Page 1

<<Contents>> <<Index>>

General

Specifications

Model PR300

Power and Energy Meter

GS 77C01E01-01E

■ Overview

This panel-mounted power and energy meter with a

large, three-row LED display integrates all the measuring functions required for power management in

locations such as factories and buildings into a single

unit.

With the objective of working toward the preservation

of the global environment by saving energy and

performing equipment maintenance, the PR300 is

designed to display and output the energy of various

types of electrical equipment.

■ Features

• Saves on cost, wiring, and space

Integrates a wide selection of functions for measuring things

like energy (active, regenerative, reactive, and apparent),

power (active, regenerative, reactive, and apparent),

voltage, current, frequency, and power factor into a single

unit.

• Employs a large, three-row LED display

Capable of displaying three-phase current and voltage

simultaneously, and the measurement items you assign.

• Analog output function

Equipped with a transducer function for power (active,

regenerative, reactive, and apparent), voltage, current,

frequency, and power factor (4 to 20 mA DC).

• Demand measurement

Measures the average power and current within a specified

period. It also allows you to set up alarm points to output

alarms.

• Equipped with a multitude of functions

Enables measurement of the maximum and minimum

values of voltage and the maximum value of current, as well

as, for example, the use of external digital input to measure

energy at arbitrary times.

• Pulse output

Capable of outputting pulses proportional to energy (one

measurement item from active, regenerative, reactive, and

apparent energy).

• Converts the phase and wire system of an AC power

system and an input voltage circuit to a universal

format

The PR300 can handle from the single-phase two-wire

system and single-phase three-wire system to the threephase three-wire system and three-phase four-wire system,

and also universally cope with input voltage circuits up to

600 V AC.

• Compatible with ANSI 4-inch round form size and

DIN 96-square instrument size

The ability to attach and detach JIS/ANSI-mounting kit

makes the PR300 compatible with panel cutouts of ANSI 4inch round form, JIS 110-square instrument size, and DIN

96-square instrument size.

•Standard equipped with an RS-485 communication

function and capable of Ethernet communication

• Compatible with overseas requirements

Power line indications A, B, and C provided for overseas

use, in addition to R, S, and T

ANSI 4-inch round form size

DIN 96-square instrument size

The ability to attach and detach JIS/ANSI-mounting kit

ensures compatibility with two sizes.

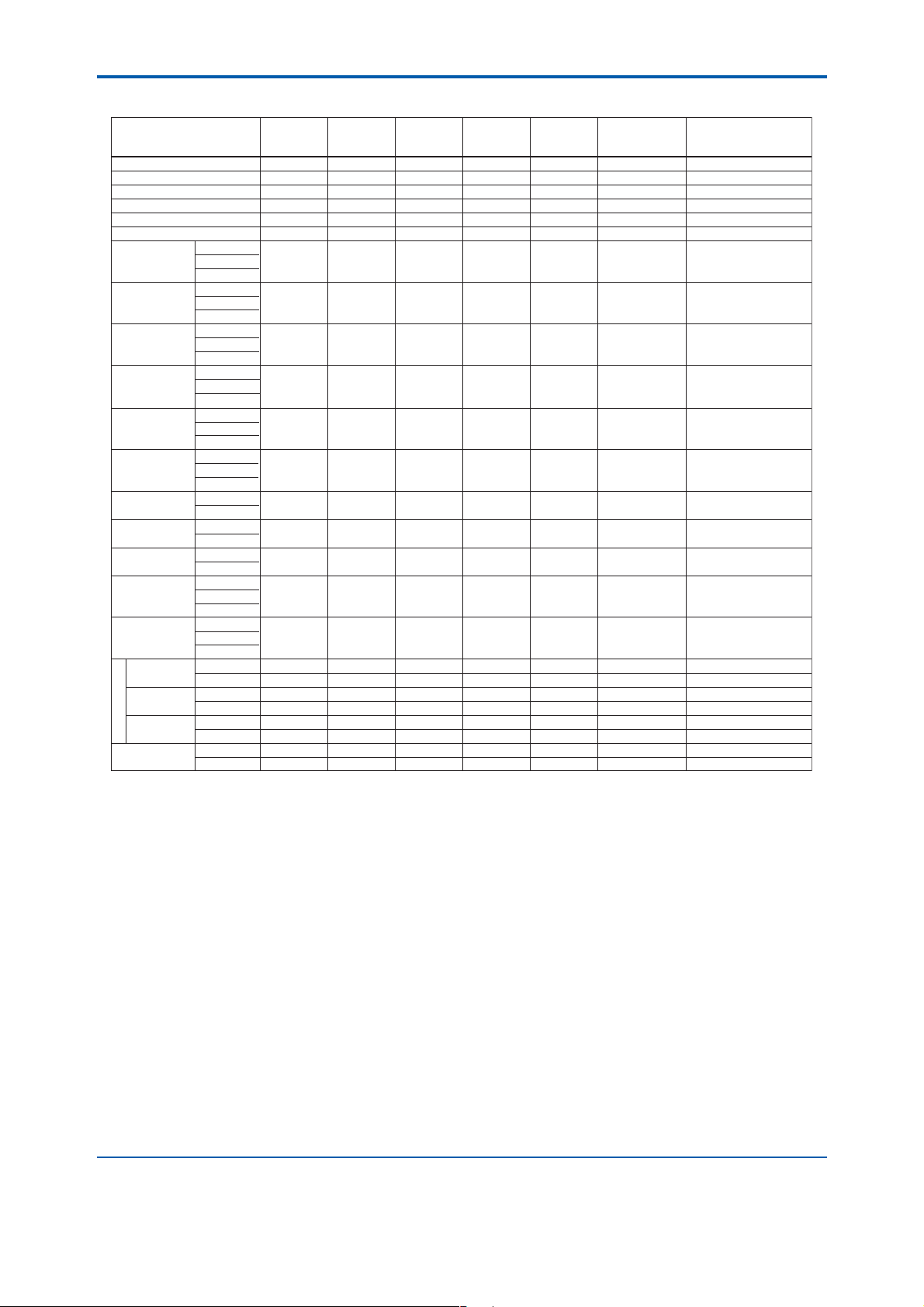

■ Model and Suffix Codes

PR300

Model

Phase and wire system

3:

Universal three-phase three-wire system

(single-phase two-wire, single-phase three-wire,

and three-phase three-wire systems)

4:

Universal three-phase four-wire system

(single-phase two-wire, single-phase

three-wire, three-phase three-wire, and

three-phase four-wire systems)

5: Three-phase four-wire system

(2.5 element)*

Input voltage/input current

1: Universal voltage input*2

(150 V, 300V, 600 V) / 1 A AC

2: Universal voltage input*2

(150 V, 300 V, 600 V) / 5 A AC

Additional input and output function

0: 1 digital input

1: 1 digital input, 1 analog output

2: 1 digital input, 1 pulse output

3:

1 digital input, 1 analog output, 1 pulse output

Communication function

0: RS-485 communication

3:

RS-485 communication, Ethernet communication

Optional measuring function

0: None

3: Demand measurement (1 demand alarm output)

Power supply

6:

100-240 V AC 10% (50/60 Hz) or 130-300 V DC 15%

Phase indication format

A: A, B, and C indications

R: R, S, and T indications

1 In cases where

*

specified, the input current specification of 1 A AC is not applicable.

(PR300-51xxx-xx-0 cannot be ordered.)

Can be used only when the voltage is in a state of equilibrium.

The phase and wire system cannot be changed.

2 Set the voltage range (150 V, 300 V, or 600 V) according to the

*

rated input voltage to be measured.

Voltage” of the Input Specifications on page 6.)

3 For Ethernet communication, the RS-485 communication interface

*

is exclusively for the Ethernet-serial gateway function.

1

“Three-phase four-wire system (2.5 element)” is

3

*

(Refer to “Rated Input

■Ordering Information

Specify the model and suffix codes.

