Page 1

User ’s

Manual

Chemical Cleaning

pH Measuring System

IM 12B07W01-04EN

IM 12B07W01-04EN

1st Edition

Page 2

u Introduction

n Chemical Cleaning pH Measuring System

Thank you for purchasing Chemical Cleaning pH Measuring System.

To have the system deliver its full capabilities, read this instruction manual thoroughly before you

use it. For safety reasons or to avoid possible damage to your equipment, strictly adhere to every

cautionary note that appears in this manual.

Chemical Cleaning pH Measuring System features automatic chemical cleaning of the pH sensor

without removing pH sensor, while maintaining its performance in pH measurement.

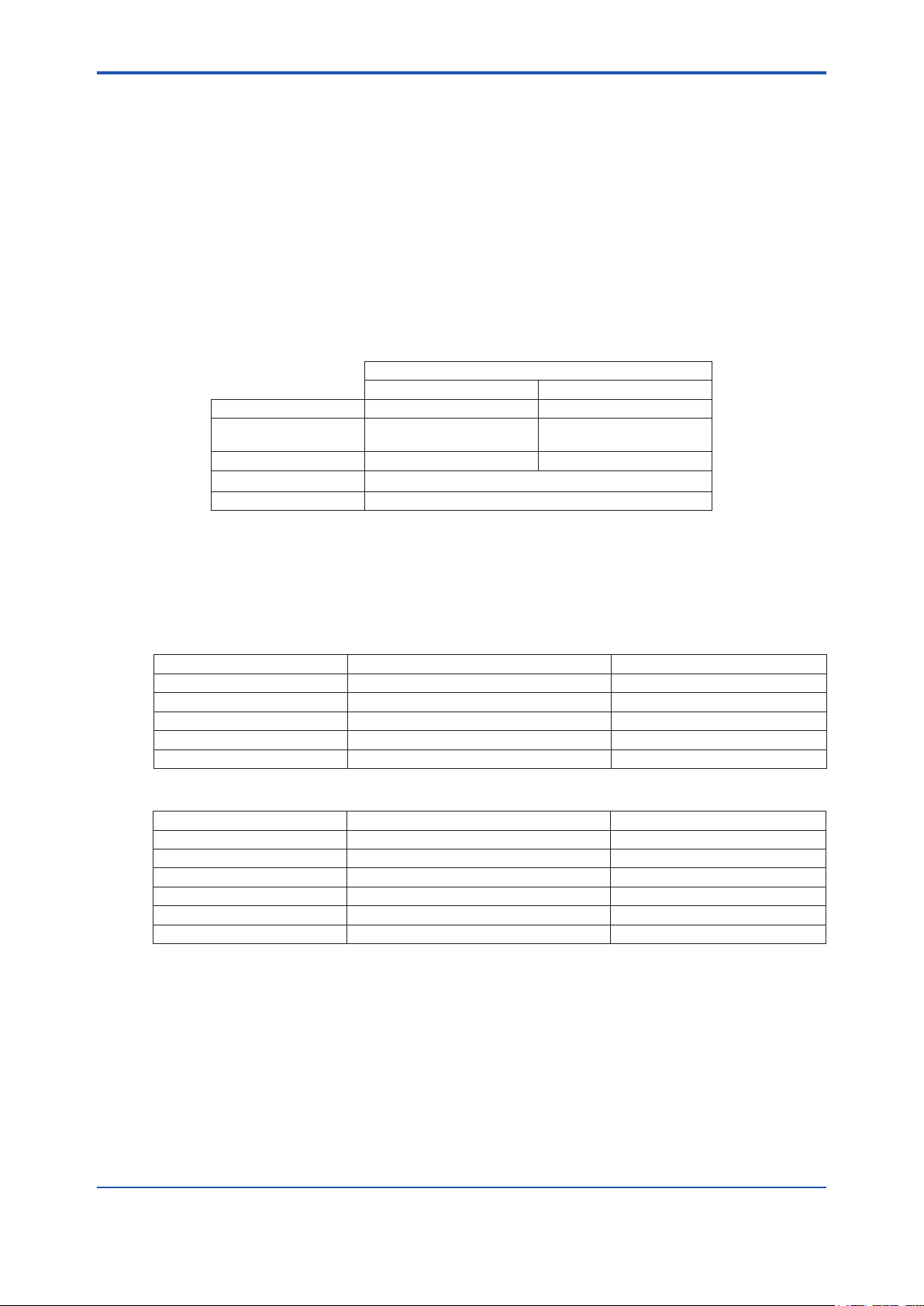

System Conguration of Chemical Cleaning pH Measuring System is as below;

Chemical Cleaning pH Measuring System

pH/ORP Converter 2-wire Analyzer

Chemical Cleaning unit PH8SM3-E PH8SM3-G or PH8SM3-F

pH analyzer PH450G FLXA202 or FLXA21

Distributor ― PH201G

pH sensor

Holder PH8HS3

(Note) You can select WTB10 Terminal Box, if necessary.

PH8EFP-□-TT2 (Note)

i

This document describes mainly PH8SM3 unit of the system and PH8HS3 Holder. For further

information on other products, please read corresponding manual attached to each product.

The related documents to each product:

General Specications

Product Model Document Name Document number

PH8SM3, PH8HS3, PH201G Chemical Cleaning pH measuring System GS 12B7A1-E

PH450G PH450G pH and Redox (ORP ) Converter GS 12B07C05-01E

FLXA202 FLXA202 2-Wire Analyzer GS 12A01A03-01EN

FLXA21 FLXA21 2-Wire Analyzer GS 12A01A02-01E

PH8EFP, WTB10 pH and ORP Sensors GS 12B07B02-E

* the “E” or “EN” in the document number is a language code.

User’s Manual

Product Model Document Name Document number

PH8SM3, PH8HS3 Chemical Cleaning pH measuring System

PH450G PH450G pH and ORP Converter IM 12B07C05-01E

FLXA202, FLXA21 FLXA202/FLXA21 2-Wire Analyzer IM 12A01A02-01E

PH201G PH201G Distributor IM 19B01E04-02E

PH8EFP, PH8EFP, KCI Filling type pH sensor IM 12B7J1-01E

WTB10 WTB10-PH□ Terminal Box IM 19D01B01-01E

* the “E” in the document number is the language code.

n Notes on Handling User’s Manuals

IM 12B07W01-04EN(this document)

• Please hand over the user’s manuals to your end users so that they can keep the user’s

manuals on hand for convenient reference.

• Please read the information thoroughly before using the product.

• The purpose of these user’s manuals is not to warrant that the product is well suited to any

particular purpose but rather to describe the functional details of the product.

Media No. IM 12B07W01-04EN 1st Edition : Nov. 2016 (YK)

All Rights Reserved Copyright © 2016, Yokogawa Electric Corporation

IM 12B07W01-04EN 1st Edition : Nov. 11, 2016-00

Page 3

• No part of the user’s manuals may be transferred or reproduced without prior written

consent from YOKOGAWA.

• YOKOGAWA reserves the right to make improvements in the user’s manuals and product at

any time, without notice or obligation.

• If you have any questions, or you nd mistakes or omissions in the user’s manuals, please

contact our sales representative or your local distributor.

n Drawing Conventions

Some drawings may be partially emphasized, simplied, or omitted, for the convenience of

description.

Some screen images depicted in the user’s manual may have different display positions or

character types (e.g., the upper / lower case). Also note that some of the images contained in this

user’s manual are display examples.

n Inspection on delivery

Each component of Chemical Cleaning pH Measuring Systems comes in a separate package.

However, PH450G pH/ORP Converters (or FLXA202/FLXA21 2-Wire Analyzer ) are delivered

with factory-installed in PH8SM3 Chemical Cleaning pH Measuring Unit ,

After the delivery, open the package carefully and inspect for damages caused during transport.

Should there be any damage or breakage on the product, please contact YOKOGAWA

immediately and keep all the packing materials, containers and boxes that came with the

product.

ii

After the unpacking, make sure the delivered products include all of the component equipment

you ordered.

After completing the unpacking, make sure that the delivered component covers all of the

required specications. When conrming the specications, refer to the model and sufx codes

indicated on the nameplate on the instrument. The models are indicated on the name plates.

Check also those of accessories. For further information on PH8SM3 or PH8HS3, please read

subsection 1.2 of this document.

l Unpacking and handling

When unpacking, place the instrument on a level surface in the position in which the instrument

will actually be installed, (Do not allow the package to undergo any intense mechanical shock by

turning it over on its side.) Avoid applying any excess force to the pipes and cables. Otherwise, a

defective pipe and / or cable connection may result

PH8SM3 Chemical Cleaning pH Measuring Unit weighs approximately 50 kg. It is recommended

that the product be unpacked as near your installation location as possible.

IM 12B07W01-04EN 1st Edition : Nov.11, 2016-00

Page 4

u Safety Precautions

n Safety, Protection, and Modication of the Product

• In order to protect the system controlled by the product and the product itself and ensure

safe operation, observe the safety precautions described in this user’s manual. We assume

no liability for safety if users fail to observe these instructions when operating the product.

• If this instrument is used in a manner not specied in this user’s manual, the protection

provided by this instrument may be impaired.

• If any protection or safety circuit is required for the system controlled by the product or for

the product itself, prepare it separately.

• Be sure to use the spare parts approved by Yokogawa Electric Corporation (hereafter

simply referred to as YOKOGAWA) when replacing parts or consumables.

• Modication of the product is strictly prohibited.

• The following safety symbols are used on the product as well as in this manual.

WARNING

This symbol indicates that an operator must follow the instructions laid out in this manual in

order to avoid the risks for the human body and health including risk of injury, electric shock, or

fatalities. or the damages to instruments. The manual describes what special care the operator

must take to avoid such risks.

iii

CAUTION

This symbol indicates that the operator must refer to the instructions in this manual in order to

prevent the instrument (hardware) or software from being damaged, or a system failure from

occurring.

The following are signal words to be found only in our instruction manuals.

CAUTION

This symbol gives information essential for understanding the operations and functions.

NOTE

This symbol indicates information that complements the present topic.

n Warning and Disclaimer

The product is provided on an “as is” basis. YOKOGAWA shall have neither liability nor

responsibility to any person or entity with respect to any direct or indirect loss or damage arising

from using the product or any defect of the product that YOKOGAWA can not predict in advance.

n Trademark policy

FLEXA, FLXA, SENCOM are the registered trade marks and trade names of Yokogawa’s

products. All other company and product and product names mentioned in this document are

trade names, trademarks or registered trademarks of their representative companies. In this

document, trademarks or trade names are not indicated with TM or ® as trademark symbols.

IM 12B07W01-04EN 1st Edition : Nov. 11, 2016-00

Page 5

u After-sales Warranty

n Do not modify the product.

n During the warranty period, for repair under warranty, carry or send the product

to the local sales representative or service ofce. Yokogawa will replace or

repair any damaged parts and return the product to you. Before returning a

product for repair under warranty, provide us with the model name and serial

number and a description of the problem. Any diagrams or data explaining the

problem would also be appreciated.

• If we replace the product with a new one, we won’t provide you with a repair report.

• Yokogawa warrants the product for the period stated in the pre-purchase quotation

Yokogawa shall conduct dened warranty service based on its standard. When the

customer site is located outside of the service area, a fee for dispatching the maintenance

engineer will be charged to the customer.

n In the following cases, customer will be charged repair fee regardless of

warranty period.

• Failure of components which are out of scope of warranty stated in instruction manual.

• Failure caused by usage of software, hardware or auxiliary equipment, which Yokogawa

Electric did not supply.

• Failure due to improper or insufcient maintenance by user.

• Failure due to modication, misuse or outside-of-specications operation which Yokogawa

does not authorize.

• Failure due to power supply (voltage, frequency) being outside specications or abnormal.

• Failure caused by any usage out of scope of recommended usage.

