Page 1

User's

Manual

PK200

CURRENT-TO-PNEUMATIC

CONVERTER

[Style:S2]

IM 21B03D01-01E

IM 21B03D01-01E

12th Edition

Page 2

CONTENTS

CONTENTS

INTRODUCTION.............................................................................................. iii

1. HANDLING PRECAUTIONS ......................................................................... 1-1

1.1 Checking the Model Suffix Code and Specifications .......................... 1-1

1.2 Transportation Precautions ................................................................. 1-1

1.3 Storage Precautions ............................................................................ 1-2

1.4 Precautions for Installation Area ......................................................... 1-2

1.5 Installation of Intrinsically Safe Type .................................................. 1-2

1.5.1 CSA Intrinsically Safe Type ......................................................... 1-2

1.5.2 TIIS Intrinsically Safe Type .......................................................... 1-3

1.6 Installation of Flameproof Type .......................................................... 1-3

1.6.1 TIIS Flameproof Type .................................................................. 1-3

1.6.2 FM Explosionproof Type .............................................................. 1-4

1.7 EMC Conformity Standard .................................................................. 1-4

2. OVERVIEW .................................................................................................... 2-1

2.1 Functional Description ......................................................................... 2-1

2.2 Standard Specifications ...................................................................... 2-1

2.3 Model and Suffix Codes ...................................................................... 2-2

2.4 Options ................................................................................................ 2-2

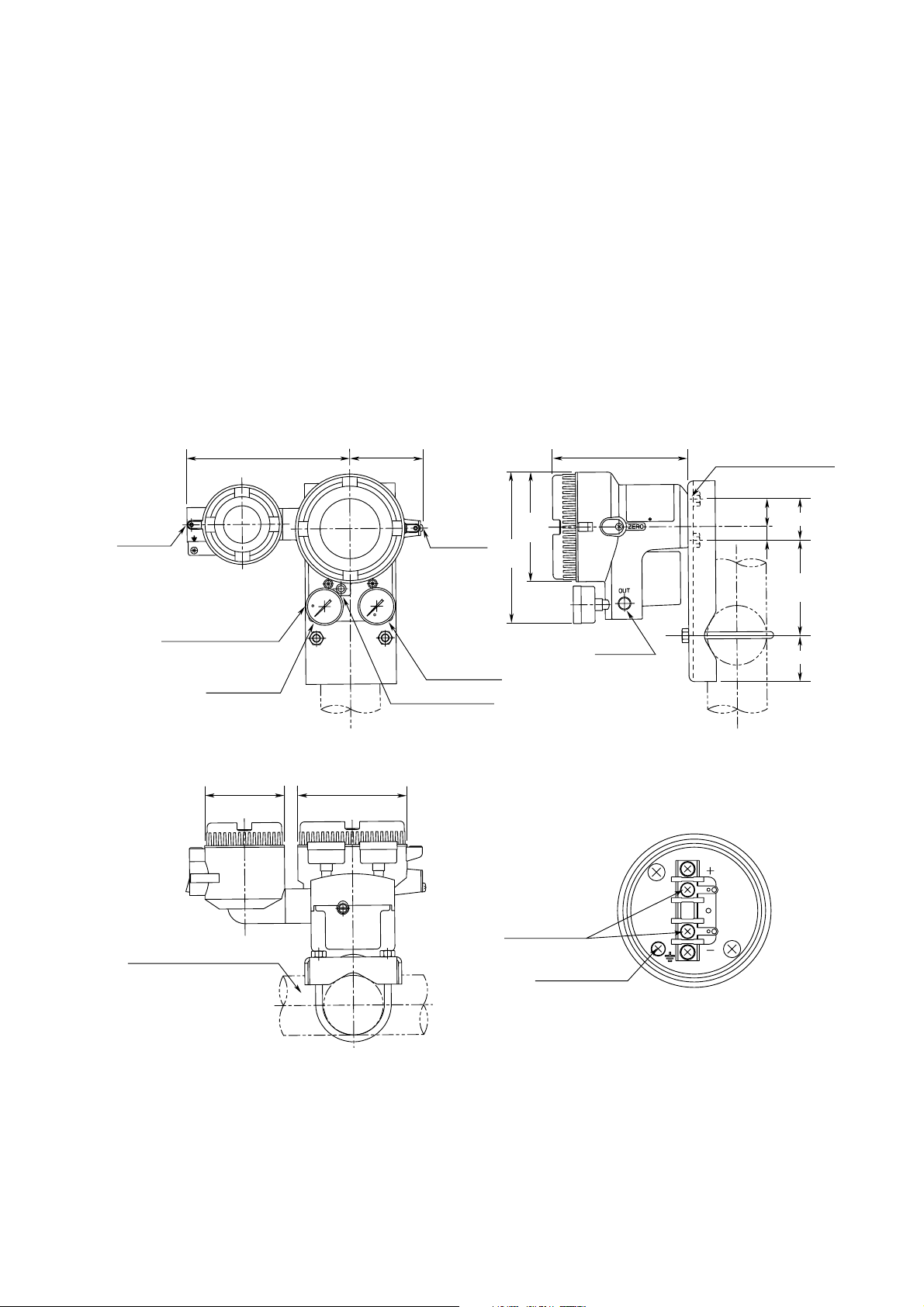

2.5 External Dimensions ........................................................................... 2-3

2.6 Part Names ......................................................................................... 2-4

3. INSTALLATION ............................................................................................. 3-1

3.1 Overview ............................................................................................. 3-1

3.2 Installation ........................................................................................... 3-1

3.2.1 Pipe Mounting .............................................................................. 3-1

3.2.2 Wall Mounting ............................................................................... 3-1

4. WIRING AND PIPING ................................................................................... 4-1

4.1 Piping .................................................................................................. 4-1

4.1.1 Supply Air ..................................................................................... 4-1

4.1.2 Air Supply Piping .......................................................................... 4-1

4.1.3 Output Piping................................................................................ 4-1

4.2 General-Use and Flameproof Type Wiring ......................................... 4-1

4.2.1 Cable Selection ............................................................................ 4-1

4.2.2 Wiring ........................................................................................... 4-2

4.2.3 Grounding ..................................................................................... 4-4

4.3 Intrinsically Safe Type Wiring ............................................................. 4-4

5. OPERATION .................................................................................................. 5-1

5.1 Auto/Manual (A/M) Transfer Mechanism ............................................ 5-1

5.2 Zero Point Adjustment ........................................................................ 5-1

5.3 Calibration ........................................................................................... 5-2

5.4 Range Adjustment ............................................................................... 5-4

5.5 4 to 20mA/10 to 50mA Selection ........................................................ 5-4

FD No. IM 21B03D01-01E

12th Edition: Aug. 2012 (KP)

All Rights Reserved, Copyright © 1992, Yokogawa Electric Corporation

i

IM 21B03D01-01E

Page 3

CONTENTS

6. MAINTENANCE............................................................................................. 6-1

6.1 Overview ............................................................................................. 6-1

6.2 Periodic Inspection .............................................................................. 6-1

6.2.1 Cleaning the Restrictor................................................................. 6-1

6.3 Parts Replacement .............................................................................. 6-1

6.3.1 Replacing the Screen Filter.......................................................... 6-1

6.3.2 Replacing the Controller Relay .................................................... 6-2

6.3.3 Replacing the Amplifier Assembly ............................................... 6-2

7. TROUBLESHOOTING................................................................................... 7-1

7.1 Overview ............................................................................................. 7-1

7.2 Operation Principle .............................................................................. 7-1

7.3 Troubleshooting Flow .......................................................................... 7-2

Appendix A. AIR SUPPLY SYSTEM................................................................ A-1

INSTALLATION AND OPERATING PRECAUTIONS FOR TIIS INTRINSICALLY

SAFE EQUIPMENT ............................................................................. Ex-A03E

INSTALLATION AND OPERATING PRECAUTIONS FOR TIIS FLAMEPROOF

EQUIPMENT ........................................................................................ Ex-B03E

Customer Maintenance Parts List

Model PK200 Current-to-Pneumatic Converter .............. CMPL 21B03D01-01E

Revision Record

ii

IM 21B03D01-01E

Page 4

INTRODUCTION

INTRODUCTION

Thank you for purchasing the Current-to-Pneumatic

Converter.

The Current-to-Pneumatic Converter is correctly

calibrated at the factory before shipment. To ensure

correct and efficient use of the instrument, please read

this manual thoroughly and fully understand how to

operate the instrument before operating it.

■ Regarding This Manual

•This manual should be passed on to the end user.

• The contents of this manual are subject to change

without prior notice.

• All rights reserved. No part of this manual may be

reproduced in any form without Yokogawa’s written

permission.

• Yokogawa makes no warranty of any kind with

regard to this manual, including, but not limited to,

implied warranty of merchantability and fitness for a

particular purpose.

• If any question arises or errors are found, or if any

information is missing from this manual, please

inform the nearest Yokogawa sales office.

• The specifications covered by this manual are

limited to those for the standard type under the

specified model number break-down and do not

cover custom-made instrument.

• Please note that changes in the specifications,

construction, or component parts of the instrument

may not immediately be reflected in this manual at

the time of change, provided that postponement of

revisions will not cause difficulty to the user from a

functional or performance standpoint.

■ Safety Precautions

• Yokogawa will not be liable for malfunctions or

damage resulting from any modification made to

this instrument by the customer.

• For the intrinsically safe equipment and

explosionproof equipment, in case the instrument is

not restored to its original condition after any repair

or modification undertaken by the customer,

intrinsically safe construction or explosionproof

construction is damaged and may cause dangerous

condition. Please contact Yokogawa for any repair

or modification required to the instrument.

• The following safety symbol marks are used in this

Manual:

WARNING

Indicates a potentially hazardous situation which,

if not avoided, could result in death or serious

injury.

CAUTION

Indicates a potentially hazardous situation which,

if not avoided, may result in minor or moderate

injury. It may also be used to alert against

unsafe practices.

IMPORTANT

Indicates that operating the hardware or software

in this manner may damage it or lead to system

failure.

• For the protection and safety of the operator and the

instrument or the system including the instrument,

please be sure to follow the instructions on safety

described in this manual when handling this instrument. In case the instrument is handled in contradiction to these instructions, Yokogawa does not

guarantee safety.

NOTE

Draws attention to information essential for

understanding the operation and features.

iii

IM 21B03D01-01E

Page 5

WARRANTY

•The warranty shall cover the period noted on the

quotation presented to the purchaser at the time of

purchase. Problems occurred during the warranty

period shall basically be repaired free of charge.

•In case of problems, the customer should contact the

Yokogawa representative from which the instrument

was purchased, or the nearest Yokogawa office.

• If a problem arises with this instrument, please

inform us of the nature of the problem and the

circumstances under which it developed, including

the model specification and serial number. Any

diagrams, data and other information you can

include in your communication will also be helpful.

• Responsible party for repair cost for the problems

shall be determined by Yokogawa based on our

investigation.

● The Purchaser shall bear the responsibility for

repair costs, even during the warranty period, if

the malfunction is due to:

•Improper and/or inadequate maintenance by the

Purchaser.

•Failure or damage due to improper handling, use or

storage which is out of design conditions.

•Use of the product in question in a location not

conforming to the standards specified by the

Yokogawa, or due to improper maintenance of the

installation location.

• Failure or damage due to modification or repair by

the party except Yokogawa or who is requested by

Yokogawa.

• Malfunction or damage from improper relocation of

the product in question after delivery.

•Reason of force majeure such as fires, earthquakes,

storms/floods, thunder/lightening, or other natural

disasters, or disturbances, riots, warfare, or radioactive contamination.

INTRODUCTION

iv

IM 21B03D01-01E

Page 6

1. HANDLING PRECAUTIONS

IMPORTANT

For installation, wiring and maintenance in

hazadous areas, please follow 1.5 Installation of

Intrinsically Safe Type, 1.6 Installation of Flameproof Type and “Installation and Operating

Precautions for TIIS Flameproof Equipment” at

the end of this manual

1. HANDLING PRECAUTIONS

The PK200 current-to-pneumatic converter is fully

factory inspected before shipment. When the instrument is delivered, visually check the instrument and

accessories to ensure that they are not damaged. This

chapter describes the handling precautions, read them

carefully before using the instrument.

For items other than those described in this chapter, see

the relevant items.

If you wish to make inquiry, contact the distributor

where you purchased the instrument or the nearest

YOKOGAWA service station.

1.1 Checking the Model Suffix

Code and Specifications

The data plate on the side face of the instrument base

shows the model suffix code and specifications. With

reference to the model suffix code and specifications in

section 2.3, confirm that the instrument is as specified

by the order.

