Page 1

User

Manual

Model PR20

Retractable fitting for

combined pH/redox electrodes

IM 12B6K3-E-E

9th Edition

Page 2

IM 12B6K3-E-E

Page 3

CONTENTS

1. GENERAL 2

1-1.Description 2

1-2.Features 2

1-3.Safety precautions 2

2. UNPACKING AND CHECKING 3

2-1.Unpacking and inspection 3

2-2.Mounting location 3

2-3.Specifications 4

2-4.Model and codes 5

2-5.Dimensions 8

3. INSTALLATION AND WIRING 9

3-1.General 9

3-2.Accessories 10

3-3.Preparing the electrode for use 10

3-4.Mounting the electrode 10

3-5.Probe insertion 12

3-6.Adjusting the iinsersion depth 13

3-7.Wiring 13

4. MAINTENANCE 14

4-1.General 14

4-2.Cleaning 14

4-3.Calibration 15

4-4.Replacing the electrode 16

4-5.Replacing the O-rings 16

4-6.Replacing the cable 17

4-7.Flush port connections 17

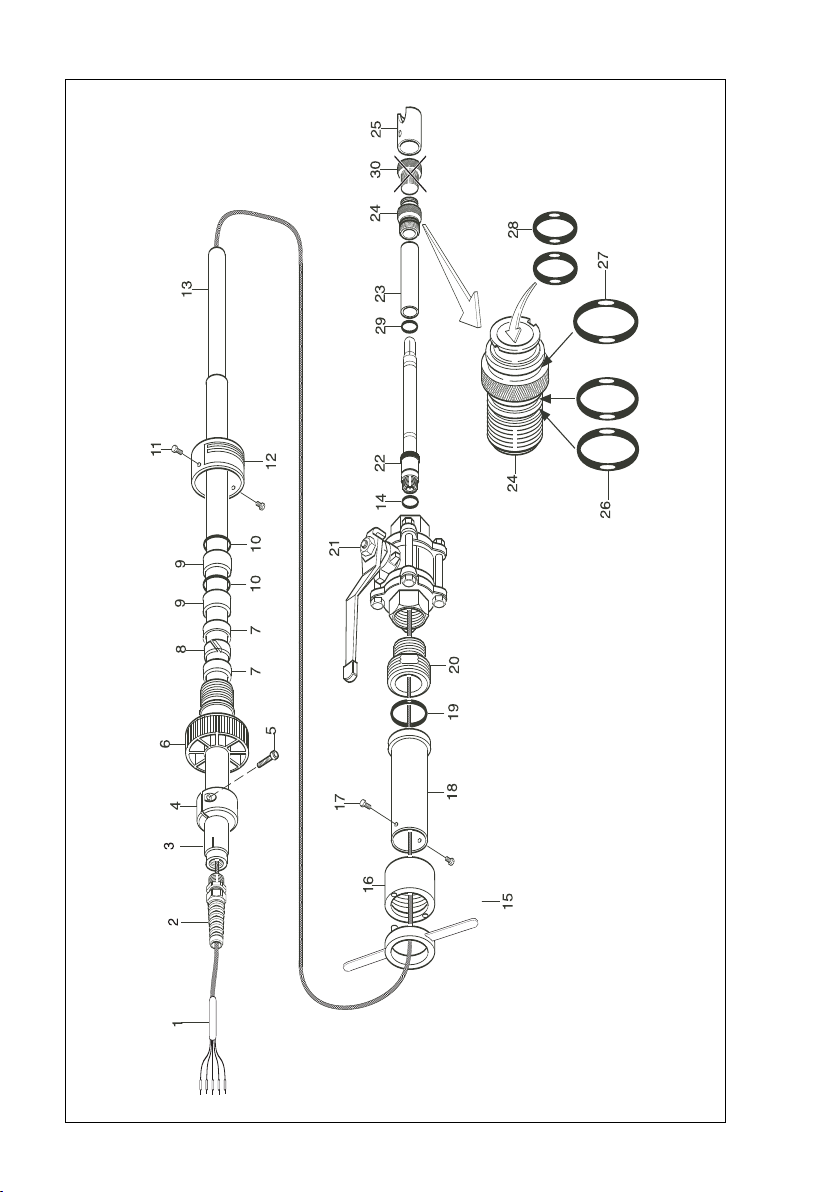

5. EXPLODED VIEW 19

6. SPARE PARTS LIST 20

IM 12B6K3-E-E

Page 4

2

1. GENERAL

1-1. Description

The retractable fitting with ball-valve

allows a safe insertion and retraction of a combined pH/reference

electrode while the process is

