Page 1

Startup

Manual

Thank you for purchasing the PR300.

This manual describes the installation and wiring procedures of the

PR300. The electronic manuals are also provided on the accompanying

CD in addition to this manual. Read them along with this manual. To ensure correct use, be sure to read the PR300 Power and Energy Meter

User’s Manual (IM 77C01E01-01E) thoroughly before beginning operation.

Printed manuals (Electronic manuals [PDF files] are also provided on the accompanying CD.)

Model PR300 Power and Energy Meter Startup Manual <Installation>

IM 77C01E01-02E (This manual)

Model PR300 Power and Energy Meter Startup Manual <Initial Setup Operations> :

IM 77C01E01-03E

Electronic manuals (PDF files)

Model PR300 Power and Energy Meter User’s Manual :

IM 77C01E01-01E

Model PR300 Power and Energy Meter Communication Interface User’s Manual :

IM 77C01E01-10E

Please keep this manual for future reference.

Checking the Package

Verify the package as explained below before starting to use the product.

Should the delivered product be wrong or the package be missing any

item, contact the vendor from which you purchased the product.

Checking the Model and Suffix Codes

The PR300 bears a nameplate. Confirm that “MODEL” and “SUFFIX”

(suffix codes) shown on the nameplate agree with those of the product ordered.

Model

PR300

Phase and

wire system

Input voltage/

input current

Additional input

and output function

Communication

function

Optional measuring

function

Power supply

Phase indication format

*1 Can be used only when the voltage is in a state of equilibrium. In cases where “Three-phase four-wire system (2.5 element)” is

specified, the input current specification of 1 A AC is not applicable.

*2 Set the voltage range (150 V, 300 V, or 600 V) according to the rated input voltage to be measured.

*3 For Ethernet communication, the RS-485 communication interface is exclusively for the Ethernet-serial gateway function.

Suffix Codes

- -6 -0

-3

-4

-5

1

2

0

1

2

3

0

3

0

3

-6

A

R

-0

Model PR300

Power and Energy Meter

<Installation>

:

IM 77C01E01-02E

3rd Edition: June 2008 (YK)

Description

Power and Energy Meter

Universal three-phase three-wire system

(single-phase two-wire, single-phase three-wire, and threephase three-wire systems)

Universal three-phase four-wire system

(single-phase two-wire, single-phase three-wire, three-phase

three-wire, and three-phase four-wire systems)

Three-phase four-wire system (2.5 element)

Universal voltage input *2 (150 V, 300 V, 600 V) / 1 A

Universal voltage input

1 digital input

1 digital input, 1 analog output

1 digital input, 1 pulse output

1 digital input, 1 analog output, 1 pulse output

RS-485 communication

RS-485 communication, Ethernet communication

None

Demand measurement (1 demand alarm output)

100-240 V AC ±10% (50/60 Hz) or 130-300 V DC ±15%

A, B, and C indications

R, S, and T indications

Always 0

*2

(150 V, 300 V, 600 V) / 5 A

*1

*3

Network Solutions Business Division

2-9-32, Naka-cho Musashino-shi, Tokyo 180-8750 Japan

Phone: +81-422-52-7179 Facsimile: +81-422-52-6619

Record the parameter settings of the PR300 on MEMO column in

Appendix 4, “Parameter List” of the user’s manual (IM 77C01E0101E) provided on the accompanying CD.

Note that in the case of a failure, the parameter settings set to the

failed product cannot be restored.

Serial Number (NO.)

Also inform this number shown in “NO.” on the nameplate when contacting the vendor from which you purchased the PR300.