• Any damage from re, earthquake, storms and oods, lightning, disturbances, riots, warfare,

radiation and other natural changes.

iv

n Yokogawa does not warrant conformance with the specic application at the

user site. Yokogawa will not bear direct/indirect responsibility for damage due

to a specic application.

n Yokogawa Electric will not bear responsibility when the user congures the

product into systems or resells the product.

n Maintenance service and supplying repair parts will be covered for ve years

after the production ends. For repair for this product, please contact the

nearest sales ofce described in this instruction manual.

IM 12B07W01-04EN 1st Edition : Nov.11, 2016-00

Page 6

Chemical Cleaning

pH Measuring System

IM 12B07W01-04EN 1st Edition

CONTENTS

u Introduction ....................................................................................................i

u Safety Precautions ......................................................................................iii

1. General ...................................................................................................... 1-1

1.1 Standard Specications ................................................................................... 1-1

1.2 Model and Sufx Codes ................................................................................... 1-4

1.3 External Dimensions ........................................................................................ 1-6

2. Installation ................................................................................................. 2-1

2.1 Installing the PH8SM3 Chemical Cleaning Unit for a Chemical Cleaning Sys-

tem ...................................................................................................................... 2-1

2.1.1 Where to install the unit ...................................................................... 2-1

2.1.2 Installation Facilities ........................................................................... 2-2

2.1.3 Installing Chemical Cleaning Unit ...................................................... 2-2

2.2 Installing the PH8HS3 Holder .......................................................................... 2-3

2.2.1 Where to install the holder ................................................................. 2-3

2.2.2 Installation Facilities ........................................................................... 2-3

2.2.3 Installing the PH8HS3 Holder ............................................................ 2-4

Toc-1

3. Piping and Wiring ..................................................................................... 3-1

3.1 Piping ................................................................................................................. 3-1

3.1.1 Line for Connecting Air Source .......................................................... 3-2

3.1.2 Line for Actuating Cylinder to Drive Sensor Pneumatically (Upward) 3-2

3.1.3 Line for Actuating Cylinder to Drive Sensor Pneumatically (Downward) 3-2

3.1.4 Line for Forced Feeding of Chemical Solution and Air-bubbling ....... 3-2

3.1.5 Line for Pressurizing KCl Reserve Tank ............................................ 3-2

3.2 Wiring ................................................................................................................. 3-3

3.2.1 Wiring for Intelligent Two-wire pH Transmitter System ......................3-4

3.2.2 Wiring system with 2-Wire Analyzer .................................................. 3-6

4. Operation ................................................................................................... 4-1

4.1 Names and Functions of Components ........................................................... 4-1

4.2 How the Chemical Cleaning pH Measuring System Works ......................... 4-3

4.2.1 Operating Modes ............................................................................... 4-3

4.2.2 WASH (Cleaning) Command .............................................................4-3

4.2.3 Wash Sequence .................................................................................4-4

4.3 Startup ................................................................................................................ 4-5

4.3.1 Inspection of Piping and Wiring ......................................................... 4-5

IM 12B07W01-04EN

1st Edition : Nov. 11, 2016-00

Page 7

Toc-2

4.3.2 Supplying Chemical Solution to Holding Tank ................................... 4-5

4.3.3 Supplying KCl Solution to Reserve Tank ........................................... 4-6

4.3.4 Adjustment of Pneumatic Pressure ................................................... 4-6

4.3.5 Setting Duration of Forced Feeding of Chemical Solution and Output of

CYLINDER FAIL Signal ..................................................................... 4-7

4.3.6 Supplying Power ................................................................................ 4-7

4.3.7 Entering Data Related to WASH Operation .......................................4-7

4.3.8 Verifying WASH Operation ................................................................ 4-8

4.3.9 Calibration with Standard Solution .................................................... 4-8

4.4 Regular Operation ............................................................................................. 4-8

4.4.1 Data Acquisition in Early Stages of Operation ................................... 4-8

4.4.2 Inspections During Regular Operation .............................................. 4-9

4.4.3 Behaviour During Power Failure/Restart ........................................... 4-9

4.4.4 Operation When Shutting Down the System ..................................... 4-9

4.4.5 Procedure When Restarting System Operation .............................. 4-10

5. Inspection and Maintenance ................................................................... 5-1

5.1 Inspection and Maintenance of Operating Unit for PH8SM3 Chemical Cleaning

System ............................................................................................................... 5-1

5.1.1 Inspection of Piping (between chemical cleaning chamber and holder) 5-1

5.1.2 Inspection of Solenoid Valves ............................................................ 5-1

5.1.3 Replacement of Fuses in the Power Supply Box .............................. 5-2

5.2 Inspection and Maintenance of PH8HS3 Holder ........................................... 5-2

5.2.1 Removing Foreign Matter from Wetted Part of Sensor Holder ......... 5-2

5.2.2 Inspecting Gasket on the Bottom Plate of Cleaning Chamber .......... 5-2

5.2.3 Cleaning and Lubricating Pneumatic Cylinder for Driving the Sensor

Holder ................................................................................................. 5-3

5.2.4 Inspecting O-rings on Sensor Holder ................................................ 5-4

5.2.5 Inspecting Terminal Block for Limit Switch .........................................5-4

6. Troubleshooting ....................................................................................... 6-1

6.1 More Than 100 ml of Chemical Solution at a Time Is Being Fed to Holder 6-1

6.2 A Smaller Quantity of Chemical Solution Is Fed to Holder .......................... 6-2

6.3 CYLINDER FAIL Signal Appears .....................................................................6-2

6.4 When Liquid keeps leaking from bottom plate of Cleaning Chamber ........ 6-2

6.5 Chemical Solution Cannot Be Fed into Cleaning Chamber ......................... 6-3

Customer Maintenance Parts List (PH8SM3).................. CMPL 12B07W01-13E

Customer Maintenance Parts List (PH8HS3)....................CMPL 12B07W01-23E

Revision Record .......................................................................................................i

IM 12B07W01-04EN 1st Edition : Nov. 11, 2016-00

Page 8

<1. General>

1. General

Chemical Cleaning pH Measuring System is designed to automatically clean pH electrodes

with a chemical solution while they remain in the system. The system is especially effective in

restoring the performance of a pH electrode which has been deteriorated through repeated

pH measurements of highly alkaline solutions. It is also effective in cleaning pH electrodes

contaminated with calcium sulfate (CaSO

1.1 Standard Specications

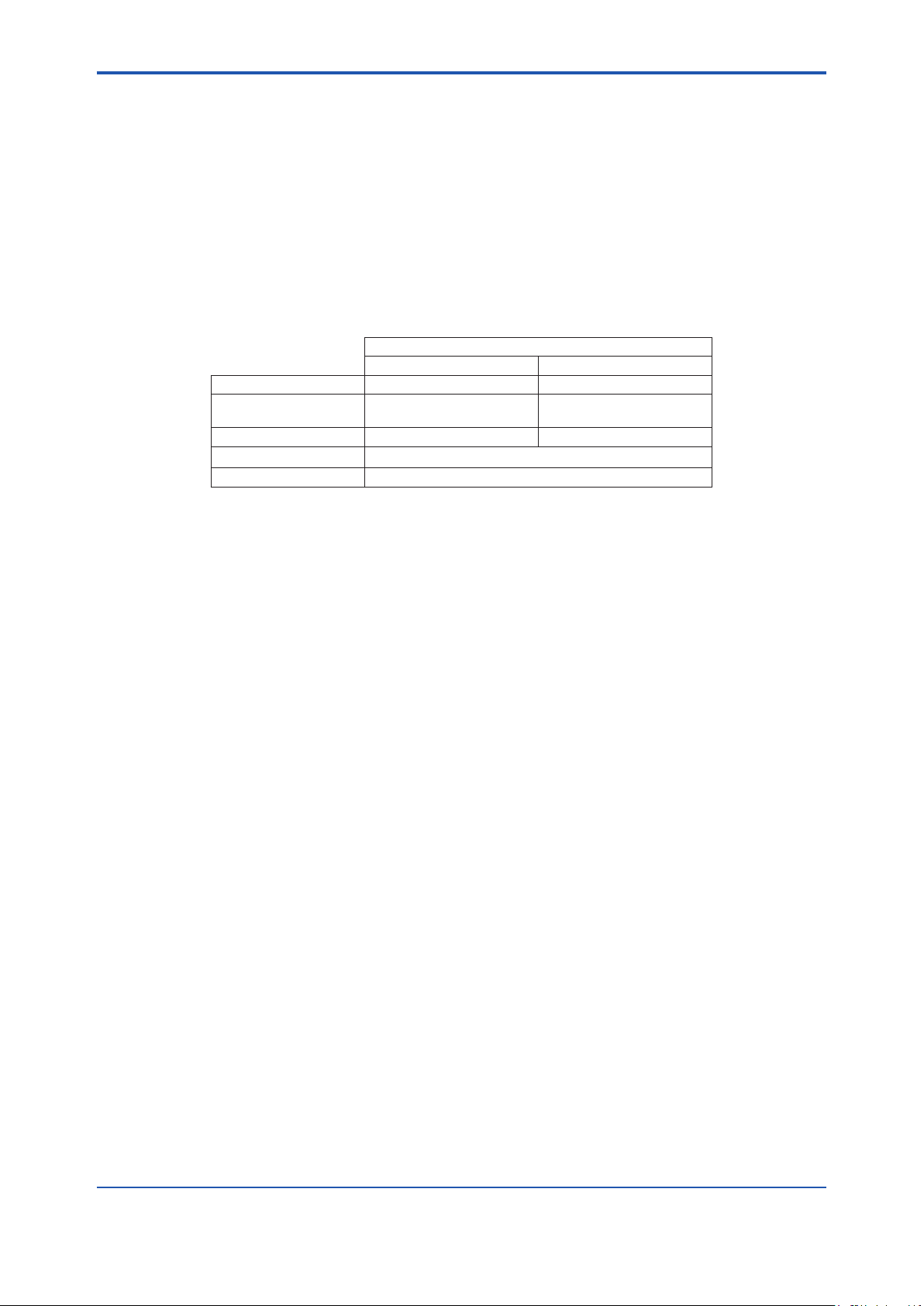

Chemical Cleaning pH Measuring System are congured as the table shown below.

pH/ORP Converter 2-wire Analyzer

Chemical Cleaning unit PH8SM3-E PH8SM3-G or PH8SM3-F

pH analyzer PH450G FLXA202 or FLXA21

Distributor ― PH201G

pH sensor

Holder PH8HS3

Note You can select WTB10 Terminal Box, if necessary.

The following are specication describing on PH8SM3 Chemical Cleaning Unit and PH8HS3

Holder. For more information on other products, please read corresponding instruction manuals

attached to each product.

) scale or calcium carbonate (CaCO3) scale.

4

Chemical Cleaning pH Measuring System

PH8EFP-□-TT2 (Note)

1-1

n PH8SM3 Chemical Cleaning Unit

Cleaning Method:

Automatic chemical cleaning by air bubbling

Interval Time:

0.1 to 36.0 hours (To be set in the pH converter)

Wash Time:

0.1 to 10 min (factory setting: 4 min)(To be set in the pH converter)

Relaxation Time:

0.1 to 10 min. (factory setting: 0.5 min.)(To be set in the pH converter)

Bubbling (SV1: On) Time:

0 to 10 min. (factory setting: Approx. 2 min.)

Cylinder Failure Time:

0 to 1 min. (factory setting: Approx. 0.5 min.)

Structure:

Freestanding rack for indoor installation.(For the uv protection,when you install the unit

outdoors, specify tank cover and select Fluoropolymer (PTFE) tube, or specify hood if

necessary.

Main Components:

Chemical solution tank, control box, air-pressure regulator, and power supply unit (for pH/

ORP Converter only)

IM 12B07W01-04EN 1st Edition : Nov. 11, 2016-00

Page 9

<1. General>

Chemicals for Cleaning:

Acid solution (e.g., hydrochloric acid or diluted sulfuric acid), or alkali solution. Organic

solvents are not allowed.

