Page 1

YSI 58

Dissolved Oxygen Meter

Operations

Manual

Page 2

Page 3

CONTENTS

SECTION 1 INTRODUCTION .......................................................................................................................1

SECTION 2 PREPARING THE METER......................................................................................................2

2.1 UNPACKING ..............................................................................................................................................2

2.2 WARRANTY CARD.................................................................................................................................. 2

2.3 BATTERIES................................................................................................................................................. 2

SECTION 3 PREPARING THE PROBE.......................................................................................................3

3.1 CHOOSING THE CORRECT PROBE...................................................................................................... 3

3.1.1 YSI 5239 DO FIELD PROBE ...........................................................................................................3

3.1.2 YSI 5905 BOD PROBE .....................................................................................................................3

3.1.3 YSI 5739 DO PROBE........................................................................................................................ 4

3.1.4 YSI 5718 DO FIELD PROBE ...........................................................................................................4

3.1.5 YSI 5750 BOD BOTTLE PROBE ....................................................................................................4

3.2 PROBE INSTALLATION - YSI 5739.......................................................................................................5

3.3 CHOOSING THE CORRECT MEMBRANE........................................................................................... 5

3.3.1 MEMBRANE INSTALLATION FOR THE 5239 PROBE............................................................ 6

3.3.2 MEMBRANE INSTALLATION FOR THE 5905 PROBE............................................................ 7

3.3.3 MEMBRANE INSTALLATION FOR THE 5700-SERIES PROBES........................................... 8

SECTION 4 OPERATION.............................................................................................................................. 10

4.1 PRINCIPLES OF OPERATION............................................................................................................... 10

4.2 TURNING THE INSTRUMENT ON...................................................................................................... 11

4.3 CALIBRATION......................................................................................................................................... 11

4.3.1 AIR CALIBRATION....................................................................................................................... 12

4.3.2 WINKLER TITRATION................................................................................................................. 13

4.3.3 AIR-SATURATED WATER CALIBRATION............................................................................. 13

4.3.4 CALIBRATION FREQUENCY .....................................................................................................14

4.4 MAKING MEASUREMENTS................................................................................................................. 14

4.4.1 ENVIRONMENTAL CONSIDERATIONS..................................................................................14

4.4.2 MEASURING OXYGEN IN FLUIDS OTHER THAN WATER................................................ 15

4.4.3 CALIBRATING TO DISPLAY OXYGEN PARTIAL PRESSURE IN MM HG.......................15

4.5 RECORDER OUTPUT.............................................................................................................................16

SECTION 5 CARE AND MAINTENANCE................................................................................................17

5.1 THE METER CASE.................................................................................................................................. 17

5.2 PROBE PERFORMANCE CHECK......................................................................................................... 17

5.3 PROBE PRECAUTIONS..........................................................................................................................17

5.3.1 5905 AND 5239 PROBE CARE .....................................................................................................18

5.3.2 5700-SERIES PROBE CARE..........................................................................................................19

5.4 PROBE STORAGE...................................................................................................................................19

5.4.1 5905 AND 5239 PROBE STORAGE............................................................................................. 19

5.4.2 5700 SERIES PROBE STORAGE.................................................................................................. 19

SECTION 6 DISCUSSION OF MEASUREMENT ERRORS.................................................................. 20

SECTION 7 TROUBLESHOOTING............................................................................................................ 21

SECTION 8 WARRANTY AND SERVICE INFORMATION................................................................ 23

APPENDIX A GENERAL SPECIFICATIONS......................................................................................... 28

i

Page 4

APPENDIX B REQUIRED NOTICE .........................................................................................................30

APPENDIX C ACCESSORIES AND REPLACEMENT PARTS...........................................................31

APPENDIX D UNIT CONVERSION CHART..........................................................................................32

APPENDIX E OXYGEN SOLUBILITY TABLE..................................................................................... 33

APPENDIX F CALIBRATION VALUES TABLE..................................................................................35

ii

Page 5

SECTION 1 INTRODUCTION

The YSI 58 Dissolved Oxygen Meter is intended for field or laboratory use for dissolved oxygen and

temperature measurement and water, but is also suitable for use in certain other fluids. See Section

4.4.2, Measuring Oxygen in Fluids Other than Water. The meter may be used with the YSI 5239

probe, 5905 probe or the 5700 Series probes.

Dissolved oxygen is displayed in mg/L (1 mg/L = 1 part per million) or in percent air saturation. The

air saturation feature is discussed in detail in the next section. Display sensitivity in the mg/L mode

may be selected to read in tenths to in hundredths of a mg/L.

Temperature is displayed in °C from -5 °C to +45 °C with 0.1°C resolution. The mg/L mode is

automatically temperature compensated for changes in solubility of oxygen in water and for

permeability of the probe membrane. A salinity compensation control allows direct determination for

mg/L of dissolved oxygen in oceanic or estuarine waters.

The probes use Clark-type membrane covered polargraphic sensors with built-in thermistors for

temperature measurement and compensation. A thin, permeable membrane stretched over the sensor

isolates the sensor elements from the environment, but allows oxygen and certain other gases to enter.

When a polarizing voltage is applied across the sensor, oxygen that has passed through the membrane

reacts at the cathode, causing a current to flow.

The membrane passes oxygen at a rate proportional to the pressure difference across it. Since oxygen

is rapidly consumed at the cathode, it can be assumed that the oxygen pressure inside the membrane is

effectively zero. Hence, the force causing the oxygen to diffuse through the membrane is proportional

to the absolute pressure of oxygen outside the membrane. If the oxygen pressure increases, more

oxygen diffuses through the membrane and more current flows through the sensor. A lower pressure

results in less current.

PERCENT SATURATION

The percent saturation feature of this instrument allows quick determination of the degree of air

saturation occurring in fresh or saline water. This feature also allows measurement in fluids of

unknown oxygen solubility.

The percent saturation displayed in this mode is the saturation that would occur if the sample were

saturated with air under a normal barometric pressure of 1013 millibars (760 mm Hg or 29.92 inches

Hg). Results reported from such measurements should be noted as air saturation, corrected to standard

pressure.

This feature also makes possible a simple and quick calibration procedure that eliminates the need to

determine exact probe temperature or to calculate the barometric pressure effect on the calibration

value.

Page 6

SECTION 2 PREPARING THE METER

2.1 UNPACKING

When you unpack your new YSI 58 Dissolved Oxygen and Temperature System for the first time,

compare the packing list with the contents of the shipping box. If there is anything missing or

damaged, contact your YSI dealer from whom you purchased the YSI 58 or YSI Customer Service at

800-765-4974 or 937-767-7241.

2.2 WARRANTY CARD

Please complete the Warranty Card and return it to YSI. The warranty card allows the entry of your

purchase of this instrument in our computer system.

2.3 BATTERIES

Batteries provide complete portability; a battery eliminator feature bypasses the instrument batteries

for extended line-powered use (not including stirrer). Instrument batteries are carried internally in one

holder while a second holder allows internal installation of batteries for powering a submersible stirrer

for use in the field.

Instrument batteries are in the upper holder. Four D-size carbon-zinc batteries are used. The LOBAT

warning shows on the display when about 50 hours of use remain. This warning reminds the operator

to change batteries at their earliest convenience. Batteries may be removed when the instrument will

be used on a long-term basis for laboratory measurement powered by the YSI 5401 or 5402 battery

eliminator.

Stirrer batteries fit in the lower battery holder. Four D-size carbon-zinc batteries are used. When

about five hours or less of battery life remains, the LOBAT warning will show on the display when

the STIRRER control is held at the spring-loaded BATT CHK position. Instrument must be turned

on. Batteries are needed only when the YSI 5795A Submersible Stirrer will be used.

YSI 5401 (115 VAC) AND 5402 (230 VAC) BATTERY ELIMINATORS

For exclusive or long-term laboratory use, the 5401 or 5402 Battery Eliminator may power the YSI

58. When the battery eliminator is in use, batteries may be removed from the instrument battery

compartment (upper compartment).

Note: The battery eliminator does not power the 5795A Field Stirrer, which operates only when

there are batteries in the stirrer battery compartment (lower compartment).

YSI Incorporated YSI 58 DO Meter 2

Page 7

SECTION 3 PREPARING THE PROBE

3.1 CHOOSING THE CORRECT PROBE

Five different YSI oxygen probes may be used with the YSI 58 Meter.

¾ YSI 5239 is designed for field use with cable lengths of 10, 25 or 50 foot.

¾ YSI 5905 is a self-stirring BOD bottle probe.

¾ YSI 5739 is designed for field use and may be used with or without a stirrer. A 5740 probe cable

or 5795A stirring cable is required for use with the 5739 probe. YSI 5795A has a dual-purpose

cable to which both stirrer and probe are connected.

¾ YSI 5750 is a BOD bottle probe with no stirrer.

¾ YSI 5718 is designed for field use with no pressure compensation and has a permanently attached

cable.

3.1.1 YSI 5239 DO FIELD PROBE

The YSI YSI 5239 probe is used for measuring dissolved oxygen in the field. It features cap

membranes for easy membrane replacement (YSI 5906 membrane caps). The probe is rugged, with

the DO and temperature sensors enclosed in a heavy-duty probe guard. A 10, 25 or 50 foot cable is

directly connected to the probe body making it waterproof. A 5-pin MS connector at the end of the

cable makes the 5239 fully compatible with all YSI 50 series DO meters retaining the accuracy of the

system. The 5239 has been optimized for YSI meters which have a microprocessor for sampling and

processing data, such as YSIs 50B and 52.

