Page 1

Technical

Information

TI 32S01J10-01E

ProSafe-RS

Installation Guidance

Yokogawa Electric Corporation

2-9-32, Nakacho, Musashino-shi, Tokyo, 180-8750 Japan

Tel.: 81-422-52-5634 Fax.: 81-422-52-9802

©Copyright Mar. 2005 (YK)

TI 32S01J10-01E

22nd Edition Aug. 2015 (YK)

Page 2

Blank Page

Page 3

Introduction

ProSafe-RS is a safety control system aimed at protecting people, environment, and equipment

from unexpected accidents or problems at a plant.

This manual describes the requirements for installation (control room size and power supply

requirements), storage and transportation, and wiring.

Chapter 1 System Installation Requirements

This chapter describes the engineering specications that cover the control room design/

environment, power supply system, grounding, noise prevention, corrosive-gas environment

compatibility and compliance with marine standards for the ProSafe-RS system.

Chapter 2 Transportation, Storage and Installation

This chapter describes precautions for the transport, unpacking and storage of the ProSafe-RS

system. This chapter also describes temperature and humidity changes when temporarily storing

the ProSafe-RS system, and how to install cabinets and rack mounted devices.

Chapter 3 Cabling

i

This chapter describes how to connect power, ground, signal and bus cables to the installed

devices, and how to connect optical ber cables.

Chapter 4 Installation Specications

This chapter covers the power consumption, power dissipation, in-rush current, and fuse and

breaker ratings as well as the parts that need replacement within 10 years. Read this section

when deciding the power supply capacity.

Chapter 5 Post-installation Inspection and Environmental Preservation

This chapter describes items that must be checked before turning on power and the precautions

to be taken to safeguard the environment after installing the system.

All Rights Reserved Copyright © 2005, Yokogawa Electric Corporation

TI 32S01J10-01E

Jun.18,2008-00

Page 4

Safety Precautions

Safety, Protection, and Modication of the Product

• In order to protect the system controlled by the product and the product itself and ensure

safe operation, observe the safety precautions described in this Technical Information

and the User’s Manuals. We assume no liability for safety if users fail to observe these

instructions when operating the product.

• If this product is used in a manner not specied in this Technical Information, the protection

provided by this product may be impaired.

• If any protection or safety circuit is required for the system controlled by the product or for

the product itself, prepare it separately.

• Be sure to use the spare parts approved by Yokogawa Electric Corporation (hereafter

simply referred to as YOKOGAWA) when replacing parts or consumables.

• Do not use the accessories (Power supply cord set, etc.) that came with the product for any

other products.

• Modication of the product is strictly prohibited.

• The following symbols are used in the product and this Technical Information to indicate that

there are precautions for safety:

ii

Indicates that a caution must be given for operation. This symbol is placed on the product

where the user is recommended to refer to the instruction manual in order to protect the

operator and the equipment against dangers such as electrical shocks. In the instruction

manuals you will nd precautions to avoid physical injury or death to the operator,

including electrical shocks.

Indicates that caution is required for hot surface. Note that the devices with this symbol

become hot. The risk of burn injury or some damages exists if the devices are touched or

contacted.

Identies a protective conductor terminal. Ensure to ground the protective conductor

terminal to avoid electric shock before using the product.

Identies a functional grounding terminal. A term “FG” is also used. This terminal is

equipped with the same function and used for purposes other than the protective

grounding. Before using the product, ground the terminal.

Indicates an AC supply.

Indicates a DC supply.

Indicates that the main switch is ON.

Indicates that the main switch is OFF.

TI 32S01J10-01E

Aug. 31, 2015-00

Page 5

Symbol Marks of this Technical Information

CAUTION

Throughout this Technical Information, you will nd several different types of symbols are used to

identify different sections of text. This section describes these icons.

Identies instructions that must be observed in order to avoid physical injury and electric

shock or death to the operator.

IMPORTANT

Identies important information required to understand operations or functions.

TIP

Identies additional information.

SEE

ALSO

iii

Identies a source to be referred to.

TI 32S01J10-01E

Oct.1, 2014-00

Page 6

Cautions for Safely Applying the Device

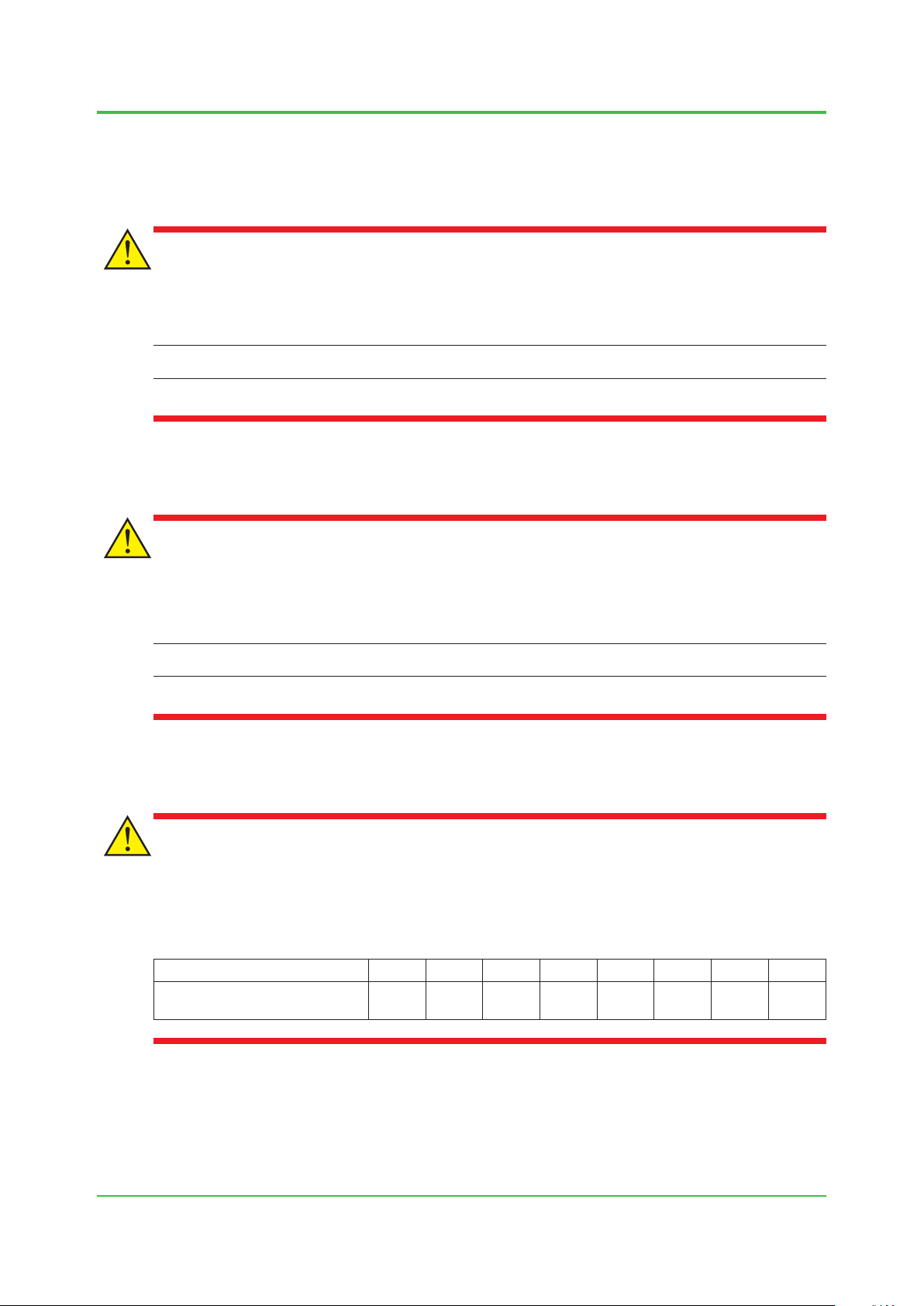

CAUTION

CAUTION

CAUTION

Wiring Power Cable

Connect the power cables according to the procedure in this document.

Power cables must conform to the safety standards of the country where the device is installed.

SEE

For Wiring Power Cable, refer to 3.2, “Connecting Power.”

ALSO

Earth Wiring

iv

This equipment requires a protective grounding dened by the safety standard.

Ground the device following the procedure in this document to prevent from electric shock and to

minimize the noise.

SEE

For Earth Wiring, refer to 3.3, “Connecting Ground Cable.”

ALSO

Tightening Torque of Screws

The tightening torque that the Product recommends is showed in the following table. However,

if the tightening torque of the screw is specied in the User’s Manuals, follow the instructions

described in the User’s Manuals.

Table Table of Recommended Tightening Torque

Nominal diameter of a screw M2.6 M3 M3.5 M4 M5 M6 M8 M10

Recommended tightening torque

(N•m)

0.35 0.6 0.8 1.2 2.8 3.0 12.0 24.0

TI 32S01J10-01E

Oct.1, 2014-00

Page 7

Battery

CAUTION

CAUTION

CAUTION

CAUTION

• Must use Yokogawa designated batteries.

• Mounting and changing batteries must follow the procedure in the hardware instruction

manual for each device.

• When changing batteries while the power supply is not shutdown, do not put hands inside of

the device since it is danger of electric shock.

Fan Unit

• When changing fan unit while the power supply is not shutdown, be careful not to touch other

parts so as to avoid electric shock.

v

SEE

For Fan Unit, refer to 4, “Installation Specications, Parts Durability.”

ALSO

Wiring I/O Cables

Wiring I/O cables must follow the procedure in this document.

SEE

For Wiring I/O Cables, refer to 3.5, “Connecting Signal Cable.”

ALSO

Connected Devices

To ensure this system’s compliance with the CSA safety standards, all devices connected to this

system shall be CSA certied devices.

TI 32S01J10-01E

Sep. 30, 2013-00

Page 8

Fuse Replacement

CAUTION

CAUTION

• Be sure to use the specied fuses.

• Switch off the power supply before exchanging the fuses.

Maintenance

• The maintenance work for the devices described in this manual should be performed only

by qualied personnel.

• When the device becomes dusty, use a vacuum cleaner or a soft cloth to clean it.

• During maintenance, put up wrist strap, and take other ESD (Electrostatic Discharge)

measures.

vi

• If the existing caution label is dirty and illegible, prepare a new label (part number: T9029BX)

to replace it.

SEE

For Maintenance, refer to 1.5.2, “Countermeasures against Static Electricity.”

ALSO

Drawing Conventions

Some drawings may be partially emphasized, simplied, or omitted, for the convenience of

description.

TI 32S01J10-01E

Sep. 30, 2013-00

Page 9

Trademark

Trademark

• ProSafe, CENTUM, PRM, STARDOM, FAST/TOOLS, Exaopc, FieldMate, and Vnet/IP are

either registered trademarks or trademarks of Yokogawa Electric Corporation.

• Other company and product names appearing in this document are registered trademarks

or trademarks of their respective holders.

• TM or ® mark are not used to indicate trademarks or registered trademarks in this

document.

