Page 1

User’s

Manual

Model PH72

Personal pH/ORP Meter

IM 12B03D02-01E

IM 12B03D02-01E

3rd Edition

Page 2

Preface

Thank you for purchasing the Model PH72 Personal pH/ORP Meter. Please read this

manual thoroughly before using the meter.

The following symbol marks are used for safety precautions in this manual.

Preface

WARNING

CAUTION

: Indicates that serious injury may result, if the user fails to

follow instructions.

: Indicates that minor injury to personnel, or damage to the

equipment, may result if the user fails to follow instructions.

WARNING

Do NOT use this instrument where there is a possibility of electrical shock.

Do NOT touch any part of the electrode immediately after using in very hot liquids —

otherwise, you may get burned.

CAUTION

Do not apply physical shock or excessive force to the glass sensor, or it may break.

If the meter will not be used for an extended period of time, be sure to remove the

batteries. Otherwise battery leakage may occur, causing damage to or malfunction of the

meter.

The contents of this manual are subject to change without prior notice.

Yokogawa Electric Corporation assumes no liability for damage, defects, or loss of the

product caused by any of the following:

Misuse by the user;

Inappropriate or out-of-specifications use of the product;

Use in an unsuitable environment;

Repair or modification of this or related products by persons other than Yokogawa-

authorized engineers.

IM 12B03D02-01E

3rd Edition: Apr. 2009 (YK)

All Rights Reserved, Copyright © 2004, Yokogawa Electric Corporation

1

Page 3

Preface

Liquid Crystal Display (LCD) Characters

On the LCD alphanumeric characters are displayed as follows.

Alphabet

A

B

C

D

E

F

G

H

I

J

K

L

M

Display

Alphabet

N

O

P

Q

R

S

T

U

V

W

X

Y

Z

Display DisplayNumerals

0

1

2

3

4

5

6

7

8

9

All display segments

Note Regarding Panels Shown in this Manual:

Panels shown in this manual should be regarded as examples. Actual panel format may

vary depending on parameter settings and on type of connected sensor.

Flashing Displays

Flashing messages, numbers and digits on the display are indicated in gray in this

manual.

F00.EPS

Flashing state: Lit state:

2

IM 12B03D02-01E

Page 4

Warranty and Service

Yokogawa products and parts are guaranteed to be free from defects in workmanship and

materials under normal use and service for a period of (typically) 12 months from the

date of shipment from the manufacturer.

Individual sales units may offer different warranty periods, so the original purchase order

should be consulted for the conditions of sale. Damage caused by normal wear and tear,

inadequate maintenance, corrosion, or due to chemical processes, is excluded from this

warranty coverage.

In the event of a warranty claim, any items that are considered to be defective should be

sent (freight paid) for repair or replacement (at Yokogawa discretion) to the service

department of the relevant sales unit. The following information must be included in a

letter accompanying the returned items:

Model code and serial number

Copy of original purchase order showing the date

Length of time used, and the measuring environment

Fault symptoms, and circumstances of failure

Statement whether service under warranty or out-of-warranty service is requested

Complete shipping and billing instructions for return of goods, plus the name and

phone number of a contact person who can be reached for further information

Goods that have been in contact with process fluids must be decontaminated / disinfected

before shipment, and a statement to this effect should be included. Safety data sheets for

all process components that the goods have exposed to should also be included.

Preface

IM 12B03D02-01E

3

Page 5

Contents

CONTENTS

Preface...................................................................................................................... 1-1

1. Outline ................................................................................................................. 1-1

1.1 Features ......................................................................................................................... 1-1

1.2 Specifications ................................................................................................................. 1-2

1.3 When You Receive the PH72 Meter Package .............................................................. 1-3

1.4 PH72 Meter Kit .............................................................................................................. 1-4

1.5 PH72 Meter — Part Names and Functions .................................................................. 1-5

1.6 Sensors — Types, Part Names and Functions............................................................. 1-6

1.7 Options (Available Separately) ...................................................................................... 1-8

1.8 Spare Parts .................................................................................................................... 1-9

2. Preparation.......................................................................................................... 2-1

2.1 Installing the Batteries ................................................................................................... 2-1

2.2 Connecting the Sensor Cable ....................................................................................... 2-2

2.3 Setting the Date and Time ............................................................................................ 2-3

2.4 Selecting pH or ORP Measurement .............................................................................. 2-4

2.5 Wetting Cap ................................................................................................................... 2-4

2.6 Manual Temperature Setting ......................................................................................... 2-5

2.7 pH Calibration ................................................................................................................ 2-5

3. Measurement ...................................................................................................... 3-1

3.1 Precautions .................................................................................................................... 3-1

3.2 Measurement Procedures ............................................................................................. 3-2

3.3 Measurement Display Panel.......................................................................................... 3-3

3.4 Saving a Measured Value ............................................................................................. 3-3

4. Calibration ........................................................................................................... 4-1

4.1 Automatic Calibration..................................................................................................... 4-3

4.2 Manual Calibration ......................................................................................................... 4-6

5. Keypad and Display Functions ......................................................................... 5-1

5.1 Keypad Functions .......................................................................................................... 5-2

5.2 Display Items ................................................................................................................. 5-4

5.3 Function Mode ............................................................................................................... 5-5

6. Maintenance ........................................................................................................ 6-1

6.1 For Optimum Meter Performance.................................................................................. 6-1

6.2 pH Electrode Cleaning................................................................................................... 6-2

6.3 Sensor Replacement ..................................................................................................... 6-3

6.4 Rehydrating the Glass Electrode................................................................................... 6-3

6.5 Replenishing the Electrode with Filling Solution (KCl solution) .................................... 6-4

6.6 Cleaning and Drying Connectors .................................................................................. 6-5

6.7 Storage and O-ring/Gasket Replacement ..................................................................... 6-6

7. Troubleshooting ................................................................................................. 7-1

7.1 Causes of Abnormal Readings and Errors ................................................................... 7-1

7.2 Error Messages, Possible Causes, and Corrective Actions ......................................... 7-2

7.3 Causes of Abnormal Measured Values......................................................................... 7-5

7.4 Other Conditions ............................................................................................................ 7-6

8. ORP Meter ........................................................................................................... 8-1

8.1 ORP Measurement ........................................................................................................ 8-1

8.2 Maintenance of ORP Sensors ....................................................................................... 8-2

8.3 Checking the ORP Sensor ............................................................................................ 8-3

9. Technical Information......................................................................................... 9-1

9.1 Measurement Principle of pH Meter (Glass Electrode Method) ................................... 9-1

9.2 Relationship between EMF of Glass Membrane and pH Value ................................... 9-2

4

IM 12B03D02-01E

Page 6

Contents

9.3 Temperature Compensation .......................................................................................... 9-4

9.4 The Asymmetry Potential .............................................................................................. 9-5

9.5 The Alkaline Error .......................................................................................................... 9-6

9.6 The Acid Error ............................................................................................................... 9-7

9.7 Calibration Calculation ................................................................................................... 9-8

9.8 ORP (Oxidation-Reduction Potential) ............................................................................ 9-9

9.9 Reference Electrode .................................................................................................... 9-10

9.10 Wetted Part Materials of Sensors ............................................................................. 9-12

9.11 References................................................................................................................. 9-12

Appendix ..................................................................................................................... 1

MSDS (Material Safety Data Sheet) ............................................................... MADS-1

Revision Record .......................................................................................................... i

IM 12B03D02-01E

5

Page 7

Contents

6

IM 12B03D02-01E

Page 8

1. Outline

The Model PH72 Personal pH/ORP Meter is a highly accurate, portable pH meter for

laboratory and field application. With its self-diagnostic function, the PH72 provides

precise measurement of pH and ORP (oxidation-reduction potential). Measurement

results can be stored and stored data can be checked on the meter display any time. The

PH72 meter is of waterproof construction so that it can safely be used outdoors on a

rainy day, and can also withstand being accidentally dropped into water.

1.1 Features

Water r esistant case

When this meter is used with its dedicated sensor, it meets the requirements of class IP67

according to “Degree of Protection Provided by Enclosure” in IEC 60529.

Simple calibration

Automatic calibration based on preprogrammed data of standard solutions or manual

calibration can be done through simple key operations.

Calendar and clock function

Internal clock functions allow “one-touch checking” of measurement date and time.

Data storage function

Up to 300 measured pH values along with their respective solution temperatures, dates

and times, can be stored and stored data can be checked on the display any time.

Auto power off function

The meter will turn off power automatically if not operated during a preset time period.

The auto power off time can be user configurable in the range of 1 to 120 minutes in

increments of 1 minute. The auto power off function can be disabled, where the meter

should be used with care to conserve the batteries.

Alarm clock function

The meter can issue an alarm signal at a specified time. Even when meter power is

turned off, the internal clock can issue an alarm signal.

Self-diagnostic function

A relevant error message will appear based on the self-diagnostic function.

Large, clear LCD

A measured pH (mV) value, solution temperature, date and time are clearly viewed on

the display.

Compact, lightweight, and handy

The meter fits comfortably your hand and also stands firm on the table.

