Page 1

User’s

Manual

Model PH202G [Style: S3], PH202S [Style: S3]

2-wire Type pH/ORP(Redox)

Transmitter

IM 12B07D02-01E

IM 12B07D02-01E

11th Edition

Page 2

TABLE OF CONTENTS

PREFACE

1. Introduction And General Description ............................................................. 1-1

1-1. Instrument check ............................................................................................ 1-1

1-2. Application ...................................................................................................... 1-3

2. PH202 Specifications ........................................................................................ 2-1

2-1. General ....................................................................................................... 2-1

2-2. Operating specifications ................................................................................. 2-2

2-3. Model and suffix codes ................................................................................... 2-6

2-4. Control Drawing of PH202S mA HART® Specification (IECEx). .................... 2-7

2-5. Control Drawing of PH202S mA HART® Specification (ATEX) ...................... 2-8

2-6. Control Drawing of PH202S mA HART® Specification ........................................

(FM Intrinsically safe design) ........................................................................... 2-9

2-7. Control Drawing of PH202S mA HART® Specification ........................................

(FM Non-incendive design). ........................................................................... 2-10

2-8. Control Drawing of PH202S mA HART® Specification (CSA). ......................2-11

2-9. Control Drawing of PH202S FF/PB Specification (IECEx) ........................... 2-12

2-10. Control Drawing of PH202S FF/PB Specification (ATEX) .......................... 2-13

2-11. Control Drawing of PH202S FF/PB Specification ..............................................

(FM Intrinsically safe Entity). .......................................................................... 2-14

2-12. Control Drawing of PH202S FF/PB Specification ..............................................

(FM Intrinsically safe FISCO) ......................................................................... 2-16

2-13. Control Drawing of PH202S FF/PB Specification ..............................................

(FM Non-incendive Entity). ............................................................................ 2-18

2-14. Control Drawing of PH202S FF/PB Specification ..............................................

(FM Non-incendive FNICO) ........................................................................... 2-19

2-15. Control Drawing of PH202S FF/PB Specification (CSA). ........................... 2-20

3. Installation And Wiring....................................................................................... 3-1

3-1. Installation and dimensions ............................................................................ 3-1

3-1-1. Installation site .................................................................................................................3-1

3-1-2. Mounting methods ...........................................................................................................3-1

3-2. Preparation ..................................................................................................... 3-3

3-2-1. Cables, terminals and glands ..........................................................................................3-3

3-3. Wiring of sensors ............................................................................................ 3-4

3-3-1. General precautions ........................................................................................................3-4

3-3-2. Additional precautions for installations in hazardous areas ...........................................3-4

3-3-3. Installation in: Hazardous Area-Non-Incendive ..............................................................3-5

3-3-4. Liquid earth ......................................................................................................................3-5

3-3-5. Access to terminal and cable entry .................................................................................3-5

3-4. Wiring of power supply ................................................................................... 3-5

3-4-1. General precautions .......................................................................................................3-5

3-4-2. Connection of the power supply ......................................................................................3-6

3-4-3. Switching the instrument on ............................................................................................3-6

3-5. Wiring the sensor system ............................................................................... 3-7

3-5-1. Impedance measurement jumper settings ......................................................................3-7

3-6. Sensor wiring .................................................................................................. 3-8

3-6-1. Connection cable .............................................................................................................3-9

3-6-2. Sensor cable connection with special grommet ............................................................3-10

3-6-3. Sensor cable connections using junction box (BA10) and extension cable (WF10) ...3-11

3-6-4. Connection VP type sensor ...........................................................................................3-11

In this manual a

IM 12B07D02-01E

11th Edition: Oct. 2009(YK)

All Rights Reserved , Copyright © 2000, Yokogawa Electric Corporation

sign appears if it concerns the PH202G (S)-E, -C, -U, -N, -K

mA

IM 12B07D02-01E

Page 3

4. Operation; Display Functions And Setting ...................................................... 4-1

4-1. Operator interface ........................................................................................... 4-1

4-2. Explanation of operating keys ......................................................................... 4-2

4-3. Setting passcodes .......................................................................................... 4-3

4-3-1. Passcode protection ........................................................................................................4-3

4-4. Display examples ............................................................................................ 4-3

4-5. Display functions ............................................................................................ 4-4

4-5-1. Display functions pH (default)..........................................................................................4-4

4-5-2. Display functions pH (ORP).............................................................................................4-5

4-5-3. Display functions pH (rH).................................................................................................4-6

5. Parameter setting ............................................................................................... 5-1

5-1. Maintenance mode ......................................................................................... 5-1

5-1-1. Manual temperature selection and adjustment ...............................................................5-2

5-1-2. Process temperature measuring in ORP mode...............................................................5-3

5-1-3. Manual activation of HOLD..............................................................................................5-4

5-1-4. Manual impedance check ................................................................................................5-5

5-2. Commissioning mode ..................................................................................... 5-6

5-2-1. Output range ....................................................................................................................5-7

5-2-2. Hold ..............................................................................................................................5-8

5-2-3. Service ...........................................................................................................................5-10

5-3. Notes for guidance in the use of service coded settings ...............................5-11

5-3-1. Parameter specific functions .........................................................................................5-11

5-3-2. Temperature compensation and measuring functions. .................................................5-13

5-3-3. Calibration functions ......................................................................................................5-15

5-3-4. mA output functions .......................................................................................................5-17

5-3-5. User interface ................................................................................................................5-19

5-3-6. Communication setup ....................................................................................................5-21

5-3-7. General .........................................................................................................................5-21

5-3-8. Test and setup mode ....................................................................................................5-21

6. Calibration ....................................................................................................... 6-1

6-1. Automatic calibration ....................................................................................... 6-1

6-2. Manual calibration ........................................................................................... 6-1

6-3. Sample calibration .......................................................................................... 6-1

6-4. Data entry ....................................................................................................... 6-1

6-5. Calibration procedures .................................................................................... 6-2

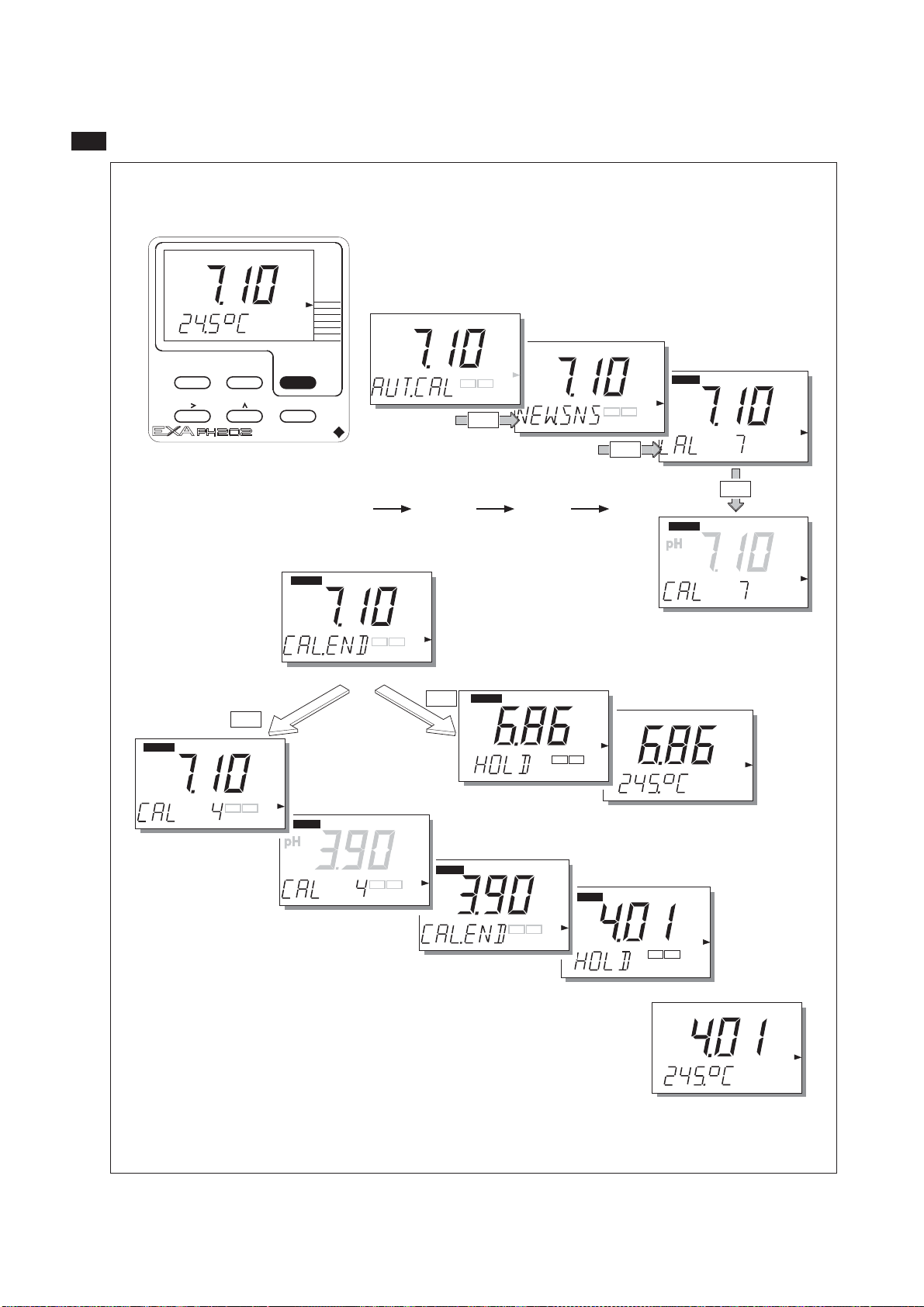

6-5-1. Automatic calibration .......................................................................................................6-2

6-5-2. Automatic calibration with HOLD active ..........................................................................6-3

6-5-3. Manual calibration (2nd parameter calibration) ...............................................................6-4

6-5-4. Sample calibration ..........................................................................................................6-6

7. Maintenance ....................................................................................................... 7-1

7-1. Periodic maintenance for the EXA transmitter ................................................ 7-1

7-2. Periodic maintenance for the sensor system .................................................. 7-1

7-3. Calibration procedures are described in step-by-step detail in chapter 6. ..........

However, follow these guidelines. .................................................................... 7-2

8. Troubleshooting ................................................................................................. 8-1

8-1. Diagnostics ..................................................................................................... 8-2

8-1-1. Off-line calibration checks ...............................................................................................8-2

8-1-2. On-line impedance checks ..............................................................................................8-2

9. Spare Parts ....................................................................................................... 9-1

IM 12B07D02-01E

Page 4

10. Appendix ..................................................................................................... 10-1

10-1. User setting table ........................................................................................ 10-1

10-2. Configuration checklist for PH202G ........................................................... 10-3

10-3. Setup for sensor compatibility ..................................................................... 10-4

10-3-1. General ........................................................................................................................10-4

10-3-2. Selection of measurement and reference electrode ...................................................10-4

10-3-3. Selecting a temperature sensor...................................................................................10-4

10-4. Set up for other functions ............................................................................ 10-5

10-5. Set up for Pfaudler Type 18 sensor ............................................................ 10-6

10-5-1. General set up .............................................................................................................10-6

10-5-2. Calibration set up .........................................................................................................10-6

10-6. Device Description (DD) menu structure .................................................... 10-7

Glossary

11. APPENDIX 2 .....................................................................................................11-1

11-1. Preface ......................................................................................................11-1

11-2. Wiring diagrams ...........................................................................................11-2

11-2-1. Example of Non-Explosionproof System ....................................................................11-2

11-2-2. Example of Intrinsically Safe Explosionproof System ................................................11-2

11-3. Sensor wiring ...............................................................................................11-2

11-3-1. Connection cable .........................................................................................................11-3

11-3-2. Sensor cable connection using terminal box ...............................................................11-5

11-4. PH201G*B Dedicated Distributor .................................................................11-5

11-4-1. Communication setup .................................................................................................11-5

11-4-2. The setting of sending WASH signal (*WASH) ..........................................................11-6

11-4-3. How to output manual wash signal ............................................................................11-8

11-4-4. Setting of errors (FAIL contact) ..................................................................................11-9

11-5. Calibration in ORP Mode ...........................................................................11-10

11-5-1 Electrode Check .........................................................................................................11-10

11-5-2. Manual Calibration .....................................................................................................11-11

11-5-3. Calibration with Sample .............................................................................................11-11

11-5-4. Data Entry ..................................................................................................................11-11

11-5-5. Calibration Procedure ................................................................................................11-12

11-6. Supplement of troubleshooting ..................................................................11-13

11-6-1. Error Codes ..............................................................................................................11-13

11-6-2. On-line impedance checks .......................................................................................11-14

11-6-3. Supplement of temperature sensor ..........................................................................11-15

11-6-4. Auto-Return .............................................................................................................11-15

11-6-5. CALEND ...................................................................................................................11-15

11-6-6. How to cancel sample calibration .............................................................................11-15

12. Appendix 3 QUALITY INSPECTION ............................................................... 12-1

12-1. PH202G, PH202SJ 2-Wire pH/ORP Transmitter ........................................ 12-1

12-2. PH202S 2-Wire pH/ORP Transmitter ......................................................... 12-5

12-3. PH202G, PH202S 2-Wire pH/ORP Transmitter .................................................

(Fieldbus Communication) ............................................................................. 12-9

12-4. PH202G, PH202S 2-Wire pH/ORP Transmitter .................................................

(Profibus Communication) ........................................................................... 12-13

Customer Maintenance Parts List (PH202G Style : S3) ........CMPL 12B07D02-03E

Customer Maintenance Parts List (PH202S Style : S3).........CMPL 12B07D02-23E

Revision Rcord ............................................................................................................i

IM 12B07D02-01E

Page 5

IM 12B07D02-01E

Page 6

PREFACE

DANGERDANGER

Electric discharge

The EXA analyzer contains devices that can be

damaged by electrostatic discharge. When servicing this equipment, please observe proper procedures to prevent such damage. Replacement

components should be shipped in conductive packaging. Repair work should be done at grounded

workstations using

grounded soldering irons and wrist straps to avoid

electrostatic discharge.

Installation and wiring

The EXA analyzer should only be used with equipment that meets the relevant international and

regional standards. Yokogawa accepts no responsibility for the misuse of this unit.

CAUTIONCAUTION

The instrument is packed carefully with shock

absorbing materials, nevertheless, the instrument

may be damaged or broken if subjected to strong

shock, such as if the instrument is dropped. Handle

with care.

Although the instrument has a weatherproof

construction, the transmitter can be harmed if it

becomes submerged in water or becomes excessively wet.

Do not use an abrasive material or solvent when

cleaning the instrument.

Do not modify the PH202 transmitter.

Notice

• This manual should be passed on to the end

user.

• The contents of this manual are subject to

change without prior notice.

• The contents of this manual shall not be

reproduced or copied, in part or in whole,

without permission.

• This manual explains the functions contained in

this product, but does not warrant that they are

suitable the particular purpose of the user.

• Every effort has been made to ensure accuracy

in the preparation of this manual.

However, when you realize mistaken

expressions or omissions, please contact the

nearest Yokogawa Electric representative or

sales office.

• This manual does not cover the special

specifications. This manual may be left

unchanged on any change of specification,

construction or parts when the change does

not affect the functions or performance of the

product.

• If the product is not used in a manner specified

in this manual, the safety of this product may be

impaired.

Yokogawa is not responsible for damage to the

instrument, poor performance of the instrument

or losses resulting from such, if the problems are

caused by:

• Improper operation by the user.

• Use of the instrument in improper applications

• Use of the instrument in an improper

environment or improper utility program

• Repair or modification of the related instrument

by an engineer not authorized by Yokogawa.

WARNING

WARNING

Electrostatic charge may cause an explosion hazard. Avoid any actions that cause the generation of

electrostatic charge, e.g., rubbing with a dry cloth.

Warning label

Because the enclosure of the pH/ORP transmitter

Type PH202S-E, -P, -F are made of aluminium, if it

is mounted in an area where the use of category

1 G Zone 0 apparatus is required, it must be

installed such, that, even in the event of rare incidents, ignition sources due to impact and friction

sparks are excluded.

Safety and Modification Precautions

• Follow the safety precautions in this manual

when using the product to ensure protection and

safety of the human body, the product and the

system containing the product.

IM 12B07D02-01E

Page 7

The following safety symbols are used on the

product as well as in this manual.

DANGERDANGER

This symbol indicates that an operator must

follow the instructions laid out in this manual in

order to avoid the risks, for the human body, of

injury, electric shock, or fatalities. The manual

describes what special care the operator must

take to avoid such risks.

DANGER

WARNINGWARNING

This symbol indicates that the operator must

refer to the instructions in this manual in

order to prevent the instrument (hardware) or

software from being damaged, or a system

failure from occurring.

CAUTIONCAUTION

This symbol gives information essential for

understanding the operations and functions.

This symbol indicates Protective Ground

Terminal

Warranty and service

Yokogawa products and parts are guaranteed

free from defects in workmanship and material

under normal use and service for a period of

(typically) 12 months from the date of shipment

from the manufacturer. Individual sales organizations can deviate from the typical warranty

period, and the conditions of sale relating to the

original purchase order should be consulted.

Damage caused by wear and tear, inadequate

maintenance, corrosion, or by the effects of

chemical processes are excluded from this warranty coverage.

In the event of warranty claim, the defective

goods should be sent (freight paid) to the service

department of the relevant sales organization for

repair or replacement (at Yokogawa discretion).

The following information must be included in the

letter accompanying the returned goods:

• Part number, model code and serial number

• Original purchase order and date

• Length of time in service and a description of

the process

• Description of the fault, and the circumstances

of failure

• Process/environmental conditions that may be

related to the installation failure of the device

• A statement whether warranty or non-warranty

service is requested

• Complete shipping and billing instructions for

return of material, plus the name and phone

number of a contact person who can be

reached for further information.

This symbol indicates Function Ground

Terminal (Do not use this terminal as the

protective ground terminal.)

This symbol indicates Alternating current.

This symbol indicates Direct current.

