Page 1

Instruction

YOKOGAWA

Manual

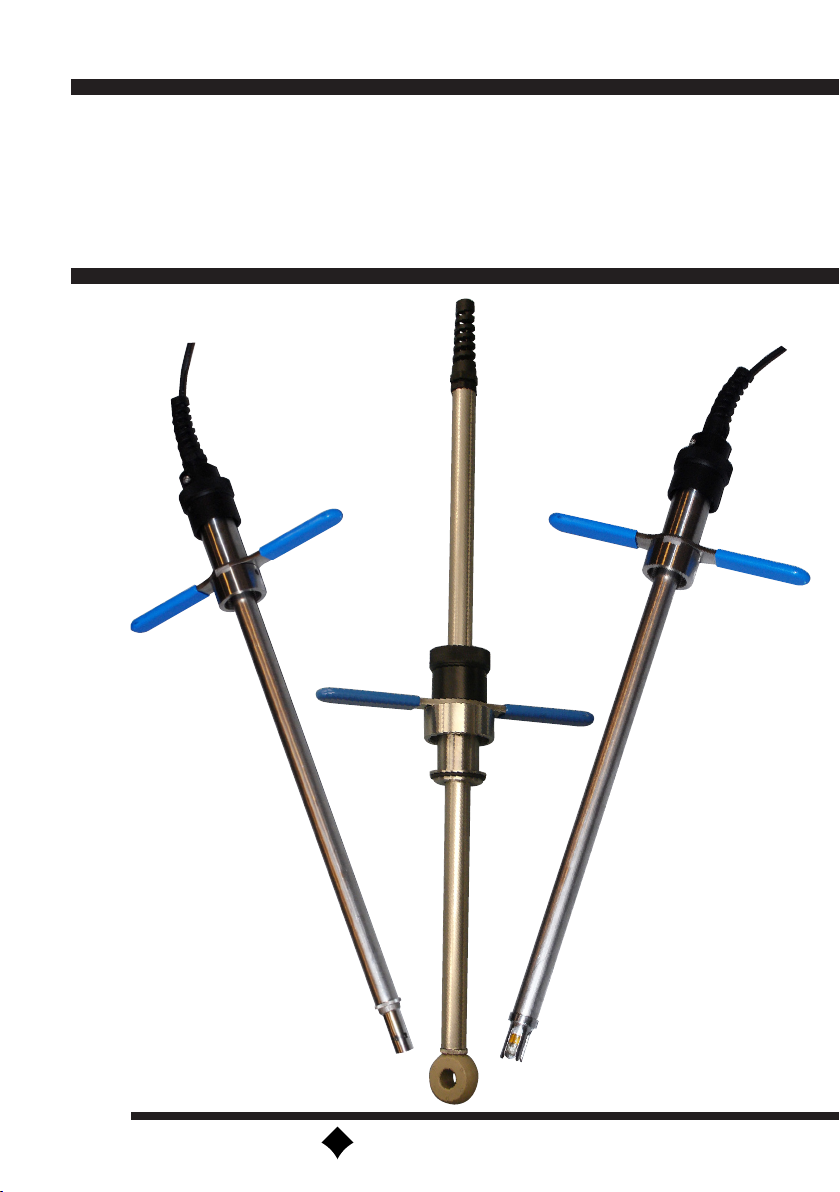

Model PR10

Manual Retractable Fitting

IM 12B6K3-01E-E

4th edition

Page 2

2

(BG)

Всички улътвания за продукти от серията

ATEX Ex ce лредлагат на английски

език. Ако се нуждаете oт улътвания за

продукти oт серията Ex на родния ви

eзик, ce свържете c най-близкия oфис или

представителство на фирма Yokogawa.

(CZ)

Všechny uživatelské příručky pro výrobky, na

něž se vztahuje nevýbušné schváleni ATEX

Ex, jsou dostupné v angličtině. Požadujete-li

pokyny týkající se výrobků s nevýbušným

schválením ve vašem lokálním jazyku,

kontaktujte prosím vaši nejbližší reprezentačni

kancelář Yokogawa.

(E)

Todos los manuales de instrucciones para

los productos antiexplosivos de ATEX están

disponibles en inglés. Si desea solicitar las

instrucciones de estos artículos antiexplosivos

en su idioma local, deberá ponerse en contacto

con la oficina o el representante de Yokogawa

más cercano.

(F)

Tous les manuels d’instruction des produits

ATEX Ex sont disponibles en langue anglaise.

Si vous nécessitez des instructions relatives

aux produits Ex dans votre langue, veuillez

bien contacter votre représentant Yokogawa le

plus proche.

(D)

Alle Betriebsanleitungen für ATEX Ex

bezogene Produkte stehen in den Sprachen

Englisch. Sollten Sie die Betriebs- anleitungen

für Ex-Produkte in Ihrer Landessprache

benötigen, setzen Sie sich bitte mit Ihrem

örtlichem Yokogawa-Vertreter in Verbindung.

(DK)

Alle brugervejledninger for produkter relateret

til CE er tilgængelige på engelsk. Skulle De

ønske yderligere oplysninger om håndtering

af CE produkter på eget sprog, kan De

rette henvendelse herom til den nærmeste

Yokogawa afdeling eller forhandler.

(EST)

Kõik ATEX Ex toodete kasutamisjuhendid on

esitatud inglise keeles. Ex seadmete muukeelse

dokumentatsiooni saamiseks pöörduge lähima

lokagava (Yokogawa) kontori või esindaja

poole.

