Page 1

User's

Manual

PM100

External Pressure Sensor

Calls attention to actions or conditions that could cause light injury to the user or damage to

CAUTION

ATTENTION

Note

the instrument or user’s data, and precautions that can be taken to prevent such occurrences.

Attire l’attention sur des gestes ou des conditions susceptibles de provoquer des

blessures légères ou d’endommager l’instrument ou les données de l’utilisateur, et

sur les précautions de sécurité susceptibles de prévenir de tels accidents.

Calls attention to information that is important for the proper operation of the

instrument.

This manual describes the safety precautions for using the external pressure sensor. To

ensure correct use, please read this manual thoroughly.

After reading this manual, keep it in a safe place.

This instrument is the external pressure sensor for CA700. Please read this manual

together with the user’s manual of the CA700.

3rd Edition: November 2018 (YMI)

All Rights Reserved, Copyright © 2017, Yokogawa Test & Measurement Corporation

Printed in Japan

IM PM100-01EN

3rd Edition

Checking the Contents of the Package

Unpack the box, and check the following before operating the instrument. If the wrong items

have been delivered, if items are missing, or if there is a problem with the appearance of

the items, contact your nearest YOKOGAWA dealer.

Instrument

Check that the product that you received is what you ordered by referring to the model

name and suffix code given on the name plate.

MODEL Suffix Code Specifications

PM100 External Pressure Sensor

Name plate

Standard Accessories

Item Model/Part No. Quantity Notes

Connection cable 95020 1 PM100 connection cable

Conversion

connector

Cap for the

pressure input port

Manuals IM PM100-01EN 1 This guide.

*1 Maximum usable pressure is 84 MPa.

*2 Maximum usable pressure is 57.1 MPa.

*3 Maximum usable pressure is 98 MPa.

Optional Accessories

The following optional accessories are available for purchase separately. For information

about ordering accessories, contact your nearest YOKOGAWA dealer.

Item Model or

Connection cable 95020 PM100 connection cable

Conversion

connector

-E For countries other than Japan

-J For Japan

-05 Shield gauge pressure: 16 MPa (7/10/16 MPa range)

-06 Shield gauge pressure: 70 MPa (25/50/70 MPa range)

-P3 1/2NPT Female thread

Maximum input pressure

Range

Example for shield gauge pressure 16 MPa model.

*1

91083

*2

91084

*2

91085

*3

91086

*3

91087

G9330DB 1 Comes attached to the PM100

IM PM100-92Z1 1 Chinese document

PIM 113-01Z2 1 List of worldwide contacts

Component

Number

91083

91084

91085

91086

91087

1

1

1

1

1

Notes

Converts to 1/8NPT female thread (maximum working pressure is 84 MPa.)

Converts to 1/4NPT female thread (maximum working pressure is 57.1 MPa.)

Converts to Rc1/4 female thread (maximum working pressure is 57.1 MPa.)

Converts to 1/4NPT female thread (maximum working pressure is 98 MPa.)

Converts to Rc1/4 female thread (maximum working pressure is 98 MPa.)

Converts to 1/8NPT female thread

Converts to 1/4NPT female thread (only for 16 MPa model)

Converts to Rc1/4 female thread (only for 16 MPa model)

Converts to 1/4NPT female thread (only for 70 MPa model)

Converts to Rc1/4 female thread (only for 70 MPa model)

Safety Precautions

This product is designed to be used by a person with specialized knowledge.

The general safety precautions described herein must be observed during all phases of

operation. If the product is used in a manner not specified in this manual, the protection

provided by the product may be impaired. YOKOGAWA assumes no liability for the

customer’s failure to comply with these requirements.

This manual is part of the product and contains important information. Store this manual

in a safe place close to the instrument so that you can refer to it immediately. Keep this

manual until you dispose of the instrument.

The following symbols are used on this instrument.

Handle with care. Refer to the user’s manual or service manual. This symbol

appears on dangerous locations on the instrument which require special

instructions for proper handling or use. The same symbol appears in the

corresponding place in the manual to identify those instructions.

