Page 1

User's

Manual

Plant Resource Manager

Reference

IM 33Y05Q10-11E

IM 33Y05Q10-11E

7th Edition

Page 2

Introduction

This manual consists of the following parts:

• Part A: About PRM

This part provides general information about PRM.

• Part B: Configuring PRM

This part describes the tools and settings for configuring PRM.

• Part C: Working with the PRM Client

This part describes the basic features and operations of the PRM Client.

• Part D: Managing devices

This part describes device-related management tasks in PRM.

• Part E: Monitoring and diagnosing devices

This part describes device monitoring, diagnosing, and maintenance-related tasks in

PRM.

• Part F: Configuring device parameters

This part describes device parameter configuration tasks in PRM.

• Part G: Maintaining PRM

This part describes how to maintain the PRM system using the backup tools and the Database Maintenance Tool.

i

• Part H: Performing an advanced diagnosis

This part describes concepts and procedures on how to perform an advanced diagnosis

using the PRM Advanced Diagnostic Application (PAA).

• Part I: Working with the PST Scheduler

This part describes how to configure the PST Scheduler and then use it to schedule, perform, and monitor partial stroke tests.

• Part J: Connecting PRM to a CMMS

This part describes about CMMS, and the settings required to connect PRM to a CMMS.

• Part K: Integrating a third-party system

This part describes the procedures to integrate PRM with a third-party system.

Media No. IM 33Y05Q10-11E (CD) 7th Edition : Feb. 2012 (YK)

All Rights Reserved Copyright © 2006-2012, Yokogawa Electric Corporation

IM 33Y05Q10-11E 7th Edition : Feb.08,2012-00

Page 3

Plant Resource Manager Document Map

Reference

n

Security Guide

n

ii

Installation

n

PRM Advanced Diagnostic Application

n

IM 33Y05Q10-11E 7th Edition : Feb.08,2012-00

Page 4

Safety precautions

Safety, protection, and modification of the product

n

• To protect the system controlled by the product and the product itself and ensure safe operation, observe the safety precautions described in this user's manual . Yokogawa Electric Corporation (hereinafter referred to as YOKOGAWA) assumes no liability for safety if

users fail to observe the safety precautions and instructions when operating the product.

• If this product is used in a manner not specified in this user's manual, the protection provided by this product may be impaired.

• If any protection or safety circuit is required for the system controlled by the product or for

the product itself, install it externally.

• Use only spare parts that are approved by YOKOGAWA when replacing parts or consumables of the product.

• Do not use the product and accessories of the product such as power cords on devices

that are not approved by YOKOGAWA. Do not use the product and its accessories for

other purposes.

• Modification of the product is strictly prohibited.

• The following symbols are used in the product and user's manual to indicate the accompanying safety precautions:

iii

Indicates that caution is required for operation. This symbol is placed on the product to

refer the user to the user's manual to protect the operator and the equipment. In the

user's manual, you will find precautions to avoid physical injury and/or death, which

may be caused by accidents, such as electrical shocks resulting from operation mistakes.

Identifies a protective grounding terminal. Before using the product, ground the terminal.

Identifies a functional grounding terminal.

Indicates an AC supply.

Indicates a DC supply.

Indicates that the power supply switch is ON.

Indicates that the power supply switch is OFF.

Notes on handling user's manuals

n

• Hand over the user's manuals to your end users so that they can keep the user's manuals

on hand for reference.

• Read and understand the information in the user's manual thoroughly before using the

product.

• For the avoidance of any doubt, the purpose of these user's manuals is not to warrant

that the product is suitable for any particular purpose but to describe the functional details

of the product.

• YOKOGAWA reserves the right to make improvements in the user's manuals and product

at any time, without notice or obligation.

• Every effort has been made in the preparation of this manual to ensure the accuracy of its

contents. However, should you have any questions or find any errors, contact our sales

IM 33Y05Q10-11E 7th Edition : Feb.08,2012-00

Page 5

representative or your local distributor. Manuals with incorrectly ordered pages or missing

pages will be replaced.

Warning and disclaimer

n

• The product is provided on an "as is" basis.

• YOKOGAWA shall have neither liability nor responsibility to any person or entity with respect to any direct or indirect loss or damage arising from using the product or any defect

of the product that YOKOGAWA can not predict in advance.

Notes on software

n

• YOKOGAWA makes no warranties, either expressed or implied, with respect to the software’s merchantability or suitability for any particular purpose, except as strictly provided

in the terms of warranty.

• The software may be used only on the specified computer. If you need to use the software on another computer, you must purchase another software.

• It is strictly prohibited and an infringement of YOKOGAWA's Intellectual Property rights to

reproduce the software except for the purpose of backup.

• Store all the original media that comes with the product in a safe place.

iv

• It is strictly prohibited and an infringement of YOKOGAWA's Intellectual Property rights to

reverse engineer, reverse compile, reverse assemble, or reduce the software to humanreadable form.

• No part of the software may be transferred, converted, or sublet for use by any third-party,

without prior written consent from YOKOGAWA, failing which any warranty statements

provided for the product and/or software shall be rendered void.

IM 33Y05Q10-11E 7th Edition : Feb.08,2012-00

Page 6

Documentation conventions

Symbol marks

n

The following symbols identify various sections of text in this user's manual.

Identifies instructions that must be observed to avoid physical

injury, electric shock, or death.

Identifies instructions that must be observed to prevent damages to the software or hardware, or defects to the system.

Identifies important information required to understand operations or functions.

Identifies additional information.

Identifies referenced content.

You can view the referenced content by clicking the green text.

v

Typographical conventions

n

The following typographical conventions are used throughout the user's manuals.

Commonly used conventions throughout user's manuals

l

• Character string to be entered

The characters that must be entered are shown in monospace font as follows:

Example:

FIC100.SV=50.0

"∆" mark indicates a space between character strings that must be entered.

Example:

AL∆PIC010∆-SC

• Character string enclosed by brackets ({ })

Indicates an option that can be omitted.

Example:

.PR∆TAG{∆.sheet name}

This action does not apply to the black text.

Conventions used to show key or button operations

l

Characters enclosed by brackets ([ ])

In descriptions of key or button operations, words enclosed in brackets indicate either a key

on the HIS (Human Interface Station) keyboard, a key on the operation keyboard, a button

name in a window, or an item on a list box displayed in a window.

Example:

To alter the function, press the [ESC] key.

IM 33Y05Q10-11E 7th Edition : Feb.08,2012-00

Page 7

Conventions used in command syntax or program statements

l

The following conventions are used within a command syntax or program statement format.

• Characters enclosed by angle-brackets

Indicate character strings that user can specify freely according to certain guidelines.

Example:

#define <Identifier><Character string>

"..." mark

Indicates that the previous command or argument may be repeated

Example:

Imax (arg1, arg2, ...)

• Characters enclosed by brackets ([ ])

Indicate those character strings that can be omitted.

Example:

sysalarm format_string[output_value ...]

• Characters enclosed by separators (| |)

vi

Indicate those character strings that can be selected from more than one option.

Example:

opeguide <format_character_string> [, <output_value> ...]

Drawing conventions

n

Some drawings may be partially emphasized, simplified, or omitted for the convenience of description.

In the user's manual, the parts in some drawings may be placed in different positions or have

different font settings. Note that some of the images in user's manuals are display examples.

OG,<element number>

IM 33Y05Q10-11E 7th Edition : Feb.08,2012-00

Page 8

Copyright and trademark notices

All rights reserved

n

The copyright of the programs and online manuals contained in the software media shall remain with YOKOGAWA.

You are allowed to print the required pages of the online manuals for the purposes of using

and/or operating the product. However, you are not allowed to print or reproduce the entire

document. You can purchase the printed manual from YOKOGAWA.

Except as stated above, no part of the online manual may be reproduced, either in electronic

or written form, registered, recorded, transferred, sold, or distributed (in any manner including

without limitation, in the forms of paper documents, electronic media, films, or transmission

via the network). Any in-action and/or silence by YOKOGAWA with regard to any breach of

the above shall not be taken as any waiver of its rights whatsoever and YOKOGAWA reserves all its rights until expressly waived by written notification and no other occasions.