Returned goods that have been in contact with

process fluids must be decontaminated/disinfected before shipment. Goods should carry a

certificate to this effect, for the health and safety

of our employees. Material safety data sheets

should also be included for all components of

the processes to which the equipment has been

exposed.

IM 12B07D02-01E

Page 8

ATEX Documentation

This procedure is only applicable to the countries

in European Union.

GB

All instruction manuals for ATEX Ex related products are available in English, German and French.

Should you require Ex related instructions in your

local language, you are to contact your nearest

Yokogawa office or representative.

DK

Alle brugervejledninger for produkter relateret

til ATEX Ex er tilgængelige på engelsk, tysk og

fransk. Skulle De ønske yderligere oplysninger

om håndtering af Ex produkter på eget sprog, kan

De rette henvendelse herom til den nærmeste

Yokogawa afdeling eller forhandler.

I

Tutti i manuali operativi di prodotti ATEX contrassegnati con Ex sono disponibili in inglese,

tedesco e francese. Se si desidera ricevere i manuali operativi di prodotti Ex in lingua locale, mettersi in contatto con l’ufficio Yokogawa più vicino o

con un rappresentante.

E

Todos los manuales de instrucciones para los productos antiexplosivos de ATEX están disponibles

en inglés, alemán y francés. Si desea solicitar las

instrucciones de estos artículos antiexplosivos en

su idioma local, deberá ponerse en contacto con

la oficina o el representante de Yokogawa más

cercano.

NL

Alle handleidingen voor producten die te maken

hebben met ATEX explosiebeveiliging (Ex)

zijn verkrijgbaar in het Engels, Duits en Frans.

Neem, indien u aanwijzingen op het gebied van

explosiebeveiliging nodig hebt in uw eigen taal,

contact op met de dichtstbijzijnde vestiging van

Yokogawa of met een vertegenwoordiger.

SF

Kaikkien ATEX Ex -tyyppisten tuotteiden käyttöhjeet ovat saatavilla englannin-, saksan- ja

ranskankielisinä. Mikäli tarvitsette Ex -tyyppisten

tuotteiden ohjeita omalla paikallisella kielellännne,

ottakaa yhteyttä lähimpään Yokogawa-toimistoon

tai -edustajaan.

P

Todos os manuais de instruções referentes aos

produtos Ex da ATEX estão disponíveis em Inglês,

Alemão e Francês. Se necessitar de instruções na

sua língua relacionadas com produtos Ex, deverá

entrar em contacto com a delegação mais próxima

ou com um representante da Yokogawa.

F

Tous les manuels d’instruction des produits

ATEX Ex sont disponibles en langue anglaise,

allemande et française. Si vous nécessitez des

instructions relatives aux produits Ex dans votre

langue, veuillez bien contacter votre représentant

Yokogawa le plus proche.

D

Alle Betriebsanleitungen für ATEX Ex bezogene

Produkte stehen in den Sprachen Englisch,

Deutsch und Französisch zur Verfügung. Sollten

Sie die Betriebsanleitungen für Ex-Produkte in

Ihrer Landessprache benötigen, setzen Sie sich

bitte mit Ihrem örtlichen Yokogawa-Vertreter in

Verbindung.

S

Alla instruktionsböcker för ATEX Ex (explosionssäkra) produkter är tillgängliga på engelska, tyska

och franska. Om Ni behöver instruktioner för

dessa explosionssäkra produkter på annat språk,

skall Ni kontakta närmaste Yokogawakontor eller

representant.

GR

IM 12B07D02-01E

Page 9

SK

CZ

PL

SLO

LT

LV

EST

H

BG

RO

IM 12B07D02-01E

M

Page 10

Introduction 1-1

1. INTRODUCTION AND GENERAL DESCRIPTION

The Yokogawa EXA 202 is a 2-wire transmitter designed for industrial process monitoring, measurement

and control applications. This user’s manual contains the information needed to install, set up, operate

and maintain the unit correctly. This manual also includes a basic troubleshooting guide to answer typical user questions.

Yokogawa can not be responsible for the performance of the EXA analyzer if these instructions are not

followed.

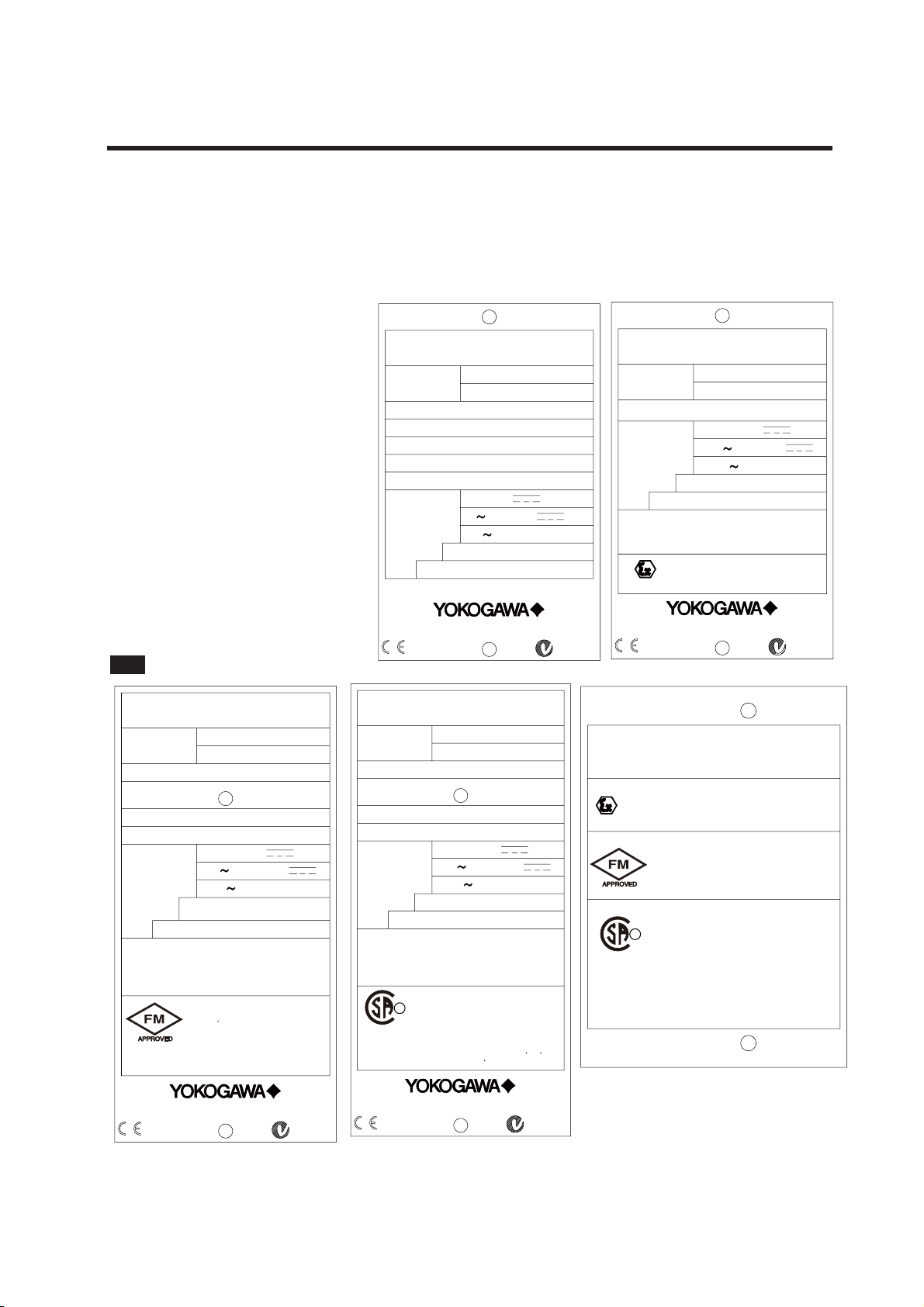

1-1. Instrument check

Upon delivery, unpack the instrument

PH/ORP TRANSMITTER

PH/ORP TRANSMITTER

carefully and inspect it to ensure that

it was not damaged during shipment.

If damage is found, retain the original

MODEL

SUFFIX

PH202

MODEL

SUFFIX

PH202S-E

packing materials (including the outer

box) and then immediately notify the

carrier and the relevant Yokogawa

sales office.

Make sure the model number on the

textplate affixed to the side of the

instrument agrees with your order.

Examples of nameplates are shown.

SUPPLY

OUTPUT

AMB.TEMP.

STYLE

No.

24V DC

4 20mA DC

-10 55°C

SUPPLY

OUTPUT

AMB.TEMP.

STYLE

No.

II 1G

24V DC

4 20mA DC

-10 55°C

No. IECEx KEM 06.0052X

Zone 0 Ex ia IIC T4

Zone 0 Ex ia IIC T6 for Ta:40

IP65

SEE CONTROL DRAWING

No. KEMA 06ATEX0218 X

Ex ia IIC T4

Ex ia IIC T6 for Ta:40

SEE CONTROL DRAWING

˚C

˚C

IP65

mA

PH/ORP TRANSMITTER

MODEL

SUFFIX

SUPPLY

OUTPUT

AMB.TEMP.

STYLE

No.

PH202S-U

24V DC

4 20mA DC

-10 55°C

No. IECEx KEM 06.0052X

Zone 0 Ex ia IIC T4

Zone 0 Ex ia IIC T6 for Ta:40

IP65

SEE CONTROL DRAWING

IS CL I, DIV 1, GP ABCD

AND AEx ia IIC

T4

Type 4X

Install per CONTROL DRAWING

IKE024-A10 P.4-1 to P.4-2

Made in Japan Tokyo 180-8750 JAPAN

N200

Made in Japan Tokyo 180-8750 JAPAN

0344

N200

PH/ORP TRANSMITTER

MODEL

PH202S-C

SUFFIX

SUPPLY

OUTPUT

AMB.TEMP.

24V DC

4 20mA DC

-10 55°C

STYLE

No.

No. IECEx KEM 06.0052X

Zone 0 Ex ia IIC T4

˚C

Zone 0 Ex ia IIC T6 for Ta:40

IP65

SEE CONTROL DRAWING

CL I, DIV 1, GP ABCD

Ex ia IIC T4

R

Ex ia IIC T6 for Ta:40

SEE CONTROL DRAWING

LR81741 C

WARNING

Substitution of

components may impair

intrinsic safety

IP65 Type 3S

AVERTISSEMENT

La substitution de composants

peut compromeltre la securite

intrinseque.

˚C

˚C

LR81741

WARNING

Substitution of

components may

impair suitability

for class I, Division 2.

PH202S-N

No. IECEx KEM 06.0052X

Ex nA[nL] IIC T4

Ex nA[nL] IIC T6 for Ta:40

IP65

SEE CONTROL DRAWING

No. KEMA 06ATEX0219

EEx nA[nL] IIC T4

II 3 G

EEx nA[nL] IIC T6 for Ta:40

IP65

SEE CONTROL DRAWING

NI CL I, DIV 2, GP ABCD AND

CL I, ZN 2, GP IIC

T4

Type 4X

Install per CONTROL DRAWING

IKE024-A10 P.4-3 to P.4-4

Ex nA[nL] IIC

NI CL I, DIV 2, GP ABCD

T4

R

T6 for Ta:40

˚C

IP65

Type 3S

SEE CONTROL DRAWING

AVERTISSEMENT

La substitution de composants

peut rendre ce materiel

inacceptable pour les

emplacements de

Classe I, Division 2.

˚C

˚C

Made in Japan

Figure 1-1. Nameplate

N200

Made in Japan

N200

IM 12B07D02-01E

Page 11

1-2 Introduction

DISSOLVED OXYGEN TRANSMITTER

MODEL

PH202G-F

SUFFIX

SUPPLY

OUTPUT

AMB.TEMP.

9 TO 32VDC

FF-TYPE113

-10 55°C

STYLE

No.

Made in Japan Tokyo 180-8750 JAPAN

N200

PH/ORP TRANSMITTER

MODEL

PH202S-F

SUFFIX

SUPPLY

OUTPUT

AMB.TEMP.

FISCO

17.5VDC

or 24VDC

/380mA/5.32W

/250mA/1.2W

FF-TYPE111 or 511

Li=0 μH, Ci=220pF

-10 55°C

STYLE

No.

Made in Japan Tokyo 180-8750 JAPAN

0344

N200

DISSOLVED OXYGEN TRANSMITTER

MODEL

PH202G-P

SUFFIX

SUPPLY

OUTPUT

AMB.TEMP.

9 TO 32VDC

PROFIBUS-PA

-10 55°C

STYLE

No.

Made in Japan Tokyo 180-8750 JAPAN

N200

PH/ORP TRANSMITTER

MODEL

PH202S-P

SUFFIX

SUPPLY

OUTPUT

AMB.TEMP.

FISCO

17.5VDC

or 24VDC

/380mA/5.32W

/250mA/1.2W

PROFIBUS-PA

Li=0 μH, Ci=220pF

-10 55°C

STYLE

No.

Made in Japan Tokyo 180-8750 JAPAN

0344

N200

PH/ORP TRANSMITTER

MODEL

SUFFIX

SUPPLY

OUTPUT

AMB.TEMP.

STYLE

No.

Cert No. GYJ081156X

Ex ia IIC T4

Ex ia IIC T6 for Ta:40

SEE USER’S MANUAL BEFORE USE

Made in Japan Tokyo 180-8750 JAPAN

FISCO field device

IECEx KEM 07.0026X

No.

Zone 0 Ex ia IIC T4

IP65

SEE CONTROL DRAWING

KEMA 07ATEX0048 X

No.

Ex ia IIC T4

II 1G

SEE CONTROL DRAWING

IS CL I, DIV 1, GP ABCD

AND AEx ia IIC

Type 4X

T4

Install per CONTROL DRAWING

IKE025-A10 P.4 to P.7

CL I, DIV 1, GP ABCD

Ex ia IIC T4

R

SEE CONTROL DRAWING

LR81741 C

WARNING

Substitution of

components may impair

intrinsic safety

IP65 Type 3S

PH202S-F/-P

PH202S-K

24V DC

4 20mA DC

-10 55°C

˚C

IP65

AVERTISSEMENT

La substitution de composants

peut compromeltre la securite

intrinseque.

PH/ORP TRANSMITTER

MODEL

PH202S-B

SUFFIX

SUPPLY

OUTPUT

AMB.TEMP.

9 TO 32VDC

FF-TYPE 113

-10 55°C

STYLE

No.

Made in Japan Tokyo 180-8750 JAPAN

Figure 1-2. Nameplate

IM 12B07D02-01E

N200

PH/ORP TRANSMITTER

MODEL

PH202S-D

SUFFIX

SUPPLY

OUTPUT

AMB.TEMP.

9 TO 32VDC

PROFIBUS-PA

-10 55°C

STYLE

No.

Made in Japan Tokyo 180-8750 JAPAN

N200

FNICO field device

No.

IECEx KEM 07.0026X

Ex nA[nL] IIC T4

Ex nA[nL] IIC T6 for Ta:40

IP65

SEE CONTROL DRAWING

KEMA 07ATEX0049

No.

EEx nA[nL] IIC T4

II 3 G

EEx nA[nL] IIC T6 for Ta:40

IP65

SEE CONTROL DRAWING

NI CL I, DIV 2, GP ABCD AND

CL I, ZN 2, GP IIC

T4

Type 4X

Install per CONTROL DRAWING

IKE025-A10 P.8 to P.9

Ex nA[nL] IIC

NI CL I, DIV 2, GP ABCD

T4

R

T6 for Ta:40

LR81741 C

WARNING

Substitution of

components may

impair suitability

for class I, Division 2.

IP65 Type 3S

SEE CONTROL DRAWING

AVERTISSEMENT

La substitution de composants

peut rendre ce materiel

inacceptable pour les

emplacements de

Classe I, Division 2.

PH202S-B/-D

°C

°C

°C

Page 12

Introduction 1-3

NOTE: Check that all the parts are present, including mounting hardware, as specified in the option

codes at the end of the model number.

For a description of the model codes, refer to Chapter 2 of this manual under General

Specifications.

Basic Parts List: Transmitter PH202

User’s Manual English

Optional mounting hardware when specified (See model code)

NOTE: mounting screws and special grommet are packed in the terminal compartment, together with a

second link for impedance selection.

1-2. Application

The EXA converter is intended to be used for continuous on-line measurement in industrial installations.

The unit combines simple operation and microprocessor-based performance with advanced self-diagnostics and enhanced communications capability to meet the most advanced requirements. The measurement can be used as part of an automated process control system. It can also be used to indicate

dangerous limits of a process, to monitor product quality, or to function as a simple controller for a dosing/neutralization system.

Yokogawa designed the EXA analyzer to withstand harsh environments. The converter may be installed

either indoors or outside because the IP65 (NEMA 4X) housing and cabling glands ensure the unit is

adequately protected. The flexible polycarbonate window on the front door of the EXA allows pushbutton access to the keypad, thus preserving the water and dust protection of the unit even during routine

maintenance operations.

A variety of EXA hardware is optionally available to allow wall, pipe, or panel mounting. Selecting a proper installation site will permit ease of operation. Sensors should normally be mounted close to the converter in order to ensure easy calibration and peak performance. If the unit must be mounted remotely

from the sensors, WF10 extension cable can be used up to a maximum of 50 metres (150 feet) with a

BA10 junction box. Except installations with dual high impedance sensors, where the maximum cable

length is 20 metres using integral cable only (no junction box).

The EXA is delivered with a general purpose default setting for programmable items. (Default settings

are listed in Chapter 5 and again in Chapter 10). While this initial configuration allows easy start-up, the

configuration should be adjusted to suit each particular application. An example of an adjustable item

is the type of temperature sensor used. The EXA can be adjusted for any one of eight different types of

temperature sensors.

To record such configuration adjustments, write changes in the space provided in Chapter 10 of this

manual. Because the EXA is suitable for use as a monitor, a controller or an alarm instrument, program

configuration possibilities are numerous.

Details provided in this user’s manual are sufficient to operate the EXA with all Yokogawa sensor

systems and a wide range of third-party commercially available probes. For best results, read this manual in conjunction with the corresponding sensor user’s manual.