1. Outline

IM 12B03D02-01E

1-1

Page 9

1. Outline

1.2 Specifications

Measuring range: pH: 0 to 14 pH*

ORP: -2000 to 2000 mV

Temperature: 0 to 1008C*

Resolution: pH: 0.01 pH

ORP: 0.1 mV (-199.9 to 199.9 mV)

1 mV (-2000 to -200 mV and 200 to 2000 mV)

Temperature: 0.18C

Repeatability (without sensor): pH: 60.01 pH 61 digit

ORP: 61 mV 61 digit

Accuracy (Temperature): 60.78C (0 to 708C)

618C (above 708C)

Temperature compensation (glass electrode emf — temperature characteristics):

Automatic compensation (or manual compensation*1)

Solution temperature: 0 to 808C (or 0 to 1008C*3) (0 to 508C when a KCl replenish-

free type sensor and its sensor cable are immersed in water)

Solution conductivity: 50 mS/cm or more

Ambient temperature: 0 to 508C

Construction: Protection class IP67 (IEC 60529)

Power source: 2x AA batteries (LR6)

Auto power off function (time configurable: 1 to 120 minutes)

Battery life: Approximately 600 hours*4 of continuous use (battery type and

operating condition dependent)

Dimensions: Approximately 150(H) x 61(W) x 42(D) mm (not including

connector part)

Weight: Approximately 220 g (including batteries)

EMC Conformity Standards:

EMI (Emission) EN 61326-1 Class B

Test Item

Electromagnetic radiation disturbance

EMS (Immunity) EN 61326-1 Table 2 (For use in inductrial locations)

Test ItemNo.

Electrostatic

1

discharge

RF amplitude

2

modulated

electromagnetic field

* A: Normal performance within the specification limits: ±20% of the measured value.

B: Temporary degration or less of function or performance which is self-recoverable.

** Display value may be affected by strong electromagnetic field.

Test Specification Basic Standard

4 kV (contact)

8 kV (air)

80 to 1000 MHz,

10 V/m (unmodulated)

80% AM (1 kHz)

1.4 to 2.0 GHz,

10 V/m (unmodulated)

80% AM (1 kHz)

2.0 to 4.0 GHz,

3 V/m (unmodulated)

80% AM (1 kHz)

*1: Display range is from -2 to 10 pH.

*2: Display range is from-10 to 1208C.

*3: When a needle type or test tube size pH sensor is used.

*4: When alkaline batteries are used.

1-2

1

2

Frequency Range

30 to 1000 MHz

IEC 61000-4-2

IEC 61000-4-3

CISPR 16-1 and 16-2

Basic Standard

T0101.EPS

Performance

Criteria*

A

B**

A

A

T0102.EPS

IM 12B03D02-01E

Page 10

1.3 When You Receive the PH72 Meter Package

Confirm that you received all package components of the PH72 meter you ordered

referring to the Model and Suffix Code and the item list in Section 1.4, “PH72 Meter

Kit.” Carefully inspect the meter and sensor, referring to Section 1.5, “PH72 Meter —

Part Names and Functions” and Section 1.6, “Sensors — Types, Part Names and

Functions.” Particular attention should be taken:

• Not to lose a wetting cap attached on the sensor tip. This cap is needed for

storage.

• Not to twist or pull the cable.

• Not to hit or drop the meter.

• Not to get connectors dirty.

• In handling of standard solutions and reagents. Solution bottles should be stored

in a cool, dark place and tightly capped after use. Once opened, the contents of a

bottle should be used early. Dispose of solutions in accordance with local

regulations.

1. Outline

IM 12B03D02-01E

1-3

Page 11

1. Outline

1.4 PH72 Meter Kit

1

7

8 11

3

9

Instrument Card

2

6

Quick Manual

4

10

No.

Item

1

Personal pH/ORP meter

2

Dry batteries, 2x AA batteries

3

User's Manual and Quick Manual

4

Non-slip pads (2 pcs)

5

Hand strap

6

Instrument Card

7

KCl replenish-free type pH sensor

8

KCl refillable type pH sensor

9

Needle type pH sensor

10

Test tube size pH sensor

11

5

KCl refillable type ORP sensor

12

Cotton swabs for sensor cleaning

13

pH 4 standard solution (50 ml)

14

pH 7 standard solution (50 ml)

15

Calibration bottles (2 bottles)

16

KCl filling solution (3.3 mol/l, 50 ml)

17

Syringe (5 ml)

13 14

PH4

PH7

16

KCl

12

15

17

1-4

Model Suffix Code

PH72

Sensors -00

-11

-13

-21

-23

-32

-33

-41

-43

-51

Label -J

language -E

- -AA

Note: On the name plate of sensor, Model and Suffix Code of sensor itself (PH72SN- -AA or

OR72SN- -AA) is indicated. (See Section 1.6.)

Specification

Personal pH/ORP meter

Without sensor

With KCl replenish-free type combination pH sensor (cable length: 0.75 m)

With KCl replenish-free type combination pH sensor (cable length: 3 m)

With KCl refillable type combination pH sensor (cable length: 0.75 m)

With KCl refillable type combination pH sensor (cable length: 3 m)

With needle type pH sensor (cable length: 0.75 m)

With test tube size pH sensor (cable length: 0.75 m)

With KCl refillable type ORP sensor (cable length: 0.75 m)

With KCl refillable type ORP sensor (cable length: 3 m)

With KCl refillable type combination pH sensor (cable length:

0.75 m) + KCl refillable type ORP sensor (cable length: 0.75 m)

Japanese

English

Always -AA

Items Included

1 to 6 in common, plus:

None

7, 12, 13, 14, 15

7, 12, 13, 14, 15

8, 12, 13, 14, 15, 16, 17

8, 12, 13, 14, 15, 16, 17

9, 12, 13, 14, 15, 16, 17

10, 12, 13, 14, 15, 16, 17

11, 12, 16, 17

11, 12, 16, 17

8, 11, 12, 13, 14, 15, 16,

17

F010401.EPS

IM 12B03D02-01E

Page 12

1.5 PH72 Meter — Part Names and Functions

1. Outline

O-ring

Sensor cable connector

Connection to a dedicated

pH (ORP) sensor.

Hand strap

attachment points

Display

pH (mV) and temperature

simultaneously.

Keypad

PERSONAL

pH/ORP METER

PH72

MODEL

S1.0

STYLE

No.

E000001

2004.

Battery box cover fixing screw

Name plate

F010501.EPS

IM 12B03D02-01E

1-5

Page 13

1. Outline

1.6 Sensors — Types, Part Names and Functions

Sensors available for use with the Model PH72 Personal pH/ORP Meter are: generalpurpose pH sensors (KCl replenish-free and KCl refillable types), needle type pH sensor,

test tube size pH sensor, and KCl refillable type ORP sensor. Check the Model and

Suffix Code on the name plate to identify the type of your sensor.

Example of Name Plate

STYLE

MODEL

PH72SN

SUFFIX NO.

Model and Suffix Code for pH and ORP Sensors

Specification

PH72SN

-11

-13

-18

-19

-21

-23

-28

-32

-33

-38

-39

-AA

Model Suffix Code

OR72SN

-41

-43

-48

-49

-AA

1

: Part number of PH81, PH82 (previous models).

*

2

: Waterproofing is not guaranteed if you use PH82-type sensor in conjunction with PH72 meter.

*

pH sensor for Personal pH/ORP meter

For PH71, PH72; KCl replenish-free type combination pH sensor (cable length: 0.75 m)

For PH71, PH72; KCl replenish-free type combination pH sensor (cable length: 3 m)

For PH81, PH82; KCl replenish-free type combination pH sensor (cable length: 0.75 m)

For PH81, PH82; KCl replenish-free type combination pH sensor (cable length: 3 m)

For PH71, PH72; KCl refillable type combination pH sensor (cable length: 0.75 m)

For PH71, PH72; KCl refillable type combination pH sensor (cable length: 3 m)

For PH81, PH82; KCl refillable type combination pH sensor (cable length: 0.75 m)

For PH71, PH72; needle type pH sensor (cable length: 0.75 m)

For PH71, PH72; test tube size pH sensor (cable length: 0.75 m)

For PH82; needle type pH sensor (cable length: 0.75 m)

For PH82; test tube size pH sensor (cable length: 0.75 m)

Always -AA

Specification

ORP sensor for Personal pH/ORP meter

For PH72; KCl refillable type ORP sensor (cable length: 0.75 m)

For PH72; KCl refillable type ORP sensor (cable length: 3 m)

For PH82; KCl refillable type ORP sensor (cable length: 0.75 m)

For PH82; KCl refillable type ORP sensor (cable length: 3 m)

Always -AA

S1.0

000001-11-AA

Made in Japan

1

RemarksModel Suffix Code

*

2

K9220YA

*

K9220YB

2

*

2

*

K9220YC

2

*

K9220YG

2

K9220YJ

*

1

Remarks

*

2

K9220YL

*

2

*

F010601.EPS

1-6

IM 12B03D02-01E

Page 14

KCl replenish-free type combination pH sensor

PH72 - 11 - - AA

PH72 - 13 - - AA

Name plate

( PH72SN-11-AA,

PH72SN-13-AA )

Waterproof cover

Prevents water ingress

that may cause

insulation failure.

Connector

Connection to pH/ORP

meter.

Glass electrode

Measures pH

values.

Protective cover

Removed only

during cleaning.

Liquid junction

Provides electrical contact

between internal reference

electrode and sample solution.

Temperature element

Wetting cap

Used to prevent glass electrode from dying out. During storage this cap

*1: On the name plate of sensor, Model and Suffix Code of sensor itself (PH72SN- -AA or OR72SN- -AA) is indicated. (See Section 1.6.)

with cotton wad moistened with water should be attached to electrode tip.

*1

*1

Sensor cable

Sensor body

Plastic body that can withstand

temperature up to 80°C.