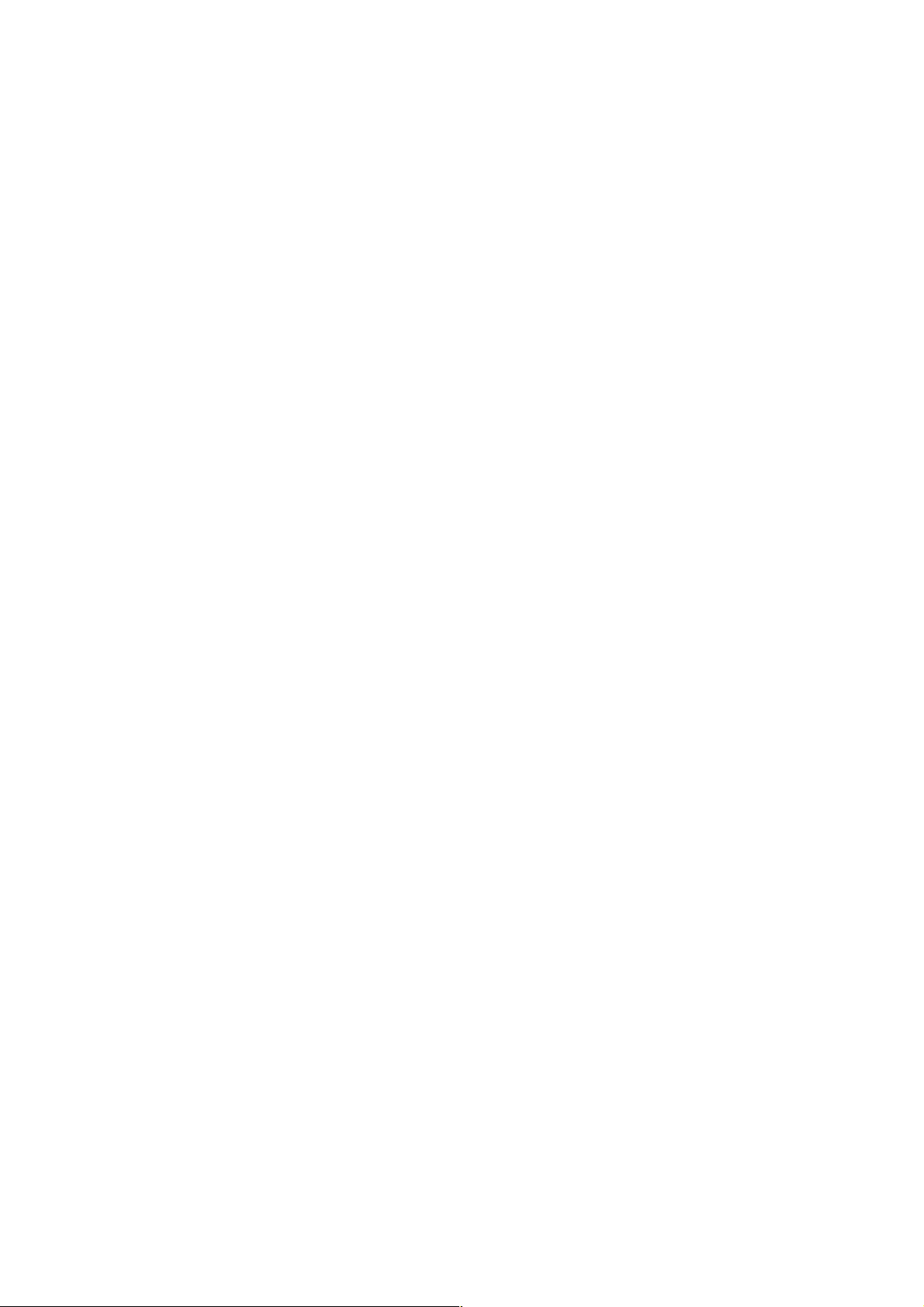

Figure 1.2 Data Plate for CSA Intrinsically Safe Type

Figure 1.3 Data Plate for FM Explosionproof Type

1.2 Transportation Precautions

To prevent damage occurring during transportation,

transport the converter in the original shipping container (box) with all packing items and equipment in its

proper position.

For inquiry, inform us of the model suffix code and

instrument serial number.

Figure 1.1 Data Plate for General-Use Type

1-1

IM 21B03D01-01E

Page 7

1. HANDLING PRECAUTIONS

1.3 Storage Precautions

(1) Select a storage place :

• Which is protected from rain and water.

• Which is free from vibration and impact.

•Whose temperature and humidity are as specified

below. Room temperature and humidity (approx.

25°C and 65%) are more recommendable.

Temperature: -10 to 60°C

Humidity: Less than 80%

(2) Store the converter in the packing condition of

shipment from YOKOGAWA whenever possible.

1.4 Precautions for Installation

Area

To use the converter stably for a long time, determine

an installation place, taking into account the following.

(1) Ambient Temperature

Avoid installing the instrument in a place subject to a

large temperature gradient and variations. If the

instrument is subject to plant-generated heat radiation,

take measures such as provision of heat protection and

good ventilation.

(2) Atmospheric Conditions

Avoid installing the converter in corrosive atmosphere.

Should it be used in corrosive atmosphere, make

provision for maintaining good ventilation.

(3) Magnetic Field

Please contact us in the case this instrument is installed

the strong Magnetic Field.

1.5 Installation of Intrinsically Safe Type

1.5.1 CSA Intrinsically Safe Type

[Intrinsically Safe]

Hazardous Location

Class I, II, III, Division 1,

Groups A, B, C, D, E, F, G

+

–

PK200

Current-topneumatic Converter

[Nonincendive]

Hazardous Location

Class I, II, III, Division 2,

Groups A, B, C, D, E, F, G

Class III, Division 1.

+

–

PK200

Current-topneumatic Converter

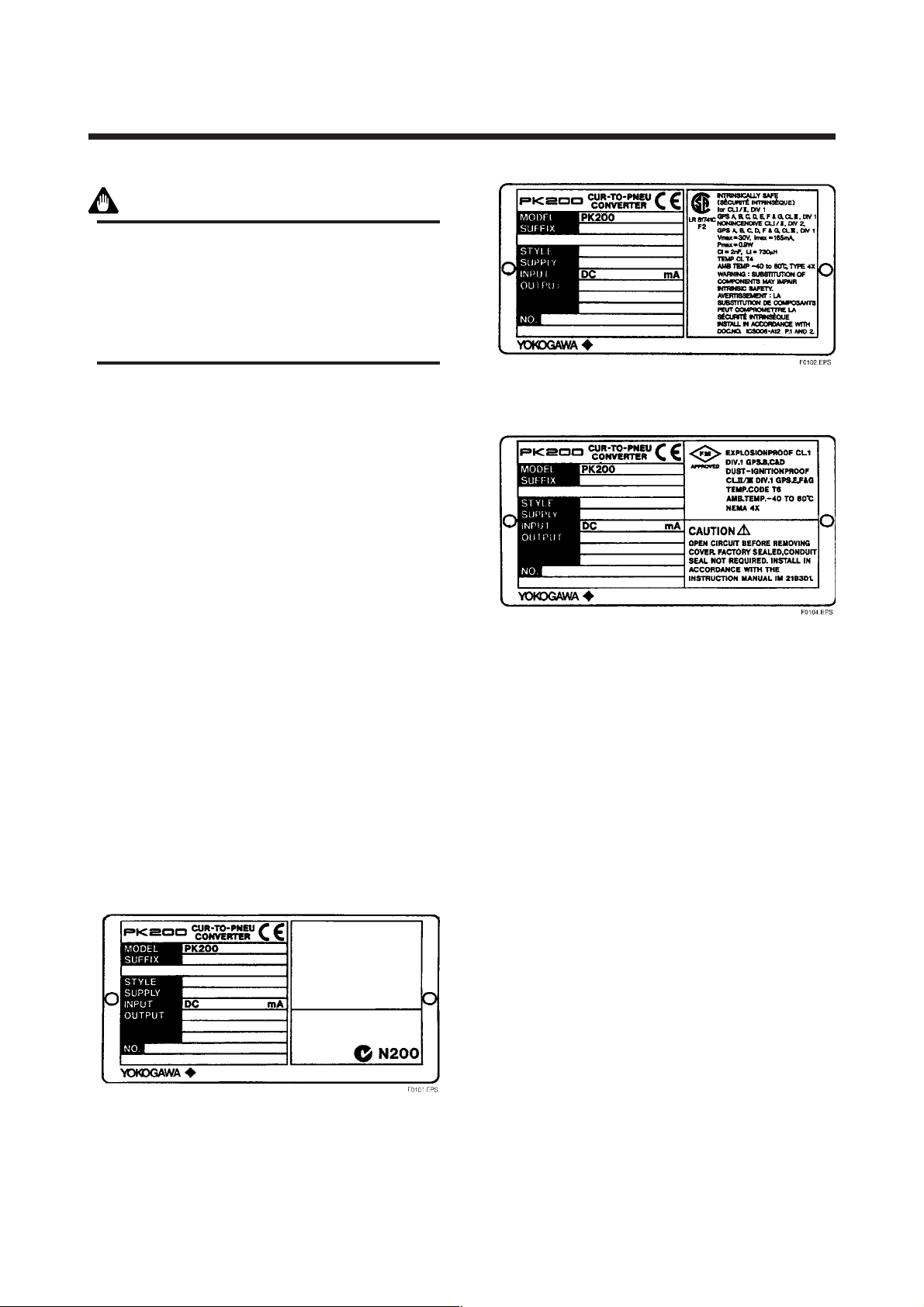

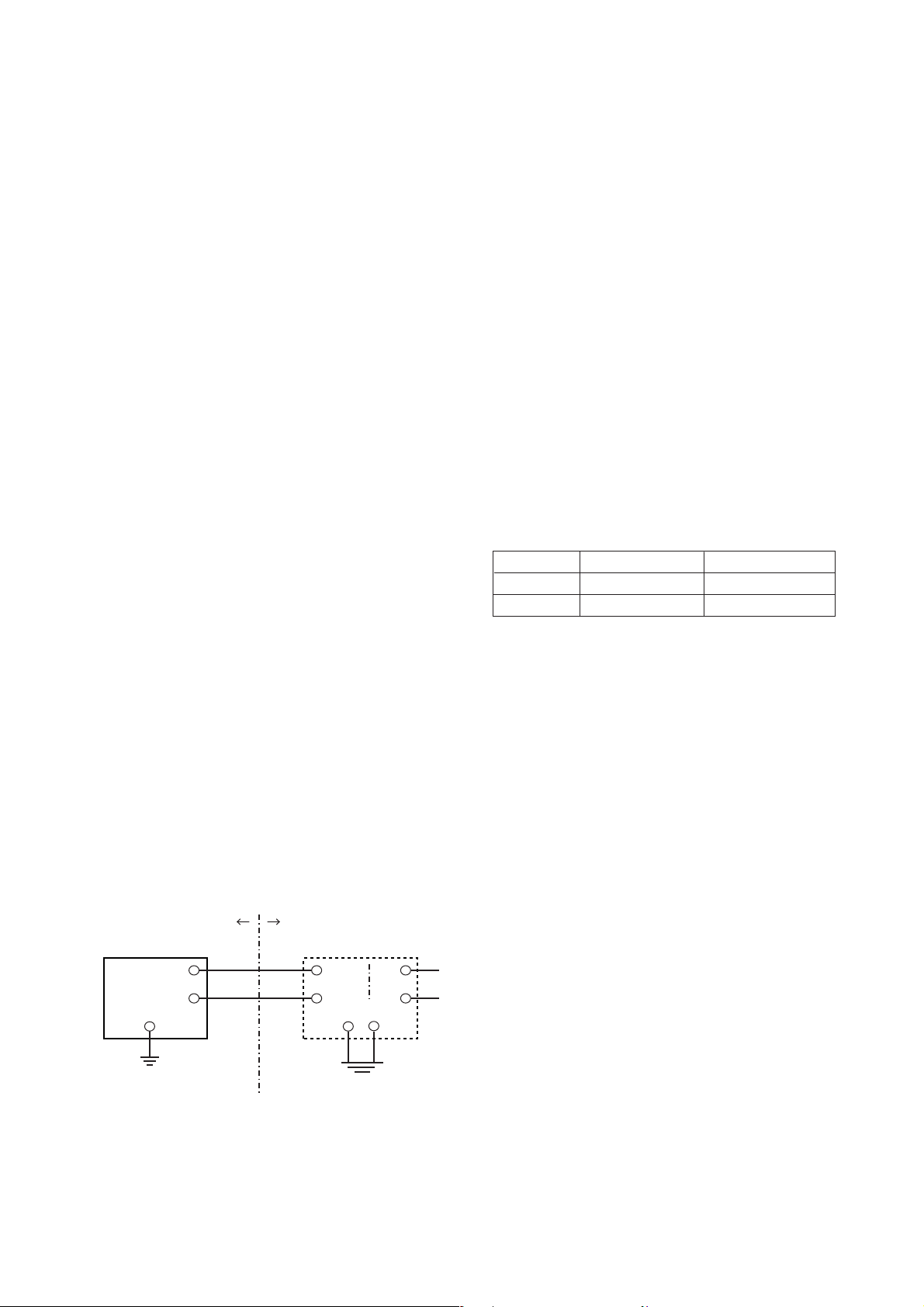

Figure 1.4 Installation of CSA Intrinsically Safe Type

1. PK200 current to pneumatic converter is

applicable for use in hazardous locations:

• Intrinsically Safe for Class I, Division 1, Groups A,

B, C & D, Class II, Division 1, Groups E, F & G

and Class III, Division 1 Hazardous Locations.