Trademark acknowledgments

n

• PRM is a registered trademark of Yokogawa Electric Corporation in the United States and

Japan.

vii

• CENTUM, Vnet/IP, and ProSafe are registered trademarks of YOKOGAWA.

• STARDOM is a trademark.

• Microsoft, Windows, Windows Vista, Visual Basic, Visual C++, and Visual Studio are either registered trademarks or trademarks of Microsoft Corporation in the United States

and/or other countries.

• Pentium is a registered trademark of Intel Corporation.

• Adobe and Acrobat are either registered trademarks or trademarks of Adobe Systems Incorporated in the United States and/or other countries.

• Oracle is a registered trademark of ORACLE Corporation.

• Maximo is a registered trademark of IBM.

• System 1, Bently Nevada, and Trendmaster are trademarks of General Electric Company.

• Ethernet is a registered trademark of XEROX Corporation.

• Java is a registered trademark of Sun Microsystems,Inc.

•

• HART is a registered trademark of HART Communication Foundation.

• All other company and product names mentioned in this manual are trademarks or registered trademarks of their respective companies.

• TM or ® mark are not used to indicate trademarks or registered trademarks in this manual.

in fieldbus is a registered trademark of Fieldbus Foundation.

• We do not use logos and logo marks in this manual.

IM 33Y05Q10-11E 7th Edition : Feb.08,2012-00

Page 9

TocA-1

Plant Resource Manager Reference

IM 33Y05Q10-11E 7th Edition

CONTENTS

PART-A About PRM.......................................................A-1

A1. The Plant Resource Manager............................................................A1-1

A2. PRM packages....................................................................................A2-1

A3. How PRM works.................................................................................A3-1

A3.1 Device connection methods.....................................................................A3-3

A4. Features..............................................................................................A4-1

IM 33Y05Q10-11E 7th Edition : Feb.08,2012-00

Page 10

TocB-1

Plant Resource Manager Reference

IM 33Y05Q10-11E 7th Edition

CONTENTS

PART-B Configuring PRM.............................................B-1

B1. Tasks after new installation..............................................................B1-1

B2. PRM Server.........................................................................................B2-1

B2.1 Server sets..................................................................................................B2-3

B3. Field Communications Server..........................................................B3-1

B3.1 Device path.................................................................................................B3-2

B3.1.1 Configuring device paths.............................................................B3-8

B3.1.2 Devices connected to CENTUM................................................B3-16

B3.1.3 Devices connected to STARDOM..............................................B3-22

B3.1.4 Devices connected to ProSafe-RS............................................B3-25

B3.1.5 Devices connected locally..........................................................B3-26

B3.2 FDT projects.............................................................................................B3-28

B3.2.1 Managing FDT projects..............................................................B3-32

B3.2.2 Configuring FDT projects...........................................................B3-36

B3.3 DD files......................................................................................................B3-51

B3.3.1 Installing DD files of other manufacturers..................................B3-53

B3.3.2 DD Copy Tool.............................................................................B3-54

B4. PRM Client..........................................................................................B4-1

B4.1 PRM Client connection settings...............................................................B4-2

B4.2 Customizing the appearance....................................................................B4-5

B4.3 Label customization...................................................................................B4-6

B4.4 DTM Setup..................................................................................................B4-7

B4.5 Copying DD files......................................................................................B4-10

B4.6 Fast Device Patrol settings for HART devices......................................B4-11

B5. Managing accounts and device security.........................................B5-1

B5.1 Group and user accounts..........................................................................B5-2

B5.1.1 PRM groups.................................................................................B5-3

B5.1.2 PRM user accounts......................................................................B5-8

B5.2 Managing device security.......................................................................B5-15

B5.2.1 Configuring device security........................................................B5-17

B5.2.2 Device security configuration examples.....................................B5-19

B6. Managing master data.......................................................................B6-1

IM 33Y05Q10-11E 7th Edition : Feb.08,2012-00

Page 11

TocB-2

B6.1 Importing and exporting master data.......................................................B6-3

B6.2 Device icons...............................................................................................B6-5

B6.2.1 Device icon assignment...............................................................B6-9

IM 33Y05Q10-11E 7th Edition : Feb.08,2012-00

Page 12

TocC-1

Plant Resource Manager Reference

IM 33Y05Q10-11E 7th Edition

CONTENTS

PART-C Working with the PRM Client..........................C-1

C1. Getting started with the PRM Client.................................................C1-1

C1.1 Accessing the PRM Client.........................................................................C1-2

C1.2 Using the PRM window..............................................................................C1-4

C1.2.1 Using the Device Navigator.........................................................C1-6

C1.2.2 Using the function pane...............................................................C1-8

C1.3 Changing server sets in the PRM Client................................................C1-13

C1.4 Using context search...............................................................................C1-14

C1.5 Viewing online manuals..........................................................................C1-16

C2. Working with the Device Navigator..................................................C2-1

C2.1 Plant view....................................................................................................C2-2

C2.1.1 Plant view structure.....................................................................C2-3

C2.1.2 Plant view operations...................................................................C2-5

C2.2 Network view..............................................................................................C2-8

C2.2.1 Network view structure................................................................C2-9

C2.2.2 Network view operations............................................................C2-14

C2.3 Class view.................................................................................................C2-19

C2.3.1 Class view structure...................................................................C2-20

C2.3.2 Class view operations................................................................C2-23

C2.4 Custom view.............................................................................................C2-25

C2.4.1 Custom view structure...............................................................C2-26

C2.4.2 Custom view operations............................................................C2-27

C3. Printing reports using the Self Document feature..........................C3-1

C3.1 Printing reports..........................................................................................C3-2

C3.2 Report structures.......................................................................................C3-9

C4. Searching using the Facility & Inspection Browser.......................C4-1

C4.1 Searching for information.........................................................................C4-4

C4.2 Searching for parameter data...................................................................C4-6

C4.3 Working with search results.....................................................................C4-9

IM 33Y05Q10-11E 7th Edition : Feb.08,2012-00

Page 13

TocD-1

Plant Resource Manager Reference

IM 33Y05Q10-11E 7th Edition

CONTENTS

PART-D Managing devices............................................D-1

D1. Registering devices...........................................................................D1-1

D1.1 Device registration methods.....................................................................D1-2

D1.2 Device registration.....................................................................................D1-3

D1.2.1 Plug & Play..................................................................................D1-4

D1.2.2 Host file set import.......................................................................D1-9

D1.2.3 Manual registration....................................................................D1-12

D1.2.4 Maintenance information import................................................D1-15

D1.2.5 FieldMate synchronization.........................................................D1-16

D1.2.6 Detecting HART devices connected to a multiplexer.................D1-17

D1.3 Replacing devices....................................................................................D1-19

D1.3.1 Updating device information in PRM after replacing devices..............

...................................................................................................D1-22

D1.3.2 Device information inheritance function.....................................D1-23

D1.4 Updating device details...........................................................................D1-25

D1.5 Changing the network location of devices............................................D1-27

D1.6 Deleting devices.......................................................................................D1-33

D2. Viewing and modifying device details.............................................D2-1

D2.1 Device tag display extension....................................................................D2-2

D2.1.1 Device tag display extension for HART devices..........................D2-3

D2.1.2 Device tag display extension for devices in STARDOM upstream

projects........................................................................................D2-4

D2.1.3 Configuring the device tag display extension in PRM..................D2-5

D2.1.4 Device tag display extension specifications.................................D2-7

D2.2 Viewing the device list in the Device List window..................................D2-9

D2.3 Viewing device details in the Device Details window...........................D2-11

D2.4 Modifying or updating devices...............................................................D2-17

D2.5 Exporting and importing the device list.................................................D2-18

D2.6 Customizing user-definable fields..........................................................D2-22

D3. Validating HART device ranges........................................................D3-1

D3.1 Validating HART device ranges................................................................D3-3

D3.1.1 Acquiring CENTUM HART range information..............................D3-4

D3.1.2 Acquiring PRM HART range information.....................................D3-6

IM 33Y05Q10-11E 7th Edition : Feb.08,2012-00

Page 14

TocD-2

D3.1.3 Comparing HART range information............................................D3-7

D3.2 HART device range validation procedure..............................................D3-13

D3.2.1 Validation operation flow of HART device ranges......................D3-14

