possible electrical shock, do not attempt to access any of the components behind the

front panel inside the 6200 DCP enclosure. Disconnect external power to the unit before

connecting or disconnecting wiring to any of the connectors located inside the DCP enclosure.

WARNING!

Turn off all power and assure power “lockout ” before servicing

to avoid contact with electrically powered circuits.

YSI Massachusetts 508.748.0366, Fax 508.748.2543 Page 4-3

Page 41

YSI 6200 DAS USER Manual

4.3 Installing the Battery

This section describes the procedure for powering a 6200 DCP that will operate in the field on

battery power only. As described in Section 2, the battery is shipped in a separate carton and

therefore must be installed into the 6200 DCP enclosure. No tools are required to install the

battery.

CAUTION!

Before installing the batt er y read all inst r uctions and safety information included with the

battery including any safety labels attached to the bat tery or its carton.

CAUTION!

If you have a unit with a 2-way radio, connect the antenna to the RF connector on the

bottom of the enclosure before powering the 6200 DCP. This will avoid possible

permanent damage to the radio t r ansceiver.

Slide the battery into the open area (shown in Figure 4.2). The battery leads should be visible

from a grommet in the interface plate. Connect the red lead to the positive terminal by sliding

the tab connector over the battery tab. Connect the blue lead to the negative terminal in the same

way. Your 6200 DCP is now powered. It will beep for about 5 seconds during boot up.

Battery

+

Analog Inputs

Digi tal I/ O

Solar Power In

Phone

COM Port

Figure 4.2 Installing the Battery

Battery

Compartment

Antenna cable

Battery

+

Desiccant Pa ck

CONNECT ANTENNA CABL E TO RF

CONNECTOR IF RADIO INSTALLED

.

YSI Massachusetts 508.748.0366, Fax 508.748.2543 Page 4-4

Page 42

YSI 6200 DAS USER Manual

4.4 Installing A C Power to the Field Station

WARNING!

Wiring should be performed only by a qualified electrician.

Do not make connections while AC main power is applied.

CAUTION!

If you have a unit with a 2-way radio, connect the antenna to the RF connector on the

bottom of the enclosure before powering the 6200 DCP. This will avoid possible

permanent damage to the radio t r ansceiver.

The 6200 DCP has a switchable power supply that can operate on 100 to 240 V~, 50/60 Hz power.

The power setting that you require must be v erified and set, if necessary . The default power setting

is 120 V~. If you need to change the voltag e setting refer to Fig ure 4.3 and do the follow ing . Use a

small blade screwdriver to pry open the fuse cover from the top. Remove the voltage selector drum,

rotate it so the desired setting will show through the window in the cov er, then replace the drum. If

you need to change the fuse, be sure that it is installed in the right side. Snap the cover back into

place and proceed with the AC power installation.

Pry open cover here

AC Power Receptacle

Fuse Compartment

Voltage Ind ica to r

Fuse Holders

Voltage Selector...100, 120, 220, 240 Vac

Remove drum, rotate to desired voltage

and replace.

Cover rotate d up

Figure 4.3 AC Power Module, Setting the Voltage

The 8ft (2.4 m) power cord provided with the 6200 can be used to check out the system in the

laboratory or other suitable location, and then later cut and spliced into AC power for permanent

installation. The power cord has a 3-prong standard plug for 120 V~ receptacles. If this plug is not

suitable for your facility, you will need to provide an equivalent cord or cut and splice the power

cable for the checkout setup. Refer to Figure 4.4 for illustrations.

A battery comes with every 6200 DCP. The AC power option is designed so that the battery is

continually charged while AC power is available. If AC power should fail, the battery serv es as a

backup.

Installation and connection of the battery is described above in Section 4.3. For now you may place

the battery in the battery compartm ent. Y ou m ay want to leave the battery terminals unconnected

YSI Massachusetts 508.748.0366, Fax 508.748.2543 Page 4-5

Page 43

YSI 6200 DAS USER Manual

until the AC power installation is complete. I f y ou connect the battery , and it is adequately charg ed,

the 6200 DCP will begin logging data to memory based on it’s last settings.

AC Power Receptacle...

3-prong male, recessed

8’ AC Power Cable...

3-prong female and standard

120 VAC male connectors

Desiccant Pack

100-240 VAC, 50/60 Hz

Switchable Power Module

Battery

+

Battery

Analog Inputs

AC Power In

Digital I/O

Solar Power In

+

Phone

Conduit

COM Port

Analog Inputs

Desiccant Pack

Conduit

8’ AC Power Cable with

3-prong female connector

Standard Outdoor

Junction Box

Digital I/O

Phone

Solar Power In

COM Port

CAUTION!

Install power switch as close as

possible to DCP enclosure.

WARNING!

Power cord with plug is not

used for permanent installation.

to be

Figure 4.4 AC Powering of 6200 DCP

To meet compliance with UL3010, EN61010 and CSA 1010, install a power switch on the AC load

line external to the 6200 DCP enclosure. We recommend that you install the switch near the 6200

DCP enclosure (see junction box in Figure 4.4) and choose a suitable switch that can be locked.

(Note: AC on/off power switch and junction box is not included with the 6200 system.) Check

local electrical codes for proper installation.

Use the following precautions from UL 508 as a g uide to safety for personnel and property.

1. AC connections and grounding must be in compliance with UL 508 and/or local electrical

codes.

2. This type 4/4X enclosure requires a conduit hub or equivalent that provides watertight

connection, REF UL 508-26.10.

3. Watertight fittings/hubs must comply with the requirements of UL 514B.

Conduit hubs are to be connected to the conduit before the hub is connected to the enclosure, REF

UL 508.26.10.

YSI Massachusetts 508.748.0366, Fax 508.748.2543 Page 4-6

Page 44

YSI 6200 DAS USER Manual

The electrical system must be g rounded to av oid possible electrical shock or damage to the

equipment. See Section 4.2 which contains information related to grounding, routing wires and

lightning and surge protection.

WARNING!

Turn off all power and assure power “lockout” before servicing

to avoid contact with electrically powered circuits.

Once you have installed AC power to the 6200 DCP, connect the battery leads as described in