•Nonincendive for Class I, Division 2, Groups A, B,

C & D, Class II, Division 2, Groups F & G, and

Class III, Division 1 Hazardous Locations.

• Outdoor Hazardous Locations, Encl Type 4X.

• Temperature Class: T4

• Ambient Temperature: -40 to 60°C

Non-hazardous Location

Safety Barrier

+

+

–

–

Non-hazardous Location

General

Purpose

Equipment

+

–

Note: Not use safety Barrier

General

Purpose

Equipment

+

–

F0105.EPS

2. Entity Parameters

• Intrinsically safe apparatus parameters

Vmax = 30V

Imax = 165mA

Pmax = 0.9W

Ci = 2nF

Li = 730µ H

• Associated apparatus parameters (CSA Certified

Barriers)

Voc ≤ 30V

Isc ≤ 165mA

Pmax ≤ 0.9W

1-2

IM 21B03D01-01E

Page 8

1. HANDLING PRECAUTIONS

3. Installation

• Control equipment connected to barrier must not use

or generate more than 250 Vrms or Vdc.

• The safety barrier must be CSA certified.

• Associated apparatus manufacturer’s installation

drawing must be followed when installing this

apparatus.

• The maximum power delivered from the barrier

must not exceed 0.9 W.

•Note a warning label worded “SUBSTITUTION OF

COMPONENTS MAY IMPAIR INTRINSIC

SAFETY” and “INSTALL IN ACCORDANCE

WITH DOC. NO. ICS006-A12 P.1 AND 2”.

1.5.2 TIIS Intrinsically Safe Type

The model PK200/JS3 current-to-pneumatic converters,

which have obtained certification according to technical criteria for explosion-protected construction of

electric machinery and equipment (Standards Notification No.556 from the Japanese Ministry of Labor)

conforming to IEC standards, is designed for hazardous

areas where explosive gases and/or inflammable vapors

may be present. (This allows installation in Division 0 ,

1 and 2 areas)

To preserve the safety of flameproof equipment

requires great care during mounting, wiring, and

piping. Safety requirements also place restrictions on

maintenance and repair activities. Users absolutely

must read the following instructions and “Installation

and Operating Precautions for TIIS Intrinsically Safe

Equipment (EX - A03E)” at the end of this manual.

1. Installation

The PK200 Current-to-Pneumatic Converter should be

used in connection with the certified safety barrier as

shown below. All wiring shall comply with local

installation requirements.

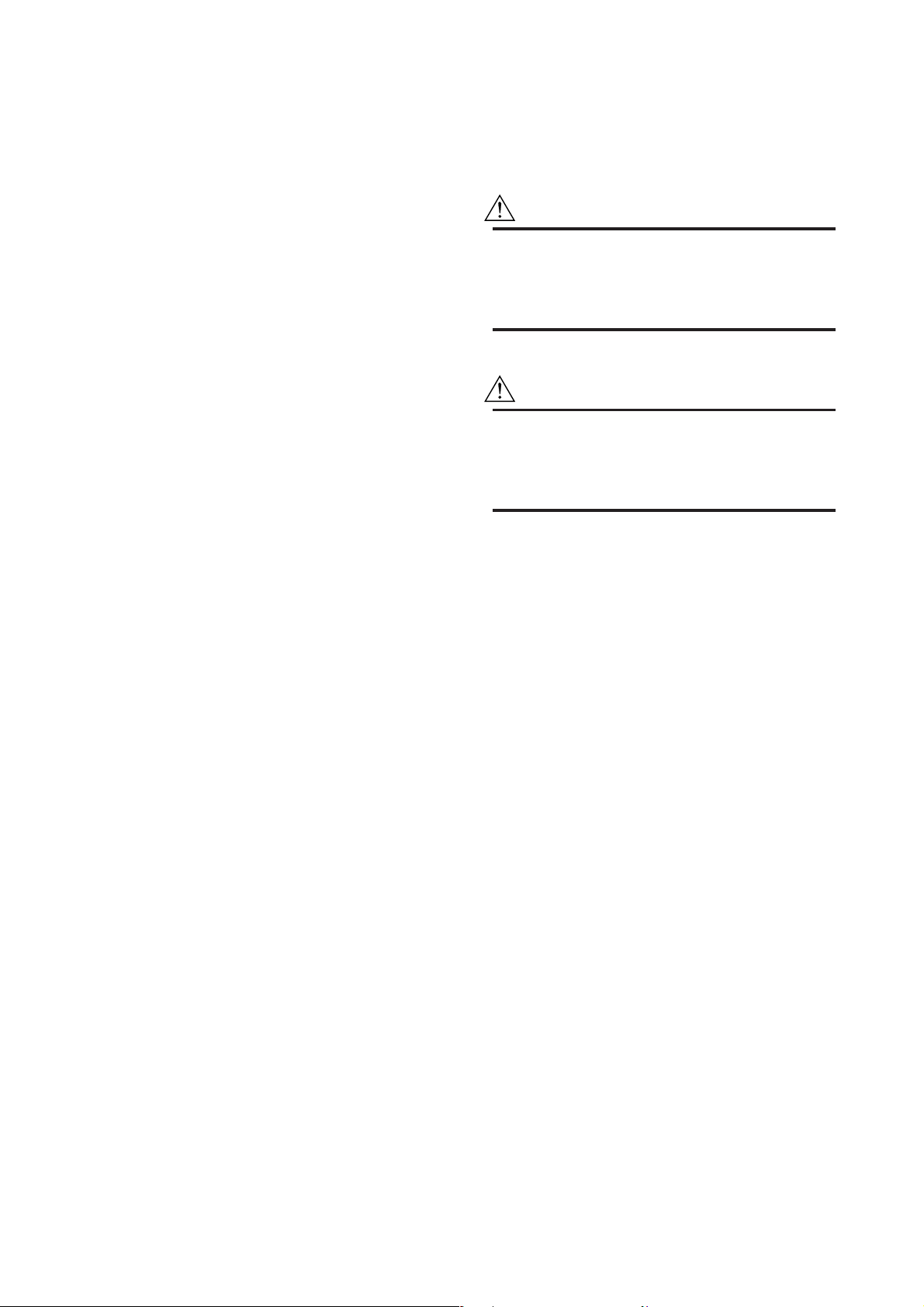

[Installation Diagram]

Hazardous Area

+

–

PK200 Current-to-pneumatic

Converter

Non-hazardous Area

+

–

Safety barrier

+

–

F0107.EPS

2. Temperature

Install the PK200, So that any part of the instrument

that may exposed to the inflammable gas or vapor

would not exceed the temperature 60°C

3. Safety Barrier

Use the certified safety barrier that satisfies the

following requirements.

• Safety Ratings

Maximum output voltage: 28V or less

Maximum output current: 94.3mA or less

Maximum output power: 0.66W or less

• Protection type and group

Protection type: ia Group: IIC

•Allowable inductance and capacitance

Maximum_external inductance: More than the

external wiring inductance

Maximum_external capacitance: More than the sum

of the external wiring capacitance and 39nF

Table 1.1 Recommended Safety Barrier

Contact each supplier for the details of the barrier.

Supplier Type Model

MTL Isolated type MTL5046

P+F Isolated type KFD2-SCD-Ex1.LK*

T0101.EPS

* To connect this barrier with PK200 converter, for

the connection between the barrier and the controller, use the terminal #7 and #9 of the barrier.

1.6 Installation of Flameproof

Type

1.6.1 TIIS Flameproof Type

The model PK200/JF3 current-to-pneumatic converters,

which have obtained certification according to technical criteria for explosion-protected construction of

electric machinery and equipment (Standards Notification No.556 from the Japanese Ministry of Labor)

conforming to IEC standards, is designed for hazardous

areas where explosive gases and/or inflammable vapors

may be present. (This allows installation in Division 1

and 2 areas)

To preserve the safety of flameproof equipment

requires great care during mounting, wiring, and

piping. Safety requirements also place restrictions on

maintenance and repair activities. Users absolutely

must read “Installation and Operating Precautions for

TIIS Flameproof Equipment (EX - B03E)” at the end

of this manual.

1-3

IM 21B03D01-01E

Page 9

1. HANDLING PRECAUTIONS

1.6.2 FM Explosionproof Type

Following items are described in the instruction

documents of this instrument to ensure certified

explosionproof properties.

1. PK200 Current to Pneumatic Converter is

applicable for use in hazardous areas;

* Explosionproof for Class I, Division 1, Groups B, C

and D.

*Dust ignitionproof for Class I/II, Division 1, Groups

E, F and G.

* Outdoor hazardous locations, NEMA 4X.

2. Wiring

*All wiring shall comply with National Electrical

Code ANSI/NEPA70 and Local Electrical Codes.

*When installed in Division 1, “FACTORY

SEALED, CONDUIT SEAL NOT REQUIRED”.

However, in case of installing a sealing fitting

(option) for waterproof or other purposes, see

4.2.2(6).

3. Operation

* WARNING: OPEN CIRCUIT BEFORE REMOV-

ING COVER.

FACTORY SEALED, CONDUIT

SEAL NOT REQUIRED.

INSTALL IN ACCORDANCE

WITH THE INSTRUCTION

MANUAL IM 21B3D1-01E

* Take care not to generate mechanical spark when

access to the instrument and peripheral devices in

hazardous location.

1.7 EMC Conformity Standard

EN61326-1 Class A, Table 2

(For use in industrial locations)

CAUTION

To meet EMC regulations, Yokogawa recommends that customers run signal wiring through

metal conduits or use shielded twisted-pair

cabling when installing this instrument in a plant.

CAUTION

This instrument is a Class A product, and it is

designed for use in the industrial environment.

Please use this instrument in the industrial

environment only.

4. Maintenance and Repair

* The instrument modification or parts replacement by

other than authorized representative of Yokogawa

Electric Corporation is prohibited and will void

Factory Mutual Explosionproof Certification.