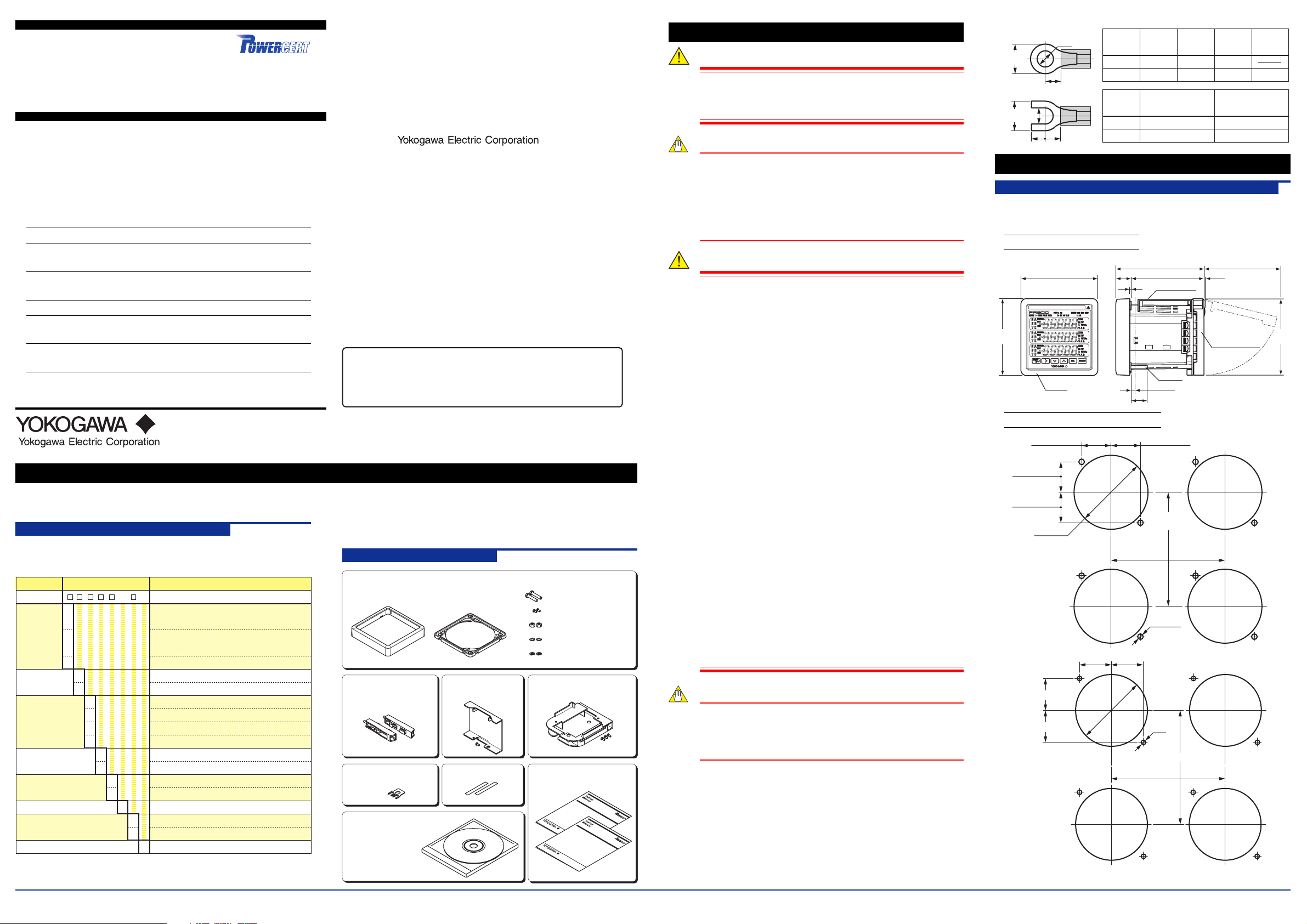

Checking the Accessories

JIS/ANSI-mounting kit

Bezel (1)

DIN-mounting brackets

(for DIN 96-square instrument

panel mounting)

Shorting bar Tag number labels Startup manuals

(for RS-485 communication

termination)

Manuals for the PR300

(This CD contains all manuals

related to the PR300.)

Panel-mounting

bracket (1)

Dust cover Terminal cover

(with 1 fixing screw)

Panel-mounting bolts (2)

Bracket-fixing screws (2)

Nuts (2)

Flat washers (2)

Spring washers (2)

(with 3 fixing screws)

(Installation/Initial Setup Operations)

Model PR300

Pow

<Installation>

er and Ener

gy Meter

M

odel PR300

Pow

<Initial S

er and Energy Meter

etup

O

p

erations>

Safety Precautions

WARNING

●

Install the PR300 in the secondary side of the exsting breaker.

●

When installing the PR300, provide spacing of 50 mm or more

between each face of the PR300 body and the instrument next

to the PR300 or between each face and the wall surface.

