Page 1

Instruction

•

Installation

•

Calibration

•

Operation

•

Maintenance

KEY

FEATURES

Instruction

Manual

Manual

Model PH87

Retraction Sensor Assembly

Yokogawa Corporation of America

2 Dart Road, Newnan, Georgia U.S.A. 30265

Tel: 1-800-258-2552 Fax: 1-770-254-0928

IM M1263JL-A

Doc. Nr. L2528

January 2012

3rd edition

Page 2

2

TABLE OF CONTENTS

Overview ....................................................................................................................................... 3

Assembly Instructions-Stage #1 .................................................................................................. 4

Assembly Installation Instructions- with /B ball valve option ......................................................................8

In-Service Installation-with /B ball valve option ................................................................................ 10

Sensor Service ........................................................................................................................................... 11

Sensor Replacement .................................................................................................................................. 14

Exploded View of PH87 ............................................................................................................................. 16

Part Numbers and Descriptions ................................................................................................................. 17

PH87 Dimensions and Clearance Requirements .............................................................................. 18

IM M1263JL-A

Page 3

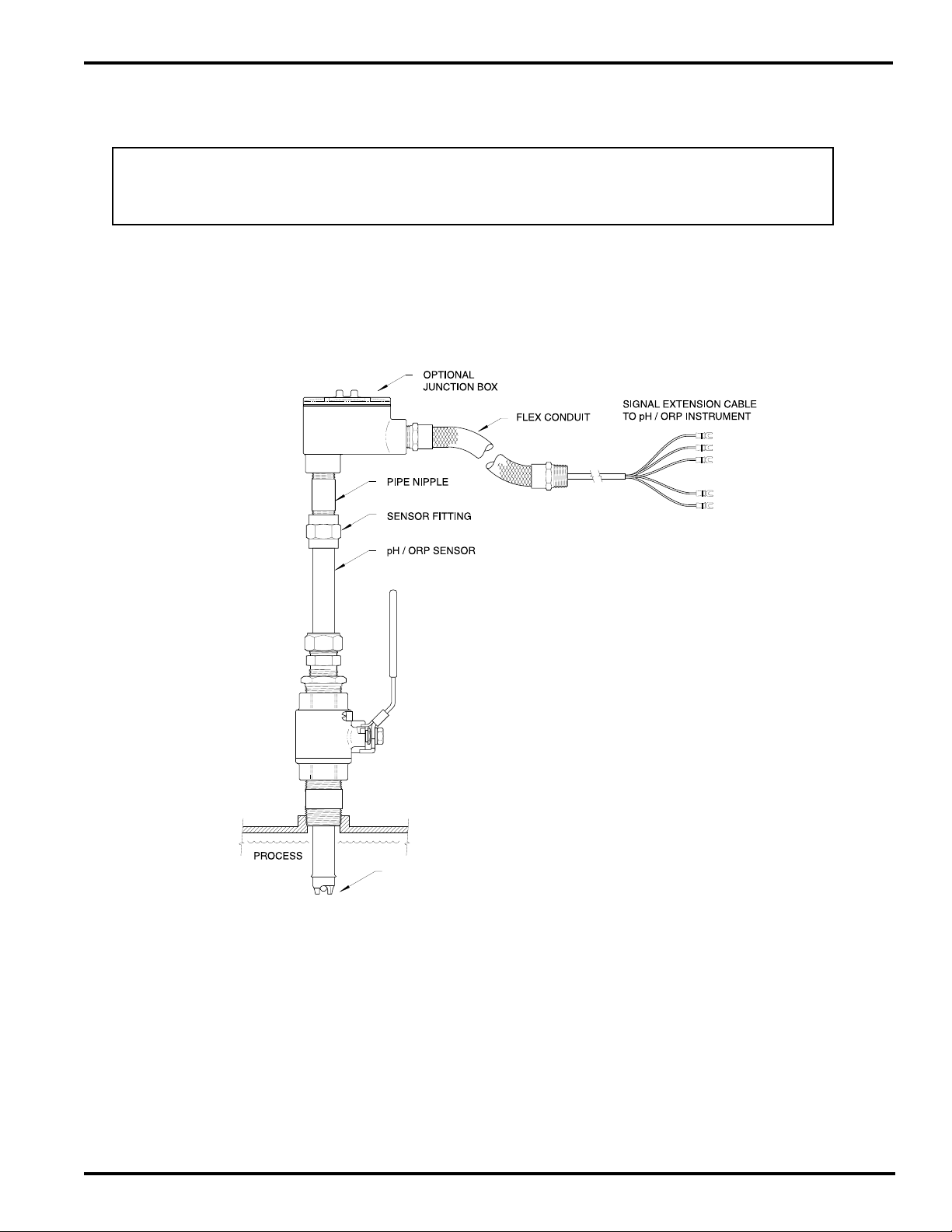

Sensor Installation Overview

Shown with Optional Ball valve

NOTE: THE FOLLOWING INFORMATION IS INTENDED TO PROVIDE THE USER WITH A PREVIEW

OF WHAT WILL BE REQUIRED TO INSTALL THE MODEL PH87 SENSOR ASSEMBLY. PLEASE

REVIEW THE DIAGRAM AND GUIDELINES BEFORE PROCEEDING.

Typical Sensor Installation Diagram

Shown with Optional /B Ball Valve

3

Sensor Installation Guidelines:

ASSEMBLY

pH/ORP SENSOR

[1]. Install the model PH97 sensor in pipe or vessel between 15° and 90° from horizontal.

