YOKOGAWA Rotamass Intense, Rotamass series, Rotamass Hygienic, Rotamass Supreme, Rotamass Giga General Instruction Manual

...Page 1

User's Manual

IM 01U10B00-00EN-R

IM 01U10B00-00EN-R, 3rd edition, 2018-07-09

ROTA

MASS

Total Insight

Coriolis Mass Flow and Density Meter

General Instruction Manual

Page 2

Table of contents

2 / 90

IM 01U10B00-00EN-R, 3rd edition, 2018-07-09

Table of contents

1 Introduction................................................................................................................................................ 4

1.1 Scope of application ......................................................................................................................... 4

1.2 Target group ..................................................................................................................................... 4

1.3 Applicable documents....................................................................................................................... 4

1.4 Explanation of safety instructions and symbols................................................................................ 5

2 Safety.......................................................................................................................................................... 6

2.1 Intended use..................................................................................................................................... 6

2.2 Technical conditions ......................................................................................................................... 6

2.3 General safety instructions ............................................................................................................... 7

3 Warranty ..................................................................................................................................................... 9

4 Product specification ................................................................................................................................ 10

4.1 Scope of delivery .............................................................................................................................. 10

4.2 Measuring principle and flow meter design ...................................................................................... 11

4.2.1 Measuring principle.............................................................................................................. 11

4.2.2 Flow meter ........................................................................................................................... 13

4.3 Identification...................................................................................................................................... 14

4.3.1 Nameplates.......................................................................................................................... 14

4.3.2 Model code .......................................................................................................................... 17

4.4 Flow meter components ................................................................................................................... 17

4.5 Mechanical specification................................................................................................................... 18

5 Transport and storage .............................................................................................................................. 19

5.1 Transport .......................................................................................................................................... 19

5.2 Storage ............................................................................................................................................. 20

6 Installation.................................................................................................................................................. 21

6.1 Installation instructions ..................................................................................................................... 21

6.1.1 Installation dimensions......................................................................................................... 21

6.1.2 Installation site ..................................................................................................................... 21

6.1.3 Instructions........................................................................................................................... 22

6.1.4 Installation position .............................................................................................................. 23

6.1.5 Sanitary Installation.............................................................................................................. 24

6.2 Installation instructions ..................................................................................................................... 26

6.3 Sensor installation ............................................................................................................................ 27

6.3.1 General installation rules ..................................................................................................... 27

6.3.2 Installation in pipe ................................................................................................................ 28

6.3.3 Installation Rotamass Nano (Option PD) ............................................................................. 30

6.3.4 Installation recommendation for viscosity measurements ................................................... 31

6.4 Insulation and heat tracing................................................................................................................ 32

6.4.1 Heat tracing.......................................................................................................................... 32

6.4.2 Customer-supplied insulation............................................................................................... 32

6.5 Transmitter installation...................................................................................................................... 33

6.5.1 Rotating and replacing the display....................................................................................... 33

6.5.2 Rotating transmitter housing (integral type) ......................................................................... 36

6.5.3 Rotating the terminal box (remote type)............................................................................... 38

6.5.4 Installing transmitter on pipe (remote type).......................................................................... 39

Page 3

Table of contents

2018-07-09IM 01U10B00-00EN-R, 3rd edition, 2018-07-09

3 / 90

6.6 Installation check list......................................................................................................................... 41

7 Wiring ......................................................................................................................................................... 42

7.1 General wiring rules.......................................................................................................................... 42

7.2 Grounding connections and sensor circuits...................................................................................... 44

7.3 Connecting cable installation............................................................................................................ 45

7.3.1 Connection terminals ........................................................................................................... 46

7.3.2 Connecting the connecting cable to sensor ......................................................................... 49

7.3.3 Connecting the connecting cable to transmitter................................................................... 50

7.4 Transmitter........................................................................................................................................ 51

7.4.1 Connection terminals ........................................................................................................... 51

7.4.2 HART communication .......................................................................................................... 52

7.4.3 MODBUS communication .................................................................................................... 52

7.4.4 Assignment of inputs and outputs........................................................................................ 53

7.4.5 Output signals ...................................................................................................................... 55

7.4.6 Input signals......................................................................................................................... 61

7.4.7 Power supply ....................................................................................................................... 62

7.4.8 Connecting power supply and external devices................................................................... 63

7.5 Wiring check list................................................................................................................................ 66

8 Commissioning.......................................................................................................................................... 67

9 System configuration and operation ....................................................................................................... 68

9.1 Operating options ............................................................................................................................. 68

9.2 Display.............................................................................................................................................. 68

9.3 Default settings................................................................................................................................. 72

9.3.1 Setting display language...................................................................................................... 72

9.3.2 Setting date.......................................................................................................................... 73

9.3.3 Setting time .......................................................................................................................... 73

9.3.4 Setting zero point ................................................................................................................. 74

9.3.5 Performing autozero ............................................................................................................ 74

9.4 Advanced settings ............................................................................................................................ 75

9.4.1 Setting hardware write-protection ........................................................................................ 75

9.4.2 MODBUS hardware setting.................................................................................................. 77

10 Troubleshooting ........................................................................................................................................ 80

10.1 Malfunction of operation ................................................................................................................... 80

10.2 Zero point unstable ........................................................................................................................... 81

10.3 Display deviating............................................................................................................................... 82

11 Maintenance and repair ............................................................................................................................ 84

11.1 Exterior cleaning ............................................................................................................................... 85

11.2 Recalibration and calibration service ................................................................................................ 85

11.3 Impairment of the display.................................................................................................................. 85

11.4 List of replacement parts .................................................................................................................. 85

12 Dismantling and disposal ......................................................................................................................... 86

12.1 Decontamination and return shipment .............................................................................................. 86

12.2 Disposal ............................................................................................................................................ 86

13 Specifications ............................................................................................................................................ 88

13.1 Ambient conditions ........................................................................................................................... 88

Page 4

General Instruction Manual

Introduction

Scope of application

4 / 90

IM 01U10B00-00EN-R, 3rd edition, 2018-07-09

1 Introduction

1.1 Scope of application

These instructions apply to the following Rotamass Total Insight product families:

▪ Rotamass Nano

▪ Rotamass Supreme

▪ Rotamass Giga

▪ Rotamass Prime

▪ Rotamass Intense

▪ Rotamass Hygienic

▪ Rotamass Total Insight transmitter in combination with any Rotamass Total Insight

sensor.

1.2 Target group

The following persons are the target group of this manual:

▪ Technicians

▪ Engineers

This manual along with its applicable documents enable the target group to complete the

following steps:

▪ Installation

▪ Commissioning

▪ Configuration (parametrization)

▪ Integration of the flow meter into a process control system

▪ Troubleshooting

▪ Maintenance and repair

▪ Dismantling and disposal

1.3 Applicable documents

The following documents supplement this manual:

▪ Explosion Proof Type Manual (Ex-IM) IM01U10X␣␣-00␣␣-R

▪ Software Instruction Manual (SW-IM) IM01U10S␣␣-00␣␣-R

▪ General Specifications (GS) GS01U10B␣␣-00␣␣-R

Page 5

Explanation of safety instructions and symbols

General Instruction Manual

Introduction

IM 01U10B00-00EN-R, 3rd edition, 2018-07-09

5 / 90

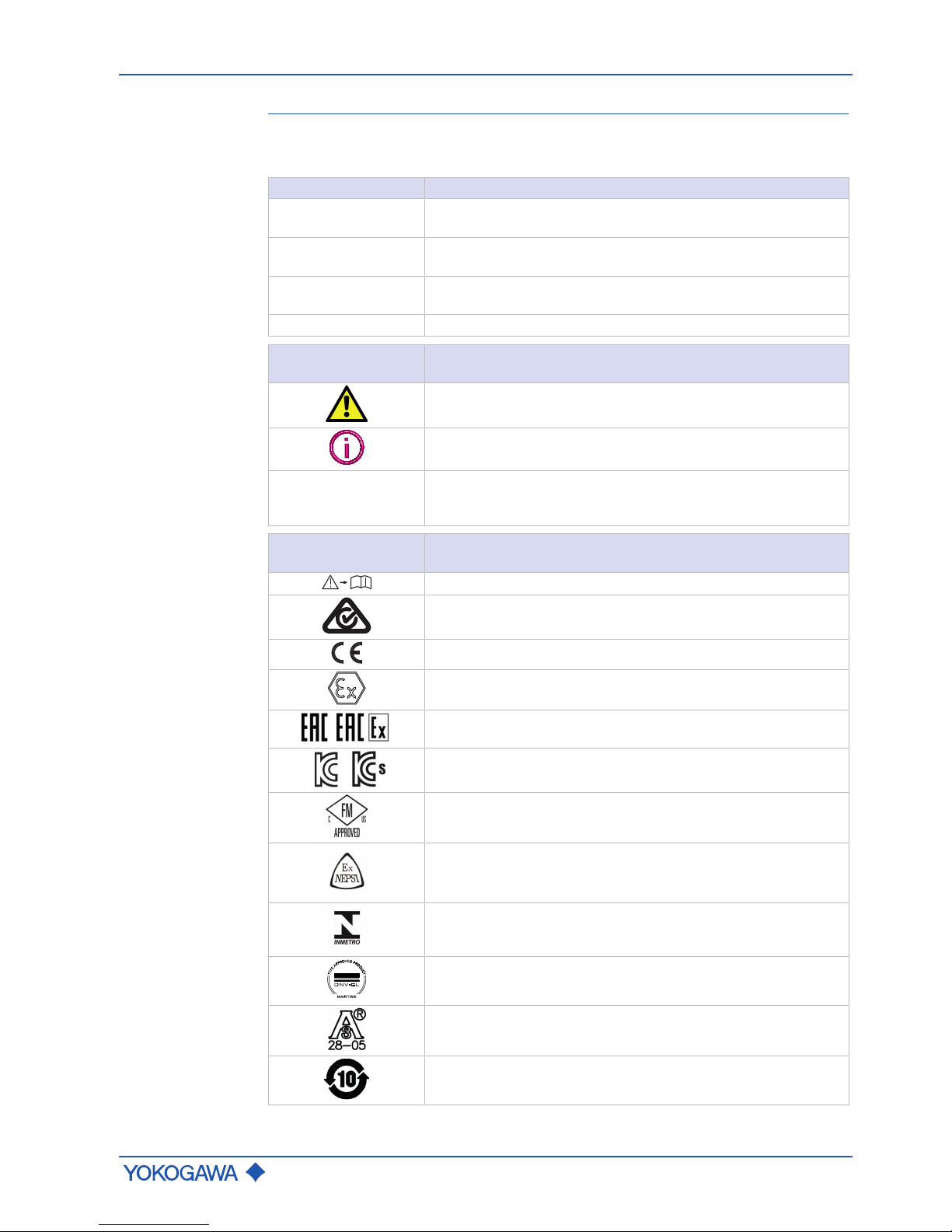

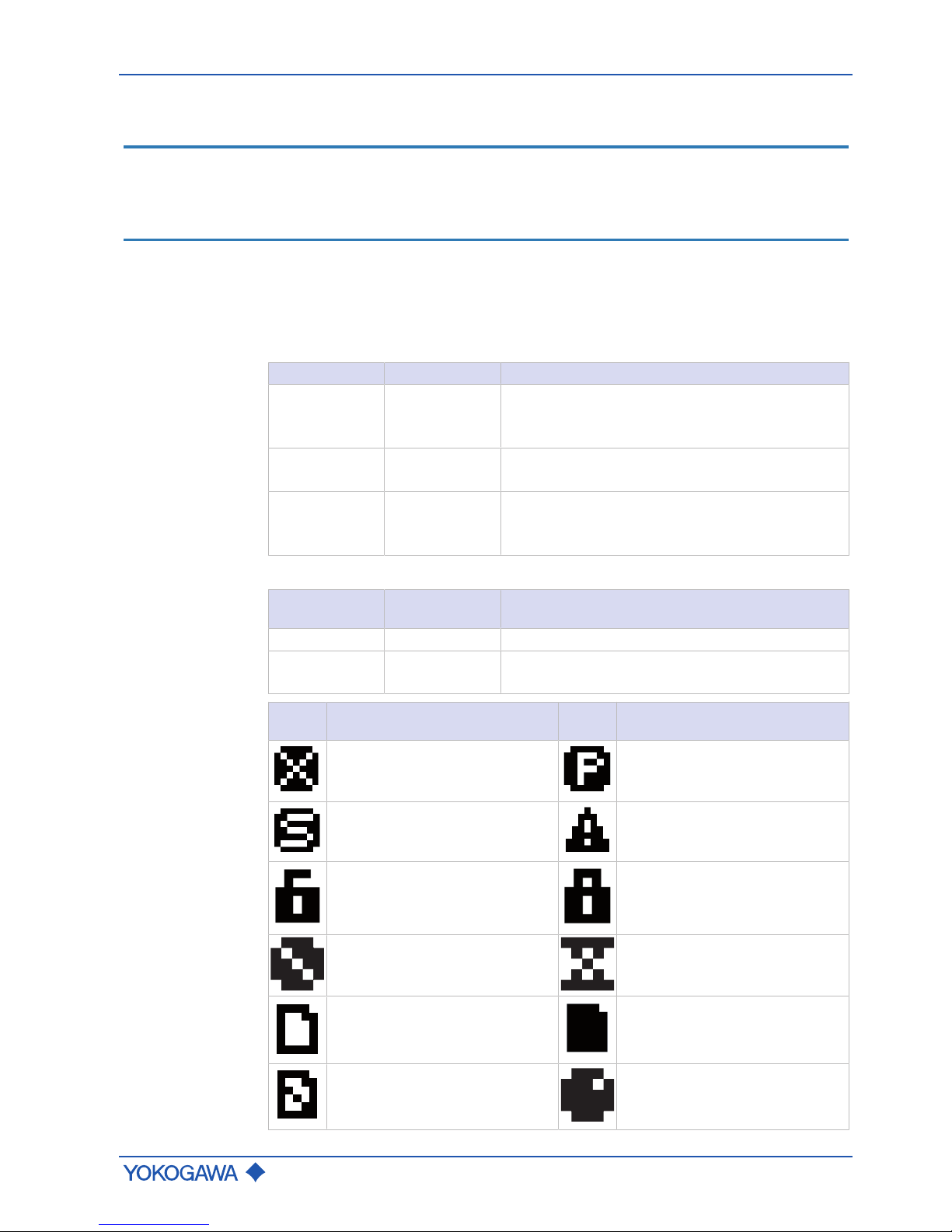

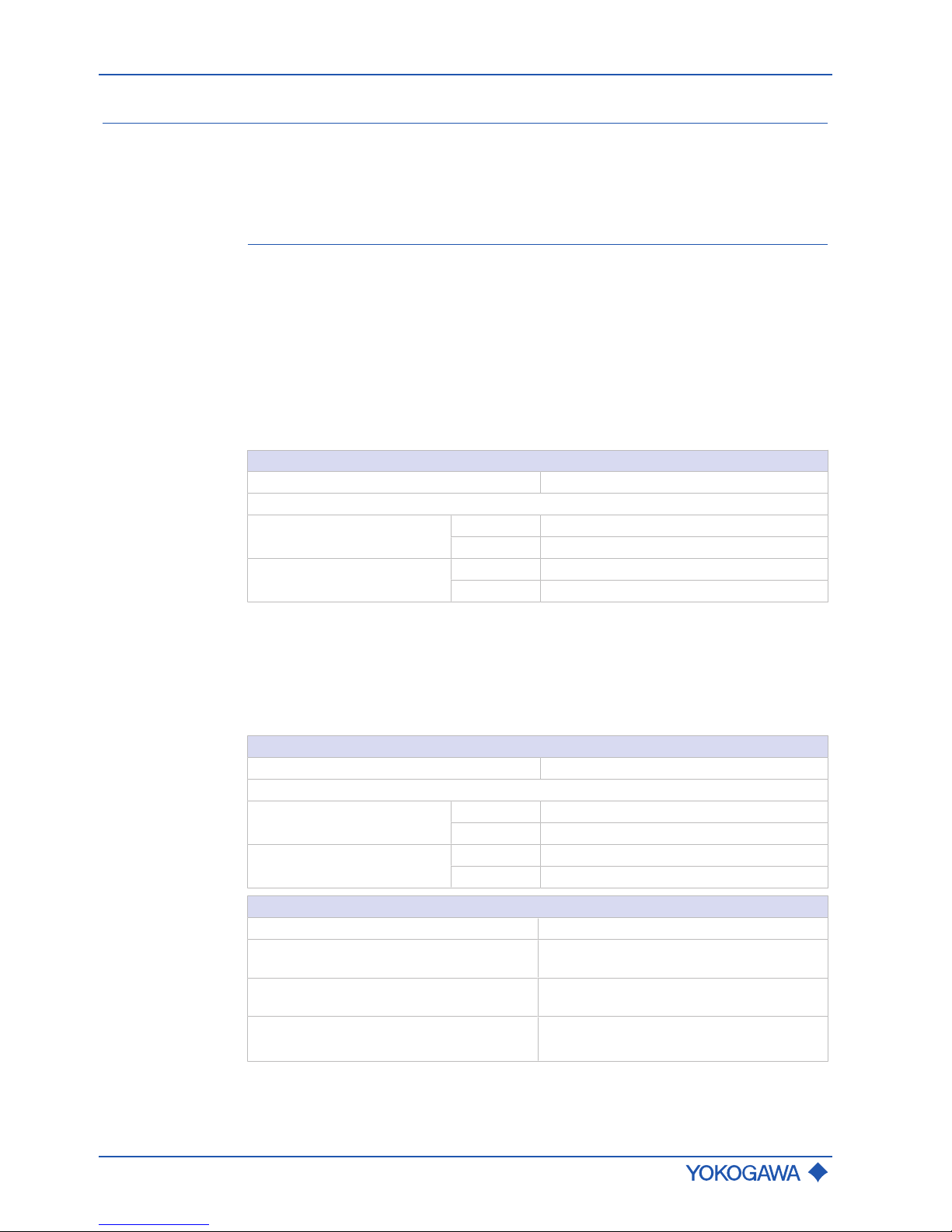

1.4 Explanation of safety instructions and symbols

Signal words

Warning notices are intended to alert users to potential hazards when working with the

flow meter. There are four hazard levels that can be identified by the signal word:

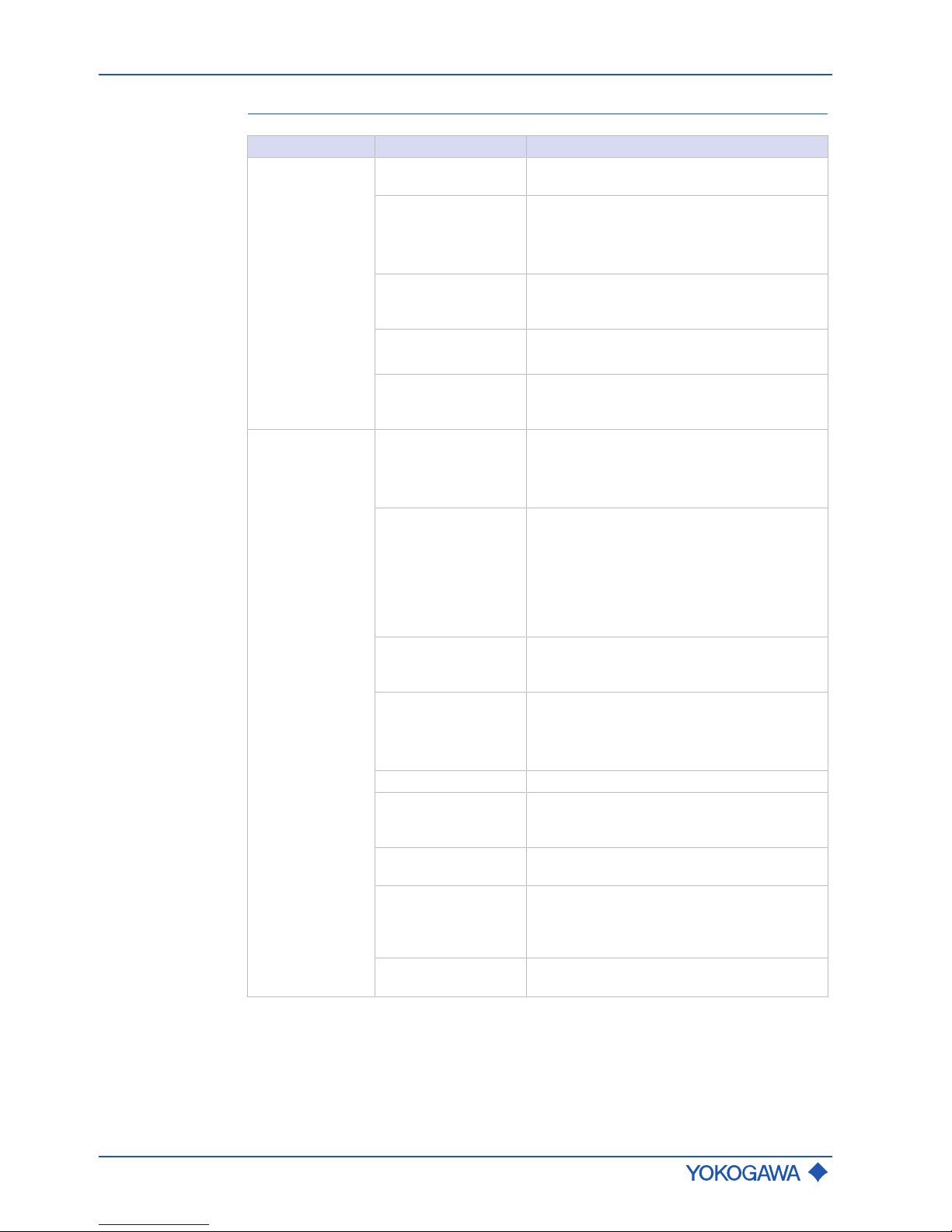

Signal word Meaning

DANGER

Identifies a high-risk hazard resulting in death or severe injury

unless avoided.

WARNING

Identifies a fluid-risk hazard that may lead to death or severe injury unless avoided.

CAUTION

Identifies a low-risk hazard that may lead to minor or moderate

injury unless avoided.

NOTICE Identifies a hazard resulting in property damage.

Explanation of

symbols

Symbols in this

document

Meaning

Indicates a hazard, documentations must be consulted.

Indicates important information.

IM01U10S01-00␣␣-R

The ␣␣ symbols in the document numbers are placeholders,

here, for example, for the corresponding language version (DE,

EN, etc.).

Symbols on the

nameplates

Meaning

Warning that requires reading the documentation

RCM marking

CE marking

ATEX explosion protection marking

,

EAC and EAC Ex marking

,

Korean (KC and KCs) marking

FM/CSA marking

NEPSI marking

INMETRO marking

DNV GL type approval marking

3-A Sanitary approval marking

China RoHS marking

Page 6

General Instruction Manual

Safety

Intended use

6 / 90

IM 01U10B00-00EN-R, 3rd edition, 2018-07-09

2 Safety

2.1 Intended use

The flow meter described in this user's manual is intended to measure mass flow of fluids

and gases while simultaneously also capturing their density and temperature. These values form the basis for calculating additional measured quantities, such as volume flow

and concentration of fluids.

The flow meter uses the Coriolis principle (see Measuring principle [}11]) and can be

used in process automation for a wide range of flow rate measurements. It allows for

measuring various fluids, e.g.:

▪ Oils, grease

▪ Gases, liquid gases

▪ Acids, solutions, solvents

▪ Emulsions and suspensions

Use of the flow meter is limited primarily by the necessary homogeneity of the fluid and

chemical resistance of the wetted parts. Details can be obtained from the responsible

Yokogawa sales organization. Operational safety cannot be ensured in the event of any

improper or not intended use. Rota Yokogawa is not liable for damage arising from such

use.

The flow meter described in this user’s manual is a class A device according to

EN 61326-1 and may only be used in an industrial environment.

2.2 Technical conditions

At normal conditions, the flow meter does not release any poisonous gases or substances.

If the flow meter is operated in faulty conditions, its safety and function may be impaired.

For this reason, the following must be observed:

▶ Operate the flow meter only when in good working order.

▶ If its operational performance changes unexpectedly, check flow meter for faults.

▶ Do not undertake unauthorized conversions or modifications on the flow meter.

▶ Eliminate faults immediately.

▶ Use only original spare parts.

Page 7

General safety instructions

General Instruction Manual

Safety

IM 01U10B00-00EN-R, 3rd edition, 2018-07-09

7 / 90

2.3 General safety instructions

DANGER

Use of fluids that are a health hazard may result in caustic burns or

poisoning

▶ When removing the flow meter, avoid touching the fluid and breathing gas residues

left in the sensor.

▶ Wear protective clothing and a breathing mask.

DANGER

Use of unproper materials through the customer may result in heavy corrosion and/or erosion

▶ The medium temperature / pressure ranges are calculated and approved without cor-

rosion or erosion.

▶ The customer is fully responsible to select proper materials to withstand his corrosive

or erosive conditions.

▶ In case of heavy corrosion and/or erosion the instrument may not withstand the pres-

sure and an incident may happen with human and / or environmental harm.

▶ Yokogawa will not take any liability regarding damage caused by corrosion / erosion.

▶ If corrosion / erosion may happen, the user has to check periodically if the necessary

wall thickness is still in place.

WARNING

High fluid temperatures may result in hot surfaces and therefore a risk of

burns

▶ Apply thermal insulation to sensor.

▶ Attach warning labels to the sensor.

▶ Wear protective gloves.

WARNING

Risk of injury from electrical shock due to inadequate clothing

▶ Wear protective clothing as required by regulations.

WARNING

Risk of injury from electrical shock at the transmitter

▶ Avoid handling the transmitter with wet hands.

▶ Wear protective gloves.

The following basic safety instructions must be observed when handling the flow meter:

▶ Carefully read the user's manual prior to operating the flow meter.

▶ When using the flow meter in areas at risk of explosion, compliance with the Explo-

sion Proof Type Manual is mandatory.

▶ Only qualified specialist personnel must be charged with the tasks described in this

user's manual.

▶ Ensure that personnel complies with locally applicable regulations and rules for work-

ing safely.

▶ Do not remove or cover safety markings and nameplates from flow meter.

▶ Replace soiled or damaged safety markings on the flow meter. For replacing please

contact the Yokogawa Service Center.

▶ If Rotamass Total Insight is used to measure safety-related quantities, ensure that the

transmitter does not display any error messages and, if applicable, the total health

check function is performed at regular intervals (see applicable General Specifications GS01U01B␣␣-00␣␣-R, chapter "Options").

Page 8

General Instruction Manual

Safety

General safety instructions

8 / 90

IM 01U10B00-00EN-R, 3rd edition, 2018-07-09

▶ Avoid erosion and corrosion as they reduce accuracy and resistance to temperature

and pressure. Over time, calibration constants change as a result of erosion and corrosion, therefore requiring recalibration. Rota Yokogawa does not assume any guaranty or liability with respect to corrosion resistance of wetted parts in any specific

process. The user is responsible for selecting the appropriate materials. Rota Yokogawa provides support in clearing up the question of corrosion resistance of the materials used (special fluids but also cleaning agents). Minor changes in temperature,

concentration or pollution degree in the process may result in differences in terms of

corrosion resistance. In case of corrosion or erosion, the pipes must be checked periodically to ensure necessary wall thickness. This can be accomplished by using, for

example, the tube health check function (see applicable General Specifications

GS01U01B␣␣-00␣␣-R, chapter "Options").