(GB)

All instruction manuals for ATEX Ex related

products are available in English. Should you

require Ex related instructions in your local

language, you are to contact your nearest

Yokogawa office or representative.

(GR)

Ολα τα εγχειριδια λειτουργιας των

προιοντων με ATEX Ex διατιθενται στα

Αγγλικα. Σε περιπτωση πον χρειαζεοτε

οδηγιεξ σχετικα με Ex στην τοπικη

γλωσσα παρακαλονμε επικοινωνηστε με

το πλησιεστερο γραφειο τηζ Yokogawa η

αντιπροσωπο τηξ.

(H)

Az ATEX Ex mûszerek gépkönyveit angol

nyelven adjuk ki. Amennyiben helyi nyelven

kérik az Ex eszközök leírásait, kérjük keressék

fel a legközelebbi Yokogawa irodát, vagy

képviseletet.

(I)

Tutti i manuali operativi di prodotti ATEX

contrassegnati con Ex sono disponibili in

inglese. Se si desidera ricevere i manuali

operativi di prodotti Ex in lingua locale,

mettersi in contatto con l’ufficio Yokogawa

più vicino o con un rappresentante.

IM 12B6K3-01E-E

Page 3

(LV)

Visas ATEX Ex kategorijas izstrâdâjumu

Lietoðanas instrukcijas tiek piegâdâtas

angïu valodâs. Ja vçlaties saòemt Ex ierîèu

dokumentâciju citâ valodâ, Jums ir jâsazinâs

ar firmas Jokogava (Yokogawa) tuvâko ofisu

vai pârstâvi.

(LT)

Visos gaminiø ATEX Ex kategorijos

Eksploatavimo instrukcijos teikiami anglø

kalbomis. Norëdami gauti priestaisø Ex

dokumentacijà kitomis kalbomis susisiekite su

artimiausiu bendrovës Yokogawa biuru arba

atstovu.

3

(PL)

Wszystkie instrukcje obsługi dla urządzeń

w wykonaniu przeciwwybuchowym Ex,

zgodnych z wymaganiami ATEX, dostępne

są w języku angielskim. Jeżeli wymagana

jest instrukcja obsługi w Państwa lokalnym ję

zyku, prosimy o kontakt z najbliższym biurem

Yokogawy.

(RO)

Toate manualele de instructiuni pentru

produsele ATEX Ex sunt in limba engleza.

In cazul in care doriti instructiunile in limba

locala, trebuie sa contactati cel mai apropiat

birou sau reprezentant Yokogawa.

(M)

Il-manwali kollha ta’ l-istruzzjonijiet għal

prodotti marbuta ma’ ATEX Ex huma

disponibbli bl-Ingliż. Jekk tkun teħtieģ

struzzjonijiet marbuta ma’ Ex fil-lingwa

lokali tiegħek, għandek tikkuntattja lill-eqreb

rappreżentan jew uffiććju ta’ Yokogawa.

(NL)

Alle handleidingen voor producten die te

maken hebben met ATEX explosiebeveiliging

(Ex) zijn verkrijgbaar in het Engels. Neem,

indien u aanwijzingen op het gebied van

explosiebeveiliging nodig hebt in uw eigen

taal, contact op met de dichtstbijzijnde

vestiging van Yokogawa of met een

vertegenwoordiger.

(P)

Todos os manuals de instruções referentes

aos produtos Ex da ATEX estão disponíveis

em Inglês. Se necessitar de instruções na

sua língua relacionadas com produtos Ex,

deverá entrar em contacto com a delegação

mais próxima ou com um representante da

Yokogawa.

(S)

Alla instruktionsböcker för ATEX Ex

(explosionssäkra) produkter är tillgängliga

på engelska. Om Ni behöver instruktioner

för dessa explosionssäkra produkter på

annat språk, skall Ni kontakta närmaste

Yokogawakontor eller representant.

(SF)

Kaikkien ATEX Ex-tyyppisten tuotteiden

käyttöhjeet ovat saatavilla englannin-. Mikäli

tarvitsette Ex-tyyppisten tuotteiden ohjeita

omalla paikallisella kielellännne, ottakaa

yhteyttä lähimpään Yokogawa-toimistoon tai

-edustajaan.

(SK)

Všetky návody na obsluhu pre prístroje s

ATEX Ex sú k dispozícii v jazyku anglickom.

V prípade potreby návodu pre Ex-prístroje vo

Vašom národnom jazyku, skontaktujte prosím

miestnu kanceláriu firmy Yokogawa.

(SLO)

Vsi predpisi in navodila za AEX Ex sorodni

pridelki so pri roki v anglišèini. Èe so Ex

sorodna navodila potrebna v vašem tukejnjem

jeziku, kontaktirajte vaš najbliši Yokogawa

office ili predstaunika.