NOTE

● Do not install the PR300 in the following types of environments, as they may cause the PR300 to malfunction or fail.

Avoid sites:

exposed to significant shock or vibration; where corrosive

gases are present; where large amounts of dust are present;

exposed to water; exposed to direct sunlight; outside; at

altitudes above 2000 m.

● The PR300 mounting position is for vertical panels only.

WARNING

● As there is a danger of electric shock, turn off the power supply and check that the cables to be connected are not conducting electricity before carring out the wiring procedure.

● For safety, be sure to install a circuit breaker switch that conforms to IEC 60947 near the PR300 so as to be operated easily, and clearly indicate that the device is used to de-energize

the PR300.

● The wiring procedure for the PR300 should be carried out by

a qualified person (an electrician etc.) with knowledge of

electrical matters and who has actual experience.

● Install a current transformer (CT) inside a panel when using a

conduit for wiring.

● Use the UL Listed Panel only for the panel on which the

PR300 is installed.

● If the voltage is below 600 V AC, it is possible to connect the

PR300 directly without using a voltage transformer (VT) and

if the current is below 5 A AC, it is possible to do so without

using a current transformer (CT). However, in order to use

the PR300 safely, the use of VT and CT is recommended.

Use the UL-approved VT and CT for the PR300.

● Perform wiring for the voltage and current input in the same

circuit.

● Check the following before turning on the power. Using the

PR300 beyond the stated specifications may cause it to heat

up and burn out.

• Check that the power supply voltage, input voltage, and input

current values to be applied to the PR300 agree with its

specifications.

• Check that the external wiring is connected to the terminals in

accordance with the specifications.

● Do not touch the screws in locations (a) to (f) shown in the

wiring diagrams. They are an essential part of the structure

of the PR300. Loosening or tightening them may result in a

malfunction or failure of the PR300.

● Be sure to attach the terminal cover to prevent electric shock

(refer to Chapter 3, “Attaching the Dust Cover and Terminal

Cover”).

NOTE

When attaching the terminal cover

• Since the terminal cover of PR300 has the structure of

preventing electric shock, the terminal cover cannot be

attached after completing all wiring. Refer to Chapter 3,

“Attaching the Dust Cover and Terminal Cover” before wiring.

Carry out the wiring referring to the diagrams in Sections 2.1 to 2.6. The

wiring for voltage input, current input, and power supply is M4 screw terminal connection. For other wiring it is M3 screw terminal connection. The