Failure to comply with the precautions below could lead to injury or death or

damage to the instrument.

WARNING

Use the Instrument Only for Its Intended Purpose

The PM100 is a sensor for measuring pressure. Use it only for measuring

pressure.

Check the Physical Appearance

Do not use the instrument if there is a problem with its physical appearance.

Conversion connector

• Models with different shield gauge pressures include conversion connector

with different maximum working pressures. Use the appropriate conversion

connector for the PM100 shield gauge in use.

• Do not use the included conversion connectors with other instruments.

Measure High-Pressure Fluids Properly

• Use piping and pressure connectors that can withstand the pressure to be

measured.

• Make sure that there are no leaks from the piping, connectors, and joints

and that the joints are not loose. If the fluid under measurement leaks or if

a joint comes loose, the pressure can endanger the user or the surrounding

instruments. Note that higher the pressure, greater the danger.

• Depending on the amount or type of gas, if you are handling gas that is 1 MPa or

higher, supervision may be required under the High Pressure Gas Safety Act.

• Do not measure flammable, explosive, poisonous, or corrosive fluids(for

example acetylene, ammonia, or hydrogen sulfide).

Such an act can endanger the user.

This instrument is not intended for Group-1 substances and mixtures (dangerous

fluids) as listed in Directive 2014/68/EU Article 13 (1) a;.

• If high-pressure fluid or gas bursts out, do not bring your hand or body close to

where it is bursting out. High-pressure fluid or gas could penetrate through the

skin, causing serious injury.

• Please increase pressure slowly when pressurizing. If it is pressurized

suddenly, this instrument and connected tubing may sweep by the straightening

force.

Observe the Pressure Limit

Do not apply pressure exceeding the allowable input range. Physical explosion

or the like could endanger the user or the surrounding instruments.

Do Not Remove Covers or Disassemble or Alter the Instrument

Only qualified YOKOGAWA personnel may remove the covers and disassemble

or alter the instrument.

Do Not Operate in an Explosive Atmosphere

This instrument is not explosion-proof.

Do not operate the instrument in the presence of flammable gases or vapors.

Doing so is extremely dangerous.

List of Manuals

The following manuals are provided for the PM100.

Manual Title Manual No. Notes

PM100 External Pressure Sensor

User’s Manual

PM100 External Pressure Sensor IM PM100-92Z1 A document for China.

The “-EN” in the manual number is the language code.

IM PM100-01EN This manual. The manual explains the handling

precautions, features, specifications, how to operate the

PM100, and so on.

Associated manual

Manual Title Manual No. Notes

CA700 Pressure Calibrator

User’s Manual

IM CA700-01EN The manual explains the handling precautions, features,

specifications, how to operate the CA700, how to set the

measurement range of the PM100 and so on.

Contact information of Yokogawa offices worldwide is provided on the following sheet.

Document No. Description

PIM 113-01Z2 List of worldwide contacts

Conventions Used in This Manual

The notes and cautions in this manual are categorized using the following symbols.

This symbol is used in conjunction with the word “WARNING” or “CAUTION.”

WARNING

AVERTISSEMENT

Ce symbole est accompagné des termes "AVERTISSEMENT" et

"ATTENTION.”

Calls attention to actions or conditions that could cause serious or fatal injury to the user,

and precautions that can be taken to prevent such occurrences.

Attire l’attention sur des gestes ou des conditions susceptibles de provoquer des

blessures graves (voire mortelles), et sur les précautions de sécurité pouvant

prévenir de tels accidents.

Install or Use the Instrument in Appropriate Locations

The instrument complies with protection level IP54. Do not install the instrument

in locations whose level exceeds this protection level.

CAUTION

• When transporting or handling the instrument, do not apply vibration or shock.

Make sure not to drop the instrument.

• When the instrument is not being used, attach caps to the pressure input port

and cable connection terminal.