D3.2.2 Acquiring CENTUM HART range information............................D3-16

D3.2.3 Acquiring PRM range information..............................................D3-17

D3.2.4 Acquiring HART range comparison result..................................D3-18

D3.3 Handling errors........................................................................................D3-19

D4. Using device templates.....................................................................D4-1

D4.1 Device classes............................................................................................D4-2

D4.2 Registering devices during plant commissioning..................................D4-3

D4.2.1 Using device templates................................................................D4-4

D4.2.2 Without using device templates...................................................D4-6

D4.3 Device template contents..........................................................................D4-8

D4.4 When to apply device templates...............................................................D4-9

D4.5 Working with device templates...............................................................D4-14

D5. Managing parts..................................................................................D5-1

D5.1 Parts code...................................................................................................D5-2

D5.2 Parts list......................................................................................................D5-5

D6. Managing document links.................................................................D6-1

D6.1 Registering documents in PRM................................................................D6-2

D6.2 Using document links................................................................................D6-5

D7. Importing and exporting maintenance information........................D7-1

IM 33Y05Q10-11E 7th Edition : Feb.08,2012-00

Page 15

TocE-1

Plant Resource Manager Reference

IM 33Y05Q10-11E 7th Edition

CONTENTS

PART-E Monitoring and diagnosing devices..............E-1

E1. Handling maintenance alarms..........................................................E1-1

E1.1 Contents of maintenance alarms..............................................................E1-5

E1.2 Configuring maintenance alarms.............................................................E1-8

E1.2.1 Configuring initial system settings..............................................E1-10

E1.2.2 Device settings...........................................................................E1-15

E1.2.3 Alarm management rules...........................................................E1-17

E1.2.4 Notification rules........................................................................E1-28

E1.3 Maintenance alarm messages.................................................................E1-36

E2. Using the Diagnosis window............................................................E2-1

E2.1 Device status integration...........................................................................E2-5

E2.2 Configuring Status Override...................................................................E2-12

E3. Viewing the status of a device..........................................................E3-1

E3.1 Device status icon......................................................................................E3-2

E3.1.1 Status colors................................................................................E3-3

E3.1.2 Status display...............................................................................E3-4

E3.1.3 Managing device status...............................................................E3-6

E3.2 Unacknowledged alarm icon.....................................................................E3-8

E3.3 Usage states.............................................................................................E3-10

E4. Diagnosing devices using DeviceViewer.........................................E4-1

E4.1 DeviceViewer window................................................................................E4-3

E4.1.1 Periodic mode..............................................................................E4-4

E4.1.2 Diagnostic Information tab...........................................................E4-5

E4.1.3 Trend Information tab...................................................................E4-8

E5. Working with maintenance marks....................................................E5-1

E5.1 Managing MTMK definitions......................................................................E5-6

E5.2 Configuring synchronization with CENTUM operation marks.............E5-11

E5.2.1 Configuring MTMK settings in the PRM Setup Tool...................E5-15

E5.2.2 Mapping CENTUM function blocks to PRM devices..................E5-17

E5.2.3 Configuring device-level synchronization settings.....................E5-18

E5.3 Configuring MTMK-related notifications................................................E5-19

E5.4 Setting and removing MTMKs in the PRM Client..................................E5-20

IM 33Y05Q10-11E 7th Edition : Feb.08,2012-00

Page 16

TocE-2

E5.5 Triggering synchronization in the Device Navigator............................E5-24

E5.6 Examples of synchronization with CENTUM.........................................E5-25

E5.6.1 Example: Unidirectional synchronization initiated from CENTUM.......

...................................................................................................E5-26

E5.6.2 Example: Bidirectional synchronization initiated from both PRM and

CENTUM....................................................................................E5-30

E6. Inspecting devices.............................................................................E6-1

E6.1 Managing service codes............................................................................E6-3

E6.2 Managing inspection schedules...............................................................E6-6

E6.3 Managing inspection memos..................................................................E6-11

E6.4 Reference codes.......................................................................................E6-21

E7. Working with history records...........................................................E7-1

E7.1 History window...........................................................................................E7-5

IM 33Y05Q10-11E 7th Edition : Feb.08,2012-00

Page 17

TocF-1

Plant Resource Manager Reference

IM 33Y05Q10-11E 7th Edition

CONTENTS

PART-F Configuring device parameters......................F-1

F1. Adjusting device parameters............................................................F1-1

F1.1 Adjusting parameters.................................................................................F1-5

F1.2 Using Parameter Manager.......................................................................F1-16

F1.3 Using DTM Works.....................................................................................F1-27

F1.4 Using DD Menu for FF-H1 devices..........................................................F1-36

F1.5 Connecting to FieldMate..........................................................................F1-39

F2. Managing calibration data.................................................................F2-1

F2.1 Workflow for managing calibration data..................................................F2-5

F2.1.1 Using a conventional device........................................................F2-6

F2.1.2 Using a Documenting Calibrator..................................................F2-9

F2.2 Working with calibration data.................................................................F2-13

F2.3 Viewing and modifying calibration data details....................................F2-17

F2.4 Managing calibration groups..................................................................F2-28

F2.5 Downloading and uploading calibration data........................................F2-31

F2.6 Approving calibration data......................................................................F2-34

F2.7 Printing documents related to calibration.............................................F2-37

F2.8 Exporting and importing of calibration data..........................................F2-39

F3. Using PLUG-IN applications..............................................................F3-1

F3.1 Working with PLUG-IN applications.........................................................F3-2

IM 33Y05Q10-11E 7th Edition : Feb.08,2012-00

Page 18

TocG-1

Plant Resource Manager Reference

IM 33Y05Q10-11E 7th Edition

CONTENTS

PART-G Maintaining PRM.............................................G-1

G1. Backing up and restoring PRM data................................................G1-1

G1.1 Using the Fast Backup tool.......................................................................G1-2

G1.2 Using the PRM System Backup Script.....................................................G1-6

G2. Maintaining PRM databases.............................................................G2-1

G2.1 Archiving, retrieving, and deleting data..................................................G2-5

G2.1.1 Procedures..................................................................................G2-7

G2.2 Cleaning up the PRM database..............................................................G2-13

G2.3 Cleaning up the Historian database.......................................................G2-15

IM 33Y05Q10-11E 7th Edition : Feb.08,2012-00

Page 19

TocH-1

Plant Resource Manager Reference

IM 33Y05Q10-11E 7th Edition

CONTENTS

PART-H Performing an advanced diagnosis...............H-1

H1. Advanced diagnosis..........................................................................H1-1

H1.1 Software packages.....................................................................................H1-2

H1.2 How it works...............................................................................................H1-4

H1.3 Data acquisition.........................................................................................H1-9

H1.4 Device Diagnosis Data Historian............................................................H1-12

H1.5 Replacing, renaming, and deleting devices..........................................H1-14

H2. Preparing for an advanced diagnosis..............................................H2-1

H2.1 Deciding on the system configuration.....................................................H2-2

H2.2 Configuration settings...............................................................................H2-4

H2.3 Acquiring and storing device diagnostic parameters............................H2-6

H3. Starting the advanced diagnosis using the Diagnosis Navigator.........