under pressure. It can be mounted

in a variety of positions as long as

the electrode is in an almost vertical

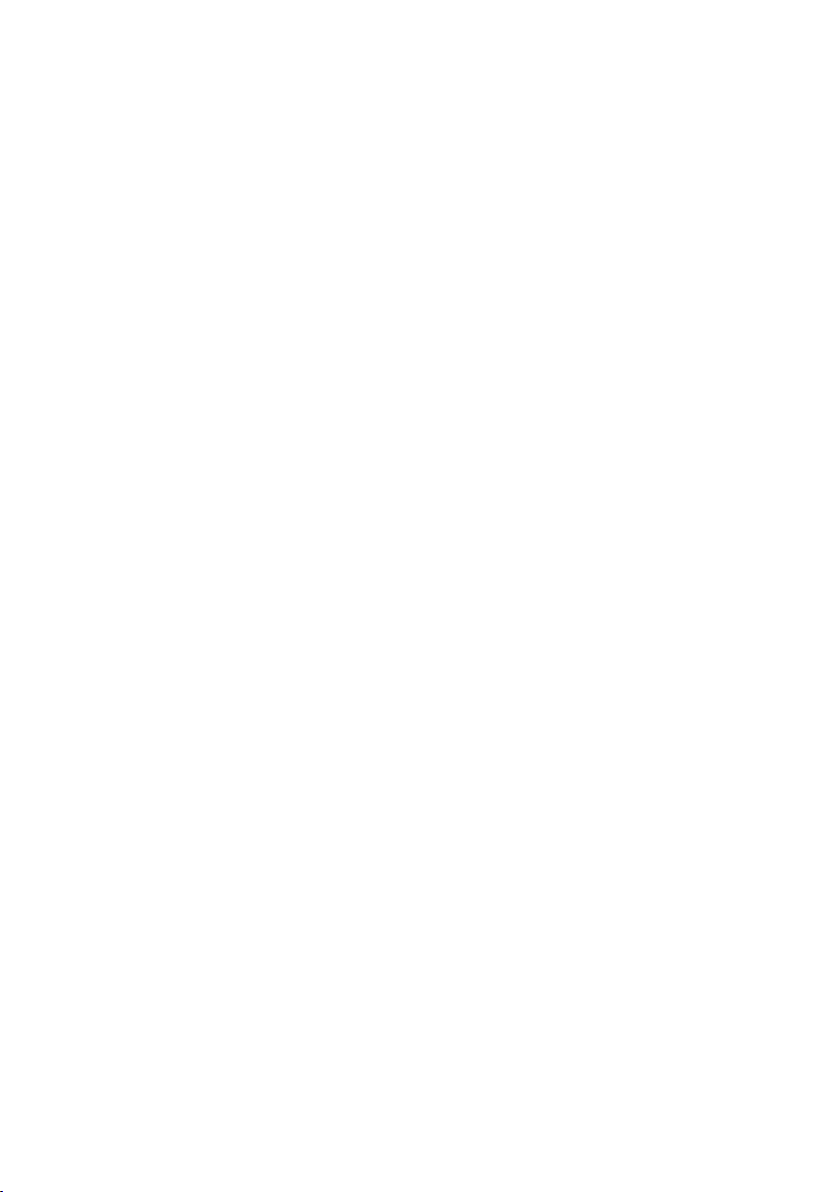

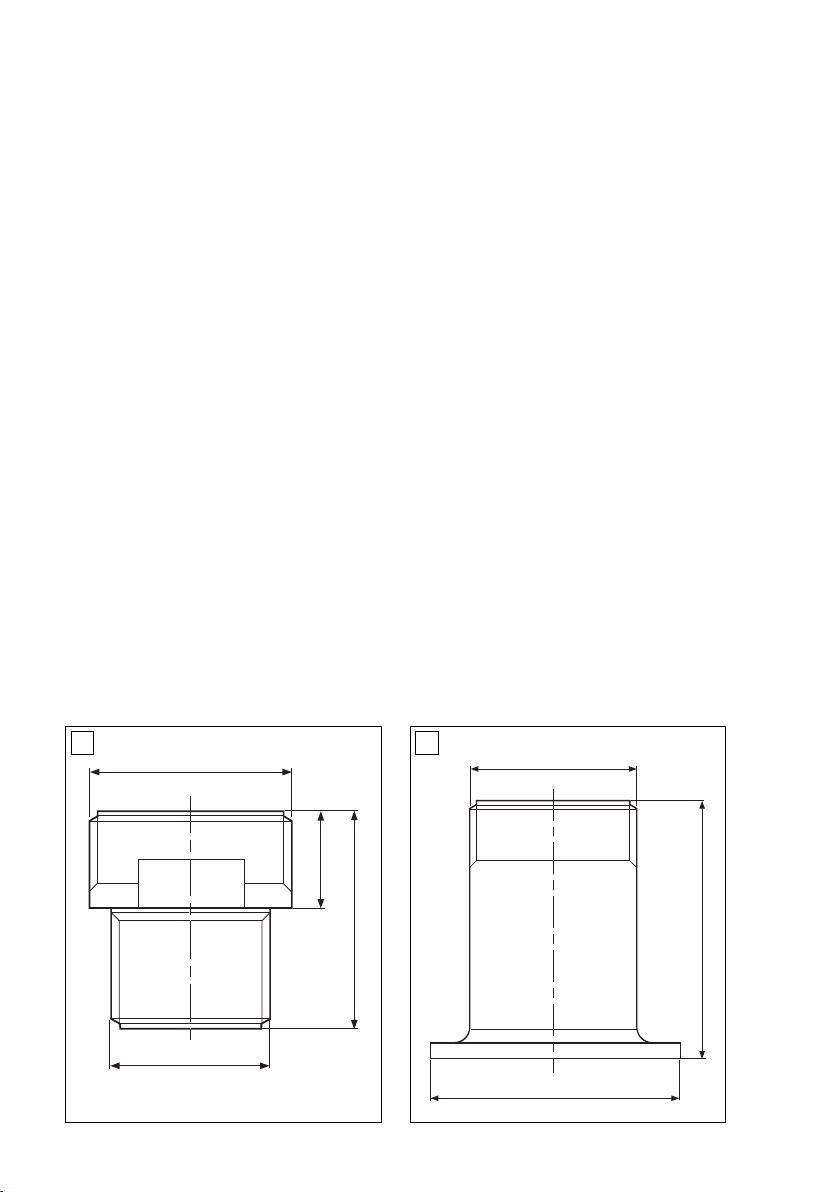

position with the tip pointing downward (see fig. 2-1).

The insertion depth can be selected

on site. A minimum insertion depth

of 0.2 mtr. into the process liquid is

advised to have a fast temperature

response. A special 'memory' ring

is provided to remember the position of the electrode after retraction.

To protect any loss of process

liquid the mechanism for releasing

the probe is designed to operate

only when the ball-valve is closed.

The combined pH/reference electrode can be replaced or calibrated

easily. The especially designed

cable has integrated leads for the

temperature sensor, shielding and

liquid earth. The end is pre-finished

with cable endings for easy mounting to industrial transmitters.

1-2. Features

- A safe "through the valve" insertion and retraction design.

- Additional safety though a special

designed 'T-bar' locking mechanism.

