Page 1

6000UPG

Multi-Parameter

Water Quality Monitor

Instruction Manual

YSI Incorporated

1725 Brannum Lane

Yellow Springs, OH 45387

(800) 765-4974 (513) 767-7241

Fax (513) 767-9353

â

Page 2

TABLE OF CONTENTS

Page

SECTION 1 INTRODUCTION

1.1 DESCRIPTION 1-1

1.2 GENERAL SPECIFICATIONS 1-3

1.3 SENSOR SPECIFICATIONS 1-4

1.4 HOW TO USE THIS MANUAL 1-6

SECTION 2 GETTING STARTED

2.1 UNPACKING 2-1

2.2 SYSTEM CONFIGURATION 2-1

2.3 SONDE SETUP 2-5

SENSORS 2-5

BATTERIES 2-12

CABLES 2-14

POWER OPTIONS 2-14

SONDE/COMPUTER INTERFACE 2-15

2.4 SOFTWARE INSTALLATION 2-15

2.5 PC6000 SOFTWARE SETUP 2-16

2.6 SONDE SOFTWARE SETUP 2-19

SECTION 3 BASIC OPERATION

3.1 GETTING READY TO CALIBRATE 3-1

3.2 CALIBRATION PROCEDURES 3-2

CONDUCTIVITY 3-4

DISSOLVED OXYGEN 3-5

DEPTH 3-6

pH 3-6

AMMONIUM 3-7

NITRATE 3-7

TURBIDITY 3-8

3.3 DISCRETE SAMPLING 3-9

3.4 UNATTENDED SAMPLING 3-12

3.5 RETRIEVING DATA 3-14

3.6 ANALYZING DATA 3-16

SECTION 4 SONDE MENU

4.1 RUN 4-1

4.2 CALIBRATE 4-9

4.3 FILE 4-14

4.4 STATUS 4-18

4.5 SYSTEM SETUP 4-19

4.6 REPORT SETUP 4-21

4.7 SENSOR SETUP 4-22

4.8 DIAGNOSTICS 4-24

Page 3

SECTION 5 PC6000 SOFTWARE

5.1 INTRODUCTION 5-1

5.2 INSTALLING THE PC6000 SOFTWARE 5-1

5.3 THE SONDE MENU 5-3

5.4 THE FILE MENU 5-3

5.5 THE SETUP MENU 5-20

5.6 DATA CAPTURE/REAL-TIME SETUP 5-23

5.7 ADVANCED SETUP 5-25

SECTION 6 PRINCIPLES OF OPERATION

6.1 CONDUCTIVITY 6-1

6.2 SALINITY 6-2

6.3 OXIDATION REDUCTION POTENTIAL (ORP) 6-2

6.4 pH 6-4

6.5 DEPTH 6-5

6.6 TEMPERATURE 6-6

6.7 DISSOLVED OXYGEN 6-6

6.8 NITRATE 6-9

6.9 AMMONIUM AND AMMONIA 6-11

6.10 TURBIDITY 6-14

Page

SECTION 7 MAINTENANCE

7.1 SONDE MAINTENANCE 7-1

7.2 PROBE MAINTENANCE 7-4

7.3 GENERAL MAINTENANCE NOTE 7-7

SECTION 8 TROUBLESHOOTING

SONDE COMMUNICATION PROBLEMS 8-2

SENSOR PERFORMANCE PROBLEMS 8-2

SOFTWARE PROBLEMS 8-5

SECTION 9 COMMUNICATION

9.1 OVERVIEW 9-1

9.2 HARDWARE INTERFACE 9-1

9.3 SDI-12 INTERFACE 9-2

9.4 RS-232 INTERFACE 9-7

9.5 FILE TRANSFER PROTOCOLS 9-7

9.6 FILE FORMATS 9-8

9.7 MODEM SETUP 9-9

Page 4

APPENDIX A HEALTH AND SAFETY

APPENDIX B REQUIRED NOTICE

APPENDIX C WARRANTY AND SERVICE INFORMATION

APPENDIX D ACCESSORIES AND REAGENTS

APPENDIX E APPLICATION NOTE

APPENDIX F SOLUBILITY AND PRESSURE/ALTITUDE TABLES

APPENDIX G SENSOR AND SONDE STORAGE RECOMMENDATIONS

APPENDIX H TURBIDITY MEASUREMENTS WITH THE 6820

APPENDIX I SYSTEM ERRORS AND WARNINGS

Page 5

1. INTRODUCTION

1.1 DESCRIPTION

The 6000UPG Environmental Monitoring System is a multiparam eter, w ater quality measurement,

and data logging system . It is intended for use in research, assessment, and regulatory com pliance

applications.

Measurement parameters include:

• Dissolved Oxygen

• Conductiv ity

• Specific Conductance

• Salinity

• Total Dissolv ed S olids

• Resistivity

• Tem perature

• pH

• ORP

• Depth

• Level

• Am monium/Ammonia

• Nitrate

• Turbidity

The 6000

UPG is ideal for profiling and monitoring w ater conditions in lak es, riv ers, w etlands,

estuaries, coastal waters, and monitoring wells. It can be left unattended for week s at a tim e with

measurement parameters sampled at a user-defined setup interval and data securely saved in the

unit's internal memory. The 6000

water, or in as little as a few inches of water. The fast sensor response of the 6000

UPG can be used 500 feet (152 meters) below the surface of the

UPG and its

built-in data logging make it ideal for vertical profiling. Its small size means it can fit dow n 4 inch

(10.2 cm) diameter monitoring wells.

A patented Rapid Pulse Dissolved Oxygen Sensor exhibits low stirring dependence and, therefore

provides accurate results without an expensive and bulky stirrer. Because stirring is not required,

battery life is extended. In addition, because of the nature of the technology, sensor drift caused by

passive fouling is minimiz ed.

The Model 6000

UPG is designed to house 4 field-replaceable probes (6 sensors) and the option to

add a depth sensor module to the sonde body. If necessary, the dissolved oxygen-conductivitytemperature, pH, amm onium, nitrate ORP, and turbidity sensors are quickly replaced in the field.

The 6000

program. Every 6000

UPG communicates with an A SC I I terminal or a computer with a terminal emulation

UPG comes with IBM-compatible PC-based software for sim ple and conv enient

setup and data handling. Reports and plots are automatically generated and their presentation easily

customized. Data is easily exported to any spreadsheet prog ram for more sophisticated data

processing.

1-1

Page 6

The RS-232C and SDI-12 interfaces provide maximu m v ersatility for system networking and real

time data collection. Several 6000

valuable water quality data at a variety of depths. For real time results, the 6000

UPG units are easily installed in a vertical string prov iding

UPG can interface to

radio telemetry system s and satellite, telephone, or cellular phone data collection platforms. In

addition, the unit can be used with our 610-D or 610-DM display /logger for profiling or spot

sampling applications. The 6000

UPG is equipped with sensor and communication circuitry to

eliminate ground loop interference.

When the 6000

UPG is factory configured for internal power, it operates using eig ht C-size alkaline

batteries. These batteries are easily replaced in the field, without disassembly of the unit. The

minimal power requirements of the Rapid Pulse Dissolv ed Oxy g en Sensor combined with

state-of-the-art electronic circuits and software can prov ide up to 90 day s of battery life during

normal use, depending on the activated sensor configuration.

The 6000

UPG comes standard with 256 kilobytes of memory; this is enough to store 150,000

individual parameter readings for a typical deploy ment.

Optional cables are available for interfacing the 6000

UPG with a computer, terminal, or

display/logger. These cables are waterproof at the sonde connection and can be used in the lab or

field.

See Appendix D for a complete list of accessories and calibration reagents.

1-2

Page 7

1.2 GENERAL SPECIFICATIONS

See also Section 1.3 Sensor Specifications.

Operating Environment

Medium: fresh, sea, or polluted water

Temperature: -5 to +45 °C

Depth: 0 to 500 feet (152 meters)

Storage Temperature: -40 to +60 °C

Material: PVC, Stainless Steel

Dimensions

Diameter: 3.5 inches (8.9 centimeters)

Length: 19.5 inches (49.5 centimeters)

Weight: 6.5 pounds (3.0 kilograms) , with batteries

Computer Interface

RS-232C

SDI-12

Software

PC6000

IBM PC compatible com puter, 3 1/2 or 5 1/4 inch, hig h or low density disk driv e.

Minimum RAM requirement: 256 k ilobytes

Optional graphic adapter for plotting

Ecowatch for Windows (optional)

IBM PC compatible com puter with 3 1/2 inch disk driv e and with a 386 processor (or

better) running Windows version 3.1 (or later).

Minimum RAM requirement: 4 megabytes

Internal logging memory size (typical deployment)

256 kilobytes (150,000 individual parameter reading s)

512 kilobytes (300,000 individual parameter reading s)

Power (two options)

12 VDC (8 C-size Alkaline Batteries)

External 12 VDC

Battery Life

120 days without dissolved oxygen and turbidity sensor activ ation

90 days without turbidity sensor activation

45 days with dissolved oxygen and turbidity sensor activ ation

1-3

Page 8

1.3 SENSOR SPECIFICATIONS

The following are typical performance specifications for each sensor.

Depth - Deep

Sensor Type...........Stainless steel strain gauge

Range.....................0 to 500 ft (152 m)

Accuracy................+/- 1 ft (0.3 m)

Resolution..............0.001 ft (0.001 m)

Depth - Medium

Sensor Type...........Stainless steel strain gauge

Range.....................0 to 200 ft (61 m)

Accuracy................+/- 0.4 ft (0.12 m)

Resolution..............0.001 ft (0.001 m)

Depth - Shallow

Sensor Type..............Stainless steel strain gauge

Range........................0-30 ft (9.1 m)

Accuracy ................ +/- 0.06 ft (0.018 m)

Range........................0.001 ft (0.001 m)

Temperature

Sensor Type...........Thermistor

Range.....................-5 to 45 °C

Accuracy................+/- 0.15 °C (optional configuration at +/- 0.05 °C)

Resolution..............0.01 °C

Dissolved Oxygen % saturation

Sensor Type...........Rapid Pulse - Clark-ty pe, polarog raphic

Range.....................0 to 200 % air saturation

Accuracy................+/- 2 % air saturation

Resolution..............0.1 % air saturation

Dissolved Oxygen mg/L (Calculated from % air saturation, temperature and salinity)

Sensor Type............ Rapid Pulse - Clark-ty pe, polarog raphic

Range.....................0 to 20 mg/L

Accuracy................+/- 0.2 mg/L

Resolution..............0.01 mg/L

Conductivity

*

Sensor Type...........4 electrode cell with autoranging

Range.....................0 to 100 mS/cm

Accuracy................+/- 0.5% of reading + 0.001 mS /cm

Resolution..............0.01 mS/cm or 1 uS/cm

* Report outputs of specific conductance (conductivity corrected to 25 C), resistivity, and total dissolved

solids are also provided. These values are automatically calculated from conductivity according to

algorithms found in Standard Methods for the Examination of Water and Wastewater (ed. 1989).

1-4

Page 9

Salinity

Sensor Type............Calculated from conductivity and tem perature

Range......................0 to 70 ppt

Accuracy.................+/- 1.0% of reading or 0.1 ppt, whichever is g reater

Resolution...............0.01 ppt

pH

Sensor Type...........Glass combination electrode

Range.....................2 to 14 units

Accuracy................+/- 0.2 units

Resolution..............0.01 units

pH - Low Ionic Strength

Sensor Type...........Glass combination electrode with open junction and low impedance glass

Range.....................2 to 14 units

Accuracy................+/- 0.2 units

Resolution..............0.01 units

ORP

Sensor type............ Platinum ring

Range.....................-999 to +999 mV

Accuracy................+/-20 mV

Resolution...............0.1 mV

Nitrate-Nitrogen

Sensor Type...........Ion selective electrode

Range.....................0 to 200 mg/L-N

Accuracy................ +/- 10% of reading or 2 m g /L, whichev er is g reater

Resolution..............0.1 mg/L

Ammonium-Nitrogen

Sensor Type...........Ion selective electrode

Range.....................0 to 200 mg/L-N

Accuracy................ +/- 10% of reading or 2 m g /L, whichev er is g reater

Resolution..............0.1 mg/L

Ammonia

Sensor Type...........Calculated from ammonium, pH, and temperature

Range.....................0 to 200 mg/L-N

Accuracy................ +/- 10% of reading or 2 m g /L, whichev er is g reater

Resolution..............0.1 mg/L

Turbidity

Sensor Type...........Optical, 90 degree scatter, mechanical cleaning

Range.....................0 to 1000 NTU

Accuracy................ +/- 5% of reading or 2 NTU, whichever is greater

Resolution..............0.1 NTU

1-5

Page 10

1.4 HOW TO USE THIS MANUAL

The manual is organized to let you quick ly understand and operate the 6000UPG system. However, it

cannot be stressed too strongly that informed and safe operation is m ore than just knowing which

buttons to push. An understanding of the principles of operation, calibration techniques, and

system setup is necessary to obtain accurate and m eaning ful results.

Sections 2 and 3 help you get started, providing initial setup information as well as calibration and

basic operating instructions. Sections 4 and 5 provide detailed information on the Sonde software

structure and YSI PC6000 software, respectively. PC6000 is PC- based software desig ned to help

the user to easily generate reports and plots from the data collected by the sonde. Sections 6-8

address principles of operation, sonde and sensor maintenance, and system troubleshooting .

Section 9 provides more detailed information on com munications protocols. Section 10 provides

service and repair information. The appendices (A-H) prov ide information on safety, warranty,

accessories, options, storage recommendations, and m ore.

NOTE: Because of the many features, configurations and applications of this versatile product,

some sections of this manual may not apply to the specific sy stem you have purchased.

The 6000

probes, cables and accessories can be ordered as options or ordered together as a system.

If you have any questions about this product or its application, please contact our customer service

department or authorized dealer for assistance. See Appendix C for contact information.

UPG can be purchased with or without internal battery power capability. A dditionally , all

1-6

Page 11

2. GETTING STARTED

This section is designed to quickly familiariz e y ou w ith the hardware and softw are components of

the 6000

connections, software installation and finally basic communication with the 6000

Diagrams, menu flow charts and basic written instructions w ill g uide y ou throug h basic hardw are

and software setup. For the first time user, we encourage the use a personal computer with PC6000

software during this initial setup procedure.

By the end of Section 2 you will have...

❏ Installed sensors in your sonde

❏ Installed PC6000 software in your PC

❏ Established communication between the sonde software and PC software

❏ Enabled appropriate sensors

❏ Assigned appropriate report parameters and units

Successful completion of the above list is essential for you to continue on to Section 3 which

focuses on performing calibrations and mak ing m easurements.

2.1 UNPACKING

UPG sonde and its accessories. You will then proceed to sensor installations, cable

UPG Sonde.

Remove the instrument from the shipping container. Be careful not to discard any parts or supplies.

Check off all items on the packing list and inspect all assemblies and components for damag e. If

any parts are damaged or m issing , contact y our representativ e immediately. If y ou do not k now

from which dealer your 6000

NOTE: Reagents for the 6000

UPG was purchased, refer to Appendix C for contact information.

UPG are not packaged in the same carton as the instrument. These

materials must be ordered separately and w ill arriv e in a separate pack ag e.