NOTE: The 5239 probe is shipped dry. A shipping membrane was installed to protect the electrodes.

A new membrane cap must be installed before first use.

3.1.2 YSI 5905 BOD PROBE

The YSI 5905 BOD (Biochemical Oxygen Demand) probe is used for measuring dissolved oxygen in

all popular size BOD bottles. This probe features a self-stirring probe and an easily replaced

membrane cap and a refurbishable electrode system.

IMPORTANT: Intended Use

The 5905 probe is intended for laboratory use, not field use. It is not waterproof and should never be

immersed past the taper on the stem of the probe.

YSI Incorporated YSI 58 DO Meter 3

Page 8

The 5905 probe is designed for use with all YSI dissolved oxygen meters, except for the YSI 55, 85

or YSI 95. The 5905 probe comes in several versions, designed to fit different bottle sizes.

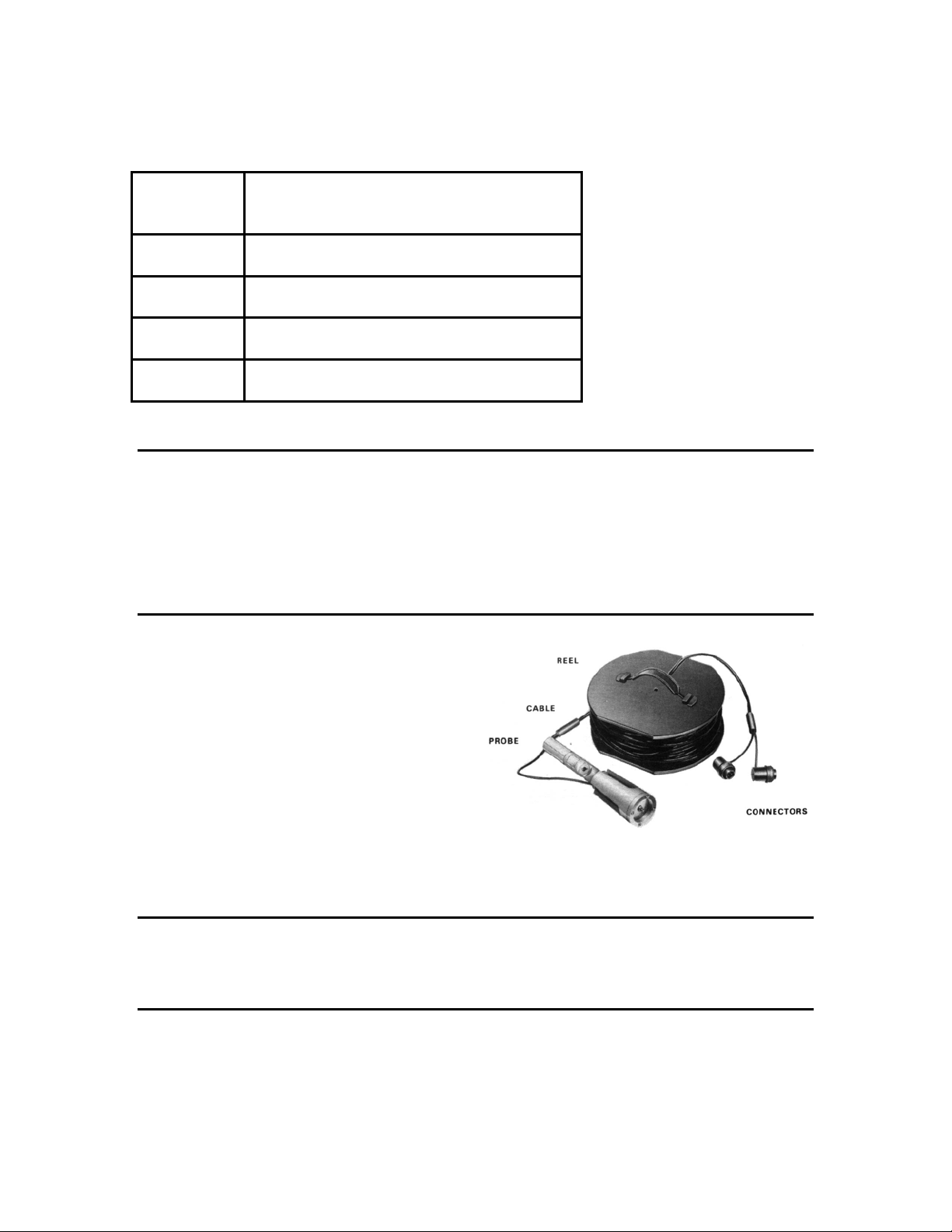

5905

5905 - J

5905 - K

5905 - L

5905 - W

5° taper per side to fit U.S. Standard BOD

bottles.

Includes an adapter to fit 5° taper per side

smaller bottles with built - in overflow funnels.

Includes a s 19 funnel.

Includes a s 24 funnel.

6″ long probe for use with wine bottles.

3.1.3 YSI 5739 DO PROBE

For user convenience, the 5739 probe is equipped with a disconnecting cable to facilitate changing

cable lengths and replacing damaged cables or probes. The probe and cable assembly is held together

with a threaded retaining nut. The connection is not designed for casual disconnection and should

only be disconnected when necessary. For sample stirring with the 5739 probe, the 5795A

Submersible Stirrer has a dual-purpose cable to which both stirrer and probe are connected.

YSI 5795A SUBMERSIBLE STIRRER

The YSI 5795A Stirrer, which can only be used

with the 5739 probe, features a single cable for

both probe and stirrer to permit convenient

manipulation and storage.

When a stirrer and probe are assembled, the

stirrer agitates the sample directly in front of the

sensor by means of a rotating eccentric weight

that causes the spring-mounted, sealed motor

housing to vibrate. An impeller on the end of

the motor housing flushes the fluid being

assayed across the sensor surface.

Figure 1

3.1.4 YSI 5718 DO FIELD PROBE

The YSI 5718 field probe has a permanently attached cable and no pressure compensation.

3.1.5 YSI 5750 BOD BOTTLE PROBE

The YSI 5750 probe is similar in design to the 5739, but has a tapered body designed to fit standard

US BOD bottles. It does not have a stirrer or cap membranes. Agitation of the sample must be

provided by other means, such as a magnetic stirrer.

YSI Incorporated YSI 58 DO Meter 4

Page 9

Four D-size carbon-zinc batteries that are housed in the lower battery compartment of the YSI 58

power the stirrer. When the stirrer will not be used for an extended period, these batteries should be

removed from the instrument.

3.2 PROBE INSTALLATION - YSI 5739

To disconnect the cable, unscrew the retaining nut and slide it down the cable to expose the

connector. Pull gently on the cable and connector until the connector comes away from the probe

body.

To reassemble, inspect the connector and O-Ring for cleanliness. If the O-ring is frayed or damaged,

remove it by squeezing it in the groove causing it to bulge, then roll it out of the groove and off of the

connector. A replacement O-ring is supplied with the cable.

Push the connector into the probe body, rotating it until the two halves match up. A VERY LIGHT

coating of silicone grease on the O-Ring will make reassembly easier.

CAUTION: DO NOT apply more than a light coating of grease, as it will attract dirt and particles that

may compromise the seal of the O-ring.

Air trapped between the connector halves that may cause them to spring apart slightly is normal.

Screw on the retaining nut, HAND TIGHTEN ONLY!

Note: If erratic readings are experienced, disconnect the cable and inspect for the presence of water. If

water is present, dry out and reconnect, replacing the O-Ring.

Pressure Compensation

The vent on the side of the probe is part of a unique pressure compensating system that helps assure

accurate readings at great depths of water. Pressure compensation is effective to 0.5% of reading with

pressures to 100psi (230 feet water). The quantity of air bubbles trapped under the membrane

determines how serious the pressure error will be, which is why proper preparation of the probe is

essential. See Section 4, Operation. The system is designed to accommodate a small amount of

trapped air and still function properly, but the amount should be kept to a minimum.

The compensating system normally does not require servicing and should not be taken apart.

However, if electrolyte is leaking through the diaphragm or if there is an obvious puncture, the

diaphragm must be replaced. A spare is supplied with the probe. Using a coin, unscrew the retaining

plug and remove the washer and diaphragm, flush any salt crystals from the reservoir, install the new

diaphragm (ridged side in), replace the washer and screw in the retaining plug.

3.3 CHOOSING THE CORRECT MEMBRANE

An extremely thin membrane increases O

probe’s response; but it achieves this at the cost of ruggedness. The membrane normally used with the

YSI 58’s probes is the 1 ml (.001”) membrane. This 1 ml membrane represents a compromise

between quickness of response, and membrane strength and integrity.

For special circumstances, a 0.5 ml (.0005”) membrane is available. This half-thickness membrane

hastens response at low temperatures and helps suppress background current at very low dissolved

2 permeability and probe signal current, and hastens a

YSI Incorporated YSI 58 DO Meter 5

Page 10

oxygen levels. When data is routinely collected with sample temperatures below 15°C and at DO

levels below 20% air saturation, the low signal current resulting from the use if the standard

membranes tends to magnify the probe’s inherent constant background signal. Using the high

sensitivity membranes in this situation will decrease the percent error due to the probe’s background

current.

For long-term monitoring situations only, a half-sensitivity, double-thickness 2 ml (.002”) membrane

is available. Order the YSI Item # 5685 2 ml membrane, which includes membranes and electrolyte

for the 5718 and 5739 probes.