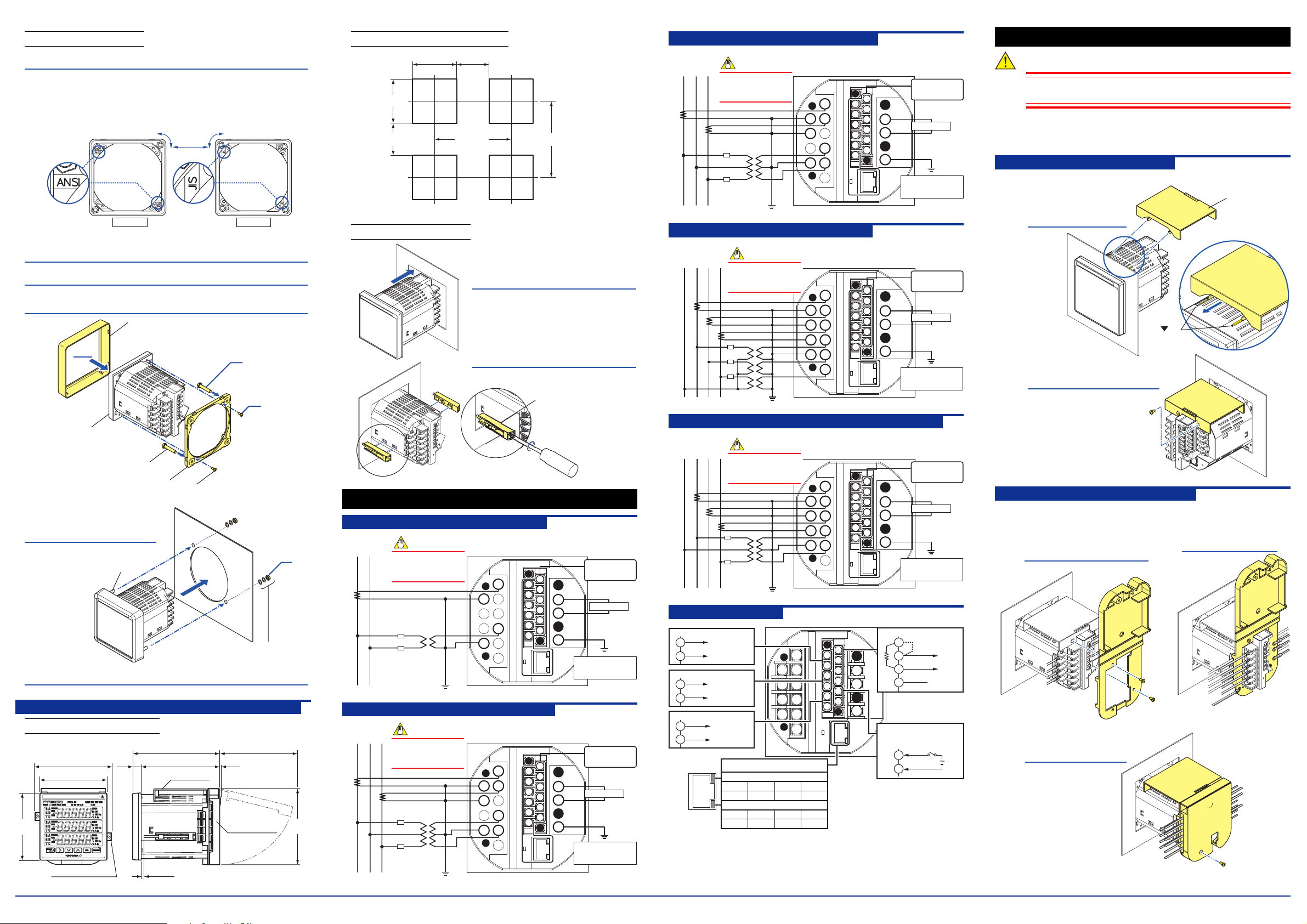

connector for connecting to the Ethernet is RJ45.

Use strand wires for the wiring. Wiring cables with a nominal cross-sectional area of 1.25 mm2 or thicker are recommended for voltage/current input and power supply; cables with a nominal cross-sectional area of 0.5

mm2 or thicker are recommended for other signals. Durable good-contact

ring tongue crimping terminals are recommended to use.

Ring tongue terminal

ød

A

F

Spade tongue terminal

ød

A

FB

Applicable

terminals

M4

M3

Applicable

terminals

M4

M3

ød

(mm)

4.4 max.

3.3 max.

Recommended

tightening torque

7.0 max.

5.8 max

1.2 N•m

0.6 N•m

A

(mm)

7.8 max.

6.7 max.

Applicable wire size

1.04 to 2.63 mm

0.25 to 1.65 mm

F

(mm)

(mm)

4.7 max.

1. Installation

1.1 Installation with the ANSI 4-inch Round Form

The PR300 can be installed so that it handles ANSI 4-inch round form or

JIS 110-square instruments panel cutouts by attaching the “JIS/ANSImounting kit” accessory.

1.1.1 External Dimensions

Unit: mm

(109)

Unit: mm

[approx. inch]

110

110

Bezel

22

2

23

1.1.2 Panel Cutout Dimensions

ANSI

[1.688±0.015]

[1.688±0.015]

JIS

42.9±0.4

[1.688±0.015]

42.9±0.4

42.9±0.4

ø101.6

[ø4.000]

160 min.

[6.299 min.]

45±0.3 45±0.3

45±0.3

45±0.3

Normal Allowable Deviation=±(Value of JIS B 0401-1998 tolerance grade IT18) / 2

ø101

160 min.

(126.5)

104.5 1.5

Dust cover

Terminal cover

2-M5

1 to 10

(Acceptable panel thickness for mounting)

42.9±0.4

[1.688±0.015]

160 min.

[6.299 min.]

ø7.9

[ø0.312]

ø6.5

160 min.

B

2

2

109

1

Page 2

1.1.3 Mounting Method

Set the direction of the panel-mounting bracket.

