Page 1

YSI Model 60

Handheld pH and

Temperature

System

Operations

Manual

Page 2

Page 3

Table of Contents

1. Introduction ............................................................................................................... 1

2. Preparing the Meter................................................................................................... 2

2.1 Unpacking............................................................................................................................2

2.2 Warranty Card......................................................................................................................2

2.3 Batteries ...............................................................................................................................2

2.4 Transport Chamber ..............................................................................................................3

2.5 Hand Strap ...........................................................................................................................3

2.6 The Meter Case....................................................................................................................3

2.7 Calibration Vessels ..............................................................................................................3

3. Preparing the Probe.................................................................................................. 4

3.1 Installing the Sensor.............................................................................................................4

4. Operation...................................................................................................................5

4.1 Turning The Instrument On .................................................................................................6

4.2 Calibration ...........................................................................................................................6

4.3 Making Measurements.......................................................................................................11

4.4 Saving Data........................................................................................................................11

4.5 Recalling Stored Data ........................................................................................................12

4.6 Erasing Stored Data ...........................................................................................................13

4.7 Display Backlight ..............................................................................................................13

5. Maintenance of the pH Sensor............................................................................... 14

5.1 pH Sensor Precautions .......................................................................................................14

5.2 pH Sensor Cleaning ...........................................................................................................14

5.3 pH Sensor Storage .............................................................................................................15

6. Discussion of Measurement Errors....................................................................... 16

7. Troubleshooting...................................................................................................... 17

8. Principles of Operation........................................................................................... 19

8.1 pH.......................................................................................................................................19

8.2 Temperature .......................................................................................................................20

9. Warranty and Repair............................................................................................... 21

9.1 Cleaning Instructions .........................................................................................................22

9.2 Packing Instructions...........................................................................................................23

10. Required Notice.....................................................................................................24

11. Accessories and Replacement Parts................................................................... 25

i

Page 4

12. Appendix A - Specifications................................................................................. 26

13. Appendix B - Health and Safety........................................................................... 27

14. Appendix C - pH Buffer Values ............................................................................ 28

ii

Page 5

1. Introduction

The YSI Model 60 Handheld pH/Temperature System is a rugged, micro-processor based, digital

meter with an attached pH and temperature probe. The pH sensor can be easily replaced in the

field.

The Model 60 has a non-detachable cable available in lengths of 10, 25, 50 or 100 feet (3, 7.6,

15.2 or 30.5 meters). The probe body has been manufactured with stainless steel to add rugged

durability and sinking weight.

The YSI Model 60 has the following features:

• Capability to measure at depths of up to 100 feet (30.5 meters)

• Microprocessor control

• Field replaceable low maintenance pH sensor

• Push-button calibration

• Simultaneous display of pH and temperature

• Automatic temperature compensation

• Data storage for 50 sets of readings with on screen recall

• Waterproof case (IP65)

The Model 60’s micro-processor allows the system to be easily calibrated with the press of a few

keys. Additionally, the micro-processor performs a self-diagnostic routine each time the

instrument is turned on. The self-diagnostic routine provides useful information about the

function of the instrument and probe.

A transport chamber, built into the instrument case, provides a convenient place to store the

probe when transporting the system. The Model 60 case is waterproof (rated to IP65) allowing

operation in the rain without damage to the instrument.

The Model 60 is powered by six AA-size alkaline batteries. A new set of alkaline batteries will

provide approximately 100 hours of continuous operation. When batteries need to be replaced,

the LCD will display a “LO BAT” message.

The YSI Model 60 is designed for use in environmental, aquaculture, and industrial applications

where accurate pH and temperature measurements are desired.

1

Page 6

2. Preparing the Meter

2.1 Unpacking

When you unpack your new YSI Model 60 Handheld pH and Temperature System for the first

time, check the packing list to make sure you have received everything you should have. If there

is anything missing or damaged, call the dealer from whom you purchased the system. If you do

not know which of our authorized dealers sold the system to you, call YSI Customer Service at

800-765-4974 or 937-767-7241, and we'll be happy to help you.

2.2 Warranty Card

Please complete the Warranty Card and return it to YSI. This will record your purchase of this

instrument in our computer system. Once your purchase is recorded, you will receive prompt,

efficient service in the event any part of your YSI Model 60 should ever need repair.