A selector switch inside the YSI 58 modifies the circuit for the membrane in use. This switch must be

set to the position corresponding to the membrane in use. Facing the back of the instrument, with the

back cover removed, the switch will be found on the top, right corner of the main PC board. Its

positions are labeled .5, 1 and 2 MIL. Also, See Section 4.4.2, Oxygen Measurements in Fluids

Other Than Water, for use of this switch in special measurement circumstances.

Membrane life depends on usage. However, if the electrolyte is allowed to evaporate and an excessive

amount of bubbles form under the membrane, or the membrane becomes damaged, thoroughly flush

the reservoir with electrolyte and install a new membrane.

If erratic readings are observed or calibration is stable, you need to replace the membrane.

The gold cathode should always be bright and untarnished. If it is tarnished, which can result from

contact with certain gases, or plated with silver, which can result from extended use with a loose or

wrinkled membrane, return it to YSI for service. You can also clean the gold cathode with the YSI

5680 Probe Reconditioning Kit. Never use chemicals or any abrasive other that what is supplied with

the kit. See Section 8 for contact information.

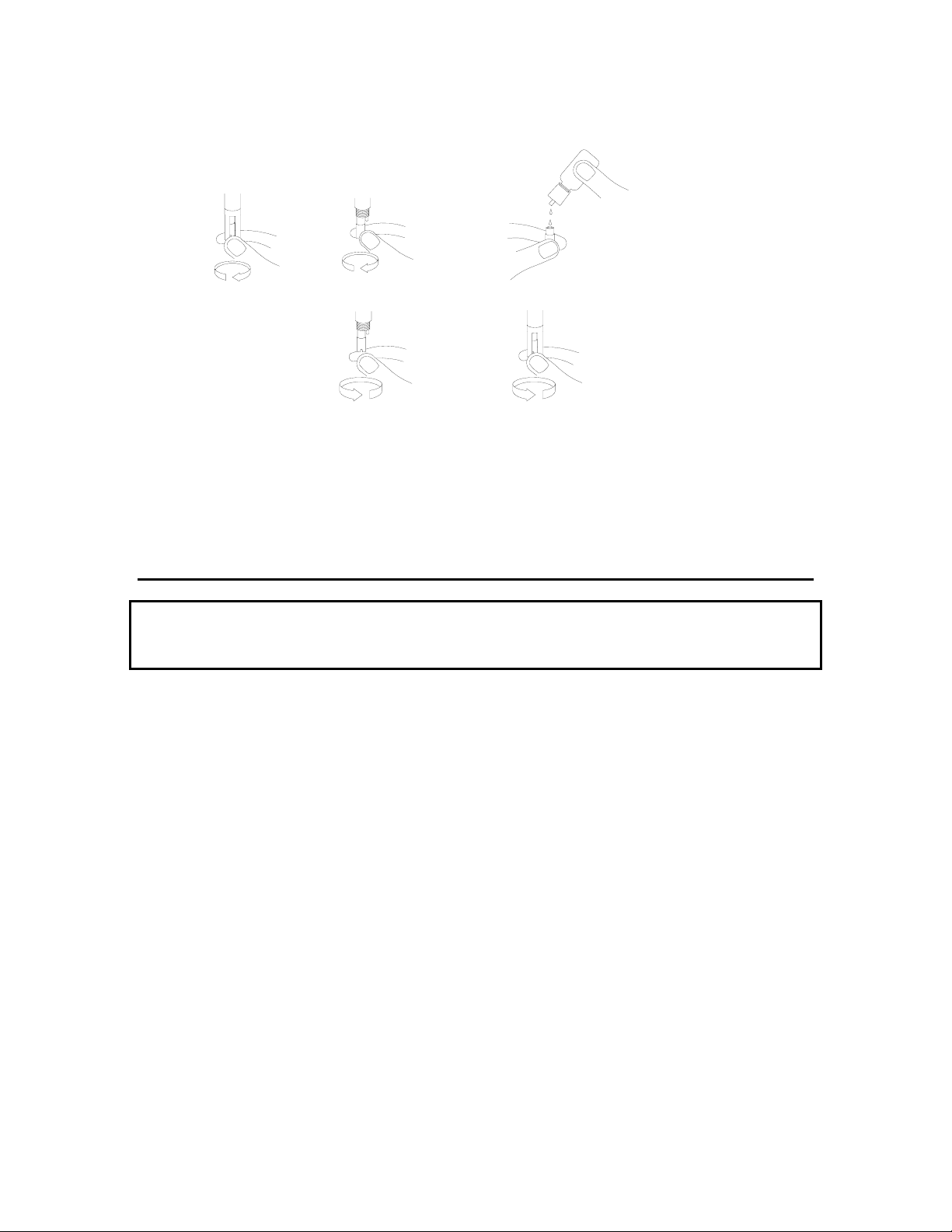

3.3.1 MEMBRANE INSTALLATION FOR THE 5239 PROBE

NOTE: The 5239 probe is shipped dry. A shipping membrane was installed to protect the electrodes.

A new membrane cap must be installed before first use.

Follow the steps below to install a membrane cap:

1. Unscrew and rem ove the probe guard. See figure 2.

2. Unscrew the old m embrane cap and rem ove it from the probe.

3. Thoroughly rinse the entire area of the silver anode, gold cathode and threads with clean

water (distilled or deionized) to remove any dry crystals of the old electrolyte.

4. Hold the m embrane cap and fill it with 6 to 7 drops of YSI standard electrolyte (KCl probe

solution) provided.

5. Tap the bottom of the mem brane cap with your finger a few times (don’t touch the

membrane) to shake loose any trapped air bubbles.

6. Screw the m embrane cap onto the probe m oderately tight. A small amount of electrolyte

should overflow.

7. Rinse off the excess electrolyte with clean water.

8. Screw the probe guard onto the probe body.

9. Place the probe in the calibration bottle provided. Verify that sponge in the bottle is wet.

YSI Incorporated YSI 58 DO Meter 6

Page 11

Fill membrane cap

with 6-7 drops of

KCl solution.

Tap cap with finger

to remove bubbles.

Unscrew guard

Unscrew cap

Screw cap on

moderately tight

Screw guard on

Moderately tight

Figure 2

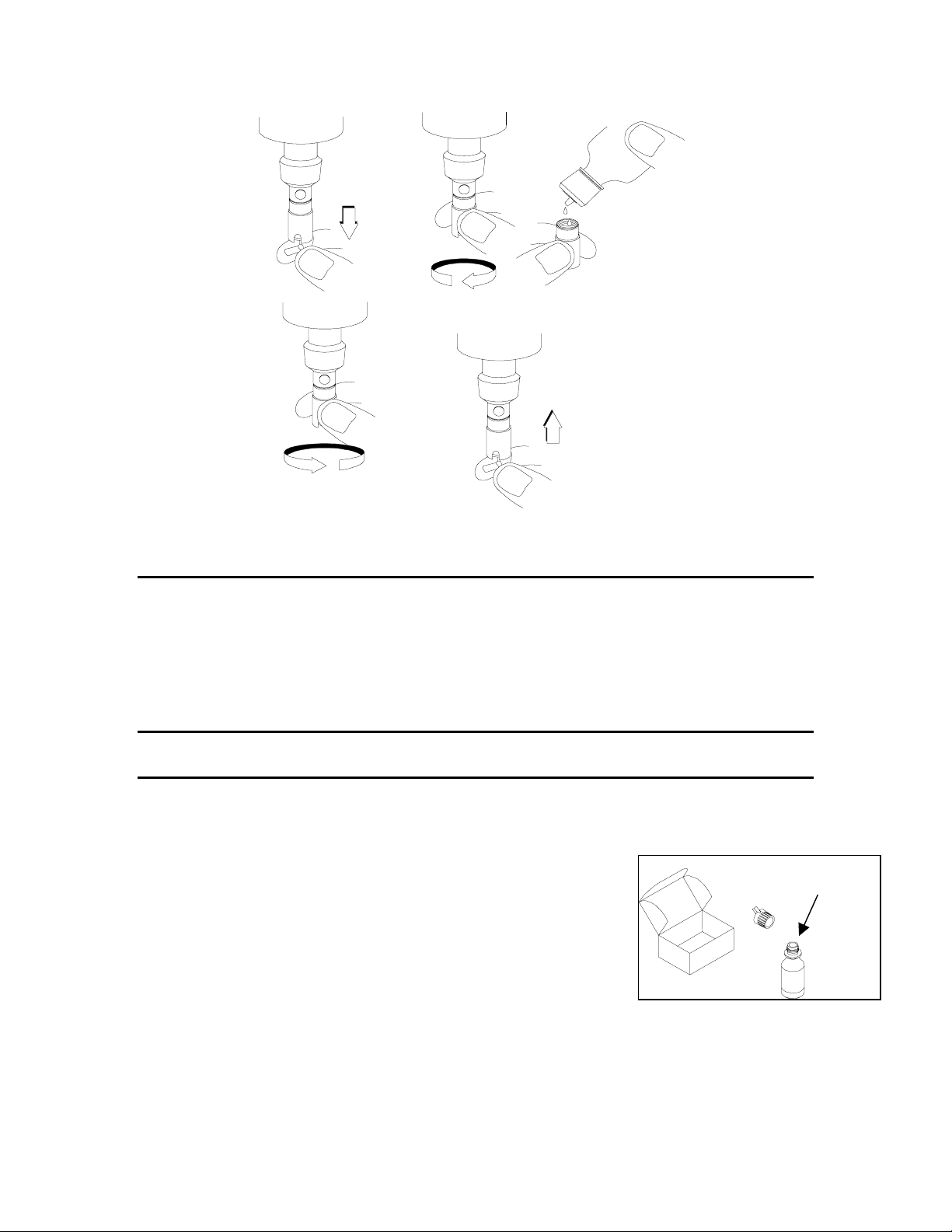

3.3.2 MEMBRANE INSTALLATION FOR THE 5905 PROBE

New Probe Use

New probes are shipped with a dry membrane cap to protect the electrodes. A new membrane

cap must be installed before first use.