IM 12B6K3-01E-E

Page 4

4

Contents

1. INTRODUCTION 5

1.1 Description 5

1.2 Features 5

1.3 Warranty 5

2. SPECIFICATIONS 5

2.1 General 5

2.2 Model- and Suffix Codes 6

3. INSTALLATION 7

3.1 Unpacking and checking 7

3.2 Installation site 7

3.3 Safety precautions 7

3.4 Installation method 7

3.5 Assembly of accessories 7

3.6 Dimensions 8

3.6.1 Dimensional drawing PR10...-D32 with mounted pH sensor 8

3.6.2 Dimensional drawing PR10...-D32 with mounted SC4A sensor 9

3.6.3 Dimensional drawing PR10...-D50 with mounted SC4A sensor 10

3.6.4 Dimensional drawing PR10...-D50 with mounted ISC40 sensor 11

3.7 Options PR10 12

3.8 Sensor mounting 14

3.8.1 Mounting a 12mm sensor 14

3.8.2 Mounting a 12mm PG13.5 sensor in pH13 14

3.8.3 Mounting the SC4A 15

3.8.4 Mounting the ISC40 15

4. MAINTENANCE 17

4.1 General 17

4.2 Probe insertion 17

4.3 Taking out the sensor 17

4.4 Replacing the sensor 17

4.5 Replacing the sealings 17

4.6 Drain ports connection 17

5. EXPLODED VIEW 18

6 SPAREPARTS 20

IM 12B6K3-01E-E

Page 5

1. INTRODUCTION

5

2. SPECIFICATIONS

1.1 Description

The retractable fitting with ball valve allows

a safe insertion and retraction of a sensor

while the process is under pressure. It

can be mounted in a variety of positions.

The insertion depth can be selected on

site. An insertion stop is provided to set

the position of the sensor in the process.

The mechanism for releasing the probe

is designed to operate only when the ball

valve is closed, thus ensuring an effective

safety precaution and avoiding production

loss. The sensor can be replaced or

calibrated easily.

1.2 Features

• One model for pH, conductivity

and inductive conductivity sensors

• Integrated protection cage

• Build-in scraper to avoid contamination

of the fitting

• Usable for wide range of sensors

• A safe “through the valve” insertion

and retraction design

• Simplified installation by optional

ball valves with flanged or tapered

connections

• Optional flush port for keeping moist,

cleaning and calibration

• Available in Stainless Steel and with

Titanium shaft cage and adapters for

more harsh applications

1.3 Warranty

Yokogawa warrants that the goods

delivered are made from new materials to

the best workmanship available. Malfunction

of any of the delivered goods or parts of

it, can only lead to replacement of the

damaged parts. No claims can be made

to damages or accidents resulting from the

use of the goods. No claims can be made

to the expected or promised performance

of the goods under any circumstances.

Damaged goods or parts should be sent to

the local service organization for warranty

claim purposes. Yokogawa has the right to

deny warranty claims after investigation of

the data and materials.

2.1 General

A. Wetted materials

- For sensor check Instruction Manual

- Stainless steel AISI 316L / Titanium

- O-ring seals: Viton 70° shore

B. Non-wetted materials

- For sensor check Instruction Manual

- Stainless steel AISI 316, 304

- Polypropylene glass filled

C. Insertion length

- Ref. mechanical drawing Fig. 2 - 5

on page 6 - 9.

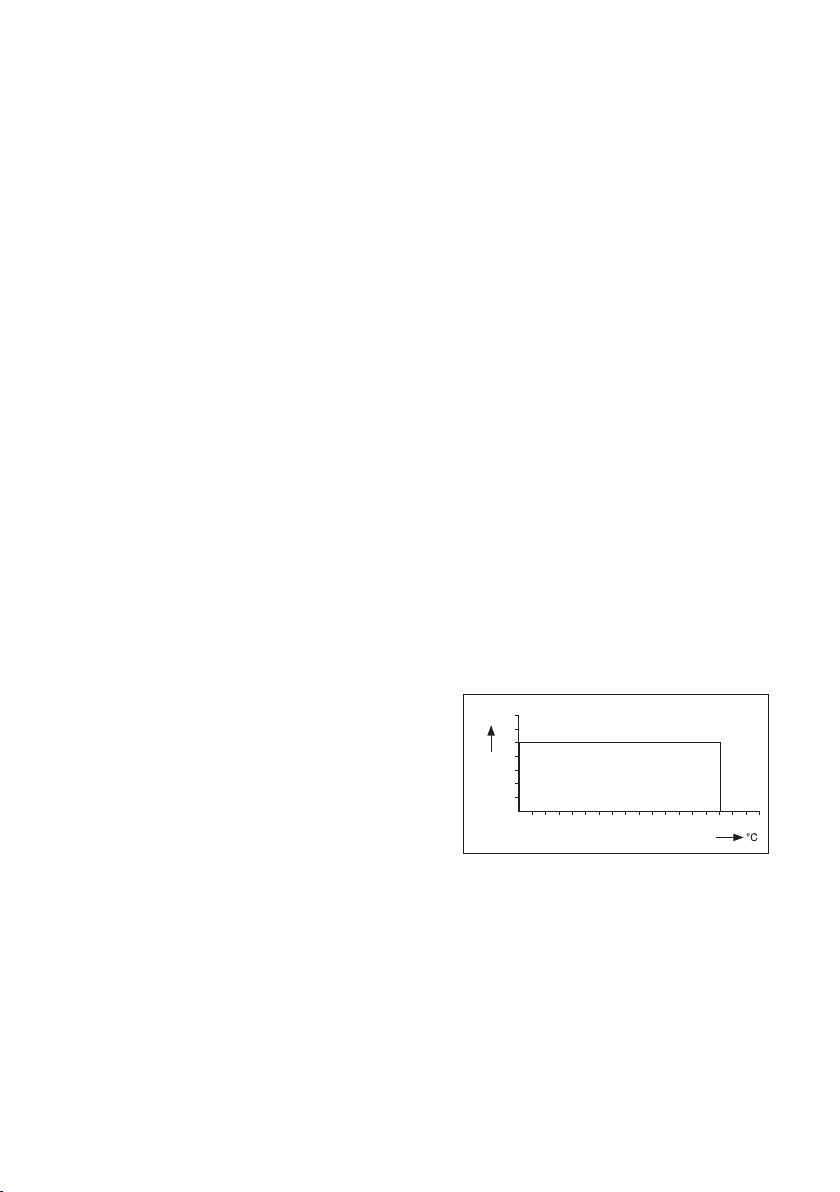

D. Pressure/temperature ratings

- Static conditions: see Fig. 1.