- Maintenance, replacement and

calibration of the electrode without

interruption of the process.

- Adjustable insertion depth for

optimal measuring position in the

process.

- Easy replacement of the electrode.

- Improved sealing and damping by

addition O-rings.

- Integrated liquid earth and temperature sensor (Pt100 or Pt1000 to

IEC 751 or DIN 43760).

- Simplified installation by optional

ball-valves with flanged or tapered

connections.

- Available in two different materials

and two different lengths (0.5 mtr.

and 1 mtr.)

1-3. Safety precautions

The PR20 has been designed to

give maximum safety in operation.

For optimum safety a flanged ballvalve is recommended.

Yokogawa does not accept any

claims or penalties on possible

damages or accidents which occurred by operation of the PR20 fitting.

The installation of the probe is to be

implemented under the local safety

regulations for pressurised vessels

or pipe-lines for retraction or insertion. The instructions given in this

manual must be followed exactly.

IM 12B6K3-E-E

Page 5

INCORRECT

15º

15º

HORIZONTAL

CORRECT

CORRECT

2. UNPACKING AND CHECKING

2-1. Unpacking and inspection

When you receive the PR20 retractable fitting it is packed in a cardboard box. Open the box and

check that the model code on the

fitting is the same as on the packing list (see §2-4). The model code

with serial number of the fitting are

on an identification plate fixed on

the protection ring.

Also check that the options you

ordered are supplied. These options

are delivered in separate bags.

If you have any problems or

questions, please contact the

nearest Yokogawa service centre or

sales organisation for assistance.

2-2. Mounting location

The PR20 fitting is intended to be

used for in-line pH measurement.

When it is delivered with an optional

ball-valve or when it is used in combination with a locally purchased 1

inch ball-valve, the process does

not need to be interrupted for maintenance of the sensor. The location

can be in a large diameter pipeline

or a vessel. The angle of the fitting

with the horizon should not be less

than 15 degrees (see fig. 2-1).

The pressure- and temperature

ratings of the electrode inside the

fitting determine the maximum

rating of the measurement point.

3

Fig. 2.1. Angle of fitting

Warranty

Yokogawa Europe B.V. warrants

that the goods delivered are made

from new materials to the best

workmanship available. Malfunction

of any of the delivered goods or

parts, can only lead to replacement

of the damaged parts. No claims

can be made to damages or accidents resulting from the use of the

goods. No claims can be made to

the expected or promised performance of the goods under any circumstances.

Damaged goods or parts should be

sent to the local Service organisation for warranty claim purposes.

Yokogawa has the right to deny

warranty claims after investigation

of the data and the materials.

IM 12B6K3-E-E

Page 6

4

2-3. Specifications

Materials (wetted parts)

Probe

Model PR20-S : Stainless steel AISI 316

Model PR20-T : Titanium

O-ring seals : Viton 70° shore

Silicone rubber 50° shore

Non-wetted : Stainless steel (AISI 316) and

parts polyphenylene sulphide (PPS)

1

/

Process conn. : 1

" BSP-female (see modelcode for other connections)

4

Insertion length :The dimensional drawing indicates the maximum

insertion length for both specified probe lengths.

Pressure/temperature ratings

Static conditions : 2 MPa at 20°C, 500 kPa at 125°C

Operating

conditions : max. 500 kPa, max. 100°C

Weight : Approx. 2.5 kg. (SS316 version without ball-valve)

Specification of the optional senors

SC21-AAP26 : 1 to 500 kPa at 0 to 110°C, (pH/ref electrode)

SC21-AGP26 : 1 to 500 kPa at 0 to 110°C, (pH/ref electrode)

SC21-ALP26 : 1 to 500 kPa at 0 to 110°C, (pH/ref electrode)

SC21-AGP24 : 1 to 500 kPa at 0 to 80°C, (pH/ref electrode)

SC29-PTP29 : 1 to 500 kPa at 0 to 110°C, (Redox/ref electrode)