.............................................................................................................H3-1

H3.1 Opening and closing Diagnosis Navigator..............................................H3-3

H3.2 Managing PAAs..........................................................................................H3-6

H3.3 Managing diagnosis modules...................................................................H3-9

H3.4 Monitoring diagnosis modules...............................................................H3-17

H3.5 Importing and exporting diagnosis module information.....................H3-20

H4. Monitoring an advanced diagnosis..................................................H4-1

H5. Displaying graphical results using the General-purpose Diagnostic

Tool......................................................................................................H5-1

H5.1 Using GDT...................................................................................................H5-3

H5.2 Trend graphs............................................................................................H5-10

H5.3 Correlation graphs...................................................................................H5-13

H5.4 Exporting data..........................................................................................H5-16

IM 33Y05Q10-11E 7th Edition : Feb.08,2012-00

Page 20

TocI-1

Plant Resource Manager Reference

IM 33Y05Q10-11E 7th Edition

CONTENTS

PART-I Working with the PST Scheduler.....................I-1

I1. About the PST Scheduler...................................................................I1-1

I2. Getting started with the PST Scheduler Client.................................I2-1

I3. Configuring the PST Scheduler.........................................................I3-1

I3.1 Managing users...........................................................................................I3-2

I3.1.1 Managing user roles......................................................................I3-4

I3.1.2 Managing user teams....................................................................I3-7

I3.1.3 Managing user accounts...............................................................I3-9

I3.2 Managing devices and groups.................................................................I3-12

I3.2.1 Importing device information.......................................................I3-14

I3.2.2 Managing PST groups.................................................................I3-19

I3.2.3 Managing hierarchy.....................................................................I3-26

I3.3 Configuring alarm and notification rules................................................I3-28

I3.4 Customizing the PST Scheduler Client interface...................................I3-30

I4. Operating the PST Scheduler.............................................................I4-1

I4.1 Scheduling a PST........................................................................................I4-2

I4.2 Manually performing PSTs........................................................................I4-12

I4.3 Registering test results and assigning PST schedules.........................I4-15

I5. Monitoring PSTs..................................................................................I5-1

I5.1 Viewing PST schedules and status............................................................I5-2

I5.2 Viewing group and device details............................................................I5-11

I6. Backing up and restoring PST Scheduler data................................I6-1

I6.1 Backing up PST Scheduler data.................................................................I6-2

I6.2 Restoring PST Scheduler data...................................................................I6-4

IM 33Y05Q10-11E 7th Edition : Feb.08,2012-00

Page 21

TocJ-1

Plant Resource Manager Reference

IM 33Y05Q10-11E 7th Edition

CONTENTS

PART-J Connecting PRM to a CMMS...........................J-1

J1. About CMMS.......................................................................................J1-1

J2. Connecting PRM to Maximo..............................................................J2-1

J2.1 Configuring PRM and Maximo...................................................................J2-2

J2.1.1 Configuring PRM..........................................................................J2-3

J2.1.2 Configuring Maximo......................................................................J2-6

J2.1.3 Synchronizing hierarchical structure and device information.....J2-14

J2.1.4 Managing work orders................................................................J2-20

J2.1.5 Device management after connecting to Maximo......................J2-22

IM 33Y05Q10-11E 7th Edition : Feb.08,2012-00

Page 22

TocK-1

Plant Resource Manager Reference

IM 33Y05Q10-11E 7th Edition

CONTENTS

PART-K Integrating a third-party system.....................K-1

K1. PRM and System 1 integration.........................................................K1-1

K1.1 How it works...............................................................................................K1-6

K1.2 Requirements.............................................................................................K1-7

K1.3 Engineering procedure to connect System 1........................................K1-10

IM 33Y05Q10-11E 7th Edition : Feb.08,2012-00

Page 23

TocApp.-1

Plant Resource Manager Reference

IM 33Y05Q10-11E 7th Edition

CONTENTS

Appendix

Appendix 1. Help codes.......................................................................App.1-1

Appendix 2. Error codes......................................................................App.2-1

Appendix 3. History messages stored in the PRM database...........App.3-1

Appendix 4. Glossary...........................................................................App.4-1

IM 33Y05Q10-11E 7th Edition : Feb.08,2012-00

Page 24

A. About PRM

This part provides general information about PRM.

Overview

n

This part consists of the following sections:

• The Plant Resource Manager

Briefly describes PRM.

• PRM packages

Identifies the basic and optional packages.

• How PRM works

Describes how PRM works and identifies the supported device communication types and

connection methods.

• Features

Describes the key PRM features and explains their availability.

<A. About PRM> A-1

IM 33Y05Q10-11E 7th Edition : Feb.08,2012-00

Page 25

<A1. The Plant Resource Manager>

A1. The Plant Resource Manager

Plant Resource Manager (PRM), a key component of the YOKOGAWA VigilantPlant Asset

Excellence initiative, is a centralized asset management system that helps to reduce plant

downtime and maintenance costs.

PRM enables you to:

• Manage device information within the plant

• Monitor device status and alarms

• Manage device inspection activities

• Configure device parameters and settings

• Manage calibration information

• Perform advanced diagnostic analysis

PRM can be configured to manage assets used for a variety of systems within a plant, including:

• CENTUM

• ProSafe-RS

A1-1

• STARDOM

PRM can also connect to the following systems and applications from third-party vendors to

expand its asset maintenance management coverage:

• IBM Maximo Asset Management

• GE Energy's System 1

• PLUG-IN applications from device vendors

IM 33Y05Q10-11E 7th Edition : Feb.08,2012-00

Page 26

A2. PRM packages

PRM includes basic and optional packages. Each package requires a license.

Basic packages

n

A PRM installation requires the following basic packages:

PRM Server

l

The PRM Server collects device information and saves it to the database. This information includes messages, device parameters, inspection data, and other related information used in

device management.

PRM Client

l

PRM Client is a graphical user interface application used to view device information, monitor

device status, and perform various operations related to device management.

Field Communications Server

l

The Field Communications Server acts as the gateway between PRM and apparatuses to

which devices are connected. The following are examples of apparatuses:

<A2. PRM packages>

A2-1

• CENTUM Field Control Station (FCS)

• ProSafe-RS Safety Control Station (SCS)

• STARDOM Field Control Node (FCN)

• STARDOM Field Control Junction (FCJ)

• HART multiplexer

PRM can connect to multiple apparatuses simultaneously. To establish the connection, the

apparatus and the computer on which the Field Communications Server is installed must be

on the same network. Multiplexers, on the other hand, must be connected directly to the COM

port of the Field Communications Server computer.

Optional packages

n

The following packages provide additional functionality to PRM:

PRM Advanced Diagnostic Server

l

PRM Advanced Diagnostic Server enables you to perform advanced device diagnosis using

algorithmic logic called PRM Advanced Diagnostic Applications (PAA). It comprises two major

components, the Advanced Diagnosis and the Device Diagnosis Data Historian.

PRM Advanced Diagnostic Application Development Kit

l

PRM Advanced Diagnostic Application Development Kit is used to develop or customize PRM

Advanced Diagnostic Applications (PAA).

Documenting Calibrator Interface

l

Documenting Calibrator Interface is used as an interface to documenting calibrators such as

FLUKE.

Interface for CMMS

l

The Interface for CMMS is used to connect PRM to a Computerized Maintenance Management System (CMMS).

IM 33Y05Q10-11E 7th Edition : Feb.08,2012-00

Page 27

<A2. PRM packages> A2-2

Interface for GE Energy's System 1

l

Interface for GE Energy's System 1 is used to connect PRM to GE Energy's System 1 and

monitor the status of rotating machinery connected to System 1.

PST Scheduler

l

PST Scheduler is used to schedule, conduct, and monitor partial stroke tests for emergency

shutdown (ESD) valves.

IM 33Y05Q10-11E 7th Edition : Feb.08,2012-00

Page 28

A3. How PRM works

PRM provides a convenient way of obtaining the health condition of instrumentation equipment throughout the plant from a single location. PRM does this by periodically communicating with devices and displaying the device status represented by color-coded icons in the

PRM Client. You can also initiate a request to obtain the device status in real time.

To communicate with devices, the Field Communications Server of PRM needs to be connected to the apparatuses to which field devices are connected. The following are examples of

apparatuses:

• CENTUM Field Control Station (FCS)

• ProSafe-RS Safety Control Station (SCS)

• STARDOM Field Control Node (FCN)

• STARDOM Field Control Junction (FCJ)

• HART multiplexer

PRM can connect to multiple apparatuses simultaneously.

PRM works most effectively with smart devices such as flow meters, control valves, rotating

machinery, among other devices commonly found in plants. These are devices that have the

capability to communicate with PRM digitally. You can use information from smart devices to

perform device diagnosis. You can also utilize advanced PRM capabilities for diagnostic analysis through the use of logical algorithms called PRM Advanced Diagnostic Application (PAA).

However, you can also register static devices or other plant assets considered as important

components in your plant processes. If there are alarms or abnormalities, you can use several

tools in PRM to configure device parameters and settings remotely without going to the actual

location of the device.