[2]. Connect ex conduit with adequate service loop to junction box.

[3]. Connect the sensor cable to the terminals inside the junction box.

[4]. Keep cable run between junction box and pH / ORP instrument as short as possible.

IM M1263JL-A

Page 4

4

8

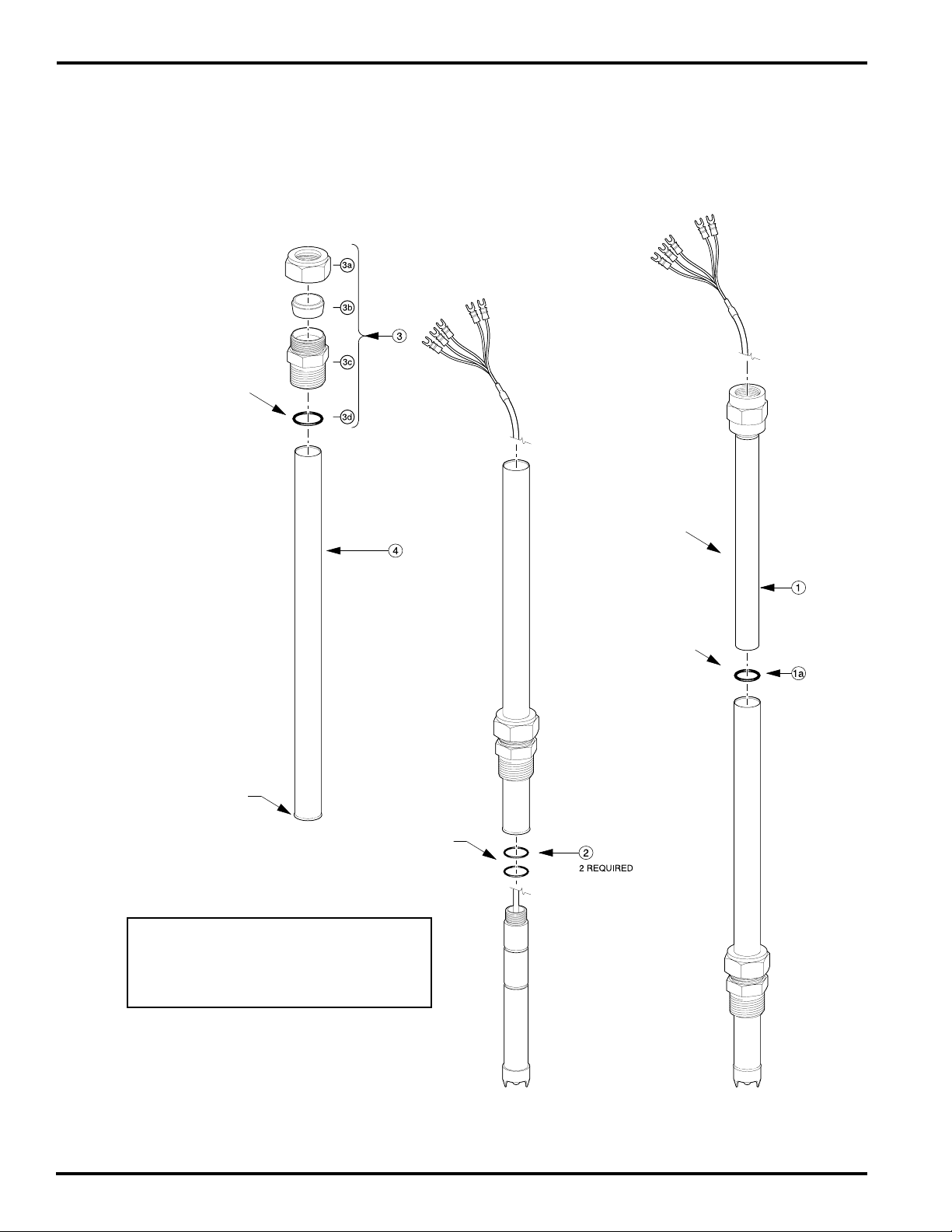

Model PH87 Retraction Sensor Assembly

Sensor Assembly Instructions-Stage1

BEGIN STAGE #1 ASSEMBLY OF THE MODEL PH87 BY FOLLOWING THE STEP-BY-STEP

INSTRUCTIONS [A] THROUGH [F] IN ORDER AS SHOWN BELOW:

[STEP B]. SLIDE

PACKING GLAND, ITEM NO.3, ONTO

SHEATH, ITEM NO.4. KEEP LOCKING

NUT AND FERRULES LOOSE BUT

ATTACHED TO PACKING GLAND

[STEP A]. INSTALL

PACKING GLAND O-RING, ITEM NO.

3d, INTO PACKING GLAND BODY,

ITEM NO. 3c.

[STEP F]. THREAD SENSOR

CABLE THROUGH COUPLER

TUBE, ITEM NO. 1, THEN SLIDE

COUPLER TUBE INTO SHEATH

UNTIL IT CONTACTS SENSOR.

[STEP D]. THREAD SENSOR

CABLE THROUGH SHEATH

AND SLIDE THE SENSOR

INTO SHEATH UNTIL IT STOPS

AGAINST FLARED END

FLARED END

OF SHEATH

[STEP C]. STRETCH O-RINGS,

ITEM NO. 2, INTO GROOVES

ON SENSOR

PLEASE NOTE

REFER TO PAGES 16 AND 17 OF THE

SENSOR ASSEMBLY AND ITEMIZED PART

LIST FOR ALL THESE COMPONENTS

REFER TO PAGES 15 AND 16 OF THE

SENSOR ASSEMBLY AND ITEMIZED PART

LIST FOR ALL THESE COMPONENTS.