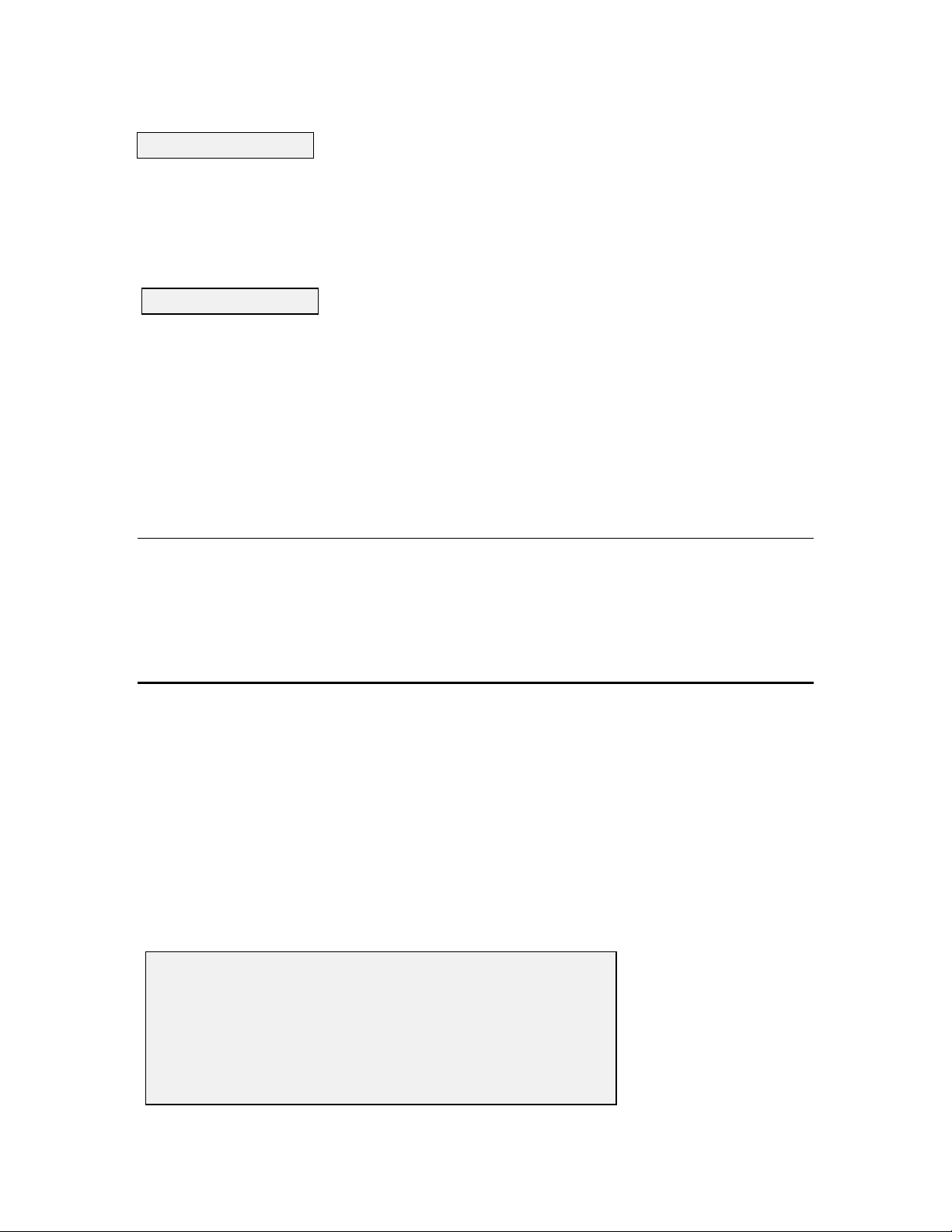

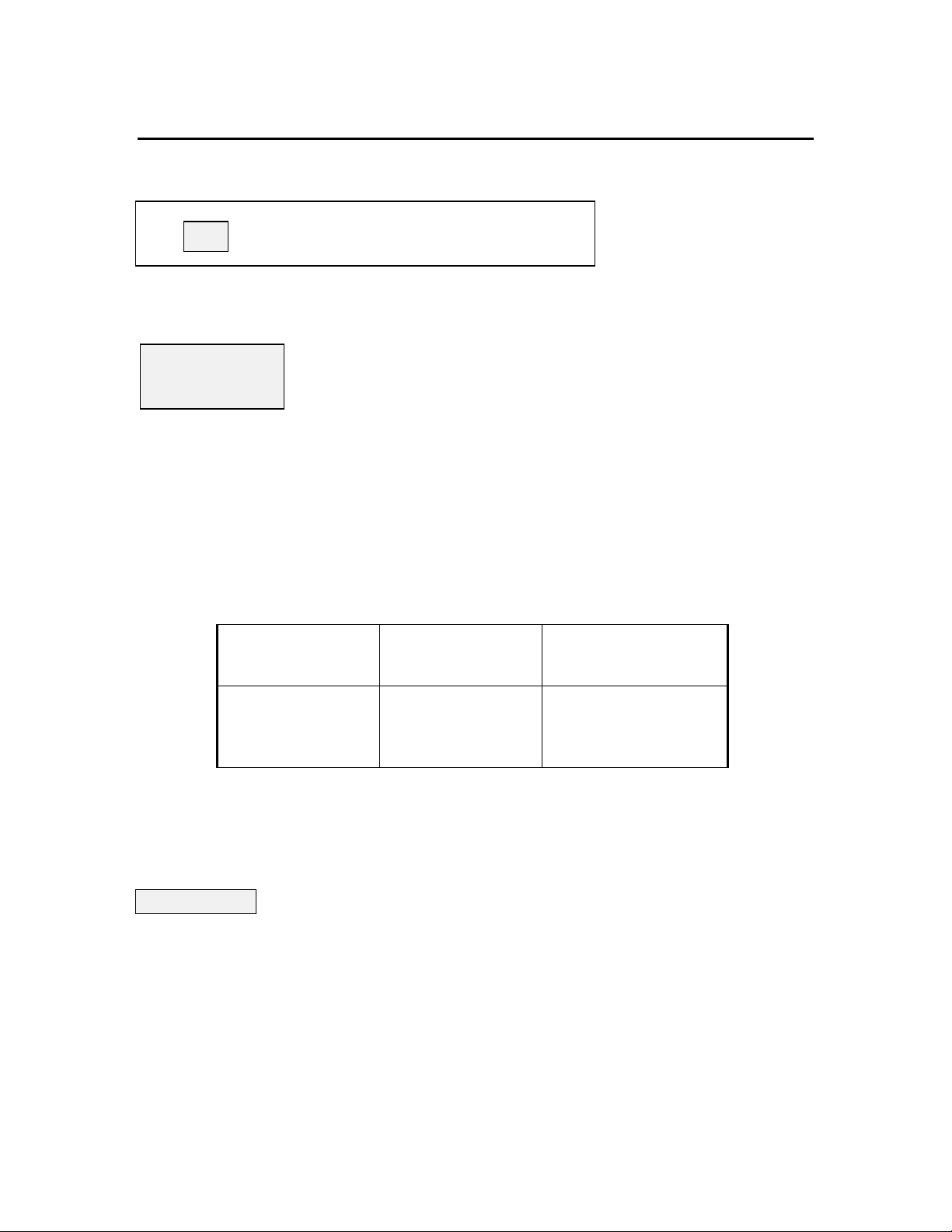

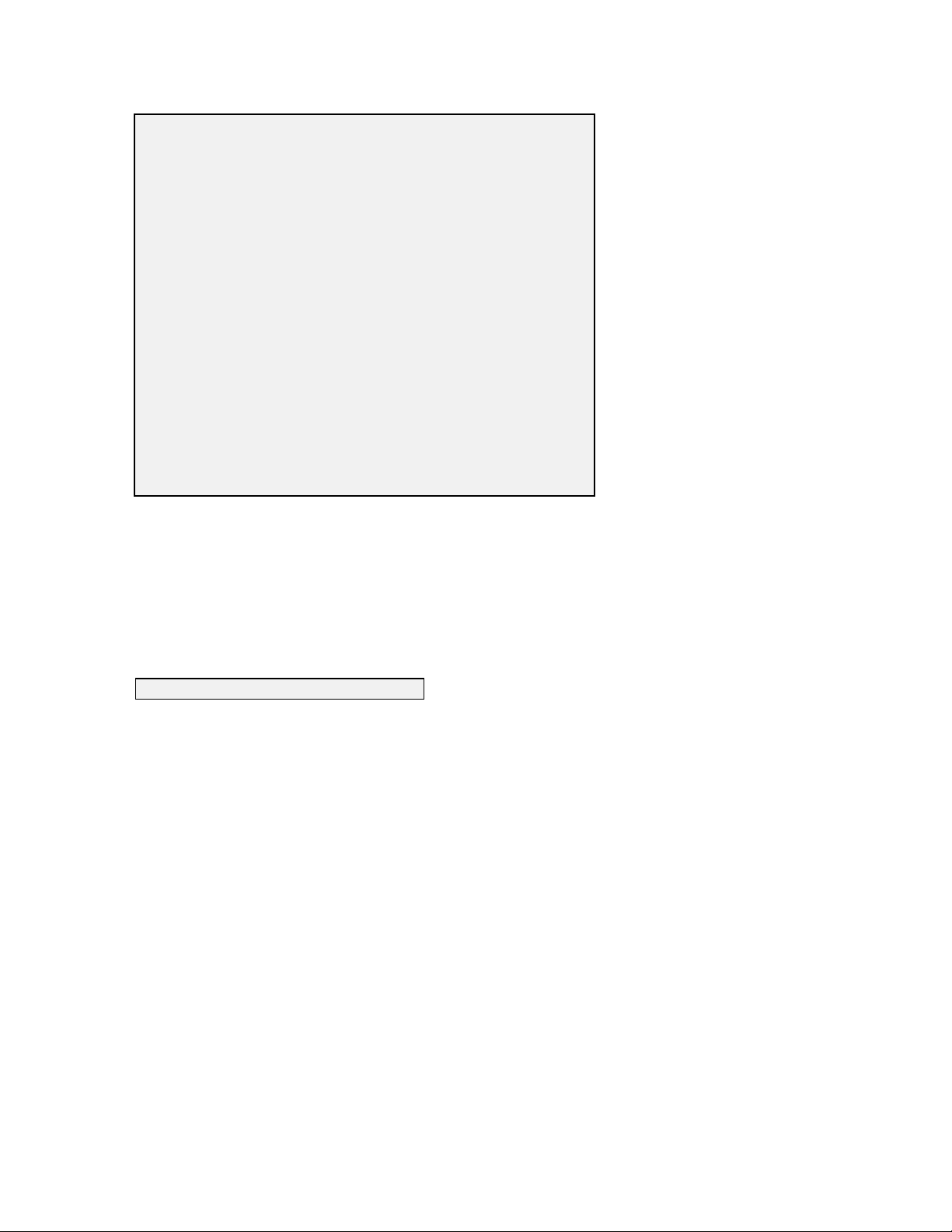

2.2 SYSTEM CONFIGURATION

There are a number of ways in which you may configure the 6000UPG Sonde with various

computers, terminals, and data collection devices. You should think about your particular

application needs and then make certain that you have all of the components you need to make

your system work. Below is a list of possible configurations that may be of interest to you. Each

is depicted in diagrammatic sketches on the next 3 pages.

❏ 6000

❏ 6000

❏ 6000

❏ 6000

❏ Upload Data from 6000

❏ Upload Data Files from YSI 610 to Lab Computer

UPG Sonde to YSI 610 Display/Logger

UPG Sonde to Portable Computer

UPG Sonde to Data Collection Platform

UPG Sonde to Lab Computer

UPG Sonde to YSI 610-DM

2-1

Page 12

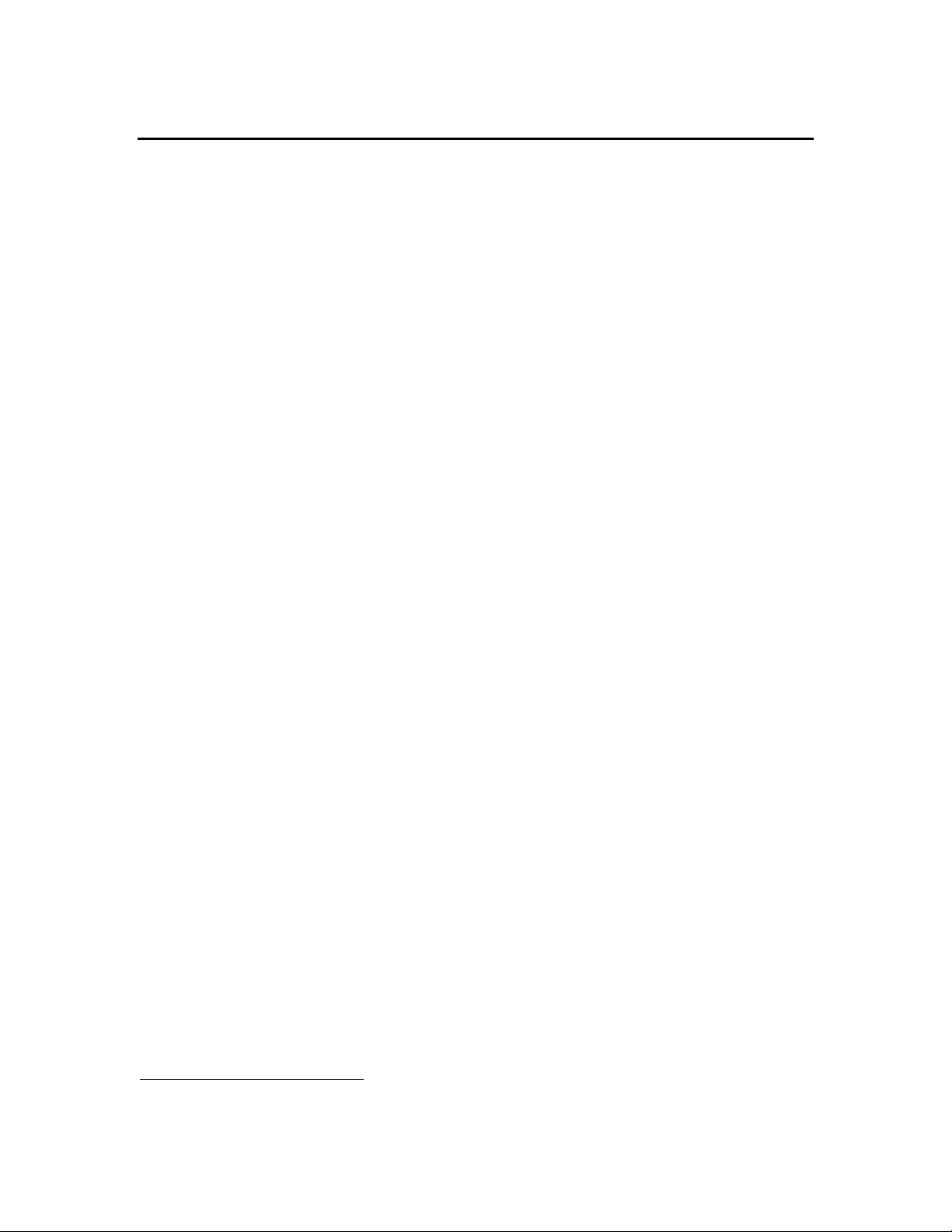

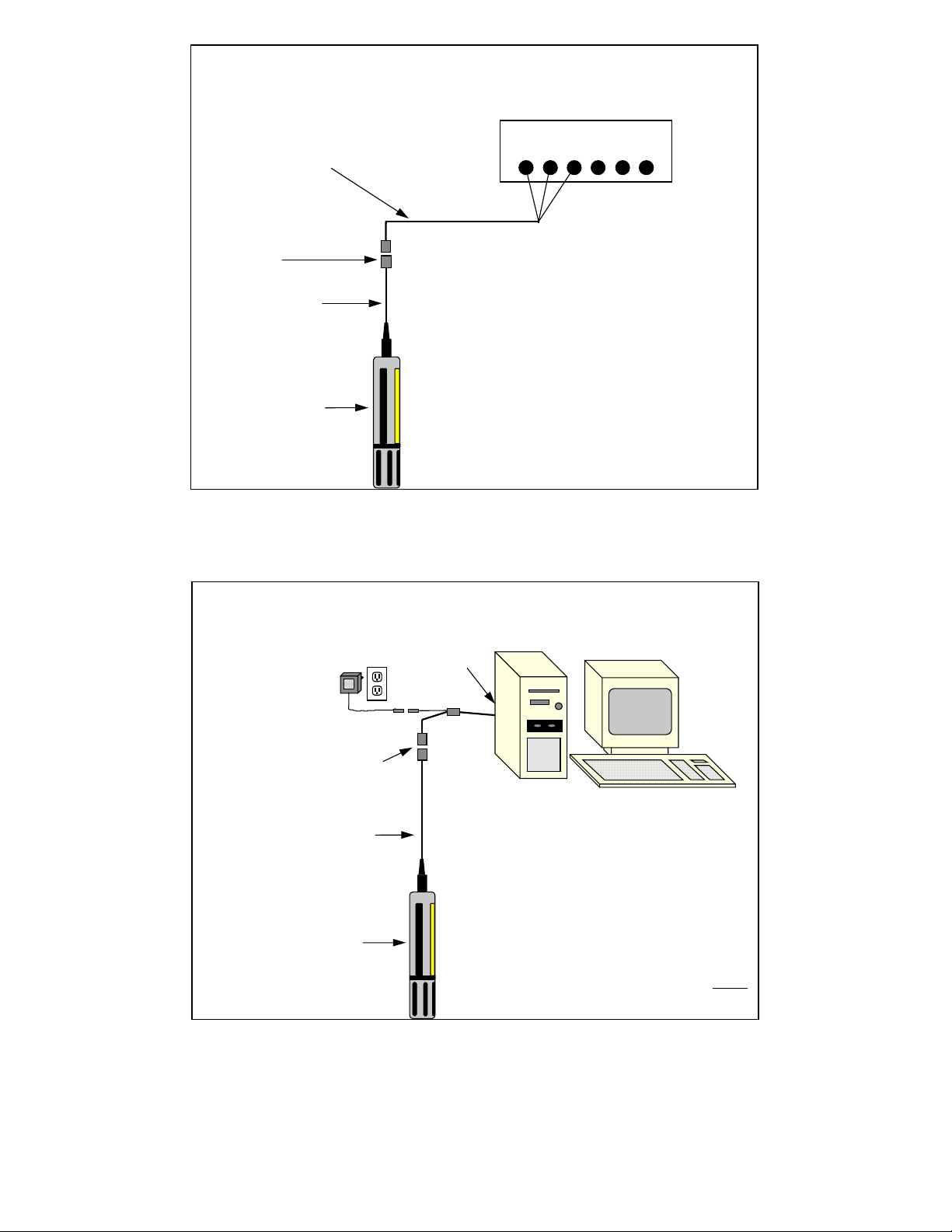

6000UPG Sonde to 610 Display/L ogger

6098 MS-8 Adapter

MS-8

Environmental

Monitoring

YSI

Systems

610-DM

610-D or 610-DM

Cable

You will need...

❑ 6000UPG Sonde

❑ 610-D Display or

6000UPG

6000UPG Sonde

❑ 610-DM Display/Logger

❑ 6098 MS-8 Adapter for 610

YSI 610’s operate on rechargeable batteries.

Each 610 comes with a 110 VAC Wall Socket Charger Unit.

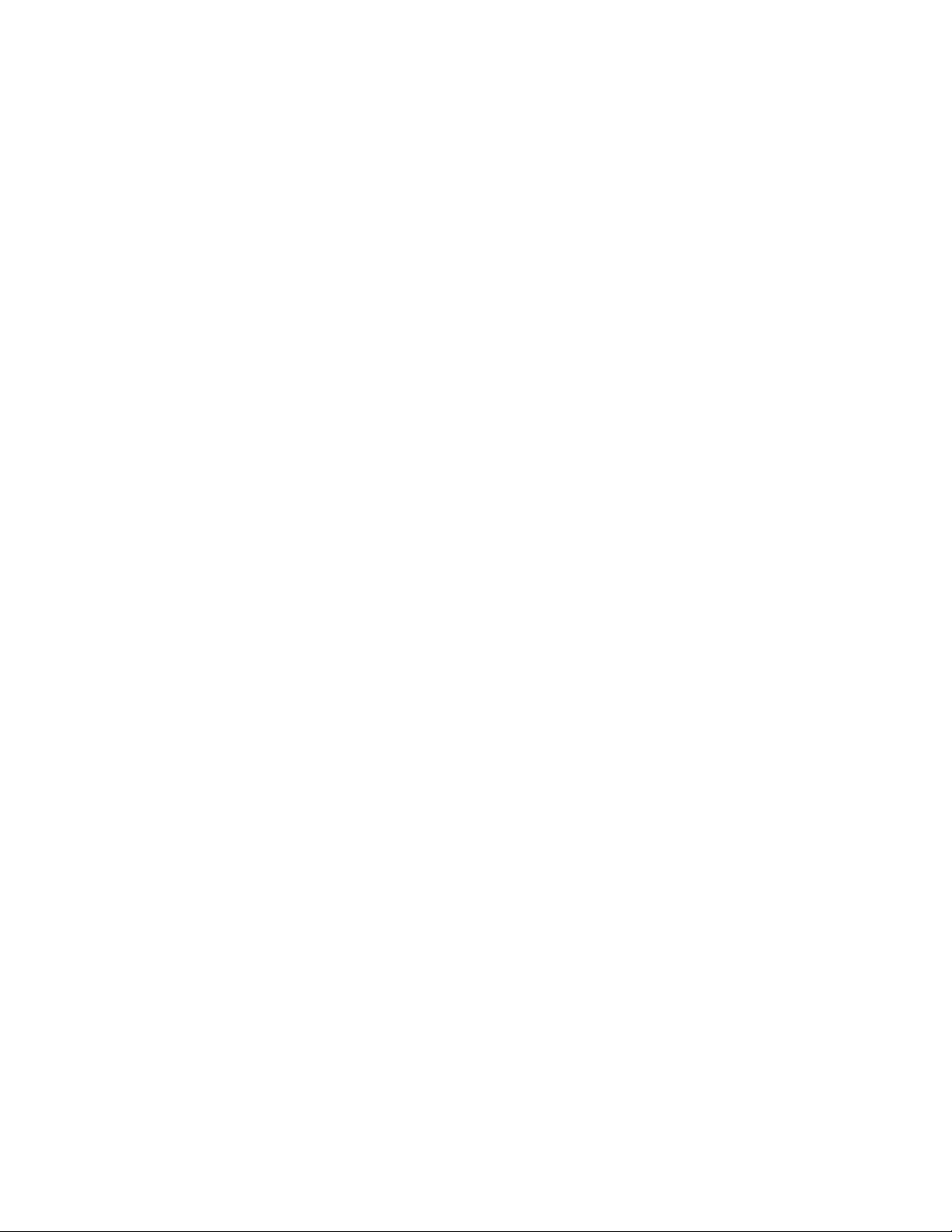

6000UPG Sonde to Portable Computer

DB-9

6095B

Adapter

MS-8

Cable

6000UPG Sonde

You will need...