Example: PR300-31000-6A-0

-0

GS 77C01E01-01E

©Copyright Apr. 2006 (KP)

5th Edition Dec. 10, 2008 (KP)

Page 2

<<Contents>> <<Index>>

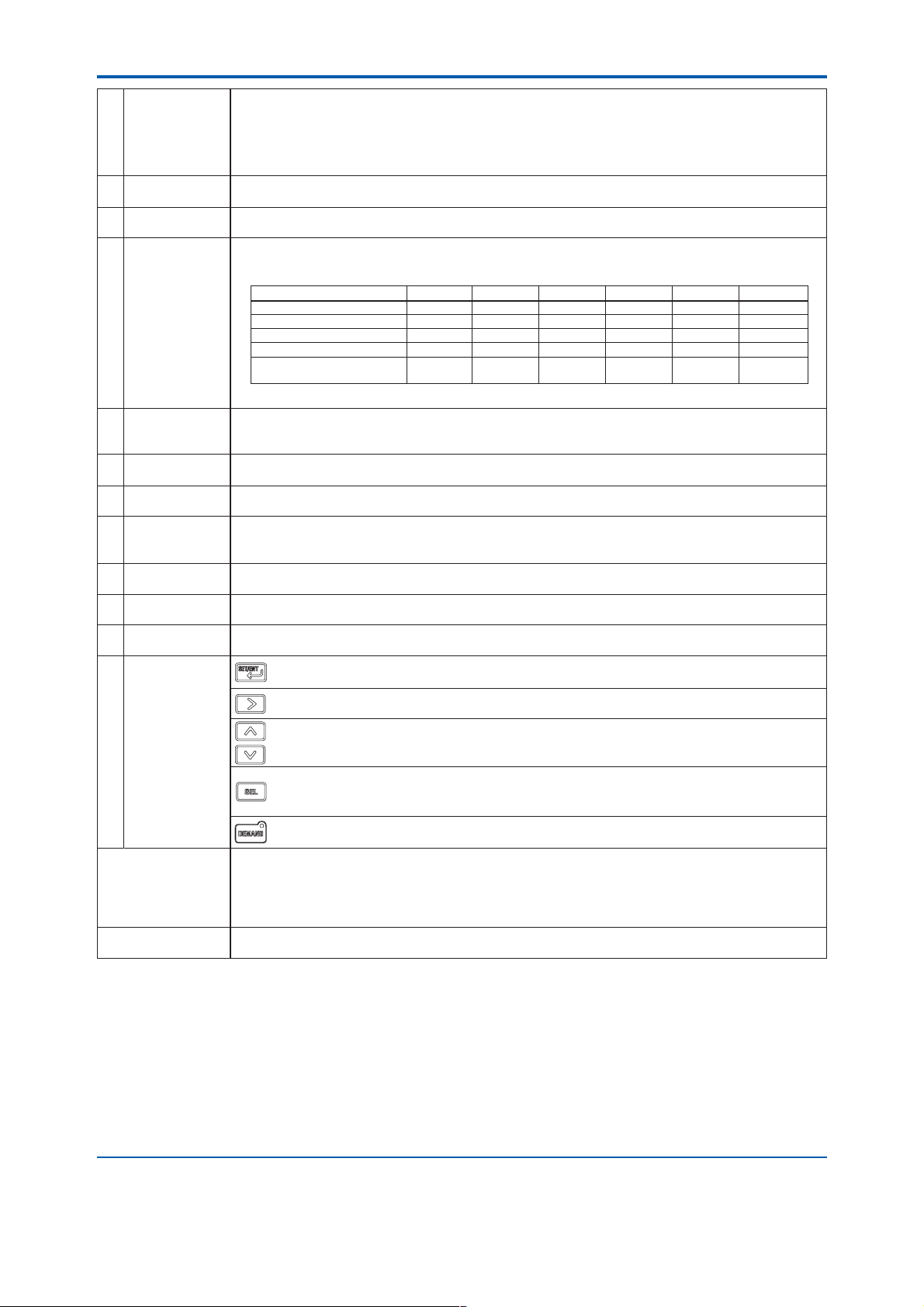

■Measuring Functions

Measurement item

Active energy () *1 ✔ ✔ ✔ ✔ ✔ kWh, MWh

Active energy () *

Reactive energy () *

Reactive energy () *

Apparent energy *

Optional active energy *

Instantaneous

Single-phase

two-wire

system

1

✔ ✔ ✔ ✔ ✔ kWh, MWh Regenerative energy

1

✔ ✔ ✔ ✔

1

✔ ✔ ✔ ✔

1

✔ ✔ ✔ ✔

1

✔ ✔ ✔ ✔ ✔ Wh

Single-phase

three-wire

system

Three-phase

three-wire

system

Three-phase

four-wire

system

Active power Maximum ✔ ✔ ✔ ✔ ✔ W, kW, MW

Minimum

Instantaneous

Reactive power Maximum ✔ ✔ ✔ ✔

Minimum

Apparent power

Instantaneous

Maximum ✔ ✔ ✔ ✔

Minimum

Instantaneous

Voltage-1 Maximum ✔ ✔ ✔ ✔ ✔ V, kV

Minimum

Instantaneous

Voltage-2 Maximum ✔ ✔ V, kV

Minimum

Instantaneous

Voltage-3 Maximum ✔ ✔ ✔ V, kV

Minimum

Instantaneous

Instantaneous

Instantaneous

Instantaneous

✔ ✔ ✔ ✔

✔ ✔ A, kA

✔ ✔

Current-1

Maximum

Current-2

Maximum

Current-3

Maximum

Frequency Maximum ✔ ✔ ✔ ✔ ✔ Hz

Minimum

Instantaneous

Power factor Maximum ✔ ✔ ✔ ✔

Minimum

2

*

Demand current-1

Maximum ✔ ✔ ✔ ✔

Demand current-2

Maximum ✔ ✔ A, kA

Demand current-3

Maximum ✔ ✔

Demand current

Demand power

*1 Integrated low-cut power can be set for each energy.

Integrated low-cut power: This is a function for not integrating power less than a set value as energy.

The setting range of integrated low-cut power is 0.05 to 20.00% of the rated power (initial value: 0.05%).

*2 Either demand power or demand current can be set as a measurement item.

*3 Can be used only when the voltage is in a state of equilibrium.

*4 Can be measured only when the current is in a state of equilibrium.

Demand

✔ ✔ ✔ ✔

Demand

✔ ✔ A, kA

Demand

✔ ✔

2

Demand

*

Maximum ✔ ✔ ✔ ✔ ✔ W, kW, MW

✔ ✔ ✔ ✔ ✔ W, kW, MW

Three-phase

four-wire system

(2.5 element)

4

*

4

*

4

*

4

*

4

*

4

*

4

*

4

*

4

*

4

*

4

*

4

*

Unit and

symbol

3

*

kvarh, Mvarh LAG:

kvarh, Mvarh LEAD:

kVAh, MVAh

var, kvar, Mvar

VA, kVA, MVA

A, kA

A, kA

COS

A, kA

A, kA

A, kA

A, kA

Remarks

Calculated from the

voltage-1

LAG:

LEAD:

2

✔: Effective

: Ineffective

All Rights Reserved. Copyright © 2006, Yokogawa Electric Corporation

GS 77C01E01-01E 5th Edition Dec. 10, 2008-00

Page 3

<<Contents>> <<Index>>

● Optional integrating function

Power is integrated while a control signal for optional integration is on.

When the control signal is switched from off to on, the optional integrated value indication is reset and integration

starts. (The integrated value prior to the reset is held in a register.) The integrated value cannot be guaranteed in

the event of a power failure occurring during integration.