[STEP E]. STRETCH O-RING,

ITEM NO. 1a, INTO GROOVE ON

COUPLER TUBE, ITEM NO. 1.

IM M1263JL-A

Page 5

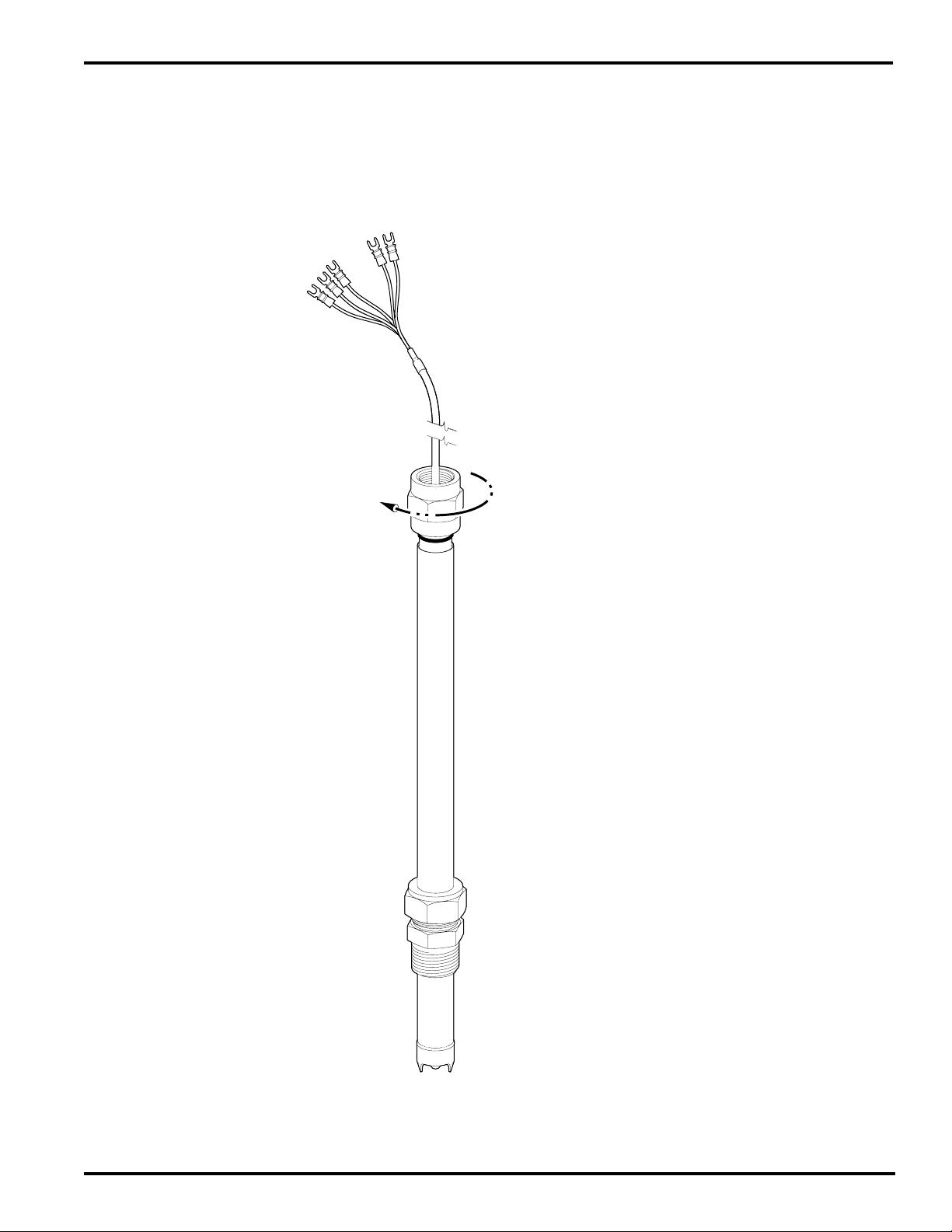

Sensor Assembly Instructions-Stage1 (Continued)

(Continued)

5

[STEP G]. THREAD SENSOR

CABLE THROUGH COUPLER

TUBE, ITEM NO. 1, THEN SLIDE

COUPLER TUBE INTO SHEATH

UNTIL IT CONTACTS SENSOR.