• Drastically reducing the pressure applied to the instrument can cause

condensation to form inside the instrument and cause the instrument to

malfunction. When changing the pressure, change it gradually so that

condensation does not occur.

Cleaning

• Cleaning units 91040 and 91041 for the CA700 cannot be used to clean the

pressure input port of the PM100.

• A pressure sensing diaphragm can be seen through the pressure input port of

the PM100. When cleaning the PM100, be especially careful not to touch the

diaphragm.

• To clean the instrument, wipe with a cloth dampened with neutral agent or

water. Do not use abrasive cleaners or organic solvents.

Operating Environment Limitations

This product is a Class A (for industrial environments) product. Operation of this

product in a residential area may cause radio interference in which case the

user will be required to correct the interference.

IM PM100-01EN

1/3

Page 2

French

AVERTISSEMENT

Utiliser l’instrument aux seules fins pour lesquelles il est prévu

Le PM100 est un capteur pour mesurer la pression. Utiliser cet instrument

uniquement pour mesurer la pression.

Inspecter l’apparence physique

Ne pas utiliser l’instrument si son intégrité physique semble être compromise.

Connecteur de conversion

• Les modèles dotés de différentes jauge de blindage comprennent un

connecteur de conversion avec différentes pressions maximales de service.

Choisir le connecteur de conversion approprié pour la jauge de blindage

PM100 utilisée.

• N'utilisez pas les connecteurs de conversion inclus avec d'autres instruments.

Mesure du fluide haute pression

• Utiliser une tuyauterie et des connecteurs pression pouvant résister à la

pression à mesurer.

• S’assurer de l’absence de fuites au niveau de la tuyauterie, des connecteurs

et des joints, et vérifier que les joints ne sont pas desserrés. En cas de fuite

du fluide mesuré ou de desserrage d’un joint, la pression risque de mettre en

danger l’utilisateur ou les instruments environnants. Il est à noter que plus la

pression est élevée, plus le danger est important.

• En cas de manipulation de gaz à 1MPa ou plus, la législation relative à la

sécurité des gaz haute pression peut rendre une surveillance obligatoire, en

fonction de la quantité ou du type de gaz.

• Ne pas mesurer des liquides inflammables, explosifs, toxiques ou corrosifs (par

exemple : acétylène, ammoniaque ou sulfure d'hydrogène).

Une telle action peut s'avérer dangereuse pour l'utilisateur.

Cet instrument ne s'adresse pas aux substances et mélanges du Groupe 1

(liquides dangereux) tels que listés dans la Directive 2014/68/EU Article 13 (1)

a ;.

• Si un liquide ou un gaz sous haute pression jaillissent, ne pas approcher la

main ou le corps du jet. Le liquide ou le gaz sous haute pression pourraient

pénétrer par la peau, entraînant des blessures graves.

• Augmenter la pression lentement lors de la pressurisation. En cas de

pressurisation soudaine, cet instrument et les tubes connectés peuvent balayer

la zone sous la force de redressage.

Respecter la limite de pression

Ne pas appliquer de pression supérieure à la plage d’entrée autorisée. Le cas

échéant, un endommagement de l’équipement risquerait de se produire.

Overview

The PM100 is a pressure sensor that is connected to a CA700 pressure calibrator for use.

For details on how to use the sensor on the CA700 and range setting of the PM100, see

the CA700 User’s manual.

Handling Precautions

Storage Location

Avoid the following kinds of places for storing the instrument:

• Where the temperature falls outside the storage temperature and humidity ranges

• In direct sunlight or near heat sources

• Outdoors or locations subject to rain or water

• In an environment with excessive amounts of soot, steam, dust, or corrosive gas

• In an environment subject to large levels of mechanical vibration

• On an unstable surface

• Where an excessive amount of soot, dust, salt, or iron is present

Installation Location

Install the instrument in a place that meets the following conditions.