IM 12B6K3-E-E

Page 7

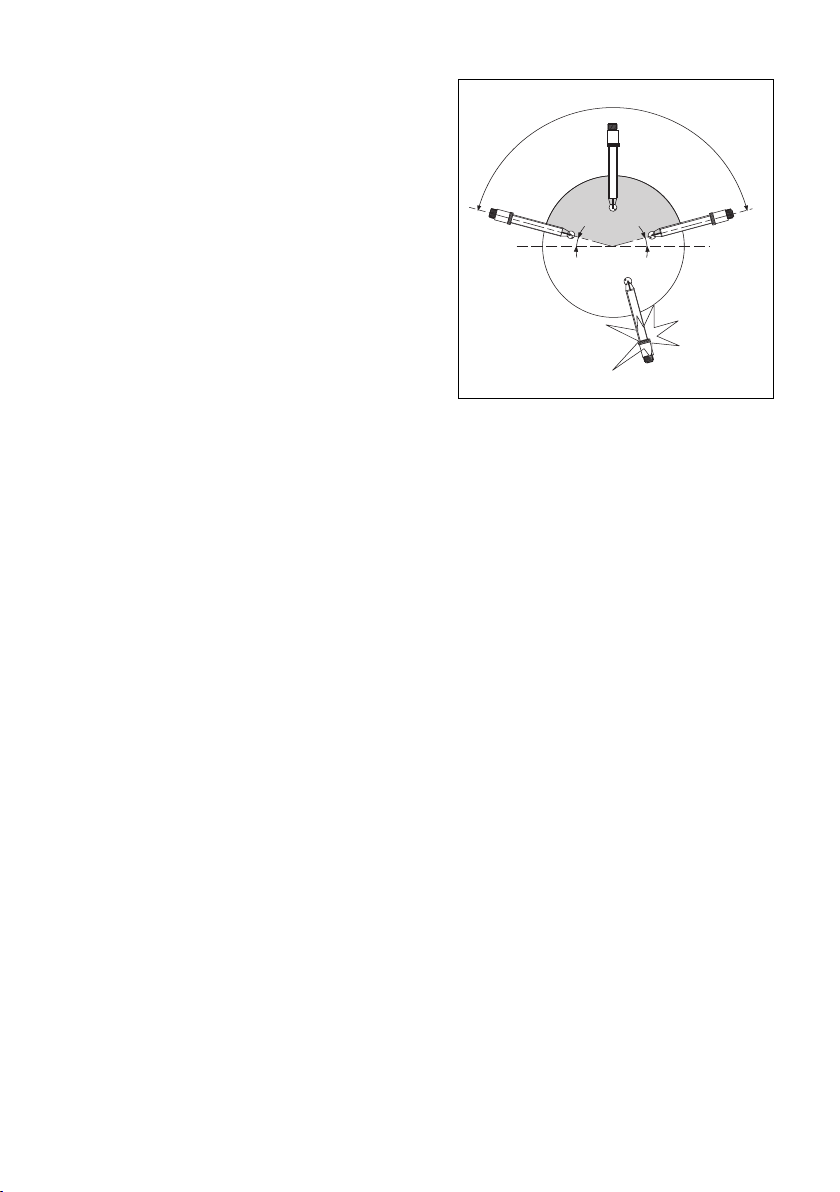

2-4. Model and codes

Model Suffix code Description

PR20 Retractable fitting

Material -S Stainless steel AISI 316

-T Titanium

Probe length*) -05 0.5 mtr.

-10 1 mtr.

Cable length -05 5 mtr.

-10 10 mtr.

Temp. sensor -T1 Pt1000

-T2 Pt100

Style *B Style code

Adapters /YYY See separate table

Certificates /M Material certificate 3.1B according to

EN-10-024 (DIN 50049) on wetted partsa

/T Test certificate for hydrostatic pressure

test (2 MPa at ambient temperature)

Combined /EB SC21-AAP26

electrode /EG SC21-AGP24

/EH SC21-AGP25

* Note: The insertion depth of the probe is given in the dimensional drawing.

5

IM 12B6K3-E-E

Page 8

6

ISO 228/1-G 1

ISO 229/1-G 1 1/4

20 (0.78)

45 (1.77)

ISO 229/1-G 1 1/4

63 (2.55)

65 (2.56)

Options

Adapter Option code Drawing

Model PR20-S PR20-T

Adapter only

1" BSP-male /SBS /TBS A

1" NPT-male /SNS /TNS A

DIN flange DN25 PN16 /SDS /TDS B, C

ANSI flange 1" 150 lbs /SUS /TUS B, C

Adapters and ball-valve

1" BSP-female /SBB /TBB A, D

1" NPT-female /SNN /TNN A, D

DIN flange DN25 PN16 /SDD /TDD B, C, E

ANSI flange 1" 150 lbs /SUU /TUU B, C, E

Adapter with flush ports

DIN flange DN25 PN16 /SES /TES F,C

ANSI flange 1" 150 lbs /SVS /TVS

Adapter with flush ports and ball-valve

DIN flange DN25 PN16 /SED /TED F, C, E

ANSI flange 1" 150 lbs /SVU /TVU F, C, E

Weld in adapters

Straight welding /SWR

Angled at 15 degrees /SWA

A B

DR 1 - 11 1/2 NPT acc. ANSI B 1.20.1

IM 12B6K3-E-E

Page 9

l

k

d

D

NW25

D

d

k

l

ø115

ø42.5

ø85

ø14

ø108

ø42.5

ø79.2

ø15.7

1 inch

95 (3.75)

125 (4.9)

65 (2.56)

23 (0.90)

ISO 229/1-G 1 1/4

63 (2.55)

DC

Internal thread (both sides)

ISO 228/1-G 1 OR

1 - 11 1/2 NPT ACC. ANSI B 1201

7

Glanges (both sides)

DN25-PN10 acc. DIN 2642 or

1”-150Lbs acc. ANSI B 16.5

FE

1/8 - 27 NPT vlg. ANSI G 1.20.1

IM 12B6K3-E-E

Page 10

8

ø

48

(ø 1.9)

ø 34

(ø 1.3)

ø 55

(

ø 2.16)

240

(

9.45)

ø 23

(ø 0.90)

390 or 890 (15.35 or 35)

550 or 1050 (21.65 or 41.35)

200 or 700

(7.9 or 27.5)

DIN 85 (3.35)

ANSI: 79.4 (3.125)

125

(4.95)

BSP: 275 or 775 max. (10.85 or 30.5)

NPT: 265 or 765 max. (10.45 or 30.1)

95 (3.75)

ø 48

(ø 1.9)

ø 21

(

ø 0.83)

2-5. Dimensions

mm (inch)

IM 12B6K3-E-E

Page 11

3. INSTALLATION AND WIRING

3-1. General

It is important to have the point of

measurement in a location that is

representing the process composition. Check whether the specifications of the electrode fulfil the maximum occurring process conditions.

The fitting has several optional connection possibilities. Check that you

received the correct size and type.

Install the fitting at a convenient

location for maintenance and calibration. For maintenance or calibration the probe will need a space of

about 2 mtr. for total retraction

(depending on probe length and

optional process adapters and/or

ball-valves). The position of the fitting must be within 15 degrees of

the horizon with the tip pointing

downward (see fig. 2-1). Installation

in a bend of a pipe-line is a good

measurement position.

When inserting the PR20 retractable fitting in a perpendicular position

to the process flow, the flow velocity will put a mechanical force on the

probe. Take care that this force is

not too large. It is recommended to

have the PR20 retractable fitting

positioned at a 45° angle into the

process stream.