▶ When performing welding tasks on the pipe, it is important not to ground the welding

equipment by way of the flow meter. Soldering and welding work on parts of the flow

meter is prohibited.

▶ Continuous temperature fluctuations in excess of 100 °C may result in tube failure

due to material fatigue and therefore must be avoided.

▶ The operator is responsible for ensuring that design limits (pressure, temperature) are

not exceeded in the event unstable fluids decay.

▶ External influences may result in failure of threaded connections. The operator is re-

sponsible for providing suitable protective measures.

▶ Compression and shock waves in pipes can cause damage to the sensor. For this

reason it is important to avoid exceeding the design limits (pressure, temperature).

▶ Fires may result in increased process pressure (caused by temperature-related vol-

ume changes) and failure of gaskets. The operator is responsible for taking suitable

measures to prevent fire-related damage.

▶ Manufacturing methods and technologies have been successfully field-tested for

decades. Erosion and/or corrosion are not taken into account.

▶ Removal of material from the flow meter with power tools such as drills or saws is not

permitted.

▶ Any repair, modification, replacement or installation of replacement parts is permitted

only so long as it is in keeping with this user's manual. Other work must be first authorized by Rota Yokogawa. Rota Yokogawa does not assume liability for damage

caused by unauthorized work on the flow meter or by improper use.

Page 9

General Instruction Manual

Warranty

IM 01U10B00-00EN-R, 3rd edition, 2018-07-09

9 / 90

3 Warranty

Please contact the Yokogawa sales organization if the device needs to be repaired.

The warranty terms for this device are described in the quotation.

If a defect for which Yokogawa is responsible occurs in the device during the warranty

period, Yokogawa will repair that defect at its own cost.

If you believe that the device is defective, please contact us and provide a detailed description of the problem. Please also tell us how long the defect has already occurred and

list the model code and serial number. Additional information, such as drawings, simplifies the identification of the cause and repair of the defect.

Based on our test results, we determine whether the device can be repaired at Yokogawa’s expense or at the expense of the customer. If, for example, the Yokogawa calibration device for the water flow rate confirms a deviation of the output signal from the

stated flow rate accuracy of the device, the device is deemed defective.

The warranty does not apply in the following cases:

▪ If the adhesion, blockage, deposit, abrasion or corrosion is the result of the device’s

actual use.

▪ If the device is mechanically damaged through solids in the fluid, hydraulic shock, or

similar influences.

▪ If the instructions in the corresponding General Specifications or user's manual that

must be met have not been followed.

▪ In case of problems, errors or damage that result from unprofessional installation by

the customer, for example due to insufficient tightness of the pipe fittings.

▪ In case of problems, errors or damage that result from operation, handling or storage

in rough ambient conditions that are beyond the specifications of the device.

▪ In case of problems, errors or damage that result from unprofessional or insufficient

maintenance by the customer, for example, if water or foreign particles enter the device due to opening the device cover.

▪ In case of problems, errors or damage that result from use or from performing mainte-

nance work on the device in a location other than the installation location specified by

Yokogawa.

▪ In case of problems, errors or damage that result from modification or repair work that

was not performed by Yokogawa or by a person authorized by Yokogawa.

▪ In case of problems, errors or damage that result from unprofessional installation, if

the location of the device has been changed.

▪ In case of problems, errors or damage that result from external factors, such as other

devices that are connected to this device.

▪ In case of problems, errors or damage that result from catastrophic external influ-

ences, such as fire, earthquake, storm, flooding or lightning.

Page 10

General Instruction Manual

Product specification

Scope of delivery

10 / 90

IM 01U10B00-00EN-R, 3rd edition, 2018-07-09

4 Product specification

4.1 Scope of delivery

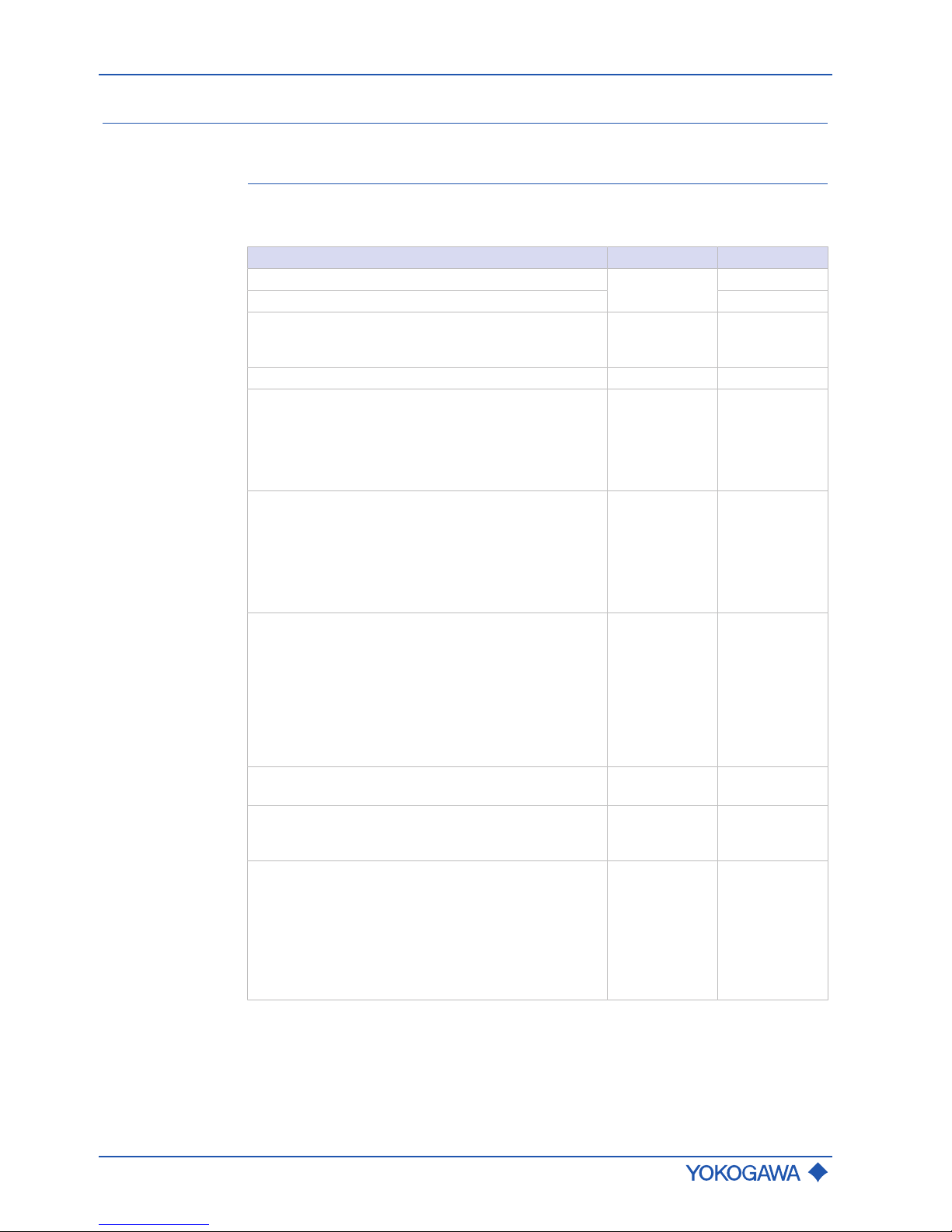

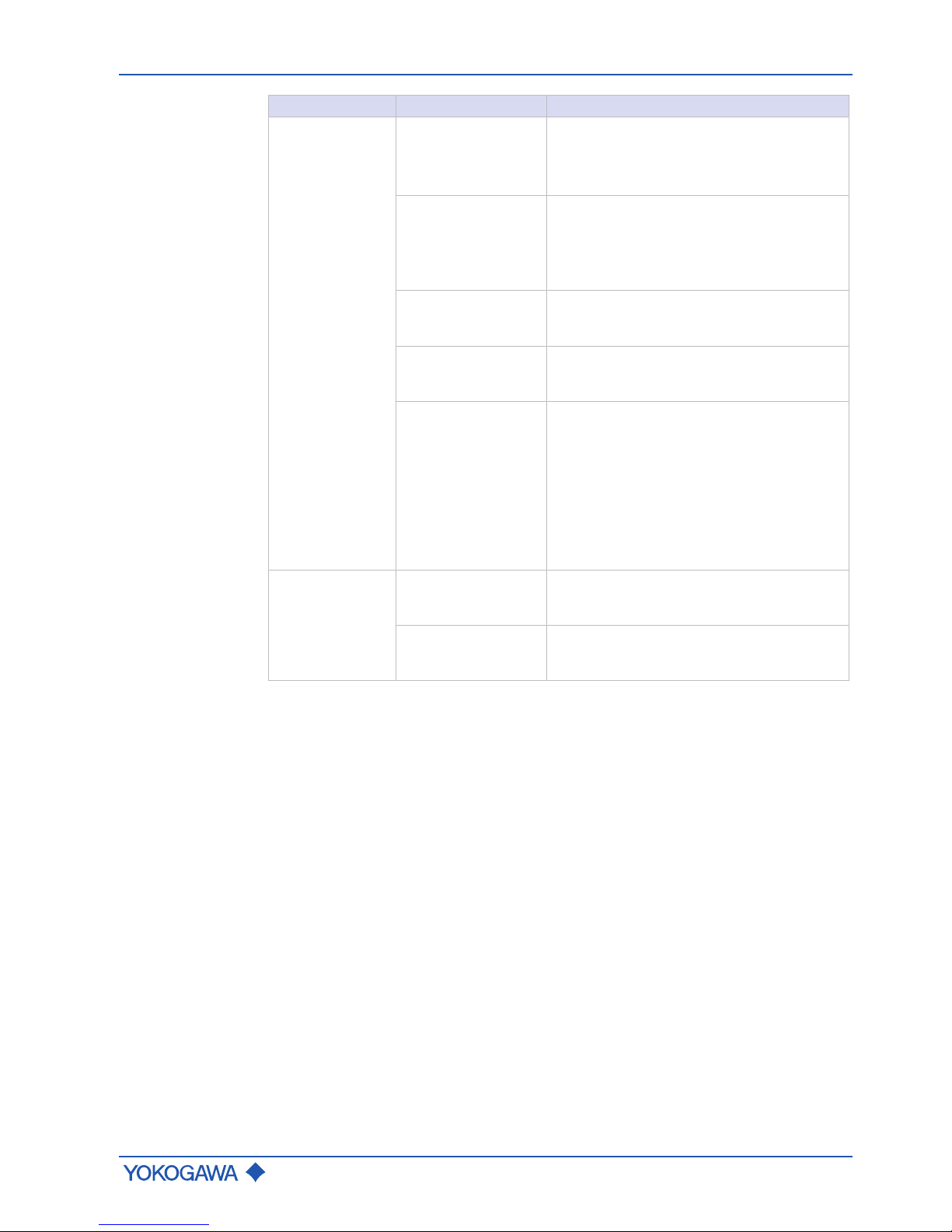

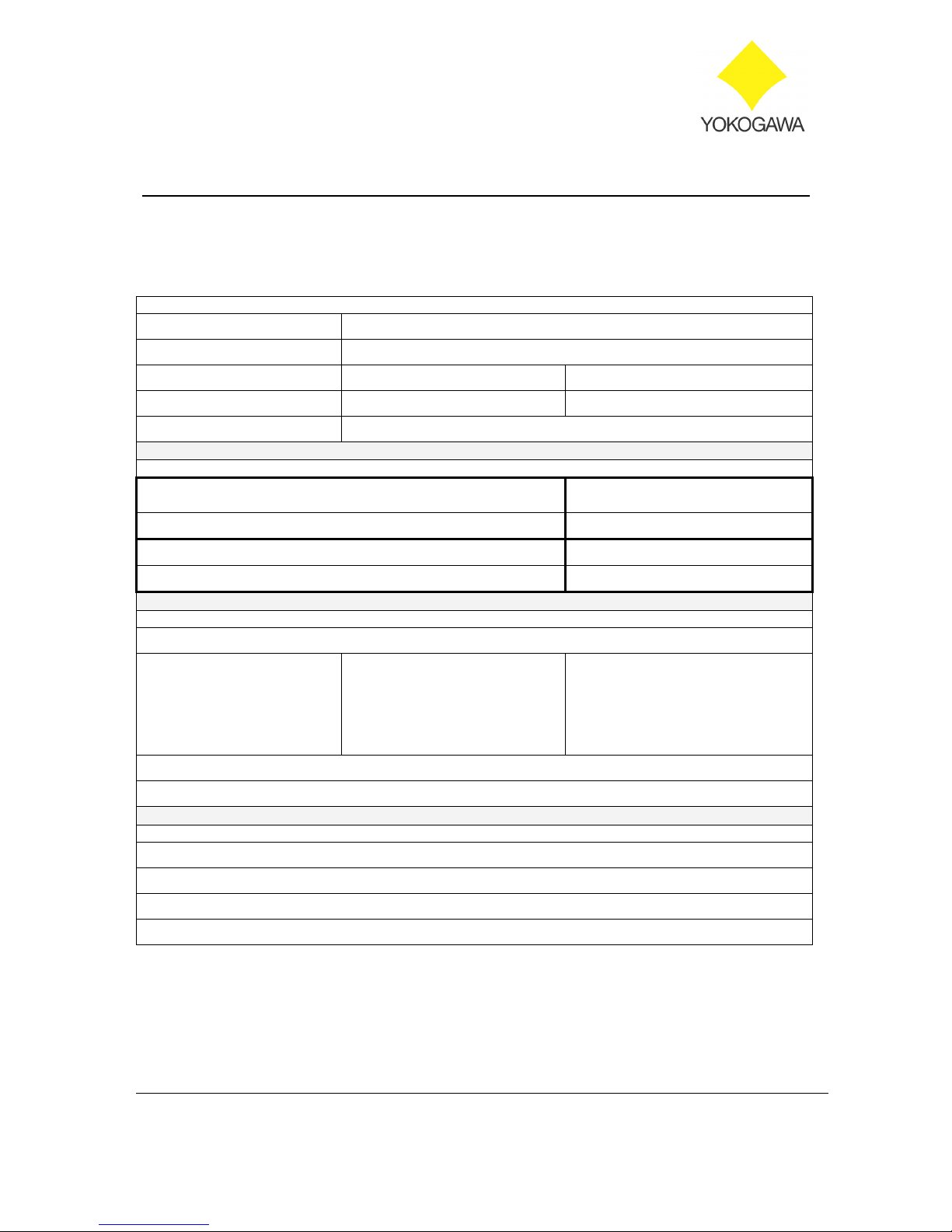

The scope of delivery of the flow meter must be checked for completeness using the following list:

Integral type Remote type

Sensor

1 unit

1 unit

Transmitter 1 unit

Connecting cable -

Length accord-

ing to model

code

Operating tool for terminals 2 units 2 units

2-inch pipe mounting bracket set

▪ Sheet metal console (bracket)

▪ Mounting bracket (U-bracket)

▪ Fixing materials (2 nuts, 2 washers, 4 Allen

screws)

- 1 set

Pipe installation set for sensor (with device option PD)

▪ Sheet metal console (bracket)

▪ Mounting bracket (U-bracket)

▪ Fixing plate

▪ Fixing materials (14 nuts, 6 washers, 4 bolts, 8

notched washers, 4 rubber buffers)

- 1 set

Cable glands are included for a device with metric

cable entries and without Ex approval.

Please note:

▪ No cable glands are included for a device with

cable entries other than metric.

▪ For a device with Ex approval the inclusion of ca-

ble glands may vary. Please refer to the applicable

Explosion Proof Type Manual.

2 units 2 units

Cable glands for connecting cable between sensor

and transmitter, metal (pre-installed)

- 2 units

Termination kit for shortening the connecting cable

(not with option L000 or Y000), including instruction

booklet.)

- 1 set

Document folder with this content:

▪ Product CD/DVD (includes the complete product

documentation)

▪ Quick reference guide

▪ Safety Regulations Manual

▪ Further documents like certificates (depending on

model code)

1 folder 1 folder

Page 11

Measuring principle and flow meter design

General Instruction Manual

Product specification

IM 01U10B00-00EN-R, 3rd edition, 2018-07-09

11 / 90

4.2 Measuring principle and flow meter design

4.2.1 Measuring principle

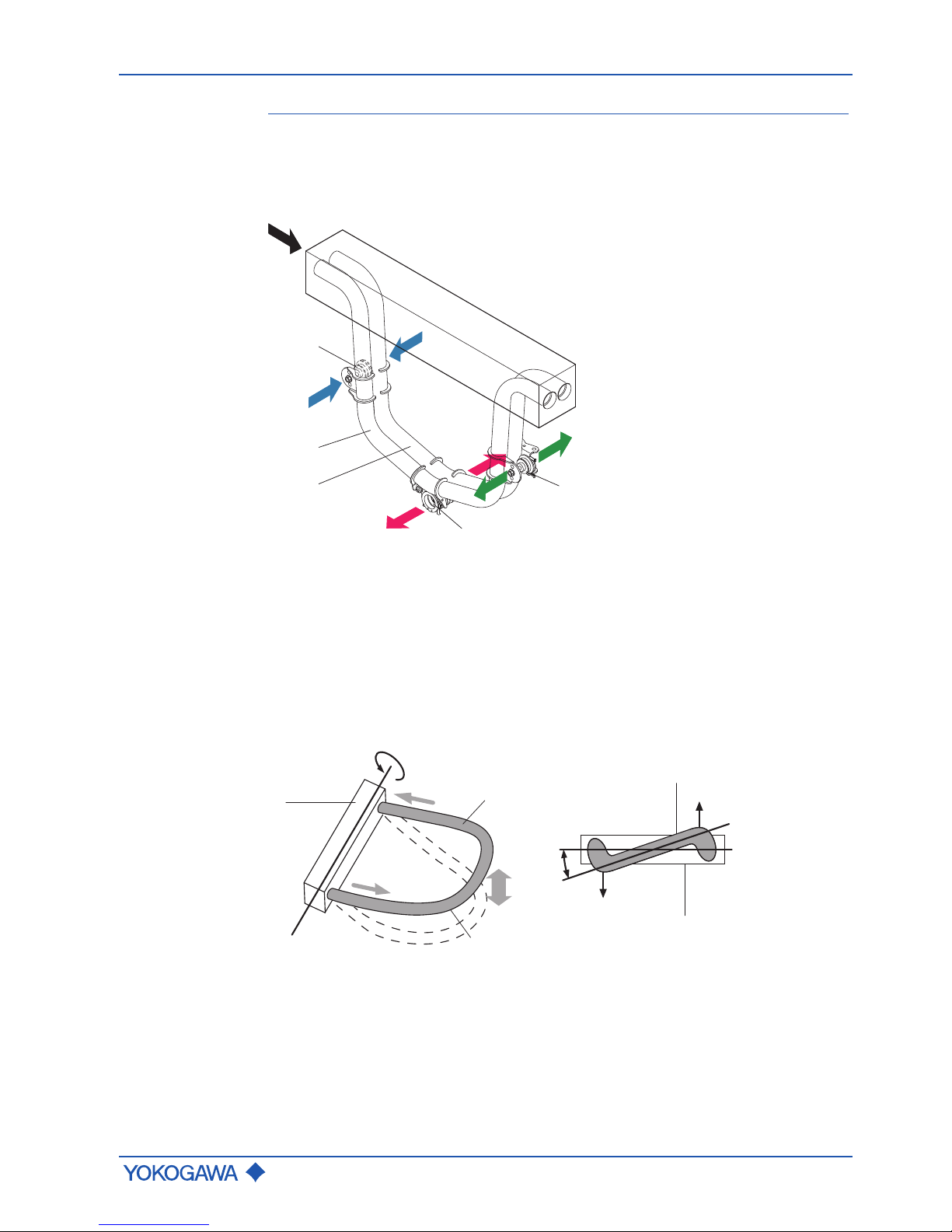

The measuring principle is based on the generation of Coriolis forces. For this purpose, a

driver system (E) excites the two measuring tubes (M1, M2) in their first resonance frequency. Both pipes vibrate inversely phased, similar to a resonating tuning fork.

A

E

F1

S1

S2

F2

M1

Q

M2

-F1

-F2

-A

inlet

outlet

Fig.1: Coriolis principle

M1,M2 Measuring tubes E Driver system

S1, S2 Pick-offs A Direction of measuring tube

vibration

F1, F2 Coriolis forces Q Direction of fluid flow

Mass flow

The fluid flow through the vibrating measuring tubes generates Coriolis forces (F1, -F1

and F2, -F2) that produce positive or negative values for the tubes on the inflow or outflow side. These forces are directly proportional to the mass flow and result in deformation (torsion) of the measuring tubes.

1

3

1

2

3

A

E

A

E

F1

F2

α

Fig.2: Coriolis forces and measuring tube deformation

1 Measuring tube mount A

E

Rotational axis

2 Fluid F1, F2 Coriolis forces

3 Measuring tube α Torsion angle

Page 12

General Instruction Manual

Product specification

Measuring principle and flow meter design

12 / 90

IM 01U10B00-00EN-R, 3rd edition, 2018-07-09

The small deformation overlying the fundamental vibration is recorded by means of pickoffs (S1, S2) attached at suitable measuring tube locations. The resulting phase shift Δ

φ

between the output signals of pick-offs S1 and S2 is proportional to the mass flow. The

output signals generated are further processed in a transmitter.

Δφ

S1

S2

y

t

Fig.3: Phase shift between output signals of S1 and S2 pick-offs

Δφ ~ FC ~

dt

dm

Δ

φ

Phase shift

m Dynamic mass

t Time

dm/dt Mass flow

F

c

Coriolis force

Density

measurement

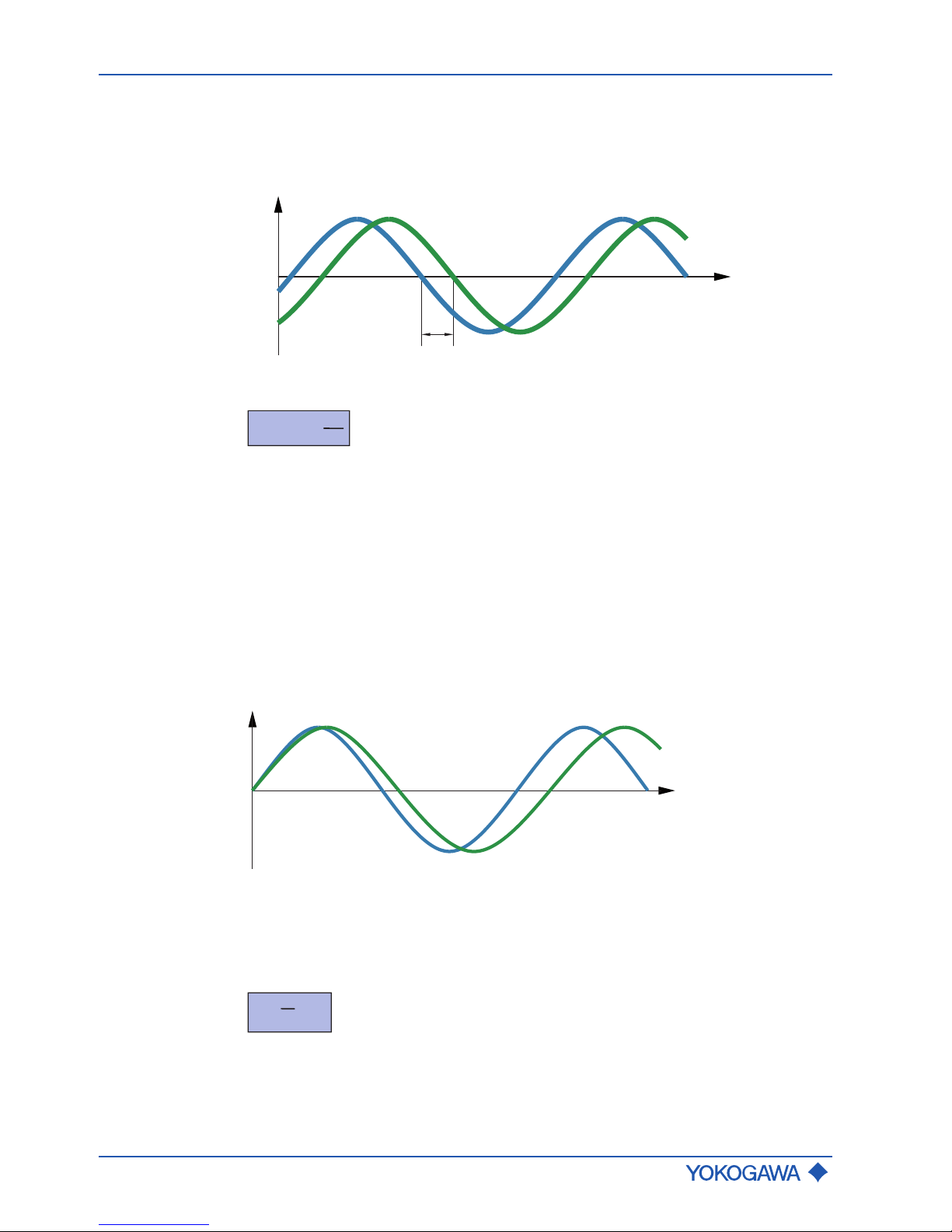

Using a driver and an electronic regulator, the measuring tubes are operated in their resonance frequency ƒ. This resonance frequency is a function of measuring tube geometry,

material properties and the mass of the fluid covibrating in the measuring tubes. Altering

the density and the attendant mass will alter the resonance frequency. The transmitter

measures the resonance frequency and calculates density from it according to the formula below. Device-dependent constants are determined individually during calibration.

A

t

ƒ

2

ƒ

1

Fig.4: Resonance frequency of measuring tubes

A Measuring tube displacement

ƒ

1

Resonance frequency with fluid 1

ƒ

2

Resonance frequency with fluid 2

ρ = + ß

ƒ

2

α

ρ

Fluid density

ƒ

Resonance frequency of measuring tubes

α, β

Device-dependent constants

Page 13

Measuring principle and flow meter design

General Instruction Manual

Product specification

IM 01U10B00-00EN-R, 3rd edition, 2018-07-09

13 / 90

Temperature

measurement

The measuring tube temperature is measured in order to compensate for the effects of

temperature on the flow meter. This temperature approximately equals the fluid temperature and is made available as a measured quantity at the transmitter as well.