• Logos and logo marks are not used in this document.

vii

TI 32S01J10-01E

Aug. 31, 2015-00

Page 10

Blank Page

Page 11

ProSafe-RS

Installation Guidance

TI 32S01J10-01E 22nd Edition

CONTENTS

1. System Installation Requirements ......................................................... 1-1

1.1 Control Room Design ....................................................................................... 1-2

1.2 Control Room Environment .............................................................................1-5

1.3 Power Supply System .................................................................................... 1-11

1.4 Grounding ........................................................................................................ 1-16

1.5 Noise Countermeasures ................................................................................ 1-19

1.5.1 Noise Sources and Noise Countermeasures .................................. 1-20

1.5.2 Countermeasures against Static Electricity ..................................... 1-24

1.6 Cabling Requirements .................................................................................... 1-25

1.7 Corrosive-gas Environment Compatibility ..................................................1-27

1.8 Compliance with Marine Standards .............................................................. 1-30

Toc-1

2. Transportation, Storage and Installation ............................................... 2-1

2.1 Precautions for Transportation ....................................................................... 2-2

2.2 Unpacking .......................................................................................................... 2-3

2.3 Storage ............................................................................................................... 2-4

2.4 Servicing Area ................................................................................................... 2-5

2.5 Installation ......................................................................................................... 2-6

2.5.1 Installation on Floor ............................................................................ 2-7

2.5.2 Rack Mounting ................................................................................. 2-11

2.5.3 Installation Guideline for Cabinet ..................................................... 2-17

2.5.4 Desktop Equipment .........................................................................2-23

2.5.5 Installing Control Network Interface Card ........................................ 2-24

3. Cabling....................................................................................................... 3-1

3.1 Cables and Terminals ....................................................................................... 3-2

3.2 Connecting Power ............................................................................................ 3-5

3.3 Connecting Ground Cable ............................................................................. 3-11

3.4 Power and Ground Cabling ........................................................................... 3-12

3.5 Connecting Signal Cable ............................................................................... 3-22

3.6 Connecting Signal Cables to I/O Modules ................................................... 3-30

3.6.1 Combination of I/O Modules and Terminal Blocks ........................... 3-30

3.6.2 Signal Cable Connections ............................................................... 3-31

3.6.3 Connecting Signal Cables to I/O Modules ....................................... 3-33

TI 32S01J10-01E

Aug. 31, 2015-00

Page 12

Toc-2

3.7 Connecting Bus Cable ................................................................................... 3-50

3.7.1 Vnet/IP network ................................................................................ 3-50

3.7.2 V net ................................................................................................. 3-53

3.7.3 ESB Bus ........................................................................................... 3-61

3.7.4 Optical ESB Bus Repeater .............................................................. 3-63

3.8 Connecting Optical Fiber Cable .................................................................... 3-68

4. Installation Specications ....................................................................... 4-1

5. Post-installation Inspection and Environmental Preservation ........... 5-1

TI 32S01J10-01E Oct.1, 2014-00

Page 13

1. System Installation Requirements

1. System Installation Requirements

This section describes installation requirements such as environmental conditions,

required space and layout considerations, power consumption, cabling and grounding.

1-1

TI 32S01J10-01E

Mar.21,2005-00

Page 14

1. System Installation Requirements

1.1 Control Room Design

Control rooms, in which the system control equipment is to be installed, should be

designed in accordance with the following conditions:

General

In designing a control room, ensure adequate oor strength and air conditioning including dustand moisture-proong.

1-2

SEE

ALSO

• 1.1 Control Room Design Air Conditioner

• 1.2 Control Room Environment Air Purity

Applied Standards (Table Installation Environment Specications)

Floor Strength and Space

The oor should have adequate strength, and you should design the layout in accordance with

the weight and size of equipment to be installed.

SEE

ALSO

• For the maintenance space required, refer to 2.4, “Servicing Area.”

• For the weight and dimensions of standard equipment, refer to applicable general specications.

Floor Structure

To prevent damage to cables by operators and maintenance equipment, do not lay cables on the

oor.

Lay cables under the oor as follows:

• Provide an “accessible” oor which also facilitates maintenance work.

• Make cable pits under the oor if it is concrete.

Flooding- & Dust-proof Floor

To protect equipment and cables, design a ooding-proof oor.

After the cabling is completed, seal all cable conduits using putty to prevent intrusion of dust,

moisture, rats, and insects into the equipment.

TI 32S01J10-01E

Mar.21,2005-01

Page 15

1. System Installation Requirements

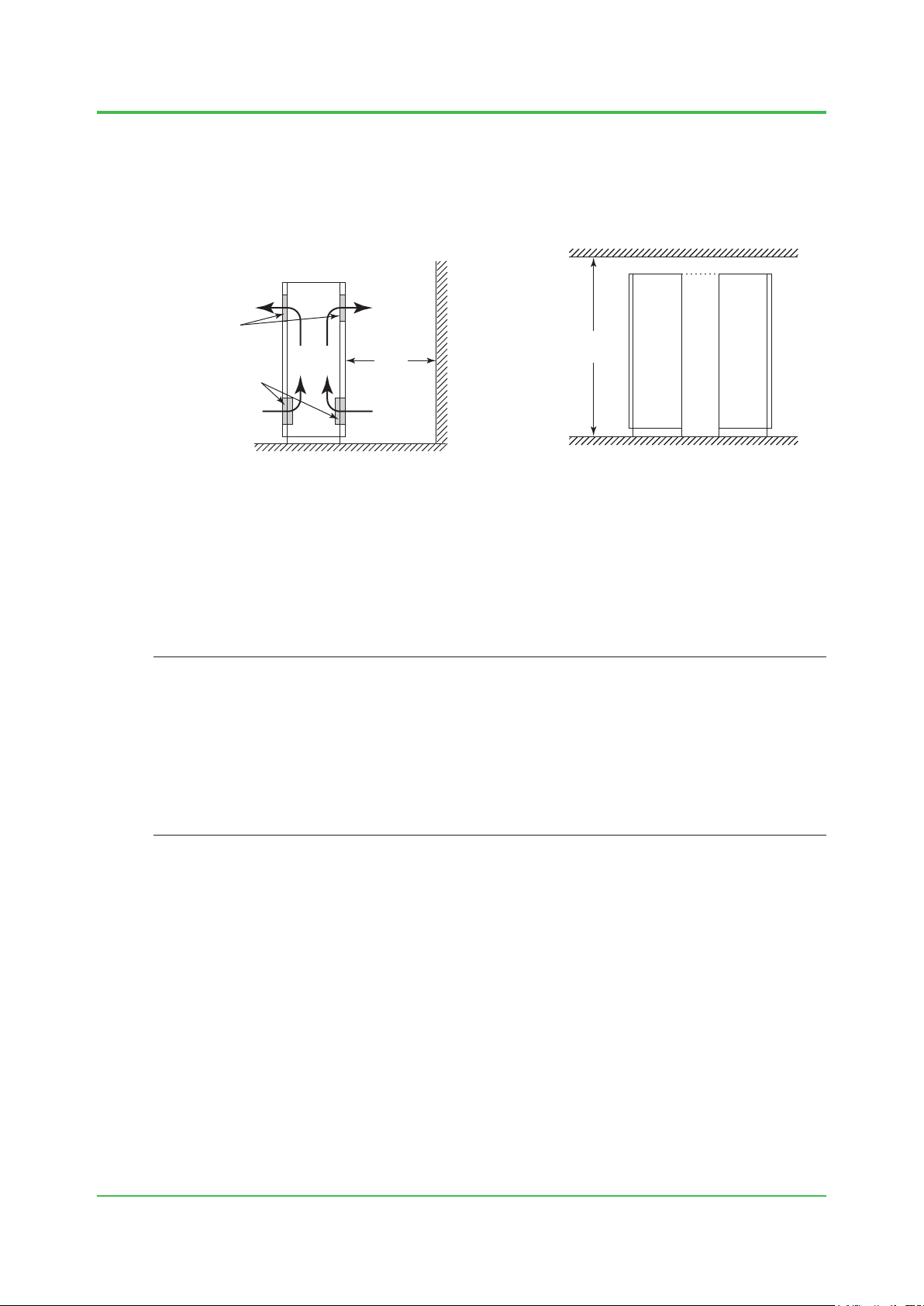

Current flow Wall

F010101.ai

Filters (outside)

and fans (inside)

Clearance From The Wall and The Floor Surface

There are ventilation holes on the front and rear doors of the cabinets. To ensure good air

ventilation and easy maintenance, provide a clearance of at least 1000 mm (including the service

areas) from the wall to the front and rear doors of the cabinets. Also make sure the height of the

ceiling is at least 2400 mm from the oor.

Ceiling

Ventilation

holes

Side of

Cabinet

Figure Wall Clearance and Ceiling Height

1000

mm

or

more

2400 mm

or more

Floor surface

Cabinet Cabinet

Illumination

1-3

The illumination level around a display unit should be 700 to 1500 lx (target illumination level:

1000 lx). The illumination level inside the control room should be reasonably uniform.

Select proper light xtures and install them in positions where they don’t cause glare on the CRT

displays and LCDs.

TIP

REFERENCE (Illumination standards):

For ultra-precision work: 1500 to 3000 lx (illumination level: 2000)

For precision work: 700 to 1500 lx (illumination level: 1000)

For ordinary work: 300 to 700 lx (illumination level: 500)

For non-detail work: 150 to 300 lx (illumination level: 200)

Passages, warehouses: 30 to 150 lx (illumination level: 50 to 100)

(Source: JIS Z9110)

Outlets for Maintenance

Outlets (approx. 1.5 kVA) for measurement devices should be provided near the installed

equipment for maintenance.

Telephone

Telephones should be installed for communications with related stations.

TI 32S01J10-01E

Aug. 10, 2011-00

Page 16

1. System Installation Requirements

Air Conditioner

The air conditioner should be operated according to the conditions below to prevent moisture

condensation on the installed equipment.

• Keep changes in temperatures within ±10°C/h.

• Install the air conditioner away from the equipment.

• Install substitute air conditioners to prevent moisture condensation as a result of the

temperature rising or falling if an air conditioner fails.

• Set the air conditioner so that its air outlet is not above the equipment (to avoid water

dropping on the equipment).

Windows

Close the windows of the control room. If a draft comes in around the windows, seal around the

windows.

Opening the window while air conditioning is running may result in condensation forming, or let in

dust or corrosive gas, adversely affecting the installed equipment. Windows on the sea side must

be closed to keep out salt air.

Install blinds, if necessary, to prevent sunlight reecting from CRT displays and LCDs.

1-4

TI 32S01J10-01E

Mar. 21,2005-01

Page 17

1. System Installation Requirements

Acceleration

A: Displacement amplitude (mm)

F010201.ai

1.2 Control Room Environment

This section describes environmental conditions of the control room to operate the

system safely, and stably over a long period of time.

It is recommended that user have the control room environment assessment. For the

assessment, contact Yokogawa if necessary.

Temperature and Humidity Limits

SEE

See “Table of Equipment Installation Specications” in this section, for the temperatures and humidity limits for

ALSO

operating and storing this equipment.

When bringing the equipment into a location where allowable operating temperature is set

from another location where the temperature exceeds the allowable operating range, following

precautions are necessary:

• The equipment should reach the ambient temperature according to the requirements for the

temperature change rate, keeping it unpacked from its case. At that time, be careful not to

let condensation form on the equipment.

1-5

• Once the equipment reaches the allowable operating temperature range, leave it for about

three hours before operation.

Under normal operation, the rate of change of ambient temperatures should be within 10°C/h. All

the equipment should be kept out of direct sunlight.

Condensation

Prevent condensation. If condensation occurs, or its trace is found on the control room, contact

Yokogawa.

SEE

See “Section 2.3 Storage” for more information.

ALSO

Vibration

Vibration in the control room should be limited as follows:

• For vibration frequency up to 8.4 Hz: Limit displacement amplitude to 1.75 mm or less.

• For vibration frequency over 8.4 Hz: Limit acceleration to 4.9 m/s2 or less.

The following is the relationship of the vibration frequency, displacement amplitude, and

acceleration:

(m/s2) = 4π2 • A • F2 • 10

-3

F: Frequency (Hz)

Consult Yokogawa if complex vibrations are involved.

TI 32S01J10-01E

Dec. 1, 2011-00

Page 18

1. System Installation Requirements

E

E : Electric field strength (V/m)

F010202.ai

Air Purity

The dust in the control room should be kept below 0.3 mg/m3. Minimize corrosive gas such as

hydrogen sulde (H

and carbon.

2

S), sulfur dioxide (SO2), chlorine, and conductive dust such as iron powder

1-6

The allowable content of H

2

S, SO2, or any other corrosive gas varies with temperatures, humidity,

or existence of other corrosive gas. Consult Yokogawa if corrosive gas exists.

Magnetic Field

Do not install the CRT near cables with heavy current owing or in the magnetic eld of a power

supply. If installed in such locations, the display may be distorted or its colors may be affected by

the magnetic elds.

Electric Field Strength (Electric Wave Condition)

For the proper and stable operation of this system, the eld electric strength of the location for the

equipment should be controlled as following:

10 V/m or less (26 MHz to 1.0 GHz)

10 V/m or less (1.4 to 2.0 GHz)

1 V/m or less (2.0 to 2.7 GHz)

In case of the usage of wireless equipment such as transceiver nearby this system, note as

following:

• The door of this system should be closed.

• In case of the usage of transceiver with 10 W or less, the distance from this system should

be kept 1 m or more.

• As for the usage of wireless equipment with 1 W or less such as mobile-telephone, PHS,

wireless telephone or LAN equipment, the distance should be kept 1 m or more. Attention

should be paid to the micro wave radiated from mobile-telephone or PHS even out of usage.