IM 12B07D02-01E

Page 13

1-4 Introduction

IM 12B07D02-01E

Page 14

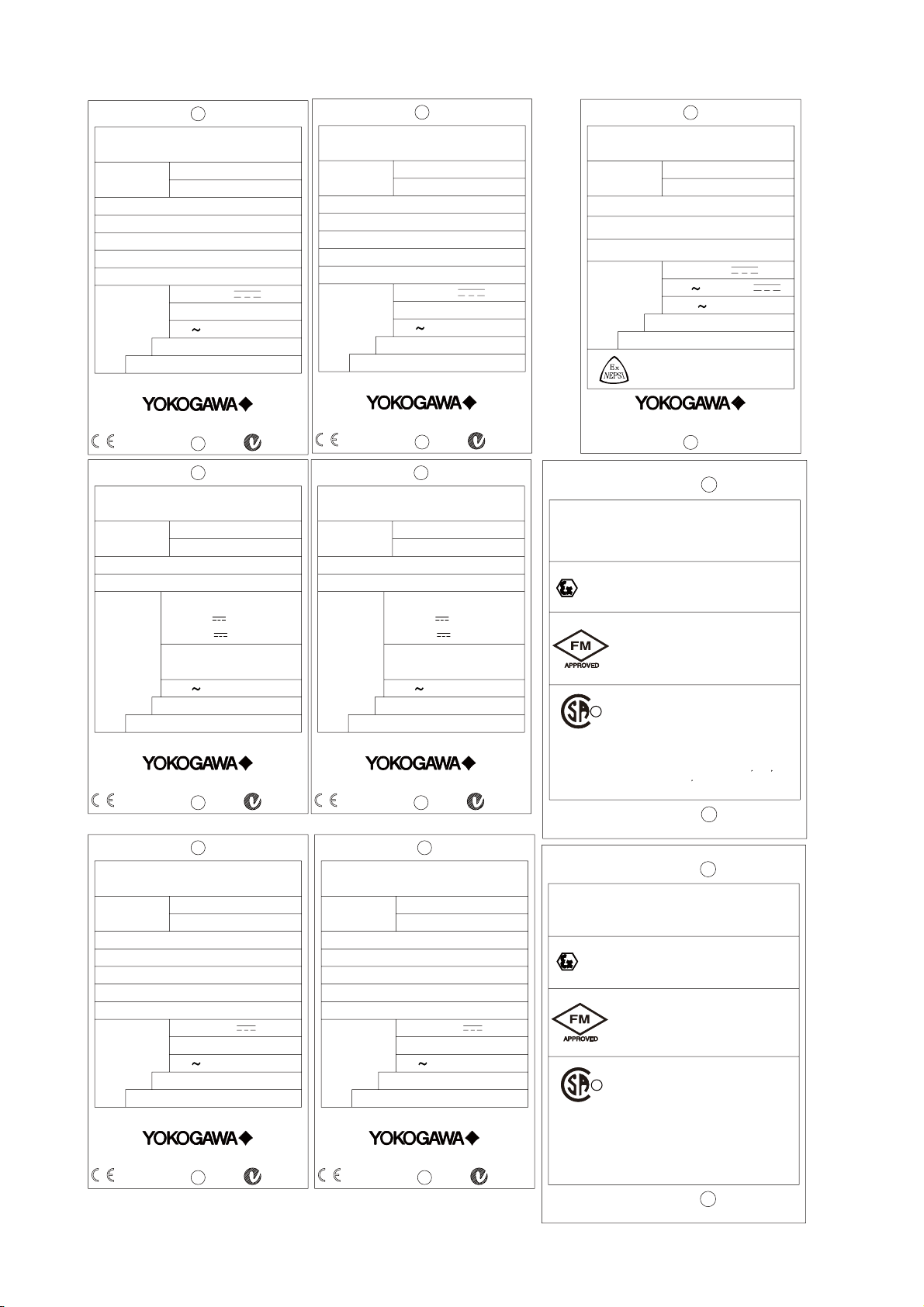

2. PH202 SPECIFICATIONS

0

200

400

600

800

12 16

17

20 24 28 32

425

775

Voltage (V)

Load Resistance (Ω)

31.5 V

Possible

0

0

200

180

400

600

800

1000

1150

17 18 20 25 30 35 40

F2.1E.eps

Voltage (V)

Load Resistance (Ω)

Possible

Specification 2-1

2-1. General

A. Input specifications

: Dual high impedance inputs (2 x 1012Ω) with

provision for liquid earth connection. Suitable

for inputs from glass or enamel pH & reference sensors and ORP metal electrodes.

B. Input ranges

- pH : -2 to 16 pH

- ORP : -1500 to 1500 mV

- rH : 0 to 55 rH

- Temperature : -30ºC to 140ºC (-20 to 300ºF)

- 8k55Ω NTC sensor: -10ºC to 120ºC (10 to

250 ºF)

- 10kΩ PTC : -20ºC to 140ºC (0 to 300ºF)

C. Output ranges

- pH : min 1 max 20 pH

- ORP : min 100 max 3000 mV

- rH : min 2 max 55 rH

- Temperature : min. 25 ºC max. 200 ºC

(for 8.55kΩ NTC sensor max. 120 ºC )

mAmA

D. Output signal

: 4-20 mA loop powered, isolated from input,

maximum load 425 Ω at 24 V DC. With the

possibility of 21 mA “FAIL” signal (burn up)

and 3.6 mA (burn down when HART® or

distributor comm. is non-used), 3.9 mA (burn

down when HART® or distributor comm. is

used).

with key diagnostic information available in the

display.

H. Serial communication

: Bi-directional HART® digital communication

superimposed on the 4-20 mA signal.

I. Display

: Custom liquid crystal display, with a main dis-

play of 3 1/2 digits 12.5 mm high.

Message display of 6 alphanumeric charac-

ters, 7 mm high.

Warning flags and units (pH and mV).

J. Power supply

: Nominal 24 volt DC loop powered system.

- PH202G : 17 to 40 volts, see Fig. 2-1.

- PH202S : 17 to 31.5 volts, see Fig. 2-2.

K. Maximum load resistance:

For the PH202G, see Fig. 2-1.

For the PH202S, see Fig. 2-2.

E. Temperature compensation

- Range :–30 ºC to 140 ºC

(for 8.55kΩ sensor –10 ºC to 120 ºC)

Sensor types: Pt100, Pt1000, 3kΩ PTC, 5.1kΩ

Automatic or manual compensation to Nernst

F. Calibration

: Semi-automatic, using tables in transmitter

G. Logbook

: Software record of important events and diag-

PTC, 8.55kΩ NTC, 350Ω PTC,

6.8kΩ PTC, 10kΩ PTC

equation. Process compensation by configurable coefficient. Adjustable ITP (Iso-thermal point

of intersection).

for pH 4, 7 & 9 buffer solutions, or using userdefined tables, with automatic check of meas-

urement stability.

Manual, using standard sample, by correcting

reading to value of standard.

Calibration by slope and asymmetry potential

setting. (IEC746-2)

nostic data. Available through HART® link,

Fig. 2-1. Supply voltage/ load diagram for the PH202G

Fig. 2-2. Minimum terminal voltage for the PH202S

(Note) In this manual a

mA

sign appears if it

concerns the PH202G (S)-E, -C, -U, -N, -K.

IM 12B07D02-01E

Page 15

2-2 Specification

2-2. Operating specifications

A. Performance : pH

- Linearity : ±0.01 pH

- Repeatability: ±0.01 pH

- Accuracy : ±0.01 pH

Performance : ORP

- Linearity : ±1 mV

- Repeatability : ±1 mV

- Accuracy : ±1 mV

Performance : Temperature with Pt1000 Ω,

3kΩ Balco, 5k1Ω, 350Ω, 6k8Ω, PTC10kΩ &

8k55Ω

- Linearity : ±0.3 ˚C

- Repeatability: ±0.1 ˚C

- Accuracy : ±0.3 ˚C

Performance : Temperature with Pt100 Ω

- Linearity : ±0.4 ˚C

- Repeatability: ±0.1 ˚C

- Accuracy : ±0.4 ˚C

Note on performance specifications:

The following tolerance is added to above

performance.

mA output tolerance : ± 0.02 mA of

"4 - 20 mA"

B. Ambient operating temperature

: -10 to + 55 ˚C (10 to 131 ˚F)

C. Storage temperature

: -30 to +70 ˚C (-20 to 160 ˚F)

D. Humidity

: 10 to 90% RH (Non-condensing)

F. Housing:

Case: Cast aluminum case with chemically

resistant coating

Cover: Polycarbonate window.

Case color: Off-white (Equivalent to Munsell

2.5Y8.4/1.2)

Cover color: Deep sea Moss green

(Equivalent to Munsell 0.6GY3.1/2.0)

Cable and terminals :

The PH202 is equipped with terminals

suitable for the connection of finished

cables in the size: 0.13 to 2.5 mm (26 to

14 AWG)

Cable entry: 2 cable glands 1/2NPT. The cable

glands will form a tight seal on cables with

an outside diameter in the range of 6 to 12

mm (0.24 to 0.47 inches).

Construction : Weather resistant to IP65 and

NEMA 4X standards

Mounting : Pipe, wall or panel mounting, using

optional hardware

Weight : Approx. 1.6 kg

G. Shipping details

: Package size w x h x d

290 x 300 x 290 mm.

11.5 x 11.8 x 11.5 in.

Packed weight approx. 2.5 kg (5lb)

H. Data protection

: EEPROM for configuration and logbook, and

lithium cell for clock.

I. Watchdog timer

: Checks microprocessor

J. Automatic safeguard

: Return to measuring mode when no keystroke

is made for 10 min.

K. Operation protection

: 3-digit programmable password.

L. Sensor impedance checking

: Independent impedance check on measuring

and reference sensor elements, with

temperature compensation. Display of sensor

impedance on message line of display. FAIL

flag in event of “out of limits” impedance, and

the possibility of 21 mA or (3.6 mA or 3.9 mA)

error signal.

M. Signal processing (pH/ORP)

: The PH202 can measure pH or ORP. Using

the FU20 allows simultaneous measurement

and display of pH and ORP. It also allows

display and out put of pH.

Grounding

terminal

IM 12B07D02-01E

Sensor

cable gland

Power/Output

cable gland

N. EMC Conformity standards

EN 61326-1 Class A, Table 2

,

(For use in industrial locations)

EN 61326-2-3

EN 61326-2-5 (pending)

CAUTION

This instrument is a Class A product, and it is

designed for use in the industrial environment.

Please use this instrument in the industrial

environment only.

Page 16

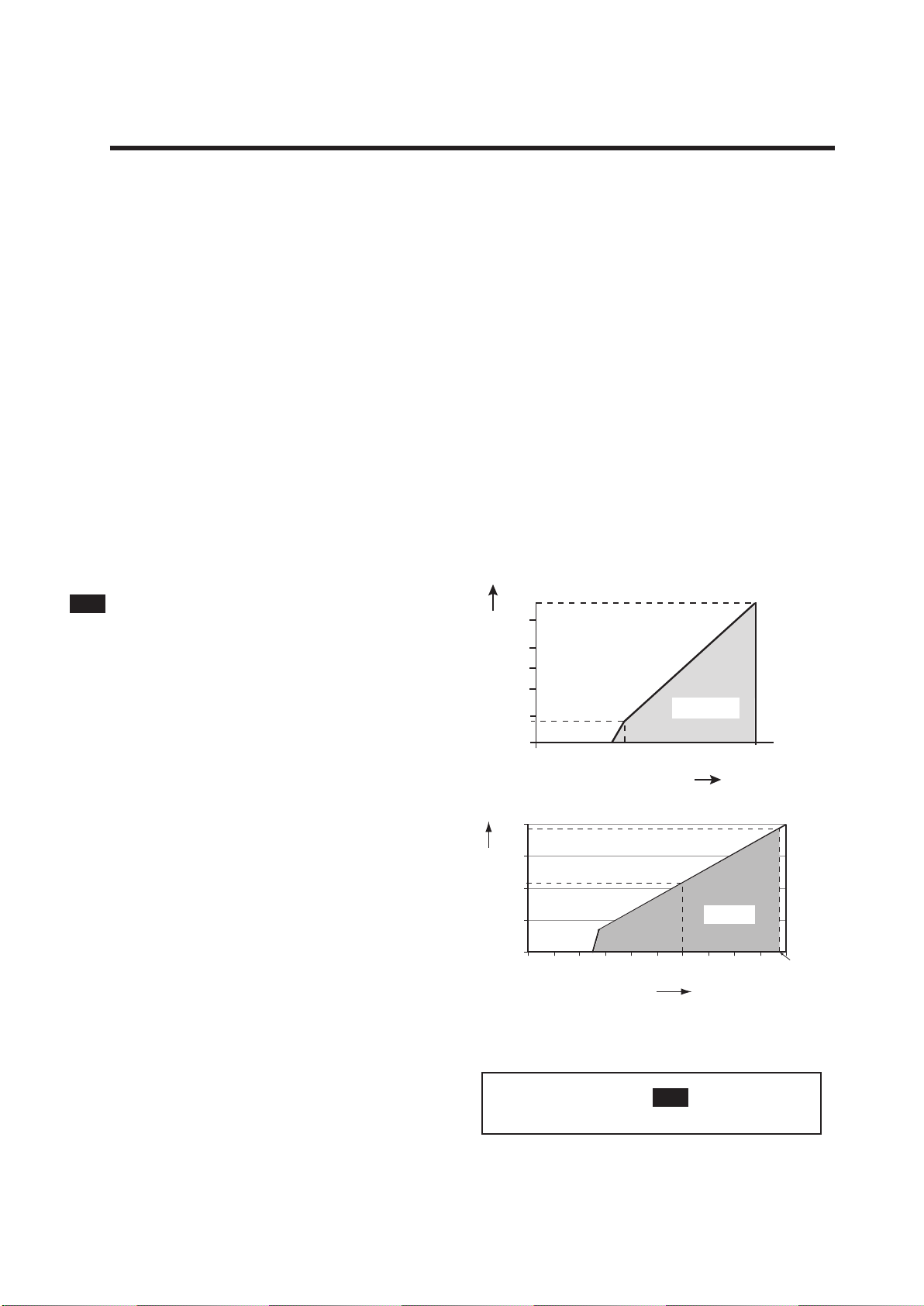

Specification 2-3

O. Intrinsically safe

Refer to conrol drawings.

mA

Item

Factory

Mutual (FM)

IECEx

CENELEC

ATE X

IECEx

Canadian

Standards

Association

(CSA)

IECEx

(Note)

IECEx

Scheme

Item

CENELEC

ATE X

Entity

CENELEC

ATE X

FISCO

CENELEC

ATE X

Item

IECEx

Scheme

Entity

IECEx

Scheme

FISCO

IECEx

Scheme

Description

FM Intrinsically safe Approval

Applicable standard: FM3600, FM3610, FM3810

Intrinsically Safe for Class I, Division 1, Groups ABCD

Class I, Zone 0, AEx ia IIC

Temp. Class: T4, Amb. Temp.: -10 to 55°C

Intrinsically Safe Apparatus Parameters

Vmax=31.5 V, Imax=100 mA,

Pmax=1.2 W, Ci=22 nF, Li=35 μH

IECEx Intrinsically safe (see Note)

CENELEC ATEX (KEMA) Intrinsically safe Approval

Applicable standard: EN60079-0, EN50020,

EN60079-26

Certificate: KEMA 06ATEX0218 X

Ex ia IIC, Group: II, Category: 1G

Temp. Class: T4, Amb. Temp.: -10 to 55°C

T6, Amb. Temp.: -10 to 40°C

Ui=31.5 V, Ii=100 mA, Pi=1.2 W, Ci=22 nF, Li=35 μH

IECEx Intrinsically safe (see Note)

CSA Intrinsically safe Approval

Applicable standard: C22.2, No.0-M1991,

C22.2, No.04-M2004, C22.2, No.157-M1992,

C22.2, No.61010-1

Ex ia Class I, Division 1, Groups ABCD,

Ex ia IIC

Temp. Class: T4, Amb. Temp.: -10 to 55°C

T6, Amb. Temp.: -10 to 40°C

Ui(Vmax)=31.5 V, Ii(Imax)=100 mA,

Pi(Pmax)=1.2 W, Ci=22 nF, Li=35 μH

IECEx Intrinsically safe (see Note)

IECEx Intrinsically safe

Applicable standard: IEC60079-0, IEC60079-11,

IEC60079-26

Certificate: IECEx KEM 06.0052X

Zone 0 Ex ia IIC

Temp. Class: T4, Amb. Temp.: -10 to 55°C

T6, Amb. Temp.: -10 to 40°C

Ui=31.5 V, Ii=100 mA, Pi=1.2 W, Ci=22 nF, Li=35 μH

Description

CENELEC ATEX (KEMA) Intrinsically safe Approval

Applicable standard: EN60079-0, EN50020

EN60079-26

Certificate: KEMA 07ATEX0048 X

Ex ia IIC, Group: II, Category: 1G

Temp. Class: T4, Amb. Temp.: -10 to 55°C

Ui=24 V, Ii=250 mA, Pi=1.2 W, Ci=220 pF, Li=0 μH

CENELEC ATEX (KEMA) Intrinsically safe Approval

Applicable standard: EN60079-0, EN50020

EN60079-26, EN60079-27

Certificate: KEMA 07ATEX0048 X

Ex ia IIC, Group: II, Category: 1G

Temp. Class: T4, Amb. Temp.: -10 to 55°C

Ui=17.5 V, Ii=380 mA, Pi=5.32 W, Ci=220 pF, Li=0 μH

CENELEC ATEX (KEMA) Type of protection "n"