Follow these instructions to change membrane caps:

1. Remove the stir paddle from the probe by pulling it straight out. See figure 3.

2. Unscrew the old membrane cap from the probe. Before installing a new membrane, clean the

probe tip with deionized water in order to remove any contaminants.

3. Hold the membrane cap and fill it at least half full with the electrolyte solution provided. Screw the

membrane cap onto the probe moderately tight. A small amount of electrolyte should overflow.

4. Rinse off excess electrolyte from the probe with deionized water.

5. Reinstall the stir paddle.

YSI Incorporated YSI 58 DO Meter 7

Page 12

D

Remove

Stir Paddle

Fill Membrane Cap

with Solution

Unscrew Cap

Replace

Stir Paddle

Screw Cap on

moderately tight

Figure 3

CHECKING THE PROBE ZERO

The probe zero is checked by immersing the probe in a sodium sulfite solution (0.08M or 3g

Na

/300mL), or in water which has an inert gas bubbling through it (e.g. nitrogen, argon). The

2SO3

meter should read less than 1% dissolved oxygen in either of these environments. If it does not,

change the membrane or clean the probe.

3.3.3 MEMBRANE INSTALLATION FOR THE 5700-SERIES PROBES

MEMBRANE INSTALLATION

All YSI 5700 Series Probes have similar sensors and should be cared for in the same way. They are

precision devices and require careful treatment if measurements of high accuracy are to be made.

Prepare the probe as described below.

WARNING: All probes are shipped dry, you must follow these

instructions!

1. Open the membrane kit and prepare the electrolyte solution.

Dissolve the KCl in the dropper bottle by filling it to the neck

with deionized or distilled water and shaking until the solids are

fully dissolved. After the KCL is dissolved, wait a few minutes

until the solution is free of bubbles.

2.

Remove the o-ring and the dry membrane from (after unscrewing the sensor guard.

Thoroughly rinse the sensor with electrolyte fluid.

1.

ADD DI OR DISTILLE

WATER

Figure

4

YSI Incorporated YSI 58 DO Meter 8

Page 13

3. Grasp the probe in your left hand (or right for left-

handers). When preparing the YSI 5739 probe, the

pressure compensating vent should be to the right.

(A left-handed operator may choose to reverse

hands and vent direction.) Successively fill the

sensor body with electrolyte, then pump the

diaphragm with the eraser end of a pencil or with

some similar soft, blunt tool. Continue filling and

pumping until no more air bubbles appear. (With practice, you can hold the probe and pump

the diaphragm with one hand while simultaneously pouring electrolyte into the sensor body

with the other.)

4. Secure a membrane between your left thumb and

the probe body. Always handle the membrane

with care, touching it only at the ends.

5. With the thumb and forefinger of your right

hand, grasp the free end of the membrane. With

one continuous motion, gently stretch it up, over,

and down the other side of the sensor. The

membrane should conform to the face of the

sensor.

6. Secure the end of the membrane under the

forefinger of your left hand.

7. Roll the O-ring over the end of the probe, being

careful not to touch the membrane surface with

your fingers. There should be no wrinkles or

trapped air bubbles. Small wrinkles may be

removed by lightly tugging on the edges of the

membrane. If bubbles are present, remove the

membrane and repeat steps 3-8.

2.

Figure 5

3

Figure 6

DRY MEMBRANE

4

5

6

7

8. Trim off any excess membrane with a sharp knife

or scissors. Rinse off any excess KCl solution,

but be careful not to get any water in the

connector.

9. Shake off excess electrolyte and reinstall the sensor guard.

10. A plastic bottle without a bottom is provided with the YSI Field probes for convenient

calibration and probe storage. Place a small piece of moist towel or sponge in the bottle and

insert the probe into the open end. This ensures 100% humidity for accurate calibration and

helps protect the probe against drying out in storage. The YSI 5905 and 5750 probes can be

stored in a BOD bottle containing about 1” of water.

8

YSI Incorporated YSI 58 DO Meter 9

Page 14

SECTION 4 OPERATION

4.1 PRINCIPLES OF OPERATION

The probes for use with the YSI 58 are a Clark type voltammetric (polarographic) sensor of dissolved

oxygen. An oxygen permeable membrane covers an electrolytic cell consisting of a cathode and an

anode. This membrane acts as a diffusion barrier and an isolation barrier preventing the fouling of the

cathode surface by impurities in the environment. The cathode is the gold electrode, and the anode is

the silver electrode that completes the electrolytic cell and acts as a reference electrode.

Upon entering the cell through the membrane, oxygen is reduced at an applied potential of -0.8 V

Temperature sensor

Anode (silver)

Figure 7

Cathode (gold)

referenced to the silver electrode. The reduction current at the cathode is directly proportional to the

partial pressure of oxygen in liquid (expressed as %-air saturation) that is also proportional to the

concentration of dissolved oxygen (in mg/L) at a particular temperature. Thus the same partial

pressure of oxygen (%-air saturation) in liquid gives different concentrations of dissolved oxygen

(mg/L) at different temperatures because of the different solubility of oxygen at different

temperatures.

Cathode reaction: O

Anode reaction: Ag + Cl ==> AgCl

+ 2H2O + 4e ==> 4OH

2

-

- -

THE DO READINGS FROM THE CATHODE REDUCTION

The oxygen reduction current is sampled and processed, by the meter, and displayed as either %-air

saturation or mg/L. While the parameter of %-air (partial pressure) is independent of temperature and

salinity, mg/L (solubility of oxygen) is a function of temperature and salinity. For instance, the same

%-air reading (same partial pressure) would give a higher mg/L reading at a lower temperature than at

a higher temperature. Also, the higher the salinity, the lower the solubility for the same %-air reading

at the same temperature.

THE FORMATION OF AgCl AT THE ANODE

While the oxygen reduction current passes through the internal circuit to be reported as the DO

reading, it also passes through the anode oxidizing the silver and forming a thin layer of silver

chloride. This oxidation of silver at the chloride medium provides a stable potential that the cathode

potential is referenced to (for instance, the polarization potential of the cathode is -0.8 V versus the

YSI Incorporated YSI 58 DO Meter 10

Page 15

potential of the Ag/AgCl redox couple at the silver anode). As more and more silver chloride (an

insoluble solid and poor conductor of electricity) accumulates at the anode, it begins to block the

passage of current in the electrolytic cell. The silver anode must be cleaned periodically to prevent

this thick layer of silver chloride from reducing the sensitivity of the sensor.

THE FUNCTION OF THE ELECTROLYTE

There are two main functions for the electrolyte:

1. Supply the chloride (Cl

oxygen reduction at the cathode.

2. Provide the ionic conduction of electricity inside the cell, especially in the thin layer between

the gold cathode and the membrane.

Under normal operating conditions, such as measuring oxygen around 100 %-air (8.27 mg/L) at 25°

C, the strength of the chloride concentration should last up to 500 hours before the chloride becomes a

limiting factor in the operation of the oxygen sensor. 500 hours translates into about 62.5 working

days at 8 hours per day operation.

-

) to the anode/reference electrode for the counter reaction of the

4.2 TURNING THE INSTRUMENT ON

The YSI 58 may be used in a vertical, horizontal or tilted position. It may be carried or moved during

use without affecting its accuracy or stability of measurement.

1. Connect the prepared probe to the PROBE receptacle and screw the retaining ring finger

tight.

2. Zero the instrument. Set the function switch to ZERO and adjust the display to read 00.0

with the O

3. If using a stirrer, connect it now. Check the stirrer battery condition by turning the

STIRRER switch to its spring-loaded BATT CHK position. The warning LOBAT will

show on the display when approximately 5 hours of battery life remain.

4. Wait at least 15 minutes for the probe to stabilize. A wait is necessary whenever the meter

has been OFF or the probe has been disconnected.

2 ZERO control.

4.3

CALIBRATION

To calibrate the YSI 58, the function switch is set to the percent saturation mode with the probe in

moist air; then the O2 CALIB control is adjusted to obtain a meter reading corresponding to the

calibration value for the local altitude. Charts for quickly determining the calibration values can be

found in Appendix F, Calibration Values Table.

This simple procedure accurately calibrates the meter for readings in both the mg/L and the percent

saturation modes. The instrument may be switched from one mode to the other without losing its

calibration. Other methods are also possible and are discussed in greater detail in Section 4.3,

Calibration.

Calibration consists of exposing the probe to a known oxygen concentration such as air at 100%

relative humidity or water of a known oxygen content, and then adjusting the 02 CALIB control so

the display shows a reading that matches the 0

2 concentration of the known sample.

YSI Incorporated YSI 58 DO Meter 11

Page 16

In the discussion of calibration below instructions for Air Calibration are given for calibrating in the

% air saturation mode, while instructions for Air Saturated Water Calibration are given for calibrating

in the mg/L mode. Take note that either calibration technique can be performed in either mode. Use

of the percent air saturation mode is normally easier since the instrument automatically compensates

for temperature variation in that mode. The operator may nevertheless elect to calibrate in the mg/L

mode if he intends to make measurements in that mode, since doing so will eliminate any possible

mode-to-mode error. See final NOTE under both Air Calibration and Air Saturated Water

Calibration.