Following formula represents the electric eld strength. However, the calculated value requests

ideal environment. Worse conditioned environment should be taken into consideration. In case

some wireless equipment is used nearby this system, this formula would be useless. The value

calculated through this formula should be considered noting other than reference.

k P

=

d

k : Coefficient (0.45 to 3.35; average 3.0)

P : Radiation power (W)

d : Distance (m)

TI 32S01J10-01E

Jan.21,2010-01

Page 19

1. System Installation Requirements

Installation Specication

Installation height: Altitude of up to 2000 m

Installation category based on IEC 61010-1 (*1)

Category I

• For YOKOGAWA products, category I applies to the device that receives the electric power

not more than 33 V AC, 70 V DC.

Category II

• For YOKOGAWA products, category II applies to the device that receives the electric power

exceeding 33 V AC or 70 V DC.

Pollution degree based on IEC 61010-1: 2 (*2)

*1: The installation category, also referred to as an overvoltage category, denes the standard for impulse voltage. The category

number from I to IV applies the devices to determine the clearance required by this standard.

Category I applies to the device intended to be connected to a power supply with impulse voltage reduced to the safe level.

Category II applies to the device intended to be supplied from the building wiring.

*2: Pollution degree indicates the adhesion level of foreign matter in a solid, liquid, or gaseous state that can reduce dielectric

strength. Degree 2 refers to a pollution level equivalent to the general indoor environment.

SEE

See “Installation Environment Specications” at the end of this chapter.

ALSO

1-7

Measurement Categories

Regarding the measurement inputs, the following requirements must be satised to meet the

specications for the device:

The category of the equipment applies to No.1 in the following table.

The rated transient overvoltage is 1500 V.

Note: Do not use the equipment for measurements within measurement categories II, III and IV.

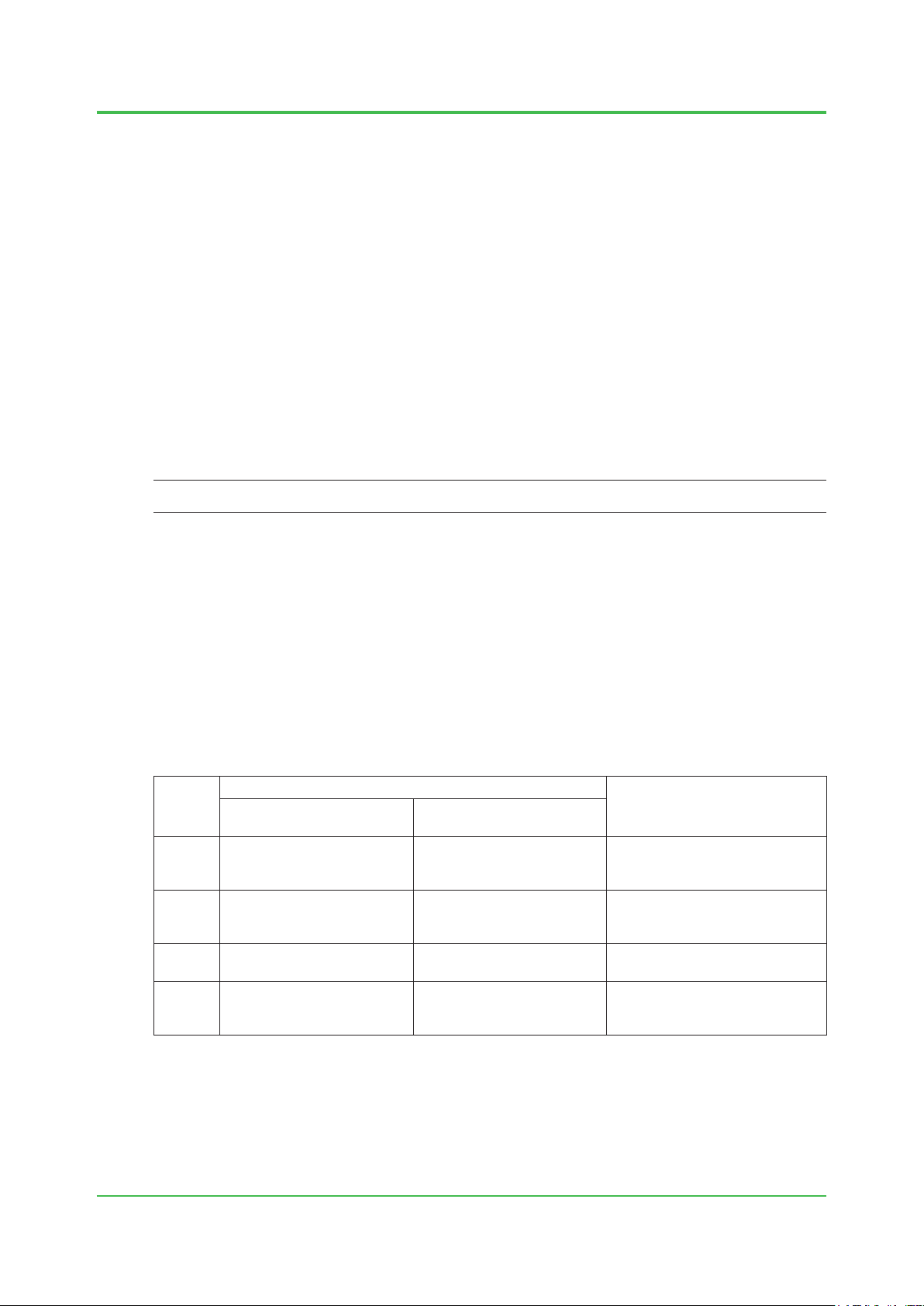

Table Measurement category

Applicable Standard

No.

No.1 Measurement category I O (Other)

No.2 Measurement category II Measurement category II

No.3 Measurement category III Measurement category III

No.4 Measurement category IV Measurement category IV

IEC/EN/CSA

61010-1:2001

EN 61010-2-030

Description

For measurements performed on

circuits not directly connected to

MAINS.

For measurements performed on

circuits directly connected to the

low voltage installation.

For measurements performed in

the building installation.

For measurements performed

at the source of the low-voltage

installation.

TI 32S01J10-01E

Aug. 31, 2015-00

Page 20

1. System Installation Requirements

Applied Standards

The ProSafe-RS complies with the standards shown below.

IMPORTANT

Different standards are applied according to the types of equipment.

For details, refer to the hardware General Specications (GS) for each equipment.

Functional Safety Standards

IEC 61508, IEC 61511-1 and IEC 62061

Standard for Programmable Controllers (*1), (*2), (*3)

IEC 61131-2

Applicable Standards (*1)

1-8

EN 54-2 (*5), EN 298 (*3), (*4), EN 50156-1, NFPA 85, NFPA 72

Safety Standards (*6), (*8), (*9), (*10)

[CSA]

CAN/CSA-C22.2 No.61010-1 (100-120 V AC power supply)

[CE Marking] Low Voltage Directive

EN 61010-1, EN 61010-2-201, EN 61010-2-030, EN 60825-1 (100-120 V AC (*7), 220-240 V AC

and 24 V DC power supply)

[EAC Marking]

CU TR 004

*1: A lightening arrester or the like is required to meet this surge immunity standard.

*2: 24 V DC and 48 V DC eld power cables to DI and DO should be a maximum of 30 m in length.

*3: Where the system power uses 24 V DC (SPW484), use an external uninterruptible power supply (UPS).

*4: 24 V DC and 48 V DC eld power cables to DI and DO should be a maximum of 10 m in length.

*5: A clamp lter (A1193MN) should be connected to the V net cable.

*6: For the rack mountable devices, DIN rail mountable devices, and wall mountable devices to meet the Safety Standards and EMC

Standards, the devices must be installed in a lockable metal cabinet. The cabinet must conform to IEC/EN/CSA 61010-2-201 or

provide degrees of protection IP3X or above and IK09 or above.

*7: SSC10-211 does not comply with CE Marking of 100 V AC.

*8: Measurement inputs of this equipment are applied to Measurement category I for IEC/EN/CSA 61010-1:2001 and O (Other) for

EN 61010-2-030.

*9: For ensuring all the hardware devices to satisfythe safety standards, the dedicated breakers in the power supply distribution

board must conform to the following specications.

[CSA] CSA C22.2 No.5 or UL 489

[CE Marking] EN 60947-1 and EN 60947-3

[EAC Marking] EN 60947-1 and EN 60947-3

*10: The ground suitable for the power distribution system in the country or region has to be used for protective grounding system.

TI 32S01J10-01E

Aug. 31, 2015-00

Page 21

1. System Installation Requirements

EMC Conformity Standards (*2), (*3)

[CE Marking] EMC Directive

EN 55011 Class A Group1 (100-120 V AC (*4), 220-240 V AC and 24 V DC power supply) (*5)

EN 61000-6-2 (100-120 V AC (*4), 220-240 V AC and 24 V DC power supply) (*1)

EN 61000-3-2 (220-240 V AC power supply) (*6)

EN 61000-3-3 (220-240 V AC power supply)

[RCM]

EN 55011 Class A Group1 (220-240 V AC and 24 V DC power supply) (*5)

[KC Marking] (100-120 V AC (*4), 220-240 V AC and 24 V DC power supply)

Korea Electromagnetic Conformity Standard

[EAC Marking]

CU TR 020

[Functional Safety]

IEC 61326-3-1

*1: A lightening arrester or the like is required to meet this surge immunity standard.

*2: 24 V DC and 48 V DC eld power cables to DI and DO should be a maximum of 30 m in length.

*3: For the rack mountable devices, DIN rail mountable devices, and wall mountable devices to meet the Safety Standards and EMC

Standards, the devices must be installed in a lockable metal cabinet. The cabinet must conform to IEC/EN/CSA 61010-2-201 or

provide degrees of protection IP3X or above and IK09 or above.

*4: SSC10-211 does not comply with CE Marking and KC Marking of 100 V AC.

*5: The analog inputs of this system fall into Measurement Category I of IEC 61010-1.

*6: A Class A hardware device is designed for use in the industrial environment. Please use this device in the industrial environment

only.

1-9

Standard for Hazardous (Classied) Locations

[FM Non-Incendive]

[Type “n”]

SEE

For more information about Standard for Hazardous Locations, refer to TI 32S01J30-01E “Explosion Protection

ALSO

(for ProSafe-RS).”

Marine Standards

ABS (American Bureau of Shipping)

BV (Bureau Veritas)

Lloyd’s Register

SEE

For more information about the components which comply with the marine standards and how to install those

ALSO

components, refer to 1.8, “Compliance with Marine Standards.”

In relation to the CE Marking, the manufacturer and the authorised representative for ProSafeRS in the EEA are indicated below:

Manufacturer: YOKOGAWA Electric Corporation

(2-9-32 Nakacho, Musashino-shi, Tokyo 180-8750, Japan.)

Authorised representative in the EEA: Yokogawa Europe B.V.

(Euroweg 2, 3825 HD Amersfoort, The Netherlands.)