Applicable standard: EN60079-0:2006,

EN60079-15:2003

Certificate: KEMA 07ATEX0049

EEx nA [nL] IIC, Group: II, Category: 3G

Temp. Class: T4, Amb. Temp.: -10 to 55°C

T6, Amb. Temp.: -10 to 40°C

Ui=32 V, Ci=220 pF, Li=0 μH

IECEx Intrinsically safe

Applicable standard: IEC 60079-0, IEC60079-11,

IEC60079-26

Certificate: IECEx KEM 07.0026X

Zone 0 Ex ia IIC

Temp. Class: T4, Amb. Temp.: -10 to 55°C

Ui=24 V, Ii=250 mA, Pi=1.2 W, Ci=220 pF, Li=0 μH

IECEx Intrinsically safe

Applicable standard: IEC 60079-0, IEC60079-11,

IEC60079-26, IEC60079-27

Certificate: IECEx KEM 07.0026X

Zone 0 Ex ia IIC

Temp. Class: T4, Amb. Temp.: -10 to 55°C

Ui=17.5 V, Ii=380 mA, Pi=5.32 W, Ci=220 pF, Li=0 μH

IECEx Type of protection "n"

Applicable standard: IEC 60079-15:2001,

IEC 60079-0:2004

Certificate: IECEx KEM 07.0026X

Ex nA [nL] IIC

Temp. Class: T4, Amb. Temp.: -10 to 55°C

T6, Amb. Temp.: -10 to 40°C

Ui=32 V, Ci=220 pF, Li=0 μH

Description

Code

-U

-E

-C

T1E.EPS

Code

-P

or

-F

-B

or

-D

ATEX.EPS

Code

-P

or

-F

-B

or

-D

IEC.EPS

Item

Factory

Mutual (FM)

CENELEC

ATE X

Canadian

Standards

Association

(CSA)

IECEx

Scheme

Item

Factory

Mutual (FM)

Item

Canadian

Standards

Association

(CSA)

Description

FM Non-incendive safe Approval

Applicable standard: FM3600, FM3611, FM3810

Non-incendive for Class I, Division 2, Groups ABCD,

Zone 2

Temp. Class: T4, Amb. Temp.: -10 to 55°C

Non-incendive Safe Apparatus Parameters

Vmax=31.5 V, Ci=22 nF, Li=35 μH

CENELEC ATEX (KEMA) Type of protection "n"

Applicable standard: EN60079-0:2006,

EN60079-15:2003

Certificate: KEMA 06ATEX0219

EEx nA [nL] IIC, Group: II, Category: 3G

Temp. Class: T4, Amb. Temp.: -10 to 55°C

T6, Amb. Temp.: -10 to 40°C

Ui=31.5 V, Ci=22 nF, Li=35 μH

CSA Non-incendive safe Approval or

type of protection "n"

Applicable standard: C22.2, No.0-M1991,

C22.2, No.04-M2004, C22.2, No.157-M1992,

C22.2, No.213-M1987, C22.2, No.61010-1

Class I, Division 2, Groups ABCD

Ex nA [nL] IIC

Temp. Class: T4, Amb. Temp.: -10 to 55°C

T6, Amb. Temp.: -10 to 40°C

Ui(Vmax)=31.5 V, Ci=22 nF, Li=35 μH

IECEx Type of protection "n"

Applicable standard: IEC 60079-15:2001,

IEC 60079-0:2004

Certificate: IECEx KEM 06.0052X

Ex nA [nL] IIC

Temp. Class: T4, Amb. Temp.: -10 to 55°C

T6, Amb. Temp.: -10 to 40°C

Ui=31.5 V, Ci=22 nF, Li=35 μH

Description

FM Intrinsically safe Approval

Applicable standard: FM3600, FM3610, FM3810

Intrinsically Safe for Class I, Division 1, Groups ABCD

Class I, Zone 0, AEx ia IIC

Temp. Class: T4, Amb. Temp.: -10 to 55°C

Intrinsically Safe Apparatus Parameters

Vmax=24 V, Imax=250 mA,

Entity

Pmax=1.2 W, Ci=220 pF, Li=0 μH

Vmax=17.5 V, Imax=380 mA,

FISCO

Pmax=5.32 W, Ci=220pF, Li=0 μH

FM Non-incendive safe Approval

Applicable standard: FM3600, FM3611, FM3810

Non-incendive Safe for Class I, Division 2,

Groups ABCD, Zone 2

Temp. Class: T4, Amb. Temp.: -10 to 55°C

Non-incendive Safe Apparatus Parameters

Vmax=32 V, Pmax=1.2 W,

Entity

Ci=220 pF, Li=0 μH

Vmax=32 V, Pmax=5.32 W,

FNICO

Ci=220 pF, Li=0 μH

Description

CSA Intrinsically safe Approval

Applicable standard: C22.2, No. 0-M1991,

C22.2, No. 04-M2004, C22.2, No. 157-M1992,

C22.2, No. 61010-1

Ex ia Class I, Division 1, Groups ABCD

Ex ia IIC

Temp. Class: T4, Amb. Temp.: -10 to 55°C

Ui(Vmax)=24 V, Ii(Imax)=250 mA,

Entity

Pi(Pmax)=1.2 W, Ci=220 pF, Li=0 μH

Ui(Vmax)=17.5 V, Ii(Imax)=380 mA,

FISCO

Pi(Pmax)=5.32 W, Ci=220 pF, Li=0 μH

CSA Non-incendive safe Approval or

type of protection "n"

Applicable standard: C22.2, No.0-M1991,

C22.2, No.04-M2004, C22.2, No.157-M1992,

C22.2, No.213-M1987, C22.2, No. 61010-1

Class I, Division 2, Groups ABCD

Ex nA [nL] IIC

Temp. Class: T4, Amb. Temp.: -10 to 55°C

T6, Amb. Temp.: -10 to 40°C

Ui(Vmax)=32 V, Ci=220 pF, Li=0 μH

Entity:

FNICO:

Ui(Vmax)=32 V, Ci=220 pF, Li=0 μH

IM 12B07D02-01E

Code

-N

T2.EPS

Code

-P

or

-F

-B

or

-D

FM.EPS

Code

-P

or

-F

-B

or

-D

CSA.EPS

Page 17

2-4 Specification

mA

mA

NEPSI Certification (PH202S-K)

NEPSI Intrinsically Safe Type

Cert No. GYJ081156X

• Applicable Standard:

GB3836.1-2000, GB3836.4-2000

• Type of Protection and Marking Code:

Ex ia IIC T4/T6

• Ambient Temperature :

T6; –10 to 40°C, T4; –10 to 55°C

Note 1 Entity Parameters

• Intrinsically safe input parameters

(terminal + and -):

Maximum Input Voltage (Ui) = 31.5 V

Maximum Input Current (Ii) = 100 mA

Maximum Input Power (Pi) = 1.2 W

Maximum Internal Capacitance (Ci) = 22 nF

Maximum Internal Inductance (Li) = 35 H

• Intrinsically safe output parameters and

maximum external parameters

(terminal 11 and 17):

Uo=14.4 V, Io=32.3 mA, Po=0.12 W, Co=600

nF, Lo=34 mH

Note 2 Installation

• Electrostatic charges on the display window shall

be avoided.

• The external earth connection facility shall be

connected reliably.

• The instrument modification or parts replacement

by other than authorized representative of

Yokogawa Electric Corporation and will void

NEPSI Intrinsically safe certification.

• The user shall not change the configuration in

order to maintain/ensure the explosion protection

performance of the equipment. Any change may

impair safety.

• For installation, use and maintenance of

the product, the end user shall observe the

instruction manual and the following standards:

GB50257-1996 "Code for construction and

acceptance of electric device for explosion

atmospheres and fire hazard electrical

equipment installation engineering''.

GB3836.13-1997 "Electrical apparatus for

explosive gas atmospheres Part 13: Repair and

overhaul for apparatus used in explosive gas

atmospheres".

GB3836.15-2000 "Electrical apparatus for

explosive gas atmospheres- Part 15: Electrical

installations in hazardous area (other than

mines)" .

GB3836.16-2006 "Electrical apparatus for

explosive gas atmospheres- Part 16: lnspection

and maintenance of electrical installation (other

than mines)".

mA-HART® communication

A. Input : Two wire system 4-20 mA

B. Power supply :

PH202G : up to 40 volts

PH202S : up to 31.5 volts

Note: The transmitter contains a switched

power supply, drawing its energy

from the 0-4 mA section of the signal.

Consequently the 17 volt limit is

applied at 4 mA. The characteristic of

the unit is such that above about 7 mA

on the output, the terminal voltage can

drop to 14.5 volts without problem.

(see figure 2-2)

C. Transmission: Isolated output of 4 to 20 mA DC.

D. Signal : Maximum load 425. (see fi gure 2-1)

Burn to signal failure acc.

NAMUR Recommendation NE43

(18.01.1994)

E. Operating range : 3.9 to 21mA

F. Communication

: HART®, 1200 Baud, FSK

modulated on 4 to 20 mA signal

G. Configuration : Local with 6 keys

H. Software : Firmware based on Yokogawa stack.

I. Hardware :

Yokogawa HART® Modem F9197UB

J. Other Control systems

: Yokogawa PRM, Rosemount AMS,

Siemens PDM

K. Hand Terminal : Rosemount HHT 275/375

L. Other control systems: Yokogawa PRM,

Rosemount AMS, Siemens PDM

M. Output span :

- pH : min 1 pH, max 20 pH.

(max 90% zero suppression)

: The instrument is user

programmable for linear or nonlinear pH ranges.

N. Cable specification

: 0.5 mm diameter or 24 AWG over

maximum length of 1500 m

O. DD specification

: The PH202 Device Description is

available enabling communications

with the Handheld Communicator

and compatible devices.

IM 12B07D02-01E

Page 18

Specification 2-5

PROFIBUS-PA communications

A. Input signal: Digital

B. Supply voltage: 9 to 32 V DC

C. Operating current: 26.0 mA

D. Operating values: According to IEC 1158-2

E. Bus connection

: Fieldbus interface base on

IEC1158-2 according to

FISCO-Model

F. Power supply: Power supply is achieved de-

pendant on the application by

means of segment coupler

G. Data transfer: According to PROFIBUS- PA

profile class B based on EN

50170 and DIN 19245 part 4

H. GSD file: The actual file can be down-

loaded from www.profibus.

com Configuration: Local with

6 keys

I. Software: Firmware based on Siemens

DPC31 stack.

J. Hardware:

PC- or PCMCIA-interfaces from

Siemens

K. Other control: Siemens PDM systems

L Electrical connection:

Terminals acc. to IEC 1158-2

M. Fieldbus-cable-types:

Twisted and shielded two

wire cable according to

recommendation based on IEC

1158-2 Cable diameter: 6 to 12

mm (0.24 to 0.47 inch)

FOUNDATION FIELDBUS H1 communications

A. Input signal: Digital

B. Supply voltage: 9 to 32 V DC

C. Operating current: 26.0 mA (base current)

D. Operating values: According to IEC 1158-2

E. Bus connection

: Fieldbus interface based on IEC

1158-2

according to FISCO-Model

F. Power supply:

Power supply is achieved

dependant on application by

means of segment coupler

G. Data transfer:

FF specification Rev. 1.4 Basic

device

H. Function blocks:

3 x AI, Transducer, Resource

I. Files: Actual file can be downloaded from

our homepage

J. Configuration: locally with 6 keys

K. Software: National Instruments:

NI-FBUS configurator

L. Hardware: F-BUS interfaces from National

Instruments (AT-FBUS, PCMIAFBUS)

M. Other control systems:

YOKOGAWA PRM, DTM

IM 12B07D02-01E

Page 19

2-6 Specification

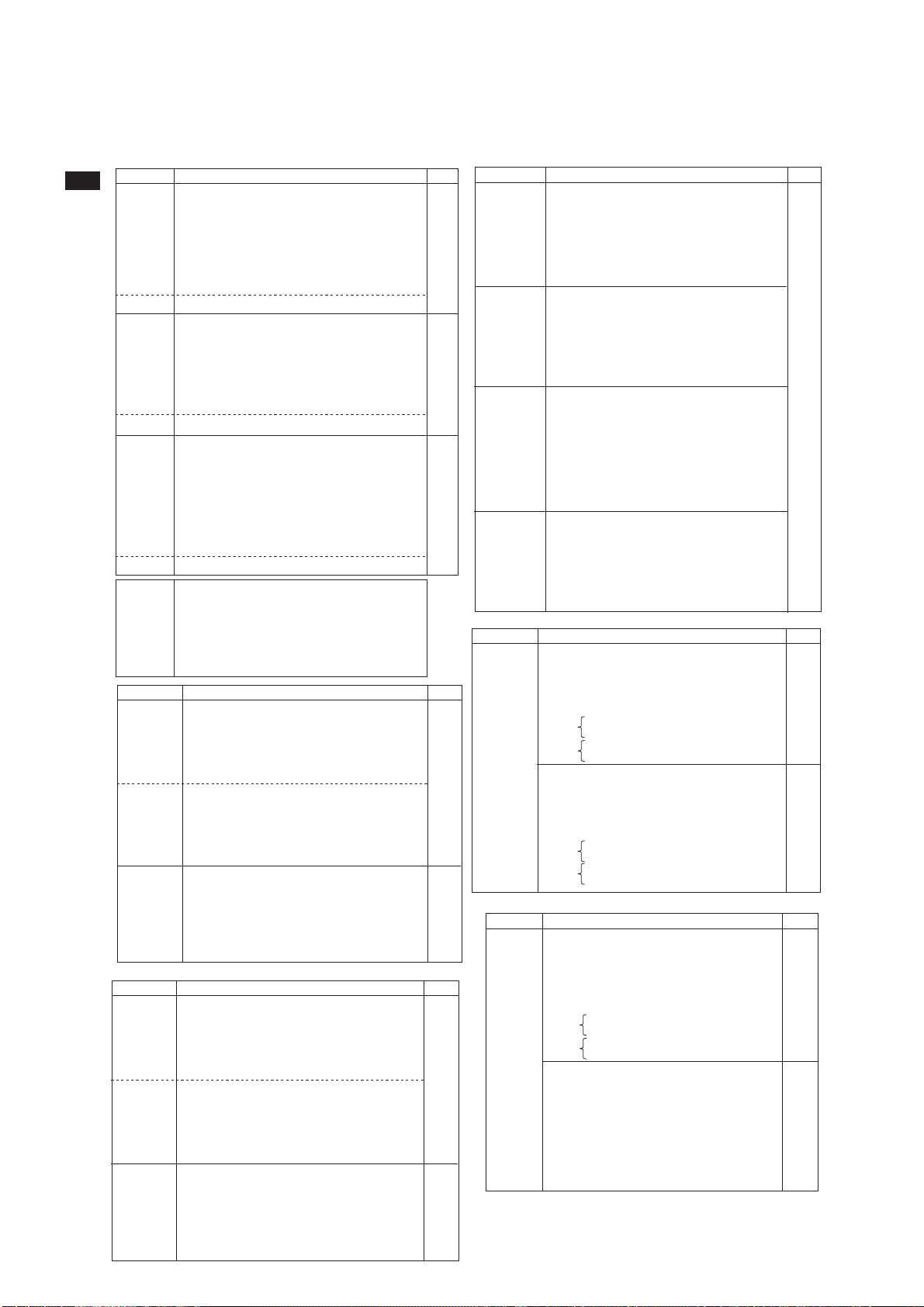

2-3. Model and suffix codes

1. 2-Wire pH/ORP Transmitter (Non-explosionproof type)

Model Suffix Code Option Code Description

PH202G

Type

Language

Option

( *1) The PH202G can be also used as ORP transmitter. (Setting can be made in the field. )

( *2) It can be specified when the suffix code -A is selected.

( *3) The housing is coated with epoxy resin.

2. 2-Wire pH/ORP Transmitter

Model Suffix Code Option Code Description

PH202S

Type

Language

Option

( *1) The PH202S can be also used as ORP transmitter. (Setting can be made in the field. )

( *2) The housing is coated with epoxy resin.

( *3) When the instrument with Suffix Code "-B,-N,-D" is used, take measures so that

the display window is not exposed to direct sunlight.