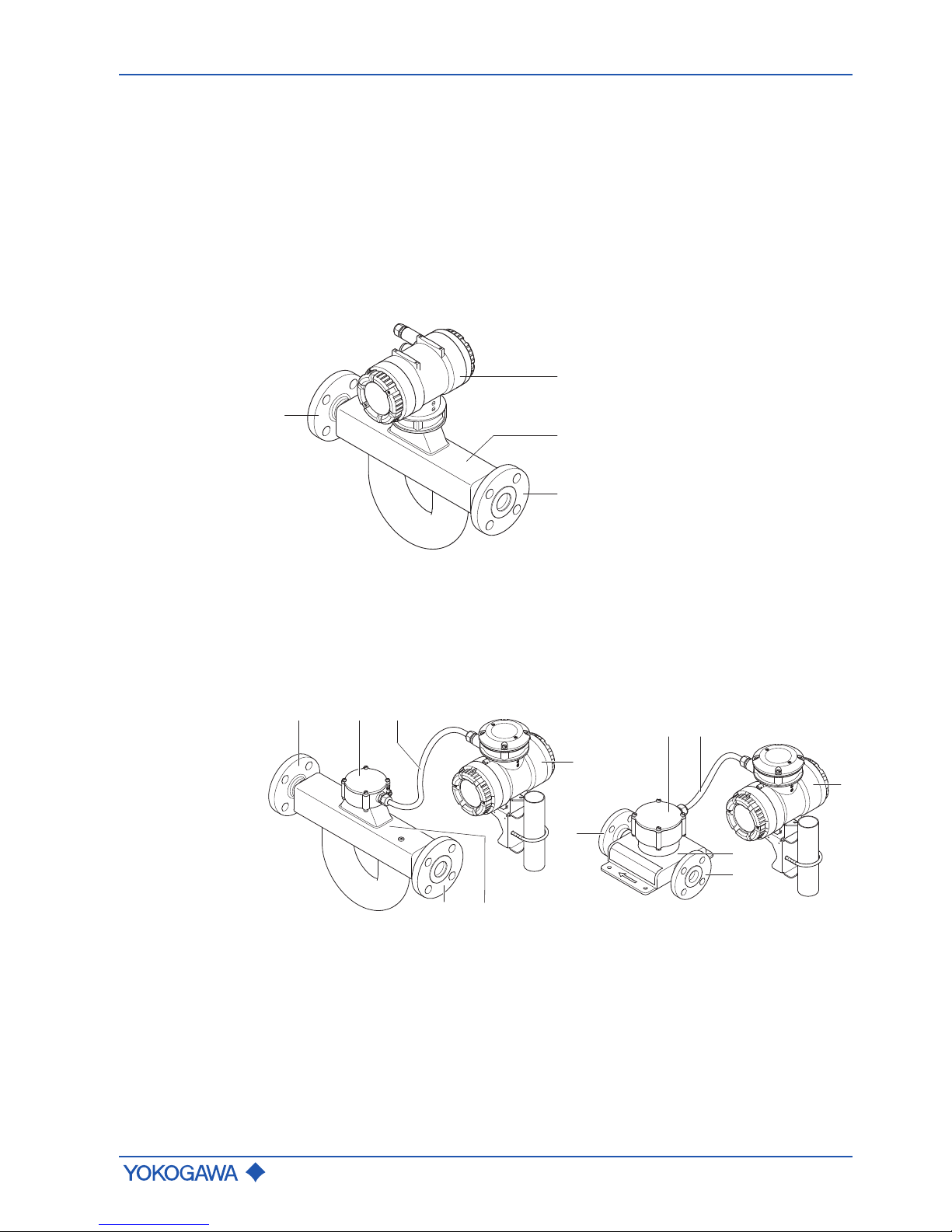

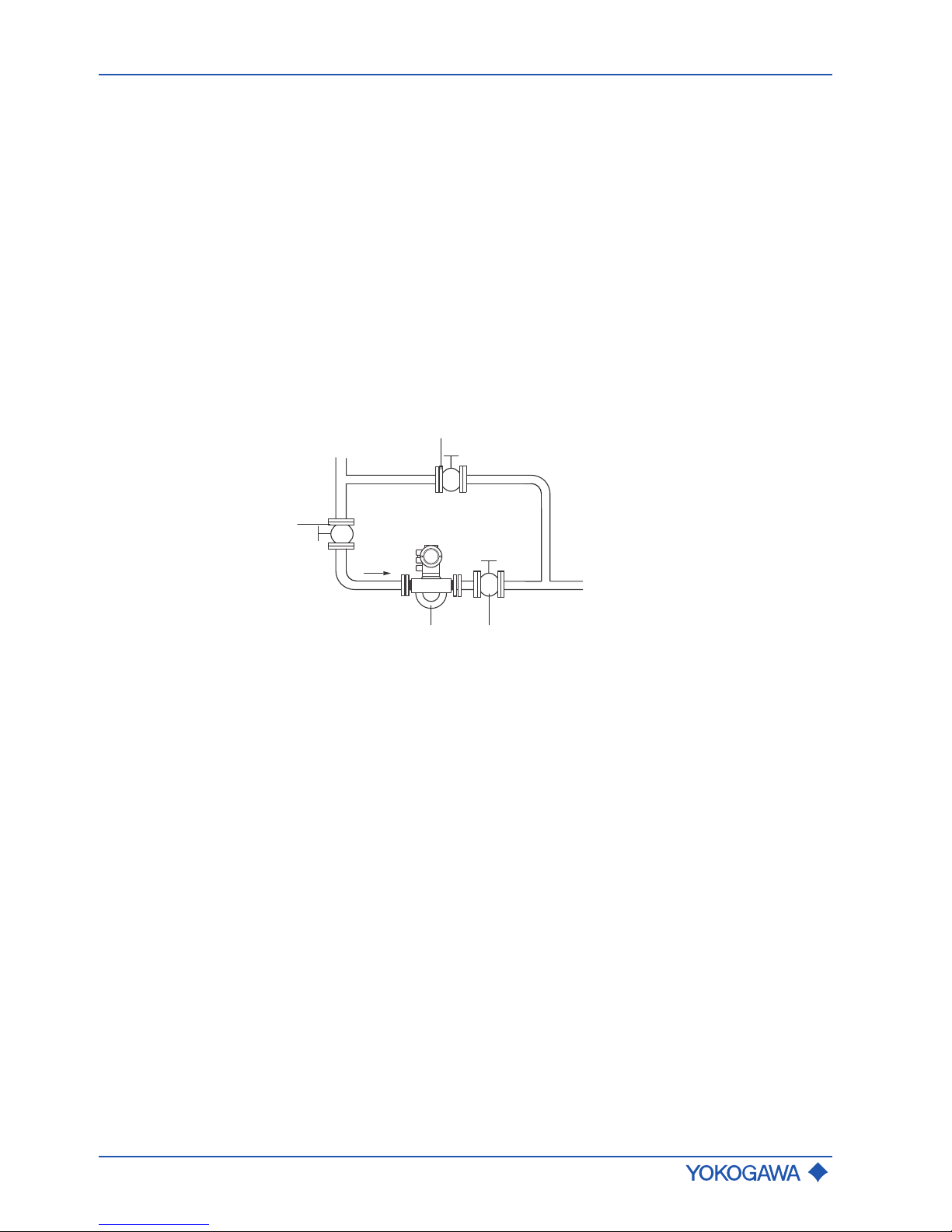

4.2.2 Flow meter

The Rotamass Total Insight Coriolis mass flow and density meter is offered in several

families (Nano, Supreme, Giga, Prime, Intense and Hygienic). It consists of the following

main components:

▪ Sensor

▪ Transmitter

In the integral type, sensor and transmitter are firmly connected.

1

2

3

3

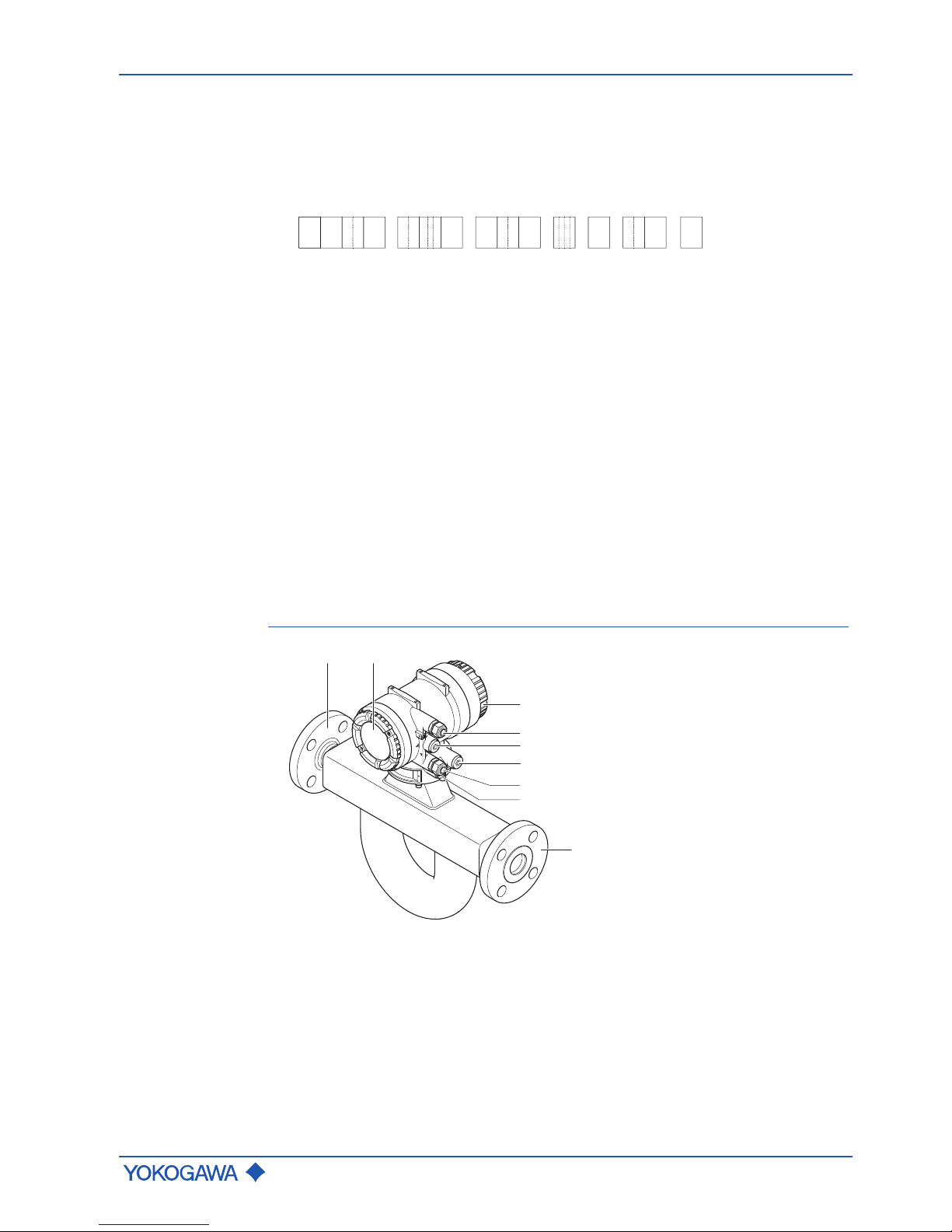

Fig.5: Design of the Rotamass Total Insight integral type (Rotamass Supreme as an example)

1 Transmitter

2 Sensor

3 Process connections

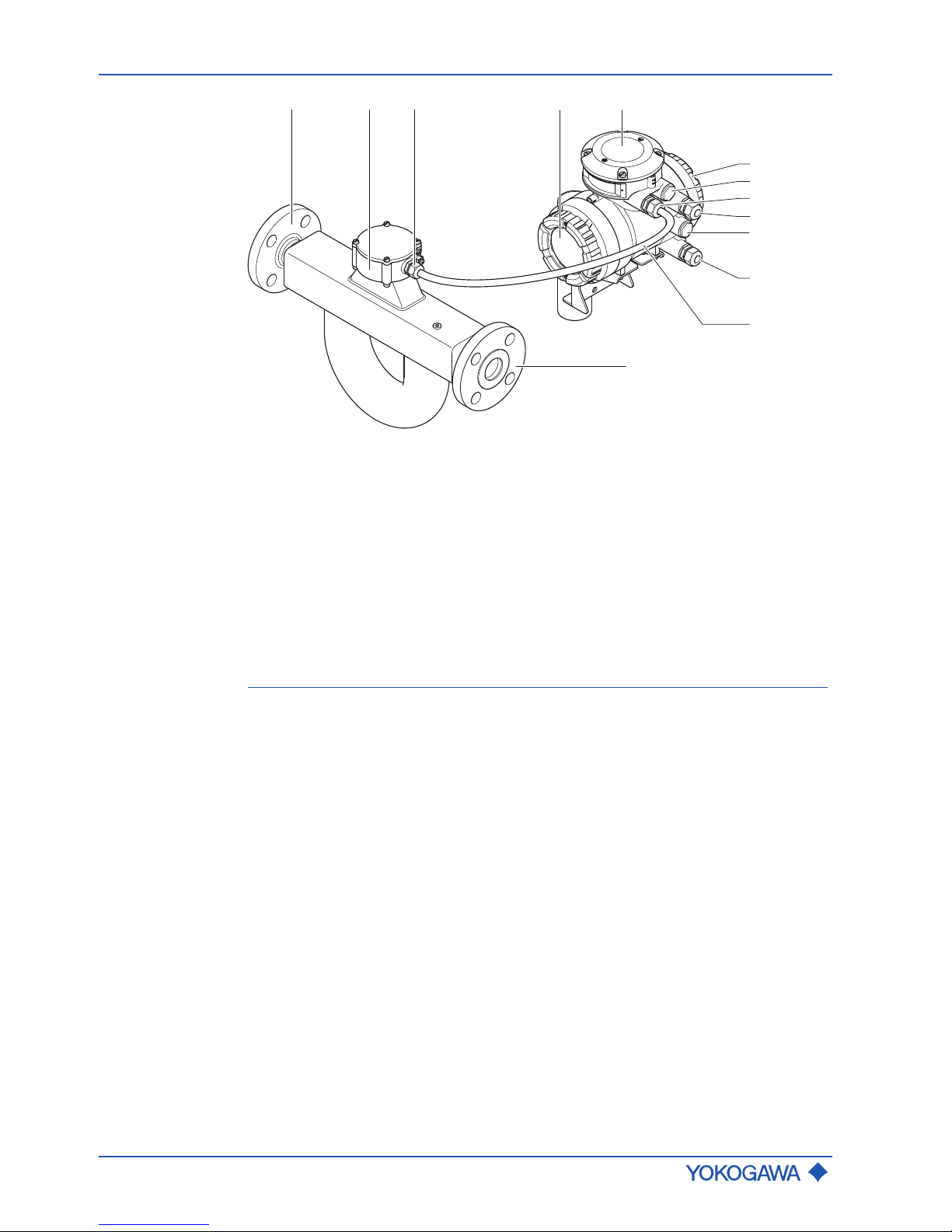

When the remote type is used, sensors and transmitters are linked via connecting cable.

As a result, sensor and transmitter can be installed in different locations.

4 53

1

23

5

3

2

1

4

3

Fig.6: Design of the Rotamass Total Insight remote type (left: Rotamass Supreme, right: Rotamass

Nano)

1 Transmitter 4 Sensor terminal box

2 Sensor 5 Connecting cable

3 Process connections

Page 14

General Instruction Manual

Product specification

Identification

14 / 90

IM 01U10B00-00EN-R, 3rd edition, 2018-07-09

General

specifications

All available properties of the Rotamass Total Insight Coriolis mass flow and density meter are specified by means of a model code.

The position of the model code relevant to the respective property is depicted and highlighted in blue.

U S 36 40H BA1 0 2 C5 A NN00 2 JA 1

P8

- - -

- /-

RC

1 2 3 4 6 75 9 10 11 12 13 14 158

Fig.7: Example of an model code

A complete description of the model code is included in the General Specifications (GS)

of the corresponding product family.

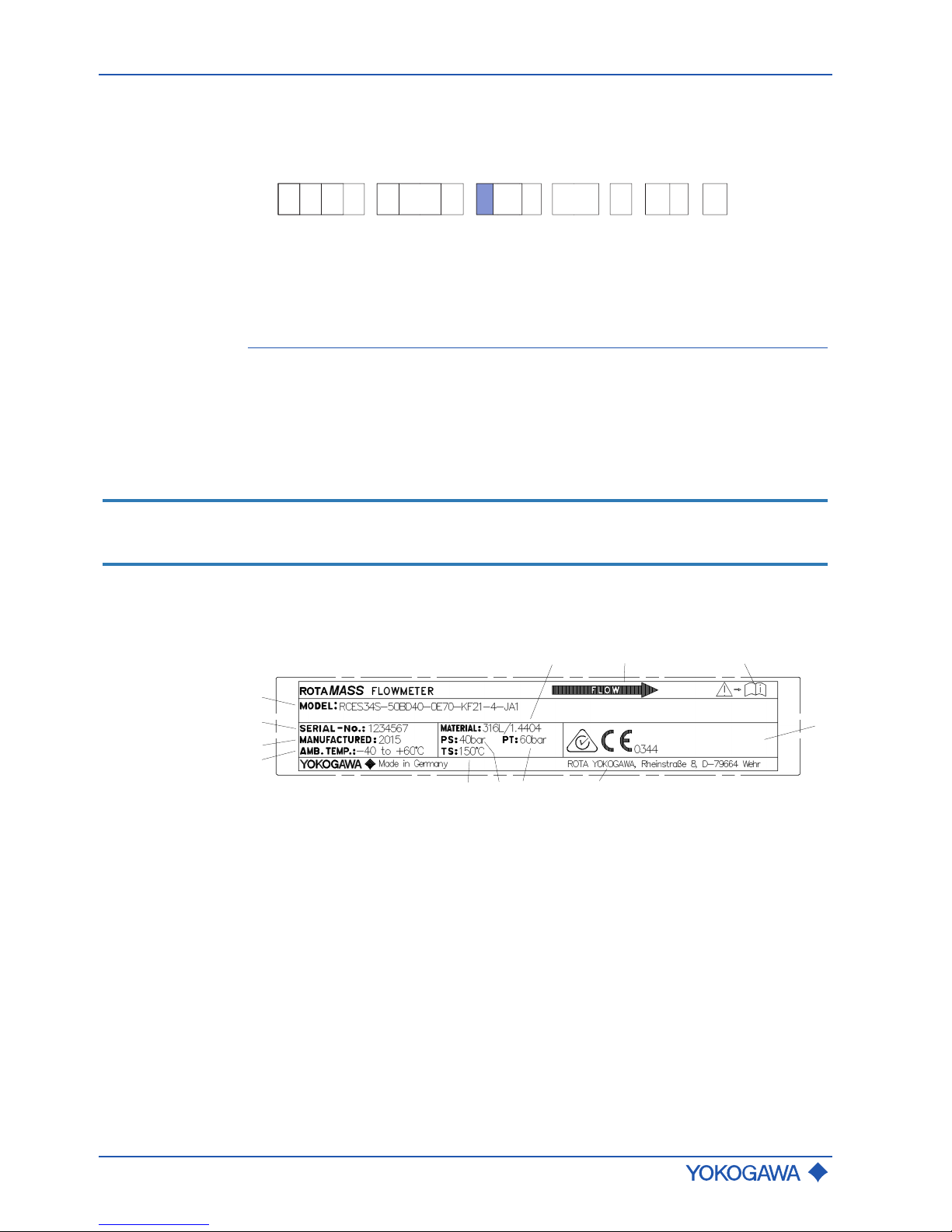

4.3 Identification

The model code can be used to identify the flow meter along with its specification. The

model code is located on each main nameplate.

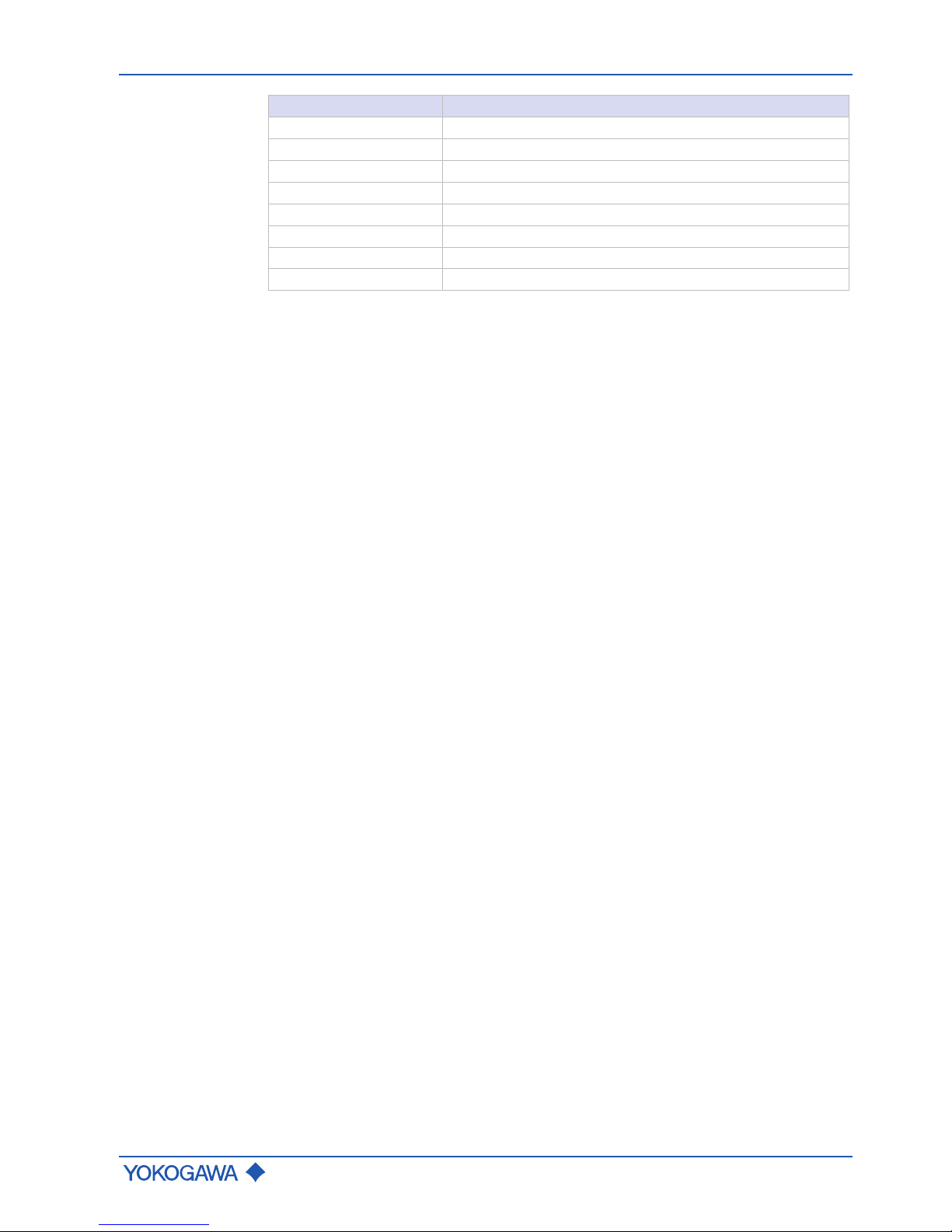

4.3.1 Nameplates

The sensor as well as the transmitter each contain a main nameplate and an additional

nameplate that feature different information.

NOTICE

For individual applications (e.g. marine applications with option MC␣) additional limitations to those on the nameplate may apply according to the respective applicable regulations.

The variants of the nameplates are described below.

Sensor

Main sensor

nameplate

1

5

4

3

2

6

7

11

10

9

8

12

1 Model code 7 Warning that requires reading the

documentation

2 Serial number 8 Area for conformity marking

3 Year of manufacture 9 Manufacturer's address

4 Ambient temperature range 10 Test pressure

5 Kind of material 11 Maximum allowed working pres-

sure at room temperature

6 Direction of flow 12 Maximum allowed process temper-

ature

Page 15

Identification

General Instruction Manual

Product specification

IM 01U10B00-00EN-R, 3rd edition, 2018-07-09

15 / 90

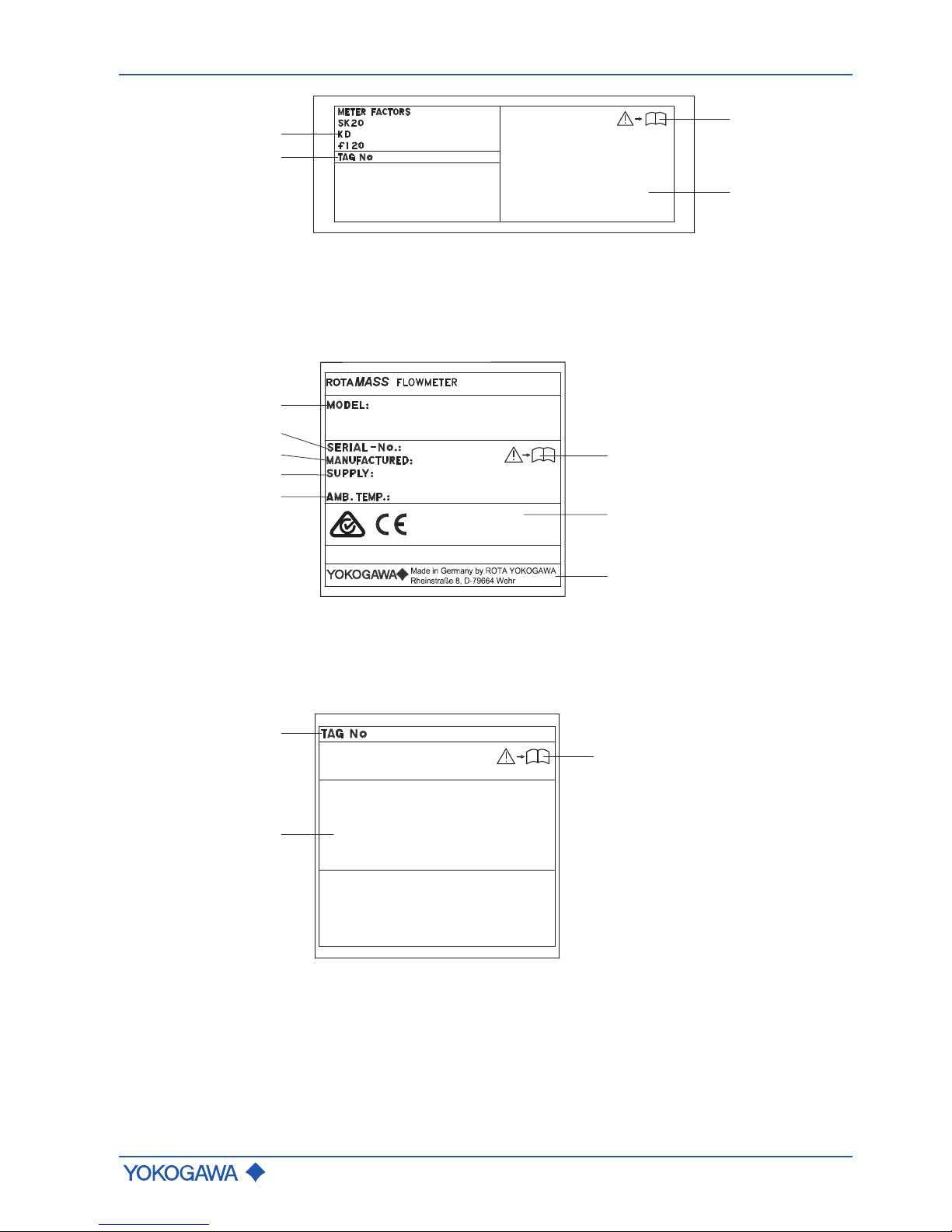

Additional sensor

nameplate

i

3

4

1

2

35

16.8

144

1 Calibration constants of sensor 3 Warning that requires reading the

documentation

2 Customer-Device location

identification (option BG)

4 Space for Ex marking (see Explo-

sion Proof Type Manual)