Flat, Even Surface

To measure pressure using the pressure sensor in the instrument, install the

instrument on a stable surface that is level in all directions. Pressure may not be

measured correctly when the instrument is placed in an unstable or inclined place.

Operating Altitude and Ambient Temperature and Humidity

Use the instrument in the following environment.

Ambient temperature: –10°C to 50°C

Ambient humidity: 20% RH to 80% RH, no condensation

Operating altitude: Up to 2000 m

Note

• To ensure high measurement accuracy, operate the instrument within 23°C ± 3°C.

• When using the instrument in a place where the ambient humidity is 30% or less, take

measures to prevent static electricity such as using an anti-static mat.

• Condensation may occur if the instrument is moved to another place where the ambient

temperature or humidity is higher, or if the temperature changes rapidly. In such cases, before

you use the instrument, allow it to adjust to the surrounding temperature for at least an hour.

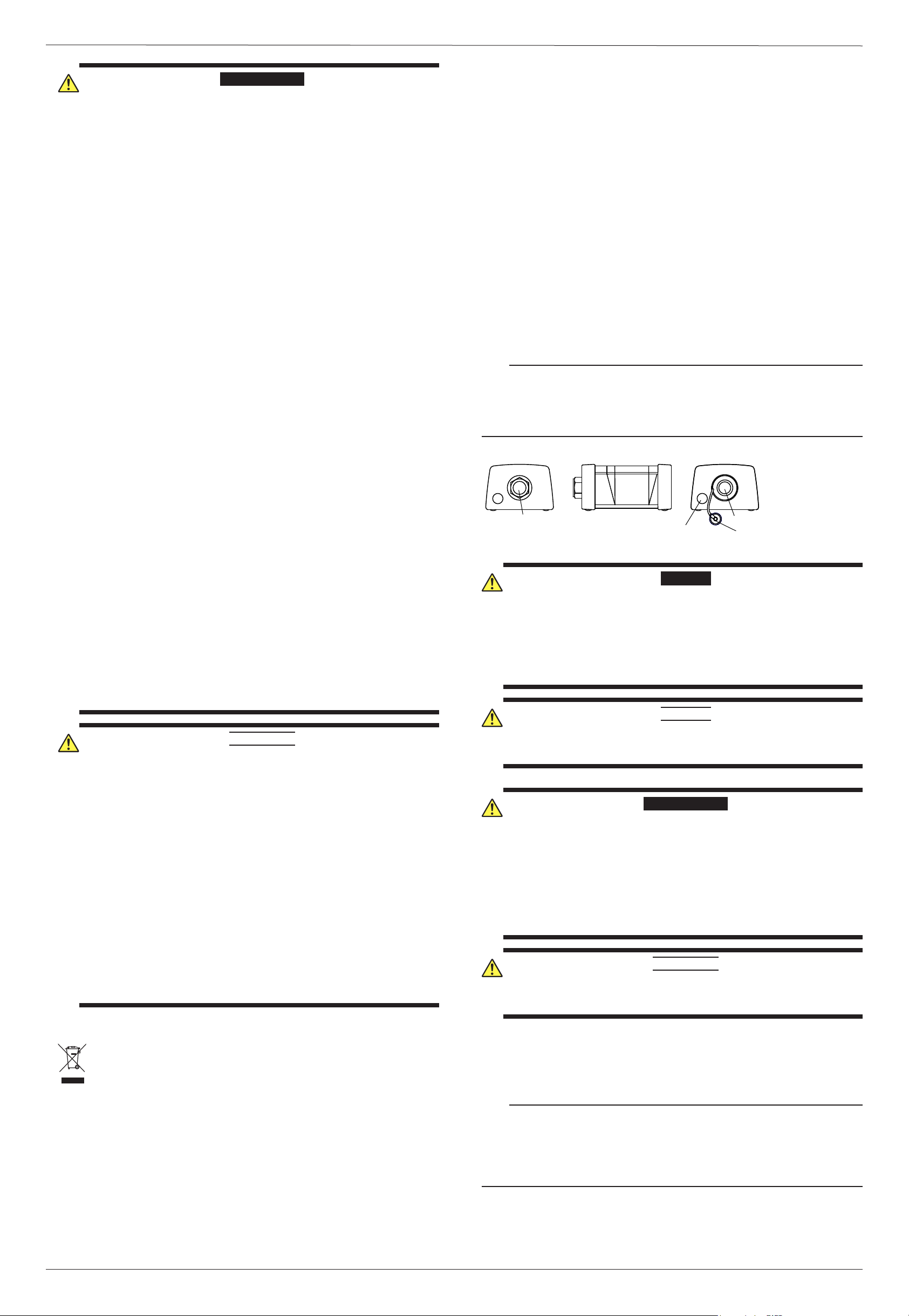

Component Names

Pressure input port

Cap holder

Cable connection terminal

Cap

Connection

Ne pas retirer le capot, ni démonter ou modifier l'instrument

Seul le personnel YOKOGAWA qualifié est habilité à retirer le capot et à

démonter ou modifier l'instrument.

Ne pas utiliser dans un environnement explosif

Cet instrument n’est pas antidéflagrant.

Ne pas utiliser l’instrument en présence de gaz ou de vapeurs inflammables.

Cela pourrait être extrêmement dangereux.

Installer et/ou utiliser l’instrument aux emplacements appropriés

L’instrument est conforme au niveau de protection IP54. Ne pas installer

l’instrument à un emplacement de niveau supérieur à ce niveau de protection.

ATTENTION

• Lors du transport ou de la manipulation de l'instrument, ne pas faire de

vibration ni de choc. S'assurer de ne pas laisser tomber l'instrument.

• Lorsque l'instrument n'est pas utilisé, attacher les capuchons au port d'entrée

de la pression et au terminal de connexion des câbles.