- Operating conditions during

extraction and insertion max.

500kPa, max. 100°C

E. Flange ratings:

- DIN flange DN32 PN10

- ANSI flange 1¼“ 150 lbs

- DIN flange DN50 PN10

- ANSI flange 2“ 150 lbs

F. Specifications of the sensor used

- Please check sensor specifications

G. Weight

- Approx 2.5 kg excl. ball valve

bar

12

10

8

6

4

2

0 10 20 30 40 50 60 70 80 100 120 140 160

FIG. 1 Pressure / Temperature graphic

AISI 316

IM 12B6K3-01E-E

Page 6

6

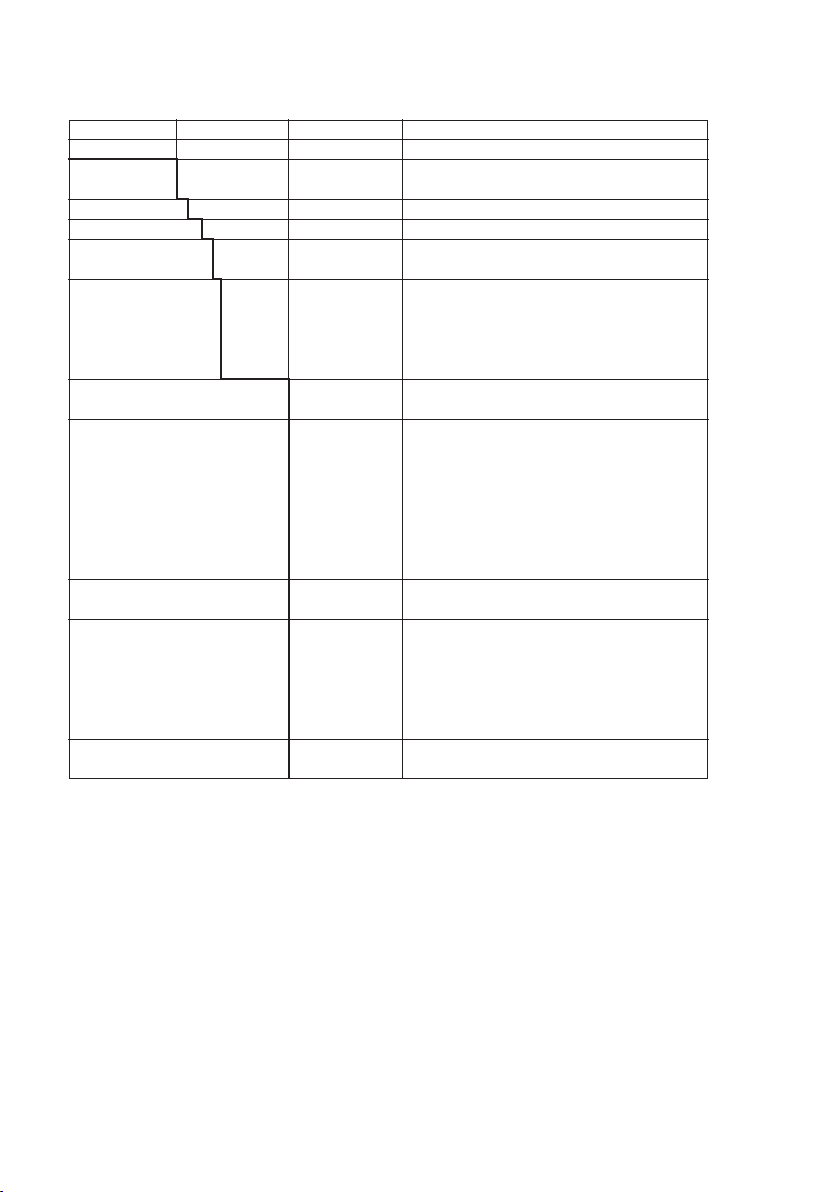

2.2 Model- and Suffix Codes

Model Suffix Options Description

PR10 Retractable fitting general purpose

Material fitting -S Stainless steel

-T Titanium (tube and sensor holder only)

Material O-rings -V Viton

Tube length -L5 Tube length 0.5 meter

Connection -D32 DN32 / 1¼”

-D50 DN50 / 2”

Measuring sensor -PH12 For 12mm pH sensors Y-cap

-PH13 For 12mm pH sensors PG13.5 cap

-SC4A For SC4A

-ISC4 For ISC40

-NNNN No parameter specification

Adapter screw-in /SA125 ISO 228/1 G1¼ to 1¼” M-NPT

/SA200 ISO 228/1 G2 to 2” M-NPT

Flange adapter /FA125 Flange adapter drain 1¼” 150 Lbs

/FN125 Flange adapter no drain 1¼” 150 Lbs

/FA200 Flange adapter drain 2” 150 Lbs

/FN200 Flange adapter no drain 2” 150 Lbs

/FAD32 Flange adapter drain DN32 PN10

/FND32 Flange adapter no drain DN32 PN10

/FAD50 Flange adapter drain DN50 PN10

/FND50 Flange adapter no drain DN50 PN10

Adapter weld-in /WA125 Straight weld-in adapter ISO 228/1 G1¼

/WA200 Straight weld-in adapter ISO 228/1 G2

Ball-valves /BF125 Ball-valve flanged 1¼” 150 Lbs*

/BF200 Ball-valve flanged 2” 150 Lbs*

/BFD32 Ball-valve flanged DN32 PN10*

/BFD50 Ball-valve flanged DN50 PN10*

/BS125 Ball-valve screw-in 1¼” F-NPT*

/BS200 Ball-valve screw-in 2” F-NPT*

Certificates /M Material certificate 3.1 according to EN-10-

024 (DIN50-049) (on wetted parts).