❑ 6000UPG Sonde

❑ Computer with Com Port

❑ 6095B MS-8/DB-9 Adapter

6000UPG

2-2

Page 13

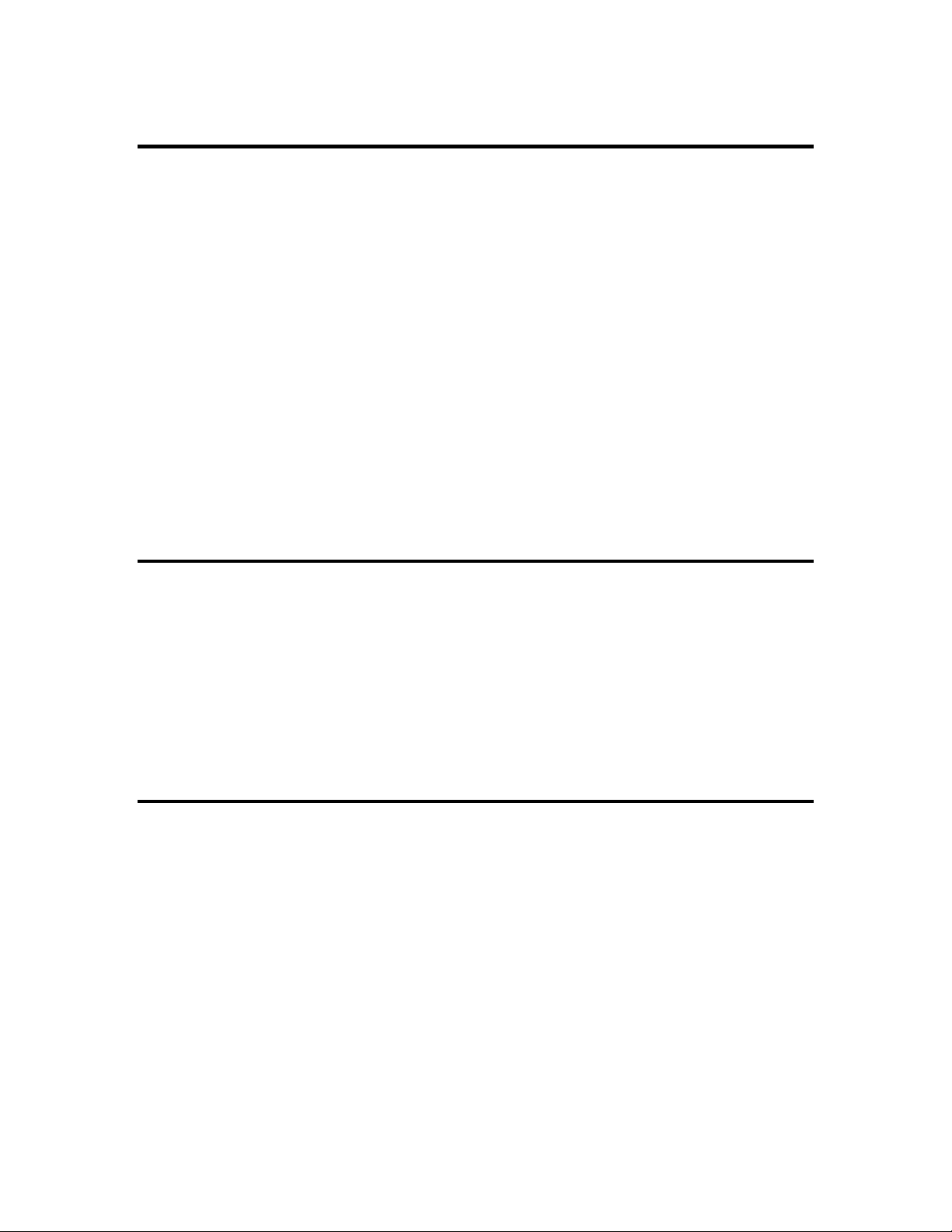

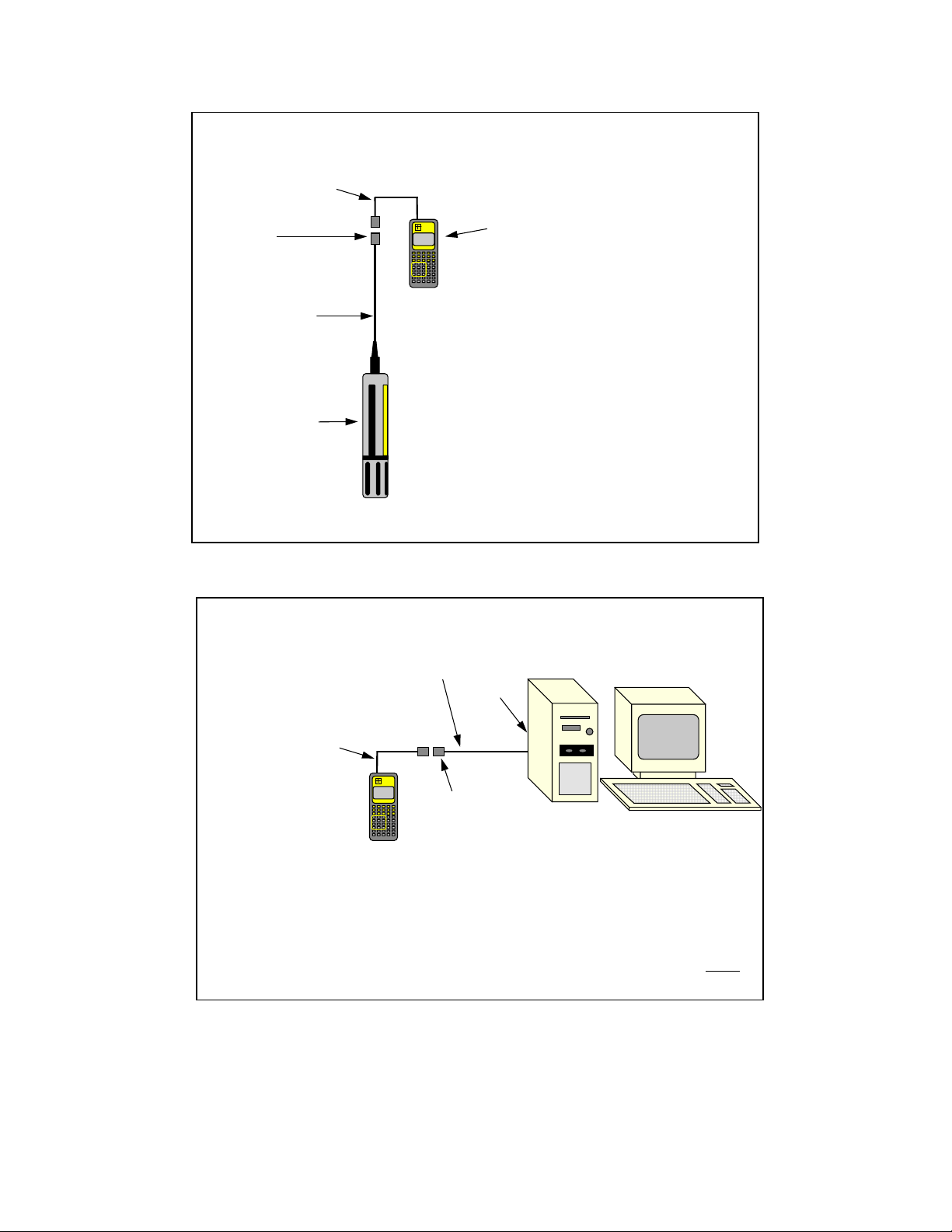

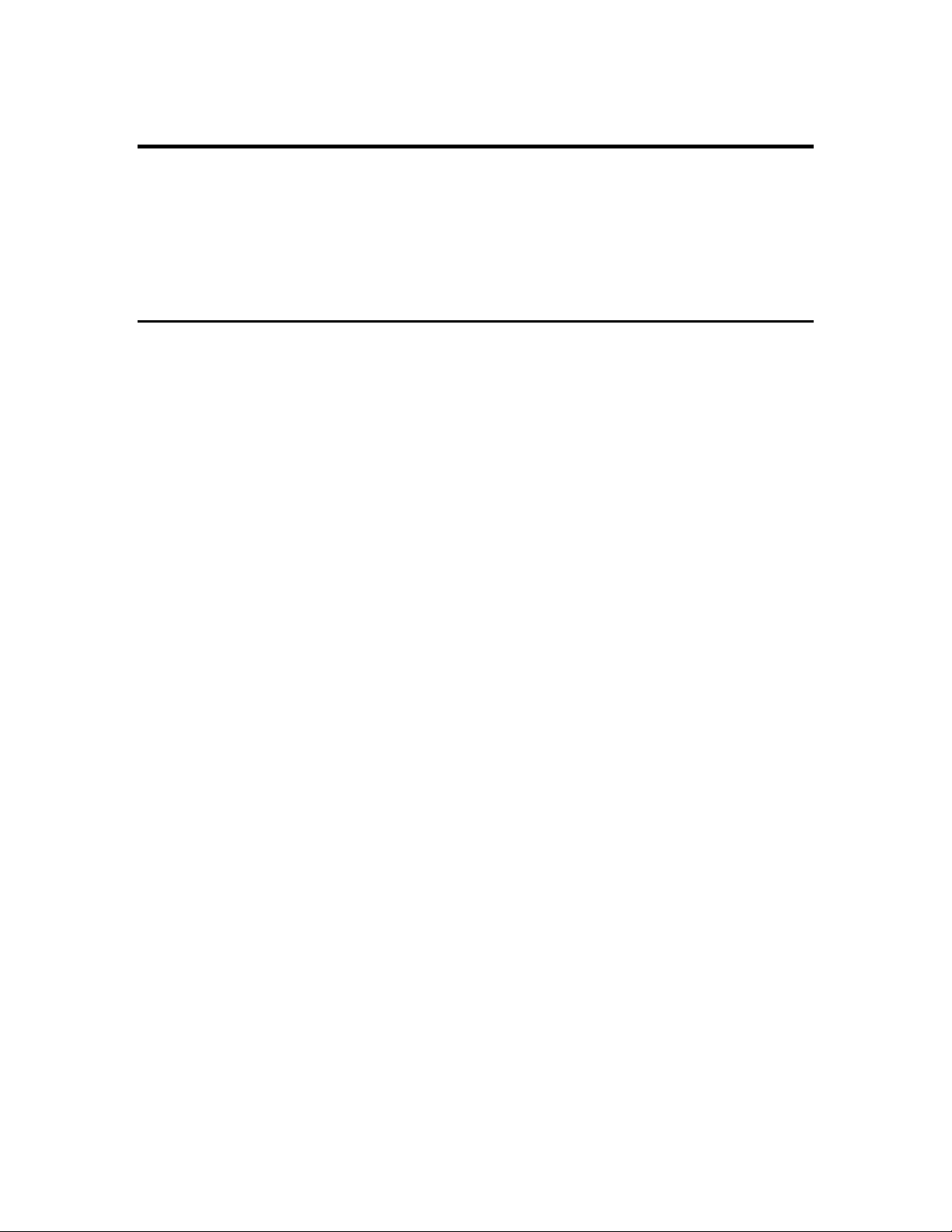

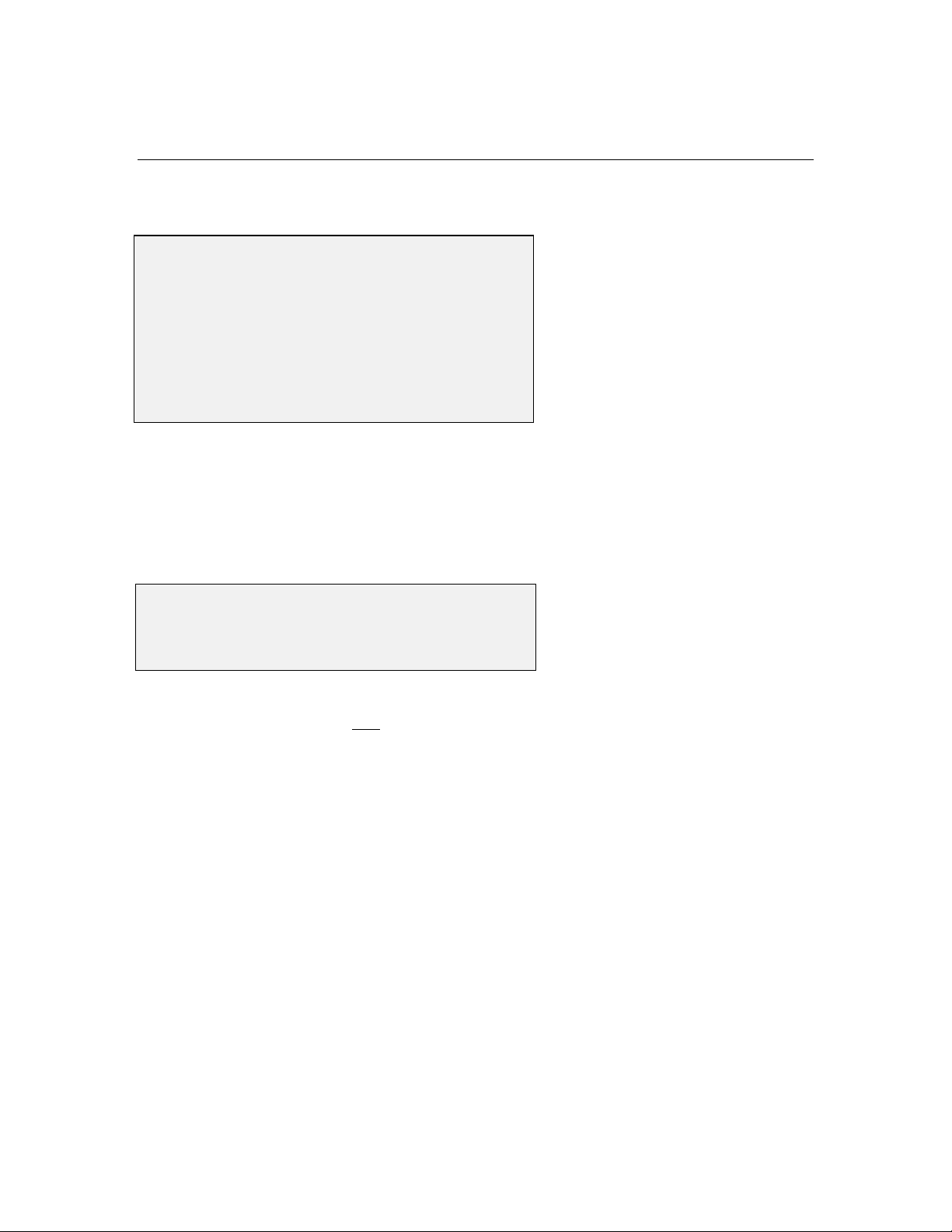

6000UPG Sonde to Data Collection Platform

DCP

6096 MS-8 Adapter with Flying Leads

MS-8

Cable

You will need...

❑ 6000UPG Sonde

6000UPG Sonde

6000UPG Sonde to Lab Computer

Power Supply*

6037: 220 VAC

6038: 110 VAC

MS-8

Cable

6000UPG

❑ 6096 Adapter with Leads

❑ Data Collection Platform

DB-9

6095B

Adapter

You will need...

6000UPG Sonde

Not required if you use

*

sonde battery power.

❑ 6000UPG Sonde

❑ Computer with Com Port

6000UPG

❑ 6095B MS-8/DB-9 Adapter

❑ Power Supply *

❑ DB-9 to DB-25 Adapter may

be needed at Co m Po rt

2-3

Page 14

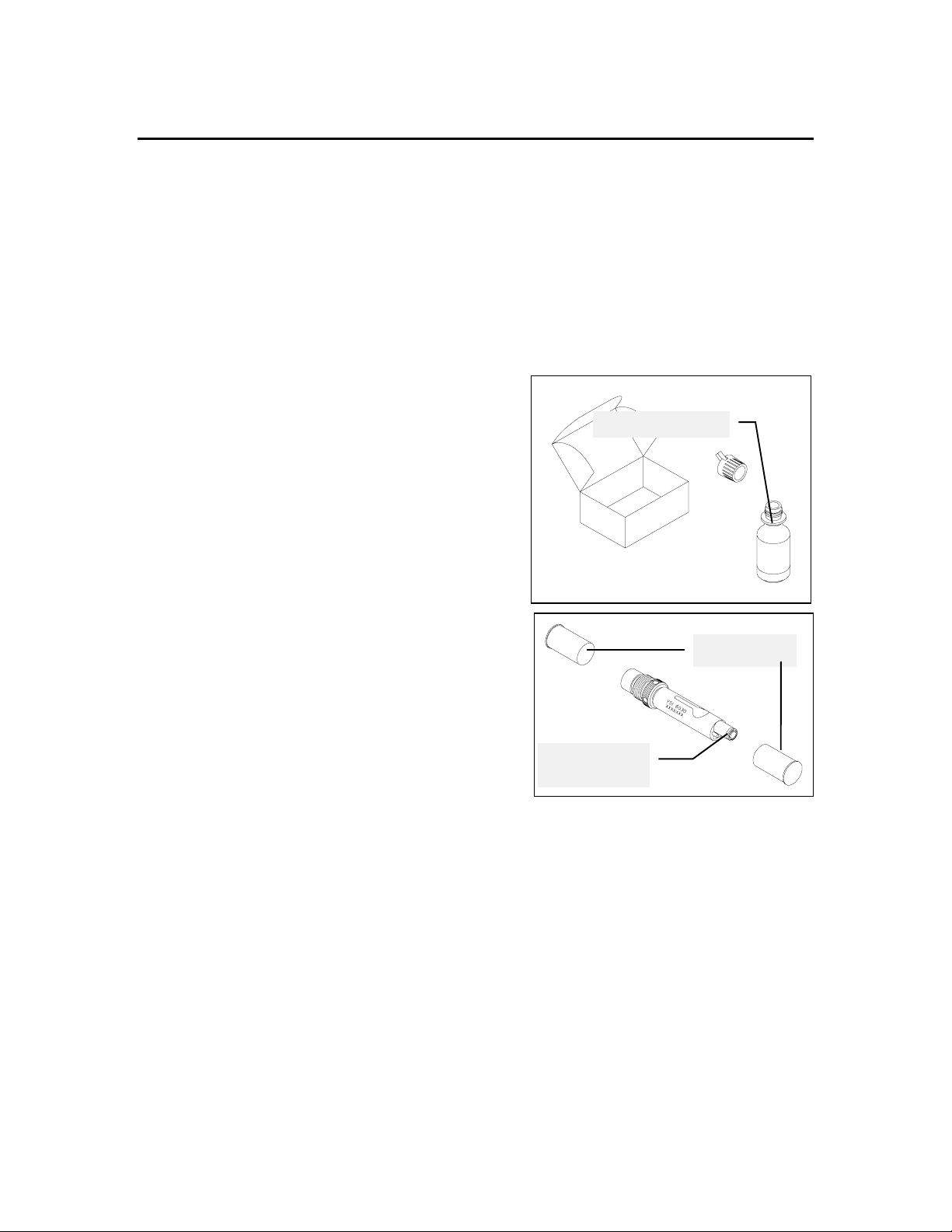

Upload Data from 6000UPG Sond e to 610-DM

6098 MS-8 Adapter

Environmental

Monitoring

YSI

MS-8

Systems

610-DM

610-DM

Cable

You will need...

❑ 6000UPG Sonde

❑ 610-DM Display/Logger

6000UPG

6000UPG Sonde

YSI 610’s operate on rechargeable batteries.

Each 610 comes with a 110 VAC Wall Socket Charger Unit.