• Une réduction drastique de la pression appliquée à l'instrument peut entraîner

une condensation à l'intérieur de l'instrument, ainsi que son dysfonctionnement.

Lors d'un changement de pression, changer graduellement pour éviter toute

condensation.

Nettoyage

• Les unités de nettoyage 91040 et 91041 pour le CA700 ne peuvent pas être

utilisées pour nettoyer le port d'entrée de la pression du PM100.

• Une membrane de détection de pression est visible par le port d'entrée de la

pression du PM100. Lors du nettoyage du PM100, prendre soin de ne pas

toucher la membrane.

• Pour nettoyer l'instrument, frotter avec un chiffon humidifié d'eau ou d'un agent

neutre. Ne pas utiliser de nettoyants abrasifs ou de solvants organiques.

WARNING

• Before applying pressure to the instrument, make sure that tubing is connected

properly. Improper connection may cause gas or liquid to leak, which may in

turn cause injury or damage to the instrument.

• After use, be sure to depressurize adequately so that compressed gas or liquid

does not burst out. Then remove tubing.

• The withstand pressure of the conversion connector supplied with the

instrument is the same as the instrument’s allowable input. Do not use the

conversion connector with other instruments.

CAUTION

When connecting a tube to the PM100 connector, use a wrench or the like to fix

the hexagonal section of the PM100 in place. Using a wrench only on the tube

side may break the inside of the instrument.

French

AVERTISSEMENT

• Avant de mettre l’instrument sous pression, s’assurer que les tubes sont

correctement connectés. Une connexion incorrecte peut provoquer une fuite de

gaz ou de liquide, ce qui à son tour peut être à l’origine de blessures ou d’un

endommagement de l’instrument.

• Après utilisation, veiller à effectuer une dépressurisation correcte, de façon à

éviter que le gaz ou le liquide comprimé ne jaillisse hors de l’instrument. Retirer

ensuite les tubes.

• La pression de résistance du connecteur fourni avec l’instrument est identique

à l’entrée autorisée pour l’instrument. Ne pas utiliser le connecteur avec d’autres

instruments.