9

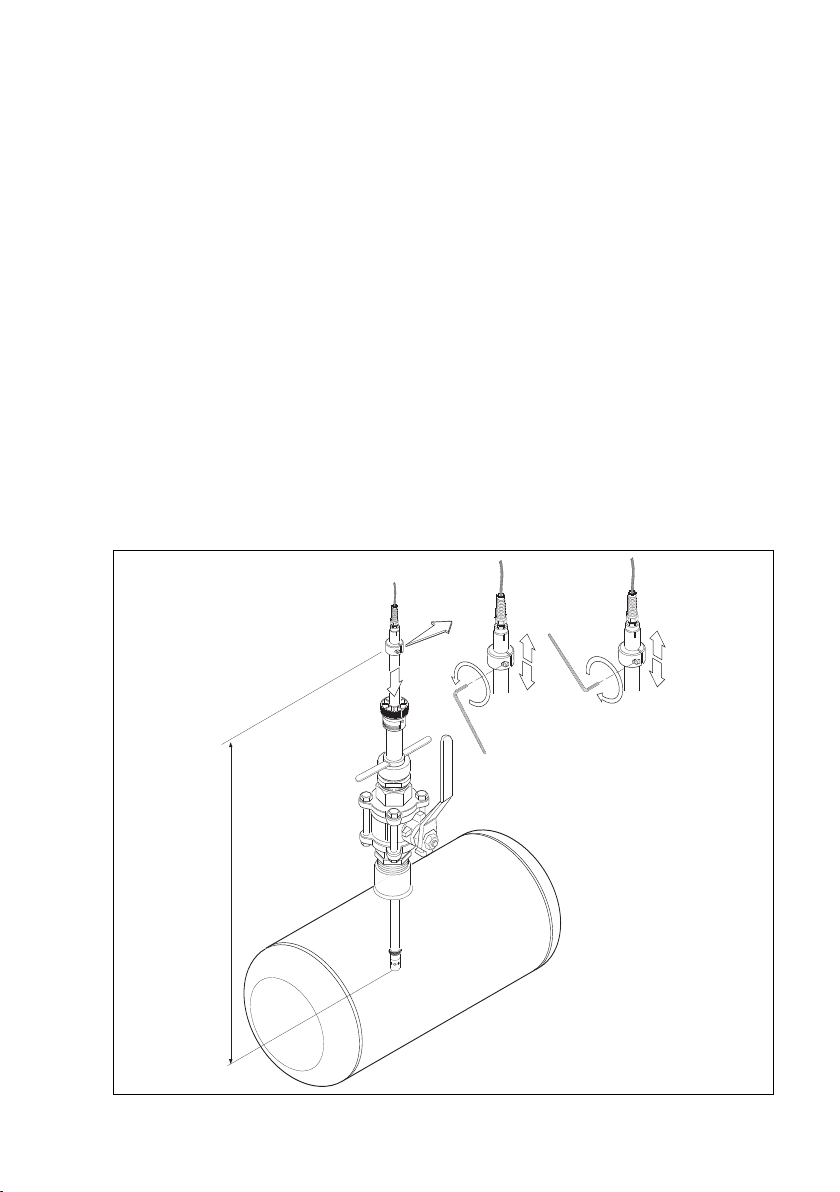

Fig. 3-1a. Pipe mounting

Fig. 3-1b. Tank mounting

IM 12B6K3-E-E

Page 12

10

ATTENTION

Do not insert the fitting into the process without the electrode mounted! Prevent liquid to come into

contact with the connector plug.

Start with the assembly of the electrode into the probe and follow the

instructions for the preparation of a

new electrode (see §3-3).

3-2. Accessories

Optional accessories are delivered

separately. When a ball-valve is

ordered as an option, this should

be mounted to the measuring position first. When the ball-valve in

place, the process line is secure.

If the ball-valve has a tapered connection, it needs to be locked with

the supplied glue. Next the adapter

at the other side of the ball-valve

needs to be mounted. This adapter

1

has 1

/

" BSPP-male thread at one

4

side and matching connection for

the ball-valve at the other side.

Mount the adapter on the ball-valve

and lock it with the supplied glue.

3-3. Preparing the electrode

1.

Romove the “wet” pocket.

Squeeze it to let in air

Remark:

The electrode used with the

retractable fitting if supplied

separately or as an option with

the fitting. The electrode is ready

for immediate use because it is

shipped in a 'wet' pocket.

2.

Remove the two O-rings (not

used). These O-rings are supplied with the electrode and NOT

used in the PR20 retractable fitting.

3.

Mount the separately delivered

O-ring on the connector plug.

Push the spacer and the O-ring

over the electrode. This is a plastic tube + O-ring delivered with

the PR20.

3-4. Mounting the electrode

1.

Push the cage onto the electrode

(see fig. 3-4.)

2.

Press the assembly into the

probe.

3.

Tighten it by turning clock-wise.

Note:

The cage fits firmly on the electrode, caused by the O-rings inside the cage. The assembly of

electrode and cage can be tightened until it stops. No tools are

necessary.

IMPORTANT NOTICES

Before the electrode is inserted into

the process, the electrode needs to

be cleaned and calibrated. The calibration procedure is normally

described in the instruction manual

of the pH transmitter. Before the

cage is pushed onto the electrode,

the stopper should be removed

(see Nr. 30 in the exploded view).

IM 12B6K3-E-E

Page 13

11

Unscrew

the pigtail.

One will

hear clicking.