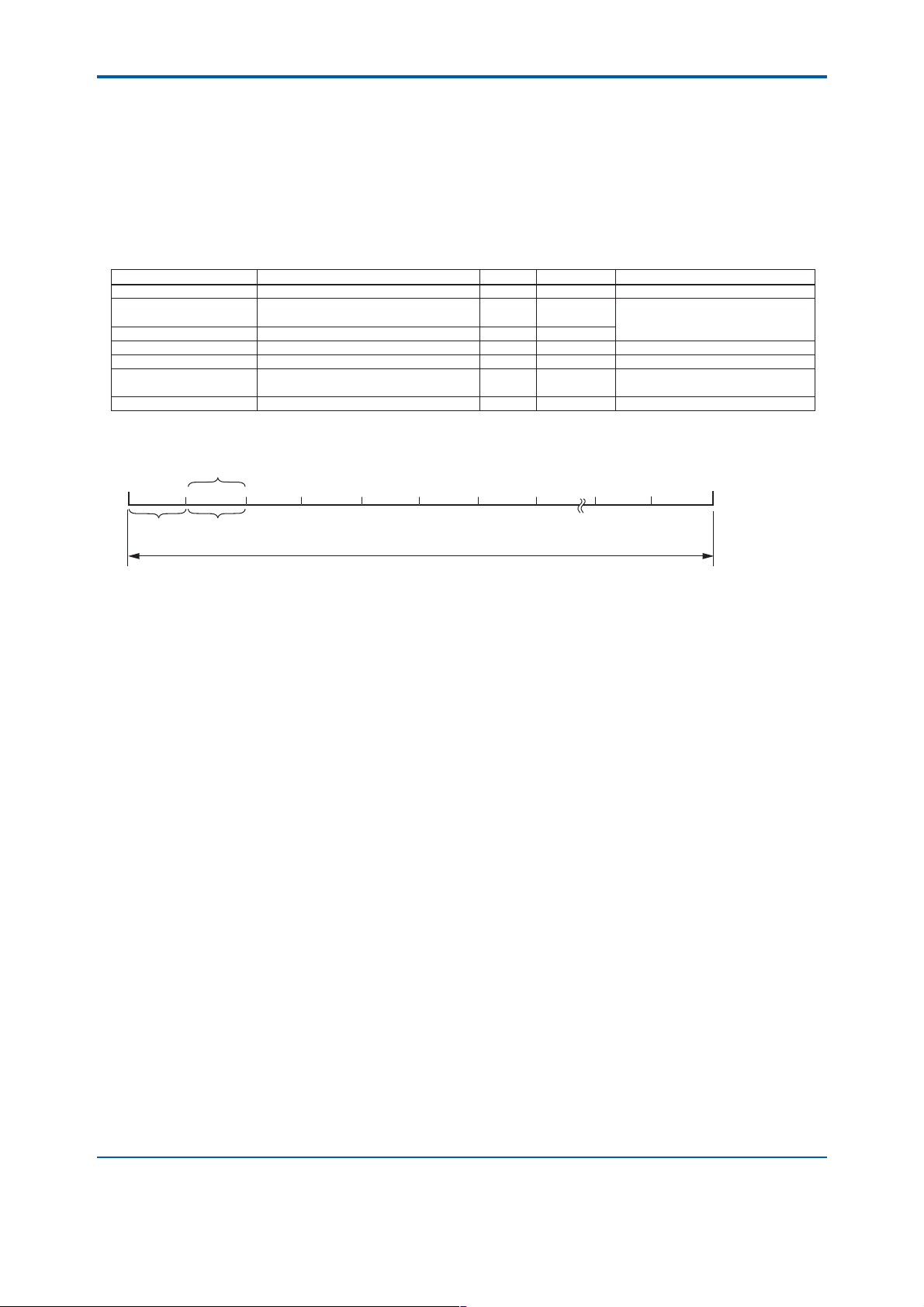

● Demand measurement (when demand measurement is specified)

The PR300 measures average power or average current within a set demand period.

The maximum demand value for the demand measuring time is held until the power is turned off, remote reset is

executed, or the next demand measurement is started.

Item Setting Range

Demand power/current

Demand period

Demand alarm mask time* 1 minute to length of demand period 1 minute 1 minute

Demand power alarm point

Demand current alarm point

Alarm release function

Data update interval

* This is the time from the start of the demand period to the set time in which no judgment is made for the alarm (alarm masked). During the

alarm mask time, no maximum demand value is updated and no alarm is output.

Active power, current Active power

10 seconds

1 to 60 minutes

(Demand

1 to 1000 kW 1 kW 100 kW When demand power is selected

1 to 1000 A 1 A 100 A When demand current is selected

Automatic release and manual release

alarm mask time to 60 minutes)

Resolution

1 minute 30 minutes

Automatic

Initial Value Remarks

Demand alarm mask time ⬉ Demand period

release

3

Start

demand

measurement

Average power

(current) update

Demand period (1 period)

Average power

(current) update

Demand measuring time

The maximum demand value for this time is held.

Stop

demand

measurement

All Rights Reserved. Copyright © 2006, Yokogawa Electric Corporation GS 77C01E01-01E 5th Edition Dec. 10, 2008-00

Page 4

<<Contents>> <<Index>>

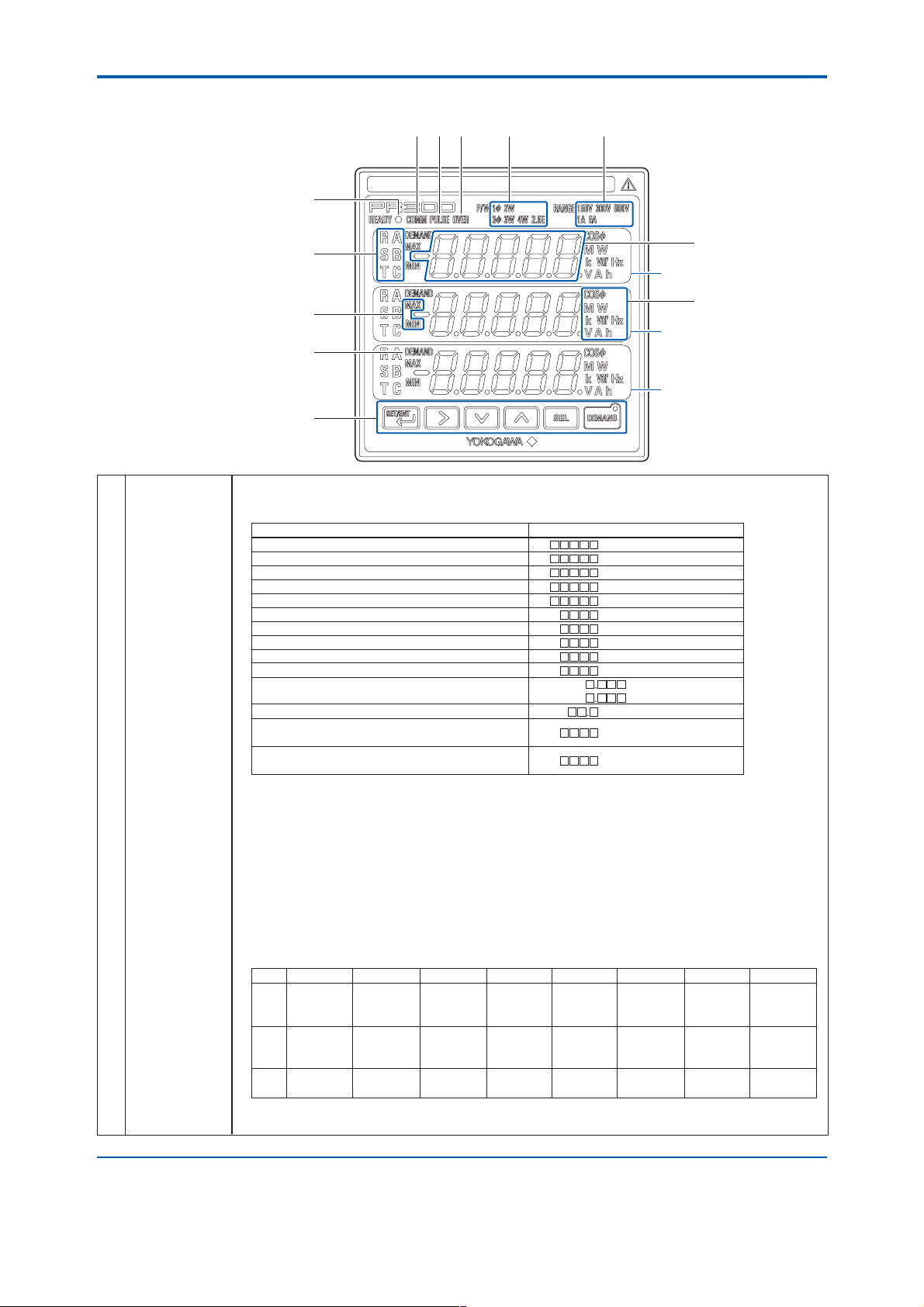

■ Display and Operation Specifications

(7)(6) (8) (9) (10)