Note: Select appropriate solution for effective cleaning.

Material, Finish, and Color of Main Components:

Control Box (K9729AN)

Material: Aluminum alloy casting

Colors:

Deep sea moss green (Munsell 0.6GY3.1/2.0) and frosty white (Munsell 2.5Y8.4/1.2)

Finish: Baked polyurethane resin coating

Power Supply Unit (for pH/ORP converter only)

Material: Carbon steel (body)

Color: Deep sea moss green (Munsell 0.6GY3.1/2.0 or equivalent)

Finish: Baked polyurethane resin coating

Mounting Rack

Material: Carbon steel

Color: Deep sea moss green (Munsell 0.6GY3.1/2.0)

Finish: Baked polyurethane resin coating

Chemical Solution Tank (20 L, 2 to 10 % diluted hydrochloric acid or diluted sulfuric acid.

Effective capacity; approximately 17 L, approximately 100 ml is used for each cleaning)

Material: Polyethylene resin (for solution tank), and hard PVC resin (for internal tank)

Tubing for Solution, Air, or KCl

Material of tubes: Polyethylene or Fluoropolymer (PTFE)

Mateirial of tting (joint): polypropylene resin or Fluoropolymer (PTFE)

Ambient Temperature: 0 to 45°C (Note ; Freezing protection is required if necessary.)

1-2

Power Supply: 100 V AC ±10%, 50/60Hz ±5%

Power Consumption: Approx. 60 VA

2

Air Supply: 300 to 950 kPa {3 to 9.5 kg/cm

}

Max. Air Consumption: Approx. 10 Nl/min.

External Dimensions:

500 (W) x 600 (D) x 1630 mm (H)

Weight: Approx. 50 kg (when the chemical tank is empty)

Output Contact Signal: Cylinder failure

Contact State: Normally open (close on error )

Contact Capacity: 24 V DC, 1 A, 110 V AC 0.3 A (resistance load)

Output:

pH/ORP Converter : 4 to 20 mA DC 2 points (isolated transmission output; maximum load of

600 Ω)

2-Wire Analyzer : 1 to 5 V DC (minimum resistive load of 2 kΩ)

Cable Connection: G 1/2 gland packing is supplied.

Terminal Size: M4

Outside Cable Diameter: Φ9 to Φ12 mm

Piping Connection: Air for Instrumentation: Rc 1/4 female thread

Note 1: Install the KCl reserve tank in an appropriate place at the job site or attached to the stand for the

chemical cleaning unit.

IM 12B07W01-04EN 1st Edition : Nov 11, 2016-00

Page 10

<1. General>

1-3

Note 2: The wiring and piping between the chemical cleaning unit, sensor, KCl reserve tank, and holder are to

Note 3: The wiring between the switch in the holder and the chemical cleaning unit is to be done by the user.

be done by the user.

The terminal size is M4.

EMC Compliance: Korea Electromagnetic Conformity Standard Class A

A급 기기 (업무용 방송통신기자재)

이 기기는 업무용(A급) 전자파적합기기로서 판매자 또는

사용자는 이 점을 주의하시기 바라며, 가정외의 지역에서

사용하는 것을 목적으로 합니다.

n PH8SM3 Holder

Functions:

Moves the pH sensor up or down using a pneumatic cylinder (air cylinder), and provides

chemical cleaning.

Structure: Constructed for indoor use (

Max. External Dimensions:

190 (W) x 170 (D) x Approx. 830 to 2030 mm (H) (when the sensor is raised)

Mounting:

Mounted on a 2-inch (50A) vertical pipe (outside diameter: 60.5 mm). Two mounting

brackets are supplied.

pH Sensor Up/Down Movement (nominal):

한국 전자파적합성 기준

For outdoor installation, select Cylinder cover /SC as Option.)

300 mm, 600 mm, 1000 mm, 1500 mm

Weight:

Approx. 8 kg (holder with 300 mm movement)

Approx. 10 kg (holder with 600 mm movement)

Approx. 12 kg (holder with 1000 mm movement)

Approx. 15 kg (holder with 1500 mm movement)

Materials

Frame: Baking nish over staineless steel

Color: Deep sea moss green (Munsell 0.6GY3.1/2.0 or equivalent)

Bottom Cover Pull-up Mechanism: Rod (PPS resin) and screws (PEEK)

Mounting bracket: staineless steel

Holder: Polypropylene and hard PVC (for part of a holder)

Solution Chamber: Hard PVC

O-ring: Fluororubber

Gasket: EPDM

Solution Temperature Range: -5 to 80°C

Ambient Temperature: 0 to 45°C

Flow Speed: 2 m/s or less

Provide an adequate ventilation when using chemicals.

IM 12B07W01-04EN 1st Edition : Nov. 11, 2016-00

Page 11

<1. General>

1.2 Model and Sufx Codes

The name plate on product describes each specication of the product. The following are Model

and Sufx Code and their details on PH8SM3 and PH8HS3.

n PH8SM3 Chemical Cleaning Unit

●Model and Sufx Codes

Model Sufx code

PH8SM3 - - - - - - - - - - - - - - - - - - Operating Unit for Chemical Cleaning System

(*1)

-E

-F

-G

-TT2 - - - - - - - - Medium-pressure reserve tank *2

-NN

-PR

-NP

pH

measuring

system

KCl reserve

tank

Pressure

regulator for KCl

tank

Air connection -JP

Tubing for cleaning

chemicals

Style code *C - - - - - - - - Style C

Option /H

*1: The pH/ORP converter or 2-wire analyzer is attached to the chemical cleaning operating unit when shipped.

*2: For PH8EFP sensor, select KCl reserve tank (sufx code “-TT2”) with a medium-pressure.

*3: Polyethylene is susceptible to degradation upon UV radiation. Specify the Fluoropolymer (PTFE) (-T10) as tube

material, when you install PH8SM3 outdoors. Specify the Fluoropolymer (PTFE) when using PH8HS3 holder

outdoors, even though you install PH8SM3 unit indoors.

*4: Specied at the outdoor installation. Hood is made of precoated SEHC.

*5: Specied at the outdoor installation. The cover is made of non-coated stainless steel.

*6: For FLXA21 or FLXA202 with the sufx code -F, or -G, specify the type -AG (for general purpose for KC

-L10

-T10

Option code

- - - - - - - -

- - - - - - - -

- - - - - - - -

- - - - - - - -

- - - - - - - -

- - - - - - - -

- - - - - - - -

- - - - - - - -

- - - - - - - -

/TC

/KC

Specications

pH/ORP converter (PH450G)

2-wire Analyzer(FLXA21)

2-wire Analyzer(FLXA202)

None

Attached to the stand

Rc1/4

1/4 NPT female thread

Polyethylene (Connections: Polypropylene)

Fluoropolymer (PTFE)

(Connections: Fluoropolymer (PTFE))

With hood *4

With tank cover *5

for Korean Certicate *6

*3

1-4

).

CAUTION

The system must undergo start-up service when the chemical cleaning pH measuring system is installed.

l Accessories

Description Qt'y Remarks

6 (OD) x 4 (ID) polyethylene

Fitting (polyethylene resin or Fluoropolymer (PTFE)) 6 3 for joint, 3 for spare parts *2

*1: 1 tube for the control box-the chemical tank assembly

3 tubes for the PH8SM3-Ph8HS3

1 tube for the pressure valve-KCI reserve tank, if the operating unit has the pressure reducing valve for KCI.

Cut the tube into an approriate length to use.

*2: If the operating unit has a pressure-reducing valve that lowers the pressure on the KCl reserve tank, one of

these spare ttings is to be used for the piping port of the valve.

resin or Fluoropolymer (PTFE) tube

40 m

For tubing *1

IM 12B07W01-04EN 1st Edition : Nov 11, 2016-00

Page 12

<1. General>

l Spare Parts

Description P/N Remarks

Fuse for power supply

box

Polyethylene tubing

Fluoropolymer (PTFE)

tubing

Polypropylene tting

Fluoropolymer (PTFE)

tting

A1109EF Rating: 1A (for pH/ORP converter only)

L9901CA

L9901LG

L9831NA

L9831NE

L9831JE

L9831TS

L9831TT

Specied length by meters

Specied length by meters

L-shape tting (R1/8)

L-shape tting (R1/4)f

I-shape tting (R1/4)

L-shape tting (R1/8)

L-shape tting (R1/4)

n PH8HS3 Holder

●Model and Sufx Codes

Model Sufx

PH8HS3 - - - - - - - - - - - - - Holder for Chemical Cleaning

Material -PP - - - - - Polypropylene

Movement -03

pH measuring

system

Cleaning system -YP - - - - - Acid or alkali solutions can be used.

Style code *C - - - - - Style C

Option /SC Cylinder cover for outdoor use *1

*1: For outdoor installation, select Cylinder cover /SC as Option.

code

-06

-10

-15

-C

-T

Option

code

- - - - -

- - - - -

- - - - -

- - - - -

- - - - -

- - - - -

Specications

300 mm (with 2 mounting brackets)

600 mm (with 2 mounting brackets)

1000 mm (with 2 mounting brackets)

1500 mm (with 2 mounting brackets)

pH/ORP Converter

2-wire Analyzer

1-5

l Accessories

(other than mounting brackets and sensor holder)

Description Qt'y Remarks

M8 x 16 mm bolts and nut

Washers

U bolts (M8)

Washers and nuts

Rubber sheet (19 x 40 mm)

Plate

Clamp

M4, 16mm screw

Piping tting (polypropylene) 3 Parts for PH8SM3 holder (used for piping port)

Cable tie 5 For KCl supply tube/sensor cable

Spare gaskets (P/N: K9729WJ) 1 Parts for cleaning chamber of PH8HS3 holder

4/pkg

Parts for mounting brackets (used to mount to the

8

holder)

Parts for mounting brackets

2

(used to mount to 2-inch pipe)

4/pkg

1

Parts for sensor holder (used to x sensor cable)

1

1

1

l Spare Parts

Description P/N

Gasket K9729WJ

O-rings K9729YK

Qt'y

1

2

Remarks

Material : EPDM

1p/pkg. Replace both of the two rings at the same time.