TI 32S01J10-01E

Aug. 31, 2015-00

Page 22

1. System Installation Requirements

1-10

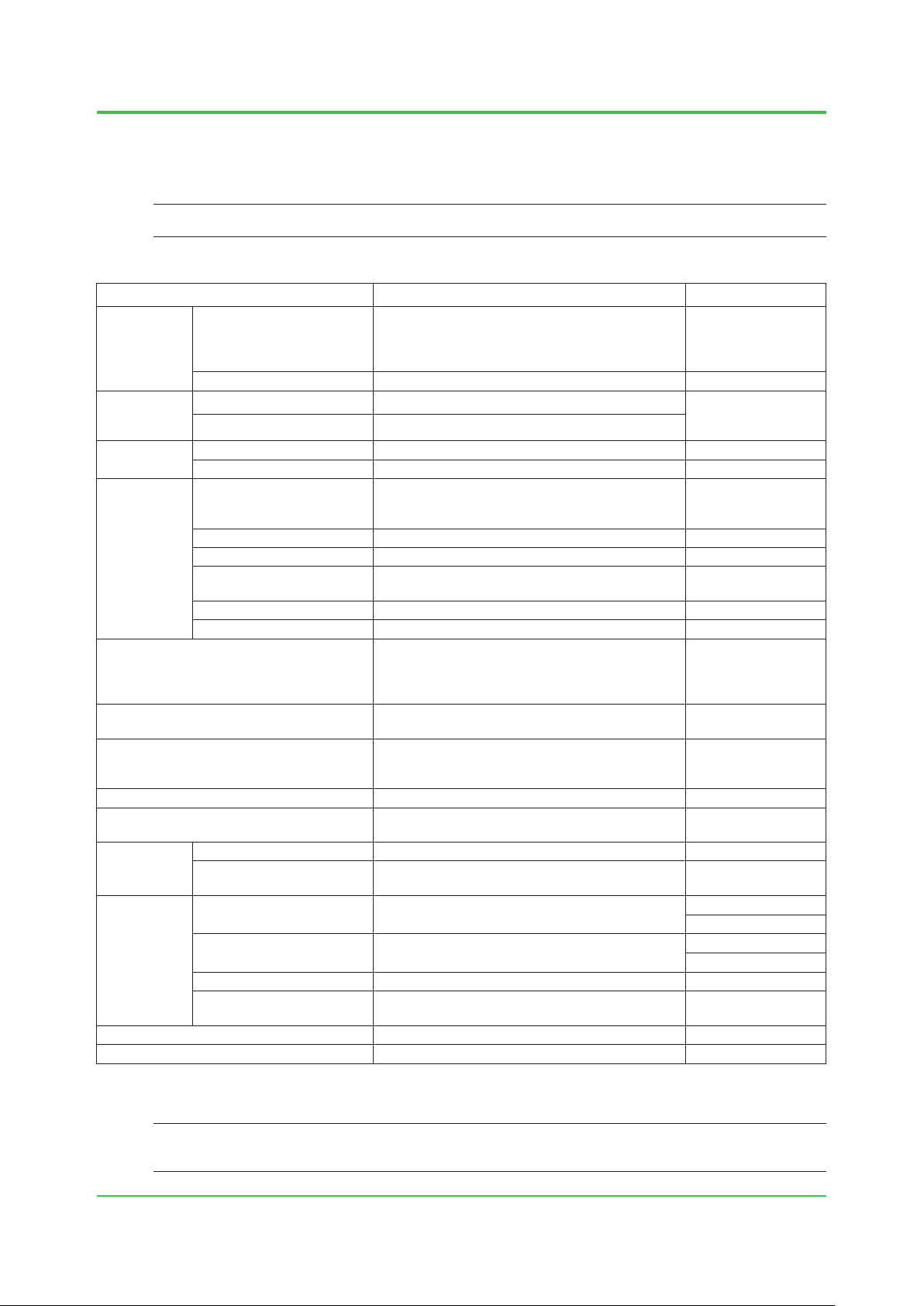

Installation Environment Specications

The following table lists environmental requirements for the installation of the ProSafe-RS

System.

SEE

For details on each equipment, refer to the ProSafe-RS general specications (GS).

ALSO

Table Installation Environment Specications

Item Specications Remarks

–20 to 50°C (basic safety control unit for V net)

–20 to 40°C (basic safety control unit for Vnet/IP)

–20 to 70°C (temperature-adaptive safety control

Temperature

Normal operation

unit and safety node unit)

Transportation/storage –40 to 85°C

Normal operation 5 to 95% RH (non-condensing)

Humidity

Temperature

change

Transportation/storage 5 to 95% RH (non-condensing)

During operation Within ± 10ºC/h

Transportation/storage Within ± 20ºC/h

100 to 120 V AC –15%, +10%

Voltage range

220 to 240 V AC –15%, +10%

24 V DC: –10% to +20%

Frequency 50/60 Hz ± 3Hz

Power supply

Distortion factor 10% or less

Crest factor

100 V system: 118 V or larger

220 V system : 258 V or larger

Momentary failure 20 ms or less (when receiving the rated AC voltage)

DC power supply ripple rate 1% p-p maximum

1500 V AC for 1 minute

Withstanding voltage

(for 100-120/220-240 V AC)

500 V AC for 1 minute

(for 24 V DC)

Insulation resistance 20 M ohms at 500 V DC

Apply the grounding system which is dened

Grounding

by the rules and standards of the country or the

region.

Dust Maximum of 0.3 mg/m

3

Corrosive gas ANSI/ISA S71.04 G3 (standard)

Electric eld 10 V/m maximum (80 MHz to 1 GHz)

Noise

Static electricity

Continuous vibration

Vibration

Non-continuous vibration

Seismic Acceleration: 4.9 m/s

Transportation

Impact 147 m/s

4 kV or less (direct discharge)

8 kV or less (aerial discharge)

Amplitude: 1.75 mm (5 Hz to 9 Hz)

Acceleration: 4.9 m/s

Amplitude: 3.5 mm (5 Hz to 9 Hz)

Acceleration: 9.8 m/s

Horizontal: 4.9 m/s

vertical: 9.8 m/s

2

, 11 ms

2

(9 Hz to 150 Hz)

2

(9 Hz to 150 Hz)

2

or less

2

or less

2

or less

Altitude 2000 m above sea level or less

*1: When ALR111-S1/ALR121-S1 is installed, the ambient temperature should range from 0 to 60 °C. In case of ALR121-SB, it should

range from 0 to 70 °C. When ALE111-S1 is installed, the ambient temperature should range from 0 to 60 °C. ALE111 supported in

R3.02.00 or later can be mounted on SSC60, SSC50 or SSC57.

(*1)

5 to 85 % RH when

the SRM53D/RM54D/

SBM54D is mounted.

Between power &

ground terminals

Between power &

ground terminals

Excluding SRM53D/

SRM54D/SBM54D

When packaged

SEE

For the level of corrosive gases permitted in an ordinary ofce, refer to TI 33Q01J20-01E “Guidelines for

ALSO

Installation Environment.”

TI 32S01J10-01E

Oct. 1, 2014-00

Page 23

1. System Installation Requirements

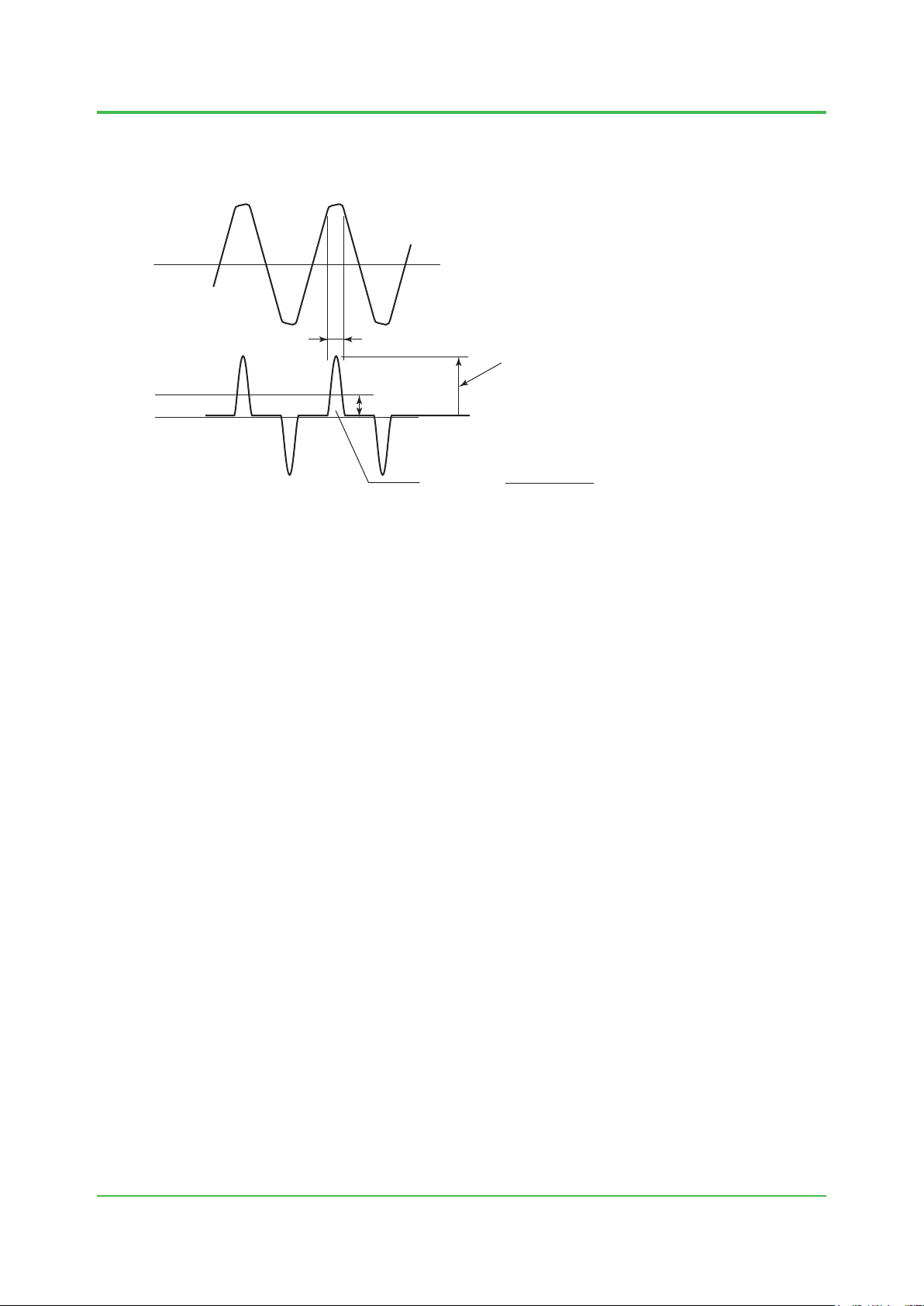

Peak A

F010301.ai

A: Ideal, non-distorted input voltage wave

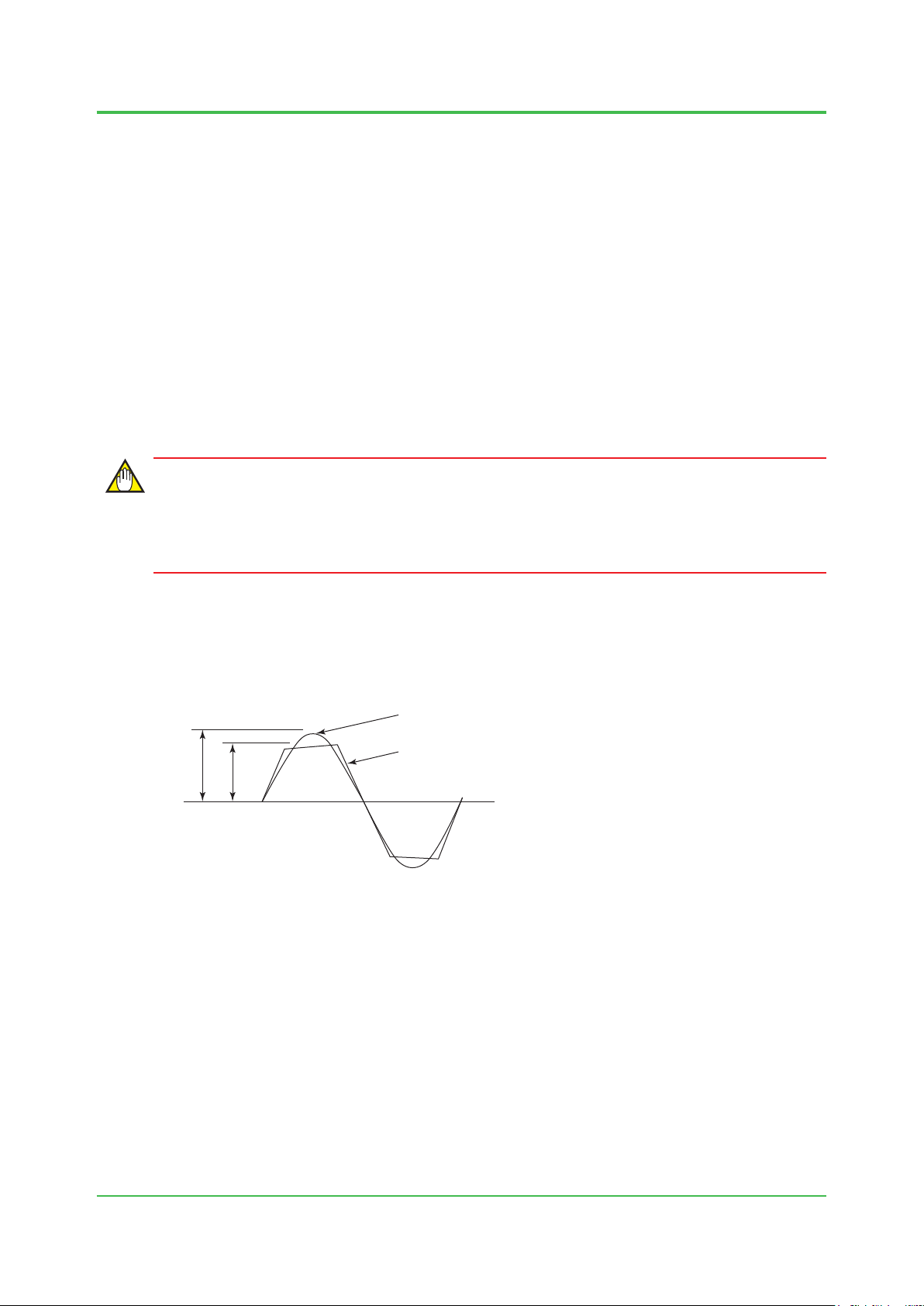

1.3 Power Supply System

The following conditions should be met:

• Voltage and frequency uctuations are within the limits specied for each system

component.

