Page 1

Instruction

Manual

IM 12B6J4-E-A

Model PH18

Differential pH sensor

Yokogawa Corporation of America

2 Dart Road, Newnan, Georgia U.S.A. 30265

Tel: 1-800-258-2552 Fax: 1-770-254-0928

IM 12B6J4-E-A

2nd Edition

Page 2

2

TABLE OF CONTENTS

PREFACE ...................................................................................................................................................... 1

1 INTRODUCTION .......................................................................................................................................... 3

2 GENERAL SPECIFICATIONS ...................................................................................................................... 5

2.1 Model PH18 differential pH sensor ........................................................................................................5

2.2 Model WU18 cable for PH18 sensor .....................................................................................................6

2.2 Dimensions of the PH18SA .................................................................................................................... 7

3 THE TYPE 18 PH PROBE ............................................................................................................................ 8

3.1 Typical applications ................................................................................................................................ 8

3.2 Handling information for the glass lined pH probe................................................................................. 8

3.3 Storage and hydration ............................................................................................................................ 8

3.4 Installation .............................................................................................................................................. 8

3.5 PH18 Installation examples .................................................................................................................... 9

4 PH202/PH402 and FLXA21/PH450 Instrument........................................................................................ 10

4.1 Set-up ................................................................................................................................................... 10

5 CALIBRATION ............................................................................................................................................ 11

5.1 Calibration set-up ................................................................................................................................. 11

5.2 Isopotential pH value ............................................................................................................................ 11

5.3 SLOPE .................................................................................................................................................. 11

5.4 ASY ....................................................................................................................................................... 11

5-5 Process Temperature compensation ................................................................................................... 11

6 CLEANING/STERILIZATION ...................................................................................................................... 12

6.1 Acceptable CIP cleaning processes ..................................................................................................... 12

6.2 Sterilization methods ............................................................................................................................ 12

7 MAINTENANCE .......................................................................................................................................... 12

8 POSITION OF THE O-RINGS .................................................................................................................... 13

9 ACCESSORIES ........................................................................................................................................... 13

APPLICATION DATA SHEET PH DIFFERENTIAL PH SENSOR ...............................................................14

IM 12B6J4-E-A

Page 3

3

IM 12B6J4-E-A

Page 4

4

Caution - Inappropriate handling can cause

damage.

Striking or scratching the sensor against hard

surfaces such as steel, stone, glass or ceramic,

may cause damage to the enamel. Such damage

may not affect the sensor performance immediately,

but after prolonged exposure to the process, aking

of the enamel may occur.

Note - Enable impedance checks in the

PH202/FLXA21 or PH402/PH450

The sensor impedance checking can give

early warning of damage to the enamel

layers. If the transmitter signals an

impedance failure of the PH18, the sensor

should be removed from the process, as

soon as possible (within 24 hours). The

loss of signicant amounts of enamel may

thus be avoided.

IM 12B6J4-E-A

Page 5

PREFACE

5

The PH18 should only be used with equipment

that meets the relevant IEC, American or Canadian

standards. Yokogawa accepts no responsibility for the

misuse of this unit.

The PH18 is packed carefully with shock absorbing

materials, nevertheless, it may be damaged or broken

if subjected to strong shock, such as if the package is

dropped. Handle with care. Although the PH18 has a

weatherproof construction, the connections can be

harmed if it becomes submerged in water or becomes

excessively wet. Do not use an abrasive in cleaning

the PH18.

Notice

Contents of this manual are subject to change without

notice. Yokogawa is not responsible for damage to

the sensor, poor performance, or losses resulting from

such, if the problems are caused by:

1. Incorrect operation by this user.

2. Use of the sensor in the wrong applications.

3. Use of the sensor in an adverse environment or

incorrect utility program

4. Repair or modication of the sensor by an engineer

not authorized by Yokogawa.

Warranty and service

Yokogawa products and parts are guaranteed free

from defects in workmanship and material under

normal use and service for a period of (typically) 12

months from the date of shipment from the

manufacturer. Individual sales organisations can

deviate from the typical warranty period, and the

conditions of sale relating to the original purchase

order should be consulted. Damage caused by wear

and tear, inadequate maintenance, corrosion, or by the

effects of chemical processes are excluded from this

warranty coverage. In the event of warranty claim, the

defective goods should be sent ( freight paid) to the

service department of the relative sales organisation for

repair or replacement (at Yokogawa discretion).

The following information must be included in the letter

accompanying the returned goods:

1. Part number, model code and serial number.

2. Original purchase order and date.

3. Length of time in service and a description of the

process.

4. Description of the fault, and the circumstances of

failure.

5. Process/environmental conditions that may be related

to the installation failure of the device.

6. A statement whether warranty or nonwarranty service

is requested.

7. Complete shipping and billing instructions for return of

material , plus the name and phone number of a

contact person who can be reached for further

information.

Returned goods that have been in contact with process

uids must be decontaminated/ disinfected before

shipment. Goods should carry a certicate to this

effect, for the health and safety of our employees.

Material safety data sheets should be included for all

components of the processes to which the equipment

has been exposed.

Unpacking and checking

Upon receipt of the goods, carefully inspect the shipping

package for any evidence of damage. If the carton is

damaged, notify the shipping agent and the sales

organisation immediately. If the shipping package is not

damaged, remove the products and parts. Conrm

that all items shown on the packing list are available

and that the package does not contain any parts or

accessories llers. Notify the sales organisation if items

are missing.

PH18 sensor

The box of the PH18 sensor contains the

following items:

Sensor complete, possible options (check part number

for possible options), instruction manual, material

certicate and quality inspection certicate. The WU18

cable is packed separately.

IM 12B6J4-E-A

Page 6

6

1. INTRODUCTION

The PH18 is not a conventional electrode. It relies on

two dissimilar ion sensitive enamel membranes to

generate the signal. The measuring element is like a pH

electrode, and the reference like a Sodium ion

electrode.