IM 12B07W01-04EN 1st Edition : Nov. 11, 2016-00

Page 13

<1. General>

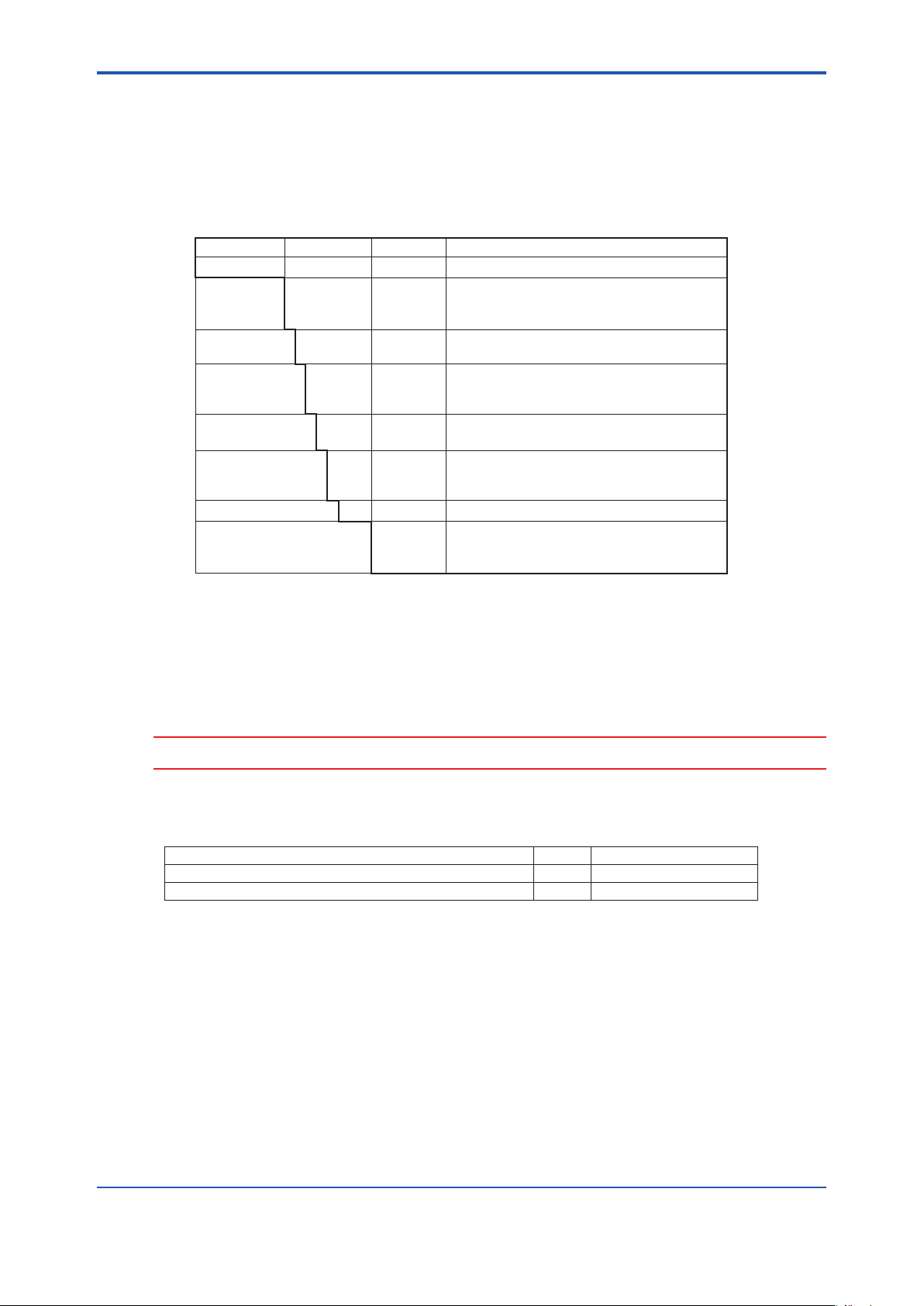

1.3 External Dimensions

n PH8SM3 Chemical Cleaning Unit

l pH/ORP Converter (PH8SM3-E)

)

Option

(

Hood

)

KCl reserve tank *1

an be installed

c

(

)

PH450G

Separated Order

(

1-6

unit:mm

Control Box

*2 Pressure Regulator

for KCI reserve tank

Tank Cover

Option

(

(AS3)

)

Power

Supply Unit

Air Inlet *3

(Rc1/4 or

1/4NPT)

Tank cover

fixing screws

option

(

)

PVC plate

30 440

500 600

4-Φ15fixing holes

l 2-Wire Analyzer (PH8SM3-G, -F)

KCI reserve tank *1

(Can be installed)

(Separated Order

FLXA21

Control Box

*2 Pressure Regulator AS3

for KCI reserve tank

(

Tank Cover

(Option)

fixing screws

)

)

Tank cover

(Option)

(1540)

(1200)

40

(30)

30 540

FLXA202

(Separated order)

Air Inlet *3

Rc1/4

(

or 1/4NPT

)

(1200)

Stand

SEHC

(

Chemical Solution

tank (20 L)

Hood(Option)

(1540)

SEHC

(

Chemical Solution

Tank (20 L)

)

Stand

1630

1600

Power Cable Inlet

Cable O.D.

(Φ9 ~ 11)

(30)

unit:mm

1630

1600

)

PVC plate

40

30 440

(30)

30 540

(30)

500 600

4-Φ15Fixing holes

*1: Mount the KCl solution reserve tank when necessary after installation. If the hood is specied, (Option code /H

is specied) mount the tank on the hood.

*2: This is a pressure valve to regulate the air that increases the pressure in the reserve tank for the KCl solution.

This valve is added only when specied.

*3: If no pressure valve is specied, there is no tube tting. Air inlet connects directly to piping port of the control

box.

IM 12B07W01-04EN 1st Edition : Nov 11, 2016-00

Page 14

<1. General>

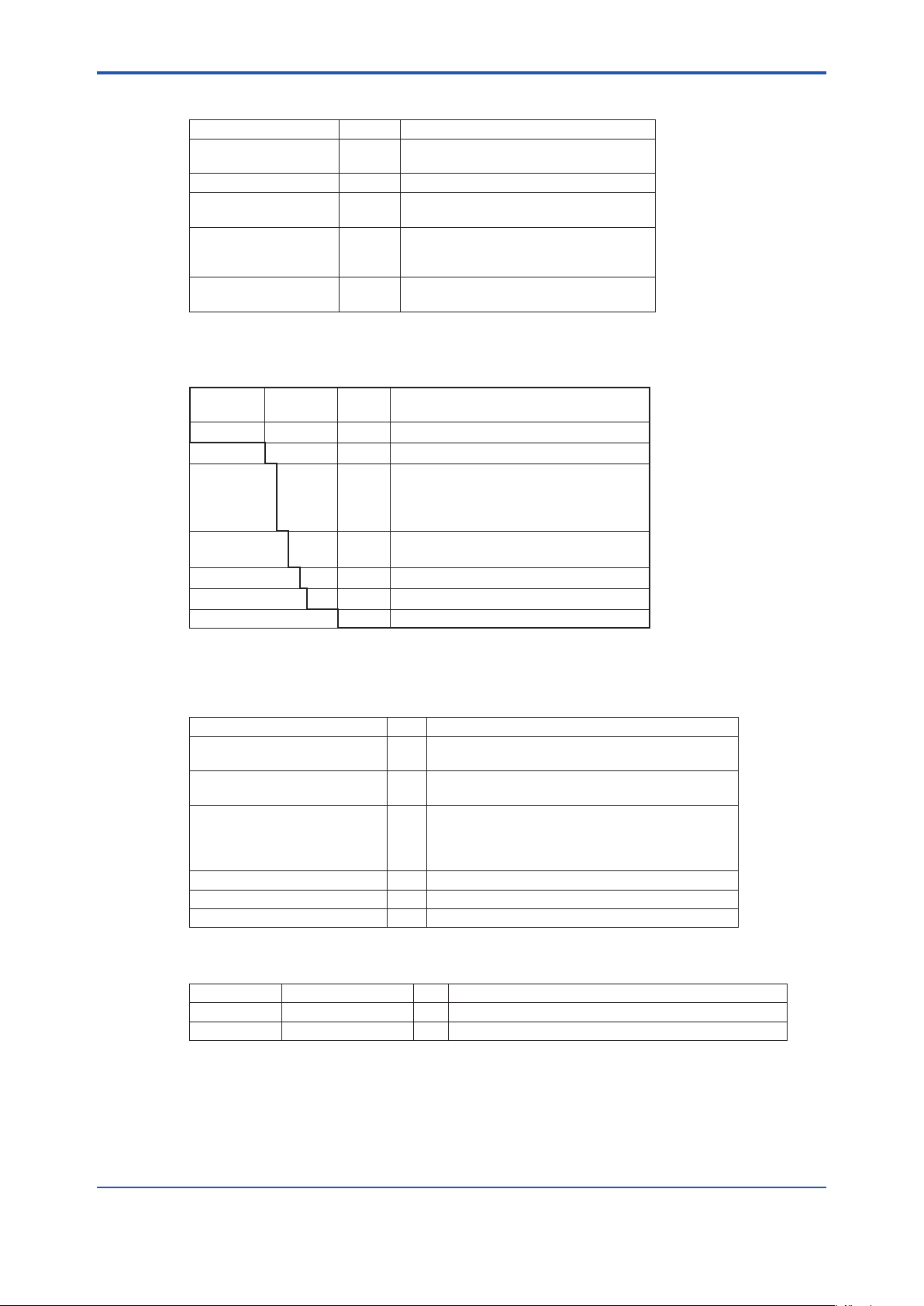

n PH8HS3 Holder

1-7

36

Cylinder Cover

(Option)

(130)

(126)

35 pitch

60

80

Grommet for

external wiring

55485 max.

48

(

70

Approx.150

Mounting bracket

with U-bolts

50A Pipe

provided by customer

2-Φ9 holes

Sensor cable

and KCI tube

Approx.110

)

Cylinder

Movement

247

(65)

C

B

L6

L5

L4

300

230

Unit: mm

L2

136

L1

(95)

A

80

L3

nominal movement

(170)

During

measurement

30mm or longer

Solution being measured

During

Cleaning

30379

During

measurement

pH electrode

20

Tubing Connections

A : Chemical solution inlet (Ø6/Ø4 tube joint)

B : Lower air inlet of cylinder (Ø6/Ø4 tube joint)

C : Upper air inlet of cylinder (Ø6/Ø4 tube joint)

Nominal

movement

300mm 340mm 1107 712 395 – – –

600mm 640mm 1707 1012 695 300 – –

1000mm 1040mm 2507 1412 1095 300 300 –

1500mm 1540mm 3507 1912 1595 300 300 300

Specify the nominal movement when ordering. L4, L5, and L6 designate the movable position for the pipe mounting bracket.

Note: ● Mounting bracket for holder will be shipped separately.

● Joint nipple will be attached with PH8SM3 Chemical Cleaning unit.

● For the outdoor installation, select /SC option of cylinder cover

Actual

movement

L1 L2 L3 L4 L5 L6

IM 12B07W01-04EN 1st Edition : Nov. 11, 2016-00

Page 15

Blank Page

Page 16

<2. Installation>

2. Installation

The chemical cleaning pH measuring system can be installed indoor/outdoors. Choose an

appropriate location (free from dust, sunlight, rain) for easy maintenance. Note that since the

system uses water for washing and a chemical solution, care must be taken to ensure that these

liquids are protected from freezing in winter.

Note: Install the PH201G distributor, which is required when using the 2-Wire Analyzer, in an

indoor location such as an instrument room.

This chapter explains the procedure for installing the component equipment, highlighting the

PH8SM3 Chemical Cleaning Unit for the chemical cleaning system and the PH8HS3 holder.

2.1 Installing the PH8SM3 Chemical Cleaning Unit for a Chemical Cleaning System

2.1.1 Where to install the unit

Install the PH8SM3 operating unit for a chemical cleaning system in a location which meets the

following requirements.

(1) Close to the pH measurement point (location where the PH8HS3 holder is installed)

2-1

The operating unit for the chemical cleaning system and the holder are connected via

electrical wiring as well as the piping through which the chemical solution is supplied. Keep

the length of the tubing for supplying the chemical solution to a minimum (less than 10 m) in

order to reduce piping resistance.

(2) The maximum tube length between the cleaning unit and the sensor holder is 10 m.

It is preferable to install the stand at the same level as the sensor holder. If this is impossible,

the stand can be installed a maximum of 2 m below the holder level. Installation above the

holder level causes no problem.

(3) Easy access for maintenance work

The location must allow users to have an easy view of the display on the PH450G pH/ORP

Converter or 2-wire Analyzer FLXA202/FLXA21, and to operate the control box with ease

to set the pressure. Also, consider the ease of work required when relling the holding tank

with the chemical solution. Furthermore, secure the clearance for maintenance access

shown in Figure 2.1.

Unit: mm

PH8SM3

Approx. 1150

Front view

Approx. 500

More than 900

Figure 2.1 Clearance for Maintenance Access

F2.1.ai

IM 12B07W01-04EN 1st Edition : Nov. 11, 2016-00

Page 17

<2. Installation>

(4) Ambient temperature is always maintained in the range of 0 to 45˚C

Check if there is any possibility that the cleaning chemical solution can freeze in winter or

if the pH/ORP Converter (or 2-Wire Analyzer) or the control box are subject to abnormal

temperature rises from direct sunlight. A location exposed to constant high humidity is not

desirable either.