• Waveform distortion is within limits.

• High-frequency noise is not at a level that affects system operation.

• Use an UPS (uninterruptible power supply) if necessary.

AC Power Specication

AC power used for the system must be within the specied rated voltage and the peak value

must be greater than the minimum specied (see below). DC power must be within 24 V DC

-10%/+20% at the power supply terminals.

IMPORTANT

If the power unit has high output impedance or high wiring impedance, the resulting voltage drop

attens the input voltage wave, forming a distorted waveform with a low peak value (“B” in the

chart below).

1-11

Even if the effective value of the distorted input voltage wave is the same as that specied for a

non-distorted input voltage wave, the voltage across the terminals of the smoothing capacitor

in the power circuit may be so low that the system detects power failure. Even if input voltage

waves A and B shown below have the same effective value of 100 V AC, wave B will have a

lower smoothing capacitor terminal voltage.

B: Distorted input voltage wave

Peak B

Figure Distorted Input Voltage Waveform

TI 32S01J10-01E

Jun. 30, 2011-01

Page 24

1. System Installation Requirements

V

V

V

Effective

F010302.ai

F010303.ai

Power/failure

Smoothing capacitor

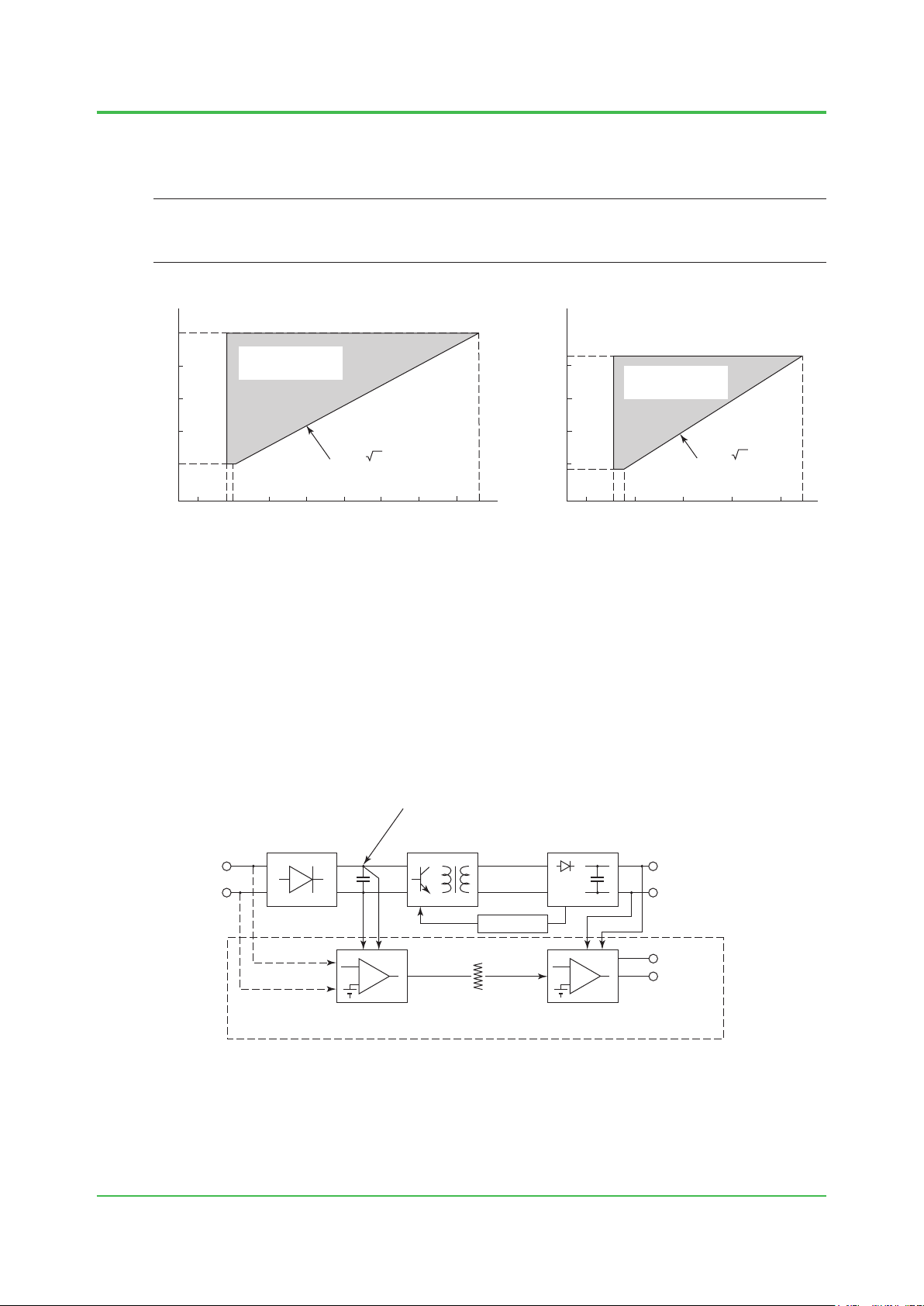

The system operating voltage range is shown below based on the relationship between effective

and peak values at the power input terminal of each system. Apply AC power within these ranges

to operate the system.

TIP

Average-value rectifying measuring instruments such as general type digital voltmeters and testers cannot

measure effective values accurately. Use Yokogawa’s digital oscilloscope DL series, power analyzer WT series or

equivalent device, which can measure effective values, peak values, and waveform distortion.

132

value

(V rms)

120

110

100

85

System operating

voltage range

Effective

V op= 2 V rms

value

(V rms)

264

240

220

200

187

System operating

voltage range

1-12

V op= 2 V rms

110

118 120

130 140 150 170

Peak value (V op)

160

180

187

V

258 264

240 330 360

270 300

Peak value (V op)

374

Figure System Operating Voltage Range

The DC stabilized power supply for the ProSafe-RS (except PCs) uses a compact and efcient

switching regulator circuit. In this circuit, output voltage cannot be maintained if the energy

(terminal potential) of the smoothing capacitor falls below a predetermined value. The circuit

monitors the capacitor terminal voltage and regards it as power failure if the voltage falls in the

danger zone, causing the system to enter power fail mode (non-detected momentary power

failure: up to 20 ms).

Current ows to the capacitor in this circuit when AC input voltage is higher than the capacitor

terminal voltage. Since the capacitor is charged by the peak value of the input waveform, it is

required that both the effective voltage value and the peak value conform to the specication

requirements.

Rectification, smoothing,

power factor correction

Input

(AC)

control

(Waveform

monitoring)

Figure Power Circuit Diagram of Safety Control Unit

Input voltage

monitoring

terminal voltage

DC/AC Rectification

PWM

Insulation

Output voltage

monitoring

ACRDY

DCRDY

Output

(DC)

System

control

signal

TI 32S01J10-01E

Jun. 30, 2011-00

Page 25

1. System Installation Requirements

Selecting a Power System

The ProSafe-RS system requires a power supply that satises power requirements in

accordance with EMC regulations. It is recommended that an external power supply unit be

used in order to prevent disruptions due to momentary or extended power failure, line noise, or

lightening surges, as well as to suppress harmonic current from various devices.

For selection of the power supply unit, consult with a power unit manufacturer taking the following

points into consideration.

Source Output Capacity

Take the following items into consideration when consulting with a power unit manufacturer to

determine the output capacity.

Power consumption: Both volt-ampere and watt data should be studied.

Device crest factor: Ratio of the peak value to the effective value of the device input

current.

Device in-rush current: The method of turning on the power should also be studied.

Backup ready time after failure: Time period required to backup the devices when power fails.

Reserve capacity: An extra power capacity should be determined as reserve to

meet any device additions.

1-13

SEE

ALSO

• Electrical Specications Table for power consumption in Chapter 4

• In-rush Current of Each Component in Chapter 4

TI 32S01J10-01E

Jun.18,2008-01

Page 26

1. System Installation Requirements

F010304.ai

Input voltage waveform

Crest factor

The crest factor is the ratio of the peak value to the effective value of the device input current.

1-14

Input current waveform

Figure Input Voltage and Input Current Waveforms

Approx. 5 ms

Effective value

Crest factor =

Peak value

Peak value

Effective value

Crest factor = Peak value of device input current / Effective value of device input current

The crest factor must be considered for the input current supplied to every device connected to

the system when estimating the power output capacity in selecting the power unit.

Approximate device crest factors should be as follows:

100-120 V supply voltage: Crest factor About 3.

220-240 V supply voltage: Crest factor About 6.

Common Method to Determine Power Unit Capacity

The following shows the commonly used method used to determine the power unit capacity

taking the crest factor into consideration - the nal determination should be made in consultation

with a power unit manufacturer:

• If the specication of power unit crest factor (the peak current value allowable for the

effective current value) is larger than the above device crest factor, the power unit can be

used for up to full rated capacity. However, in-rush current, backup time, reserve capacity,

etc., must be separately taken into consideration.

• If the power unit crest factor is smaller than the device crest factor, the power unit capacity

needs to be calculated in the expression shown below. In-rush current, backup time, reserve

capacity, etc., must be separately taken into consideration.

Power unit output capacity = Total device power consumption x Capacity coefcient

Capacity coefcient = Device crest factor / Power unit crest factor specication

TI 32S01J10-01E

Jun.18,2008-01

Page 27

1. System Installation Requirements

In-Rush Current

When the equipment is turned on, a large in-rush current ows as the capacitor is

instantaneously charged and the transformer is excited. When any equipment is turned on, this

should not cause any voltage uctuation that could adversely affect other equipment. Do not turn

on all equipment at the same time. Start equipment one by one.

Power may be switched to backup or AC line power if in-rush current activates the overload

protection circuit on power-up. After such an overload, select an uninterruptible power unit, with

automatic-recovery.

Suppressing Harmonic Current

In order to suppress harmonic current supplied to a low-voltage distribution system, it is

necessary to install a power unit or an active harmonic suppressor, such as indicated below,

between a device and the distribution system:

• Power unit equipped with the harmonic suppression function (a high power-factor inverter-

type uninterruptible power unit, etc.)

• Active harmonic suppressor

In Europe, a power unit should be selected so that harmonic current emissions are within the

limits specied by EMC regulations.

The capacity of the harmonic suppression unit should be determined in consultation with a power

unit manufacturer in the same manner as the selection of power unit’s output capacity previously

discussed.

1-15

Cabling

Observe the following when cabling the power unit to the ProSafe-RS system equipment:

• Protect signal cables from induced noise.

• Protect signal cables from induction from high-voltage power lines.

• Separate the ProSafe-RS system power supply from other equipment power supplies.

• Provide a dedicated breaker for each power supply.

• Install breakers and devices in the same room.

• Label the breakers with the name of the connected equipment.

• Install the breakers where they can be easily operated.

• The breaker, must not interrupt connection by wiring to protective grounding system.

• As far as possible install power supply cables and high-voltage power lines in metallic

• Use shielded cables if metallic conduits cannot be provided.

Use a separate power distribution board.

conduits.

TI 32S01J10-01E

Aug. 31, 2015-00

Page 28

1. System Installation Requirements

1.4 Grounding

To avoid electric shocks and minimize the inuences of external noise, the installed

devices must be grounded to the protective grounding system which complies with the

safety standards, the electrical installations standard, and the power distribution system

of the country or the region.

As for the protective grounding systems, the meshed grounding systems described in

IEC 60364, IEC 62305 and IEC 61000-5-2 can be applied.

A protective device is to be installed in compliance with the rules and regulations, in order

to prevent electric shocks caused by a ground fault.

A plug type power cable has to be connected to the receptacle connected to the protective

grounding system.