1-4

IM 21B03D01-01E

Page 10

2. OVERVIEW

2. OVERVIEW

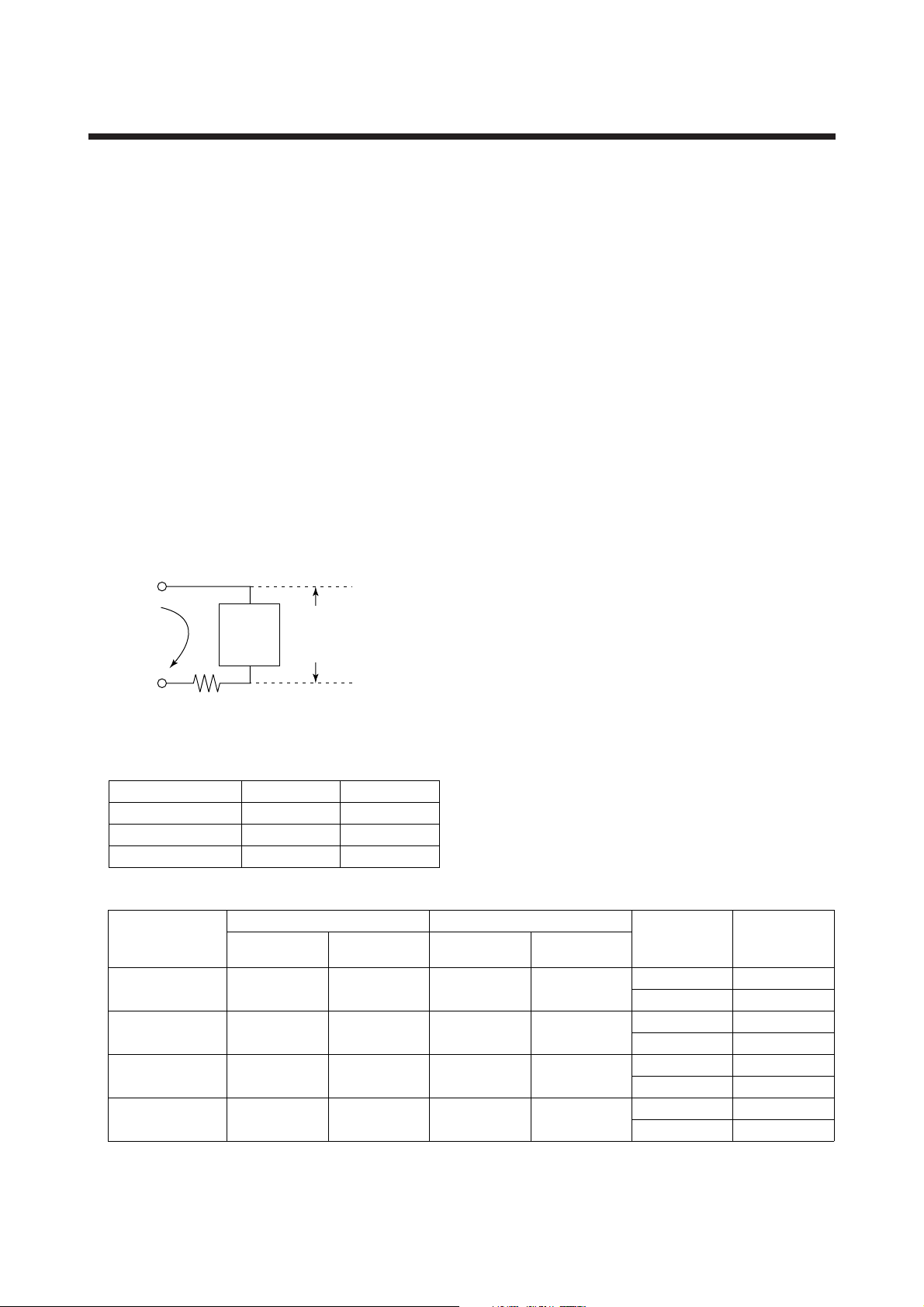

2.1 Functional Description

The PK200 current-to-pneumatic converter is a signal

converter that receives an electronic controller or DCS

control signal and converts it into a pneumatic pressure

signal.

I/O Action: Output pressure increases as input

increases.

Manual Operation: Available using auto/manual (A/M)

transfer switch (Optional)

Zero Point Adjusting Range: Within 0 to ±10% of span

Span Adjusting Range: Within 100 to 125% of span

Air Consumption: 4Nl/min maximum (for a supply air

pressure of 140kPa)

Max. Air Delivery: 110Nl/min maximum (for a supply

2.2 Standard Specifications

Materials: Case: Aluminum die-cast

Paint: Polyurethane resin-baked finish

Paint color: Deep-sea moss-green

(Munsell 0.6GY3.1/2.0 or equivalent)

Pressure Gauge Case: Stainless steel

JIS SUS304

Input Signals: 4 to 20mA DC or 10 to 50mA DC

Input Resistance: PK200 is not a constant resistor.

Equivalent circuit of PK200 is shown in Fig. 2.1

Minimum Load Capacity:

Ambient Temperature:

Water Proof Construction:

air pressure of 140kPa)

1m copper tube with 4mm I.D. +20cc

-40 to 80°C (for general use)

-20 to 60°C (TIIS Explosionproof ,

TIIS Intrinsically safe type)

-40 to 60°C (for FM Explosionproof,

CSA Intrinsically safe type)

IEC IP54

NEMA type 4X

Input Signal

4 to 20mA DC

Constant

Vol tage

Circuit

5V DC

(8V DC for CENELEC

Intrinsically safe type and

TIIS Intrinsically safe type.)

Intrinsically Safe Construction:

CSA Intrinsically Safe (/CS1) : Intrinsically Safe for

Class I, Division 1, Groups A, B, C

& D Class II, Division 1, Groups E, F

50Ω MAX

Fig. 2.1 Equivalent Circuit

Operating Voltage:

Input Signal Min. Max.

4 to 20mA (except /JS3) 5.2V (at 4mA) 6.0V (at 20mA)

4 to 20mA (for /JS3) 8.2V (at 4mA) 9.0V (at 20mA)

10 to 50mA 5.35V (at 10mA) 6.75V (at 50mA)

F0201.EPS

T0200.EPS

& G and Class III, Division 1

Hazardous Locations.

Nonincendive for Class I, Division 2,

Groups A, B, C & D, Class II,

Division 2, Groups F & G, and Class

III, Division 1 Hazardous Locations.

Outdoor Hazardous Locations, Encl

Type 4X.

Temperature Class: T4

Output Signals:

Standard Output

Output Signal

Pa calibration 20 to 100kPa 0 to 200kPa 40 to 200kPa 0 to 400kPa 130 to 150kPa 0 to 200kPa

kgf/cm2 calibration 0.2 to 1.0 kgf/cm20 to 2kgf/cm20.4 to 2.0 kgf/cm20 to 4kgf/cm21.3 to 1.5kgf/cm20 to 2kgf/cm

Bar calibration 0.2 to 1.0bar 0 to 2bar 0.4 to 2.0bar 0 to 4bar 1.3 to 1.5bar 0 to 2bar

P calibration 3 to 15psi 0 to 30psi 6 to 30psi 0 to 60psi 19 to 22psi 0 to 30psi

*1: Set supply air pressure in the range given in the upper column for standard output and in the range given in the lower column for

multiplied pressure output.

Output Signal

Pressure Gauge

Scale

Doubled Output

Output Signal

3 to 27psi 33 to 37psi 0 to 60psi

Pressure Gauge

Scale

Recomended

Supply Air

Pressure *

230 to 260kPa 0 to 400kPa

2.3 to 2.6kgf/cm20 to 4kgf/cm

2.3 to 2.6bar 0 to 4bar

1

Supply Air

Pressure Gauge

Scale *

1

2

2

T0201.EPS

2-1

IM 21B03D01-01E

Page 11

2. OVERVIEW

TIIS Intrinsically Safe (/JS3):

Intrinsically Safe Ex ia IIC T4

Certificate: TC18266

Explosionproof Construction:

TIIS Explosionproof (/JF3): Flameproof Exd II

B+H2 T6X

FM Explosionproof (/FF1): Explosionproof for Class

I, Division 1, Groups B, C and D.

Dust ignitionproof for Class II/III,

Division 1, Groups E, F and G.

Temperature Class: T6.

Outdoor hazardous locations, NEMA

4X.

Dustproof Construction: IEC IP54

Connections:

Air Connection: Rc1/4 or 1/4NPT female

Electrical Connection: G1/2, G3/4 female or

1/2NPT, 3/4NPT female

Mounting: Vertical or horizontal 50mm (2-

INCH) pipe mounting

Wall mounting

Mass (weight): 2.8kg (6.1lb)

Accuracy: ±0.5% of span

Linearity: ±0.2% of span

Hysteresis: 0.2% of span

Repeatability: 0.1% of span

2.4 Options

• Option Code/JF3: JIS Flameproof

TIIS flameproof Exd II B+H2 T6X

• Option Code/G11: Packing adapter for TIIS Flameproof

Electrical connection: G1/2 female, Applicable cable

O.D.: 8 to 12mm

• Option Code/G21: Packing adapter for TIIS Flameproof

Electrical connection: G3/4 female, Applicable cable

O.D.: 10 to 16mm

• Option Code/FF1: FM Explosionproof

• Option Code/JS3: TIIS Intrinsically Safe

Applicable only with input signal code-A.

• Option Code/CS1: CSA Intrinsically Safe

• Option Code/SCF-: Special Color Finished on

converter cover

Allows the paint color of only a converter cover to

be selectable by specifying the color in the specification item with reference to GS22D1F1.

• Option Code/X1: Epoxy Paint

Epoxy resin-baked coating.

Not applicable for special color finished.

2.3 Model and Suffix Codes

Model Suffix Code Description

PK200

Input Signal -A 4 to 20mA DC

-C 4 to 20mA/10 to 50mA DC selection type

Output Signal 1 Output signal Pa calibration 20 to 100kPa scale 0 to 200kPa

2 Output signal Pa calibration 40 to 200kPa scale 0 to 400kPa

3 Output signal kgf/cm2 calibration 0.2 to 1.0 kgf/cm2scale 0 to 2kgf/cm

4 Output signal kgf/cm2 calibration 0.4 to 2.0 kgf/cm2scale 0 to 4kgf/cm

5 Output signal bar calibration 0.2 to 1.0bar scale 0 to 2bar

6 Output signal bar calibration 0.4 to 2.0bar scale 0 to 4bar

7 Output signal P calibration 3 to 15psi scale 0 to 30Psi

8 Output signal P calibration 6 to 30psi scale 0 to 60Psi

9 Output signal P calibration 6 to 27psi scale 0 to 60Psi

Connections 1 Air connection: Rc 1/4, Electrical connection: G1/2 female

2Air connection: Rc 1/4, Electrical connection: G3/4 female

3Air connection: 1/4 NPT female, Electrical connection: 1/2NPT female

4Air connection: 1/4 NPT female, Electrical connection: 3/4NPT female

Option / See section 2.4.

T0202.EPS

2

2

2-2

IM 21B03D01-01E

Page 12

2. OVERVIEW

• Option Code/L: Lightning Protector

Installed in the terminal box to protect internal

circuitry from high voltage surges such as those

caused by lightning induced.

• Option Code/AM: AUTO/MANUAL Switch

Mounted on front of housing, in manual mode,

output signal is varied by adjusting the external

supply pressure regulator.

• Option Code/GW: Double Scale Pressure Gauge

Double scales are kPa and kgf/cm2.

2.5 External Dimensions

165.5(6.52)

Electrical

Connection

74(2.91)

Zero

Adjustment

Screw

•Option Code/SS: Stainless Steal Screw and Bracket

Screw and bracket, both are made of stainless steal.

• Option Code/RA: Reverse Action

Increasing of input signal to make output pressure

decrease.

Unit: mm

38(1.50)

97

(3.82)

153.5

(6.04)

ø111

(4.37)

137.5(5.41)

Wall Mount Screw 2-M8

24(0.94)

14(0.55)

Air Supply Connection

Supply Gauge

ø81(3.19) ø111(4.37)

Nominal 50 mm (2-inch) Pipe

Figure 2.2 External Dimensions

Output Gauge

A/M Transfer Switch

(optional)

Input Terminal

Ground Terminal

Output

Connection

Terminal Configuration

47(1.85)