(5) Free from vibration

The location must be free from such vibrations that might loosen piping connections.

(6) Free from corrosive gases

It is desirable that the location be free from any corrosive gas which may adversely affect

the components within the pH/ORP converter (or 2-Wire Analyzer) or the control box.

2.1.2 Installation Facilities

The PH8SM3 operating unit for the chemical cleaning system has a stand-alone construction

and can be securely attached with nuts to anchor bolts set in a concrete base.

l Construction of concrete base to install operating unit for chemical cleaning system

The PH8SM3 operating unit of the chemical cleaning system weighs approximately 60 kg when

the tank is lled with the chemical solution. Consequently, the facilities must be strong enough to

hold the weight of the entire unit. The facilities must also provide good drainage, Prepare anchor

bolts with M10 threads to secure the unit. Figure 2.2 shows how to set these anchor bolts in the

installation site.

2-2

Unit: mm

Dimensions of vat for operating unit of

M10 thread

Concrete base

Note: The holes (four) for the anchor bolts on the operating unit of the chemical cleaning system are 15 mm in diameter.

Figure 2.2 Setup of Anchor Bolts for Attaching Operating Unit of Chemical Cleaning System

chemical cleaning system

25

Approx. 60

540 600

Position of anchor bolt

Front view

440

500

F2.2.ai

2.1.3 Installing Chemical Cleaning Unit

After completing construction of the installation facilities, install the operating unit of the chemical

cleaning system. Tighten the nut securely (with nuts in all four locations.).

IM 12B07W01-04EN 1st Edition : Nov 11, 2016-00

Page 18

<2. Installation>

2.2 Installing the PH8HS3 Holder

2.2.1 Where to install the holder

The PH8HS3 holder must be installed in a location which is appropriate for pH measurement and

control and satises the following requirements.

(1) Safe and easy access for maintenance work.

This requirement must be satised since the holder is raised and removed when attaching/

detaching the pH sensor.

(2) Even in winter, the temperature must remain above that temperature at which the

chemical solution freezes.

Also, any condensation on the moving parts of the PH8HS3 holder cannot be allowed to

freeze.

(3) Protected from excessive dust in the air.

The presence of excessive dust may lead to an increased need to clean (removal of dust

from the cylinder).

2.2.2 Installation Facilities

The PH8HS3 holder is mounted on a 50A (OD: 60.5 mm) pipe installed in an upright position.

Provide the installation location with facilities to set the pipes and inserting sensors Special

attention must be paid to the following points when constructing these facilities:

2-3

l Position of pH measurement point (position of pH sensor) in relation to the

mounting pipe

Mounting pipe

pH sensor

Approx. 150

pH sensor

485 maximum

(Can be shorted in length of 205 mm by 35 mm pitch)

Figure 2.3 Position of pH Sensor in Relation to Mounting Pipe with Dimensions of Opening for

Inserting pH sensor

110 or more

160 or more

Machining of opening for inserting pH sensor

(for tanks with a covering)

60 or more

l Height (length) of mounting pipe

Position of upper mounting bracket

(Pitch: 300 mm)

Position of lower mounting bracket

More than 310

Covering (machined

to provide an opening)

Measured solution

Figure 2.4 Length (Height) of Mounting Pipe

P L

H

Ground

Mounting pipe

(OD: 60.5 mm)

Note: When employing a covering to prevent

the chemical solution from spattering,

refer to the dimensions of the opening

for inserting the pH sensor shown in

Figure 2.3.

Nominal Stroke L P H

300 mm 400 minimum 300 500 to 590

600 mm 700 minimum 300x2 500 to 890

1000 mm 1000 minimum 300x3 500 to 1290

1500 mm 1000 minimum 300x4 500 to 1790

Unit: mm

F2.3.ai

Unit: mm

F2.4.ai

IM 12B07W01-04EN 1st Edition : Nov. 11, 2016-00

Page 19

<2. Installation>

2.2.3 Installing the PH8HS3 Holder

Follow the procedure below to mount the PH8HS3 holder onto the pipe.

(1) Attach the mounting brackets (two pairs) to the holder by adjusting the position of the pH

sensor to satisfy the required distance to the pipe. To attach brackets, use the bolts (two

each), washers (four each) and nuts (two each) that with the holder.

(2) Assemble the U bolts, washers and nuts into the brackets (see Figure 2.5).

Nut

(Pipe)

U bolt

Figure 2.5 Parts for Mounting Bracket (Included)

Washer

Mounting bracket

Washer

Nut

Bolt (M8)

Washer

Chassis

F2.5.ai

2-4

(3) Assemble the PH8EFP pH sensor onto the sensor holder.

a. First remove the rubber cap on the top end of the sensor holder. Then thread the cable of

the pH sensor and the KCI supply tube from the bottom end of the sensor holder and then

pull them out from the top end.

b. Insert the pH sensor into the sensor holder so the sensor ange contacts the bottom end of

the sensor holder.

Note: Two O-rings are used to seal the openings of the sensor holder to prevent the

measured solution from leaking into the holder.

c. Using the supplied parts (plate, clamp, screw and rubber sheet), attach the given latch

mechanism to the sensor cable to prevent the sensor and sensor holder from coming apart

(see Figure 2.6).

KCl supply tube

Plate

Note:

·Fasten only the sensor cable with the clamp.

·Make sure that there is no slack in the sensor

cable inside the sensor holder.

Sensor cable

Rubber sheet (19 x 40 mm) [P/N K9729WE]

Attach the rubber sheet around the sensor cable

with the 40 mm length parallel with the cable.

Clamp

Screw

Sensor holder

Figure 2.6 Treatment to Prevent the pH Sensor from Coming Apart

d. Replace the rubber cap on the sensor holder.

e. Using the cable tie (included), securely fasten the sensor cable and the KCl supply tube to

the sensor holder. ( Figure 2.7)

IM 12B07W01-04EN 1st Edition : Nov 11, 2016-00

Page 20

<2. Installation>

Rubber cap

Sensor holder

Cable tie

Pass the cable tie through the

opening of the metal fitting

and then fasten the sensor cable

and, the KCI supply tube together.

KCl supply tube

Figure 2.7 Fixing the Sensor Cable and KCI Supply Tube

Metal fitting

Sensor cable

F2.7.ai

(4) Fix the PH8HS3 holder to the pipe

CAUTION

When installing the holder, avoid any contamination or moist/wet on the tip of the sensor cable.

2-5

When xing the holder, make sure both of the following requirements are completely satised:

• During measurement, the tip of the pH sensor must be submerged in the measured

solution.

Carefully observe any changes in the liquid level.

• The bottom plate of the holder’s cleaning chamber must not become wet with the

measured solution.

Contamination of the gasket on the bottom plate by the solution will lead to a decrease in the

gasket’s sealing capability.

CAUTION

When the bottom plate of the holder’s cleaning chamber is open, good ventilation must attend its use

to prevent the holder from corrosive gas.

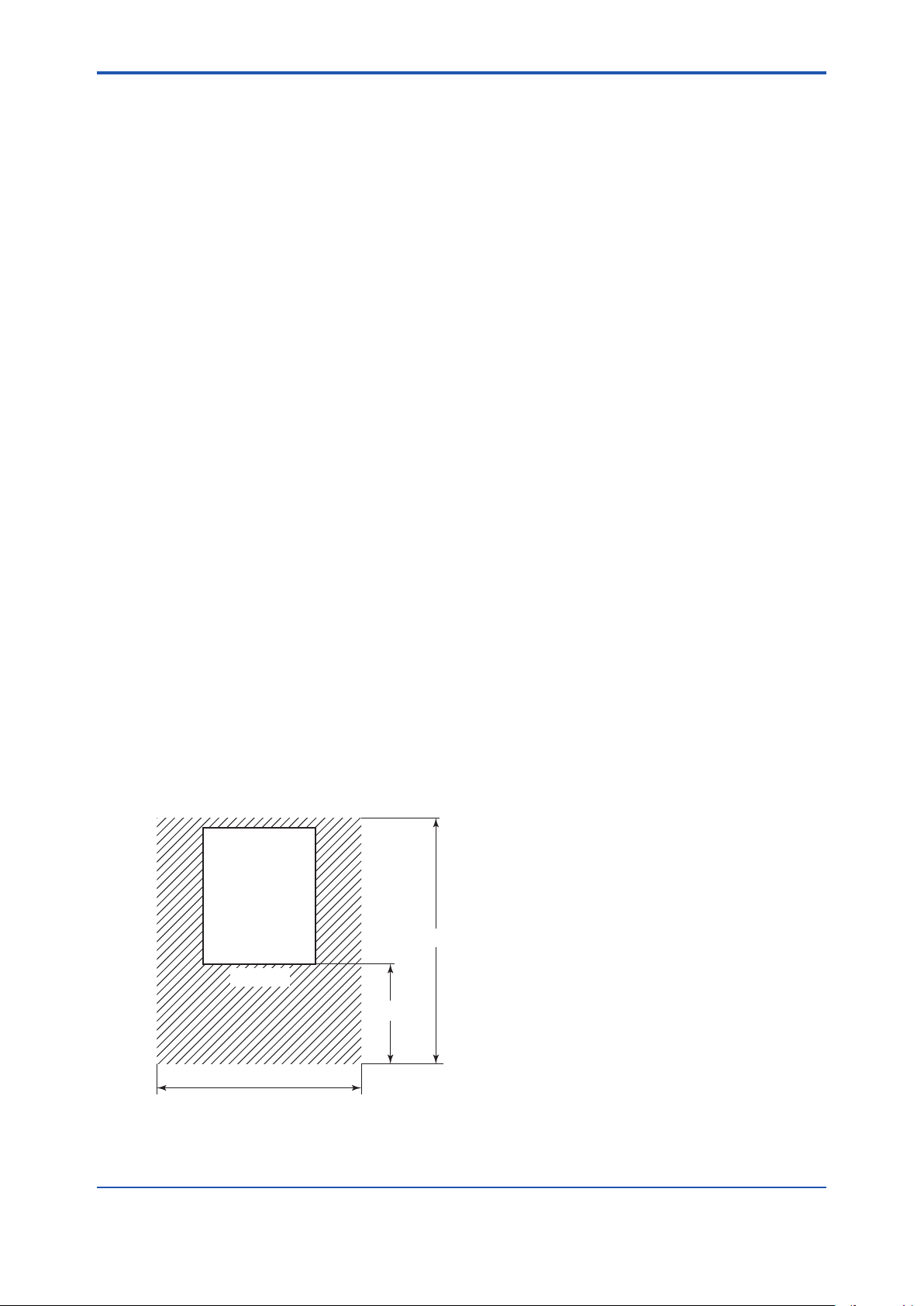

Figure 2.8 illustrates the PH8HS3 holder when it is installed.

IM 12B07W01-04EN 1st Edition : Nov. 11, 2016-00

Page 21

<2. Installation>

Install the holder so the tip of the pH

sensor drops into the measured

solution to a depth of 30 to 90 mm.

2-6

Do not allow the bottom

plate of the cleaning

chamber to become

submerged in the

measured solution.

Measured

solution

Figure 2.8 Installed PHSHS3 Holder

Tank

Measured

solution

F2.8.ai

l Installing the medium-pressure KCl reserve tank

The KCl reserve tank supplied with the PH8EFP KCl-lling type pH sensor can be installed in the

operating unit for the chemical cleaning system (see Figure 1.1).

Note: Use an appropriate length of KCI supply tube for PH8EFP KCI supply PH sensor.

If installing the KCl reserve tank in other locations, choose a location which is higher than where

the cleaning chamber of the PH8HS3 holder is positioned.

Note This is important to maintain the normal position of liquid junction even when the supply of the pressurizing

air stops.