1-16

TI 32S01J10-01E

Oct. 1, 2014-00

Page 29

1. System Installation Requirements

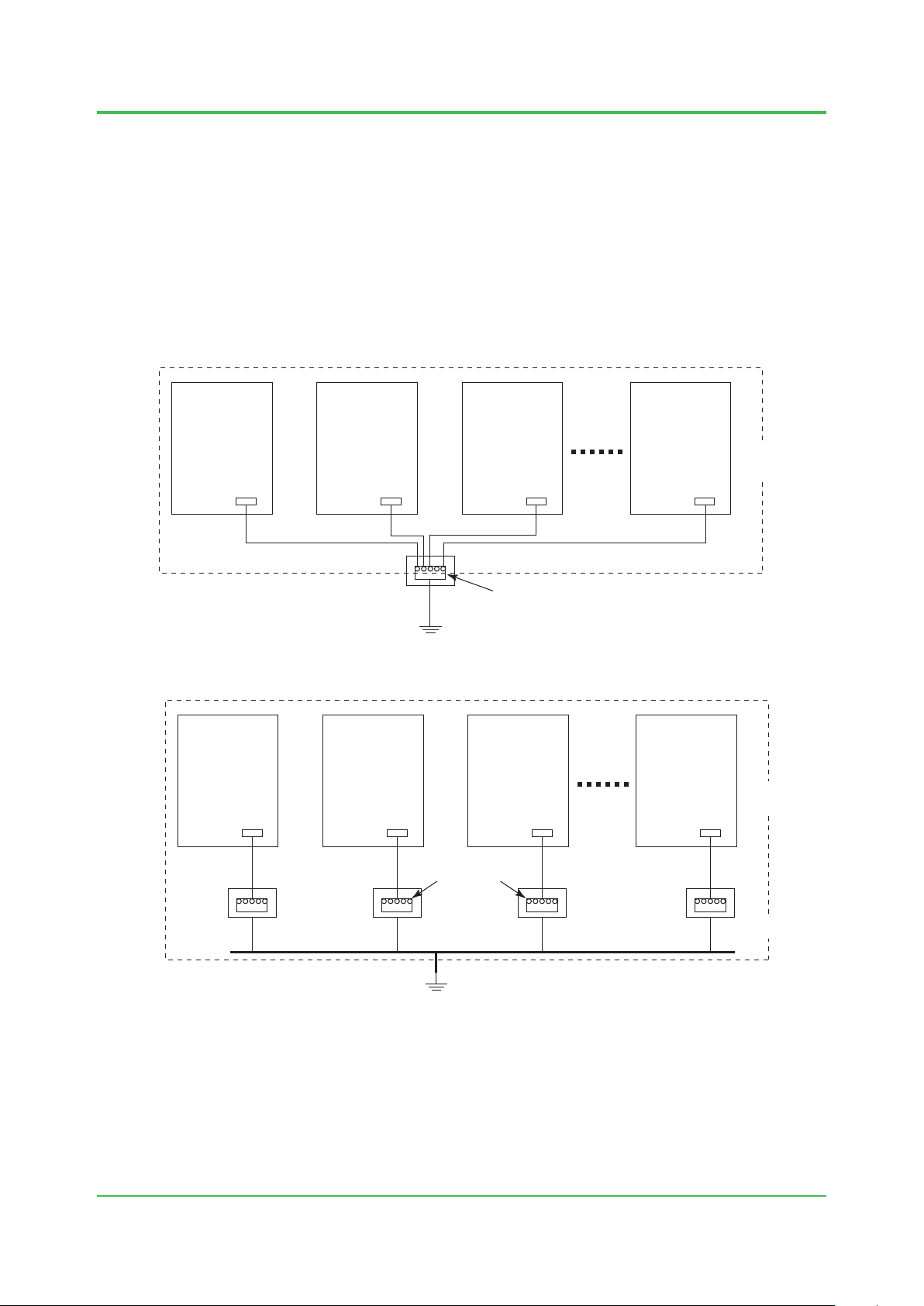

Grounding Circuit

Grounding examples are given below.

If ProSafe-RS systems are housed in a cabinet, the cabinet must be grounded according to the

grounding network topology of the building or plant for installation.

In order to connect a cabinet with a protective grounding system, the grounding topology shown

in the gures “Grounding connected to a single grounding bus inlet” or “Grounding connected to

each grounding bus inlet” can be used.

When providing lightning arresters on power and signal lines, those arresters need to be

grounded to the same bus. For details, see Section 1.5, “Noise Countermeasures.”

Cabinet Cabinet Cabinet Cabinet

G G G G

1-17

In same

control room

Grounding bus inlet

G: Grounding Bar

Protective grounding system

Figure Grounding connected to a single grounding bus inlet

Cabinet Cabinet Cabinet Cabinet

G G G G

Grounding bus inlet

Protective grounding

system

G: Grounding Bar Protective grounding system

Protective grounding

system

Protective grounding

system

Figure Grounding connected to each grounding bus inlet

F010401.ai

In same

control room

Protective grounding

system

F010402.ai

TI 32S01J10-01E

Oct. 1, 2014-00

Page 30

1. System Installation Requirements

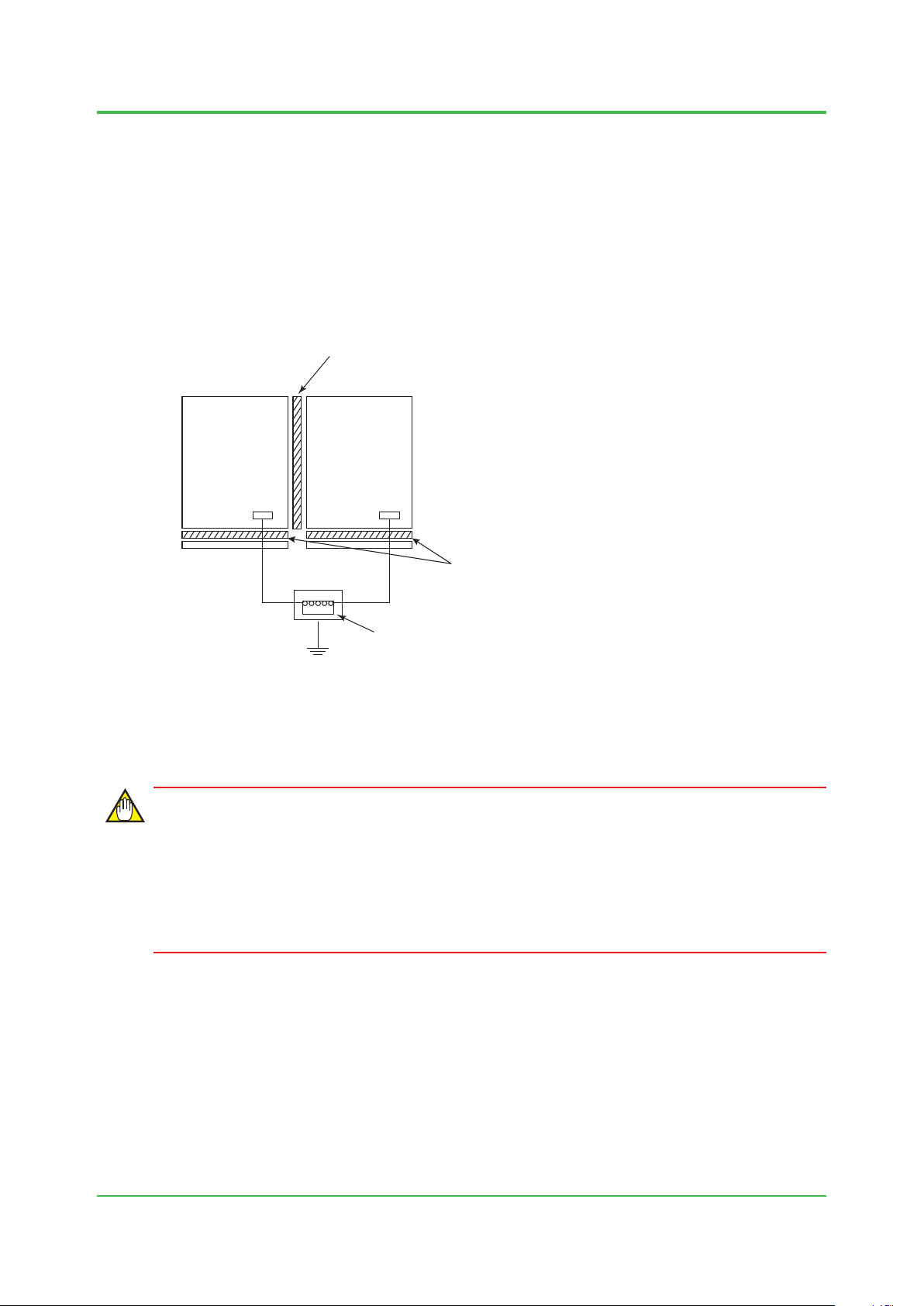

Grounding with Other System

Do not connect ProSafe-RS’s cabinet with other system cabinets or consoles electrically using

bolts or other connection mechanism in order to avoid unexpected electrical connection or

interference.

When ProSafe-RS is joining side by side with other system cabinets or consoles, ensure to insert

insulating sheets.

The cabinets or consoles other than ProSafe-RS must be insulated from a oor and connect it to

a protective grounding system using a different grounding cable.

CENTUM VP can be treated as the ProSafe-RS system in this page.

Insulating sheet

1-18

ProSafe-RS

Cabinet Cabinet

G

G: Grounding Bar

Figure Grounding Using Insulating Sheets

Other system

Equipmment

/Console Type

G

Grounding bus inlte

Protective grounding system

IMPORTANT

Insulating sheet material:

Thickness:

Insulating sheet

PVC or

PL-PEV, PL-PEM Bakelite

5-10 mm

F010404.ai

Do not install the following systems side-by-side with ProSafe-RS:

• Systems using power supply voltages over 300 V AC.

• Systems with current consumption over 50 A.

• System containing high frequency sources.

TI 32S01J10-01E

Oct. 1, 2014-00

Page 31

1. System Installation Requirements

1.5 Noise Countermeasures

Noise may be induced by electromagnetic induction, electrostatic induction, or come

from radio waves, lightning, inductive loads, static electricity and ground potential

differences.

It can be picked up by power, signal and ground cables, and devices. With computerized

control systems, noise-induced errors in A/D conversion or in an instruction word may

lead to malfunction. Therefore, it is necessary to prevent the noise from being generated

or coming too much from the outside.

To prevent noise and electrostatic buildup, take the measures described in this section

when deciding cable type, cable routing, and grounding.

1-19

TI 32S01J10-01E

Oct. 1, 2014-00

Page 32

1. System Installation Requirements

1.5.1 Noise Sources and Noise Countermeasures

It is not easy to identify the cause of any noise-triggered errors or failures due to their lack of

reproducibility.

To prevent noise generation, it is necessary to consider the installation environments such as the

external cable routing, cable types, and grounding.

The following table lists typical noise sources, symptoms of noise problems, and preventive

countermeasures:

Table Noise Sources & Countermeasures

Noise sources Effects Countermeasures

• Maintain separation from magnetic-eld

source.

• Shield power cables with metallic conduits.

• Shield magnetic eld using ferromagnetic

substance (e.g. Permalloy). Or use LCD.

• Use twisted-pair cables.

• Use shielded signal cables.

• Electrically separate power and signal cables

using metallic conduits and separators.

• Lay power and signal cables which intersect at

right angles.

• Lay cables underground.

• Use optical ber cables.

• Lay cables as close to ground as possible if the

cables cannot be laid underground.

• Install and ground arresters on eld and

system.

• Discharge static electricity from operators.

• Provide proper humidity.

• Ground equipment properly.

• Use antistatic oor material and clothing.

• Add spark-killer to noise source.

• Separate laying of cables.

• Keep at least 1 m away from devices to use

a transceiver or a PHS or a cellular phone

(max. output is 1W).

• Avoid multipoint grounding of signal cable.

Electromagnetic induction

(magnetic eld)

Electrostatic induction

Lightning

Electrostatic discharge

Inductive load open/close

Radio (electric eld)

Ground potential difference

• CRT display instability, distortion,

color shift, color fringing.

• Destroys magnetic/exible disk data.

• Equipment maloperation.

• Interference with signals.

• Interference with signals.

• Equipment maloperation.

• Component damage.

• Equipment maloperation.

• Electronic component deterioration,

damage.

• Paper jam.

• Spike noise interference to power

andsignal lines.