Therefore the PH18 can only be used in

combination with pH meters that feature:

1 Dual high impedance inputs

2 Adjustable setting for Isothermal Point

3 Adjustable temperature coefcient

The Yokogawa models PH202 and

PH402 satisfy these requirements.

In both cases the membrane enamels are bonded

directly to the metal substrate with no lling solution.

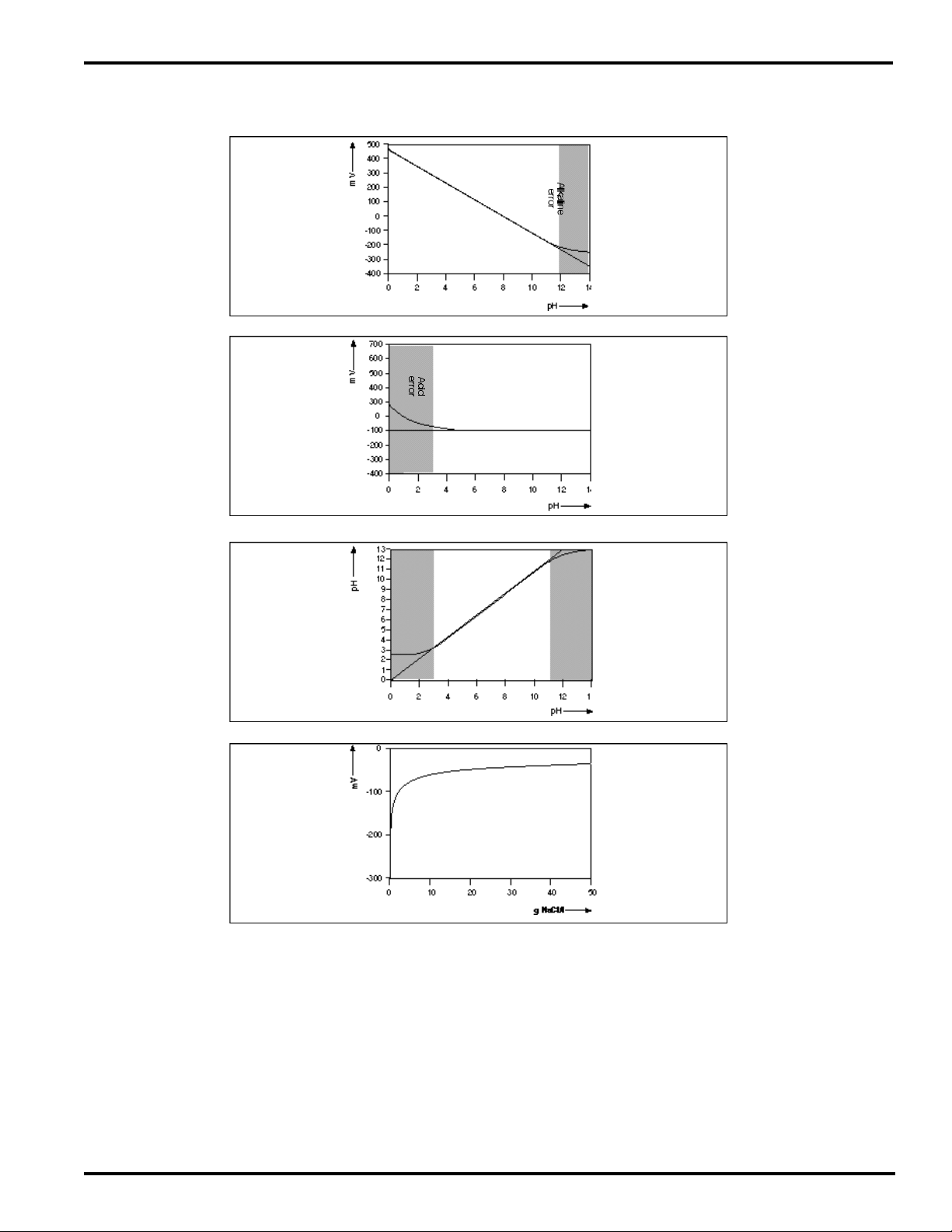

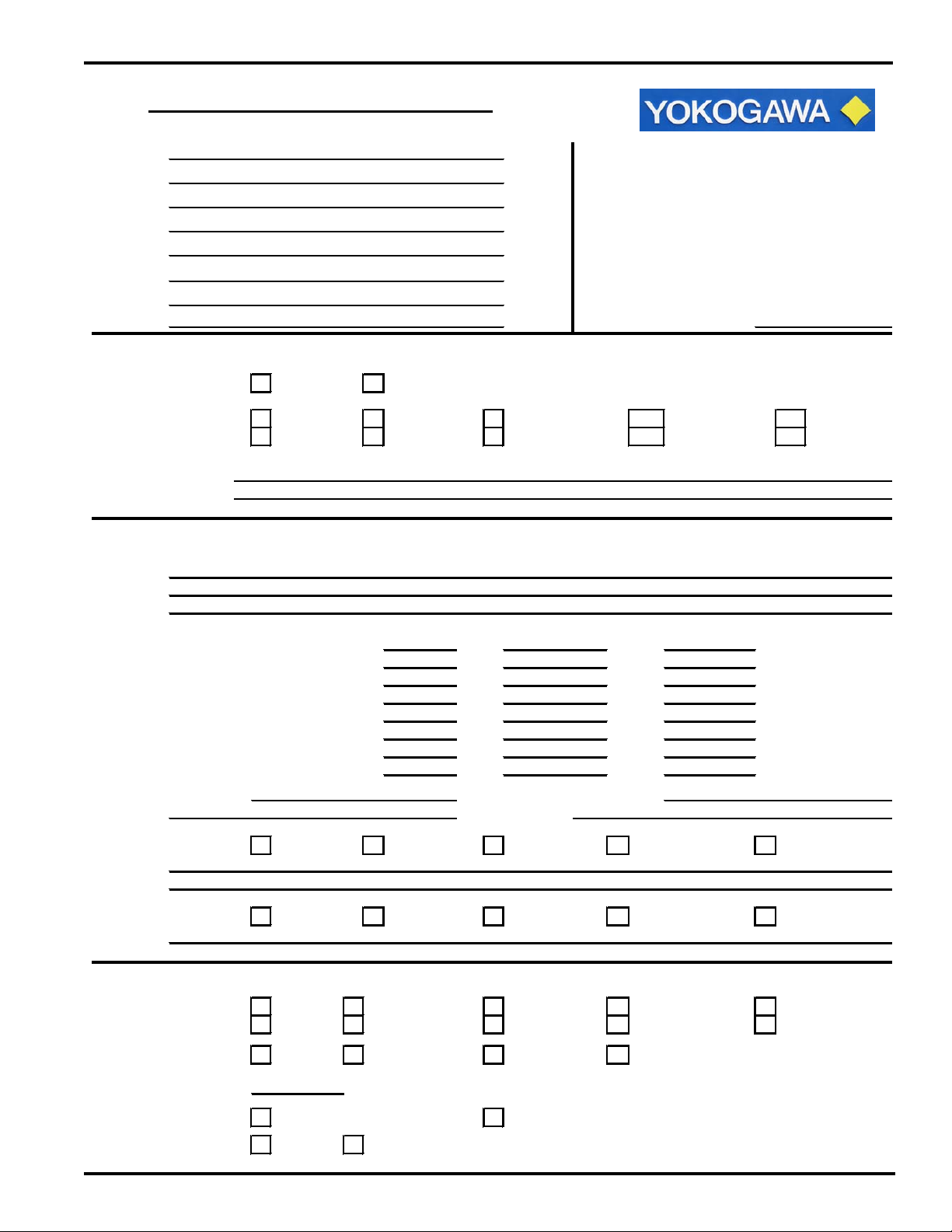

The response curves Fig. 1 (pH), Fig. 2 (reference) and

Fig. 3 (application range) show the way in which the

potential is generated at each element and combined

in the output of the sensor.

Fig. 1 Above pH11 the effect of sodium on the pH

membrane starts to cause non-linearity (Sodium

error)

Fig. 2 Below pH3 the high Hydrogen ion content

causes a change in the reference response

Fig. 3 A linear response to pH is obtained between 3

and 11 pH

Fig. 4 A plot of reference voltage against Sodium

content.

The revolutionary measuring principle has some big

advantages. The absence of lling solutions and

reference junctions virtually eliminates the problems

caused by aging and pollution of the reference sensor.

Regular cleaning of the sensor virtually eliminates drift,

and the sensor benets from a very long working life. It

is vital, however, to t the sensor to the application

correctly. The special nature of the reference element

dictates that there must be a certain Sodium level in

the process.

Fig. 4 shows a plot of reference voltage against

Sodium content.

Because of the exponential nature of the response, it

is plain that above about 0.5 N Na+ (30 g NaCl/l) in the

solution, the reference output remains virtually constant.

Of course when the Sodium concentration remains

constant in a process the reference voltage will also be

constant at much lower levels of Sodium.

It is because of the need to evaluate the chemistry

of the process, that it is necessary to have an

Application Data Sheet (page 16) completed before

approval for this sensor can be made.

The mechanical construction of the sensor also means

that it may be used in processes involving both high

temperatures and pressures. By eliminating the lling

solutions, the sensor is truly robust and can even

withstand severe thermal shocks that would ruin most

systems.

The stainless steel mounting adapter forms the liquid

earth (solution ground) connection needed to ensure

best stability of measurement. EXA also uses this