Glass electrode

(Platinum electrode)

KCl refillable type combination pH sensor,

ORP sensor

PH72 - 21 - - AA

PH72 - 23 - - AA

PH72 - 41 - - AA

Name plate

( PH72SN-21-AA,

PH72SN-23-AA,

OR72SN-41-AA,

OR72SN-43-AA )

Connector

Sensor grip

Wetting cap

*1

Sensor body

Temperature element

Protective cover

PH72 - 43 - - AA

PH72 - 51 - - AA

Waterproof

cover

Fill hole plug

Liquid

junction

Fill hole for KCl filling solution

Measures solution temperature

and compensates for temperature

effect on pH electrode.

3.3 mol/l KCl solution is used.

*1

Sensor cable

Sensor grip

Prevents filling solution from

leaking from fill hole during

storage. Always unplugged

during measurement.

1. Outline

F010602.EPS

IM 12B03D02-01E

1-7

Page 15

1. Outline

1.7 Options (Available Separately)

The following options are available for the Model PH72 Personal pH/ORP Meter for

your convenience. When ordering, specify the part number.

pH 9 Standard solution

(Part no. : K9220XF)

Used for calibration when

anticipated pH value of sample

solution is alkaline. (50ml)

Soft carrying case

(Part no. : B9269KJ)

Unit: mm

Approx. 280

Approx. 140

A soft black carrying case holds

pH/ORP meter and sensor.

Approx. 30

Sensor stand

(Part no. : K9220XN)

Holds a sensor when pH/ORP

meter is used on the table.

Made of rustproof stainless

steel.

F010 701 .EPS

1-8

IM 12B03D02-01E

Page 16

1.8 Spare Parts

1. Outline

pH 4 Standard solution

(Part no. : K9084KF)

Used for calibration. (250 ml)

KCl solution

(Part no. : K9220XH)

Used to replenish KCl refillable

type sensor. 3.3 mol/l, 2 bottles x

50 ml

pH 7 Standard solution

(Part no. : K9084KG)

Used for calibration. (250 ml)

Quinhydrone reagent

(Part no. : K9024EC)

Used to check ORP electrode. 3

packs, one pack for 250 ml

solution.

pH 9 Standard solution

(Part no. : K9084KH)

Used for calibration. (250 ml)

Calibration bottle

(Part no. : K9220WW)

Used during calibration. 2 10-ml

bottles.

2 gaskets for battery box

2 O-rings for connector

IM 12B03D02-01E

O-ring and gasket set

(Part no. : K9654AY)

Cap set

(Part no. : K9220ZY)

Used for sensor.

1 protective cover

1 wetting cap

F010801.EPS

1-9

Page 17

1. Outline

O-rings and gaskets are important parts to ensure that the PH72 meter is water resistant.

Replace these parts as required. Refer to Section 6.7, “Storage and O-ring/Gasket

Replacement” for replacement.

1-10

IM 12B03D02-01E

Page 18

2. Preparation

2.1 Installing the Batteries

Install the batteries first.

CAUTION

Select a relatively moisture-free location when installing batteries in the meter.

When installing batteries, observe correct polarity (battery orientation). Failure to do so

may damage to the meter.

Remove batteries from the meter if it is to be stored for an extended period of time.

Do not leave dead batteries in the meter. They may leak and cause meter failure or

erratic operation of the meter.

When replacing batteries, replace both batteries at the same time. If only one battery is

replaced, the new battery may discharge into the old battery, which may leak chemicals

and damage the meter.

If the battery box gasket is damaged or dirty then the unit may no longer be waterproof;

replace the gasket in this case.

(1) Loosen the screw holding the battery

box cover using a coin or similar

object.

(2) Remove the battery box cover, and

then install the batteries observing

polarity diagram inside.

(3) Make sure the gasket on the inside

458 or more

Batteries

Gasket

Press with

your fingers

rim of the battery box is free of

foreign material.

(4) Put the cover back on. Insert the tabs

on the top of the cover into the slots

at an angle of at least 458 and lower

the cover into position.

(5) Press the both ends of the cover down

with your fingers and tighten the

screw to fix the cover onto the unit

using a coin or similar object.

Note: Do not attempt to tighten further

when you feel resistance before the

cover is fastened in place. Loosen

the screw once and retighten.

2. Preparation

IM 12B03D02-01E

F020101.eps

2-1

Page 19

2. Preparation

2.2 Connecting the Sensor Cable

Connect the sensor cable.

CAUTION

Connect the sensor cable in a place free from moisture.

When connecting the sensor cable, tighten by turning only the silver locknut, do not turn

the cable or waterproof cover. Also take care not wet or contaminate the connector.

Sensors for the PH81 or PH82 meters can be connected. When used in conjunction with

the PH72 meter, however, water resistance is not guaranteed. This is due to the different

construction of the connector cover.

(1) Pull the waterproof cover along the

sensor cable away from the

connector to expose the locknut.

(2) Connect the connector to the meter

body*. Then tighten firmly by

turning only the locknut.

* Align the slots of the sensor cable

connector with the posts of the

connector on the meter.

(3) Move the waterproof cover toward

the connector until it contacts with

the O-ring* on the meter body.

* Make sure that the O-ring is free of

foreign material.

(4) Push and rotate the waterproof cover

1/4 turn (90 degrees) clockwise to

lock into place.

(2)

Waterproof cover

O-ring

(3)

Locknut

(Silver)

(1)

(4)

F020201.eps

Note: It is recommended that the sensor be kept connected to the meter to avoid

contamination of the connectors.

2-2

IM 12B03D02-01E

Page 20

2.3 Setting the Date and Time

After installing the batteries, set the date and time. Note that if the power is turned off

before completing minute setting, start with the date setting when you turn on the power

next time. By replacing the batteries, the date setting is not affected but the time setting

is. So the time must be reset.

Note: If a sensor cable is not connected to the meter, fluctuating readings or an error

message may appear. Before pressing

been connected.

• Setting Procedure

After installing the batteries, press and hold

LCD segments appears momentarily and then the date setting display starts

automatically. Set year, month, day, hours, and minutes following the flowchart below.

Note: If you attempt to abort the setting procedure before completing, the meter will

beep three times and reject the attempt. Continue until the minute setting is

completed.

POWER

Press

for at least 1 sec.

POWER

key, make sure that a sensor has

POWER

key for at least one second. All

2. Preparation

Day setting Hour setting (24-hour format)

IM 12B03D02-01E

Year setting

After

several

seconds

F/ENT

to set

to set

F/ENT F/ENT

to confirm

F/ENT

to set

After

several

seconds

F/ENT

to confirm

to confirm

to confirm

to confirm

or

Month setting

to set

Minute setting

to set

F020301.EPS

2-3

Page 21

2. Preparation

2.4 Selecting pH or ORP Measurement

Upon completing the date and time setting, the meter is ready for pH measurement. The

display shows a pH value with a “pH” unit to the left of the value.

To use the meter for ORP measurement, make sure that an ORP sensor is connected to

the meter. Then, change the display for ORP measurement following the procedure

described in Section 5.3 (3), “Set measurement unit (PV.U) panel.” The display should

show a “mV” unit at the lower right beneath a value when the meter is ready for ORP

measurement.

2.5 Wetting Cap

The glass electrode should be kept wet during storage. If the glass electrode dries out, it

will take hours to rehydrate and in the meantime the meter may give erroneous readings.

The wetting cap is used to prevent the glass electrode from drying out. Sensors are

shipped with a wetting cap containing a cotton wad moistened with a few drops of water.

For storage replenish the cap with a few drops of water (tap water) and attach to the

sensor firmly.

Protective cover

Lug

Slot

Figure 2.1 Wetting Cap

To remove cap, rotate counterclockwise

and pull out until lugs on cap clear

protective cover through slots.

Removed cap can be

attached onto sensor cable

during measurement.

F0201.EPS

2-4

IM 12B03D02-01E

Page 22

2.6 Manual Temperature Setting

If a sensor without a built-in temperature element (needle type or test tube size pH

sensor) is connected to the meter, mark will appear on the display. In this case,

measure the temperature of the solution being measured and manually set the measured

temperature into the PH72 meter for reliable measurement. The procedure is described in

Section 5.3 (2), “Manual temperature setting (M.tP) panel.”

Temperature compensation is performed based on a temperature shown on the display of

the PH72 meter. If a temperature shown on the display is different from the actual

temperature of the sample being measured, the displayed measured value may not be

true. The bigger the difference between the temperature displayed on the meter and the

actual temperature of the solution, the bigger the error between the displayed measured

value and the true value.

If mark appears on the display even though a sensor with a built-in temperature

element is connected, refer to Section 7.4.

2.7 pH Calibration

The PH72 meter needs to be calibrated:

• when the sensor is connected for the first time;

• after the sensor is replaced;

• after the meter has been stored for a long period;

• after the electrode is cleaned; or

• when necessary.

The calibration procedure is described in Chapter 4, “Calibration.”

Note: Calibration results are saved in the meter when the batteries are replaced.

2. Preparation

IM 12B03D02-01E

2-5

Page 23

2. Preparation

2-6

IM 12B03D02-01E

Page 24

3. Measurement

3.1 Precautions

(1) After storage for an extended period of time, it is recommended that the meter

should be calibrated before taking measurements.

(2) When using a KCl refillable type sensor, check the level of filling solution. (Refer

to Section 6.5.)

(3) Do not use the meter in a solution with the temperature exceeding 808C (1008C for

the needle type and test tube size pH sensors). When a KCl replenish-free type

sensor is used and its sensor grip is immersed, the temperature of the solution

should not exceed 508C. Also, do not use the meter in strongly corrosive

solutions, such as a solution containing hydrofluoric acid.