Move the

pigtail

Move the

plug-in

connector

Move

the cable

Turn thight

Press

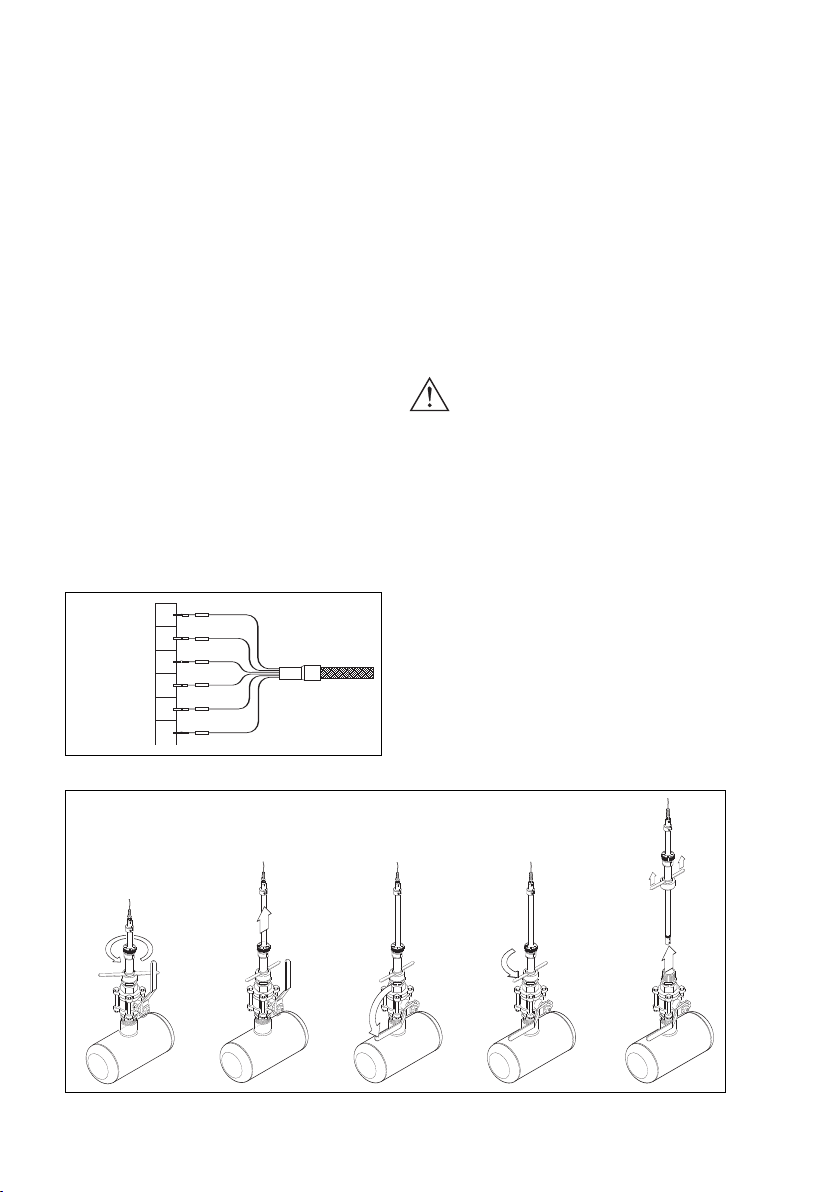

figure 3.3 preparing the

electode for use

figure 3.4 Mounting the electrode in the PR20

fitting

IM 12B6K3-E-E

Page 14

12

FIXING SCREW

3-5. Probe insertion

Insert the probe according to next

procedure (see also fig. 3-5):

1.

Position the probe for insertion.

2.

Turn the T-bar key clockwise

3.

Open the ball-valve.

4.

Push the probe into the process.

5.

Fix the probe by turning the

fixing screw clockwise.

Remarks:

1.

Turning the T-bar key can

ONLY be done when the valve is

closed. Make sure the probe is

firmly fixed.

1

2.

Pushing the probe into the process needs a force to overcome

the pressure of the system and

the friction of the damping rings

in the fitting.

3. The locking mechanism can be

turned until the probe is firmly

fixed at the measuring position.

4. The memory ring can be fixed at

the actual insertion position. See

§3-6 on adjusting the insertion

depth.

4

Fig. 3-5. Probe insertion

IM 12B6K3-E-E

2

5

3

Page 15

13

3-6. Adjusting the insertion

depth

The insertion depth of the electrode

can be adjusted to your preference

(see fig. 3-6). An insertion depth of

at least 0.2 m is recommended for

a fast response of the temperature

sensor. This sensor is located

above the combined electrode.

When the probe is inserted for 0.2

m or more the temperature sensor

will follow the process temperature

accurate.

The 'memory'ring can be positioned at the actual insertion position

of the probe. The "Allan"key, supplied with the fitting is used to fix

the 'memory'ring at the desired

position. The maximum insertion

depth is related to the probe length

mentioned in the model code of the

fitting.

3-7. Wiring

The cable used in the PR20

retractable fitting is prepared for

easy connection to pH transmitters.

The numbering of the wires is

accordingly to the standard numbering of Yokogawa transmitters.

Remark:

To make full use of the capabilities

of the combined pH/Reference

electrode, the cooperation with

Yokogawa pH transmitters is

preferred.

fig. 3-6 variable insertion depht

IM 12B6K3-E-E

Page 16

14

Temperature 11

Temperature 12

Reference 13

Liquid Earth 14

Glass electrode 15

Shield 16

Transparent

Yellow

Red

Black

Black

Blue

4. MAINTENANCE

4-1. General

Before the combined electrode can

be serviced, the probe with the

electrode should be physically

separated from the process. The

PR20 retractable fitting can be

retracted from the measuring position in the maintenance position by

following the procedure described

in §4-2.

When (optional) flush ports are available, it is not necessary to disassemble the probe as indicated in

items [4] and [5] of fig. 4-2. The

flush ports enable you to clean

and/or calibrate the electrode in the

position shown in [3] of fig. 4-2.

For replacement of the electrode

the probe has to be disassembled.

Fig. 4.1. Cable markers

4-2. Cleaning

Retract the probe from the process

for cleaning the electrode (see also

fig. 4-2):

1.

Release the fixing screw.

2.

Pull out the probe.

3.

Close the ball-valve (*).

4.

Unlock the probe.

5.

Take out the probe.

* If flush ports are available the sensor can be flushed with cleaning

liquid.

ATTENTION:

1. Stand clear when releasing

the fixing screw! Due to the

process pressure the probe

can be pressed out.

2. The T-bar can only be operated when the ball-valve is closed. Make sure it is closed

completely.

3. The friction of the O-rings will

slow down the probe when it is

retracted.