connection in the diagnostic circuit.

The PH18 is a differential pH sensor. It does not

measure absolute pH except in limited applications.

It does, however, measure a single control

point accurately, repeatably and with minimum

maintenance.

IM 12B6J4-E-A

Page 7

7

4

Measuring Enamel mV vs.

pH in solution containing

+

0.1N Na

Operating range

pH of sample

Fig. 1

Reference Enamel mV vs

pH in solution containing

+

0.1N Na

Operating range

pH of sample

Fig. 2

Fig. 3

Fig. 4

PH18 system output

pH reading vs. pH in

solution containing

+

0.1N Na

Operating range

pH of sample

Reference Enamel mV vs Na+content

IM 12B6J4-E-A

Page 8

8

2. GENERAL SPECIFICATIONS

2-1. Model PH18 differential pH sensor

Temperature sensor

: Pt1000 W RTD

Wetted parts

- pH sensor : pH sensitive enamel

- Reference sensor : Na+ sensitive enamel

- Liquid earth : via SS adapter

- O-rings : EPDM

- Adapters : SS 316

Max. measuring range

: 3 to 11 pH

(The actual range will be advised with reference to the completed application data sheet)

Temperature range : 0 to 140 ºC (284 ºF)

Pressure range : -1 to 15 Bar (214 psi)

NOTE:

The use of this sensor is highly application specic. Your local Yokogawa sales ofce will be

pleased to advise on the suitability of your application, on receipt of the completed

application data sheet. Any and all information received by Yokogawa will be treated in the

strictest condence. To maintain traceability, the completed application data sheet will form

part of the contract of sale.

Yokogawa offers no function guarantee for applications where the attached data sheet

(page 16) has not been satisfactorily completed. This does not affect the normal Yokogawa

warranty covering defects in materials or workmanship.

MODEL AND SUFFIX CODE

Model Sufx

code

PH18 ............ ................ Model PH18 Differential pH sensor

Sensor

mounting

O-ring

material

Instruction

manual

Options SA K1520EK Angled weld-in adapter (SS316)

-SA...... ................ Compatible with 25mm process connection

-E... ................ Ethylene-propylene (EPDM)

-E... ................ English language

Option

Description

code

K1520EJ STRAIGHT WELD-IN ADAPTER (SS316)

M1289BA ADAPTER 1” NPT (SS316)

237230 BLIND PLUG SS316

Note:

The sensor is supplied with

cable connector. For rst

installation cable must be

specied as well. (see par.2-2)

Note:

The material certicate 3.1.B is

supplied with the sensor and

the options.