Limitations relatives à l’environnement opérationnel

Ce produit est un produit de classe A (pour environnements industriels).

L’utilisation de ce produit dans un zone résidentielle peut entraîner une

interférence radio que l’utilisateur sera tenu de rectifier.

Waste Electrical and Electronic Equipment

Waste Electrical and Electronic Equipment

(This directive is valid only in the EU.)

This product complies with the WEEE directive marking requirement. This

marking indicates that you must not discard this electrical/electronic product

in domestic household waste.

Product Category

With reference to the equipment types in the WEEE directive, this product is

classified as a “Monitoring and control instruments” product.

When disposing of products in the EU, contact your local Yokogawa Europe

B.V. office. Do not dispose in domestic household waste.

Pressure Equipment Directive

This product is categorized as Sound Engineering Practice(SEP) under the Pressure

Equipment Directive(PED).

Authorized Representative in the EEA

Yokogawa Europe B.V. is the authorized representative of Yokogawa Test & Measurement

Corporation for this product in the EEA. To contact Yokogawa Europe B. V., see the

separate list of worldwide contacts, PIM 113-01Z2.

ATTENTION

Lors de la connexion d'un tube au connecteur du PM100, utiliser une clé pour fixer

la section hexagonale du PM100. L'utilisation d'une clé uniquement du côté du

tube risquerait de casser l'intérieur de l'instrument.

Connecting to the CA700

Using the connection cable supplied with the PM100, connect the PM100’s cable

connection terminal to the CA700’s external sensor terminal.

Firmly tighten the screws on both ends of the connection cable. The IP54 specifications

cannot be met if the screws are loose.

Note

• Power to the PM100 is supplied from the CA700 through the connection cable.

• The PM100 is available when connecting to the following CA700.

16 MPa model: CA700 in 1.10 or later firmware versions

70 MPa model: CA700 in 1.20 or later firmware versions

You can download the latest firmware version of the CA700 from our website.

• Be careful not to bend the connection cable as an accessory in a radius of 30 mm or less.

Doing so causes breaks in the connection cable.

IM PM100-01EN

2/3

Page 3

Pressure Input Port

1.

Wrap seal tape around the threads of the tube.

2.

Using two wrenches, firmly attach the conversion connector of the tube to the

pressure input port of the instrument.

External Dimensions

Unit: mm

148

3.

The pressure input port of the PM100 is 1/2NPT female thread (-P3 input connection

specification). If the tubing connector does not match the port, use the supplied

connector.

91083 (conversion connector): Converts to 1/8NPT female thread

(maximum working pressure is 84 MPa.)

91084 (conversion connector): Converts to 1/4NPT female thread

(maximum working pressure is 57.1 MPa.)

91085 (conversion connector): Converts to Rc1/4 female thread

(maximum working pressure is 57.1 MPa.)

91086 (conversion connector): Converts to 1/4NPT female thread

(maximum workinge pressure is 98 MPa.)

91087 (conversion connector): Converts to Rc1/4 female thread

(maximum working pressure is 98 MPa.)

Specifications

16 MPa Model

Item Specification

Pressure type Shield gauge pressure

Measurement range 0 to 7 MPa sg 0 to 10 MPa sg 0 to 16 MPa sg

Measurement display

range

Accuracy (6 months

after calibration)

(after zero calibration††)

Accuracy (1 year after

calibration)

(after zero calibration††)

Display resolution 0.0001MPa(0.1kPa)

Allowable input 2.7 kPa abs to 23 MPa sg

Temperature effect ±(0.001% of reading + 0.16 kPa)/°C or less

Orientation effect Zero point ± 1 kPa or less

Response time

†

†††

to 8.4000 MPa to 12.0000 MPa to 19.2000 MPa

Positive pressure ±(0.01%

†

of reading + 2 kPa)

Positive pressure ±(0.01%

of reading +2.8 kPa)

2.5s or less

Positive pressure ±(0.01%

of reading +3 kPa)

Positive pressure ±(0.01%

of reading +3.8 kPa)

Positive pressure ±(0.01%

of reading +5 kPa)

Positive pressure ±(0.01%

of reading +5.8 kPa)

75

112

Unless otherwise specified, tolerances are ±3% (however, tolerances are ±0.3 mm when below 10 mm).