F0202.EPS

2-3

IM 21B03D01-01E

Page 13

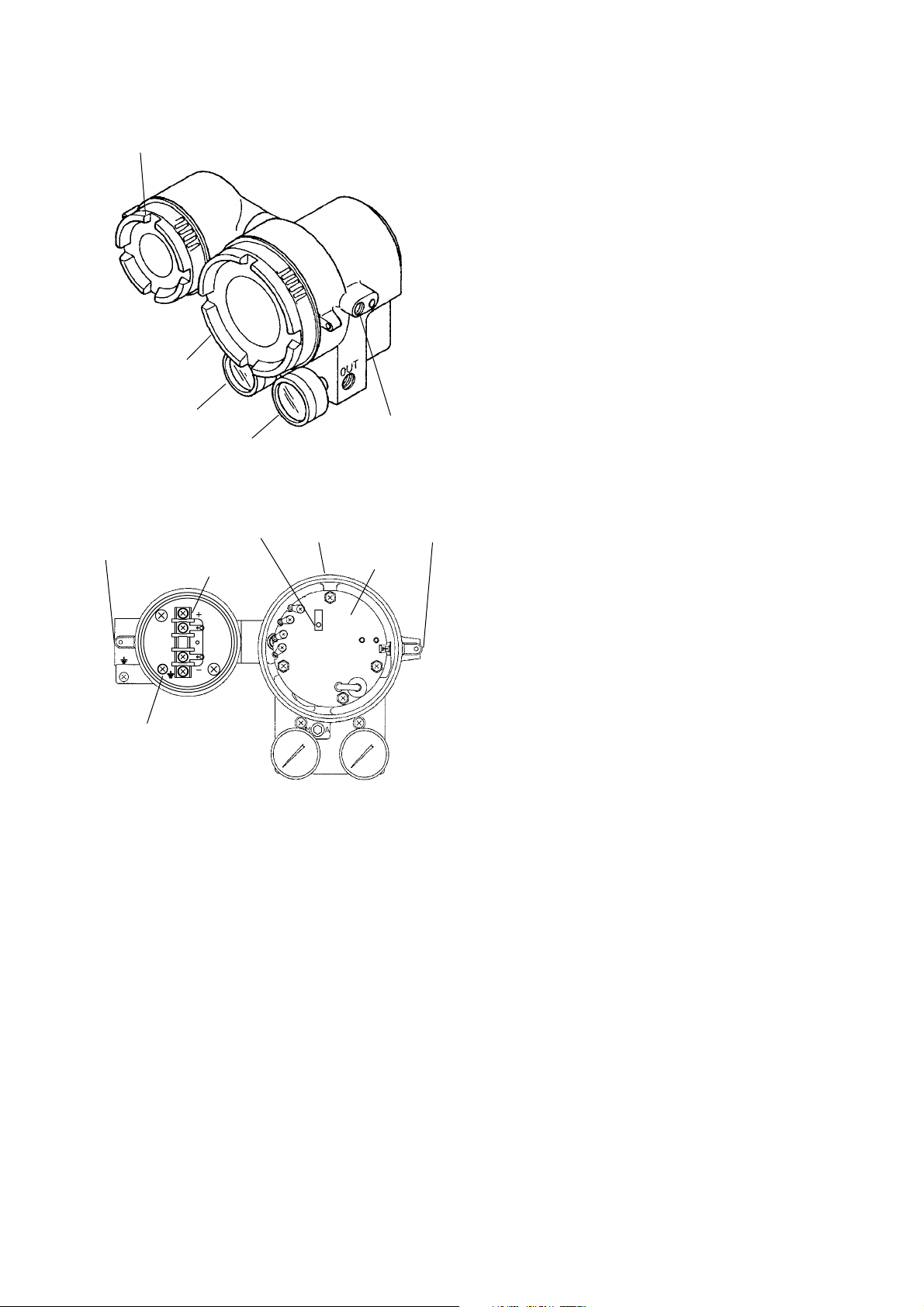

2.6 Part Names

Terminal box cover

Converter cover

2. OVERVIEW

Supply gauge

Output gauge

Figure 2.3 Part Names (1)

Span adjustment

Electrical connection

Te rminal board

Ground terminal

Figure 2.4 Part Names (2)

Case

Zero adjustment

F0203.EPS

Zero adjustment

Amplifier

F0204.EPS

2-4

IM 21B03D01-01E

Page 14

3. INSTALLATION

3. INSTALLATION

3.1 Overview

When installing the PK200 converter, see section 1.4

“Precautions for Installation Area.” For the ambient

environmental conditions of an installation place, see

section 2.2 “Standard Specifications.”

3.2 Installation

PK200 can be installed on a pipe using a mounting

bracket provided or directly installed on the wall.

Select either method, taking into account the installation space and service method.

3.2.1 Pipe Mounting

When this instrument is mounted on a pipe, use the

mounting bracket and U-bolt provided. The pipe dia.

available is 50mm (2-INCH) and the instrument can be

installed on either a horizontal or vertical pipe.

3.2.2 Wall Mounting

When the instrument is installed on the wall, use the

two M8 screws provided.

PK200

Figure 3.2 Wall Mounting

F0302.EPS

Figure 3.1 Pipe Mounting

PK200

Pipe

Mounting bracket

F0301.EPS

3-1

IM 21B03D01-01E

Page 15

4. WIRING AND PIPING

IMPORTANT

4. WIRING AND PIPING

4.1 Piping

4.1.1 Supply Air

For easy operation and maintenance, supply air must

be clean and dry.

Thoroughly study selection of an air supply

system, supply air suction point, installation of

the header, and air supply piping so that no

water, oil, or dust is carried into the current-topneumatic converter via the piping.

Table 4.1 shows the air supply pressure for this

instrument.

For air consumption, see the standard specifications.

Table 4.1 Recommended Supply Air Pressure

Output Signal Code Output Signal Supply Air Pressure

1 20 to 100kPa 130 to 150kPa

2 40 to 200kPa 230 to 260kPa

3 0.2 to 1.0kgf/cm

4 0.4 to 2.0kgf/cm

5 0.2 to 1.0bar 1.3 to 1.5bar

6 0.4 to 2.0bar 2.3 to 2.6bar

73 to 15psi 19 to 22psi

86 to 30psi 34 to 37psi

93 to 27psi 34 to 36psi

2

1.3 to 1.5kgf/cm

2

2.3 to 2.6kgf/cm

T0401.EPS

4.1.3 Output Piping

Connect output air piping to the output connection

of the converter.

OUT

Generally, use copper tubes of 6mm O.D. and 4mm

I.D., air piping, and coupling to install output air

piping. After installing the piping, check for leakage.

4.2 General-Use and Flameproof Type Wiring

4.2.1 Cable Selection

(1) Use twisted wires or cables with performance

equal to or better than that of 600V vinyl-insulated

cables (JIS C 3307) for wiring cables.

(2) Use shielded cables for wiring in a place suscep-

tible to noise influence.

(3) For wiring in an area where high or low ambient

temperatures exist, use wires or cables that meet

service environment requirements.

2

2

IMPORTANT

If the PK200 is flameproof and the ambient

temperature is 50°C or more, use an external

cable having a maximum allowable heat resistance of at least 70°C in consideration of the

instrument’s generation of heat or the cable’s

self-heating.

4.1.2 Air Supply Piping

Connect air supply piping to the supply pressure

connection

Generally, use copper tubes of 6mm O.D. and 4mm

I.D., air piping, and coupling to install air supply

piping. After installing the piping, check for leakage.

of the converter.

SUP

(4) For use in an atmosphere where harmful gas,

liquid, oil, or solvent exists, use wires or cables

with materials sufficiently durable to such substances.

4-1

IM 21B03D01-01E

Page 16

4.2.2 Wiring

(1) Install wiring away from noise sources such as a

large capacity transformer, motor, or power supply.

(2) Remove terminal box cover and wiring connection

dustproof plugs, then connect wiring.

Using an Allen wrench (width 3mm), unscrew the

locking setscrew and remove the flameproof cover.

Then, connect the wiring and when installing the

cover, do not neglect to fasten shrouding metal.

(3) It is recommended that clip-on terminals R1.25-5

or R2-5 be used for wiring termination (JIS C

2805).

(4) It is also recommended that wiring be installed in

conduits and ducts to provide protection against

water or external damage. For flameproof external

wiring, see 1.6 Installation of Flameproof Type”

and “INSTALLATION AND OPERATING

PRECAUTIONS FOR TIIS FLAMEPROOF

EQUIPMENT” at the end of this manual.

(5) When installing a flameproof gland packing

adapter (option code: /G11 and /G21) for cable

wiring, observe the following steps.

a. Release the shrouding metal and remove the

terminal box cover.

b.Measure the outside dia. of the cables to be used

in two directions in 0.1mm unit.

c. Obtain the average value of the measured values

in two directions and select a gland packing

whose inner dia. is nearest to the average value

from among those in Table 4.1.

d.Screw the flameproof packing adapter into the

terminal box until the O-ring touches the

terminal box wiring port (at least 6 full turns),

and tighten the lock nut.

e. Insert the cable through the union cover, the

union coupling, the clamp nut, the clamp ring,

the gland, one washer, the rubber packing, and

the packing box, in that order.

f. Insert the end of the cable into the terminal box.

g.Tighten the gland to grip the cable. When

tightening the union cover, tighten approximately

one turn past the point where the cable will no

longer move up and down.

Proper tightening is important. If it is too tight, a

circuit break in the cable may occur; if not tight

enough, the flameproof effectiveness will be

compromised.

4. WIRING AND PIPING

CAUTION

Tighten the gland approximately one turn after

the point where you can no longer shift the cable

up and down by hand.

Take great care in this step, since proper

tightening is very important.

h.Fasten the cable with tightening the clamp nut.

i. Tighten the lock nut on the union cover.

j. Connect the cable wires to each terminal.

Table 4.2 Type of Packing and Applicable Cable O.D.

Wiring port

thread diameter

G1 / 2 8-10 16 8-10 G9601AM

G3 / 4 10-12 22 10-12 G9601AN

Appropriate

cable outer

diameter (mm)

10.1-12 16 10-12

12.1-14 22 12-14

14.1-16 22 14-16

Identifying

mark

Part Number

T0402.EPS

(6) Install a sealing fitting (option) to be used for

metal conduit lines, in the following order.

a. Assemble a sealing fitting into the instrument.

Apply sealing compound to the nipple provided

and screw in the nipple by seven to eight turns,

then fix it with a lock nut.

b.Install wiring using insulated wires and provide a

compound filling chamber of inorganic material

by using sealing dams. (See Figure 4.5.)

c. Fill sealing compound from the compound filling

port until the fitting is filled with the compound.

Example of sealing compound

Shimada Electric (1kg can)

For FG5: Approx. 100g/P. filling

For FG6: Approx. 115g/P. filling

d.After the compound has been sufficiently

softened, screw the plug into the filling port.

e. Connect a metal conduit for piping (JIS C 8305)

or explosion-proof flexible fitting to the sealing

fitting by engaging five or more threads.

f. For the details of sealing, see 3.3.2.3 in the

“Recommended Practice of Explosion-Protected

Electrical Installations in General Industries”

published by the Industrial Safety Institute,

Ministry of Labor (Japan).

4-2

IM 21B03D01-01E

Page 17

Figure 4.1 General-Use and Flameproof Type Wiring

4. WIRING AND PIPING

Figure 4.2 Flameproof Metal Conduit Wiring

Figure 4.3 Flameproof Gland Packing Installation (Option code: /G11 and /G21)

4-3

IM 21B03D01-01E

Page 18

4.2.3 Grounding

(1) Provide grounding with a ground resistance of

100Ω.

(2) Grounding terminals are provided inside and

outside of the terminal box. Use either terminal.

(3) Use 600V PVC insulated wire for grounding

wiring.

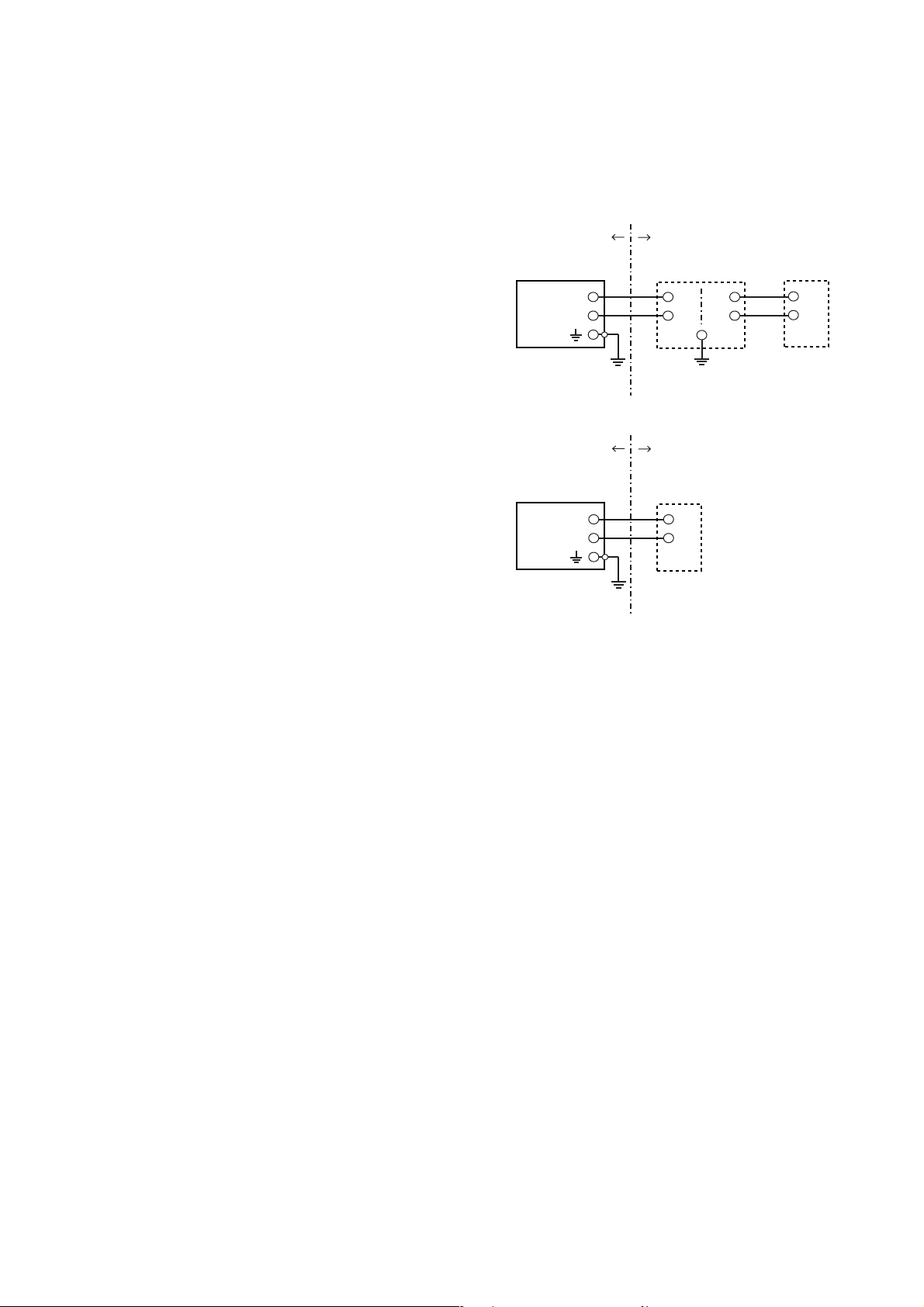

4.3 Intrinsically Safe Type Wiring

The wiring of the intrinsically safe circuit between the

converter and the safety barrier must be kept routed

with sufficient physical separation from other circuits

so as not to be affected by electromagnetic induction,

etc., and should be implemented using metallic conduit

or shielded cable.