4. When the sensitivity of the electrode has decreased or the

response has slowed down, the

electrode should be cleaned.

12345

Fig. 4.2. Exsertion of the probe

IM 12B6K3-E-E

Page 17

15

If cleaning with hot water is not

water is not sufficient, more aggressive water based agents should be

used.

- Deposits of limes, hydroxides or

carbonates can be removed by

immersing the electrode in a solution containing diluted hydrochloric acid. Afterwards rinse the electrode with water.

- Deposits of oil and fat can be

removed with hot water in conjunction with a detergent. When

the results are unsatisfactory a

mild (carbonate based) abrasive

can be used.

- Protein (albuminous) deposits

should be removed with a protein

enzymatic solution. For instance a

solution containing 8.5 ml concentrated hydrochloric acid and

10 gr pepsin in 1 litre water.

ATTENTION

Avoid using non-polar solvents like

tri-chloro ethylene, toluene or hexane. Even cleaning with ethanol or

acetone is not recommended.

These solvents will break up the

gel-layer on the glass bulb and

afterwards needs to remain soaked

in water for at least 12 hours before

functioning normal.

The PTFE diaphragm of the combined electrode can sometimes be

regenerated by putting it in hot (60

to 80°C) 1 molar Potassium chloride (KCl) solution and letting it cool

to room temperature.

After cleaning the probe is re-inser

ted into the process by following

the reverse procedure (see §3-5).

4-3. Calibration

It is recommended to start calibration with a clean electrode. Always

calibrate a new electrode.

With the electrode connected to the

transmitter a calibration can take

place. Check the appropriate chapters in the instruction manual of the

pH transmitter for details.

To take out the probe for cleaning

the electrode, follow the procedure

described in §4-2.

General procedure for calibration

To calibrate a pH transmitter two

buffer solutions with known pH

value are required. It is recommended that one buffer solution has a

value near pH 7.

Depending on the liquid to be

measured the second buffer solution should either be in the acidic or

base area. Normally the buffers pH

4.01 or 9.22 are used.

Generally the procedure for calibration is as follows:

- Clean the electrode

- Rinse the electrode with water

- Immerse the electrode in the first

buffer solution (pH 7)

- Adjust the asymmetry setting of

the transmitter for reading a

known value

- Rinse the electrode with water

- Immerse the electrode in the

second buffer (pH 4 or pH 9)

- Adjust the slope setting of the

-

transmitter for reading a known

value

- Rinse the electrode with water.

IM 12B6K3-E-E

Page 18

16

1

2

3

click

123

4

180º

pin

slot

27

26

28

During calibration the temperature

compensation should be active. It is

advised to, calibrate with buffer

solutions at a temperature near the

process temperature.

After calibration the probe with

electrode is replaced following the

procedure in §3-5.

4-4. Replacing the electrode

Start with removing the probe by

following the procedure described

in §4-2.

1

Turn the cage anti-clockwise

2

Pull out the assembly.

3

Take off the cage, spacer

and O-ring.

Now the electrode can be exchanged for a new one. See §3-3 for

preparation of the new electrode.

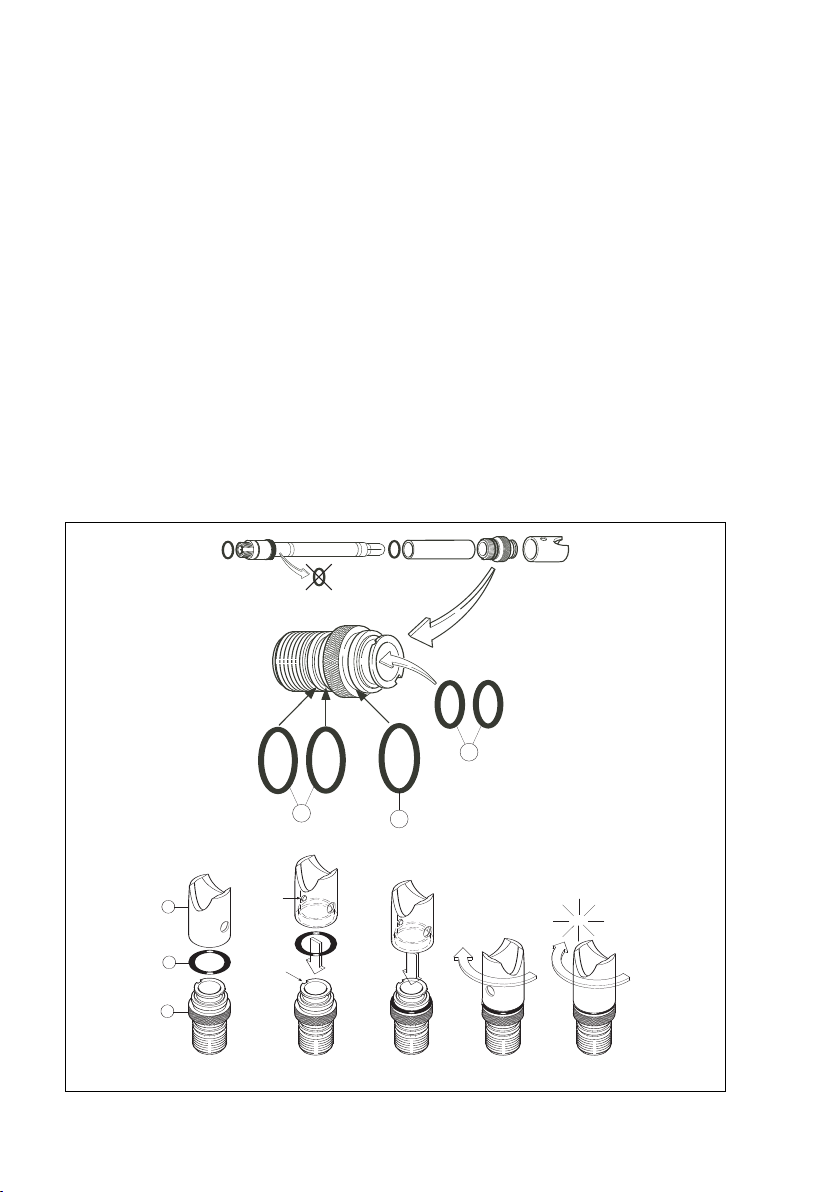

4-5. Replacing the O-rings

The drawing (see fig. 4-3) shows

the position of the sealing O-rings

on the outside and the inside of the

cage. Exchange them when renewing the electrode.