4.3.1 AIR CALIBRATION

Air Calibration is the quickest and by far the simplest calibration technique. Experience has shown

that it is reliable and is recommended for the YSI 58. Air Calibrate the YSI 58, with any field probe

as follows:

1. Set the function switch to % Mode.

2. To calibrate the probe, place a moist sponge or a piece of cloth in the plastic calibration

bottle. Loosen the bottle lid about ½ turn and slip the bottle over the probe guard up to the

body. Place the probe in a protected location where temperature is not changing, or wrap it in

a cloth or other insulator.

3. The BOD probes can be placed in a BOD bottle containing about one inch of water to

provide a 100% relative humidity calibration environment.

4. Remem ber that the highest accuracy of measureme nt is achieved when the probe is zeroed

and calibrated at a temperature as close as possible to the temperature of the sample to be

measured.

5. Set the function switch to ZERO and readjust the display to read 0.00. Switch back to

percent air saturation mode.

6. Determine the local altitude or the “true” atmospheric pressure. Using the pressure/altitude

chart, determine the correct CALIB VALUE for your pressure or altitude

Note: True atmospheric pressure is as read on a mercury barometer. Weather Bureau reporting of

atmospheric pressure is corrected to sea level.

7. When the display reading has stabilized, unlock the 02 CALIB control locking ring and

adjust the display to the CALIB VALUE indicated in the pressure/altitude chart in Appendix

F. Relock the locking ring to prevent inadvertent changes.

NOTE: The oxygen content of air is affected by water vapor content. The use of air at 100% relative

humidity assures proper calibration. Moreover, air at less than 100% relative humidity can cause

evaporation of moisture from the probe’s temperature sensor, producing a local cooling effect. Errors

of up to 8% can result from calibrating in dry air.

NOTE: Should the user elect to air calibrate in the mg/L mode, Air Saturated Water Calibration steps

2-5 should be followed.

YSI Incorporated YSI 58 DO Meter 12

Page 17

4.3.2 WINKLER TITRATION

An alternative to air calibration is to calibrate the probe to a method such as Winkler Titration as

follows:

1. Draw a volume of nearly air saturated water from a single source and divide it into four

samples. Determine the oxygen in three samples using the Winkler Titration technique, and

average the three values. If one of the values differs from the other two by more than 0.5

mg/L, discard that value and average the remaining two.

2. Place the probe in the fourth sample and stir.

3. Set the SALINITY control to 0 (FRESH) or to the appropriate value of the sample.

4. Readjust zero if necessary.

5. Switch to the 0.1 mg/L mode and while conti nuing to stir the sample, allow the probe to

remain in the sample for at least two minutes; then set the 02 CALIB control to the average

value determined above. Leave the probe in the sample for an additional two minutes to

verify stability. Readjust if necessary.

4.3.3 AIR-SATURATED WATER CALIBRATION

A third technique for calibration is by means of air-saturated water. This has proven an uncertain

method, as it is difficult to secure precise and stable saturation. Proceed as follows:

1. Air saturate a volume of water by aerating for at least 15 minutes at a constant temperature.

2. Place the probe in the sample and stir. Switch the function switch to TEMP from the

solubility of oxygen chart in Appendix E, note the temperature of the sample, and record the

mg/L value corresponding to the temperature indicated.

3. Determine the local altitude or the “true” atmospheric pressure. Using the pressure/altitude

chart, determine the correct CALIB VALUE for your pressure or altitude

Note: True atmospheric pressure is as read on a mercury barometer. Weather Bureau reporting of

atmospheric pressure is corrected to sea level.

4. Multiply the mg/L value from the solubility of oxygen table by the CALIB VALUE from

the pressure/altitude table and divide by 100 to determine the correct mg/L oxygen content of

the saturated sample.

EXAMPLE: Temperature 21°C: oxygen value at sea level or 760 mm Hg

Pressure = 8.92 mg/L

Altitude 1400 feet: calibration value = 95

Corrected calibration value =

5. Readjust zero if necessary.

6. Check that the SALINITY knob is set at zero. Adjust the 02 CALIB control to the

calibration value determined in the foregoing step. Wait two minutes to verify stability;

readjust if necessary.

8.92 x 95 = 8.47 mg/L

100

YSI Incorporated YSI 58 DO Meter 13

Page 18

NOTE: If calibration is performed in the percent air saturation mode, the operator need not calculate

for temperature; but will simply set the display to read CALIB VALUE for the pressure/altitude table

according to the local altitude or the true barometric pressure at the point of measurement.

4.3.4 CALIBRATION FREQUENCY

Daily calibration is generally appropriate. Calibration can be disturbed by physical shock, touching

the membrane, fouling of the membrane or drying out of the electrolyte. Check calibration after each

series of measurements, and in time you will develop a realistic schedule for recalibration. When

probes are not in use, store them according to the procedures in Section 5, Care and Maintenance.

4.4 MAKING MEASUREMENTS

For accurate measurement, water movement of one foot per second or more is required so that the

oxygen –depleted layer of the sample at the membrane surface is flushed away and replenished. A

moving stream can provide this motion; alternatively, the probe can be moved through the sample by

hand. The YSI 5795A Submersible Stirrer supplies the necessary stirring for the 5739 probe. The YSI

5905 BOD probe has its own line powered stirrer for laboratory use. When the 5750 BOD probe is

used, stirring must be provided such as with a magnetic stirrer.

1. With the instrument prepared for use, and the probe calibrated, place the probe in the sam ple.

If the 5795A stirrer is to be used, connect it and turn the STIRRER switch to ON. Connect

the recorder, if it is used.

2. Adjust the SALINITY control to the salinity of the sample. (Not required when reading %

air saturation).

3. Turn the function switch to 02 ZE RO and readjust if necessary.

4. Turn the function switch to the desired readout mode and read the dissolved oxygen value in

mg/L or in % air saturation when the meter reading has stabilized.

4.4.1 ENVIRONMENTAL CONSIDERATIONS

¾ Erroneous readings will be made in any environment where the probe’s Teflon membrane will

become rapidly coated with oxygen consuming or oxygen evolving organisms. In some cases, the

YSI 5795A Submersible Stirrer can provide adequate cleaning action due to its high turbulence.

¾ Erroneous readings will be made in any environment where heavy residue may coat the probe’s

membrane. In such instances, problems generally can be eliminated by more frequent probe

service and/or cleaning.

¾ Erroneous readings will be made in any environment where dissolved gases are present that will

chemically interfere with the probe’s electrochemistry. Known interfering gases are hydrogen

sulfide, sulfur dioxide, halogens, neon, nitrous oxide and nitric oxide.

¾ Also avoid any environment that contains substances that may attack the probe materials. Some

of these substances are concentrated acids, caustics and strong solvents. The probe materials that

YSI Incorporated YSI 58 DO Meter 14

Page 19

come in contact with the sample include FEP Teflon, acrylic plastic, ABS plastic, EPR rubber,

stainless steel, epoxy and the polyurethane cable covering.

¾ Long-term use, as for monitoring, in certain applications can magnify the effect of factors that

impair probe accuracy.

4.4.2 MEASURING OXYGEN IN FLUIDS OTHER THAN WATER

The YSI 58 is normally used for measuring the oxygen content of naturally occurring waters and

wastewaters. The % air saturation feature of the instrument additionally permits 02 measurement in

some non-water fluids including air, most gases, foods and some non-aqueous liquids.

Suitable fluids for measurement are those that do not attack the sensor materials and are of

sufficiently low viscosity to permit sample stirring across the probe’s membrane. Strong acids and

solvents capable of swelling or dissolving the probe’s ABS plastic body or EPR o-rings must be

avoided. See Section 3, Preparing the Probe, for a list of interfering gases.

The percent air saturation of any fluid not excluded in the description above may be measured

directly. The instrument is calibrated by the customary air calibration technique and measurement is

carried out just as in natural waters.

In measuring non-aqueous liquids, the mg/L mode should not be used. Such samples may have an

oxygen solubility or Bunsen coefficient significantly different from that automatically programmed in

the mg/L mode for water.

4.4.3 CALIBRATING TO DISPLAY OXYGEN PARTIAL PRESSURE IN mm HG

For some liquid measurements, and for most gas phase measurements, it m ay be desirable to read the

meter in oxygen partial pressure units such as millimeters of mercury (mm Hg). To calibrate the % air

saturation mode to mm Hg units (0 to 200.00 mm Hg range), proceed as follows:

1. Remove the back cover and move the m em brane selector switch to the 2 MIL position, BUT

DO NOT CHANGE THE MEMBRANE. The standard 1 MIL membrane is used in this

measurement. Replace the back cover.

2. Place the probe in a constant room temperature air environm ent. Determine the room ’s

oxygen partial pressure (Dry air at 760 mm Hg total pressure has an 0

20.94% of the total pressure, or 159.1 mm Hg.)

∗

Example: 760 mm Hg x 0.2094 = 159.1 mm Hg.

3. Adjust the 02 CALIB control until the meter reading (read as m m Hg instead of the m arked

%) matches the oxygen partial pressure of the room air. Once calibrated, oxygen partial

pressure may be measured in any gas environment between 0 and 45°C, and at any pressure

from atmospheric to 100 psi (7 atmospheres). Vacuum conditions should be avoided because

the probe’s internal electrolyte can outgas and cause membrane distortion.

CAUTION: When making gas phase measurements, the operator must avoid rapid temperature

fluctuations. The thermal sensor located in the stainless steel tube on the oxygen sensor operated to

∗

L. Machts, “Atmospheric Oxygen in 1967 to 1970, “Science, Volume 168, June 26, 1970, pp. 1582-1594.

2 partial pressure of

YSI Incorporated YSI 58 DO Meter 15

Page 20

compensate automatically for changes in membrane permeability caused by variations in temperature.