2.3 Batteries

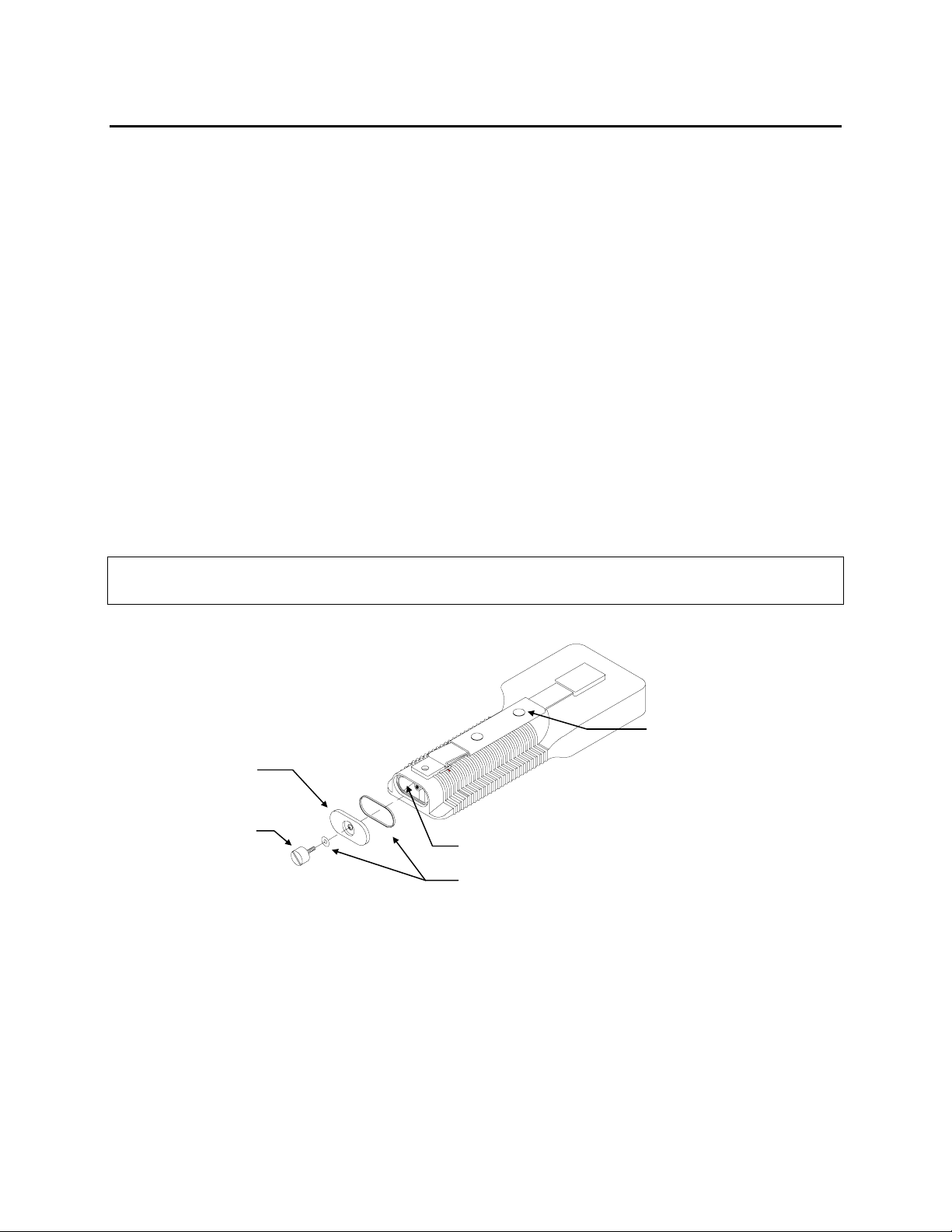

There are a few things you must do to prepare your YSI Model 60 for use. First, locate the six

AA-size alkaline batteries and the battery cover kit which were included. Then locate the

markings inside each of the two battery-chamber sleeves that illustrate the correct way to install

the batteries. Install the batteries are shown.

NOTE: It is very important that the batteries be installed ONLY as illustrated. The instrument

will not function and may be damaged if the batteries are installed incorrectly.

Hand strap

Battery chamber

cover

Thumb screw

Attach the battery chamber cover to bottom of the instrument using the thumb screw as shown in

Figure 1. Make sure that the o-rings are in place. The battery-chamber cover is marked with the

words "OPEN" and "CLOSE."

Turn the instrument on by pressing and releasing the ON/OFF key on the front of the

instrument. The liquid crystal display (LCD) should come on. Allow a few seconds for the

instrument to complete its diagnostic routine. If the instrument does not operate, consult the

chapter entitled Troubleshooting.

Polarity marking

O-rings

Figure 1

2

Page 7

You may also want to take the instrument into a dark location and, with the instrument ON, hold

down the LIGHT key. The instrument back-light should illuminate the LCD so that the display

can be easily read.

2.4 Transport Chamber

The Model 60 has a convenient transport chamber built into the instrument’s side. This chamber

provides a storage area and protection for the pH sensor while transporting the system in the

field. Insert the round sponge (provided with the Model 60) into the bottom of the chamber. Put

6-8 drops of tap water into the sponge. The wet sponge creates a humid environment for the pH

sensor to prevent it from drying out during transport in the field (up to one week). The transport

chamber is NOT intended for long term storage of the pH sensor. See 5.3 pH Sensor Storage.

Probe transport

chamber

Figure 2

2.5 Hand Strap

The hand strap (see Figure 1 on previous page) is designed to allow comfortable operation of the

Model 60 with minimum effort. If the hand strap is adjusted correctly, it is unlikely that the

instrument will be easily dropped or bumped from your hand.

To adjust the hand strap on the back of the meter, unsnap the vinyl cover and pull the two Velcro

strips apart. Place your hand between the meter and the strap and adjust the strap length so that

your hand is snugly held in place. Press the two Velcro strips back together and snap the vinyl

cover back into place.

2.6 The Meter Case

The meter case is sealed at the factory and is not intended to be opened, except by authorized

service technicians. Do not attempt to separate the two halves of the meter case as this may

damage the instrument, break the water-resistant seal and may void the manufacturer's

warranty.

2.7 Calibration Vessels

A plastic 100 mL graduated cylinder and a plastic container are provided with the Model 60. The

graduated cylinder provides a convenient place to calibrate the pH sensor minimizing the amount

of solution needed. The plastic container should be filled with distilled water and used as a rinse

vessel while in the field. See section 4.2 Calibration for details.

3

Page 8

3. Preparing the Probe

The YSI Model 60 is shipped without the pH sensor installed. The pH sensor must be installed

before using the system (see section 3.1 Installing the Sensor, below). The sensor is shipped with

a protective bottle filled with a mixture of pH 4 buffer and KCl solution. Do not remove the

bottle until you are ready to use the instrument. Save the bottle for long term storage of the

probe.