*With Ball-valves flange adapters or screw-in adapters are necessary.

IM 12B6K3-01E-E

Page 7

3. INSTALLATION

7

3.1 Unpacking and checking

When you receive the PR10 retractable

fitting it is packed in a cardboard box. Open

the box and check that the model code on

the fitting is the same as the one on the

packing list. Refer to paragraph 2.2 for the

model code. Also check that it is supplied

with the options you ordered. The options

can be delivered in separate boxes. If you

have any problems or questions, contact

your nearest Yokogawa service centre or

sales organization for support. The PR10

retractable fitting has an identification plate

on the protection ring with the full model

code and a serial number.

3.2 Installation site

The PR10 fitting is intended to be used for

in-line measurement. When it is delivered

with an optional ball valve or when it is used

in combination with a locally purchased

ball valve, the process does not need

to be interrupted for maintenance of the

sensor. Mounting location can be in a large

diameter pipeline or a vessel.

3.3 Safety precautions

The PR10 fitting is designed for maximum

safety in operation. For optimum safety

a flanged ball valve is recommended.

Yokogawa does not accept any claims

or penalties on possible damages or

accidents that occur in operation of the

PR10 fitting. The installation of the probe

is to be implemented under the local

safety regulations for pressurized vessels

or pipelines for retraction or insertion. The

instructions given in this manual must be

followed exactly.

3.4 Installation method

It is important to have the point of

measurement in a location that is truly

representing the process composition.

Check whether the specifications of the

sensor fulfill the maximum occurring

process conditions. The fitting has several

optional connection possibilities. Check

that you received the correct size and

type. Install the fitting in a convenient

location for maintenance and calibration.

For maintenance or calibration the probe

will need a space of about 2m for total

retraction (depending on probe length

and optional adapters and/or ball valves).

Installation in a bend of a pipe line is a good

measurement position. When inserting the

PR10 retractable fitting in a perpendicular

position to the process flow, the flow

velocity will put a mechanical force on the

probe. Take care that this force is not too

large. It is recommended to have the PR10

retractable fitting positioned at a 90° angle

into the process stream.

Note: Do not insert the fitting into the

process without the sensor mounted!

The sensor is delivered separately in

a box. Start with the assembly of the

sensor into the probe and follow the

instructions for the preparation of a

new sensor. Refer to paragraph 3.8.

3.5 Assembly of accessories

Optional accessories are (often) delivered in

separate boxes. When an optional ball valve

is ordered, it should be mounted to the

measuring position first. When the ball valve

is in place, the process line is secure.

IM 12B6K3-01E-E

Page 8

8

Dimensional drawing PR10...-D32 with

mounted pH sensor

3.6 Dimensions

3.6.1 Dimensional drawing PR10...-D32 with mounted pH sensor

unit mm (inches)

381 (15")

110

PR10-..-..-....-D32.-PH...../SA125/BS125

414 (16.3")

54

PR10-..-..-....-D32-PH...../F..125/BF125

PR10-..-..-....-D32-PH...../F..D32/BFD32

520 (20.5")

PR10- .. -V-L5-D32-PH12

PR10- .. -V-L5-D32-PH13

FIG. 2 Dimensional drawing PR10...-D32 with mounted pH sensor

IM 12B6K3-01E-E

Page 9

Dimensional drawing PR10...-D32 with

mounted SC4A sensor

3.6.2 Dimensional drawing PR10...-D32 with mounted SC4A sensor

unit mm (inches)

390 (15.35")

9

110 (4.35”)

PR10-..-..-....-D32-SC4A/SA125/BS125

54 (2.15”)

PR10-..-..-....-D32-SC4A/F..125/BF125

PR10-..-..-....-D32-SC4A/F..D32/BFD32

779 (30.7")

PR10- .. -V-L5-D32-SC4A

423 (16.7")

529 (20.8")

FIG. 3 Dimensional drawing PR10...-D32 with mounted SC4A sensor

IM 12B6K3-01E-E

Page 10

10

3.6.3 Dimensional drawing PR10...-D50 with mounted SC4A sensor

unit mm (inches)

362 (14.25")

PR10-..-..-....-D50-SC4A/SA200/BS200

142 (5.6”)

390 (15.4")

PR10-..-..-....-D50-SC4A/F..200/BF200

82 (3.25”)

PR10-..-..-....-D50-SC4A/F..D50/BFD50

779 (30.7")

529 (20.8")

PR10- .. -V-L5-D50-SC4A

FIG. 4 Dimensional drawing PR10...-D50 with mounted SC4A sensor

IM 12B6K3-01E-E

Page 11

11

3.6.4 Dimensional drawing PR10...-D50 with mounted ISC40 sensor

unit mm (inches)

366 (14.4")

PR10-..-..-....-D50-ISC4/SA200/BS200

142 (5.6”)

394 (15.5")