• CRT display disruption.

• Equipment maloperation.

• Interference with signals.

• Equipment Maloperation

(noise imposed on signal lines)

1-20

TI 32S01J10-01E

Oct. 1, 2014-00

Page 33

1. System Installation Requirements

Grounding with Lightning Arresters

Connect the protective conductor terminals of arresters and ProSare-RS equipment to the

grounding pole as shown in the diagram below.

The grounding method must comply with the grounding system dened by rules and standards of

the country or the region.

Concatenation grounding a lightning arrester and other equipment may cause high-tension in

each equipment by the product of lightning current from arrester and grounding resistance. To

prevent from electrication, overall connection should be equipotential including the oor and the

case of other equipment.

Shield the cable

Cabinet internal shield ground bar

(with an insulated board)

Connection to grounding bar

Grounding bar for connecting

grounding conductor

1-21

Arrester

To cabinet grounding bar

Apply the grounding system which is defined by

the rules and standards of the country or the region.

Figure Grounding with Lightning Arresters

Cabinet

F010501.ai

TI 32S01J10-01E

Dec. 26, 2014-00

Page 34

1. System Installation Requirements

Examples of Arrester

The following shows how to install an arrester as a countermeasure against lightning-Induced

noise.

1-22

2-wire transmitter

+

2-wire

transmitter

Resistance temperature detector

A

B

B

AR AR

-

Field wiring

AR

Field wiring

Figure Examples of Arrester Installation

AR

System side

Input

module

GND

System side

Input

module

GND

Thermocouple

+

-

Field wiring

Power supply

Field wiring

: Induced lightning strike point

AR: Arrester

AR

AR

Input

module

GND

System side

System

F010502E.ai

モ

ジ

ュ

ー

ル

GND

TI 32S01J10-01E

Oct. 1, 2014-00

Page 35

1. System Installation Requirements

F010503.ai

Examples of Spark-killer Installation

The following shows how to install a spark-killer as a countermeasure against inductive

load-caused noise:

1-23

Relay contact

The spark killer protects relay

contacts from noise occurring when

inductive loads working under AC

operation are turned off.

*1: A diode, which protects the output transistor from noise occurring during

on-to off transition of the relay, is incorporated in the output module except SDV526.

Power supply

The spark killer prevents noisecaused equipment failure when

a fluorescent lamp or fan is

turned on or off.

Example

R: 120 ohms

C: 0.1 to 0.3 μF

Fluorescent

lamp or fan

Example

R: 120 ohms

C: 0.1 μF

Relay

Spark

killer

Spark

killer

Relay

100 V AC

24 V DC

Output

Module

Tr

Controller

control signal

Diode (*1)

ProSafe-RS

Figure Examples of Spark-killer Installation

TI 32S01J10-01E

Oct. 1, 2014-00

Page 36

1. System Installation Requirements

F010504.ai

1 M ohm

Wrist strap

1 M ohm

1.5.2 Countermeasures against Static Electricity

Take countermeasures against electrostatic damage when handling cards with semi-conductor

IC components, for maintenance or to change settings.

Observe the following to prevent electrostatic damage:

• When storing or carrying maintenance parts, keep them in a conductive bag (when

delivered from the factory, they are packed in such bags with labels warning about static

electricity).

• When doing maintenance work, wear a wrist strap connected to a ground wire with a

grounding resistance of 1 M ohm. Be sure to ground the wrist strap.

Conductive sheet

1-24

Grounding resistance

of 1 M ohm

Wrist strap

Connect to earth terminal

or unpainted part of frame

(grounded)

Figure Example of Use of A Wrist Strap and Conductive Sheet

When working with a card with battery

(power supply unit) on a conductive sheet,

set the BATTERY ON/OFF switch to the OFF

position or remove the battery.

• When working on cards: keep conductive sheets, grounded via a resistance of 1 M ohm, on

the work bench. Wear a grounded wrist strap. Remove electrostatic plastics from the work

bench.

• Be sure to wear a wrist strap and use a conductive sheet when handling maintenance parts.

• Wrist straps and conductive sheets are available from Yokogawa.

TI 32S01J10-01E

Oct. 1, 2014-00

Page 37

1. System Installation Requirements

Separator (steel plate)

separate from ProSafe-RS system grounding

F010601.ai

F010602.ai

Signal cables

1.6 Cabling Requirements

The following requirements must be fullled to prevent an equipment malfunction when

laying power and signal cables (these are shielded cables unless specied).

Signal cables used for high-voltage, high-frequency signals (inductive load ON/OFF) must

be separated from other signal cables.

Separator

To prevent an equipment malfunction, provide a separator between power and signal cables as

illustrated below:

1-25

Signal

cables

Figure Separator Used in Duct/Pit

Power

cables

Protective grounding system

Distance between Cables

If a separator cannot be used, keep a distance between signal cables and power cables.

The distances between cables due to operating voltages and currents are shown below.

Table Required Distance between Power & Shielded Signal Cables

Operating voltage Operating current Distance

240 V AC max

240 V AC min

10 A max 150 mm min

10 A min 600 mm min

10 A max 600 mm min

10 A min Cannot be laid together

Figure Distance between Cables under Pit/Free-access Floor

150 mm

or more

Power cables

Signal cables Power cables

150 mm

or more

TI 32S01J10-01E

Oct. 1, 2014-00

Page 38

1. System Installation Requirements

Signal cables

Steel plate (1.6 mm or thicker, grounded)

F010603.ai

Intersecting Cables

With unshielded power cables, place a grounded steel plate with a thickness of at least 1.6 mm

over the cables where they intersect with signal cables.

1-26

Protective grounding system

Figure Intersecting Cables under Pit/Free-access Floor

Ambient Temperature

The ambient temperature where signal and bus cables are laid must be within the limits specied

for each cable.

Measures against EMI

As a rule, avoid laying the cables on the oor. However, lay them on the oor only if there are no

duct and no pit. In that case, it is required to cover them with shield plates or take other measures

to suit the EMC Directive.

Unshielded power cables

TI 32S01J10-01E

Oct. 1, 2014-00

Page 39

1. System Installation Requirements

1.7 Corrosive-gas Environment Compatibility

The ProSafe-RS system complies with the ANSI/ISA G3 environment requirements,

allowing use in a corrosive gas-susceptible environment.

G3 Environment-compatible Products

Table G3 Environment-compatible Products (1/2)

No. Product Model Description

Safety control unit (rack mountable type, for Vnet/IP)

Safety control unit (rack mountable type, for Vnet/IP)

Safety control unit (rack mountable type, for Vnet/IP-Upstream)

Safety control unit (rack mountable type)

1 Node unit

SSC60

SSC50

SSC57

SSC10

SNB10D Safety node unit (rack mountable type)

SAI143-S Analog input module (4 to 20 mA, 16-channel, Module isolation)

1-27

2 Input/output module

ESB Bus Interface

3

Module

Unit for Optical Bus

4

Repeater Module

Optical ESB Bus

5

Repeater Module

SAI143-H

SAV144 Analog input module (1 to 5 V/1 to 10 V, 16-channel, Module isolation)

SAI533

SAT145

SAR145

SDV144

SDV521 Digital output module (24 V DC/2 A, 4-channel, Module isolation)

SDV526 Digital output module (100-120 V AC, 4-channel, Module isolation)

SDV531 Digital output module (24 V DC, 8-channel, Module isolation)

SDV53A Digital output module (48 V DC, 8-channel, Module isolation)

SDV541 Digital output module (24 V DC, 16-channel, Module isolation)

SEC402

SEC401 ESB Bus Coupler Module

SNT10D Unit for Optical Bus Repeater Module

SNT401 Optical ESB Bus Repeater Master Module

SNT501 Optical ESB Bus Repeater Slave Module

SNT411

SNT511

Analog input module (4 to 20 mA, 16-channel, Module isolation,

HART Communication)

Analog output module (4 to 20 mA, 8-channel, Module isolation,

HART Communication)

TC/mV Input Module (16-channel, Isolated Channels)

RTD Input Module (16-channel, Isolated Channels)

Digital input module (no-voltage contact, 16-channel, Module isolation)

ESB Bus Coupler Module (for SSC60, 2-port)

Optical ESB Bus Repeater Master Module 5 km - 50 km

(for SSC60, SSC50, SSC57)

Optical ESB Bus Repeater Slave Module 5 km - 50 km

(for SSC60, SSC50, SSC57)

TI 32S01J10-01E

Oct. 1, 2014-00

Page 40

1. System Installation Requirements

Table G3 Environment-compatible Products (2/2)

No. Product Model Description

ALR111-1

Serial communication module (RS-232C, 2-port)

ALR121-1

Communication

6

module

7 Wiring check adapter

8 Power supply bus unit

ALR121-B

ALR121-3

ALE111-1

ALE111-3

SCB10

AEPV7D-6

AEPV7D-F

AEP7D-6

AEP7D-F

Serial communication module (RS-422/RS-485, 2-port)

Ethernet communication module (*1)

Wiring check adapter for digital input module

Power Supply Bus Unit, Vetical Type

Primary power supply bus unit

SEA4D Analog terminal board (Single and Dual-redundant, 16-channel x 2)

SBA4D

SBT4D

SBR4D

Terminal board for Analog: DIN rail mount type

(Single and Dual-redundant, 16-channel x 1)

Terminal board for TC/mV: DIN rail mount type

(Single and Dual-redundant, 16-channel x 1)

Terminal board for RTD input: DIN rail mount type

(Single and Dual-redundant, 16-channel x 1)

SED2D Digital terminal board (Single and Dual-redundant, 4-channel x 4)

9 Terminal Board

10 Router

*1: ALE111 supported in R3.02.00 or later can be mounted on SSC60, SSC50 or SSC57.

SED3D Digital terminal board (Single and Dual-redundant, 8-channel x 4)

SED4D Digital terminal board (Single and Dual-redundant, 16-channel x 2)

SWD2D

SBD2D

SBD3D

SBD4D

AVR10D-

1

Digital terminal board

(Single and Dual-redundant, 100 to 120 V AC, 4-channel x 4)

Terminal board for Digital output: DIN rail mount type

(Single and Dual-redundant, 4-channel x 1, for SDV521)

Terminal board for Digital output: DIN rail mount type

(Single and Dual-redundant, 8-channel x 1, for SDV53)

Terminal board for Digital: DIN rail mount type

(Single and Dual-redundant, 16-channel x 1, for SDV144/SDV541)

Duplexed V net router

1-28

TI 32S01J10-01E

Dec. 26, 2014-00

Page 41

1. System Installation Requirements

Outline of G3 Environment Compatibility

The classication of the environment in which the process control equipment is installed is

determined by the ANSI/ISA S71.04 “Environmental Conditions for Process Control Systems”

standard. The environment having an atmosphere which contains steams and mists (liquids,

coded L), dusts (solids, coded S), or corrosive gases (gases, coded G) is classied into four

categories according the levels of these substances determined.

The four categories of the corrosive gas environment are dened as follows:

G1 (Mild): A well-controlled environment in which corrosive gas is not the major cause

adversely affecting the reliability of plant equipment. The corrosion level on the

copper test piece is below 0.03 µm (see note below).

G2 (Moderate): An environment in which corrosive gas can be detected and it could be

determined that the gas is the major cause adversely affecting the reliability of

plant equipment. The corrosion level on the copper test piece is below 0.1 µm

(see note below).

G3 (Harsh): An environment in which corrosive gas is frequently generated to cause

corrosion and that it is necessary to provide special measures or employ

specially designed or packaged plant equipment. The corrosion level on the

copper test piece is below 0.2 µm (see note below).

GX (Severe): A corrosive gas-polluted environment that demands special protective chassis

for the plant equipment, specications of which should be seriously determined

by the user and a power unit manufacturer. The corrosion level on the copper

test piece is 0.2 µm or more (see note below).

Note: Copper test pieces are used to determine the level of corrosion for the classication of the plant environment.

The test piece is an oxygen-free copper sheet, which is 15 cm

piece is placed in the plant site for one month and checked for any change before and after the test to determine the degree of

corrosion (see table below). If the test period is shorter than one month, the result is calculated to obtain equivalent data using a

expression dened by the standard.