However, the thermal response of this sensor is much slower in air or gas than the membrane’s

response to a change in gas temperature. Therefore, rapid temperature fluctuations are liable to

prevent the automatic compensation that is necessary for accurate measurement. This is not a problem

is liquid measurements.

4.5 RECORDER OUTPUT

Output at full scale is 1VDC. (0.0005V = 1 digit). Use a recorder with input impedance of at least

50K OHM, and operate it with the terminals ungrounded.

A recorder output plug is provided. Cable for connecting the recorder must be supplied by the user.

YSI Incorporated YSI 58 DO Meter 16

Page 21

SECTION 5 CARE AND MAINTENANCE

5.1 THE METER CASE

Each opening of the case is gasketed to resist entry of water. When the case has been opened for any

reason, be sure that the main case gasket is accurately seated between both halves of the case, and that

the four case screws are drawn down securely (but not so tight as to deform the rubber feet).

5.2 PROBE PERFORMANCE CHECK

Every month when the probe is in daily use (less frequently otherwise), or whenever the probe

response is slow or calibration is unstable, check the probe performance.

1. Speed of Response

¾ Prepare and calibrate the probe.

¾ With the probe in air, switch to the percent air saturation mode.

¾ Immerse the probe in a 25°C O

prepared by adding approximately one gram of sodium sulfite to a half liter of water.)

¾ A properly functioning probe will respond down scale to 10% air saturation in 20

seconds or less.

-depleted sample. (An O2 depleted sample may be

2

2. Background Current

¾ After performing the Speed of Response steps, leave the probe in the depleted sample for

approximately five minutes. The reading should fall below 1% air saturation.

3. Calibration Stability

¾ Carefully calibrate the probe in moist air inside the calibration bottle with the instrument

set in the % air saturation mode.

¾ Allow the instrument to operate for one hour.

¾ A properly functioning probe will hold calibration within

first hour of operation.

If the probe fails any of the three tests above, check for:

¾ Damaged or wrinkled membrane. Change the membrane and retest.

¾ Fouled or silver coated cathode. Clean as instructed in Section 3, Preparing the Probe.

¾ Fouled anode. Soak for 24 hours in 3% ammonia (NH3); rinse thoroughly with distilled water

and retest.

If these steps do not restore the probe to specification performance, return the probe to the factory for

service. See Section 8, for Warranty and Service Information.

+ 1% for one hour, after the

5.3 PROBE PRECAUTIONS

Membrane life depends on usage. It is recommended that membrane caps not be re-used.

1. To keep the electrolyte from drying out, store the probe in a moist environment, such as the

calibration chamber with the wet sponge inside.

2. Erratic readings are a result of loose, wrinkled, damaged, or fouled membranes, or from large

(more than 1/4 of the circumference of the probe) bubbles in the electrolyte reservoir. If erratic

YSI Incorporated YSI 58 DO Meter 17

Page 22

readings or evidence of membrane damage occurs, you should replace the membrane cap and the

probe solution.

3. If the membrane is coated with oxygen consuming (e.g. bacteria) or oxygen evolving organisms

(e.g. algae), erroneous readings may occur.

4. Chlorine, sulfur dioxide, nitric oxide, and nitrous oxide can affect readings by behaving like

oxygen at the probe. If you suspect erroneous readings, it may be necessary to determine if these

gases are the cause.

5. Avoid any environment that contains substances that may attack the probe materials. Some of

these substances are concentrated acids, caustics, and strong solvents. The probe materials that

come in contact with the sample include FEP Teflon, stainless steel, epoxy, polyetherimide and

the polyurethane cable covering.

6. Do not allow the probe to strike hard objects. The m embrane or sensor inside m ay be damaged.

5.3.1 5905 AND 5239 PROBE CARE

ELECTRODE CLEANING

The 5905 and 5239 probes should be cleaned only when erratic readings occur or after about every

500 hours of use (two months). Each cleaning removes material, so excessive cleaning should be

avoided.

GOLD CATHODE

For correct probe operation, the gold cathode must be textured properly. It can become tarnished or

plated with silver after extended use. The gold cathode can be cleaned by using the adhesive backed

sanding disc provided in the 5906 Membrane Kit. Stick the disc to a small

cap, then sand the gold with a twisting motion about 3 times or until all silver deposits are removed

and the gold appears to have a matte finish. If the cathode remains tarnished, return the probe for

service.

flat object, like a bottle

Temperature

Sensor

Anode

(Silver)

Cathode

(Gold)

Figure 8

SILVER ANODE

YSI Incorporated YSI 58 DO Meter 18

Page 23

It is normal for a dark layer of silver chloride to cover the silver anode. After prolonged use it may

become necessary to clean the anode. Soak the probe in a 14% ammonium hydroxide solution for 2 to

3 minutes or overnight in a 3% ammonium hydroxide solution. Rinse with deionized water, recharge

with electrolyte, and install a new membrane.

5.3.2 5700-SERIES PROBE CARE

GOLD CATHODE

Inspect the gold cathode when changing the membrane; it should be bright and untarnished. If it is

untarnished, which can result from contact with certain gases, or plated with silver, which can result

from extended use with a loose or wrinkled membrane, clean it with a YSI 5680 Probe

Reconditioning Kit, or return it to an authorized YSI Repair Center. Never use chemicals or any

abrasive other than that supplied with the Reconditioning Kit.

SILVER ANODE

If the silver anode becomes contaminated, successful calibration can be prevented. Soak the probe

overnight in a 3% ammonia solution; rinse with deionized water, and follow the steps to install a new

membrane. If it is not possible to calibrate, return the probe to an authorized YSI Repair Center.

5.4 PROBE STORAGE

For long term storage (4 weeks), remove the membrane, thoroughly rinse the sensor with deionized or

distilled water and install a new membrane. Store the sensor in a humid environment such as the

calibration chamber with the wet sponge inside. Do NOT store the probe dry.

5.4.1 5905 AND 5239 PROBE STORAGE

When the probe is not in use, store the probe in a BOD bottle containing at least 1 inch of water. For

long-term storage, remove the membrane cap, rinse the probe tip with deionized water, and install a

dry membrane cap (without electrolyte solution).

5.4.2 5700 SERIES PROBE STORAGE

Store the field probes in the plastic bottle provided. To keep the electrolyte from drying out, place a

small piece of moist towel or sponge in the bottle and insert the probe in one end. Store the BOD

probe in a BOD bottle containing at least an inch of water. Do not immerse the probe in water.

YSI Incorporated YSI 58 DO Meter 19

Page 24

SECTION 6 DISCUSSION OF MEASUREMENT ERRORS

There are three basic types of dissolved oxygen errors. Type 1 errors are related to limitations of

instrument design and tolerances of instrument components. These are primarily the meter linearity

and the resistor tolerances. Type 2 errors are due to basic probe accuracy tolerances, mainly

background signal, probe linearity, and variations in membrane temperature coefficient. Type 3 errors

are related to the operator's ability to determine the conditions at the time of calibration. If calibration

is performed against more accurately known conditions, type 3 errors are appropriately reduced.

Type 1 Errors

A. Meter linearity error: ±0.5% of full scales reading, or ±0.04 mg/l at 25°C whichever is greater.

B. Component and circuitry error: ±0.04 mg/l

Type 2 Errors

A. DO errors caused by temperature compensation for measurements at ±10°C from calibration

temperature: ±1% of 25° C (±0.08 mg/l)

B. DO errors caused by temperature measurement errors: A maximum ±0.2°C temperature error is

equal to ±0.5% (0.04mg/L at 25°C).

Type 3 Errors

A. Altitude: The maximum DO error caused by calibrating to altitude in increments of 100 feet:

±0.18% (< 0.015 mg/l at 25°C)

B. Humidity: Errors occur if calibration is performed at less than 100% humidity. The worst

possible case would be calibration at 0% humidity. The error varies with the calibration

temperature as follows:

Temperature Calibration Error at 0% humidity

0

o

C 0.09 mg/l

10oC 0.14 mg/l

20oC 0.21 mg/l

30oC 0.33 mg/l

40oC 0.50 mg/l

Approximating the Error

It is unlikely that the actual error in any measurement will be the maximum possible error. A better

error approximation is obtained using a root mean squared (r.m.s.) calculation:

r.m.s. error = ±[1a

2

+ 1b2 + 2a2 + 2b2 + 3a2 + 3b2]½ mg/l

NOTE: This calculation is for a near extreme set of conditions.

If the probe is calibrated in water-saturated air, then type 3B errors (humidity), the largest error of all

types, is virtually eliminated and the maximum possible error is in the order of 0.1 mg/L for the case

of calibrating around 25°C.

YSI Incorporated YSI 58 DO Meter 20

Page 25

p

SECTION 7 TROUBLESHOOTING

Symptom Possible Cause Action Ref

Instrument will not turn on

Instrument will not calibrate

Instrument "locks up"

Dissolved Oxygen readings

are inaccurate

LCD displays "LO BAT" Batteries are low or damaged Replace batteries 2.3

Does not return to calibration

value

Unstable readings

Low battery voltage Replace batteries 2.3

Batteries installed wrong Check battery polarity. 2.3

Meter requires service Return system for service 8

Membrane is fouled or damaged Replace membrane 3.2

Probe anode is fouled or dark Clean anode 5

Probe cathode is fouled Resurface cathode 5

System requires service Return system for service 8

Instrument has recorded a shock Remove battery lid, wait 15

seconds for reset, and replace lid.