PR10-..-..-....-D50-ISC4/F..200/BF200

82 (3.25”)

PR10-..-..-....-D50-ISC4/F..D50/BFD50

783 (30.8")

533 (21")

PR10- .. -V-L5-D50-ISC4

FIG. 5 Dimensional drawing PR10...-D50 with mounted ISC40 sensor

IM 12B6K3-01E-E

Page 12

12

C

D

A

L

C

A

L

E

D

A

C

A

L

B

E

D

L

A B

C

D

A

L

C

A

L

B

A

L

E

A B

C

D

F

G

A

L

B

A

B

L

C

A

L

B

Bb

L

Di

L

C

D

A

A

E

A B

C

D

F

G

A

L

B

A

B

L

C

A

L

B

A

L

B

3.7 Options PR10

A

L

B

C

FIG. 6 Dimensions of the PR10 options

Table 1 Dimensions options in mm (inches)

Option Description Fig. A B L C Bb D E Di Dg K

/SA125 ISO 228/1 G1¼ to 1¼” M-NPT A ISO 228/1 - G1¼ 1¼” NPT 60 (2.4)

/SA200 ISO 228/1 G2 to 2” M-NPT A ISO 228/1 - G2 2” NPT 58 (2.3)

/FA125 Flange adapter drain 1¼” 150 Lbs D , G ISO 228/1 - G1¼ 69.5 (2.7) 66 (2.6) 29 (1.1) 15.7 (0.6) 117.3 (4.6) 1/8” NPT 47 (1.9) 15.7 (0.6) 88.9 (3.5)

/FN125 Flange adapter no drain 1¼” 150 Lbs C , G ISO 228/1 - G1¼ 69.5 (2.7) 66 (2.6) 29 (1.1) 15.7 (0.6) 117.3 (4.6) 47 (1.9) 15.7 (0.6) 88.9 (3.5)

/FA200 Flange adapter drain 2” 150 Lbs D , G ISO 228/1 - G2 101 (4) 77 (3) 32 (1.3) 25 (1) 165 (6.5) 1/8” NPT 73 (2.9) 19 (0.7) 120-125 (4.7)-(4.9)

/FN200 Flange adapter no drain 2” 150 Lbs C , G ISO 228/1 - G2 101 (4) 54 (2.1) 32 (1.3) 25 (1) 165 (6.5) 73 (2.9) 19 (0.7) 120-125 (4.7)-(4.9)

/FAD32 Flange adapter drain DN32 PN10 D , G ISO 228/1 - G1¼ 69.5 (2.7) 66 (2.6) 29 (1.1) 16 (0.6) 140 (5.5) 1/8” NPT 47 (1.9) 18 (0.7) 100 (3.9)

/FND32 Flange adapter no drain DN32 PN10 C , G ISO 228/1 - G1¼ 69.5 (2.7) 66 (2.6) 29 (1.1) 16 (0.6) 140 (5.5) 47 (1.9) 18 (0.7) 100 (3.9)

/FAD50 Flange adapter drain DN50 PN10 D , G ISO 228/1 - G2 101 (4) 77 (3) 32 (1.3) 25 (1) 165 (6.5) 1/8” NPT 73 (2.9) 19 (0.7) 120-125 (4.7)-(4.9)

/FND50 Flange adapter no drain DN50 PN10 C , G ISO 228/1 - G2 101 (4) 54 (2.1) 32 (1.3) 25 (1) 165 (6.5) 73 (2.9) 19 (0.7) 120-125 (4.7)-(4.9)

/WA125 Straight weld-in adapter ISO 228/1 G1¼ B ISO 228/1 - G1¼ 42 (1.7) 45 (1.8)

/WA200 Straight weld-in adapter ISO 228/1 G2 B ISO 228/1 - G2 49 (1.9) 45 (1.8)

/BF125 Ball-valve flanged 1¼” 150 Lbs F 54 (2.1) 118 (4.6) 32 (1.3) M14 89 (3.5)

/BF200 Ball-valve flanged 2” 150 Lbs F 82 (3.2) 150 (5.9) 50 (2) M16 121 (4.8)

/BFD32 Ball-valve flanged DN32 PN10 F 54 (2.1) 140 (5.5) 32 (1.3) M16 100 (3.9)

/BFD50 Ball-valve flanged DN50 PN10 F 82 (3.2) 165 (6.5) 50 (2) M16 125 (4.9)

/BS125 Ball-valve screw-in 1¼” F-NPT E 1¼” NPT 110 (4.3) 32 (1.3)

/BS200 Ball-valve screw-in 2” F-NPT E 2” NPT 142 (5.6) 50 (2 )

IM 12B6K3-01E-E

A

L

B

A

E

B

L

B

A

Di

L

Page 13

C

D

F

G

A

L

B

C

Dg

A

L

B

E

13

L

Di

K

D

Dg

Bb

Di

K

D

IM 12B6K3-01E-E

Page 14

14

3.8 Sensor mounting

3.8.1 Mounting a 12mm sensor

in pH12

1. Take the cable out of the box and cut off

the cable tie.

2. Tape the separate wires of the cable

together.

3. Take the fitting out of the box and

remove the sensor holder and Y-cap

adapter.

4. Slide the Y-cap adapter over the cable.

5. Release the pigtail (cable gland) com-

pletely. Do not undo the part in the metal

tube!

6. Lead the sensor cable through the tube

of the fitting, from the side where the

sensor holder has been removed.

7. Take the sensor out of the box.

8. Slide the O-ring (12x1) over the connec-

tor.