Transmitter

Main transmitter

nameplate

8

1

2

3

4

5

6

7

i

RCES34S-50BD40-OE70- -4-JA1

1234567

2015

24VAC or 100...240VAC, 50/60Hz

24VDC or 100...120VDC; 10W

-40...+60 oC

1 Model code 5 Ambient temperature range

2 Serial number 6 Warning that requires reading the

documentation

3 Year of manufacture 7 Area for conformity marking

4 Power supply range 8 Manufacturer's address

Additional

transmitter

nameplate

i

3

2

1

1 Customer-Device location identification (option BG)

2 Space for Ex marking (see Explosion Proof Type Manual)

3 Warning that requires reading the documentation

Page 16

General Instruction Manual

Product specification

Identification

16 / 90

IM 01U10B00-00EN-R, 3rd edition, 2018-07-09

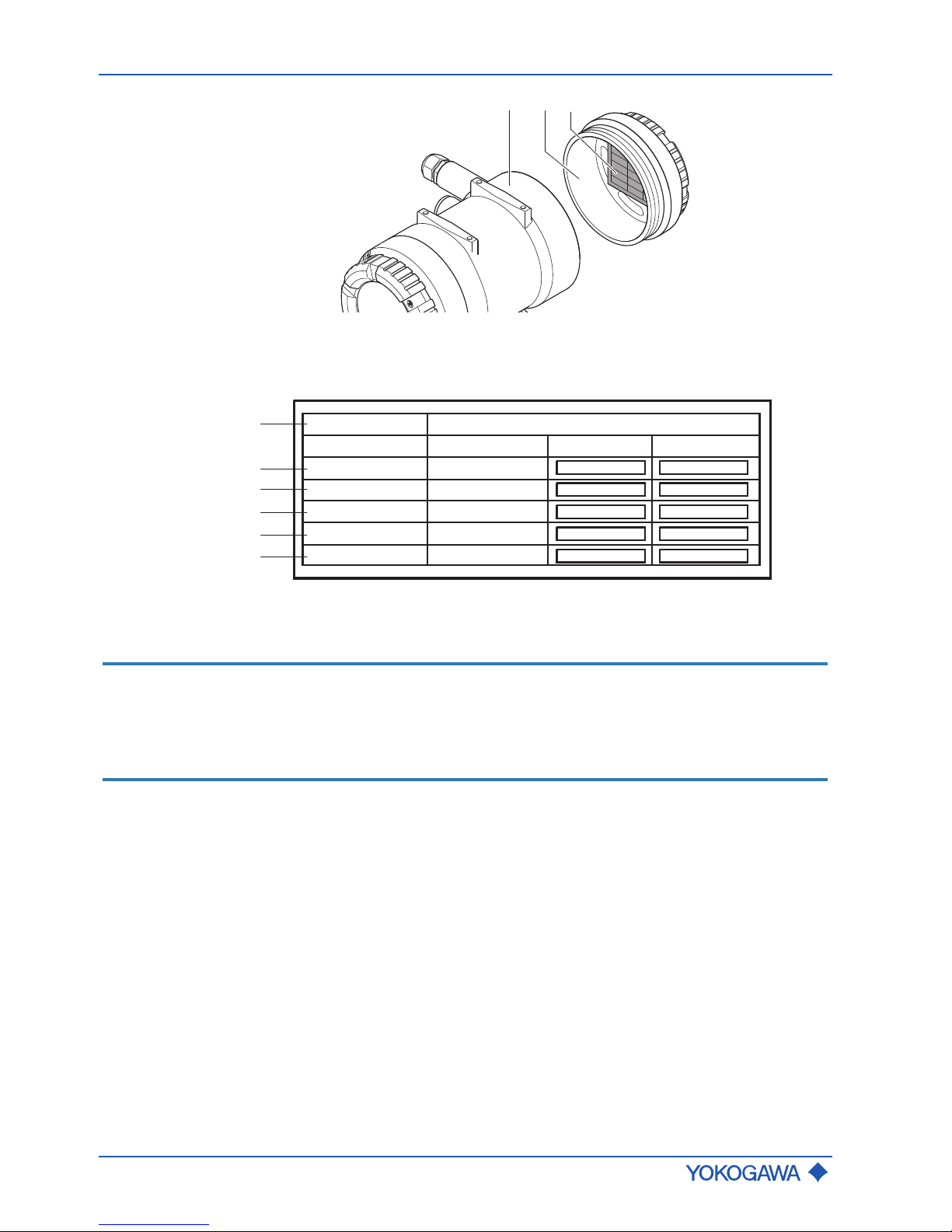

Label transmitter

3

1 2

1 Transmitter

2 Transmitter back cover

3 Label

SERIAL No.:

CPU FW :

DSP FW :

HMI FW :

HW :

Date :

Ex works:

D1xxxxxxxx

xx.xx.xx

xx.xx.xx

xx.xx.xx

xx.xx.xx

2016-03-15

Update 1: Update 2:

1

2

3

4

5

6

1 Serial number 4 Indicator software revision

2 Main software revision 5 Hardware revision

3 Sensor software revision 6 Date of Ex works/ Update

NOTICE

Software revisions are also shown on the Indicator after power on, with the following

designations:

▶ "CPU FW" indicated as "Main"

▶ "DSP FW" indicated as "Sensor"

▶ "HMI FW" indicated as "Indicator"

Page 17

Flow meter components

General Instruction Manual

Product specification

IM 01U10B00-00EN-R, 3rd edition, 2018-07-09

17 / 90

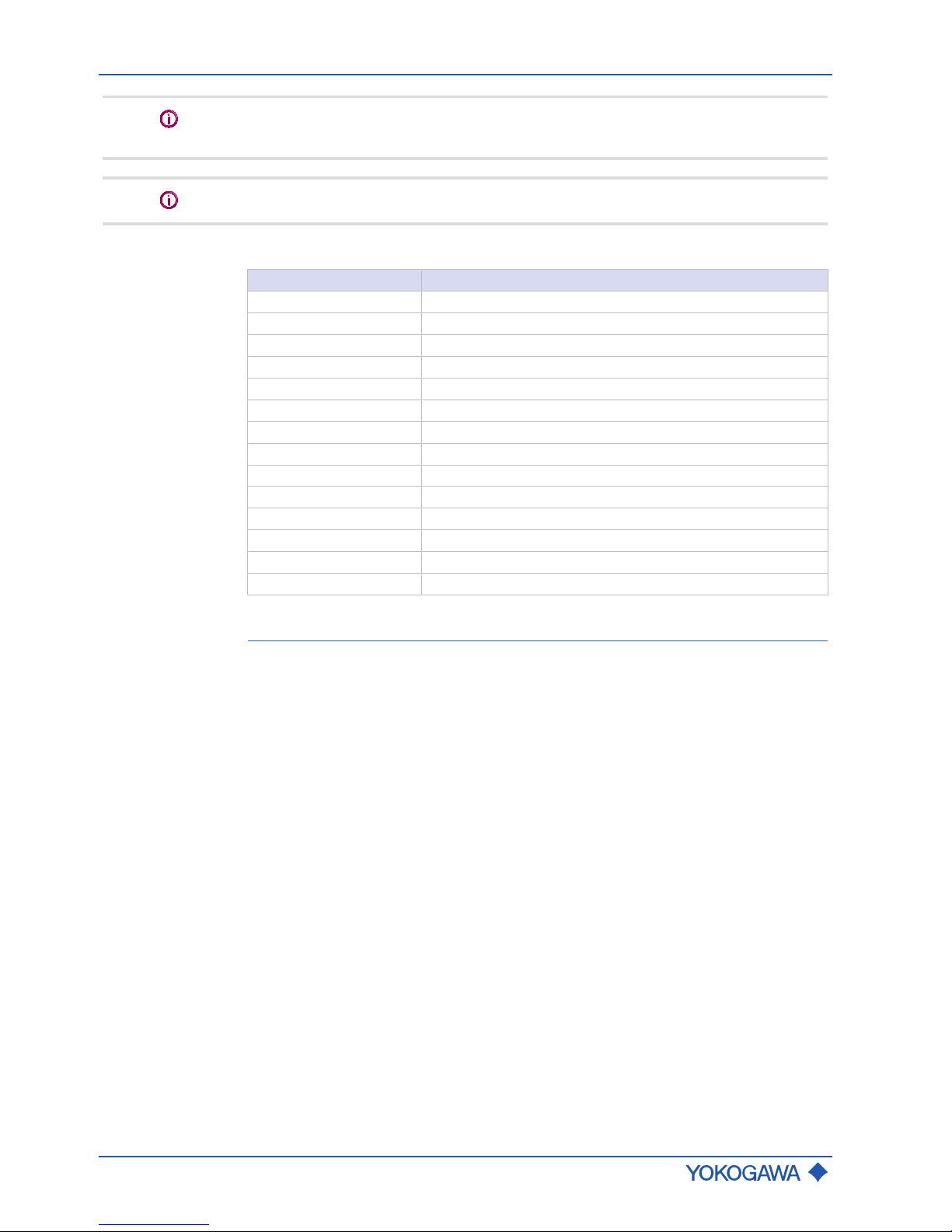

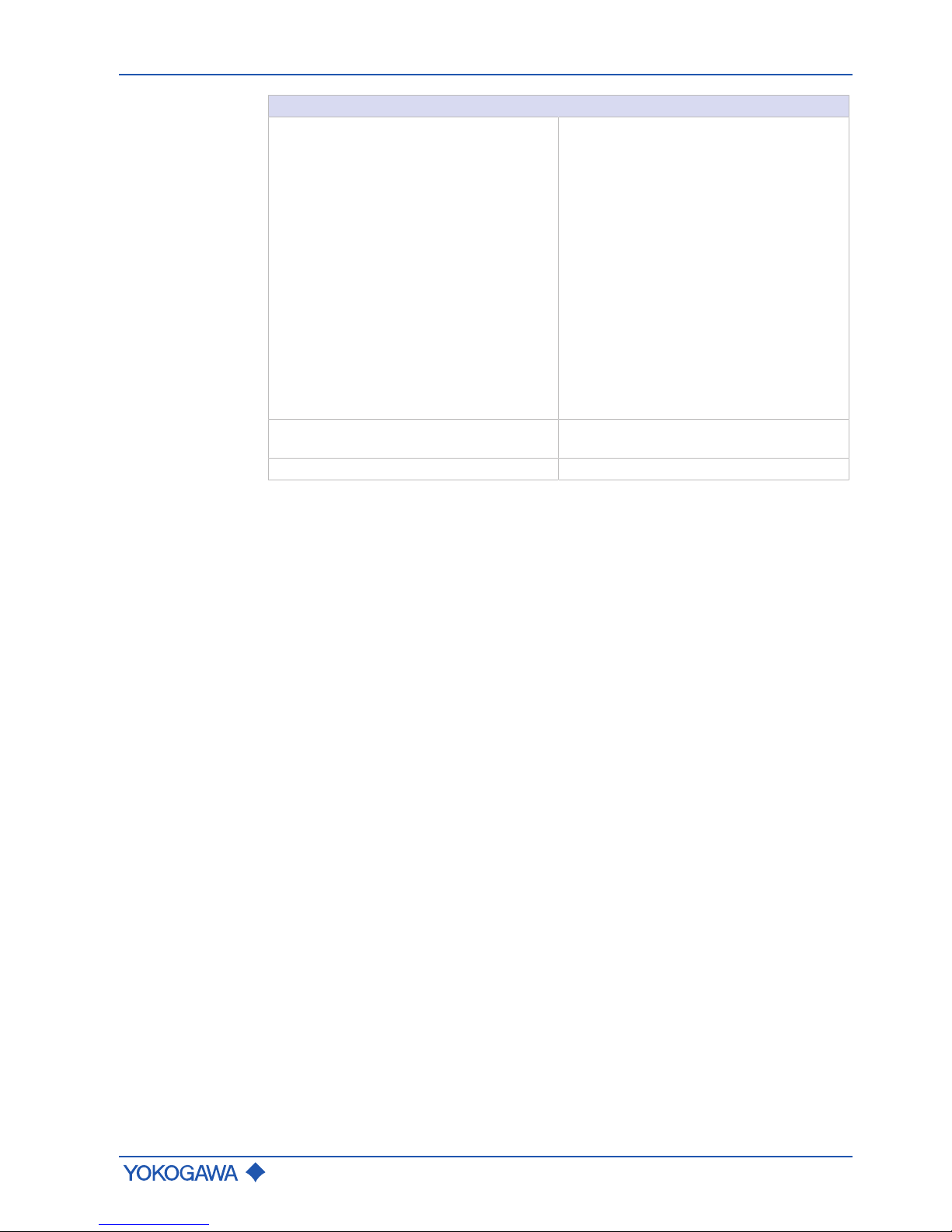

4.3.2 Model code

The model code of the Rotamass Total Insight is explained below.

Items 1 through 14 are mandatory entries and must be specified at the time of ordering.

Device options (item 15) can be selected and specified individually by separating them

with slashes.

- - - - /-

RC

1 2 3 4 6 75 9 10 11 12 13 14 158

1. Transmitter

2. Sensor

3. Meter size

4. Material wetted parts

5. Process connection size

6. Process connection type

7. Sensor housing material

8. Process fluid temperature range

9. Mass flow and density accuracy

10. Design and housing

11. Ex approval

12. Cable entries

13. Communication type and I/O

14. Display

15. Options

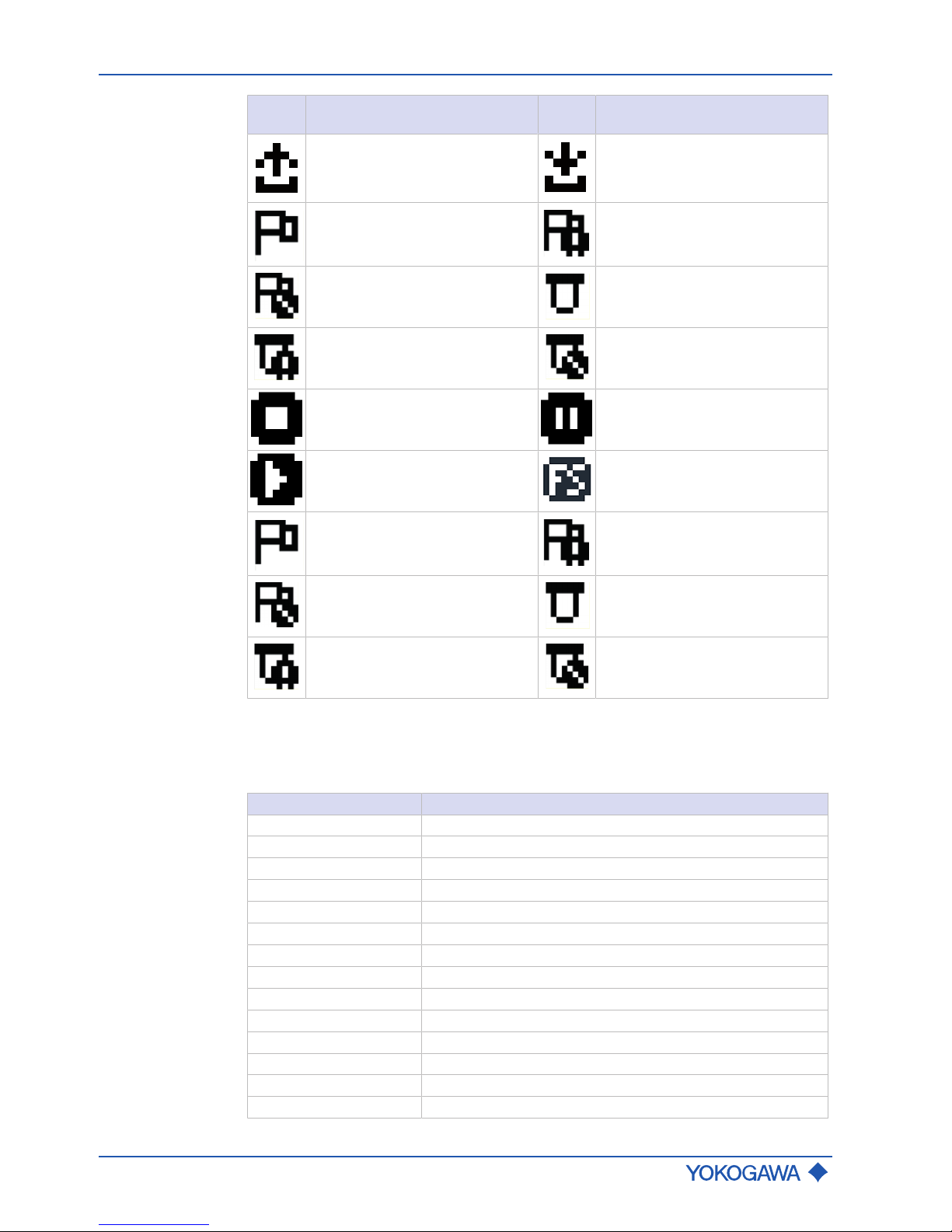

4.4 Flow meter components

Integral type

4

5

2

5

1

5

1

3

6

1 Process connections

2 Back cover for inputs and outputs, and power supply

3 Display cover

4 Power supply cable entry

5 Blind plug

6 Inputs/outputs cable entry

Page 18

General Instruction Manual

Product specification

Mechanical specification

18 / 90

IM 01U10B00-00EN-R, 3rd edition, 2018-07-09

Remote type

4

6

7

7

9

10

3

1

21

3

8

5

1 Process connections

2 Terminal box

3 Cable entry for connecting cable

4 Display cover

5 Sensor connection cover

6 Back cover for inputs and outputs, and power supply

7 Blind plug

8 Inputs/outputs cable entry

9 Power supply cable entry

10 Connecting cable

4.5 Mechanical specification

Mechanical specifications are defined in the related General Specifications (GS):

see GS01U10B0␣␣-00␣␣-R

Page 19

Transport

General Instruction Manual

Transport and storage

IM 01U10B00-00EN-R, 3rd edition, 2018-07-09

19 / 90

5 Transport and storage

5.1 Transport

The following rules apply when transporting the flow meter:

▶ Observe the transport-related instructions on packaging.

▶ In order to avoid damage, do not unpack the flow meter until it is at the installation

site.

▶ Do not remove protective materials, such as protective stickers or covers from

process connections during transport.

▶ Starting at a weight of 15 kg, have at least two persons and/or use suitable tools

(shoulder straps, lifting device, cart) to lift and transport the flow meter.

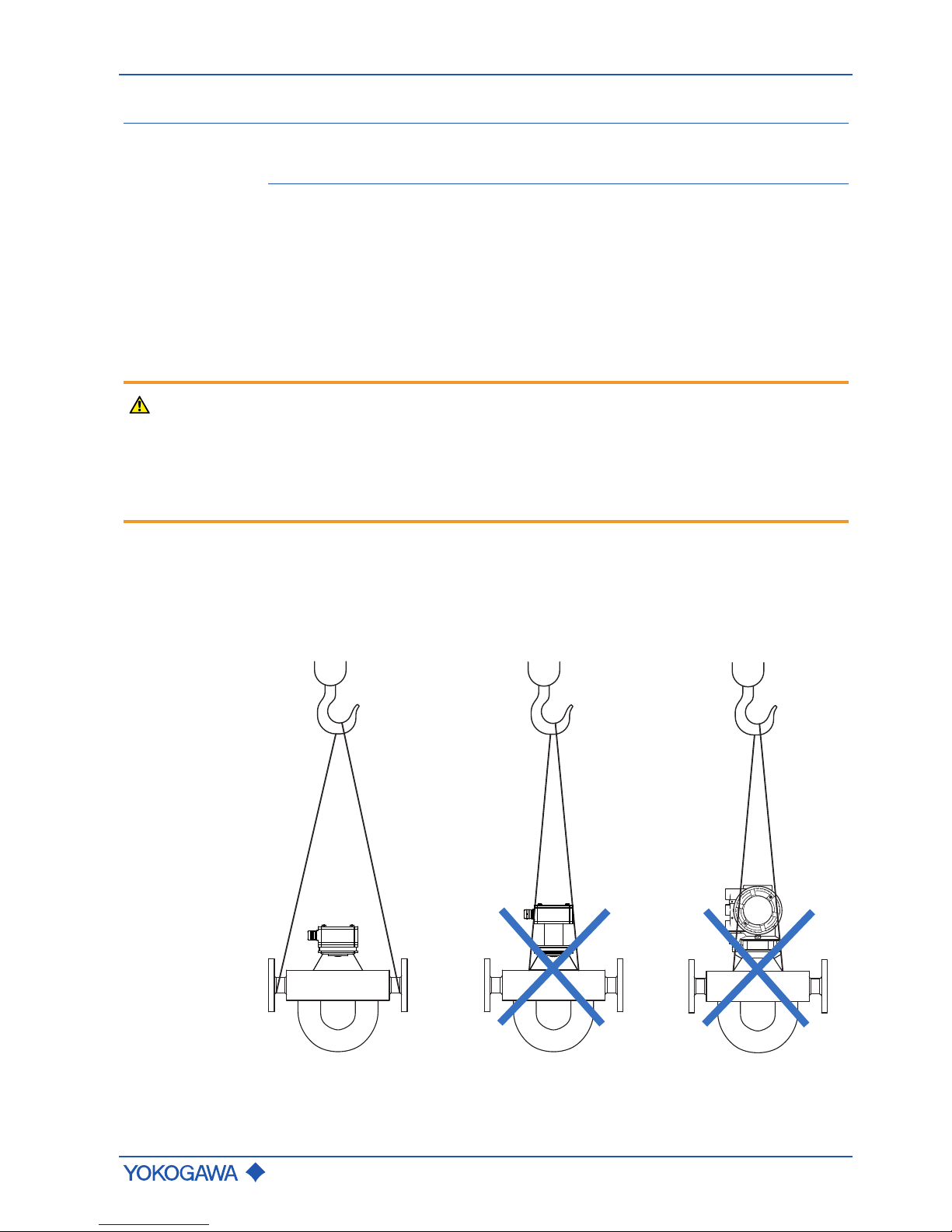

WARNING

Risk of injury from slipping or falling flow meter

▶ Ensure that suspension points of the ropes are located above the flow meter's center

of gravity.

▶ Use a lifting device meeting local regulations.

▶ Attach lifting ropes to process connections.

▶ Do not suspend flow meter from transmitter housing, neck of sensor or flange holes.

The lifting ropes must always be attached to the sensor at the process connections (except for the Rotamass Nano). The depictions that are crossed out in the figure below

show impermissible attachment types. This applies to the remote type, the remote type

with long neck and the integral type, independent of the design. If the process

connections are others than flanges, the holding ropes must be secured against slipping,

if necessary (for example, for the Rotamass Hygienic).

Fig.8: Attachment of the transport ropes to the sensor independent of the design (impermissible attachment types are crossed out)

Page 20

General Instruction Manual

Transport and storage

Storage

20 / 90

IM 01U10B00-00EN-R, 3rd edition, 2018-07-09

5.2 Storage

Please note the following rules apply when storing the flow meter:

NOTICE

Risk of damage to the flow meter due to storage in a damp environment

▶ Protect flow meter from rain and humidity.

▶ Ensure that a relative humidity of 95 % is not exceeded.

NOTICE

Risk of damage to the flow meter due to mechanical wear during storage

▶ Store flow meter in a location that is secured against mechanical influences.

▶ Ensure compliance with the allowed storage temperature, see Specifications [}88].

▶ Protect flow meter against direct insolation to prevent exceeding the allowed storage

temperature.

▶ Protect flow meter from rain and inappropriate humidity.

▶ Keep protective materials such as protective stickers or covers on process

connections or re-apply them.

▶ Prior to storing a used flow meter, completely drain all fluids from the measuring tube,

as well as from the process and heat tracing connections (if applicable), and thoroughly clean the flow meter, see Dismantling and disposal [}86].

Page 21

Installation instructions

General Instruction Manual

Installation

IM 01U10B00-00EN-R, 3rd edition, 2018-07-09

21 / 90

6 Installation

6.1 Installation instructions

WARNING

Risk of injury during installation due to insufficiently trained personnel

▶ Only have skilled personnel install the flow meter.

NOTICE

Risk of damage to the flow meter due to excessive mechanical stress

▶ The flow meter must not be used as a support for climbing (e.g. during installation

work on the tube system). The flow meter must not be used to support external loads

(e.g. as a support for pipes) or as a surface for depositing heavy tools (e.g. during installation work on the pipe system).

▶ The weight of the flow meter may generate additional mechanical forces on the pip-

ing that might lead to tensions at process connections. Design measures must be

taken to prevent the above.

NOTICE

Risk of damage to the flow meter due to mechanical influences

▶ Protect the flow meter from vibration, shocks and mechanical strain.

NOTICE

Meet the environmental conditions of the respective General Specifications

(see GS01U10B0␣␣-00␣␣-R) to prevent disturbance of other sensitive electrical equipment due to increased electromagnetic emissions.

6.1.1 Installation dimensions

Dimensions and installation lengths of sensor and transmitter are listed in the General

Specifications of the corresponding Rotamass Total Insight family in the chapter Mechan-

ical specification.

6.1.2 Installation site

In order to ensure stability while operating the flow meter, the following rules regarding

placement must be followed:

CAUTION

Risk of injury during installation, if space for free movement is insufficient

▶ Select an installation site that offers enough space for installation, electrical installa-

tion, maintenance, etc.

NOTICE

Risk of damage to the flow meter due to extreme environmental conditions

▶ Do not install flow meter in locations subject to severe temperature fluctuations.

▶ Do not install flow meter in locations subject to direct insolation or install additional

sun protection.

▶ Avoid installation sites susceptible to cavitation, such as immediately behind a control

valve.

▶ Install flow meter far removed from motors, transformers or other transmitters.

▶ If the plan calls for installing two sensors of the same kind back-to-back, use a cus-

tomized design. Contact the responsible Yokogawa sales organization.

▶ Operate the flow meter below an elevation of 2000 m above sea level.

▶ If possible, avoid installing the flow meter at the end of a downpipe.

Page 22

General Instruction Manual

Installation

Installation instructions

22 / 90

IM 01U10B00-00EN-R, 3rd edition, 2018-07-09

▶ When installing in a hazardous area, the separate Explosion Proof Type Manual must

be considered.

▶ Install flow meter away from magnetic compasses as it contains no precaution to pre-

vent it from causing compass deviations.

▶ Density indication of the Coriolis flow meter depends on installation orientation and

has to be corrected. For vertical and horizontal orientation (maximum deviation ± 5°)

of the sensor this can be done by the transmitter automatically if the appropriate sensor orientation is selected. For other orientations (inclinations to vertical or horizontal

orientation ≥ 5°) this can not be automatically corrected and has to be taken into account. For highest density accuracy it is recommended to avoid sensor orientations

different to horizontal or vertical installation.

6.1.3 Instructions

Observe the following general installation instructions during installation:

▶ Install the flow meter avoiding shock and vibration as much as possible.

▶ Use closing valves and bypass line to facilitate zero point setting.