IM 12B6J4-E-A

Page 9

2-2. Model WU18 cable for model PH18

differential pH sensor

Max. temperature :110 ºC (230 ºF)

Material :Thermoplastic Rubber (T.P.R.)

Colour :Blue.

Shipping details sensor and adapter

- Package :wxhxd 350 x 220 x 110 mm

- Weight :approx. 1.4 kg

Shipping details cable

- Package :wxhxd 350 x 220 x 110 mm

- Weight :2 m. approx. 0.6 kg

:5 m. approx. 0.9 kg

:10 m. approx. 1.4 kg

MODEL AND SUFFIX CODE

9

Model Sufx

code

WU18 ............ ................ Cable for Differential pH Sensor

-02......

-05......

-10......

Option

Description

code

................ 02 meter connection cable

................ 05 meter connection cable

................ 10 meter connection cable

IM 12B6J4-E-A

Page 10

10

4

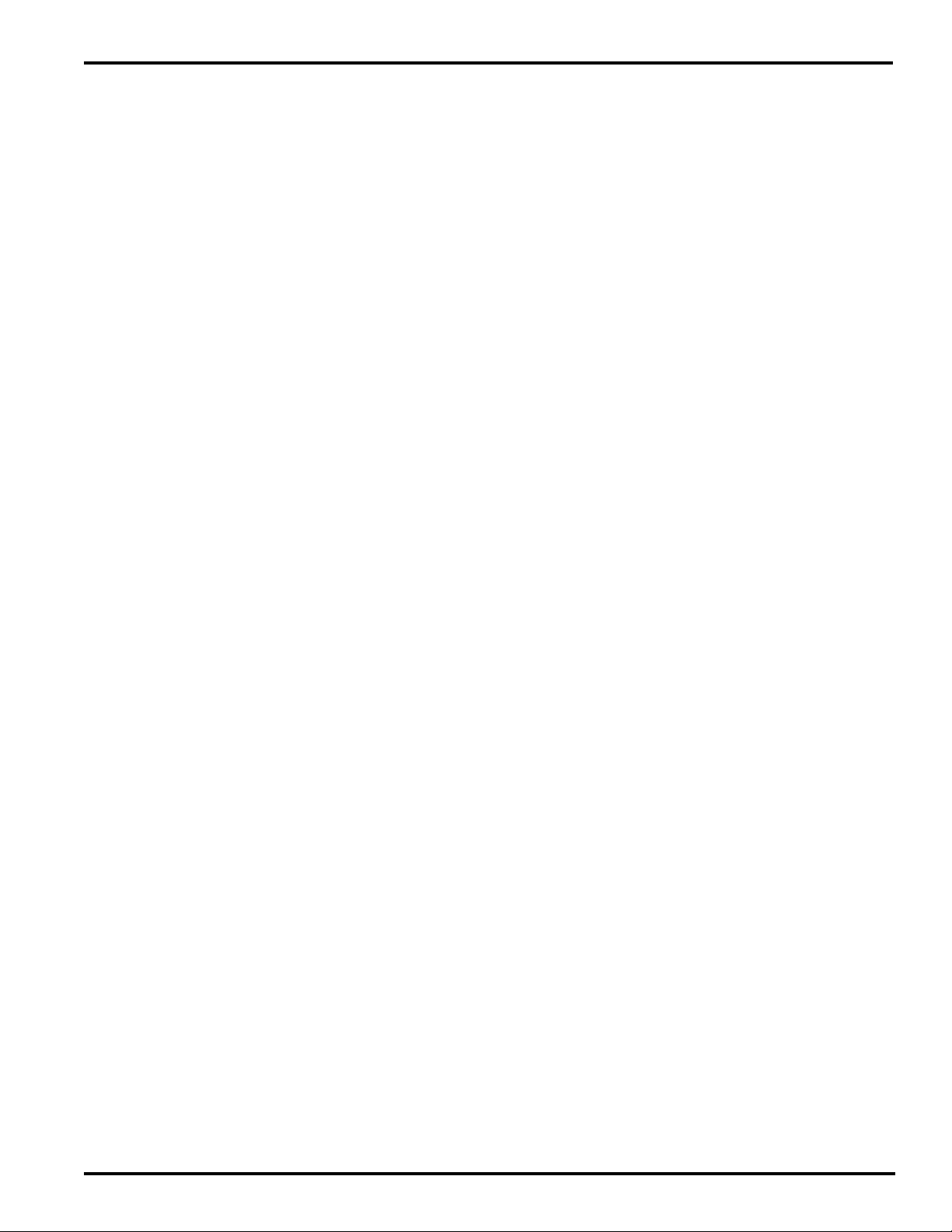

DIMENSIONS PH18-SA

Fig. 7. PH18-SA and the adapters

Fig. 8. External dimensions of the PH18-SA

237574

237202

237230

PH18SA

in mm (inches)

M1289BA

K1520EJ

K1520EK

7

2-3. Dimensions of the PH18-SA

in mm (inches)

Fig. 5 PH18-SA and the adapters Fig. 6 External dimensions of the

44

(1.73)

K1520EJ

242574

51

(2.09)

PH18-SA

55

(2.17)

26

(1.02)

1”

237202

K1520EK

M1289BA

M1289BA 237230

237230

22.5

(0.89)

IM 12B6J4-E-A

Page 11

11

3. THE TYPE 18 PH PROBE

3-1. Typical applications

• Fermentation

• Continuous reactions

• Production of diary products

• Product monitoring

3-2. Handling information for the glass

lined pH probe.

The differential pH probes are pressure and thermal

shock resistant due to the fused steel/enamel

construction. The probes have a very high mechanical

stability and are extremely strong.

Inappropriate handling, e.g. hitting and scratching the

probe on steel, ceramics, glass or stone may cause

damage to the probe. Depending on the scope of the

damage, the probe may not fail immediately but

rather when the temperature changes. If a defective

measuring probe remains in aqueous solutions for

prolonged periods of time enamel may ake.