<A3. How PRM works>

A3-1

PRM can be customized to match the existing operations and procedures you conduct in your

plant. For example, you can create rule sets to define how alarms and messages will be processed. This gives you the capability to add necessary information about the issue, cause, or

recommended action in the message so that the intended recipient understands clearly how

to handle the message. You can also define notification rules to determine if PRM should

block or relay the information to an engineer or another computer station in the network.

IM 33Y05Q10-11E 7th Edition : Feb.08,2012-00

Page 29

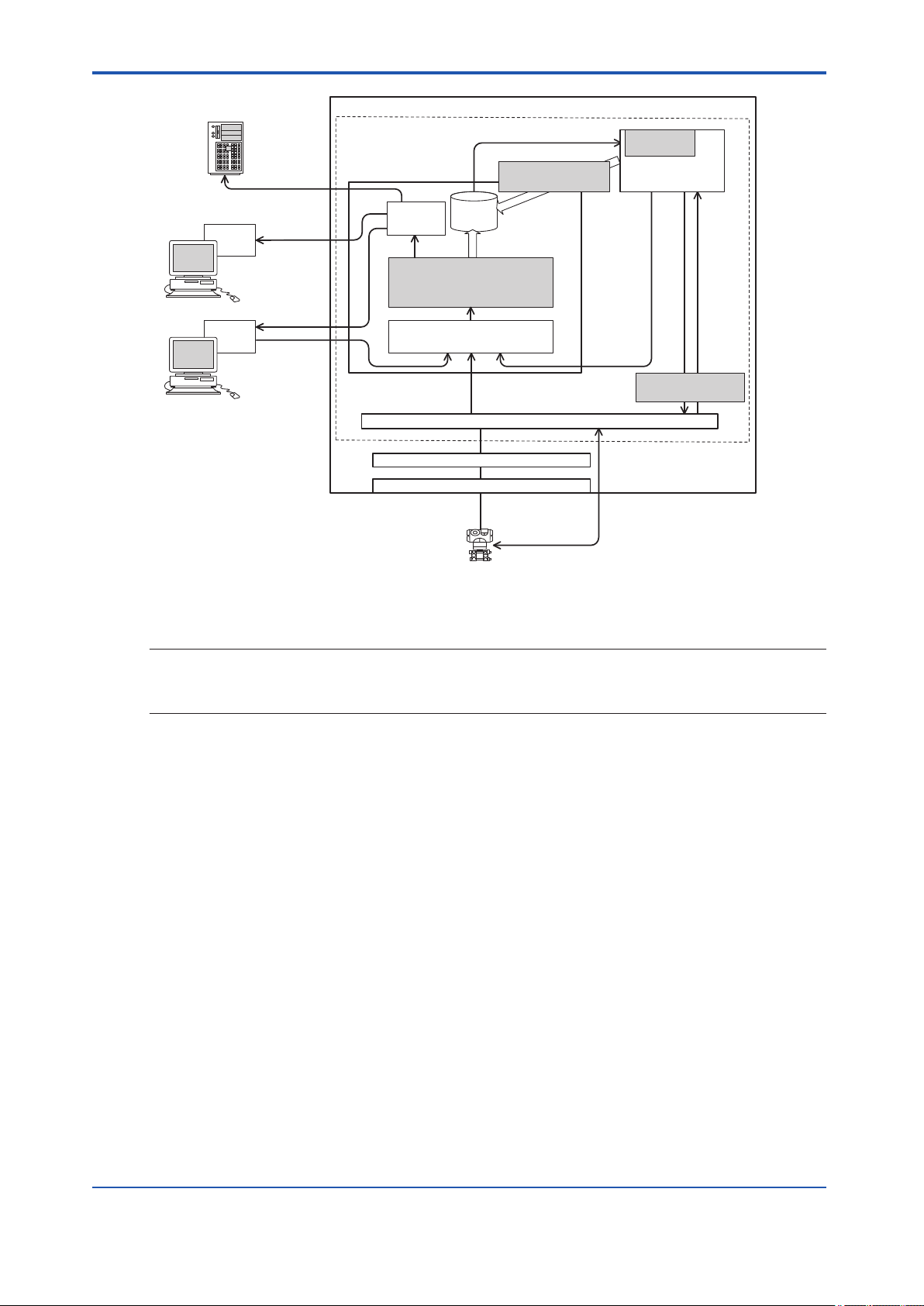

PRM

database

OPC

server

Basic PRM system

Field Communications Server

Control bus, Field network

Field devices

Device

parameter

PRM Server

Acquiring device parameters

(device diagnosis information)

· Device management

· Audit trail

Online device

parameter adjustment

Saving maintenance

alarm message

Operator guide

notification

Acquiring

alarm notification

Manual

alarm input

SMTP Server

(E-mail Server)

HIS or other systems

(System 1, OPC interface)

Alarm

notification

E-mail

notification

- Alarm management

- Basic diagnosis

CAMS

for HIS

HIS

Hardware (Control bus, Communication port)

Communication driver

PRM Client

Device status

display

Message and data

acquisition

Message

notification

<A3. How PRM works>

A3-2

SEE

ALSO

GUID-A5C69D43-5993-4602-987A-53753DD51CD0-default-pdf.pdf

Figure A3-1 PRM in a plant

For more information about PRM installation and configuration procedures, refer to:

Plant Resource Manager Installation (IM 33Y05Q12-11E)