Current signal

Figure 4.4 Wiring

4. WIRING AND PIPING

⫹

⫺

G

Ground

F0404.EPS

Figure 4.5 Intrinsically Safe Type Wiring

4-4

IM 21B03D01-01E

Page 19

5. OPERATION

5. OPERATION

5.1 Auto/Manual (A/M) Transfer Mechanism

Please refer to following instruction for the model with

A/M selector switch (optional code: /AM).

For the model without A/M selector switch, please go

to section 5.2.

Use of A/M transfer mechanism requires that a supply

pressure adjusting reducing valve be installed.

(1) Set the A/M selector switch provided at the front

(on the supply air pressure gauge side) of the

converter to “M.” (Turn the switch clockwise.)

(2) This allows supply air pressure to be output, which

is supplied to the control valve.

(3) Output air pressure can be regulated using the

pressure regulator. Because the output pressure is

not same as supply pressure, it is necessary to

adjust it watching an output pressure gauge

attached to this instrument. Pressure gauge minimum unit is 10kPa (standard output type) or 20kPa

(doubled output type).

5.2 Zero Point Adjustment

(1) For the model with A/M selector switch, please set

the A/M selector switch to A (Auto). (Turn the

switch counterclockwise.)

(2) Apply supply air pressure to the current-to-

pneumatic converter.

For supply air pressure, see the data plate or Table

5.1 “Supply Air Pressure.”

Standard output applies for model suffix output

signal code “1, 3, 5, 7” and multiplied pressure

output for model suffix output signal code “2, 4, 6,

8, 9.”

Table 5.1 Recommended Supply Air Pressure

Output Signal Code Output Signal Supply Air Pressure

1 20 to 100kPa 130 to 150kPa

2 40 to 200kPa 230 to 260kPa

30.2 to 1.0kgf/cm

40.4 to 2.0kgf/cm22.3 to 2.6kgf/cm

50.2 to 1.0bar 1.3 to 1.5bar

60.4 to 2.0bar 2.3 to 2.6bar

73 to 15psi 19 to 22psi

86 to 30psi 34 to 37psi

93 to 27psi 34 to 36psi

2

1.3 to 1.5kgf/cm

2

2

T0501.EPS

A/M selector switch

Figure 5.1 Auto/Manual Transfer Mechanism

F0501.EPS

(3) Then input an input signal.

Input a 0% electric signal.

Apply 4mA for 4 to 20mA input or 10mA for 10

to 50mA input.

(4) Make zero point adjustment so that the output air

pressure reaches the specified pressure.

For output air pressure, see the data plate or Table

5.2 “Output Signals.”

To increase output air pressure, turn the zero

adjustment clockwise. To decrease the pressure,

turn the zero adjustment counterclockwise. (See

Figure 5.2.)

For the model with reverse action (/RA), please

turn zero adjustment counterclockwise to increase

output air pressure. To decrease output air pressure, please turn zero adjustment clockwise.

5-1

IM 21B03D01-01E

Page 20

5. OPERATION

<Example: 20 to 100Pa output signal for 4 to

20mA input signal>

Adjust the zero adjustment so that an output signal of

20kPa is obtained when a 4mA input signal is applied.

Table 5.2 Output Signals

Output Signal Code Output Signal

1 20 to 100kPa

2 40 to 200kPa

3 0.2 to 1.0kgf/cm

4 0.4 to 2.0kgf/cm

5 0.2 to 1.0bar

6 0.4 to 2.0bar

73 to 15psi

86 to 30psi

93 to 27psi

2

2

T0502.EPS

5.3 Calibration

CAUTION

Always perform calibration in a non-hazardous

area.

(1) For the model with A/M selector switch, please set

the A/M selector switch to A (Auto). (Turn the

switch counterclockwise.)

(2) Remove the converter cover.

WARNING

For flameproof specifications or intrinsically safe

explosion-proof specifications, first conduct a gas

detector check to confirm that there is no explosive gas in the area.

Table 5.3 Recommended Supply Air Pressure

Output Signal Code Output Signal Supply Air Pressure

1 20 to 100kPa 130 to 150kPa

2 40 to 200kPa 230 to 260kPa

30.2 to 1.0kgf/cm

40.4 to 2.0kgf/cm22.3 to 2.6kgf/cm

50.2 to 1.0bar 1.3 to 1.5bar

60.4 to 2.0bar 2.3 to 2.6bar

73 to 15psi 19 to 22psi

86 to 30psi 34 to 37psi

93 to 27psi 34 to 36psi

2

1.3 to 1.5kgf/cm

(4) Then input a 0% input signal.

Apply 4 mA for 4 to 20mA input or 10mA for 10

to 50mA input.

Control the zero adjustment so that the output air

pressure reaches the specified pressure.

For 0% output air pressure, see the data plate or

Table 5.4 “Output Signals.”

To increase output air pressure, turn the zero

adjustment clockwise. To decrease the pressure,

turn the zero adjustment counterclockwise.

For the model with reverse action (/RA), please

turn zero adjustment counterclockwise to increase

output air pressure. To decrease output air pressure, please turn zero adjustment clockwise.

Table 5.4 Output Signals

Output Signal Code Output Signal

1 20 to 100kPa

2 40 to 200kPa

3 0.2 to 1.0kgf/cm

4 0.4 to 2.0kgf/cm

5 0.2 to 1.0bar

6 0.4 to 2.0bar

73 to 15psi

86 to 30psi

93 to 27psi

2

2

2

2

T0503.EPS

T0504.EPS

(3) Apply supply air pressure to the current-to-

pneumatic converter.

For supply air pressure, see the data plate or Table

5.3 “Supply Air Pressure.”

Standard output applies for model suffix output

signal code “1, 3, 5, 7” and multiplied pressure

output for model suffix output signal code “2, 4, 6,

8, 9.”

(5) Input a 100% input signal.

Apply 20mA for 4 to 20mA input or 50mA for 10

to 50mA input.

Control the zero adjustment so that the output air

pressure reaches a specified pressure.

For 100% output air pressure, see the data plate or

Table 5.2 “Output Signals.” (See Figure 5.3.)

To increase output air pressure, please turn span

adjustment clockwise. To decrease output air

pressure, please turn span adjustment counterclockwise. (See Figure 5.3.)

5-2

IM 21B03D01-01E

Page 21

5. OPERATION

For the model with reverse action (/RA), please

turn span adjustment counterclockwise to increase

output air pressure. To decrease output pressure,

please turn span adjustment clockwise.

Zero adjustment

Figure 5.2 Zero Point Adjustment Mechanism

(6) Input a 0% input signal.

Confirm if 0% output air pressure reaches the

specified pressure. If not, make zero point adjustment.

(7) Input a 100% input signal

Confirm if 100% output air pressure reaches the

specified pressure. If not, make span adjustment.

(8) Repeat steps (6) and (7) two to three times to

adjust the zero point and span.

Table 5.5 Input and Output Signals

Input Current of the model with / RA is shown in ( ).

Input

Output

Signal

4 to 20mA 4mA 8mA 12mA 16mA 20mA

10 to 50mA 10mA 20mA 30mA 40mA 50mA

Output Signal 0% 25% 50% 75% 100%

1 20kPa 40kPa 60kPa 80kPa 100kPa

2 40kPa 80kPa 120kPa 160kPa 200kPa

30.2kgf/cm

40.4kgf/cm20.8kgf/cm21.2kgf/cm

50.2bar 0.4bar 0.6bar 0.8bar 1.0bar

60.4bar 0.8bar 1.2bar 1.6bar 2.0bar

7 3psi 6psi 9psi 12psi 15psi

8 6psi 12psi 18psi 24psi 30psi

9 3psi 9psi 15psi 21psi 27psi

(20mA) (16mA) (12mA) (8mA) (4mA)

(50mA) (40mA) (30mA) (20mA) (10mA)

2

0.4kgf/cm20.6kgf/cm

F0502.EPS

(9) After completing adjustments, change the input

signal to 0%, 25%, 50%, 75%, and 100% and

confirm if the specified output is reached at the

relevant input.

Confirm the accuracy with reference to the input

and output signal reference values given in Table

5.5 “Input and Output Signals.”

Span adjustment

Zero adjustment

F0503.EPS

Figure 5.3 Span Adjustment Mechanism

<Example: For 20 to 100 kPa output signal at 4

to 20 mA input signal>

Calibrate the input and output signals with reference to

Table 5.6. Accuracy should be within ±0.5% of span.

Table 5.6 Input and Output Signals

Input Signal Output Signal

0% 4mA 20kPa

25% 8mA 40kPa

50% 12mA 60kPa

75% 16mA 80kPa

100% 20mA 100kPa

2

0.8kgf/cm21.0kgf/cm

2

1.6kgf/cm22.0kgf/cm

2

2

T0505.EPS

T0506.EPS

5-3

IM 21B03D01-01E

Page 22

5.4 Range Adjustment

Perform the following to change to an output signal

other than those specified in Table 5.4 “Output

Signals.”

Zero point adjustable range is ±10% of span and the

span adjustable range is from 100 to 125%.

An output signal can be flexibly regulated within these

ranges using the zero and span adjustments.

Table 5.7 Zero and Span Adjustable Ranges

5. OPERATION

Output Signal Code

1 12 to 28kPa 80 to 100kPa

*1

2

3 0.12 to 0.28kgf/cm20.8 to 1.0kgf/cm

*2

4

5 0.12 to 0.28bar 0.8 to 1.0bar

*3

6

7 1.8 to 4.2psi 12 to 15psi

*4

8

*5

9

*1 Please set the supply air pressure at the maximum working

pressure plus 30 to 60kPa.

*2 Please set the supply air pressure at the maximum working

pressure plus 0.3 to 0.6kgf/cm

*3 Please set the supply air pressure at the maximum working

pressure plus 0.3 to 0.6bar.

*4 Please set the supply air pressure at the maximum working

pressure plus 4 to 7psi.

*5 Please set the supply air pressure at the maximum working

pressure plus 7 to 9psi.

Zero Adjustable Range

24 to 56kPa 160 to 200kPa

0.24 to 0.56kgf/cm21.6 to 2.0kgf/cm

0.24 to 0.56bar 1.6 to 2.0bar

3.6 to 8.4psi 24 to 30psi

0.6 to 5.4psi 24 to 30psi

2

.

Span Adjustable Range

2

2

T0507.EPS

5.5 4 to 20mA/10 to 50mA Selection

Figure 5.4 4 to 20mA/10 to 50mA Selection

Take the following steps to select an input signal by

using 4 to 20mA/10 to 50mA selecting function.

4 to 20mA or 10 to 50mA can be selected by changing

the SOCKET switch on the amplifier shown in Figure

5.4. (Input signal is calibrated at 4 to 20mA at the time

of delivery.)

For 4 to 20mA input, insert the SOCKET switch to the

two right pins. For 10 to 50mA input, insert the

SOCKET switch to the two left pins.

NOTE

Before switching the SOCKET switch, always cut

off the input signal.

5-4

IM 21B03D01-01E

Page 23

6. MAINTENANCE

6. MAINTENANCE

6.1 Overview

The PK200 converter components are structured as

units to allow easy maintenance.

This chapter describes cleaning of each component and

part replacement to be conducted for PK200 maintenance.

This converter is a high-precision instrument and thus,

read the following description carefully before performing maintenance.

For maintenance, also see the operation items in

Chapter 5.

CAUTION

Cautions for intrinsically safe apparatus

Intrinsically safe apparatus shall be repaired by

the manufacturer.