❑ 6098 MS-8 Adapter for 610

Upload 610 Data Files to Lab Computer

Null Modem Cable

6099 DB-9 Adapter

DB-9

Environmental

Monitoring

YSI

Systems

610-DM

610-DM

DB-9

You will need...

❑ 610-DM

❑ 6099 DB-9 Adapter

❑ Null Modem Cable

❑ DB-9 to DB-25 Adapter may

be needed at Com Port

2-4

Page 15

2.3 SONDE SETUP

In the following section, you will be prov ided w ith step-by-step instructions on how to g et y our

UPG up and running. We recomm end following the steps in the order listed. Howev er,

6000

depending on your sonde configuration and the optional sensors which you hav e purchased, som e

of the steps may not apply to your setup. If so, simply skip to the next step in the protocol which is

relevant to your application.

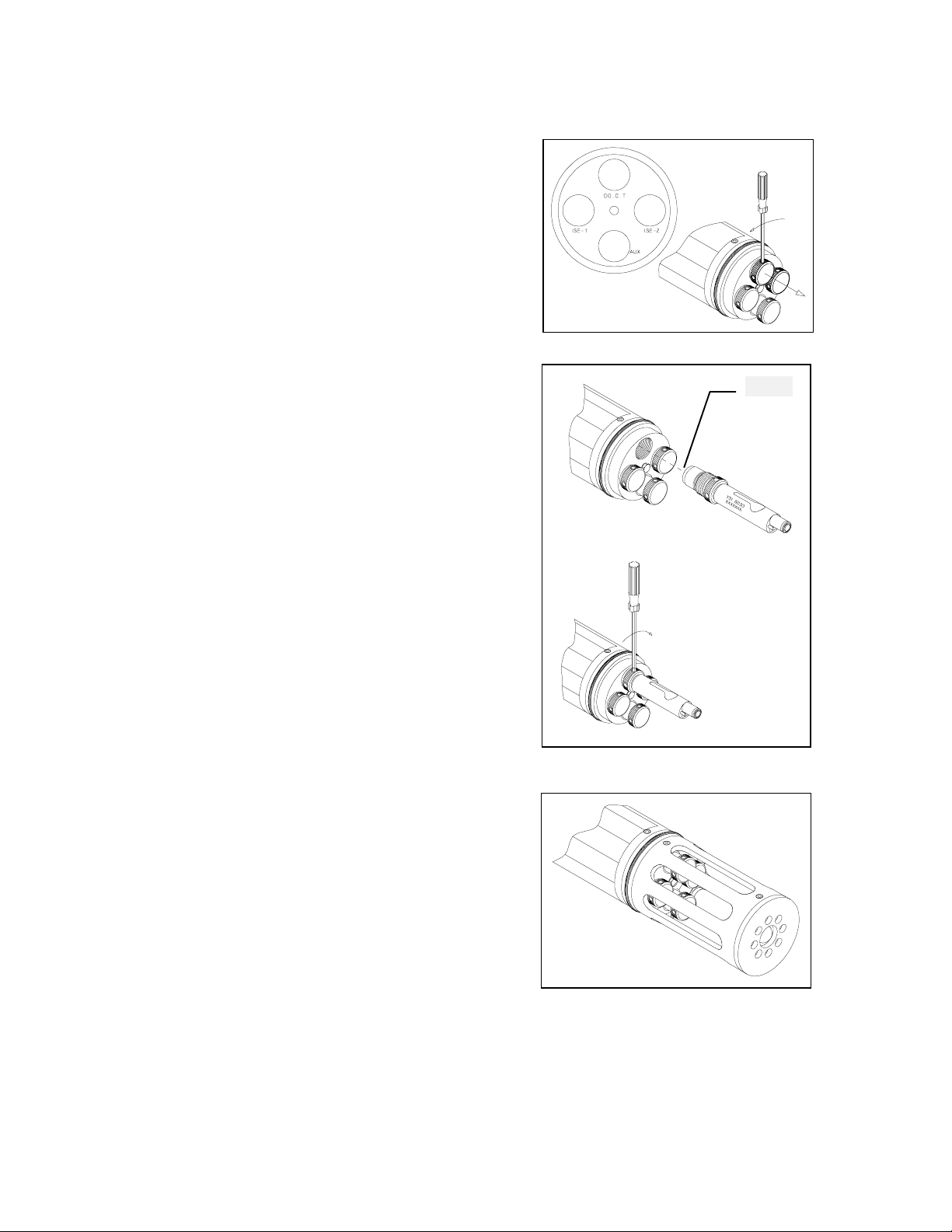

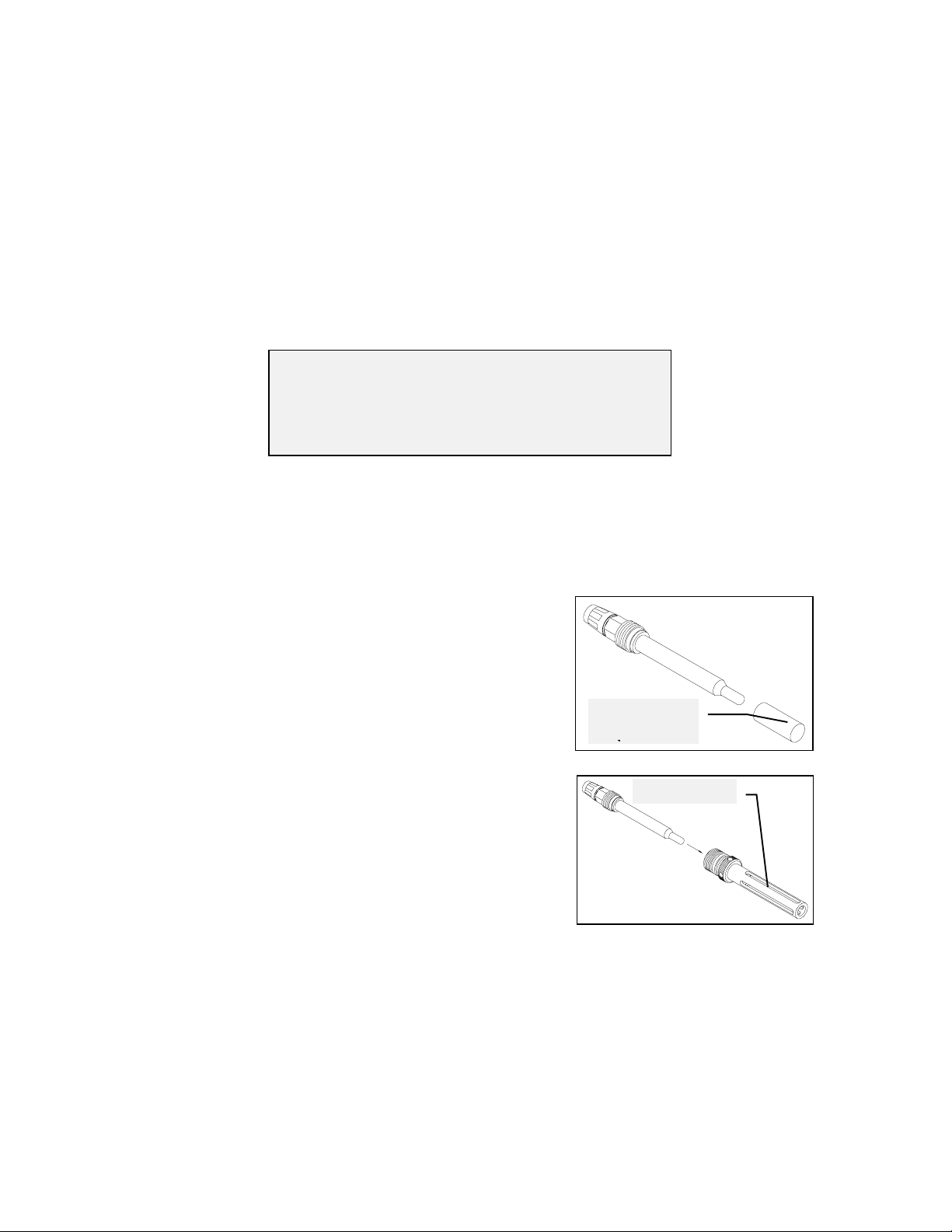

STEP 1. INSTALL YSI 6030 DO/COND/TEMP PROBE

Follow these instructions to prepare your new probe

and install it in the Model 6000

UPG.

1. Open the membrane k it and prepare the electroly te.

Dissolve the KCl crystals in the dropper bottle by

filling it to the neck with distilled water and shaking

until the solid is dissolved. Insure that the crystals are

fully dissolved before use.

2. Remove the two protectiv e caps and the dry

membrane from the 6030 probe.

NOTE: Your probe is shipped with a protective dry

membrane on the dissolved oxy g en sensor tip. It is

very important not to scratch or contam inate the sensor

tip. Handle the new probe with care. Avoid touching or

accidentally hitting the sensor tip.

Add distilled water

Protective Caps

Protective Dry

Membrane

2-5

Page 16

3. Follow the procedure described below to install a

new membrane on the dissolved oxy g en sensor tip.

A. Hold the probe in a vertical position and apply a

few drops of KCl solution to the tip. The fluid should

completely fill the small moat around the electrodes

and form a meniscus on the tip of the sensor. Be sure

no air bubbles are stuck to the face of the sensor. If

necessary, shake off the electrolyte and start over.

B. Secure a membrane between your left thum b and

the probe body. Always handle the memb rane with

care, touching it at the ends only.

C. With the thumb and forefinger of your right hand,

grasp the free end of the membrane. With one

continuous motion, gently stretch it up, over, and

down the other side of the sensor. The membrane

should conform to the face of the sensor.

D. Secure the end of the membrane under the

forefinger of your left hand.

E. Roll the O-ring over the end of the probe, being

careful not to touch the membrane surface with your

fingers. There should be no wrinkles or trapped air

bubbles. Small wrinkles may be removed by lightly

tugging on the edges of the m embrane.

F. Trim off any excess mem brane with a sharp k n ife or

scissors. Make sure the stainless steel temperature

sensor is not covered by excess mem brane. Being

careful not to get water in the connector, rinse off the

excess KCl solution.

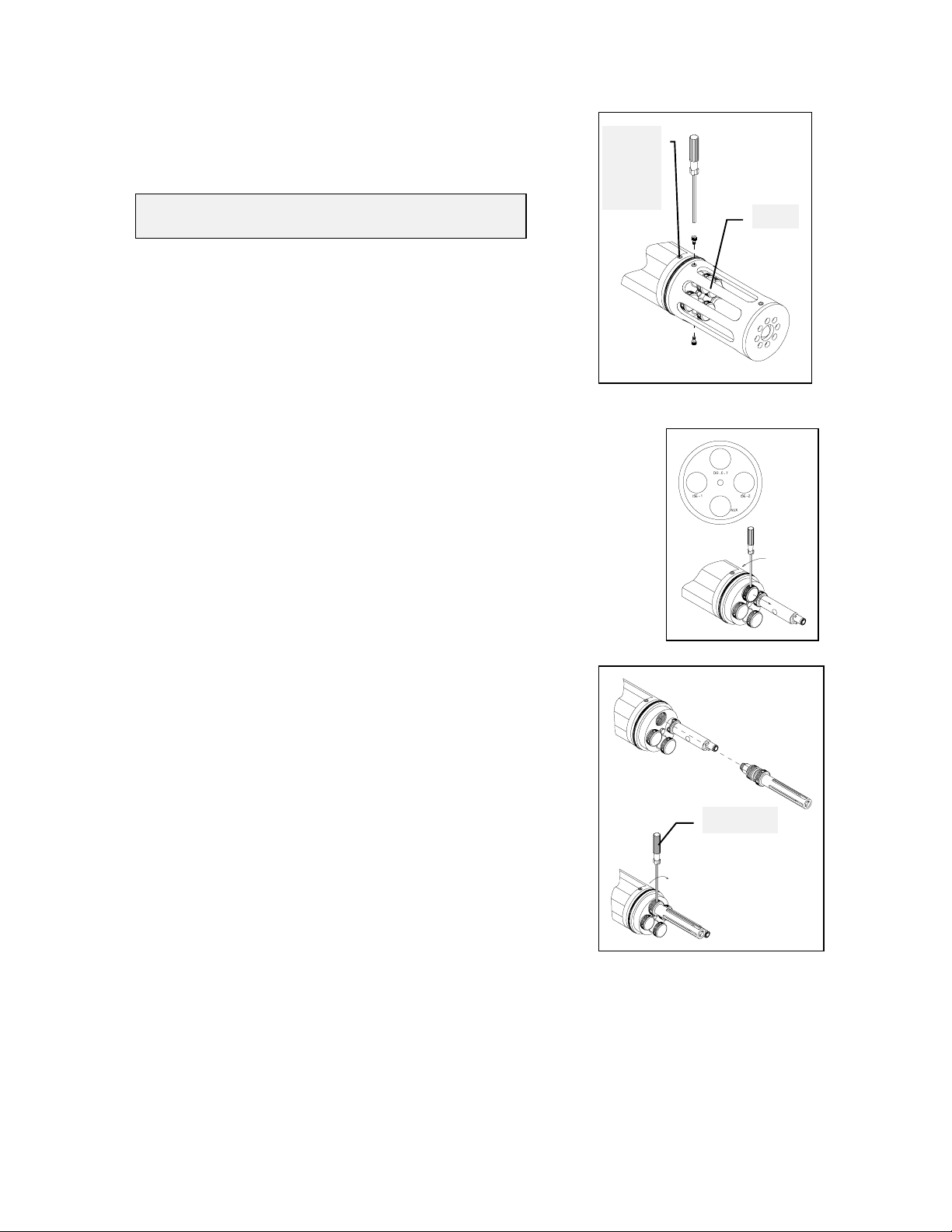

4. Using the hex driver supplied in the 6040

Maintenance Kit, remove the probe guard m ounting

screws from the sonde. Set the probe guard aside.

NOTE: Do not remove the two allen screws above the

guard.

E F

Hex Driver

Probe Guard

Mounting

Screws

Probe

Guard

2-6

Page 17

5. Locate the plug which seals the DO.C.T. port on the

g

sonde. Using the hex driver to assist you, remov e the

plug.

6. Install the 6030 probe into the sonde as described

below.

A. Apply a very thin coat of O-ring lubricant (supplied

in the 6040 Maintenance Kit) to the O-ring on the

connector side of the probe. Insert the probe in the port

marked DO.C.T.

B. With the connectors aligned, screw down the probe

nut, making sure that the probe and sonde connectors

are fully meshed. Use the hex driver to assist y ou in

tightening the nut.

DO NOT OVER TIGHTEN.

7. Replace the probe guard and tighten the probe guard

mounting screws.

O-rin

2-7

Page 18

STEP 2. INSTALL OTHER PROBES

If you have purchased any optional YSI probes, follow instructions provided below for all items

other than the 6029 conductivity/temperature sensor which is installed in an identical fashion to the

6030. The 6031 pH, 6032 ORP, 6033 low ionic strength pH, 6084 nitrate, and 6083 ammonium

probes can be ordered as options and do not require factory installation (see Section 4.7 for

software setup). The 6026 turbidity probe is installed by the user according to its accomp any ing

instructions, but requires an additional PCB which must be factory installed. The depth sensors are

factory installed options.

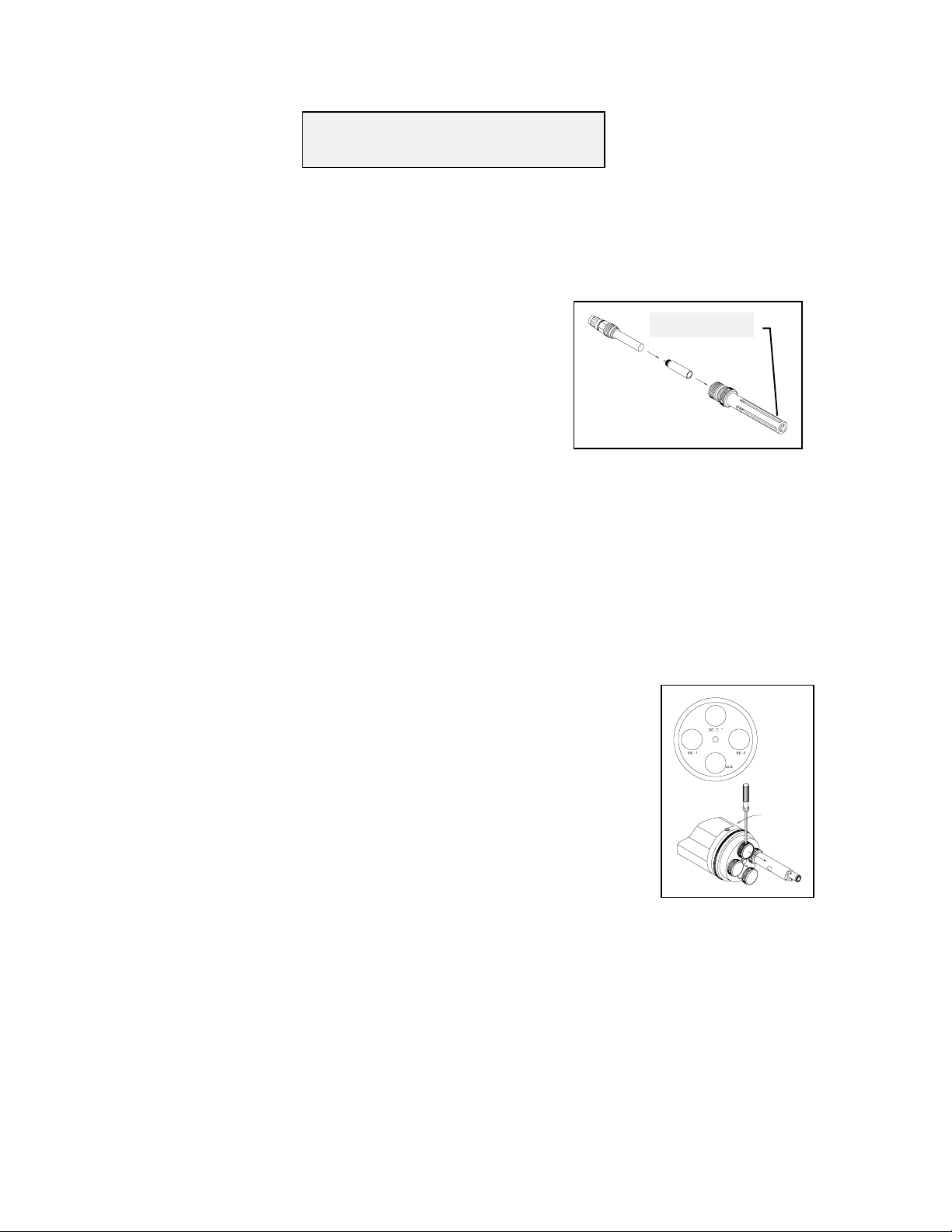

YSI 6031 pH Probe

YSI 6032 ORP Probe

YSI 6033 Low Ionic Strength pH Probe

Follow these instructions to prepare your new probe and install it in the 6000

NOTE: Instructions for preparation of use, maintenance and storage are included with each

electrode.

1. Remove the storage bottle or hy drating cap and rinse the

glass portion of the electrode with distilled water.

Hydrating Cap

or Storage

2. Apply a very thin coat of O-ring lubricant (supplied in the

YSI 6040 Maintenance Kit) to the O-ring on the glass shaft of

the new electrode. Insert the electrode into the probe housing

and hand tighten.