IM 33Y05Q10-11E 7th Edition : Feb.08,2012-00

Page 30

PRM

Server

PRM

Client

Field

Communications

Server

PROFIBUS

DP/PA

coupler

Ethernet/

PROFIBUS

converter

V net

Ethernet

multiplexer

Field

Wireless

integrated

gateway

FF-H1/HSE

linking device

PROFIBUS

PROFIBUS PA

device

PROFIBUS DP

device

HART

device

FF-H1

device

HART

device

FF-H1

device

Device path configuration

FDT project configuration

ISA100

wireless device

HART

device

PROFIBUS

I/O module

Other FDT-

compliant

devices

ALE111

Ethernet

Layer-3

switch

RS-485/Ethernet

converter

FF-H1

I/O module

HART

I/O module

Other

FDT-compliant

communication

devices

PROFIBUS/

HART

converter

<A3.1 Device connection methods>

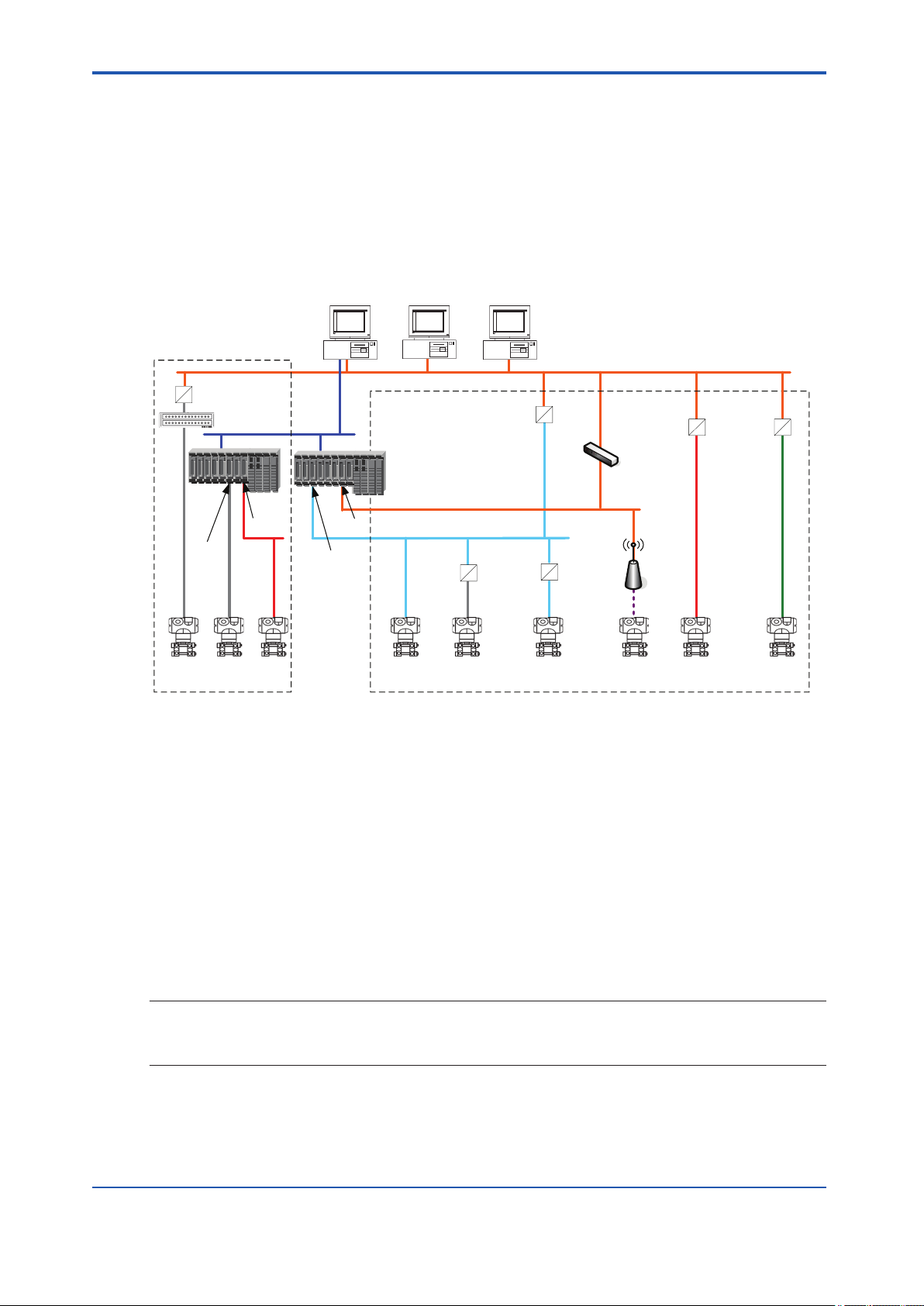

A3.1 Device connection methods

PRM can communicate with devices that use different communication types and connection

methods. To connect to a particular device, you must either configure a device path or a Field

Device Tool (FDT) project. The following diagram shows the connection methods that PRM

supports and classifies them into these categories:

• Device path configuration

• FDT project configuration

A3-3

GUID-75FFEA0F-3C37-4C11-B4DA-D301E0222992-default-pdf.pdf

Figure A3.1-1 Device connection methods

Device path configuration

n

A device path is a communication path to the location on the physical network to which a device is connected. You must configure device paths to enable PRM to communicate with the

following devices:

• FF-H1 and HART devices connected to an I/O module on CENTUM or STARDOM

• HART devices connected to an I/O module on ProSafe-RS

• FF-H1 devices connected to the Field Communications Server through an NI-FBUS card

• HART devices connected to the Field Communications Server through a multiplexer or

modem

SEE

For more information about configuring device paths, refer to:

ALSO

n

B3.1, “Device path” on page B3-2

FDT project configuration

A Field Device Tool (FDT) project defines a network topology comprising of communication,

gateway, and device DTMs, and stores the configuration settings of all the DTMs in the topol-

IM 33Y05Q10-11E 7th Edition : Feb.08,2012-00

Page 31

<A3.1 Device connection methods> A3-4

ogy. You must configure FDT projects to enable PRM to communicate with the following devices:

• FF-H1 devices connected to an FF-H1/HSE linking device

• PROFIBUS PA and DP devices connected to an Ethernet/PROFIBUS converter

• HART devices connected to a PROFIBUS network through a PROFIBUS/HART converter

• ISA100 devices connected to a ISA100 wireless gateway

• FDT-compliant devices connected to other FDT-compliant communication devices

When PRM communicates with a device defined on an FDT project, PRM Client contacts the

Field Communications Server. The Field Communications Server then runs the required communication and gateway DTMs.

SEE

For more information about PROFIBUS DP and PA, refer to:

ALSO

“n PROFIBUS” on page App.4-6

For more information about configuring FDT projects, refer to:

B3.2, “FDT projects” on page B3-28

For more information about the definitions of FDT and DTM, refer to:

Appendix 4., “Glossary” on page App.4-1

IM 33Y05Q10-11E 7th Edition : Feb.08,2012-00

Page 32

<A4. Features>

A4. Features

This section describes the key PRM features. It also explains feature availability for each

combination of device communication type and connection method.

Store device maintenance information in a central location

n

PRM acts as the central database for device maintenance information. This information can

include details about device parts, links to device documents, device description files, details

about device inspection activities, device parameter history, and device messages. You can

also use PRM to manage the information acquired from device calibration tools and applications by downloading or synchronization.

Record all activities, events, and messages

n

PRM tracks and records all activities, events, messages, and system transactions as history

information in the PRM database.

SEE

For more information about history information, refer to:

ALSO

E7.1, “History window” on page E7-5

A4-1

Support multiple server architecture

n

PRM supports a multiserver configuration. Multiple servers are necessary to distribute the

load and stabilize the computing performance in a plant that has many devices. A single PRM

Client can connect to different servers, one at a time, to monitor the status of devices registered in each server.

Monitor device status and alarm messages

n

From PRM, you can monitor real-time device status and alarm messages for devices being

used in the plant. Performing this activity from a central location gives you the capability to

react faster and maintain the reliability of the plant.

SEE

For more information about monitoring device status, refer to:

ALSO

E3., “Viewing the status of a device” on page E3-1

Display devices organized in different views

n

PRM can display devices in different views. Each view is organized in a different structure.

The structure can be based on the plant hierarchy, network, classification, or a customized

structure.

SEE

For more information about the different views, refer to:

ALSO

C2., “Working with the Device Navigator” on page C2-1

By plant hierarchy

l

You can view devices according to the plant hierarchy prescribed by the ISA 88.01 standard.

The plant hierarchy provides a clear view about your plant setup.

IM 33Y05Q10-11E 7th Edition : Feb.08,2012-00

Page 33

<A4. Features>

By network

l

You can view devices based on the network they belong. In this view, you will see how a device is physically connected to the network. You can also filter the devices that appear in the

view based on their communication type.

By class

l

You can view devices based on classes such as communication type, vendor, model, and release version.

Custom

l

You can create a customized structure for devices in the Custom view. This view enables you

to organize devices based on the unique requirements in your plant.

Manage devices used within different kinds of plant control systems

n

PRM can be used to manage and receive messages from devices being used in different

kinds of plant control systems.

SEE

For more information about the requirements for connecting with different plant control systems, refer to:

ALSO

Plant Resource Manager Installation (IM 33Y05Q12-11E)

A4-2

CENTUM

l

PRM can manage devices connected to CENTUM, an integrated production control system.

To use PRM to determine the device status and perform device parameter adjustment for devices connected to CENTUM, the computer on which the PRM Field Communications Server

is installed needs to be in the same network as the CENTUM Field Control Station (FCS).

TIP

A single PRM Server cannot be connected to multiple CENTUM systems. To connect to multiple CENTUM

systems, multiple PRM server sets are required.

ProSafe-RS

l

PRM can manage devices connected to ProSafe-RS, a safety-instrumented system. To establish the connection, the Field Communications Server of PRM needs to be in the same

network as the Safety Control Station (SCS) of ProSafe-RS.

As part of plant safety measures, you can use PRM, ProSafe-RS, and PLUG-IN ValVue ESD

to conduct a Partial Stroke Test (PST). ProSafe-RS shuts down the plant process when a failure occurs. PST is a proof test conducted to periodically test valves to ensure that they will

respond in case a shutdown event occurs.

TIP

• PRM can communicate with HART devices in a ProSafe-RS system, making it unnecessary to install additional wiring and multiplexers.

• When PRM is connected to ProSafe-RS and CENTUM systems, alarm messages of these systems are

acquired through the CENTUM OPC Server.

IM 33Y05Q10-11E 7th Edition : Feb.08,2012-00

Page 34

Control Bus

FCS

Device

Viewer

PRM

OPC

server

HIS

Exaopc OPC

Interface Package

(for HIS)

Control Bus Interface Card

Control Bus Driver

Field Communications Server

PRM Server

PRM

Acquisition/setting of

device parameters

Acquisition

messages

of alarm

Notification

of operator

guide

messages

PRM

Client

PLUG-IN

Application

Device

Viewer

PRM

CAMS

for HIS

HIS

SENG

CPUCPU

HART I/O

Module

HART devices

SCS

Notification of alarm messages

CENTUMProSafe-RS

IMPORTANT

<A4. Features> A4-3

GUID-73564E22-049B-46FC-A1F4-41337A37671E-default-pdf.pdf

Figure A4-1 System configuration when connected with ProSafe-RS

STARDOM

l

You can connect PRM to a STARDOM system in order to manage and monitor the devices

connected to STARDOM. When connected, PRM functions as an OPC client and acquires

messages from the STARDOM OPC Server (FCN/FCJ OPC Server for Windows).