Batteries are low or damaged Remove battery lid, wait 15

seconds for reset, and replace lid.

System requires service Return system for service 8

Cal value is incorrect Recalibrate w/correct value 4.3

Probe not in 100% water

saturated air during Cal

rocedure

Membrane fouled or damaged Replace membrane 3.2

Probe anode is fouled or dark Clean anode 5

Probe cathode is fouled Resurface cathode 5

System requires service

Moisten sponge & place in Cal

chamber w/ probe & Recal

Return system for service 8

Allow sufficient time for

temperature and oxygen

stabilization

Check for water droplets on

membrane

Change membrane 3.2

Clean probe (see instructions

under Electrode Cleaning)

Allow sufficient time for

temperature and oxygen

stabilization

Allow 60 sec for reading to

stabilize

Change membrane 3.2

Clean probe (see instructions

under Electrode Cleaning)

2

2

4.3

4.3

3.2

5

4.4

5

YSI Incorporated YSI 58 DO Meter 21

Page 26

Symptom Possible Cause Action Ref

Motor not working on the

5905

Check power supply

Manually turn the stir paddle to

help start the motor

3.1.2

Replace motor 8

Loud motor on the 5905

Check if stir paddle is pushed all

the way in

3.1.2

Replace motor 8

Bent stir paddle Replace stir paddle 8

Membrane cap is tight on the

5905

Use pliers to loosen the cap (turn

counter clockwise while facing

3.2

sensor tip)

YSI Incorporated YSI 58 DO Meter 22

Page 27

SECTION 8 WARRANTY AND SERVICE INFORMATION

YSI 58 Dissolved Oxygen Meters are warranted for two years from date of purchase by the end user

against defects in materials and workmanship. YSI 58 probes and cables are warranted for one year

from date of purchase by the end user against defects in material and workmanship. Within the

warranty period, YSI will repair or replace, at its sole discretion, free of charge, any product that YSI

determines to be covered by this warranty.

To exercise this warranty, write or call your local YSI representative, or contact YSI Customer

Service in Yellow Springs, Ohio. Send the product and proof of purchase, transportation prepaid, to

the Authorized Service Center selected by YSI. Repair or replacement will be made and the product

returned transportation prepaid. Repaired or replaced products are warranted for the balance of the

original warranty period or at least 90 days from date of repair or replacement.

LIMITATION OF WARRANTY

This Warranty does not apply to any YSI product damage or failure caused by (i) failure to install,

operate or use the product in accordance with YSI’s written instructions, (ii) abuse or misuse of the

product, (iii) failure to maintain the product in accordance with YSI’s written instructions or standard

industry procedure, (iv) any improper repairs to the product, (v) use by you of defective or improper

components or parts in servicing or repairing the product, or (vi) modification of the product in any

way not expressly authorized by YSI.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED,

INCLUDING ANY WARRANTY OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE. YSI’s LIABILITY UNDER THIS WARRANTY IS LIMITED TO

REPAIR OR REPLACEMENT OF THE PRODUCT, AND THIS SHALL BE YOUR SOLE AND

EXCLUSIVE REMEDY FOR ANY DEFECTIVE PRODUCT COVERED BY THIS

WARRANTY. IN NO EVENT SHALL YSI BE LIABLE FOR ANY SPECIAL, INDIRECT,

INCIDENTAL OR CONSEQUENTIAL DAMAGES RESULTING FROM ANY DEFECTIVE

PRODUCT COVERED BY THIS WARRANTY.

YSI Incorporated YSI 58 DO Meter 23

Page 28

AUTHORIZED U.S. SERVICE CENTERS

For information on the nearest authorized service center contact:

YSI Technical Support • 1725 Brannum Lane • Yellow Springs, Ohio • 45387

Phone: (800) 765-4974 (US) • +1 (937) 767-7241 • Email: environmental@ysi.com

www.ysi.com

YSI Incorporated YSI 58 DO Meter 24

Page 29

YSI Incorporated YSI 58 DO Meter 25

Page 30

CLEANING INSTRUCTIONS

NOTE: Before they can be serviced, equipment exposed to biological, radioactive, or toxic

materials must be cleaned and disinfected. Biological contamination is presumed for any

instrument, probe, or other device that has been used with body fluids or tissues, or with waste water.

Radioactive contamination is presumed for any instrument, probe or other device that has been used

near any radioactive source.

If an instrument, probe, or other part is returned or presented for service without a Cleaning

Certificate, and if in our opinion it represents a potential biological or radioactive hazard, our service

personnel reserve the right to withhold service until appropriate cleaning, decontamination, and

certification has been completed. We will contact the sender for instructions as to the disposition of

the equipment. Disposition costs will be the responsibility of the sender.

When service is required, either at the user's facility or at YSI, the following steps must be taken to

insure the safety of our service personnel.

1. In a manner appropriate to each device, decontaminate all exposed surfaces, including any

containers. 70% isopropyl alcohol or a solution of 1/4 cup bleach to 1 gallon tap water is suitable

for most disinfecting. Instruments used with waste water may be disinfected with 0.5% Lysol if

this is more convenient to the user.

2. The user shall take normal precautions to prevent radioactive contamination and must use

appropriate decontamination procedures should exposure occur.

3. If exposure has occurred, the customer must certify that decontamination has been accomplished

and that no radioactivity is detectable by survey equipment.

4. Any product being returned to the YSI Repair Center, should be packed securely to prevent

damage.

5. Cleaning m ust be completed and certified on any product before returning it to YSI.

PACKING INSTRUCTIONS

1. Clean and decontam inate items to insure the safety of the handler.

2. Com plete and include the Cleaning Certificate.

3. Place the product in a plastic bag to keep out dirt and packing m aterial.

4. Use a large carton, preferably the original, and surround the product completely with packing

material.

5. Insure for the replacem ent value of the product.

YSI Incorporated YSI 58 DO Meter 26

Page 31

Cleaning Certificate

Organization ________________________________

Department _________________________________

Address ___________________________________

City _______________ State ______ Zip ________

Country __________________

Model No. of Device ______ Lot Number _________

Contaminant (if known) _____________________

Cleaning Agent(s) used _____________________

Radioactive Decontamination Certified?

(Answer only if there has been radioactive exposure)

___ Yes ___ No

Cleaning Certified by _________________________

Name Date

YSI Incorporated YSI 58 DO Meter 27

Page 32

APPENDIX A GENERAL SPECIFICATIONS

YSI 58 SPECIFICATIONS

Power: 4 D-size Alkaline Batteries (included)

Approximately 1000 hours operation from each new set of batteries.

Low battery indicator signal (LOBAT) appears automatically when approximately 50 hours

of battery life remain.

Water Resistance: With RECORDER OUT, BATT ELIM and STIRRER receptacles capped,

every case opening is splash resistant.

Operating Environment

Medium: fresh, sea, or polluted water and most other liquid solutions.

Temperature: 0 to +45 °C

Storage Temperature: 0 to +45 °C

System Performance Specifications:

Measurement Range Resolution Accuracy

Temperature -5 to +45 °C 0.1° C

Dissolved Oxygen 0 to 200 % Air Sat.

0 to 20.00 mg/L

0.1%

.01 mg/L

± 0.3 °C, plus probe

interchangeability

+0.3% Air Saturation

0.03 mg/L

Temperature Compensation:

The mg/L modes are automatically temperature compensated to an accuracy of

dissolved oxygen reading between 5 and 45°C; and to an accuracy of

°C. See Temperature Sensitivity in probe specifications.

Salinity Compensation:

Salinity Range: 0 to 40 parts per thousand

Accuracy:

Mode to Mode Accuracy (mg/L to percent air saturation)

Recorder Output:

Voltage: 0 to 1 volt, full scale

Accuracy: + 0.4 % of full scale, + 1 least significant digit (in the 0.01 mg/L mode)

Minimum Load Impedance: 50 K OHM

+ 0.5% of reading, + 2 least significant digits (in the 0.01 mg/L mode)

+ 0.3% of reading + 1 digit

+2% between 0 and 5.

+ 1% of the

YSI Incorporated YSI 58 DO Meter 28

Page 33

PROBE SPECIFICATIONS (YSI 5739, 5905, 5239, 5718 AND 5750 PROBES)

Cathode: Gold

Anode: Silver

Membrane: .001” FEP Teflon

.0005” FEP Teflon available, YSI 5776

Electrolyte for the 5739, 5718, and 5750 probes: KCL with Kodak Photo-Flo

Electrolyte for the 5905, 5239 probes: KCl with NA

Dissolved Oxygen Accuracy: ± 0.1 mg/L or ± 1% of reading, whichever is greater

Operating Temperature Range: 15° to 35°C

Temperature Sensitivity: When measuring oxygen, the probe output current increases

approximately 3.5% per 1°C of increase in temperature. The circuitry automatically compensates for

this effect in a typical probe. However, the exact temperature sensitivity of an individual probe may

vary slightly according to its condition. Therefore, a probe should be calibrated at a temperature close

to the measurement temperature in order to minimize the possible effect of such variation.

Temperature Sensor Accuracy: + 0.2°C

Pressure Compensation: Effective 0.5% of reading with pressures to 100 psi (230 feet of seawater)

Polarizing Voltage: 0.8 volts nominal

Probe Current: Air at 30°C, 19 microamps nominal

Nitrogen at 30°C, 15 microamps or less

Probe Response Time: Typical response for temperature and dissolved oxygen readings is 90% in

10 seconds at a low constant temperature of 30°C with the 5775 membrane. DO response and low

temperature and low DO is typically 90% in 30 seconds. YSI 5776 High Sensitivity membranes may

be used to improve response at low temperature and DO concentrations.