DO NOT OVER TIGHTEN.

UPG.

Probe

2-8

Page 19

3. Using the hex driver (supplied in the YSI 6040 Maintenance

Kit), remove the probe guard m ounting screws from the sonde.

Set the probe guard and mounting screws aside.

Do Not

Remove

These

Screws

CAUTION:

Do not remove the two allen screws above the guard.

4. Locate the plug which seals the port ISE-1 or I S E- 2 on the sonde. pH

probes must be installed in the ISE- 1 port; ORP probes m u st be installed in

ISE-2 port.

Using the hex driver to assist you, remov e the plug.

Guard

5. Install the 6031, 6032 or 6033 probes into the sonde as

described below.

A. Remove the connector cap from the electrode and check to be

certain the electrode is still firmly seated in the probe housing, as

described in Step 2.

B. Apply a very thin coat of O-ring lubricant (supplied in the YSI

6040 Maintenance Kit) to the O-ring on the connector side of the

probe and to the O-ring on the probe housing. I nsert the probe

assembly into the selected sonde port.

C. Screw the probe assembly into the sonde. Use the hex driver to

assist you in tightening the probe into the sonde.

DO NOT OVER TIGHTEN.

Hex Driver

2-9

Page 20

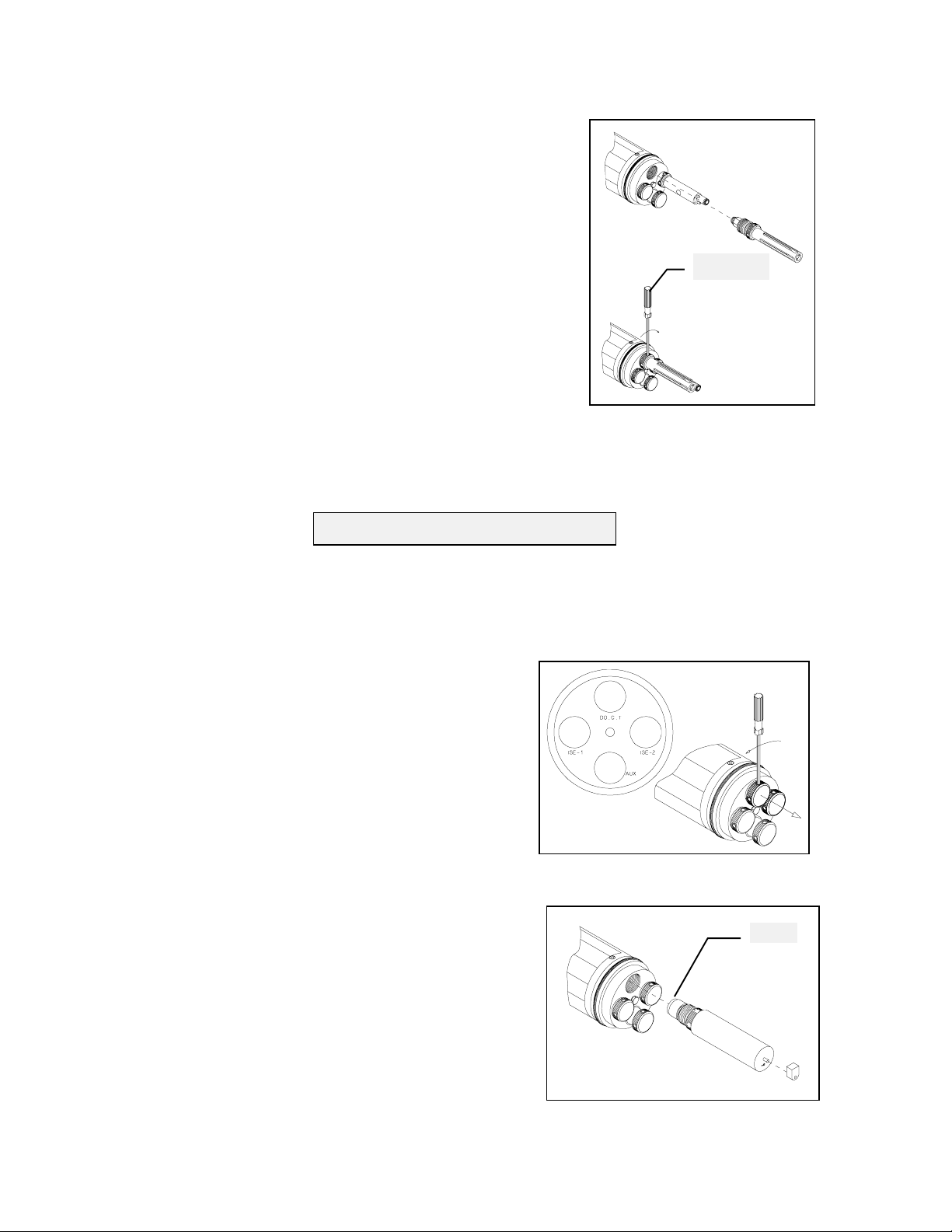

YSI 6083 Amm onium Pr obe

YSI 6032 Nitrate Probe

Follow these instructions to prepare your new probe and install it in the Model 6000UPG.

NOTE: Instructions for preparation of use, maintenance and storage are included with each

electrode.

1. Note that the ammonium and nitrate probes consist of two

parts: A probe body and a membrane m odule which threads

into the end of the probe body.

2. Apply a very thin coat of O-ring lubricant (supplied in the

YSI 6040 Maintenance Kit) to the O-ring on m em brane

module. Thread the membrane m odule into the end of the

probe body and tighten by hand until the units mesh

completely.

Do not over tighten and in no case ever use any tools such as pliers in this operation.

Apply a very thin coat of O-ring lubricant (supplied in the YSI 6040 Maintenance Kit) to the

3.

O-ring on the plastic shaft of the new electrode. Insert the electrode into the probe housing and hand

tighten.

Probe

DO NOT OVER TIGHTEN.

Locate the plug which seals the port ISE-2 on the sonde. The am monium

4.

and nitrate sensors must be installed in this port.

Using the hex driver to assist you, remov e the plug.

2-10

Page 21

5. Install the 6083 or 6084 probe into the sonde as described

g

below.

A. Apply a very thin coat of O-ring lubricant (supplied in the

YSI 6040 Maintenance Kit) to the O-ring on the connector side

of the probe and to the O-ring on the probe housing. I nsert the

probe assembly into the selected sonde port.

B. Screw the probe assembly into the sonde. Use the hex driver

to assist you in tightening the probe into the sonde.

DO NOT OVER TIGHTEN.

YSI 6026 Turbidity Probe

Hex Driver

1

. Remove the turbidity probe from its box and any protectiv e caps from the probe.

2. Locate the plug which seals the auxiliary (AUX) port

on the sonde. Using the hex driver to assist you, remov e

the plug.

3. Install the 6026 probe into the sonde as described

below.

A. Apply a very thin coat of O-ring lubricant (supplied in

the 6040 Maintenance Kit) to the O-ring on the

connector side of the probe. Insert the probe in the port

marked AUX.

O-rin

B. With the connectors aligned, screw down the probe

nut, making sure that the probe and sonde connectors are

2-11

Page 22

fully meshed. Use the hex driver to assist y ou in tig htening the nut.

DO NOT OVER TIGHTEN.

After all probes have been installed, replace the probe

guard and tighten the probe guard mounting screws.

Mounting

Screw

2-12

Page 23

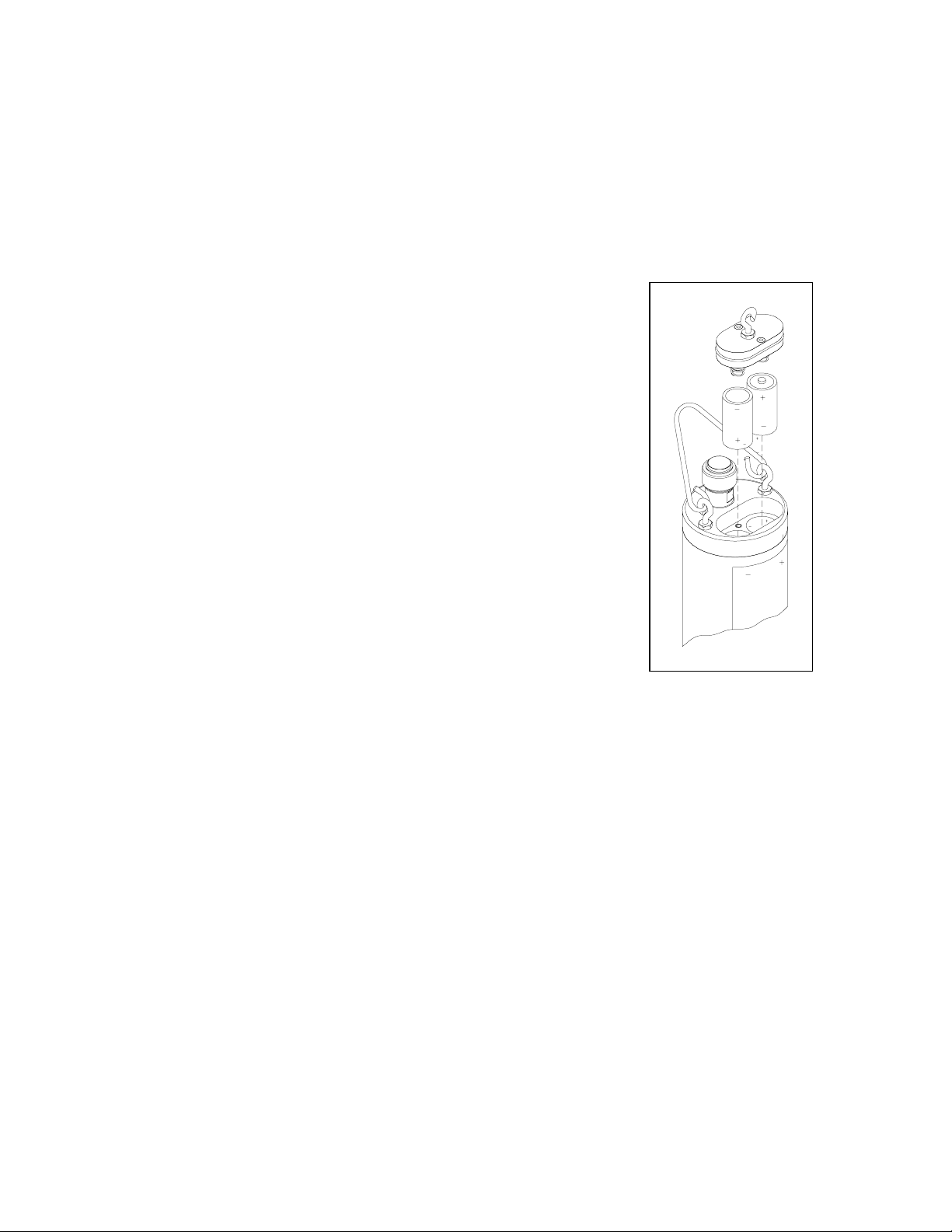

STEP 3. INSTALL BATTERIES

NOTE: Some 6000UPGs are not configured with internal battery capability. If the 6000UPG you

have purchased is configured to operate from internal batteries, it will hav e a battery compartment

and battery lid as illustrated below.

these battery installation instructions.

Your first set of batteries is supplied with the instrument. Install 8 C -size

alkaline batteries as follows:

Use the hex driver, supplied in the 6040 Maintenance Kit, to loosen the

battery lid screws.

NOTE: The battery lid screws are captive. It is not necessary to rem ov e

them from the lid comp letely .

Remove the battery lid and install the batteries, as show n.

NOTE: Observe the correct polarity before installing the batteries into

the battery chamber.

Be sure the bottom O-ring is installed in the g roov e of the lid. C heck the

O-ring and sealing surfaces for any contaminates which could interfere

with the O-ring seal of the battery chamber. Remove any contaminates

present. Also clean the protective O-ring w hich located in the middle of

the side of the battery lid.

If your 6000UPG does not have a battery compartment, ignore

Apply a very thin coat of O-ring lubricant (supplied in the 6040 Maintenance Kit) to both battery

chamber O-rings.

Return the battery lid and tighten the screws.

DO NOT OVER TIGHTEN.

2-13

Page 24

STEP 4. ATTACH CABLE

r

Remove the waterproof cap from the

sonde connector and set it aside for later

Waterproof

Cap

reassembly. Connect a PC interface cable

to the sonde connector. A built-in key will

ensure proper pin alignment. Rotate the

cable connector gently until the key

engages and then tighten the connectors

together by rotating clockwise. N ote that

the attachment is by hand only! No tools

are required nor should they be used.

Attach the strain relief connector to the

Sonde

Connecto

sonde handle. Rotate the strain relief

connector nut to close the connector's

opening.

The other end of the cable is a militarystyle 8-pin connector. This connector

plugs directly into the 610-D and 610- DM

display loggers. Most other applications

will require the use of an adapter. For example, to connect the 6000

6095b MS-8 to DB-9 adapter.

Strain Relief

Connector

UPG to a computer, use a YSI

STEP 5. REVIEW POWER OPTIONS

Some type of external power supply can be used to power the 6000UPG sonde in lieu of batteries.

For laboratory setup and calibration with the sonde interfaced to a computer, the YSI 6038 (110

VAC) or 6037 (220 VAC) can be employed. Most adapters include a short pigtail for power that

plugs into the power supply. After attaching the three pin connector on the power supply to the

pigtail, simply plug the power supply into the appropriate outlet. If you have purchased a 610-series

display/logger for use with your 6000

to be powered from the batteries in the display/logger or from the 610 power supply if the 610

internal batteries are not fully charged. However, the 6000

current draw on the 610 batteries resulting in less usable battery life than for other YSI instruments

such as the 600, 600XL, and 6000

the 6000

UPG if a 610 is used as the terminal.

See pages 2-2 to 2-4 for specific inform ation on cables, adapters and power supplies required for

connecting your 6000

UPG to various devices.