Cautions for flameproof type instruments

(a) Flameproof type instruments must be, as a

rule, removed to a non-hazardous area for

maintenance and be disassembled and

reassembled to the original state. For details,

see “Installation and Operating Precautions

for TIIS Flameproof Equipment” later in this

manual.

(b) On the flameproof type instruments the cover

is locked by a setscrew. When a setscrew is

driven clockwise by an Allen wrench, it is

going in and cover lock is released, and then

the cover can be opened. When a cover is

closed it should be locked by a setscrew

without fail.

6.2 Periodic Inspection

6.2.1 Cleaning the Restrictor

Remove the restrictor shown in Figure 6.1 using a

screw driver and thread a wire with 0.3mm dia. into

the restrictor for cleaning.

Figure 6.1 Restrictor Removal

Figure 6.2 Cleaning the Restrictor

6.3 Parts Replacement

6.3.1 Replacing the Screen Filter

If the mesh filter located at the rear of the supply

pressure connection and output air pressure connection

is clogged, use a sharp-edged tool such as tweezers to

remove the filter and replace it with a new one.

Periodic inspection is required for maintaining normal

plant operations. During periodic inspection, pay

special attention to the following.

(1) Is the appearance normal?

(2) Is there pressure leakage from the converter or its

peripheral piping?

(3) Is drainage present, or is there adhesion of dust or

oil, in the air supply system?

Periodically clean the restrictor and nozzle flapper,

which are easily subject to contamination. The

following describes their cleaning.

Figure 6.3 Removing the Screen Filter (OUT Side)

6-1

Screen filter

F0603.EPS

IM 21B03D01-01E

Page 24

Screen filter

F0604.EPS

6. MAINTENANCE

6.3.3 Replacing the Amplifier Assembly

An amplifier for replacement comes with a tube and

four set screws.

Removing the Amplifier

(1) Turn off the power and set the air supply pressure

to zero.

(2) Turn the amplifier cover counterclockwise to

remove it.

Figure 6.4 Removing the Screen Filter (IN Side)

6.3.2 Replacing the Controller Relay

(1) Set the air supply pressure to zero.

(2) Remove the controller relay from the bottom of the

converter.

Unscrew the two mounting screws on the lower

front face of the converter main body (see Figure

6.5) using a Phillips screwdriver. The relay can be

removed downward.

(3) When installing a new relay, attach the relay to the

bottom of the converter, then fasten the relay using

the two mounting screws at the front face of the

converter.

(3) Adjust the zero adjustment control to the position

indicated in Figure 6.6.

Zero adjustment screw

Zero adjustment

Closeup of zero adjustment

Figure 6.6 Zero Adjustment

F0606.EPS

(4) Remove the silicon tube (a) from the pressure

sensor on the amplifier.

Figure 6.5 Removing the Control Relay

Control relay

F0605.EPS

(5) Remove the four set screws (b) for fixing wires on

the amplifier and then disconnect the wires.

(6) Remove the four set screws (c) for fixing the

amplifier.

(c)

(b)

(b)

(b)

(b)

(c)

Figure 6.7 Pressure Sensor and Amplifier Set Screws

6-2

(a) (a)

(c)

F0607.EPS

IM 21B03D01-01E

(c)

Page 25

6. MAINTENANCE

(7) Pull out the amplifier directly, taking care not to

bend the zero adjustment control.

(8) Remove the silicon tube left in the case.

Mounting the Amplifier

(1) Insert the accessory silicon tube into the body cap

firmly.

Tube pin on case

F0608.EPS

Figure 6.8 Silicon Tube Case Cap

NOTE

1.Do not apply undue pressure to the pressure

sensor.

2.Do not bend the zero adjustment volume knob

to prevent it from contacting the zero adjustment set screw.

(4) Fasten the four set screws for fixing the amplifier

(see Figure 6.7).

(5) Connect the four wires in the order of yellow

(ACT+), white (ACT-), red (IN+) and black (IN-).

(6) Insert the silicon tube into the amplifier pressure

sensor firmly.

Silicon tube

CAUTION

Be sure to use the accessory silicon tube that

comes with the amplifier for replacement. Note

that the tube size varies depending on the

amplifier to be used. Be sure to use the proper

tube to prevent air leakage and precision deterioration.

(2) Adjust the angle so that the volume knob of zero

adjustment forms a right angle with the amplifier.

Volume Knob of zero point adjustment

Figure 6.9 Zero Adjustment Control

F0609.EPS

(3) Pass the silicon tube through an amplifier hole and

mount the amplifier directly so that the sleeve of

the pressure sensor leads into the hole of the case.

Pressure sensor

Figure 6.10 Pressure Sensor and Silicon Tube

F0610.EPS

(7) In a model allowing 4-20/10-50mA selection, refer

to 5.5 to set the socket switch as necessary.

(8) Mount the amplifier cover.

Inspection after Amplifier Replacement

After replacing the amplifier, perform the insulation

resistance test and withstand voltage test. Be sure to

perform them according to the following procedure,

referring to the corresponding tester instruction

manuals.

CAUTION

(1) Overvoltage of the test voltage that is so

small that it does not cause an dielectric

breakdown may in fact deteriorate insulation

and lower the safety performance; to prevent

this it is recommended that the amount of

testing be kept to a minimum.

(2) The voltage for the insulation resistance test

must be 500V DC or lower, and the voltage

for the withstand voltage test must be 500V

AC or lower. Failure to heed these guidelines

may cause faulty operation.

6-3

IM 21B03D01-01E

Page 26

(3) Where a built-in arrester is provided (suffix

code: /A), the voltage for the insulation

resistance test must be 100V DC or lower,

and the voltage for the withstand voltage test

must be 100V AC or lower. Failure to heed

these guidelines may cause faulty operation.

Follow the steps below to perform the test, the wiring

of the communication line must be removed before

initiating testing.

Insulation resistance test procedure

1. Lay transition wiring between the + terminal and the

- terminal.

2. Connect the insulation resistance meter (with the

power turned OFF) between the transition wiring of

Step 1 above and ground terminal. The polarity of

the input terminals must be positive and that of the

ground must be negative.

3. Turn the power of the insulation resistance meter

ON and measure the insulation resistance. The

duration of the applied voltage must be the period

during which 100 MΩ or more is confirmed (or 20

MΩ if the unit is equipped with a built-in arrester).

4. Upon completion of the test, remove the insulation

resistance meter, connect a 100 kΩ resistor between

the transition wiring, and allow the electricity to

discharge. Do not touch the terminal with your bare

hands while the electricity is discharging for more

than one second.

6. MAINTENANCE

Withstand voltage test procedure

Testing between the input terminals and the grounding

terminal

1. Lay the transition wiring between the + terminal and

the - terminal, and connect the withstand voltage

tester (with the power turned OFF) between the

transition wiring and the grounding terminal.

Connect the grounding side of the withstand voltage

tester to the grounding terminal.

2. After setting the current limit value of the withstand

voltage tester to 10 mA, turn the power ON, and

gradually increase the impressed voltage from 0 V

to the specified value.

3. The voltage at the specified value must remain for a

duration of one minute.

4. Upon completion of the test, carefully reduce the

voltage so that no voltage surge occurs.

6-4

IM 21B03D01-01E

Page 27

7. TROUBLESHOOTING

7. TROUBLESHOOTING

7.1 Overview

If the PK200 converter does not operate normally,

check the condition carefully and solve any problem in

accordance with section 7.3 Troubleshooting Flow.

If problem appears difficult to correct, consult

YOKOGAWA service personnel.

7.2 Operation Principle

The PK200 current-to-pneumatic converter accepts a 4

to 20mA or 10 to 50mA current signal from an

electronic controller as an operating signal. This signal

is input to a torque motor via an electric circuit,

generating a torque proportional to the current signal.

An increase in the input signal causes the flapper at the

end of the torque motor moving piece to move in the

nozzle closing direction. When the nozzle is closed,

back pressure increases, displacing the input diaphragm

inside the control relay. This causes the control relay

output air pressure to increase.

This output air pressure is output as PK200 converter

output pressure and is also input to a feedback pressure

sensor. The sensor then converts the pressure input into

an electric signal, which is fed back to the electric

circuit. The signal is then compared with the manipulated output signal, the result of which activates

modification action until an output air pressure

balanced with the input signal is obtained.

In this way, an output air pressure proportional to the

input signal, which is a manipulated output signal, is

obtained.

Voltage

4 to 20mA

input

Figure 7.1 PK200 Current-to-Pneumatic Converter Operation Principle Diagram

+

–

Torque

motor

Voltage

Nozzle

Position Air

flapper

pressure

Pressure

sensor

Pilot relay

Air

pressure

20 to 100 kPa

Output

F0701.EPS

7-1

IM 21B03D01-01E

Page 28

7. TROUBLESHOOTING

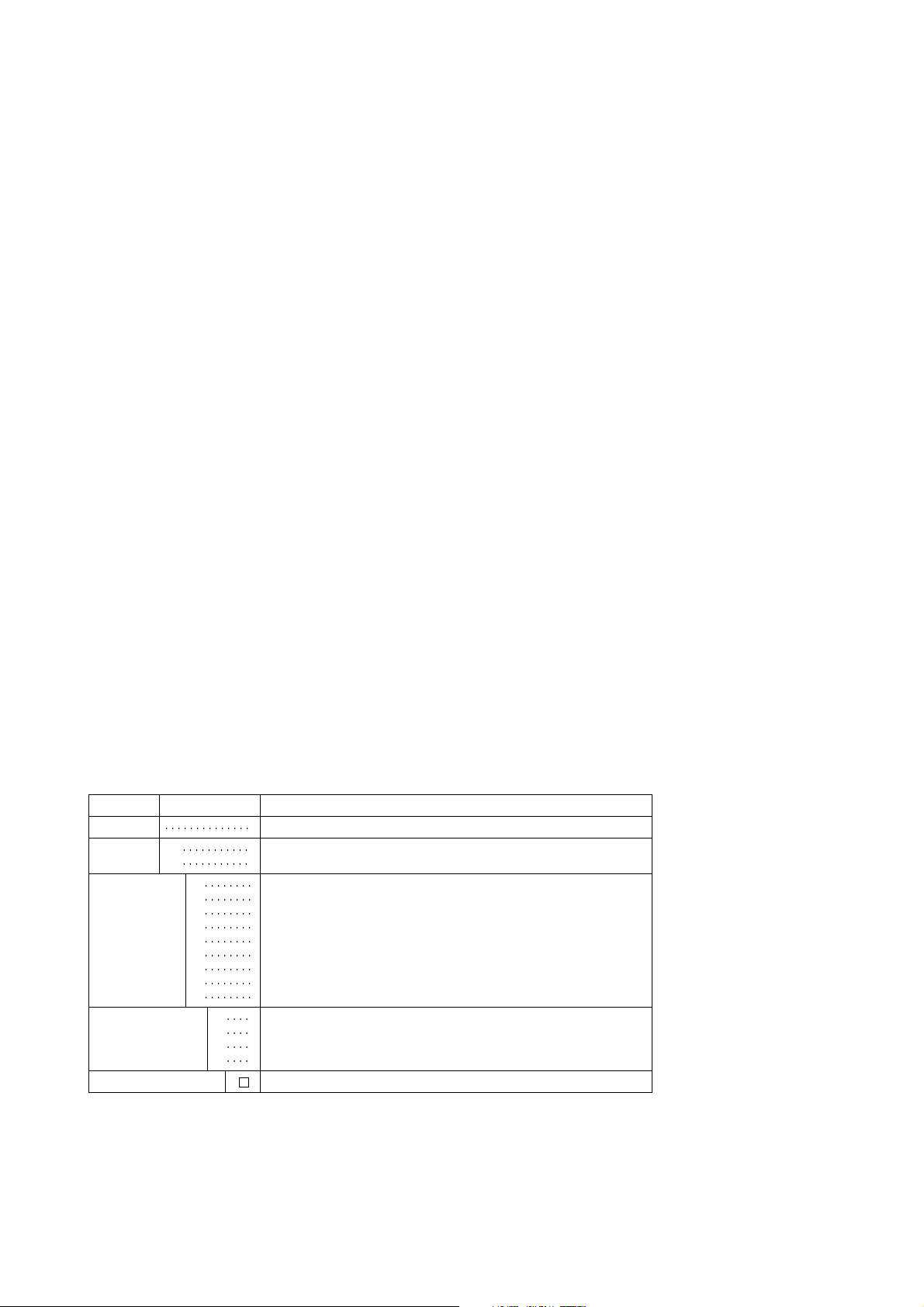

7.3 Troubleshooting Flow

The PK200 current-to-pneumatic converter causes

relatively few problems as long as it is used correctly.