(5)

4

Measured

(1)

Value Display

<Continued on the

following page>

(4)

(1)

Upper display

(2)

(3)

Middle display

(11)

Lower display

(12)

5-digit, 3-row, 7-segment LED display

Display color: red

Measured Value display:

Measurement Item Display

Active energy [kWh, MWh] *1

Reactive energy [kvarh, Mvarh] *2

Apparent energy [kVAh, MVAh] *1

Regenerative energy [kWh, MWh] *2

Optional active energy [Wh]

Active/regenerative power (instantaneous, maximum, and minimum values)

Reactive power (instantaneous, maximum, and minimum values)

Apparent power (instantaneous, maximum, and minimum values)

Voltage (instantaneous, maximum, and minimum values)

Current (instantaneous and maximum values) [A, kA] *2, *4

Power factor (instantaneous, maximum,

and minimum values)

Frequency (instantaneous, maximum, and minimum values)

Demand power

Maximum demand power

Demand current

Maximum demand current

*1: Without sign, but with a decimal point

*2:

With a sign and a decimal point ("+" is not indicated). Regenerative power (energy) always shows "−" negative

indication.

*3: "MAX" lights up for the maximum value and "MIN" lights up for the minimum value.

*4: "MAX" lights up for the maximum value.

Measured Value screen:

Display pattern: The measurement items you want to display are assigned to each of the upper, middle, and lower displays

Number of display patterns: Can be set in the range of 1 to 8. Pressing the SET/ENT key switches the display from

Display Pattern-1 Display Pattern-2 Display Pattern-3 Display Pattern-4 Display Pattern-5 Display Pattern-6 Display Pattern-7 Display Pattern-

Upper

display

Middle

display

Lower

display

* The display of current (phase switch indication) is switched between current-1, current-2, and current-3 each time the SEL key is

Current

(Phase switch

indication)*

Voltage

(Phase switch

indication)*

Active power

pressed. The display of voltage (phase switch indication) is switched between voltage-1, voltage-2, and voltage-3 each time the SEL key

is pressed.

LAG: G [COS]

The position of a decimal point differs depending on the primary rated power, VT ratio, and CT ratio.

to provide indications using three display rows as one pattern. Up to eight display patterns can be set.

The initial values are as shown in the following table. (Combinations other than those shown in the

following table are also available if the parameters are set.)

"display pattern-1," "display pattern-2," and so on in order according to the number of patterns set. The

initial value is "1" and only display pattern-1 is displayed when this value is set.

Active power

Reactive

power

Power factor

LEAD: d [COS]

Active energy

LEAD reactive

energy

Apparent

energy

[W, kW, MW] *2, *3

[var, kvar, Mvar] *2, *3

[VA, kVA, MVA] *1, *3

[V, kV] *1, *3

*3

[Hz] *3

[W, kW, MW] [DEMAND] *4

[A, kA] [DEMAND] *4

Current-1

Current-2

Current-3

Voltage-1

Voltage-2

Voltage-3

Current

(Phase switch

indication)*

Voltage

(Phase switch

indication)*

Frequency

Current

(Phase switch

indication)*

Active power

Power factor

8

Active power

Maximum

demand value

Demand

value

All Rights Reserved. Copyright © 2006, Yokogawa Electric Corporation

GS 77C01E01-01E 5th Edition Dec. 10, 2008-00

Page 5

<<Contents>> <<Index>>

VT ratio/CT ratio:

If the VT ratio and CT ratio are set, input to the PR300 is displayed after converting it to the primary input value before VT

or CT. The VT and CT ratios can be set via communication or using the operation keys.

VT ratio setting range: 1 to 6000*

CT ratio setting range: 0.05 to 32000*

* Set the VT ratio and CT ratio so that [secondary rated power] [VT ratio] [CT ratio] is smaller than 10 GW.

(2) Unit Lamps The relevant unit lamp lights up according to a measurement item and measured value.

Display color: red

(3)

MAX and MIN Lamps

(4)

Phase Indication Lamps

should be specified in accordance with the suffix code.)

Display color: red

* Can be measured only when the current is in a state of equilibrium.

(5) Power Lamp Lights up when power is supplied.

Blinks (4 times/sec) until it returns to normal when the communication error occurs.

(6)

Communication Lamp

Display color: green

(7) Pulse Output Lamp

Display color: green

(8)

Demand Alarm Lamp

lights up to indicate the occurrence of an alarm.

Display color: red

(9) Phase and Wire The lamps of the phase and wire system that have been set light up.

System Lamps Display color: green

(10) Input Range Lamps The input voltage range (150 V, 300 V, or 600 V) and input current range (1 A or 5 A) that have been set light up.

Display color: green

(11) DEMAND Lamp Lights up when a demand value is displayed.

Display color: red

(12) Operation Keys

Indicator-out Mode Setting

The ON/OFF setting of the indicator-out mode function and the wait time before entering the indicator-out mode can

be set using the operation keys. (Cannot be set via communication.)

Indicator-out mode: ON/OFF (

Indicator-out mode wait time: 1 to 60 minutes (resolution: 1 minute) (

A/D Sampling Rate,

A/D sampling rate: 4.8 kHz

Data Update Interval

Internal measurement data: display/communication data is updated at an interval of 1 second or less

Either the MAX or MIN lamp lights up when a maximum or minimum measured value is displayed.

Display color: red

Indicate the phase to which the measured value corresponds. (The A, B, and C indications or R, S, and T indications

Phase and Wire System Voltage-1 Voltage-2 Voltage-3 Current-1 Current-2 Current-3

Single-phase two-wire system A (R) − − A (R) − −

Single-phase three-wire system

Three-phase three-wire system

Three-phase four-wire system A (R) B (S) C (T) A (R) B (S) C (T)

Three-phase four-wire system

(2.5 element)

Display color: green

Blinks during communication (RS-485 or Ethernet).

Lights up when output is produced during pulse output, and goes out when no output is produced.

If a demand value exceeds the demand alarm point at a time other than during the alarm mask time, the OVER lamp

Used to switch measured value display patterns.

This key is also used for setting parameters.

Used to move the display digit during energy indication.

This key is also used for setting parameters.

Used to display the maximum or minimum measured value.

These keys are also used for setting parameters.

Used to switch phase indications when the PR300 displays a voltage or current for which phase indication can be

changed. (Phase switch indication is not available for single-phase two-wire system.)

This key is also used for setting parameters.

Used to start/stop demand measurement.

The lamp in the key lights up during demand measurement. Display color: green

This function turns off LEDs after a certain time elapses, with the exception of the power lamp (LED).

A, B (R, S) B, C (S, T) − A (R) C (T) −

A, B (R, S) − B, C (S, T) A (R) − C (T)

A (R) − C (T) A (R)* − C (T)*

initial value: OFF)

initial value: 10 minutes)

5

All Rights Reserved. Copyright © 2006, Yokogawa Electric Corporation GS 77C01E01-01E 5th Edition Dec. 10, 2008-00

Page 6

<<Contents>> <<Index>>

■ Input Specifications

Phase and Wire

System

Frequency

Rated Input Voltage

Rated Input Current

Rated Input Power

and Measuring Range

(When VT and CT are

used, their respective

secondary values)

• Universal three-phase three-wire system (switch the setting from single-phase two-wire system, single-phase three-wire

system, or three-phase three-wire system)

• Universal three-phase four-wire system (switch the setting from single-phase two-wire system, single-phase three-wire

system, three-phase three-wire system, or three-phase four-wire system)

• Three-phase four-wire system (2.5 element)

45 to 65 Hz

Rated V oltage Voltage Range (Variable)

120 V 150 V

240 V 300 V

480 V 600 V

Rated Current Current Range (Fixed)

1 A 1 A

5 A 5 A

• Single-phase two-wire system

Input (AC)

120V/1A

120V/5A

240V/1A

240V/5A

480V/1A

480V/5A

• Three-phase three-wire system

Input (AC)

120V/1A

120V/5A

240V/1A

240V/5A

480V/1A

480V/5A

• Input measuring range when VT and CT are used

The primary input power (Secondary rated power 1.2 VT ratio CT ratio) is smaller than 10 GW and the

value calculated by the following equation is within the input measuring range mentioned above.