After completing installation of the KCl reserve tank, connect the KCl supply tube of the pH

sensor to the outlet of the KCI reserve tank.

l Submersion of pH sensor when the measured solution ows fast.

Rapid and continuous ow of measured solution can give the sensor holder distortion, which

hampers the ascent/descent motion of the holder, therefore the result of the measurement may

be affected. Appropriate installation must be guaranteed without distortion of the sensor holder.

If the ow of measured solution gives the sensor holder distortion, install the holder so the tip of

the pH sensor drops in to the solution to a depth of 30 to 90 mm. If this method is not available,

reduce the ow speed so that the distortion never occurs. For the stability of the measurement

result as well, the ow speed must be 2 m/sec or less at a measuring point.

IM 12B07W01-04EN 1st Edition : Nov 11, 2016-00

Page 22

<3. Piping and Wiring>

3. Piping and Wiring

3.1 Piping

The following lines must be provided to the chemical cleaning pH measuring system.

Lines (2) through (4) are polyethylene resin tubing or joints supplied with the system. Always

make sure that the length of each line is kept to a minimum (less than 10 m).

(1) Line for connecting air source

(2) Line for actuating cylinder to drive sensor pneumatically (upward)

(3) Line for actuating cylinder to drive sensor pneumatically (downward)

(4) Line for forced feeding of chemical solution and air-bubbling

(5) Line for pressurizing KCl reserve tank

Note: If you specify, polyethylene tube or Fluoropolymer (PTFE) tube of 40 m in length come with PH8SM3

with their corresponding tting.

If you do not use the piping materials that came with your system, refer to the notes given in

Subsection 5.1.1. Figure 3.1 shows the pipe lines in the system.

PH8SM3 Operating unit for chemical cleaning system

3-1

AS3

Internal tank

PG3

AS2

AS1

A

Air

Control box

PG2

PG1

SV1

B C D E

F G

Chemical solution

Tank (20 l)

SV2

Purge

(purge air outlet)

KCl tank (medium pressure)

(The KCl tank of the pH

sensor is used)

Dedicated tube

K

J

H

Process

liquid bath

PH8HS3

Holder

pH sensor

Pressure reduction valve

AS1:

for forced feeding of

chemical solution

Pressure reduction valve

AS2:

foe actuating cylinder

AS3:

Pressure reduction valve

(optional) for pressurizing

the KCl tank

PG1:

PG2:

PG3:

SV1:

SV2:

Figure 3.1 Piping Diagram

Pressure gauge

Pressure gauge

Pressure gauge (optional)

2-way solenoid valve

(N, C)

4-way solenoid valve

<Piping>

Air source connection

A:

Rc1/4 or 1/4NPT

Pneumatic line

B - F:

for forced feeding of

chemical solution

Pneumatic line raise

C - J:

the sensor holder

Pneumatic line to lower

D - K:

the sensor holder

Line for forced feeding

G - H:

of chemical solution

IM 12B07W01-04EN 1st Edition : Nov. 11, 2016-00

Page 23

<3. Piping and Wiring>

3.1.1 Line for Connecting Air Source

Air with a pressure of 300 to 950 kPa (3 to 9.5 kg/cm2) is supplied to the operating unit of the

chemical cleaning system. Use a steel or stainless steel line with an inner diameter greater than

6 mm to connect the air source to piping port “A” (air) in the control box.

Note : The piping port is Rc1/4 thread or 1/4 NPT female-thread (as specied when ordering).

The maximum air consumption is approximately 10 normal litter/min.

3.1.2 Line for Actuating Cylinder to Drive Sensor

Pneumatically (Upward)

This line is provided to allow the pH sensor to be withdrawn from the measured solution during

cleaning and then housed in the cleaning chamber. This line connects the holder (the piping

port labelled “J”) with the control box (piping port “C” [the lower section of the cylinder] ). Use the

tubing supplied with the system when connecting these ports.

3.1.3 Line for Actuating Cylinder to Drive Sensor

Pneumatically (Downward)

This line is provided to allow the pH sensor once housed in the cleaning chamber to be returned

to a measurement position after cleaning. This line connects the holder (the piping port labelled

“K”) with the control box (piping port “D” [the upper section of the cylinder]), Follow the same

piping procedure as that discussed in Subsection 3.1.2.

3-2

3.1.4 Line for Forced Feeding of Chemical Solution and Air-

bubbling

This line is provided to supply air for forced feeding of approximately 100 ml of the chemical

solution into the cleaning chamber during cleaning and then to bubble the chemical solution in

the chamber. During piping, connect the control box (piping port “B” [forced feeding of chemical

solution]) with the metering tank (piping port “F” [IN]) built in the holding tank for the chemical

solution, Also, connect the metering tank (piping port “G” [OUT]) with the holder (piping port “H”).

If the holding tank is positioned above the holder, always connect the tubing so at least a part

of the tubing is positioned above the cleaning chamber. Failure to observe this instruction may

result in the chemical solution fed to the cleaning chamber owing back into the holding tank after

air bubbling.

Follow the same piping procedure as that discussed in Subsection 3.1.2.

3.1.5 Line for Pressurizing KCl Reserve Tank

An air pressure of approximately 10 kPa (0.1 kg/cm2) is applied to the KCI reserve tank for the

pH sensor. Connect the outlet of the pressure reduction valve with the pneumatic connection

port of the KCI reserve tank. If so specied, the operating unit of the chemical cleaning system is

supplied with an “AS3” pressure reduction valve along with a polyethylene tube (10 m long) for

piping

IM 12B07W01-04EN 1st Edition : Nov 11, 2016-00

Page 24

<3. Piping and Wiring>

3.2 Wiring

The following six electrical connections must be provided to the chemical cleaning pH measuring

system. Note that slightly different wiring procedures are used depending on the system

conguration, either the intelligent two-wire pH transmitter system or the intelligent four-wire pH

converter system.

(1) Connection for pH sensor cable

Connect the pH sensor cable assembled in the PH8HS3 holder with the terminals of the

PH450G pH/ORP converter or 2-wire analyzers’ (FLXA202/FLXA212) terminals.

NOTE

The standard pH sensor cable is 3 m or 20 m long. If the PH8HS3 holder is located away from

the PH8SM3 operating unit at a distance greater than either of these lengths, it may become

necessary for you to use the PH8TBG/WTB10 terminal box through which this connection is

made.

(2) Connection for DETECT UPPER LIMIT signal (signal for detecting the upper limit of the

sensor holder’s position)

Connect the terminals of the PH8HS3 holder with the terminals of the control box in the

PH8SM3 operating unit.

3-3

(3) Connection for power supply and ground

For the intelligent four-wire pH converter system, set up power-supply connections with the

power supply box in the PH8SM3 operating unit. For the two-wire pH transmitter system, set

up power-supply connections with the terminals of the control box in the PH8SM3 operating

unit, Supply power to the PH201G distributor.

Note: The methods of power-supply connection (either a plug or terminal connection) differ

depending on the specications of the PH201G distributor. For further details, see the

IM19B01E04-02E user’s manual.

(4) Connection for pH signal

For the intelligent four-wire pH converter system, set up wiring for signal output on the

PH450G pH/ORP converter.

For the two-wire pH transmitter system, set up connection (for a transmission signal)

between the PH202G intelligent pH transmitter and the PH201G distributor, with the wiring

for an output signal provided to the PH201G distributor.

(5) Connection for contact output of CYLINDER FAIL signal

Set up this connection with the control box in the PH8HS3 operating unit.

(6) Connection for contact input of WASH (cleaning) signal

This connection is essential for the two-wire pH transmitter system. Set up the connection

between the control box and the PH201G distributor.

Note: For the four-wire pH converter system, connect the control box with the PH450G pH /

ORP converter (this connection is already made before shipment).

IM 12B07W01-04EN 1st Edition : Nov. 11, 2016-00

Page 25

<3. Piping and Wiring>

3.2.1 pH/ORP Converter System

Figure 3.2 illustrates electrical connections for pH/ORP converter system.

PH450G

Output signal

(4 to 20 mA DC, HART)

Output signal

(4 to 20 mA DC)

Remote

Contact input

Air Cylinder

21

22

Jumper

mA1

mA2

CONTACT

IMP.LOW

13

11

12

14

15

16

POWER

S1

S2

S3

S4

(Failsafe)

NC

NO

NC

NO

NC

NO

NC

NO

1

2

C

C

C

C

3-4

pH

Holder

1

2

pH Sensor

Position signal

PH8SM3

Control Box

8

9

Ground to earth

4

5

6

7

1

2

3

Cleaning signal

A1 A2

L1

L1

L2

L2

Power

supply unit

Cylinder failure signal

wiring by customer

100V AC

Figure 3.2 Wiring for pH/ORP Converter (PH8SM3-E)

(1) Connection for pH sensor cable

Connect the sensor cable so that the code on each core wire matches the corresponding

code on the PH450G pH/ORP Converter. For more information about sensor cable

connection, see the user’s manual “PH450G pH/ORP Converter.” Also refer to “WTB10

Relay Terminal Box” user’s manual if your system uses a relay terminal box.

CAUTION

The sensor cable and the KCI supply tube move up and down in synchronization with the sensor

holder along the PH8HS3 holder. No slack in cable or tube is allowed. Provide an installation

location to ensure that a smooth up-and-down motion takes place. The cable or tube may be

damaged if, during the up-and-down motion, it comes into accidental contact with the PH8HS3

holder or other structures.

(2) Connection for DETECT UPPER LIMIT signal (signal for detecting the upper limit of

sensor holder’s position)

Use a two-core cable with an outer diameter of 9 to 12 mm for this connection. Treat both

ends of each cable core so they t M4 threads. Connect terminal 1 of the terminal block for

the limit switch of the PH8HS3 holder to terminal 8 of the control box, and terminal 2 with

terminal 9.

Note: There will not be a problem if you connect terminal 1 with terminal 9 and terminal 2 with

terminal 8.

The cable inlet of the PH8HS3 holder is located on the right-hand side of the chassis’s upper

section. When wiring the cable, loosen the two screws and remove the cover (for protection

against drips). After the completion of wiring, always make sure the cover is reinstalled in

place.

IM 12B07W01-04EN 1st Edition : Nov 11, 2016-00

Page 26

<3. Piping and Wiring>

(3) Connection for power supply and ground

<Connection for power supply>

A power supply voltage of 100 V AC ±10%, 50/60 Hz is applied to the power supply unit of

the chemical cleaning pH measuring system.

CAUTION

Chemical Cleaning pH Measuring System has no power switch. To avoid the possible hazard of

electrical shock or damage to the instrument, always install a power switch (double-pole) in the

power line.

NOTE

The fuse (1 A) in the power supply unit is installed for the pH/ORP converter. (The pH/ORP

converter itself contains an additional power-line fuse (0.1 A)).

Use a two-core cable with an outer diameter of 9 to 12 mm for this connection. Treat both

ends of each core wire of the cable extending from the power supply so they t M-4 thread

and then connect them with terminals L1 and L2 of power supply unit.

3-5

<Connection for ground>

The control box and pH/ORP Converter of the system must be grounded with a grounding

resistance of less than 100Ω). The grounding terminal of the control box can be found in the

bottom of the control box casing. The grounding terminal of the pH/ORP Converter can be

found in the bottom of the control box casing.

(4) Connection for contact output of CYLINDER FAIL signal

PH8SM3 Chemical Cleaning System outputs a CYLINDER FAIL contact signal. This

contact signal is output to let the operator know that a failure has occurred in the upward

movement of the pneumatic cylinder of the PH8HS3 holder. The system uses the DETECT

UPPER LIMIT signal (the signal for detecting the upper limit of the sensor holder’s position)

discussed in step 2 above for this purpose.