STARDOM is a YOKOGAWA network-based control system that consists of the following:

• Versatile Data Server (VDS), a high-performance Supervisory Control And Data Acquisition (SCADA) software

• Autonomous controllers, which are of two types: the Field Control Node (FCN) and the

Field Control Junction (FCJ)

• You cannot install PRM packages on a computer installed with STARDOM Versatile Data

Server (VDS).

• We recommend that you install FCN/FCJ OPC Server for Windows on a computer where

PRM is not installed.

If you want to install FCN/FCJ OPC Server for Windows on a computer installed with PRM,

use the revision combinations mentioned in the following table. For other combinations, FCN/

FCJ OPC Server for Windows must be installed on a separate computer.

Table A4-1 Revision combinations for installing FCN/FCJ OPC Server for Windows and PRM on the

same computer

Revision of FCN/FCJ OPC Server for Windows Revision of PRM

R1.90 R3.02

R2.20 R3.03, R3.04

IM 33Y05Q10-11E 7th Edition : Feb.08,2012-00

Page 35

FCN/FCJ

OPC server for Windows

Control network

FCN

PRM Client

PRM Server

FF-H1 FF-H1

Controller

DA server

A&E server

HDA server

(HMI client)

HMI server

Data server

PRM Client

PRM

CPU PSU

FCJ

(Foundation

Fieldbus-enabled

model)

HMI

VDS

HMI client

VDS/HMI

Information network

Logic designer

Resource Configurator

(PRM Client)

PRM Server

Field Communications Server

FF-H1 I/O

MODULE

<A4. Features>

A4-4

Revision of FCN/FCJ OPC Server for Windows Revision of PRM

R3.01 R3.05

The following figures are system configuration examples where PRM is connected to a STARDOM system with FF-H1 and HART devices.

GUID-0F41CE73-B8C1-46AF-A8D2-456BFC82AA25-default-pdf.pdf

Figure A4-2 Example of connection to a STARDOM system with FF-H1 devices

IM 33Y05Q10-11E 7th Edition : Feb.08,2012-00

Page 36

HMI

HART I/O module

HART devices configurator

HART device

Control Network

Information network

FCN

Logic designer

Resource Configurator

Controller

VDS/HMI

PRM

PSU CPU

(PRM Client)

PRM Server

Field Communications Server

PRM Client

HMI client

PRM Client

PRM Server

DA Server

A&E Server

HDA Server

(

HMI client

)

HMI server

Data server

VDS

FCN/FCJ

OPC server for Windows

<A4. Features>

A4-5

n

SEE

ALSO

n

GUID-07FCFD30-F5E7-4E16-A771-FB9E5921E64C-default-pdf.pdf

Figure A4-3 Example of connection to a STARDOM system with HART devices

HART multiplexers

l

You can directly connect PRM to HART devices through a HART multiplexer by using a converter. This converter must be connected to the COM port of the computer on which the Field

Communications Server is installed.

Set maintenance marks on devices

PRM enables you to set maintenance marks (MTMKs) on a device to indicate the maintenance status of a device. You can synchronize MTMKs of devices with operation marks of the

corresponding function blocks in CENTUM. This enables PRM and CENTUM users to exchange information about the status of devices and function blocks. You can also notify other

plant personnel about MTMK-related changes by means of operator guides or e-mail messages.

For more information about maintenance marks, refer to:

E5., “Working with maintenance marks” on page E5-1

Adjust device parameters using a variety of tools

Upon installation, PRM is equipped with various tools that can help you to adjust device parameters online. Device parameter adjustment tools include Parameter Manager, DTM Works,

and DD Menu. PRM can also work with third-party applications to perform device parameter

adjustment. PRM enables you to define which tool to use for each type of device.

IM 33Y05Q10-11E 7th Edition : Feb.08,2012-00

Page 37

SEE

For more information about adjusting device parameters, refer to:

ALSO

F., “Configuring device parameters” on page F-1

Perform advanced device diagnosis

n

PRM enables you to conduct advanced diagnostic analysis for devices by using algorithms

called PRM Advanced Diagnostic Application (PAA). When diagnosis is started, PRM periodically acquires data from the devices, analyzes them, and depending on your configuration, it

can raise maintenance alarms if an abnormality is detected. You can choose to store the acquired data in a database, enabling you to view the data in the form of graphs.

SEE

For more information about performing an advanced device diagnosis, refer to:

ALSO

H., “Performing an advanced diagnosis” on page H-1

Manage partial stroke test for safety devices

n

PRM enables you to manage partial stroke tests for safety devices. Instead of scheduling

PSTs individually for each safety device using different tools, you can plan, conduct, and monitor PSTs for all registered safety devices using the PST Scheduler. You can also use PST

Scheduler as a repository of PST results that are conducted without the use of the PST

Scheduler Client.

<A4. Features>

A4-6

SEE

For more information about partial stroke tests, refer to:

ALSO

I1., “About the PST Scheduler” on page I1-1

Integrate with other systems and applications

n

A typical plant utilizes several systems and multiple applications from different vendors. PRM

was developed with the capability to be used with these systems and applications.

FieldMate

l

FieldMate, a YOKOGAWA product, is used to configure field devices and record device information for maintenance activity. FieldMate includes the PRM Synchronization tool, which enables you to transfer device information between PRM and FieldMate.

IBM Maximo Asset Management

l

IBM Maximo Asset Management is a Computerized Maintenance Management System

(CMMS), which is an enterprise application used to improve the administrative tasks of managing, planning, maintenance, and purchasing activities of plant equipment and all the other

assets. With this integration, you can view the PRM device information in Maximo, initiate the

creation of work orders, and check work order progress from PRM.

GE Energy's System 1

l

GE Energy's System 1 performs condition monitoring and diagnosis for rotating machinery.

After integrating it with PRM, the PRM Client can display System 1 reports, such as display

status and guidance messages generated from devices.

PLUG-IN applications

l

PLUG-INs are applications developed by vendors for their devices, which can have additional

functionality that is not available on generic tools.

IM 33Y05Q10-11E 7th Edition : Feb.08,2012-00

Page 38

<A4. Features> A4-7

TIP

Aside from device applications, PRM also classifies systems from third-party vendors as PLUG-INs.

PRM PLUG-IN ValveNavi

l

PRM PLUG-IN ValveNavi is a PLUG-IN application used to calibrate and operate the YOKOGAWA Advanced Valve Positioner (YVP110). When installed, you can directly access and

open ValveNavi from the PRM Client.

Consolidated Alarm Management Software (CAMS for HIS)

l

Consolidated Alarm Management Software (CAMS for HIS) is an application installed on a

CENTUM HIS computer that integrates the acquisition of all alarms and event data. You can

configure CAMS for HIS to receive maintenance alarm messages from PRM.

SEE

For more information about configuring CAMS for HIS to receive maintenance messages from PRM, refer to:

ALSO

Plant Resource Manager Installation (IM 33Y05Q12-11E)

For more information about CAMS for HIS , refer to:

CENTUM VP Installation (IM 33K01C10-50E)

Feature availability by communication type and connection method

n

The availability of some PRM features depends on the communication type and the connection method of the target device.