(4) Remove stains from the PH72 meter body using a soft cloth or tissue. If necessary,

use a neutral detergent.

(5) If an abnormal symptom occurs during measurement, locate the cause of the

problem and take corrective actions referring to Chapter 7, “Troubleshooting.”

(6) After measurement, rinse off dirt or the sample solution from the sensor with water

and store it. (Refer to Chapter 6, “Maintenance.”)

(7) Keys should be operated by fingers.

Using the PH72 Meter on a Table

The meter is designed as a portable instrument; however, to use it on a table, attach nonslip pads (supplied with the instrument) at top and bottom of the meter to stop it from

moving when the sensor is moved.

3. Measurement

IM 12B03D02-01E

Non-slip pads

PERSONAL

pH/ORP METER

MODEL

PH72

STYLE

S1.0

No.

E000001

2004.

F0301.EPS

Figure 3.1 Position of Non-slip Seats

3-1

Page 25

3. Measurement

3.2 Measurement Procedures

Immersing the sensor

Immerse the sensor so that the protective cover part goes under the sample solution level.

The sensor does not need to be immersed deeply.

When using a KCl refillable type sensor, the filling solution level must be above the

level of solution being measured. This is to prevent the KCl filling solution from being

mixed with the sample solution.

Fill hole

(left open during measurement)

Level of filling solution

Level of sample solution

(refill when level is low)

Sample solution

KCl refillable type sensor must be immersed so filling

solution level is above the level of sample solution.

Protective cover

F0302.EPS

Figure 3.2 How to Immerse the KCl Refillable Type Sensor

Bubbles trapped in the glass electrode tip may interfere with accurate measurement.

Before taking measurements, check the electrode tip for bubbles. If present, gently shake

the sensor, as shown in Figure 3.3, to dislodge bubbles from the tip.

Enlarged View of A

* No bubbles

Bubbles

allowed in tip.

Filling solution

F0303.EPS

Filling solution

A

Glass electrode tip

Figure 3.3 How to Dislodge Bubbles from Glass Electrode Tip

3-2

IM 12B03D02-01E

Page 26

3.3 Measurement Display Panel

When immersing the sensor in a sample solution, a measured pH (or mV) value will be

shown on the display. There are three types of measurement display panels: the standard,

3. Measurement

day month yearSolution temperature

MEAS

key to cycle through these display panels.

MEAS

calendar, and clock display panels. Use

Standard panel Calendar panel Clock panel

pH value

(or mV)

MEAS MEAS

3.4 Saving a Measured Value

There are two ways to save a measured value: holding temporarily and storing as a

record in nonvolatile memory. Measured values stored in nonvolatile memory are not

deleted even by replacing the batteries.

(1) HOLD

If

temporarily and the displayed value no longer changes. Press

return to the measurement mode.

key is pressed during measurement, the currently measured value is held

HOLD

HOLD

or

hour:minute

MEAS

F030301.EPS

key to

IM 12B03D02-01E

HOLD

HOLD

or

MEAS

F030401.EPS

3-3

Page 27

3. Measurement

(2) Data storage

DATA

If the

F/ENT

key is pressed during measurement, mark starts flashing. Press the

key, then currently measured data can be stored in nonvolatile memory. Data

stored are measured conductivity, measured temperature, date and time. Up to 300 data

including individually deleted data can be stored. If you attempt to store more data,

will be displayed.

If is displayed before the data number has reached 300, run defrag referring to

Section 5.3 (15), “Defrag memory (DFLG) panel.” This will free up memory occupied

by deleted data, allowing data to be stored newly. To check stored data, refer to Section

5.3 (1), “Display stored data (dAt) panel.”

Pressing

DATA

or

MEAS

key while mark is flashing cancels data storage and

returns the meter to measurement mode.

Abort data storage.

While is flashing, press

or keys to abort data storage.

MEAS

Execute data storage.

Press key to store data while is flashing.

F/ENT

DATA

DATA

F030402.EPS

3-4

IM 12B03D02-01E

Page 28

4. Calibration

Calibration using standard solutions means to measure the pH value of a certified

standard solution and to adjust the pH meter so it reads the same value as the certified

value of the standard solution. The PH72 meter can be calibrated automatically or

manually.

The PH72 meter must be calibrated before measurement if:

• it has been stored for a long period;

• the electrode has been cleaned; or

• otherwise necessary.

Precautions

(1) Use certified standard solutions. Using deteriorated standard solutions will result

in inaccurate calibration. Standard solutions are available as spare parts (see

Section 1.8).

Pour a portion of the standard solution into a calibration bottle (supplied) and use

for calibration. Do not reuse the portion. Discard it and use a fresh portion for

another calibration.

4. Calibration

(2) Do not press

results may be changed.

key unless calibration is needed. Otherwise, saved calibration

CAL

Before Calibration

The following should be checked and set before calibration.

(1) Contamination of the sensor

Make sure that no dirt or deposits are present on the sensor.

(2) Temperatur e setting

When using a sensor without a built-in temperature element, i.e., a needle type or test

tube size pH sensor, the temperature of a standard solution to be used should be set into

the meter. (Refer to Section 5.3 (2), “Manual temperature setting (M.tP) panel.”)

(3) Battery condition

Check the battery condition indicator for remaining life. If the indicator is flashing,

calibration cannot be performed. Replace the batteries. (Refer to Section 2.1, “Installing

the Batteries.”)

IM 12B03D02-01E

4-1

Page 29

4. Calibration

Error Messages during Calibration

If the meter detects an abnormality during calibration, , , or

may be displayed. In such a case take corrective actions referring to Chapter 7,

“Troubleshooting.”

Canceling Calibration

To cancel the calibration procedure, press

measurement mode.

CAL

or

MEAS

key. The meter will return to

1-point and 2-point Calibrations

There are two types of calibrations: 1-point calibration using only one standard solution

and 2-point calibration using two standard solutions. One-point calibration is a simplified

calibration method which can be used only when the anticipated pH values of sample

solutions are near the certified pH value of a standard solution used for calibration. Twopoint calibration is generally recommended.

Calibration results are not affected by turning off the power and saved until the next

calibration or the initialization of calibration parameters (see Section 5.3 (11)). The last

two calibration results are saved in the meter. Therefore, for 1-point calibration, first

initialize calibration parameters and then perform a 1-point calibration, or without

initializing, perform a 1-point calibration twice using the same standard solution.

4-2

IM 12B03D02-01E

Page 30

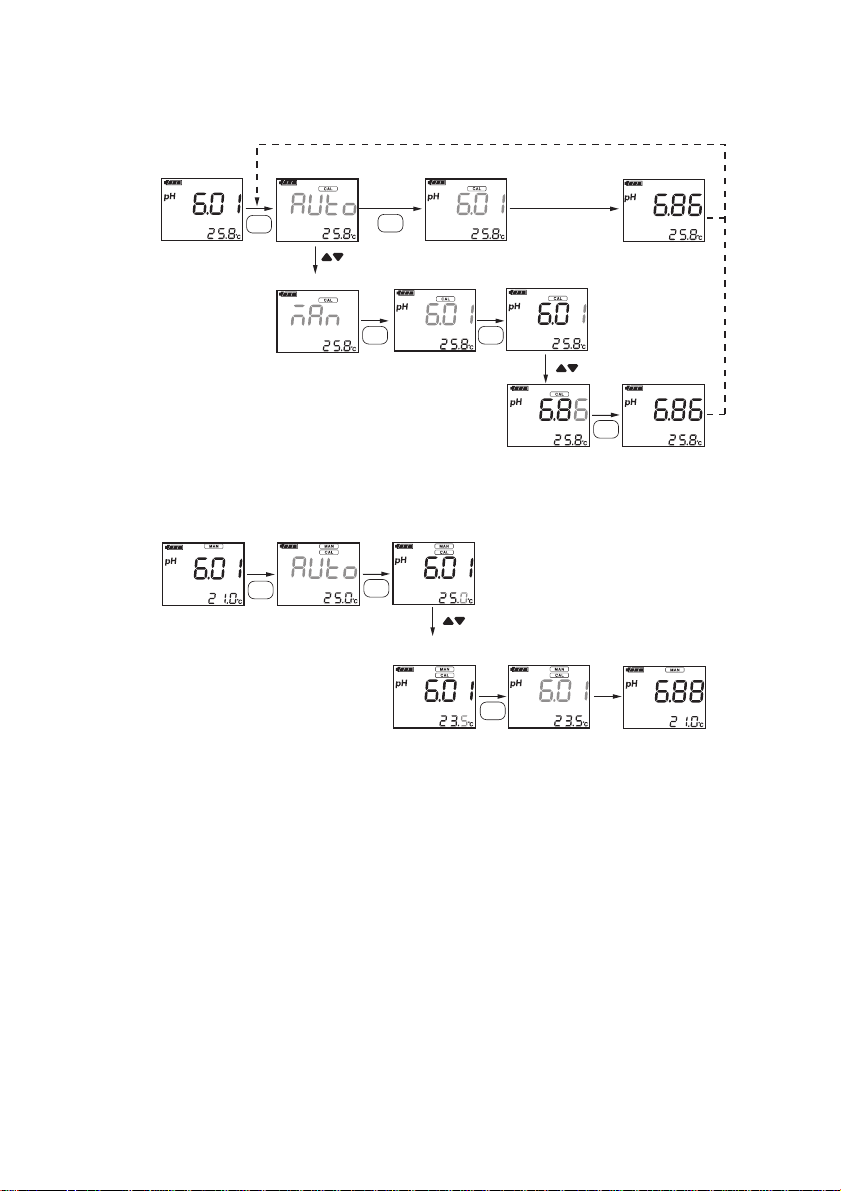

4.1 Automatic Calibration

In automatic calibration the Model PH72 Personal pH/ORP Meter automatically

recognizes standard solutions being used and calibrates itself using values of Table 4.1.