UPG, attachment of the cable to the 610 will allow your sonde

UPG circuitry will place a substantial

UPG. For this reason, we recomm end that batteries be installed in

2-14

Page 25

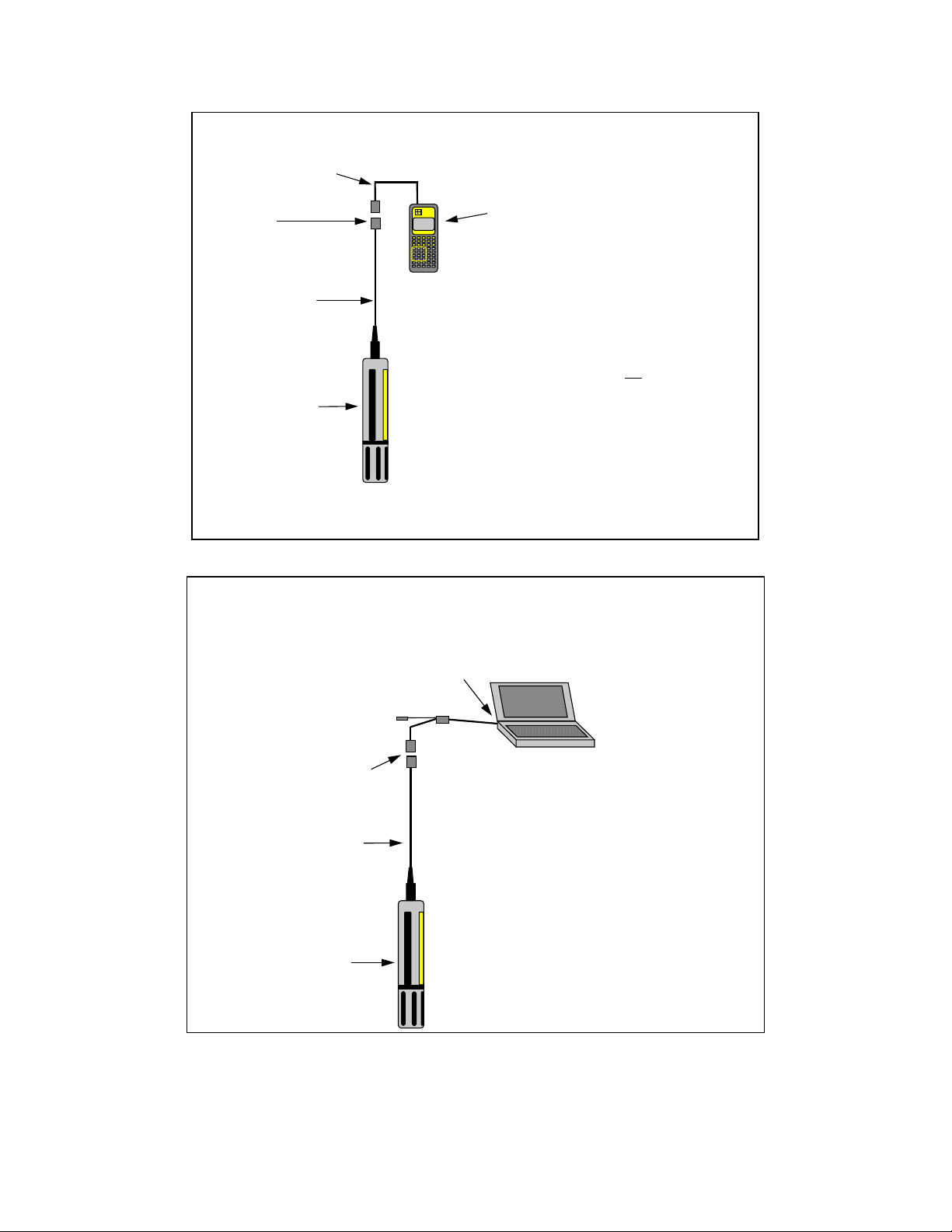

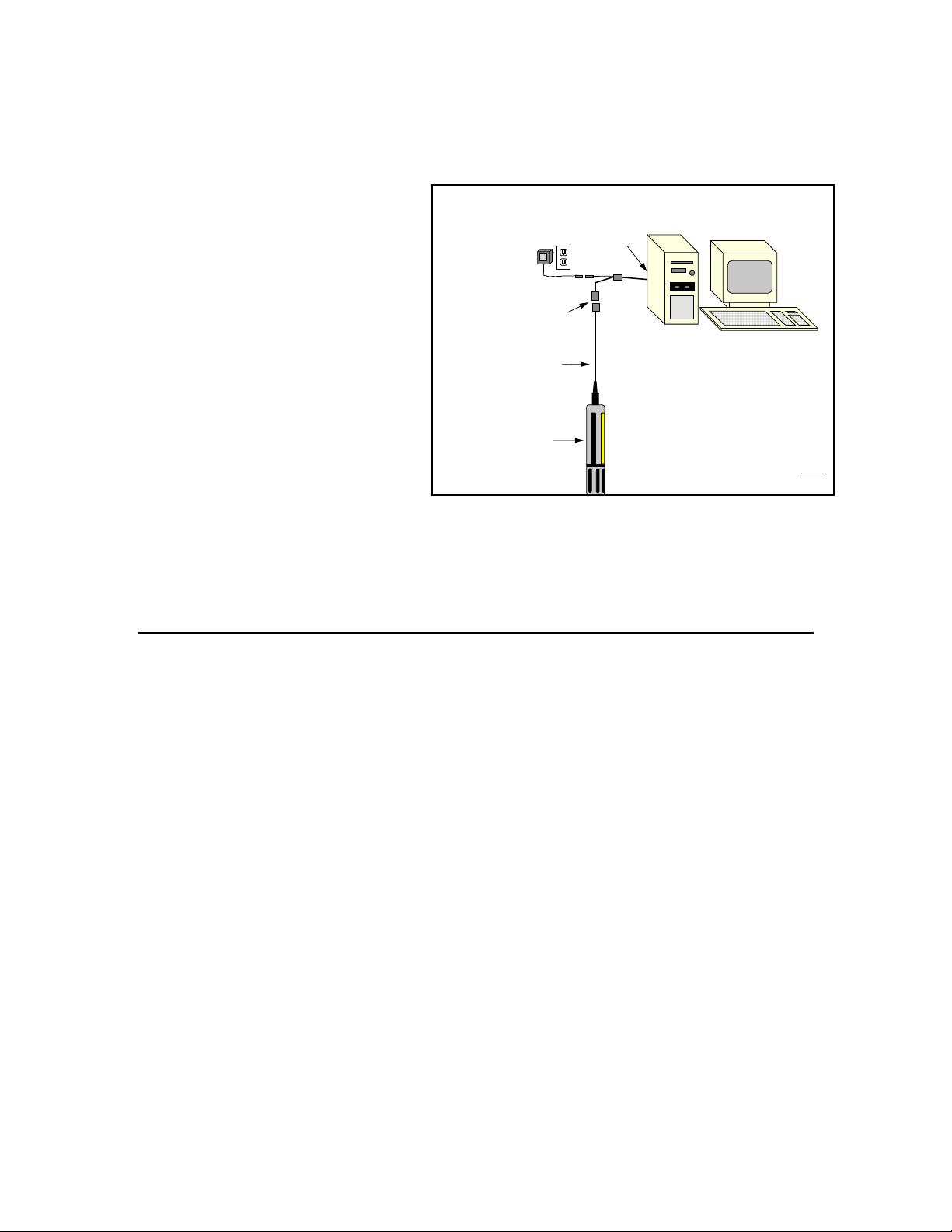

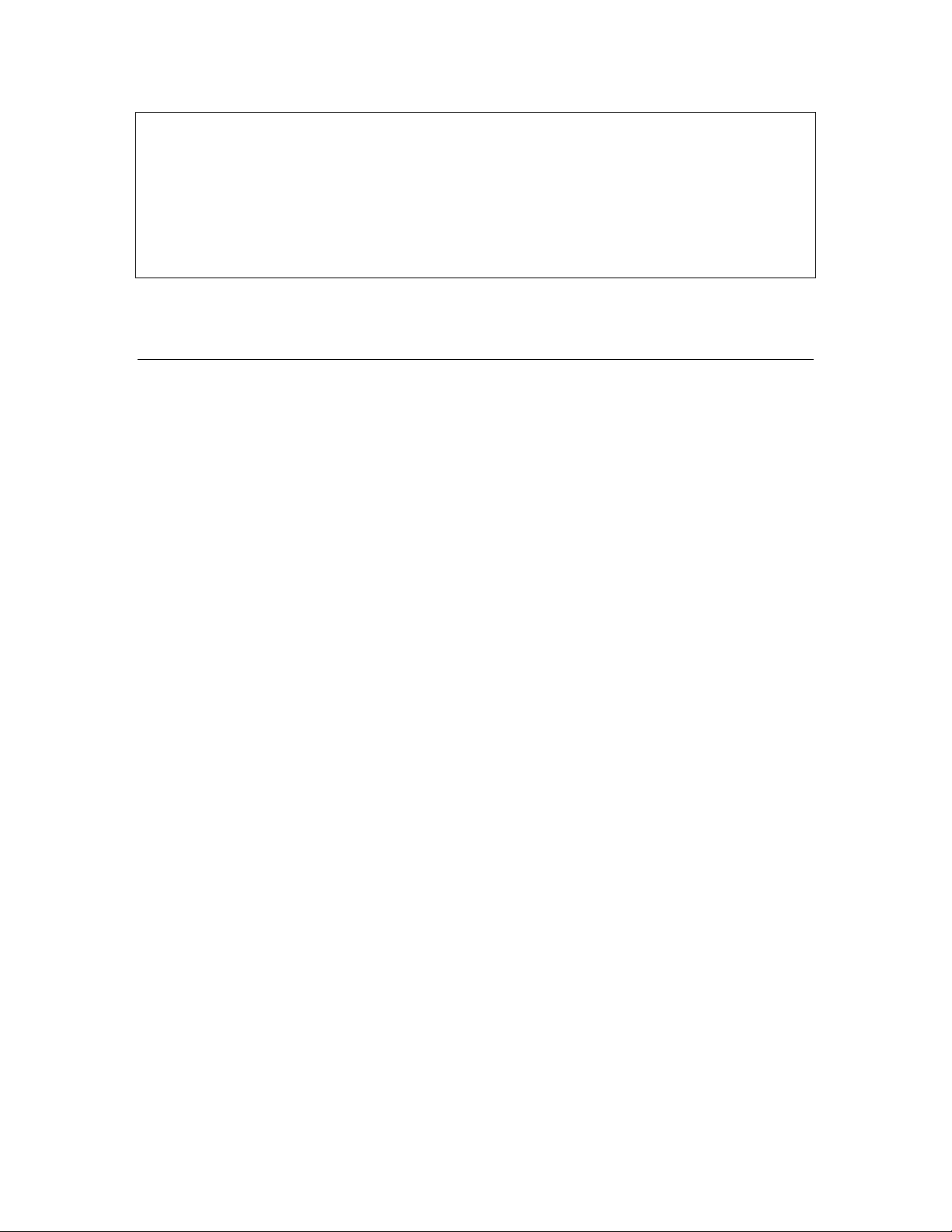

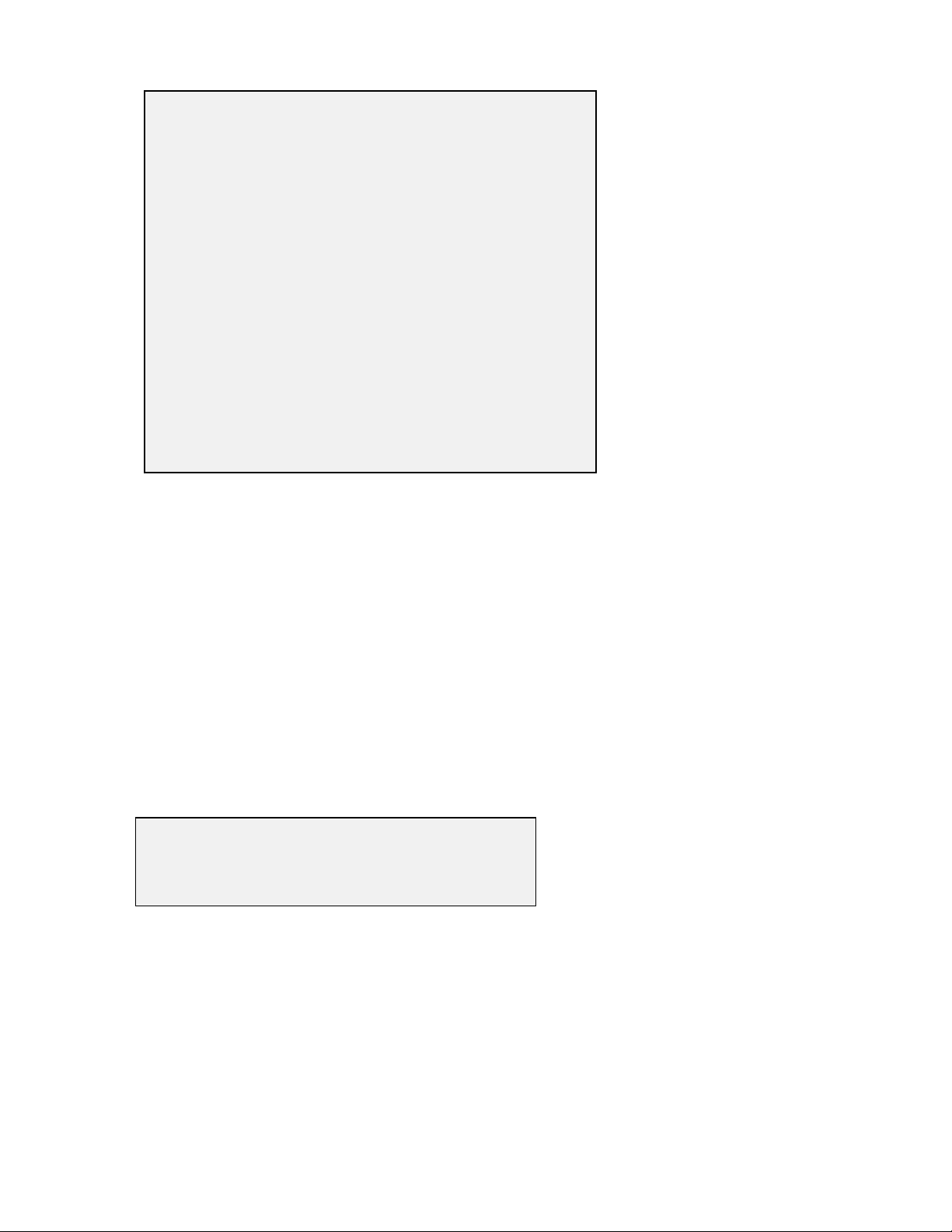

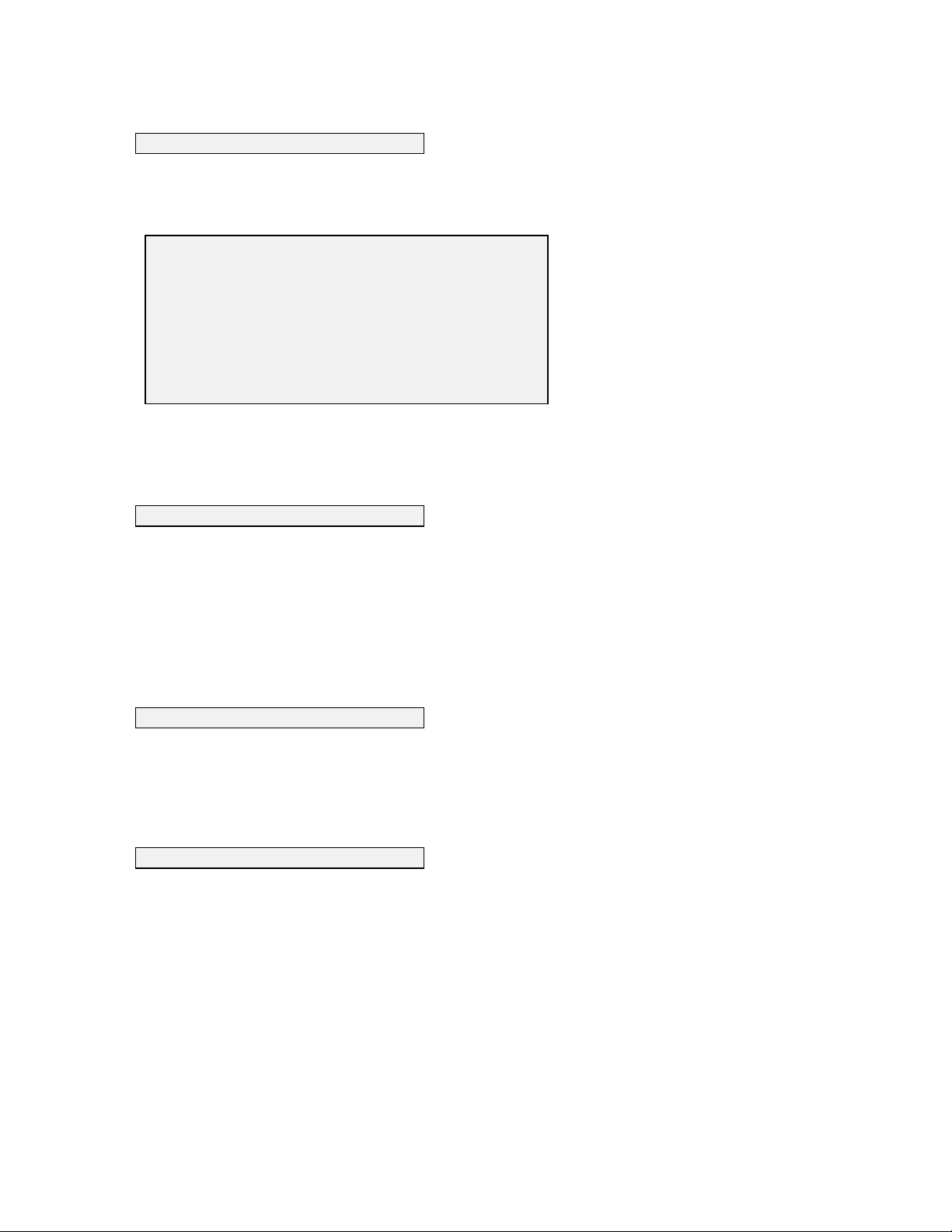

STEP 6. REVIEW SONDE/COMPUTER INTER F AC E

The system configuration best suited

for initial setup is shown in the

diagram to the right.

Below we will describe how to install

PC6000 software on your computer and

Power Supply*

6037: 220 VAC

6038: 110 VAC

communicate with the Sonde software.

If you have purchased a YSI 610 handheld display/logger, refer to the 610

manual which was enclosed with the 610

unit.

Note that the power supply is optional --

Not required if you use

the unit may be powered by internal,

user-installed batteries.

Your 6000

UPG is now physically set up for use. Proceed to the next section on software installation.

*

sonde battery power.

2.4 SOFTWARE INSTALLATION

6000UPG Sonde to Lab Computer

DB-9

6095B

Adapter

MS-8

Cable

6000UPG Sonde

You will need...

❑ 6000UPG Sonde

❑ Computer with Com Port

6000UPG

❑ 6095B MS-8/DB-9 Adapter

❑ Power Supply *

❑ DB-9 to DB-25 Adapter may

be needed at Com Port

PC6000 software is provided with the 6000UPG and is found on a disk in the back of this instruction

manual. Use this software with an IBM-compatible PC with at least 256KB of RAM and DOS 3.0

or later. If your system is not I B M-compatible, use any term inal em ulation prog ram with your

computer.

Insert the disk into your disk driv e. At the C :\ prompt, type the letter of the drive in which the

program disk was inserted followed by a colon, then press

Enter.

Example: A: [Enter]

To install PC6000 software execute the following command from the DOS prom pt:

INSTALL <destination>

where destination is the drive and directory in which you want the PC6000 files to be installed.

For example, the command:

INSTALL C:\PC6000 will install the PC6000 software to the C:

drive and \PC6000 directory.

If you are using a two disk driv e sy stem, follow the instructions in Section 5.2. After installing the

software, remove the disk from the drive and keep the original disk in a safe place.

2-15

Page 26

ECOWATCH FOR WINDOWS

If you have purchased Ecowatch for Windows, install the program from the Program Manag er

menu of your Windows system . Use this software with an I B M- compatible PC with a 386 (or

better) processor. The computer should also have at least 4MB of RAM and Windows Version 3.1

or later. First close any Windows applications which are currently running. After inserting the

Ecowatch floppy disk in your disk driv e, access the File command from the top m enu bar of the

Program Manager window. Click on Run and ty pe “a:\ setup.exe” at the prom pt. Press

click on “OK” and the display will indicate that Ecowatch is proceeding w ith a setup routine.

After the setup is complete, you will be prom pted to confirm that all applications have been closed

and choose the hard drive location where Ecowatch will be installed. After answering these

questions, the installation of Ecowatch will take place automatically . Simply follow the instructions

on the screen after installation is complete.

Enter or

2.5 PC6000 SOFTWARE SETU P

To start the software, make your current drive C:\P C6000 (or another directory where y ou hav e

installed PC6000). Type

menu bar will appear at the top of the computer screen:

PC6000 and press Enter. The PC6000 software will load. The PC6000

Sonde File Setup Real-Time Exit PC6000

2-16

Page 27

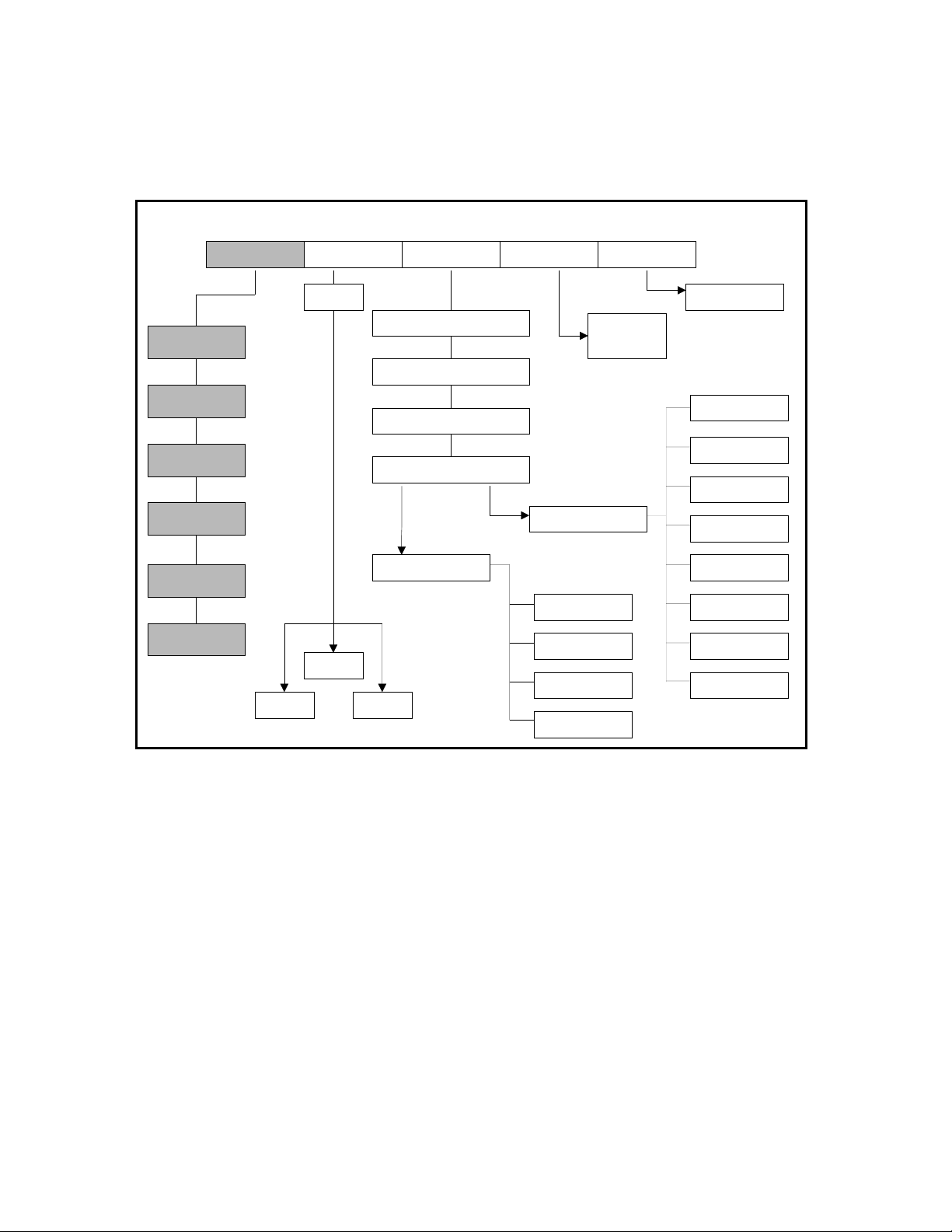

Use the arrow keys to move the cursor and hig hlig ht menu options. Press Enter to select a

highlighted option. Press

Esc to cancel an entry. A PC6000 Menu Flow Chart is shown below.