2SO4

YSI Incorporated YSI 58 DO Meter 29

Page 34

APPENDIX B REQUIRED NOTICE

The Federal Communications Commission defines this product as a computing device and requires

the following notice:

This equipment generates and uses radio frequency energy and if not installed and used properly, may

cause interference to radio and television reception. There is no guarantee that interference will not

occur in a particular installation. If this equipment does cause interference to radio or television

reception, which can be determined by turning the equipment off and on, the user is encouraged to try

to correct the interference by one or more of the following measures:

• re-orient the receiving antenna

• relocate the computer with respect to the receiver

• move the computer away from the receiver

• plug the computer into a different outlet so that the computer and receiver are on

different branch circuits.

If necessary, the user should consult the dealer or an experienced radio/television technician for

additional suggestions. The user may find the following booklet, prepared by the Federal

Communications Commission, helpful: "How to Identify and Resolve Radio-TV Interference

Problems." This booklet is available from the U.S. Government Printing Office, Washington, DC

20402, Stock No. 0004-000-00345-4.

YSI Incorporated YSI 58 DO Meter 30

Page 35

APPENDIX C ACCESSORIES AND REPLACEMENT PARTS

The following parts and accessories are available from YSI or any Franchise Dealer authorized by

YSI.

YSI Order Number Description

5905 Self-Stirring BOD Bottle Probe

5750 Non-Stirring BOD Bottle Probe

5740 –10

5740 – 25

5740 – 50

5740 – 100

5740 – 150

5740 – 200

5739, 5718, 5239 Oxygen/Temperature Probe for Field Use

5401 Battery Eliminator (115 VAC)

5402 Battery Eliminator (230 VAC)

5795A Submersible Stirrer. With power and probe cables. Requires 5739 probe.

5050 Carrying Case

5906 Membrane Kit

5775 Membrane and KCl Kit. Standard. Includes two 15-membrane packets (.001”

5776 Membrane and KCl kit, High Sensitivity. Includes tow 15-membrane packets

Detachable leads for use with the 5739 probe only. Comes in 10, 25, 50, 100,

150, 200 feet lengths.

thick standard membranes) and a 30 ml bottle of KCl electrolyte with Kodak

Photo-Flo.

(.0005” thick high sensitivity membranes) and a 30 ml bottle of KCl electrolyte

with Kodak Photo-Flo.

5945 O-Ring Pack

5986 Diaphragm Kit. For use with the 5739 probe only.

5680 Probe Reconditioning Kit

YSI Incorporated YSI 58 DO Meter 31

Page 36

APPENDIX D UNIT CONVERSION CHART

To Convert From To Equation

Feet Meters Multiply by 0.3048

Meters Feet Multiply by 3.2808399

Degrees Celsius Degrees Fahrenheit (9/5oC)+32

Degrees Fahrenheit Degrees Celsius 5/9(oF-32)

Milligrams per liter (mg/l) Parts per million (ppm) Multiply by 1

YSI Incorporated YSI 58 DO Meter 32

Page 37

APPENDIX E OXYGEN SOLUBILITY TABLE

Solubility of Oxygen in mg/l in Water Exposed to Water-Saturated Air at 760 mm Hg Pressure.

Salinity = Measure of quantity of dissolved salts in water.

Chlorinity = Measure of chloride content, by mass, of water.

0

/00) = 1.80655 x Chlorinity (0/00)

S(

Temp

o

C

0.0 14.62 13.73 12.89 12.10 11.36 10.66

1.0 14.22 13.36 12.55 11.78 11.07 10.39

2.0 13.83 13.00 12.22 11.48 10.79 10.14

3.0 13.46 12.66 11.91 11.20 10.53 9.90

4.0 13.11 12.34 11.61 10.92 10.27 9.66

5.0 12.77 12.02 11.32 10.66 10.03 9.44

6.0 12.45 11.73 11.05 10.40 9.80 9.23

7.0 12.14 11.44 10.78 10.16 9.58 9.02

8.0 11.84 11.17 10.53 9.93 9.36 8.83

9.0 11.56 10.91 10.29 9.71 9.16 8.64

10.0 11.29 10.66 10.06 9.49 8.96 8.45

11.0 11.03 10.42 9.84 9.29 8.77 8.28

12.0 10.78 10.18 9.62 9.09 8.59 8.11

13.0 10.54 9.96 9.42 8.90 8.41 7.95

Chlorinity:0

Salinity:0

5.0 ppt

9.0 ppt

10.0 ppt

18.1 ppt

15.0 ppt

27.1 ppt

20.0 ppt

36.1 ppt

25.0 ppt

45.2 ppt

14.0 10.31 9.75 9.22 8.72 8.24 7.79

15.0 10.08 9.54 9.03 8.54 8.08 7.64

16.0 9.87 9.34 8.84 8.37 7.92 7.50

17.0 9.67 9.15 8.67 8.21 7.77 7.36

18.0 9.47 8.97 8.50 8.05 7.62 7.22

19.0 9.28 8.79 8.33 7.90 7.48 7.09

20.0 9.09 8.62 8.17 7.75 7.35 6.96

21.0 8.92 8.46 8.02 7.61 7.21 6.84

22.0 8.74 8.30 7.87 7.47 7.09 6.72

23.0 8.58 8.14 7.73 7.34 6.96 6.61

24.0 8.42 7.99 7.59 7.21 6.84 6.50

YSI Incorporated YSI 58 DO Meter 33

Page 38

Oxygen Solubility Table Appendix E

Temp

o

C

Chlorinity:0

Salinity:0

5.0 ppt

9.0 ppt

10.0 ppt

18.1 ppt

15.0 ppt

27.1 ppt

20.0 ppt

36.1 ppt

25.0 ppt

45.2 ppt

25.0 8.26 7.85 7.46 7.08 6.72 6.39

26.0 8.11 7.71 7.33 6.96 6.62 6.28

27.0 7.97 7.58 7.20 6.85 6.51 6.18

28.0 7.83 7.44 7.08 6.73 6.40 6.09

29.0 7.69 7.32 6.96 6.62 6.30 5.99

30.0 7.56 7.19 6.85 6.51 6.20 5.90

31.0 7.43 7.07 6.73 6.41 6.10 5.81

32.0 7.31 6.96 6.62 6.31 6.01 5.72

33.0 7.18 6.84 6.52 6.21 5.91 5.63

34.0 7.07 6.73 6.42 6.11 5.82 5.55

35.0 6.95 6.62 6.31 6.02 5.73 5.46

36.0 6.84 3.52 6.22 5.93 5.65 5.38

37.0 6.73 6.42 6.12 5.84 5.56 5.31

38.0 6.62 6.32 6.03 5.75 5.48 5.23

39.0 6.52 6.22 5.98 5.66 5.40 5.15

40.0 6.41 6.12 5.84 5.58 5.32 5.08

41.0 6.31 6.03 5.75 5.49 5.24 5.01

42.0 6.21 5.93 5.67 5.41 5.17 4.93

43.0 6.12 5.84 5.58 5.33 5.09 4.86

44.0 6.02 5.75 5.50 5.25 5.02 4.79

45.0 5.93 5.67 5.41 5.17 4.94 4.72

YSI Incorporated YSI 58 DO Meter 34

Page 39

APPENDIX F CALIBRATION VALUES TABLE

Calibration values for various atmospheric pressures and altitudes.

Note: This table is for your information only. It is not required for calibration.

Pressure Inches

of Hg

30.23 768 102.3 -276 -84 101

29.92 760 101.3 0 0 100

29.61 752 100.3 278 85 99

29.33 745 99.3 558 170 98

29.02 737 98.3 841 256 97

28.74 730 97.3 1126 343 96

28.43 722 96.3 1413 431 95

28.11 714 95.2 1703 519 94

27.83 707 94.2 1995 608 93

27.52 699 93.2 2290 698 92

27.24 692 92.2 2587 789 91

26.93 684 91.2 2887 880 90

26.61 676 90.2 3190 972 89

26.34 669 89.2 3496 1066 88

26.02 661 88.2 3804 1160 87

25.75 654 87.1 4115 1254 86

25.43 646 86.1 4430 1350 85

25.12 638 85.1 4747 1447 84

24.84 631 84.1 5067 1544 83

24.53 623 83.1 5391 1643 82

24.25 616 82.1 5717 1743 81

23.94 608 81.1 6047 1843 80

23.62 600 80.0 6381 1945 79

23.35 593 79.0 6717 2047 78

23.03 585 78.0 7058 2151 77

22.76 578 77.0 7401 2256 76

22.44 570 76.0 7749 2362 75

22.13 562 75.0 8100 2469 74

21.85 555 74.0 8455 2577 73

21.54 547 73.0 8815 2687 72

21.26 540 71.9 9178 2797 71

20.94 532 70.9 9545 2909 70

20.63 524 69.9 9917 3023 69

20.35 517 68.9 10293 3137 68

Pressure

mm Hg

Pressure

kPA

Altitude

in feet

Altitude

in meters

Calibration

Value in %

YSI Incorporated YSI 58 DO Meter 35

Page 40

1700/1725 Brannum Lane

Yellow Springs, Ohio 45387 USA

(800) 765-4974 (US), +1 (937) 767-7241

FAX: (937) 767-9353

Website: www.ysi.com

Email: environmental@ysi.com

ITEM # 069387 - Web

DRW # A58020K

January 1999

Loading...

Loading...