Two types of standard solutions are preprogrammed: NIST (solutions prepared in

accordance with Japanese standards, factory default) and US (solutions prepared in

accordance with the U.S. standards). If NIST is selected, the meter recognizes standard

solutions with pH 2, 4, 7, 9, and 12. The meter recognizes standard solutions with pH 4,

7, and 10 if US is selected.

Table 4.1 pH-Temperature Relationship in pH Standard Solutions

d NIST

Temperature 8C

Std. Solution

pH2

pH4

pH7

pH9

pH12

d US

Temperature 8C

Std. Solution

pH4

pH7

pH10

Before Automatic Calibration

0 5 10 15 20 25 30 35 40 4550

-

4.003

6.984

9.464

13.423

1.668

3.999

6.951

9.395

13.207

1.670

3.998

6.923

9.332

13.003

1.672

3.999

6.900

9.276

12.810

1.675

4.002

6.881

9.225

12.627

1.679

4.008

6.865

9.180

12.454

1.683

4.015

6.856

9.139

12.289

1.688

4.024

6.844

9.102

12.133

1.694

4.035

6.838

9.068

11.984

1.700

4.047

6.834

9.038

11.841

1.707

4.060

6.833

9.011

11.705

1.715

4.075

6.834

8.985

11.574

0 5 10 15 20 25 30 35 40 4550

4.000

7.120

10.317

3.998

7.090

10.245

3.997

7.060

10.179

3.998

7.040

10.118

4.001

7.020

10.062

4.005

7.000

10.012

4.010

6.990

9.966

4.018

6.980

9.926

4.027

6.980

9.889

4.038

6.978

9.856

4.050

6.970

9.828

4.064

6.980

9.828

Make sure that the correct type of standard solutions to be used for automatic calibration

has been selected. (Refer to Section 5.3 (10), “Standard solution setting (Std) panel.”)

4. Calibration

55 60 70 80

1.723

1.743

4.126

6.845

8.921

-

1.766

4.164

6.859

8.885

T0402.EPS

4.091

6.836

8.962

11.449

55 60

4.080

6.980

9.828

-

IM 12B03D02-01E

4-3

Page 31

4. Calibration

d Procedure

Example 1: 2-point calibration using pH 7 and pH 4 standard solutions

Water

POWER

Calibration

at 2nd point

Wash sensor with

water thoroughly.

Wash sensor with water

thoroughly (or wash in

water in beaker).

to select auto calibration (AUto)

Auto calibration in progress

F/ENT

Water

Wipe off washing water

from sensor thoroughly

and then immerse sensor

in standard solution.

( to select auto calibration (AUto))

Auto calibration in progress

Wipe off washing water

from sensor thoroughly

and then immerse sensor

in standard solution.

(1st point)

Std. sol.

(2nd point)

Std. sol.

Auto calibration at 1st point

After

a few

seconds

Wait until

reading

stabilizes.

CAL

Auto calibration at 2nd point

After

a few

seconds

Wait until

reading

stabilizes.

CAL

is complete

is complete

F/ENT

The last two calibration results are saved in the meter. Therefore, for 1-point calibration,

perform a 1-point calibration twice using the same standard solution, or initialize

calibration parameters (refer to Section 5.3 (11), “Initialize calibration parameters (I.CP)

panel”) before performing a 1-point calibration.

4-4

F0401.EPS

IM 12B03D02-01E

Page 32

4. Calibration

Example 2: Calibration of a sensor without a built-in temperature element* using a pH

7 standard solution

* Needle type or test tube size pH sensor

Water

POWER

Wash sensor with water

thoroughly (or wash in

water in beaker).

25.08C fixed

Auto calibration in progress

to select auto calibration (AUto)

F/ENT

After

a few

seconds

Thermometer

Wipe off washing water

from sensor thoroughly

and then immerse sensor

in standard solution.

F/ENT

Auto calibration is complete

Temperature set on 'M.tP' panel

Std. sol.

to enter

standard

solution

temperature

Wait until

reading

stabilizes.

CAL

Input of standard solution

temperature

Standard

solution

temperature

F0402.EPS

For 2-point calibration, continue the procedure in the same way as Example 1. The

difference between Example 1 and 2 is that appears on the display and the

temperature of a standard solution should be entered manually.

IM 12B03D02-01E

4-5

Page 33

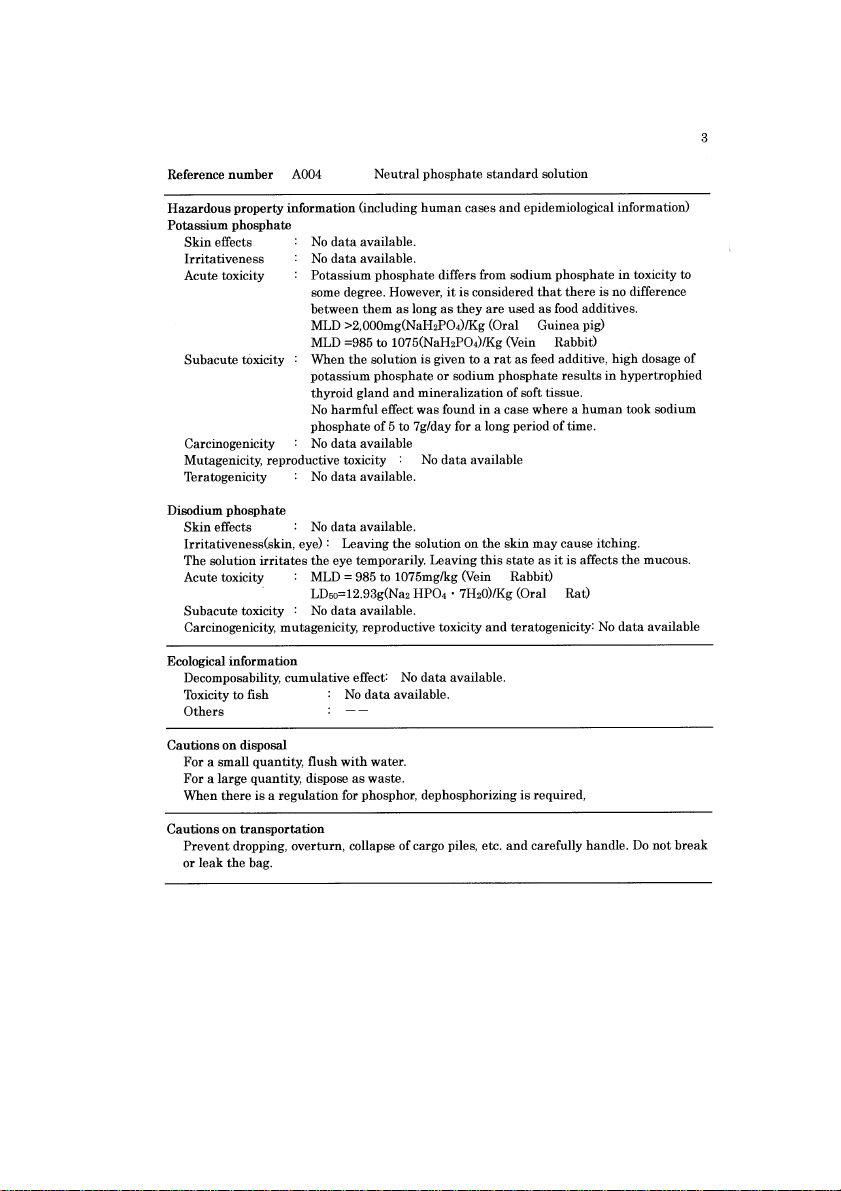

4. Calibration

4.2 Manual Calibration

When using standard solutions other than those preprogrammed for automatic calibration

(see Section 4.1), calibration should be performed manually.

In 2-point calibration, manual calibration can be performed at both two points or manual

calibration performed at one point (either 1st or 2nd) in combination with automatic

calibration using a specified standard solution at the other point.

Note: Although manual calibration can be performed using standard solutions the same

as the ones preprogrammed for automatic calibration, it only makes the

procedure more complicated. When using these standard solutions, automatic

calibration should be generally performed.

d Precautions

(1) The difference between the pH values of two standard solutions to be used for 2-

point calibration must be at least 0.7 pH. If not, the meter will recognize the two

standard solutions as the same calibration point. That is, the second calibration

result will override the first calibration value, resulting in 1-point calibration.

(2) When using alkaline standard solutions, use the standard solution with lower pH

for the first point calibration. If not, may appear.

4-6

IM 12B03D02-01E

Page 34

d Procedure

Example 3: Manual calibration

Water

POWER

Wash sensor with water

thoroughly (or wash in

water in beaker).

Std. sol.

Wipe off washing water

from sensor thoroughly

and then immerse sensor

in standard solution.

4. Calibration

(2-point calibration)

Wait until

reading

stabilizes.

CAL

Prompting

to select

manual

calibration

(MAn)

to enter

F/ENT

F/ENT

Manual calibration is complete

F/ENT

to confirm

F0403.EPS

For 2-pont calibration, continue the procedure following the dotted line. When using a

sensor without a built-in temperature element (needle type or test tube size pH sensor),

enter the temperature of standard solution following the procedure described in Section

4.1, Example 2.