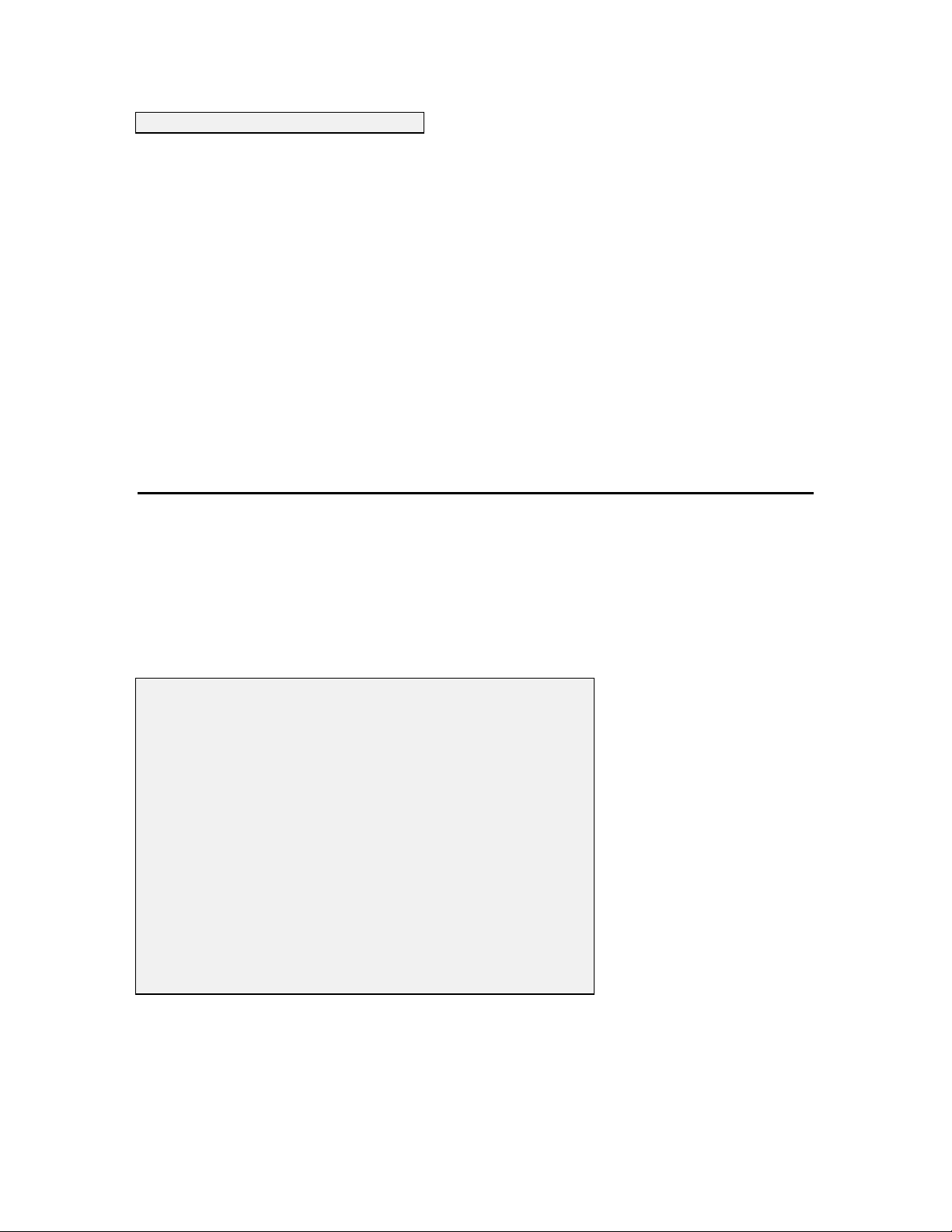

This menu chart should help you to locate submenus m ore easily .

6820

1. Run

2. Calibrate

3. System

4. Report

5. Sensor

6. Advanced

PC6000 MENU FLOW C HART

Sonde File Setup Real-Time Exit

Filename

View

Display Format

Computer Connection

Computer Display

More Setup

Advanced Setup

Advanced Setup

SystemModify

Data Capture

Global Switch

User-defined

Readings

Displayed

Data Fi l e s

Export

5/96

Return to DOS

Parser

Site Name

Instrument ID

Filename

Autoconfigure

X-axis Time

Parameter/Plot

Beep Notify

2-17

Page 28

To start, highlight Setup then press Enter. Check the default setup values.

---DISPLAY -FORMATS---------COMPUTER-CONNECTIONS------------Date format: MDY Com m port: 1

Date separator: / Baud rate 9600

Time separator: : Printer Port 1

Radix mark: . Printer type HP LaserJet laser

-------MORE-SETUP-------------COMPUTER-DISPLAY---------------------Data capture setup... Menu colors: User-defined menu colors

Advanced Setup... Plot colors: User-defined plot colors

Graphics mode: Automatic selection hi-res

Comm port:

Select this option to enter the number of the Comm port (1 or 2) to which the 6000

Be sure to press

Enter to confirm a new entry. If the default setting is correct there is no need to

UPG is connected.

change it.

Baud rate:

Select this option to check the baud rate. If the baud rate is not set to 9600, set it to 9600. To set

the baud rate, highlight it and press

from the list and press

Enter. NOTE: The Model 6000UPG default baud rate is 9600.

Enter. A list of possible baud rates will appear. Select 9600

Printer port:

Select this option to specify the parallel port (LPT1, LPT2 or LPT3) to which y our printer is

connected. If no printer is connected select LPT1. Press

Enter after making your selection.

Printer type:

Select this option to select the type of printer connected to your computer sy stem . F rom the list,

choose the selection that best describes your printer. If your printer is not on the list, refer to your

printer's instruction manual to determine w hat ty pe of printer your printer emulates. Press

Enter

after making your selection.

2-18

Page 29

Menu colors:

Select this option to choose a color scheme for the PC6000 menus. As you m ov e the cursor

between color schemes, the screen changes to display y our selection. Press

Enter to confirm a

selection.

Plot colors:

Select this option to choose a color scheme for the PC6000 plots. As you mov e the cursor between

color schemes, the screen changes to display your selection. Press

Enter to confirm a selection.

The other setup functions are described in Section 5.5, but usually are not necessary for a quick

start into 6000

UPG operations. Press Esc to exit the setup menu. The cursor will return to the

menu bar.

ECOWATCH FOR WINDOWS

No setup is required for this program after installation. Use the “Help” comm and in the top menu

bar to learn about the program.

2.6 SONDE SOFTWARE SETUP

There are two sets of software at work within the 6000UPG system. One is resident in your PC

(called PC6000) and was provided on floppy disk with this instruction manual. The other software

is resident in the sonde itself. When you select

software, begins direct communication with the sonde based software via standard VT100 term inal

emulation.

Using the arrow keys, highlight and select

will be displayed.

========================================

Main

----------------------------------------

1. Run 5. System setup

2. Calibrate 6. Report setup

3. File 7. Sensor setup

4. Status 8. Diagnostics

Select option (0 for previous menu):

Sonde from the PC6000 top-line menu, the PC based

Sonde from the top-line menu. The sonde Main m enu

2-19

Page 30

NOTE: If no menu is displayed and a # appears at the top of the computer screen, follow the

instructions on the screen and type

displayed, press

Esc until the Main menu appears. If you cannot get to the Main menu, check to be

MENU and press Enter. If a menu other than the Main menu is

sure the cable is properly connected, the batteries are properly installed and the Comm port and

other software parameters are set up as described in Section 2.4, or see Section 8, Troubleshooting.

NOTE: The sonde software is menu driven. Select a function by typing its corresponding number.

It is not necessary to press

Enter after a number selection. Use the 0 or Esc key to return to a

previous menu.

At the Main menu, select

========================================

System-setup

----------------------------------------

1. Date & time 4. Batteries

2. Radix 5. Instrument ID

3. Communication 6. Page Length

Select option (0 for previous menu):

1. Date & time

5. System setup. The System setup menu w ill be display ed.

Select this option to choose the date format and set the correct date and time. Select the format y o u

desire; month/day/year, day/m onth/year or year/month/day. Next enter the date and time as

prompted on the screen. Be sure to enter the hour, minute, and second values for the Time. The

software will reject a Time entered with hour and minute entries only. Press Enter after each entry.

NOTE: For convenience any non-numeric key (such as space) in addition to / and : will separate

the fields in the date and time entries.

4. Instrument ID

Select this option to identify your instrument with its serial number (located on the back of the

sonde) or any other name or number y ou wish, up to 31 characters. Then press

Enter.

Other options in the System setup menu are explained in detail in Section 4. Press Esc to backup to

the Main menu.

2-20

Page 31

========================================

Main

----------------------------------------

1. Run 5. System setup

2. Calibrate 6. Report setup

3. File 7. Sensor setup

4. Status 8. Diagnostics

Select option (0 for previous menu):

You must now enable (or activate) the sensors which have been installed in your 6000UPG sonde.

Select

7. -Sensor setup

========================================

Sensor-setup

---------------------------------------1-(*) Temp 7-( ) ISE2 ORP

2-(*) Cond 8-( ) ISE2 NH4+

3-(*) DO 9-( ) ISE2 NO34-( ) Depth A-(*) Batt

5-(*) ISE1 pH B-( ) Turb

6-( ) ISE1 mV C-( ) TDG

Select option (0 for previous menu):

Enter the corresponding number to enable the sensor(s) that are installed on the sonde. The

activated selection is indicated by the asterisk.

You will see reference to TDG (total dissolved gas) in the Sensor setup menu. This is for

possible future upgrade and is not currently available for your 6000

UPG.

NOTE: The sensors that you have installed in your sonde may not include all that are shown

“enabled” in the above screen. The display is only an example.

After all installed sensors have been enabled, press

0 or Esc to return to the Main Menu.

========================================

Main

----------------------------------------

1. Run 5. System setup

2. Calibrate 6. Report setup

3. File 7. Sensor setup

4. Status 8. Diagnostics

Select option (0 for previous menu):

Even if all of your installed sensors are enabled, the measurements for that sensor may not

appear on your display. In order for a specific parameter to be displayed:

1. The sensor must first be enabled (turned on).

2-21

Page 32

2. That parameter must be activated in the Report section of the Main Menu.

Select

4-Report from the Main sonde menu. The Report Setup menu will be displayed.

========================================

Report-setup

---------------------------------------1-(*) Date G-(*) Sal ppt

2-(*) Time H-(*) DO %

3-(*) Temp C I-(*) DO mg/L

4-( ) Temp F J-( ) Depth ft

5-( ) Temp K K-( ) Depth m

6-(*) SpCond mS/cm L-(*) pH

7-( ) SpCond uS/cm M-( ) pH mV

8-( ) Cond mS/cm N-( ) ORP mV

9-( ) Cond uS/cm O-( ) NH4+ mg-N/L

A-( ) Resist MOhm*cm P-( ) NH3 mg-N/L

B-( ) Resist KOhm*cm Q-( ) NO3- mg-N/L

C-( ) Resist Ohm*cm R-( ) Turb NTU

D-( ) TDS g/L S-( ) TDG mm-Hg

E-( ) TDS kg/L T-(*) Batt V

F-( ) TDS mg/L

Select option (0 for previous menu):

The asterisk (*) following a given number or letter indicates that the parameter will appear on all

outputs and reports.

To turn a parameter on or off, type the number or letter of that parameter at

the cursor. Continue this process until all parameters are either on or off as you wish.

After configuring your display with the desired parameters, press

0 or Esc to return to the Main

Menu.

See Section 4 for a more detailed description of the sonde menus. The sonde software is now set

up and ready to calibrate and run. Proceed to Section 3.

2-22

Page 33

3. BASIC OPERATION

In the previous Section, you learned how to install probes and set up the PC6000, Ecowatch for

Windows, and 6000

Model 6000

6000

UPG with a 610-series display/logg er, refer to the operations manual for the 610 to obtain

UPG and how to view your data on a computer display. I f y ou choose to use y our

similar instructions to those provided below.

3.1 GETTING READY TO CALIBRATE

WARNING: Reagents used to calibrate and check this instrument may be haz ardous to y our health.

Refer to Appendix A for health and safety information.

Before you begin the calibration procedures outlined below, you m ay find it helpful to follow some

or all of these calibration tips.

1. You will need one or more containers to hold calibration standards. YSI prov ides a calibration

cup, but a standard 800 mL beaker also works well.

UPG sonde software. In this section, you will learn how to calibrate and run the

2. If you use the 6000

UPG Transport Cup for dissolved oxygen calibration, mak e certain to loosen

the seal to allow pressure equilibration before DO calibration (water-saturated air calibration).

3. For maximum accuracy, the use of a small amount of previously -used calibration solutions to

prerinse the sonde is suggested. You may wish to sav e old calibration standards for this purpose.

4. Fill a large bucket with ambient temperature water for rinsing the sonde between calibration

solutions.

5. Have several clean, absorbent paper towels or cotton cloths available to dry the sonde between

rinses and calibration solutions. It is important to remov e as much residual liquid as possible from

the sonde after each rinse. Shake the sonde to remove excess rinse water from the inside of the

guard. Then dry the outside of the sonde and probe guard. Drying the sonde and probes in this way

reduces carry-over contam ination of calibrator solutions and increases the accuracy of the

calibration, particularly when using lower conductivity calibration standards.

6. It is not necessary to remov e the probe g uard to rinse and dry the probes between calibration

solutions. The inaccuracy resulting from simp ly rinsing the probe compartment and drying the

outside of the sonde is minimal.

3-1

Page 34

3.2 CALIBRATION PROCEDURES

WARNING: Calibration reagents may be hazardous to your health. Refer to Appendix A for

health and safety information.

A calibration cup is supplied with the Model 6000

UPG. Because the calibration cup fits over the

outside of the sonde probe guard, it is not recommended or necessary to rem o v e the probe g uard to

calibrate the sensors. Follow the procedures below to calibrate the sensors. Temperature does not

require calibration and is, therefore, not included in the Calibrate menu. ORP calibration is

required only infrequently and is discussed in Section 4.2. For more detailed calibration

procedures, which can be used to enhance the accuracy of some measurements, see Section 4.2.

The following sequence is provided as an EXAMPLE of the process the user will utilize to

calibrate all sensors. Although conductivity was chosen for this general example, more detailed

instructions for the calibration of the conductivity sensor are found in the next section.

From the sonde Main menu select 2. Calibrate.

========================================

Main

----------------------------------------

1. Run 5. System setup

2. Calibrate 6. Report setup

3. File 7. Sensor setup

4. Status 8. Diagnostics

Select option (0 for previous menu):

The Calibrate menu will be displayed.

========================================

Calibrate

----------------------------------------

1. Conductivity 6. pH

2. DO% 7. Ammonium

3. DO mg/L 8. Nitrate

4. Depth 9. Turbidity

5. ORP A. TDG

Select option (0 for previous menu):

Selection of any of the parameters from the Calibrate menu listing will require the user to input a

numerical value and then press Enter. For example, for calibration of the conductivity sensor, y ou

should select 1. Conductivity from the Calibrate menu and then 1. SpCond from the Cond

Calibration menu. The following display will be show n during the calibration sequence.

Enter SpCond in mS/cm (10):

3-2

Page 35

The number in parentheses is the default value of this parameter and will be used in the calibration

if only Enter is pressed without typing in another value. Remember that this entry should reflect

the actual value of your solution and that entry of values other than the default m ay be necessary.

Similar prompts will be display ed for calibration of all param eters.

========================================================

Date Time Temp SpCond Sal DO pH Batt

MM/DD/YY hh:mm:ss C mS/cm ppt % V

-------------------------------------------------------To calibrate, press <Enter> when the readings are stable.

05/22/96 09:53:43 27.73 5.05 2.72 54.9 8.73 12.2

After the calibration value is input (or the default accepted) and Enter is pressed, a real-time

display similar to that shown above will appear on the screen. N ote that all parameters which have

been enabled will appear, not just the one being calibrated at the moment. You should carefully

observe the stabilization of the readings of the parameter w hich is being calibrated and, w hen the

readings are stable for approximately 30 seconds, press Enter to accept the calibration. The

acceptance will be acknowledged and calibration of the chosen sensor is complete. Then, as

instructed, Hit any key to return to the Calibrate menu.

NOTE: If an ERROR message appears, begin the calibration procedure again. Be certain that the

value you enter for the calibration standard is correct. Also see Section 8, Troubleshooting for

more information on error messag es. If error messages continue to be observed during calibration,

contact YSI Customer Service (see Appendix C for contact inform ation).

CAUTION: With rare exception, be certain to immerse the entire array of sensors in solution

standards for calibration of all parameters. Most calibrations require readings not only from the

sensor being calibrated but also from the temperature sensor. Tem perature compensation is an

important criterion in nearly all of the calibration procedures. In addition to temperature, the

conductivity reading of the standard is required in several calibration routines and the reference

electrode of the pH probe must be in the same solution as the nitrate and ammonium sensors for

proper function.

Specific start-up calibration procedures for all sensors which commonly require calibration are

provided in the following paragraphs of this section. Remember that these are basic protocols

designed to get the user up and running with regard to the 6000

UPG. The more-detailed discussion

of sensor calibration found in Section 4.2 should be examined prior to use of the instrument in the

field.

NOTE: If the particular sensor listed is not installed in your sonde, proceed to the next sensor until

the calibration protocol is complete.

3-3

Page 36

IMPORTANT MESSAGE!

WHAT IF THERE IS NO RESPONSE TO A KEYSTROKE?

To save power, the 6000UPG will power down automatically if no interaction from the keyboard

occurs for approximately 30 seconds. When the software is in this “sleep” mode, the first

subsequent keystroke simply “wak es it up” and has no visible effect on the display. The next

keystroke after the unit is “awakened” w ill be input to the softw are in the intended m anner. Thus,

if you press a key after the 6000UPG has been inactive for some time and nothing seems to happen,

press the key again.

CONDUCTIVITY

NOTE: This procedure calibrates not only conductivity, but also specific conductance, salinity,

and total dissolved solids.

Place approximately 500 mL of conductiv ity standard in a clean and dry calibration cup.

The conductivity standard you choose should be within the same conductiv ity rang e as the water

you are preparing to sample. However, we do not recommend using standards less than 1 mS/cm.

For example:

❏ For fresh water choose a 1 mS/cm conductivity standard.

❏ For brackish water choose a 10 mS/cm conductiv ity standard.

❏ For sea water choose a 50 mS/cm conductivity standard.

Caution: Before proceeding insure that the sensor is as dry as possible. Ideally, rinse the

conductivity sensor with a small am ount of standard that can be discarded. Be certain that y ou

avoid cross contamination of standard solutions with other solutions. Make certain that there are no

salt deposits around the oxygen and pH/ORP probes, particularly if you are em ploy ing standards of

low conductivity.

Without removing the probe guard, carefully immerse the probe end of the sonde into the solution.

Gently rotate and/or move the sonde up and down to rem ov e any bubbles from the conductivity cell.

The probe must be completely im mersed past its vent hole.

Allow at least one minute for temperature equilibration before proceeding .