1

The diagram below shows the front of the bracket (the side into which the

panel-mounting bolt is inserted). Rotating the bracket 90 makes the bracket

compatible with either ANSI or JIS panel cutouts. Set the bracket to either

the ANSI or JIS mark according to which type of panel you are installing, as

shown in the diagram.

Front of the bracket

Rotate 90

Front of the bracket

ANSI JIS

Insert two panel-mounting bolts into the front of the panel-mounting bracket as

2

shown in the diagram.

Fix the panel-mounting bracket securely to the back of the PR300 with two

3

bracket-fixing screws as shown in the diagram.

(recommended tightening torque: 0.4 N•m)

4

Attach the bezel from the front of the PR300.

Bezel (standard accessory)

4

2

3

PR300

Panel-mounting bolt

(standard accessory: 2 bolts)

Panel-mounting bracket

(standard accessory)

Insert the PR300 from its rear

5

through the mounting cutout in the

2

Bracket-fixing screw

(standard accessory: 2 screws)

3

6

panel as shown in the diagram.

Panel-mounting bolt

5

Flat washer, spring washer, and nut

(standard accessory: 2 of each)

Secure the PR300’s panel-mounting bolts by tightening them with the washers and nuts.

6

(recommended tightening torque: 2.0 N•m)

1.2

Installation with the DIN 96-square Instrument Size

1.2.1 External Dimensions

(124.5) (109)

110

96

96

Mounting bracket

(2 places)

2

12.3

112.2

1.5

Dust cover

Terminal cover

1 to 10

(Acceptable panel thickness for mounting)

6

Unit: mm

109

1.2.2 Panel Cutout Dimensions

+0.8

92

+0.8

92

0

(68)

Normal Allowable Deviation=±(Value of JIS B 0401-1998 tolerance grade IT18) / 2

(68)

0

160 min.

160 min.

1.2.3 Mounting Method

Insert the PR300 from its rear through the

1

1

mounting cutout in the panel as shown in

the diagram.

Affix the mounting brackets to the left and

2

right sides of the PR300. Secure the

brackets to the PR300 by tightening the

screws in the end of the mounting brackets

with a screwdriver as shown in the

diagram.

(recommended tightening torque: 0.4 N•m)

2

2

2. Wiring

2.1 Single-phase two-wire system

Power-source

side

12

k

K

CT

L

l

Load side

2.2 Single-phase three-wire system

Power-source

side

1N2

k

K

CT

L

K

l

L

Load side

NOTE

Do not ground the input

circuit when connecting

voltage and current directly

without using VT and CT.

u

U

Fuse

v

V

VT

NOTE

Do not ground the input

circuit when connecting

voltage and current directly

without using VT and CT.

k

CT

l

U

Fuse

u

v

V

v

V

u

U

VT

c

1

a

1S

1L

2

4

6

P1

P2

8

b

a

1S

1L

2

2S

2L

4

6

P1

P0

8

P2

b

11

12

3

13

5

14

15

7

16

9

10

c

1

11

12

3

13

5

14

15

7

16

9

10

Unit: mm

Mounting bracket

(standard accessory: 2 brackets)

Refer to

e

Lⴙ

23

Nⴚ

24

f

PE

25

e

Lⴙ

23

Nⴚ

24

f

PE

25

“Other Wiring”

Power supply

Power supply voltage

100-240V AC±10% or

130-300V DC±15%

Refer to

“Other Wiring”

Power supply

Power supply voltage

100-240V AC±10% or

130-300V DC±15%

17

18

19

20

21

22

d

17

18

19

20

21

22

d

2.3 Three-phase three-wire system

Power-source

side

123

A

(R)B(S)C(T)

K

k

CT

L

l

Load side

K

L

NOTE

Do not ground the input

circuit when connecting

voltage and current directly

without using VT and CT.

k

CT

l

u

U

Fuse

v

V

v

V

u

U

VT

c

1

a

1S

1L

2

3S

3L

P1

P2

P3

3

4

5

6

7

9

8

b

10

17

11

e

18

12

13

14

15

16

Lⴙ

19

23

Nⴚ

20

24

21

f

22

PE

25

d

Power supply voltage

100-240V AC±10% or

130-300V DC±15%

2.4 Three-phase four-wire system

Power-source

side

N1

A

(R)B(S)C(T)

K

k

CT

L

lk

Load side

23

K

CT

L

l

NOTE

Do not ground the input

circuit when connecting

voltage and current directly

without using VT and CT.