1

2

23

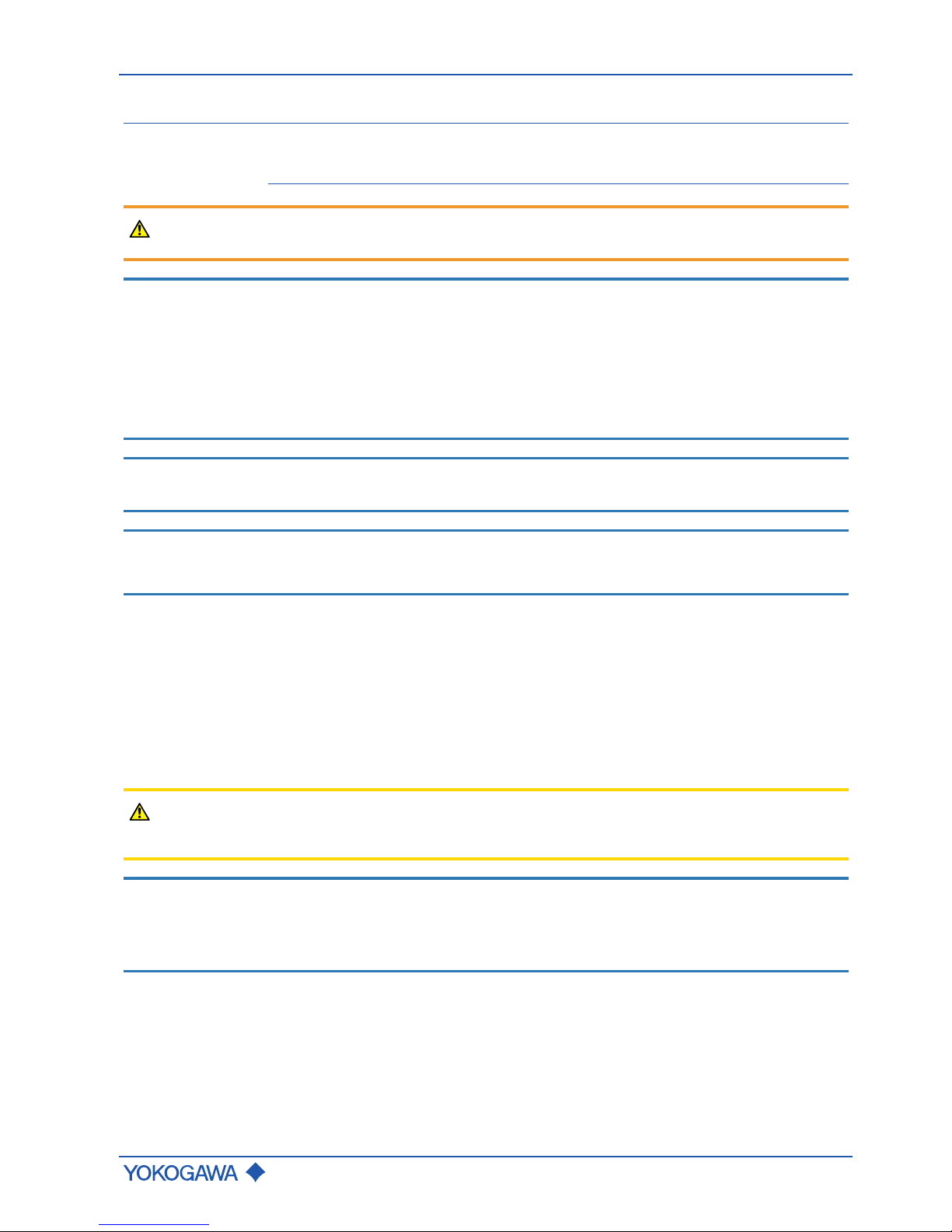

Fig.9: Closing valves and bypass line

1 Bypass valve

2 Closing valve

3 Coriolis flow meter

▶ For application involving fluids, avoid installation at highest point of piping. Formation

of gas bubbles and accumulation of gas in measuring tube may result in increased

measurement uncertainties.

▶ In case of gas measurements, avoid installation directly in front of lowest point in pip-

ing. Accumulation of fluids, such as condensate, may result in lower accuracy.

▶ Do not install immediately in front of a free pipe outlet in a downpipe.

▶ Avoid letting the sensor run idle while taking the measurement, e.g. when installed in

front of an air gap to containers in case of filling applications. Doing so may result in

incorrect measurements. To avoid this, install a restriction in the open downpipe or

use an orifice gauge with a diameter smaller than the nominal pipe width.

▶ Each device is tested for pressure prior to delivery.

Page 23

Installation instructions

General Instruction Manual

Installation

IM 01U10B00-00EN-R, 3rd edition, 2018-07-09

23 / 90

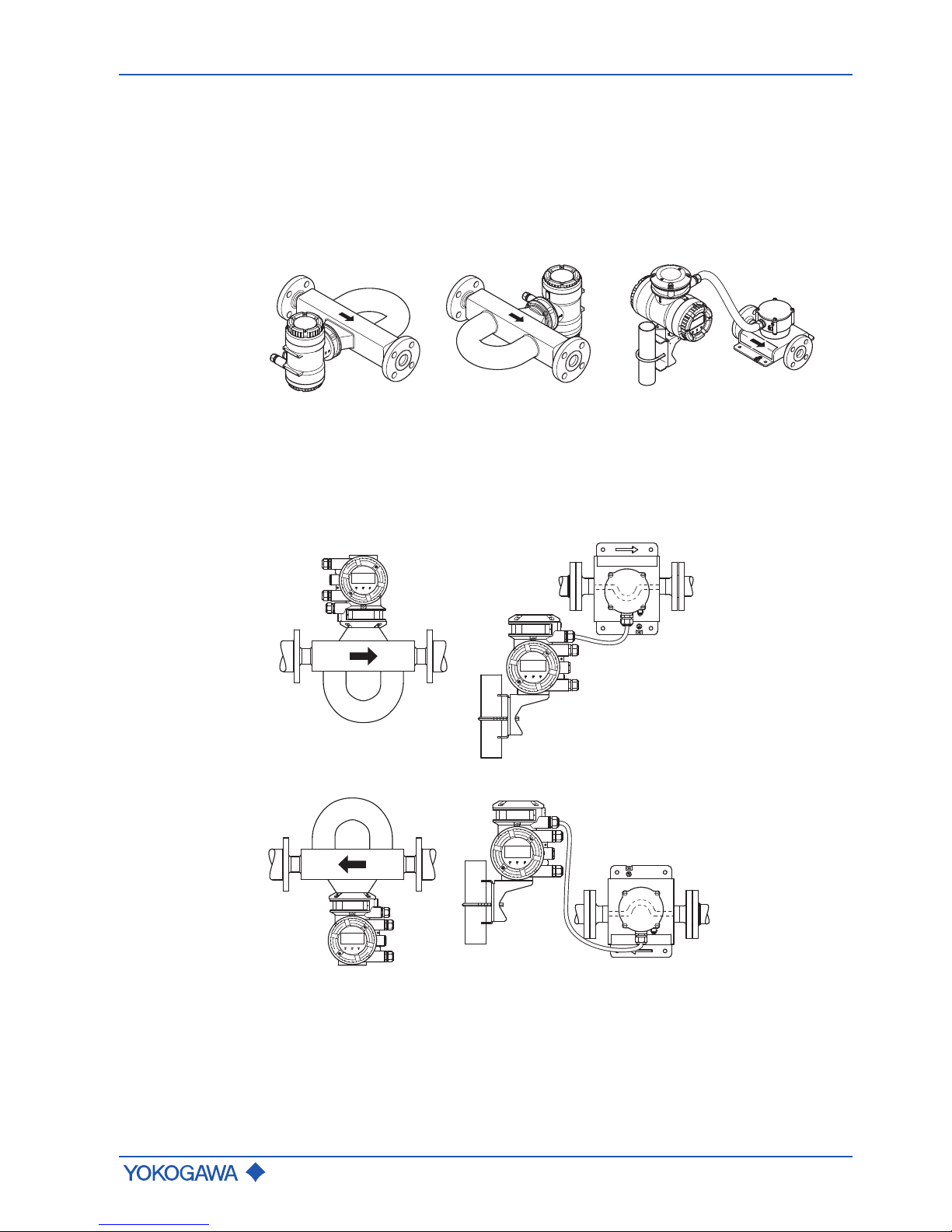

6.1.4 Installation position

Rotamass Total Insight Coriolis mass flow and density meters can be mounted horizontally, vertically and at an incline. The measuring tubes should be completely filled with the

fluid during this process as accumulations of air or formation of gas bubbles in the measuring tube may result in errors in measurement. Straight pipe runs at inlet or outlet are

not required.

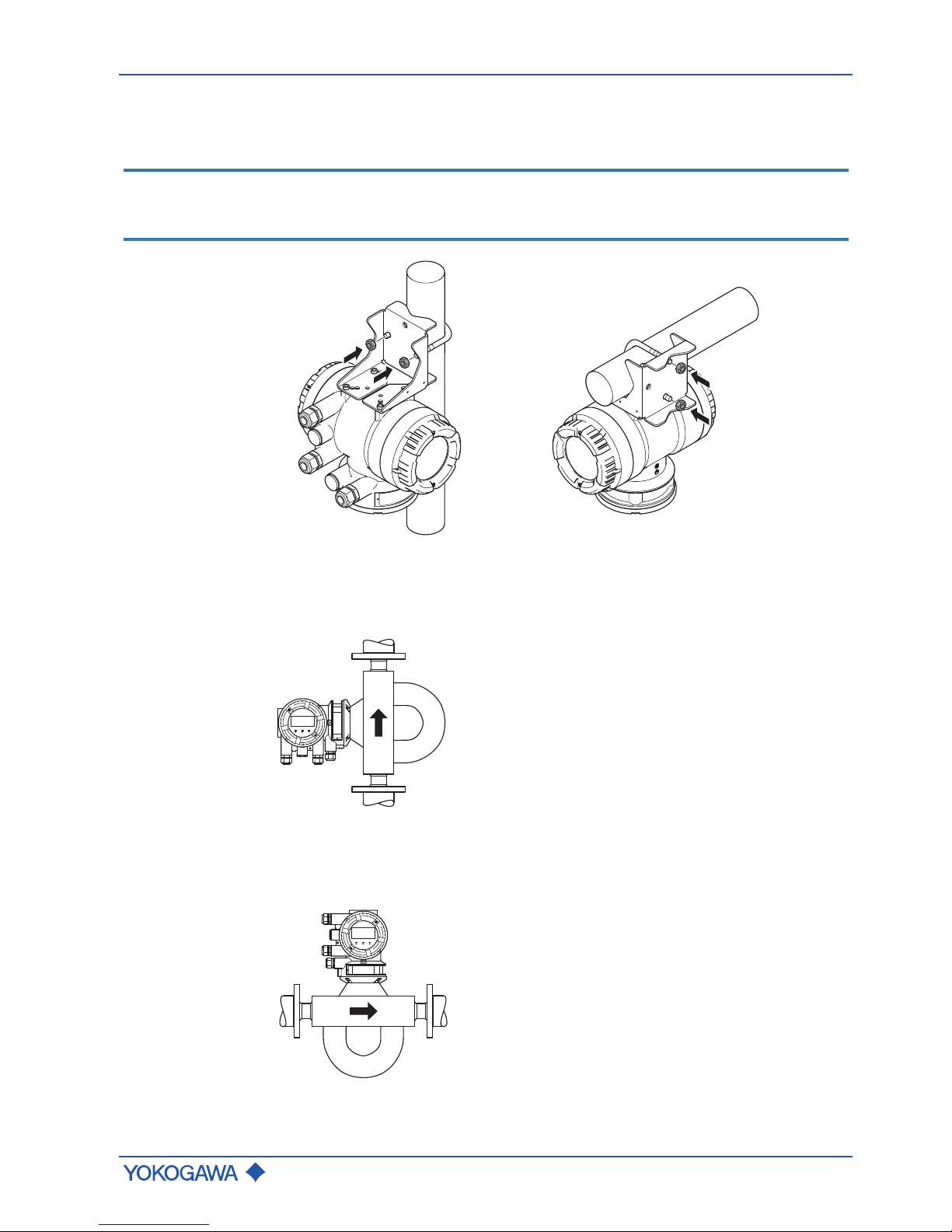

Sideways position

The sideways position must be avoided when installing the flow meter, because this may

result in a deterioration of accuracy.

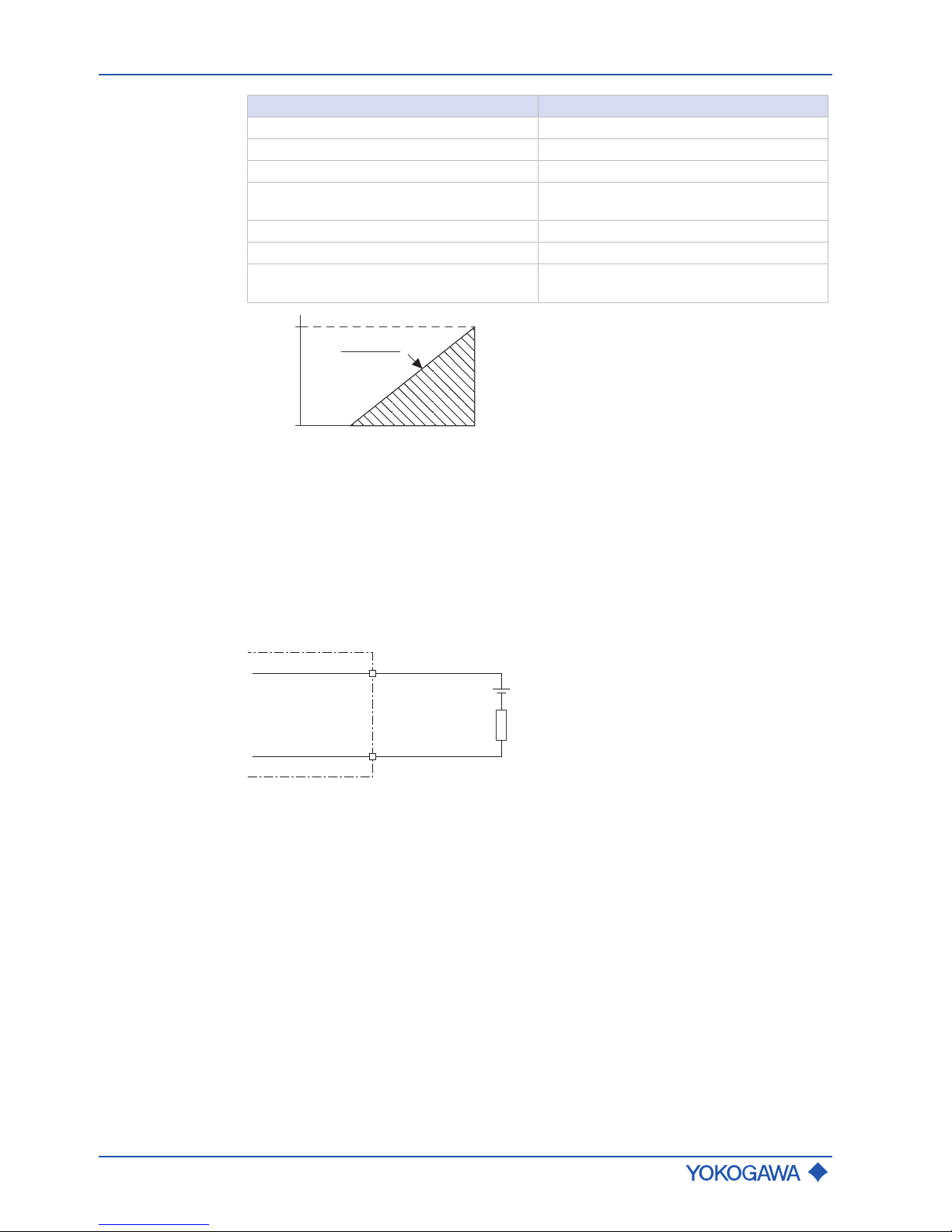

Fig.10: Installation positions to be avoided: Flow meter in sideways position

Horizontal

installation

▶ In case of fluids, install the measuring tubes downward so as to avoid gas accumula-

tion in case of a low flow rate.

▶ For gas applications, install the measuring tubes upward so as to avoid fluid accumu-

lation in case of a low flow rate.

Fig.11: Horizontal installation, measuring tubes downward

Fig.12: Horizontal installation, measuring tubes upward

Page 24

General Instruction Manual

Installation

Installation instructions

24 / 90

IM 01U10B00-00EN-R, 3rd edition, 2018-07-09

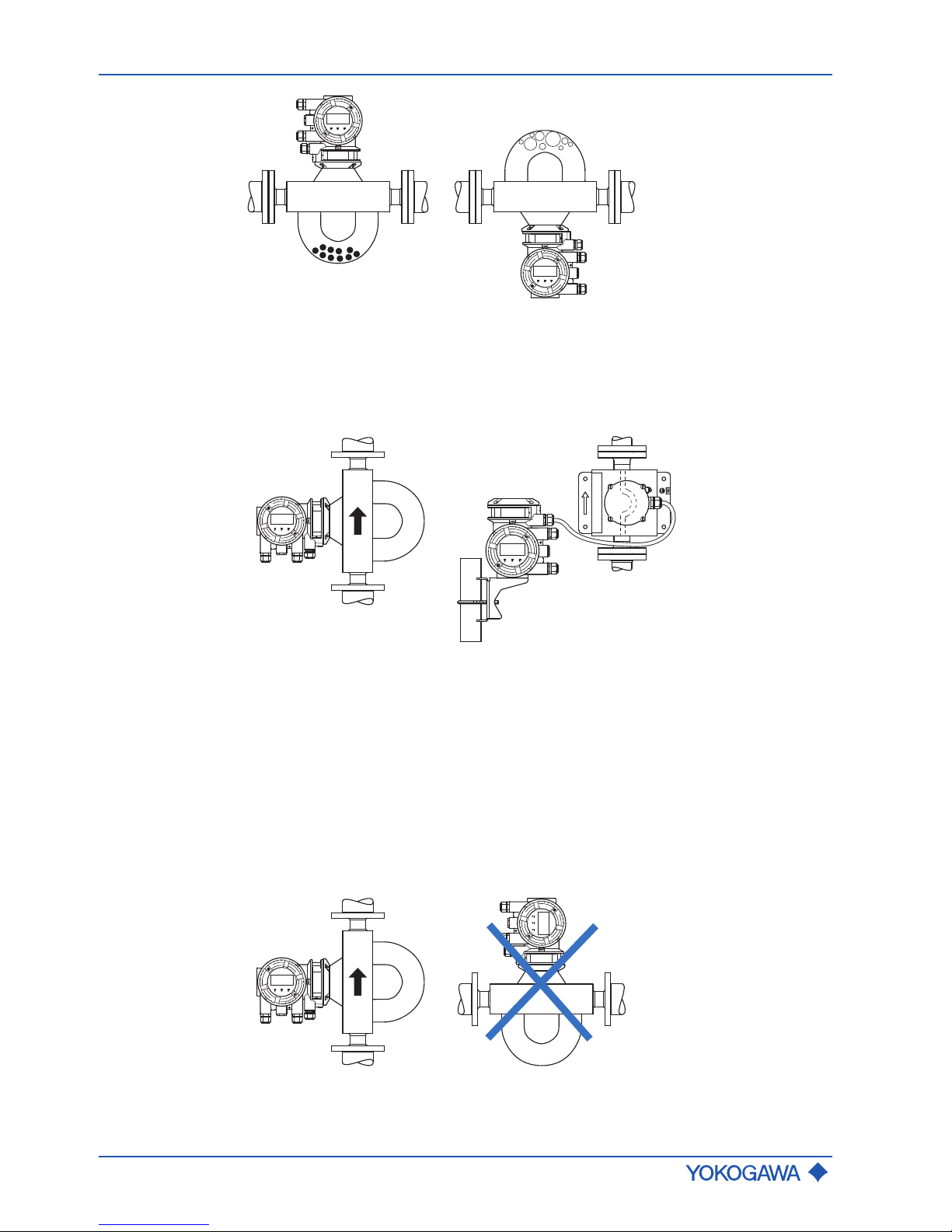

Fig.13: Risk of solid matter and/or gas accumulation

Vertical installation

(recommended)

▶ Draining the pipe is easier in case of maintenance, production start or product

change.

▶ Allows gas bubbles to escape more easily.

▶ Only one shut-off valve required to ensure zero flow rate when running autozero.

Fig.14: Vertical Installation

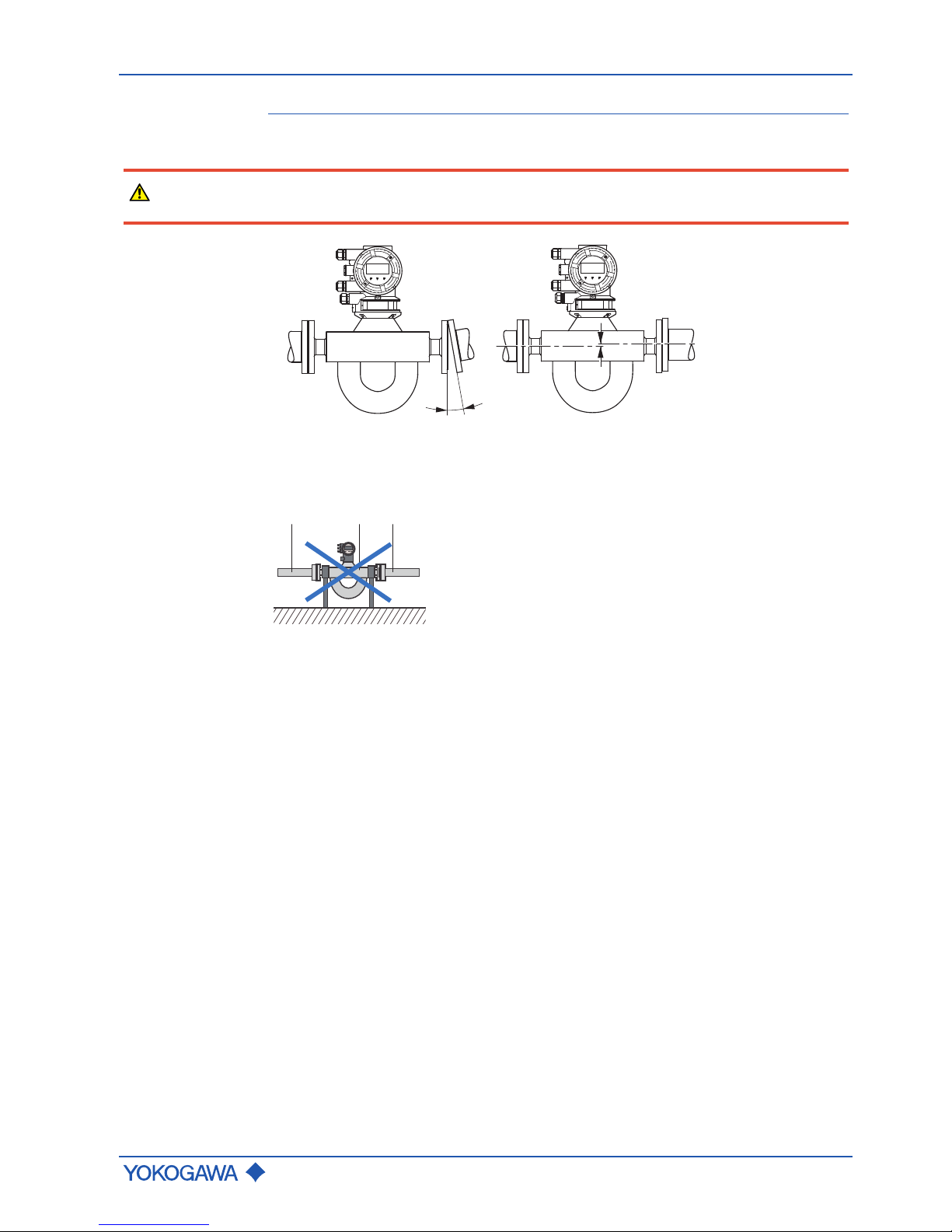

6.1.5 Sanitary Installation

EHEDG compliant installation

In order to comply with the requirements of the European Hygienic Engineering and Design Group (EHEDG), the following aspects need to be considered:

▶ The installation must ensure a self-draining of the device (see figure below). A vertical

installation is recommended.

▶ An EHEDG compliant process connection requires a combination of process

connections and gaskets according to the latest version of the EHEDG Position Paper: "Easy cleanable Pipe couplings and Process connections".

Fig.15: EHEDG compliant installation position

Page 25

Installation instructions

General Instruction Manual

Installation

IM 01U10B00-00EN-R, 3rd edition, 2018-07-09

25 / 90

3-A compliant installation

Remote transmitter

installation

▶ For compliance with 3-A sanitary standards, remote transmitter is restricted to hang-

ing installation, as shown in figure below.

NOTICE

Fixation of the transmitter

For fixation of the transmitter at the bracket either hexagon head srews (M6x10) or socket

head screws with rubber cap must be used.

Fig.16: Hanging installation for remote transmitter

Sensor installation

(remote or integral

version)

▶ For compliance with 3-A sanitary standards, a vertical installation of sensor with fluid

flowing upwards (self-draining) is recommended, as shown in figure below.

Fig.17: Vertical (self-draining) installation

▶ A horizontal installation of sensor with tubes down, as shown in figure below, shall be

drained via air purge.

Fig.18: Horizontal installation with tubes down

Page 26

General Instruction Manual

Installation

Installation instructions

26 / 90

IM 01U10B00-00EN-R, 3rd edition, 2018-07-09

▶ For Cleaning-In-Place (CIP) application, the standard minimum flow velocity of

1.5 m/s shall be used for cleaning the sensor. Volumetric flow shall be determined by

using the cross-sectional area at process connection.

Notes on fittings

and gasket

▶ General note: It must be ensured that the inner diameter (ID) of adjacent pipe

matches the ID of process connection of the sensor fitting to ensure 3-A compliance.

▶ For compliance of DIN 11851 process connection (process connection HS2) with 3-A

standards, a special sanitary gasket such as the k-flex gasket system by Kieselmann

GmbH, or similar must be used to retain 3-A compliance.

6.2 Installation instructions

Note the following rules prior to installation:

▶ Check packaging and contents for damage.

▶ Do not remove protective materials such as protective stickers or caps on process

connections until the start of the installation process.

▶ Dispose packaging materials in compliance with country-specific regulations.

Page 27

Sensor installation

General Instruction Manual

Installation

IM 01U10B00-00EN-R, 3rd edition, 2018-07-09

27 / 90

6.3 Sensor installation

6.3.1 General installation rules

DANGER

Risk of injury due to escaping fluids, if pipe connection is faulty

▶ Correct slope and mismatch of pipe connections before inserting the sensor.

Fig.19: Avoid: Slope and mismatch

▶ Avoid fixing anything directly to the sensor. Doing so may result in increased devia-

tions.

1

1

2

Fig.20: Installation to be avoided: Fixing the sensor

1 Pipe

2 Sensor

▶ Secure pipes before installing the flow meter.

▶ Avoid damaging the process connections.

▶ Flush new pipes before installing the flow meter to remove foreign matter, such as

shavings or other residues.

Avoiding creation of noise

Zero point stability is a prerequisite for exact mass flow measurement. Insufficient installation may lead to mechanical tensions or flow noise which impact zero point stability.

Countermeasures to help avoid noise creation:

▶ Support sensor weight by using soft coupling (silicone or other types of cushioning

materials).

▶ Avoid bending or tensioning the sensor while aligning the pipe.

▶ Avoid reductions or expansions in pipe directly up- or downstream of flow meter.