The CYLINDER FAIL contact signal is given if the DETECT UPPER LIMIT signal is not

present even if the setting for timer T1 in the control box is reached. This connection is

applied when the above function is used. Use a two-core cable with an outer diameter of 9

to 12 mm for this connection. Treat both ends of each core wire of the cable so they t M4

threads and then connect terminals 6 and 7 of the control box with the instrument being

used, such as an annunciator. For the contact capacity and other details, see subsection

1.1.

(5) Connection for pH signal

PH450G pH/ORP Converter sends two 4 to 20 mA signal (pH, temperature) and receives

the contact input for cleaning start. Use a two-core cable with a nished outer diameter

of 9 to 12 mm for this connection. For the output signal from pH/ORP Converter, connect

the terminals “mA1 +” or “mA1 -” to those corresponding terminals at the receiving

instrument. For the second output signal, connect the terminals “mA2 +” or “mA2 -” to those

corresponding terminals at the receiving instrument.The terminal CONTACT on a pH/ORP

Converter is for connection of remote contact input. For cable shield, connect a cable to the

terminal SHLD.

CAUTION

Connect the cable shield to the grounding at pH/ORP converter.

IM 12B07W01-04EN 1st Edition : Nov. 11, 2016-00

Page 27

<3. Piping and Wiring>

(6) Connection for contact input of WASH (cleaning) signal

It is already been wired.

3.2.2 Wiring system with 2-Wire Analyzer

Figure 3.3 illustrates wiring the system with 2-Wire Analyzer.

3-6

PH201G

Distributor

A(+)

(+)C

B(

(

-)

-)D

e

f

Output signal

(1-5V DC)

100V AC

pH

Holder

1

2

pH sensor

Air Cylinder

Position signal

FLXA202 or FLXA21

13

+

12

-

11

14

15

16

PH8SM3

Control box

4

5

6

8

7

9

1

2

3

Cleaning Signal

Cylinder failure signal

Wiring by customer

100V AC

Figure 3.3 wiring for 2-Wire Analyzer (PH8SM3-G, -F)

(1) Connection for pH sensor cable

Connect the sensor cable so that the code on each core wire matches the corresponding

code on 2-Wire Analyzer; FLXA202 or FLXA21. For more information about sensor cable

connection, see the user’s manual on “FLXA 202/FLXA21 ” Also refer to “WTB10 Relay

Terminal Box” user’s manual if your system uses a relay terminal box.

CAUTION

The sensor cable and the KCI supply tube move up and down in synchronization with the sensor

holder along the PH8HS3 holder. Give adequate consideration to any slack in the cable or tube

and to the installation location to ensure that a smooth up-and-down motion takes place. The

cable or tube may be damaged if, during the up-and-down motion, it comes into accidental

contact with the PH8HS3 holder or other structures.

(2) Connection for DETECT UPPER LIMIT signal

Use a two-core cable with an outer diameter of 9 to 12 mm for this connection. Treat both

ends of each core wire of the cable so they t M4 threads and then connect terminal 1 of the

terminal block for the limit switch of the PH8HS3 holder with terminal 8 of the control box,

terminal 2 with terminal 9.

Note: There will not be a problem if you connect terminal 1 with terminal 9 and terminal 2 with

terminal 8.

The cable inlet of the PH8HS3 holder is located on the right-hand side of the chassis’s upper

section. When wiring the cable, loosen the two screws and remove the cover (for protection

against drips). After the completion of wiring, always make sure the cover is reinstalled in

place.

IM 12B07W01-04EN 1st Edition : Nov 11, 2016-00

Page 28

<3. Piping and Wiring>

(3) Connection for power supply and ground

<Connection for power supply>

A power supply voltage of 100V AC ±10%, 50/60 Hz is box of the PH8HS3 operating unit of

the chemical cleaning system.

CAUTION

The chemical cleaning pH measuring system has no power switch. To avoid the possible hazard

of electrical shock or damage to the instrument, always install a power switch (double-pole) in the

power line.

Use a two-core cable with an outer diameter of 9 to 12 mm for this connection. Treat both

ends of each core wire of the cable extending from the power supply so they t M4 thread

and then connect them with terminal1 and 2 on the control box. For information on the

distributor power supply, refer to the user’s manual “PH201G Distributor”.

Note Power voltage or connection varies depending on the specication of distributors.

<Connection for ground>

The control box and pH transmitter of the chemical cleaning pH measuring system must

be grounded with a grounding resistance of less than 100Ω. The grounding terminal of

the control box can be found in the bottom of the control box casing. As for the grounding

terminal of the 2-Wire Analyzer, refer to the corresponding instruction manual.

3-7

(4) Connection for contact output of CYLINDER FAIL signal

The chemical cleaning system outputs the CYLINDER FAIL contact signal. The contact

signal is output to let the operator know that a failure has occurred in the upward movement

of the pneumatic cylinder of the PH8HS3 holder. The system uses the DETECT UPPER

LIMIT signal discussed in step 2 above for this purpose.

The CYLINDER FAIL contact signal is given when DETECT UPPER LIMIT is not signaled

even if the setting for timer T1 in the control box is reached. This connection is applied

when the above function is used. Follow the same procedure as for the two-wire pH

transmitter system. Use a two-core cable with a nished outer diameter of 9 to 12 mm for

this connection. Treat both ends of each core wire of the cable so they t M4 threads and

then connect terminals 6 and 7 of the control box with the instrument being used, such as an

annunciator.

Note: For the contact capacity and other details, see Subsection 1.1.

(5) Connection for pH signal

To PH201G distributor, 2-Wire Analyzer FLXA202 or FLXA21 sends a 4 to 20 mA output

signal and 2 mAp-p <WASH> signal which is superimposed on the 4 to 20 mA DC signal.

The distributor outputs 1 to 5 V DC signal. Use a double-core shielded cable with a nished

outer diameter of 9 to 12 mm for this connection. For wiring between 2-Wire Analyzer and

the distributor, connect + terminal of 2-Wire Analyzer to terminal A of the distributor, and

connect a minus terminal to terminal B. Shiled of cables must be connected to the ground

terminal G of the 2-Wire Analyzer.

Connect output cables to each corresponding terminal on the distributor or receptor, such as

terminal C, or D. Shield of cables must be grounded on each receptor side.

(6) Connection for contact input of WASH (cleaning) signal

Use a double-core shielded cable with a nished outer diameter of 9 to 12 mm for this

connection. Treat both ends of each core wire of the cable so they t M4 threads and then

connect terminals 4 and 5 of the control box with the distributor terminal e and terminal f.

IM 12B07W01-04EN 1st Edition : Nov. 11, 2016-00

Page 29

Blank Page

Page 30

<4. Operation>

4. Operation

This chapter gives an overview of the functions and operations of the components the system

along with their names and explains the start-up procedure required implement optimum cleaning

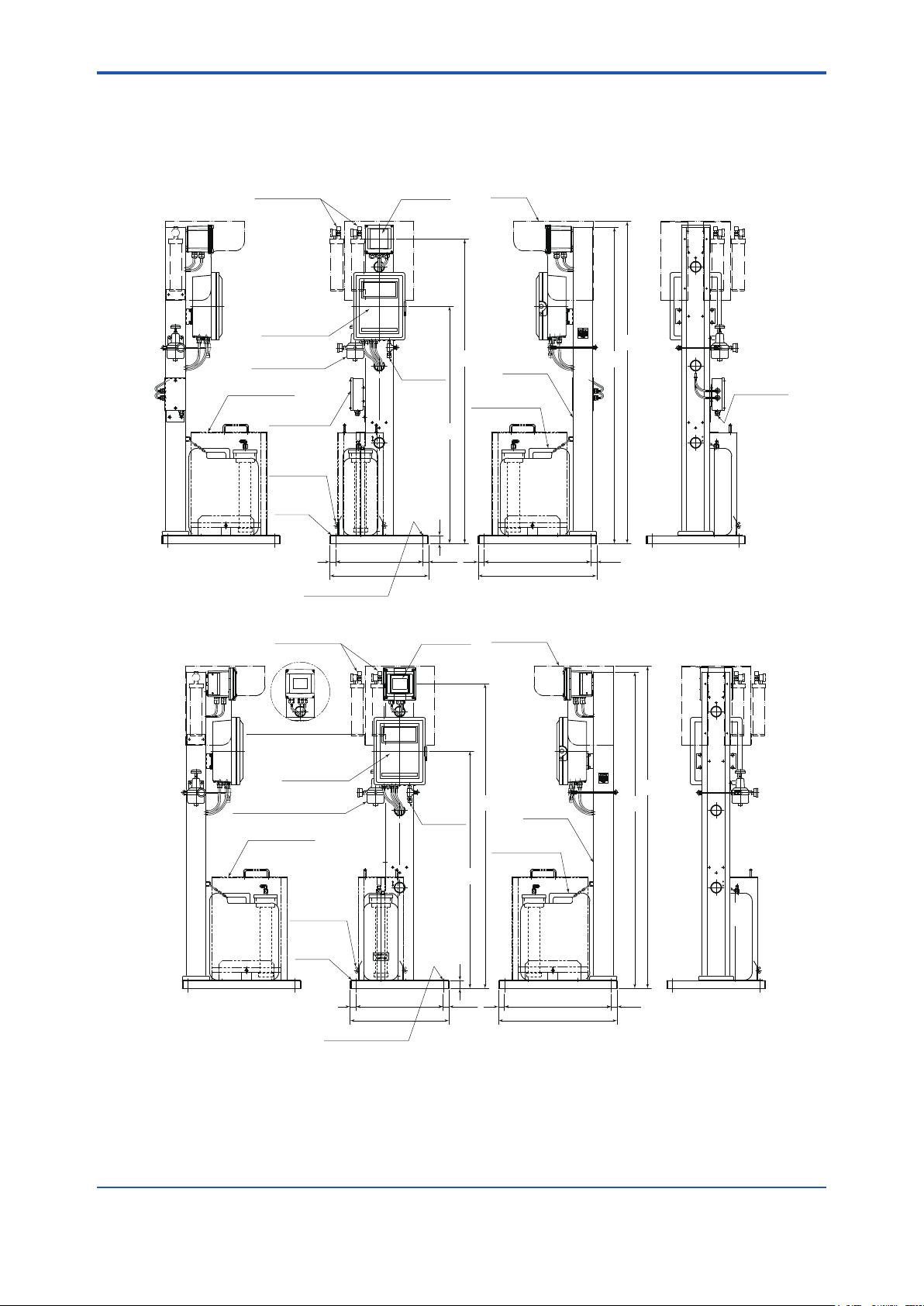

4.1 Names and Functions of Components

n PH8SM3 Chemical Cleaning Unit

(Reserver tank for KCl solution)

4-1

(pH/ORP converter)

(2-Wire Analyzer)

Pressure reduction valve AS3

Sets the pressure of the air that

pressurizes the KCl reserve tank.

(Supplied when specified accordingly.)

Power supply box

(Supplied with the pH/ORP

converter system for outdoor use.)

Holding tank for chemical solution

A tank (with an effective capacity

of approximately 17 liters) to contain

a chemical cleaning solution.

Awning hood

Protects against an abnormal

temperature rise in the pH converter

(or the pH transmitter) or the control box

due to direct sunlight (Supplied when

specified accordingly.)

Control box

Controls the operation sequence of

the chemical cleaning pH measuring system.

Tank cover

Optional for outdoor use,

to protect against UV rays.

Pressure gauge (PG1)

Indicates the air pressure for forced

feeding of the chemical solution.

Pressure reduction valve (AS1)

Sets the air pressure for forced

feeding of the chemical solution.

Timer (T2)

Sets the time required to air-bubble

the chemical solution within the

cleaning chamber during cleaning.

Control Box

Pressure gauge (PG2)

Indicates the air pressure for

actuating the pneumatic cylinder.

Pressure reduction valve (AS2)

Sets the air pressure for actuating

the pneumatic cylinder.