2. Fasten probe with union nut

3. Connect cable. For this purpose, loosen the heavy

gauge conduit connection at the protective plastic

cover, push out the connector, put the connector in

the proper position, and rmly press it into the

female connector of the probe (water- tight

interlock). Push the protective cover and O ring

sealing onto the probe until the stop and tighten the

heavy gauge conduit connection again manually.

4. The cable with high temperature stability (blue) must

be fastened vibration free. The cable must not be

laid together with power cables.

Only suitable transmitters with symmetrical

high impedance inputs may be used. The

following units are approved:

• Yokogawa EXA PH 202

• Yokogawa EXA PH 402w

Enable the EXA impedance monitoring. If sensor

damage is indicated, the measuring probe must be

immediately removed (within 24h) after an alarm

message. All probes for use in the food sector are

tested with a voltage of 12 kV and conditioned for 5

hours in steam at a temperature of 134 °C.

3-3. Storage and hydration

The PH18 Probe can be stored dry for an indenite

period of time at temperatures between -30 and +80

ºC. After prolonged storage or if this is a new probe

from the factory a simple steam sterilization should

be performed for 15-30 minutes prior to calibration.

This procedure revitalizes the probes giving it a stable

reference potential. If steaming is not possible soak

the PH 18 for 45-60 minutes in hot water (65 to 85 ºC).

If steaming or a hot soak can not be done, place the

Probe in a standard pH7 Buffer solution for 24 hours

prior to installation. The probe must be immersed

so that both measuring elements are covered with

buffer.

3-4. Installation

Procedure:

1. Remove the probe from the packaging, remove the

protective plastic hose and carefully introduce the

probe into the nozzle.

IM 12B6J4-E-A

Page 12

12

9

3-5. PH18 Installation examples

3-5. PH18 Installation examples

Socket for connection

cable

Primary adapter

pH enamel

Fig. 11 The primary adapter is used to make a

connection to the process used by the transmitter as

the liquid earth (solution ground). This is needed for

optimum stability of the measurement and is used in

the impedance checking circuit.

Example A. Straight weld-in adapter through a vessel

wall.

Example B. 1” Screw-in adapter with existing pipe

nipple through a vessel wall.

Example C. Angled weld-in adapter in large bore pipe.

Example D. Angled weld-in adapter mounted in a

bend

Example E. Screw or weld-in adapter mounted in a

large bore pipe.

Example F. Screw or weld-in adapter mounted on top

Reference enamel

Fig. 12. Model 18 elements

Note 1:

When measuring in plastic tanks or pipes, ensure that the adapter is

wetted by the process. Avoid installations where an air pocket can

be created (see g 12 F). This isolates the adapter, and hence loses

the liquid earth connection.

Note 2:

Flow rate from the side of the sensor (Fig 11) should not exceed 2

meters/second in low viscosity uids. In high viscosity uids (> 5cP)

use only installation as

shown in Fig. 12 (D).

IM 12B6J4-E-A

Page 13

13

ENGLISH

11

4-1. Set-up

The EXA PH202 and PH402 are both

designed with dual matched high

impedance inputs which are necessary

when using a pH probe like the Model PH

18 with both a measuring and a reference

electrode that are high impedance. To

prepare the EXA instrument to work with

the PH18 make sure the input impedance

jumpers are placed in the correct positions:

PH202: See table 3-1 and fig. 3-8 on

page 3-7 in the PH202 Instruction

Manual (IM 12B6C3-E-H) for

jumper positions.

PH402: See figure 3-9a on page 3-8 in the

PH402 Instruction Manual

(IM 12B6B3-E-H) for jumper

positions.

Since the Model PH18 has high impedan-

ces for both the measuring and the

reference elements, the high impedance

check functions (Service Codes 03 & 04)

must be set up according to the procedures

outlined in Section 5.3.1 in either the PH202

or the PH402 Manual.

The Calibration check also needs to be

changed. Here you are instructed to set:

Service Code 03:

Change settings from 1.1.1 to 1.0.1 by

using the ^ and > keys.

Low limit 1Megohm. High limit 1 Gigaohm.

Service Code 04:

Change settings from 0.0.1 to 1.0.1 by

using the ^ and > keys.

Low limit 1Megohm. High limit 1 Gigaohm.

Service Code 05:

Change settings from 1.1 to 0.1 by using

the ^ and > keys. This disables the As.

Pot. check which is not appropriate for the

PH18 system.

Once the jumpers and impedance Service

Codes (03 & 04), Calibration Check (05)

and Temperature element have been set

correctly, wire the probe cable to the

instrument as shown in Fig. 13. Power

wiring instructions are located in the

respective instrument manuals:

PH202: See section 3-4-3 on page 3-6 in

the PH202 Instruction Manual

(IM 12B6C3-E-H).

PH402: See section 3-3-3 on page 3-5 in

the PH402 Instruction Manual

(IM 12B6B3-E-H).

4. EXA PH202 OR PH402 INSTRUMENT

0 1 2 4 6 8 10 12 14

60

140

120

100

80

60

40

20

0

NOT RESISTANT

RESISTANT

1

pH of sample

Measuring range

ENGLISH

11

Service Code 03:

Change settings from 1.1.1 to 1.0.1 by

using the ^ and > keys.

Low limit 1Megohm. High limit 1 Gigaohm.

Service Code 04:

Change settings from 0.0.1 to 1.0.1 by

using the ^ and > keys.

Low limit 1Megohm. High limit 1 Gigaohm.

Service Code 05:

Change settings from 1.1 to 0.1 by using

the ^ and > keys. This disables the As.

Pot. check which is not appropriate for the

PH18 system.

Once the jumpers and impedance Service

Codes (03 & 04), Calibration Check (05)

and Temperature element have been set

correctly, wire the probe cable to the

instrument as shown in Fig. 13. Power

wiring instructions are located in the

respective instrument manuals:

PH202: See section 3-4-3 on page 3-6 in

the PH202 Instruction Manual

(IM 12B6C3-E-H).

PH402: See section 3-3-3 on page 3-5 in

the PH402 Instruction Manual

(IM 12B6B3-E-H).