9. Connect the sensor to the cable.

10. Slide the sensor holder over the sensor.

11. Screw the Y-cap adapter onto the sensor

holder.

12. Hold the sensor still and turn the metal

tube onto the sensor holder. Don’t rotate

the sensor, but rotate the tube of the

fitting, because the cable can be disconnected from the sensor, when rotating it

13. Lead the loose part of the pigtail onto the

cable and screw it onto the fixed part.

14. Remove the tape.

3.8.2 Mounting a 12mm PG13.5

sensor in pH13

.

1. Take the cable out of the box and cut

off the cable tie

2. Tape the separate wires of the cable

together.

3. Take the fitting out of the box and

remove the sensor holder.

4. Release the pigtail (cable gland)

completely. Do not undo the part in the

metal tube!

5. Lead the sensor cable through the tube

of the fitting, from the side where the

sensor holder has been removed.

6. Take the sensor out of the box.

7. Screw the sensor in the sensor holder.

8. Connect the sensor to the cable.

9. Hold the sensor still and turn the metal

tube onto the sensor holder. Don’t

rotate the sensor, but rotate the tube

of the fitting, because the cable can be

disconnected from the sensor, when

rotating it

10. Lead the loose part of the pigtail onto

the cable and screw it onto the fixed

part.

11. Remove the tape.

Y CAP adapter

FIG. 7 Mounting pH sensor with pH12

FIG. 8 Mounting pH sensor with pH13

IM 12B6K3-01E-E

sensor holder

sensor holder

Page 15

15

3.8.3 Mounting the SC4A

1 Take the sensor out of the box and cut

off the cable tie

2 Bind the separate wires of the cable

together with a piece of tape.

3 Take the fitting out of the box and

remove the option(s), if necessary.

4 Release the pigtail (cable gland)

completely. Do not undo the part in the

metal tube!

5 Lead the sensor cable through the tube

of the fitting, from the side where the

knurled knob has been removed.

6 Hold the sensor still and turn the metal

tube onto the sensor. Don’t rotate the

cell, but rotate the tube of the fitting,

because the cable can be disconnected

from the cell, when rotating it

7 Lead the loose part of the pigtail onto

the cable and screw it onto the fixed

part.

8 Remove the tape.

3.8.4 Mounting the ISC40

1 Take the sensor out of the box and

remove the cable tie carefully

2 Bind the separate wires of the cable

together with a piece of tape

3 Take the fitting out of the box and

remove the option(s), if necessary

4 Release the pigtail (cable gland)

completely. Do not undo the part in the

metal tube!

5 Lead the sensor cable through the tube

of the fitting, from the side where the

knurled knob has been removed

6 Hold the sensor still and turn the metal

tube onto the sensor. Don’t rotate the

cell, but rotate the tube of the fitting,

because the cable can be disconnected

from the cell, when rotating it

7 Lead the loose part of the pigtail onto

the cable and screw it onto the fixed

part

8 Remove the tape

5

5

FIG. 10 Mounting the ISC40FIG. 9 Mounting the SC4A

IM 12B6K3-01E-E

Page 16

16

FIXING

SCREW

Remarks:

• Turning the T-bar key can only be done

when the valve is closed.

• Pushing the probe into the process needs

a force to overcome the pressure of the

system and the friction of the dampening

rings in the fitting.

• The locking mechanism can be tightened

until the probe is firmly fixed in the

measuring position.

• The insertion stop can be fixed in

the actual insertion position. Refer to

paragraph 4.5

for adjusting the insertion depth.

FIG. 11 Probe insertion

IM 12B6K3-01E-E

Page 17

4. MAINTENANCE

CAUTION

Retract/ insert at P < 5 Bar. Do not stand

behind immersion tube while retracting/

inserting

17

• The T-bar key can only be operated when

the ball valve is closed. Make sure it is closed

completely.

• The friction of the O-rings will slow down

the probe when it is retracted.

4.1 General

Before the sensor can be serviced, the probe

with the sensor inside should be physically separated from the process. The PR10

retractable fitting can be retracted from its

measuring position in the maintenance position by following the five step procedure mentioned in paragraph 4.2 in reverse order.

4.2 Probe insertion

1 Position the probe for insertion.

2 Turn the T-bar key clockwise.

3 Open the ball valve.

4 Push the probe into the process.

5 Fix the probe by turning the fixing screw

clockwise.

4.3 Taking out the sensor

Retract the probe from the process

according to the following procedure:

• Release the fixing screw.

• Pull out the probe.

• Close the ball valve (*).

• Turn the T-bar counter clockwise

• Take out the probe.

* If the option provides a drain port, the

process pressure can be relieved before

removing the sensor.

• Stand clear when releasing the fixing

screw! Due to the process pressure the

probe can be pressed out.

4.4 Replacing the sensor

Refer to paragraph 3.8

4.5 Replacing the sealings

For prevention of leakage due to aging

of the seals, the O-ring seals may need

replacement. Hereto, follow the procedure

below.

Procedure:

Remove the probe from the process. Follow

the procedure described in paragraph 4.2

Dismount the sensor. Follow the procedure

described in paragraph 3.8 in reverse order:

• Disassemble the housing of the insertion

tube.

• Replace the o-rings with the proper tools

(like K1525AF).

4.6 Drain ports connection

The PR10 retractable fitting can be

equipped with optional drain (or flush) ports

on the flanged adapter. The drain ports are

tapered 1/8” NPT female for small diameter

connectors.