▶ Avoid placing control valves, apertures or other devices generating noise near the

sensor.

Page 28

General Instruction Manual

Installation

Sensor installation

28 / 90

IM 01U10B00-00EN-R, 3rd edition, 2018-07-09

6.3.2 Installation in pipe

Depending on process connections, the sensor is connected to the pipe by means of

flanges, terminals or thread. The model code provides information on the process

connections selected.

DANGER

Risk of injury due to escaping fluids and damage, if fixing materials are inappropriate or not professionally installed

▶ Fixing materials (screws, nuts, terminals, terminal connectors, gaskets, etc.) are not

included in the delivery and must be provided by the customer. The operator is responsible for selecting suitable gaskets and defining corresponding torque values.

▶ Protective materials such as protective stickers or caps on process connections must

be removed immediately before installation.

▶ The direction in which the fluid flows through the pipe is indicated by an arrow on the

flow meter. The sensor must be installed in accordance with the flow direction indicated to ensure optimal measuring results for density measurements.

Otherwise, the parameter flow direction in the transmitter menu must be changed,

see applicable software instruction manual.

Clamp connection

The clamp connection must be installed as shown in the figure below.

3

2

1

Fig.21: Clamp connection

1 Terminal

2 Gasket

3 Terminal connector

Page 29

Sensor installation

General Instruction Manual

Installation

IM 01U10B00-00EN-R, 3rd edition, 2018-07-09

29 / 90

Fixing the flange

▶ Use screws and nuts suitable for the flanges.

▶ In case the nominal width of the piping deviates from the flow meter, use the appropri-

ate reductions.

▶ Inner gasket diameters should not fall below the inner diameters of the flange.

3

1

2

4

5

Fig.22: Fixing the flange

1 Pipe flange

2 Gasket

3 Sensor flange

4 Bolt

5 Nut

Internal thread

connection

For process connections with an internal thread, the connection must be installed in accordance with the following figure.

1

2

3

Fig.23: Internal thread connection

1 Sensor

2 Gasket (not use in case of NPT)

3 Pipe

Page 30

General Instruction Manual

Installation

Sensor installation

30 / 90

IM 01U10B00-00EN-R, 3rd edition, 2018-07-09

NOTICE

Use of seal tape for installation

In case of process connection with internal thread NPT you have to use a seal tape for installation.

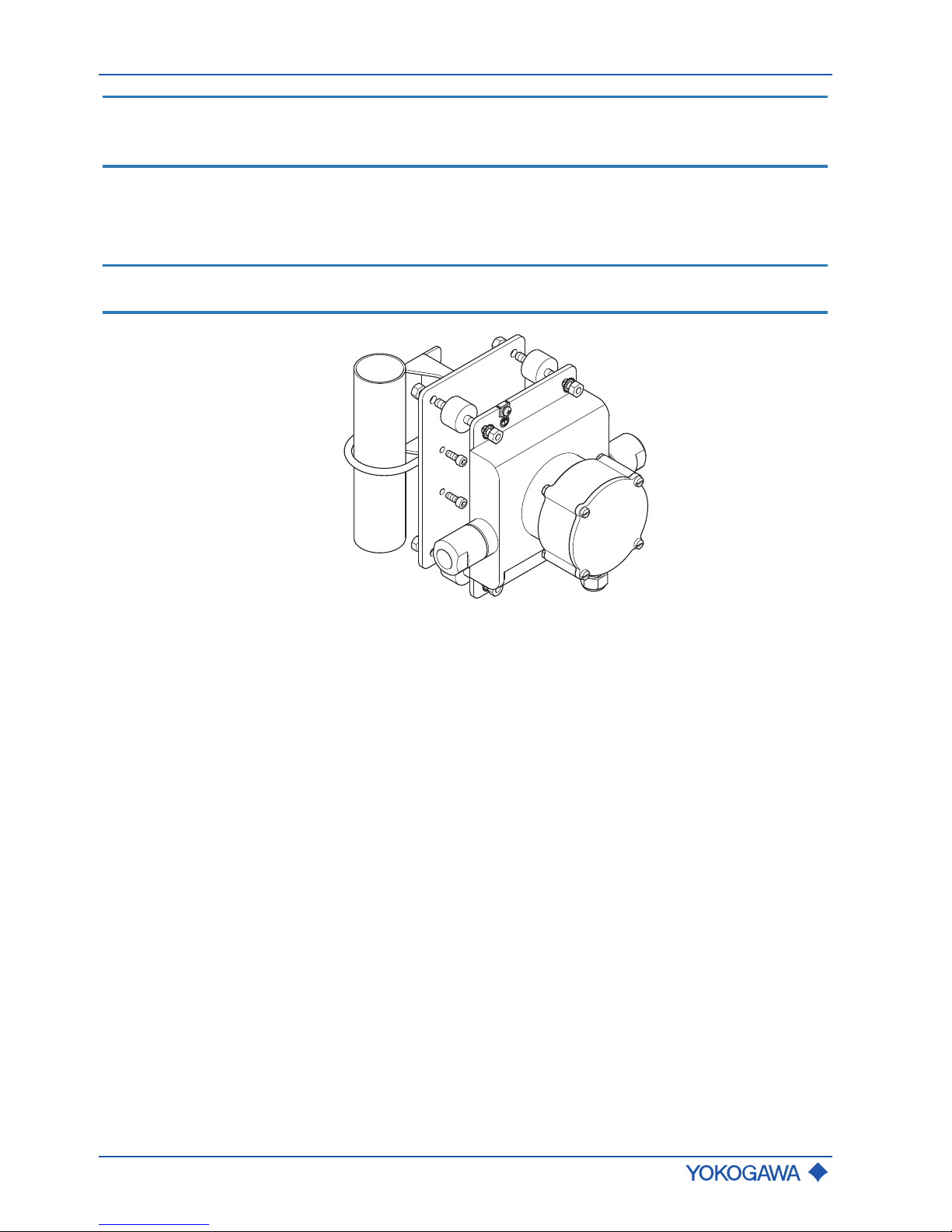

6.3.3 Installation Rotamass Nano (Option PD)

For the Rotamass Nano the sensor can be installed on a DN50 (2") pipe by using a

bracket and U-bolt assy (model code position 15, option PD).

NOTICE

The bracket contains vibration dampers, but for extreme cases of vibration stronger

damping arrangements may be necessary to ensure best performance.

Fig.24: 2" fixing device option /PD for Nano

Page 31

Sensor installation

General Instruction Manual

Installation

IM 01U10B00-00EN-R, 3rd edition, 2018-07-09

31 / 90

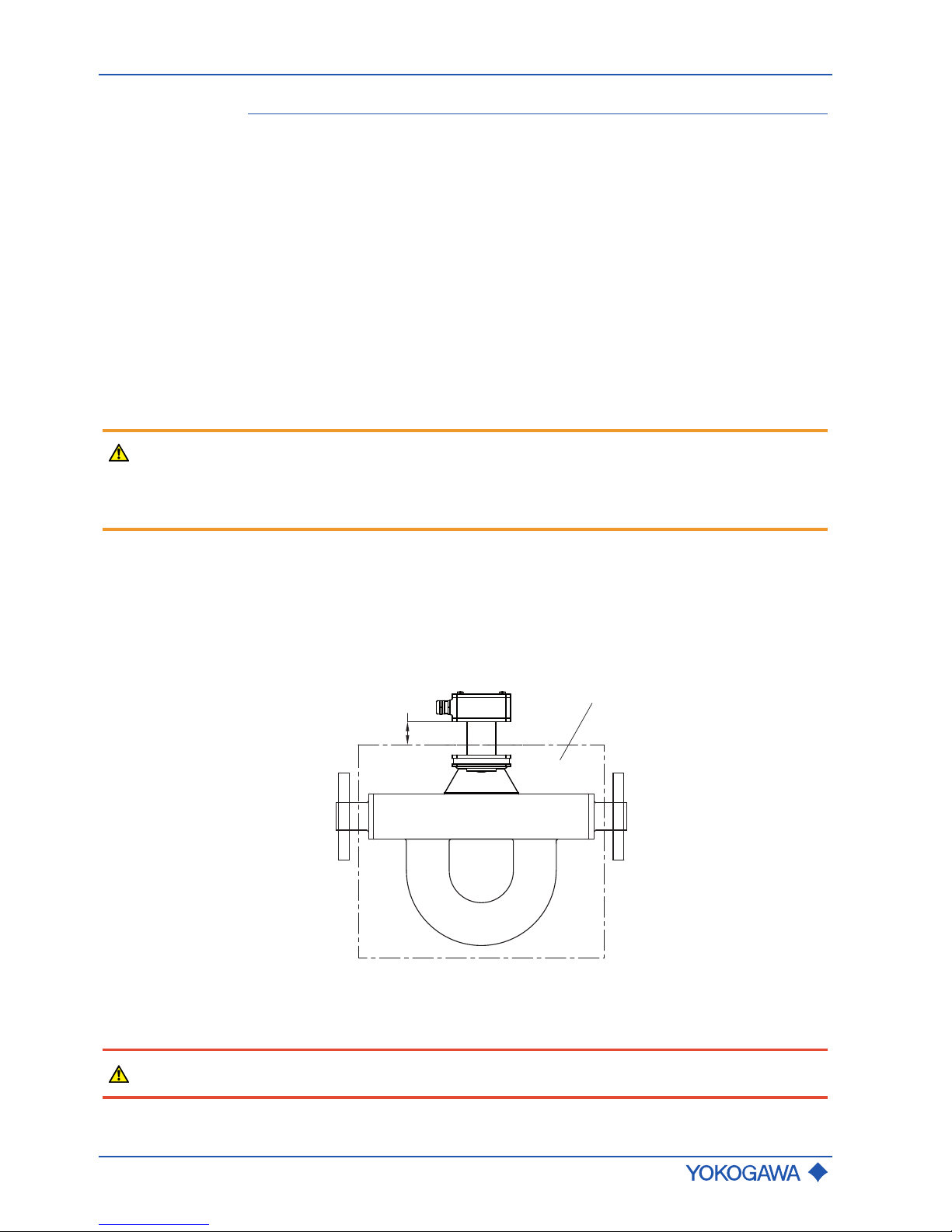

6.3.4 Installation recommendation for viscosity measurements

For the Rotamass sensor this function can only be used if it is present an external differential pressure transmitter (to order separately) measuring the pressure difference at the

flow line. The accuracy of the estimated viscosity is strongly depending on the accuracy

of the pressure transmitter and the correct position and implementation of the pressure

taps.

NOTICE

The needed pressure taps have to be placed at the flow line at approximately 4D … 5D

upstream and downstream of the Rotamass sensor. The differential pressure transmitter

is directly connected via analog input to the Rotamass transmitter (analog input function

must be available).

Fig.25: Positioning of pressure taps

① Mounting flanges ④ Differential pressure transmitter

② Pressure taps ⑤ HART communication

③ Rotamass Total Insight

x = approx. 4 to 5 x D

x Flow line upstream or downstream of the Rotamass Total Insight sensor

D Inner diameter of process line

Page 32

General Instruction Manual

Installation

Insulation and heat tracing

32 / 90

IM 01U10B00-00EN-R, 3rd edition, 2018-07-09

6.4 Insulation and heat tracing

6.4.1 Heat tracing

The majority of applications do not require or provide insulation or heat tracing for the

sensor. Product versions with insulation and/or heat tracing are available for specific

technical applications, see applicable General Specifications. Starting with fluid temperatures of approx. 80 °C above or below the ambient temperature, insulating the sensor is

recommended if the goal is to maintain utmost accuracy. These measures are also sensible with increased requirements for fluid temperature stability.

The sensor is heated by means of heat tracing via a heat transfer fluid running through

stainless steel pipes. The heat transfer fluid is supplied through process connections that

can be selected. The operator is responsible for temperature control of the heat carrier.

Here the specifications for pressure and the temperature of the heat transfer fluid must be

met, see applicable General Specifications.

Heat tracing is only available for the remote type of flow meter and must be selected by

including an appropriate device option when placing the order, see applicable General

Specifications.

WARNING

Risk of overheating the transmitter due to increased ambient temperature

Failure of measuring electronics

▶ Observe the maximum allowable ambient temperature for the transmitter.

▶ Install the transmitter at a sufficient distance from heat sources.

6.4.2 Customer-supplied insulation

For insulation provided by the customer it is important to select a sensor with the appropriate design type (remote type, sensor with long neck). The space between upper insulation edge and lower edge of the sensor's terminal box must be at least 40 mm.

Recommended insulation thickness is 80 mm and recommended heat transfer coefficient

0.4 W/m² K.

1

min. 40 mm

Fig.26: Customer-supplied insulation

1 Insulation box

DANGER

When installing in hazardous areas, the applicable Explosion Proof Type Manual must be

considered.

Page 33

Transmitter installation

General Instruction Manual

Installation

IM 01U10B00-00EN-R, 3rd edition, 2018-07-09

33 / 90

6.5 Transmitter installation

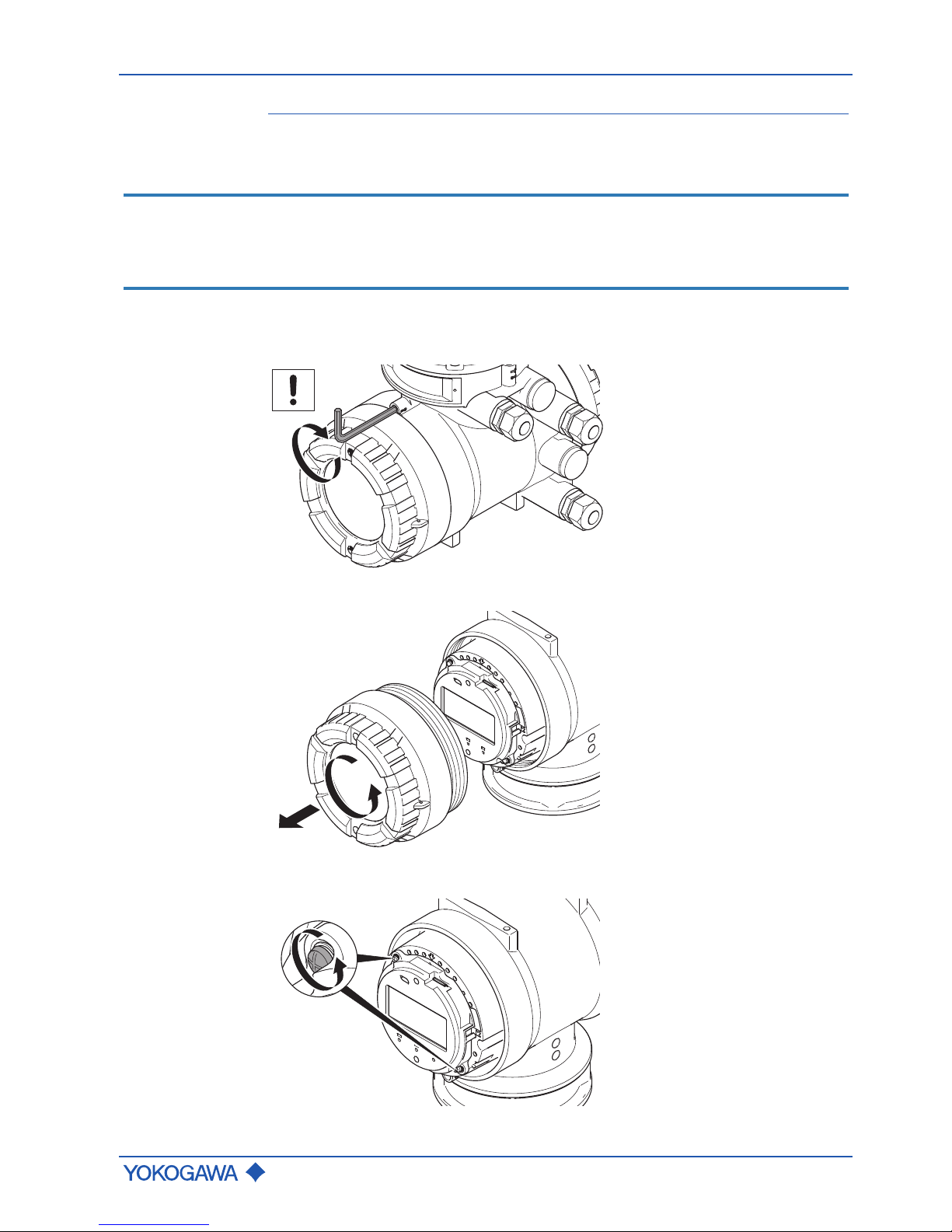

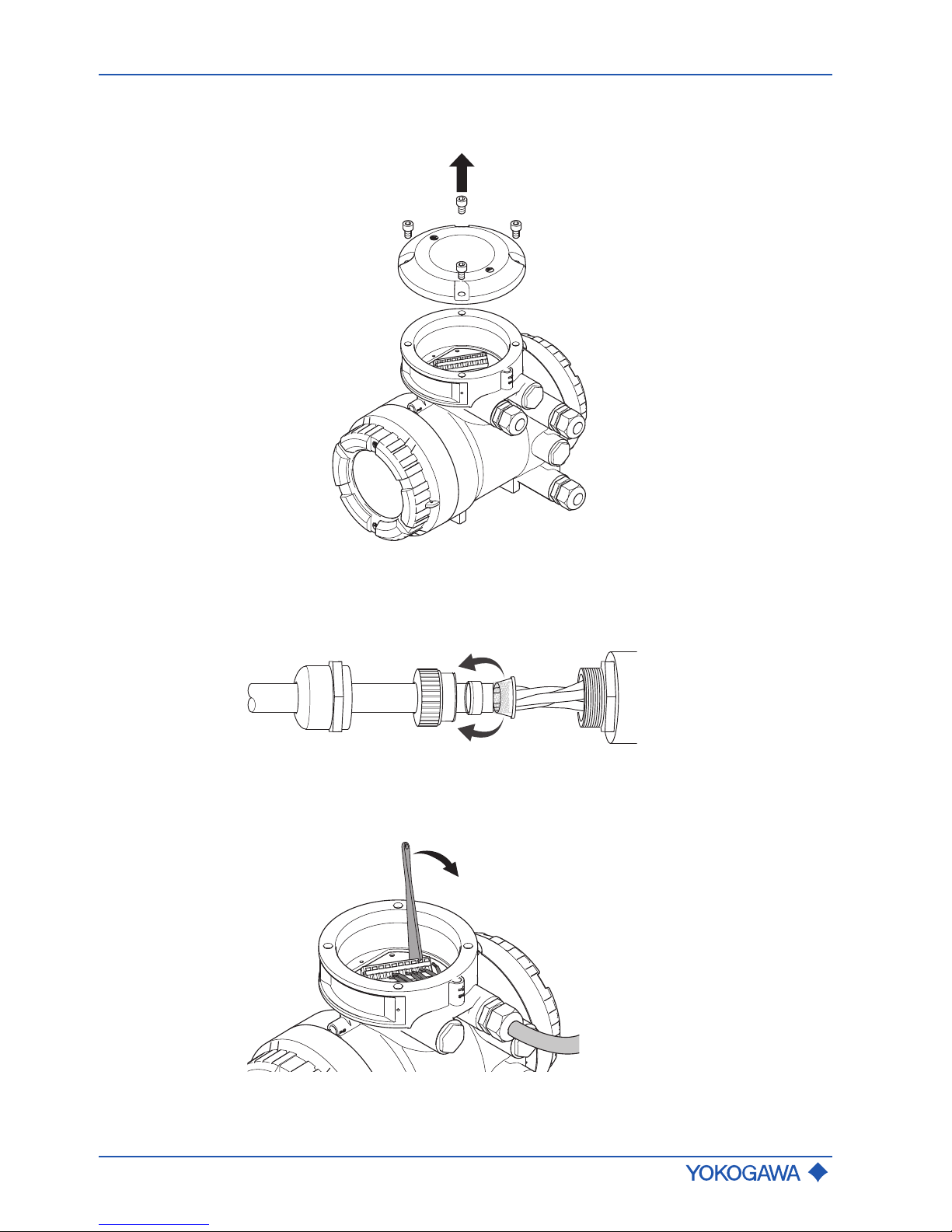

6.5.1 Rotating and replacing the display

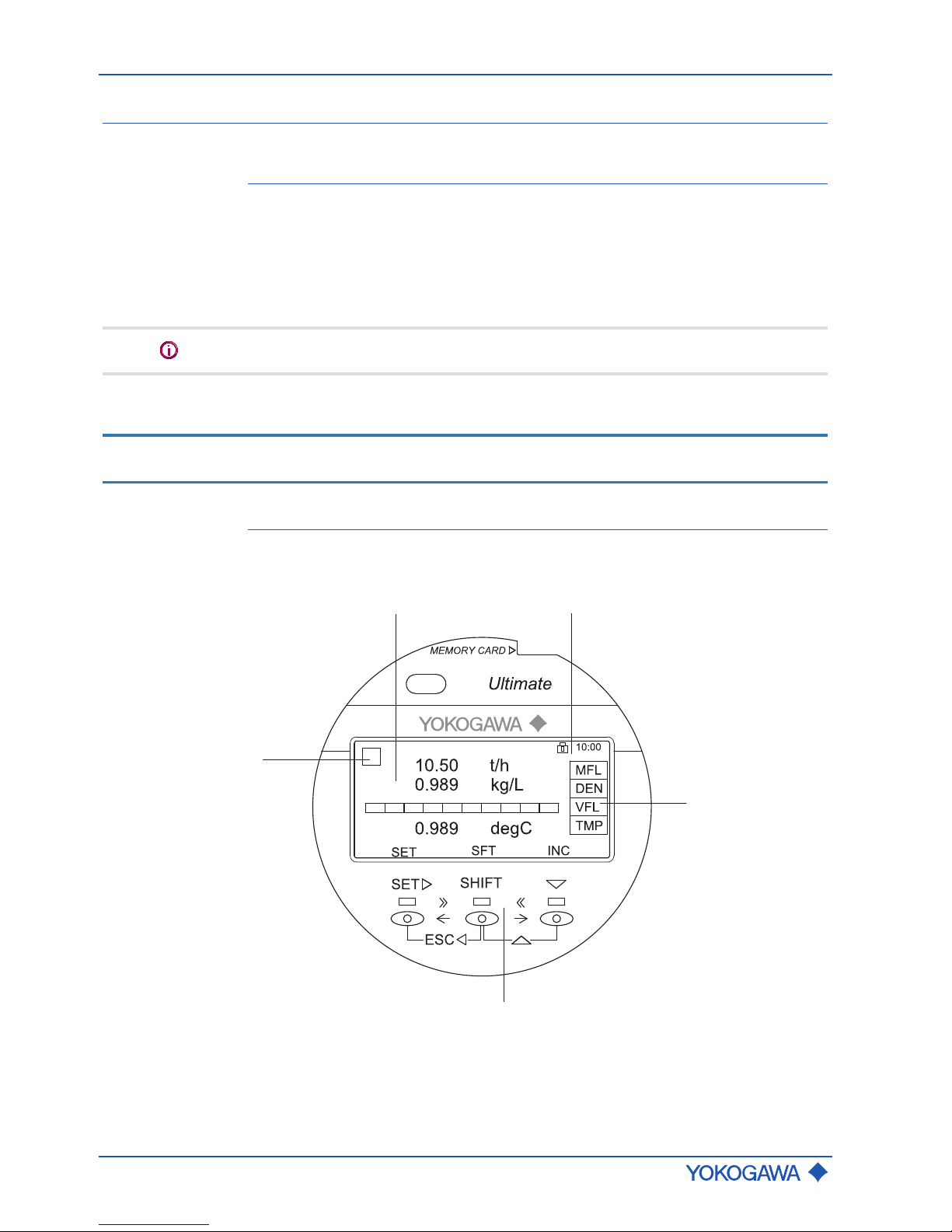

The transmitter display can be oriented in line with the flow meter installation position.