IM 12B03D02-01E

4-7

Page 35

4. Calibration

4-8

IM 12B03D02-01E

Page 36

5. Keypad and Display Functions

5. Keypad and Display Functions

There are eight membrane keys on the keypad of the Model PH72 Personal pH/ORP

Meter. The following key functions are provided.

• Displaying a pH (or mV) value and temperature

• Displaying a pH (or mV) value, date and time

• Holding a pH (or mV) value and temperature

• Storing data — pH (or mV) value and associated information

• Function mode

• Calibration

Turns power on or off.

Automatic Power Off

function (default: 20 min).

Moves to calibration

mode.

Holds the currently

measured value.

Stores the currently

measured value in

memory.

Auto Power Off

POWER

CAL

HOLD

DATA

MEAS

F/ENT

Moves to measurement

mode or switches

measurement display

panels. Also exits from the

current function and returns

to measurement mode.

Moves to function

mode or confirms data

entry.

Changes setting or

value.

F050001.EPS

IM 12B03D02-01E

5-1

Page 37

5. Keypad and Display Functions

5.1 Keypad Functions

POWER

: Power On/Off key

Pressing and holding this key for at least one second when nothing is displayed on the

LCD, will turn the meter on. The meter will be turned off by pressing and holding this

key for at least two seconds when the meter is on. If no keys are pressed for a preset

time, the meter turns off power automatically. (Refer to Section 5.3 (8), “Set Auto Power

Off time (A.oFF) panel.”)

: Calibration key

CAL

When pressed during measurement, mark turns on and the meter moves to

calibration mode. To return to measurement mode, press

: HOLD key

HOLD

CAL

When pressed during measurement, mark turns on and the currently displayed

measured pH (or mV) value and temperature are held. Pressing

will turn mark off and return the meter to measurement mode.

: DATA key

DATA

or

HOLD

MEAS

or

key.

MEAS

key

When pressed during measurement, mark flash and the currently displayed

measured pH (or mV) value and temperature are held temporarily. Pressing

while mark is flashing, will store the held data in memory. After the data is

stored successfully, the meter returns to measurement mode automatically. To cancel

data storage, press

DATA

or

MEAS

key while mark is flashing. mark

will turn off and the meter will return to measurement mode.

MEAS

: Measurement key

In measurement mode each press of this key cycles through three measurement display

panels. (Refer to Section 3.3, “Measurement Display Panel.”) Pressing this key in other

modes will return the meter to measurement mode. If you want to cancel any operation,

press this key to return to measurement mode.

: Setting change keys

Used to change settings.

5-2

F/ENT

key

IM 12B03D02-01E

Page 38

5. Keypad and Display Functions

F/ENT

: Entry key

Pressing this key during measurement moves the display to function mode. (Refer to

Section 5.3, “Function Modes.”) This key is also used to confirm data entry.

Beep sound

When a key is pressed, the meter acknowledges it using a beep sound.

(1) One beep

The meter will beep once confirming a valid key entry.

(2) Three beeps

The meter will beep three times if the key entry is invalid.

To disable the beep, refer to Section 5.3 (9), “Set beep on/off (bZ.o) panel.” Note that

the volume of the beep sound is not adjustable.

IM 12B03D02-01E

5-3

Page 39

5. Keypad and Display Functions

5.2 Display Items

Display items and their descriptions are provided below.

Battery condition indicator

Temperature setting mode

Manual mode

Data mode

HOLD mode

Calibration mode

Sensor check mode

(1) Battery condition indicator

Indicates the level of the remaining battery life stepwise. means that there is

plenty of life left. A flashing means that the batteries are low and need to be

replaced immediately. When the indicator is flashing, access to calibration mode by

pressing

key is rejected. To replace the batteries, first press

CAL

off power and make sure the display has been turned off, and then replace referring to

Section 2.1, “Installing the Batteries.”

(2) T emperatur e setting mode

Appears while manual temperature setting is being performed. (Refer to Section 5.3 (2),

“Manual temperature setting (M.tp) panel.”)

(3) Manual mode

Appears when a sensor without a built-in temperature element (needle type or test tube

size pH sensor) is connected to the meter. (Refer to Section 2.6, “Manual temperature

setting.”)

(4) Data mode

Appears when measured data are stored or when stored data are accessed. (Refer to

Section 5.1, “Keypad Functions,” and Section 5.3 (1), “Display stored data (dAt) panel.”)

(5) HOLD mode

Appears while measured data are being held temporarily. (Refer to Section 5.1, “Keypad

Functions.”)

(6) Calibration mode

Appears during calibration using standard solutions. (Refer to Chapter 4, “Calibration.”)

POWER

F050201.EPS

key to turn

(7) Sensor check mode

This mark may appear when:

• the pH electrode deteriorated significantly (check is performed during calibration);

• the standard solution used for calibration changed in quality;

• deposits are present on the electrode (check is performed during calibration).

If deposits are present, clean the sensor (see Section 6.2); or,

• calibration is performed improperly.

5-4

IM 12B03D02-01E

Page 40

5.3 Function Mode

Outline

5. Keypad and Display Functions

Various functions are supported by function mode. Press

key while the meter is

F/ENT

in measurement mode to move to function mode.

Note: The last selected and executed item is displayed when you move to function

mode. Use keys to cycle through the items listed in Table 5.1 in that

order.

Setting Procedures

Use keys to move to the desired item. While the desired item is flashing, press

F/ENT

key to access that item panel. To return from function mode to measurement

mode, press

Item*

dAt

M.tP

PV.U

dEL.A

dAtE

tIME

ALM

A.oFF

bZ.o

Std

I.CP

tP.U

VEr

dFLG

MEAS

key anytime.

Table 5.1 Function Mode Item List

1

Description

Display stored data

Manual temperature setting

Set measurement unit

Delete all stored data

Date setting

Time setting

Alarm time setting

Set Auto Power Off time

Set beep on/off

Standard solution setting

Initialize calibration parameters

Set temperature unit

Check version number

Defrag memory

*1: For displayed digital characters, see Alphanumeric Display Table in Preface.

*2: "2" denotes that the item is not user configurable.

Default*

no dAtA

25 8C

pH

2

2004, 1 (month), 1 (day)

0 hour 0 minute

oFF

20 min

on

nISt

no

8C

2

2

2

For details, refer to:

Item (1)

Item (2)

Item (3)

Item (4)

Item (5)

Item (6)

Item (7)

Item (8)

Item (9)

Item (10)

Item (11)

Item (12)

Item (13)

Item (14)

T0501.EPS

IM 12B03D02-01E

5-5

Page 41

5. Keypad and Display Functions

Operating procedures on each panel are described below.

(1) Display stored data (dAt) panel

Shows stored data on the LCD with mark. When you access this panel, the last

stored pH (mV) value and temperature will be displayed with the data number flashing at

the lower left of the display. Pressing keys scrolls through all stored data. If no

data are stored, “no dAtA” is displayed at the bottom of the display. Each press of

key cycles through the day/month, year, and time of the stored data, and “Delete

DATA

stored data” panels.

• Individual Deletion

By pressing

displayed stored data can be deleted. First is flashing. Use keys to switch to

flashing and then press

of “dEL” will be deleted.

• Data Numbering after Deletion

The number displayed at the bottom left indicates the stored data number relative to the

beginning of the data store. This number does not necessarily represent the number of

stored data. If a data item is deleted, item numbers of data that follow it will be

decreased by one.

• Data Display after Deletion

If a data item is deleted, the data item after it is displayed. If there is no data after the

deleted data item (i.e., it was the last stored data item), the data item before the deleted

data item is displayed.

F/ENT

key when “dEL” appears underneath the value, the currently

key. The stored data with the number to the left

F/ENT

When data item 012 (latest data) is deleted:

5-6

Item 012 is deleted,

so item 011

becomes the latest.

When data item 011 is deleted

Item 011 is deleted,

so item numbers of

following items (only

item 012 in this case)

are decremented by 1.

F050300.EPS

IM 12B03D02-01E

Page 42

5. Keypad and Display Functions

Stored measurement data

Latest data

F/ENT

When no stored data.

F/ENT

DATA

F/ENT

to display other data

Day and month data item was stored

DATA DATA

"Delete stored data" panel

DATA

Delete

stored data

F/ENT

Year data item was stored

DATA

Time data item was stored

IM 12B03D02-01E

F/ENT

F050301.EPS

5-7

Page 43

5. Keypad and Display Functions

(2) Manual temperature setting (M.tP) panel

Used to input the temperature of a solution into the meter when using a sensor without a

built-in temperature element (needle type or test tube size pH sensor). This setting is not

required when a sensor connected has a built-in temperature element. The setting range is

from -10.0 to 110.08C.

to set

to confirm

F/ENT

F/ENT

F050302.EPS

(3) Set measurement unit (PV.U) panel

Used to set a pH unit for pH measurement or a mV unit for ORP measurement.

F/ENT

to

proceed

F/ENT

to confirm

(4) Delete all stored data (dEL.A) panel

Used to delete all stored data. Press

will be flashing. Use keys to select . Press

data completely.

F/ENT

to

proceed

F/ENT

F/ENT

to execute

key on the flashing “dEL.A” panel.

F/ENT

to toggle

to toggle

to cancel

F050303.EPS

F/ENT

key to delete all stored

F050304.EPS

5-8

IM 12B03D02-01E

Page 44

5. Keypad and Display Functions

(5) Date setting (dAtE) panel

Used to set the year (four digits), month and day in this order. Use keys to set the

year, month, and day, and press

F/ENT

key to confirm each entry.