THE COUPLER TUBE AND

SENSOR SHOULD BE

THREADED TOGETHER UNTIL

BOTH ARE SEATED AGAINST

THE ENDS OF THE SHEATH,

IM M1263JL-A

Page 6

6

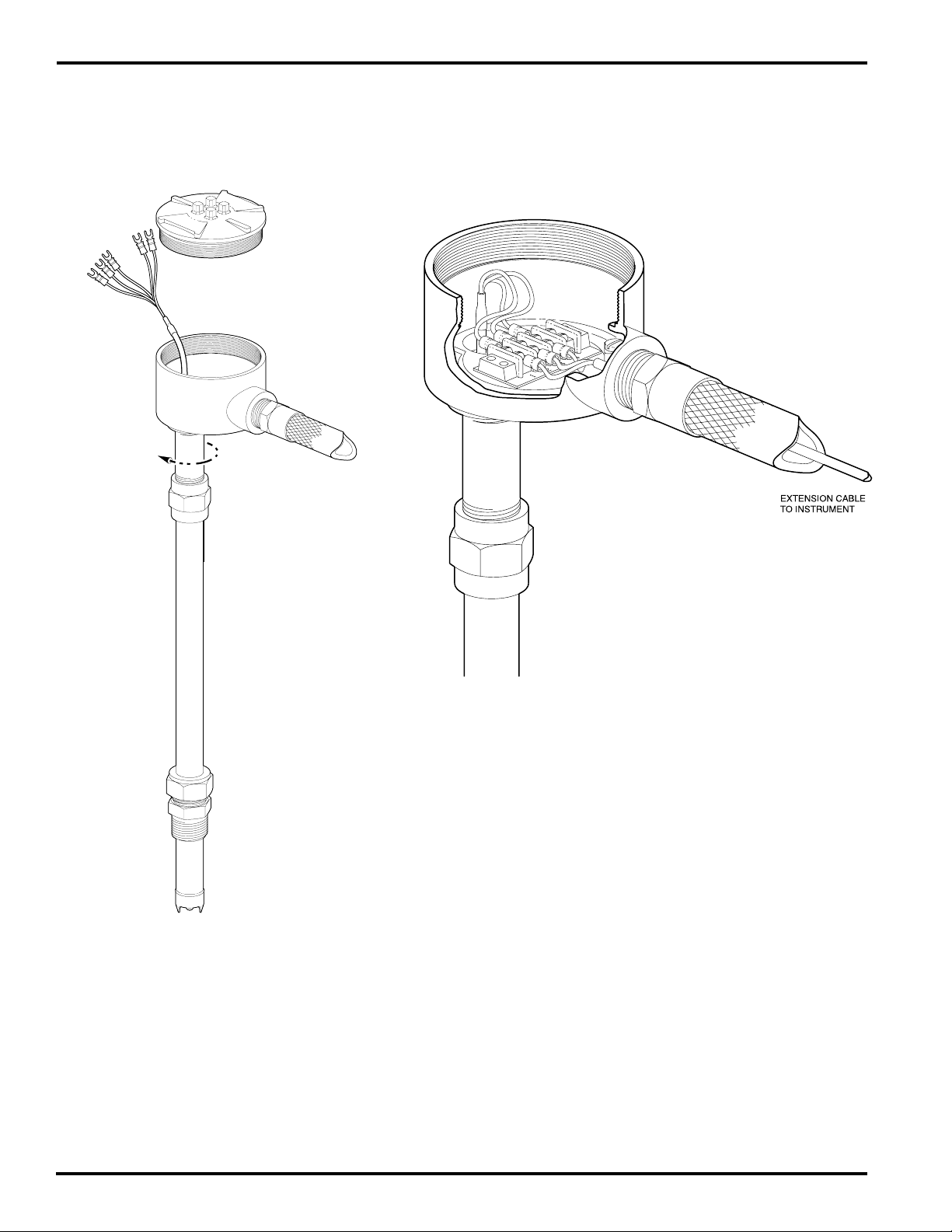

Sensor Assembly Instructions—Stage1

(Continued)

Model PH87 Retraction Sensor Assembly

Sensor Assembly Instructions-Stage1 (Continued)

[STEP H]. REMOVE JUNCTION BOX

COVER AND THERAD SENSOR CABLE

[Step H]. REMOVE

THROUGH JUNCTION BOX ASSEMBLY

JUNCTION BOX COVER AND

(JUNCTION BOX AND PROVIDED

THERAD SENSOR CABLE THROUGH

PIPE NIPPLE). THREAD JUNCTION

JUNCTION BOX ASSEMBLY

BOX ASSEMBLY PIPE NIPPLE INTO

(JUNCTION BOX AND PROVIDED

SENSOR COUPLER ASSEMBLY,

PIPE NIPPLE). THREAD JUNCTION

ITEM NO. 1.INSTALL SUITABLE FLEX

BOX ASSEMBLY PIPE NIPPLE INTO

CONDUIT LONG ENOUGH TO ALLOW

SENSOR COUPLER ASSEMBLY,

FOR SERVICING OR REPLACEMENT

ITEM NO. 1.INSTALL SUITABLE FLEX

OF SENSOR.

CONDUIT LONG ENOUGH TO ALLOW

FOR SERVICING OR REPLACEMENT

OF SENSOR.

[STEP I]. CONNECT THE SENSOR

WIRES TO THE 5-TERMINAL STRIP IN

[Step I]. CONNECT THE SENSOR

THE JUNCTION BOX IN THE

WIRES TO THE 5-TERMINAL STRIP IN

FOLLOWING ORDER. THE RED TC WIRE

THE JUNCTION BOX IN THE FOL-

CONNECTS TO TERMINAL #1 AND

LOWING ORDER. THE RED TC WIRE

THE BLACK TC WIRE TO TERMINAL

CONNECTS TO TERMINAL #1 AND

#2. CONNECT THE SENSOR

THE BLACK TC WIRE TO TERMINAL

REFERENCE (BLACK) TO #3,

#2. CONNECT THE SENSOR REFER-

THE SOLUTION GROUND (GREEN)

ENCE (BLACK) TO #3, THE SOLUTION

TO TERMINAL #4 AND PH (CLEAR) TO

GROUND (GREEN) TO TERMINAL #4

TERMINAL #5. THREAD THE EXTENSION

AND pH (CLEAR) TO TERMINAL #5.