Input

Rated

Power

100 W

500 W

200 W

1000 W

400 W

2000 W

Rated

Power

200 W

1000 W

400 W

2000 W

800 W

4000 W

Measuring

Range

120 to 120 W

600 to 600 W

240 to 240 W

1200 to 1200 W

480 to 480 W

2400 to 2400 W

Input

Measuring

Range

240 to 240 W

1200 to 1200 W

480 to 480 W

2400 to 2400 W

960 to 960 W

4800 to 4800 W

Input measuring range (W) =

The primary voltage of VT

900 kV

1800 kV

3600 kV

The primary current of CT

32 kA

160 kA

• Single-phase three-wire system

Approximate

Consumed VA

Voltage Current

0.2 VA

0.4 VA

0.2 VA

0.8 VA

Approximate

Consumed VA

Voltage Current

0.2 VA/

phase

0.4 VA/

phase

0.8 VA/

phase

0.2 VA/

phase

*

*

*

*Input specification of 1 A AC is not available for 2.5 element.

Primary input power (W)

VT ratio CT ratio

Allowable Input Voltage

Allowable Input Current

1.2 times the current range (continuous)

Twice the current range (10 seconds) or

10 times the current range (3 seconds)

Input (AC)

240V / 1A

240V / 5A

Rated

Power

200 W

1000 W

Input

Measuring

Range

240 to 240 W

1200 to 1200 W

• Three-phase four-wire system

Input (AC)

120V / 1A

120V / 5A

240V / 1A

240V / 5A

480V / 1A

480V / 5A

Rated

Power

300 W

1500 W

600 W

3000 W

1200 W

6000 W

Input

Measuring

Range

360 to 360 W

1800 to 1800 W

720 to 720 W

3600 to 3600 W

1440 to 1440 W

7200 to 7200 W

150 V

300 V

600 V

Approximate

Consumed VA

Voltage Current

0.2 VA/

phase

Approximate

Consumed VA

Voltage Current

0.2 VA/

phase

0.4 VA/

phase

0.8 VA/

phase

0.2 VA/

phase

0.2 VA/

phase

6

■ Digital Input Specifications

For digital input, either the optional integration start/stop or the demand alarm release can be used.

If demand measurement is specified for an optional measuring function, digital input enters demand alarm release

status. In this case, the optional integration start/stop cannot be used.

● Control signal for optional integration

Starts or stops optional integration.

Function

Number of Inputs

Input Signal

ON signal: 4.5 to 25 V DC

OFF signal: within 1 V DC

Minimum ON time 50 ms

* A special order can be placed for no-voltage contact.

Note: Optional integration control is also possible via communication.

Once control is performed by digital input, only digital input-based control is available. Communication-based control is no longer

possible until the power is turned off/on or remote reset is executed.

● Demand alarm release (when demand measurement is specified)

Function Cancels demand alarm.

Number of Inputs

Input Signal

ON signal:4.5 to 25 V DC

OFF signal: within 1 V DC

Minimum ON time 50 ms

* A special order can be placed for no-voltage contact.

All Rights Reserved. Copyright © 2006, Yokogawa Electric Corporation

1

Voltage signal*

1

Voltage signal*

GS 77C01E01-01E 5th Edition Dec. 10, 2008-00

Page 7

<<Contents>> <<Index>>

■ Analog Output Specifications (When Analog Output is Specified)

Function Converts measurement data into DC current for output.

Measurement Item for Output

power factor, and frequency

Output Signal 4 to 20 mA DC

Output Accuracy Measurement accuracy of measurement item for output (0.5% of F.S.)

Allowable Load Resistance

Response speed 2 seconds or less (until 1% of the final value is reached)

Setting Item Measurement item for output and the lower and upper limits of scaling.

Active power rated power (W) to rated power (W)

Setting Range of

Reactive power

Lower/Upper Limits

Apparent power 0 to rated power (VA)

of Scaling According to

Voltage (1 to 3) 0 to voltage range (V)

Measurement Item

Current (1 to 3) 0 to current range (A)

for Output

Power factor (LEAD)0.5 to 1 to (LAG)0.5

Frequency 45 to 65 (Hz)

One item selected from active power, reactive power, apparent power, voltage (1 to 3), current (1 to 3),

0 to 600

Initial value: active power (W), lower limit of scaling: 50% (0 W), upper limit of scaling: 100% (maximum value of

Scaling setting condition: upper limit of scaling lower limit of scaling ⭌ 50%

the input measuring range W)

rated power (var) to rated power (var)

■ Pulse Output Specifications (When Pulse Output is Specified)

Function Outputs pulses proportional to energy.

Measurement Item for Output

Number of Outputs 1

Output Signal Open collector

Contact Capacity 30 V DC at 200 mA

Pulse Unit 0.1 to 5000.0 kWh/pulse* (set in 100 Wh increments)

Setting Item Measurement item for output, pulse unit, and ON pulse width

ON Pulse Width Represents the ON time of pulses to be output. (Set the pulse width so that the maximum ON pulse width obtained

by the following equation is not exceeded.)

Within the range of 10 to 1270 ms (set in 10 ms increments)

* The units are kvarh/pulse for reactive energy and kVAh/pulse for apparent energy.

One item selected from active energy, regenerative energy, reactive energy (LEAD, LAG), and apparent energy

Initial value: active energy (kWh), pulse unit: 1 kWh/pulse, and ON pulse width: 50 ms

Maximum ON pulse width (ms) =

Secondary rated power [W] VT ratio CT ratio 1.2 2

Pulse unit [kWh/pulse]* 3600 1000

2

7

■ Demand Alarm Output Specifications (When Demand Measurement is

Specified)

Function

Output Signal

Contact Capacity

Alarm Release Function

* Refer to “Demand alarm release” of the Digital Input Specifications.

Outputs an alarm if the measured demand value exceeds the set demand alarm point.

Open collector

30 V DC at 200 mA

Automatic release: Cancels the alarm if demand falls below the demand alarm point when the next measurement is

performed.

Manual release*: Holds the status of an alarm that occurred once. Cancels the alarm by digital input or the operation

key, or via communication.

All Rights Reserved. Copyright © 2006, Yokogawa Electric Corporation GS 77C01E01-01E 5th Edition Dec. 10, 2008-00

Page 8

<<Contents>> <<Index>>

■ Communication Specifications

● RS-485 communication

Example:

PC

Maximum communication distance: 1200 m

Maximum number of slave stations to be connected: 31

Station number 01 Station number 02 Station number 31

Function RS-485 communication enables you to use the command/response method to read a variety of measurements and

write various settings.

Protocol PC link (with checksum, without checksum), Modbus (RTU, ASCII), PR201 original

Transmission Distance Approx. 1200 m maximum (when 24 AWG twisted-pair cable is used)

Connection Method Multi-drop connection (a maximum of 32 units [including a higher-level device])

Station Number 01 to 99 (maximum number of units to be connected: 31 [number of units that can be connected to a PC etc.])

(Setting range: 01 to 31 is recommended)

Transmission Method Half-duplex communication

Synchronization Method Start-stop synchronization

Baud Rate 19200, 9600, and 2400 bps

Xon/Xoff Control None

Data Format Data length 8 bits, 7 bits

Parity None, even, odd

Stop bit 1 bit, 2 bits

For details, refer to the user’s manual for communications of each device to be connected.

(Note 1) The settings cannot be written.

(Note 1)

8

Example of Connection Diagram

RS-232C

straight

cable

PC

120 Ω (external resistor)

*

Use the external resistor

without using the built-in

resistor of ML2.

Notes:

The PR300 employs a two-wire system for RS-485 communication.

SG: The SG terminal is connected to match the signal level of the RS-485 communication line.

FG: All shielded wires must be connected and then grounded at one place to provide noise protection for

RS-485 communication lines.