Disposing of the Instrument

When disposing of the instrument, follow the laws and ordinances of your country or

region.

70 MPa Model

Item Specification

Pressure type Shield gauge pressure

Measurement range 0 to 25 MPa sg 0 to 50 MPa sg 0 to 70 MPa sg

Measurement display

range

Accuracy (6 months

after calibration)

(after zero calibration††)

Accuracy (1 year after

calibration)

(after zero calibration††)

Display resolution 0.0001 MPa(0.1 kPa)

Allowable input 2.7 kPa abs to 98 MPa sg

Temperature effect ±(0.001% of reading + 0.7 kPa)/°C or less

Orientation effect Zero point ± 1 kPa or less

Response time

†

†††

to 30.0000 MPa to 60.0000 MPa to 77.0000 MPa

Positive pressure ±(0.01%

†

of reading + 6 kPa)

Positive pressure ±(0.01%

of reading +9.5 kPa)

2.5s or less

Positive pressure ±(0.01%

of reading +10 kPa)

Positive pressure ±(0.01%

of reading +13.5 kPa)

Positive pressure ±(0.01%

of reading +16 kPa)

Positive pressure ±(0.01%

of reading +19.5 kPa)

Common Specifications

Item Specification

Volume Approx. 6 cm

Input connection 1/2NPT female thread

Warm-up time Approx. 5 minutes

Measured fluid Gas and liquid (nonflammable, nonexplosive, nontoxic, noncorrosive fluid) only

Measured fluid

temperature

Pressure sensor Silicon resonant sensor

Measurement unit

material

Protection level IP54

Recommended

calibration period

Connection connector Waterproof connector

Cable length 1 m

External dimensions 112 mm (W) × 75 mm (H) × 148 mm (D)

Weight Approx. 1.2 kg

Operating environment

conditions

Storage environment

conditions

Safety standards Compliant standards EN 61010-1

Emissions Compliant standards EN 61326-1 Class A

Immunity Compliant standards EN61326-1 Table 2 (for industrial environments)

Environmental standard Compliant standard: EN50581 Monitoring and control instruments including those for

(Measuring the pressure of Group 1 substances and mixtures (dangerous fluids) as

listed in Directive 2014/68/EU Article 13 (1) a is not allowed).

–10 to 50°C, but 5 to 50°C for liquid

Diaphragm: Hastelloy C276 or ASTM N10276

Input port: SUS316L or ASTM grade 316L

1 year

Excluding the input port and protrusions

Temperature: –10 to 50°C Humidity: 20 to 80% RH (no condensation)

Altitude: Up to 2000 m

Temperature: –20 to 60°C Humidity: 20 to 80% RH (no condensation)

Pollution degree 2

EMC standards of Australia and New Zealand

EN55011 Class A, Group 1

Korea Electromagnetic Conformity Standard (

This product is a Class A (for industrial environments) product. Operation of this

product in a residential area may cause radio interference in which case the user will

be required to correct the interference.

Influence in the immunity testing environment (criteria A)

Measurement input: Within ±20% of range

industrial use

3

††††

한국 전자파적합성기준

)

† Yokogawa pressure standard accuracy is excluded.

†† Zero calibration condition: Under atmospheric pressure

††† Response time measurement conditions: Time for the readout to settle within 0

MPa ± 3.5 kPa after releasing 3.5 MPa pressure to the atmosphere

(where the input unit is under no load)

†††† The pollution degree refers to the degree of adhesion of a solid, liquid, or gas

which deteriorates withstand voltage or surface resistivity. Pollution degree 2

applies to normal indoor atmospheres (with only non-conductive pollution).

IM PM100-01EN

3/3

Loading...

Loading...