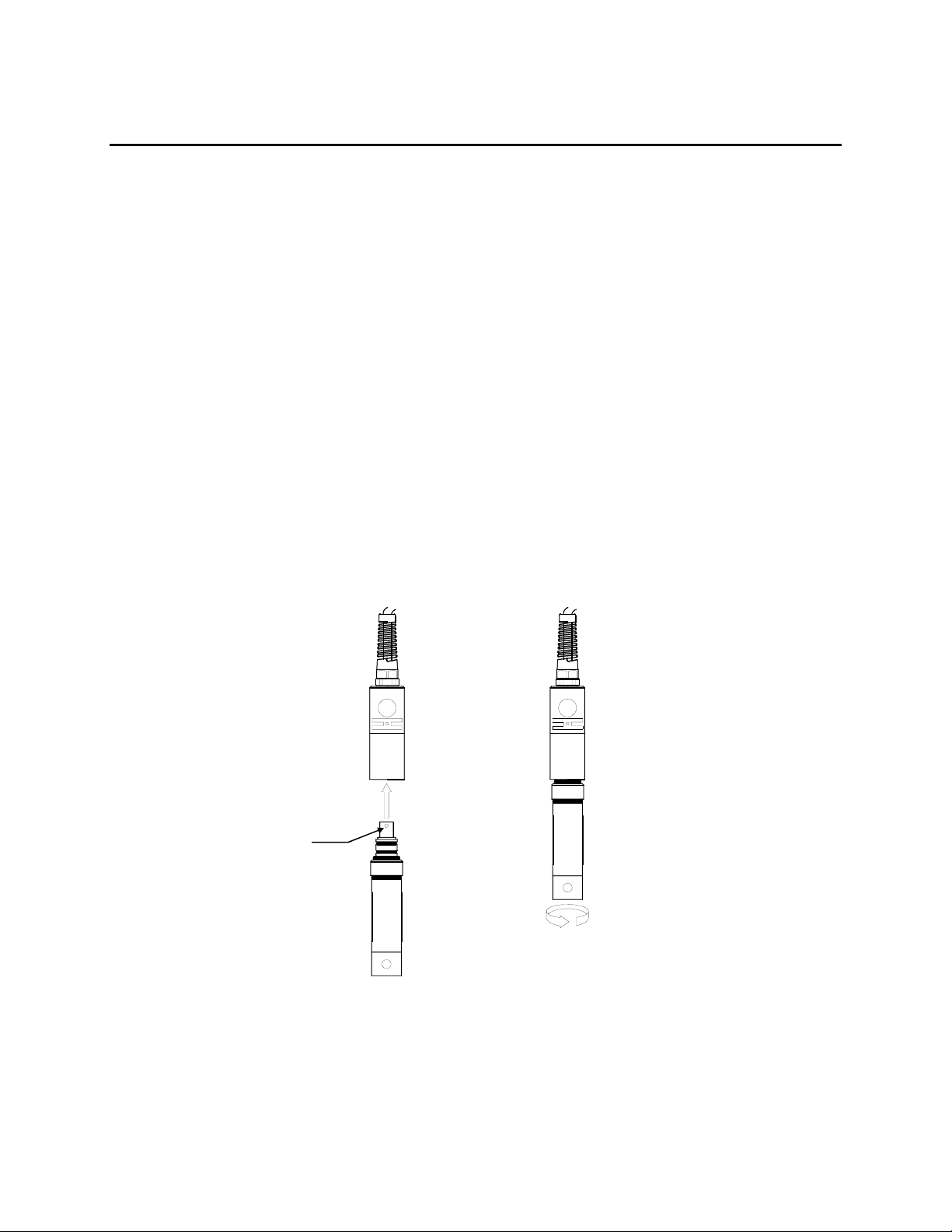

3.1 Installing the Sensor

A pH sensor is included with the Model 60. Install the pH sensor as follows:

1. Remove the sensor from its protective packing.

2. Insert the pH sensor into the probe body (be sure to align the tabs on the sensor with the slots in

the probe body) and twist 1/4 turn to lock in place. See Figure 3.

NOTE: Once installed, leave the pH sensor attached to the probe until replacement is needed.

3. Carefully remove the protective bottle (containing pH 4 buffer/KCl solution) from the sensor.

Save the bottle and solution for long term (over one week) storage of the sensor. Seal the storage

bottle with the cap provided.

4. Rinse the sensor tip with distilled or deionized water.

5. Calibrate the system before use. See section 4.2 Calibration.

Align tabs with

slots in probe

body

Turn sensor 1/4 turn

to lock in place

Insert pH sensor

into probe body

Figure 3

4

Page 9

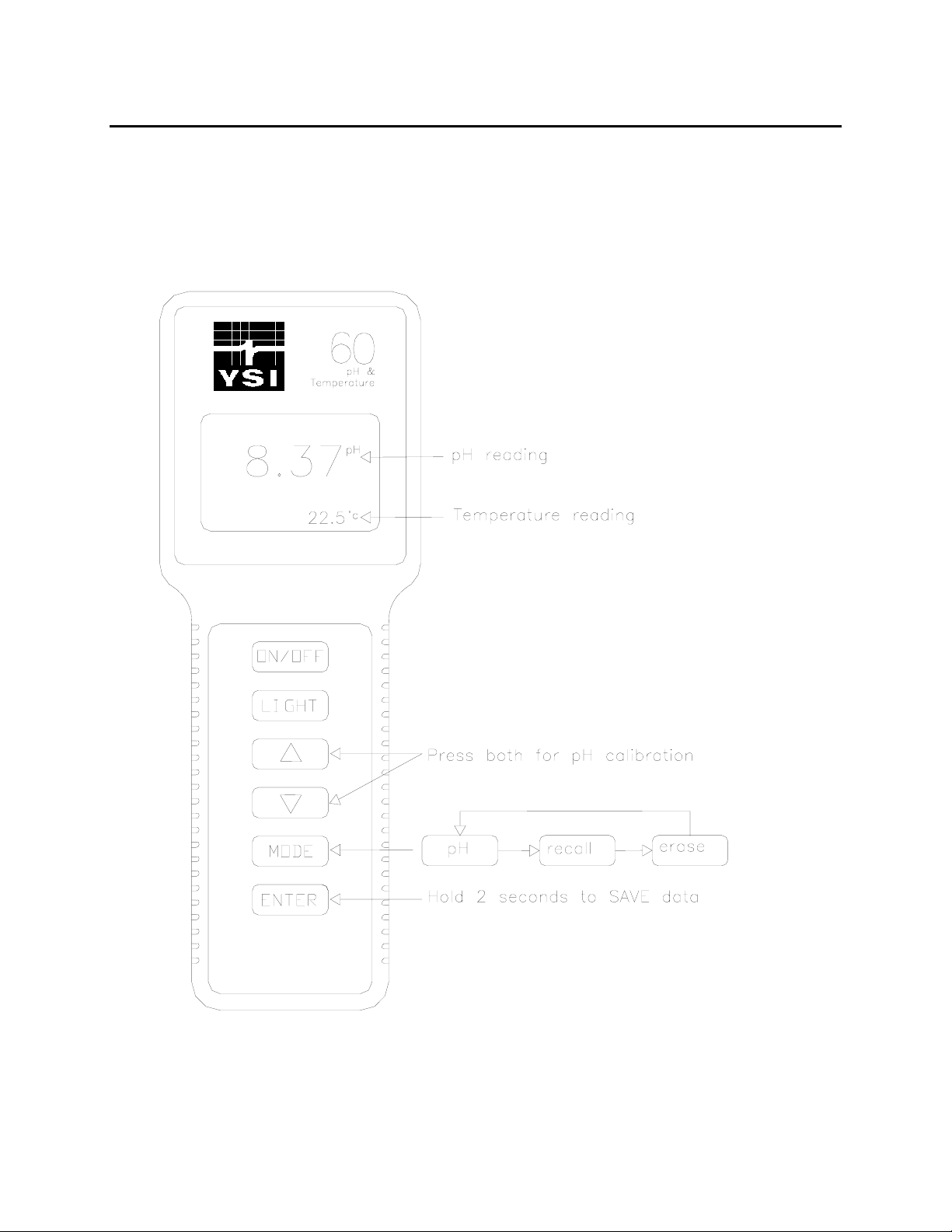

4. Operation

The following diagram is an overview of the operation of the Model 60. See the following

sections for details of operation.

Figure 4

5

Page 10

4.1 Turning The Instrument On

With the batteries installed correctly, press the ON/OFF key. The instrument will activate all

segments of the display for a few seconds, which will be followed by a self test procedure which

will last for several more seconds. During this power on self test sequence, the instrument’s

microprocessor is verifying that the system is working properly. If the instrument were to detect

a problem, a continuous error message would be displayed. See the chapter entitled

Troubleshooting for a list of error messages.