4. EXA PH202/FLXA21 or PH402/

PH450 INSTRUMENT

4-1. Set-up PH202/PH402

The EXA PH202/FLXA21 and PH402/PH450 are all

designed with dual matched high impedance inputs

which are necessary when using a pH probe like the

Model PH18 with both a measuring and a reference

electrode that are high impedance. To prepare the

Yokogawa instruments to work with the PH18 make

sure the input impedance jumpers are placed in the

correct positions:

PH202: See table 3-1 and g. 3-8 on page

3-7 in the PH202 Instruction Manual

(IM 12B6C3-E-H) for jumper positions.

FLXA21: See g. 3.11 on page 3-8 in the FLXA21

Instruction Manual (IM 12A01A02-01E) for

jumper positions.

PH402: See gure 3-9a on page 3-8 in the

Instruction Manual (IM 12B6B3-E-H) for

jumper positions.

PH450: See table 3-1 and gure 3-9a on page 12 in

the PH450 Instruction Manual

(IM 12B07C05-01E) for jumper positions.

4-2. Set-up PH202 and PH402

Since the Model PH18 has high impedances for both

the measuring and the reference elements, the high

impedance check functions (Service Codes 03 & 04)

must be set up according to the procedures outlined

in Section 5.3.1 in either the PH202 or the PH402

Manual. The Calibration check also needs to be

changed. Here you are instructed to set: The

Calibration check also needs to be changed. Here you

are instructed to set:

Service Code 03:

Change settings from 1.1.1 to 1.0.1 by using the ^ and

> keys. Low limit 1 Megohm. High limit 1 Gigaohm.

1

15

8

9

2

5

&34 6

Model PH18

sensor

FIG.13 Connection diagram WU18 for

PH202/FLXA21 and PH402/PH450

measure

16

screen

17

screen

13

reference

14

liquid

12

temperature

11

temperature 2

Service Code 04:

Change settings from 0.0.1 to 1.0.1 by using the ^ and

> keys. Low limit 1 Megohm. High limit 1 Gigaohm.

Service Code 05:

Change settings from 1.1 to 0.1 by using the ^ and

> keys. This disables the As. Pot. check which is not

appropriate for the PH18 system.

Once the jumpers and impedance Service Codes (03

& 04), Calibration Check (05) and Temperature element

have been set correctly, wire the probe cable to the

instrument as shown in Fig. 13.

For the FLXA21/PH450

Since the Model PH18 has high impedances for

both the measuring and the reference elements, the

impedance setting must be set up to reect dual high

impedance according to the procedures outlined in

Section 5-6 in the PH450 or in Section 5.2.5in the

FLXA21 Manual. The Calibration check also needs to

be changed. Here you are instructions to set:

Impedance Settings:

Select the Execute Wrench from the Main Display.

Select Commissioning Measurement Setup

Impedance Settings

Ensure that Input 1 and Input 2 are set to High

Press the Home key to return to measuring mode.

Once the jumpers and impedance Settings have

been changed correctly, wire the probe cable to the

instrument as shown in Fig. 13.

Power wiring instructions are located in the respective

instrument manuals:

PH202: See section 3-4-3 on page 3-6 in the PH202

Instruction Manual (IM 12B6C3-E-H).

FLXA21: See section 3.3 on page 3-4 in the FLXA21

Instruction Manual (IM 12A01A02-01E).

PH402: See section 3-3-3 on page 3-5 in the PH402

Instruction Manual (IM 12B6B3-E-H).

PH450: See section 3-3-3 on page 10 in the PH450

Instruction Manual (IM 12B07C05-01E).

60

1

140

120

100

80

earth

1

60

40

20

0

0 1 2 4 6 8 10 12 14

pH of sample

FIG.14 Corrosion curve of the Model

PH18 Enamel

Measuring range

NOT RESISTANT

RESISTANT

IM 12B6J4-E-A

Page 14

14

12

5. CALIBRATION

5-1. Calibration set-up

All pH sensors are characterized by

Isopotential (ITP), Asymmetry Potential

(ASY) and SLOPE (SL). Typically the ITP is

set by the factory for specific sensor types

and the ASY and the SL are adjusted by the

user during his buffer calibrations.

Calibration of the PH18 is slightly different

from calibration of conventional pH

sensors due to the differential nature of

the measurement. The ITP and SL are set

during commissioning and ASY is adjusted

by the user during his Grab Sample

calibrations.

5-2. Isopotential pH value

to perform a regular SLOPE check to verify

proper functioning of the sensor.

5-4. ASYMMETRY Potential

The default setting for Asymmetry potential

is 0 mV at Isopotential pH value. This value

is always wrong for the PH18 sensor and

therefore the Asymmetry Potential must

be calibrated always. This cannot be done

with conventional pH buffer solutions,

since these buffer solutions will have salt

compositions, which differ from the actual

process. Therefore the calibration is done

using the grab sampling method: During

the most important stage of the pH control

application a sample is drawn and the pH

of the sample is measured with a calibrated

conventional pH meter. The analyzer is

adjusted to this value using the MAN.CAL

mode.

Notes: This adjustment should be done

at the normal working temperature at the

most important stage of the process (the

control setpoint, or the critical part of the

pH profile). This avoids the need for process

temperature compensation for constant

temperature processes.

ITP as function of Conductivity for Na Cl

5. CALIBRATION

5-1. Calibration set-up

All pH sensors are characterized by Isopotential (ITP),

Asymmetry Potential (ASY) and SLOPE (SL). Typically

the ITP is set by the factory for specic sensor types

and the ASY and the SL are adjusted by the

user during his buffer calibrations. Calibration of

the PH18 is slightly different from calibration of

conventional pH sensors due to the differential nature

of the measurement. The ITP and SL are set during

commissioning and ASY is adjusted by the user during

his Grab Sample calibrations.