However, inadequate preparation such as in mounting

or service conditions may result in a problem.

If the converter does not operate normally, take correct

measures by following the flow chart below. Some

problems include a complex cause which may not be

uncovered by the following flow chart. If a problem

appears difficult to correct, contact our service personnel.

Large output error.

Is air

supplied at normal supply

pressure?

YES

Supply air at normal supply pressure.

NO

The converter does not operate even when

input signal is applied.

supplied at normal supply

Is air

pressure?

YES

Is A / M selector switch

set to A?

YES

Is the restrictor clogged?

NO

Supply air at normal supply pressure.

Select “A.”

Clean the restrictor.

NO

NO

YES

Is the

converter installed

in a place subject to large

temperature changes?

NO

Is control relay defective?

NO

Replace the converter using a spare.

Provide heat protection or good

ventilation.

Replace the control relay.

YES

YES

F0702.EPS

Is control relay defective?

NO

Replace the converter using a spare.

Replace the control relay.

YES

F0703.EPS

7-2

IM 21B03D01-01E

Page 29

Appendix A. AIR SUPPLY SYSTEM

Appendix A. AIR SUPPLY SYSTEM

1. Overview

Pneumatic industrial instruments are one of the most

maintenance-free, highly reliable industrial instrument

systems and are in wide use. Such features are fully

demonstrated only when suitable service conditions

where the characteristics of pneumatic instruments are

sufficiently taken into account are established.

One of such service conditions includes an air supply

system. Pneumatic instruments require clean, dry air

and thus, an aftercooler, filter, and air drier are

installed after a compressor to prevent water, oil, and

other contaminants from entering into the instruments.

Also, care should be exercised as described below at

service points.

Air supply pipe for

instrument

Shut-off value

Pressure gauge

2. Air Supply System

(1) Example of Panel-Mounting Instrument

When air is to be supplied to multiple instruments it is

recommended that two reducing valves are used in

parallel as shown in Figure 1. Parallel arrangement

protects instruments from interference even if one

reducing valve is suspended due to clogging. Also, use

of a three-way cock as shown in Figure 1 allows any

of air supply systems to be separated for maintenance.

Generally, both air supply systems are used in parallel

for operation. To supply clean and dry air to instruments, considerations should be made, such as provision of water drain, filter, and downward pitch (1/100

or more) for piping.

Regulator

Slope approximately 10 mm

per meter length (1/100)

Drain valve

Figure 1 Example of Air Supply System (for Panel-Mounting Instrument)

Clean dry air

supply

3-way cock

Air filter

High

pressure

air

supply

F0A01.EPS

A-1

IM 21B03D01-01E

Page 30

Appendix A. AIR SUPPLY SYSTEM

(2) Example for Field-Mounting Instru-

ments

Figure 2 shows an air-supply system for service point

with respect to field-mounting instruments (individually installed instruments).

Securely install a filter and reducing valve in air supply

piping that is nearest to an instrument. (These devices

are not required if the instrument has a filter and

reducing valve.)

Also, it is recommended that a shut-off valve be

installed in the air supply pipe to allow removal of

individual instruments without cutting off the entire air

supply system.

Air supply pipe

Air header pipe

Samp

Unregulated air supply

It is recommended that an air supply pipe be

provided with a shut-off valve so that individual

instruments can be removed.

• Air Filter

A filter removes moisture, oil, and other contaminants that cannot be removed by the main air supply

system. In general a cock installed at the bottom of

a filter is opened to discharge moisture, oil, and

other contaminants. If the amount of moisture and

oil is large, increase the number of draining times.

The above-noted methods and units are an example and

there are other various methods and units. Use a

method and units suitable for the process type to

supply clean, dry air to instruments.

Supply Regulator

To instrument

Air filter

Figure 2 Example of Air Supply System (for Field-

Mounting Instruments)

Shut-off valve

F0A02.EPS

(3) Air supply System for Field-Mounted

Instruments

• Supply Air

Clean, dry air is required. An aftercooler, filter, air

drier are used to eliminate water, oil, and other

contaminants.

• Air Supply Header (Air Header)

The air header that supplies air to a series of

instruments is installed with a minimum downward

pitch of 10 mm/m (1/100) so that moisture and oil

entrapped in the header can be discharged.

• Air Supply Piping

An air supply pipe connected to an instrument is

branched from the upper part of an air header to

prevent moisture entry. Even if this is not possible,

an air supply pipe should be branched from the side

of the air header, i.e., it must not be branched from

the bottom part of the header.

A-2

IM 21B03D01-01E

Page 31

INSTALLATION AND OPERATING PRECAUTIONS FOR TIIS INTRINSICALLY SAFE EQUIPMENT

INSTALLATION AND OPERATING PRECAUTIONS FOR

TIIS INTRINSICALLY SAFE EQUIPMENT

Apparatus Certified Under Technical Criteria (IEC-compatible Standards)

and from “RECOMMENDED PRACTICES for Explosion-Protected Electrical Installations in General Industries,” published in 1979

1. General

The following describes precautions on electrical apparatus

of intrinsically safe construction (hereinafter referred to as

intrinsically safe apparatus).

Following the Labor Safety and Health Laws of Japan, an

intrinsically safe apparatus must undergo type tests in order

to be certified by the Technical Institute of Industrial Safety,

Inc. These tests are required to satisfy either the technical

criteria for electrical machinery and equipment in compliance

with explosionproof standards involving inflammable gases

or vapors and for machinery and equipment having

explosionproof performance (standards notification no. 556

from the Japanese Ministry of Labor) (hereinafter referred to

as technical criteria), in conformity with IEC Standards, or

the “Recommended Practice for Explosion-Protected

Electrical Installations in General Industries,” published in

1979. Such a certified apparatus can be used in hazardous

locations where inflammable gases or vapors may be present.

Certified apparatus includes a certification label and an

equipment nameplate with the specifications necessary for

explosion requirements as well as precautions on explosion

protection. Please confirm these precautionary items and use

them to meet specification requirements.

For electrical wiring and maintenance servicing, please refer

to “Internal Wiring Rules” in the Electrical Installation

Technical Standards as well as “USER’S GUIDELINES for

Electrical Installations for Explosive Gas Atmospheres in

General Industry,” published in 1994.

To meet intrinsically safe requirements, equipment that can

be termed an “intrinsically safe apparatus” must:

(1) be certified by the Technical Institute of Industrial

Safety, Inc. in accordance with the Labor Safety and

Health Laws of Japan and have the appropriate mark of

certification labeled on its case, and

(2) be used in compliance with the specifications marked on

its certification label, equipment nameplate and

precautionary information furnished.

Note: Intrinsically safe apparatus satisfy their performance under

specific conditions. They are not always absolutely safe under

every operational and environmental condition. In other

words, they are not safe products involved with factors such

as chemical reactions, geographical changes or the like other

than affected by electric energy from the equipment itself.

2. Electrical Apparatus of Intrinsic

Safety Type of Explosion-Protected Construction

The intrinsic safety type of explosion-protected construction

is a method of protection applicable to a circuit or part of a

circuit in which, under prescribed test conditions, no spark or

thermal effect, whether produced normally or accidentally, is

capable of causing a prescribed explosive gas to ignite. In

other words, electrical apparatus of this construction is

intended to suppress electrical energy thereby preventing

ignition of a given explosive gas atmosphere even though

spark or high thermal effect occurs in the electric circuitry.

Intrinsically safe electrical apparatus generally comprise

intrinsically safe apparatus installed in a hazardous location

and a safety barrier (associated apparatus), installed in a non-

hazardous location, aimed at preventing electrical energy

from flowing into the electric circuitry of intrinsically safe

apparatus.

However, battery-operated, portable intrinsically safe

apparatus or the like may be used alone.

3. Terminology

(1) Intrinsically safe apparatus: Electrical apparatus in which

all the circuits are intrinsically safe circuits.

(2) Associated apparatus: Electrical apparatus in which there

are both intrinsically safe circuits and non-intrinsically

safe circuits that can affect the safety of intrinsically safe

circuits.

(3) Safety barrier: A specific type of associated apparatus,

which consists mainly of safety barrier elements, and

serves to limit the flow of excessive electrical energy,

which is capable of causing ignition of a given explosive

gas or vapour of a non-intrinsically safe circuit into

concerned intrinsically safe circuits.

(4) Apparatus of category “ia”: Intrinsically safe electrical

apparatus and associated apparatus which are incapable

of causing ignition of a given explosive gas or vapour

with the appropriate safety factors such as:

1

EX-A03E

Page 32

INSTALLATION AND OPERATING PRECAUTIONS FOR TIIS INTRINSICALLY SAFE EQUIPMENT

— when up to two countable faults are applied and, in

addition,

— when non-countable faults produce an onerous

condition.

(5) Apparatus of category “ib”: Intrinsically safe electrical

apparatus and associated apparatus which are incapable

of causing ignition of a given explosive gas or vapour,

with the appropriate safety factors such as:

— when up to one countable fault is applied and, in

addition,

— when non-countable faults produce an onerous

condition.

(6) Safety rating: A rating to be designated to intrinsically

safe apparatus as well as associated apparatus and is the

maximum rating allowable for maintaining intrinsic

safety of concerned intrinsically safe circuits.

4. Caution on Combining Intrinsically Safe Apparatus and

Safety Barriers

(1) A combination of certified intrinsically safe apparatus

and safety barriers needs to satisfy combination

requirements. If intrinsically safe apparatus specify

safety barriers for combination, safety barriers other than

specified cannot be used (see Note 1 for more details).

(2) Certified intrinsically safe systems specify specific safety

barriers in combination with intrinsically safe apparatus.

So safety barriers other than specified cannot be used

(see Note 2 for more details).

(3) Other than limitations of combining intrinsically safe

apparatus and safety barriers as given in (1) and (2)

above, two or more pieces of apparatus certified under

different standards cannot be combined with each other

(see Note 3 for more details). In addition, bear in mind

that classifications of explosion protection such as “IIA,”

“IIB” and “IIC” and category “ia” and “ib” limit a

combination of intrinsically safe apparatus and safety

barriers.

For more details, see the “Type Certificate Guide for

Explosion-Protected Constructionfor Electrical

Machinery and Equipment,” issued by the Japanese

Ministry of Labour, the Research Institute of Industrial

Safety.

Note 1: Testing Apparatus

Intrinsically safe apparatus and safety barriers are assessed

individually to ensure that their safety requirements are

satisfied. Tested and certified intrinsically safe apparatus and

safety barriers incorporate individual certification numbers.

A combination of intrinsically safe apparatus and safety

barriers involves the following two limitations:

(1) A safety barrier which meets the combination require-

ments by referring to its safety rating and combination

parameters shall be selected.

(2) For pressure transmitters, pH transmitters, temperature

detectors and the like, safety barriers that can be

combined are already specified. Other safety barriers

cannot be used.

Note 2: Testing Intrinsically Safe System

An assembly (as a system) in which intrinsically safe

apparatus and safety barriers are combined is assessed to

ensure that its safety requirements are satisfied. A tested and

certified system incorporates a certification number

(intrinsically safe apparatus and safety barriers have the same

certification number).

Note 3: Impossible Combinations of Apparatus Certified Under

Different Standards

Intrinsically safe apparatus certified under technical criteria

and safety barriers certified under the “Recommended

Practice for Explosion-Protected Electrical Installations in

General Industries” (1979) and vice versa cannot be

combined even if their combination requirements are

satisfied.

5. Installation of Intrinsically Safe

Apparatus and Safety Barriers

(1) Classification of installation location

Intrinsically safe apparatus may be installed, depending upon

applicable gases, in a hazardous area in Zone 0, 1 or 2 (Note

4 below), where the specified gases are present. However,

note that apparatus certified under Technical Criteria, in

category “ib” shall be installed only in Zone 1 or 2. Safety

barriers (associated apparatus) that are combined with these

intrinsically safe apparatus shall be installed only in a non-

hazardous area. In cases where safety barriers are installed in

a hazardous area, they shall be enclosed, for example, in a

flameproof enclosure.

Note 4: Hazardous areas are classified in zones based upon the

frequency of the appearance and the duration of an explosive

gas atmosphere as follows:

Zone 0: An area in which an explosive gas atmosphere is

present continuously or is present for long periods.

Zone 1: An area in which an explosive gas atmosphere is

likely to occur in normal operation.

Zone 2: An area in which an explosive gas atmosphere is not

likely to occur in normal operation and if it does

occur it will exist for a short period only.

(2) Ambient temperature limits for intrinsically

safe apparatus

Intrinsically safe apparatus shall be installed in a location