7.23 pH

24.8

°C

4.2 Calibration

The YSI Model 60 MUST be calibrated before making pH measurements. Calibration may be

performed at 1, 2 or 3-points (at pH 7, 4 and 10, or at pH 6.86, 4.01 and 9.18). Perform a 1-point

calibration (at pH 7 or at pH 6.86) ONLY if a previous 2 or 3-point calibration has been

performed recently. In most cases, a 2-point pH calibration will be sufficient for accurate pH

measurements, but if the general range of pH in the sample is not known, a 3-point calibration

may be necessary. 3-point calibration assures accurate pH readings regardless of the pH value of

the sample. See Section 8.1 pH for more details.

WARNING: Calibration reagents may be hazardous to your health. Refer to Appendix B -

Health and Safety for more information.

Before calibrating the YSI Model 60, complete the procedures discussed in the Preparing

the Meter and Preparing the Probe chapters of this manual.

The user can choose from two sets of pH buffer values for 3-point calibration. The first set

consists of the standard YSI pH buffer values of pH 7 (YSI 3822), pH 4 (YSI 3821) and pH 10

(YSI 3823). The second set available is the NIST pH 6.86, 4.01 and 9.18. Note that the first

calibration point must be either pH 7 or pH 6.86. Calibration is performed as follows:

1. Turn the instrument on by pressing the ON/OFF key. If the instrument was already on, press

the MODE key until pH is displayed.

2. Rinse the probe with deionized or distilled water, then carefully dry the probe (or rinse it

with some of the pH buffer solution to be used for calibration).

3. Place 30 to 35 mL of the pH buffer you have chosen to calibrate the system with (pH 7 or

6.86) in the 100 mL graduated cylinder (provided with the Model 60). The graduated

cylinder minimizes the amount of solution needed. Immerse the probe making sure that both

the pH and temperature sensors are covered by the solution (see Figure 5 on the following

page).

6

Page 11

For best results:

• Calibrate as close as possible to the sample temperature.

• After storage in pH 4 buffer/KCl solution, place the pH sensor in pH 7 (6.86) buffer and

allow to acclimate before calibrating (5 to 10 minutes).

• Always give the pH and temperature sensors enough time to equilibrate with the

temperature of the buffer.

Temperature sensor

pH sensor (covered by sensor guard)

Figure 5

4. To enter the calibration menu, use two fingers to press and release both the UP ARROW

and DOWN ARROW keys at the same time. The Model 60 display will show CAL at the

bottom, STAND will be flashing and the main display will show 7.00 (the buffer to be used

to adjust the offset).

First buffer value.

Flashing

7.00 pH

STAND CAL 24.8

°C

Used to adjust the offset.

NOTE: If you will be calibrating with pH buffers of 6.86, 4.01 and 9.18 (instead of 7, 4 and

10), press both the UP ARROW and DOWN ARROW keys again. The display will change

to 6.86.

NOTE: The Model 60 automatically accounts for the fact that the true pH of the buffers

changes with temperature, therefore, the pH values displayed during calibration will vary

with temperature. For example, pH 7 buffer at 20°C (rather than 25°C) has an actual pH of

7.02 and this number (rather than 7.00) will appear on the display when the probe is placed

in the solution. See Appendix C - pH Buffer Values.

7

Page 12

5. Press the ENTER key. The Model 60 display will show CAL at the bottom, STAND will

g

stop flashing and the pH calibration value is shown with the middle decimal point flashing.

7.00 pH

STAND CAL 24.8

6. When the reading is stable (does not change by 0.01 pH in 10 seconds), the decimal point

will stop flashing. Press and hold the ENTER key to save the calibration point. The Model

60 will flash SAVE on the display along with OFS to indicate that the offset value has been

saved.

°C

Flashes until

readin

is stable

SAVE

OFS

7. SLOPE will now appear on the display and be flashing. This indicates that the slope is ready

to be set using a second pH buffer. The system is now calibrated at a single point. If you are

only performing a single point calibration, press the MODE key to return to normal

operation.

7.00 pH

SLOPE

CAL 24.8

8. Rinse the probe with deionized or distilled water, then carefully dry the probe.

STOP HERE IF PERFORMING A 1-POINT CALIBRATION.

9. If you are performing a 2-point or 3-point calibration, fill a clean container with the second

value pH buffer (pH 4 or 10, or pH 4.01 or 9.18) and immerse the probe into the solution.

Make sure that the temperature sensor is immersed.

10. Press the ENTER key. The Model 60 display should now show CAL at the bottom, SLOPE

will stop flashing and the pH calibration value (automatically sensed by the instrument) is

shown with one of the decimal points flashing.

°C

Flashing

8

Page 13

.4.01 pH

Second buffer value

SLOPE

CAL 24.8

°C

Left decimal flashes (until

reading is stable) for buffers

lower than first cal point

If the second pH buffer is less than the first buffer (which was used to adjust the offset; pH 7

or pH 6.86), the left decimal point will flash as shown above. If the second pH buffer is

greater than the first, the right decimal point will flash as shown below.

Second buffer value

10.0.0 pH

SLOPE

CAL 24.8

°C

Right decimal flashes (until

reading is stable) for buffers

higher than first cal point

11. When the reading is stable (does not change by 0.01 pH in 10 seconds), the decimal point

will stop flashing. Press and hold the ENTER key to save the first SLOPE. The Model 60

will flash SAVE on the display along with SLP to indicate that the first slope value has been

saved.

SAVE

SLP

12. SLOPE will start flashing again indicating that the slope is ready to be set using a third pH

buffer.

.4.01 pH

SLOPE

CAL 24.8

°C

13. The system is now calibrated at two points. If you are only performing a two point

calibration, press the MODE key to return to normal operation.

14. Rinse the probe with deionized or distilled water, then carefully dry the probe.

Flashing

STOP HERE IF PERFORMING A 2-POINT CALIBRATION.

9

Page 14

15. If you are performing a 3-point calibration, fill a clean container with the third value pH

p

buffer (pH 4 or 10, or pH 4.01 or 9.18) and immerse the probe into the solution. Make sure

that the temperature sensor is immersed.

NOTE: The third buffer must not be the same as the second buffer. For example; if the

second buffer was less than pH 7, the third buffer must be greater than pH 7.

16. Press the ENTER key. The Model 60 display will now show CAL at the bottom, SLOPE

will stop flashing and the pH calibration value (automatically sensed by the instrument) is

shown with one of the decimal points flashing. If the third pH buffer is less than the first

buffer (which was used to adjust the offset; usually pH 7), the left decimal point will flash. If

the third pH buffer is greater than the first, the right decimal point will flash.

Third buffer value

1.0.0.0 pH

SLOPE

CAL 24.8

or

°C

Right decimal flashes (until

reading is stable) for buffers

higher than first cal point

Third buffer value

.4.0.1 pH

SLOPE

CAL 24.8

17. When the reading is stable (does not change by 0.01 pH in 10 seconds), the decimal point

will stop flashing. Press and hold the ENTER key to save the second SLOPE. The Model 60

will flash SAVE on the display along with SLP to indicate that the second slope value has

been saved.