5-2. Isopotential pH value

8

6

4

pH

2

0

0,01 0,1 1 10 100

mS/cm

Fig. 15 ITP Curve

The default setting for the Isopotential point is 0 mV

at 7.00 pH, because most manufacturers of Glass

electrodes use 7 pH as internal ll solution. The PH18

differential sensor has two measuring elements: one

pH element which has an Isopotential pH value of 1 pH

and one pNa element, which has an Isopotential pNa

value of –2. The Isopotential pH value of the differential

sensor depends on the Salt concentration. It is

recommended to set the ITP as a function of the

Conductivity according to the graph.

5-3. SLOPE

The default setting for SLOPE is 100% of theoretical

value, which is 59,16 mV/pH@25°C. It is only possible

to calibrate the SLOPE, if pH buffers are used with

identical salt concentration. These buffers are not

commercially available, so it is recommended not to

perform a SLOPE calibration, but leave the analyzer

in its default settings. It is however recommended

to perform a regular SLOPE check to verify proper

functioning of the sensor.

5-4. ASYMMETRY Potential

The default setting for Asymmetry potential is 0 mV

at Isopotential pH value. This value is always wrong

for the PH18 sensor and therefore the Asymmetry

Potential must be calibrated always. This cannot be

done with conventional pH buffer solutions, since

these buffer solutions will have salt compositions,

which differ from the actual process. Therefore the

calibration is done using the grab sampling method:

During the most important stage of the pH control

application a sample is drawn and the pH of the

sample is measured with a calibrated conventional pH

meter. The analyzer is adjusted to this value using the

MAN.CAL mode.

Notes: This adjustment should be done at the normal

working temperature at the most important stage of

the process (the control setpoint, or the critical part of

the pH prole). This avoids the need for process

temperature compensation for constant temperature

processes.

5-5. Process Temperature

Compensation

This setting is needed only when the temperature of

the process is not (reasonably) constant. When setting

process TC, it should be done before step 5-4. to

avoid inuencing the Asymmetry potential calibration.

The procedure is as follows: -Allow sensor to stabilize

fully in the process. Note down the temperature and

pH readings (t1 & pH1). Allow sample and sensor to

cool (together) to room temperature, and stabilize.

Again note down the temperature and pH readings (t2

& pH2) T.C. = (pH1-pH2)x10/(t1-t2) pH/10°C

NOTE: to calculate TC from temperature readings in

Fahrenheit, TC = (pH1-pH2)x18/(t1-t2) of a large bore

pipe

IM 12B6J4-E-A

Page 15

6. CLEANING/STERILIZATION 7. MAINTENANCE

15

The probe can be cleaned/sterilized inside the

reactor. For CIP cleaning it must be ensured that the

admissible alkali and acid concentration as well as the

maximum temperature or cleaning time are not

exceeded. Otherwise, the enamel of the electrode

would be subject to increased corrosion.

NOTE: With alkali cleaning, corrosion is doubled with

every temperature jump of 10 ºC. The use of

oxidizing acids, such as HNO3, is limited to

solutions of 1.5% at a maximum of 50 °C.

6-1. Acceptable CIP cleaning processes

1. 1.5 - 2% alkaline solution, max 85 ºC, max 1 hour.

2. 1.5% acid (HNO3), 50 ºC, max. 15 min.

3. Steam 134 ºC, max. 2 hours

After cleaning with alkaline solution without acid and

steam sterilization, a transitional measuring error may

occur if the wetting time is too short.

6-2. Sterilization methods

The probe is resistant to the following sterilization

methods:

• with product

• with steam

• with alcoholic solutions

• with antiseptic solutions

The PH18 does not normally require maintenance, as

long as it is kept clean. Buffer checks may be done if it

is suspected that the sensor performance has

drifted appreciably. It is best, however, simply to do

a single point “Manual” calibration against a grab

sample taken at the process temperature and normal

pH value.

For cleaning or removal of residues dilute acids may

be used for a short time at room temperature only.

Limescale may be removed with commercially

available “antiliming” agents. The non-abrasive

material intended for ceramic cookers may be used to

remove sticky coatings from the PH18 - Do not use

any metallic or abrasive substances!