-E

-C

-U

-P

-F

-J

-E

Mounting Hardware

Hood

Tag Plate

Conduit Adapter

(Explosionproof type)

-E

-C

-U

-K

-P

-F

-B

-N

-D

-J

-E

Mounting Hardware

Hood

Tag Plate

Conduit Adapter

/U

/PM

/H

/H2

/SCT

/AFTG

/ANSI

/TB

/X1

/U

/PM

/H

/H2

/SCT

/AFTG

/ANSI

/X1

2-Wire pH/ORP Transmitter (*1)

mA with HART (Europe type)

mA with HART (Canada type)

mA with HART (North America type)

Profibus

FF

Japanese

English

Pipe, wall mounting bracket (Stainless steel)

Panel mounting bracket (Stainless steel)

Hood for sun protection (Carbon steel)

Hood for sun protection (Stainless steel)

Stainless steel tag plate

G 1/2

1/2 NPT

Screw terminal (*2)

Epoxy baked finish (*3)

2-Wire pH/ORP Transmitter (*1)

Intrinsic safe mA with HART (ATEX)

Intrinsic safe mA with HART (CSA)

Intrinsic safe mA with HART (FM)

Intrinsic safe mA with HART (NEPSI)

Intrinsic safe Profibus (ATEX, CSA, FM)

Intrinsic safe FF (ATEX, CSA, FM)

Non-incendive FF (ATEX, CSA, FM)(*3)

Non-incendive mA with HART (ATEX, CSA, FM) (*3)

Non-incendive Profibus (ATEX, CSA, FM) (*3)

Japanese

English

Pipe, wall mounting bracket (Stainless steel)

Panel mounting bracket (Stainless steel)

Hood for sun protection (Carbon steel)

Hood for sun protection (Stainless steel)

Stainless steel tag plate

G 1/2

1/2 NPT

Epoxy baked finish (*2)

[Style : S3]

[Style : S3]

IM 12B07D02-01E

Page 20

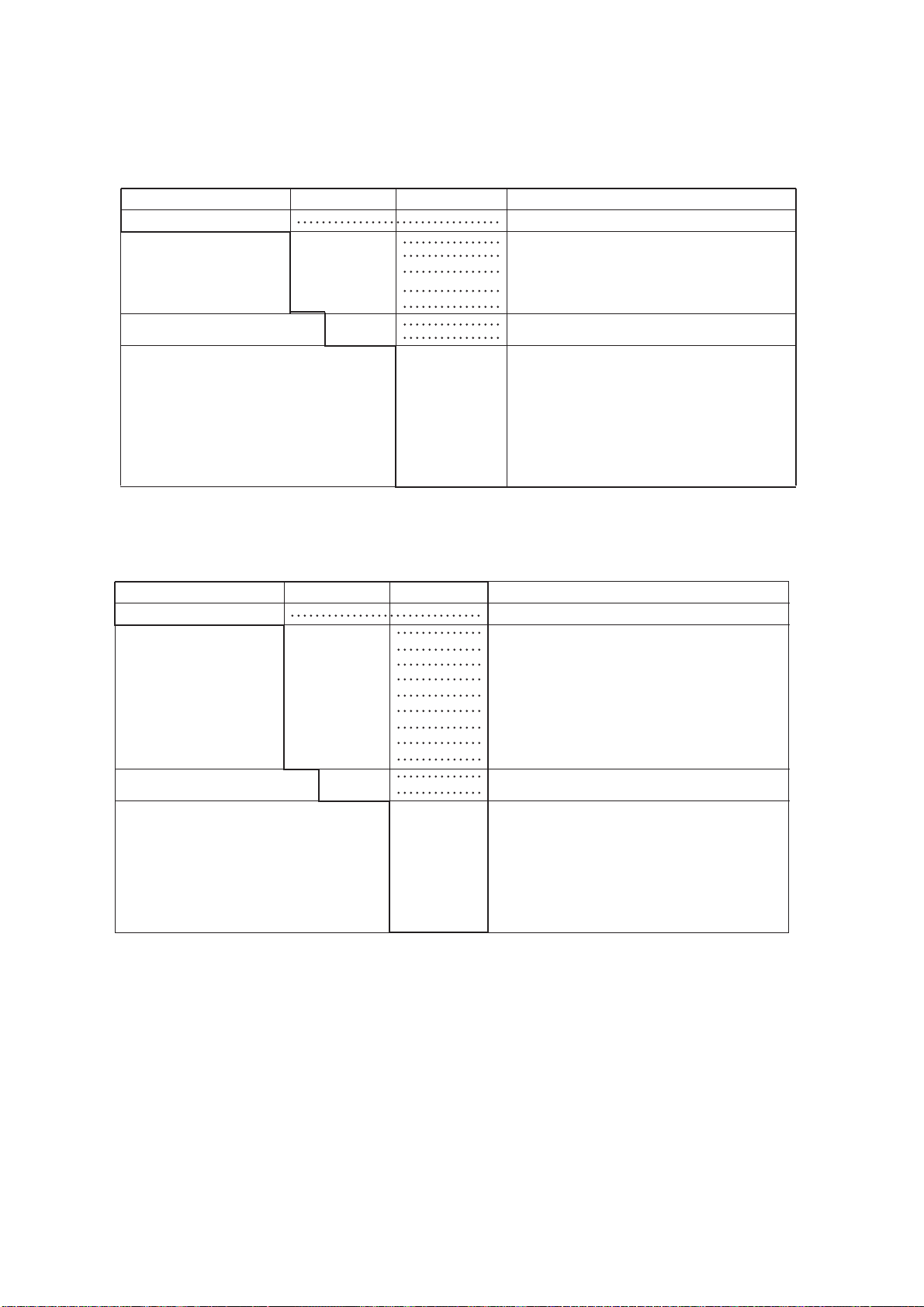

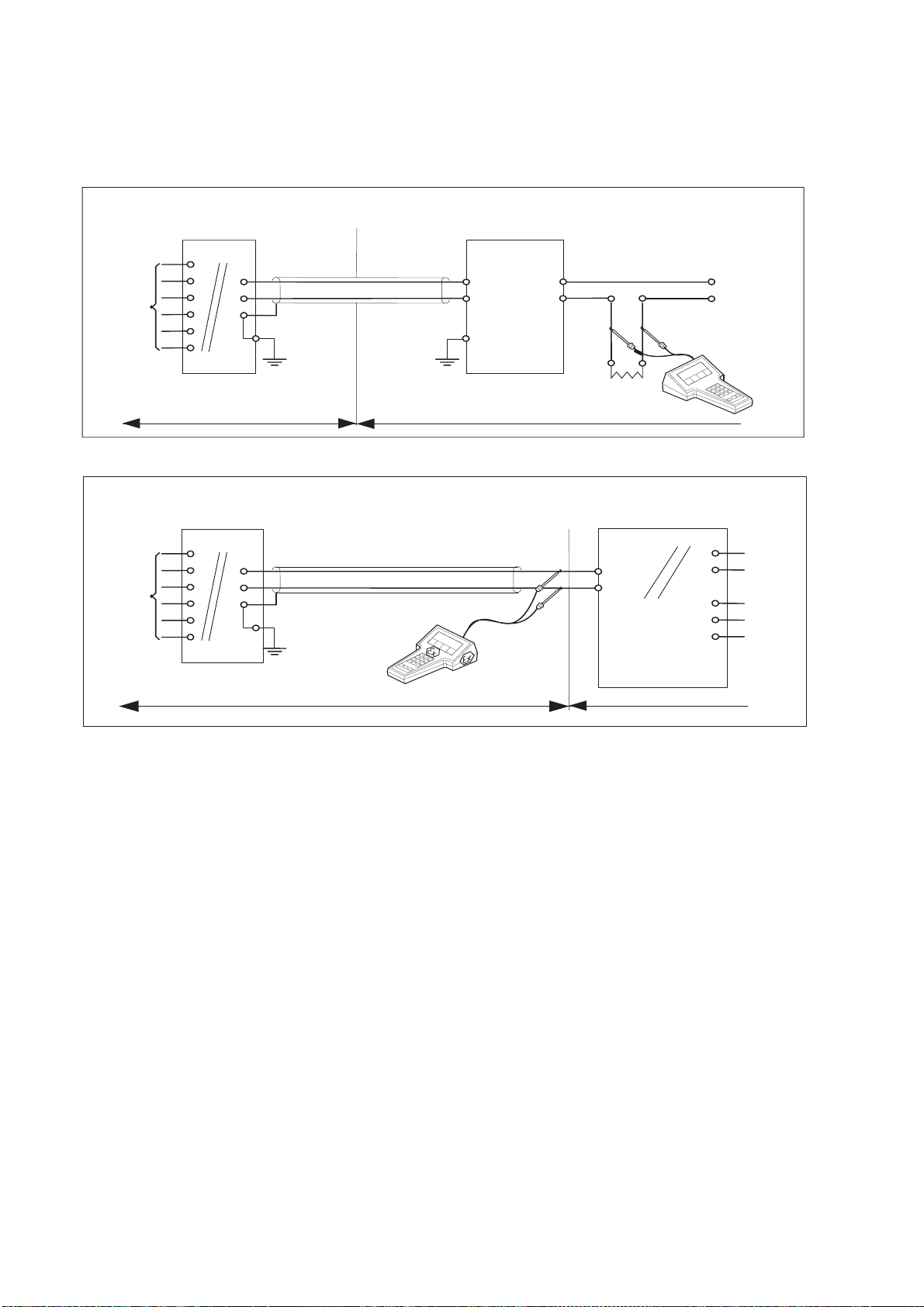

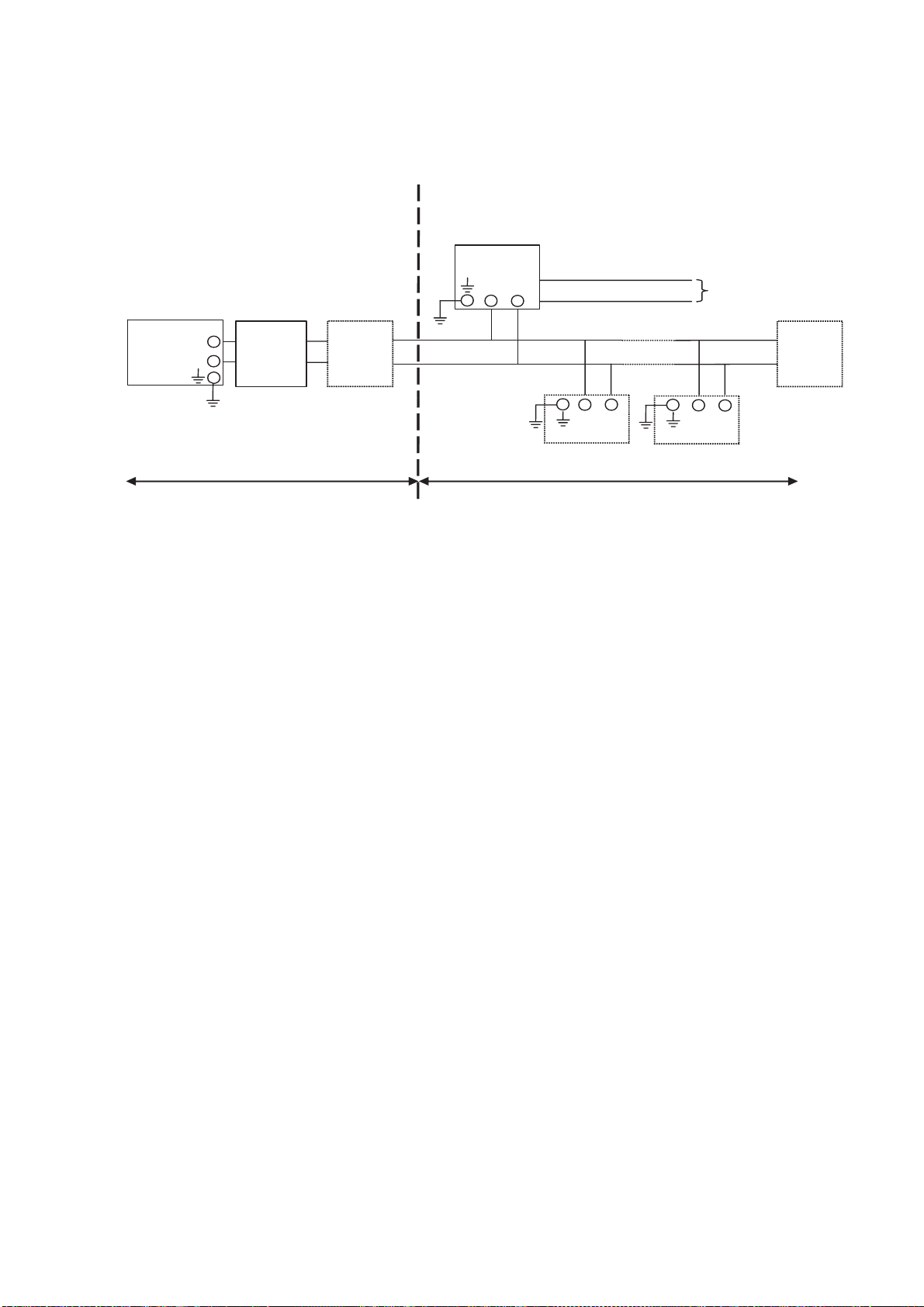

2-4. Control Drawing of PH202S mA HART® Specification (IECEx).

_

_

_

_

Specification 2-7

SENSOR(S)

terminals 11-17

SENSOR(S)

termin als 1 1 -1 7

Intrinsically safe design

IEC-E x s tand ard E X ia IIC : T4 for am bien t tem p. < 5 5°C

Certificate nr. IECEx KEM 06.0052X

PH202S

(pH/O R P -tra nsm itter)

T6 for ambient temp. < 40°C

+

G

Functional

earth

Hazardous area Safe area

Zone 0 or 1

Intrinsically safe design

IECE x s tan da rd E X ia IIC : T 4 for a mb ient te m p. < 55 ° C

Certificate nr. IECEx KEM 06.0052X

(pH/O R P -tra nsm itter)

PH202S

T6 for ambient temp.< 40°C

+

G

Functional

earth

Hazardous area

Zone 0 or 1

Functional

earth

EX ia or ib

Certified safety barrier or power

with Rint=300

(HART compatible)

Uo = 31 .5 V o lt DC

Io = 100 mA

:

24 volts DC Nominal

Supply Voltage.

Load

Resistance

EX ia or ib Certifie d R e p e a te r

Power Supply

(HAR T Comp atible )

+

Uo = 31.5 Volt DC

Io = 100 mA

Po = 1.2 Watt

Safe area

+

Output

Supply

・ Sensor(s) are of a passive type to be regarded as ‘simple apparatus’.

・ Electrical data of the PH202S.

- Supply and output circuit (terminals + and -):

Maximum input voltage U

= 31.5 V. Maximum input current Ii= 100 mA.

i

Maximum input power Pi = 1.2 W.

Effective internal capacitance Ci = 22 nF.

Effective internal inductance L

= 35 PH.

i

- Sensor input circuit (terminals 11 through 17):

Maximum output voltage Uo = 14.4 V. Maximum output current Io = 32.3 mA.

Maximum allowed external capacitance Co = 600 nF. (for PH202S-E,-C,-U),

Co = 3.5 PF (for PH202S-N).

Maximum allowed external inductance Lo = 34 mH (for PH202S-E,-C,-U),

Lo = 76 mH (for PH202S-N).

・ Barriers and power supply specification must not exceed the maximum values as shown

in the diagram above. These safety descriptions cover most of the commonly used

industry standard barriers, isolators and power supplies.

・ The Hand Held Communicator must be of a IECEx certified intrinsically safe type in

case it is used on the intrinsically safe circuit in the hazardous area or of a IECEx

certified nonincendive type in case it is used in the nonincendive circuit in the

hazardous area.