°C

Left decimal flashes (until

reading is stable) for buffers

lower than first cal

oint

SAVE

SLP

The system is now calibrated at three points and will return to normal operation.

18. Rinse the probe with deionized or distilled water.

10

Page 15

4.3 Making Measurements

After the system has been set-up and pH has been calibrated as described in 4.2 Calibration, it is

ready to make measurements. Simply insert the probe into the sample, shake gently to remove

any trapped air bubbles and wait for the readings to stabilize (approximately 60 seconds). The

first reading after storage in buffers may take longer to stabilize (5 to 10 minutes), therefore, the

probe should be stored in the transport chamber when making field measurements. It is

important that the probe be inserted into the sample far enough so that both the pH sensor and

temperature sensor are covered by the liquid (see Figure 5 on page 7).

The Model 60 has three modes:

¾ pH -- Displays pH and temperature (°C)

¾ Recall -- Allows previously stored data to be displayed.

¾ Erase all -- Allows ALL previously stored data to be deleted.

To change between the Model 60 modes, simply press and release the MODE key. The Model

60 will cycle through the modes as follows:

pH and

Temperature °C

NOTE: When the Model 60 is first turned on, it is in the pH mode.

Recall Erase all

4.4 Saving Data

The Model 60 is equipped with non-volatile memory that is capable of storing up to 50 different

sets of readings. Non-volatile means that you do not need to worry that your data will be lost due

to a power failure or interruption, such as when the batteries are removed. Each set consists of

pH and temperature. The Model 60 will also assign a site identity number to each set of readings

to allow easy review of the data. This feature is useful in situations where transcribing data is

difficult or not available.

SAVE

01

Site identity

While pH is displayed on the screen, press the ENTER key and hold it for approximately 2

seconds. The meter will flash SAVE on the display along with the current site identity (1

through 50) being used.

When all 50 sites are full, the display will flash FULL on the screen. This message will remain

on the screen (even after power down) until a key is pushed.

11

Page 16

FULL

Once you have acknowledged the memory is full, any subsequent saved data will begin

overwriting existing data starting with site #1. No additional warning will be displayed.

4.5 Recalling Stored Data

1. To put the Model 60 into the RECALL mode, press the MODE key until “rcl” is displayed

on the screen along with the site ID number in the lower right corner.

rcl

01

2. Press the ENTER key to review the last set of data that was saved. The Model 60 will

display the pH and temperature.

3. Press the UP ARROW key to move up through the saved sets of data.

4. Press the DOWN ARROW key to move down through the saved sets of data.

5. When the correct Site ID# is displayed, press the ENTER key to display the data.

6. When you have finished recalling data, press MODE two times to return to normal

operation.

NOTE: The Model 60 will recall data as a list. When the UP ARROW is pressed the Model 60

will display the Site ID# for the previously recorded data. For example: If you are reviewing Site

ID# 5 and the UP ARROW is pressed, the Model 60 will display Site ID#4. If you are reviewing

Site ID# 5 and Site ID# 5 was the last set of data stored, the DOWN ARROW key will display

Site ID# 1.

Here is an example of the Model 60 memory.

Site ID #1

Site ID #2

Site ID #3 If the UP ARROW key was pressed the Model 60 would display Site ID #2

Site ID #4

Site ID #5

Site identity

12

Page 17

4.6 Erasing Stored Data

1. To erase the data that is stored in the Model 60’s memory, press the MODE key until the

Model 60 displays ErAS on the screen.

2. Press and hold the DOWN ARROW and ENTER keys simultaneously for approximately 5

seconds.

ErAS

3. Successful erasure is indicated by the Model 60 displaying DONE on the display for 1 to 2

seconds.

dOnE

The instrument will automatically change to normal operation after completion and the next

saved data will be stored in site ID# 1.

IMPORTANT: Data in all 50 site ID’s will be erased completely and will be lost forever. Do

not use the erase function until all recorded data has been transcribed to an archive outside the

Model 60.

4.7 Display Backlight

At times it may be necessary to take measurements with the Model 60 in dark or poorly lit areas.

To help in this situation, the Model 60 comes equipped with a backlight which will illuminate

the display so that it can be easily read. To activate the backlight, press and hold the LIGHT

key. The display will remain lit as long as the key is pressed. When you release it, the light goes

out to preserve battery life.

13

Page 18

5. Maintenance of the pH Sensor

5.1 pH Sensor Precautions

1. When making measurements or performing the calibration procedure, make certain that the

level of sample or pH buffer is high enough to cover both the pH and temperature sensors.

2. Rinse the probe with deionized water between changes of calibration buffer solutions.

3. During pH calibration, allow the sensors time to stabilize with regard to temperature

(approximately 60 seconds) before proceeding with the calibration protocol. The pH readings

after calibration are only as good as the calibration itself.

4. Clean and store the probe according to the instructions found below.

5.2 pH Sensor Cleaning

Cleaning is required whenever deposits or contaminants appear on the glass pH sensor. Unscrew

and remove the small guard that protects the pH sensor. Use tap water and a clean cloth or lens

cleaning tissue to remove all foreign material from the glass sensor.

If good pH response is not restored by the above procedure, perform the following additional

procedure:

1. Soak the probe for 10 to 15 minutes in clean water containing a few drops of commercial

dishwashing liquid.

2. GENTLY clean the glass bulb by rubbing with a cotton swab soaked in the cleaning solution.

3. Rinse the probe in clean water, wipe with a cotton swab saturated with clean water, and then

rerinse with clean water.

If good pH response is still not restored by the above procedure, perform the following

additional procedure:

1. Soak the probe for 15 to 30 seconds in one molar (1 M) hydrochloric acid (HCl).

2. GENTLY clean the glass bulb by rubbing with a cotton swab soaked in the acid.

3. Rinse the probe in clean water, wipe with a cotton swab saturated with clean water, and then

rerinse with clean water.

4. Reinstall the small guard that protects the pH sensor.

If biological contamination of the reference junction is suspected or if good response is not

restored by the above procedures, perform the following additional cleaning step:

1. Soak the probe for approximately 1 hour in a 1 to 1 dilution of commercially-available

chlorine bleach.

2. Rinse the probe with clean water and then soak for 1 hour in clean water to remove residual

bleach from the junction.

14

Page 19

5.3 pH Sensor Storage

For short term storage between measurements in the field (up to one week), place the probe in

the transport chamber in the side of the instrument case. Make sure that the sponge inside the

chamber is wet (tap water).

For long term storage (over one week), place the probe in the storage bottle (provided)

containing a mixture of 50% pH 4 buffer and 50% 1.5M KCl. This will assure the fastest

possible pH response. If this mixture is not available, storage in tap water is the next best choice.

Do NOT store the probe dry or in distilled or deionized water.