CABLE THROUGH CONDUIT. ATTACH

THREAD THE EXTENSION CABLE

THE LABELED WIRES TO THE

THROUGH CONDUIT. ATTACH THE

TERMINALS IN THE SAME ORDER AS

LABELED WIRES TO THE TERMINALS

THE SENSOR WIRES LISTED ABOVE.

IN THE SAME ORDER AS THE SEN-

SOR WIRES LISTED ABOVE. SLIDE-

REPLACE THE JUNCTION BOX COVER.

THE PROTECTIVE INSULTING BOOT

OVER CONNECTORS AND REPLACE

THE JUNCTION BOX COVER.

IM M1263JL-A

Page 7

pH9

(Continued)

Sensor Assembly Instructions-Stage1 (Continued)

THE STAGE #1 ASSEMBLY OF THE pH97 SENSOR IS NOW COMPLETE AND

SHOULD APPEAR AS ONE OF THE TWO ASSEMBLIES SHOWN BELOW

STANDARD ASSEMBLY

STANDARD ASSEMBLY

7

[STEP J]. PERFORM A 2-POINT CALIBRATION WITH

PH BUFFER SOLUTIONS BEFORE PROCEEDING

FURTHER WITH THE ASSEMBLY AND INSTALLATION.

NOTE: REFER TO PH 97 SENSOR INSTRUCTIONS FOR

WIRING AND CALIBRATION PROCEDURES.

NOTE: REFER TO PH 97 SENSOR INSTRUCTIONS

FOR WIRING AND CALIBRATION PROCEDURES.

IM M1263JL-A

Page 8

8

Sensor Assembly Installation Instructions—/B Option

8/B OPTION FOR

Model PH87 Retraction Sensor Assembly

Sensor Assembly Instructions-/B Ball Valve Option

BEGIN ASSEMBLY OF THE /B BALL VALVE OPTION FOR MODEL PH87 SENSOR BY FOLLOWING THE STEP-BY-STEP

INSTRUCTIONS [A] THROUGH [D] IN ORDER AS SHOWN BELOW:

PLEASE NOTE

REFER TO PAGES 16 AND 17 OF THE

REFER TO PAGES 15 AND 16 OF THE

SENSOR ASSEMBLY AND ITEMIZED

SENSOR ASSEMBLY AND ITEMIZED PART

PART LIST FOR ALL THESE

LIST FOR ALL THESE COMPONENTS.

COMPONENTS

[STEP A]. THREAD THE REDUCER

BUSHING, ITEM NO.6, USING TEFLON

TAPE TO SEAL AND TIGHTEN IN

PLACE

[STEP B]. THREAD THE NIPPLE, ITEM

NO.7, INTO BALL VALVE, ITEM NO.6,

USING TEFLON TAPE TO SEAL AND

TIGHTEN IN PLACE

[STEP C]. THREAD THE NIPPLE, ITEM

NO.7, ALONG WITH BALL VALVE,

ITEM NO.6, AND REDUCER BUSHING,

ITEM NO.5, INTO WELDALET OR APPROPRIATE PROCESS FITTING. USE

TEFLON TAPE TO SEAL THREADS AND

TIGHTEN IN PLACE

[STEP D]. INSURE THAT THE VALVE IS

IN THE CLOSED POSTION AS SHOWN

BELOW BEFORE PROCEEDING TO

NEXT STEP.

PLEASE NOTE: /B OPTION IS REQUIRED (OR CUSTOMER SUPPLIED BALL VALUE IS

REQUIRED) FOR RETRACTION OF PH87 WHILE PROCESS IS UNDER PRESSURE

IM M1263JL-A

Page 9

Sensor Assembly Installation Instructions-/B Ball Valve (Continued)

8

/B OPTION

THE ASSEMBLY OF THE PH87

SENSOR IS NOW COMPLETE

AND SHOULD APPEAR AS

SHOWN. DO NOT TIGHTEN

PACKING GLAND LOCKING

NUT OR OPEN BALL VALVE

UNTIL SENSOR ASSEMBLY

IS READY TO GO ON-STREAM.

COMPLETE /B BALL VALVE OPTION ASSEMBLY OF THE MODEL PH87 BY FOLLOWING THE STEP-BY-STEP

INSTRUCTIONS [E] AND [F] IN ORDER AS SHOWN BELOW:

9

[STEP E]. APPLY TEFLON TAPE TO

PIPE THREADS OF PACKING GLAND

FITTING AND SLIDE FITTING TO

SENSOR END OF SHEATH. INSTALL

STAGE #1 SUBASSEMBLY INTO VALVE

TAKING CARE NOT TO FORCE THE

SENSOR INTO THE BALL PORTION OF

THE VALVE TO PREVENT BREAKAGE

OF THE GLASS BULB.

[STEP F]. SECURELY TIGHTEN

PACKING GLAND FITTING INTO

VALVE ASSEMBLY TO PROVIDE A

PROPER SEAL.

THE ASSEMBLY OF THE PH87

SENSOR IS NOW COMPLETE

AND SHOULD APPEAR AS

SHOWN. DO NOT TIGHTEN

PACKING GLAND LOCKING

NUT OR OPEN BALL VALVE

UNTIL SENSOR ASSEMBLY

IS READY TO GO ON-STREAM.

IM M1263JL-A

Page 10

10

Sensor Assembly In-Service Instructions—/B Option

Model PH87 Retraction Sensor Assembly

Sensor Assembly In-Service Instructions-/B Ball Valve Option

PLEASE NOTE

REFER TO PAGES 16 AND 17 OF THE

REFER TO PAGES 15 AND 16 OF THE

SENSOR ASSEMBLY AND ITEMIZED

SENSOR ASSEMBLY AND ITEMIZED PART

PART LIST FOR ALL THESE

LIST FOR ALL THESE COMPONENTS.