Table Classication of Corrosive-gas Corrosion Levels

Environment category

Copper corrosion level

G1

(Mild)

< 300

(< 0.03)

2

in area, 0.635 mm in thickness, 1/2 to 3/4H in hardness. The test

G2

(Moderate)

< 1000

(< 0.1)

G3

(Harsh)

< 2000

(< 0.2)

GX

(Severe)

≥ 2000

(≥ 0.2)

1-29

[Å]

( [µm] )

Group A H

Group B HF < 1 < 2 < 10 ≥ 10

Note: The gas density data indicated in the table are for reference only, with the relative humidity of 50% RH or less.

The category goes up one rank higher every time the humidity increases 10% exceeding the 50% RH or over 6% per hour.

S < 3 < 10 < 50 ≥ 50 [mm3/m3]

2

, SO3 < 10 < 100 < 300 ≥ 300

SO

2

< 1 < 2 < 10 ≥ 10

Cl

2

NOx < 50 < 125 < 1250 ≥ 1250

< 500 < 10000 < 25000 ≥ 25000

NH

3

< 2 < 25 < 100 ≥ 100

O

3

The Group-A gases shown in the table may coexist and cause inter-reaction. Inter-reaction

factors are not known for the Group-B gases.

Yokogawa Service Division will carry out environmental diagnosis in accordance with this

standard.

TI 32S01J10-01E

Oct. 1, 2014-00

Page 42

1. System Installation Requirements

1.8 Compliance with Marine Standards

The ProSafe-RS offers compliance with the following marine standards:

• American Bureau of Shipping (ABS)

• Bureau Veritas (BV)

• Lloyd’s Register

This Section introduces the components of systems which comply with the marine

standards, and precautions for installing those components.

Marine Standard-compliant ProSafe-RS Components

The table below shows the ProSafe-RS components which comply with the marine standards.

Table Marine Standard-compliant ProSafe-RS Components (1/3)

Product Model Module Type Description

Including SCP461, SPW481, SPW482

and SPW484.

SSC60S-S and SSC60D-S do not

comply.

Including SCP451, SPW481, SPW482

and SPW484.

Including SCP401, SPW481, SPW482

and SPW484.

Including SSB401, SPW481, SPW482

and SPW484.

(*1)

SAI143-HC does not comply.

Including SCCC01, STB4D, STB4S and

STK4A.

(*1)

(*2)

SDV144-SC does not comply.

SDV521-S3C does not comply.

(*2)

SDV531-L complies with Marine

Standards from style code S3.

SDV531-LC does not comply.

(*2)

SDV541-SC does not comply.

Including SPW481, SPW482 and

SPW484.

Node Unit

Input/Output Module

Wiring Check Adapter

Unit for Optical Bus

Repeater Module

*1: Including SCCC01, STA4D, STA4S and STK4A.

*2: Including SCCC01,SCCC02, STB4D, STB4S and STD4A.

SSC60S-F

SSC60D-F

SSC50S

SSC50D

SSC57S

SSC57D

SSC10S

SSC10D

SNB10D

SAI143

SAV144

SAT145

SAR145

SAI533

SDV144

SDV521

SDV531

SDV53A

SDV541

SDCV01 Dummy cover (for I/O modules)

SCB100

SCB110

SNT10D

Safety control unit

(19 inch rack mountable)

Safety control unit

(19 inch rack mountable)

Safety control unit

(19 inch rack mountable)

Node unit for dual-redundant ESB

bus (19 inch rack mountable)

Analog input module (4 to 20 mA,

16-channel, and module isolation)

Analog input module (1 to 5 V/1 to

10 V and module isolation)

TC/mV Input Module (16-channel,

Isolated Channels)

RTD Input Module (16-channel,

Isolated Channels)

Analog output module (4 to 20 mA,

8-channel and module isolation)

Digital input module (16-channel,

contact input and module isolation)

Digital output module (4-channel,

24 V DC/2A, and module isolation)

Digital output module (8-channel,

24 V DC, and module isolation)

Digital output module (8-channel,

48 V DC, and module isolation)

Digital output module (16-channel,

24 V DC, and module isolation)

Wiring check adapter for digital

input

Unit for optical bus repeater

module

1-30

TI 32S01J10-01E

Oct. 1, 2014-00

Page 43

1. System Installation Requirements

Table Marine Standard-compliant ProSafe-RS Components (2/3)

Product Model Module Type Description

Optical ESB bus repeater master

module

Optical ESB bus repeater master

module 5 km to 50 km

Optical ESB bus repeater slave

module

Optical ESB bus repeater slave

module 5 km to 50 km

ESB bus coupler module

Serial communications module

(RS-232C, 2-port)

Serial communications module

(RS-422/RS-485, 2-port)

(*3)

(*3)

ALR121-SB does not comply.

Optical ESB bus repeater

module

ESB Bus Interface

Module

Communication Module

SNT401

SNT411

SNT501

SNT511

SEC402

SEC401

ALR111

ALR121

ALE111 Ethernet comunication module

SEA4D

SED2D

SED3D

SED4D

Analog terminal board (single and

dual-redundant, 16-channel x 2)

Digital terminal board (single and

dual-redundant, 4-channel x 4)

Digital terminal board (single and

dual-redundant, 8-channel x 4)

Digital terminal board (single and

dual-redundant, 16-channel x 2)

Terminal board for TC/mV: DIN

SBT4D

rail mount type (Single and Dual-

redundant, 16-channel x 1)

Terminal board for RTD input: DIN

SBR4D

rail mount type (Single and Dual-

redundant, 16-channel x 1)

Terminal Board

SBA4D

Terminal board for Analog: DIN

rail mount type (Single and Dual-

redundant, 16-channel x 1)

Terminal board for Digital output:

SBD2D

DIN rail mount type (Single and

Dual-redundant, 4-channel x 1, for

SDV521)

Terminal board for Digital output:

SBD3D

DIN rail mount type (Single and

Dual-redundant, 8-channel x 1, for

SDV53)

Terminal board for Digital: DIN rail

SBD4D

mount type (Single and Dual-

redundant, 16-channel x 1, for

SDV144/SDV541)

SRM53D

SRM54D

Relay Board

SBM54D

8 × 2 dry contact output

(safety relay built-in, M4 terminals)

16 × 1 dry contact output

(safety relay built-in, M4 terminals)

Relay board for Digital output:

DIN rail mount type (Single and

Dual-redundant, 16-channel x 1,

for SDV541)

Control Bus Interface

VI702

VF702 (*4)

VI701

Control bus interface card

(*4)

VF701

Vnet Router AVR10D Duplexed V net router

*3: Only style code S1 complies with Marine Standards.

*4: Noisecut transformer shall be attached in the power-line cable of SENG.

1-31

TI 32S01J10-01E

Dec. 26, 2014-00

Page 44

1. System Installation Requirements

Table Marine Standard-compliant ProSafe-RS Components (3/3)

Product Model Module Type Description

YCB301 ESB bus cable

YCB141 V net cable (10BASE-2)

YCB111 V net cable (10BASE-5)

Cable, etc.

AKB651

AKB331 Signal Cable (50 - 50 pins)

AKB136

AKB161 RS-422/RS-485 cable

AKB611

KS1 Signal cable (40 - 40 pins)

YCB148 V net terminator

YCB146 T-shaped control bus connector

YCB128 Terminator for IRIG (GPS)

Signal Cable (50 - 50 pins) (for

connections between SDV521 and

Terminal Board)

RS-232C null modem cable (9 - 25

pins)

Signal cable (for connections

between SAR145 and Terminal

Board)

When AKB651 is connected to

SDV531-L, SDV53A or SDV541,

it does not comply.

Precaution on Selecting System Components

1-32

When building a system, use components which have already obtained type approval for marine

standards. For the SENG and HISs too, use generic computers (including monitors, keyboards,

mice, and other peripheral devices) which are accredited by the required marine standards.

Precaution on Installing Components

Each component shall be installed in accordance with its installation guidance. In addition, all

components related with SSC60-F, SSC50, SSC57, SSC10, SNB10D, SNT10D and

SENG shall be installed in a metal cabinet.

• The cabinets including their doors and side panels must be made of a metal.

• Securely connect the cabinet frames and ground bosses on doors and side panels to each

other to ensure electric contacts.

• Attach noise suppression devices, such as noise lters and ferrite cores, to the cables

connecting each component.

Installation of Power-line Noise Filter

Attach a noise lter on the power line for the following components:

• Safety Control Unit (SSC60-F, SSC50,SSC57, SSC10)

• Safety Node Unit (SNB10D)

• Unit for Optical Bus Repeater Module (SNT10D)

• Safety Control PC (SENG) installed control bus interface (VI702, VF702)

TI 32S01J10-01E

Oct. 1, 2014-00

Page 45

1. System Installation Requirements

F010805.ai

Allowed Not allowed

Power-line for SSC60-F, SSC50, SSC57, SSC10, SNB10D and SNT10D

Attach a noise lter in each power line of SPW48, FAN and external power supply unit.

Alternatively, other devices such as noisecut transformer and insulating transformer can be used

if its characteristic of noise-reducing effects is same as the following equipment.

Noise lter and external power supply unit shall be installed in the same cabinet of the connecting

terminal board for them.

If digital Input/output modules such as SDV144, SDV521, SDV531, SDV53A and SDV541 are

used, power line for an external power shall be separated from the power line of SPW48 and

FAN.

This means that two AC power cables are out from the cabinet.

It is possible to use power tap outside of the cabinet. Please refer to the following gure.

SSC60

/SSC50

SSC60/SSC50

/SSC57/SSC10

/SSC57/SSC10

1-33

External PSU External PSU

Tap

Noise Filter Noise Filter

AC power feed

Tap

Tap

Figure Wiring for AC power cables

The following table shows example of a noise lter.

Category Manufacturer Model no. Power Source

Noise lter

OKAYA Electric Industries Co., LTD SUPH-EX10-ER-6

COSEL Co., LTD NBH-20-432 24 V DC (*1)

AC/DC

SNB10D SNB10D

AC/DC AC/DC AC/DC

Tap

Tap

Noise Filter

AC power feed

Tap

100 - 120 V AC

220 - 240 V AC

*1: For expansion or modication of unit, the existing TDK Lambda PSHN-2020 can also be used.

IMPORTANT

Lay the incoming wires to a noise lter separately from its outgoing wires.

Minimize the wiring to the ground terminals of the noise lters to minimize the impedance.

TI 32S01J10-01E

Oct. 1, 2014-00

Page 46

1. System Installation Requirements

Power-line for SENG

Noisecut transformer shall be installed in the cabinet and attached in the power-line cable of

SENG in case of using VI702, VF702.

The following table shows applicable noisecut transformer.

Table Applicable noisecut transformer

Description Manufacturer Model

Noisecut Transformer DENKENSEIKI

Research Institute CO., Ltd

TAMURA Corporation NRPT-TB0.5 (*2)

*1: Purchase it through distributer.

*2: Sales was terminated. Use NCT-I1 when purchase noisecut transformer newly.

NCT-I1 (*1)

IMPORTANT

Lay the incoming wires to a noisecut transformer separately from its outgoing wires.

Minimize the wiring to the ground terminal of the noisecut transformer to minimize the

impedance.

1-34

Installation of Ferrite Cores for Vnet/IP

Attach ferrite cores on the power cables, the communication cables and the signal cables.

The following table shows the cables to which ferrite cores are to be attached, the models and

quantities of the ferrite cores to be attached, and the locations at which they are to be attached.

Ferrite core is not required if the component is not listed below. See also the gure following the

table for the locations of installation.

Table Cables that Need Ferrite Cores to be Attached to, and Ferrite Core Models and Quantities for

Vnet/IP (1/2)

Component Description

Power supply

Fan

External power

supply (Input side)

SSC60

-F Power module

Power module

SSC50

Power module

SSC57

SNB10D Power module AC/DC power cable ZCAT3035-1330 4 (2)

SNT10D Power module AC/DC power cable ZCAT3035-1330 2 (3)

AVR10D Power module AC/DC power cable ZCAT3035-1330 4 (4)

SSC60

-F Fan unit

-F Fan unit

SSC50

-F Fan unit

SSC57

Power Supply

(SDV531, SDV541)

AC/DC power cable ZCAT3035-1330 3 (1)

AC/DC power cable ZCAT3035-1330 2 –

AC/DC power cable ZCAT3035-1330 2 –

AC/DC power cable ZCAT3035-1330 3 (5)

AC/DC power cable ZCAT3035-1330 2 –

AC/DC power cable ZCAT3035-1330 2 –

AC power cable

(Input side)

Ferrite Core

Model (*1)

ZCAT3035-1330 1 (6)

ZCAT2032-0930 1

Quantity

Location

(See the

Figures)