NOTE: After storage in the pH 4/KCl solution described above, place the probe in the transport

chamber in the side of the instrument case or soak the probe in pH 7 buffer for 5 to 10 minutes

allowing it to acclimate before calibrating.

If the probe has been inadvertently left in air and the reference electrode junction has dried out,

good function can usually be restored by soaking the probe in the pH 4/KCl solution described

above.

15

Page 20

6. Discussion of Measurement Errors

There are two basic types of pH errors. The first type are errors related to limitations of

instrument design and tolerances of components. The second type are errors due to basic sensor

accuracy tolerances, mainly background signal, linearity, and variations in temperature

coefficient. It is unlikely that the actual error in any measurement will be the maximum possible

error.

Errors

• Component and circuitry error: ±0.03 pH

• pH error caused by sensor accuracy and temperature compensation:

±0.1 pH for measurements at 10°C from calibration temperature

±0.2 pH for measurements at 20°C from calibration temperature

16

Page 21

7. Troubleshooting

Error Messages

The instrument performs a Power On Self Test each time it is turned on. The following error

messages are provided to facilitate troubleshooting. They appear on the LCD when an error is

detected.

Symptom Possible Cause Action

1. Instrument will not turn on

16. Instrument "locks up"

16. Instrument will not calibrate due to

unstable readings (decimal point

keeps flashing)

16. pH readings are inaccurate

16. LCD displays "LO BAT"

16. Main Display reads “nOnE”

16. Main Display reads “OVEr”

16. Main Display reads “undr”

16. Main Display reads “OVEr”

(Secondary display reads “ovr”)

16. Main Display reads “undr”

(Secondary display reads “udr”)

• Low battery voltage

• Batteries installed wrong

• Meter requires service

• Instrument has received a shock

• Batteries are low or damaged

• System requires service

• pH sensor is fouled

• pH sensor is bad

• System requires service

• pH buffers out of spec

• Cal procedure not correct

• Sample temperature is over 20°C

from cal temperature

• pH sensor is fouled or damaged

• pH Sensor is bad

• System requires service

• Batteries are low or damaged • Replace batteries (pg 2)

• During recall, no data is currently

stored in memory.

• When calibrating, pH level is over

range allowed for the buffer value

selected.

• When measuring, pH level is > 14

• When calibrating, pH level is under

range allowed for the buffer value

selected.

• When measuring, pH level is < 0

• Temperature reading is >75°C

• Temperature reading is <-5°C

• Replace batteries (pg 2)

• Check battery polarity (pg 2)

• Return system for service (pg 21)

• Remove battery lid, wait 15 seconds

for reset, replace lid. (pg 2)

• Replace batteries (pg 2)

• Return system for service (pg 21)

• Clean pH sensor (pg 14)

• Replace pH sensor (pg 4, 25)

• Return system for service (pg 21)

• Recalibrate with known good

standards (pg 6)

• Calibrate within ±20°C of sample

temp (±10°C for best results)

• Clean pH sensor (pg 14)

• Replace pH sensor (pg 4, 25)

• Return system for service (pg 21)

• Store data before attempting to recall

(pg 11)

• Recalibrate with known good

standards (pg 6)

• Clean pH sensor (pg 14)

• Replace pH sensor (pg 4, 25)

• Return system for service (pg 21)

• Recalibrate with known good

standards (pg 6)

• Clean pH sensor (pg 14)

• Replace pH sensor (pg 4, 25)

• Return system for service (pg 21)

• Measure samples at a temperature

within the range of the system.

• Measure samples at a temperature

within the range of the system.

17

Page 22

Symptom Possible Cause Action

11. Main display reads “PErr”

12. Main display reads “Err”

(Secondary display reads “ra”)

13. Main display reads “Err”

(Secondary display reads “ro”)

16. Main display reads “FAIL”

(Secondary display reads “eep”)

16. Readings on main display don’t

change

• Incorrect sequence of keystrokes. • Refer to manual section for step by

step instruction for the function you

are attempting.

• System has failed its RAM test

check procedure.

• System has failed its ROM test

check procedure.

• EEPROM has failed to respond in

time.

• Meter is in recall mode. • Press MODE key to return to Normal

• Turn instrument OFF and back ON

again.

• Return the system for service (pg 21)

• Turn instrument OFF and back ON

again.

• Return the system for service (pg 21)

• Return the system for service (pg 21)

Operation (pg 5, 11)

18

Page 23

8. Principles of Operation

8.1 pH

The YSI Model 60 employs a field replaceable pH sensor for the determination of hydrogen ion

concentration. The sensor is a combination electrode consisting of a proton selective glass

reservoir filled with buffer at approximately pH 7 and a Ag/AgCl reference electrode which

utilizes gelled electrolyte. A silver wire coated with AgCl is immersed in the buffer reservoir.

Protons (H+ ions) on both sides of the glass (media and buffer reservoir) selectively interact with

the glass, setting up a potential gradient across the glass membrane. Since the hydrogen ion

concentration in the internal buffer solution is invariant, this potential difference, determined

relative to the Ag/AgCl reference electrode, is proportional to the pH of the media.

Our testing of the Model 60 pH sensor indicates that it should provide long life, good response

time and accurate readings in most environmental waters, including fresh water of low ionic

strength. No special sensor is required (nor offered) for water of low conductivity.

Calibration And Effect Of Temperature

The software of the YSI Model 60

calculates pH from the established linear relationship between

pH and the millivolt output as defined by a variation of the Nernst equation:

E = E

+ 2.3RT * pH where E = millivolts output

o

nF

E

= a constant associated with the reference electrode

o

T = temperature of measurement in degrees Kelvin

R, n, and F are invariant constants

Thus, in simplified y = mx + b form, it is (mv output) = (slope)x(pH) + (intercept). In order to

quantify this simple relationship, the instrument must be calibrated properly using buffers of

known pH values. In this procedure, the millivolt values for two standard buffer solutions are

experimentally established and used by the YSI Model 60

software to calculate the slope and

intercept of the plot of millivolts vs. pH. Once this calibration procedure has been carried out,

the millivolt output of the probe in any media can readily be converted by the YSI Model 60

software into a pH value, as long as the calibration and the reading are carried out at the same

temperature. This last qualifier is almost never met in actual environmental measurements, thus,

a mechanism must be in place to compensate for temperature or, in other words, to accurately

convert the slope and intercept of the plot of pH vs. millivolts established at T

calibration) into a slope and intercept at T

(temperature of measurement). Fortunately, the

m

(temperature of

c

Nernst equation provides a basis for this conversion.