IM 12B07D02-01E

Page 21

2-8 Specification

_

_

_

_

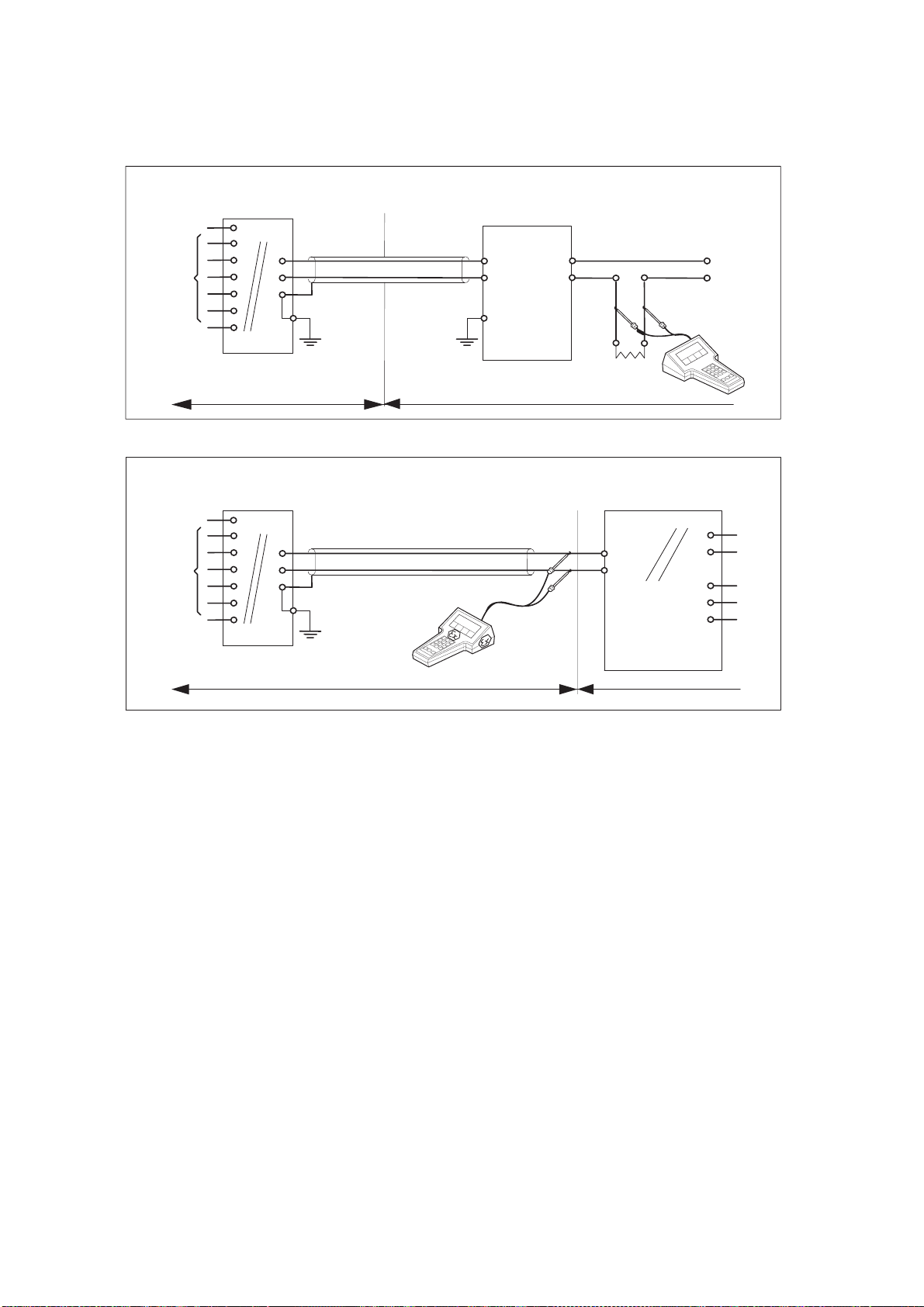

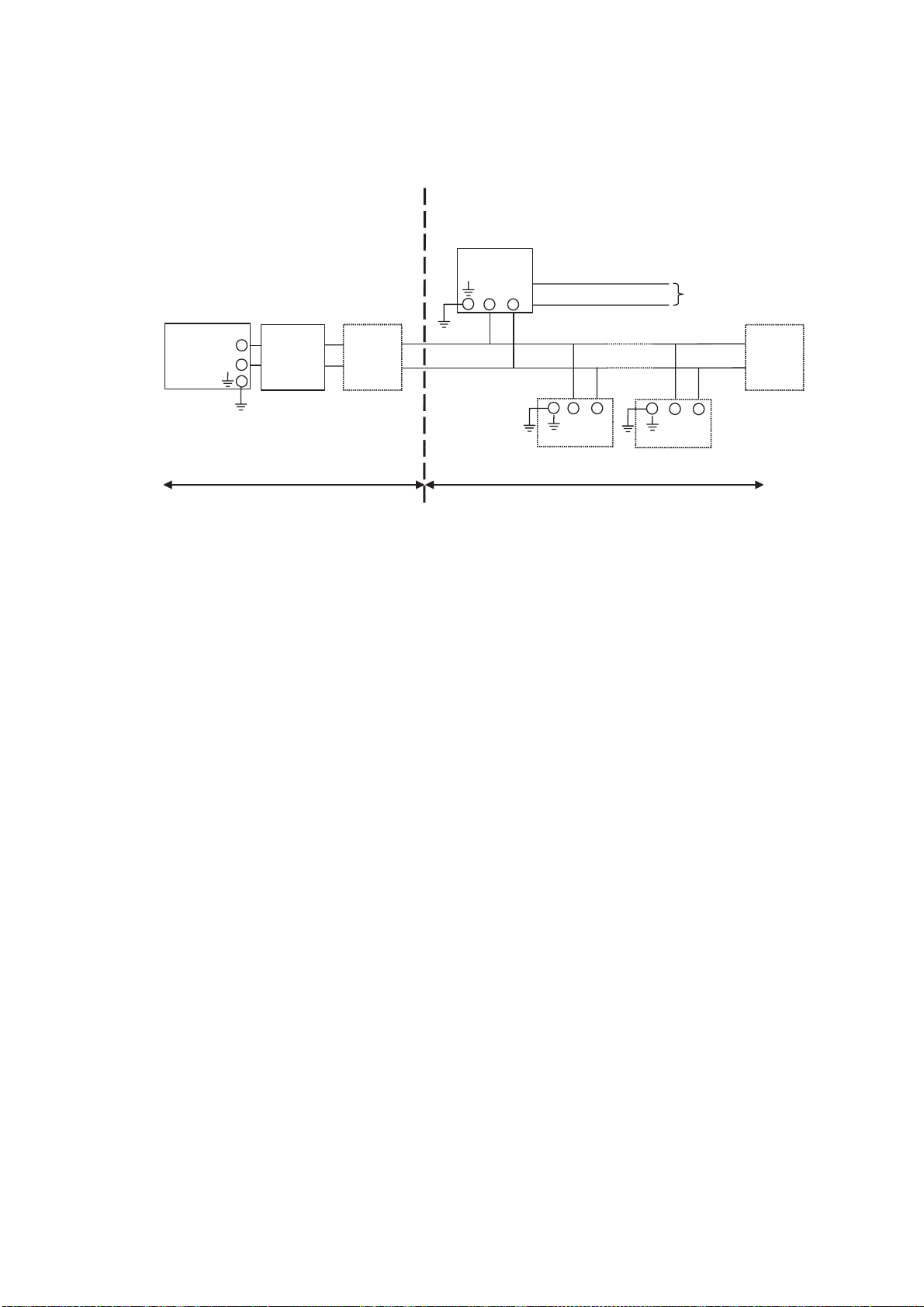

2-5. Control Drawing of PH202S mA HART® Specification (ATEX)

Intr in s ic ally s a fe de sign

CENELE C sta nd ard E E X ia IIC : T 4 fo r am b ien t tem p. < 55°C

T6 for ambient temp. < 40°C

Certificate nr. KEMA 06ATEX0218 X

(pH/O R P -tra n s mitte r )

PH202S

+

G

EEx ia or ib

Certified safety barrier or power

with Rint=300

(HAR T c o m pa tible)

Uo = 31.5 Volt DC

Io = 100 mA

:

24 volts DC Nominal

Supply Voltage.

+

SENSOR(S)

terminals 11-17

SENSOR(S)

termin als 1 1 -1 7

Hazardous area Safe area

Zone 0 or 1

Intrinsically safe design

CENELEC standard EEx ia IIC: T4 for ambient temp. < 55°C

T6 for ambient temp.< 40°C

Certificate nr. KEMA 06ATEX0218 X

(pH/ORP-trans m itte r)

PH202S

Hazardous area

Zone 0 or 1

Functional

earth

+

G

Functional

earth

Functional

earth

Load

Resistance

EEx ia or ib Certified Repeater

Power Supply

(HART Compatible)

+

Uo = 31.5 Volt DC

Io = 100 mA

Po = 1.2 Watt

Safe area

Output

Supply

・ Sensor(s) are of a passive type to be regarded as ‘simple apparatus’.

・ Electrical data of the PH202S.

- Supply and output circuit (terminals + and -):

Maximum input voltage U

= 31.5 V. Maximum input current Ii= 100 mA.

i

Maximum input power Pi = 1.2 W.

Effective internal capacitance C

Effective internal inductance L

= 22 nF.

i

= 35 PH.

i

- Sensor input circuit (terminals 11 through 17):

Maximum output voltage U

= 14.4 V. Maximum output current Io = 32.3 mA.

o

Maximum allowed external capacitance Co = 600 nF. (for PH202S-E,-C,-U),

Co = 3.5 PF (for PH202S-N).

Maximum allowed external inductance Lo = 34 mH (for PH202S-E,-C,-U),

Lo = 76 mH (for PH202S-N).

・ Barriers and power supply specification must not exceed the maximum values as shown

in the diagram above. These safety descriptions cover most of the commonly used

industry standard barriers, isolators and power supplies.

・ The safety barrier shall be certified by notify body.

・ Installation should be in accordance with local installation requirements.

・ If use ordinary wirings, the general purpose equipment must have Nonincendive

Field Wiring terminal approved.

・The Hand Held Communicator must be of a ATEX certified intrinsically safe type in case

it is used on the intrinsically safe circuit in the hazardous area or of a ATEX certified

non-incendive type in case it is used in the non-incendive circuit in the hazardous area.

IM 12B07D02-01E

Page 22

Specification 2-9

_

_

_

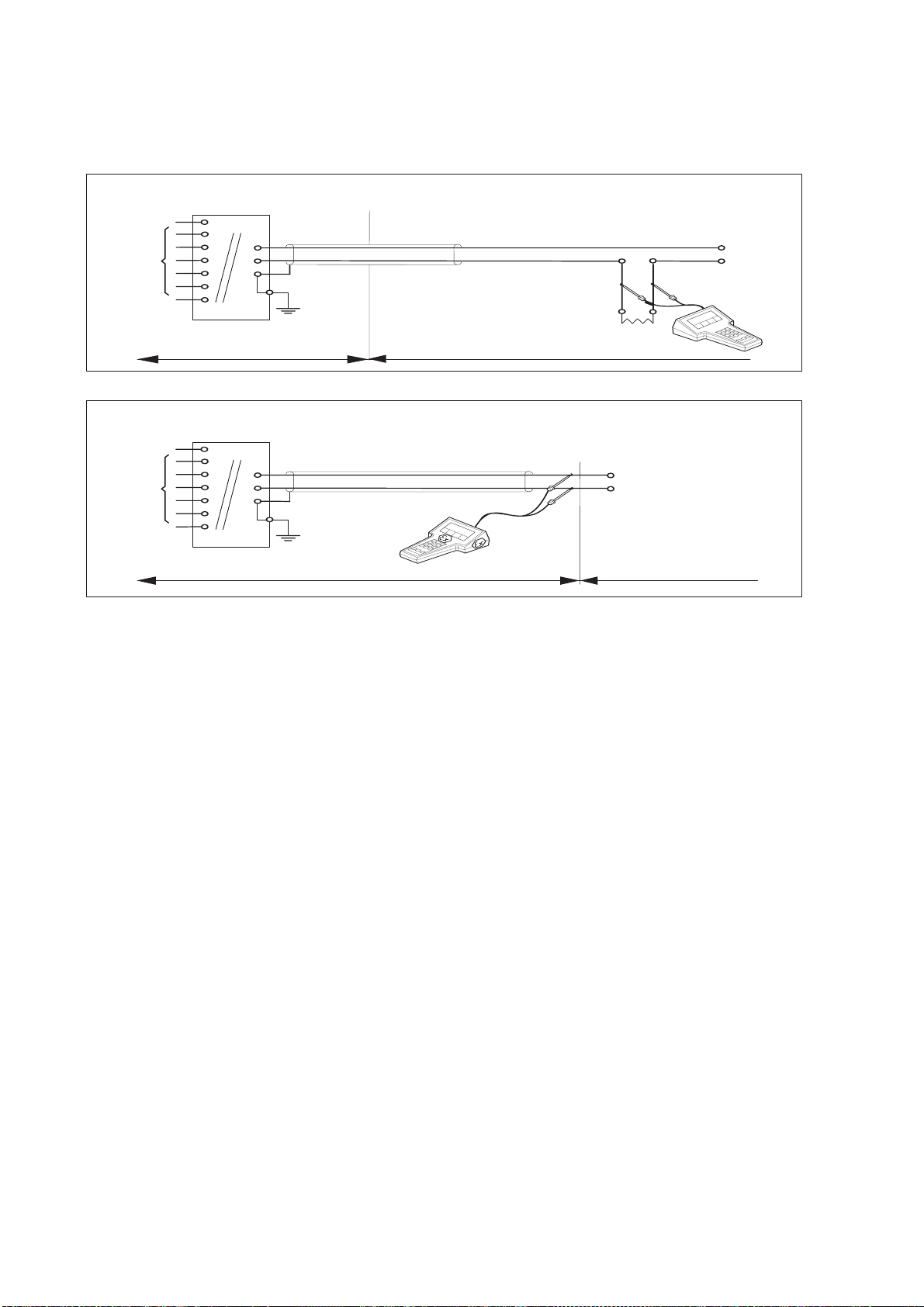

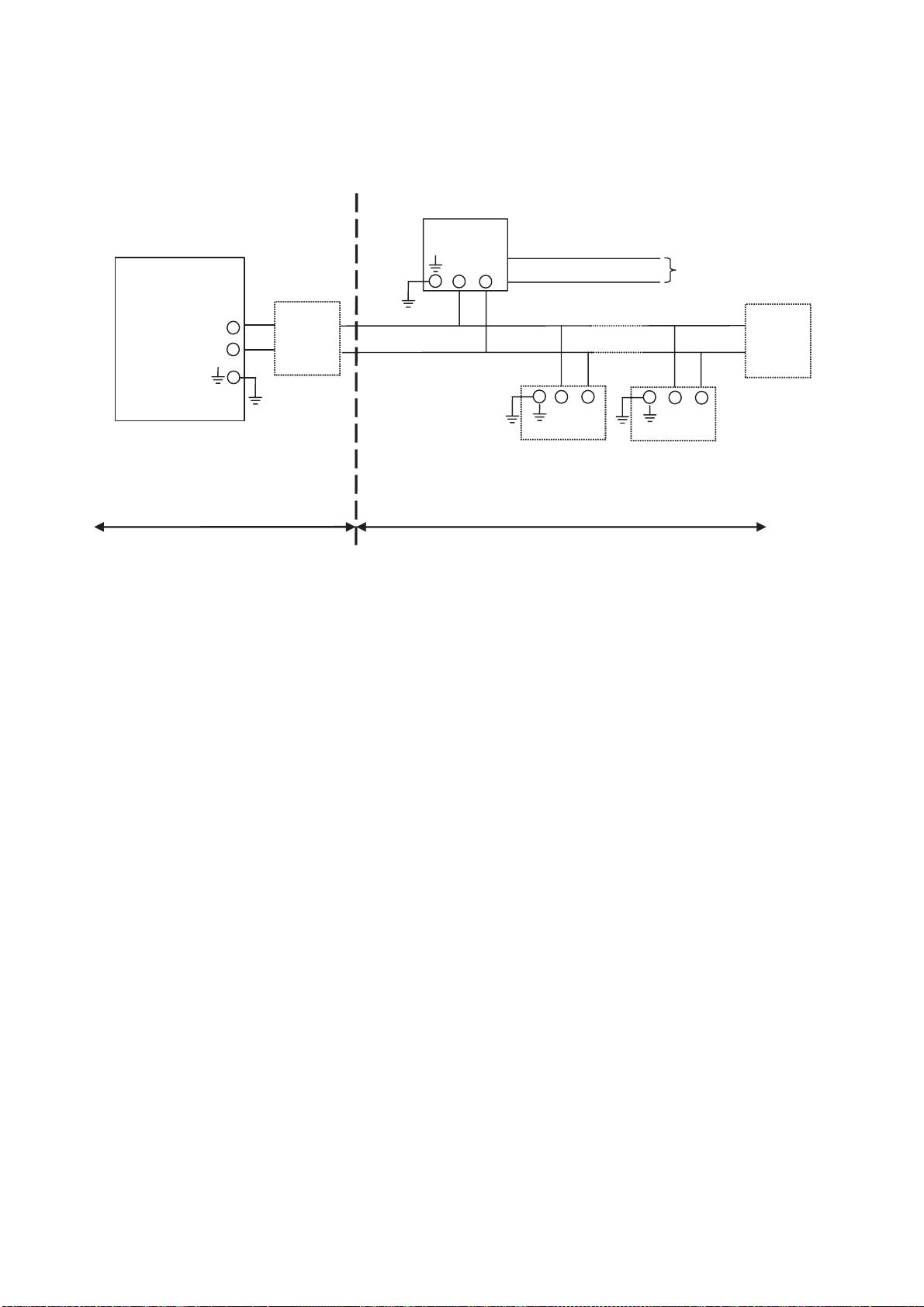

2-6. Control Drawing of PH202S mA HART® Specification (FM Intrinsically safe design)

Intrins ically sa fe design

FM Class I, Div.1, Group ABCD, T4 for ambient temp. < 55°C

T6 for ambient temp. < 40°C

PH202S transmitter

Sensor(s)

terminals 11-17

Max. cablelength: 60 mtr.

Cable dia. : 3…12 mm.

Intrins ically safe desig n

FM Class I, Div.1, Group ABCD, T4 for ambient temp. < 55°C

T6 for ambient temp. < 40°C

PH202S transmitter

+

G

For electrical data:

see text be low .

Classified Location

+

G

Functional

earth

FM Approved safety barrier or

power supply

with Rint = 300 :

(HART compatible)

Functional

earth

Unclassified Location

24 volts DC Nominal

Load

Resistance

FM Approved

Power Supply

(HART compatible)

+

Supply Voltage.

+

-

Figure 1

Output

Supply

Sensor(s)

terminals 11-17

Max. cablelength: 60 mtr.

Cable dia.: 3…12 mm.

For electrical data:

see text below.

Classified Location

Functional

earth

Ùnclassified Location

Figure 2

・Electrical data of the PH202S.

-Supply circuit (terminals + and -):

Maximum input voltage Vmax = 31.5 V. Maximum input current Imax = 100 mA.

Maximum input power Pmax = 1.2 W.

Effective internal capacitance Ci = 22 nF. Effective internal inductance Li = 35 PH.

- Sensor input circuit (terminals 11 through 17):

Maximum output voltage Vt = 14.4 V. Maximum output current It = 32.3 mA.

Maximum allowed external capacitance Ca = 600 nF.

Maximum allowed external inductance La = 34 mH

・If Hand Held Terminal (HHT) is not connected to the power supply lines of the PH202S

(see figure 1):

Any FM Approved barrier or power supply may be used that meets the following requirements.

Voc or Vt d 31.5 V ; Isc or It d 100 mA; Ca t 22nF + Ccable ; La t 35PH + Lcable

If HHT is connected to the power supply lines of the PH202S (see figure 2):

The Hand Held Terminal must be FM Approved. Refer to the manufacturers control drawing of

the HHT and the barrier/power supply to determine the cable parameters.

(Voc or Vt ) + VHHT d 31.5 V; (Isc or It ) + IHHT d 100 mA;

Ca t 22nF + Ccable+ CHHT ; La t 35PH + Lcable+ LHHT

When installing this equipment, follow the manufacturer’s installation drawing.

Installation should be in accordance with ANSI/ISA RP 12.06.01 “Installation of Intrinsically Safe

Systems for Hazardous (Classified) Locations” and the National Electrical Code (ANSI/NFPA 70).

Control equipment connected to the barrier/power supply must not use or generate more than

250 Vrms or Vdc.

・Resistance between Intrinsically Safe Ground and earth ground must be less than 1.0 Ohm.

・In case of using cable glands in Outdoor location, they shall be UV rated or made of metal.

WARNING

- Substitution of components may impair Intrinsic Safety

- To prevent ignition of flammable or combustible atmospheres, disconnect power before servicing

or read, understand and adhere to the manufacturer’s’live maintenance procedures.