The following table describes the features available for each combination of communication

type and connection method:

Table A4-2 Feature availability by communication type and connection method

Configuration

type

Communication

type and con-

nection method

Retrieve and store device information

Device details,

excluding parameter information

Plug & Play registration

Monitor and diagnose devices

Periodic or manual device status

updates using

Basic Diagnosis

Alarm event notification from

CENTUM

Device status update triggered by

alarm event notification from

CENTUM

DeviceViewer Yes Yes Yes Yes No No No No No

Device path con-

figuration

FF-H1

(*1)

Yes Yes Yes Yes Yes Yes Yes Yes Partial

Yes Yes Yes Yes Partial

Yes Yes (*7) Yes Yes No Yes Yes Yes No

Yes No No No Yes Yes Yes No No

Yes No No No No Yes Yes No No

HART

(*2)

FF-H1

on link-

ing de-

vice

HART

on

PROFI-

BUS

(*3)

FDT project configuration

PROFIBUS DP

(non-PA

Profile)

(*6)

PROFIBUS

DP (PA

Profile)

Yes Yes Yes Partial

PROFI-

BUS PA

ISA100 Others

(*4)

(*5)

(*6)

IM 33Y05Q10-11E 7th Edition : Feb.08,2012-00

Page 39

<A4. Features> A4-8

Configuration

type

Communication

type and con-

nection method

Serve as a data

acquisition target

for Advanced Diagnosis and InsightSuiteAE Diagnosis

Configure devices

DTM Works Yes Yes Yes Yes Yes Yes Yes Yes Yes

DD Menu Yes No Yes No No No No No No

Parameter Manager

Communication

with PLUG-IN applications, such

as Valve Navi

and ValVue

Others

FieldMate Synchronization

Device path con-

figuration

FF-H1

(*1)

Yes Yes Yes Yes No No No No No

Yes Yes Yes Yes No No No No No

Yes Yes Yes Yes No No No No No

Yes Yes Yes Yes Yes Yes Yes No No

HART

(*2)

FF-H1

on link-

ing de-

vice

HART

on

PROFI-

BUS

(*3)

FDT project configuration

PROFIBUS DP

(non-PA

Profile)

PROFIBUS

DP (PA

Profile)

PROFI-

BUS PA

ISA100 Others

(*4)

*1: Connected to an NI-FBUS card or to an I/O module on CENTUM or STARDOM

*2: Connected to a multiplexer or an I/O module on CENTUM, STARDOM, or ProSafe-RS

*3: HART on PROFIBUS means HART devices connected to a PROFIBUS network using a PROFIBUS/HART converter

*4: This refers to devices defined in an FDT project using all other communication types and connection methods

*5: Supports only the standard set of fields available to a static device

*6: Needs to be manually added to a FDT project before Plug & Play.

*7: Supports Fast Device Patrol.

Additional requirements for PROFIBUS devices

l

For PROFIBUS devices, the availability of some PRM features depends on the following additional factors:

• The PROFIBUS network versions that the device supports

• The device application profile

• The availability and revision of the GSD file for the device

Table A4-3 Additional requirements for PROFIBUS devices

Feature Requirements

Display error codes and their corresponding messages in device-related maintenance alarm messages from CENTUM

DTM Works The device must support both DP V0 and DP V1.

Retrieve device details from the device

during Plug & Play

A GSD file must be available for the device.

The device must:

• Support both DP V0 and DP V1

• Conform to PA Profile V3.0 or later

For devices that do not satisfy these conditions, you need to enter device details manually when adding them to the FDT

project.

IM 33Y05Q10-11E 7th Edition : Feb.08,2012-00

Page 40

Feature Requirements

Device status updates using Basic Diagnosis

The device must:

• Support both DP V0 and DP V1

• Conform to PA Profile V3.0 or later

For devices that do not satisfy these conditions, Basic Diagnosis

always display the Uncertain status, color-coded in white.

Display device-specific diagnosis information in maintenance alarm messages

The device must:

• Support both DP V0 and DP V1

• Conform to PA Profile V3.02 or later

In addition, a GSD file of revision 3 or later must be available for

the device.

SEE

For more information about PROFIBUS DP and PA, refer to:

ALSO

“n PROFIBUS” on page App.4-6

For more information about basic diagnosis, refer to:

“n Basic Diagnosis” on page E2-5

For more information about Maintenance alarm messages, refer to:

E1.3, “Maintenance alarm messages” on page E1-36

<A4. Features> A4-9

IM 33Y05Q10-11E 7th Edition : Feb.08,2012-00

Page 41

B. Configuring PRM

This part describes the tools and settings for configuring PRM.

Overview

n

This part consists of the following sections:

• Tasks after installing PRM for the first time

Describes the tasks that you must perform after installing PRM for the first time.

• PRM Server

Describes the contents of the PRM Server and the procedure for configuring server sets.

• Field Communications Server

Describes the workflows for configuring device paths and FDT projects to enable connection to devices. This section also describes the installation of DD files.

• PRM Client

Describes the procedures for customizing the PRM Client appearance and user-definable

labels, connecting to the PRM Server, setting up DTMs, and copying DD files.

• Managing accounts and device security

Describes settings required to manage PRM accounts and device security.

<B. Configuring PRM>

B-1

• Managing master data

Describes the procedures for importing and exporting master data and explains device

icons.

IM 33Y05Q10-11E 7th Edition : Feb.08,2012-00

Page 42

<B1. Tasks after new installation>

B1. Tasks after new installation

After you install PRM for the first time, you must use the PRM Setup Tool to perform the following tasks:

• For the PRM Server

• Configure server sets

• Configure Device Patrol settings

• Configure Message Acquisition settings

• For the Field Communications Server

• Configure device paths

• Configure FDT projects

• Install DD files

• For the PRM Client

• Configure connection settings

• Associate DTM files to device classes

B1-1

If you are using devices manufactured by vendors other than YOKOGAWA, then you must install the vendor-provided DTMs and the corresponding DD files. If you intend to use PLUG-IN

applications, install them on the PRM Client.

After configuring the settings in the PRM Setup Tool, you must use Plug & Play in the PRM

Client to detect and register the devices. Registered devices are displayed in the PRM Client.

SEE

For more information about using Plug & Play to detect and register devices, refer to:

ALSO

D1.2.1, “Plug & Play” on page D1-4

PRM Setup Tool

n

The PRM Setup Tool enables you to configure the settings for the following PRM packages:

• PRM Server

• PRM Client

• Field Communications Server

• PRM Advanced Diagnostic Server

This tool is also included with FieldMate and DeviceViewer installed on CENTUM HIS. When

you start the tool from FieldMate or CENTUM, you can configure the settings to communicate

with PRM.

IM 33Y05Q10-11E 7th Edition : Feb.08,2012-00

Page 43

<B1. Tasks after new installation>

Table B1-1 Functions of the PRM Setup Tool

Package or system Settings Description

PRM Server Server set Define a server set by specifying the computer names

or IP addresses of the following:

• Field Communications Server

• Advanced Diagnosis Server

• Diagnosis Historian Server

Device Patrol Configure the patrol period for each object criticality lev-

el.

Message acquisition Specify the message acquisition source and message

categories to acquire.

Maintenance mark Specify if maintenance marks need to be synchronized

with CENTUM operation marks. If you choose to synchronize maintenance marks with CENTUM, you need

to provide the user name and password for connecting

to CENTUM.

Alarm management Start the Alarm Management Tool to set the alarm man-

agement rules. These rules define how maintenance

alarm messages are processed in the PRM Server.

Notification configuration

Third-party system Define the settings to enable PRM to connect to third-

PRM Client Connection Define the server sets to which the PRM Client is con-

Appearance Specify details on the icon and font sizes used in the

DTM Setup Start DTM Setup to assign vendor-provided DTMs to a

Field Communications

Server

PRM Advanced Diagnosis

Device path Configure device paths.

FDT Project Management

DD Copy Tool Start DD copy tools to import vendor-provided DD files.

Server set Include details about the server set to which Advanced

PAA message Configure notification settings for PAAs.

Start the Notification Configuration Tool to define the

notification rules. These rules define how to forward

alarm messages.

party systems.

nected. You can configure the client to connect to single

or multiple server sets.

PRM Client.

particular device model

Configure FDT projects.

Diagnosis Server and/or Device Diagnosis Data Historian belong.

This function is available only if PRM is upgraded from

version R3.01 onwards, and the alarm notification settings are configured before upgrading.

For the new installations, PAA settings must be configured using the Notification Configuration Tool.

B1-2

SEE

For more information about using the PRM Setup Tool after installing PRM, refer to:

ALSO

Plant Resource Manager Installation (IM 33Y05Q12-11E)

Starting the PRM Setup Tool

l