Manuel cleaning commend switch

When turned on, this switch initiates

the cleaning sequence; when turned off,

it shuts down the sequence.

Figure 4.1 Names and Functions of Components in PH8SM3 Chemical Cleaning System

IM 12B07W01-04EN 1st Edition : Nov. 11, 2016-00

Page 31

<4. Operation>

n PH8SM3 Holder

4-2

Terminal block

for limit switch

Limit switch

Senses that the

upper limit of the

sensor holder's

position is reached.

Spring

helps the bottom plate

of cleaning chamber

to tightly close during

cleaning.

Drip-proof cover protects against rain or dust.

Cable inlet

Allows the cable (for the signal

which detects the upper limit of

the sensor holder's position)

to get through to the terminal

block for the limit switch.

Optional pneumatic cylinder cover,

to protect against dust.

Arm to support sensor holder

The sensor holder is installed

by simply inserting it into this arm.

Air connection part for

actuating pneumatic

cylinder (downward)

Mounting bracket

Used to mount the PH8HS3

holder to a two-inch pipe.

Pneumatic cylinder

Slider of pneumatic

cylinder

Goes up or down

pneumatically.

Air connection part for

actuating pneumatic

cylinder (upward)

Bottom plate of

cleaning chamber

Closes during cleaning

to hold the chemical

solution supplied from the

tank within the cleaning

chamber.

Cleaning chamber

Accommodates the

pH sensor during cleaning

and allows the sensor

electrodes to be cleaned.

(pH sensor)

Piping port for forced

feeding of chemical solution

Sensor holder

Holds the pH sensor.

The sensor holder goes up

or down along with the slider

of the pneumatic cylinder.

O-ring

Protects the holder from

precipitation of solutions

Figure 4.2 Names and Functions of Components in PH8HS3 Holder

(Note) When you remove the sensor holder out of the unit during calibration or for some reasons,

take off the cover on the upper chassis. However, put the cover back to where it was to maintain

the isolation of limit switch terminals and prevent operation errors.

l How the slider of air cylinder moves

The slider of air cylinder moves up and down by the strength of magnet inside the pneumatic

cylinder. Stain or dust around the air cylinder hampers a smooth sliding of the cylinder. We highly

recommend the installation of cylinder be guaranteed in a clean environment.

IM 12B07W01-04EN 1st Edition : Nov 11, 2016-00

Page 32

<4. Operation>

4.2 How the Chemical Cleaning pH Measuring System Works

4.2.1 Operating Modes

There are two operating modes in the chemical cleaning pH measuring system: the

measurement mode and cleaning mode.

l Measurement mode

The system performs pH measurement. The sensor holder is in its lowest position, submerging

the pH electrodes in the chemical solution.

l WASH (Cleaning)mode

The sensor holder begins rising from its lowest position by way of the wash command, performs

cleaning of the pH electrodes and then goes into the measurement mode again. The cleaning

mode includes the relaxation interval required after the washing sequence. In the wash mode, it

is possible to hold the output signal as a certain value, such as the last value before the WASH

mode starts.

4.2.2 WASH (Cleaning) Command

4-3

WASH command in normal operation is issued from the pH/ORP converter or the 2-Wire

analyzers at the intervals set in these instruments. For the pH measuring system for outdoor use,

the WASH command can be issued on demand using a remote contact input. A WASH command

sent from the pH/ORP converter or 2-wire analyzers consists of two time elements, i.e., the

washing time and the relaxation interval.

Chemical cleaning can also be implemented using the MANUAL Wash (cleaning) switch in the

control box. Turning on this switch causes the chemical cleaning pH measuring system to enter

the wash mode; turning off causes the system to exit from the wash sequence. Note that, when

washing is carried out using the MANUAL WASH switch, neither the pH/ORP converter nor the

2-Wire analyzer performs the functions (such as a holding of the output signal) available in the

wash mode.

If there is a conict between a WASH command sent from the pH/ORP converter or 2-wire

analyzer and the same command issued with the MANUAL WASH switch in the control box, the

sensor holder behaves according to the timing diagram shown in Figure 4.3.

pH/ORP Converter or 2-Wire

Analyzer

WASH signal (automatic cleaning)

MANUAL WASH switch on

Sensor holder

Highest position

Lowest position

Power on

Washing time

Interval between wash

Relaxation interval

Interval between wash

Holding of pH output signal

(WASH mode)

Note:

The interval between wash, washing cycle(time) and relaxation interval are set on the pH/ORP Converter or

2-Wire Analyzer. Hold of the pH output signal is implemented only in the washing sequence

(WASH mode) initiated by a command issued from the pH/ORP converter or 2-Wire Analyzer.

Hold can be off, too. Forced air feeding / Air bubbling of chemical solution continues for a determined length of time ( set in Timer T2) only after

the sensor holder moves from Lowest position to Highest position.

Figure 4.3 Behaviour of the Sensor Holder If There Is a Conict Between the Automatic-

WASH Command and Manual-WASH Command

Air for forced feeding of chemical solution

IM 12B07W01-04EN 1st Edition : Nov. 11, 2016-00

Page 33

<4. Operation>

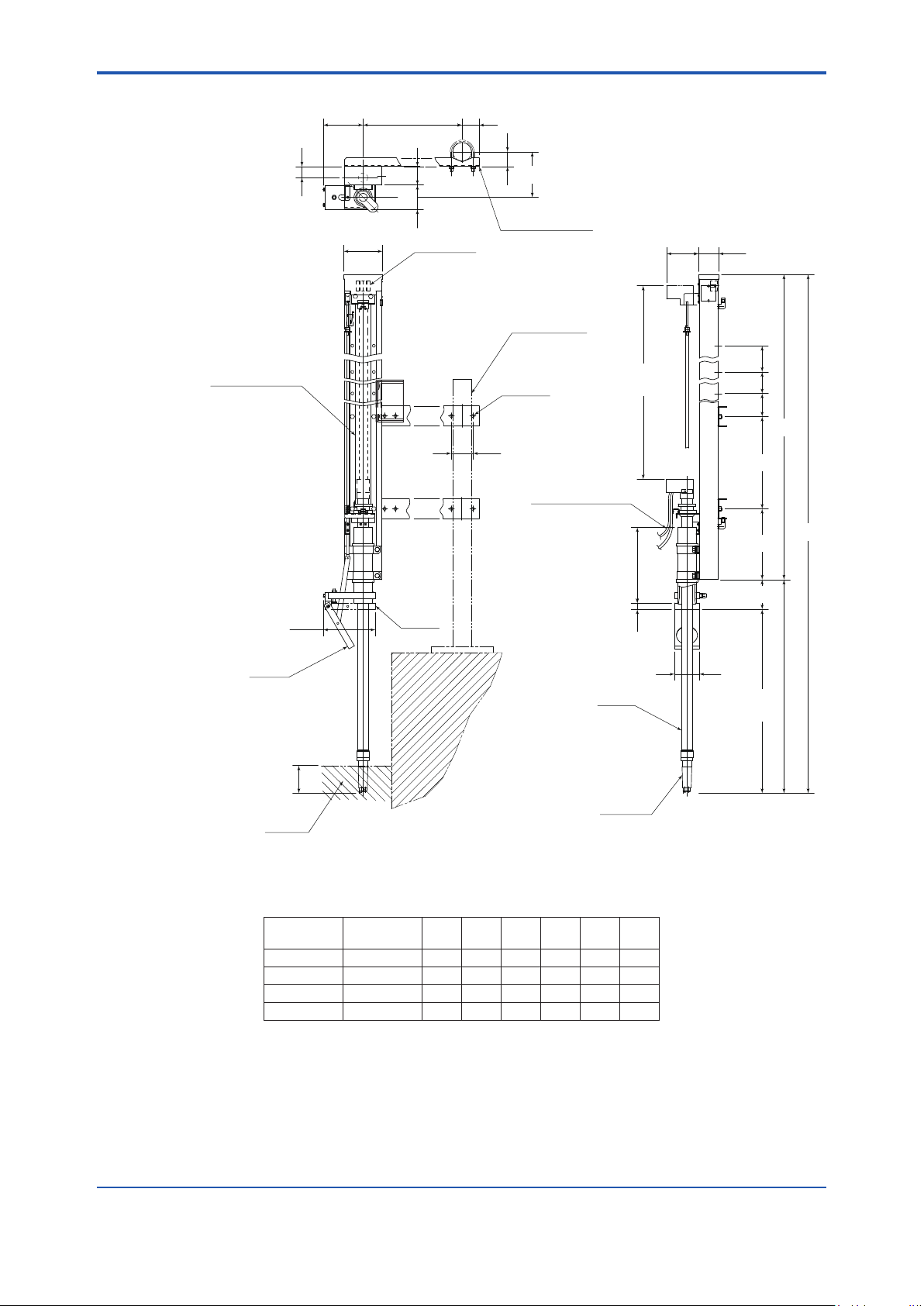

4.2.3 Wash Sequence

Figure 4.4 shows the actions that the system implements to clean the electrodes when

it receives a WASH (cleaning) command from either PH450G or FLXA202/FLXA21.

Holding of pH output signal

WASH

Chemical cleaning system

SV2 solenoid valve for

actuating cylinder

Sensor holder

Bottom plate of

cleaning chamber

DETECT UPPER LIMIT

signal

CYLINDER FAIL signal

SV1 solenoid valve for

forced feeding of chemical

solution and air bubbling

pH meter

Highest position

Lowest position

Closes

Opens

(Measurement mode) (Measurement mode)

Contact signal

for WASH

Air is injected to raise the cylinder

t1≥

t1<

(WASH mode)

WASH

When can not reach

the highest position.

Open (air is fed to the metering tank.)

t2

Relaxation

4-4

t1: Setting of timer T1 t2: Setting of timer T2

Figure 4.4 WASH Sequence

l Output of WASH (cleaning) signal

When the setting the interval between WASH (in pH/ORP Converter or 2-Wire Analyzer ) times

out, the system enters the WASH sequence. The WASH signal is then output to the control box

of the operating unit in the chemical cleaning system for the period equivalent to the value set in

the timer.

l Actuation of SV2 solenoid valve

The SV2 solenoid valve in the control box is active while it is receiving the WASH signal. This

causes a pneumatic pressure to be applied to the port that raises the cylinder on the PH8HS3

holder. Consequently, the sensor holder goes up in conjunction with the cylinder slider.

l Output of DETECT UPPER LIMIT signal and CYLINDER FAIL signal

When the sensor holder reaches the upper limit, the bottom plate of the cleaning chamber closes

and the limit switch is turned on. The ON signal from the limit switch then starts timer T2 in the

control box, causing solenoid valve SV1 to be actuated (the valve is opened). Solenoid valve

SV1, when opened, causes a pneumatic pressure to be applied to the interior of the metering

tank, resulting in an approximately 100 ml of the chemical solution being forced into the cleaning

chamber of the holder. The air is kept supplied until timer T2 times out, bubbling the chemical

solution within the cleaning chamber to enhance the cleaning of the pH sensor electrodes.

Note that if the sensor holder does not reach the upper limit when timer T1, which starts at the

same time the WASH signal is output, is timed out, the CYLINDER FAIL signal is given. This

signal stops (the contact opens) when the WASH contact signal is no longer present.

IM 12B07W01-04EN 1st Edition : Nov 11, 2016-00

Page 34

<4. Operation>

l End of WASH sequence

When the WASH time elapses, the WASH contact signal stops. The air circuit for solenoid valve

SV2 switches to apply a pneumatic pressure to the port that lowers the cylinder. The sensor

holder goes down and the bottom plate of the cleaning chamber opens, causing the chemical

solution within the cleaning chamber to drain out. The pH/ORP Converter (or 2-Wire Analyzer)

then enters a relaxation interval after the WASH time has elapsed. The pH/ORP Converter

or 2-Wire ajayzer still holds the output signal during that period (if HOLD OUTPUT SIGNAL