From the Calibrate menu, select 1. Conductivity to access the Conductivity calibration procedure

and then 1. SpCond to access the specific conductance calibration procedure. Enter the calibration

value of the standard you are using (mS/cm at 25 C) and press Enter. The current values of all

enabled sensors will appear on the screen and will change with time as they stabiliz e.

3-4

Page 37

Observe the readings under Specific Conductance or Conductivity and when they show no

significant change for approximately 30 seconds, press Enter. The screen will indicate that the

calibration has been accepted and prompt you to Hit any key to return to the Calibrate menu.

Rinse the sonde in tap or purified water and dry the sonde.

DISSOLVED OXYGEN

Place approximately 1/8 inch (3 mm ) of w ater or a wet spong e in the bottom of the Calibration Cup

or Transport Cup. Place the probe end of the sonde into the cup. Make certain that the DO and the

temperature probes are not immersed in the water. Wait approximately 10 minutes for the air in the

calibration cup to become water saturated and for the temperatures of the thermistor and the oxy g en

probe to equilibrate.

CAUTION: If the Transport Cup is used, make certain that the cup is vented to the atmosphere by

loosening the vent screw.

From the Calibrate menu, select 2. DO% to access the D O % calibration procedure.

Enter the current barometric pressure in mm of Hg . (Inches of Hg x 25.4 = mm Hg ).

NOTE: Remember that barometer readings which appear in meteorological reports are generally

corrected to sea level and are not useful for your calibration procedure unless they are

uncorrected.

Press Enter and the computer will indicate that the calibration procedure is in progress.

Calibration will AUTOMATICALLY occur after warmup interval.

Warming Sensors: 27

After approximately 1 minute, the calibration will be complete. Press any key, as instructed, and

the screen will display the percent saturation value which corresponds to your local barometric

pressure input. For example, if your barometer reads 742 m m Hg, the screen will display 97.6 %

(742/760) at this point.

After the calibration is complete, press any key to return to the Calibrate menu.

NOTE: Calibration of dissolved oxygen in the DO % procedure also results in calibration of the

DO mg/L mode and vice v ersa.

Rinse the sonde in water and dry the sonde.

3-5

Page 38

DEPTH

Following the DO calibration, leave the sonde in water-saturated air. Make certain that the sonde is

not submerged in water for the depth calibration.

From the Calibrate menu, select 3. Depth to access the depth calibration procedure. Input 0.00 or

some known sensor offset in feet (the depth sensor is about 0.46 feet above the bottom of the probe

compartment). Press Enter and monitor the stabilization of the depth reading s w ith tim e. When no

significant change occurs for approximately 30 seconds, press Enter to confirm the calibration and

zero the sensor with regard to current barometric pressure. Then, as instructed, Hit any key to

return to the Calibrate menu.

pH 2-POINT

Place approximately 400 mL of pH 7 buffer in a clean calibration cup. Carefully immerse the

probe end of the sonde into the solution.

Allow at least 1 minute for temperature equilibration before proceeding .

From the Calibrate menu, select 6. pH to access the pH calibration choices and then 2. 2-Point.

Press Enter and input the value of the buffer (or accept the default) at the prompt. Press Enter and

the current values of all enabled sensors will appear on the screen and will change with tim e as they

stabilize in the solution. Observe the readings under pH and when they show no significant change

for approximately 30 seconds, press Enter. The display will indicate that the calibration is

accepted.

After the pH 7 calibration is complete, Hit any key, as instructed on the screen, to continue.

Rinse the sonde in water and dry the sonde before proceeding to next step.

Place approximately 400 mL of a second pH buffer solution in a clean calibration cup. The second

buffer might be pH 4 if the sample is expected to be acidic or pH 10 if the sam ple is expected to be

basic. Carefully imm erse the probe end of the sonde into the solution.

Allow at least 1 minute for temperature equilibration before proceeding .

Press Enter and input the value of the second buffer at the prompt. Press Enter and the current

values of all enabled sensors will appear on the screen and will change with tim e as they stabiliz e in

the solution. Observe the readings under pH and when they show no significant chang e for

approximately 30 seconds, press Enter. After the second value calibration is complete, Hit any

key, as instructed on the screen, to return to the Calibrate m enu.

Rinse the sonde in water and dry the sonde.

Thoroughly rinse and dry the calibration cups for future use.

3-6

Page 39

AMMONIUM (NH

+

) and NITRATE (NO

4

-

) 3-POINT

3

WARNING: AMMONIUM AND NITRATE SENSORS CAN ONLY BE USED AT DEPTHS

OF LESS THAN 50 FEET (15 METERS). USE OF T HE SENSORS AT GREAT ER DEPT HS IS

LIKELY TO PERMANENTLY DAMAGE THE SENSOR MEMBRANE.

NOTE: The calibration procedures for ammonium and nitrate are sim ilar to pH except for the

reagents in the calibration solutions. Suggested values for calibrants are 1 and 100 m g /L of either

ammonium-nitrogen (NH

-N) or nitrate-nitrogen (NO3-N).

4

NOTE: The following procedure requires one 500 mL portion of 100 mg/L calibrant and two

500

mL portions of 1 mg/L calibrant. The 100 m g /l solution and one of the 1 mg/L solutions should be

at ambient temperature. The other 1 mg /L solution should be chilled to less than 10 C° prior to

beginning the procedure.

CAUTION: Proper calibration of the ammonium and nitrate sensors requires that the pH,

conductivity, and temperature probes also be im mersed in the same solution as the sensor being

calibrated. Therefore, do not remove the probe guard and attem pt to immerse individual sensors in

different vessels. For the ammonium and nitrate sensors to function at all, there must be solution

contact between the pH and the ammonium or nitrate probe.

Place 500 mL of 100 mg/L standard into a clean calibration cup. Carefully immerse the probe end

of the sonde into the solution.

Allow at least 1 minute for temperature equilibration before proceeding .

Select 7. Ammonium or 8. Nitrate to access the appropriate calibration choices. Then select

3. 3-Point. Press Enter and input the concentration value of the standard as requested or accept

the default. Press Enter and the current values of all enabled sensors will appear on the screen and

will change with time as they stabiliz e in the solution. O bserv e the readings under NH4+ or NO3- .

When they show no significant change for approximately 30 seconds, press Enter.

After the second value calibration is complete, as instructed, Hit any key to continue.

Rinse the sonde in water and dry the sonde prior to the next step.

Place 500 mL of the ambient temp erature 1 m g /L standard solution in a clean calibration cup.

Carefully immerse the probe end of the sonde into the solution.

Allow at least 1 minute for temperature equilibration before proceeding .

Press Enter and input the concentration value of the standard as requested or accept the default.

Press Enter and the current values of all enabled sensors will appear on the screen and will change

with time as they stabilize in the solution. Observ e the readings under NH4+ or NO3- and w hen

they have show no significant change for approxim ately 30 seconds, press Enter.

After the second value calibration is complete, as instructed, Hit any key to continue.

3-7

Page 40

Place 500 mL of the chilled 1 mg/L standard solution in a clean calibration cup. Carefully immerse

the probe end of the sonde into the solution.

Allow at least 5 minutes for temperature equilibration before proceeding. Press Enter and input the

concentration value of the standard as requested or accept the default. Press Enter and the current

values of all enabled sensors will appear on the screen and will change with tim e as they stabiliz e in

the solution. Observe the readings under NH4+ or NO3- and when they show no sig nificant chang e

for approximately 30 seconds, press Enter.

After the third value calibration is complete, Hit any key to return to the Calibrate menu.

Thoroughly rinse and dry the calibration cups for future use.

CALIBRATION TIP: AVOIDING DRIFT DURING CALIBRATION OF THE NH4+ AND

NO3- PROBES AFTER pH CALIBRATION. Exposure to the high ionic content of pH buffers

can cause a significant, but temporary, drift in either the ammonium or the nitrate probe.

Therefore, when calibrating the nitrate or ammonium sensor, we recommend that you use one of

the following methods to minimize errors in the subsequent readings:

❏ Calibrate pH first, immersing all of the probes in the pH buffers. After calibrating pH, place

the probes in 100 mg/L nitrate or ammonium standard and monitor the reading. Usually, the

reading starts low and may take as long as 30 minutes to reach a stable value. When it does,

proceed with the calibration.

❏ When calibrating pH, remove the probe guard and immerse only the pH and temperature

probes in the buffers. You can then calibrate nitrate or ammonium immediately after pH

calibration.

TURBIDITY 2-POINT

WARNING: THE TURBIDITY SENSOR CAN ONLY BE USED AT DEPTHS OF LESS THAN

200 FEET (61 METERS). USE OF THE PROBE AT GREATER DEPTHS IS LIKELY TO

PERMANENTLY DAMAGE THE SENSOR.

Select 9. Turbidity from the Calibrate Menu and then 2. 2-Point.

NOTE: One standard must be 0 NTU, and this standard must be calibrated first.

To begin the calibration immerse the sonde in approximately 300 mL of 0 NTU standard (clear

deionized, distilled, or tap water), as instructed, and press Enter. Input the value 0.00 NTU at the

prompt, and press Enter. After calibration of the mechanical wiper speed, the screen will display

real-time readings wh ich will allow y ou to determine when the turbidity values have stabiliz ed. If

the readings appear unusually high or low or are unstable, there are probably bubbles on the optical

surface. Activate the mechanical wiper by pressing the “3” k ey to remove the bubbles. After

stable readings are observed for approximately 40 seconds, press Enter to “confirm” the first

calibration and then, as instructed, Hit any key to continue.

3-8

Page 41

Dry the sonde and probes carefully and then place the sonde in approximately 300 mL of the second

turbidity standard (100 NTU is suggested). Input the correct turbidity value in NTU, press Enter,

and view the stabilization of the values on the screen in real-time. As described above, if the

readings appear unusually high or low or are unstable, activate the wiper to rem ove bubbles and be

sure to wait at least 40 seconds before confirming the calibration. After the readings have

stabilized, press Enter to “confirm” the calibration and then, as instructed, Hit any key to return to

the Calibrate menu.

Thoroughly rinse and dry the calibration cups for future use.

CAUTION: If the turbidity system has been set up as outlined in Section 2 of the manual, sig n al

averaging will be taking place during calibration and the response time of the sensor will be slightly

slower than that of the other sensors. This effect makes it critical to observe at least 40 seconds of

stable readings prior to “confirming” the calibration. Be particularly careful to tak e y our time

during the calibration of the turbidity system.

3.3 DISCRETE SAMPLING

To start taking readings with your 6000UPG, use the Discrete sampling m ode to turn on or turn off

the continuous sampling function. Data will be displayed to the screen and optionally saved to

internal flash disk memory or to a computer or logger display.

Select 1. Run from the sonde Main menu. The Run menu w ill be display ed.

========================================

Run

----------------------------------------

1. Discrete sample

2. Conditional Sample

3. Unattended sample

Select option (0 for previous menu):

Select 1. Discrete sample from the Run menu. The Run Discrete sam ple menu will be displayed.

========================================

Discrete-sample

----------------------------------------

1. Start sample

2. Site description

3. Sample interval

4. Close file

5. Set Auto-stop timer

Select option (0 for previous menu):

3-9

Page 42

Select the different functions in this menu to become fam iliar with the D iscrete sam p ling m ode.

Remember to use Esc or 0 to cancel functions or to back up to the previous display.

1. Start discrete sample

Select this option to start discrete sampling. After the initial sam pling time interval has passed, data

will be displayed on the screen.

A single line of data can be logged to flash disk mem ory by pressing 1. (screen prompt reads

'1-LOG last sample').

A set of data can be logged to flash disk by pressing 2. (screen prom pt reads '2-LOG ON/OFF'). A

message will be displayed that LOG is on, turn it off by selecting 2.

If installed, the turbidity probe face can be cleaned by pressing 3 (screen prompt reads ‘3-Clean

optics’).

Select Esc to exit discrete sampling.

2. Site description

Select this option to name the site of the sample if you intend to log data w hile discrete sampling.

Up to 31 characters can be entered, but only the first 8 will be used in naming the file after transfer

to a computer for analysis. The site description you enter will be display ed w ith the file nam e to

help you identify the file later.

3. Sample interval

Select this option to set the interval which will pass between sam ples. Enter the desired interval in

seconds. The default sample interval is 4 seconds.

4. Close file

Select this option to close any discrete sample file. A file is opened autom atically w henev er data is

logged to flash disk memory. When you exit discrete sample mode, you can close the file using this

function or you can leave it open and log to it later.

5. Set Auto-stop timer

3-10

Page 43

Select this option to set up a timer to automatically turn off discrete sampling. If you beg in a

discrete sample and forget to turn it off later, battery life will be g reatly reduced. F or this reason,

the Auto-stop timer can be set up to automatically turn off any activ e discrete sample if it has been

left on for a specified period of time. Simply ty pe in what y ou feel is an appropriate amount of

minutes, and the program will turn off discrete sampling after that many minutes have passed.

Setting the timer to 0 disables the Auto-stop timer and discrete sampling will never be stopped by

the Auto-stop timer.

After you have become fam iliar w ith these selections, press 1-Start Discrete Sample and observe

the data appear on your computer screen. The general form at of the display w ill be as follows,

although the detail will depend on which parameters which y ou hav e activated.

======================================================================

Date Time Temp SpCond Sal DO DO pH Turb Batt

MM/DD/YY hh:mm:ss C uS/cm ppt % mg/L NTU V

----------------------------------------------------------------------

*** 1-LOG last sample 2-LOG ON/OFF, 3-Clean optics ***

06/17/96 09:20:44 27.73 995 0.49 50.9 4.42 7.42 0.3 12.2

06/17/96 09:20:48 27.73 995 0.49 48.5 4.21 7.42 0.4 12.2

06/17/96 09:20:52 27.73 995 0.49 47.2 4.09 7.42 0.4 12.2

06/17/96 09:20:56 27.73 995 0.49 46.3 4.02 7.42 0.4 12.3

06/17/96 09:21:00 27.73 995 0.49 45.7 3.96 7.42 0.4 12.2

06/17/96 09:21:04 27.73 995 0.49 45.2 3.92 7.42 0.4 12.2

06/17/96 09:21:08 27.73 995 0.49 44.8 3.81 7.42 0.4 12.2

06/17/96 09:21:12 27.73 995 0.49 44.9 3.87 7.42 0.4 12.2

To stop the Discrete Sample mode, press Esc or ‘0’ until the sonde Main m enu is displayed.

3-11

Page 44

3.4 UNATTENDED SAMPLING

The Unattended Sampling Mode is designed to log reading s of all user-defined parameters at

intervals you specify. The 6000

Throughout the deployment, data is stored to internal flash disk m emory. This data can be

uploaded to the PC6000 software upon completion of the study, or at anytim e during the study

without stopping the logging.

Select 1. Run from the sonde Main menu. The Run menu w ill be display ed.

========================================

Run

----------------------------------------

1. Discrete sample

2. Conditional Sample

3. Unattended sample

Select option (0 for previous menu):

Select 3. Unattended sample from the Run menu. The current time and date, all activ e sensors,

battery voltage, and free flash disk space w ill be display ed.

UPG can be deployed for weeks at a tim e using this feature.

NOTE: If the current time and date are not correct, your unattended sampling study will not begin

or end when you desire. To correct the time and date see Section 2.5.

You will be asked to enter the following inform ation concerning the unattended sam p ling study y ou

wish to set up.

Enter starting date (XX/XX/XX):

Enter starting time (XX:XX:XX):

Enter duration in days (XX.XXX):

Enter interval in minutes (XX):

Enter site description (UNTITLE):

To gain experience, set up an unattended sampling study with the following responses to the abov e

questions:

Enter starting date: today's date

Enter starting time: current time

Enter duration in days: 1

Enter interval in minutes: 2

Enter site description: First-test

3-12

Page 45

NOTE: The time entry must include not only hours and m inutes, but also seconds. For example, if

you want to start a study at 8 AM, you must enter 8:00:00, and not just 8:00. The software will

prompt you with a beep if the time is entered incompletely.

You will be asked if all start-up inform ation is correct. C heck the information carefully and, if you

want to change something, press “N”. If all information is correct, press “Y”. The following

message will be displayed briefly :

*************************************

* INSTRUMENT IS IN UNATTENDED MODE *

*************************************

To continue the “First-test” study you have just started, disconnect the cable from the sonde and

screw on the waterproof connector cap. The unit is now ready for deployment. If the calibration

cup is installed, remove it and place the 6000

UPG in at least 6 inches of water. Leave it there for an

hour. Proceed to the next section.

CAUTION: If you intend to transfer data logged in an Unattended study to a 610-DM at a later

time, it is important back com p letely out of the sonde m enu structure before disconnecting the

cable. To do this, press the Esc key until you reach the Main menu. Then press Esc once more

and when the question “Exit menu? (Y/N)” appears, enter “Y”: The message “OK” followed by the

# sign will appear. At this point, disconnect the cable from the unit and allow data to be log g ed to

memory. Depending on the version of software in your 610, if you do not back out of the menu

structure, no communication will occur when using a 610 at a later time.

3-13

Page 46

3.5 RETRIEVING DATA FR OM THE 6000UPG

Attach the PC cable to the 6000UPG. Connect the other end of the cable to the serial port of your

computer.

Run the PC6000 software and select Sonde from the top-line menu using the arrow keys.

Sonde File Setup Real-Time Exit PC6000

NOTE: If communication with the sonde fails, first check all cable connections and the com m port

information under Setup of the PC6000 top-line menu. If all cable connectors are properly attached

and the comm port setting is correct, it is lik ely that the sonde batteries hav e been depleted. To

replace the sonde batteries see Section 2.2.

From the sonde Main menu select 1. Run.

NOTE: If the instrument is busy taking a sample it will display the following m essage:

** Instrument is busy. Please wait. **

Wait until the Run menu appears and select 3. Unattended Sample. The screen will display a

prompt asking if you wish to cancel the unattended sam p ling study .

** INSTRUMENT IS IN UNATTENDED MODE **

Start date and time : 05/31/96 11:04:08

Duration (days) : 30.000

Interval (minutes) : 2

Site description : First-test

UNATTENDED mode active. Cancel (Y/N)?

NOTE: Data can also be uploaded while an unattended sampling study is in progress.

3-14

Page 47

NOTE: If unattended sampling has already stopped autom atically because the duration y ou entered

earlier has expired, press Esc twice to return to the Main menu.

Press “Y” and Enter to stop the Unattended study.

Return to the sonde Main menu using the Esc key. Select 3. File to display the File menu.

========================================

File

----------------------------------------

1. Directory 5. Quick view file

2. Upload 6. Delete file

3. Quick Upload 7. Format FlashDisk

4. View file 8. Test FlashDisk

Select option (0 for previous menu):

Select 3. Quick upload to display the Quick-Up load m enu.

========================================

File Quick Upload

----------------------------------------

1. PC6000

2. Comma&''Delimited

3. ASCII Text

Select option (0 for previous menu):

Select 1. PC6000 to upload to the PC6000 software. A secondary menu will appear to show the

progress of the upload.

NOTE: Comma & " " Delimited and ASCI I Text formats are available for uploading data to a

spreadsheet or database program. See Section 4.3 for more details.

When the upload is complete, press Esc until the sonde Main menu returns. Press F10 to exit the

sonde menu and return to the PC6000 top-line menu.

3-15

Page 48

3.6 ANALYZING DATA WITH PC6000

Select File from the top-line menu.