All Rights Reserved. Copyright © 2006, Yokogawa Electric Corporation

ML2

RS-232C/RS-485

Converter

(Yokogawa)

(A)

(B)

(SG)

*

PR300 PR300 PR300

Approx. 1200 m maximum (31 units maximum)

(B)(A)(B)(A)

(SG)(SG)

(FG)

GS 77C01E01-01E 5th Edition Dec. 10, 2008-00

120⍀ (built-in)

(A)

(TERM)

(B)

RS-485RS-485RS-485

(SG)

Terminator

Page 9

<<Contents>> <<Index>>

● Ethernet communication (when the Ethernet communication function is specified)

Example:

PC

IP address: 192.168.1.1

HUB

LAN

connection

Ethernet

9

Station number 01

IP address: 192.168.1.2

Function

Ethernet communication enables you to use the command/response method to read

a variety of measurements and write various settings.

The PR300 can be connected to IEEE802.3-compliant networks

(10BASE-T/100BASE-TX).

Communication

Specifications

Protocol Modbus/TCP

Access Control CSMA/CD

Station number 01

IP address: 192.168.1.3

Station number 01

IP address: 192.168.1.4

Station number 01

IP address: 192.168.1.5

Application layer

Transport layer

Network layer

Data link layer

Physical layer

Higher-level device (PC etc.)

MODBUS/TCP

TCP, UDP

IP, ICMP, ARP

Ethernet

10BASE-T/100BASE-TX

Baud Rate 10 Mbps/100 Mbps

Maximum Segment Length 100 m (distance between the hub and module)

Maximum Connecting

Configuration

Maximum of 4 levels of cascading (for 10BASE-T) or maximum of 2 levels of cascading (for 100BASE-TX)

(Number of hubs that can be cascade connected)

IP Address IP addresses can be set using the operation keys on the front of the PR300.

Modbus/TCP

03

Function

06

08

16

Overview of

Modbus/TCP

The structure of Modbus/TCP protocol is as follows:

Protocol

Code

Reads data from multiple D registers

Writes data into D register

Performs loopback test

Writes data into multiple D registers

MBAP Header

Function

Function code Data

Capable of reading data from up to 64 registers continuously.

Capable of writing data into one register.

Capable of performing a communication test.

Capable of writing data into up to 32 registers continuously.

PDU

The Modbus Application Protocol Header(MBAP Header) is made of the following seven bytes:

Description

The Simple Protocol Data Unit (PDU) is

the same as Modbus/RTU (Modbus

protocol via serial communication).

Byte No 0 1 2 3 4 5 6

Description Transaction ID Protocol ID Number of bytes Unit ID

Transaction ID:

Set any value for identifying the transaction. The PR300 returns a value received from a higher-level device as a response.

Protocol ID: Specify "0" for the Modbus/TCP protocol.

Number of bytes: Number of bytes after the unit ID (byte number 6)

Unit ID: The PR300 returns a value received from a higher-level device as a response.

Ethernet-

Serial Gateway

Function

The PR300 has an RS-485 communication terminal in

addition to an Ethernet communication connector.

Modbus/TCP commands received by Ethernet are relayed

to the RS-485 terminal. This enables the PR300 to connect

to a device with an RS-485 communication function

(Modbus/RTU protocol) via a network.

Example:

Higher-level device

IP address: 192.168.1.1 (arbitrary)

Ethernet

10BASE-T/100BASE-TX

RS-485 communication

Protocol Modbus/RTU

Baud Rate

9600 bps

Parity Even, odd, or none

Stop Bit 1 bit

(with Ethernet communication

PR300

function)

RS-485 connection

Station number 01 (fixed)

IP address: 192.168.1.2

(arbitrary)

Data Length 8 bits

RS-485 serial

communication device

Power monitor of POWERCERT Series

Digital indicating controller of

GREEN Series

Signal conditioner of JUXTA Series

Station number 02

(arbitrary)

Station number 10

For details, refer to the user’s manual for communications of each device to be connected.

Note: If Ethernet communication is used, the RS-485 communication interface is used specifically for the Ethernet-serial gateway function.

Therefore, it is not possible for a higher-level device such as a PC to access the PR300 via the RS-485 communication interface.

(arbitrary)

All Rights Reserved. Copyright © 2006, Yokogawa Electric Corporation GS 77C01E01-01E 5th Edition Dec. 10, 2008-00

Page 10

<<Contents>> <<Index>>

■ Standard Performance

Accuracy Rating

Calculation Accuracy

Backup upon Power Failure

Insulation Resistance

Withstand Voltage

Impulse Withstand Voltage

Effects of Magnetic Field

Effects of Changes in Ambient

Temperature

Effects of Power Supply Voltage

Variations

Effects of Input Frequency

Power Supply

Power Consumption

Active energy/optional active energy (Wh)

Active power (W)

Voltage (V)

Current (A)

Frequency (Hz)

Demand

The value is calculated to an accuracy of ±1 digit from the measured value for reactive energy, apparent energy,

reactive power, apparent power, power factor or current*.

* Current is only for the 2.5 element measurement.

The last integrated values obtained immediately before the power failure are held for active energy,

regenerative energy, reactive energy, and apparent energy.

Between each of the voltage input, current input, power,

ground, digital input, pulse output, analog output, RS485

communication output, Ethernet communication output, and

alarm output terminals

Between each of the voltage input, current input, power, and

ground terminals:

Between (the voltage input, current input, power and ground

terminals) and the digital input, pulse output, analog output,

alarm output, RS-485 communication output, and Ethernet

communication output terminals:

Between each of the digital input, pulse output, analog output,

alarm output, and (RS-485 communication output, Ethernet

communication output) terminals:

Between the RS-485 communication output, and Ethernet

communication output terminals:

Between all of the voltage input, current input, and power terminals and the ground terminal:

Between all of the output and ground terminals and all of the voltage input and current input terminals:

6 kV (1.2/50s), 10 times for positive and negative

400 A/m or less Active power: ±0.5% of F.S. Voltage/Current: ±0.25% of F.S.

0.03%/°C for a temperature change rate of 10°C/h or less (when 0.05 In ≤ I ≤ I max, power factor = 1)

0.05%/°C for a temperature change rate of 10°C/h or less (when 0.1 In ≤ I ≤ I max, power factor = LAG 0.5)

In: rated current, I: present current input

Active power: ±0.25%, Voltage/Current: ±0.125%

(for variations within the power supply operating range (when 0.01 In and power factor = 1)) In: rated current

Active power: ±0.25%, Voltage/Current: ±0.125% (for variation of 45 to 65 Hz)

100-240 V AC ±10% (50/60 Hz) or 130-300 V DC ±15%

AC drive: 10 VA maximum, DC drive: 5 W maximum

(EN60687 accuracy: class 0.5 or equivalent)

±0.5%

±0.5% of F.S.

±0.25% of F.S. (voltage rms)

±0.25% of F.S. (current rms)

±0.5 Hz

±0.5%

100 M⍀ or more (at 500 V DC)

2500 V AC for 1 minute

2500 V AC for 1 minute

1000 V AC for 1 minute

500 V AC for 1 minute

10

■ Safety and EMC Standards

Safety Standards

Measurement category

Installation category

Rated measurement input

EMC-compliant Standards

All Rights Reserved. Copyright © 2006, Yokogawa Electric Corporation

Compliant with

IEC/EN61010-1

UL61010-1

CAN/CSA C22.2 No.61010-1-04 (C-UL Listed)

600V CAT. III

Measurement Category

CAT.I

CAT.II

CAT.III

CAT.IV

CAT. II

Pollution degree: 2 (IEC/EN61010-1)

Voltage input:

Current input:

Compliant with EN61326

During testing, the instrument continues to operate at a measurement accuracy within the range of 20%.

600V AC (between terminals)

600V AC (across ground)

Circuits not directly connected to main power supply

Circuits directly connected to low-voltage facility

Circuits in building facilities

Supply sources to low-voltage facilities

Description

Remarks

Home-use equipment, portable tools, etc.

Switchboards, circuit breakers, etc.

Overhead lines, cable systems, etc.