19

Page 24

According to the Nernst equation as shown above, the slope of the plot of pH vs. millivolts is

directly proportional to the absolute temperature in degrees Kelvin. Thus, if the slope of the plot

is experimentally determined to be 59 mv/pH unit at 298 K (25 C), then the slope of the plot at

313 K (40 C) must be (313/298) * 59 = 62 mv/pH unit. At 283 K (10 C), the slope is calculated

to be 56 mv/pH unit ((283/298) * 59). Determination of the slope of pH vs. mv plots at

temperatures different from T

is thus relatively simple. In order to establish the intercept of the

c

new plot, the point where plots of pH vs. mv at different temperatures intersect (the isopotential

point) must be known. Using standard pH determination protocol, the YSI Model 60 software

assigns the isopotential point as the mv reading at pH 7 and then calculates the intercept using

this assumption. Once the slope and intercept to the plot of pH vs. mv are assigned at the new

temperature, the calculation of pH under the new temperature conditions is straightforward, and

is automatically carried out by the software.

Number of Calibration Points

When calibrating the YSI Model 60, you have the choice of 1-point 2-point, or 3-point

calibration. Perform a 2 or 3 point calibration at least once per day for accurate results.

Select the 1-point option only if you are adjusting a previous calibration. If a 2-point or 3-point

calibration has been performed previously (at least once per day), you can adjust the calibration

by carrying out a 1-point calibration at pH 7 (or pH 6.86). This calibration procedure adjusts

only the pH offset and leaves the previously-determined slope unaltered.

Select the 2-point option to calibrate the pH probe using only two calibration standards. In this

procedure, the pH sensor is calibrated using a pH 7 (or pH 6.86) buffer and one additional

buffer. A two point calibration procedure (as opposed to a 3-point procedure) can save time if

the pH of the sample is known to be either basic or acidic. For example, if the pH of a sample is

known to vary between 5.5 and 7, a two point calibration with pH 7 and pH 4 buffers is

appropriate. Three point calibration with an additional pH 10 buffer will not increase the

accuracy of this measurement since the pH is not within this higher range.

Select the 3-point option to calibrate the pH probe using three calibration solutions. In this

procedure, the pH sensor is calibrated with a pH 7 (or pH 6.86) buffer and two additional

buffers. The 3-point calibration method assures maximum accuracy when the pH of the media to

be monitored cannot be anticipated.

8.2 Temperature

The YSI Model 60 system utilizes a thermistor which changes predictably in resistance with

temperature variation. The algorithm for conversion of resistance to temperature is built-in to the

Model 60 software, and accurate temperature readings, in degrees Celsius, are provided

automatically. No calibration or maintenance of the temperature sensor is required.

20

Page 25

9. Warranty and Repair

YSI Model 60 pH Meters are warranted for two years from date of purchase by the end user

against defects in materials and workmanship. YSI Model 60 probes, cables and sensors are

warranted for one year from date of purchase by the end user against defects in material and

workmanship. Breakage of pH sensors is NOT covered under warranty. Within the warranty

period, YSI will repair or replace, at its sole discretion, free of charge, any product that YSI

determines to be covered by this warranty.

To exercise this warranty, write or call your local YSI representative, or contact YSI Customer

Service in Yellow Springs, Ohio. Send the product and proof of purchase, transportation prepaid,

to the Authorized Service Center selected by YSI. Repair or replacement will be made and the

product returned, transportation prepaid. Repaired or replaced products are warranted for the

balance of the original warranty period, or at least 90 days from date of repair or replacement.

Limitation of Warranty

This Warranty does not apply to any YSI product damage or failure caused by (i) failure to

install, operate or use the product in accordance with YSI’s written instructions, (ii) abuse or

misuse of the product, (iii) failure to maintain the product in accordance with YSI’s written

instructions or standard industry procedure, (iv) any improper repairs to the product, (v) use by

you of defective or improper components or parts in servicing or repairing the product, or (vi)

modification of the product in any way not expressly authorized by YSI.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED OR

IMPLIED, INCLUDING ANY WARRANTY OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE. YSI’s LIABILITY UNDER THIS WARRANTY IS LIMITED TO

REPAIR OR REPLACEMENT OF THE PRODUCT, AND THIS SHALL BE YOUR SOLE

AND EXCLUSIVE REMEDY FOR ANY DEFECTIVE PRODUCT COVERED BY THIS

WARRANTY. IN NO EVENT SHALL YSI BE LIABLE FOR ANY SPECIAL, INDIRECT,

INCIDENTAL OR CONSEQUENTIAL DAMAGES RESULTING FROM ANY DEFECTIVE

PRODUCT COVERED BY THIS WARRANTY.

YSI Authorized Service Centers

Please visit www.ysi.com or contact YSI Technical Support for the nearest authorized service center.

YSI Incorporated • Technical Support • Phone: +1 937 767-7241 • 800 897-4151 • Fax: 937 767-1058 • Email: environmental@ysi.com

21

Page 26

9.1 Cleaning Instructions

NOTE: Before they can be serviced, equipment exposed to biological, radioactive, or toxic

materials must be cleaned and disinfected. Biological contamination is presumed for any

instrument, probe, or other device that has been used with body fluids or tissues, or with waste

water. Radioactive contamination is presumed for any instrument, probe or other device that has

been used near any radioactive source.

If an instrument, probe, or other part is returned or presented for service without a Cleaning

Certificate, and if in our opinion it represents a potential biological or radioactive hazard, our

service personnel reserve the right to withhold service until appropriate cleaning,

decontamination, and certification has been completed. We will contact the sender for

instructions as to the disposition of the equipment. Disposition costs will be the responsibility of

the sender.

When service is required, either at the user's facility or at YSI, the following steps must be taken

to insure the safety of our service personnel.

1. In a manner appropriate to each device, decontaminate all exposed surfaces, including any

containers. 70% isopropyl alcohol or a solution of 1/4 cup bleach to 1 gallon tap water are

suitable for most disinfecting. Instruments used with waste water may be disinfected with

.5% Lysol if this is more convenient to the user.

2. The user shall take normal precautions to prevent radioactive contamination and must use

appropriate decontamination procedures should exposure occur.

3. If exposure has occurred, the customer must certify that decontamination has been

accomplished and that no radioactivity is detectable by survey equipment.

4. Any product being returned to the YSI Repair Center, should be packed securely to prevent

damage.

5. Cleaning must be completed and certified on any product before returning it to YSI.

22

Page 27

9.2 Packing Instructions

1. Clean and decontaminate items to insure the safety of the handler.

2. Complete and include the Cleaning Certificate.

3. Place the product in a plastic bag to keep out dirt and packing material.

4. Use a large carton, preferably the original, and surround the product completely with packing

material.

5. Insure for the replacement value of the product.

Cleaning Certificate

Organization

Department

Address

City _______________ State ______ Zip

Country __________________ Phone

Model No. of Device ______ Lot Number

Contaminant (if known)

Cleaning Agent(s) used

Radioactive Decontamination Certified?