Year setting Month setting

F/ENT

F/ENT

Day setting

F/ENT

F/ENT

F050305.EPS

The calendar function will be valid through to year 2090.

(6) Time setting (tIME) panel

Used to set the time — hour (24-hour format) and minute in this order. Use keys

to set the time and press

F/ENT

key to confirm each entry.

Hour setting (24-hr clock) Minute setting

F/ENT F/ENT

F/ENT

F050306.EPS

IM 12B03D02-01E

5-9

Page 45

5. Keypad and Display Functions

(7) Alarm time setting (ALM) panel

Used to enable/disable the alarm clock and set the alarm clock in minutes and seconds.

Use keys to select the desired alarm cycle: 7 days (everyday), 5 days (weekdays)

or once. See Item (6), “Time setting (tIME) panel” for setting the time for alarm. The

alarm sounds for about 15 seconds. Acknowledge the alarm by pressing any key. The

alarm sound will stop. If no key is pressed (no acknowledgement), the alarm sounds for

15 seconds again 3 and 6 minutes after the preset alarm time. Note that the day of the

week is not displayed.

F/ENT

alarm sounds

at preset time

every day

alarm sounds at

preset time

from Monday

to Friday

F/ENT

Hour setting (24-hr clock)

F/ENT

Minute setting

5-10

alarm sounds

once

at preset time

F050307.EPS

IM 12B03D02-01E

Page 46

5. Keypad and Display Functions

(8) Set Auto Power Off time (A.oFF) panel

Used to set the automatic power off time. The meter turns off power automatically if no

key is pressed during this preset time. The time range is from 1 to 120 minutes. If 0 is

set, the Auto Power Off function will be disabled. Use the meter taking care to conserve

the batteries.

to set

F/ENT

F/ENT

to confirm

F050308.EPS

(9) Set beep on/off (bZ.o) panel

The beep sound on key press can be enabled/disabled in this panel. Use keys to

F/ENT

F/ENT

key to confirm. Note that this beep setting does not

select on or off and press

affect the alarm sounding (See Item (7)).

F/ENT

to turn ON (enable).

F/ENT

to turn OFF (disable).

(10) Standard solution setting (Std) panel

Used to select the type of standard solutions: NIST or US. The factory default is NIST.

When using standard solutions prepared in accordance with the Japanese standards, use

the meter with the factory default of NIST. Select US only when using standard solutions

prepared in accordance with the U.S. standards. (Refer to Chapter 4, “Calibration.”)

F/ENT

F/ENT

IM 12B03D02-01E

to toggle

to confirm

F050309.EPS

F050310.EPS

5-11

Page 47

5. Keypad and Display Functions

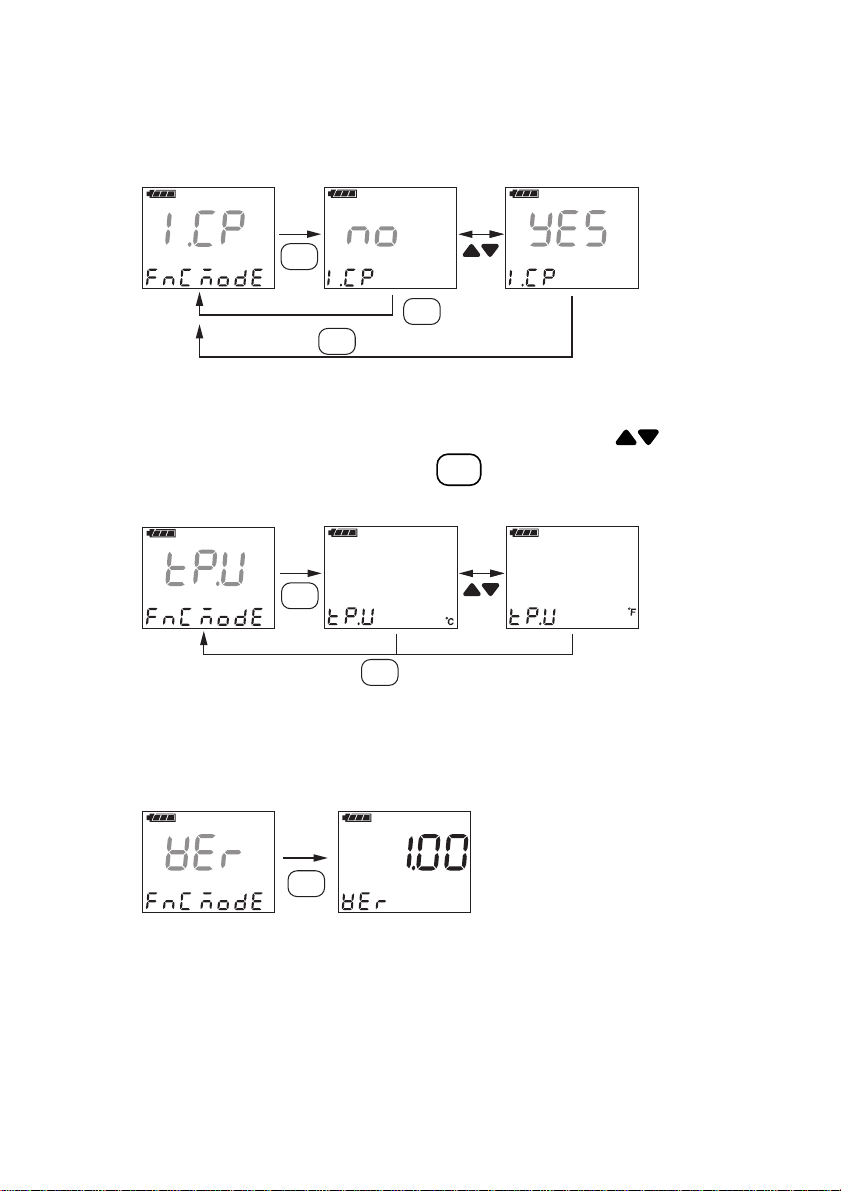

(11) Initialize calibration parameters (I.CP) panel

Used to initialize the parameters saved by calibration to default settings: slope at 1.000

and asymmetry potential at 0.0 mV.

F/ENT

to

proceed

F/ENT

to execute

F/ENT

to toggle

to cancel

F050311.EPS

(12) Set temperature unit (tP.U) panel

Used to select the temperature unit: Celsius (8C) or Fahrenheit (8F). Use keys to

to confirm

F/ENT

key to confirm.

to toggle

F050312.EPS

select the desired temperature unit and press

F/ENT

F/ENT

(13) Check version number (VEr) panel

Used to check the version number of the program. This is not user configurable.

5-12

F/ENT

F050313.EPS

IM 12B03D02-01E

Page 48

5. Keypad and Display Functions

(14) Defrag memory (dFLG) panel

Up to 300 data can be stored. Unnecessary data can be individually deleted (refer to Item

(1), “Display stored data”), but this individual deletion does not free up memory

occupied by deleted data. Therefore, may be displayed even though less than

300 data are stored. In such a case, use the defrag function to consolidate data and free

up the space occupied by deleted data, thereby allowing up to 300 data to be stored.

While memory defrag is in progress, do NOT turn off the power. In addition, before

starting memory defrag check that there is enough battery life left to avoid battery

shutoff during memory defrag.

• Procedure

F/ENT

Press

key on the flashing “dFLG” display. will be flashing. Use

keys to select , then press

F/ENT

key. While defrag is in progress, “WAIt” may

flash. (It may not flash depending on the amount of deleted data.) When defrag is

complete, “End” appears.

F/ENT

to

proceed

(may not appear if deleted data amount is small)

After a few

seconds

F/ENT

F/ENT

to toggle

to cancel

to execute

F050314.EPS

IM 12B03D02-01E

5-13

Page 49

5. Keypad and Display Functions

5-14

IM 12B03D02-01E

Page 50

6. Maintenance

6.1 For Optimum Meter Performance

The Model PH72 Personal pH/ORP Meter is simple to operate, but is a precision

instrument. To ensure accurate results from the meter, the following precautions should

be observed.

Flow Diagram

Measurement

MaintenanceCa l i b ration

Storage

F060101.EPS

Table 6.1 Precautions in Each Step

Calibration using standard solutions:

Calibration

Measurement

Maintenance

Storage

• 1- or 2-point calibration. 2-point calibration is recommended for

accurate pH measurement.

• Always use certified standard solutions (pH 2, 4, 7, 9, 10, or 12).

Sample solution requirements:

• pH range: 0 to 14 pH

• Temperature: 0 to 808C (0 to 1008C when using needle type or test

tube size pH sensor)

• After measurement, rinse off remaining sample solution from the

electrode thoroughly.

• Avoid a place with high temperature and humidity.

• Keep the wetting cap (moisten the cotton wad in the cap with a few

drops of water) attached to prevent the glass electrode and liquid

junction from drying out.

6. Maintenance

T0601.EPS

IM 12B03D02-01E

6-1

Page 51

6. Maintenance

6.2 pH Electrode Cleaning

Dirt or deposits on the glass electrode or liquid junction can often interfere with accurate

measurement. Periodical cleaning is required depending on the nature of the solution

being measured.

CAUTION

Do not apply physical shock or excessive force to the glass sensor, or it may break. Do

not rub the glass membrane strongly, or it may be damaged or break.

• Suspended Solids, Adhesive Material, Microorganisms, Greasy Substances,

etc.