GS 77C01E01-01E 5th Edition Dec. 10, 2008-00

Page 11

<<Contents>> <<Index>>

11

■ Environmental Conditions

Normal Operating Conditions

Warm-up time

Ambient temperature

Temperature change

Ambient humidity

Magnetic field

Continuous vibration

Short-time vibration

Shock

Installation

Mounting position

Installation altitude

Effects on Operating Conditions

Effects of ambient

temperature

Effects on supply

voltage variations

Transport and Storage Conditions

Temperature

Humidity

Shock and dropping of

package

At least 30 minutes

0 to 50°C (reference temperature: 23 2°C)

10°C/h or less

20 to 90% RH (no condensation)

400 A/m or less

10 to 60 Hz, 0.035 mm, 75 minutes

60 to 150 Hz, 4.9 m/s

2

for 15 seconds or less

14.7 m/s

2

or less (for shock time of 11 ms)

98 m/s

Indoor installation only

Vertical surface mounting only

2000 m or less

Analog output: 0.05% of F.S./°C or less

Analog output: 0.05% of F.S./°C or less

20 to 70°C

5 to 95% RH (no condensation)

90 cm (provided that an external packing

box is used)

2

, 75 minutes

■ Initial Settings (Time of Shipment)

The PR300 has the following initial settings at the

time of shipment. Settings can be modified after

delivery.

Setting Item

Phase and wire system

Voltage range

Input

VT ratio

CT ratio

Integrated low-cut power

Station number

Protocol

Baud rate

Parity

Stop bit

Data length

IP address *

Communication

Port number *

Subnet mask *

Default gateway *

2

Measurement item for pulse output

Pulse unit

Pulse

Output *

ON pulse width

Measurement item for analog output

3

Lower limit of scaling

Upper limit of scaling

Analog

Output *

4

Demand power/current

*

Demand period

Demand alarm mask time

Demand power alarm point

Demand current alarm point

Demand

Measurement

Alarm release function

Indicator-out mode/indicator-out

Other

mode wait time

*1 When the Ethernet communication function is specified

*2 When pulse output is specified

*3 When analog output is specified

*4 When demand measurement is specified

1

1

1

1

Initial Value

Three-phase three-wire system

(for three-phase three-wire system)

Three-phase four-wire system

(for three-phase four-wire system)

300 V

1

1.00

0.05 %

01

PC link with checksum

9600 bps

None

1 bit

8 bits

192.168.1.1

502

255.255.255.0

0.0.0.0

Active energy (kWh)

1 kWh/pulse

50 ms

Active power (W)

50% (0 W)

100% (maximum value of the

input measuring range W)

Active power

30 minutes

1 minute

100 kW

100 A

Automatic release

Off/10 minutes

■ Power Items and Equations

Phase and Wire

Syatem

Single-phase

two-wire system

Single-phase

three-wire

system

Three-phase

three-wire

system

Three-phase

four-wire system

Three-phase

four-wire system

(2.5 element)

* For distorted wave input, there may be differences between the PR300 and a

measuring instrument that uses a different measurement principle.

Apparent Power

VA= VA

VAi= ViAi

i=1, 2

⌺VA= VA1+VA2

VAi= ViAi

i= 1, 3

⌺VA= 3 /2(VA1+VA3)

VAi= ViAi

i=1, 2, 3

⌺VA= VA1+VA2+VA3

VAi= ViAi

i= 1, 3

⌺VA= 3 /2(VA1+VA3)

Reactive Power

(without using reactive

power meter method)

Q= ((VA)

Qi= ((VAi)2Pi2)

⌺Q = Q1+Q2

Qi= ((VAi)2Pi2)

⌺Q = Q1+Q3

Qi= ((VAi)2Pi2)

⌺Q = Q1+Q2+Q3

Qi= ( 3 /2(VAi)2Pi2)

⌺Q = Q1+Q3

(V and A are rms values)

2P2

i= 1, 2

i= 1, 3

i= 1, 2, 3

i= 1, 3

Power Factor

)

⌺P/⌺VA

(without using

reactive

power meter

method)

■ Mounting and Shape

Materials

Mounting Method

Connection Method

External Dimensions

(including a terminal cover)

Weight

Casing: polycarbonate resin (PC), UL94 V-0

Terminal block: polybutylene terephthalate (PBT),

Terminal cover: polyamide resin (PA6), UL94 V-2

Panel mounting (refer to Panel Cutout

Dimensions)

M3 screws for terminal connections:

analog output, pulse output, demand alarm output,

digital input, and RS-485 communication

M4 screws for terminal connections:

voltage/current input and power supply

RJ45 connection: Ethernet communication

110(H) 110(W) 128(D) mm or

96(H) 96(W) 126(D) mm

Approx. 600 g (when the accessories such as

mounting bracket are attached)

UL94 V-0

■ Accessories

JIS/ANSI-mounting kit

DIN-mounting bracket

Dust cover (with a screw)

Terminal cover (with screws)

Shorting bar (for RS-485 communication termination)

Tag number label

1 set

2

1

1

1

2

All Rights Reserved. Copyright © 2006, Yokogawa Electric Corporation GS 77C01E01-01E 5th Edition Dec. 10, 2008-00

Page 12

<<Contents>> <<Index>>

■ Connection Diagrams

A phase and wire system can be selected by specifying the parameters.

If measurement input does not exceed 600 V AC or 5A AC, direct input without using a VT or CT is possible. Do not

ground the input circuit when a VT or CT is not used. Perform wiring for the voltage and current in the same circuit.

● Single-phase two-wire system

12

Power-source side

12

k

K

CT

L

l

Load side

Fuse

UVu

VT

Pulse output

13

14

v

Contact capacity:

30V DC, 200mA

1S

1L

P1

P2

1

23

45

6

7

9

8

10

Analog output

11

12

17

11

18

12

19

13

20

14

21

15

22

16

Demand alarm output

ALM

15

CAUTION

Screws marked with ● are an essential part

of the structure. For safety reasons, do not

touch them.

*1: If Ethernet communication is used, the RS-485 communication

interface is used specifically for the Ethernet-serial gateway function.

*2: If demand measurement is specified, the demand alarm release is selected.

16

ALM

Output signal:

4 to 20mA DC

23

24

25

LED

LED

Contact capacity:

30V DC, 200mA

(resistive load)

RS-485 communication*

TERM

17

R: 120⍀ (built-in)

R

A

18

19

20

When terminating on wiring,

short-circuit terminals and .

B

SG

RS-485

1

18

17

Power supply

L

23

Power supply

N

24

PE

25

Operating range:

100-240V AC 10% or

130-300V DC 15%

Optional integration control signal

or demand alarm release

DI

21

DI

22

Voltage signal

ON signal: 4.5 to 25V DC

OFF signal: within

1V DC

2

*

Ethernet communication

RJ45 connector

10BASE-T/100BASE-TX

Link LED (top)

Color Description

Off Stopped

Orange

10Mbps

Green 100Mbps

Switching between 10BASE-T and 100BASE-TX takes place automatically.

Switching between half duplex and full duplex takes place automatically.

Active LED (bottom)

Color

Description

Off Stopped

Orange Half duplex

Green

Full duplex

All Rights Reserved. Copyright © 2006, Yokogawa Electric Corporation

GS 77C01E01-01E 5th Edition Dec. 10, 2008-00

Page 13

<<Contents>> <<Index>>

● Single-phase three-wire system

13

Power-source side

1N2

k

K

CT

L

l

k

K

CT

L

l

Load side

Pulse output

13

14

Contact capacity:

30V DC, 200mA

Analog output

11

12

17

1

23

45

6

7

9

8

10

Fuse

1S

1L

2S

2L

U

u

P1

V

V

U

VT

P0

v

P2

v

u

CAUTION

Screws marked with ● are an essential part

of the structure. For safety reasons, do not

touch them.

*1: If Ethernet communication is used, the RS-485 communication

interface is used specifically for the Ethernet-serial gateway function.

*2: If demand measurement is specified, the demand alarm release is selected.

11

18

12

19

13

20

14

21

15

22

16

Demand alarm output

ALM

15

ALM

16

Output signal:

4 to 20mA DC

23

24

25

LED

LED

Contact capacity:

30V DC, 200mA

(resistive load)

RS-485 communication*

TERM

17

R: 120⍀ (built-in)

R

A

18

19

20

When terminating on wiring,

short-circuit terminals and .