K

k

CT

L

l

U

Fuse

u

v

V

u

U

v

V

u

U

v

V

VT

c

1

a

1S

1L

23

2S

2L

45

3S

3L

6

P1

P0

P2

P3

7

9

8

b

10

17

11

e

18

12

13

14

15

16

Lⴙ

19

23

Nⴚ

20

24

21

f

22

PE

25

d

Power supply voltage

100-240V AC±10% or

130-300V DC±15%

2.5 Three-phase four-wire system (2.5 element)

Power-source

side

N1

A

(R)B(S)C(T)

K

k

CT

L

lk

Load side

23

K

CT

L

l

NOTE

Do not ground the input

circuit when connecting

voltage and current directly

without using VT and CT.

K

k

CT

L

l

U

Fuse

u

V

v

v

V

u

U

VT

c

1

a

1S

1L

23

2S

2L

45

3S

3L

6

P1

P0

P3

7

9

8

b

10

17

11

e

18

12

13

14

15

16

Lⴙ

19

23

Nⴚ

20

24

21

f

22

PE

25

d

Power supply voltage

100-240V AC±10% or

130-300V DC±15%

2.6 Other Wiring

Analog output

+

11

12

Pulse output

13

14

Demand alarm output

15

16

−

+

−

ALM+

ALM−

RJ45

connector

10BASE-T

100BASE-TX

Output signal:

4 to 20mA DC

Contact capacity:

30V DC, 200mA

(resistive load)

Contact capacity:

30V DC, 200mA

(resistive load)

Ethernet communication

Color

Description

Color

Description

Switching between 10BASE-T and

100BASE-TX takes place automatically.

Switching between half and full duplex

takes place automatically.

Link LED

Off

Stopped

Active LED

Off

Stopped

1

a

23

45

6

7

9

8

b

10

Orange

10Mbps

Orange

Half duplex

c

11

12

13

14

15

16

Green

100Mbps

Green

Full duplex

17

18

19

20

21

22

d

*1 If Ethernet communication is used, the RS-485

*2 In the case of the PR300 with the demand

RS-485 communication

17

e

23

24

f

25

communication interface is used specifically for

the Ethernet-serial gateway function.

measuring function, the demand alarm release

is selected.

R

18

19

20

When terminating, short-circuit

terminals 17 and 18 with the

shorting bar

Optional integration

control signal or

demand alarm release

DIⴙ

21

DIⴚ

22

Voltage signal

ON signal : 4.5 to 25V DC

OFF signal : within ±1V DC

Refer to

“Other Wiring”

Power supply

Refer to

“Other Wiring”

Power supply

Refer to

“Other Wiring”

Power supply

TERM

Aⴚ

Bⴙ

SG

R: 120 (built-in)

3.

Attaching the Dust Cover and Terminal Cover

WARNING

As there is a danger of electric shock, do not attach the dust

cover and terminal cover while the wires are live.

• Attach the dust cover before attaching the terminal cover.

• The recommended tightening torque for the screws for attaching the

dust cover and terminal cover is 0.4N•m.

3.1 Attaching the Dust Cover

Insert the two protruding

1

portions on the underside of the

dust cover into the grooves on

the upper side of the PR300 as

Dust cover

(standard accessory)

shown in the diagram below.

Insert into

the

marked

grooves

Secure the dust cover with the screw

2

provided as shown in the diagram below.

(recommended tightening torque: 0.4 N•m)

3.2 Attaching the Terminal Cover

Complete the wiring to the terminals

1

2, 4, 6, 8, 23, 24, and 25, then

secure the terminal cover in the

open state shown in the diagram

below with the two screws provided.

(recommended tightening torque: 0.4 N•m)

*1

*2

Close the terminal cover and secure it

3

with the screw provided as shown in

the diagram below.

(recommended tightening torque:

0.4 N•m)

Complete the wiring to other

2

terminals with the terminal

cover open shown in the

diagram below.

IM 77C01E01-02E 3rd Edition June 20, 2008

Loading...

Loading...