COMPONENTS

THE FINAL ASSEMBLY IS NOW

READY TO BE PLACED INTO

SERVICE, WITH PACKING GLAND

LOCKING NUT ENGAGED BUT NOT

TIGHTENED AND SENSOR IN THE

RETRACTED POSITION.

[STEP A]. TO PLACE ASSEMBLY

[Step A]. TO PLACE ASSEMBLY

INTO SERVICE OPEN BALL

INTO SERVICE OPEN BALL

VALVE COMPLETELY.

VALVE COMPLETELY.

Caution: OPENING VALVE

CAUTION: OPENING VALVE

SUBJECTS SENSOR ASSEMBLY

SUBJECTS SENSOR ASSEMBLY

TO LINE PRESSURE. IF THE

TO LINE PRESSURE. IF THE

SENSOR IS NOT RETRACTED

SENSOR IS NOT RETRACTED

COMPLETLY AGAINST STOP,

COMPLETLY AGAINST STOP,

OPENING THE VALVE COULD

OPENING THE VALVE COULD

RESULT IN THE SENSOR

RESULT IN THE SENSOR

SUDDENLY RETRACTING THE

SUDDENLY RETRACTING THE

REMAINING DISTANCE

REMAINING DISTANCE

CAUSING DAMAGE TO THE

CAUSING DAMAGE TO THE

SENSOR ASSEMBLY OR INJURY

SENSOR ASSEMBLY OR INJURY

TO THE SERVICE PERSON.

TO THE SERVICE PERSON.

[STEP B]. INSERT STAGE #1

SUBASSEMBLY INTO PROCESS.

[STEP C]. SECURE SENSOR IN

PLACE BY TIGHTENING

LOCKING NUT AND

FERRULES OF GLAND FITTING,

ITEM NO.3.

DO NOT INSERT TIP OF

SENSOR BEYOND INSIDE

WALL OF PROCESS PIPE

TO AVOID TORQUE AND

POSSIBLE BREAKAGE.

THE IN-SERVICE ASSEMBLY SHOULD

APPEAR AS SHOWN BELOW.

IM M1263JL-A

Page 11

11

Sensor Service Instructions

BEFORE SERVICING REMOVE THE MODEL PH97 SENSOR FROM SERVICE FOLLOWING THE

STEP-BY-STEP INSTRUCTIONS [A] AND [B] IN ORDER AS SHOWN BELOW:

Model PH87 Retraction Sensor Assembly

Sensor Service Instructions

BEFORE SERVICING REMOVE THE MODEL PH97 SENSOR FROM SERVICE FOLLOWING THE STEP-BY-STEP

INSTRUCTIONS [A] AND [B] IN ORDER AS SHOWN BELOW:

[STEP B]. FULLY

RETRACT STAGE #1 SUBASSEMBLY

SHAFT.

[Step B]. FULLY

RETRACT STAGE #1 SUB-

ASSEMBLY SHAFT.

[STEP A]. LOOSEN LOCKING

NUT AND FERRULES OF GLAND

[Step A]. LOOSEN LOCKING

FITTING, ITEM NO. 3.

NUT AND FERRULES OF GLAND

CAUTION: THE SENSOR ASSEMBLY

FITTING, ITEM NO. 3.

IS STILL UNDER PRESSURE.

Caution: THE SENSOR ASSEMBLY

LOOSENING THE LOCKING NUT

IS STILL UNDER PRESSURE.

LOOSENING THE LOCKING NUT

COULD RESULT IN THE SENSOR

COULD RESULT IN THE SENSOR

RETRACTING SUDDENLY AND

RETRACTING SUDDENLY AND

WITH A GREAT DEAL OF FORCE.

WITH A GREAT DEAL OF FORCE.

THIS COULD CAUSE DAMAGE

THIS COULD CAUSE DAMAGE

TO THE SENSOR ASSEMBLY

TO THE SENSOR ASSEMBLY

OR INJURY TO THE SERVICE

OR INJURY TO THE SERVICE

PERSON.

PERSON.

IM M1263JL-A

Page 12

12

Sensor Service Instructions

9

(Continued)

Model PH87 Retraction Sensor Assembly

Sensor Service Instructions (Continued)

BEFORE SERVICING REMOVE THE MODEL PH97 SENSOR FROM SERVICE FOLLOWING THE STEP-BY-STEP

INSTRUCTIONS [C] AND [D] IN ORDER AS SHOWN BELOW:

[STEP C]. CLOSE BALL VALVE

COMPLETELY.

[STEP D]. COMPLETELY UNTHREAD

GLAND FITTING, ITEM NO.4, FROM

VALVE ASSEMBLY

IM M1263JL-A

Page 13

Sensor Service Instructions (Continued)

(Continued)

9

CONTINUE SERVICING OF THE MODEL PH97 SENSOR BY FOLLOWING THE STEP-BY-STEP INSTRUCTIONS

[E] THROUGH [G] IN ORDER AS SHOWN BELOW:

[Step G]. TO TEST SENSOR PERFORM A 2-POINT

CALIBRATION WITH pH BUFFER AS SHOWN BELOW.

[STEP E]. REMOVE STAGE #1

ASSEMBLY FROM VALVE ASSEMBLY.

WITH THE STAGE #1 SUBASSEMBLY

COMPLETELY REMOVED FROM THE

VALVE ASSEMBLY THE SENSOR MAY

NOW BE TESTED OR REPLACED.