NOTICE

The following instruction must only be performed at the following ambient conditions:

▶ at temperatures up to 31°C: relative humidity maximum 80 %

▶ at temperatures between 31°C and 40°C: from 80 % linearly decreasing to 50 % of

maximum relative humidity

1. Switch off power supply.

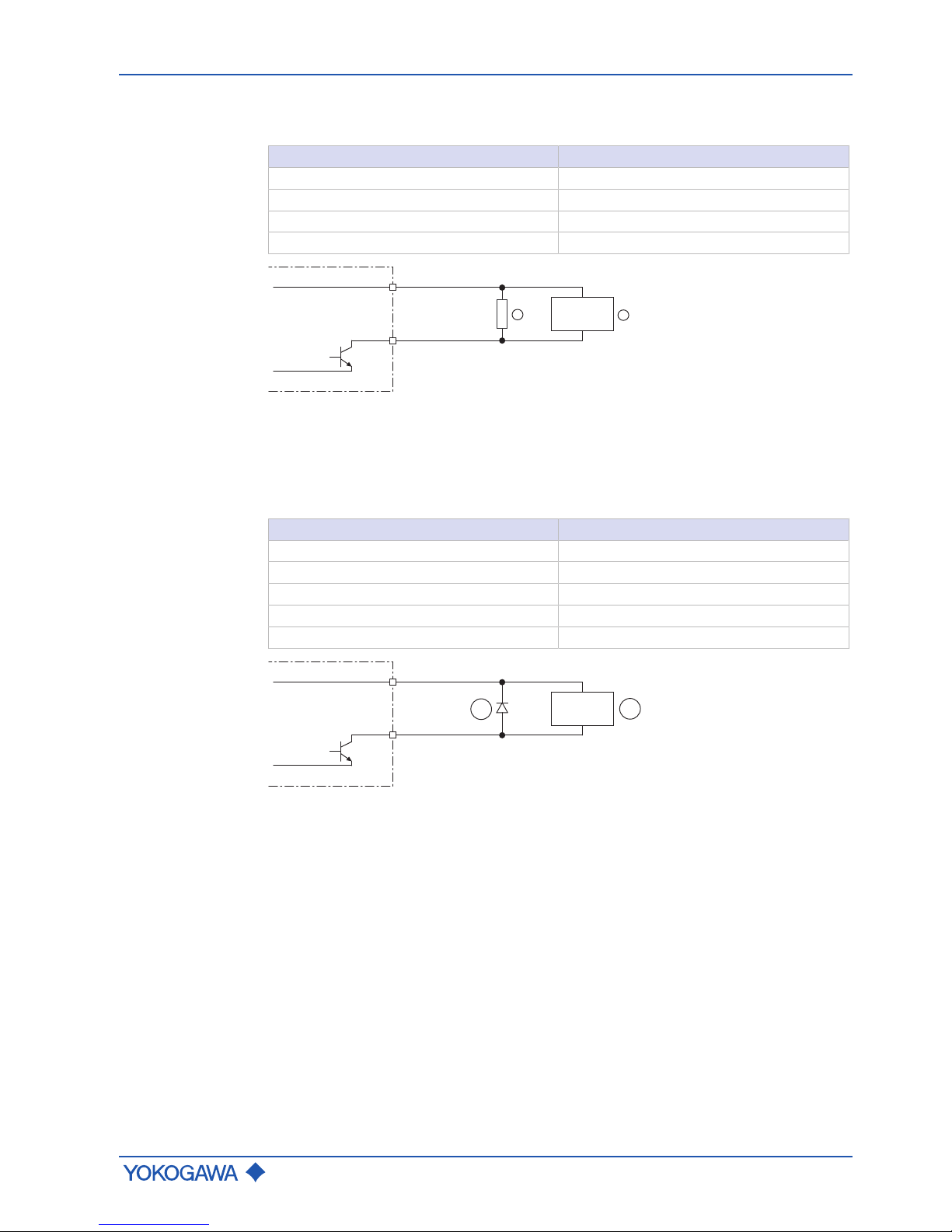

2. Using an Allen wrench (size: 3.0), turn the locking screw on display screw plug clockwise to remove.

3. Unscrew display cover from transmitter housing.

4. Remove the two screws from the display.

Page 34

General Instruction Manual

Installation

Transmitter installation

34 / 90

IM 01U10B00-00EN-R, 3rd edition, 2018-07-09

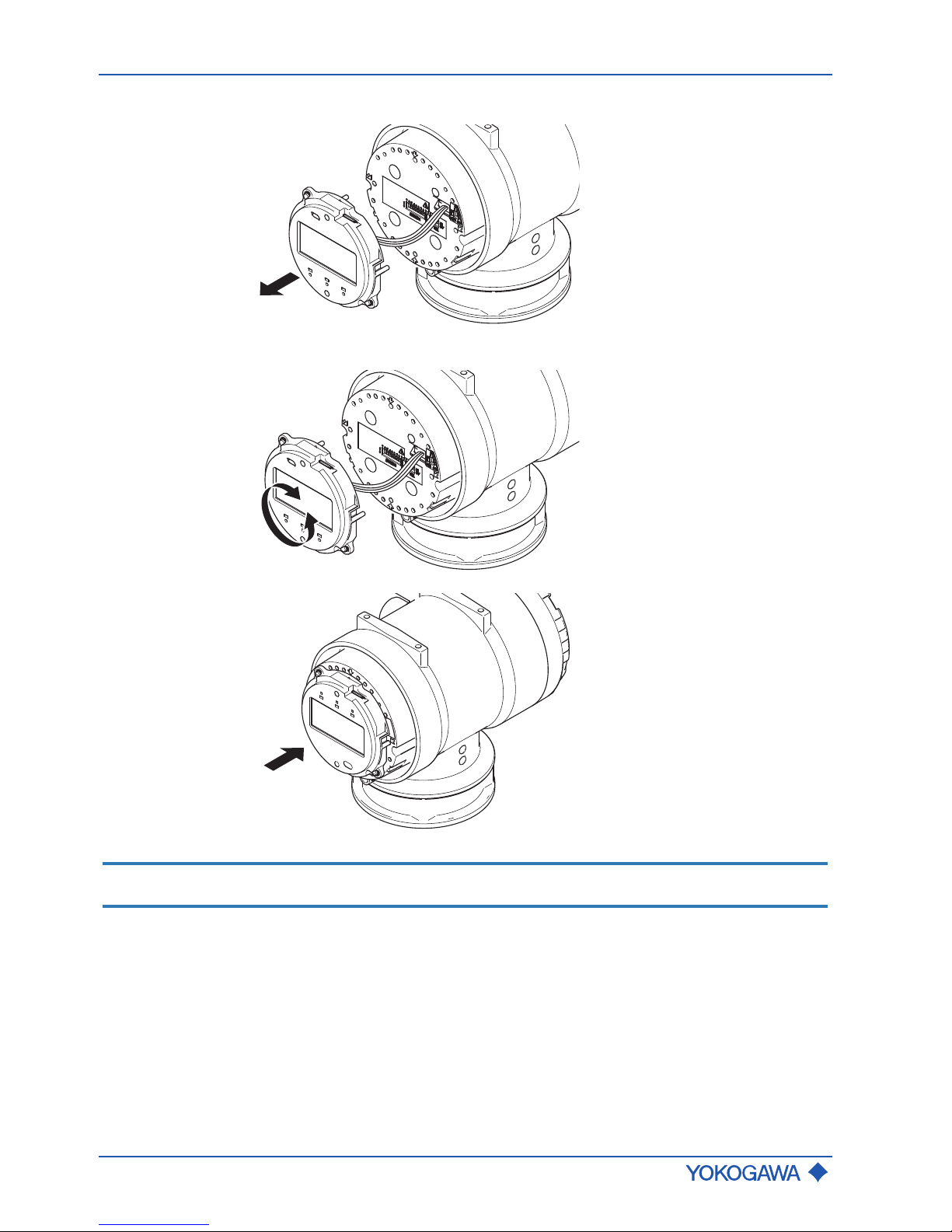

5. Remove the display from housing by pulling forward.

6. Rotate display and push back into housing in the orientation desired.

NOTICE

The display can be removed and replaced by loosening the connector.

Page 35

Transmitter installation

General Instruction Manual

Installation

IM 01U10B00-00EN-R, 3rd edition, 2018-07-09

35 / 90

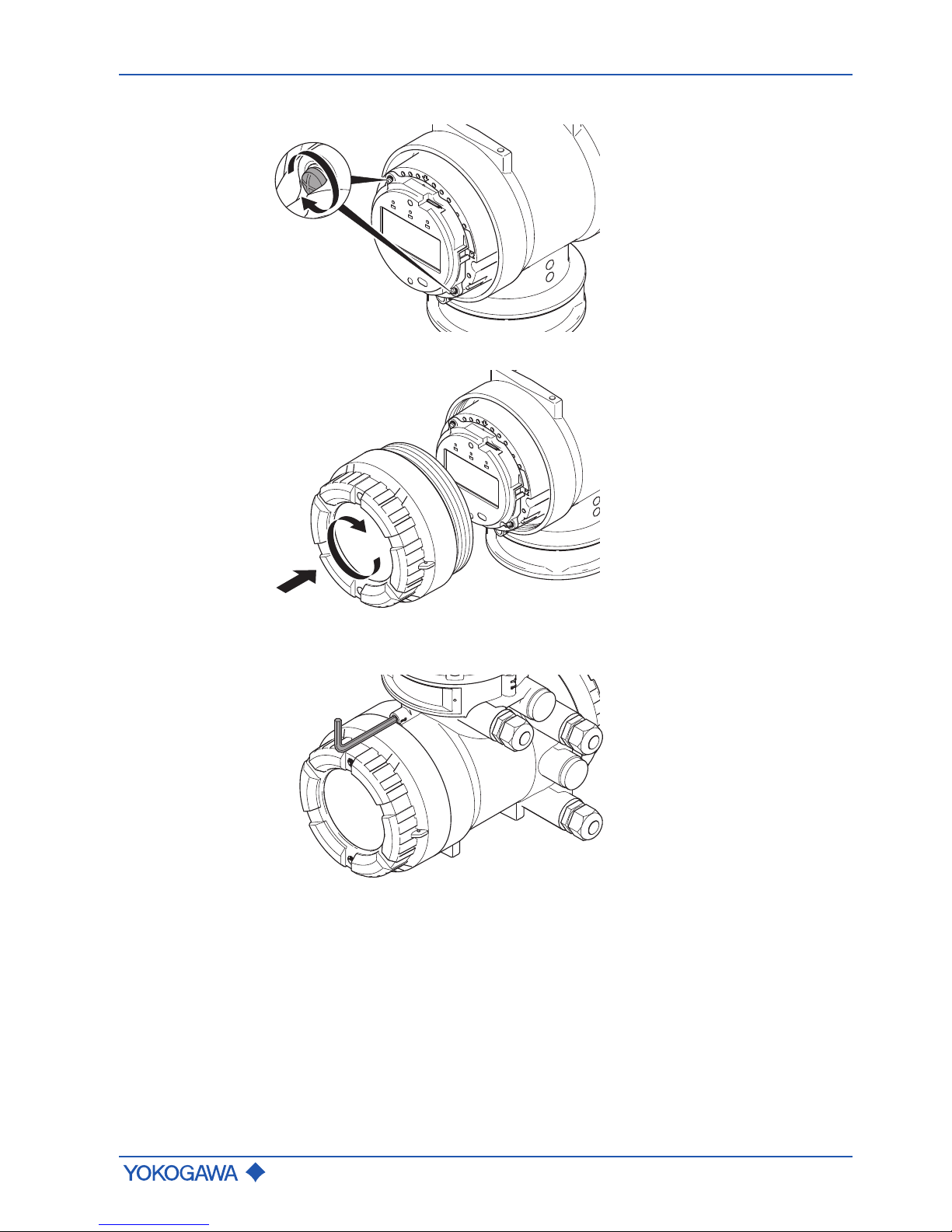

7. Tighten screws.

8. Screw display cover back onto transmitter housing.

9. Using an Allen wrench (size: 3.0), turn the locking screw on display screw plug

counter-clockwise to tighten.

Page 36

General Instruction Manual

Installation

Transmitter installation

36 / 90

IM 01U10B00-00EN-R, 3rd edition, 2018-07-09

6.5.2 Rotating transmitter housing (integral type)

The transmitter housing can be installed in any one of four orientations.

WARNING

Short-circuit hazard caused by penetrating water

Failure of measuring electronics

▶ In order to prevent any water from penetrating the flow meter by way of the cable,

install the transmitter in a way so that the cable gland is not pointed upward.

WARNING

Insufficient sensor grounding connection

Electric shock and ignition in hazardous areas

▶ Use a minimum torque of 4.3 Nm when tightening the screws.

NOTICE

Damage to flow meter

Rotating the transmitter housing several times in the same direction may damage the

connection between sensor and transmitter.

▶ Do not turn transmitter housing more than 270° in the same direction.

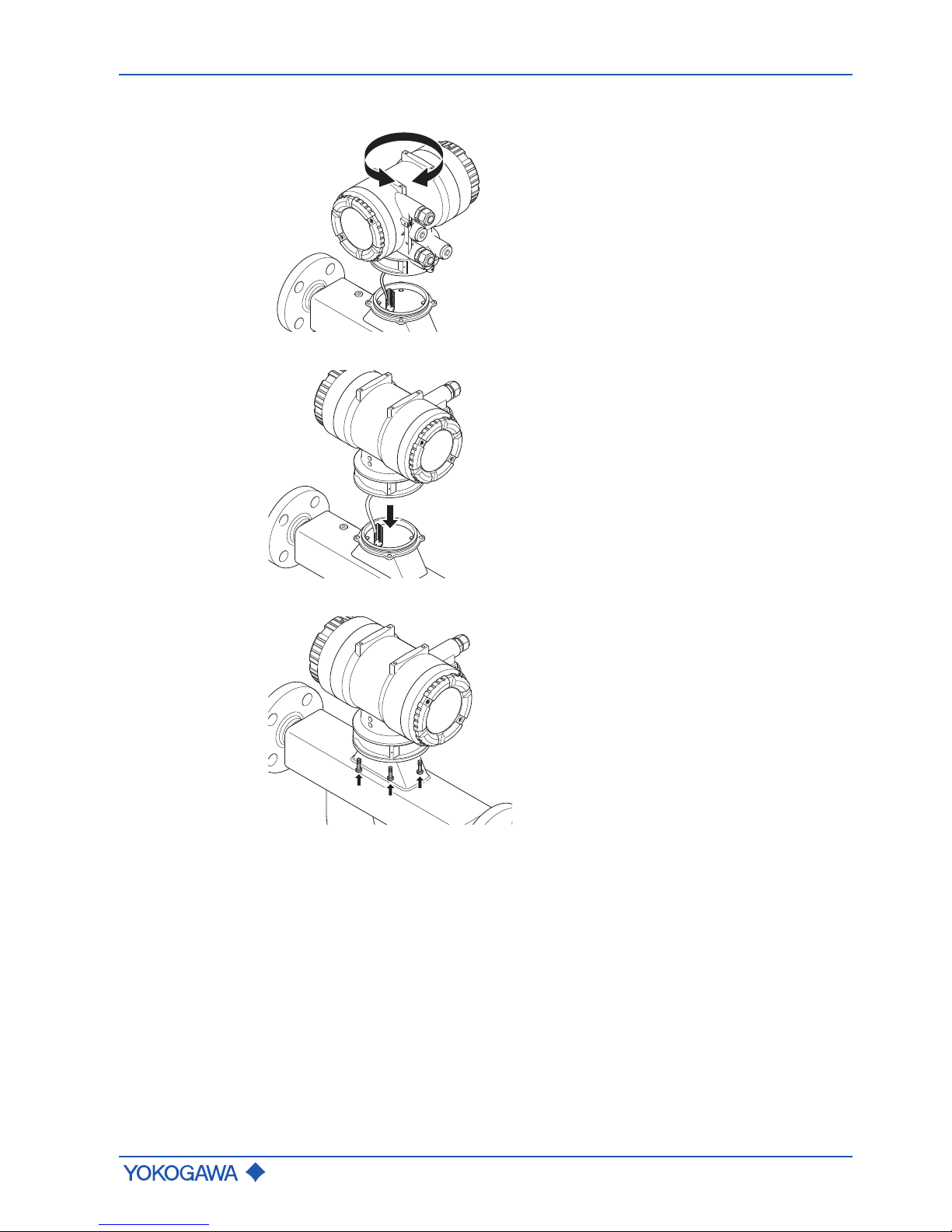

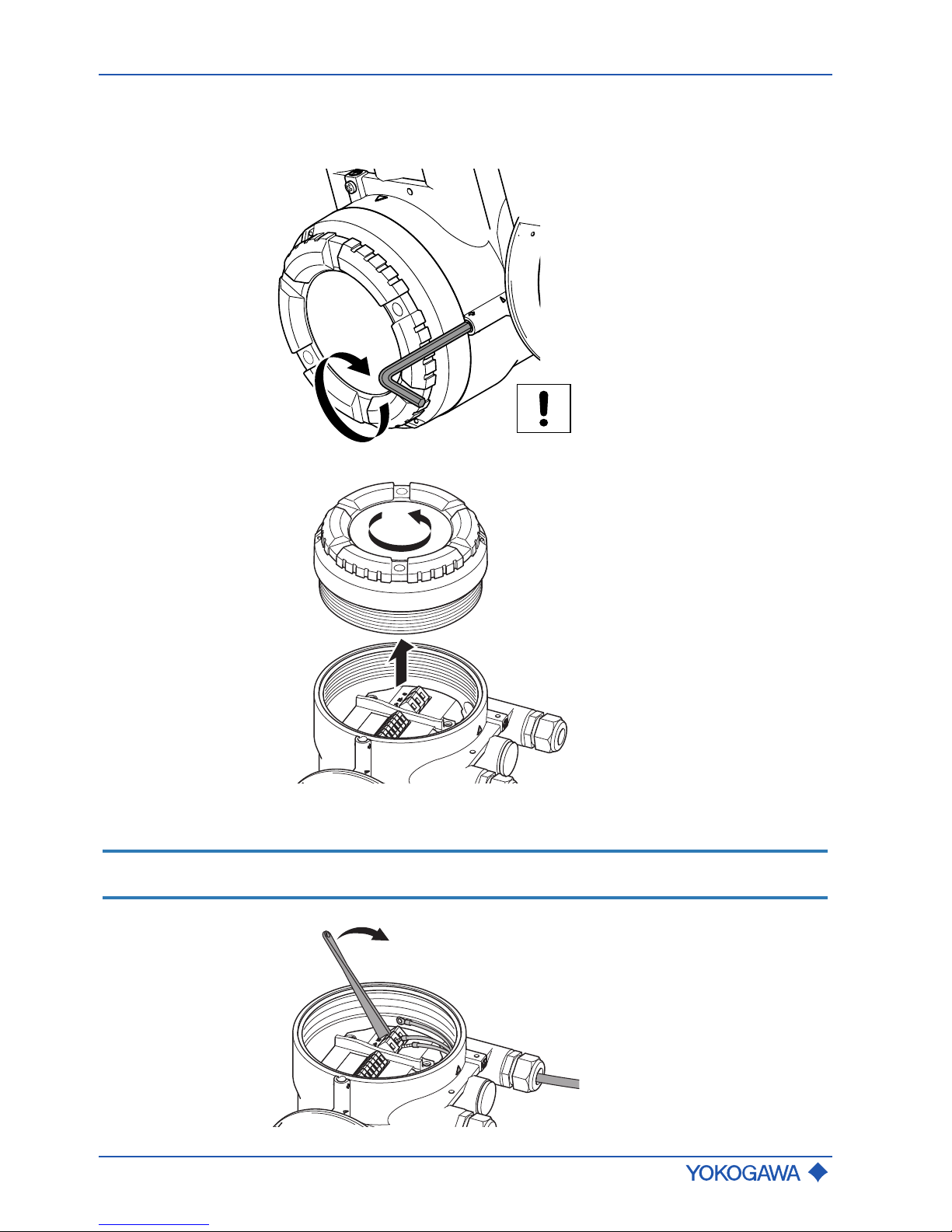

1. By using an Allen wrench (size: 5.0), remove the four fixing screws.

2. Lift transmitter housing.

Page 37

Transmitter installation

General Instruction Manual

Installation

IM 01U10B00-00EN-R, 3rd edition, 2018-07-09

37 / 90

3. Rotate transmitter housing at angles of 90°, 180° or 270°.

4. Place transmitter housing.

5. Tighten the four fixing screws.

Page 38

General Instruction Manual

Installation

Transmitter installation

38 / 90

IM 01U10B00-00EN-R, 3rd edition, 2018-07-09

6.5.3 Rotating the terminal box (remote type)

The terminal box can be installed in any one of four orientations.

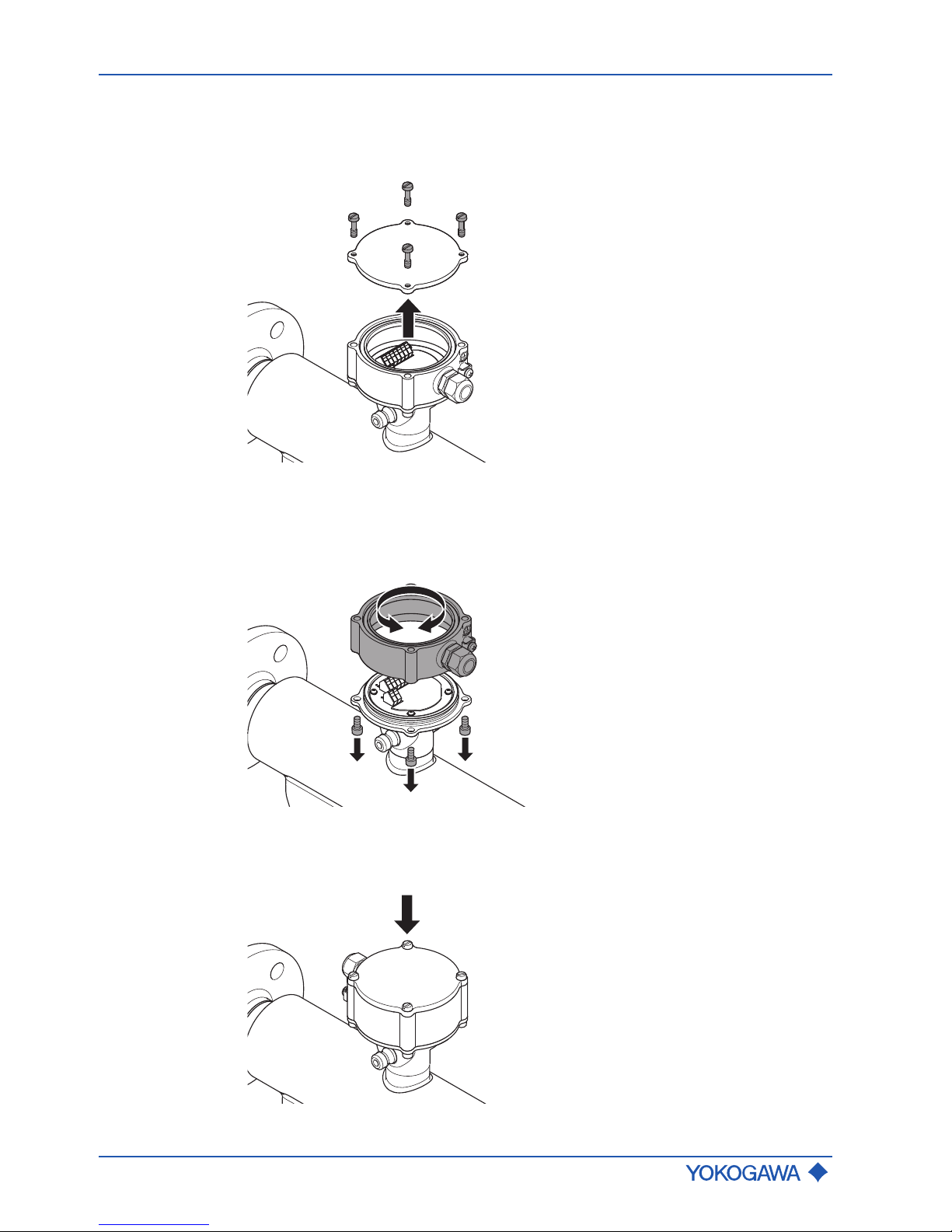

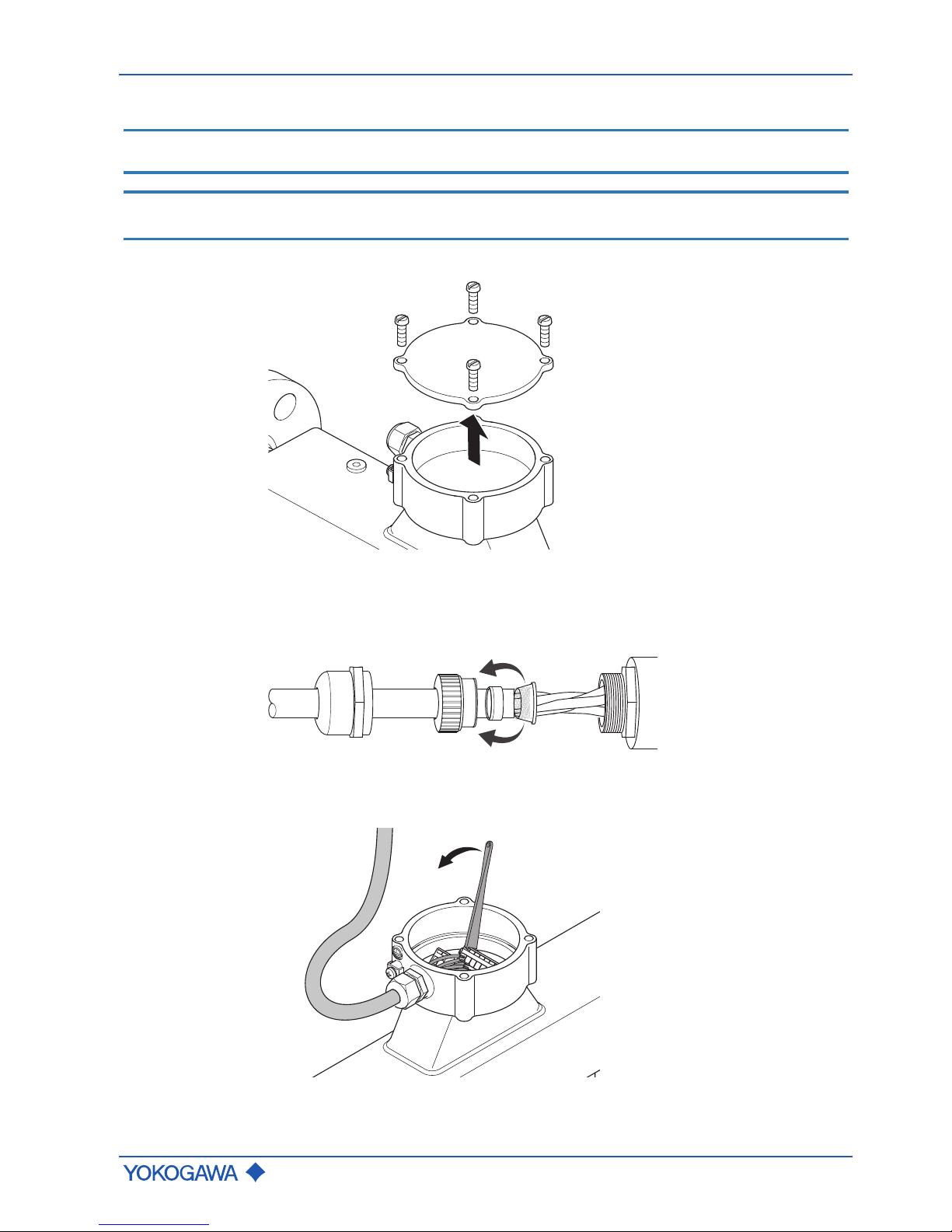

1. Loosen the four fixing screws and remove the cover.

2. Remove the cables so that none of the cables inside can accidentally become

trapped and damaged.

3. By using an Allen wrench (size: 5.0), remove the bottom fixing screws and rotate the

terminal box at an angle of 90°, 180° or 270°.

4. Place the terminal box and tighten the bottom fixing screws using a minimum torque

of 7.4Nm.

5. Attach the cover and tighten the fixing screws using a minimum torque of 7.4Nm.

Page 39

Transmitter installation

General Instruction Manual

Installation

IM 01U10B00-00EN-R, 3rd edition, 2018-07-09

39 / 90

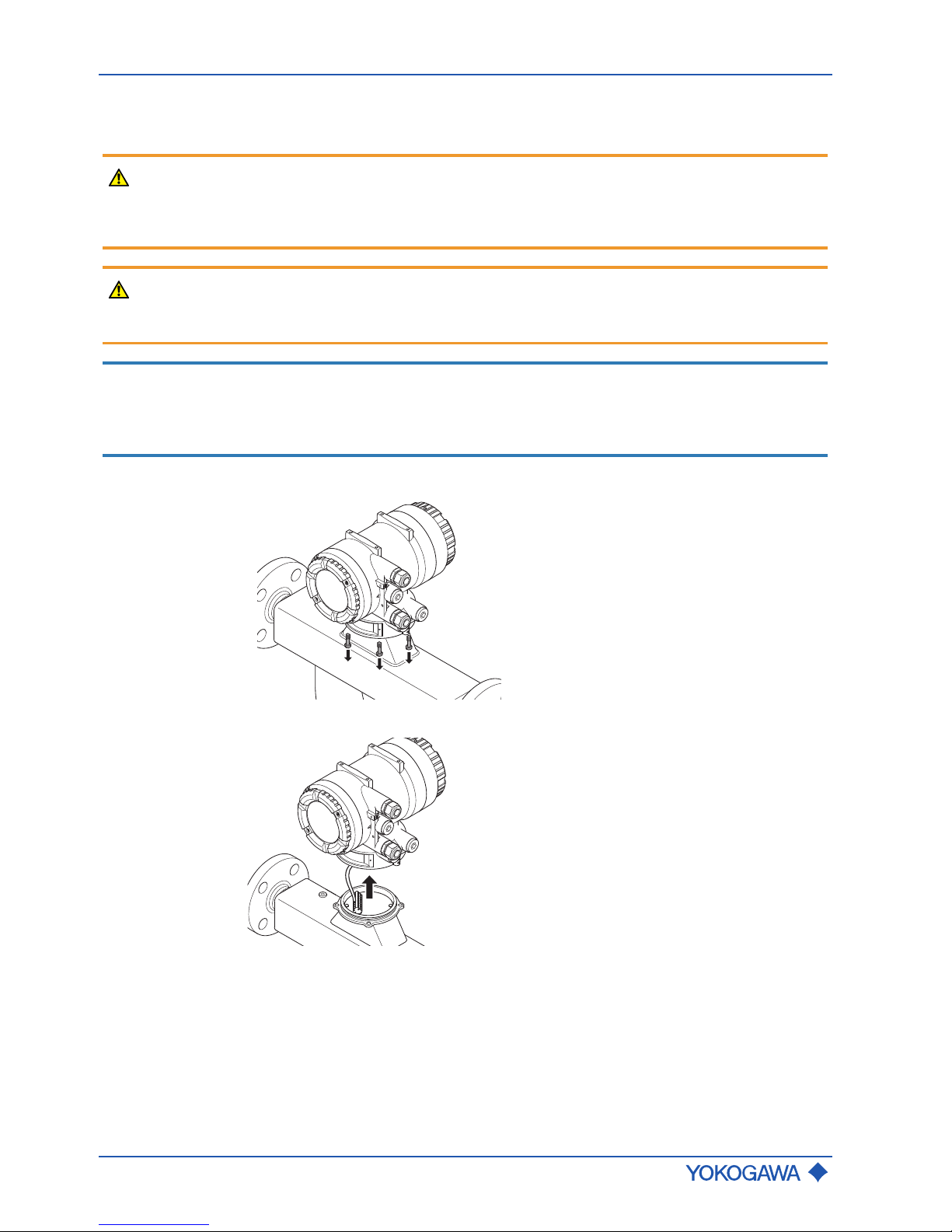

6.5.4 Installing transmitter on pipe (remote type)

WARNING

Risk of overheating the transmitter due to increased ambient temperature

Failure of measuring electronics

▶ Observe the maximum allowable ambient temperature for the transmitter.