IM 12B6J4-E-A

Page 16

16

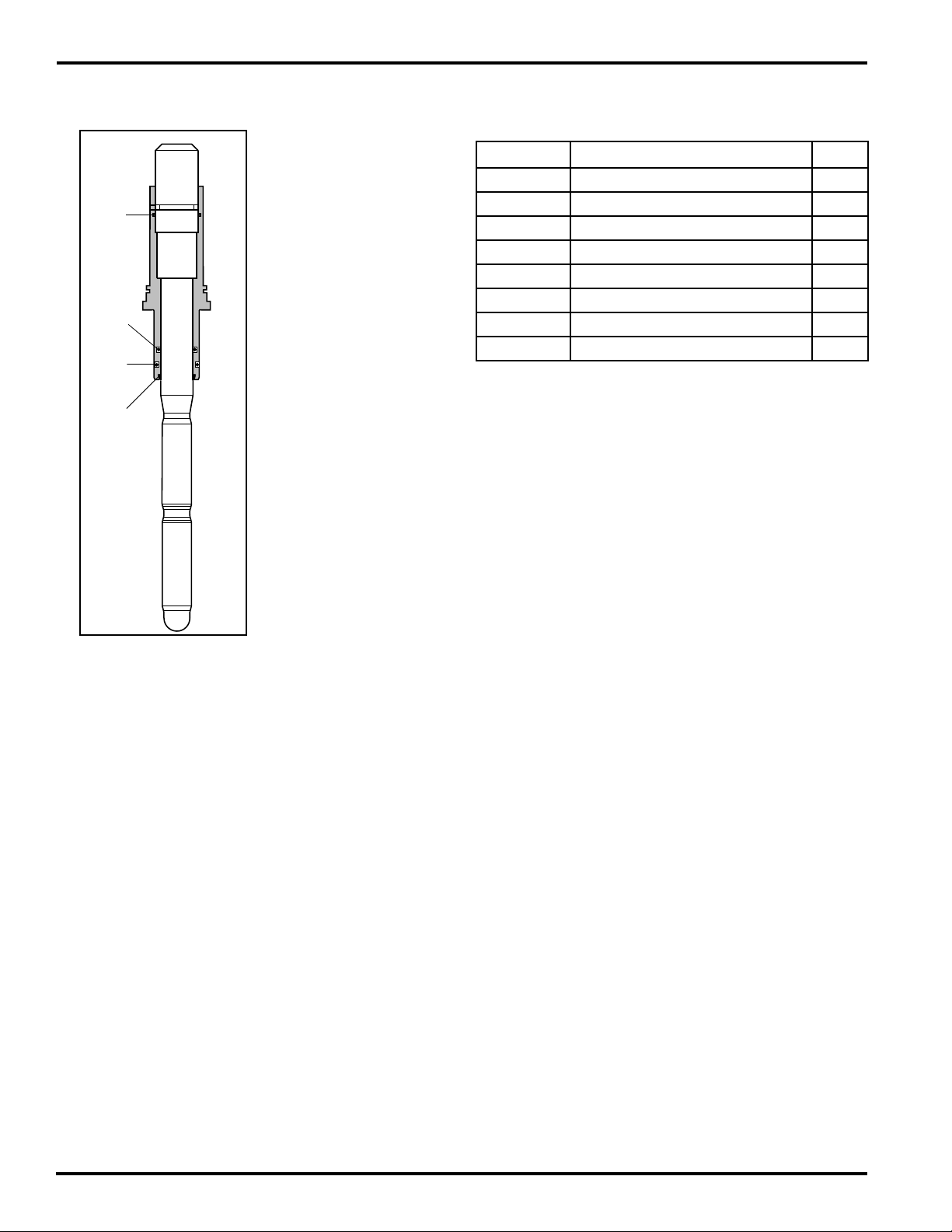

9. ACCESSORIESl

PH18 differential pH sensor

A

C

D

A

B

C

E

Number Description Q’ty

K1500BJ Set O-rings 20.3 x 5

2.62 (EPDM) unit

K1500BK O-ring 20.3 x 2.62 1

(KALREZ) unit

K1500BQ Set O-rings 17.12 x 1

2.62 (KALREZ) unit

K1500BR Set O-rings 17.12 x 2.62 5

(EPDM) unit

K1500BS Set O-rings 25.12 x 1.78 1

(EPDM) unit

K1522FK Set O-rings 17.04 x 3.53 5

(EPDM) unit

K1522FL Set O-rings17.04 x 3.53 1

(KALREZ) unit

K1500BT Nut 1

K1522ER /SWR Straight 1

weld-in adapter

K1522EQ /SWA Angled 1

weld-in adapter

K1522ET /SBS Adapter 1

ISO 7/1-R1, JIS 1”

K1522ES /SNS Adapter 1

1” NPT

PH18-SE

8. POSITION OF THE O-RINGS

PH18-SA

9. ACCESSORIES

PH18 differential pH sensor

Number Description Q’ty

M1263YB O-ring 20.0 x 2.5 (EPDM) unit 1

M1263YC O-ring 17.0 x 2.5 (EPDM) unit 1

M1263XZ O-ring 25.0 x 1.5 (Viton A) unit 1

K1500BT Nut 1

K1520EJ Straight weld-in adapter 1

K1520EK Angled weld-in adapter 1

M1289BA Adapter 1” NPT 1

237230 Blind plug 1

Size of the O-ring Materials

A= 17.0 x 2.5 EPDM-FDA Approved

B= 20.0 x 2.5 EPDM-FDA Approved

C= 25.0 x 1.5 Viton A

D= 17.0 x 3.0 EPDM

Fig. 16 Location of the O-rings

IM 12B6J4-E-A

Page 17

SC24V or PH18 Application Data Sheet

Address:

Contact:

Rep Name: Authorization No.

1. PROCESS DATA:

2. PROCESS CONDITIONS:

3. INSTALLATION DATA:

Customer: Please complete a seperate form for each process

Tag No: stream to be analyzed and return to the attention of:

Yokogawa Corporation of America

Analytical Business Unit

2 Dart Road

Telephone: Newnan, Georgia 30265 - 1040

Email: FAX - (770) 304-1613

17

Sensor Selection:

Application: Chemical Power Pharmaceutical Pulp & Paper Other

Operation Batch Control Continous Monitor Other

Type of Solution:

Descrition:

pH Value Max

Conductivity Value Max

Sodium Concentration Max

Temperature (°C/°F) Max

Pressure (psig) Max

Flow Rate (ft/sec) Max

Concentration of Solids: Concentration of Organics:

Type(s): Type(s):

PH18 SC24V

Min

Min Norm

Min

Min

Min

Min Norm

NormMin

Norm

Norm

Norm

Norm

NormMin

Max

Max

Problems: Fouling Abrasion Coating Poisoning Other

Describe:

Cleaning/Sterilization: w/ Product Caustic Steam Hot Water Other

Describe:

Mounting: Insertion Flow Through Retractable Immersion Other

Off Line On Line Pipe On Line tank Sample Line Flanged

Wetted Materials: 316SS EPDM Kynar Kalrez

Distance to Converter:

Instrument: General Purpose Intrinsic Safe

Power Supply: 115 VAC 24 VDC

ft

IM 12B6J4-E-A

Page 18

Yokogawa Corporation of America

North America

2 Dart Road, Newnan, GA 30265-1094, USA

Phone: 800-258-2552 Fax: 770-254-0928

12530 West Airport Blvd., Sugar Land, TX 77478

Phone: 281-340-3800 Fax: 281-340-3838

Mexico

Melchor Ocampo 193, Torre C, Ocina 3”B”

Veronica Anzures D.F., C.P. 11300

Phone: (55) 5260-0019, (55) 5260-0042

Yokogawa Canada, Inc.

Bay 4, 11133 40th Street SE, Calgary, AB Canada T2C2Z4

Phone: 403-258-2681 Fax: 403-258-0182

Yokogawa has an extensive sales and

distribution network.

Please refer to the website

(www.yokogawa.com/us) to contact your

nearest representative.

IM 12B6J4-E-A 02-1207 (A) I

Subject to change without notice Printed in The USA

Copyright ®

Loading...

Loading...