Application Doc. No.: IKE024-A10 P.4-1 to P.4-2

IM 12B07D02-01E

Page 23

2-10 Specification

_

_

N

N

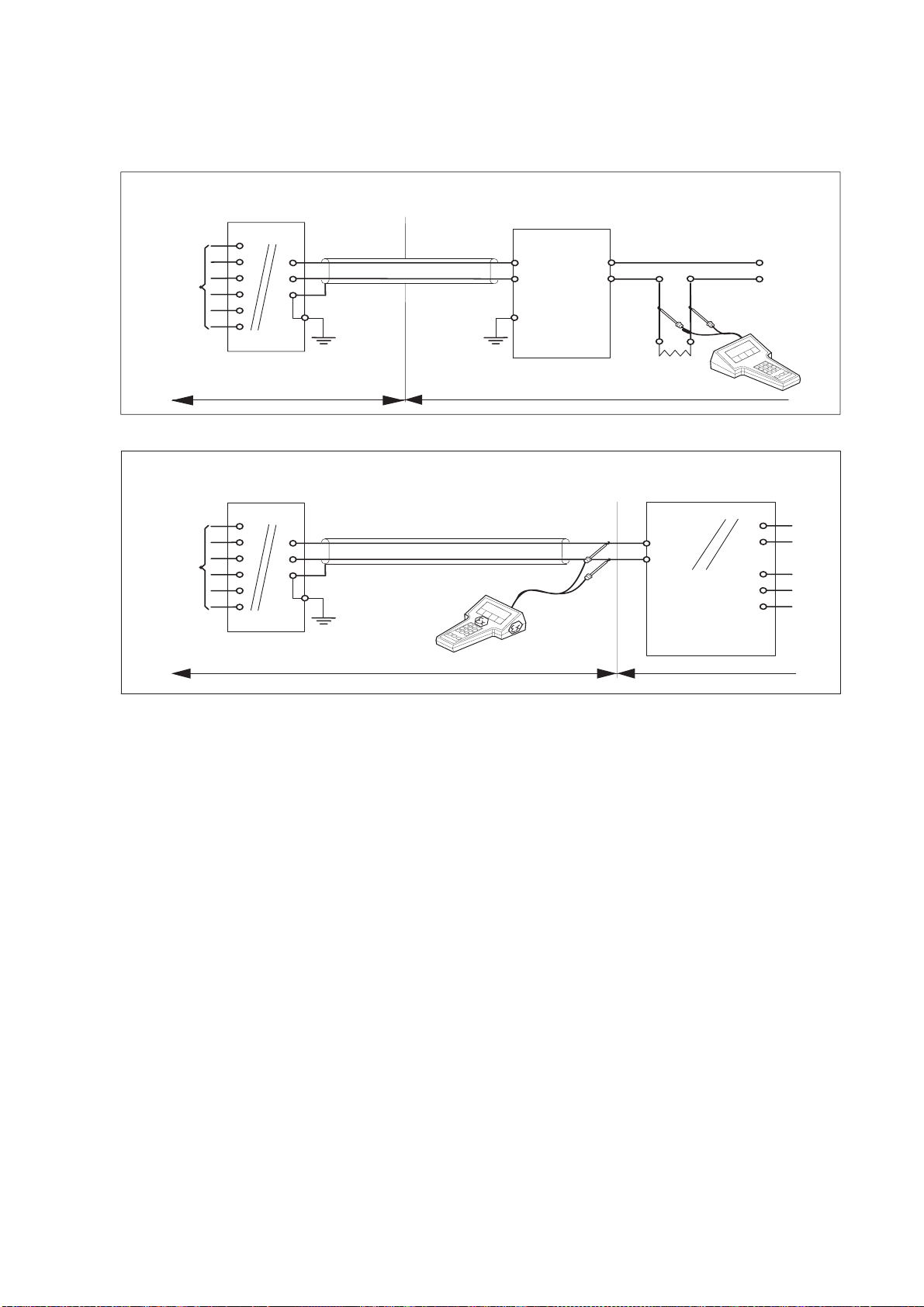

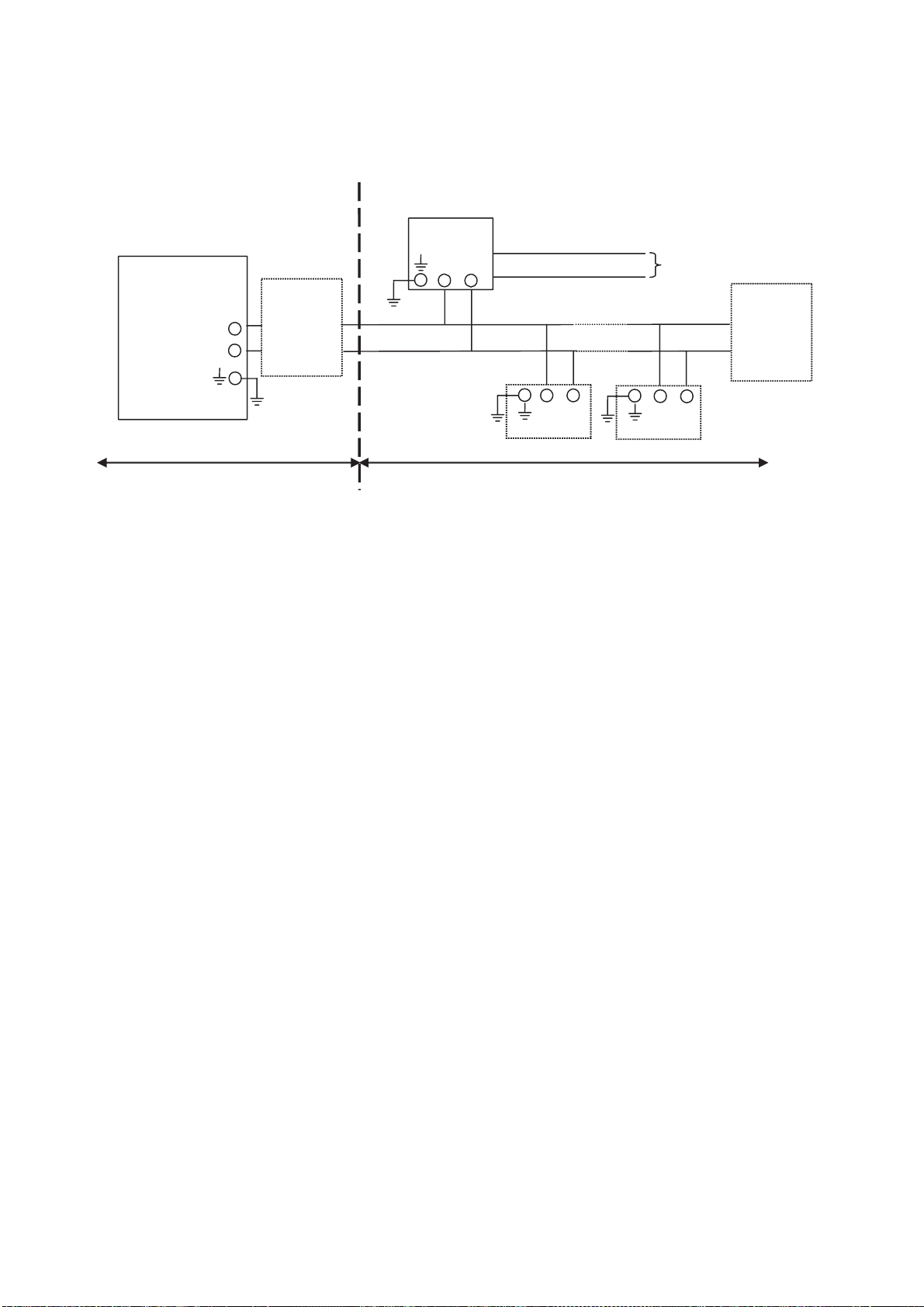

2-7. Control Drawing of PH202S mA HART® Specification (FM Non-incendive design).

onincendive design

FM C lass I, Div.2, Group ABCD, T 4 for ambient temp. < 55°C

T6 for ambient temp. < 40°C

PH202S transmitter

FM A pproved

power supply

Voc ≦ 31.5 VDC

+

G

Sensor(s)

terminals 11-1 7

Ma x. cablelength: 60 mtr.

Cable dia. : 3…12 mm.

For electrical d ata:

see text below.

Classified Location Unclassified Location

onincendive design

FM C lass I, D iv.2, G rou p A B C D , T4 fo r a m bie nt te m p. < 55 °C

T 6 fo r a m b ient te m p . < 40 ° C

PH202S transmitter

Functional

earth

+

G

Sensor(s)

terminals 11-1 7

Ma x. cablelength: 60 mtr.

Cable dia.: 3…12 mm

For electrical data:

see text below.

Classified Location

Functional

earth

・Electrical data of the PH202S.

- Supply circuit (terminals + and -):

Maximum input voltage V

= 31.5 V. Maximum input power P

max

Effective internal capacitance Ci = 22 nF Effective internal inductance Li = 35 μH

- Sensor input circuit (terminals 11 through 17):

Maximum output voltage V

= 14.4 V. Maximum output current It = 32.3 mA.

t

Maximum allowed external capacitance C

Maximum allowed external inductance L

= 2.29PF.

a

= 64.96mH.

a

Load

Resistance

FM A pproved

power supply

Voc ≦ 31.5 V D C

+

-

Ùnclassified Location

max

+

-

= 1.2 W

・The Hand Held Terminal must be FM Approved in case it is used in the classified location.

When installing this equipment, follow the manufacturers installation drawing. Installation shall

be in accordance with Article 501.4(B) of the National Electrical Code.

Non-incendive field wiring may be installed in accordance with Article 501 of the National

Electrical Code.

・ Grounding shall be in accordance with Article 250 of the National Electrical code.

・ In case of using cable glands in Outdoor location, they shall be UV rated or made of metal.

WARNING

- Substitution of components may impair suitability for Division 2

- Do not remove or replace while circuit is live unless area is know to be non-hazardous

- Explosion Hazard – Do not disconnect equipment unless area is know to be non-hazardous

- Do not reset circuit breaker unless power has been removed from the equipment or the area is

know to be non-hazardous

Application Doc. No.: IKE024-A10 P.4-3 to P.4-4

IM 12B07D02-01E

Page 24

2-8. Control Drawing of PH202S mA HART® Specification (CSA).

_

_

_

_

Specification 2-11

Sen so r(s)

terminals 11-17

Sen sor (s)

term inals 11-17

Intr ins ically s a fe des ig n

CSA Ex ia Class I, Div.1, Group ABCD

T4 fo r a m bie nt te m p . < 5 5 °C

PH202S

T6 fo r a m bie nt te m p . < 4 0 °C

(pH/O R P -tra n sm itte r)

+

G

For electrical data:

see text below.

Hazardous area S afe area

Intr ins ically s a fe des ig n

CSA Ex ia Class I, Div.1, Group ABCD

T4 fo r a m bie nt te m p . < 5 5 °C

PH202S

T6 for a m b ient te mp . < 4 0° C

(pH/O R P -tra n sm itte r)

Functional

earth

+

G

For electrical data:

see text below.

Hazardous area

Functional

earth

Functional

earth

CSA certified

safety ba rrier or p o w er s up p ly

(HA R T com p a tible )

Suitable values are:

Vmax = 31.5 VoltDC

Imax = 100 mA

Load

Resistance

CSA certified

Power Supply

(HA R T comp a tible ) )

+

Suitable values are:

Vmax = 31.5 VoltDC

Imax = 100 mA

Pmax = 1.2 Watt

Safe area

24 volts DC Nominal

Supply V o lta g e .

+

Output

Supply

・Sensor(s) are thermocouples, RTD’s, passive resistive switch devices, or are CSA entity approved

and meet connection requirements.

・Electrical data of the PH202S.

- Supply and output circuit (terminals + and -):

Maximum input voltage Vmax = 31.5 V. Maximum input current Imax = 100 mA.

Maximum input power Pmax = 1.2 W.

Effective internal capacitance Ci = 22 nF. Effective internal inductance Li = 35 PH.

- Sensor input circuit (terminals 11 through 17):

Maximum output voltage Voc = 14.4 V. Maximum output current Isc = 32.3 mA.

Maximum allowed external capacitance Ca = 600 nF

Maximum allowed external inductance La = 34 mH.

・Barriers and power supply should be CSA certified. The specifications must not exceed

the maximum values as shown in the diagram above.

Installation should be in accordance with Canadian Electrical Code, Part I.

Maximum safe area voltage should not exceed 250 VRMS.

For Class I, Div. 2, Group ABCD the CSA certified barrier is not required, and the Sensor

input circuit (terminals 11 through 17) is non-incendive having the parameters :

Maximum output voltage Voc = 14.4 V. Maximum output current Isc = 32.3 mA.

Maximum allowed external capacitance Ca = 3.5 PF.

Maximum allowed external inductance La = 76 mH.

・The Hand Held Communicator must be of a CSA certified intrinsically safe type

in case it is used on the intrinsically safe circuit in the hazardous area, or of a

CSA certified

non-incendive type in case it is used on the non-incendive circuit in the

hazardous area.

IM 12B07D02-01E

Page 25

2-12 Specification

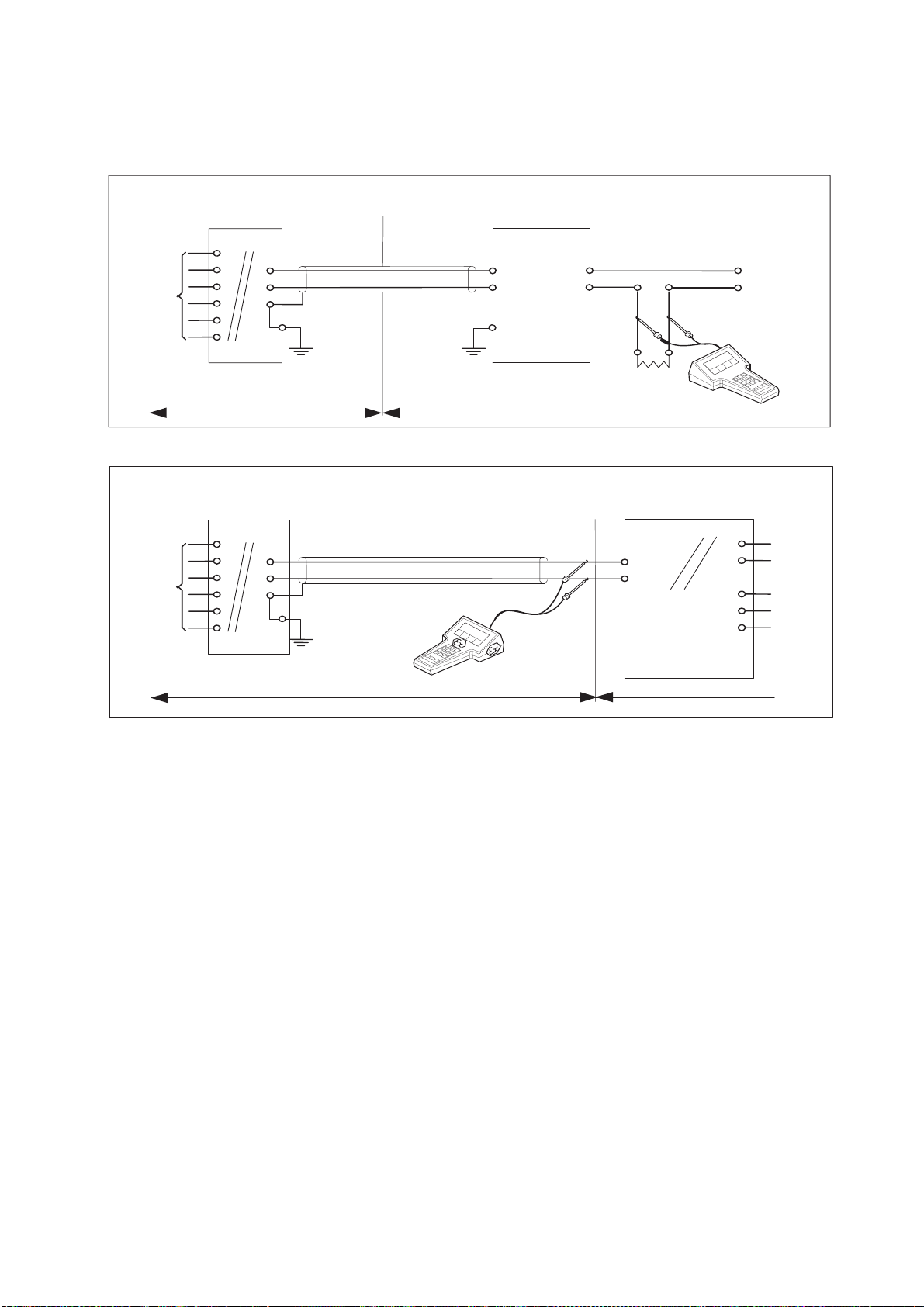

2-9. Control Drawing of PH202S FF/PB Specification (IECEx)

Ex ia IIC

T4 fo r ambien t temp. d 55 qC

Ui = 24 V or U i = 17,5 V

Ii = 250 mA Ii= 380 mA

Pi = 1,2 W Pi = 5,32 W

PH202S-F

or PH202S-P

+

-

Sensor

Connections

Safe area

Apparatus

+

-

Safe area

I.S.

interface

I.S.

certified

Terminator

+

Transm itter

Zone 0 or 1

Hazardous area

-

x Sensor(s) are of a passive type to be regarded as 'simple apparatus'.

x Electrical data of the PH202S-F & PH202S-P:

- Supply and output circuit:

Maximum input voltage Ui=24 V

Maximum input current Ii=250 mA

Maximum input power Pi=1.2 W

Effective internal capacitance Ci= 220 pF;

Effective internal inductance Li= 0

H.

or

FISCO field device

Maximum input voltage Ui=17.5 V

Maximum input current Ii=380 mA

Maximum input power Pi=5.32 W

Effective internal capacitance Ci= 220 pF;

Effective internal inductance Li= 0

H.