(Answer only if there has been radioactive exposure)

___ Yes ___ No

Cleaning Certified By

Name Date

23

Page 28

10. Required Notice

The Federal Communications Commission defines this product as a computing device and

requires the following notice:

This equipment generates and uses radio frequency energy and if not installed and used properly,

may cause interference to radio and television reception. There is no guarantee that interference

will not occur in a particular installation. If this equipment does cause interference to radio or

television reception, which can be determined by turning the equipment off and on, the user is

encouraged to try to correct the interference by one or more of the following measures:

• re-orient the receiving antenna

• relocate the computer with respect to the receiver

• move the computer away from the receiver

• plug the computer into a different outlet so that the computer and receiver are on

different branch circuits.

If necessary, the user should consult the dealer or an experienced radio/television technician for

additional suggestions. The user may find the following booklet, prepared by the Federal

Communications Commission, helpful: "How to Identify and Resolve Radio-TV Interference

Problems." This booklet is available from the U.S. Government Printing Office, Washington, DC

20402, Stock No. 0004-000-00345-4.

24

Page 29

11. Accessories and Replacement Parts

The following parts and accessories are available from YSI or any Franchise Dealer authorized

by YSI.

YSI Order Number Description

3821 pH Buffer Solution, 4

3822 pH Buffer Solution, 7

3823 pH Buffer Solution, 10

060992 Calibration buffer bottle, without cap

060991 Cap, Calibration buffer bottle

5050 Carrying Case

031133 pH sensor

113135 Probe body/Cable Assembly (10 feet)

113141 Probe body/Cable Assembly (25 feet)

113151 Probe body/Cable Assembly (50 feet)

113171 Probe body/Cable Assembly (100 feet)

031131 Front Case Cover

055242 Rear Case Cover

055210 Battery Cover Kit

055204 Case Gasket and Screw

031128 Main Board Assembly

031189 Graduated Cylinder, 100 mL

060992 Container, Plastic (uses 060991 cap)

060991 Cap, Plastic Container (for 060992 container)

25

Page 30

12. Appendix A - Specifications

Materials: ABS, Stainless Steel, and other materials

Dimensions:

Height: 9.5 inches (24.13 cm)

Thickness: 2.2 inches (5.6 cm)

Width: 3.5 inches max. (8.89 cm)

Weight: 1.7 pounds (w/ 10’ cable) (.77 kg)

Display: 2.3”W x 1.5”L (5.8 cm W x 3.8 cm L)

Power: 6 AA-size Alkaline Batteries (included)

Approximately 100 hours operation from each new set of batteries

Automatic shutoff after 10 hours without a key press

Water Tightness: Meets or exceeds IP65 standards

Probe Operating Environment

Medium: fresh, sea, or polluted water and most other liquid solutions.

Temperature: -5 to +75 °C

Depth: 0 to 10, 0 to 25, 0 to 50, or 0 to 100 feet (depending on cable length)

Meter Ambient Operating/Storage Temperature: -5 to +45 °C

System Performance Specifications

Measurement Range Resolution Accuracy

± 0.1 pH unit within ±10°C

pH 0 to 14 0.01 unit

Temperature -5 to +75 °C 0.1 °C

pH Response Time: 3 sec for 95% of the change at 25°C

Temperature Response Time: 20 sec for 95% of the change

Temperature Compensation: Automatic

of calibration temperature

or

± 0.2 pH unit within ±20°C

of calibration temperature

± 0.1°C ±1 LSD

Data Storage: 50 points with ID number.

26

Page 31

13. Appendix B - Health and Safety

YSI pH 4, 7 & 10 Buffer Solutions: 3821, 3822, 3823

pH 4 Ingredients:

) Potassium Hydrogen Phthalate

) Formaldehyde

) Water

pH 7 Ingredients:

) Sodium Phosphate, Dibasic

) Potassium Phosphate, Monobasic

) Water

pH 10 Ingredients:

) Potassium Borate, Tetra

) Potassium Carbonate

) Potassium Hydroxide

) Sodium (di) Ethylenediamine Tetraacetate

) Water

CAUTION - Avoid inhalation, skin contact, eye contact or ingestion. May

affect mucous membranes.

Inhalation may cause severe irritation and be harmful. Skin contact may cause irritation;

prolonged or repeated exposure may cause Dermatitis. Eye contact may cause irritation or

conjunctivitis. Ingestion may cause nausea, vomiting and diarrhea.

FIRST AID:

INHALATION - Remove victim from exposure area to fresh air immediately. If

breathing has stopped, give artificial respiration. Keep victim warm and at rest.

Seek medical attention immediately.

SKIN CONTACT - Remove contaminated clothing immediately. Wash affected

area with soap or mild detergent and large amounts of water (approx. 15-20

minutes). Seek medical attention immediately.

EYE CONTACT - Wash eyes immediately with large amounts of water (approx.

15-20 minutes), occasionally lifting upper and lower lids. Seek medical attention

immediately.

INGESTION - If victim is conscious, immediately give 2 to 4 glasses of water and

induce vomiting by touching finger to back of throat. Seek medical attention

immediately.

27

Page 32

14. Appendix C - pH Buffer Values

YSI pH 4, 7 and 10 Buffer Solutions: 3821, 3822, 3823

The following table lists the values of YSI pH buffer solutions at various temperatures.

Temperature pH 4 pH 7 pH 10

0°C 4.01 7.13 10.34

5°C 4.00 7.10 10.26

10°C 4.00 7.07 10.19

15°C 4.00 7.05 10.12

20°C 4.00 7.02 10.06

25°C 4.01 7.00 10.00

30°C 4.01 6.99 9.94

35°C 4.02 6.98 9.90

40°C 4.03 6.97 9.85

50°C 4.06 6.97 9.78

60°C 4.09 6.98 9.70

NIST pH 4.01, 6.86 and 9.18 Buffers: SRM 185g, SRM 186-Ie/IIe, SRM 187c

The following table lists the values of NIST pH buffer solutions at various temperatures.

Temperature pH 4.01 pH 6.86 pH 9.18

0°C 4.005 6.984 9.463

5°C 4.003 6.950 9.395

10°C 4.001 6.924 9.333

15°C 4.002 6.899 9.277

20°C 4.003 6.879 9.226

25°C 4.005 6.863 9.180

30°C 4.010 6.852 9.139

35°C 4.020 6.844 9.102

37°C 4.025 6.842 N/A

40°C 4.033 6.840 9.070

45°C 4.047 6.837 9.042

50°C 4.061 6.836 9.018

28

Page 33

1725 Brannum Lane

Yellow Springs, Ohio 45387 USA

937 767-7241 • 800 765-4974 • Fax 937 767-9353 A31136A - Web

environmental@ysi.com • www.YSI.com January 07

© 1998 YSI Incorporated

031136

Loading...

Loading...