The O-rings are available as spare

parts. Refer to the exploded view

for the numbers.

The protection cage can be split

into two parts. The threaded part

[24] contains five O-rings. Three

O-rings on the outside [26 and 27]

Fig. 4-3. Replacing the O-rings

IM 12B6K3-E-E

Page 19

17

can be replaced by new ones easily.

Two O-rings [28] are located inside

the protection cage and need to be

taken out, using a pointed tweezers

or needle. This will damage the

material, so the rings cannot be

used again.

Put in new O-rings without using

mechanical tools, preferably with

your fingers. Fold the O-ring before

inserting it into the cage. It will pop

into place easily.

The single O-ring [14] at the connector is delivered with the fitting

and seals the plug for moisture.

Replace it when it is damaged or

when you think it is necessary.

4-6. Replacing the cable

Follow the procedures for retraction

and disassembling from the previous chapters (see §4-1 to 4-5).

After removing the electrode the

cable can be removed by disassembling the cable gland [2] as

indicated in the exploded view in

chapter 5.

Then the cable [1] can be removed

and a new one can be inserted.

Reassemble the cable gland onto

the cable and tighten it.

4-7. Flush port connections

The PR20 retractable fitting can be

equipped with (optional) flush ports

on the flanged adapters. This enables you to flush the electrode with

water or cleaning agent when the

probe is in the fully retracted position (see fig. 4-4).

There are four (4) flush ports available. They can be used according to

your preferences. The flush ports

are tapered 1/8" NPT-female for

small diameter connectors.

It is also possible to make buffer

solution flow through and calibrate

the combined electrode without

dismounting the probe.

Fig. 4-4. Flush ports

IM 12B6K3-E-E

Page 20

18

IM 12B6K3-E-E

Page 21

5. EXPLODED VIEW

1 Cable with plug-in connector

2 Cable gland

3 Outer tube

4 Positioning ring

5 "Allan" screw

6 Main fixing screw

7 Squeezing ring (2pcs)

8 Clamping ring

9 Bushing (2pcs)

10 O-rings (2pcs), Viton 70° shore (20.2x3.5)

11 Fixing screws (2 pcs)

12 Protection ring

13 Inner tube

14 O-ring Viton 70° shore (12x1)

15 T-bar with key

16 Nut

17 Fixing screws (2 pcs)

18 Chamber

19 O-ring Viton 70° shore (29.7 x 3.5)

20 Adapter (optional)

21 Ball-valve (optional)

22 Combined pH/reference electrode

23 Spacer

24 Electrode holder

25 Protection sleeve

26 O-rings (2 pcs), Viton 70° shore (15.6 x 1.78)

27 O-ring, Viton 70° shore (17.12 x 2.62)

28 O-rings (2 pcs), Viton 70° shore (11 x 3)

29 O-ring EPDM 70° shore (11.92 x 2.62)

30 Stopper (remove)

19

IM 12B6K3-E-E

Page 22

20

6. SPARE PARTS LIST

K1520AX O-ring set 1 26, 27, 28, 14

K1520AY O-ring set 2 10, 19

K1520KA Holder set (AISI 316) 24, 25, 26, 27, 28

K1520KE Holder set (titanium) 24, 25, 26, 27, 28

K1520AW Gland set 2

K1520LP Cable 5 m (Pt100) 1

K1520LQ Cable 5 m (Pt1000) 1

K1520LS Cable 10 m (Pt100) 1

K1520LT Cable 10 m (Pt1000) 1

K1520AZ Spacer 23

K1520KD Clamp ring 8

K1520KC Fixing screw 6

K1520KF Positioning ring 4, 5

K1520TA Clamping set 7, 8, 9

K1520TF Nut 16

K1520TK Key 15

K1520TN Outer tube 3

K1520UB Clamping set (Titanium) 7, 8, 9

K1520UH Outer tube 1.0 m (SS) 3

K1520UF Outer tube 0.5 m (Ti) 3

K1520UJ Outer tube 1.0 m (Ti) 3

IM 12B6K3-E-E

Page 23

21

IM 12B6K3-E-E

Page 24

YOKOGAWA HEADQUARTERS

9-32, Nakacho 2-chome,

Musashinoshi

Tokyo 180

Japan

Tel. (81)-422-52-5535

Fax (81)-422-55-1202

E-mail: webinfo@mls.yokogawa.co.jp

www.yokogawa.co.jp

YOKOGAWA CORPORATION OF AMERICA

2 Dart Road

Newnan GA 30265

United States

Tel. (1)-770-253-7000

Fax (1)-770-251-2088

E-mail: info@yca.com

www.yokogawa.com/us

Yokogawa has an

extensive sales and

distribution network.

Please refer to one of our

web-sites to contact your

nearest representative.

YOKOGAWA EUROPE B.V.

Databankweg 20

3821 AL AMERSFOORT

The Netherlands

Tel. +31-33-4641 611

Fax +31-33-4641 610

E-mail: info@nl.yokogawa.com

www.yokogawa.com/eu

YOKOGAWA ELECTRIC ASIA Pte. Ltd.

5 Bedok South Road

Singapore 469270

Singapore

Tel. (65)-241-9933

Fax (65)-241-2606

E-mail: webinfo@yas.com.sg

www.yokogawa.com.sg

IM 12B6K3-E-E 09-510 (A) Q

Subject to change without notice

Copyright

©

Printed in The Netherlands

Loading...

Loading...