B

SG

RS-485

1

18

17

Power supply

L

23

Power supply

N

24

PE

25

Operating range:

100-240V AC 10% or

130-300V DC 15%

Optional integration control signal

or demand alarm release

DI

21

DI

22

Voltage signal

ON signal: 4.5 to 25V DC

OFF signal: within

1V DC

2

*

Ethernet communication

RJ45 connector

10BASE-T/100BASE-TX

Link LED (top)

Color Description

Off Stopped

Orange

10Mbps

Green 100Mbps

Switching between 10BASE-T and 100BASE-TX takes place automatically.

Switching between half duplex and full duplex takes place automatically.

Active LED (bottom)

Color

Description

Off Stopped

Orange Half duplex

Green

Full duplex

● Three-phase three-wire system

U

V

V

U

VT

Pulse output

13

14

u

v

v

u

1S

1L

3S

3L

P1

P2

P3

Contact capacity:

30V DC, 200mA

Power-source side

123

A

(R)B(S)C(T)

K

k

CT

L

l

k

K

CT

L

l

Fuse

Load side

CAUTION

Screws marked with ● are an essential part

of the structure. For safety reasons, do not

touch them.

*1: If Ethernet communication is used, the RS-485 communication

interface is used specifically for the Ethernet-serial gateway function.

*2: If demand measurement is specified, the demand alarm release is selected.

1

23

45

6

7

9

8

10

Analog output

11

12

17

11

18

12

19

13

20

14

21

15

22

16

Output signal:

4 to 20mA DC

23

24

25

LED

LED

Demand alarm output

ALM

15

16

ALM

Contact capacity:

30V DC, 200mA

(resistive load)

RS-485 communication*

TERM

17

R: 120⍀ (built-in)

R

A

18

19

20

When terminating on wiring,

short-circuit terminals and .

B

SG

RS-485

1

18

17

Power supply

L

23

Power supply

N

24

PE

25

Operating range:

100-240V AC 10% or

130-300V DC 15%

Optional integration control signal

or demand alarm release

DI

21

DI

22

Voltage signal

ON signal: 4.5 to 25V DC

OFF signal: within

1V DC

2

*

Ethernet communication

RJ45 connector

10BASE-T/100BASE-TX

Link LED (top)

Color Description

Off Stopped

Orange

10Mbps

Green 100Mbps

Switching between 10BASE-T and 100BASE-TX takes place automatically.

Switching between half duplex and full duplex takes place automatically.

Active LED (bottom)

Color

Description

Off Stopped

Orange Half duplex

Green

Full duplex

All Rights Reserved. Copyright © 2006, Yokogawa Electric Corporation GS 77C01E01-01E 5th Edition Dec. 10, 2008-00

Page 14

<<Contents>> <<Index>>

● Three-phase four-wire system

14

Power-source side

N1

23

A

(R)B(S)C(T)

K

k

CT

L

lk

K

CT

L

l

K

L

Load side

Pulse output

13

14

Contact capacity:

30V DC, 200mA

Analog output

11

12

17

1

23

45

6

7

9

8

10

CT

Fuse

1S

1L

2S

2L

k

l

U

V

U

V

U

V

VT

3S

3L

P1

u

P0

v

P2

u

v

P3

u

v

CAUTION

Screws marked with ● are an essential part

of the structure. For safety reasons, do not

touch them.

*1: If Ethernet communication is used, the RS-485 communication

interface is used specifically for the Ethernet-serial gateway function.

*2: If demand measurement is specified, the demand alarm release is selected.

11

18

12

19

13

20

14

21

15

22

16

Demand alarm output

ALM

15

ALM

16

Output signal:

4 to 20mA DC

23

24

25

LED

LED

Contact capacity:

30V DC, 200mA

(resistive load)

RS-485 communication*

TERM

17

R: 120⍀ (built-in)

R

A

18

19

20

When terminating on wiring,

short-circuit terminals and .

B

SG

RS-485

1

18

17

Power supply

L

23

Power supply

N

24

PE

25

Operating range:

100-240V AC 10% or

130-300V DC 15%

Optional integration control signal

or demand alarm release

DI

21

DI

22

Voltage signal

ON signal: 4.5 to 25V DC

OFF signal: within

1V DC

2

*

Ethernet communication

RJ45 connector

10BASE-T/100BASE-TX

Link LED (top)

Color Description

Off Stopped

Orange

10Mbps

Green 100Mbps

Switching between 10BASE-T and 100BASE-TX takes place automatically.

Switching between half duplex and full duplex takes place automatically.

Active LED (bottom)

Color

Description

Off Stopped

Orange Half duplex

Green

Full duplex

● Three-phase four-wire system (2.5 element)

Power-source side

N1

23

A

(R)B(S)C(T)

K

k

CT

L

lk

K

CT

L

l

K

L

Load side

k

CT

l

Fuse

*1: If Ethernet communication is used, the RS-485 communication

interface is used specifically for the Ethernet-serial gateway function.

*2: If demand measurement is specified, the demand alarm release is selected.

Pulse output

13

14

Contact capacity:

30V DC, 200mA

1S

1L

2S

2L

3S

3L

UVu

V

U

P1

P0

v

P3

v

u

VT

CAUTION

Screws marked with ● are an essential part

of the structure. For safety reasons, do not

touch them.

1

23

45

6

7

9

8

10

Analog output

11

12

17

11

18

12

19

13

20

14

21

15

22

16

Output signal:

4 to 20mA DC

23

24

25

LED

LED

Demand alarm output

ALM

15

16

ALM

Contact capacity:

30V DC, 200mA

(resistive load)

RS-485 communication*

TERM

17

R: 120⍀ (built-in)

R

A

18

19

20

When terminating on wiring,

short-circuit terminals and .

B

SG

RS-485

1

18

17

Power supply

L

23

Power supply

N

24

PE

25

Operating range:

100-240V AC 10% or

130-300V DC 15%

Optional integration control signal

or demand alarm release

DI

21

DI

22

Voltage signal

ON signal: 4.5 to 25V DC

OFF signal: within

1V DC

2

*

Ethernet communication

RJ45 connector

10BASE-T/100BASE-TX

Link LED (top)

Color Description

Off Stopped

Orange

10Mbps

Green 100Mbps

Switching between 10BASE-T and 100BASE-TX takes place automatically.

Switching between half duplex and full duplex takes place automatically.

Active LED (bottom)

Color

Description

Off Stopped

Orange Half duplex

Green

Full duplex

All Rights Reserved. Copyright © 2006, Yokogawa Electric Corporation

GS 77C01E01-01E 5th Edition Dec. 10, 2008-00

Page 15

<<Contents>> <<Index>>

■ External Dimensions

● ANSI 4-inch round form size (when a bezel is attached)

15

110

110 109

Bezel

(for ANSI-mounting)

22

2

(126.5) (109)

104.5

Dust cover

2-M5

1 to 10

23

(Acceptable panel thickness for mounting)

1.5

Terminal cover

<Panel Cutout Dimensions>

ANSI

42.9±0.4

(1.688±0.015)

42.9±0.4

(1.688±0.015)

42.9±0.4

(1.688±0.015)

ø101.6

(ø4.000)

Unit: mm

(approx. inch)

Unit: mm

42.9±0.4

(1.688±0.015)

Multiple Mounting

ø7.9

(ø0.312)

160 min.

(6.299 min.)

160 min.

(6.299 min.)

Normal Allowable Deviation= ±(Value of JIS B 0401-1999 tolerance grade IT18)/2

All Rights Reserved. Copyright © 2006, Yokogawa Electric Corporation GS 77C01E01-01E 5th Edition Dec. 10, 2008-00

Page 16

<<Contents>> <<Index>>

● DIN 96-square instrument size

16

110

96

96

<Panel Cutout Dimensions>

+0.8

92 (68)

0

(124.5) (109)

12.3

1 to 10

(Acceptable panel

thickness for mounting)

112.2

Dust cover

1.5

Terminal cover

Mounting bracket

2 places

Unit: mm

Unit: mm

109

92

(68)

+0.8

0

Min. 160

Min. 160

Normal Allowable Deviation= ±(Value of JIS B 0401-1999 tolerance grade IT18)/2

All Rights Reserved. Copyright © 2006, Yokogawa Electric Corporation

Subject to change without notice.

GS 77C01E01-01E 5th Edition Dec. 10, 2008-00

Loading...

Loading...