[STEP F]. BEFORE TESTING THE

SENSOR BE SURE THAT IT IS CLEAN

IF THE SENSOR TESTS WITHIN ACCEPTABLE

LIMITS REINSTALL AND PLACE SENSOR BACK

IN SERVICE BY FOLLOWING ASSEMBLY

INSTRUCTIONS.

IF TESTING PROVES SENSOR T0 BE FAULTY

CONTINUE WITH THE SERVICE INSTRUCTIONS

FOR SENSOR REPLACEMENT.

13

[STEP G]. TO TEST SENSOR PERFORM A

2-POINT CALIBRATION WITH PH BUFFER AS

SHOWN BELOW.

IF THE SENSOR TESTS WITHIN ACCEPTABLE

LIMITS REINSTALL AND PLACE SENSOR

BACK IN SERVICE BY FOLLOWING ASSEMBLY

INSTRUCTIONS.

IF TESTING PROVES SENSOR T0 BE FAULTY

CONTINUE WITH THE SERVICE INSTRUCTIONS

FOR SENSOR

REPLACEMENT.

IM M1263JL-A

Page 14

14

Model PH87 Retraction Sensor Assembly

Sensor Replacement Instructions

TO DISASSEMBLE THE MODEL PH87 SENSOR WITH A SENSOR MOUNTED JUNCTION BOX,

FOLLOW THE STEP-BY-STEP INSTRUCTIONS [A] THROUGH [D] IN ORDER AS SHOWN BELOW:

Sensor Replacement Instructions

BEFORE SERVICING REMOVE THE MODEL PH87 SENSOR FROM SERVICE FOLLOWING THE STEP-BY-STEP

INSTRUCTIONS [A] AND [D] IN ORDER AS SHOWN BELOW:

[Step C]. WHILE FIRMLY GRIPING

SHEATH PUSH ON COUPLER TUBE -

[STEP C]. WHILE FIRMLY GRIPING SHEATH

JUNCTION BOX ASSEMBLY TO

PUSH ON COUPLER TUBE JUNCTION BOX

UNSEAT SENSOR O-RINGS

ASSEMBLY TO UNSEAT SENSOR O-RINGS

[Step A]. REMOVE

JUNCTION BOX COVER AND DISCON-

[STEP A]. REMOVE

NECT ALL WIRES FROM TERMINALS.

JUNCTION BOX COVER AND DISCONNECT

ALL WIRES FROM TERMINALS.

[Step B]. WHILE FIRMLY GRIPING

[STEP B]. WHILE FIRMLY GRIPING

THE SENSOR AND THE SHEATH AT

THE SENSOR AND THE SHEATH AT

THE SAME TIME UNTHREAD THEM

THE SAME TIME UNTHREAD THEM

FROM THE COUPLER ASSEMBLY BUT

FROM THE COUPLER ASSEMBLY BUT

DO NOT COMPLETELY DISENGAGE

DO NOT COMPLETELY DISENGAGE

THREADS.

THREADS.

[Step D]. COMPLETELY UNTHREAD

[STEP D]. COMPLETELY UNTHREAD

SENSOR FROM COUPLER TUBE

SENSOR FROM COUPLER TUBE

ASSEMBLY.

ASSEMBLY.

CONTINUE WITH SERVICE

INSTRUCTIONS AT STEP "N".

CONTINUE WITH SERVICE

INSTRUCTIONS AT STEP “N”.

IM M1263JL-A

Page 15

Sensor Replacement Instructions (Continued)

(Continued)

DISASSEMBLE THE ASSEMBLY INTO THE COMPONENT PARTS AS SHOWN IN ONE OF THE ILLUSTRATIONS BELOW.

TO INSTALL A NEW SENSOR AND RETURN THE MODEL PH87 TO SERVICE FOLLOW THE ASSEMBLY INSTRUCTIONS

STARTING FROM STAGE

#1 STEP “D” (PAGE 4)

15

FIGURE 1: STANDARD

ASSEMBLY READY FOR

FIGURE 1: STANDARD

SENSOR REPLACEMENT

ASSEMBLY READY FOR

SENSOR REPLACEMENT

FIGURE 2: ASSEMBLY WITH SENSOR

FIGURE 2: ASSEMBLY WITH

MOUNTED JUNCTION BOX READY FOR

SENSOR MOUNTED JUNCTION

SENSOR REPLACEMENT

BOX READY FOR SENSOR

REPLACEMENT

IM M1263JL-A

Page 16

16

Model PH87 Retraction Sensor Assembly

Sensor Housing Assembly

Sensor Housing Assembly

8

JUNCTION BOX

JUNCTION BOX

2 REQUIRED

9

pH SENSOR

(SEE MODEL PH97

SPEC SHEET)

PH SENSOR

(SEE MODEL PH97

SPEC SHEET)

PLEASE NOTE

REFER TO PAGES 15 AND 16 OF THE SENSOR

ALL O-RINGS REQUIRE PROPER LUBRICATION PRIOR TO

SERVICING. WE RECOMMEND USING PARKER O LUBE OR

ASSEMBLY AND ITEMIZED PART LIST FOR ALL

EQUIVALENT. FOLLOW THE LUBRICATION INSTRUCTIONS

THESE COMPONENTS

PROVIDED BY THE MANUFACTURER.