▶ Install the transmitter at a sufficient distance from heat sources. Also note the tem-

perature of the fixing pipe.

WARNING

Short-circuit hazard caused by penetrating water

Failure of measuring electronics

▶ In order to prevent any water from penetrating the flow meter by way of the cable,

install the transmitter in a way so that the cable gland is not pointed upward.

CAUTION

Risk of injury and damage to the flow, meter if it is insufficiently attached to

the pipe

▶ Observe the installation notes below.

▶ Tighten screws by using a minimum torque of 7.4 Nm.

NOTICE

Installation at high vibration levels

The mounting bracket for the pipe installation of the transmitter may not be suitable for installation environments with very high levels of vibration. In this case the user is advised

to employ more rugged methods of fixation using the threaded bottom holes directly.

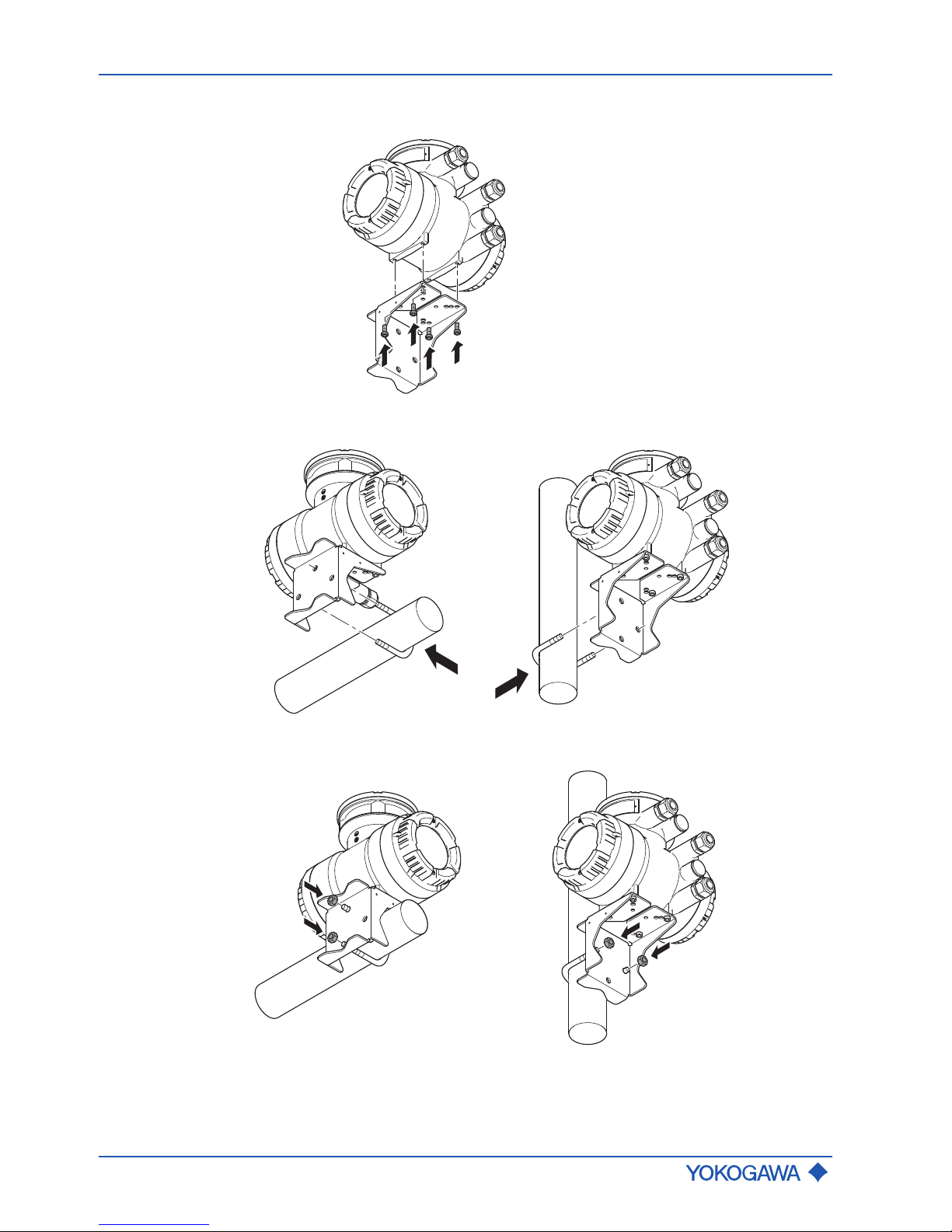

If it is a remote type transmitter, it can be mounted to a pipe size DN50 (2") using the angle bracket and retaining clip included in the delivery.

Page 40

General Instruction Manual

Installation

Transmitter installation

40 / 90

IM 01U10B00-00EN-R, 3rd edition, 2018-07-09

1. Screw angle bracket to bottom of transmitter.

2. Place retaining clip around pipe and slide through drill holes on angle bracket.

3. Fasten retaining clip to bracket using the nuts.

Page 41

Installation check list

General Instruction Manual

Installation

IM 01U10B00-00EN-R, 3rd edition, 2018-07-09

41 / 90

6.6 Installation check list

The following checks must be performed once the flow meter is installed in the pipe:

Check Performed?

State and specification of device

▪ Flow meter checked for external damage?

▪ Does flow meter meet the specifications of the measuring point

(process fluid temperature, process pressure, ambient temperature, measuring range, etc.)?

Installation

▪ Does flow direction on flow meter correspond to the actual flow di-

rection in the pipe?

▪ If not, has the appropriate parameter in the transmitter menu been

switched?

▪ Do measuring point number and nameplate labeling match the in-

stallation site?

▪ Do mounting position and installation match usage (measurement

of gas, liquid) in the process environment and under process conditions?

▪ Is meeting the permissible ambient temperature for the transmitter

ensured?

Process environment and conditions

▪ Is the flow meter protected from environmental influences (precipi-

tation, direct insolation)?

Page 42

General Instruction Manual

Wiring

General wiring rules

42 / 90

IM 01U10B00-00EN-R, 3rd edition, 2018-07-09

7 Wiring

7.1 General wiring rules

Be sure to handle the transmitter cover carefully so that there are no damages and foreign matter adhesion at its thread and O-ring when it is opened or attached.

DANGER

Life-threatening injuries from electric shock

▶ Switch off power supply.

▶ Secure power supply against inadvertent switch-on.

▶ Check that power supply is free of voltage.

DANGER

Life-threatening injuries from ignition of explosive atmospheres

▶ Wait 20 minutes before opening the housing until the capacitors have discharged

and components have cooled off.

▶ Avoid electrostatically charging the device, e.g. by rubbing it with dry cloths.

DANGER

Explosion hazard from electrostatic discharge or brush discharge

Life-threatening injuries or ignition of explosive atmospheres

▶ Avoid actions that could lead to electrostatic discharges. For example, do not wipe

the coated surface of the transmitter using a piece of cloth.

DANGER

When connecting flow meters in hazardous areas, the applicable Explosion Proof Type

Manual must be observed.

WARNING

Risk of injury due to electrical shock

▶ Only have skilled personnel to connect the flow meter.

▶ Do not perform wiring outdoors if it is raining.

WARNING

Risk of injury due to electrical shock, as well as sparking and damage to

the flow meter, if an inappropriate connecting cable is used

▶ It is imperative to adhere to the cable diameter of 0.5 – 2.5 mm for sensor and trans-

mitter connection terminals. When using Litz wire, it must be combined with wire end

ferrules.

▶ The outer cable diameter must meet the specification of the cable glands used.

▶ Install cables tension-free.

WARNING

Risk of sparking and damage to the flow meter due to incorrect wiring

▶ Observe connection diagram for the connecting cable according to chapter Connec-

tion terminals [}46] and Connection terminals [}51].

Page 43

General wiring rules

General Instruction Manual

Wiring

IM 01U10B00-00EN-R, 3rd edition, 2018-07-09

43 / 90

WARNING

Risk of injury due to electrical shock, as well as damage to the flow meter

due to insufficient clamping of the connecting wires

▶ Completely open connection terminal by using the operating tool.

▶ Insert connecting wires with wire end ferrules into the corresponding connection ter-

minal up to the stop.

▶ Close connection terminal.

CAUTION

Don't install the connecting cable at ambient temperatures below -10 °C.

NOTICE

Wiring Work must only be performed at max. 80 % humidity and temperatures up to

31°C, linearly decreasing to 50 % relative humidity at 40°C.

NOTICE

Be aware that conducted and radiated electromagnetic emission may effect the EMC of

adjacent areas.

NOTICE

Be aware that improper earthing, false wiring and use of cable out of specification may

lead to instrument damage and/or disturbance of other sensitive electrical equipment due

to increased electromagnetic emissions/immunity.

NOTICE

Be aware that wrong input voltage may lead to disturbance of other sensitive electrical

equipment due to increased electromagnetic emissions.

▶ The applicable national standards must be considered for installation.

▶ Only sensors and transmitters with compatible model codes may be interconnected. If

these instructions are not observed, flawless function of the flow meter cannot be

guaranteed.

▶ In case of cabling in pipes (Conduit), guide the pipe through the opening in the wiring

and use watertight gaskets to avoid that water runs in. Install the installation pipe at

an angle, as shown in the figure below. Install a drain valve in the bottom end of the

vertical pipe and regularly open that valve.

Drain valve

▶ Unused cable entries must be closed using blind plugs.

▶ Install cables hanging down to prevent water from flowing along the cable into the

flow meter.

▶ The electrical connection between potential equalization system and grounding

connection must be safe, see Grounding connections and sensor circuits [}44].

▶ Ensure that housing gaskets are positioned in the lining grooves and not damaged.

Page 44

General Instruction Manual

Wiring

Grounding connections and sensor circuits

44 / 90

IM 01U10B00-00EN-R, 3rd edition, 2018-07-09

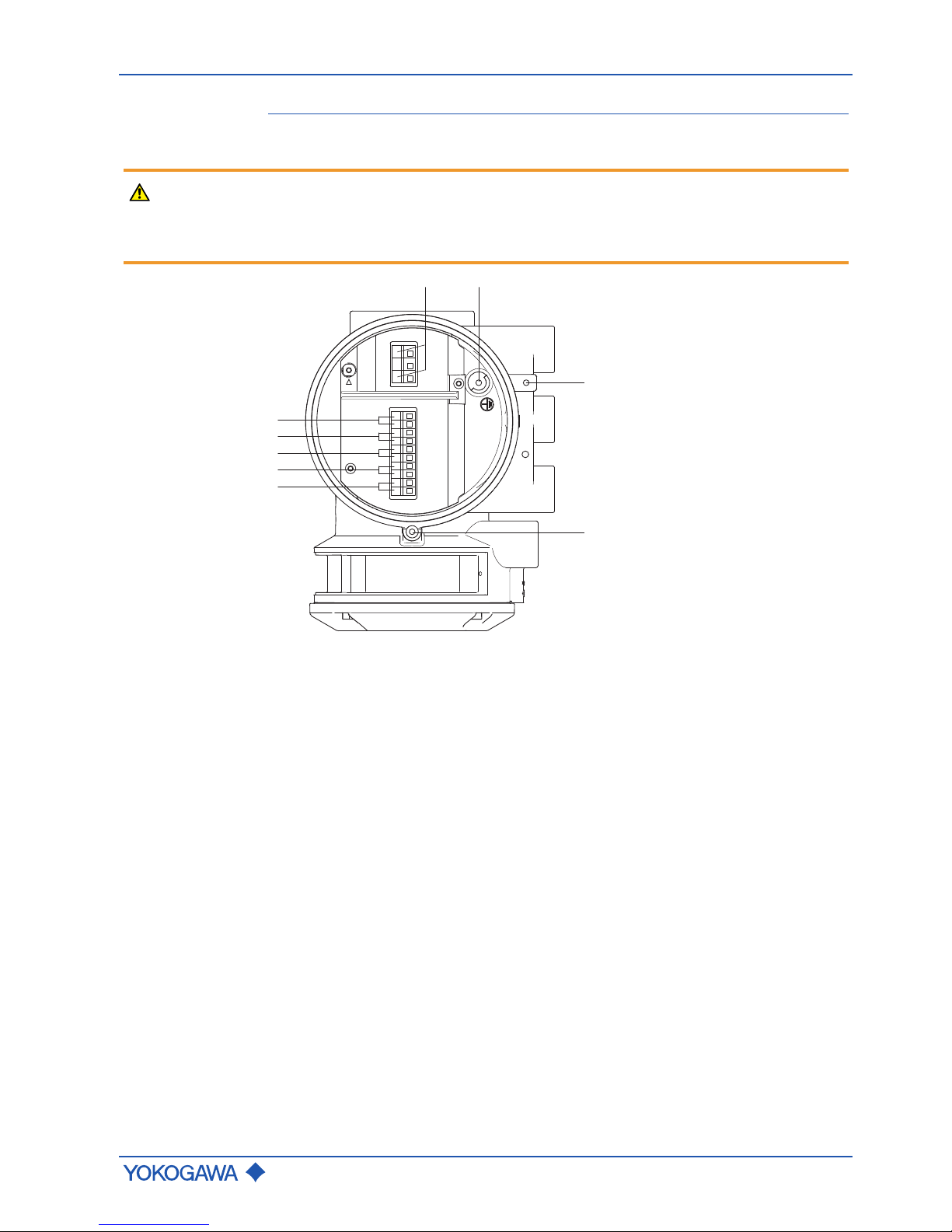

7.2 Grounding connections and sensor circuits

WARNING

Risk of injury from electrical shock due to inadequate grounding

▶ Perform potential equalization at the grounding terminals provided for this purpose

according to the figure “Grounding connections on transmitter and sensor”.

3

2

1

Fig.27: Grounding connections on transmitter and sensor

1 Grounding screw in transmitter terminal box for grounding conductor

2 Grounding terminal on transmitter for potential equalization

3 Grounding terminal on sensor for potential equalization

D +

D -

S1 +

S1 -

S2 +

S2 -

TP1

TP2

TP3

D +

D -

S1 +

S1 -

S2 +

S2 -

TP1

TP2

TP3

COM

3 2 1

1 2 3 4 5 6

Fig.28: Connection terminal circuits (transmitter on the left side, sensor on the right side)

1 Driver circuit (D+/D-) 4 Signal grounding

2 Sensor circuits (S1+/S1-, S2+/S2-) 5 Transmitter

3 Temperature measurement circuit

(TP1, TP2, TP3)

6 Sensor

Page 45

Connecting cable installation

General Instruction Manual

Wiring

IM 01U10B00-00EN-R, 3rd edition, 2018-07-09

45 / 90

7.3 Connecting cable installation

With remote type flow meters, sensors and transmitters are connected by means of connecting cables.

CAUTION

Risk of damage to the flow meter due to incorrect sealing

In case of metric cable entry ensure appropriate IP rating and suitability of O-ring of used

accessory (e.g. cable glands).

In case of NPT cable entry ensure appropriate sealing measures (e.g. use of sealing

tape).

In order to obtain optimum measuring results and ensure compliance with the specification, it is imperative that an original connecting cable and original glands from Rota Yokogawa are used. In order to ensure the IP code, the cable must be professionally installed

at the entries. If necessary, the cable may be shortened using the enclosed termination

kit. Refer to the cable termination instructions enclose to each termination kit that is attached to each cable.

1 2 3

4

7 8

65

Fig.29: Cable gland parts mounting

1 Cap nut 5 Outer cable shield

2 Connecting cable 6 Outer cone part

3 Plastic part 7 Mounting thread

4 Inner cone part 8 Housing cable entry

If the connecting cable, included in the delivery, is too short, additional lengths can be

procured through the Yokogawa sales organization.

Page 46

General Instruction Manual

Wiring

Connecting cable installation

46 / 90

IM 01U10B00-00EN-R, 3rd edition, 2018-07-09

7.3.1 Connection terminals

The delivery includes an operating tool for connecting the connecting cable to the

connection terminals.

D +

D -

S1 +

S1 -

S2 +

S2 -

TP1

TP2

TP3

D +

D -

S1 +

S1 -

S2 +

S2 -

TP1

TP2

TP3

COM

3 2 1

1 2 3 4 5 6

Fig.30: Connection terminal circuits (transmitter on the left side, sensor on the right side)

1 Driver circuit (D+/D-) 4 Signal grounding

2 Sensor circuits (S1+/S1-, S2+/S2-) 5 Transmitter

3 Temperature measurement circuit

(TP1, TP2, TP3)

6 Sensor

Installation of

standard connecting

cable option L

␣␣␣

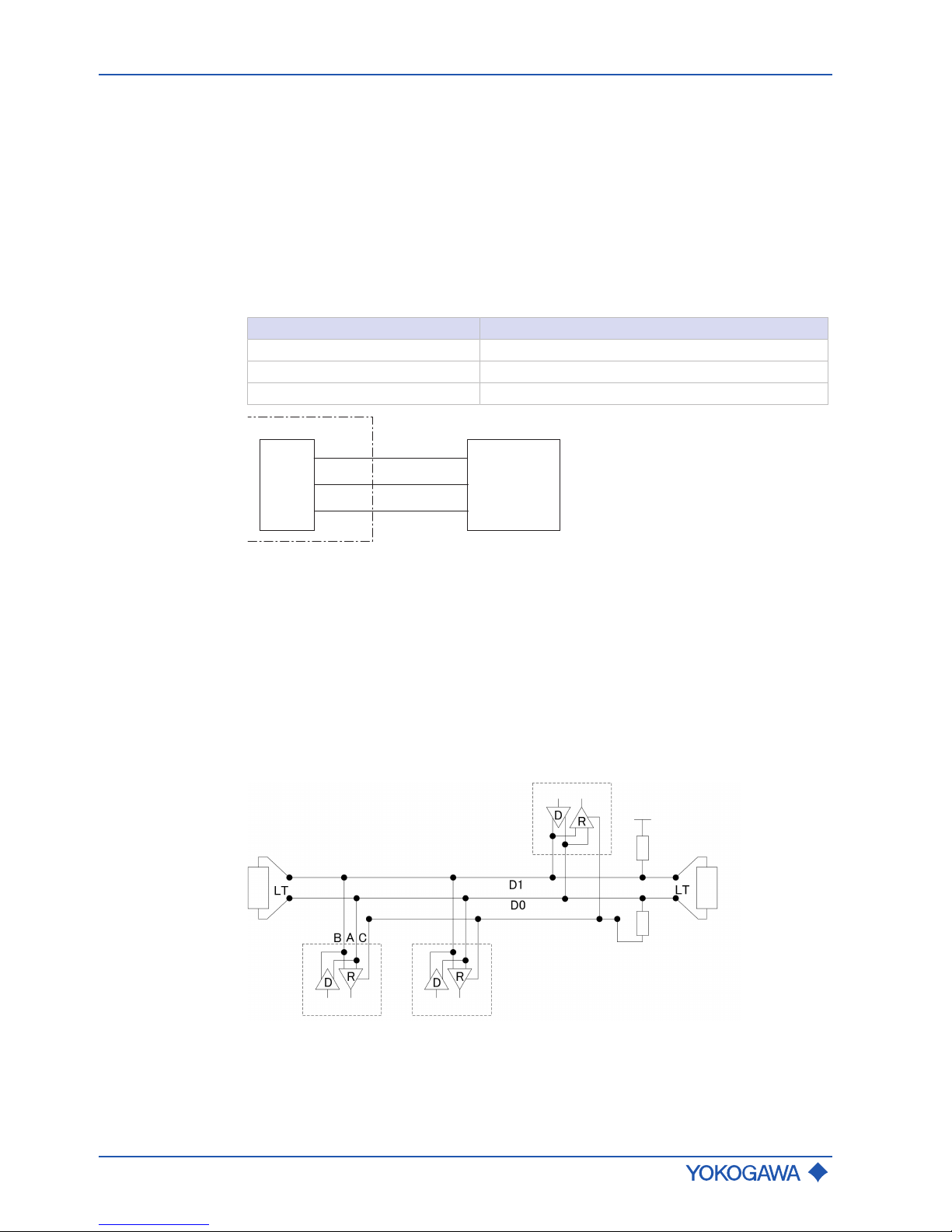

Fig.31: Transmitter and sensor interconnection diagram

1 Sensor

2 Transmitter

3 Potential equalization system

Page 47

Connecting cable installation

General Instruction Manual

Wiring

IM 01U10B00-00EN-R, 3rd edition, 2018-07-09

47 / 90

green

red

blue

white

brown

yellow

drain

wire

Fig.32: Terminated standard connecting cable L␣␣␣, transmitter side

Connection scheme of standard connecting cable option L␣␣␣

Standard connecting cable option L

␣␣␣

Signal Coaxial wire

Coaxial wire pair colour Wire type Wire colour

D+

green

Core wire transparent

D- Shield black

S1+

red

Core wire transparent

S1- Shield black

S2+

blue

Core wire transparent

S2- Shield black

Standard connecting cable option L

␣␣␣

Signal Single wire

Wire type Wire colour

TP1

Conductor

white

brownTP2

TP3 yellow

COM

1)

Drain wire

1)

–

1)

Present only at transmitter side

Page 48

General Instruction Manual

Wiring

Connecting cable installation

48 / 90

IM 01U10B00-00EN-R, 3rd edition, 2018-07-09

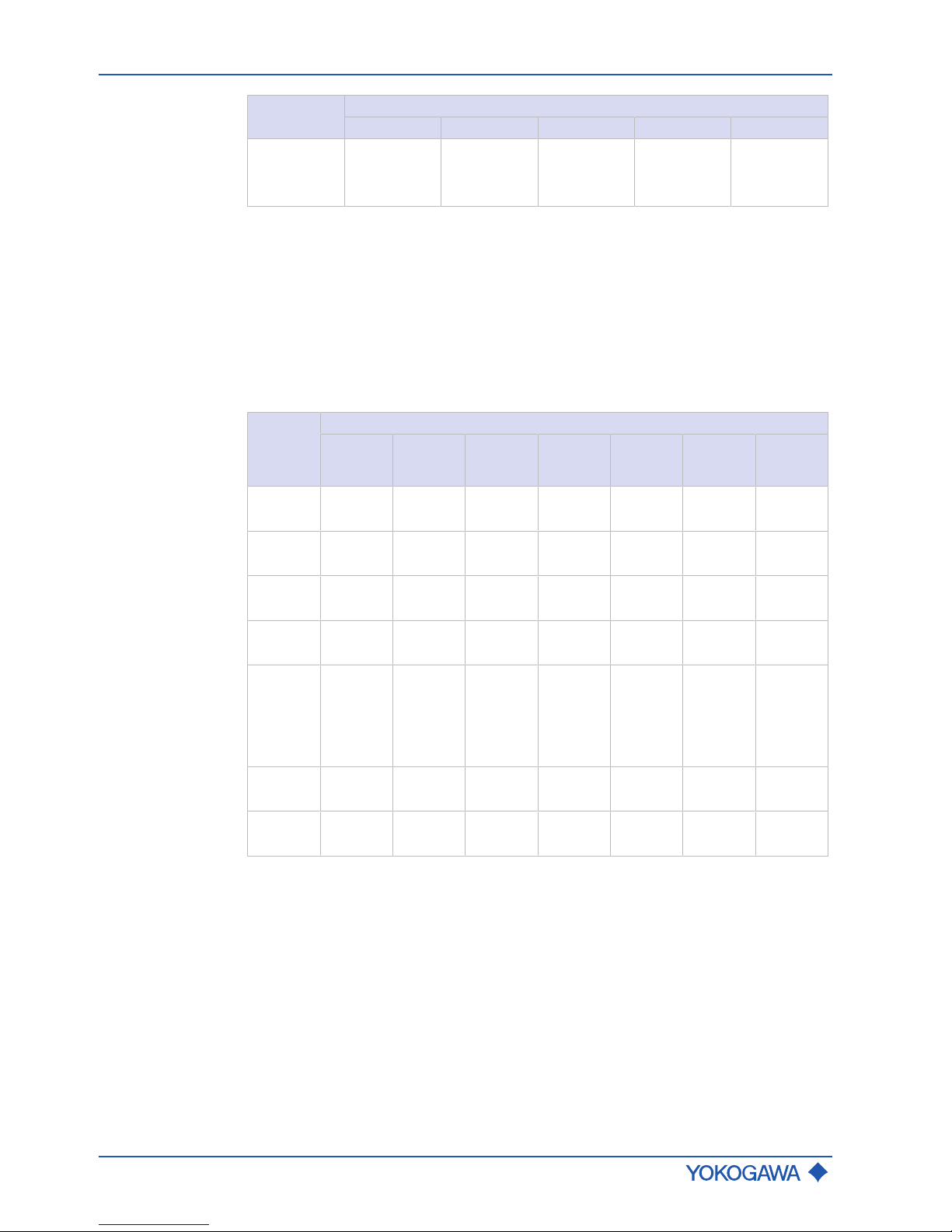

Installation of fire

retardant connecting

cable option Y

␣␣␣

1 2

3

D+

D–

S1+

S1–

S2+

S2–

TP1

TP2

TP3

D+

D–

S1+

S1–

S2+

S2–

TP1

TP2

TP3

COM

Fig.33: Transmitter and sensor interconnection diagram

1 Sensor

2 Transmitter

3 Potential equalization system

2

4

5

3

Shield wire

1

Fig.34: Terminated fire retardant connecting cable Y␣␣␣, transmitter side

Connection scheme of fire retardant connecting cable option Y␣␣␣

Y

␣␣␣

-cable

Signal Conductor pair number

1)

Conductor colour

D+

1

white

D- blue

S1+

2

white

S1- blue

S2+

3

white

S2- blue

TP1

4

white

TP2 blue

TP3 5 white

COM

2)

Shield wire

2)

–

1)