Adjusting the insertion depth

The insertion depth of the sensor can be

adjusted to your preference. The insertion

stop can be set for the desired insertion

depth, using the key supplied with the fitting.

FIG. 12 Drain Port Connection FIG. 13 Flush Port Connection

IM 12B6K3-01E-E

Page 18

18

131415 161718

PR10- .. -V-L5-D32-....

13 25

27

161726

PR10- .. -V-L5 -D50-....

36 34

36 35

5. EXPLODED VIEW

2

1

3

31

37

36

5

6

4

7

33 43

8 9 10 / 10a

OR

PR10- .. -V-L5-D..-....

* Note: For sparepart numbers see Tabel 2

36

Spare part set

FIG. 14 Exploded view

PR10-S-V-L5-D32-PH12

PR10-S-V-L5-D32-PH13

PR10-S-V-L5-D32-SC4A

PR10-S-V-L5-D50-ISC4

PR10-S-V-L5-D50-SC4A

K1525AG Adapter Y-cap 30

K1525AB Sensor holder PG13.5 31

K1525AP Adapter SC4A - ISC40 32

K1525AA Outer tube 33

K1525BA O-ring set PR10-S-V-L5-D32 34

K1525BB O-ring set PR10-S-V-L5-D50 35

K1525BC Key set 36

K1525BD Squeezing set; 37

37

IM 12B6K3-01E-E

Page 19

36 34

131415 161718

PR10- .. -V-L5-D32-....

36 35

13 25

PR10- .. -V-L5 -D50-....

27

161726

34

303430

22 28 21/21a 20 19

OR

PR10- .. -V-L5-D32- PH13

PR10- .. -V-L5-D32- PH12

35

34

32

42

32

23

42

24/24a

PR10- .. -V-L5-D..- SC4A

PR10- .. -V-L5-D50- ISC4

31

35

34

32

42

30

34

41 41

31

19

34

30

PR10-T-V-L5-D32-PH12

PR10-T-V-L5-D32-PH13

PR10-T-V-L5-D32-SC4A

PR10-T-V-L5-D50-ISC4

PR10-T-V-L5-D50-SC4A

K1525AG Adapter Y-cap 30/40

K1525CB Sensor holder PG13.5 Titanium 41

K1525CP Adapter SC4A - ISC40 Titanium 42

K1525CA Outer tube Titanium 43

K1525BA O-ring set PR10-S-V-L5-D32 34

K1525BB O-ring set PR10-S-V-L5-D50 35

K1525BC Key set 36

K1525BD Squeezing set; 37

IM 12B6K3-01E-E

Page 20

6 Spareparts

Part no. Description

K1520LS Cable retractable fitting 10M PT100

K1520LT Cable retractable fitting 10M PT1000

K1525BZ Cable gland (5 pcs) 1

K1525AA Outer tube 33

K1525AB Sensor holder PG13.5 31

K1525AF O-ring pick up tool

K1525AG Adapter Y-cap 30

K1525BA O-ring set PR10-S-V-L5-D32 34

K1525BB O-ring set PR10-S-V-L5-D50 35

K1525BC Key set 36

K1525BD Squeezing set 37

K1525BE Set M16 bolt & washer (8 pcs)

K1525BF Set M14 bolt & washer (8 pcs)

K1525BG Gaskets ball valves - D50

K1525BH Gaskets ball valves - D32 + 1¼”

K1525BJ Gaskets ball valves - 2”

K1525BK Gaskets ball valves - 1¼”

K1525CA Outer tube titanium 43

K1525CB Sensor holder PG13.5 Titanium 41

K1525CP Sensor holder SC4a Titanium 42

K1525YA PR10/SA125

K1525YB PR10/FA125

K1525YC PR10/FN125

K1525YD PR10/FR200 - FAD50

K1525YE PR10/FN200 - FND50

K1525YF PR10/FAD32

K1525YG PR10/FND32

K1525YH PR10/WA125

K1525YJ PR10/WA200

K1525YK PR10/BF125

K1525YL PR10/BF200

K1525YM PR10/BFD32

K1525YN PR10/BF50

K1525YP PR10/BS125

K1541EM Adapter 2” NPT - G2SS

Table 2 Spare Parts

YOKOGAWA ELECTRIC CORPORATION

World Headquarters

9-32, Nakacho 2-chome, Musashino-shi

Tokyo 180-8750

Japan

www.yokogawa.com

YOKOGAWA CORPORATION OF AMERICA

2 Dart Road

Newnan GA 30265

USA

www.yokogawa.com/us

YOKOGAWA EUROPE BV

Euroweg 2

3825 HD AMERSFOORT

The Netherlands

www.yokogawa.com/eu

YOKOGAWA ELECTRIC ASIA Pte. LTD.

5 Bedok South Road

Singapore 469270

Singapore

www.yokogawa.com/sg

YOKOGAWA CHINA CO. LTD.

3F Tower D Cartelo Crocodile Building

No.568 West Tianshan Road Changing District

Shanghai, China

www.yokogawa.com/cn

YOKOGAWA MIDDLE EAST B.S.C.(c)

P.O. Box 10070, Manama

Building 577, Road 2516, Busaiteen 225

Muharraq, Bahrain

www.yokogawa.com/bh

Yokogawa has an extensive sales and

distribution network.

Please refer to the European website

(www.yokogawa.com/eu) to contact your

nearest representative.

IM 12B6K3-01E-E 04-1303 (A) I

Subject to change without notice Printed in The Netherlands

Copyright ®

Loading...

Loading...