Dirt or deposits on the glass electrode, liquid junction or temperature element should be

removed. Clean using a cotton swab soaked with a neutral detergent, and rinse off with

water. If necessary, use a toothbrush to clean.

Temperature

element

Glass electrode

Liquid junction

Figure 6.1 How to Clean Using a Toothbrush

F0601.EPS

• Chemical Contaminants

Chemical contaminants can affect the electrode performance even though the electrode

appears to be clean. If appears on the display, soak the electrode in dilute

hydrochloric acid (approximately 0.1 mo/l, 1 to 2 pH) for 10 to 20 minutes (this process

is called acid cleaning). Since an electrode deteriorates gradually in service, its

performance cannot be recovered completely even if acid cleaning is conducted. After

cleaning, rinse off cleaning solution from the electrode with water.

Note: Dilute hydrochloric acid is commercially available at a pharmacy. Handle with

care.

6-2

IM 12B03D02-01E

Page 52

0.1 mol/l dilute

hydrochloric acid

6. Maintenance

After 10 to 20

minutes

Cleaning water

Soak in 0.1 mol/l hydrochloric acid

Rinse thoroughly in water

Figure 6.2 Acid Cleaning

6.3 Sensor Replacement

Since a pH sensor undergoes chemical changes with time, its performance deteriorates

gradually. Under normal operating conditions a sensor can be used for one or two years.

Sensor deterioration, however, speeds up depending on the nature of a sample solution,

e.g., a high temperature solution. Storage conditions also affect the sensor life.

If or appears while calibration is being performed with a sensor for

which is displayed, replace the sensor.

6.4 Rehydrating the Glass Electrode

A dry glass electrode gives fluctuating pH readings. If a glass electrode has dried up,

soak it in water (tap water) for 1 to 2 hours or longer to rehydrate. The sensor will give

stable pH readings.

F0602.EPS

IM 12B03D02-01E

6-3

Page 53

6. Maintenance

6.5 Replenishing the Electrode with Filling Solution (KCl solution)

Replenishment is required only when a KCl refillable type combination sensor is used.

An electrode filling solution leaks from the liquid junction little by little during

measurement. When the level of filling solution drops to the level shown in Figure 6.3,

replenish with a 3.3 mol/l KCl solution supplied.

CAUTION

A syringe tip is sharp. Handle with care.

Syringe (supplied)

Filling solution level

Fill hole for KCl solution

20mm

Protective cover

Replenish when filling solution

level drops to the level shown above.

Figure 6.3 Replenishment of Filling Solution

How to fill using syringe

F0603.EPS

6-4

IM 12B03D02-01E

Page 54

6.6 Cleaning and Drying Connectors

Deteriorated insulation between connector pins can cause inaccurate readings. To remove

stains and/or moisture that may cause deteriorated insulation, clean the connector with a

dry cloth or a cloth moistened with anhydrous alcohol. If necessary, use a dryer.

O-ring

Wipe off stains and/or moisture on

meter connector with a dry cloth.

Check that there are no stains on

the O-ring.

Hot air

Use a dryer if necessary to

remove moisture from

connector of sensor cable.

6. Maintenance

F060601.eps

CAUTION

Use anhydrous alcohol to clean the connectors so no moisture remains. Dry connectors

completely.

IM 12B03D02-01E

6-5

Page 55

6. Maintenance

6.7 Storage and O-ring/Gasket Replacement

• Storage Precautions

Care is required when storing the meter and sensor. To maintain in good condition,

observe the following:

(1) Before storage, wash off remaining sample solution from the sensor with water.

Deposits on the liquid junction, if any, must be removed thoroughly, or the

junction may be clogged. A clogged junction will cause invalid measurements,

e.g., unstable pH readings.

Keep a wetting cap attached to the sensor. For KCl refillable type sensors, seal the

fill hole with a plug.

(2) Leave the sensor connected to the meter body to protect the connectors and O-ring

from staining. Contamination may cause deteriorated insulation of connectors or

poor water resistance by the O-ring.

(3) Do not place any object on top of the sensor or on the top of the PH72 meter.

Attach wetting cap containing cotton

wad moistened with a few drops of

water.

For KCl refillable type sensor,

seal fill hole with plug.

Protective cover

Wetting cap

Figure 6.4 Sensor Storage Condition

• Storage Location

When not in use, store the meter and sensor in a safe place. If it is to be stored for a long

period, store it in a place:

• With low humidity at or near normal temperatures

• Not exposed to direct sunlight or water

• No corrosive gases are present

• Replacing the O-ring and Gasket

A gasket in the battery box and an O-ring on the sensor connector of the meter can be

replaced. Heavily contaminated or damaged gasket and/or O-ring should be replaced.

CAUTION

When installing an O-ring and gasket, clean them and their mounting surfaces with a

cloth moistened with alcohol so that they are free from dirt. Otherwise, water resistance

may not be assured.

6-6

F0604.EPS

IM 12B03D02-01E

Page 56

6. Maintenance

(1) Replacing the O-ring

Install the O-ring on the cylindrical flat part of the connector, as shown below.

O-ring

F060701.EPS

(2) Replacing the Gasket

Install the gasket on the groove on the battery box so the raised part fits in place as

shown below. The gasket is symmetrical right to left and front to back.

Gasket

PH72 meter top

Raised part

IM 12B03D02-01E

F060702.EPS

6-7

Page 57

6. Maintenance

6-8

IM 12B03D02-01E

Page 58

7. Troubleshooting

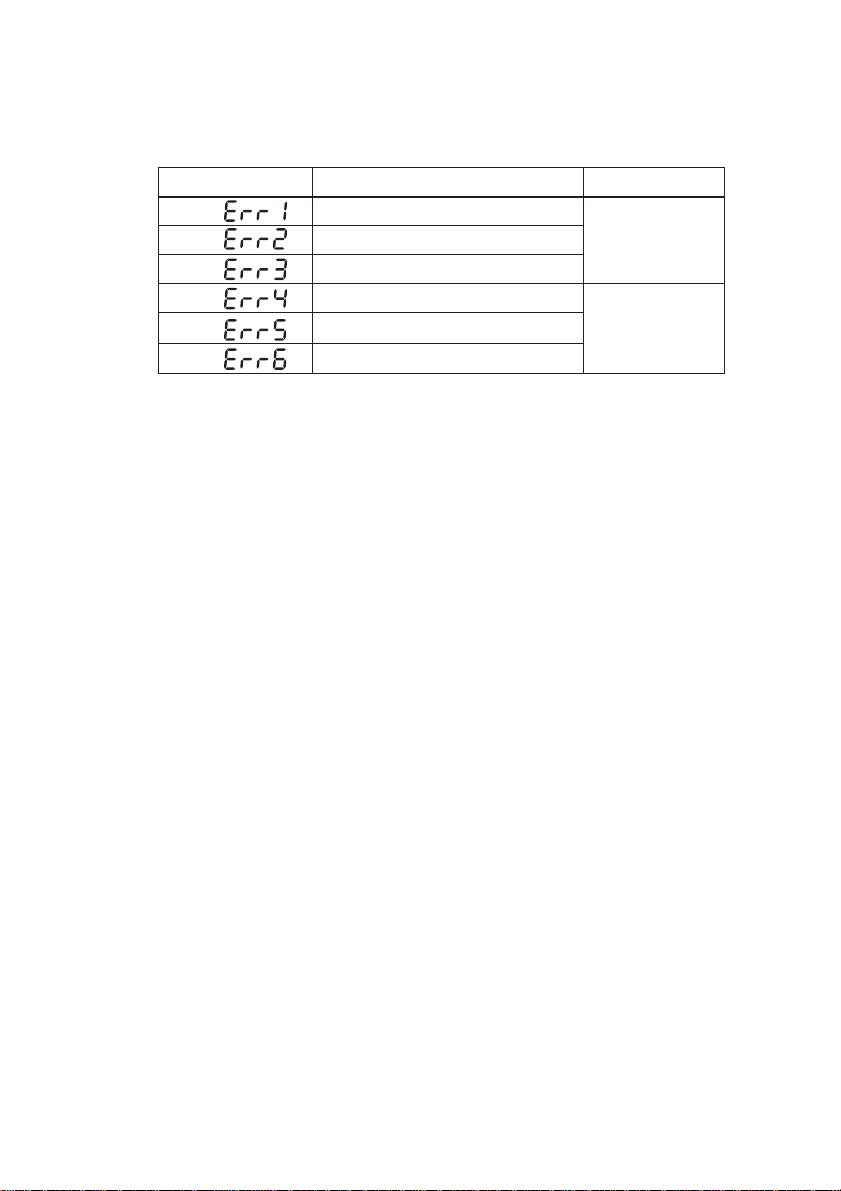

7.1 Causes of Abnormal Readings and Errors

If the pH reading is unstable or abnormal, or an error message appears, during

measurement or calibration, check the following:

(1) Improper maintenance or usage

(2) Expired consumables

(3) Failure

If any trouble occurs, determine the cause and take corrective actions referring to Section

7.2. If the trouble cannot be fixed, contact your nearest Yokogawa sales office.

d Unstable reading

Symptom

d Abnormal reading

d Error message

Expired consumables

d Electrode

d Batteries

Improper maintenance

d Improper calibration

d Stained electrode

d Dry glass electrode

d Deteriorated insulation of connectors

7. Tr oubleshooting

IM 12B03D02-01E

Meter failure

Contact Yokogawa

F0701.EPS

Figure 7.1 Causes of Abnormal Symptoms

7-1