IM M1263JL-A

Page 17

Sensor Housing Assembly

THESE ARE THE INDIVIDUAL PART NUMBERS FOR THE ITEMS SHOWN IN THE EXPLODED VIEW ON

THE PREVIOUS PAGE. PART NUMBERS FOR A COMPLETE ASSEMBLY ARE LISTED ON NEXT TWO

PAGES, ON THE SPECIFIC DRAWING.

Item Part Number Description

1 M1234DQ Coupler Assembly, Kynar (PVDF), N=7”

M1234TV-A Coupler Assembly, Kynai (PVDF), N=21”

These part numbers includes the o-ring

1a, 2 M1234DS O-rings, viton, sensor, size -019, quantity of 10

3 M1234DT Compression Fitting, 1” Tube x 1” MNPT

3a M1234DW Compression Fitting, Nut

3b M1234DX Compression Fitting, Ferrule, Kynar (PVDF)

3c M1234EJ Compression Fitting, Body, Titanium

3d M1234DZ Compression Fitting, O-ring, viton, size -120

4 M1234EA Sheath, Titanium, N=7”

M1234JQ-A Sheath, Titanium, N=21”

17

5 M1234WZ-A Bushing, 1.25” MNPT x 1” FNPT

6 M1234WY-A Ball Valve, Full Port, 1.25” NPT

7 M1234XA-A Nipple, 1.25” NPT

8 M1234EE Junction Box Assembly, Sensor Mount

9 See pH Sensor Specications

IM M1263JL-A

Page 18

18

Scale:

Drwg Nr:

Sheet:

Date:

Drawn By:

21-July_00

Rev:

R. Ramus

Group:

1 / 1

Title:

P2254

Type:

Product Data

Part Nr:

PH87/B

PH87/B Insertion Assembly:

Dimensions & Clearance Requirements

2 Dart Road, Newnan, GA 30265

27.25" 40.05" 41.40"

MODEL NO. "N" LENGTH "R" DIMENSION "C" DIMENSION

PH87-07/B

PH87-21/B

13.25" 28.05"

29.40"

Insertion

Length

Retraction

Distance

Minimum

Clearance

"N" = FULLY INSERTED

3.72"

5.22"

1 1/4" MNPT

Minimum

Clearance

“C” DIMENSION

Distance

Retraction

“R” DIMENSION

"C" = MINIMUM CLEARANCE REQUIRED FOR SENSOR REMOVAL

"R" = FULLY RETRACTED

15.65" FULLY INSERTED

3/4" FNPT

Length

Insertion

PH87-21/B 21” 40.05” 41.40”

MODEL NO. “N” LENGTH

PH87-07/B 7” 28.05” 29.40”

PH87 With /B Ball Valve Insertion Assembly:

Dimensions & Clearance Requirements

2 Dart Road, Newnan, GA 30265

Tel.: 770-254-0400 Fax.:770-251-6427

IM M1263JL-A

Page 19

27.25"

33.15" 36.90"

Scale:

Drwg Nr:

Sheet:

Date:

Drawn By:

21-July_00

Rev:

R. Ramus

Group:

1 / 1

Title:

P2254

Type:

Product Data

Part Nr:

PH87

PH87 Insertion Assembly:

Dimensions & Clearance Requirements

"N" = FULLY INSERTED

MODEL NO. "N" LENGTH "R" DIMENSION "C" DIMENSION

PH87-07

PH87-21

13.25" 19.15"

22.90"

Insertion

Length

Retraction

Distance

Minimum

Clearance

2 Dart Road, Newnan, GA 30265

3.72"

Minimum

Clearance

“C” DIMENSION

Distance

Retraction

“R” DIMENSION

19

9.65"

FULLY

INSERTED

"R" = FULLY RETRACTED

"C" = MINIMUM CLEARANCE

3/4" FNPT

REQUIRED FOR SENSOR REMOVAL

1 " MNPT

Length

Insertion

MODEL NO. “N” LENGTH

PH87-21 27.25” 33.15” 36.90”

PH87-07 13.25” 19.15” 22.90”

PH87 Insertion Assembly:

Dimensions & Clearance Requirements

2 Dart Road, Newnan, GA 30265

Tel.: 770-254-0400 Fax.:770-251-6427

IM M1263JL-A

Page 20

YOKOGAWA HEADQUARTERS

9-32, Nakacho 2-chome,

Musashinoshi

Tokyo 180

Japan

Tel. (81)-422-52-5535

Fax (81)-422-55-1202

E-mail: webinfo@mls.yokogawa.co.jp

www.yokogawa.com.jp

YOKOGAWA EUROPE B.V.

Euroweg 2

3825 HD Amersfoort

The Netherlands

Tel. +31 (0)88-4641000

Fax +31 (0)88-4641111

E-mail: info@nl.yokogawa.com

www.yokogawa.com/eu

YOKOGAWA CORPORATION OF AMERICA

2 Dart Road

Newnan GA 30265

United States

Tel. (1)-770-253-7000

Fax (1)-770-251-2088

E-mail: info@yca.com

www.yokogawa.com/us

YOKOGAWA ELECTRIC ASIA Pte. Ltd.

5 Bedok South Road

Singapore 469270

Singapore

Tel. (65)-241-9933

Fax (65)-241-2606

E-mail: webinfo@yas.com.sg

www.yokogawa.com.sg

Yokogawa has an extensive sales

and distribution network.

Please refer to the website

(www.yokogawa.com/an/index.htm) to contact your

nearest representative.

IM M1234JL-A

Subject to change without notice Printed in The USA

Copyright © 2008

IM M1263JL-A

Loading...

Loading...