+

Transm itter

I.S.

certified

Terminator

-

- Sensor input circuit:

Maximum output voltage Uo=14.4 V; Maximum output current Io=32.3 mA

Maximum allowed external capacitance Co=600 nF

Maximum allowed external inductance Lo=34 mH

x Any I.S. interface may be used that meets the following requirements:

FISCO power supply

Uo d 24 V or Uo d 17.5 V

Io d 250 mA Io d 380 mA

Po d 1.2 W Po d 5.32 W

Co t 220 pF + Ccable; Lo t 0

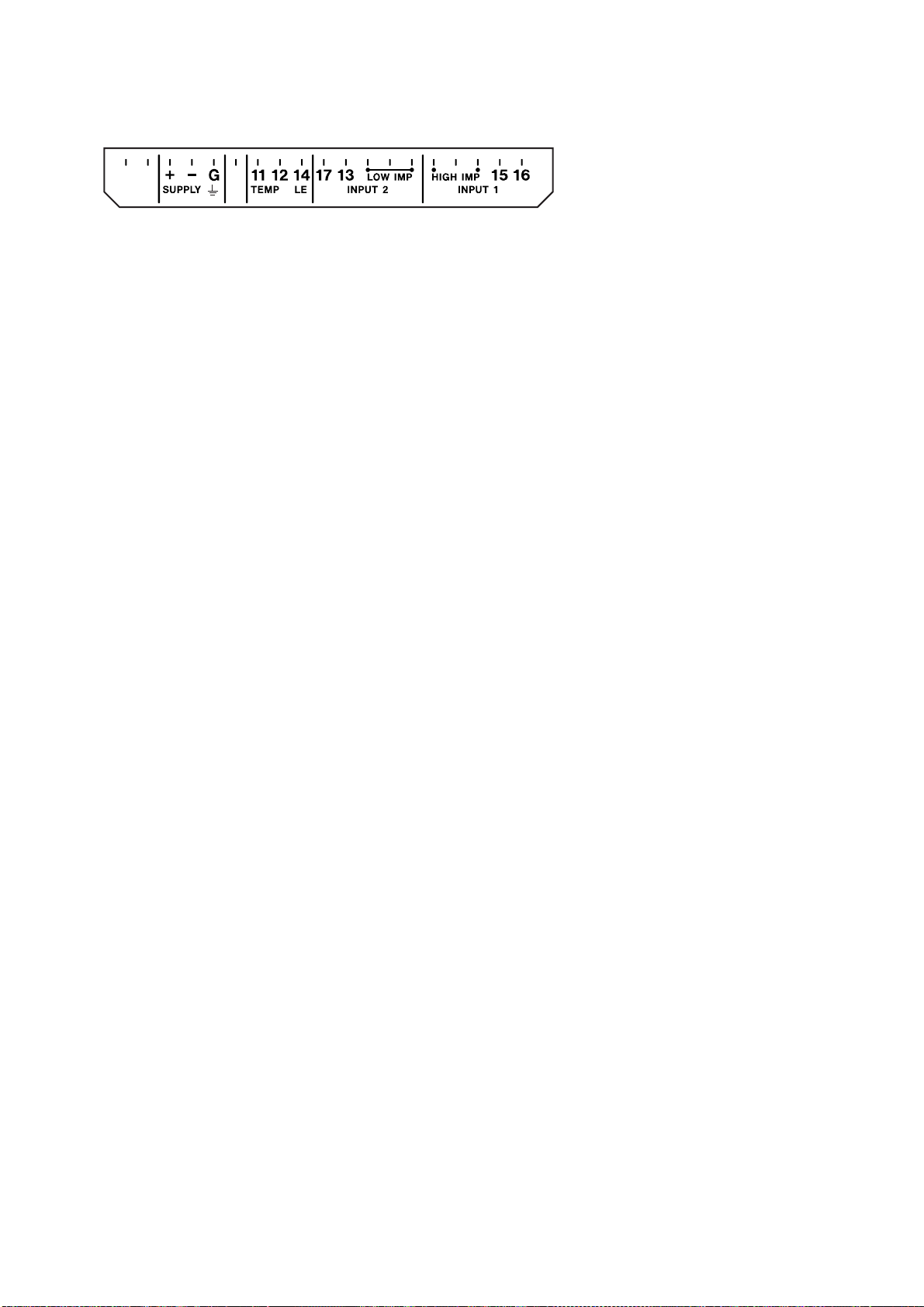

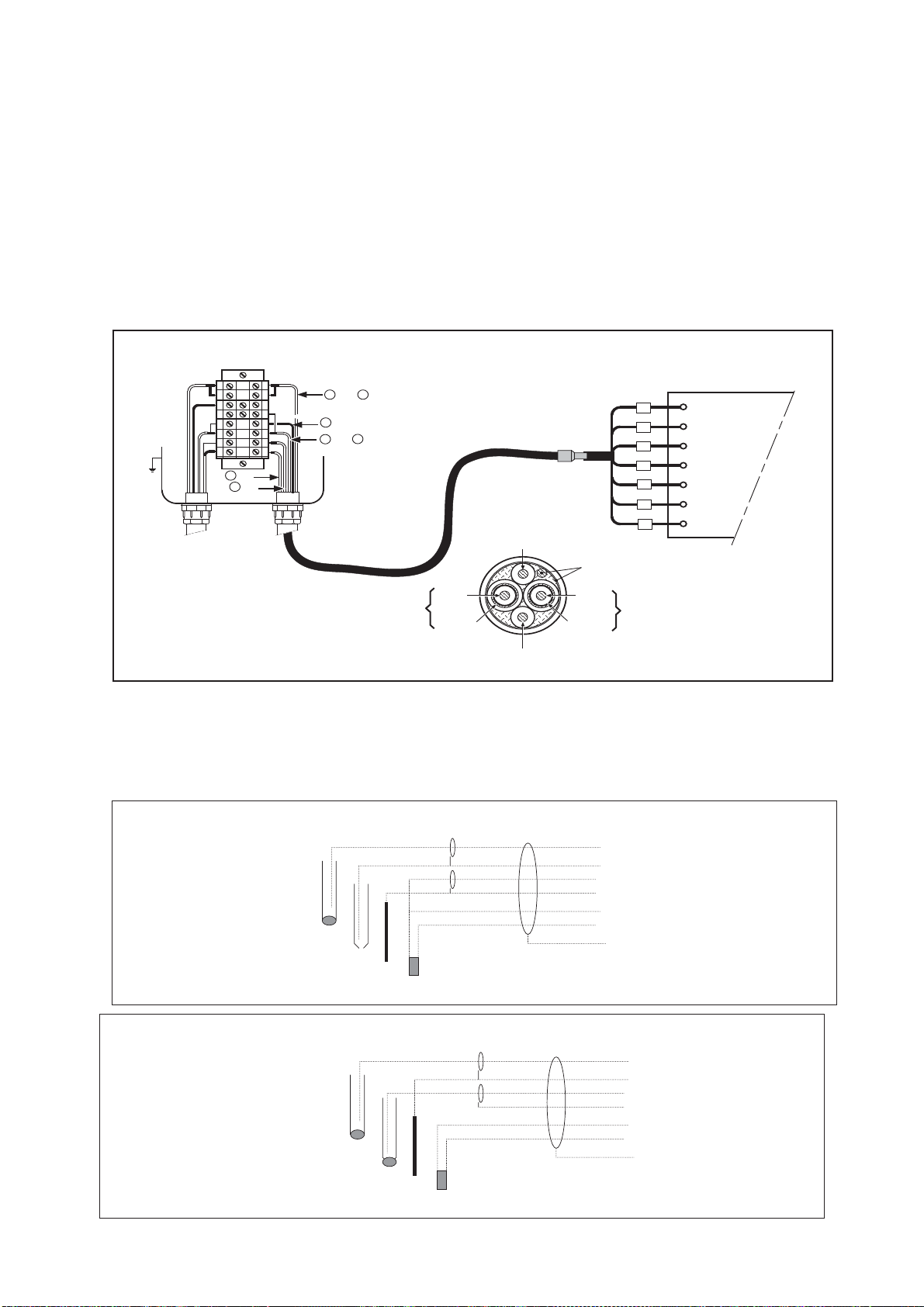

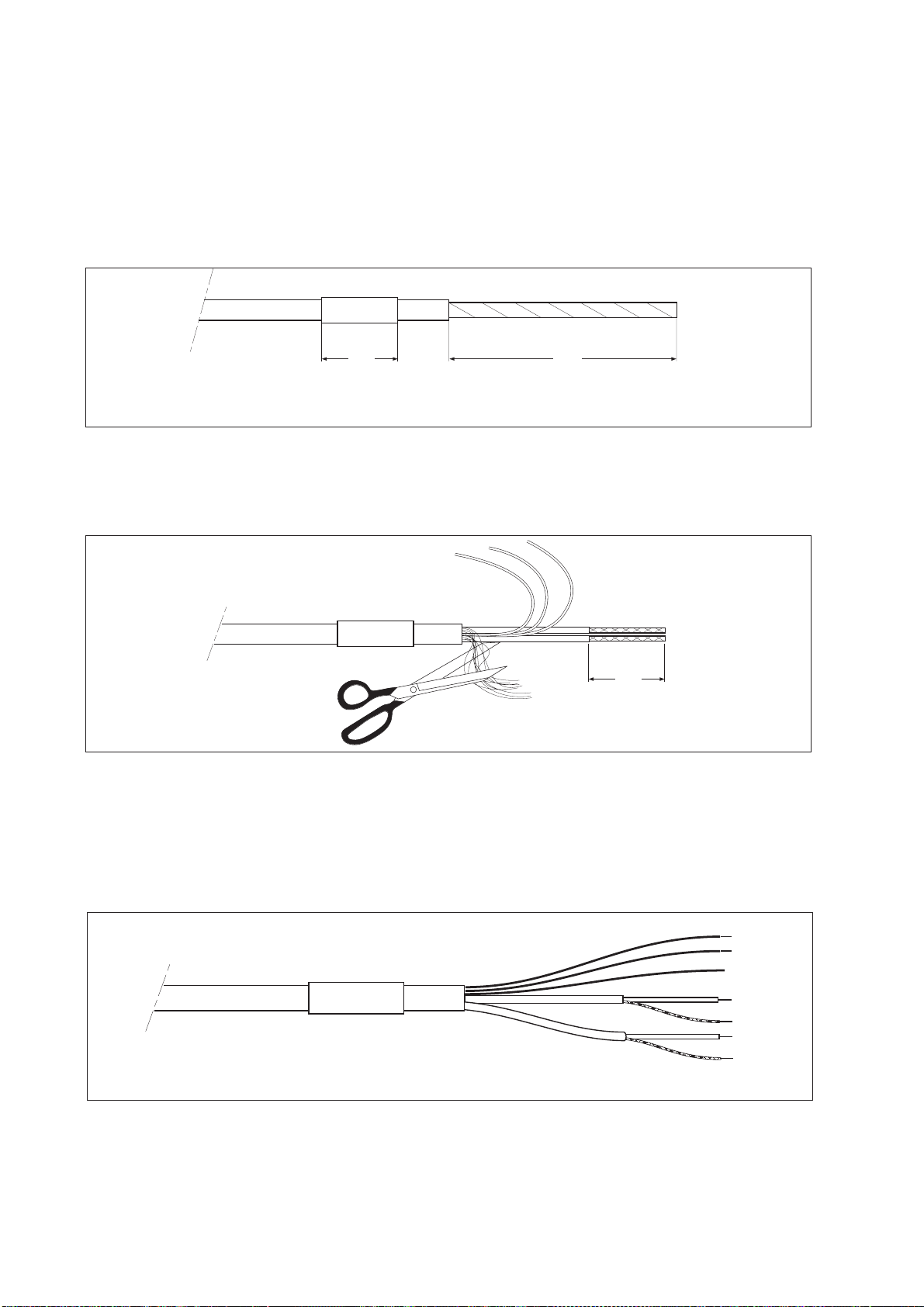

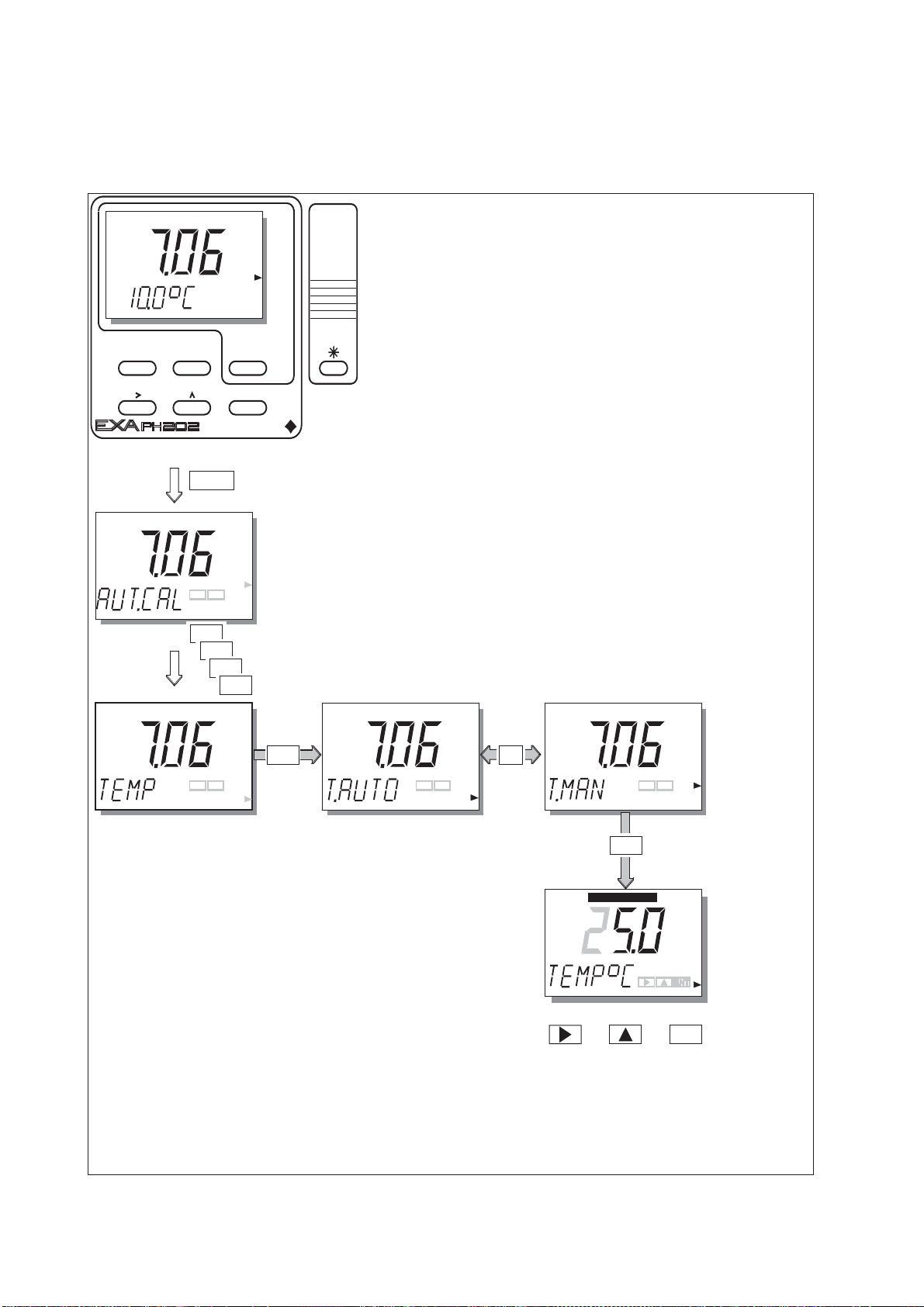

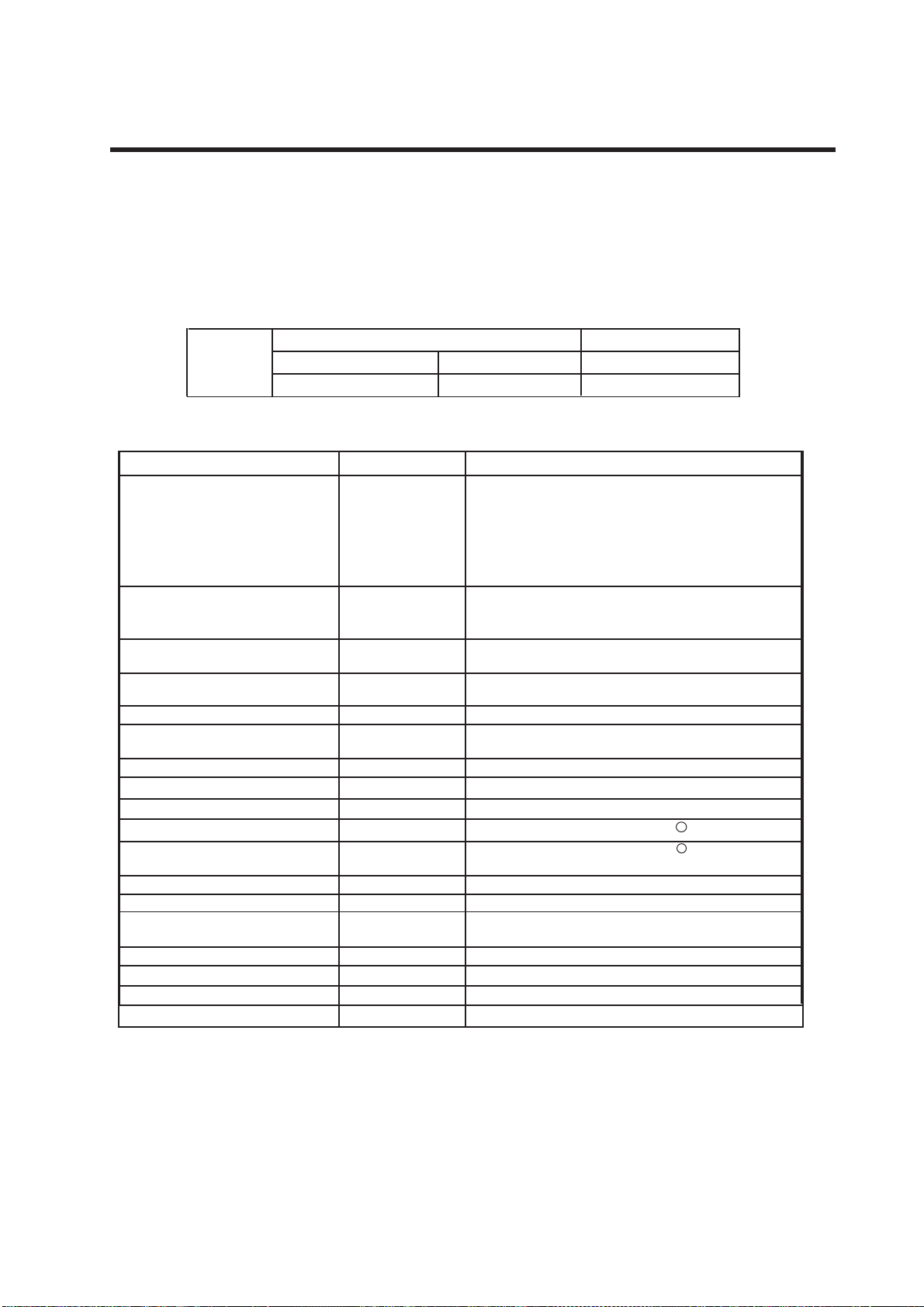

H + Lcable